Page 1

Purchasing

HIGHLEAD

GC20698 Series

Dept

Copy

•

Long

Material Lockstitch Sewing Machine

Arm

Version,Compound-feed,Heavy

Instruction

Parts

Catalog

Manual

SHANGHAI HUIGONG

N0.3

SEWING MACHINE FACTORY

Page 2

CONTENTS

PRECAUTIONS

PREPARATION

l. Power cable connection --------

2.

Connection

3.

Adjustment

CAUTIONS

I. Oiling (

2.

Oiling (2)

3.

Oiling condition ---------------·

4.

Adjustment

5.

Cautions on operation ----------·

BEFORE

FOR

of

control

of

needle

ON

USE

l)

------------

-----------------·--------------------------------------------------4

of

oiling to rotating hook -----------------------------------------------------------5

STARTING

OPERATION

box

----------------------------------------------------------------------3

bar

stop position ---------------------------------------------------------3

OPERATION

1.

Installation

2.

Winding

3. Selection

4.

Threading

5.

Adjustment offeed (stitch) length and stitch reversing (touch-back) -

6.

Setting

7.

Threading

8.

Tension adjustment

9. Balance

10.

Needle thread tension ------------

l l. Adjustment

12.

Timing between rotating hook motion

13.

Adjustment

of

needles---

of

bobbin thread

of

thread ---------------------------

of

needle threads ---------------------------------------------

of

bobbin -------------------------------------------------------------------------------7

of

bobbin threads

of

thread tension ----------------

of

presser foot pressure

of

feed dog height

----------------------------

of

bobbin threads ----------------------------------------------------------9

OPERATION

·---

----

------------------------------------------------------4

---------

----------------------------------------------------------------5

---------------------------

----

---

----------------

------------------------------------and

_________________________

- -------------------------------------4

--

·--------

---------------

needle

motion

-------------------------------------- l

--------------------------------2

---------------------------------------------5

--

------

--

-

--------------6

-----------------------------------6

-----------------------6

--------------------

------------------------------------

---------------

--------------

--------------------------------------9

\_

_____________________________________

---

----------------

--

--------------9

----------------9

-------7

-----8

---

--9

10

14.

Relationship between rotating hook

15.

Relationship between hook motion and opener

16.

Relationship between needle motion

17.

Safety clutch device --------------------------------------------------------------------------

18.

Upper

feed

adjustment (needle side)'-----------------------

19.

Outside presser foot and inside presser vertical stroke adjustment -

20.

Adjustment

21.

Installation

22.

Adjustment

23. Adjustment

24

. Adjustment

25.

Sharpening

26.

Adjustment for change

SPECIFICATIONS

of

forward/backward stitch

of

movable knife ------

of

thread trimmer

of

needle threads tension release assembly -

of

scissoring pressure

of

fixed knife----------

of

needle

-----------------------------------------

motion

cam

--------------

of

------------------------------------------------

to

needle distance---

and take-up lever motion

motion

and

feed

dog motion ------------------------------------

length ---

---

---------

movable

----

------

---

---------------- ----

knife and fixed knife

---

·-

----

---

--------·-

---------

--

------

--

----

------

----

----------·- - - - ---

-------------

--

--

------------------------14

---

---------

---

--

----

--

----

--

- --

----------

--

--------------

---

---

-------

----------

---

---------

---------

--

·----

---

--------17

--

----

------

---

---

-----

---

--

11

11

11

12

13

14

14

15

16

16

17

18

Page 3

PARTS

CATALOG

I . Ann bed its accessories

2.

Thread tension regulator mechanism

3.

Ann shaft mechanism

4.

Upper shaft & presser foot mechanism --;-

5.

Needle bar & thread take-up lever mechanism

6.

Stitch regulator mechanism

7.

Lower shaft & feed rock shaft mechanism

8.

Hook saddle mechanism

9.

Knife mechanism ( I ) -------------------------------------------

10.

Knife mechanism

11

. Touch back mechanism & detector mechanism

12.

Accessories

GAUGE

PARTS

-----------

LIAT

---------------------------------------------

-----------------------------------------------------------

---

------------------------------------------------,---------------------

(II)

--------------------------------

--

----------------------------

---------------------

------------------------------------------------

------------------------------------------------

---

-------------------------------------------

-------------------------------------------------

----

---

---------------------------

------------------

----

---

-------------

------------

--

---------------------------

---

----

19

21

24

26

29

--

32

34

37

39

41

44

46

48

Page 4

PRECAUTIONS BEFORE STARTING OPERATION

1.

Safety precautions

I) When turning the power on, keep your hands and fingers away from the area around/under the

needle and the area around the pulley.

2) Power must be turned

3) The power must be turned

adjusting the machine,

4) Avoid placing fingers, hairs, bars etc. near the pulley,

when the machine

5) Do not insert fingers into the thread take-up cover, under/round the needle, or pulley when the

is

in

machine

If

a belt cover, finger guard, and/or eye guard are installed,

6)

these safety devices :

2.

Precaution before Starting Operation

I)

If

the machine's oil pan has an oil sump, never operate the machine before filling

2)

If the machine

3) When a new sewing machine

the power on. (the pulley should rotate counterclockwise when viewed from the pulley.)

4)

Verify the voltage and (single or three) phase with those given on the motor nameplate.

operation.

is

off

when the machine

off

before tilting the machine head, installing

or

when replacing.

is

operation. Injury could result.

lubricated by a drop oiler, never operate the machine before lubricating.

is

first turned on, verify the rotational direction

is

not used,

or

when the operator leaves his/her seat.

or

removing the

"V"

belt, bobbin winder pulley, or motor

do

not operate the machine without

it.

of

the pulley with

"V"

belt,

3. Precaution for Operating Conditions

I) Avoid using the machine at abnormally high temperature (35°C

Cor

lower). Otherwise, machine failure may result.

°

in

2) Avoid using the machine

3) Avoid using the machine in areas where too much electrical noise, resulted from the

high-frequency welder and others,

dusty conditions.

is

generated.

or

higher)

or

low temperature (5

-1-

Page 5

PREPARATION

FOR

OPERATION

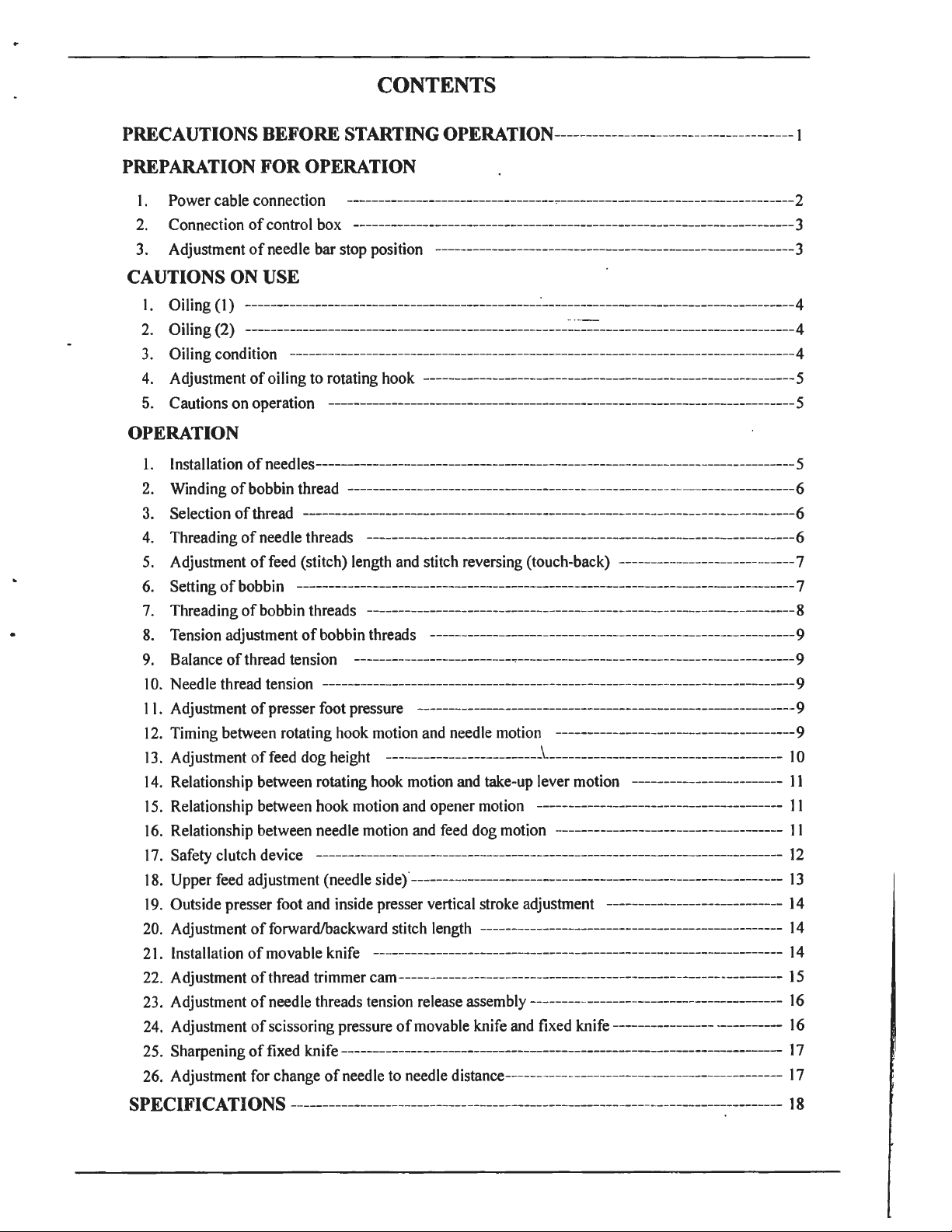

~-----------------------------,

Operation

overall view

sewing machine

1 .. Power cable connection

1)

of

assembled

Connection to Power Supply

When connecting the

plugged in the proper receptacle after confirming the connector type and matching direction.

A.

In

case

of

the

"V

" phase

depends,

power

three-phase electrical power system, the

to

the white lead, and the "

how

eve

r,

upon the setting

Power

push

button

X-type servo

motor

Control

supply connector to the control box, the connector should be completely

"IJ"

phase should be connected to the red lead,

W"

phase to the black lead.

of

the internal switch in the control box as described

The

motor rotary direction

box

in

Paragraph 1-(3)

CAUTION:

the motor properly.

B. The appropriate power fuse capacity

The

green wire must be connected to the ground terminal

is

as follows. Power supply

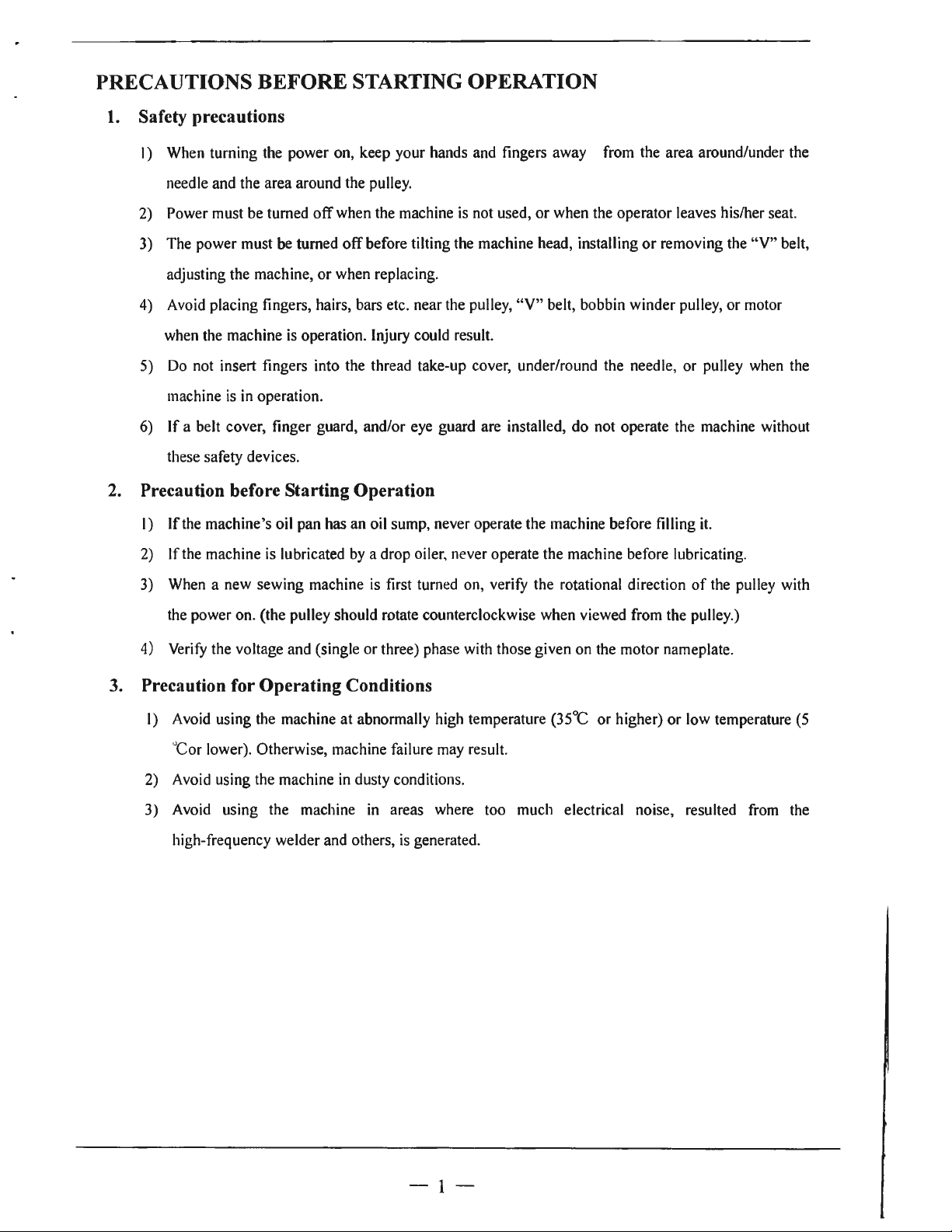

2) Lamp Leads

A. When installing the illuminating lamp(6V, 15-20W),

the Control box.

removed and connected by

removing the insulating tube

from the wire and stripping

properly.

should be, then, insulated by

wrapping insulating tape on

the wires.

