Highlead GC22618 User Manual

®

HIGH

LEAD

GC22618

CYLINDER-BED UNISON FEED SEWING MACHINE

Instruction Manual

Parts

SHANGHAI HUIGONG

N0.3

Catalog

SEWING MACHINE FACTORY

CONTENTS

INSTRUCTION MANUAL

1,

PRECAUTIONS BEFORE STARTING OPERATION .................................................................................... !

2,

SPECIFICATIONS ....................................................................................................................................... 1

3,

PRECAUTIONS FOR SEWING OPERATE ................................................................................................. 2

4,

NEEDLE ......................................................................................................................................................... 3

5,

WINDING THE LOWER THREAD ............................................................................................................ 3

6,

ADJUSTING OF THE BOBBIN WINDER ................................................................................................... 4

7,

REMOVING AND INSERTING THE BOBBIN ........................................................................................... 4

8,

THREADING ................................................................................................................................................. 4

9,

ADJUSTING OF THREAD TENSION ......................................................................................................... 5

10, ADJUSTING THE PRESSURE OF PRESSER FOOT .............................................................................. 6

11, STITCH LENGTH & REVERSING LEVER ........................................................................................... 6

12, ADJUSTING THE LIFT OF THE ALTERNATING PRESSER FOOT ....................................................... 6

13, RE-SET THE SAFETY CLUTCH MECHANISM ...................................................................................... 7

14, ADJUSTING THE HEIGHT OF THE FEED DOG ................................................................................... 7

15, RELATIVE POSITION OF THE FEED DOG TO NEEDLE PLATE ......................................................... 7

16, ADJUSTING THE HEIGHT OF THE NEEDLE BAR ................................................................................ 8

17, ADJUSTING THE HEIGHT OF THE PRESSER FOOT .......................................................................... 8

18, TIMING OF THE VIBRATING PRESSER FOOT .................................................................................... 9

19, ADJUSTING THE THREAD TAKE-UP SPRING ...................................................................................... 9

CATALOG

A,

ARM BED AND ITS ACCESSORIES ...................................................................................................... 1 0

B,

TAKE-UP THREAD AND ARM SHAFT MECHANISM ........................................................................

C,

ROTATING HOOK SHAFT MECHANISM ...............................................................................................

D,

FEEDING AND FEED LIFTING MECHANISM ....................................................................................

E,

STITCH REGULATOR MECHANISM .................................................................................................... 20

F,

NEEDLEBARFEEDINGMECHANISM

G,

PRESSER FOOT MECHANISM ............................................................................................................

H,

ACCESSORIES .........................................................................................................................................

..............................................................................................

13

15

18

22

25

27

-1-

1..

PRECAUTIONS BEFORE STARTING OPERATION

1) Safety precautions

(I)

and

the

machine,

When turning the power

the

area around

(2)

Power

(3)

Power

Avoid

(4)

the

must be turned off when

must be turned off when tilting the machine

or

when replacing.

placing fingers, hairs, bars

pulley.

on,

keep your

the

bands

machine

etc.,

near

and

fingers

is

not in

the

pulley, "V" belt, bobbin winder pulley,

away from the area around/under

use,

or when the operator leaves

head,

installing or removing the "V" belt, adjusting

the

the

seat

or

motor when

needle

the·machine

(5)

is

in operation.

(

devices.

2)

Precautions before starting operation

(I)

(2)

lubricating.

(3)

power

(4)

3)

Precautions for o.perating conditions

(

lower) .

(2)

is

in operation.

Do

not insert fingers into the thread take-up

6)

If

a belt

cover,

finger guard, eye guard are installed,

If

the

machine's oil pan has an oil

If

the

on.

1)

machine

When

a new sewing machine

(The

pulley should rotate counterclockwise when viewed

Verify

the

Avoid

using the machine at abnormally high temperatures C 3 5

Avoid

using

is

lubricated

voltage

and

(single or three) phase with

the

machine in dusty conditions.

by

is

cover,

under/around the needle, or pulley when the machine

do

not operate the machine without these safety

sump,

never operate

a drop oiled (consider revising), never operate the machine before

first turned

on,

the

machine before filling

verify the rotational direction

from

the pulley)

those

given on the machine nameplate.

·c

or higher) or low temperatures C 5

it.

of

the pulley with the

·c

or

2

...

