Page 1

Parts Catalog

SHANGHAI HUIGONG NO.3 SEWING MACHINE FACTORY

GC20688-1/-2BDL

Single-needle/Twin-needle Long arm heavy duty

compound feed lockstitcher with trimmer

Instruction Manual

Page 2

Item

GC20688-1BDL

GC20688-2BDL

Max. Speed

2400rpm

2400rpm

Stitch length

0 to 9mm

0 to 9mm

Needle bar stroke

34mm

34mm

Presser foot

clearance

By hand

9 mm

9 mm

By knee

16 mm

16 mm

Rotating hook

Large vertical hook (2.5times)

Large vertical hook (2.5 times)

Needle

DP×17 #18-#25

DP×17 #18-#25

Presser foot alternation

1-7mm

1-7mm

Auto presser foot lifter

Pneumatic

Pneumatic

Oil lubrication method

Automatic lubrication

Automatic lubrication

Bed dimensions

710×140 mm

710×140 mm

Needle gauge(mm)

3.2 6 8 10 12 16

1. PRECAUTIONS BEFORE STARTING OPERATION

1) Safety precautions

(1) When turning the power on, keep your hands and fingers away from the area around/under the needle

and the area around the pulley.

(2) Power must be turned off when the machine is not used, or when the operator leaves his/her seat.

(3) The power must be turned off before tilting the machine head, installing or adjusting the machine, or

when replacing.

(4) Avoid placing fingers, hairs, bars etc. nears the pulley, bobbin winder pulley, when the machine is

operation. Injury could result.

(5) Do not insert fingers into the thread take-up cover, under/round the needle, or pulley when the

machine is in operation.

(6) If a mini motor cover, finger guard, and/or eye guard are installed, do not operate the machine

without these safety devices.

2) Precaution before starting operation

(1) If the machine's oil pan has an oil sump, never operate the machine before filling it.

(2) If the machine is lubricated by a drop oiler, never operate the machine before lubricating.

(3) When a new sewing machine is first turned on, verify the rotational direction of the pulley with the

power on. (The pulley should rotate counterclockwise when viewed from the pulley.)

(4) Verify the voltage and (single or three) phase with those given on the machine nameplate.

3) Precaution for Operating Conditions

(1) Avoid using the machine at abnormally high temperature (35℃ or higher) or low temperatures (5℃

or lower). Otherwise, machine failure may result.

(2) Avoid using the machine in dusty conditions. Avoid using the machine in areas where too much

electrical noise, resulted from the high-frequency welder and others, is generated

2. SPECIFICATIONS

— 1 —

Page 3

If sewing with stitch length of 6 mm or more, set the sewing speed to 1600 rpm or less.

3. PREPARATION BEFORE STARTING TO OPERATE

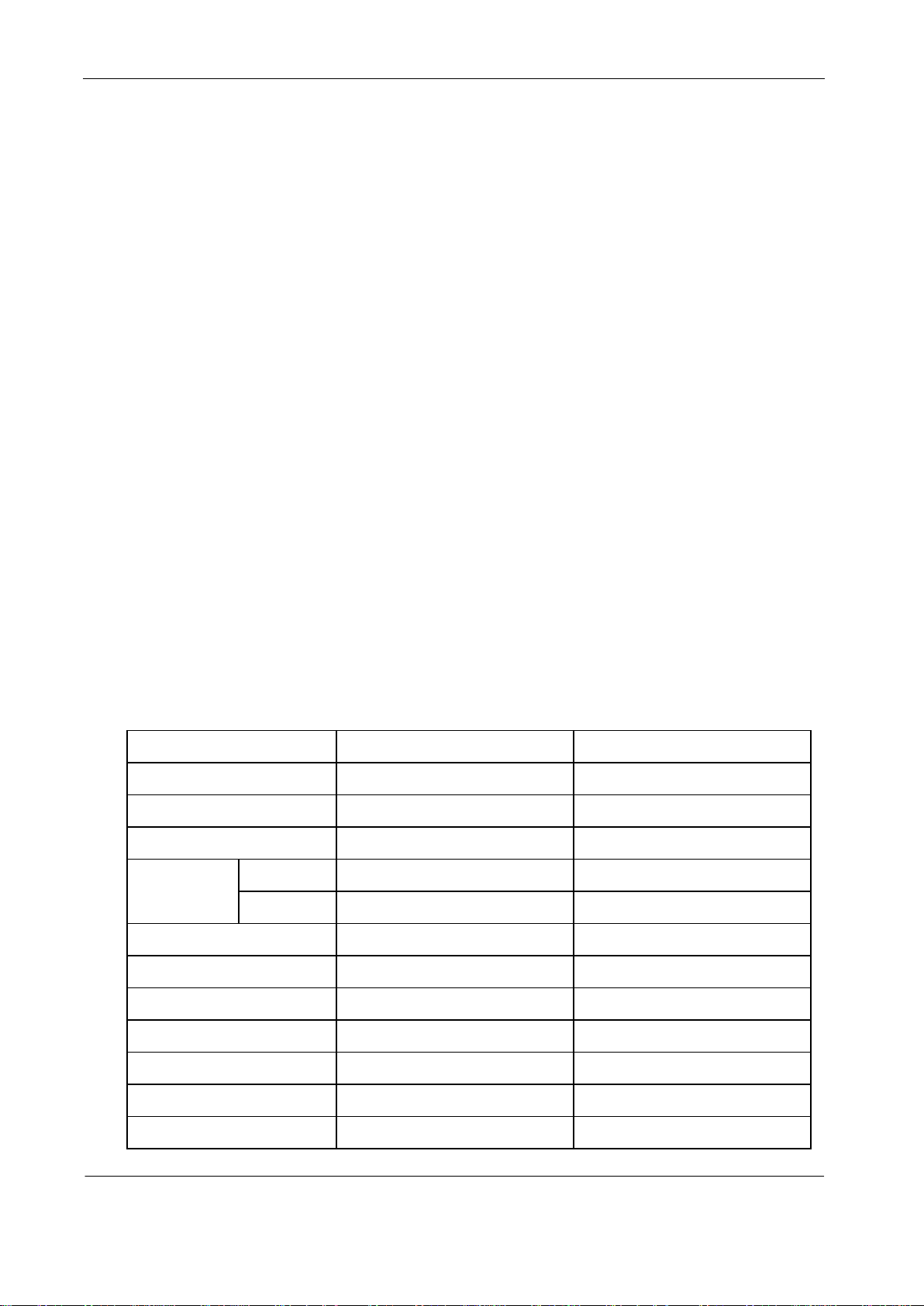

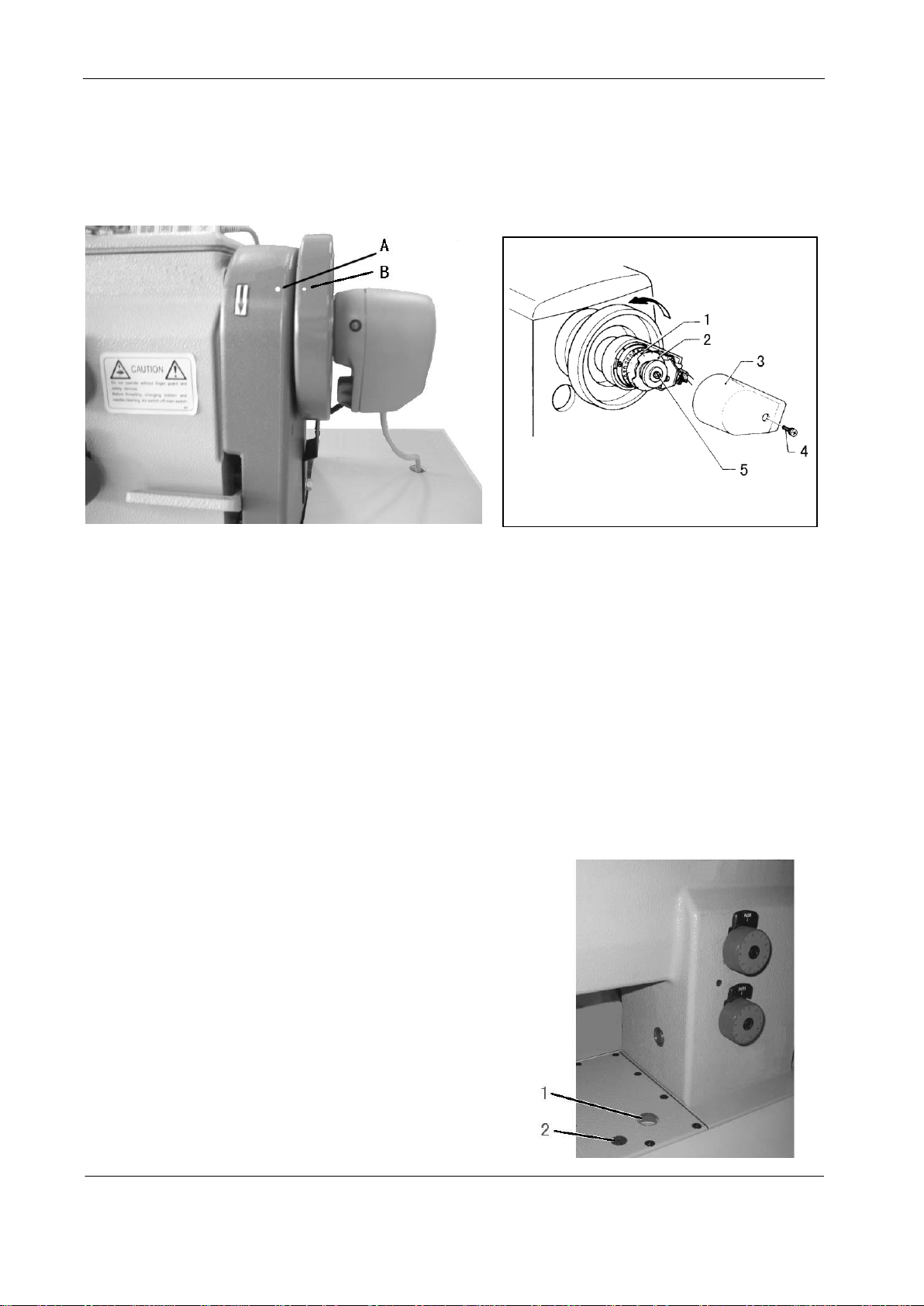

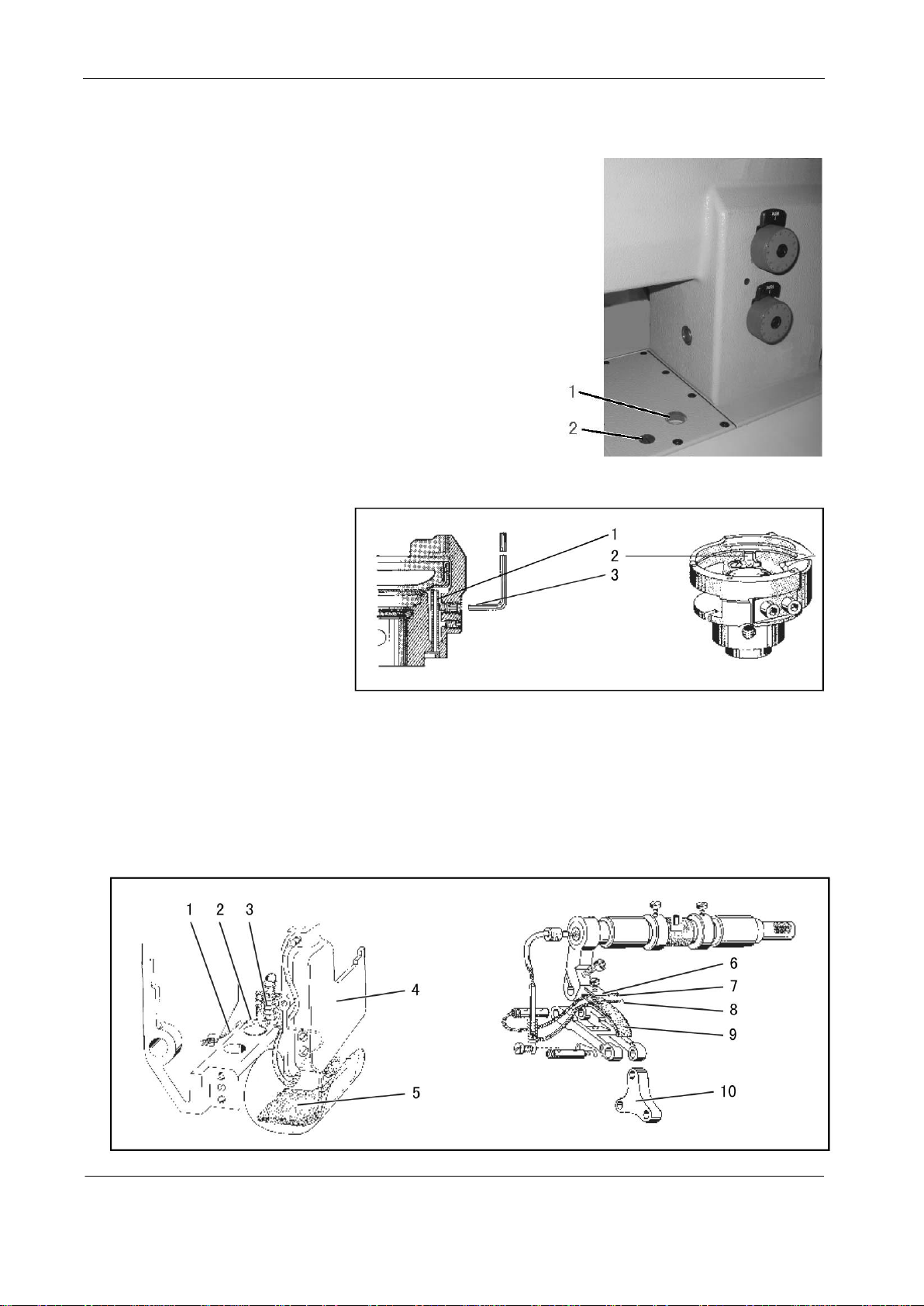

1) Connection of control box

It shows the connection of the electrical wires

of the whole machine on the right picture.

When the machine needs to be assembled,

each line should be linked to the right joint

according to the instruction of the picture.

All the pins on the control box have signals of function showing, and usually, different wires have different

kinds of joint.

Caution: the pin of synchronizer wire is the

same with another two external pins and if

there is a misconnection, the synchronizer

might be burn.

When connecting the pipes, please check the joint at the picture

of the whole machine above as reference.

And also there have an instruction mark of each joint of the

solenoid at the setting board.