The

It

should be

wire connections

(

a)

Lamp

leads

in

order to ground

200V

-240V: I 0A

I00V-120V: 15/\

Thc

connecting wire is attached on the back

(b)

Bare

wire

Insulating

(2

to 3 turns

tape

wrapped)

lns~ating

tape

(2

to

3

turns

wrapped)

Lamp

leads

of

- 2 -

Page 6

CAUTION: The power switch must be Turned

off

before connecting the lamp.

B. When the illuminating lamp

shown

control box will be possibly burned out.

in

CAUTION: The illuminating lamp must not be connected with any heater, such

3) Rotary direction

It

is

possible to change the rotary direction

bottom left side

switch. The built-in lamp in the internal switch

facing to the motor pulley, and on when rotating clockwise. The rotary direction has been set to

counterclockwise as facing to the motor pulley, matching with the machine prior to shipping

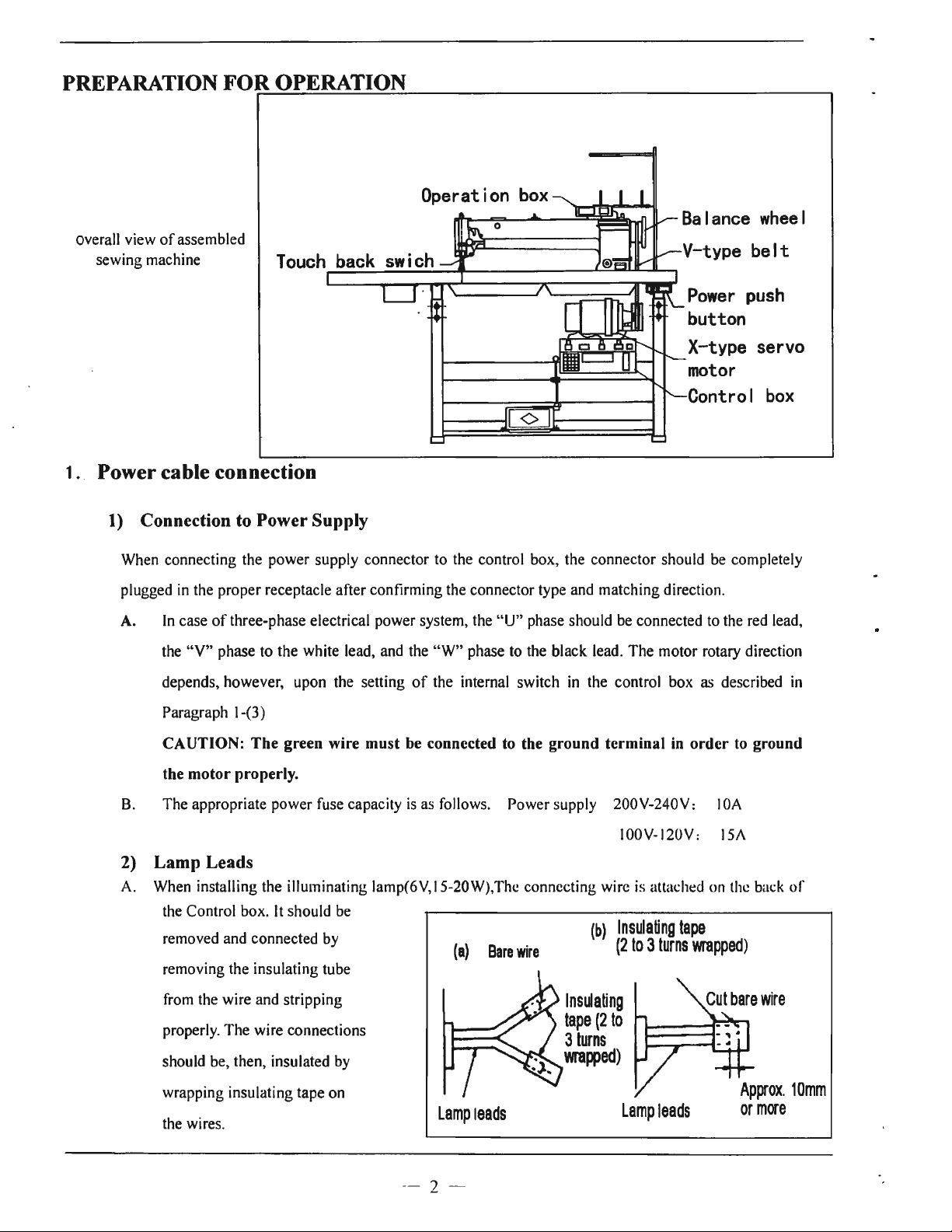

2. Connection

The control box should be connected

as shown to the right.

the figure

on

warmer and others,

It

may cause transformer winding burned out.

of

of

control box

is

not used, the end

right side.

the front cover on the control box; and push the internal direction selector

If

a short circuit occurs failing to insulate, the transformer in the

in

parallel. Otherwise, the load capacity will be exceeded.

Operation

of

the lamp leads must be insulated as (a)

of

the motor by removing the rubber cap

is

off

when the motor

box

Round

In

table

is

rotating counterclockwise as

hole

or

as

from

(b)

as

a foot

the

Note: (1) Be sure to turn the power swih

off

for safety before connecting

or disconnecting the connectors.

of

(2) The combination

the machine

heads with the motor control

panels are specified below.

Use special care for the correct

combination when replacing the machine head or motor control panel.

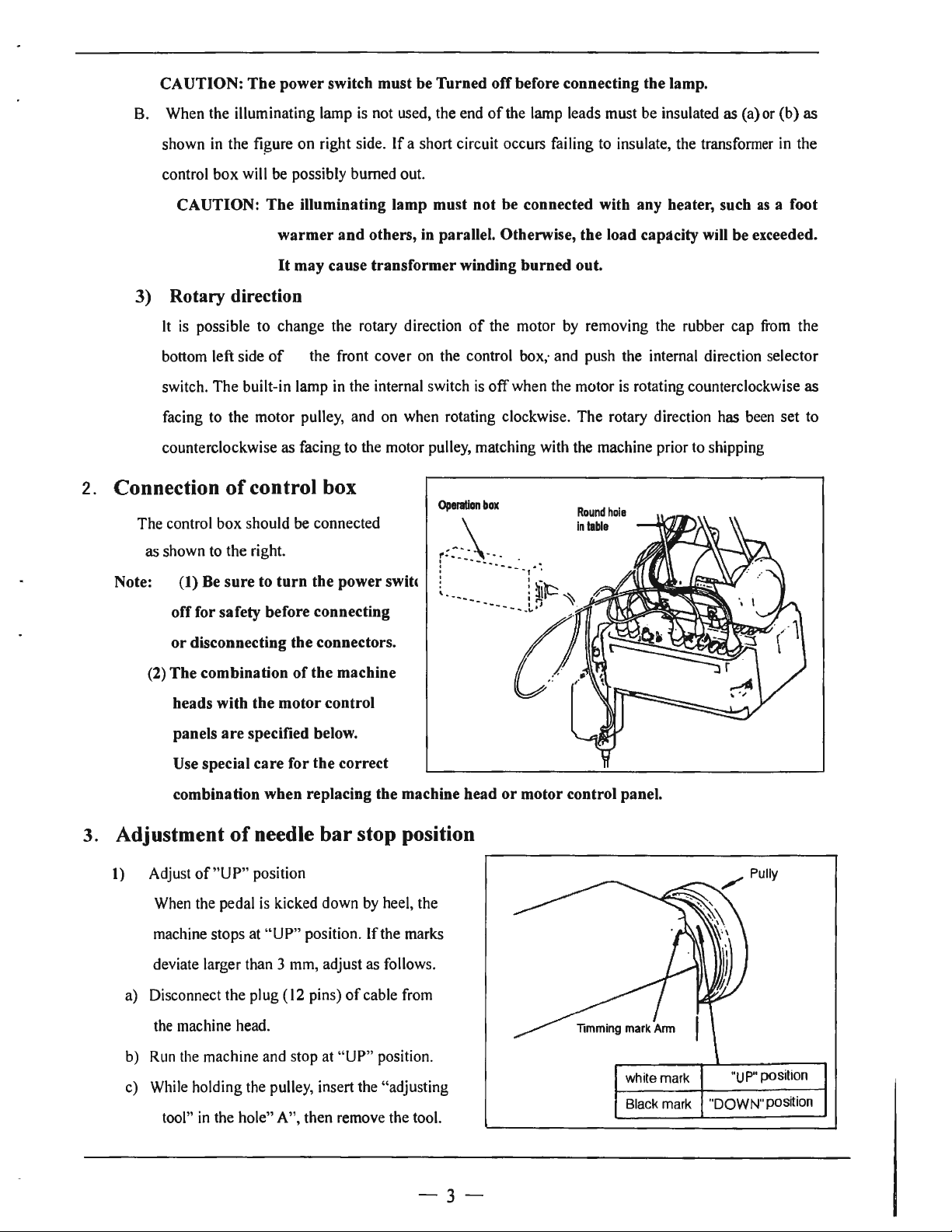

3. Adjustment

1) Adjust

When the pedal

machine stops at

deviate larger than 3 mm, adjust as follows.

a) Disconnect the plug (12 pins)

the machine head.

of

of

needle bar stop position

"UP"

position

is

kicked down by heel, the

"UP"

position . If the marks

of

cable from

b)

Run

the machine and stop at

c) While holding the pulley, insert the "adjusting

tool"

in

the hole" A", then remove the tool.

"UP"

position.

-3-

while mark "UP" positi

Black

mark

"DOWN" positi

on

on

Page 7

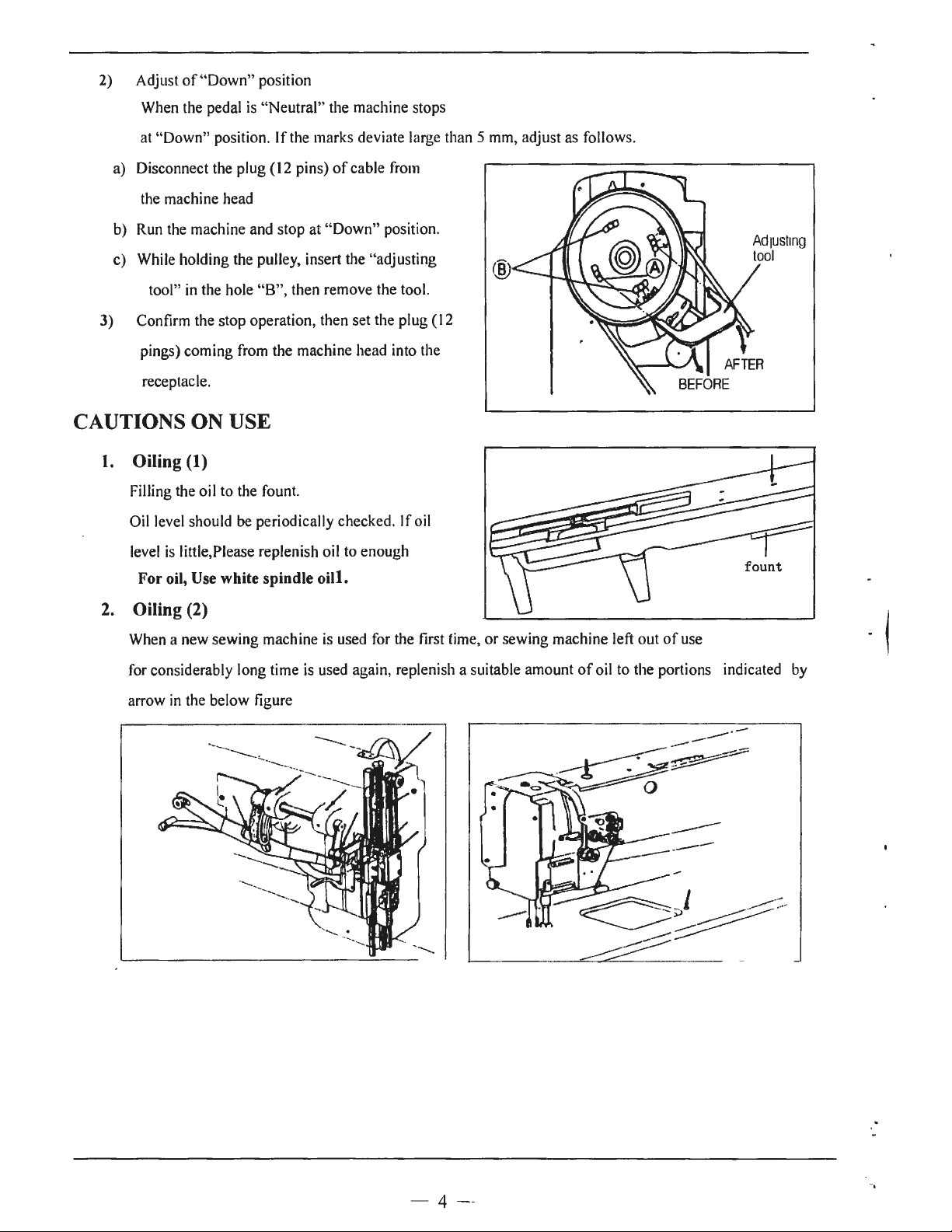

2) Adjust

When

at

"Down" position. If the marks deviate

a)

Disconnect

the

machine

b)

Run

the

While

c)

tool"

of

"Down" position

the

pedal

is

"Neutral" the machine stops

the

plug (

12

pins)

of

cable

head

machine

holding

in

the hole "B", then remove the tool.

and

stop at "Down" position.

the

pulley, insert the "adjusting

large

from

than 5

mm,

adjust

as

follows.