SPECIFICATIONS

Max.

Sewing

Max.

Stitch Length

Thread

Needle Bar Stroke

Presser Foot Stroke

Alternating Movement

Needle

Rotating

Lubrication System

Electric Machinery

Speed

Take-up

Hook

Lever Stroke

By Hand

n

...... v-....

oy

l'>..llvv

Lifting

Presser

,..

Foot

-1-

2200rpm

5nnn

61.5nnn

33.4nnn

8nnn

1A-

.l""tllllll

4.3nnn

DPX17

KRT31-11SG

Manual

1400 rpm370W

22#

3-.

PRECAUTIONS

FOR

SEWING OPERATE

1) Cleaning

Before leaving the factory, the machine parts are coated with rust-preventive grease, which may

hardened and contaminated

gasoline.

the

machine

by

dust during storage and shipment

This

grease nrust

l;>e

2) Examination

Though every machine

machine parts may be loosen or deformed after long distance transportation with

examination must

running obstruction, parts collision, uneven resistance or abnon1lal noire.

made accordingly before run-in operation.

be

perfmmed after cleaning the machine. Turn the balance wheel

is

confirmed

by

strict inspection and test before leaving the factory, the

jolt

to

see

If

these exist, adjustment nrust

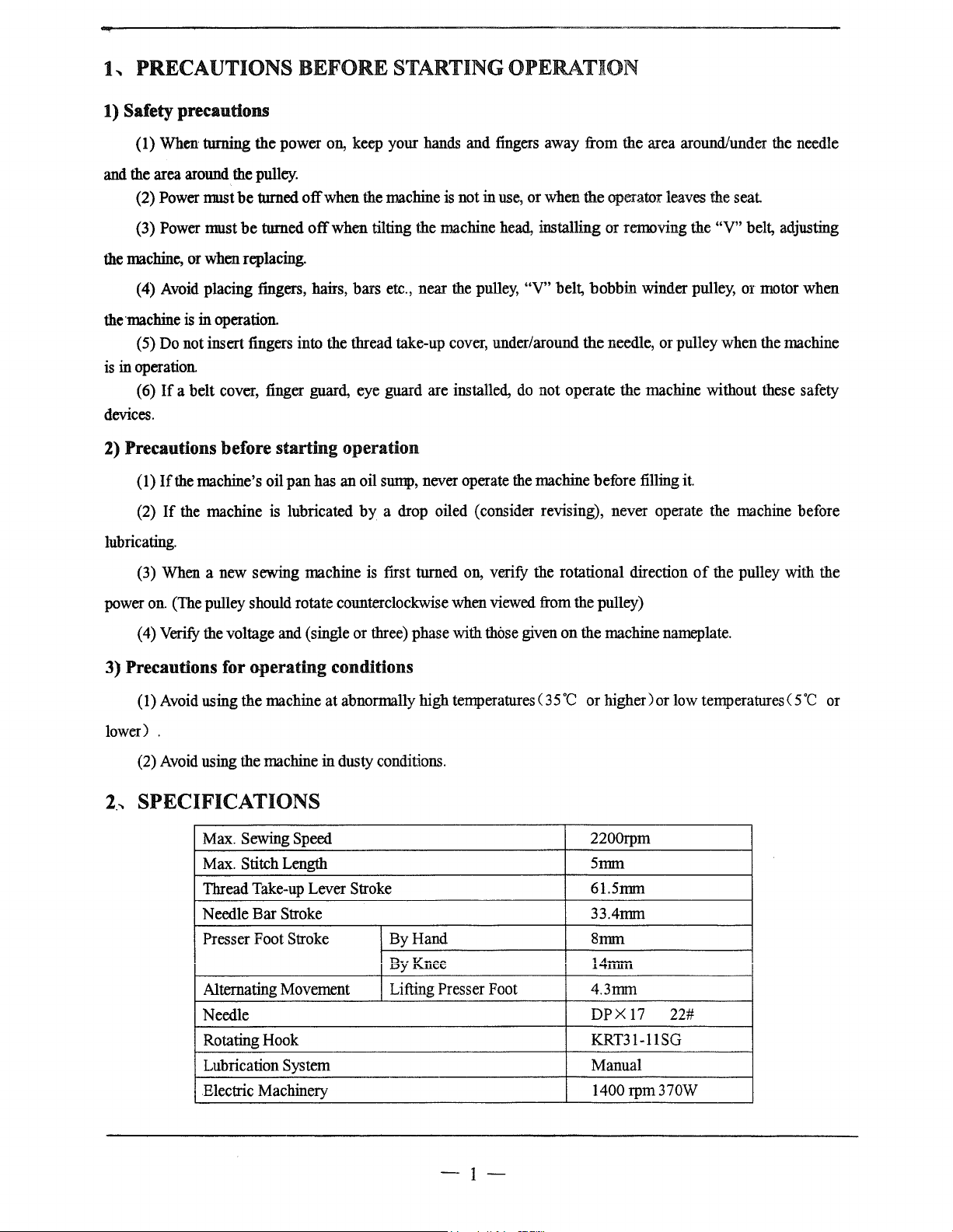

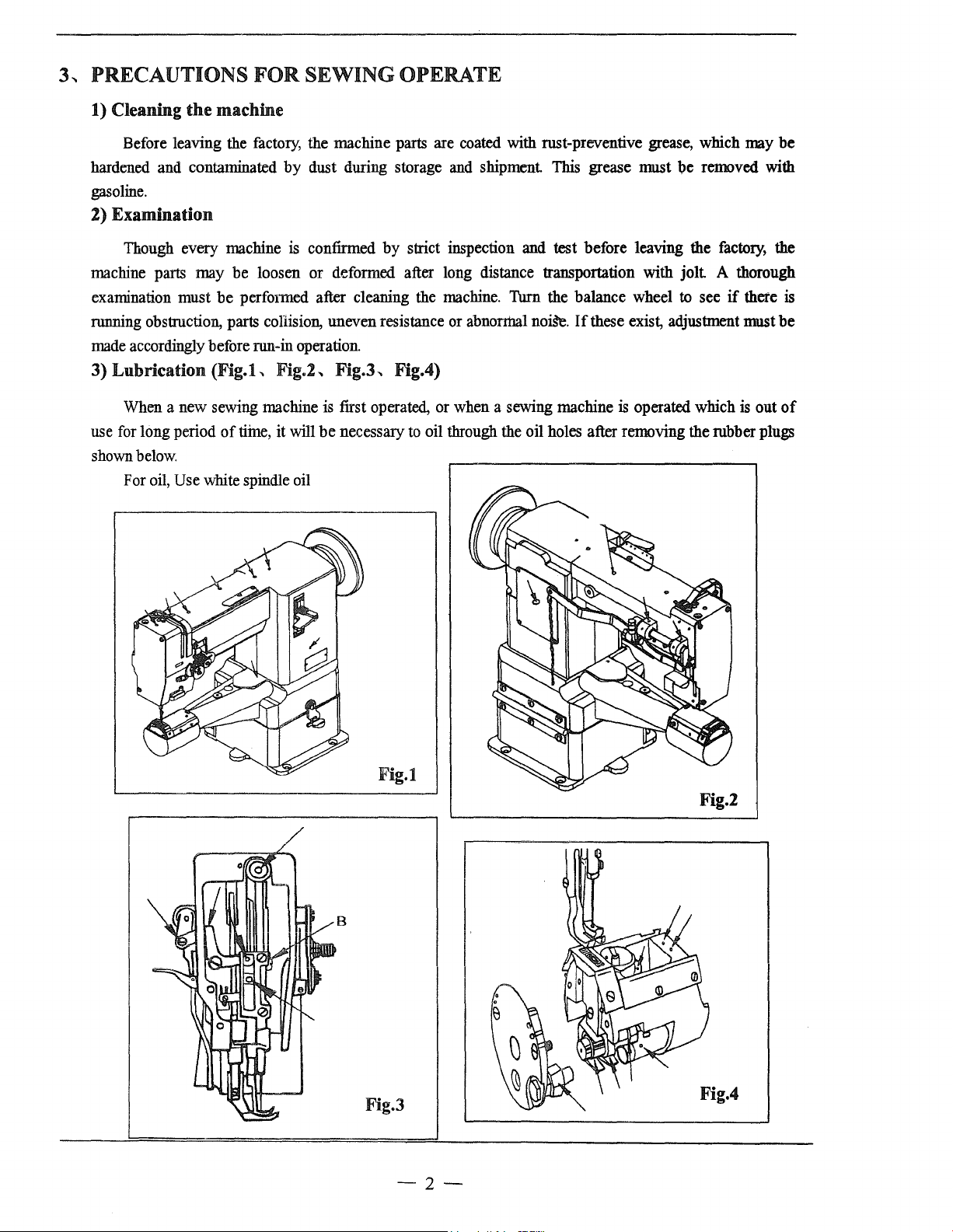

3) Lubrication (Fig.l-. Fig.2, Fig.3, Fig.4)

When a new sewing machine is first operated, or when a sewing machine

use for long period

shown below.