— 2 —

Page 4

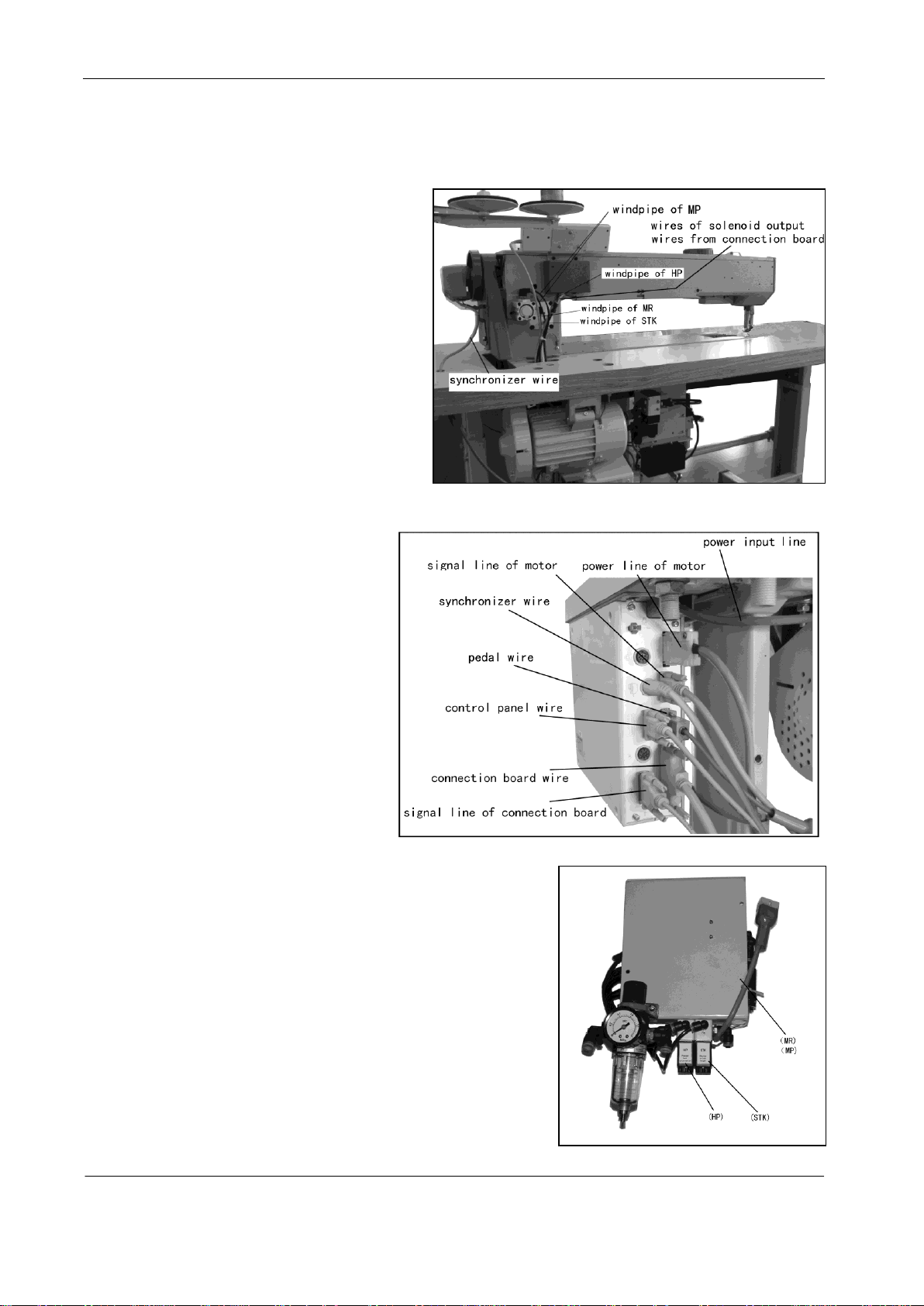

2) Oil pan

(1) Install the oil pan 3 to the underside of the worktable 1 in the place shown in the illustration using the

nails 2.

(2) From front view, the oil pan 3 to the side is

60mm; from right view, the oil pan 3 to the side is

80mm.

3) Operation panel

(1) Install the operation panel 1 to the

set plate 2 with the three screws 3.

(2) Install the set plate 2 to the back of

the machine arm with the two screws 4.

4) Adjusting the needle stop position

(1) Adjusting the needle up stop

position

When the sewing machine stops in the needle up stop position (the stop position of trimming) and the

treadle is pressed back, the red mark on the pulley should be consistent with the mark on the belt cover A.

Adjust as follows:

a. Turn off the power switch.

b. Loosen the screw 4, and then remove the cover 3.

— 3 —

Page 5

c. When the red mark stops in a position over the mark on the belt cover, the needle up stop position disc 1

should be turned in the opposite direction as the direction of machine pulley rotation. When the red mark stops

in a position under the mark on the belt cover, Turn the disc 1 in the same direction as the pulley rotation

direction.

(2) Adjusting the needle down stop position

When the sewing machine stops in the needle down stop position, the black mark on the pulley should be

consistent with the mark on the belt cover A. Adjust as follows:

a. Turn off the power switch.

b. When the black mark stops in a position over the mark on the belt cover, the needle down stop position

disc 2 should be turned in the opposite direction as the direction of machine pulley rotation. When the black

mark stops in a position under the mark on the belt cover, Turn the disc 2 in the same direction as the pulley

rotation direction.

c. After adjusting, install the cover 3, with screw 4.

Note: There is no need to loosen the screw 5, when turning the discs.

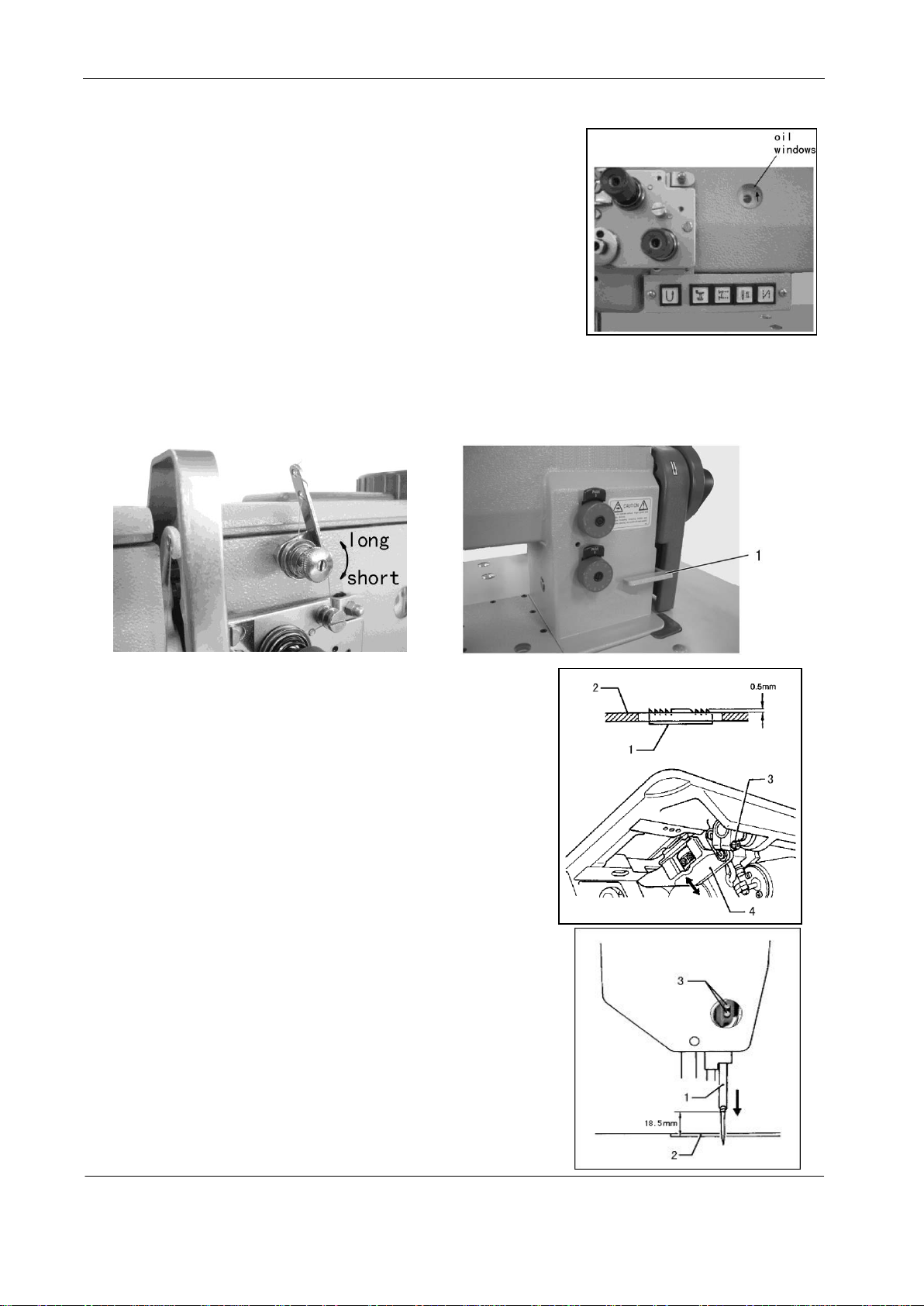

5) Lubrication

Before the new machine is used, please loosen the screw 2

and full the oil into the oil case. Set the oil level between

“EMPTY” and “FULL”. Then replace oil-filling screw 2.

— 4 —

Page 6

4. HOW TO USE THE MACHINE

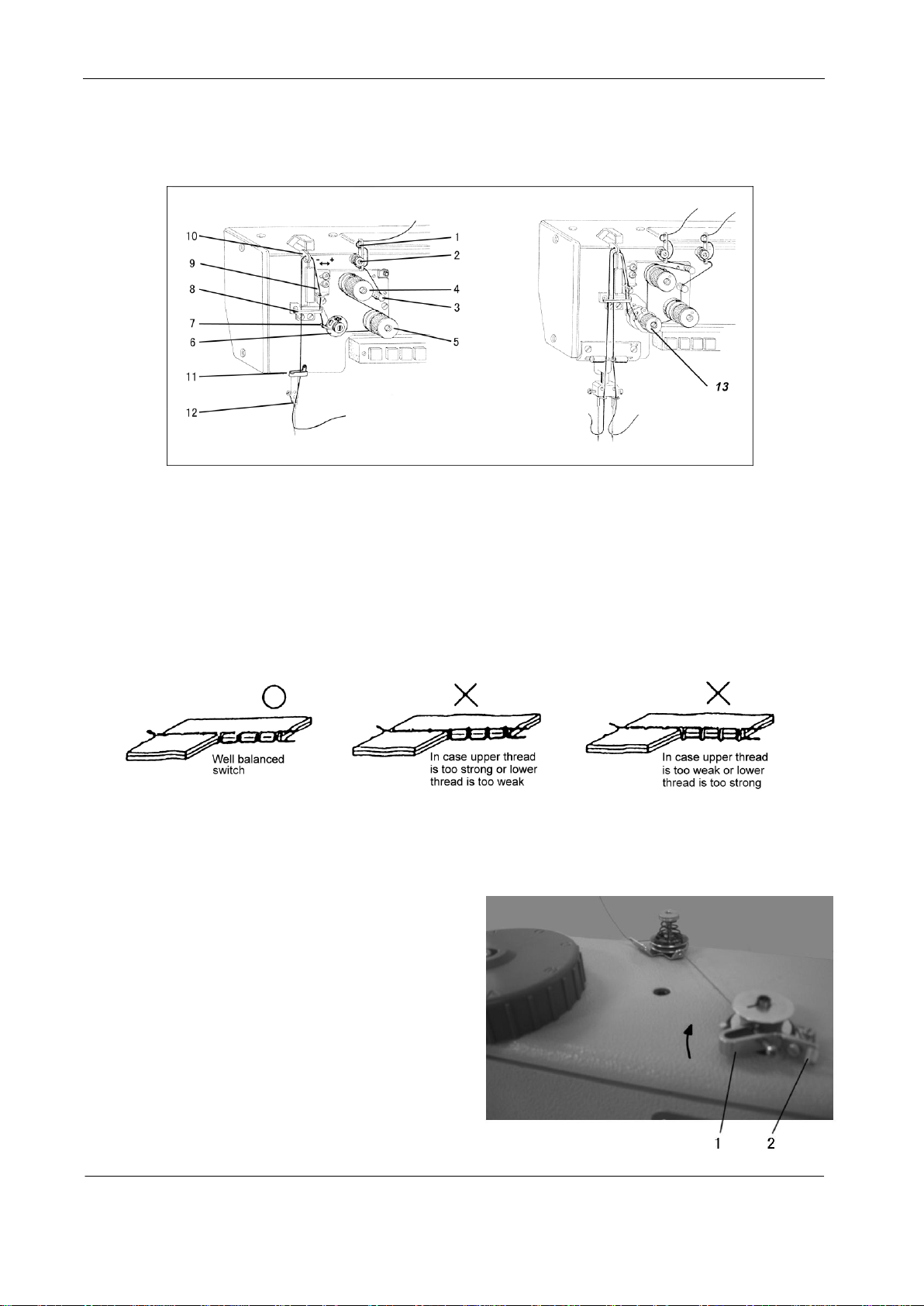

1) Threading

Raise the thread take-up lever to its highest position and thread the upper thread in the following order.

2) Adjusting of the thread regulator

The thread regulator 9 (see the right picture) regulates the amount of needle thread necessary for stitch

formation. The setting depends on the following factors: material thickness, yarn characteristics and stitch

length.

The thread regulator is fitted with slots for this purpose. Moving in the “+”direction increases the quantity

of needle thread; Moving in the “-”direction reduces the quantity of needle thread.

3) Adjusting of upper thread tension

Tension should be as low as possible. The crossover point should be in the center of the material. Upper

thread tension can be adjusted by thread tension nut 4 and 5 (see the picture of above). Turn the thread tension

nut clockwise to increase the needle thread tension. Turn the thread tension nut counter-clockwise to decrease

the needle thread tension.

4) Winding the lower thread

(1) Place the bobbin onto the bobbin winder shaft.

(2) Pass the thread for winding thread as shown in

the figure, and wind the end of the thread clockwise

around the bobbin several times.

(3) Push the bobbin presser 1 toward the bobbin.

(4) The operation will automatically stop when

winding is completed. The amount of thread wound onto

the bobbin should be a maximum of 80% if the bobbin

capacity.

— 5 —

Page 7

(5) After the thread has been wound

on, remove the bobbin and cut the thread

with the thread-trimming knife 2.