3) Confirm the stop operation, then set the plug (

pings) coming

receptacle.

from

the machine

head

CAUTIONS ON USE

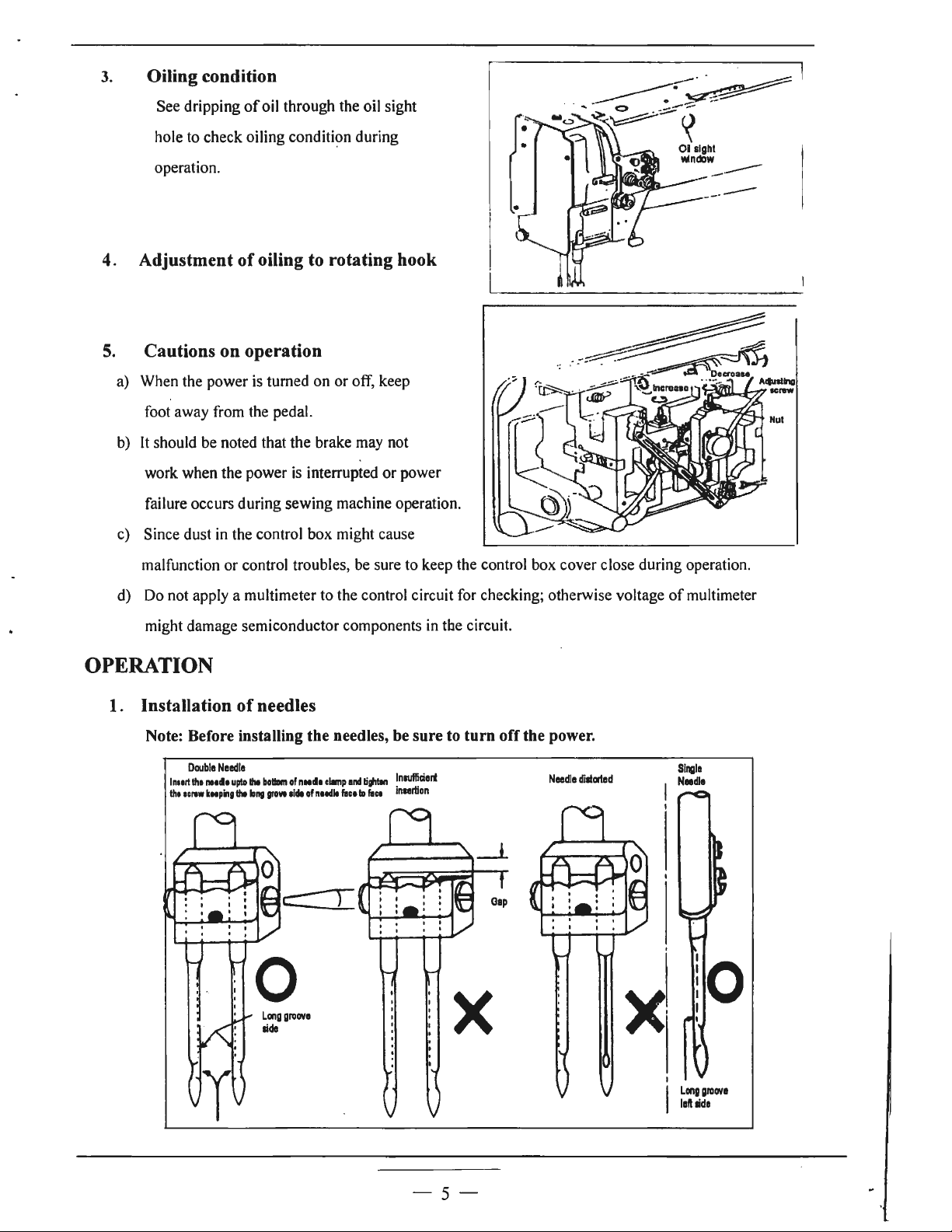

1.

Oiling (1)

Filling

the

oil

to

the

fount.

Oil

level

should

level

is

little,Please replenish

For oil, Use white spindle

2. Oiling (2)

When a new

for

considerably long time

arrow

in

the

be

periodically checked. I foil

oil

oill.

sewing machine

below figure

is

is

used

to

enough

used

for

again, replenish a suitable amount

----~

into

the

the

first

12

time,

or sewing machine left out

of

of

use

oil

to

the portions indicated

. I

by

- 4 -

------

Page 8

3.

Oiling condition

See dripping

hole to check oiling condition during

operation.

4. Adjustment

Cautions on operation

5.

a) When the power

foot away from the pedal.

b)

It

should be noted that the brake may not

work when the power is interrupted

failure occurs during sewing machine operation.

c)

Since dust

of

oil through the oil sight

of

oiling to rotating hook

is

turned

in

the control box might cause

on

or

off, keep

or

--·--

ICl9W

Nul

power

malfunction

d) Do not apply a multimeter to the control circuit for checking; otherwise voltage

might damage semiconductor components in the circuit.

or

control troubles, be sure to keep the control box cover close during operation.

OPERATION

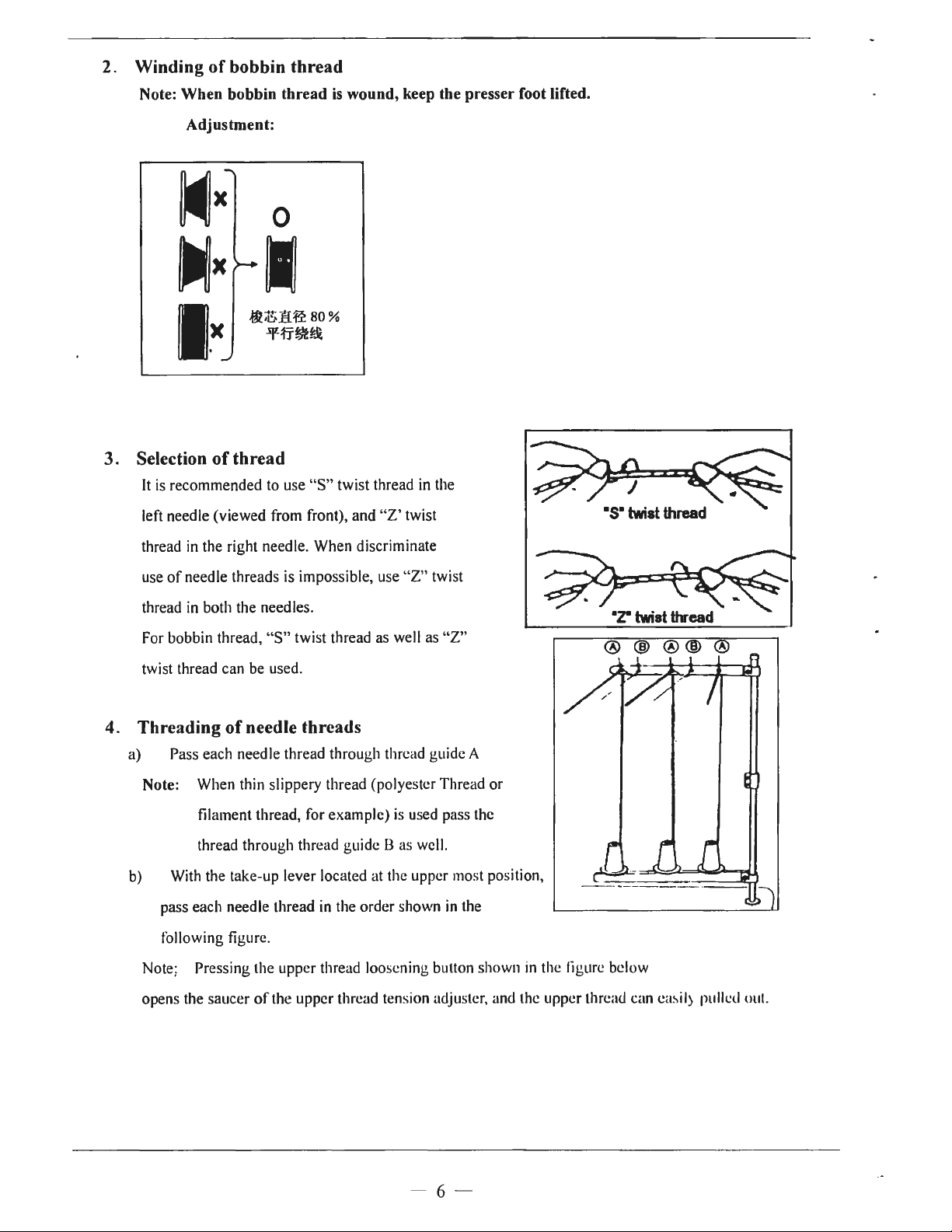

1. Installation

Note: Before installing the needles, be sure to turn

Double

lnutl

lhl

1crew

lh•

Needle

1111cl1

kNping

of

needles

upto

lhl

lhl

long

bollllm

grow

of

tide

nNclt

of

clamp

n1tdll

flee

and

ID

ti~

flee

~nlllfficieri

111Nr1lon

off

the power.

Needle

dillarled

0

Long

gro1111e

tide

X

of

multimeter

Sil'lle

Needle

I

!O

I

I

- 5 -

Long

groove

leftlide

Page 9

2. Winding

Note: When bobbin thread

of

bobbin thread

Adjustment:

is

wound, keep the presser foot lifted.

3. Selection

It

is recommended

left needle (viewed from front), and

thread in the right needle. When discriminate

use

thread in both the needles.

For bobbin thread,

twist thread can be used.

4. Threading

a) Pass each needle thread through thread guide A

Note: When thin slippery thread (polyester Thread

b) With the take-up lever located at the upper most position,

pass each needle thread in the order shown

of

thread

to

use

"S"

twist thread in the

"Z'

twist

of

needle threads is impossible, use

"S"

twist thread

of

needle threads

filament thread, for example) is used pass the

thread through thread guide B

as

well as "

as

"Z"

well.

twist

Z"

in

the

or

following figure.

Note; Pressing the upper thread loosening button shown in the figure

opens the

saucer

of

the

upper

thread tension adjuster, and the upper thread can easil) pulled out.

- 6 -

below

Page 10

uJI1, -

GC20698-

CiHIIII

1

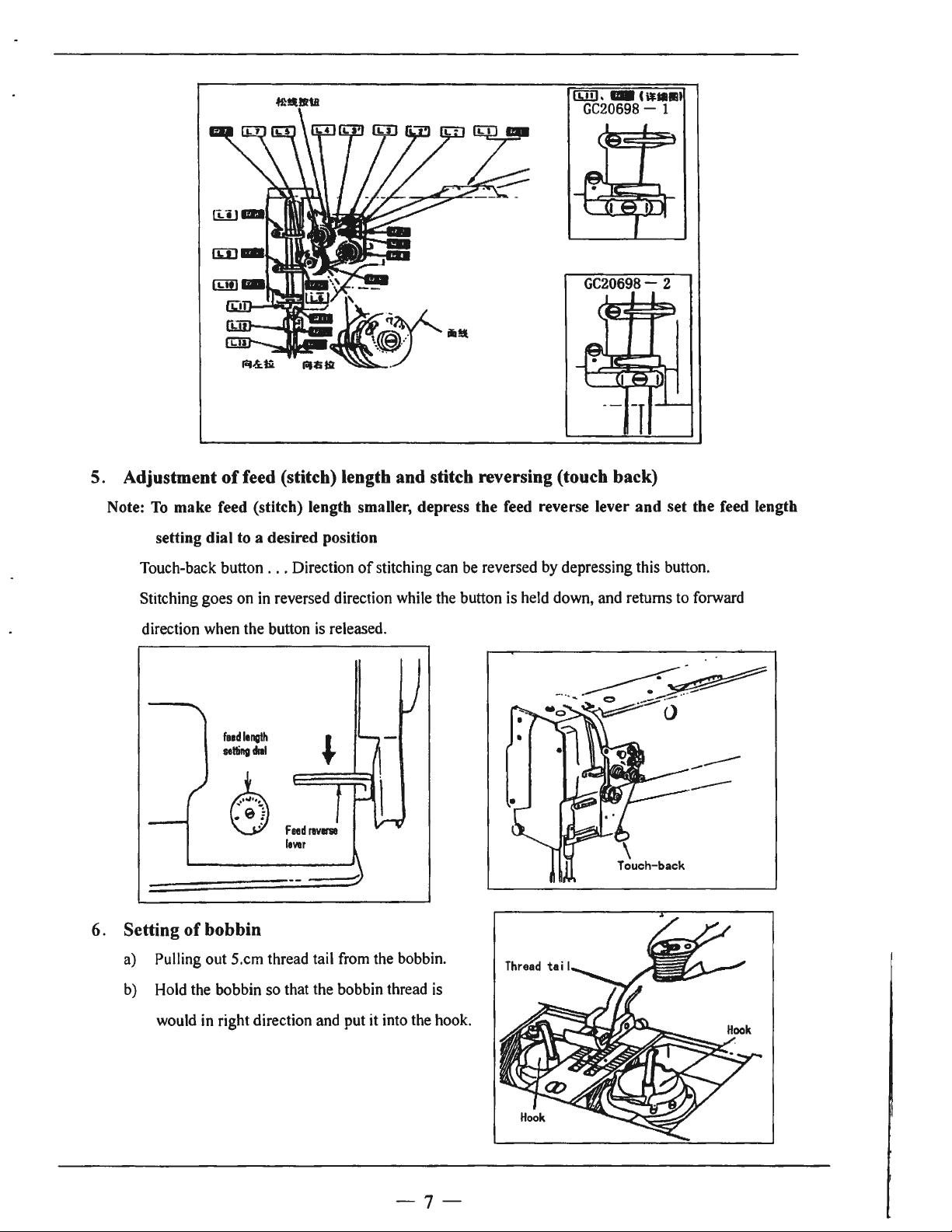

5. Adjustment

Note:

To

make feed (stitch) length smaller, depress the feed reverse lever and set the feed length

setting dial to a desired position

Touch-back button

Stitching goes on in reversed direction while the button is held down, and returns

direction when the button is released.