For oil,

of

tiine, it will

Use white spindle oil

be

necessary

to

oil through the oil holes after removing the rubber plugs

is

operated which

be

removed with

A thorough

if

there

is

be

is

out

of

Fig.l

B

I

I

Fig.3

-2-

Fig.2

Fig.4

4)'Broken-in

It

is

imperative that

1600rpm in

4..

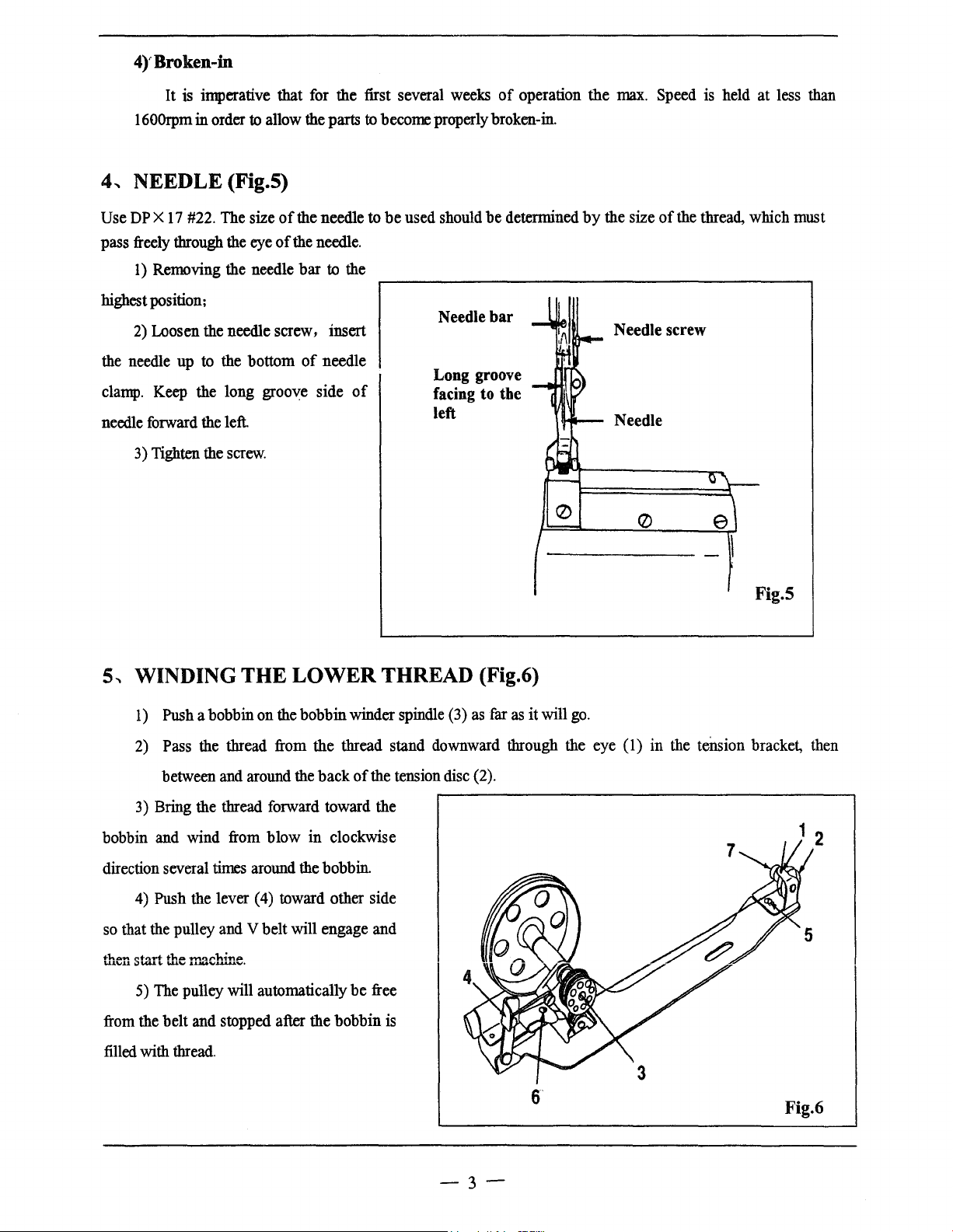

NEEDLE (Fig.5)