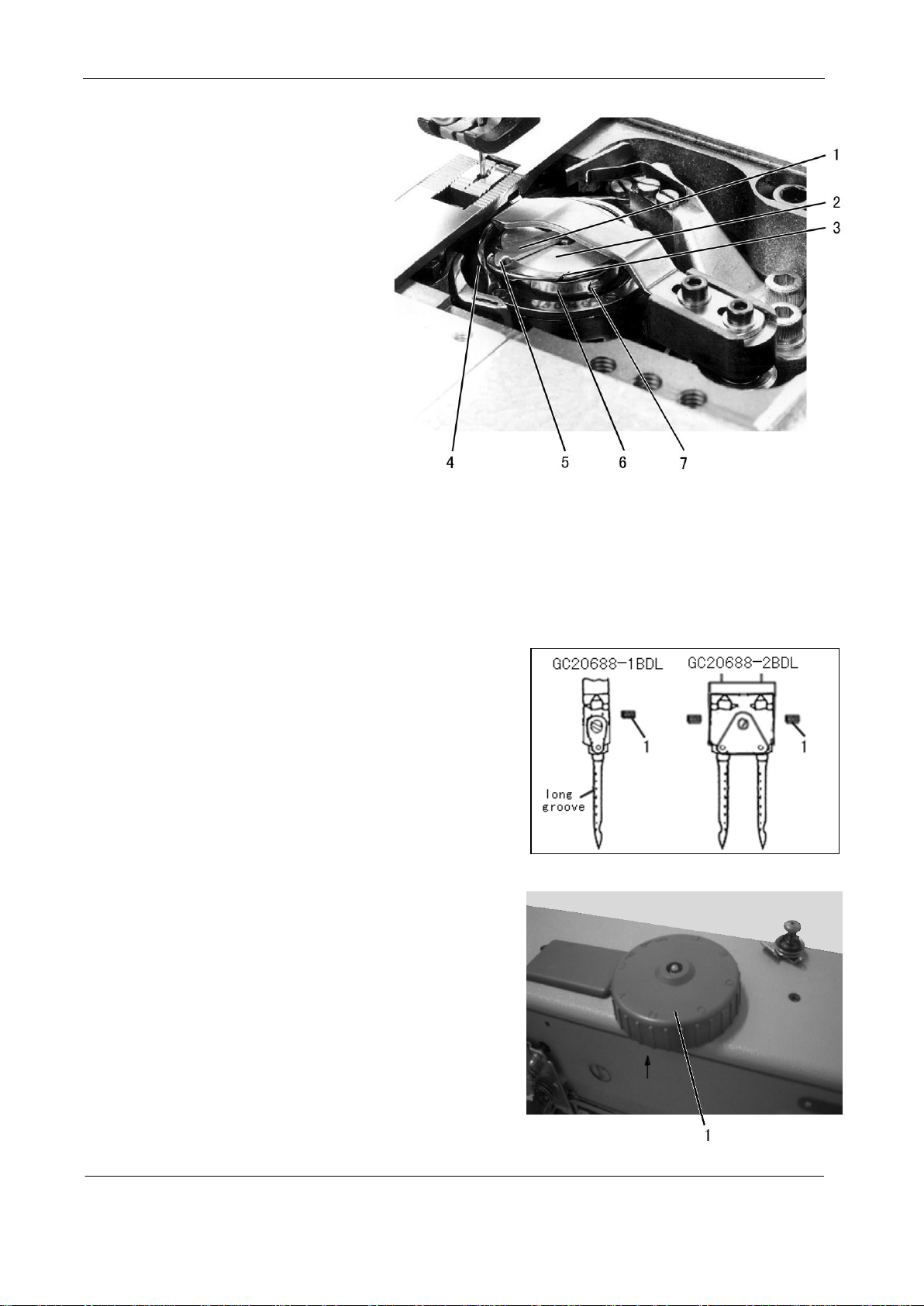

5) Threading the lower thread

(1) Raise flap 1 and remove the

empty bobbin.

(2) Insert bobbin 2 in such a way that

when the thread is unwound from it moves

in the opposite direction to the gripper.

(3) Pass the thread through slit 3 and

below spring 6, pass the thread through

slit 4 and pull about 3 cm through.

(4) Close flap 1 and pass the thread through the flap’s guide 5.

6) Adjusting the lower-thread tension

The lower-thread tension should be set in accordance with the type of seam required. Adjust the tension

with screw 7. (See the picture of above)

7) Installing the needle

Note: Before attach needle, be sure to turn off the power.

1) Turn the balance wheel by hand to raise the needle bar to its

highest position;

2) Loosen the needle clamping screw;

3) Hold the needles so that the two needles side with the long

grooved (faces each other), and insert it as deeply as it will go

into the needle clamping holes( model GC20688-2-D);Hold the

needle to its side with the long groove side(left),then insert the

needle as deeply as it will go into the needle clamping hole(model

GC20688-1-D).

4) Tighten the needle clamping screw.

8) Alternating presser foot movement amount

The alternating movement amount for the inner presser

foot and the outer presser foot can be adjusted within the range

of 1-7 mm using the alternating presser foot movement dial 1.

Turn the alternating presser foot movement dial 1 clockwise or

counterclockwise to align the mark. (MIN. A, B, C, D, E, F

MAX. )

— 6 —

Page 8

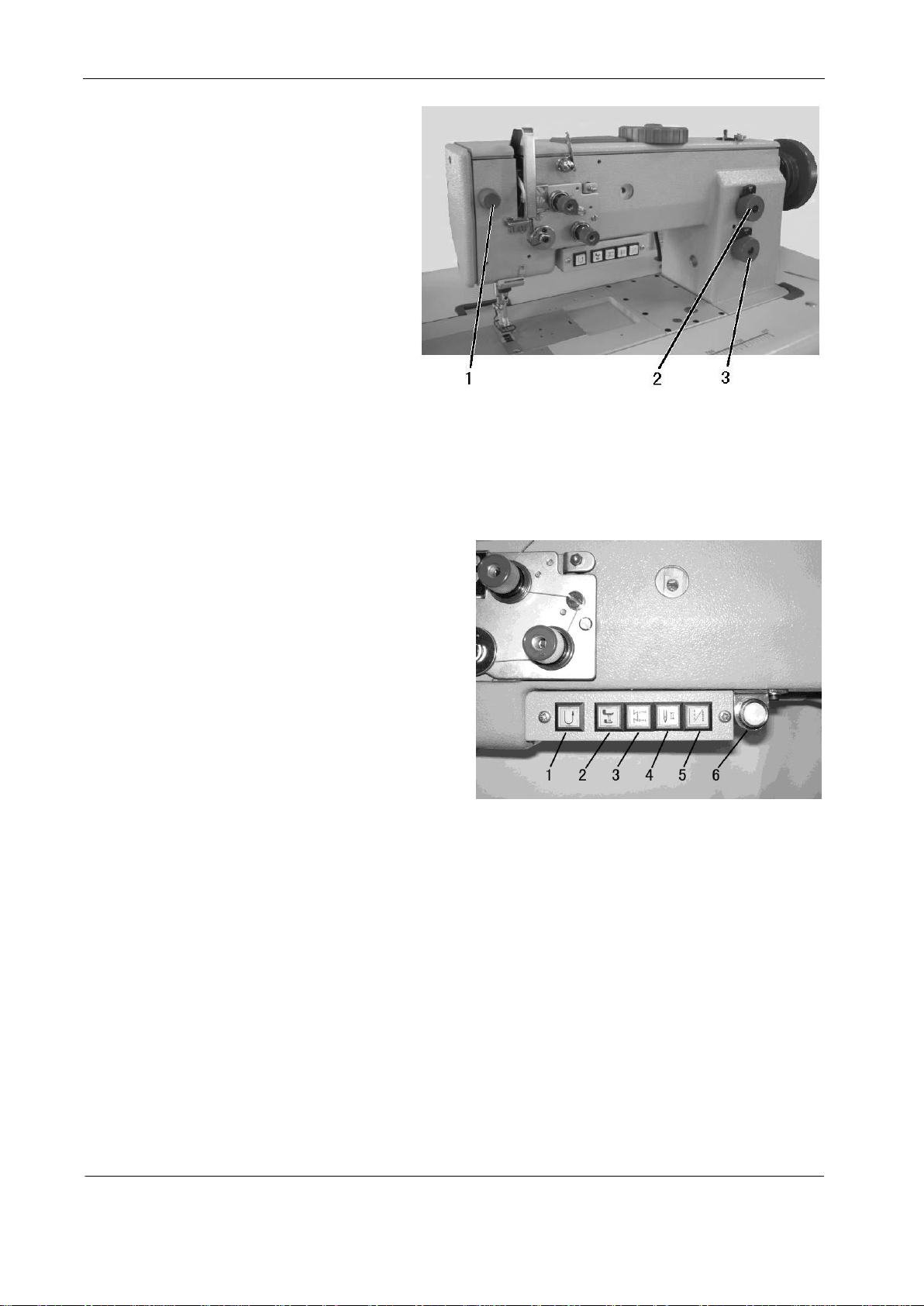

9) Adjusting the presser foot pressure

The presser foot pressure should be set as

weak as possible, but strong enough so that the

material does not slip. If the presser-adjusting

dial 1 is turned clockwise, the presser foot

pressure will become stronger, and if it is turned

counterclockwise, the pressure will become

weaker.

10) Adjusting the stitch length

The feed adjustment dials 2 and 3 can be

used to set two different types of stitch length. (See the picture of above) Use feed adjustment dial 2 to set the

big stitch length. Use feed adjustment dial 3 to set the little stitch length. The sewing machine will switch

between the two stitch lengths each time the stitch length change switch is pressed.

11) Using the manual switches

(1) Quick reverse switch

Back tacking is carried out during sewing only

while the switch 1 is being pressed.

(2) Alternating presser foot movement change switch

The sewing machine can be switched between

two different alternating presser foot movement

amounts each time when the switch 2 is pressed.

(3) Auto back tacking select switch

If the switch 3 is pressed when either start back

tacking or end back tacking has been set to ON at

the operation panel, back tacking is canceled for the first time only. Furthermore, if the switch 3 is pressed

when neither starting nor end back tacking has been set, back tacking is carried out for the first time only.

(4) Needle up or down switch

If the switch 4 is pressed, The needle will move up to the needle up stop position from down stop

position or move down to the needle down stop position from up stop position.

(5) Stitch length change switch

The stitch length changes alternately between two different stitch length settings each time the switch 5

is pressed. OFF: Sewing is carried out using the big stitch length; ON: Sewing is carried out using the

little stitch length.

(6) Feed wheel switch 6:

If the switch is pressed, the feed wheel will move up to the feed wheel up stop position from down

position or move down to the feed wheel down stop position from up position.

— 7 —

Page 9

12) Cleaning

(1) The area around the feed dog and the hook should be cleaned every day.

(2) Remove any thread scraps from inside the rotary hook.

(3) Keep the control box clean.

13) Lubrication

(1) Check the oil level at the sight glass 1 every week. If the oil is

not enough, remove oil-filling screw 2 and pour in oil. Check

oil level at sight glass 2. The oil level must be between

“EMPTY” and “FULL”. Replace oil-filling screw 2. After

running for 500 hours since buying the new sewing machine,

the oil must be changed. Then change the oil every two years.

(2) The oil quantity is pre-set at a relatively high level in order to

ensure adequate lubrication during running–in. This setting should be checked and corrected after

running-in. (approx. 50 hours).

The hook is to have positive

lubrication with the least

possible amount of oil. Let the

sewing machine run approx.2

minutes. And run in intervals.

Hold a piece of paper next to

the hook and check if sufficient oil is spun oil onto the paper. Remove cover plate 2. Loosen screw 3 until

the tube 1 no longer moves. This is the case when the tube is in the center of the drilled hole. Turn screw 3

in until the tube movement just starts and then a 1/8 turn farther. The hook lubrication is preset. Attach

cover plate 2 again. Setting the hook lubrication with screw 3.

(3) Lubricating wicks and felt (see the picture of above)

— 8 —

Page 10

a. The wick 1 leading from the oil sump to the oscillating crank 4 must be fixed between the groove 2 in the

arm and the spring 3 of the recirculation wick.

b. When the oil satchel is changed, the flock side should be faced to

connecting plate 10. The oil wick 7 and 8 should be set between the

oil satchel 9 and plate 8.

(4) Checking the lubrication oil.

Turn on the power switch. Depress the treadle gently and check

that the oil level rises in the oil sight glass.

14) Adjusting the trailing length after thread trimming

Adjust by turning the pre-tensioner 1. If the tension of the pre-tension is increased, the lengths of the

threads trailing from the needle tips will be reduced; if the tension is reduced, the lengths will be increased.

15)Back tacking

When the reverse lever 1 or the quick reverse switch is

pressed during sewing, the feed direction will be reversed. When

it is released, the feed direction will return to normal.

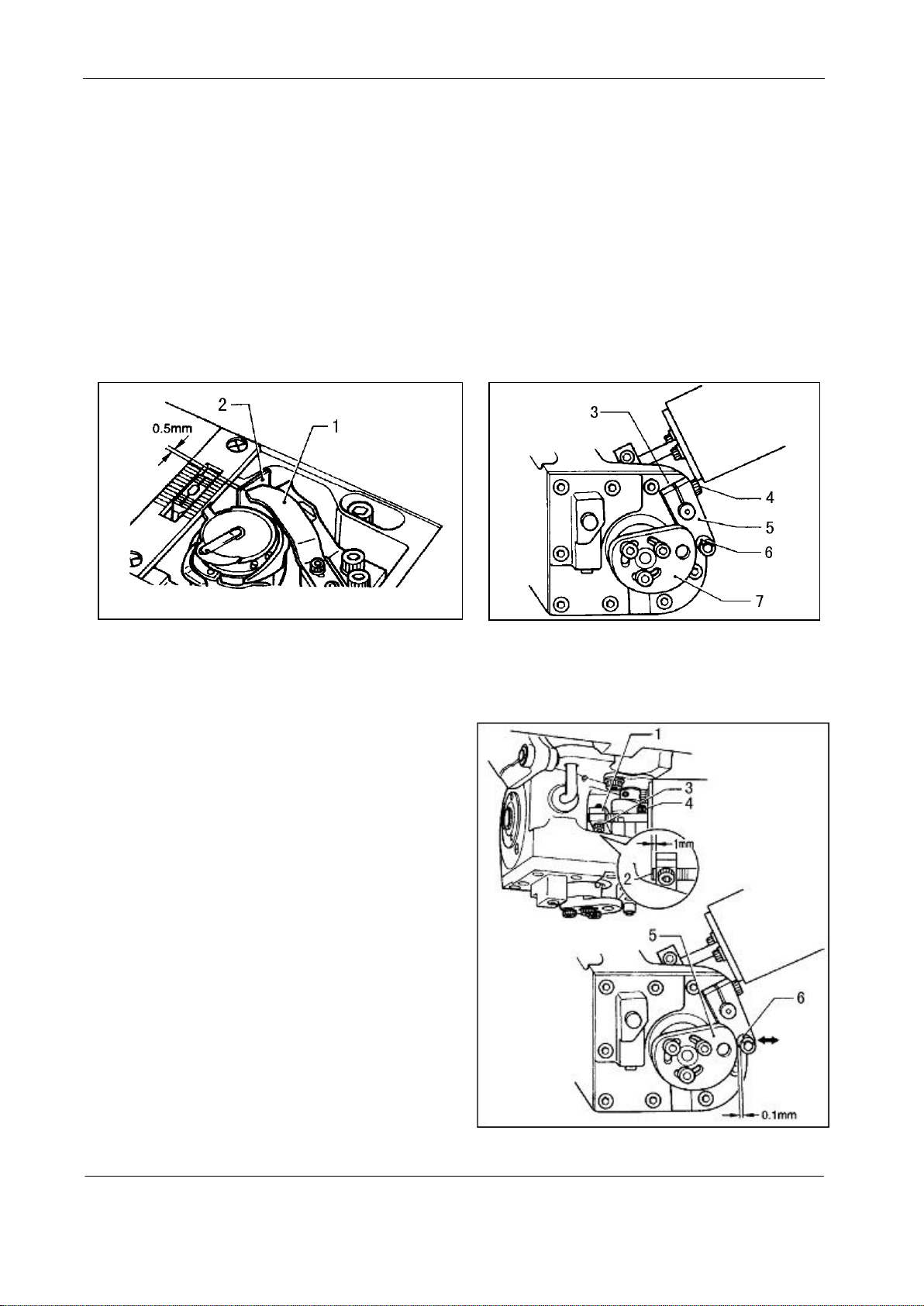

16) Adjusting the feed dog

Set the feed adjustment dials to the minimum settings. Then

adjust as follows so that the feed dog 1 is at its highest position

(0.5mm above the top of the needle plate 2) when the needle bar

is at its lowest position.

(1) Turn the machine pulley to set the feed dog 1 is at its highest

position.

(2) Loosen the screw 3.

(3) Adjust the feed dog’s height.

(4) Tighten the screw 3.

17) Adjusting the needle bar height

Set the feed adjustment dials to the minimum settings. Then adjust so

that the distance from the setting surface of the needle plate 2 to the end

— 9 —

Page 11

of the needle bar 1 is 18.5mm when the needle bar 1 is at its lowest position.

(1) Remove the face plate.

(2) Set the feed adjustment dials to “0”.

(3) Turn the pulley to set the needle bar 1 to its lowest position.

