Page 1

HI

Customer

Copy

®

Service

Basting Machine

In struction

a

t Cata

al

SHANGHAI HUIGONG

N0.3

SEWING MACH INE FACTORY

Page 2

Page 3

•

CAUTIONS

1,

Cautions on operation

I)

When the power

to

the UP position when the power switch is turned

2)

Note that braking does not work

operation.

3)

Since dust or other foreign matter entering into the control box may cause malfunction or trouble, be

sure

to

keep control box cover closed during operation.

4)

Do

not use a multi meter to check the control circuit. Otherwise, semiconductors in the control circuit

might be damaged by voltage from the multimeter.

2.

Precautions before

I ) Never operate the machine before filling the machine's oil pan.

2)

When a new sewing machine is first turned on, verify the rotational direction

ON

USE

is

turned on and off, keep your foot away from the

on.

if

the power is turned off, or power failure takes place, during machine

starting

operation:

pedal

Note that the needle goes up

of

the pulley with the

power 0

3.

or lower) .

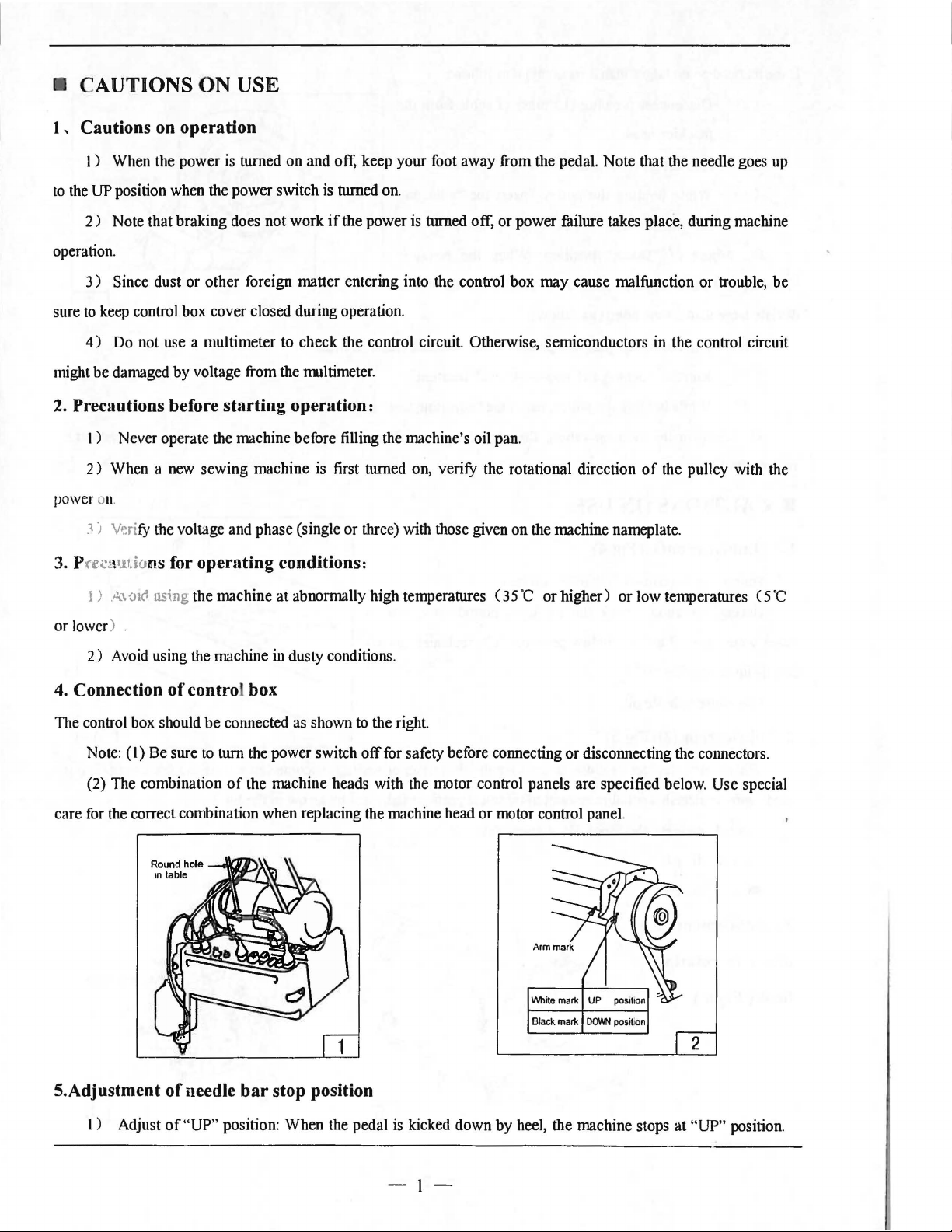

4.

The control box should be connected

care

11

.

~)

V'!ri

fy

the voltage and phase (single

Pfuautions for operating conditions:

1)

A\Olcl

us'ng the machine

2)

Avoid

using the machine in dusty conditions.

Connection

Note:

(2) The combination

for

the correct combination when replacing the machine head or motor control panel.

(I)

of

contro box

Be sure

to

turn the power switch

of

at

abnormally high temperatures (

as

shown

the machine heads with the motor control panels are specified below. Use special

or

three) with those given on the machine nameplate.

35

'C or higher) or low temperatures ( 5

to

the right.

off

for safety before connecting or disconnecting the connectors.