Use

DP

X

pass

freely

1)

Removing

17

#22.

through

order

The

the

the

to

allow

the

size

of

the

eye

of

the

needle bar

for

the

parts

needle

needle.

to

first several

to

become

to

be used

the

weeks

properly

should

of

operation the

broken-

be determined by

in.

the

max.

size

Speed

of

the

is

held

thread,

at

less

than

which must

highest

the

clamp.

needle

position:

2)

Loosen

needle

Keep

forward

3)

Tighten

5..

WINDING

1)

Push

2)

Pass

the

up

to

the

the

the

a bobbin

the

needle screw, insert

the

bottom

long groove side

left.

screw.

THE

thread

LOWER

on

the

bobbin winder

from

of

needle

the thread stand

Needle bar

Long groove

of

facing to tbe

left

THREAD (Fig.6)

spindle

(3)

as

downward

far

as

through

it will

go.

the

eye

Needle

(1)

in

the

tension bracket,

Fig.S

then

between

3)

Bring

4)

that

5)

and

Push

the

The

the

with

belt

bobbin

direction several

so

from

filled

and

around

the

thread

wind

from

times

the

lever (

pulley

and

V belt will engage and

pulley will automatically be

and

stopped after the bobbin

thread.

the

back

forward

blow in clockwise

around

4)

the

toward

toward the

bobbin.

other side

of

the

free

is

tension

disc

(2).

-3-

1 2

Fig.6

---··-~·---~--------

6

..

ADJUSTING THE BOBBIN WINDER (Fig.6)

1)

In

case

of

uneven

winding

Loosen the screw ( 5 )

required.

2)

Winding

Adjustment screw (

on the bobbin.

3)

Winding

Strength

7-..

REMOVING AND INSERTING

1) Take

Open the cover and take out the bobbin.

2) Install

Replace the bobbin to the bobbin case;

pull the thread to the left.

amount

strength

of

the winding can be adjusted with the nut (

out

the

bobbin

the

bobbin

in

the tension bracket and move the bracket

of

thread

6)

can be turned in or out to increase or to decrease the amount

THE

to

the right

7)

BOBBIN (Fig.7)