GC20698-

of

feed (stitch) length and stitch reversing (touch back)

...

Direction

of

stitching can be reversed by depressing this button.

2

to

forward

f11d

lenvth

selling

dill

k

~

6. Setting

a) Pulling out 5.cm thread tail from the bobbin.

b) Hold the bobbin so that the bobbin thread is

of

bobbin

would in right direction and put it into the hook.

-

-----

---

- 7 -

Page 11

7. Threading

a) Put the hook into the bobbin case

of

bobbin threads

and press

The

the bed .

b)While holding the

by left hand, rotate the hand-wheel

one turn by right hand.

By pulling up the needle threads,

as shown

will be lifted. Each combination

thread and needle thread should be aligned

down

the latch

thread end should be left on

two

in

the figure, the bobbin threads

CD

.

needle threads

of

bobbin

and led backward .

- 8 -

Page 12

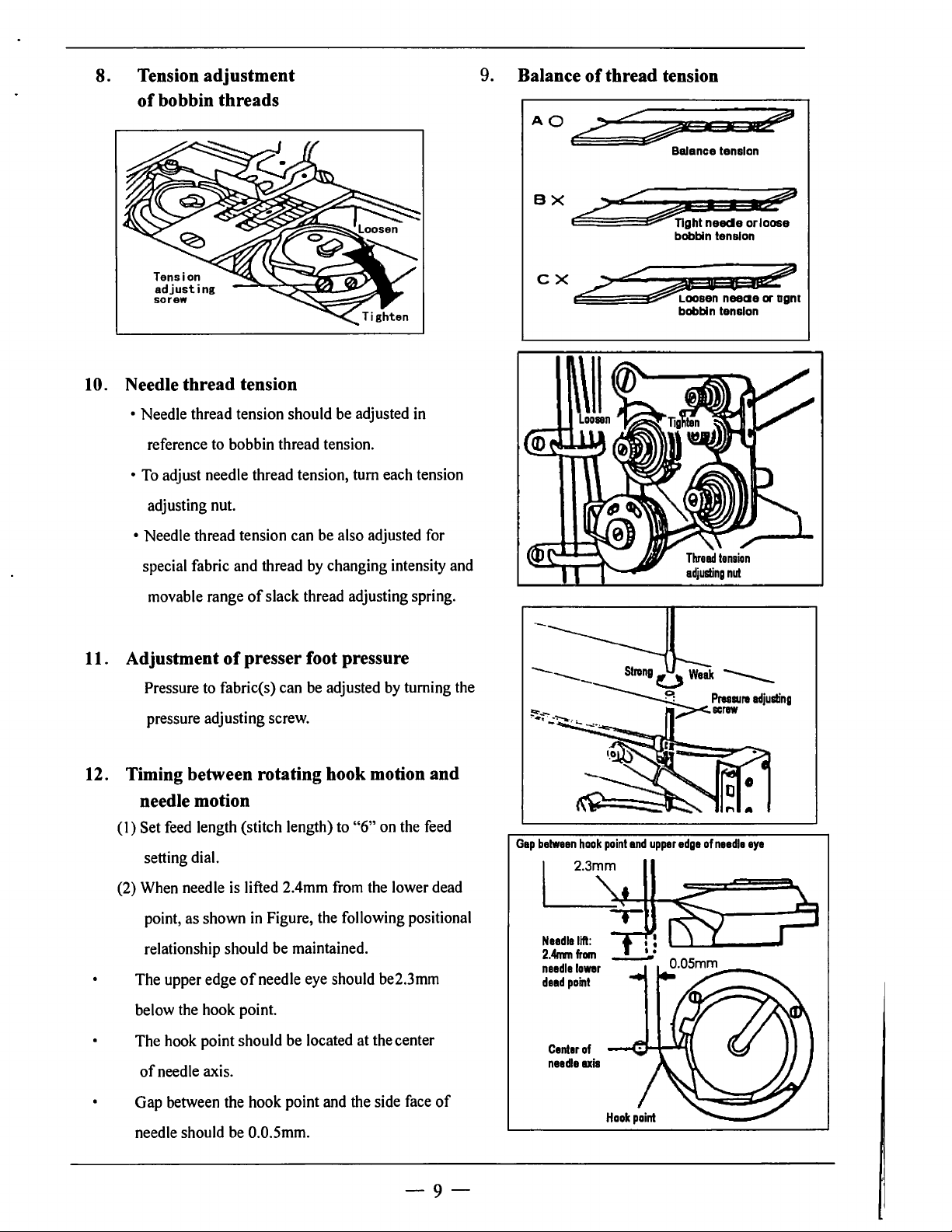

8. Tension adjustment

of

bobbin threads

9.

Balance

of

thread tension

Tension

adjusting

SOl"8W

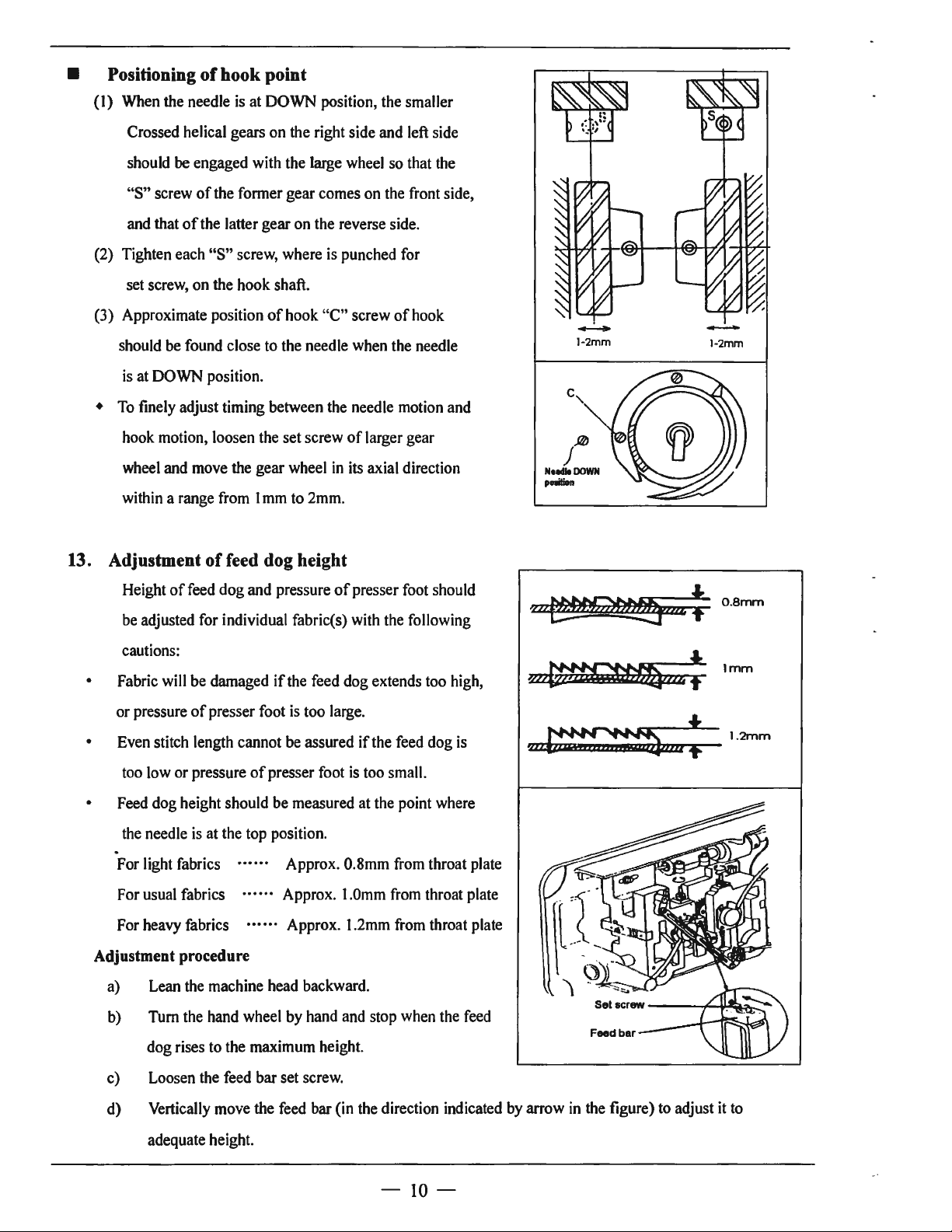

10. Needle thread tension

• Needle thread tension should be adjusted in

reference to bobbin thread tension.

To

adjust needle thread tension, tum each tension

•

adjusting nut.

• Needle thread tension can be also adjusted for

special fabric and thread by changing intensity and

of

movable range

slack thread adjusting spring.

BX

2:::~

'~ht

C X /

,

Balance

bobbin

~:;..;?

~n

bobbin

tension

I I

1;?

neecle orloose

tension

neeae

or

tension

ogn1

11. Adjustment

Pressure to fabric(s) can be adjusted

of

presser foot pressure

by

turning the

pressure adjusting screw.

12. Timing between rotating hook motion and

needle motion

(I)

Set feed length (stitch length) to

setting dial.

(2) When needle is lifted 2.4mm from the lower dead

point, as shown

in

Figure, the following positional

relationship should be maintained.

of

The upper edge

needle eye should be2.3mm

below the hook point.

The hook point should be located at the center

of

needle axis.

Gap between the hook point and the side face

"6"

on the feed

of

------

Strang O Weak

--------9

~"i-:-

..

~ . ,i><.screw

- .

:._

.....:•.

Gap

betwean

haak

paint

and

upper

Needle

lift:

2.4nmfram

needle

lower

dead

paint

Center

af

needleuis

edge

----

Pressure

af

needle

adjusting

eye

needle should be 0.0.Smm.

-9-

Page 13

• Positioning

(I)

When the needle

-Crossed helical gears on the right side and left side

should

"S"

and that

(2) Tighten each

set screw, on the hook shaft.

(3) Approximate position

should be found close to the needle when the needle

is at DOWN position.

To

finely adjust timing between the needle motion and

•

hook motion, loosen the set screw

wheel and move the gear wheel

within a range from I mm to 2mm.

of

be

engaged with the large wheel so that the

screw

of

of

the latter gear on the reverse side.

hook point

is

at DOWN position, the smaller

the fonner gear comes on the front side,

"S"

screw, where is punched for

of

hook

"C"

screw

of

hook

of

larger gear

in

its axial direction

-

l-2mm

j,@

N1.U.DOWN

poeition

-

1-2mm

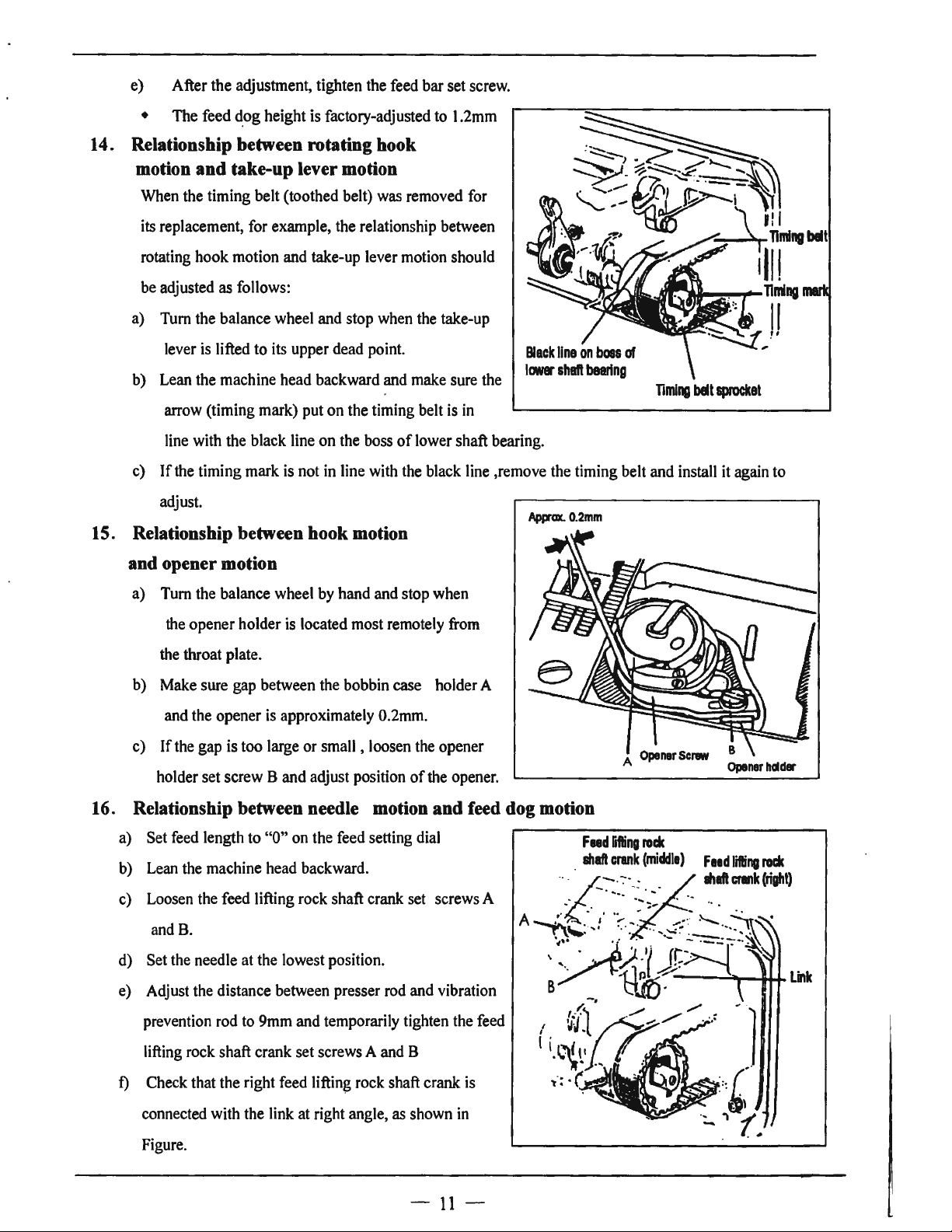

13. Adjustment

Height

be adjusted for individual fabric(s) with the following

cautions:

• Fabric will be damaged

or pressure

• Even stitch length cannot be assured

too low or pressure

• Feed dog height should be measured at the point where

the needle is at the top position .

of

feed dog height

offeed

dog and pressure

if

of

presser foot is too large.

of

presser foot

of

presser foot should

the feed dog extends too high,

if

the feed dog

is

too small.