·c

INMe

mark

Black mark

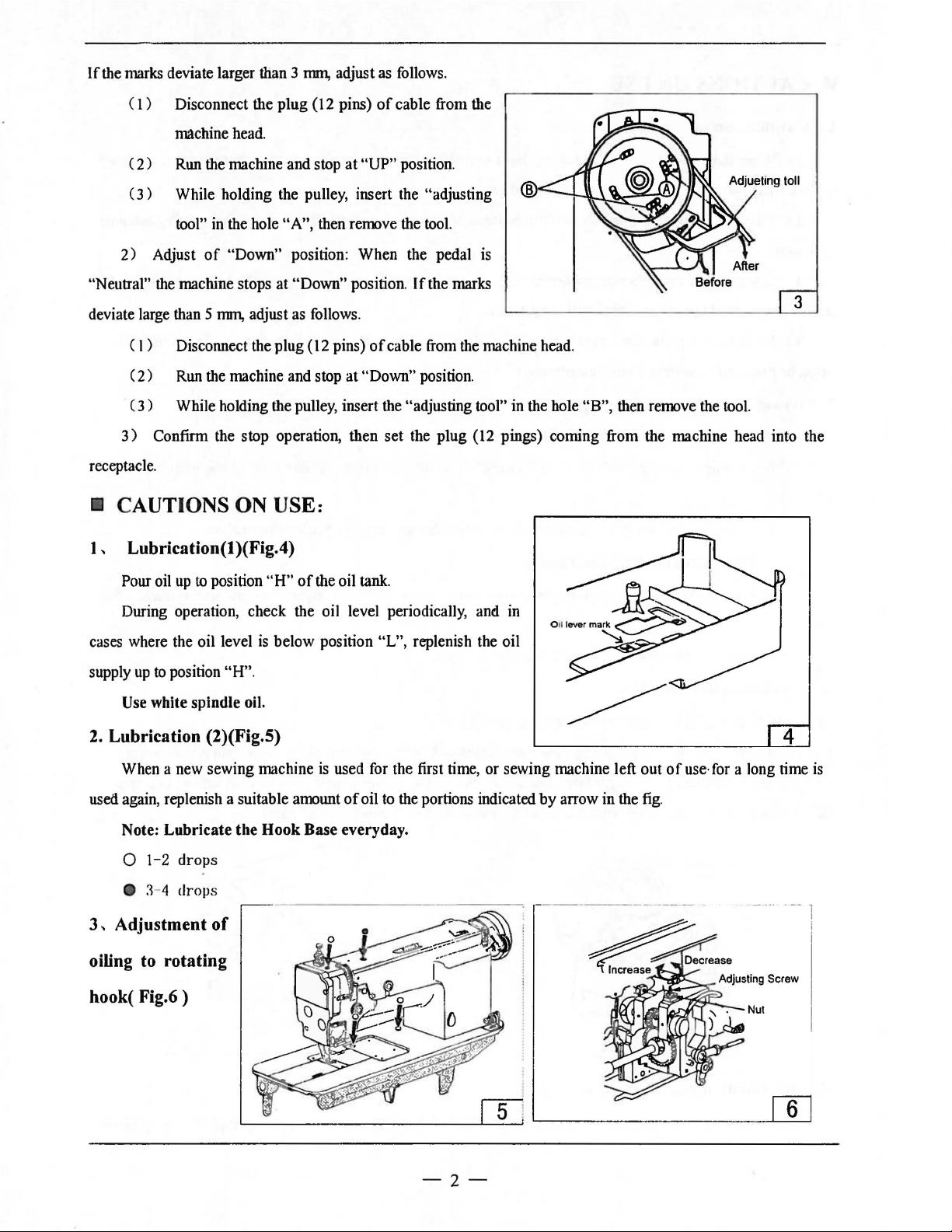

S.Adjustment

I)

Adjust

of

needle

of"UP"

bar

stop position

position: When the pedal

is

kicked down by heel, the machine stops

-1-

UP

DOWN

pos1110n

position

at

"UP" position.

Page 4

If

the marks deviate larger than 3 nnn, adjust

(

l)

Disconnect the plug (12 pins)

machine head.

(

2)

Run the machine and stop

(3)

While holding the pulley, insert the "adjusting ®

tool"

in

the hole "A", then remove the tool.

2)

Adjust

of

"Down" position: When the pedal is

at

as

follows.

of

cable from the

"UP"

position.

"Neutral" the machine stops at "Down" position.

deviate large than

(I

) Disconnect the plug (

(

2)

(

3)

3)

Confirm the stop operation, then set the plug (12 pings) coming from the machine head into the

receptacle.

•

CAUTIONS

5 nnn, adjust as follows .

12

pins)

Run the machine and stop

While holding the pulley, insert the "adjusting tool" in the hole "B", then remove the tool.

at

"Down" position.

ON USE:

If

the marks

of

cable from the machi

1 , Lubrication(! )(Fig.4)

Pour oil

During operation, check the oil level periodically, and in

cases where the oil level

supply

Use

up

to

position

up

to

position

white spindle oil.

"H"

"H"

of

the oil tank.

is

below position "L", replenish the oil

.

ne

3

head.

2.

Lubrication (2)(Fig.5)

When a new sewing machine

used again, replenish a suitable amount

is

used for the first time, or sewing machine left out

Note: Lubricate the Hook Base everyday.

0 1-2

e

3,

Adjustment

~

- 4

drops

drops

of

oiling to rotating

hook( Fig.6 )

of

oil

to

the portions indicated

-2-

by

arrow in the fig.