(4) Loosen the screw 3 and then move the needle bar 1 up or down to adjust so that the distance from the

setting surface of the needle plate 2 to the end of the needle bar 1 is 18.5 mm.

(5) Tighten the screw 3, install the face plate.

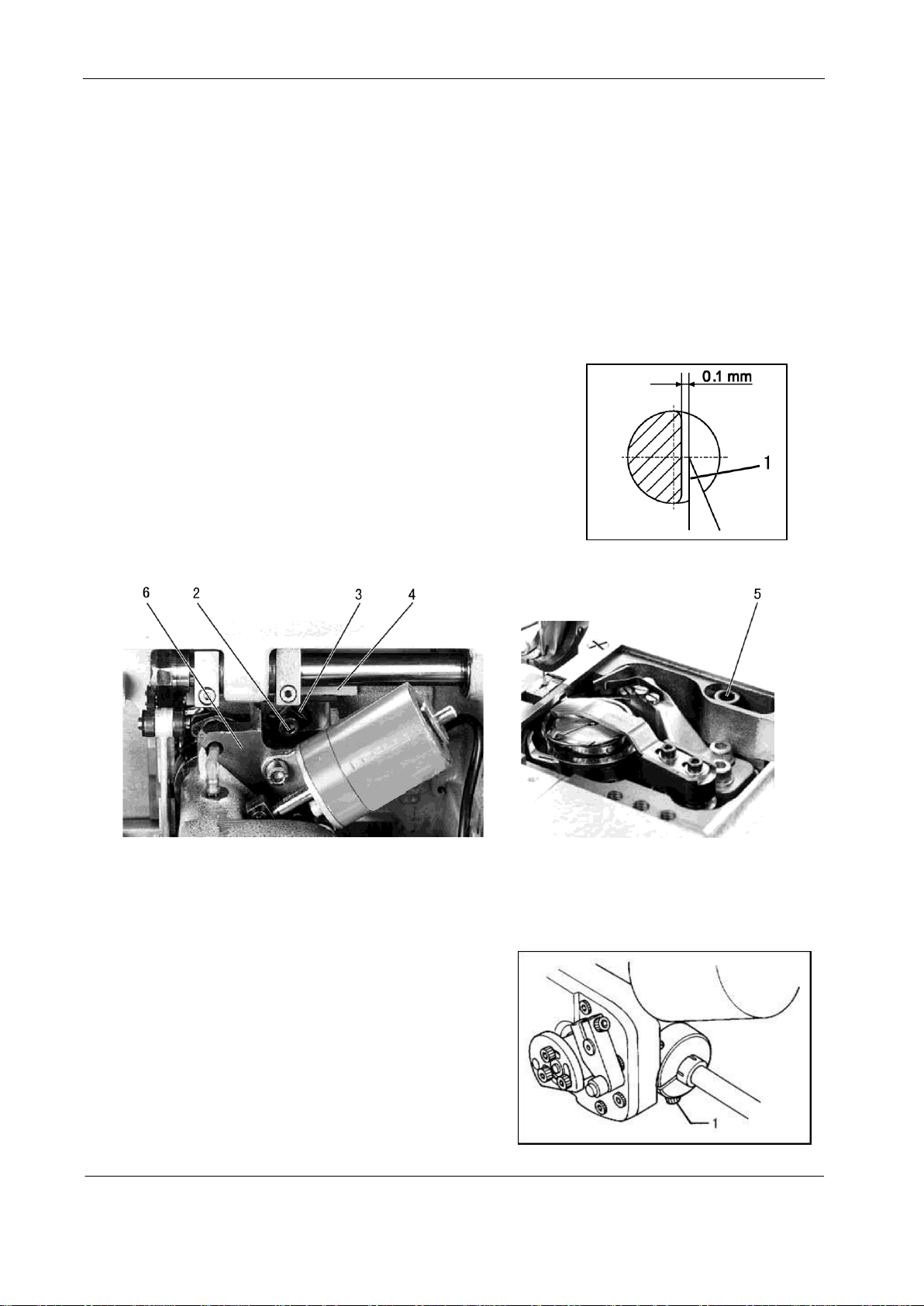

18) Adjusting the gap between the needle and the rotary hook tip

The gap between the needle and the rotary hook tip 1 is 0.1 mm.

Set the rotary hook tip at the level of the middle of the needle. Then

adjusting the gap as follow:

(1) Loosen the screws 2 and 5 (see the picture of below).

(2) Set the hook base 6 to the fit position.

(3) Rotate the adjusting plate 3, let the hook base 6 depend on the bed

plate 4.

(4) Tighten the screws 2 and 5.

19) Adjusting of the needle and the hook timing

(1) Set the stitch length to “0”.

(2) Remove the needle plate.

(3) Overturn the arm.

(4) Loosen the screw 1

(5) Turn the machine pulley to raise the needle bar from its

low position to the point that the needle rises 2.4 mm.

(6) Turn the rotary hook to align the rotary hook tip with the

center of the needle.

(7) Tighten the screw 1.

— 10 —

Page 12

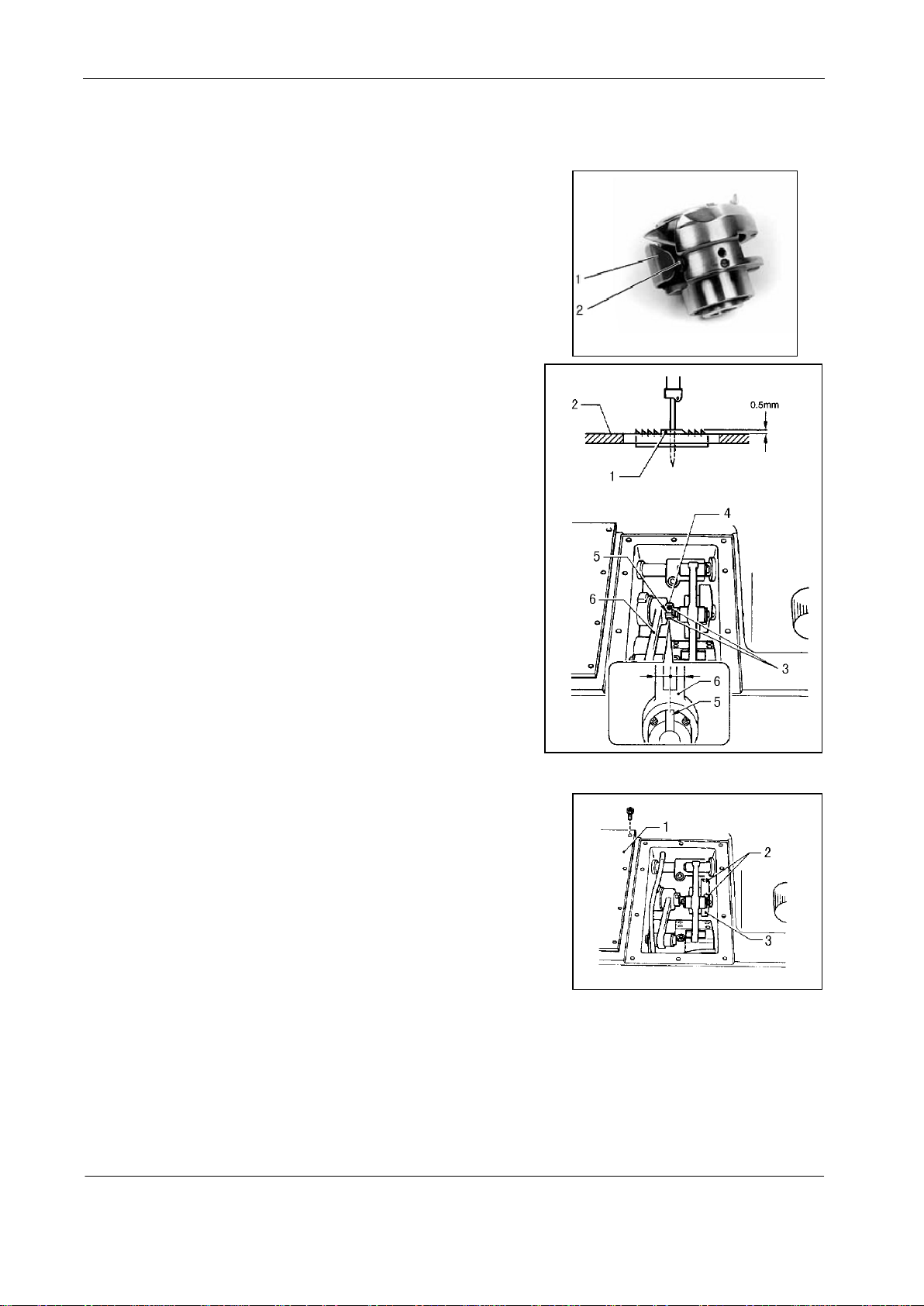

20) Hook protection

In looping stroke position the needle must abut on the hook protection 1 without being displaced.

Move needle in looping stroke position by pulley. In looping stroke

position the hook tip is at the level of the middle of the needle. Press

needle against hook protection 1 manually. The needle should not touch

the hook tip.

21) Adjusting the needle and feed mechanism timing

(1) Horizontal feed direction

Set the feed adjustment dials to the maximum settings. Then turn

the machine pulley until the needle bar is at its lowest position.

Then adjust so that the needle and the feed dog do not move even

when the reverse lever is moved up and down at this time.

a. Remove the bed upper cover 1.

b. Set the feed adjustment dial to the maximum settings.

c. Loosen the two screws 2.

d. Turn the machine pulley until the needle bar is at its lowest

position.

e. Turn the lower feed cam 3 gradually until it is at the position

where the needle and the feed dog do not move even when

the reverse lever is moved up and down.

f. Tighten the two screws 2.

(2) Vertical feed direction

Set the feed adjustment dials to the minimum settings. Then adjust

as follows so that the feed dog 1 is at its highest position (0.5mm above

the top of the needle plate 2) when the needle bar is at its lowest

position.

a. Loosen the two screws 3

b. Turn the machine pulley to set the needle bar to its lowest

position.

c. Turn feed cam 4 to align the point 5 of feed cam 4 with the centerline of feed rod 6

d. Tighten the screws 3

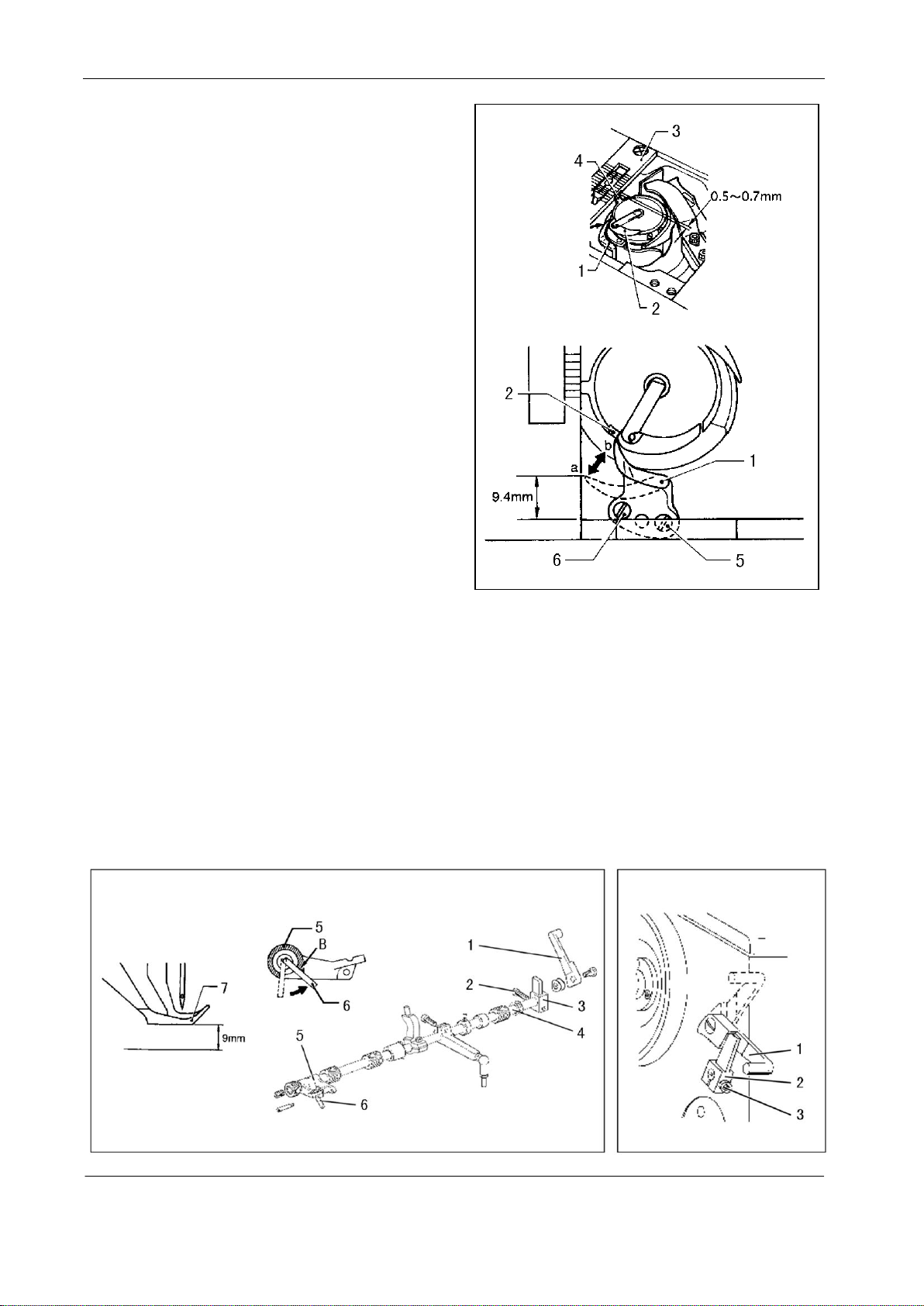

22) Adjusting the opener position

Adjust so that the clearance between the needle plate 3 and the stopper 4 of the inner rotary hook 2 is 0.5-0.7

mm when the opener 1 is at its closest position to the inner rotary hook 2.

(1) Turn the machine pulley to move the opener 1 in direction “a” (opening direction), and then loosen the

— 11 —

Page 13

screw 5

(2) Turn the machine pulley to move the opener 1 in

direction “b” (closing direction), and then loosen the

screw 6.

(3) Turn the machine pulley to move the opener 1 as

close to the inner rotary hook 2 as possible.

(4) While pressing the opener 1 against the inner

rotary hook 2 with your finger, adjust so that the

clearance between the needle plate 3 and the stopper 4 of

the inner rotary hook 2 is 0.5-0.7 mm.

(5) Tighten the screw 6.

(6) Turn the machine pulley to move the opener 1 in

direction “a” (opening direction), and then tighten the

screw 5.

23) Adjusting the presser foot height

The standard height of the outer presser foot 7 is 9 mm

when it is raised by the presser lifter bar 1.

(1) Remove the belt cover.

(2) Loosen the presser adjusting screw, to release the presser foot pressure.

(3) Raise the presser lifters bar 1 and then loosen the screw 2.

(4) Move the outer presser bar up or down to adjust so that the height of the outer presser foot 7 is 9 mm.

(5) While the stopper pin 6 is touching against the notch B in the presser foot lifter connection 5 and while

pushing the presser lifter shaft so that there is no play in the thrust direction, tighten the screw 2.

(6) Turn the presser adjusting screw to adjust the presser foot pressure.

(7) Install the belt guards.