.

For light fabrics

For usual fabrics

For heavy fabrics

Adjustment procedure

a) Lean the machine head backward.

Approx. 0.8mm from throat plate

Approx. 1.0mm from throat plate

Approx. 1.2mm from throat plate

is

0.

8mm

Imm

b) Tum the hand wheel by hand and stop when the feed

dog rises to the maximum height.

c) Loosen the feed bar set screw.

d) Vertically move the feed bar (in the direction indicated

adequate height.

-

IO-

by

arrow

in

the figure) to adjust

it

to

Page 14

e) After the adjustment, tighten the feed bar set screw.

• The feed ~og height is factory-adjusted to

14. Relationship between rotating hook

motion and take-up lever motion

When the timing belt (toothed belt) was removed for

its replacement, for example, the relationship between

rotating hook motion and take-up lever motion should

be adjusted as follows:

a) Tum the balance wheel and stop when the take-up

lever is lifted

b) Lean the machine head backward and make sure the

arrow (timing mark) put on the timing belt is in

line with the black line on the boss

c)

If

the timing mark is not in line with the black line ,remove the timing belt and install it again to

adjust.

to

its upper dead point.

of

15. Relationship between hook motion

and opener motion

t .2mm

lower shaft bearing.

App-ax.

0.2mm

Timing

belt

sprocket

a) Tum the balance wheel by hand and stop when

the opener holder is located most remotely from

the throat plate.

b) Make sure gap between the bobbin case holder A

and the opener

c)

If

the gap is too large

holder set screw

b) Lean the machine head backward.

c) Loosen the feed

and B.

d) Set the needle at the lowest position.

e) Adjust the distance between presser rod and vibration

prevention rod to 9mm and temporarily tighten the feed

is

approximately 0.2mm.

or

small , loosen the opener

Band

adjust position

Ii

fti

ng rock shaft crank set screws A

of

the opener.

A

Opener

Scl'IIW

Opener

hdder

lifting rock shaft crank set screws A and B

f)

Check that the right feed lifting rock shaft crank is

connected with the link at right angle, as shown in

Figure.

-

11

-

Page 15

g)

If

the connection

cover, loosen screw C and move the right link to connect

the right feed lifting rock shaft with the link at right angle.

is

not at right angle, remove the back

h) After the completion

screws

A,

Band

• At this time make certain that needle can enter the

feed dog needle hole at the center

of

adjustment, fully tighten the

C.

of

the hole.

I

I

-,--l""T"-==---

I

Needle rod

Vibration

prevention

rod

Feed

shaft

lifting

crank

rock

(righl)

. I

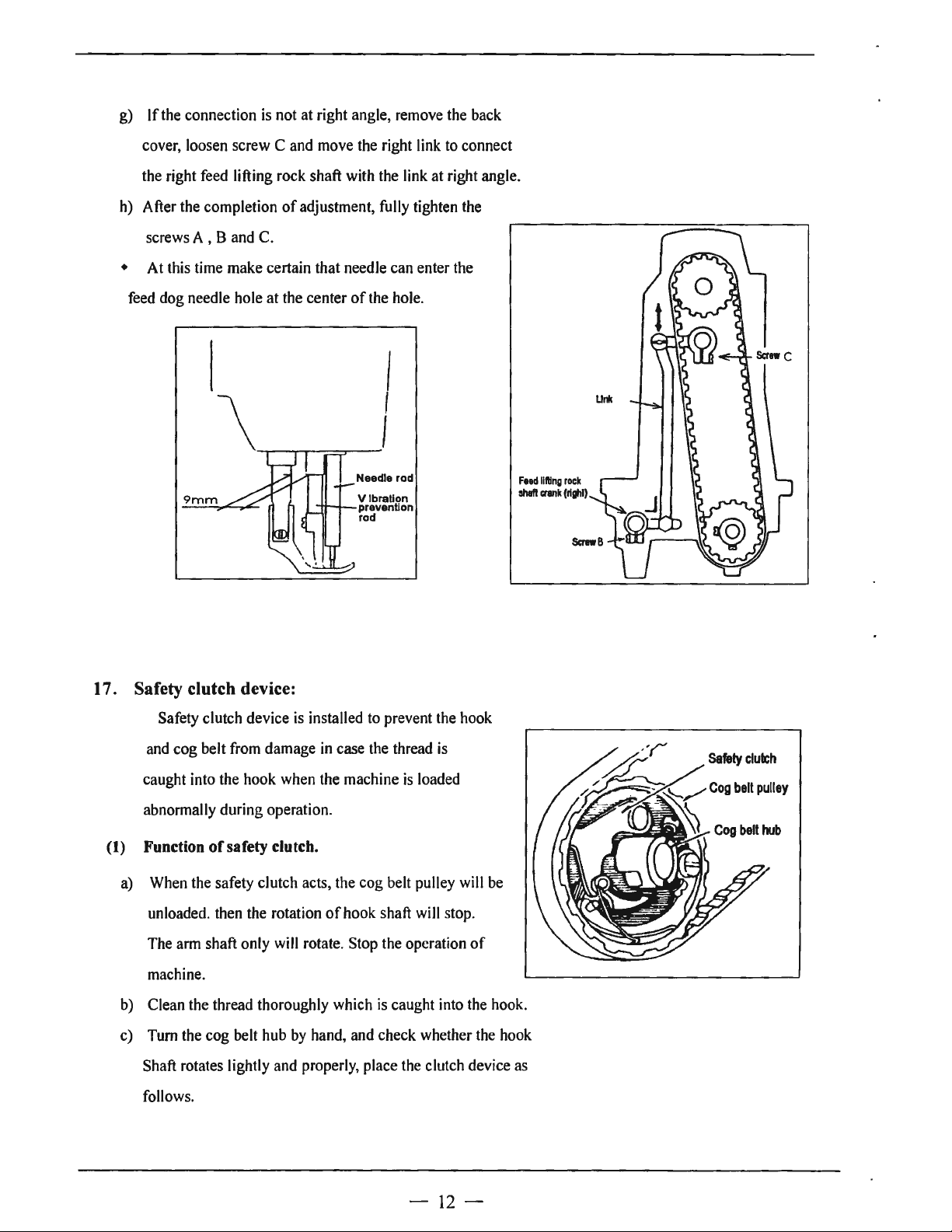

17. Safety clutch device:

Safety clutch device

and cog belt from damage

caught into the hook when the machine

abnormally during operation.

(1) Function

a) When the safety clutch acts, the cog belt pulley will be

unloaded. then the rotation

The arm shaft only will rotate. Stop the operation

machine.

b) Clean the thread thoroughly which

c) Turn the cog belt hub by hand, and check whether the hook

Shaft rotates lightly and properly, place the clutch device as

follows.

of

safety clutch.

is

installed to prevent the hook

in

case the thread

of

hook shaft will stop.

is

caught into the hook.

is

loaded

is

of

-

12

-

Page 16

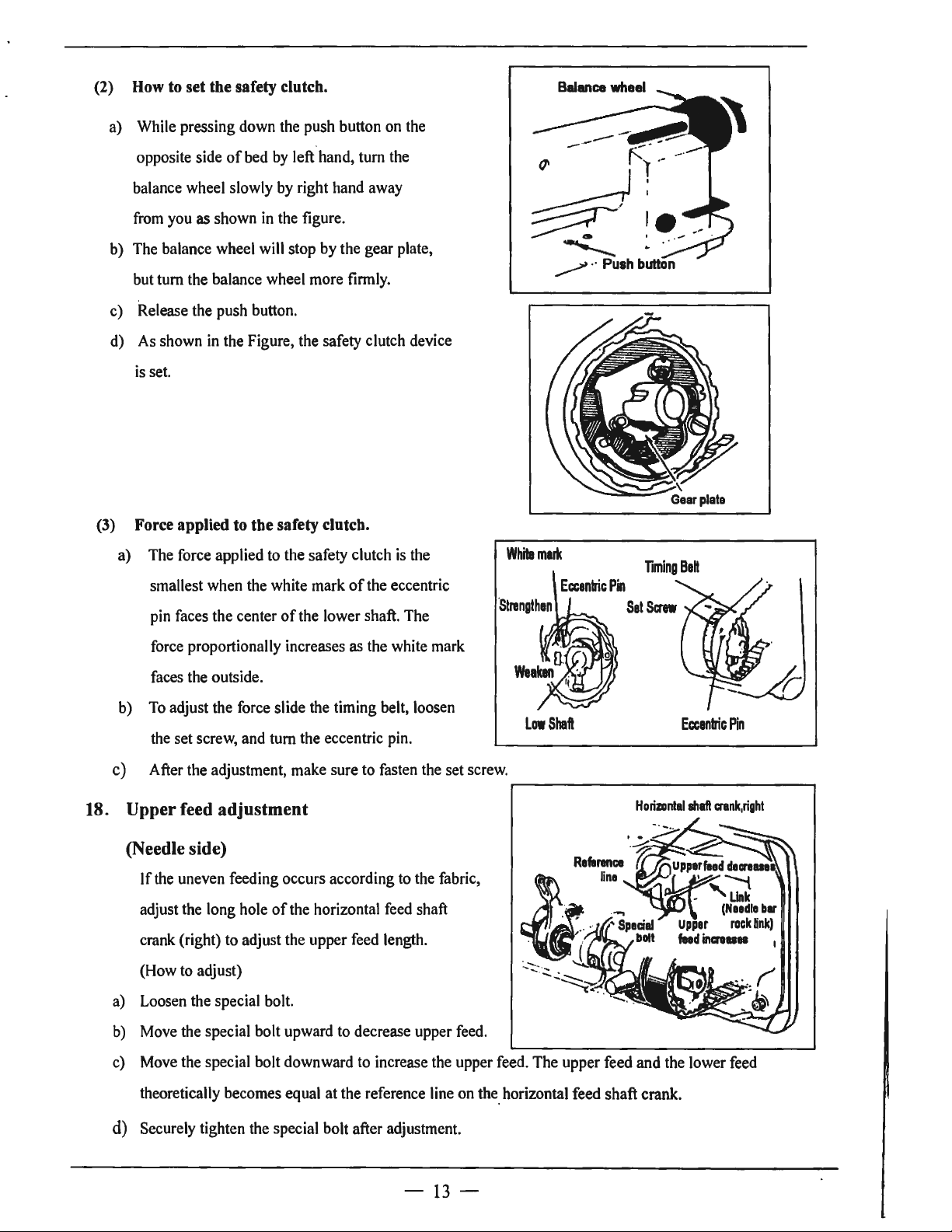

(2)

How

to

set the safety clutch.

a) While pressing down the push button on the

opposite side

balance wheel slowly by right hand away

from you

b) The balance wheel will stop by the gear plate,

but

tum

c) Release the push button.

d) As shown in the Figure, the safety clutch device

is set.

(3)

Force applied

a) The force applied to the safety clutch

smallest when the white mark

pin faces the center

of

bed by left hand, tum the

as

shown

the balance wheel more finnly.

in

the figure.

to

the safety clutch.

of

the lower shaft. The

of

the eccentric

is

the

White

mark

Eccentric

·

strengthen

Pin

Sat

TmingBett

Screw

force proportionally increases as the white mark

faces the outside.

b) To adjust the force slide the timing belt, loosen

the set screw, and tum the eccentric pin.

After the adjustment, make sure to fasten the set screw.

c)

18.

Upper feed adjustment

(Needle side)

If

the uneven feeding occurs according to the fabric,

of

adjust the long hole

crank (right) to adjust the upper feed length.

(How to adjust)

a) Loosen the special bolt.

Move the special bolt upward to decrease upper feed.

b)

c) Move the special bolt downward to increase the upper feed.

theoretically becomes equal at the reference line on the_ horizontal feed shaft crank.

the horizontal feed sha

ft

Low

Shaft

Horizontal

The

upper feed and the lower feed

Eccentric

lhaft

c:rank,right

Pin

d) Securely tighten the special bolt after adjustment.