of

use· for a long time

is

Page 5

OPERATION

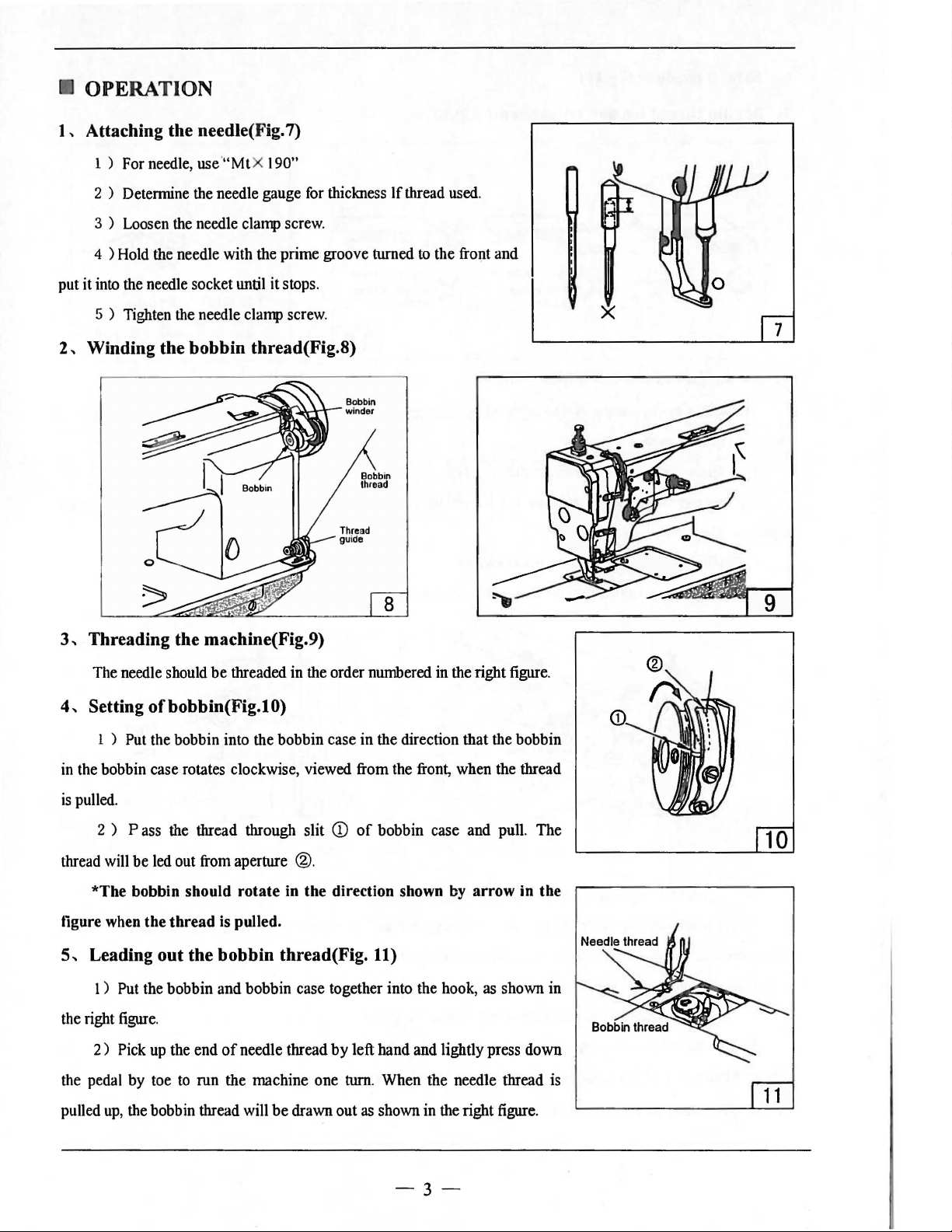

1 , Attaching the needle( Fig. 7)

1 ) For needle, use '

2 ) Determine the needle gauge for thickness If thread used.

3 ) Loosen the needle clamp screw.

4 ) Hold the needle with the prime groove turned

put it into the needle socket until it stops.

5 ) Tighten the needle clamp screw.

2,

Winding the

"Mt

bobbin

X 190"

thread(Fig.8)

to

the front and

7

9

3,

Threading the machine(Fig.9)

The needle should

4,

Setting ofbobbin(Fig.lO)

1 ) Put the bobbin into the bobbin case in the direction that the bobbin

in the bobbin case rotates clockwise, viewed from the front, when the thread

is

pulled.

Pass

2 )

thread will be led out from aperture

*The bobbin should rotate in the direction shown by arrow in the

tigure when the thread

5,

Leading

I ) Put the bobbin and bobbin case together into the hook, as shown in

the right figure.

2)

the pedal by toe

Pick

out

up

be

threaded in the order numbered in the right figure.

the thread through slit

CD

of

bobbin case and pull. The

®.

is

pulled.

the

bobbin

the end

of

to

run the machine one turn. When the needle thread is

thread(Fig.

needle thread

11)

by

left hand and lightly press down

<D

up,

pulled

the bobbin thread will

be

drawn out

as

shown in the right figure.

-3-

Page 6

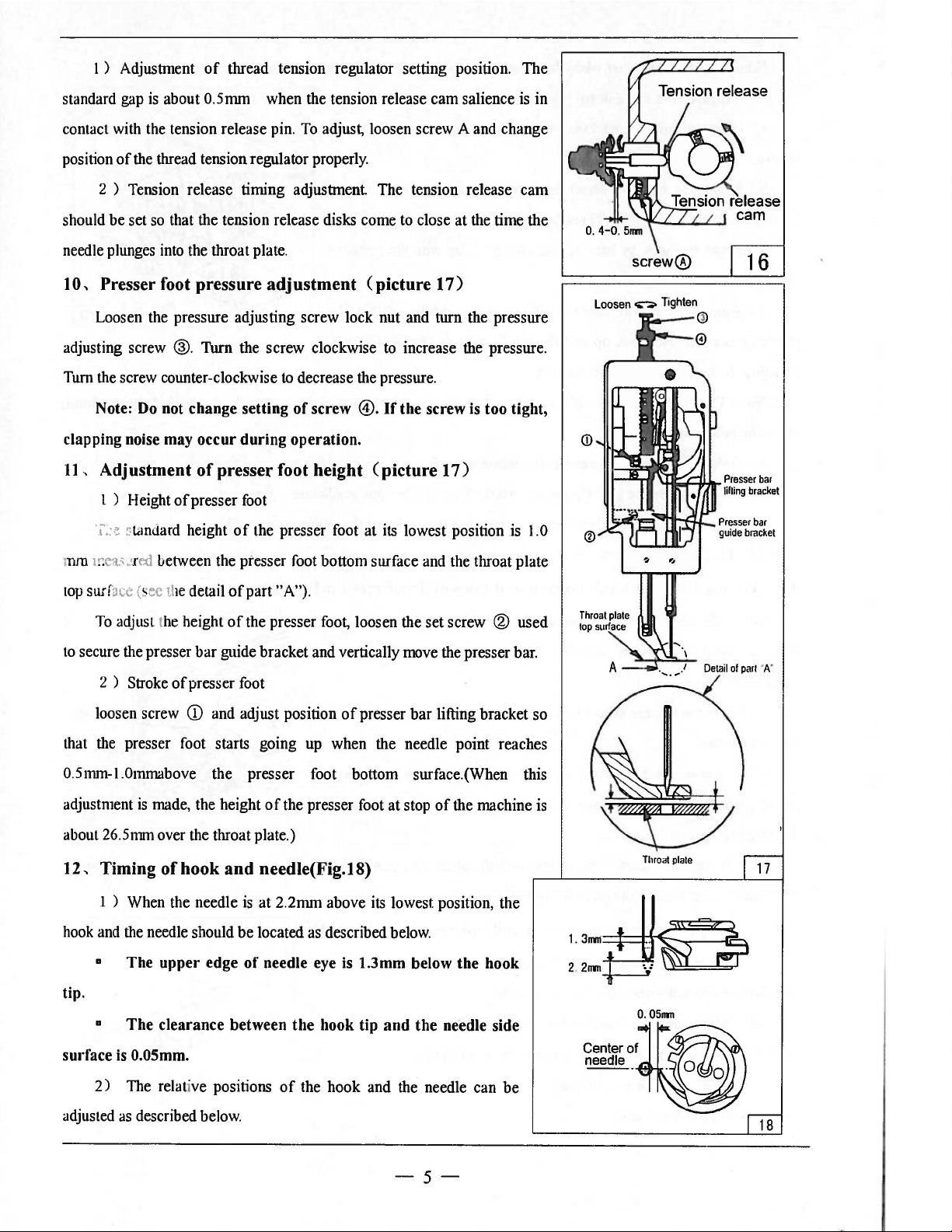

6..

Thread

tension (Fig.12)

7" Bobbin

0 Balance tension

8

..

Needle thread tension

The needle thread tension can

the thread take-up spring.

1 ) Tension disk presstrre adjustment (Fig.

(1) In most cases, thread tension can by properly adjusted only by changing tightness

regulator thmnb nut.

(2)

thread

To

increase presstrre, ttrrn the nut clockwise.

tension

adjustment(

Tight needle or

loose bobbin

tension

adjustl!'~dt

be

adjusted

.Fig.13)

Loosen needle

or

tight bobb in

tension

by

changing presstrre

l4)

Loosen

Bobbin tension

adjusting screw

of

the tension disk, and force and stroke

'J)Tighten

of

the tension

13

of

(3)

To

decrease pressure, ttrrn the nut counter-clockwise.