— 12 —

Page 14

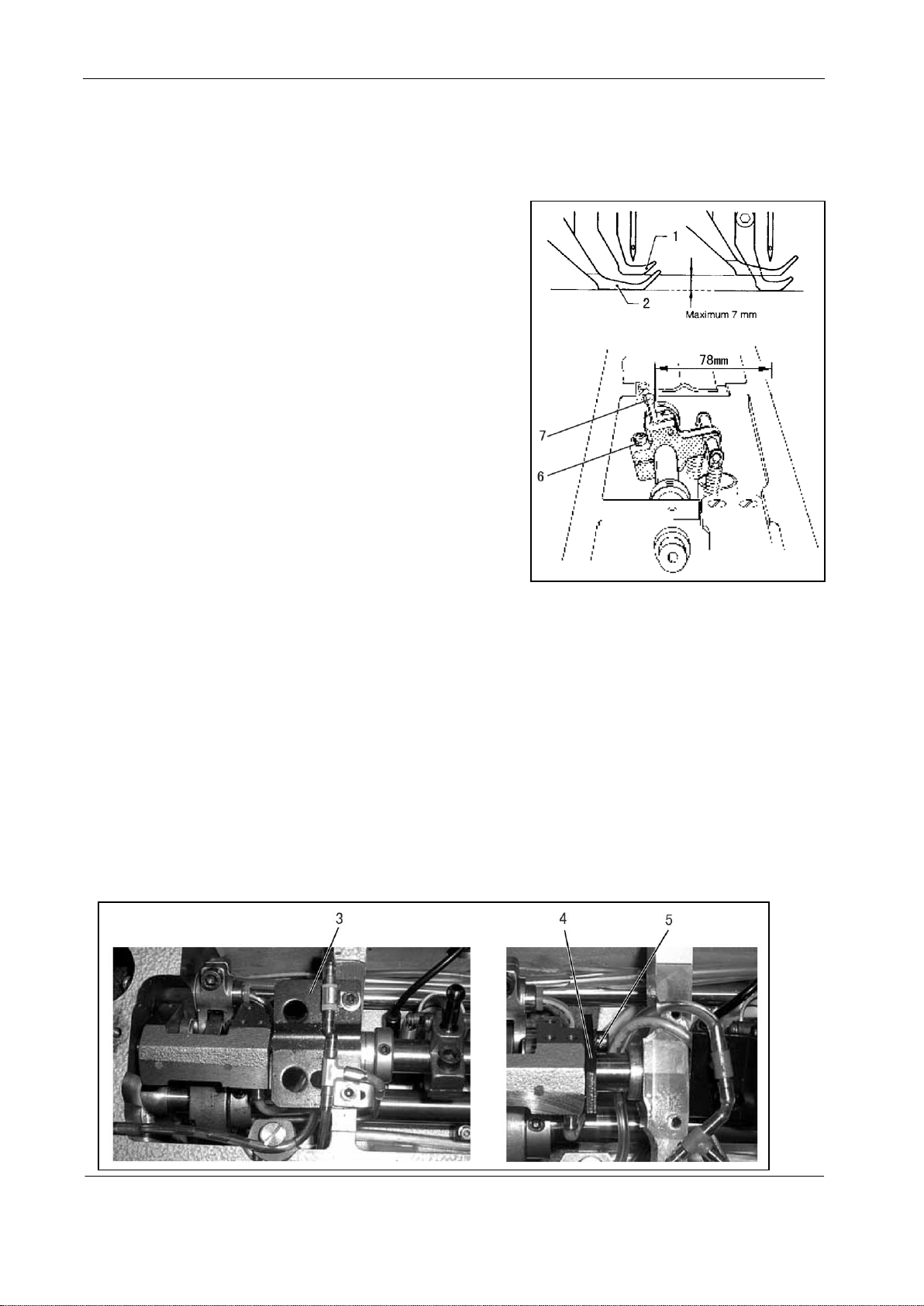

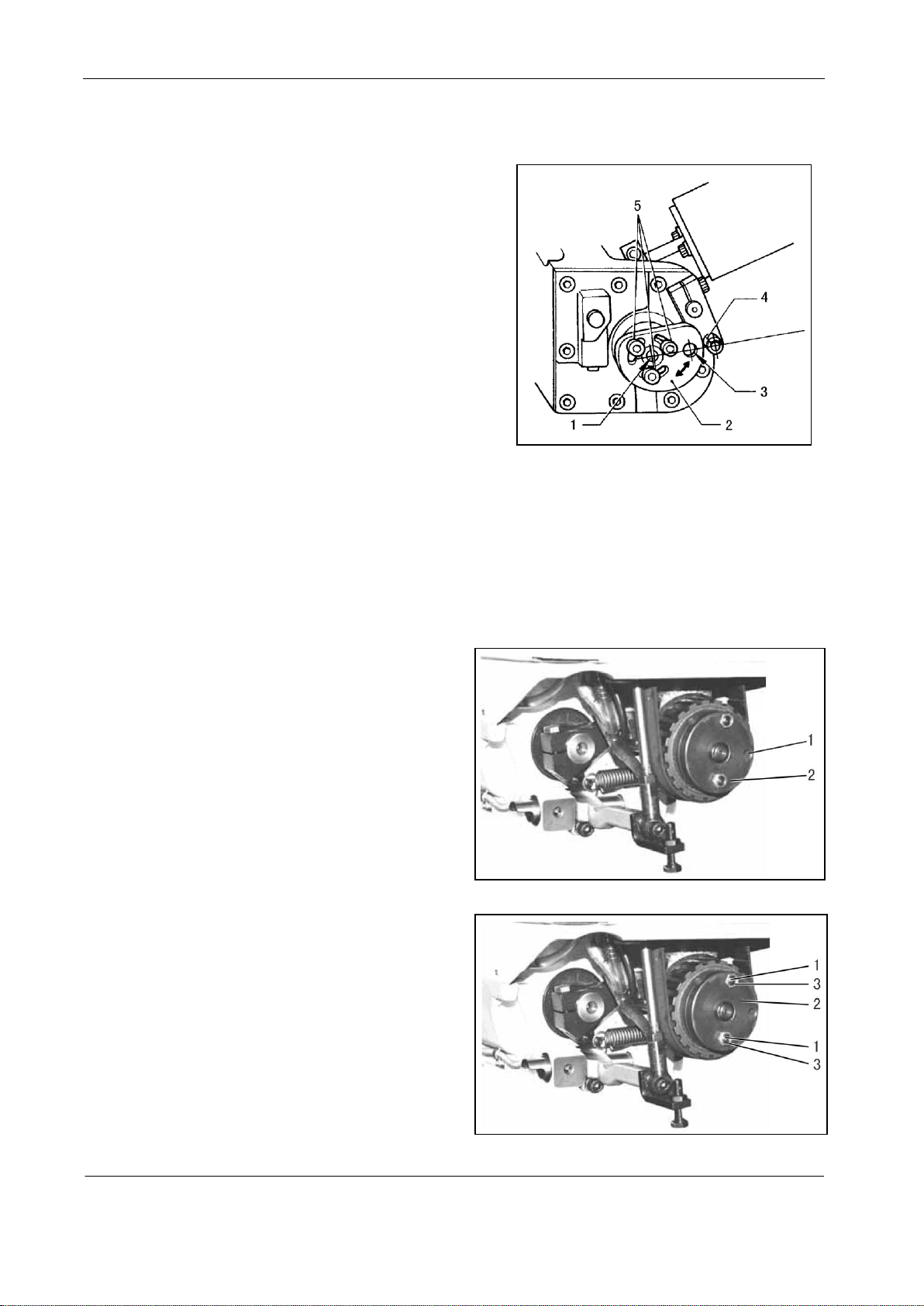

24) Adjusting the alternating presser foot movement amount

(1) Maximum alternating presser foot movement amount. Carry out the following adjustment to set the

maximum alternating movement amounts for the inner presser foot 1 and outer presser foot 2 to the maximum of

7 mm.

a. Remove the upper plate.

b. Remove the adjusting bracket 3.

c. Loosen screw 5 of adjusting bracket collar 4.

d. Adjust the adjusting bracket collar 4. If the adjusting

bracket collar 4 is be installed at the highest position, the

alternating presser foot movement amount is 1-6mm. If it is at the

lowest position, the alternating presser foot movement amount is

1.6-7mm.

e. Tighten the screw 5.

f. Install the adjusting bracket 3.

d. Loosen the bolt 6 and turn connecting lever 7 to adjust so

that the distance from the outer edge of the arm to the outer edge

of the pin 7 is 78 mm at this time. Then tighten the bolt 6. (When

installing the upper plate, set the alternating presser foot movements dial to the “min.” position.)

(2) Inner presser foot 1 and outer presser foot 2 movement amounts. Carry out the following adjustment to

make the movement amounts for the inner presser foot 1 and outer presser foot 2 equal when the presser feet are

lowered and the machine pulley is turned.

a. Set the feed adjustment dials to the maximum settings.

b. Open the cover 4

c. Turn the alternating presser foot movement dial to the “B” position.

d. Loosen the screw 3

e. Turn the machine pulley toward you to align the tip of the needle and the top of the feed dog with the top

of the needle plate.

— 13 —

Page 15

f. Move the connecting lever to adjust so that both the inner presser foot 2 and outer presser foot 1 are in

contact with the top of the needle plate at this time. Then

tighten the screw 3.

25) Adjusting the presser foot timing

When the presser feet are lowered and the

machine pulley is turned toward you. The

inner presser foot should touch the feed dog

before the needle arrives at the feed dog. Then

when the needle lifts up, the tip of the needle

should move away from the feed dog before

the inner presser foot moves away.

(1) Remove the upper cover 4.

(2) Loosen the two screws 1.

(3) Turn the machine pulley until the needle tip and the feed

dog’s up face is the same plane.

(4) Turn inner presser cam 2 to adjust so that the point of inner

presser cam 2 is facing straight up.

(5) Tighten the screws 1.

(6) Install the upper cover.

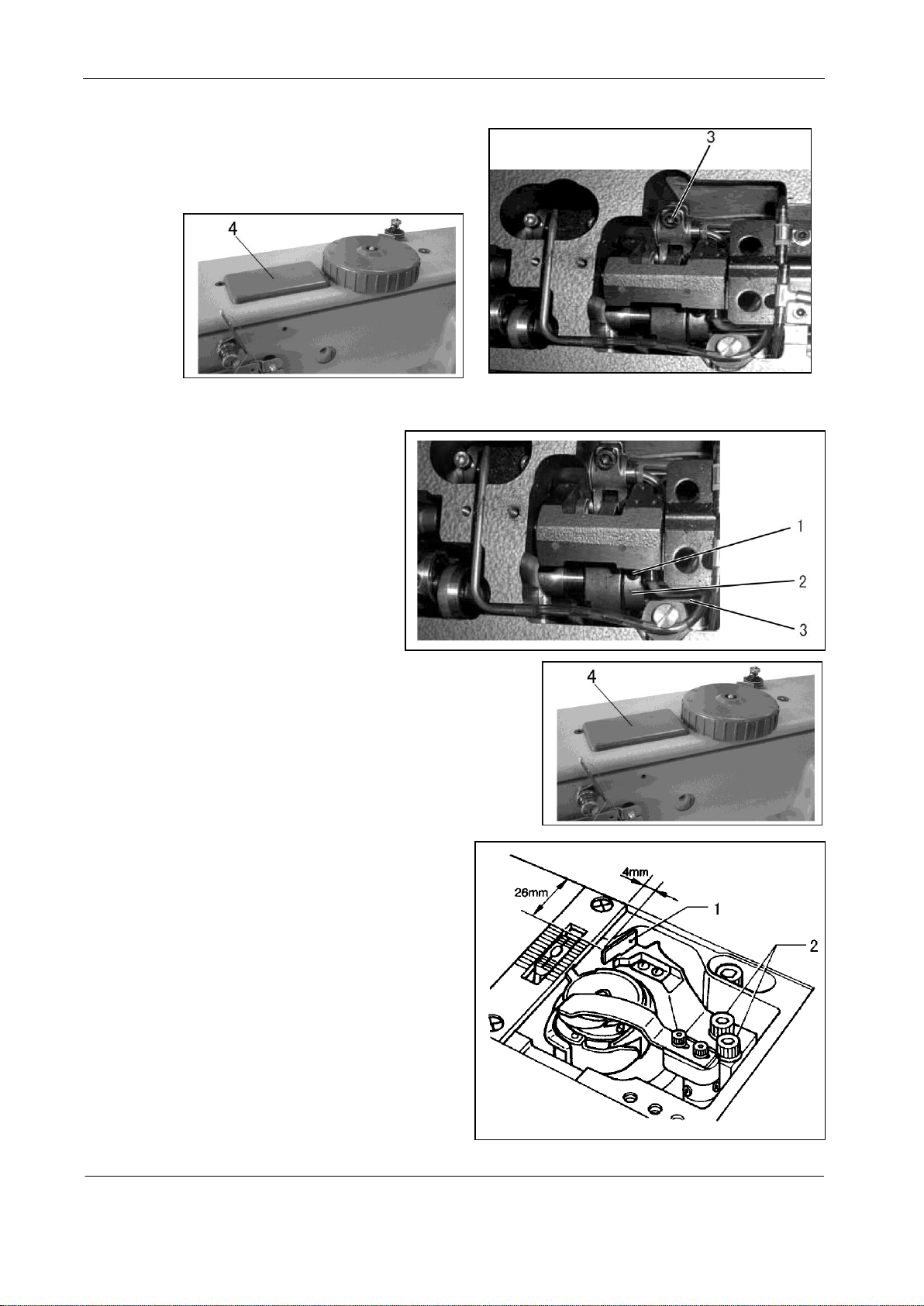

26) Adjusting the fixed knife position

The distance from the groove of slide plate to the

fixed knife 1 should be 26 mm. Furthermore, the distance

from the edge of the needle plate to the left edge of the

tip of the fixed knife 1 should be 4 mm.

(1) Loosen the two bolts 2.

(2) Adjust the position of the fixed knife 1, and then

tighten the bolts 2.

— 14 —

Page 16

27) Adjusting the thread holding spring position (see the picture of above)

The thread holding spring 1 holds the lower thread after

thread trimming to prepare it for the next sewing operation. The

clearance between the thread holding spring 1 and the side of

the fixed knife 2 should be 1.4-1.6 mm.

(1) Loosen the two screws 3.

(2) Move the thread holding spring 1 to adjust its position,

and then tighten the screws 3.

28) Adjusting the knife timing position

After adjusting the position of the fixed knife 1, adjust the

knife timing position.

Adjust so that the driving knife 1 starts touching the fixed knife at a position 5.5 mm along the front edge of the

driving knife 1.

(1) Loosen the two bolts 3 and 4.

(2) Move the driving knife 1 to the left or right to adjust its position.

(3) Then tighten the bolts 3 and 4.