or

to the left as may

of

thread wound

be

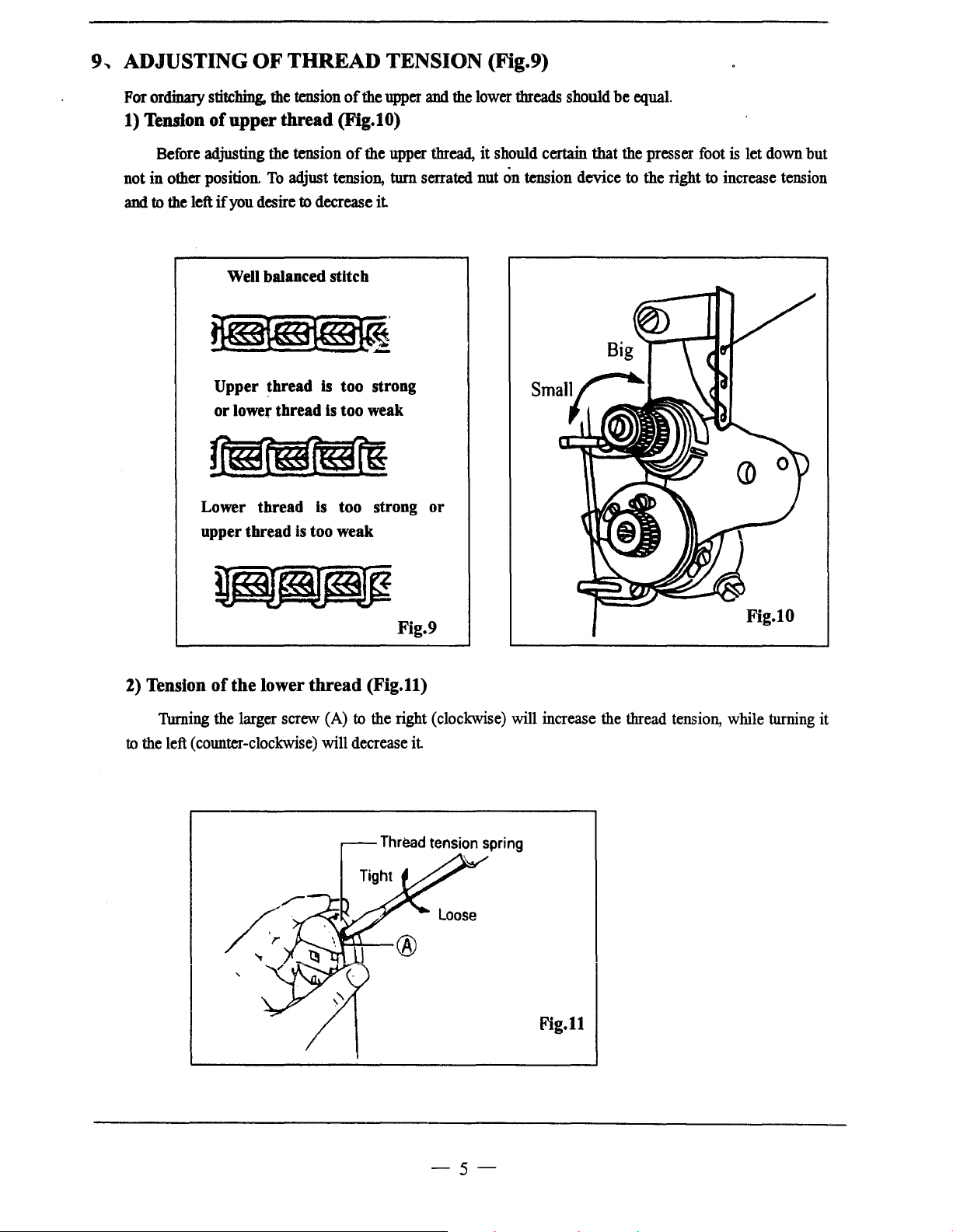

8"

THREADING (Fig.8)

Raise the needle

and thread the upper thread in the following

order.