2)

Thread take-up spring force/stroke adjustment

Apply a scre\vdriver to the thread take-up spring stud and ttrrn the stud. Spring force increases when the

screwdriver

face plate and loosen the screw

3 ) Thread take-up spring force/stroke adjustment ( Fig.

is

ttrrned counter-clockwise, and decreases when ttrrned clockwise.

of

tension regulator slightly.

(Fig

. 15)

15

If

the stud is tight, remove the

)

Loosen the stop screw, adjusting the stopper block , After the adjustmen

The standard stroke

9,

Adjustment

of

thread take-up spring

of

thread

tension regulator (Fig.

is

from 6mrn

to

8nm1

16)

-4-

t,

be sure

to

tighten the set screw.

Page 7

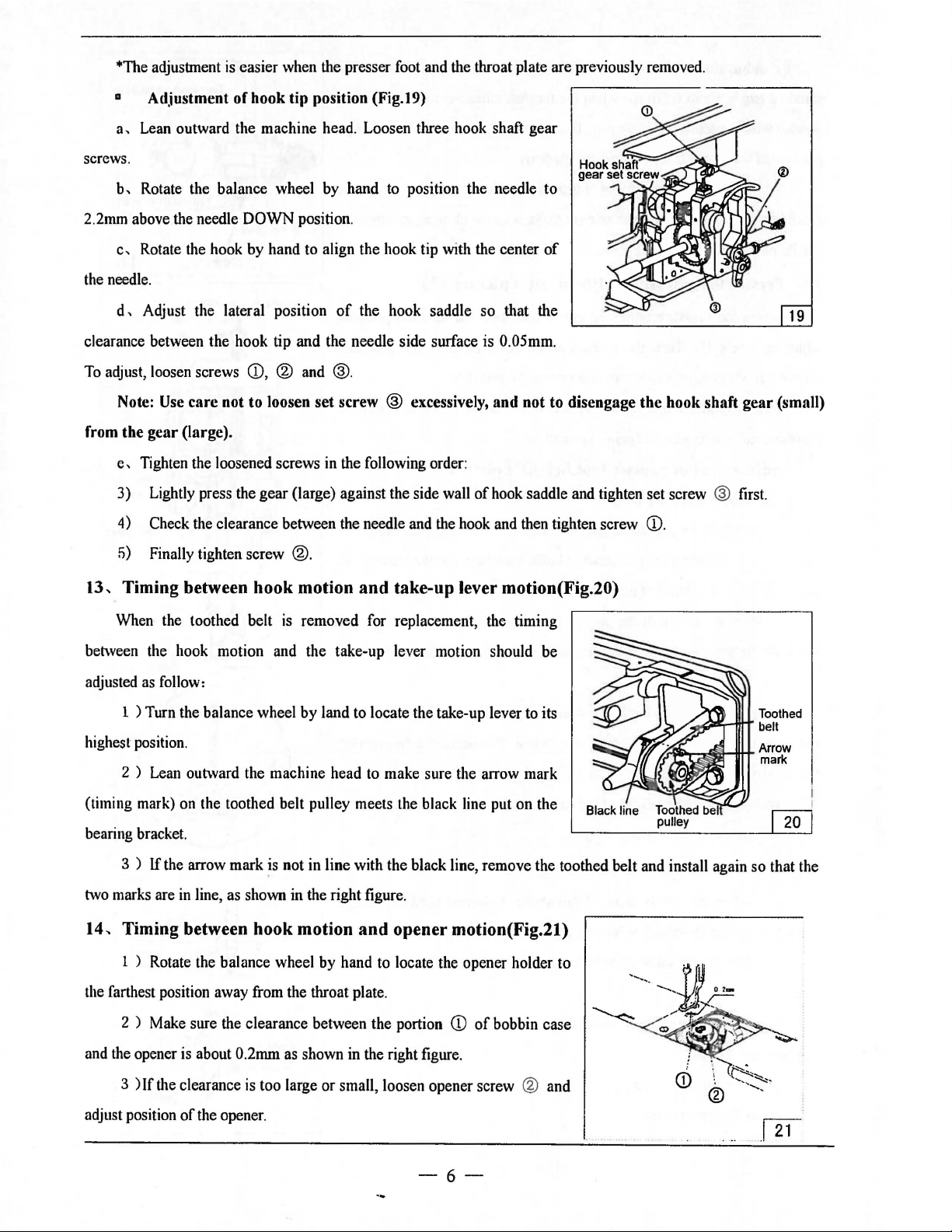

1 ) Adjustment

of

thread tension regulator setting position. The

standard gap

contact with the tension release pin.

position

2 ) Tension release timing adjustment The tension release

should

needle plunges into the throat plate.

10,

Presser foot pressure

Loosen the pressure adjusting screw lock nut and turn the pressure

adjusting screw

Turn the screw counter -clockwise

Note: Do not change setting

clapping noise may

11

, Adjustment

l ) Height

'i'.>'!

is

about 0.5mm when the tension release cam salience is in

To

adjust, loosen screw A and change

of

the thread tension regulator properly.

be

set so that the tension release disks come to close at the time the

®.

Turn the screw clockwise

occur

of

of

presser foot

~

tandard

height

adjustment

to

decrease the pressure.

of

screw

during

operation.

presser foot height

of

the presser foot at its lowest position is 1.0

(picture

to

@.

If

(picture

17)

increase the pressure.

the

screw is too tight,

17)

cam

Loosen

screw®

.;-:.

Tighten

1010.---<ID

mm 1

r.

eas mxi

top

surface (sec the detail

To

to

secure the presser

2 ) Stroke

loosen screw

that the presser foot starts going up when the needle point reaches

0.5mm-l.Ommabove the presser foot bottom surface.(When this

adjustment

about 26.5nnn over the throat plate.)

12,

Timing

1 ) When the needle

hook and the needle should

•

tip.

•

surface is 0.05mm.

between the presser foot bottom surface and the throat plate

of

part "A").

adjust the height

of

is

made, the height

of

The

upper

The

clearance

of

the presser foot, loosen the set screw ® used

bar

guide bracket and vertically move the presser bar.

presser foot

CD

and adjust position

of

hook

and

needle(Fig.18)

is

at 2.2mm above its lowest position, the

be

located as described below.

edge

of

needle eye is 1.3mm below

between

the presser foot at stop

the

of

hook

presser

tip

and

bar

lifting bracket so

of

the

needle side

the machine is

the

hook

Center

needle

Throat

0.0511111

of

plate

2)

adjusted

The relative positions

as

described below.

of

the hook and the needle can

be

-5-

18

Page 8

*The adjustment

is

easier when the presser foot and the throat plate are previously removed.