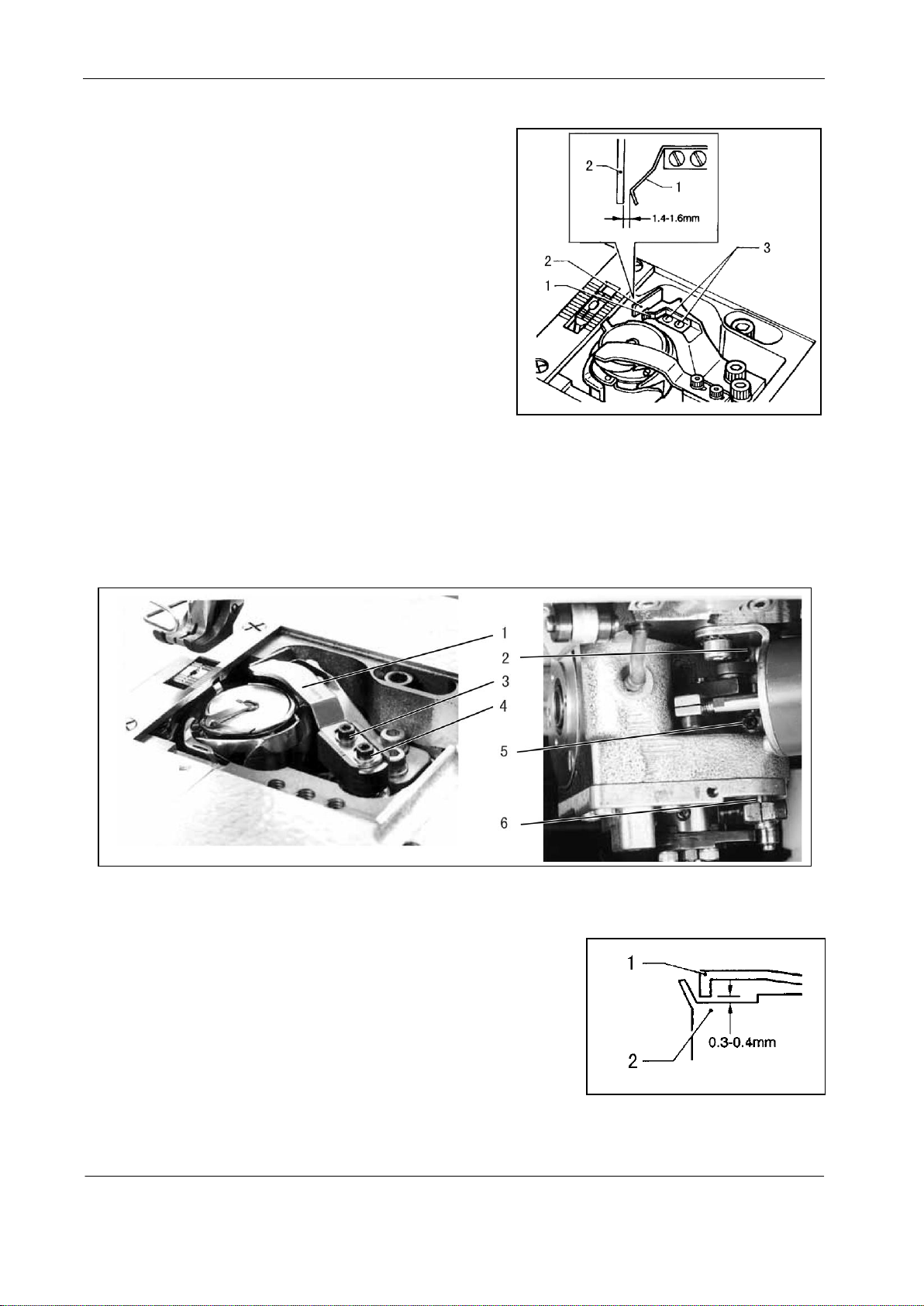

29) Adjusting the driving knife height

The clearance between the lower blade edge of the driving knife 1

and the lower surface of the inner rotary hook should be 0.3-0.4mm.(see

the picture on the right)

(1) Loosen the two screws 2 and 5.(see the picture of above)

(2) Move the driving knife shaft 6 up or down to adjust the position of

the driving knife 1.

(3) Tighten the screws 2 and 5 on the setting collars again.

— 15 —

Page 17

30) Adjusting the driving knife stop position

The distance from the blade of the fixed knife 2 to the end of the driving knife 1 should be 0.5 mm when

the driving knife 1 has moved as far as possible toward the fixed knife 2.

(1) Tilt back the machine head.

(2) Turn the machine pulley to move the roller 4 of the driving knife arm 3 to the outermost side (right side) of

the thread trimmer cam 5.

(3) Loosen the bolt 6.

(4) Move the driving knife 1 so that the distance between the blade of the fixed knife 2 to the end of the

driving knife 1 is 0.5 mm, and then tighten the bolt 6.

31) Adjusting the driving knife operating position

The standard distance from the left side of driving knife arm 1 to the screw tip on the plunger 2 of the thread

trimming solenoid is 1 mm. The clearance between the

outermost side (right side) of the thread trimmer cam 5

and the roller 6 of the driving knife arm should be 0.1

mm.

(1) Overturn the arm.

(2) Loosen the bolt 3

(3) Turn the plunger 2 of the thread trimming solenoid

so that the distance from the left side of driving knife arm

1 to the screw tip on the plunger 2 of the thread trimming

solenoid is 1 mm, and then tighten the bolt 3.

(4) Loosen the bolt 4.

(5) Set the plunger 2 to the position where it projects

as far as possible to the left.

(6) Turn the machine pulley to move the roller 6 of the

driving knife arm to the outermost side (right side) of the thread trimmer cam 5.

— 16 —

Page 18

(7) Move the roller 6 so that the clearance between the outermost side (right side) of the thread trimmer cam 5

and the roller 6 is 0.1mm, and then tighten the bolt 4.

32) Adjusting the thread trimming timing

The center of the pin 1, the center of the reference hole 3

and the center of the roller 4 of the driving knife arm should be

in a straight line when the thread take-up lever is at the highest

position. (The white point on the pulley and the point on the

belt cover are in a straight line.)

(1) Turn the machine pulley until the white point on the

pulley and the point on the belt cover are in a straight line.

(2) Overturn the arm.

(3) Loosen the three bolts 5

(4) Turn the thread trimmer cam 2 to adjust the position of the thread trimmer cam 2 so that the center of the

pin 1, the center of the reference hole 3 and the center of the roller 4 of the driving knife arm are in a straight

line.

(5) Tighten the bolts 5.

33) Safety clutch

The standard safety clutch 2 in the lower toothed belt wheel protects the hook from being displaced or

damaged in case of thread jamming in the hook path.

When the hook is blocked, the safety clutch 2 must come

out.

(1) Set free blocked hook.

(2) Stick a pin in drill-hole 1 of the outer clutch

disc.

(3) Turn the pulley until the pin can be stuck in the

drill-holes of both clutch parts.

(4) Turn the pulley forwards and backwards until the

hook is freely movable again.

(5) Pull out pin.

(6) Hold down hook and turn the pulley until safety

clutch 2 engages.

Adjust transmittable torque

Standard checking

The supplier by means of a torque spanner should

adjust the torque transmittable from safety clutch 4.

— 17 —

Page 19

(1) Loosen counter-nuts 3.

(2) Adjust torque

(3) Tighten counter-nuts 3 again.

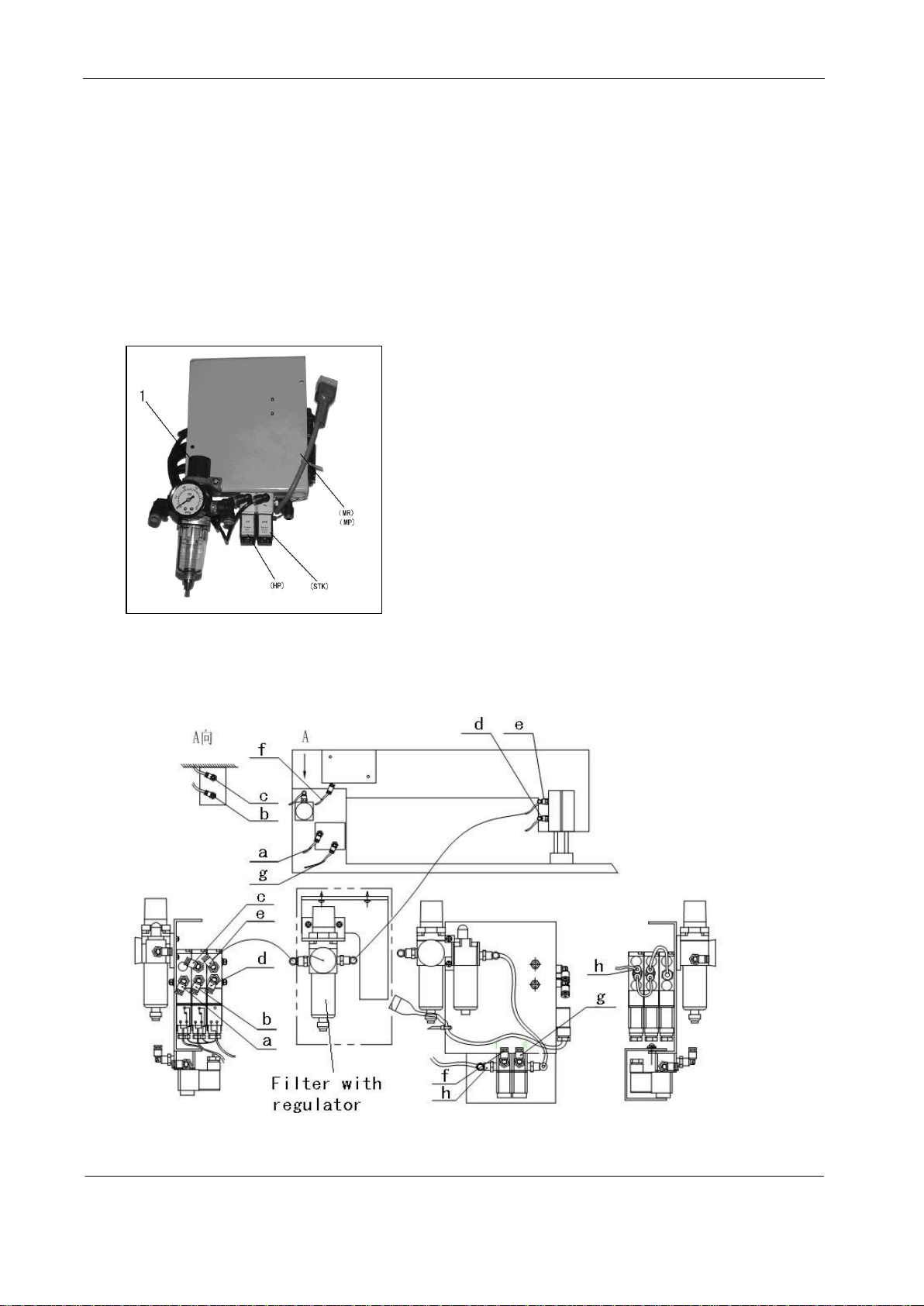

34) Regulate the atmospheric pressure

When the air cylinder works normally, the necessary atmospheric pressure is 5.5~6.5bar. Can find out

through the dial plate of the filtering .

(1) Lifting knob 1, clockwise rotation , the pressure increases.

(2)Lifting knob 1, anticlockwise rotation, the pressure is reduced

The air pressure of the feed wheel cylinder should between 1~2bar, it can be adjusted by need.

(For filter with regulator)

— 18 —

Page 20

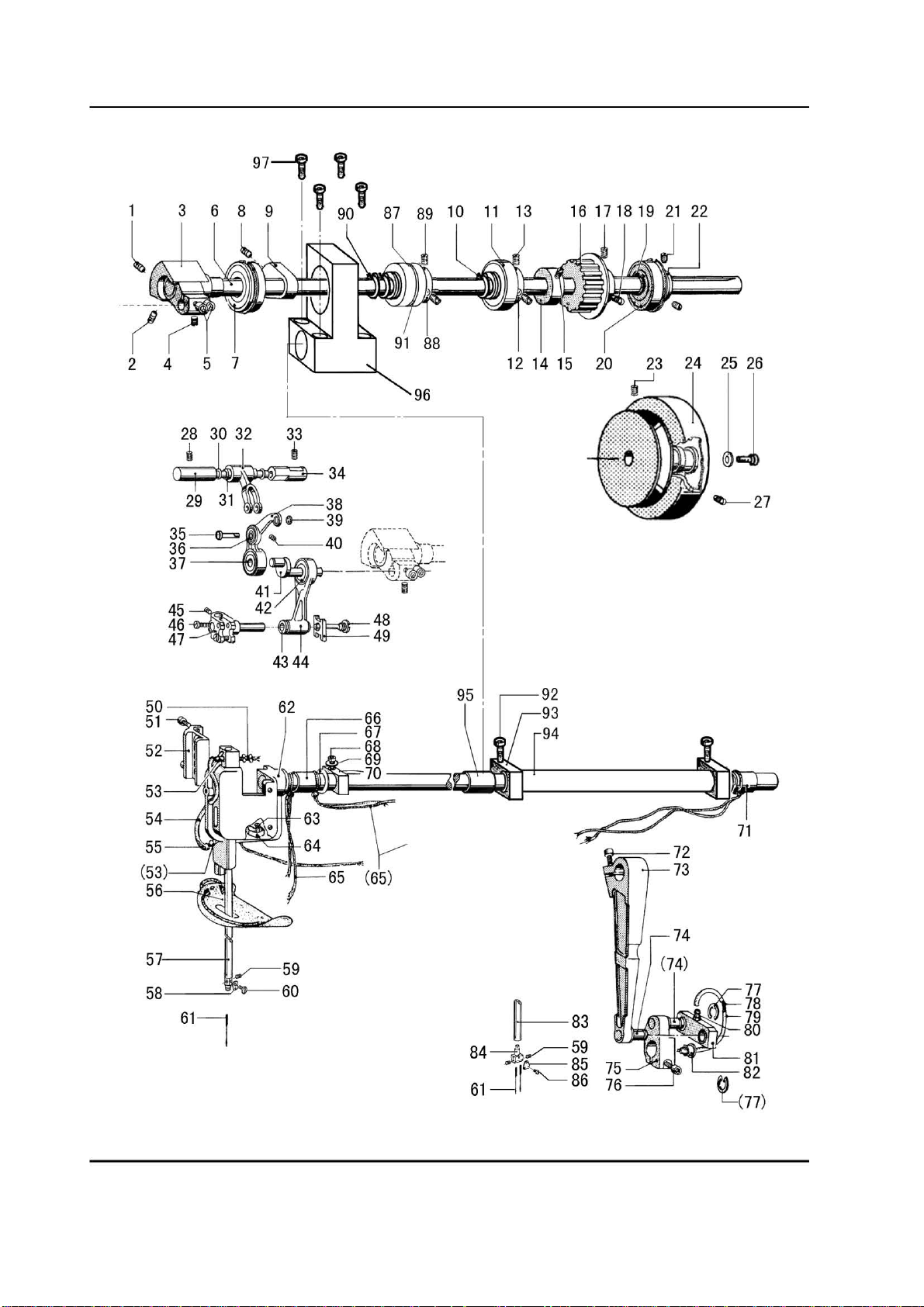

A.ARM BED AND ITS ACCESSORIES

— 19 —

j

~==

6

~

~~~~

47

"'ro----------""'---

"'

J~~-

f' l <....:.

48

49

0

@

0

46

13

14

16

18

J

19~

----!R----e-----~----

s s (1)

~

==

97

·,;,·

==:::!:.

1====--

(47

46)

"'

,.J

£:-' '\

~

'

""",;,· ==:::!:.

15

17

·-

-,

~~~

(47 46)

"'

J

F

~~~~~30

38

- - __jj

39--

40----

41---

42

-

~~

-----

45

------"'~

--

r----

l:..

r--

--~

~

'--+rl---28

~~~===29

=,r---

.1:m

-.-1-11

--.Ji\11

-..o

;F---

0

Ql

0

Ql

20

- -

21

~

--

-

--

-

[181

22

23

24

25

26

27

f'r-

---

~-

~'

79

80 84

107

106

11

2

./"'\4~~(.....,../

1

21

'