-

13

-

Page 17

19. Outside presser foot and inside presser vertical stroke adjustment

When fabric with large elasticity

of

thickness

(movable range)

adjusted as follows:

Adjustment

a) Loosen the special bolt.

b) The vertical strokes

c) maximum when the crank rod

d) The vertical strokes becomes minimum when the nut

is

moved downward and set.

e) After the adjustment, fully tighten the special bolt.

The verticai strokes

•

fabric changes, the vertical stroke

of

the presser feet should be

of

the presser feet become

of

the presser feet can be adjusted within a range from 6mm to 2mm .

is

sewn, or when

is

moved upward and set.

20. Adjustment

Screwing the pin that connects the link

the tolerance

of

between the stitches. Screwing the pin

of

back-sewing with the crank

Specillbol

of

back-sewing (down) can adjust

in

clockwise can increase the stitch

of

forward

sewing; otherwise, the stitch

21. Installation

(1)

Installation

a.

Tum the balance wheel and lower the needle bar to the lowest position.

b.

Push the cam follower crank so that the cam roller enters into the thread trimmer cam groove.

c.

Tum the balance wheel until the black mark point on the arm meets the white mark point on the

balance wheel. Set the cam follower crank at this position with a screwdriver temporarily preventing

the cam roller coming out from the cam groove.

d.

Loosen the thread trimmer rocking crank clamp bolts A and

e.

Adjust the movable knife so that the movable knife end slant portion protrudes

0-0.5

mm

of

of

from the fixed knife, as shown

of

back-sewing

movable knife

movable knife

will

be increased.

B.

in

Figure and tighten the bolts A and

B.

-

14

-

Page 18

Thread

~a_.--r~

(2)

Gap between movable knife and bobbin case holder stopper

trimmer

rocking crank

a. Tum the balance wheel by hand until needle reaches the

Lowest position.

b. With the needle at the lowest position, depress cam follower

crank,

tum

the balance wheel until the movable knife reaches

Monable

knife

the extremity

c. Manually rotate the inner hook

of

its stroke.

in

the direction indicated

by

--.i1~-Approx

arrow in Figure and adjust gap between the movable knife

and the inner hook stopper to about 0.5 mm (the screws A and B should

22.

Adjustment

a.

Turn the balance wheel

b.

Maintaining the needle position, depress the cam follower crank and put the cam roller into the

groove

c.

Turning the balance wheel

of

of

thread trimmer

by

hand until the needles reach the lowest position.

thread trimmer cam.

by

cam

hand, _adjust the thread trimmer cam so that the movable knife starts

moving, when the green mark point on the balance wheel comes

be

loosened for this adjustment).

in

line with the black mark point on

the arm.

• To adjust, loosen two thread trimmer cam clamp screws

Cam

follower

A.

Green

mark

point

0.2

mm

Thread

trimmer

cam

15

-

Black

point

mark

Page 19

23.

Adjustment

of

needle threads tension release assembly

a. Tum the balance wheel by hand until the needles reach the lowest position.

b. Maintaining the needle position, depress the cam follower crank and put the cam roller into the groove

of

thread trimmer cam.

c. Turning the balance wheel

by

hand, adjust the thread tension release cam so that the

~nsion

when the white mark point on the balance wheel comes in line with the black mark point on the arm.

To

adjust, loosen two tension release cam clamp screws A.

d.

Opening degree

convex portion

e. Make fine adjustment by loosening the nut

f.

Loosen the nut D and make the outer casing approach rightward to increase the opening value.

of

tension disc should be adjusted with the tension release roller B mounted on the

of

thread release cam, as shown

in

Fig.To adjust, loosen the screws C and draw the wire.

D.

White

perk point

CID

Cam

follower

Thread

tenson

lever

'-....

disc close

I

trimmer

ScrewC

Nut

D

of

movable knife and fixed knife

24.

Adjustment

Thread

cam

of

scissoring pressure

a. Loosen the fixed knife bracket clamp bolt A.

b.

Turn the vertical position adjusting screw B to adjust meshing pressure and then righter the hexagon

socket head cap screw A.

Note:

Since excess pressure causes large

torque to the thread trimming mechanism

and trimming failure, adjust it so that

thread can be trimmed with minimum

Fixed kni

bracker

fe

pressure.

c. Move the movable knife and check that

the thread can

be

sharply trimmed.

Hexacon

cap

screw

socket

A

head

Vertical

position

adjustinc

screw

B

-

16

-

Page 20

25.

Sharpening

of

fixed knife

When the knives dull, the fixed should

be sharpened as illustrated in Fig.

it

is

Since

replace

26.

Adjustment for change

(I)

Replace the throat plate, feed dog and needle clamp.

very difficult to sharpen the movable knife,

it

with a new one when it dulls.

(Since the throat plate and feed dog are special parts designed

for thread trimming machine, be sure to use those specified

of

neecile-to-needle distance

by

us.)

(2) Lean the machine

head backward.

(3) Loosen two connecting

A

link clamp bolts

J.

( 4) Remove the spring

M.

Screw

(5) Loosen the hook bracket

clamp screws A and B and

Connecting

link

adjust gap between each

needle and hook.

(6) When the needles and

hooks have been adjusted,

install the spring

M.

Bolt J Stopp r

pin F Thread trimmer

--

rockmi:i crank

D

$crew

B

(7) Contact the rocking cranks

C and D to the stopper pins E and F and tighten the connecting link clamp bolt

(8) Turn the balance wheel by band until the needles reach the lowest position.

J.

Cam follower

crank

Thread trimmer

cam

(9) Loosen the nuts G and

(

10)

Depress the cam follower crank K and adjust the connecting rod L so that the cam roller can

smoothly enter the groove

of

(11) Adjustment

i.

ii.

Push the cam follower crank K so that the cam roller enters into the cam groove.

Turn the connecting rod

the cam groove and the cam roller

H.

of

thread trimmer cam.

Land

adjust the clearance between the cam roller and the cam

groove surface L as small as possible, and tighten the nuts G and H.

iii. Push the cam follower crank K again and check that the cam roller enters into the thread

trimmer cam groove smoothly.

-

17

-

Page 21

SPECIFICATIONS

-I

Model

Number Single-needle Double-needle Single-needle

Application Heavy material

Max. sewing speed

Stitch length

Thread take-up

lever stroke

Needle-bar stroke 36(mm)

Presser-foot stroke

Vertical stroke

upper feed

Needle No.

of

GC20698-1

GC20698-2

16(mm) by Leg

DPX17

GC20698-1-D

1800(rpm)

0,..._,9(mm)

74.5(mm)

2,..._,6(mm)

#23

GC20698-2-D

Double-needle

8(mm) by hand

Hook

Thread take-up

lever

Stitch adjusting

system

Lubrication system Manual lubrication

Clutch motor 370W Servo motor 550W

Needle

gauge

Note: +

Motor

Standard

Special 3.2 4 4.8 8

Some

those listed above.

materials, gauge sizes, and/or sewing conditions may require specifications other than

(Horizontal full-rotating) Large

Slide lever

Dial

6.4(mm)

9.5 12.7

16

19

25.4(mm)

+ Feed dog, throat plate, rotating hook, bobbin case and bobbin should be those designed for thread

timer.

+ Bobbin should be

of

high quality free from deformation.

+ This specification

is

subject to change for machine improvement.

-

18

-

Page 22

A.ARM BED AND ITS ACCESSORIES

-19-

Page 23

A.ARM BED AND ITS ACCESSORIES

I I

-

Fig.

No.

A0I

A02

A03

A04

A05

A06

A07

A08

A08

A09

AIO

All

Al2

Al3 H3219B0067

Al4

Al5 H4722B8001

Al6

Al7

Al8 H4725B8001 Thread guide I I

Al9

A20

A21

A22

A23

A24

A25

A26

A27

A28

A29

A30

A30

A31

A32

A33

A34

A35

A36

A37

A38

A39

Part No. Description

HA300B2090 Rubber plug

I-IA300B2170

1-14716B8001

1-14717B8001

1-14715B8001

1-14718B8001

1-12000B2010

H4919B8001 Side cover (right)

H4719B8001 Side cover (right) I

HA700B2060 Screw 2

1-12400B2100

HA307B0673 Rubber plug

H2000M0080 Cap 2

1-13200B2170

H4723B8001 Spring I I

1-14724B8001

H3200B2100 Screw I I

HA300B2190

H3200B2120 Screw

H3000D2160 Screw I I

H4726B8001

H4727B8001 Face plate I I

H2400B2080

H2400B2070 Thread guide (upper) I

H4730B8001 Guide mounting plate I I I I

H2400B2060

1-13200B2060

H4911B8001

H5015B8001 Cover I

H7007D7101

H7014D7IOI

1-14912B8001

H4913B8001 Supporter

H4915B8001 Cover

H4914B8001 Screw 2 4

H4916B8001

H4742E8001 Screw

H4751B8001

Screw

Oil

guard plate

Thread take-up cover

Rubber plug

Side cover (left)

Rubber plug

Thread guide I I

Slide plate complete I

Screw

Screw I I

Plate I I

Screw 2 I

Thread guide (middle)

Screw

for

oil

Plate

Oil

guard

Cover I

Bobbin complete

Down-lead complete

Screw

Pin

Tension releasing plate

guard I

00

1.0 1.0

°' °'

0

N N

u u

0

2 2

15

I I

I I

I

I I

I I I I

I I

I

2

I

I I

I I

2

I

Cl

N

00

0

0

15

I I

I

-

00

1.0 1.0

°'

0 0

N

u u

0 0

2 2

15

I I

I I

I I I

I I

I I

I

2

2 2

I I

I

2

2 2

I

I I

I I

I I

I I

I I

2

I

I I

I I I

I

2

2 2

I

I I

I

I I

I

I I

I

I

2 2

I

I I

2

I

Cl

N

00

°'

N

15

I

I

I

I

I

I

I

I

I

I

I

SMI

1/64

q,13

q,13

1/64

SMI

SM13/64

SMl/8

SM9/64

1/64

SMI

SM9/64

SM9/64

SM3/16

SM

1/4

SM9/64

1/64

SMI

Remarks

(40)

(40)

02)

(44)

x3

(40)

(40)

06) x6.5

(40) x6.5

(28)

< 24) , 9

<

40)

(40)

x8

x8

x4.8

x6.5

x8

xii

x6

~6

-

20-

Page 24

B.THREAD TENSION REGULATOR MECHANISM

8 9

14

15

16

so

49

\

I

\

I

J.

27

3

35

3

-

21

-

Page 25

B.THREAD TENSION REGULATOR MECHANISM

.....

N

I

Fig.

No.

801 H32218681 I

802 H322183142 Tension releasing plate I

803

804

805

806

807 H4707C800!

808 H007013050

809

BIO HA300C2030

Bil

812

813

814

815

816

817 H322180684 Thread tension spring I 2 I

B18

B19

821

822 HAI0680676

B23

B24

B25

826

827 HA31080705

828

B29

B30

831

832

B33

B34

B35

B36

837

838

839

B40

841

842

843

B43

Part

No.

Screw

H322186812

H4705C8001

H4706C8001

HA731

H322186820 Mounting plate

H322186810 Nut I

H4708C8001

H4709C8001

H322180685 Thread tension stud I

H322180683 Thread tension stud

HAI

1280693 Thread tension disk 2 4 2 4

HA710B0671

H322180682

H3306B0661

HA31080702 Thread tension releasing plate

H4710C8001

HAI

15B7010

HA310B0701

H3221B6816

H3221B0689 Thread tension stud I I

H322180686 Thread tension stud I

H32481B721

H324818621 Take-up spring guide

H32481BC21

H32481BB21

H32481B921

H324818521

H324818821 Bushing I I

H32481BF21

H4712C8001

H32481BE21

H4713C8001

H32481BD21

H4804C8001

H32481B42I

Tension releasing spring

Screw

Lever

Screw

IC306

:·,iounting plate

Stop

ring I I I

Screw

Spring I I I

Push

button

Thumb nut I

Pin

Thread guide I I I

Screw

Thread tension spring I 2 I 2

Thumb nut revolution stopper

Thumb nut complete I

Thread tension disk 2 4 2

Pin

Thumb nut

Screw I I

Stopper

Thread tension post

Screw

Plate complete I I

Thread take-up spring I I

Plate

Thread take-up spring I I

Plate complete I I

Screw

Screw

Description

--

00

\0

°' °'

0 0

N N

u u

c:, c:,

I

00

\0

2

2

I I I

I I

I

I I I I SM9/64

I I I I

I I I

I I I

I I

2

2

I

I I I I

I

I

2 I

2 3 2 3

I I I

I

2 I 2

2

I

2

I I

I

I

I

I I

I I

I

2 2

I I

I I

I I

Cl

Cl

I I

.....

N

•

00

00

0\

\0

\0

°'

0 0

N

N

u u

c:, c:,

2

2

I

2 2

I

I I

2

2

I 2

I 2

4

I

I I

I I

I

•

SM9/64

I

SM9/64 ( 40)

I

I

GB/T896 5

I

I

SMI

I

I

I

I

I

I

I

I

1/64

SM9/64 ( 40) x6

SMl/4

SM9/64

SMl/8

SM9/64

Remarks

(40)

(40)

x4.5

(40)

(40)

(40) ><6

(44)

Y3.9

C 40) x2.9

-

22

-

Page 26

B.THREAD TENSION REGULATOR MECHANISM

N

I

I

$

0

°'

N

I I

I I

I

I I I

I I I I

I I

I I

I

I I I I

Fig.

No.

B44 H3248IB121

B45

B46

B47 H3221B6817

B48 H322186818

B48 H4916B8001

B49

B50

Part

No.