• Ad.iustment of hook tip position (Fig.19)

a,

Lean outward the machine head . Loosen three hook shaft gear

screws.

b,

Rotate the balance wheel by hand

2mm

2.

the needle.

clearance between the hook tip and the needle side surface is 0.05mm.

To

above the needle DOWN position.

c,

Rotate the hook by hand to align the hook tip with the center

d,

Adjust the lateral position

adjust, loosen screws

Note:

Use

care not to loosen set screw ® excessively, and not to disengage the hook shaft gear (small)

CD,

® and

of

®.

to

position the needle to

of

the hook saddle so that the

from the gear (large).

e,

Tighten the loosened screws

3) Lightly press the gear (large) against the side wall

in

the following order:

of

hook saddle and tighten set screw ® first.

19

Check the clearance between the needle and the hook and then tighten screw

4)

5)

Finally tighten screw

13, Timing between hook motion

When the toothed belt

between the hook motion and the take-up lever motion should be

as

adjusted

highest position.

(timing mark) on the toothed belt pulley meets the black line put on the

bearing bracket.

two marks are

follow:

1 ) Turn the balance wheel

2 ) Lean outward the machine head

3 )

If

the arrow mark

in

line, as shown in the right figure.

14, Timing between hook motion

l ) Rotate the balance wheel by hand to locate the opener holder to

®.

and

take-up lever motion(Fig.20)

is

removed for replacement, the timing

by

land to locate the take-up lever to its

to

make sure the arrow mark

~s

not in line with the black line, remove the toothed belt and install again so that the

and

opener motion(Fig.21)

CD

.

/ - ..GASr-11tT belt

Toothed

Arrow

mark

the

farthest position away from the throat plate.

CD

of

2 ) Make sure the clearance between the portion

and the opener is about 0.2mm as shown in the right figure.

3 ) If the clearance is too large or small, loosen opener screw

adjust position

of

the opener.

bobbin case

® and

-6-

Page 9

• ADJUSTMENT

OF

THREAD TRIMMER

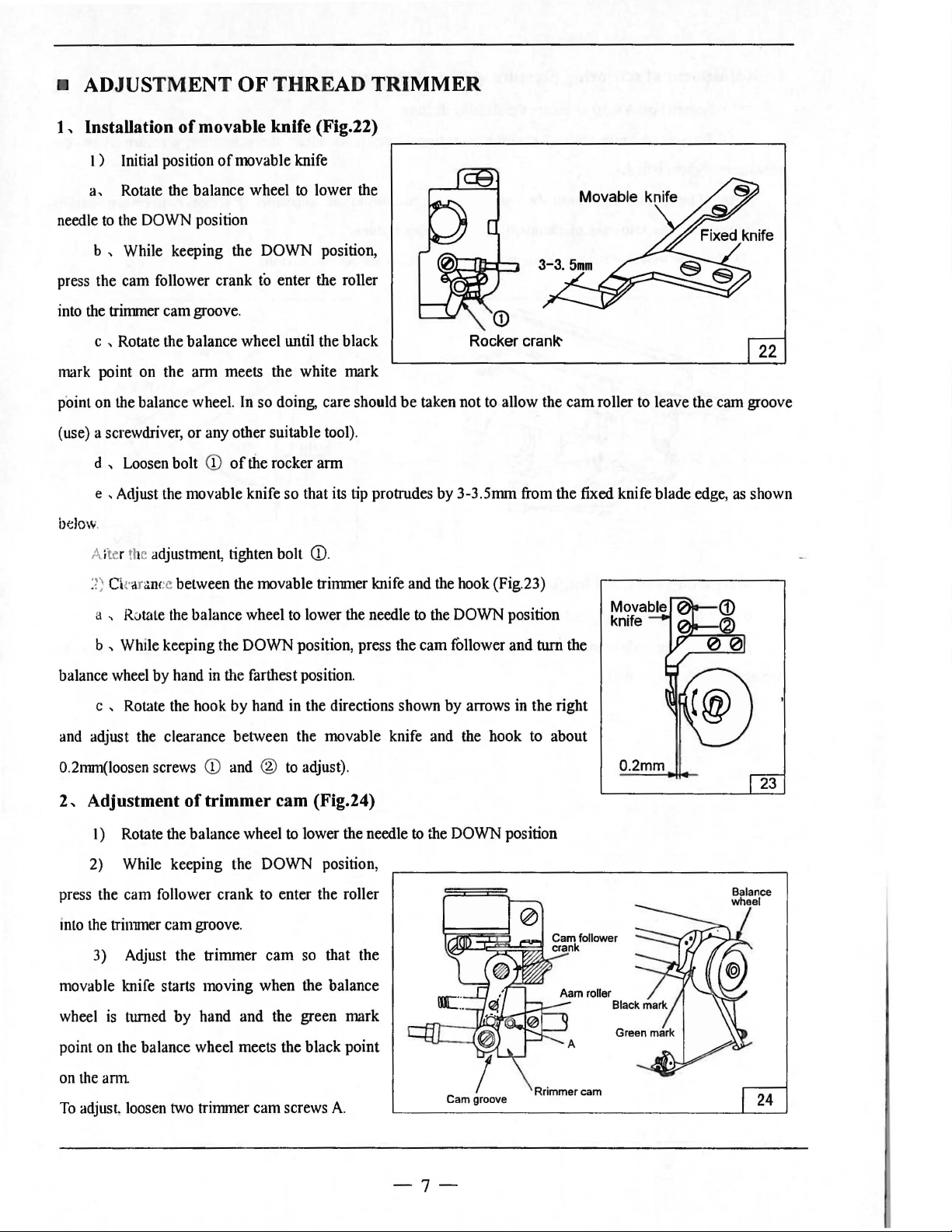

1 , Installation

l)

Initial position

a,

Rotate the balance wheel

needle

to

the DOWN position

b , While keeping the DOWN position,

press the cam follower crank to enter the roller

into the trimmer cam groove.

c , Rotate the balance wheel until the black

mark point on the arm meets the white mark

point on the balance wheel. In so doing, care should

(use) a screwdriver,

d , Loosen bolt

e , Adjust the movable knife so that its tip protrudes by 3-3.5mm from the fixed knife blade edge, as shown

btl

ow

.

Alter the adjustment, tighten bolt

of

movable knife (Fig.22)

of

movable knife

to

lower the

or

any other suitable tool).

CD

of

the rocker arm

CD.

Rocker

be

taken not to allow the

crank-

cam

roller to leave the cam groove

2) Ck anmcc between the movable trinnuer knife and the hook (Fig.23)

a , Rotate the balance wheel to lower the needle

b , While keeping the DOWN position, press the cam follower and

balance wheel by hand in the farthest position.

c , Rotate the hook by hand in the directions shown

and adjust the clearance between the movable knife and the hook to about

0.2nnn(loosen screws

2,

Adjustment

I) Rotate the balance wheel

2) While keeping the DOWN position,

press the cam follower crank to enter the roller

into the trinnner cam groove.