124 122

55

1

19

120

123

I

56

57

58

~-

~

-

~

--12=

~5

76 77

61

86

,

87 (57) 88

~

~-

78

-

~

67

68

69

70

Page 21

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

A01 HF914B8001 Screw M5×12 6 6

A02 H005001040 Washer 1 1

A03 H415040080 Screw 1 1 M4×8

A04 HE41B38001 Thread take-up cover 1 1

A05 HF930B8001 Plug 1 1

A06 HF933B8001 Dial 1 1

A07 HF935B8001 Dial shaft 1 1

A08 HF936B8001 Guard plate 1 1

A09 HF931B8001 Cover 1 1

A10 H003024040 Hexagonal nut 1 1 M4

A11 H005001040 Washer 2 2

A12 H401040060 Screw 1 1 M4×6

A13 HA710B0671 Pre-tension adjusting nut 1 1

A14 H6739B8001 Thread tension spring 1 1

A15 HA310B0705 Thread tension discs 2 2

A16 H6736B8001 Thread guide 1 1

A17 HF974B8001 Thread tension stud 1 1

A18 H4728H8001 Washer 1 1

A19 H5344B8001 Nut 1 1

A20 HF965B8001 Fixing clamp 1 1

A21 HF964B8001 Winder shaft 1 1

A22 H401030120 Screw 1 1 M3×12

A23 HF952B8001 Disc 1 1

A24 H5731F8001 Presser spring 1 1

A25 HF954B8001 Knife 1 1

A26 H401030040 Screw 1 1 M3×4

A27 HF947B7101 Release lever 1 1

A28 HF949B8001 Winder lever 1 1 M3×12

A29 H403040080 Screw 2 2 M4×8

A30 HE21B58001 Arm cover 1 1

A31 HE21B68001 Washer 1 1

A32 HF942B7101 Winder block 1 1

A33 HF944B8001 Release cam 1 1

A34 H431050060 Screw 1 1 M5×6

A35 HF958B8001 Block 1 1

A36 HF956B8001 Bushing 1 1

A37 H007013035 E-type stop ring 3.5 1 1

A38 HF961B8001 Presser spring 1 1

A39 HF957B8001 Washer 1 1

A40 HF960B8001 Arm 1 1

A41 HF959B8001 Presser spring 1 1

A42 HF966B8001 Washer 2 2

A43 HF967B8001 Winder wheel 1 1

A.ARM BED AND ITS ACCESSORIES

— 20 —

Page 22

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

A44 H7331D8001 Rubber ring 1 1

A45 H431050050 Screw 1 1 M5×5

A46 HF999B8001 Cord cover 3 3

A47 H7331G8001 Screw 6 6

A48 HF914B8001 Screw M5×12 1 1

A49 HF915B8001 Screw M5×12 1 1

A50 HF918B8001 Bar 1 1

A51 HF913B8001 Face plate 1 1

A52 HF919B8001 Bar 1 1

A53 HF920B8001 Oil pillow 1 1

A54 HF998B8001 Leg 1 1

A55 HF980B8001 Slide Plate 1

A56 HF988B8001 Needle plate 1

A57 HF989B8001 Screw 2 2

A58 HF981B8001 Slide Plate 1

A59 HE23B98001 Slide Plate 1 1

A60 HF986B8001 Spring for slide plate 2 2

A61 H401020025 Screw 2 2 M2×2.5

A62 HF982B8001 Stopper 1 1

A63 H7331G8001 Screw 2 2

A65 HF914B8001 Screw M5×12 10 10

A66 HF997B8001 Gasket 10 10

A67 HE22B38001 Cover 1 1

A68 HF992B8001 Oil indicator 1 1

A69 HF993B8001 Screw 1 1

A70 HF994B8001 Gasket 1 1

A71 HE22B48001 Gasket 1 1

A72 H3108B0692 Felt 1 1

A73 H3108B0691 Thread guide 1 1

A74 HF938C8001 Screw 1 1

A75 HA307B0674 Rubber plug 1 1

A76 HF90AB8001 Gasket 2 2

A77 100010 Screw 1 1 M10×1

A78 HE21I38001 Rubber plug 1 1

A79 HF981I8001 Pin 1 1

A80 H7335C8001 Washer 2 2

A81 H428080120 Screw 1 1 M8×12

A82 H007013060 E-type stop ring 6 1 1

A83 HF980I8001 Bearing 2 2

A84 HF980I8001 Spacer 1 1

A85 HF979I8001 Belt tensioner 1 1

A86 HG005B8001 Slide Plate 1

A87 HG007B8001 Needle plate 1

A.ARM BED AND ITS ACCESSORIES

— 21 —

Page 23

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

A88 HG006B8001 Slide Plate 1

A89 H415040060 Screw 1 1

A90 HE41B58001 Bobbin seat 1 1

A91 HF923B8001 Washer 1 1

A93 HE21B38001 Setting plate 1 1

A94 H415050160 Screw 5 5

A95 HE22B58001 Setting plate 1 1

A96 H415060160 Screw 4 4

A97 HE22B78001 Setting plate 1 1

A98 HE22B88001 Feed shaft 1 1

A99 HE22B98001 Feed wheel(up) 1 1

A100 H431050060 Screw 1 1

A101 H415040160 Screw 4 4

A102 HE24B27101 Cylinder 1 1

A103 H415040250 Screw 4 4

A104 HE23B28001 Setting plate 1 1

A105 HF805H8001 Bushing 2 2

A106 HF806H8001 Screw 1 1

A107 HA100B2110 Screw 1 1

A108 HE24B37101 Feed wheel 1 1

A109 HE23B38001 Feed shaft(down) 1 1

A110 HF821H8001 Collar 1 1

A111 HA100B2110 Screw 2 2 11/64(40)×5.5

A112 H415060150 Screw 3 3

A113 HE23B48001 Setting plate 1 1

A114 H415060250 Screw 2 2

A115 HE23B58001 Crack 1 1

A116 H415050160 Screw 1 1

A117 HE23B68001 Link 1 1

A118 H5315E8001 Screw 1 1

A119 HE23B78001 Crack 1 1

A120 H3208G0676 Screw 1 1 SM15/64×28

A121 HE928J8001 Screw 1 1

A122 H005005060 Washer 1 1

A123 H003002060 Nut 1 1

A124 HA104C0655 Ball bearing 1 1

A.ARM BED AND ITS ACCESSORIES

— 22 —

Page 24

B.THREAD TENSION REGULATOR MECHANISM

— 23 —

(30)

(31) 24

26__/

..

27~'