bar

to

its highest position

Fig.7

-4-

Fig.8

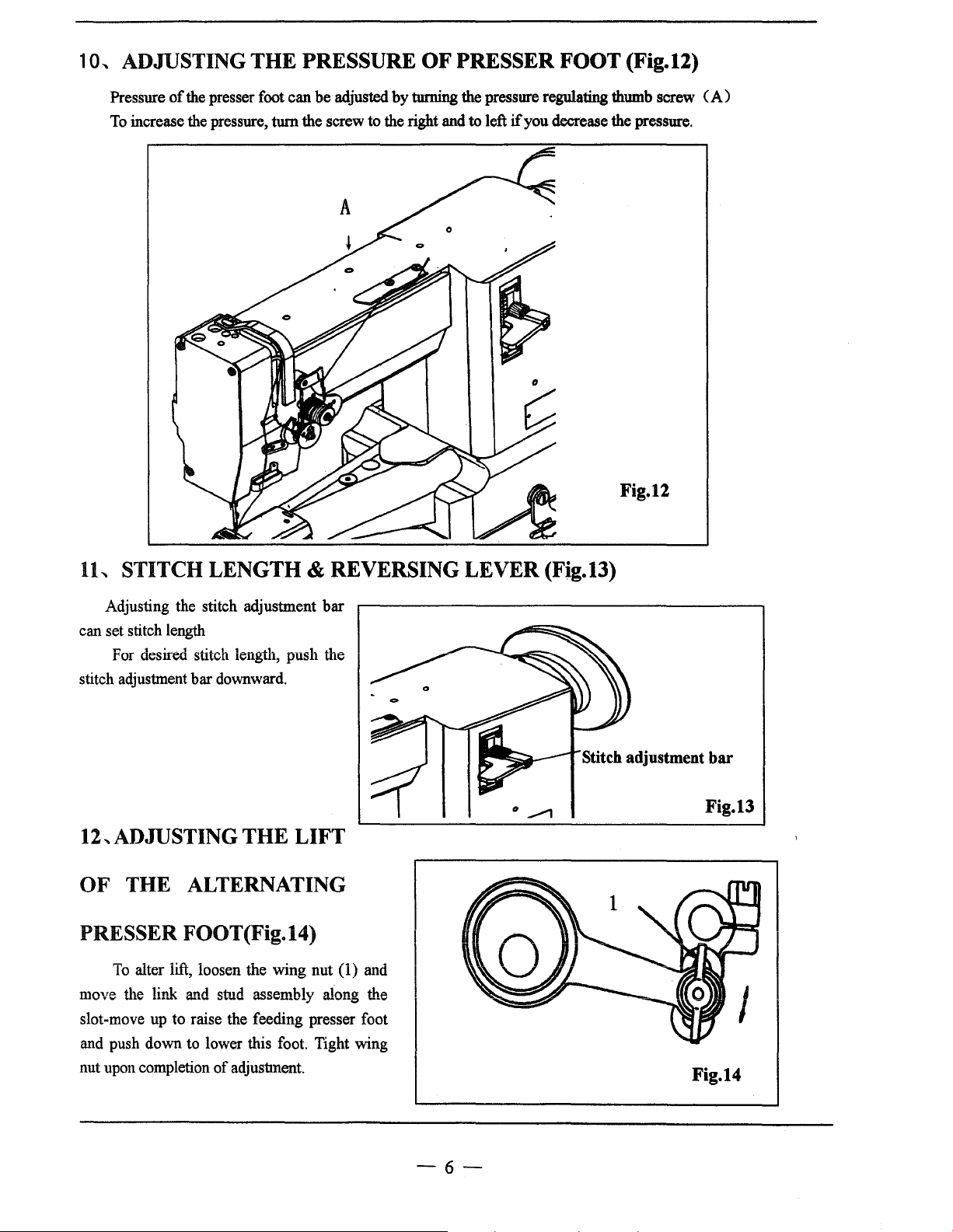

9,

ADJUSTING

OF

THREAD TENSION (Fig.9)

For ordinary

1) Tension

Before adjusting the tension

not in other position.

and

to

stitching.

of

upper

the

left

if

you

Well balanced stitch

Upper thread

or

Lower thread

upper thread

desire

lower thread

the

tension

thread

To

adjust tension, turn serrated nut on tension device

is

of

(Fig.lO)

of

to

decrease

is

too strong

is

too weak

is

too strong or

too weak

the

upper

the upper

it

and

the

thread,

lower

threads should be

it should certain that the presser foot

equal.

to

the right

is

let down but

to

increase tension

2)

Tension

Turning

to

the

of

the lower

the

larger screw

left (counter-clockwise) will decrease

thread

(A)

Fig.9

(Fig.ll)

to

the

right (clockwise) will increase

it

Fig.ll

the

thread

tension,

Fig.lO

while

turning

it

-5-

10,

ADJUSTING THE PRESSURE OF PRESSER FOOT (Fig.12)

Pressure

To

of

the presser foot can be adjusted by turning the pressme regulating thumb screw

increase the pressure,

tum

the screw to the right and to left

if

you decrease the pressure.

Fig.12

(A)

11, STITCH LENGTH & REVERSING LEVER (Fig.13)

Adjusting the stitch adjustment bar

can set stitch length

For desired stitch length,

stitch adjustment bar downward.

12-.ADJUSTINGTHE

OF

THE ALTERNATING

push the

LIFT

PRESSER FOOT(Fig.14)

To

alter iift, ioosen the wing nut

move the link and stud assembly along the

slot-move up to raise the feeding presser foot

and push down to lower this foot. Tight wing

of

nut upon completion

adjustment.