3) Adjust the trimmer

movable knife starts moving when the balance

wheel

is

turned

CD

and ®

of

trimmer cam (Fig.24)

by

hand and the green mark

to

adjust).

to

lower the needle

cam

so that the

to

the DOWN position

by

arrows in the right

to

the DOWN position

tum

the

0.2mm

point on the balance wheel meets the black point

on the

ann

To

adjust loosen two trimmer cam screws

A.

Cam groove

-7-

Page 10

3,

Adjustment

( 1 ) Loosen bolt A used to secure the fixed knife base.

(

2)

Turn fixed knife vertical position adjusting screw 8 to adjust the scissoring pressure. After the

of

scissoring pressure

of

thread

trimmer

(Fig.25)

adjustment, tighten bolt

Note:

The

over-torque to

(3) Move the movable trirruner knife to make sure threads are cut successfully.

4,

Sharpening the fixed knife(Fig.26)

If the fixed knife becomes dull, sharpen it as shown

A.

pressure

the

trimmer

should

mechanism,

be

adjusted

and

trimming

Fixed knife

base

A

B

as

minimum

failure.

in

the figure below.

as

possible. Excessive

pressure

causes

Since it

movable knife becomes dull.

is

impossible to sharpen the movable "knife, replacement with a new one is required when the

-8-

Page 11

A.ARM

BED

AND

ITS

ACCESSORIES

16

33323~

-9-

Page 12

A.ARM BED AND ITS ACCESSORIES

Fig.

No.

AOl

A02 H2400B2060

A03

A04

A05

A06 HA300B2170 Screw

A07 Il3200B2030

A08

A09

AlO H3200B2040

All

Al2

Al3

Al4

Al5

Al6

Al7

Al8

Al9

A20

A21

A22

A23

A26 H4813B!l001

A27

A28

A29

A30

A31

A32 HA300B:?.

A33

A34

A35

A36

I 37 H675GB8001 Thread cutter 1

t\38

Part

No.

H3000D2160

H3200B2060 Oil

1-1320082070

H2400B20MO

H3200B2050

H2400J2010 Oil

H2000B2010 Rubber plug

HA700B2060

H2400B2100 Thread guide

HA100E2150 Screw 2

HH415B7101

H6658B8001

HA100E2150 Screw 1

HAJOOB2070 Washer

HI-142787101

H2000M0090

H4913B8001 Needle

14491288001

H3200B20MO

H5015B8001

H4914B8001

HH411B8001 Needle plate

HI-141288001

HH413B8001

H4747B8

HA106B0673 Rubber plug 2

HA300B2160 Screw

l-13

20082020

H6762B8001

Screw

Spacer

guide plate 1

Thread guide

Screw 3

Ann

side cover (left)

'fbrend

take-up cover

cap 1

Ann

>'

ide cover (right)

Screw

Bobbin winder complete

Rubber ring

Thread guide complete

Cap 2

bar

supporter

Screw

Thread guide

Slide plate (Jell)

Cover

Screw

Needle holder

Scr<Jw

l90 Sere 2

Slide plate (right)

001

Face plate

Screw 2

Description

Pes.

2

1

I

11

1

1

(<ll13)

1

(<ll13)

1

2

1

SM11164(40)xlO

1

<ll35

1

SMll/64

<ll4.5x<IJ8x

1

1

1

2

2

l 3/32-5/

1

2

1

I

1

SM11/64(40)x6.5

3/32-1/4

1

(<ll19)

2

1

SM91

Ci4(40)X4

!l

Remarks

(40J

1

.5

xl()

-10-

Page 13

B.

THREAD

TENSION

1 2

MECHANISM

3 4

5 6 7

19 18

L

24

20

21

22

23

17

16

15

14

13

12

11

10

-11-

Page 14

B.THREAD TENSION MECHAN ISM

Fig.

No.

801

802

803

804

805

806

807

80!!

809

810

811

812

813

814

1315

816

817

818

819

820

821

822

8:!3 HA31080701

8:!4

Part No.

Thread

l-1322180687

HAI0680676 Screw I

.1-1322186820

HA300C2030 Screw

H3221B6810

H322180683

HAII2B0693

1-13221806!!4

HA71080671

H2504C0658

l-1324818221

H324818D21

H4804C8001 Screw I

H2504C0652

1-1200410067

H320082100

H322186819 Stopper

HH406C8001

HH407C8001

HA31080705 Thread tension

HA31080702 Tension releasing plate

HA60780068 Spring

HA3411D30!! Screw

guide I

Mounting plate I

Nut 2

Thread tension stud

TIU'ead

tension disc 2

Spring

Thumb nut I

Thumb nut

Thread Take-up spring

Plate complete

TIU'cud

tension stud

Screw I

Screw

TIU'ead

tension stud

Thread releasing pin

Thumb nut

Description

elise

Pes.

SM 9/64( 40) x6

2

SMIII6

SMII/64(40)x3

SMII/64(40)x14

I

I

I

I

I

SM9/64(40)x22

I

SM9/64(40)x7

SM9/64(40)x6.5

I

I

I

I

2

I

I

I

I

Remarks

4(40)x8

-

!2-

Page 15

C.THREAD

TAKE-UP

LEVER

MECHANISM

&

ARM

SHAFT

MECHANISM

1 2 5 7 8 6 9

10

11

12

13

14 15 16 17 18

25

26

-13-

Page 16

C.THREAD TAKE-UP MECHANISM & ARM SHAFT MECHANISM

Fig.

No.

COl

C02 H32422CI08

C03

C04

cos

C06

C07 H240SD0662

COB

C09 H32111D704

CIO

Cll

Cl2

Cl4

CIS

Cl6

Cl7

Cl8

Cl9

C20 H3204C06SI Arm shaft

C21

C22

C23

C24 HAIOOF2130

C2S

C26

C27

C28

C29

C30

C31

C32

C33

C34

C3S

C36

C37

C38

C39

C40

Part

No.

Oil

H240SD1122

HAI10D0672

H240SDIIII

H240SDI112

H24211D30S

H240SD0662

HA307C0662 Screw I

HAIOSD0662 Screw 1

HAIOOC2070 Screw I

HAIOOC2060 Screw

H240SD0664

H32111BI04 Felt 1

H3204BOOII Arm shaft bushing left (complete) I

HA30SE0662 Screw 2

HH404D8001

H320SC0661 Spring flange 3

HAII3F0684 Screw

H3207C0671 Pulley I

H3200C2030 Cog belt 1

H320SC1021 Pulley

HA104F06S4 Screw 2

H4931L8001 Machine pulley 1

HAIIOD0672

H4930L8001

HA700R0030

H4928L8001

HA700R0040

HA700ROOSO

HA700R0060

H007009300 Retaining ring C-type I

H320SJ0662 Ball bearing

HA300C2030

HA703R0067

HA703R006S

wick I

Thread Take-up guide bracket pin I

Screw

Thread Take-up lever I

Thread Take-up slide block

Plug I

Thread take-up crank pin I

Oil

wick I

Needle bar connecting link 1

Screw I

Thread releasing

Screw I

Screw 2

Speed command disk

Spacer A 2

Speed command disk F20 (up) I

SpacerB

Spacer

Stopper

Screw

Washer

Detector bracket

Description

cam

Fl1

(down)

Pes.