H4805C8001

H3230K0751 Screw

H3200B2100 Screw

H3221B6819 Stopper

Description

Thread tension stud

Thread tension stud

Pin

Tension releasing pin

Tension releasing pin

-

00 00

°'

'°

~

u u

0 0

Cl Cl

I I

N

I

-

00

00

°'

0 0

'°

'°

N N

u u

0 0

I I

I

I

SMl

1/64

SM9/64

Remarks

(40)

xJO

(40)

x6.5

-

23

-

Page 27

C.ARM

SHAFT

MECHANISM

7 8

9

10

11

12

1l

14

15 16 17

19

-24-

Page 28

C.ARM SHAFT MECHANISM

Fig.

No

COi

CO2

C03

C04

C05

C06

C07

C08

C09

CIO

CII

Cl2

Cl3

Cl4

Cl5

Cl6

Cl7

Cl8

Cl9

C20

C2I

C22

C23

C24

C25

C26

C27

C28

C29

C30

C3I

C32

Part

.

No.

HA307C0662

H4706D8001

HAI05D0662

HAIOOC2060

HAIOOC2070

H3211

H4708D8001

H3211

H7004D8001

H3205C0661

HAll3F0684 Screw I

H3205CI021 Belt pulley (upper) I

HAIOOF2130

H3205J0662

H3205J0661

HAll3F0684 Screw 2

H3204J0652 Pulley I

HAIIOD0672 Screw 2

H3200C2030 Cog belt I

H47l3D8001 Spring plate

H47l4D8001

H4715D800I

H0070l3025

H4716D800I Twist spring

H47l7D8001 Plate

H47l8D8001

H47l9D800I Plate

H4720D800I

B4721D800I Screw

IIA

I 04F0654

114722D800I

l14723D800I

Set screw

Crank

Screw

Set screw

Screw

Ann shaft bushing (left) I I I

IB204

Screw

IBI04 Felt

Ann shaft I

Spring flange 3

Screw I I I I

Bearing

Collar

Pin

Link

E-typc stop ring

Pin

Bushing

Screw

Belt

pulley (lower)

Screw

Description

Q

N

I

-

00

00

\0 \0

°'

°'

0

0

N

N

u

u

0

0

I

I

I

I

I

I

I

I I

I

I I I

I I I

I I I

I

I

I I I I

I

I

I I

I

I

I

2

I

I

I I

-

00 00

\0

°'

0

N

u u

0 0

I I

I

I

I

I

I

I

I

I I

I

I I

I

I

I

I

I

3

3

I I

I

1 I

I

I

2

I

2

I I

I I GB/f896 2.5

I

I

I

I

I

I

I

I I

I

I

I I

I

I I

I

2

2

Q

I

N

\0

°'

0

N

SMl/4

I

SMl/4

I

SM9/32

I

SM9/32 ( 28) x

I

SMl/4

I

I

3

SM

SMl5/64

SMl5/64

SMI

I

I

I

I

I

I

I

SMl5/64

1

SMl5/64

SMl5/64

2

(40)

(40) x3.5

(24) xt3

15/64

1/64

Remarks

x7

(28)

xt4

13

( 28)

x8.5

(28)

xt4.5

(28)

x8.5

(28)

xt2

(28)

xto.5

(28)

xto

(28)

x4.5

-

25

-

Page 29

D.UPPER SHAFT & PRESSER FOOT MECHANISM

12

13

l4

51""-

.

-

26-

Page 30

D.UPPER

Fig.

No.

DOI

D02

D03

D04

D05

D06

D07

D08

D09

DIO

D11

D12

D13

D14

D15

D16

D17

D18

D21

D22

D23

D24

D25

D26

D27

D28

D29

D30

D31

D32

033

D34

D35

D36

1)37

1)38

1)39

1)40

D41

D42

D43

D44

1)45

Part

H4705E8001

H4706E8001

H4707E8001

HS9l

165206

H4709E800I

H3l

15F0671

H2013J0065

H2014J0066 Connecting rod I I I

H2000J2100

H47l3E8001

H2011

H007009250 C-type stop ring I

H47l4E8001 Eccentric I I I

HA307C0662

H7008E8001

H7009E8001

H7007E800I

H7005E8001

H3100G2l70 Screw I I

H4730E800I

H4729E8001

H4727E800I

H4728E8001

H3l00G2l30

H4726E800I Nut

H4725E8001

HAI

1100683 Screw

114

723

114744E800I

114754E800I

l-l3200E2020

H4746E800I

I

14768E8001

112404!0034

114748E800I

1l4767E8001

114

752E800 I

114749E800I

1147

I 5E800I

I

12004J0655

114717E8001

ll47l8E8001 Screw I I

11200410662

SHAFT

No.

ICI06

E800

I

& PRESSER

Description

Feed

lifting rock shaft I

Screw

Bushing 2 2 2 2

Nut I I I I

Lever I

Screw I I

Washer I I

Bolt I

Oil pipe

Spring

Screw 2

Screw 2 2

Plate

Plate I I I I

Plate

Lever spring I I

Screw I I

Twist spring I I I

Knee

Screw

Screw

Guide I

Bushing

Presser bar

Screw

Spring bracket I I I I

Thread releasing plate

Screw

Li

Spring

Bracket I

Screw

Bell

Support shaft I I I I

Roller I I I I

Screw

& wick complete I I

(B)

(A)

lifting lever I I I

Iler lever I I I I

crank I I I I

FOOT

MECHANISM

I

-

00

\0 \0

°'

0 0

N N

u

0

2

I

I

I

I

I I

I

2 2 2 2

I

I

I I I I

I

I I

I

I

0 0

N

00

°'

u

0

I I

I

I

-

00

\0

°'

0

N

u

0

I I I

2

2 2

I I I

I

I

I

I

I

I I I

I

I

2

2

2

I I

I

I I

I I

I

I

I

I

I I

I I

I

I I

I I

I

I I

I

I I

I

I

I

I I

I

I

I I

N

I

00

:g

°'

N

u

0

SMl/4

M6x0.

SMl/4

I

I

I

I

I

I

GBff894. I

I

SMl/4

2

SMl/4

2

I

SMl/4

I

I SM15/64

I

I

SMl/4

I

I SMl/4

SMI 1/64(40)xl2

I

SMl/8

SM9/64(40)x

I

SMI

1/64

SMI J/64(32)x6

I

SMl/4(40)x5

Remarks

(24)

75

(28)

25

(40)

(24)

(24)

(28)

(24)

(24) xt9

(44)

8.5

(40)

x7

xJ6

x6

xJ4

xJ7

x7

x9

x79

x

8.5

-

27

-

Page 31

D.UPPER SHAFT & PRESSER FOOT MECH

I I

-

00

Fig.

No.

D46

D47

D48

D49

D50

D51

D52

D52

Part No.

H4719E8001 Link

HAIO0E2150

H4722E8001

H4721E8001

H4753E8001

H4708D8001

Screw

Washer

Bell crank guide

Screw

Screw

H4757E8001 Lifting presser fool

H3114G8001

Lifting presser fool

Description

a, a,

\0

0 0

N N

u u

c.,

1

2 2 2 2

2 2 2 2

1 1

1

2 2 2 2

1 1

AN

ISM

N

00

\0

c.,

1 1

1 1 1

1 1

0 0

I I

N

I

-

00

00

a,

a,

\0

\0

0

0

N

N

u u

c.,

c.,

1 I

I

1

SM 11/

64( 40)

SM11/64(4Q)x 14.5

SM

l/4(24)x

Remarks

><

I 0

13

-

28

-

Page 32

E.NEEDLE BAR AND THREAD TAKE-UP MECHANISM

2

"~

"17

24 23

22

so------,

cE::::::

46

47

48

49

-

29

-

Page 33

E.NEEDLE BAR AND THREAD TAKE-UP MECHANISM

0

0

Fig.

No.

E0I

E02

E03

E04

E05

E06

E07

E08

E09

EIO

Ell

El2

El3

El4

EIS

El6

El7

El8

El9

E20

E21

E21

E22

E23

E24

E25

E26

E27

E28

E29

E30

E31

E32

E33

E34

E35

E36

E37

E38

E39

E40

E41

E42

Part No. Description

H2421

IDN05

Oil

wick

H4706F8001

H4707F8001

HAIOOC2020

H2421

H24211DM05

H4712F8001

H2405D1112

H2421

H2421

HAIIOD0672

H2405D0662

H4716F8001

H4717F8001

H4719F8001

H321

I ID304

H4721F8001

H3204D6513

H4722F8001

H321

I ID604 Screw

H4724F8001

H4806F8001

H4725F8001

H3400C2020

H3200l2030

H3400C2010

H4726F8001

H4753E8001

H4728F8001

H4729F8001

H4730F8001

Needle bar guide bracket stud

Screw

Screw

Oil

IDN05

ID405

wick

Thread

take-up lever support stud

Thread

take-up lever

Thread

take-up slide brock

wick

Oil

ID305 Plug

Screw I

Needle bar crank

Oil

wick

Connecting link I

Needle bar guide bracket I

Screw

Spacer

Felt

Needle bar holder I I

Needle bar

Needle bar

Vibrating presser bar

Screw

Washer

Needle bar guide

Vibrating presser bar link I

Screw 2 2 2

Vibrating presser bar guide I I I

Spring I

Vibrating presser spring guide

pin

H3410C301P Square block

H3406C0671

Crank pin

H3406C0672 Needle bar vibrating crank (left) I I

H602040240 Taper

H4734F8001

H7004F8001

Collar I

Needle bar vibrating shaft

H3204B0652 Needle bar vibrating shaft bushing 2

H2012N0652

H3407C0661

H3231

Screw

Needle bar vibrating crank (right) I

ID506 Nut

H3407C0662 Connecting link

ID306

Screw

H3231

N

I

-

00

00

a,

a,

\0 \0

0

0

N N 0

u

u

C,

C,

I I

I I I I

I

I I I

I

I

I I I I

I

I I I

I

I I I I

I

6

2 2 2 2

I I I I

I

I I

I I I I

I

I

I

I I I

I I I I

I I I

I

I

I

I

I

I I

I I

I

N

I I

-

00 00

a,

a,

\0

\0

0

N

N

u u

C, C,

I I

I I I SM5/16

I

I I

I

I I I

I I I

I

I I I

I

I

I SMl5/64

I I I

I I

I

I I I

6 6 6 SM3/32

I I

I I I

I I

I

I I

I I I

I I I

I I I

2

I

I I I

I

I

I

I

I I I

I I

I

. I

I I

2 2 2

I I I

I

I

I

I I

I

I I

I

I I SM5/16 (24)

SMl5/64

SM9/64

SMll/64

SM

I 5/64(28)x I 0

17 4x24

GB/Tl

SMl/4

Remarks

(28)

xJ0.4

(28)

(28) xJ2

C 56) x4

(40)

x8

(40)

(24) xJ6

xto

.5

xl7.5

-

30

-

Page 34

E.NEEDLE

Fig.

No.

E43

E44

E45

E46

E47

E48

E49

E50

Part No. Description

H3231

ID406

H3129F0691

HAIO0C2170

H3129F0693

H32132Dl04

H4739F8001

H4740F8001

HA700F2100

BAR

AND

Oil

wick

Screw

Screw

Thread guide I

Screw

Needle clamp(l//4)

Needle

Screw

THREAD

TAKE-UP

MECHANISM

0

0

N

I

-

00

oO

$

°'

:g

0

N

D

u

0 0

I

I I

I

I 2 I 2

I

I I

~

I

-

00 00

\0

°'

°'

:g

0

N

a

u

0 0

I I I

I

I

2 2

I I

I

I I

Remarks

SM3/32(56)x2.S

SMl/8(44)x4.S

SM9/64(40)x3

SMI

l/64(40)x7

-

31

-

Page 35

F.STITCH REGULATOR MECHANISM

11

2 3 4

6

1

~------13

31

30

16 17

.I.I

24

22

21

-

32

-

Page 36

F.STITCH REGULAT

Fig.

No

FOi

F02

F03

F04

F05

F06

F06

F07

F07

F08

F09

FIO

Fil

Fil

Fl2

Fl3

Fl4

FIS HA300C2030 Screw I

Fl6

Fl7

FIS

Fl9

F20

F21

F22

F23

F24

F26

F27

r-211

F29

F30

F31

F32 I 147 I 9Ci800 I Felt

FD

F34

F35

F36 I 14723G800

F37 I IAJOOC2030

Part No. Description

.

Feed

H4706G8001

HAI

13F0684

H3200F2020 Screw I

H4707G8001

HAIOOG2070

H4709G8001

H4909G8001

H3207F0671

H4905G8001

I-IA800F2020

HAIOOF21

HAI

H471

H4906G8001

H3207F0672 Screw I

H47IOG8001

H3200F2050 Guide plate I I

H3200F2110 Spring I I

HA700F2030

HA720F0686

HA720F0685

l-

14910G8001

1-IA742trl20

I

IA

I-IA720F0687

I-

IA109F0671

113206F0662

11415050200

11428050060

114714G8001

11471507101

IIA34 I ID308

114

114721GIIOOI

1147220800

IO

13F0684

IG8001

720F0683

7200800 I

regulator

Screw

Link

Eccentric shaft I

Reverse stitch shaft (upper)

Reverse stitch shaft (upper)

Ann I

Arm

Screw I

Spring Washer I

Screw 2 2

Reverse

Reverse sewing lever

Spring I I

Pin

Screw

Bushing I

Stitch length indicating plate

Dial

Stopper

Coil

spring

Screw bar I

Pin

Screw

Screw 2 2

Reverse

Collar

Screw

Rversc

Felt I

Square

I

I Guide plate 2

Screw

OR

cam

sewing

lever

pin

releasing lever

sewing crank

hlock

block

MECHANISM

0

N

I I

-

00 00

\0 \0

°'

°'

0

0

N N

u u

C,

C,

I I

2 2

I I

I I

I I

I I I I

I

I I

I I

I

I

I I

I I

I I

I I

2 2

I I

I

2

4 4

I I

I I

-

00

\0

°' °'

0 0

N N

u u

C,

I I

2

I I I

I I

I I I

I

I

I I

I I I

I

I I

I I I SMll/64

I

I SMI

I I

I

I

I I I

I I

I I

I

I

I I I

I I I

I I

I I GBff70.I

2 2 GBff77

I I

I I

2 2

I I

I I I

I

I

2 2

2 2 2

4 4

0

N

00

\0

C,

2

SM

SM

I

I

SM3/16(28)x

I

I

SMl5/64

I

2

SMI

15/64

15/64

1/64

1/64

Remarks

C 28) x8.5

(28)

(40) x8.5

(40)

18

M5x20

M5

x6

(28)

(40)

x

xS

x7

x8

12

-

33

-

Page 37

G.LOWER SHAFT & FEED ROCK SHAFT MECHANISM

43

42 45

44

(41) (30)

(33) (32)

-

34-

Page 38

G.LOWER

Fig.