(i)

and

Fig.13

Fig.14

-6-

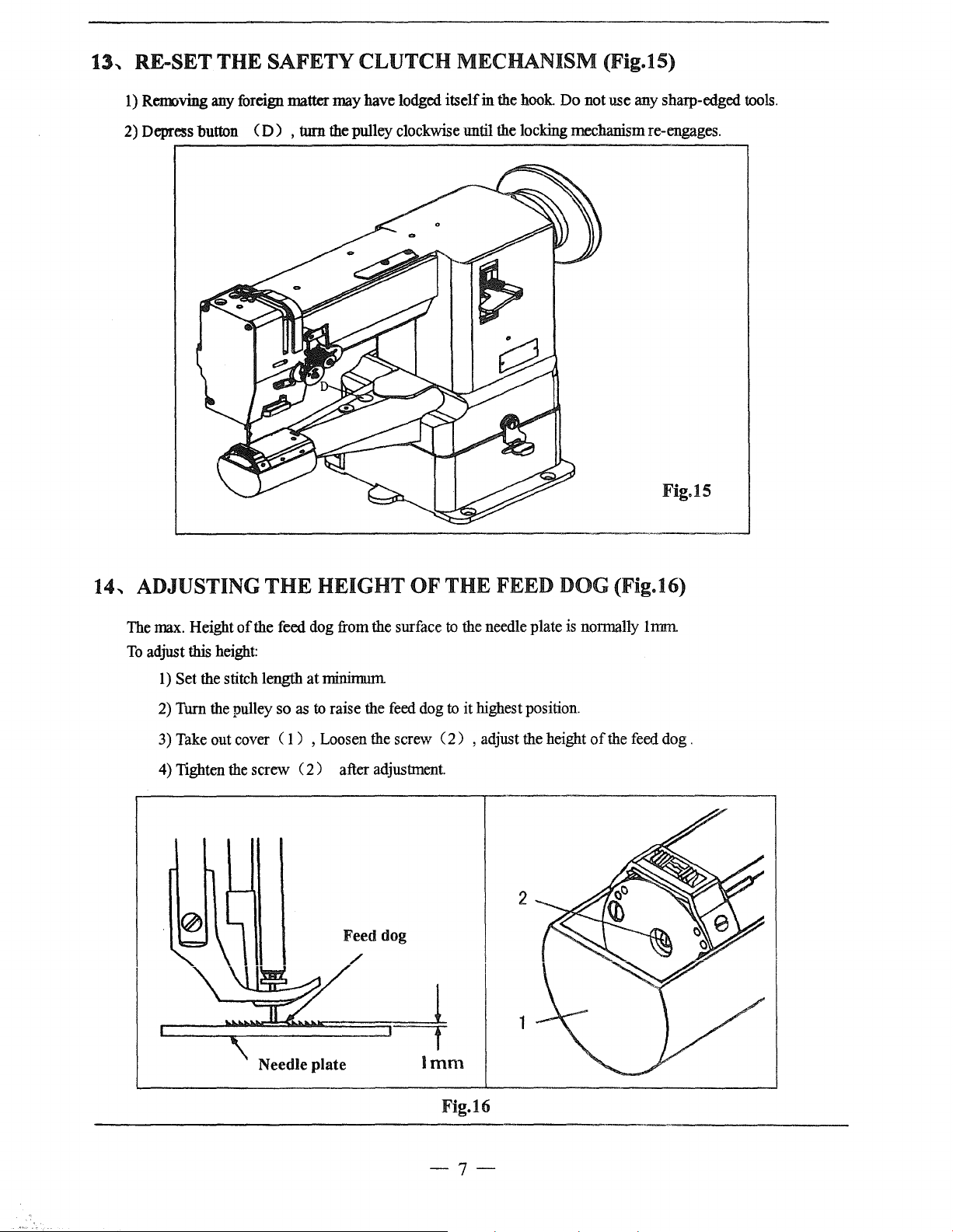

13..

RE-SET THE SAFETY CLUTCH MECHANISM (Fig.15)

1) Retmving

2) Depress button

any

foreign matter may have lodged itself in

(D)

, turn

the

pulley clockwise until

the

hook.

Do not use

the

locking mechanism re-engages.

any

sharp-edged

Fig.15

tools.

14

..

ADJUSTING

The

max.

To

adjust

1)

2) Thrn

3)

4) Tighten

Height

this

Set

Take

THE

of

the

height:

the

stitch length at mininrum

the

pulley

out

cover

the

screw (

HEIGHT

feed

dog

so

as

to

( 1 ) , Loosen

2)

from

raise

after

OF

THE

the

surface

the

feed

the

screw ( 2 ) , adjust

adjustment.

dog

to

to

1

t

lmm

FEED DOG (Fig.16)

the

needle plate

it highest position.

the

2

1

is

height

normally

of

the

lmm

feed

dog .

Fig.16

-7-

Loading...

Loading...