2.Sx240

SMIS/64{28)x 12

3

I

SMI/4{40)x6

SMI/4(40)x4

SM9/32(28)xiO

SM9/32(28)x

I

SMIS/64(28)xl4

I

I

SMIS/64{28)x8.S

I

SM IS/64(28)X6. 7

I

I

1

1

I

I

I

1

1

Remarks

13

-14-

Page 17

D.NEEDLE

BAR & PRESSER

28::-i

::~

25~

22

FOOT

MECHANISM

29

~30

16

7

8

9

6

-15-

Page 18

D.NEEDLE

BAR

& PRESSER FOOT MECHANlSM

Fig.

No.

DOl

D02 HD41708001 Bushing

D03

D04 HH406E8001

D05 H32111D504 Needle bar connecting

D06 H32111D604

D07 HD415D8001 Crank guide

D08 HAIOOC2190

D09

DID

011 HD41308001 Bushing

Dl2

Dl3

Dl4

Dl5

Dl6

Dl7

Dl8

Dl9

D20 HA300C2030 Screw

D21

D22

D23

D24

D25

D26 H2400GOI40

D27

028

029

030

031

Part

No.

H2405D0664 Screw

HH405E8001

HD41608001

HH417E8001

H620408001 Needle clamp

HA500C2030

HAIOOC2170

HD404D0651 Needle

HH407E8001

H3200E2020 Screw

HH408E8001 Bushing

HH409E8001 Presser bar position guide bracket

HH411E8001 Bracket

HH412E8001 Lever spring

HH413E8001 Presser bar

HH414E8001 Spring

HAI17H0692

H2400GOI60 Nut I

H2400G0150 Screw

HA70400657 Rubber plug

HE016L8001 Felt

HH416E8001

Washer

Rubber ring

Screw

Screw

Bell crank guide

Needle bar

Needle bar thread guide

Screw

Lining

presser

Nut

Screw

Pin I

Description

Pes.

3 SM 15/64(28)x

I

4

2

I

I SM9/64(40)x8.5

I

SMI1164(40)x8

2

I

I

I

I

I

SMI/8(44)x4.5

I

MTxl90

I

I

I/8(44)X9

I

1

1

SMII/64(40)x8

2

I

I

I

I

SMI/2X28

I

SM 112(28)x55

I

SMII/64(40)

SM11164(40)x48

I

I

I

16#

Remarks

14

-

16-

Page 19

E.

HOOK

SADDLE

MECHANISM

9

10

--------n

---------18

27

26

-17-

Page 20

E.HOOK SADDLE MECHANISM

Fig.

No .

EOI

E02 H320410021

E03 H320710661

E04 H320710066 Bushing 1

E05

EO'

E07

EOS

E09 H321531504

E10 H321531204

Ell

E12

El3

E14

E15 H320012020 Opener 1

E16

E17

E18

E19

E20 HAI05D0662

E21

E22

E23

E24

E25

E26

E27

E2l!

E29

E30

E31

Part No.

HH404F8001

H850417101 Hook complete I

H6906H8001 Spring

Hl!50518001

H320410656 Oil wick

H321531304 Ling

H32153l104

H2004J0067 Screw I

H3200l2030

H005008050 Spring washer 1

HA104G0658 Nut 1

H320410657

H321421204 Gear (small) 1

H320410653

H2013J0065 Washer

H320012050 Screw

H320410658

H320410659 Nut 1 SM3/16{28)

H005014050 Spring washer 1

HA305E0662

H321421104

HA307C0662

H320416510

H850618001

Hook saddle (right) I

Hook shaft bushing (upper) complete

Screw

Bobbin 1 B0-112(A)M

Bobbin case opener holder pin I

Screw 1

Bobbin case opener holder

Washer I

Screw

Screw 3

Hook shatl bushing (lower)

Screw 1

Screw

Gear (large)

Screw

Screw

Bobbin case

Description

Pes.

1

SM 15/64(28)x30

1

HSH-12-15M

1

2.5x)5

2

SM3/16

1

I

SM9/64

GBrf93

SM3/16(28)x14.5

1

SMJ/4

1

1

SMI/4(24)x23

1

SM3/16x(28)X43

GBrf955

2 SM15164 (

I

SMJ/4(40)x6

1

SM114(40)x6.5

1

1 CP-12C

(30)

(40

5

(40)

) x7

5

2X)

Remarks

(3)

x7.8

X4

X4.5

-18-

Page 21

F.

KNIFE

MECHANISM

(10)

15 16

17

19 20

21

22

.lJI.

-19-

Page 22

F.KNIFE MECHANlSM

Fig

.

No.

FOJ

F02 H4915J8001

F03

F04

F05

F06 H4925J8001

F07

F08 H4911J800J

F09

FlO

FJ

Fl2

Fl3

Fl4

Fl5

Fl6

Fl7

Fl8

Fl9

F20 HA710E0692

F21

F22

F23

F24

F25

F26

F26

F27 H4974K8001 Arm

F28

F29

F30

F31

F32

F33

F34

F35

F36

F37

F38 H4943K.8001

F39

F40 H4965K.800 I Set

F41

F42

Part No.

H492JJ8001

H4920J8001

1-!492418001

H69041800I

H4912J8001

H4913J8001

H4908J8001

I Hl-140408001

H4914J8001

H4922J8001 Cover (right)

H4914B8001 Screw 4

H4909J8001 Fixed blade 2

H4907J8001 Trimming knife holder

H4906J8001

H4905J80ul

H4932K8001

HAl 13F0684 Screw

H6904J8001 Bushing

H4979K8001 Solenoid complete

H4977K8001 Mounting plate I

H003008050 Nut

H4951K8001

H4951K.8001 Nut I

HAIIIG0683

H4981K8001

H4972K.8001

H4971K8001

H4970K.8001 Screw

H4967K8001 Screw

H4966K8001 Stopper

H41

1050160 Screw

H3205Gll14

H4957K7101 Vibrating crank complete

HAIOOH2080 Pin type

H2012N0652 Screw I

H4963K8001 Shat\ I

Lever

Screw

Roller

Knife pad (right)

Guide (right) I

Screw

Screw I

Move knife I

Screw 1

Screw

Rever~ing

Spring plate I

Bolt 2

Screw 2

Cam

Screw

Nut I

Screw

Holder

Screw

Lever

Screw

Spring 1

spring

plate 1

Description

Pes.