No.

GOI

G02

G03

G04

GOS

G06

G07

G08

G09

010

Gil

Gl2

Gl3

014

015 H007009260 C-type stop ring I I I I OB/f894. I

016

017

Gl8

019

020

021

022

023

024

025

026

027

028

029

030 HAI00O2120

031

032

033

034

035

036

037

038

039

040

041

042

043

Part No.

H4706H800I

H4707H8001

H7004H8001

H4710H8001

H3205H0654

H4712H8001

H4713H8001

H007013050 Stop ring 2 2 2 2 OB/f896 5

H4714H8001

H4715H8001

H2405D0664

H4717H8001

H4718H8001

H4719H8001

H4720H8001

H4721H8001

H7006H7101

H4725H8001

HAI05D0662

H3205H0654

H4723H8001

H4727H8001

HA7311C306

H4728H8001

H4729H8001

HS91165206

H4731H8001

H2012N0652

H4708D8001

HA I 08O066

HAI05D0662

H2012N0652

H4736H800I

H4737H8001

H007013050

H4738H8001

H4739H8001

H7005H8001

H4740H8001

H3204O0031

H3200O2030

SHAFT & FEED

Lower shaft bushing (left)

Oil

wick

Lower shaft

Feed

eccentric

Screw I I I I SMl/4(40)x5

Lower shaft bushing (right)

Oil

wick

Spring

Push

button I I I I

Screw

Feed

eccentric I I I I

Feed

connecting

Needle bearing

Oil

wick

Shaft I I I I

Lower

Bushing I I I I

Screw

Screw

Ball

bearing

Bearing holder I I I I

Screw

Washer

Screw

Nut I I I I

Feed

connection crank (right)

Screw

Feed

rock

Screw

t ·

Collar 2 2 2

Screw

Screw I I I I

Feed

connection crank (middle)

Link

E-type

Pin

Oil

wick

Feed

rock

Felt

Oil wick

Clip

cam

rod

shaft bushing complete (middle) I I I I

shaft bushing

stop ring

shaft

ROCK

Description

SHAFT

MECHANISM

Q Q

N

I I

-

00 00

\0

\0

°'

°'

0

~

N 0 0

u

u

0 0

I I I I

I I I I

I I I I

I I I I

I I

I

I I

2

I I I

I I I I

I I I I

I I I I

I I I I

I I I I

3 3

I I I I

I I I I

I I I I

I I I

2

2 2 2

4 4 4 4

I I I I

I I I I

2 2 2 2 OBff896

I

I I I I

I I

2 2 2 2

I I I I

I I I I

I I

N

I I

-

00

00

\0

\0

°' °'

N N

u

u

0 0

I I

I I

I

I I

2

2 2

3 3

2 2 2

I

I

I I

SM15/64(28)x

I

SMl/4 (40)

SMl/4 (40)

SM9/64

M6

OB52008

I SMl/4 (24) xl6

SMl/4 (24)

2

2

SMl/4 (40)

SMl/4(24)xl6

I

Remarks

14

26

x4

x5

(40)

x7

M6

xJ3

x4

5

-

35

-

Page 39

G.LOWER SHAFT & FEED ROCK SHAFT MECHANISM

Cl

I I

I I

-

00

IQ

°'

0 0

N N

u

0

I

I I

I

I

I I

Cl

N

00

IQ

°'

u

0

2

I

I

2

I

I

Fig.

No.

044

045

045

046

047

G4S

049

050

050

050

051 H3200H2040

052

053

054

055

056

057

Part No. Description

HAl04G00l2 Screw

Feed

H4905H8001

H3205GI032

H32243G205

H3205G0662 Oil

H3221

IG205 Bolt 2 2 2

H429050050

H4742H8001

H4805H8001

H4942H8001

connection crank (left)

Feed

connection crank (left) I

Feed

bar shaft

wick

Bolt

Feed

bar I

Feed

bar I

Feed

bar I

Screw

H2013J0065 Washer

H003002030 Nut

H429030140

H3205H0653

Screw

Screw

H3205H0652 Felt I

H4743H8001

Feed

bar forked connection I I I

N

I

00

IQ

u

I

-

00

IQ

°' °'

0 0

N N

u

0 0

2 2 2

I

I

I

I

I I

I

I

I

I I I

I

I I I

I I

I I

I I

I I I

Remarks

SMJ/16

SMl/8

(28) xJ2

(40)

x7

GBITTS M5x5

SMl5/64

GBff6170

(28)

M3

GBff78 M3xJ4

SMl/8

(44)

x4

xt7

-

36-

Page 40

H.HOOK SADDLE MECHANISM

11----S

GC20698-1

GC20698-2

7

6

5

9

12

26

27

GC20698-1-D

GC20698-2-D

31

Cl!>

!----

1

32

2

31

Ca)

30

!--32

-

37

-

29

28

Page 41

H.HOOK

SADDLE

MECHANISM

Fig.

No.

H0I

H0I

H02

H03

H04

H05

H06

H07

HOS

H09

H09

HIO

Hll

HII

Hl2

Hl3

Hl4

Hl5

Hl6

Hl7

HIS

Hl9

H20

H21

H22

H22

H23

H24

H24

H25

H25

H26

H27

H28

H28

H29

H29

H30

H31

H31

H32

H32

Part

No.

H700518001

H4906l8001

H3207I0661

H3207I0662

H4707l8001

H4706l8001

H4708l8001

H4709l8001

H4705l8001

H3306I0067

H4912l8001

H4922l8001

H4908l7101

H4708l7101

H3204I0656

H32153l504

H32153l204

H331311204

H331311104

H2004J0067

H3200I2030

H3305I0066

H005008050

HAI04G0658

H7006l8001

H4909l8001

H3204I0657

H331211204

H4910l8001

H3204I0653

H491118001

H2013J0065

H3200I2050

H3204I0659

H4914l8001

H3204I0658

H4915l8001

HA305E0662

H4917l8001

H7004l8001

H3200l2050

H491318001

Description

Hook

saddle (right)

Hook

saddle (right)

Screw

Bushing

Screw

Hook

driving gear (large)

Screw

Screw

Hook

driving gear (small)

Bobbin

Bobbin

Spring

Hook

complete

Hook

complete

Oil

wick

Opener bracket shaft

Screw

Link

Opener bracket

Screw

Washer

Opener

Spring

washer

Nut

Hook

shaft bushing (upper)

Hook

shaft bushing (upper)

Screw

Washer

Washer

Hook

shaft bushing (lower)

Hook

shaft bushing

Washer

Screw

Nut

Nut

Screw

Screw

Screw

Hook

saddle (left)

Hook

saddle (left)

Screw

Screw

(lower)

....

I I

00

1.0

°'

0

N N 0

u

c,:,

I I

I 2 I 2 SMl5/64 (28)

I

3

I 2 I 2

I 2 I 2 SMl/4 (40)

I 2 I 2

I 2 I 2

I 2

I 2

2 4 2 4

I 2 I 2

I 2 I 2

I 2 I 2

I

I

I 2 I 2

I 2 I 2

I

I 2 I 2

I 2

I 2 I 2

I 2

I 2

I 2 I 2

I I

I 2

I 2

I 2

Cl Cl

N

00

°'

8

u

c,:,

I I

....

I I

00

1.0 1.0

°'

N

u

c,:,

I I

2 I 2

6 3 6

I 2

I 2

I 2

2 I 2

2

I 2

I

2

I 2

I 2

I 2

I I

I 2

I 2

2 4

I

I 2

N

00

°'

0

N

u

c,:,

SMl/4 (40)

SMl/4 (40)

BO-B872(A)

SM3/16

2

SM3/16

SMl/4 (24)

I

SMl/4 (24)

SMl/4 (24)

Remarks

02)

(28) xJ4.5

x22

x4

x6.5

x5

x7.8

x23

x23

x30

-38-

Page 42

I.THREAD TRIMMER MECHANISM

4 5 7 8 9

3

(

15) ( 14) ( 11

)

- 39 -

Page 43

I.THREAD TRIMMER MECHANISM

Fig.

No.

IOI

102

103

104

l05 H4909J8001 Fixed blade

106

107

l08 H4912J8001

l09

110

Ill

112

113

114

115

116

117

118

119

120

121

Part

No.

H4905J8001 Screw

H4906J8001 Bolt

H4907J8001 Trimming knife holder

H4908J8001 Screw

H491488001 Screw

H491

IJ8001 Moved knife

Screw

H4913J8001 Screw

H4914J8001 Spring plate

H4915J8001 Screw

H4916J8001 Reversing spring

H4917J8001 Guide

H4920J8001 Roller

H4921J8001 Lever

H4922J8001 Cover

H4923J8001 Guide (right)

H4924J8001 Knife pad (right)

H4925J8001 Screw

H4926J8001 Knife pad (left)

H4927J8001

Cover

Description

N

00

°'

'°

0

I

....

I I

00

°'

'°

N

u u

C,

I 2

I

I 2

3 6

I

2 4 SM9/64 (

I 2

I 2

I 2 SM9/64 (

I 2

3

I 2

I

I 2

I 2

I I

I I

I I

I

I I

I I

....

I I

00

°'

0 0

'°

N N 0 0

u u

C, C,

0

N

00

°'

'°

N

C,

2

2

6

I

I

I

SMll/64

SM9/64 (

SMl/8

(44)

SM3/32 (

SM9/64

Remarks

(40)

xJ2

40)

x4

40)

x4

x9.2

40)

x4.5

56)

x3.8

(40)

x9.5

-40-

Page 44

J.THREAD TRIMMER MECHANISM

36

37

38

8 9

44

1 2

& 7

&1

62

-

41

-

Page 45

J.THREAD TRIMMER MECHANISM

Fig.

No.

JOI

102

103

104

105

J06

J07

108

109

JIO

JII

Jl2

JIJ

Jl4

Jl5

Jl6

Jl7

Jl8

Jl9

J21

•125

Part No. Description

HA300C2020

H4915K7101

H4918K8001

H4919K7101

H240012040

HA300B2170

H0604K7101

H4912K8001

H49l3K8001 Bolt I I SMl5/64

H4945K8001

H4950K8001

H4949K8001

H4952K8001

H4953K8001

HA700Q0030

H4925K8001

H003002050

HA300C2030

H4908K8001

J20

H4907K8001

H4906K8001

J22

H4905K8001

HAIOOH2080

J23

H4946K7101

J24

H4943K8001

J26

H4951K8001

H4954K8001

121

H4956K8001

J28

129

H4955K8001

JJO

H4957K7101

JJI

H4944K8001

J32

H4962K8001

HA708P0668

J33

HAll3F0684 Screw

J34

H4931K8001

J35

J36

H4909K8001

H005001050

J37

H491

J38

J39

J40

J41

J42

J43

IK800I Bolt 2

H4936K8001

H4987K8001

H4940K8001

H4939K800I Bolt I I

8003002050

Screw

Thread releading bracket

Spring

Thread releading plate

Screw I I

Screw 4 4

Flexible wire complete I I

Arm

Spring I

Screw

Roller I I

Screw I I

Mounting plate

Nylon

clip I

Mounting plate I

Nut

Screw

Arm

Bolt I

Link I

Screw

Pin type I I

Thread releasing lever

Spring I I

Nut I I

Nut

Screw

Bushing

Vibrating crank I

Screw

Screw

Nylon

clip

Bushing I

Link I

Washer

Screw

Bolt

Nut (left) I

Nut (right)

N

I

-

00

\0 \0

°' °'

0

N N

u u

0 0

•

00

0

Cl

•

I

-

00

\0

°'

0

N N

u

0

2 2

I I

I I

I I

I I

I

I

I

2

I

2 2

I

I

2

I

I

2

I

2 2

2 2

I I

I

Cl

•

N

•

00

\0

°'

0

u

0

SMI

1/64

SMll/64

1/64

SMI

I

SMI

I

I

I

I

2 GB/T6170

I

I

I

I

2

I

I

I

2

I

I

I

I

I

1/64

SMJ/16

1/64

SMI

SMl5/64

M5 C0.

1/64

SMI

SMJ/16

SMl/8

SMI

1/64

M5x5

SMl5/64

GB/T97

M5

(0.5) x

M5

GB/T6170M5

Remarks

(40)

(40)

(40)

(28)

(40)

(28)

M5

(40)

(28) xJ2.5

5)

x7.5

(40)

(28)

(44)

x7

(40)

(28) x8.5

.I 5

8.5

x8

x5

xS

xl2.5

xJ.6

x5

x7

x5.5

-

42

-

Page 46

J.THREAD TRIMMER MECHANISM

Q Q

N

I I

-

00

00

-

Fig.

No.

144