1

SM3/32

2

1

I

SM9/64

I

SM1/8

SM9/64

2 SM9/64

I

I

SM9/64

2

SMII/64

SM9/64

I

SMI/4 ( 40) X9.5

2

SMI5/64

2

I

I

2 GB/T6172.1 M5

SMII/64

SMil/64

I

I

SMI

I

SMil/64

I

I

I

SMil/64

3

SMII/64

I

GB'TXI9. 1 M5xJ6

2

M5 x5

2

I

I

SM ), 4 ( 24 ) X I

(56)

(40) >'9.5

(44)

(40)

(40)

(40)

(40)

(40)

(28)

(40)

(40)

1/64 C40J

(40)

(40J

C40J

Remarks

X .8

x9.2

x4.5

x4

X4

x12

x7

X8.5

x)2

x6.8

x6

x7

()

-20-

Page 23

F.KNIFE MECHANISM

Fig.

No.

F43 H4944K8001

F44

F45

F46

F47 H4939K8001 Bolt 1

F4H

F49 H4987K8001

F50 H4912K8001 Arm

rst

F52 H4905K8001

fo53

rs4

rss

F56

F57 HAIOOE2150

rss

Part No.

Screw

H4936KROOI

H3405D0663 Ball joint (right) I

H003002050 Nut (right) I

H4940K8001

H4913K8001 Bolt

H4980K8001

HA300B2170

Hl-140508001

HA700N0080

Hl-140608001

Screw 2

Nut (Jell) 1

joint

Boll

Screw

Holder 2

Screw

Bracket

Screw

Screw I

Screw

(Jell) 1

Description

Pes. Remarks

SMII/64

I

M5(0.5)X8.5

0Brf6170

M5(1ell)

SM15/64 (2H)

I

M5(0.5)x7.5

2

SMII/64

2

I

I

SMI5/64

SM

11/64

SM11164

1

(40)

x5.5

M5

xl2.5

(40)

x8

(:?.8)

xJ:?.

(40) X 10

(40)

-21-

Page 24

G.

LOWER

SHAFT & OIL

LUBRICATION

MECHANISM

31

30

29 28

2726

25

2423

-22-

22

21

20

19

18 17

16

Page 25

G.LOWER SHAFT & OIL LUBRICATION MECHANISM

Fig.

No.

GO!

002

003

004

005

006

007

008

009

010

Gil

012

013

014

015

016

017

018

019

t

i:!O

021 H320406510

02:! H3215K0693

023

024

025

026

0:!7 HA106B0676 Screw

G:!X

0:!9

030

031 H3200K0170 Holder

032

033

GJ4 H3:!16K0070 Oil pipe & wick complete

035

036

037

03X H3200H2010 Lower shall

039

Part

No.

HA300C2030 Screw

H3200K0170 Holder 1

H32422C208

H32175B304 Felt

H3209K0066 pipe & felt complete

H3200K0200 Holder 1

HA300B2170 Screw

HA7311C306 Screw

H3200H2060

H3208H0661 Ball bearing

H3208H0662 Bushing

HAII203012

HAI0500662

H3230K0751 Screw

H3230K0752 Bushing

Illi404H71

H3215K0696

H110012070

HIIOOI2090

HI 10012110 Spring holder

H3215K0692 Filter

H3215K0694 Screw

H3215K4011 Base plate complete

H3:!15K0695

H3:!311

HA300B2130 Screw

HG805J8001

H3211K0068 Oil reservoir complete

H32132B204 Oil wick

H3200KOI60

HA100E2150 Screw

H3204B0032 Lower shall bushing .Jctl (complete)

H3204B0043 Lower shatl bushing right (complete)

Pipe 1

Bearing holder

Ring

Screw

01

Lower shatl bushing middle (complete)

Pipe

Pin

Spring

Screw

Screw

Holder

0606

Holder

Pipe

Holder

Description

Pes.

4 SMI!/64{40)x8

2

1

SMII/64(40)x9

3

SM9/64(40)x7

3

1.

1

1

I

SMI/4(40)x4

2

2 SMI1/64(40)xiO

I

1

1

1

1

1

SM 1/8( 44)x4.8

I

SM9/64(40)x5

I

1

SM9/64(40)x7

1

1

1

SM9/64(40)X6

1

3

6

SMII/64(40)x5.5

1

1

1

2

1

3

SM11164{40)x10

2

1

1

1

Remarks

-23-

Page 26

H.

ACCESSORIES

22~

19------------r

2

13~

~

3

-4

7

12

11

10

-24-

9 8

Page 27

H.ACCESSORIES

Fig

.

Part

No

.

HOI

HO:!

HOJ

1-

104

1-

105

1106

1107

l-108

1109

HIO

III I H3213L

I-II:!

1-

113

1114

1-115

1-1

16

1-117

HI!! HA300J2210 Screw driver( small)

1119

1-120

121

11-

122

No.

I-ID40400651 Needle

I-16907H!!OOI

H3200L0020 Vibration preventing rubhcr 2

l-13:!00

L0030 Vibration preventing rubber

HA307J0067

HA I OOJ2120

HA300J2070 Screw driver(large) I

HA104J0653 Washer I

HAI04J0652

I-

IAIOOB2150

1-145001-1:!0

HA I OOJ21

H3218L0681 Felt I

H3200LOI30 Oil can

HA200J:!030 Cotton :;land

HA300J2200 Screw driver(middle)

HAIOOJ21

HH404l7101 Belt cover (complete)

HA300J22XO

HA704S0654 Adjusting plute for speed commund disk

Bobbin

Hinge complelt:

Magnet block lhr

Screw

Rubber plug I

Oil

rc:;'-.,-

OM

I

I 0 V-bclt I

Vit~yl

XO

10

Oiler I

Screw

voir I

cover

Description

re~crvoir

Pes.

3

3

:!

:!

I

I

I

I

I

I

I

I

2

I

MTx

i90

16#

SM5/ l

<l(:!X)x I:!

<l>l

:U!

M44

SM 15/64 (

Remarks

28)

X

l!

-25-

Page 28

SHANGHAI HUIGONG

N0.3

SEWING MACHINE FACTORY

ADD: 1418, Yishan Road, Shanghai,

China

Zip Code: 201103

Overseas

Business: TEL: 86-21-64853303 FAX: 86-21-64854304

E-mail: highlead@online.sh.cn http://www .highlead.com.cn

The

descri

ption

covered

in this

manuuli~

subject

tu

change for imp rov

emen

t of the c

ommod

ity without notice

ZO

4.11. Printed

Loading...

Loading...