23

31

28_/

29~

30~

~

FJ

~

32

Page 25

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

B01 H003002050 Nut 1 2 M5

B02 HF930C8001 Thead hook 1 2

B03 HF929C8001 Thread tension stud 1 2

B04 HA112B0693 Thread tension discs 1 2

B05 HA710B0672 Tension spring 1 2

B06 HA710B0671 Tension adjusting nut 1 2

B07 HF907C8001 Thread tension stud 2

B08 HF917C8001 Thread guide 1 1

B09 H3221B6817 Thread tension releasing pin 2 1

B10 H3221B6811 Shoulder screw 2 2

B11 H7316B8001 Screw 2 2

B12 HF925C8001 Thread guide 1

B13 H7322B8001 Screw 2 2

B14 H7316B8001 Screw 2 2

B15 HF905C8001 Tension plate 1 1

B16 HF923C8001 Rod 1 1

B17 HF924C8001 Sping 1 1

B18 HF915C8001 Tension release plate 1 1

B19 HF916C8001 Thread guide 1 1

B20 HA310B0705 Tension discs 4 4

B21 HA310B0702 Tension release discs 2 2

B22 H3300B2040 Tension spring 2 2

B23 HA115B7010 Stopper 2 2

B24 HA310B0701 Tension nut 2 2

B25 H431040040 Screw 1 1 M4×4

B26 HF936C8001 Thread tension post 1 1

B27 H431050050 Screw 1 1 M5×5

B28 H4805C8001 Thread tension stud 1 1

B29 H4804C8001 Screw 1 1

B30 H32481BD21 Plate complete 1 2

B31 H4713C8001 Thread take-up spring 1 1

B32 H32481B721 Thumb nut 1 1

B33 H003045050 Nut 1 1 M5

B34 H003002050 Nut 1 1 M5

B35 HF918C8001 Release lever 1 1

B36 H007013050 E-type stop ring 5 1 1

B37 HF919C8001 Bolt 1 1

B38 HF921C8001 Hook 1 1

B39 HF908C8001 Spring 1 1

B40 HF909C8001 Block 1 1

B41 H005001040 Washer 1 1

B42 H415040080 Screw 1 2 M4×8

B43 HF927I8001 Washer 1 1

B.THREAD TENSION REGULATOR MECHANISM

— 24 —

Page 26

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

B44 H415040080 Screw 2 1 M4×8

B45 HF906C8001 Magnet support 1 1

B46 HE22C28001 Solenoid 1 1

B47 H403050120 Screw 2 2 M5×12

B48 H003002040 Nut 1

B49 H003045040 Nut 1

B50 H4712C8001 Thread take-up spring 1

B51 H32481BF21 Plate complete 1

B52 H32481B821 Bushing 1

B53 H32481B521 Screw 2

B54 H32481B621 Take-up spring guide 1

B55 H32481BB21 Stopper 1

B56 H32481BC21 Screw 1

B57 H32481B921 Thread tension post 1

B58 H32481BE21 Plate complete 1

B59 HG008C8001 Thread tension stud 1

B60 HG007C8001 Screw 1

B61 HG009C8001 Tension release discs 1

B62 H3221B0689 Thread tension stud 1

B63 H3221B0686 Thread tension stud 1

B64 HG005C8001 Thread guide 1

B65 H4710C8001 Tension spring 1 2

B.THREAD TENSION REGULATOR MECHANISM

— 25 —

Page 27

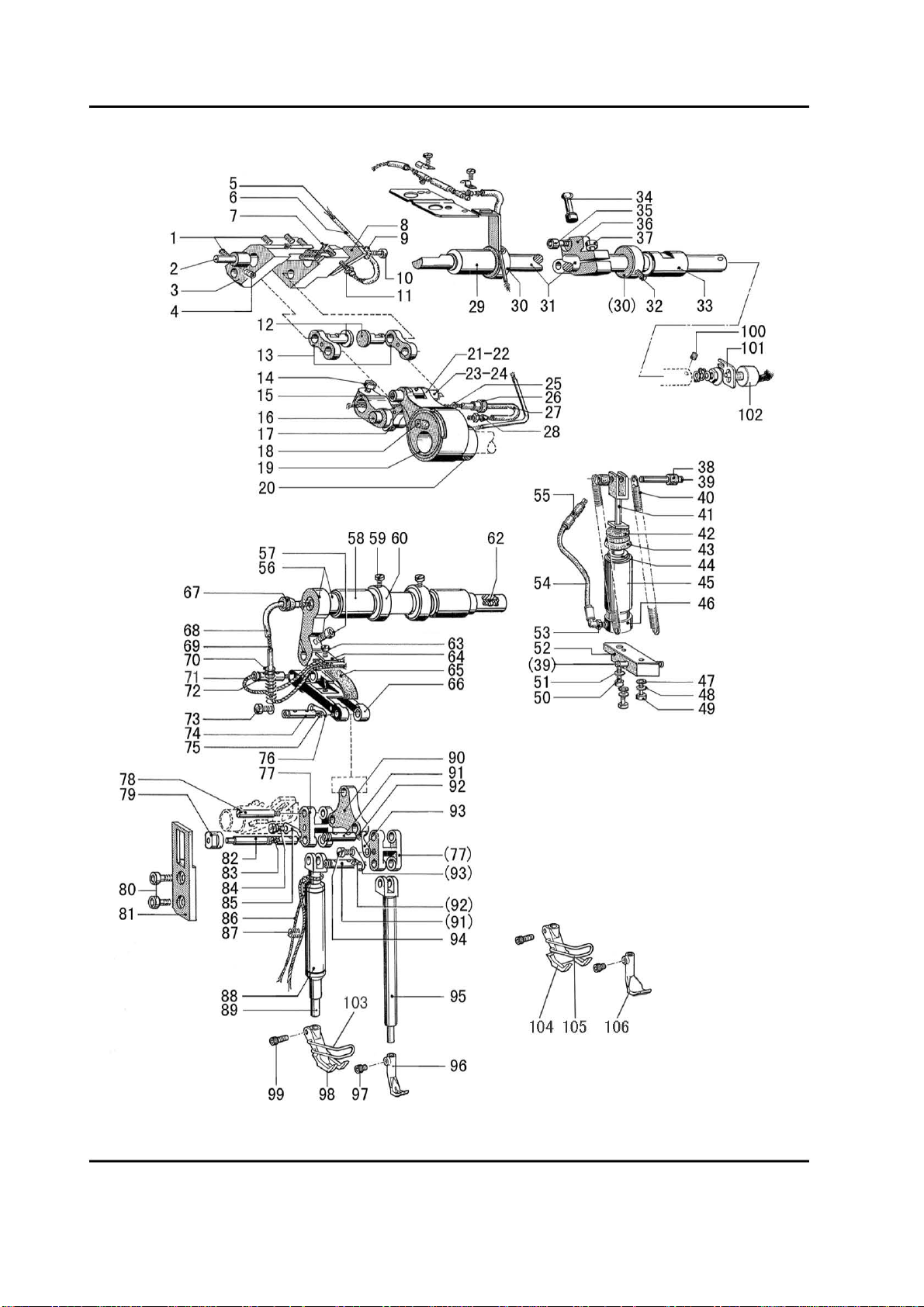

C.NEEDLE BAR AND THREAD TAKE-UP MECHANISM

— 26 —

1

89

1

l

2

0

11

13

16 17

18

19

21

22

~

27

&---

84

61

~

~!c--

I~

""-----

-l

83

59

85

8 6

Page 28

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

C01 H6715C8001 Screw 1 1

C02 H431060080 Screw 1 1 M6×8

C03 HF907D8001 Crank 1 1

C04 H431060060 Screw 1 1 M6×6

C05 HF914B8001 Screw 2 2

C06 HE20D58001 Upper shaft 1 1

C07 H3205J0662 Ball bearing 1 1

C08 H431080100 Screw 1 1 M8×10

C09 HF913D8001 Counterweight 1 1

C10 H007009200 Retainer ring 1 1

C11 HF921D8001 Ball bearing 1 1

C12 HF918D8001 Bushing 1 1

C13 H431060060 Screw 2 2 M6×6

C14 HF943D8001 Bobbin winder driving wheel 1 1

C15 H431060100 Screw 2 2 M6×10

C16 HF923D8001 Belt pulley(upper) 1 1

C17 H431060080 Screw 1 1 M6×8

C18 H429060100 Screw 1 1 M6×10

C19 H007009200 Retainer ring 1 1

C20 HF932D8001 Ball bearing 1 1

C21 H431060080 Screw 2 2 M6×8

C22 HF929D8001 Bushing 1 1

C23 H431060100 Screw 1 1 M6×10

C24 HF934D8001 Pulley 1 1

C25 H005008080 Washer 1 1

C26 H415080250 Screw 1 1 M8×25

C27 H429060100 Screw 1 1 M6×10

C28 H428050060 Screw 1 1 M5×6

C29 HF913G8001 Thread take-up pin 1 1

C30 HF918G8001 Gasket 2 2

C31 H7221G8001 Needle bearing 2 2

C32 HF916G8001 Thread take-up support 1 1

C33 H428050120 Screw 1 1 M5×6

C34 HF911G8001 Thread take-up pin bushing 1 1

C35 HF919G8001 Support screw 1 1

C36 HF909G8001 Bearing 1 1

C37 H6722I8001 Bearing 1 1

C38 HE40G78001 Thread take-up lever 1 1

C39 HF908G8001 Bushing 1 1

C40 H431030040 Nut 1 1 M3

C41 HF920G8001 Thread take-up crank 1 1

C42 HF923G8001 Bearing 2 2

C43 HF926G8001 Bushing 1 1

C.NEEDLE BAR AND THREAD TAKE-UP MECHANISM

— 27 —

Page 29

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

C44 HF922G8001 Needle bar link 1 1

C45 H431030050 Screw 1 1 M3×5

C46 H401040100 Screw 2 2 M4×10

C47 HF924G8001 Needle bar holder 1 1

C48 HF928G8001 Threaded bolt 1 1

C49 HF927G8001 Slide block 1 1

C50 HF938G8001 Oil wick 1 1

C51 H415040100 Screw 2 2 M4×10

C52 HF933G8001 Slide guide 1 1

C53 HF939G8001 Oil feeding pipe 2 2

C54 HF936G8001 Oil pipe 1 1

C55 HF937G8001 Oil wick 1 1

C56 HF940G7101 Rubber 1 1

C57 HE21G58001 Needle bar 1 1

C58 HF971G8001 Thread guide 1 1

C59 H402030040 Screw 1 2 M3×3

C60 HF972G8001 Screw 1 1

C61

Neddle 1 2 DP×17 #23

C62 HE20G97101 Needle bar bracket 1 1

C63 H403040100 Screw 1 1 M4×10

C64 HF943G8001 Oil satchel 1 1

C65 HF947G8001 Oil wick 3 3

C66 HF927E8001 Bushing 1 1

C67 HF968G8001 Support disc 2 2

C68 H415040120 Screw 2 2 M4×12

C69 H005001040 Washer 2 2

C70 HF965G8001 Collar 2 2

C71 HF924E8001 Bushing 1 1

C72 H415060200 Screw 1 1 M6×20

C73 HE21G38001 Upper feed connecting rod 1 1

C74 HF951G8001 Shoulder screw 1 1

C75 HF949G8001 Connecting lever 1 1

C76 H415060160 Screw 1 1 M6×16

C77 H007013080 E-type stop ring 8 2 2

C78 HF958G8001 Oil wick 1 1

C79 HF957G8001 Oil pipe 1 1

C80 HF956G8001 Oil feeding pipe 1 1

C81 HF952G7101 Pull rod 1 1

C82 HF959G8001 Plug 1 1

C83 HE30G58001 needle bar 1

C84 HG006G8001 needle bar connecting stud 1

C85 HG007G8001 Thread guide 1

C86 HG008G8001 Screw 1

C.NEEDLE BAR AND THREAD TAKE-UP MECHANISM

— 28 —

Page 30

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

C87 HG608C8001 Bearing 2 2 6804 ZZNR/5K 20×32×7

C88 HF918D8001 Bushing 1 1

C89 H431060060 Screw 2 2

C90 H007009200 Retainer ring 1 1

C91 H9108D8001 Washer 1 1

C95 HF924E8001 Bushing 1 1

C96 HE22B18001 Bearing setting plate 1 1

C97 H415060250 Screw 4 4

C.NEEDLE BAR AND THREAD TAKE-UP MECHANISM

— 29 —

Page 31

D.PRESSER FOOT MECHANISM

— 30 —

5

---.,.

6

-----..

7

4

--~12

68

69

70

71-~~~

72 ---""""""""'

73

74

75

--""""

---'11!

--

-------

----

----

~

13

~.

14

15 ' .

16

---

17

----

18

----~

19

----~

20

----------'

--,.

'

~

~D

---

',

'

~

58 59 60

-----

----

----

--

---

~-

--

,---

•,

',,'

63

64

65

66

90

91

92

93

29

62

30

(

55

53

~~

~

51

50

-~~==~

llr----

~--

:1-;-,.----

~-

• ;;;:;or;...;

.11----;-:t----

...

0 0

__

.--'-+--

~

~

38

39

40

41

42

43

44

45

46

47

48

49

~~~

I.Xl*

~~~

~~~~

L--

L---

o!-----

~-(

l---1!!+--

-----f!.

+---

-fHI-

--

ll

oll---

(

77

)

93

)

(

92

)

(

91

)

94

95

p

~·

104 105 106

-

f

Page 32

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

D01 H428050080 Screw 4 4

D02 HF919E8001 Support pin 1 1

D03 HF906E8001 Adjusting bracket 1 1

D04 H428050080 Screw 1 1

D05 HF912E8001 Oil wick 1 1

D06 HF911E8001 Oil pipe 1 1

D07 HF908E8001 Oil wick 2 2

D08 HF913E8001 Plate 1 1

D09 H005018050 Washer 1 1

D10 H415050100 Screw 1 1

D11 HF956G8001 Oil feeding pipe 1 1

D12 HF917E8001 Link pin 2 2

D13 HF916E8001 Link 2 2

D14 H415060200 Screw 1 1

D15 HF951E8001 Connecting lever 1 1

D16 HF956E8001 Pin 1 1

D17 HF953E7101 Link 1 1

D18 HA104D0652 Plug 1 1

D19 HF942E8001 Inner presser cam 1 1

D20 H428060060 Screw 2 2

D21 HF946E8001 Inner presser rod 1 1

D22 HF947E8001 Bearing 1 1

D23 HF948E8001 Rod pin 1 1

D24 HF949E8001 Oil wick 1 1

D25 HF960E8001 Oil wick 1 1

D26 HF961E8001 Plug 1 1

D27 HF959E8001 Oil pipe 1 1

D28 HF956G8001 Oil feeding pipe 1 1

D29 HF924E8001 Bushing 1 1

D30 HF923E8001 Collar 2 2

D31 HF921E8001 Adjusting shaft 1 1

D32 H431050050 Screw 2 2

D33 HF927E8001 Bushing 1 1

D34 HF928E8001 Ball pin 1 1

D35 H415050120 Screw 1 1

D36 HF926E8001 Lever 1 1

D37 H415060200 Screw 1 1

D38 HF940E8001 Pipe 2 2

D39 HF914E8001 Pin 2 2

D40 HF918E8001 Spring 2 2

D41 HF933E8001 Draught rod 1 1

D42 HF936E8001 Disc 1 1

D43 HF935E8001 Gasket 1 1

D.PRESSER FOOT MECHANISM

— 31 —

Page 33

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

D44 HF934E8001 Piston 1 1

D45 HF931E8001 Pipe 1 1

D46 HF932E8001 Cylinder base 1 1

D47 HF997B8001 Gasket 2 2

D48 H005001050 Washer 2 2

D49 H415050180 Screw 2 2

D50 H415040160 Screw 1 1

D51 H005001040 Washer 1 1

D52 HF943E8001 Spacer 1 1

D53 HF937E8001 Coupling 1 1

D54 HF938E8001 Hose 1 1

D55 HF939E8001 Coupling 1 1

D56 HF962E7101 Shaft 1 1

D57 H415040120 Screw 1 1

D58 HF924E8001 Bushing 2 2

D59 H402050080 Screw 2 2

D60 HF923E8001 Collar 2 2

D61 HF970E8001 Sponge 1 1

D62 HF964E8001 Oil wick 1 1

D63 H415030060 Screw 1 1

D64 HF974E8001 Plate 1 1

D65 HF973E8001 Oil satchel 1 1

D66 HF972E8001 Draught rod 1 1

D67 HF961E8001 Plug 1 1

D68 HF983E8001 Oil pipe 1 1

D69 HF984E8001 Oil wick 1 1

D70 HF982E8001 Spring 1 1

D71 HF986E8001 Oil wick 1 1

D72 HF977E8001 Pin 1 1

D73 H401040040 Screw 1 1

D74 HF977E8001 Pin 1 1

D75 HF978E8001 Oil wick 1 1

D76 HF979E8001 Stopper claw 1 1

D77 HF925F8001 Joint 1 1

D78 HF926F8001 Pin 1 1

D79 HF933F8001 Slide block 1 1

D80 HF914B8001 Screw 2 2

D81 HF934F8001 Guide 1 1

D82 HF928F8001 Pin 1 1

D83 HF930F8001 Oil wick 1 1

D84 HF932F8001 Screw 1 1

D85 HF979E8001 Stopper claw 1 1

D86 HF939F8001 Oil wick 1 1

D.PRESSER FOOT MECHANISM

— 32 —

Page 34

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

D87 H431050100 Screw 1 1

D88 HF940F8001 Bushing 1 1

D89 HE20F58001 Outer presser bar 1 1

D90 HF946F8001 Presser connecting plate 1 1

D91 HF977E8001 Connecting pin 2 2

D92 HF978E8001 Oil wick 2 2

D93 HF979E8001 Stopper claw 2 2

D94 H401040040 Screw 1 1 M5×10

D95 HE20F68001 Inner presser bar 1 1

D96 HF959F8001 Inner presser foot 1

D97 HF960F8001 Screw 1 1

D98 HF943F8001 Outer presser foot 1

D99 HF944F8001 Screw 1 1

D100 H431040040 Screw 1 1

D101 HF987E8001 Holder 1 1 M4×4

D102 HF922E8001 Potentiometer control 1 1

D103 HF945F8001 Finger gusrd 1

D104 HG005F8001 Outer presser foot 1

D105 HG006F8001 Finger gusrd 1

D106 HG008F8001 Inner presser foot 1 M4×10

D.PRESSER FOOT MECHANISM

— 33 —

Page 35

E.UPPER FEED LIFTING ROCK SHAFT MECHANISM

— 34 —

57

58

59

52

51

33

f

34

Page 36

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

E01 H007013080 E-type retaining ring 8 1 1

E02 HF965F7101 Press adjusting plate assy 1 1

E03 HF963F8001 Pin 1 1

E04 HF961F7101 Press adjusting dial 1 1

E05 H007013050 E-type retaining ring 5 1 1

E06 H609030080 Spring pin 2 2

E07 HF976F8001 Spring support (U) 1 1

E08 HF972F8001 Spring 1 1

E09 HF975F8001 Hose 1 1

E10 HF973F8001 Shaft 1 1

E11 HF974F8001 Spring support (D) 1 1

E12 H428080120 Bolt 1 1 M8×12

E13 HF905F8001 Press-foot lifter shaft bush(L) 1 1

E14 HF922F8001 Oil wick 1 1

E15 HF919F7101 Press-foot lifter connection assy 1 1

E16 H605050320 Pin 1 1

E17 HE20F48001 Press bar lifter shaft 1 1

E18 HF906F8001 Spreader shaft bush(L2) 1 1

E19 H424050160 Set screw 1 1

E20 H003002050 Nut 1 1

E21 HF997F8001 Stopper 1 1

E22 HF996F8001 Crack 1 1

E23 H415060160 Screw 1 1 M6×16

E24 HF910F8001 Set screw collar 1 1

E25 H401050060 Screw 1 1

E26 HF908F8001 Bushing(R2) 1 1

E28 HF907F8001 Bushing(R) 1 1

E29 H415060200 Screw 1 1 M6×20

E30 HF913F8001 Crack 1 1

E31 HF915F8001 Washer 2 2

E32 H005014080 Wave washer 1 1

E33 HF916F8001 Lifter lever 1 1

E34 HF917F8001 Screw 1 1

E35 HF980F8001 Lever(U) 1 1

E36 H415060160 Screw 1 1 M6×16

E37 H415050180 Screw 1 1 M5×25

E38 H003002050 Nut 1 1 M5

E41 HF982F8001 Main spring 1 1

E49 HF90IF8001 Crack 1 1

E50 H415060160 Screw 1 1

E51 HF91IF8001 Pump 1 1 SDA32×20

E52 HF912M8001 Windpipe joint 2 2 EPL4-01 φ 4-1/8"

E54 HF91BF8001 Coupling 1 1

E.UPPER FEED LIFTING ROCK SHAFT MECHANISM

— 35 —

Page 37

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

E55 H428060160 Screw 1 1

E57 H415040550 Screw 4 4

E58 H005008040 Spring washer 4 4

E59 H005004040 Washer 4 4

E.UPPER FEED LIFTING ROCK SHAFT MECHANISM

— 36 —

Page 38

F.STITCH REGULATOR MECHANISM

— 37 —

20

21

~3

23

24

~

30

1

37

2 3 4

~)

38

5

6

~

7

~®

~

~

10

~

11

1

1

.

~

14

15

16

17

41

42

57

56

Page 39

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

F01 HF925H8001 Spring 1 1

F02 HF924H8001 Washer 1 1

F03 HF922H8001 Feed adjusting arm 1 1

F04 HF923H8001 Pin 1 1

F05 H431050080 Bolt 1 1 M5×8

F06 HF914H8001 Feed adjusting screw (long) 1 1

F07 HA700F2030 Positioning pin 2 2

F08 H3200F2110 Spring 2 2

F09 HA109F0674 O ring 2 2

F10 HF914H8001 Feed adjusting screw (short) 1 1

F11 HA720F0687 Spring 2 2

F12 HA720F0683 Support plate 2 2

F13 HA7421F120 Feed adjusting dial 2 2

F14 HF909H8001 Feed adjusting dial plate(L) 1 1

F15 HA720F0685 Bushing 2 2

F16 HA720F0686 Screw 2 2

F17 HF918H8001 Feed adjusting dial plate(S) 1 1

F18 HF928H8001 Reverse shaft bushing(L) 1 1

F19 HF932H8001 Pin 1 1

F20 H428060080 Bolt 2 2 M6×8

F21 HF930H8001 Reverse stitching arm(U) 1 1

F22 HF934H8001 Pin 1 1

F23 H428060060 Bolt 1 1 M6×6

F24 HF927H8001 Collar 1 1

F25 HE20H48001 Rod 1 1

F26 H007013050 E-tpye retaining ring 5 2 2

F27 HF970H8001 Reverse stitching shaft 1 1

F28 HF931H8001 Reverse shaft bushing(R) 1 1

F29 H6511H8001 Pin 1 1

F30 H4937L8001 Bolt 1 1

F31 H4938L8001 Rubber ring 1 1

F32 HF969H8001 Spring 1 1

F33 HF968H8001 Reverse stitching lever 1 1

F34 HA3411D308 Bolt 1 1

F35 H4936L8001 Reverse stitching lever block 1 1

F36 HA113F0684 Bolt 1 1

F37 HF937E8001 Coupling 2 2

F38 H403060120 Screw 4 4 M6×10

F39 HF947H8001 Pump 1 1

F40 HF954H8002 Ring 1 1

F41 HF951H8001 Ring 1 1

F42 HF950H8001 Piston 1 1

F43 HF953H8001 Piston 1 1

F.STITCH REGULATOR MECHANISM

— 38 —

Page 40

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

F44 H005001060 Washer 1 1

F45 H104060250 Screw(D) 1 1 M6×25

F46 HF939H8001 Bolt 1 1

F47 HF937H8001 Reverse stitching arm(D) 1 1

F48 HF974H8001 S shaped hook 1 1

F51 HE20H78001 Pull spring 1 1

F52 H424100100 Thread pin 1 1 M10×10

F53 H3100D2090 Presser spring 1 1

F54 HF963H8001 Key 1 1

F55 HF966H8001 Oil seal 1 1

F56 HF958H8001 Shaft 1 1

F57 HF967H8001 Oil seal 1 1

F58 HF961H8001 Guide 2 2

F59 H005009050 Elastic washer 4 4

F60 H415050160 Screw 4 4 M5×16

F.STITCH REGULATOR MECHANISM

— 39 —

Page 41

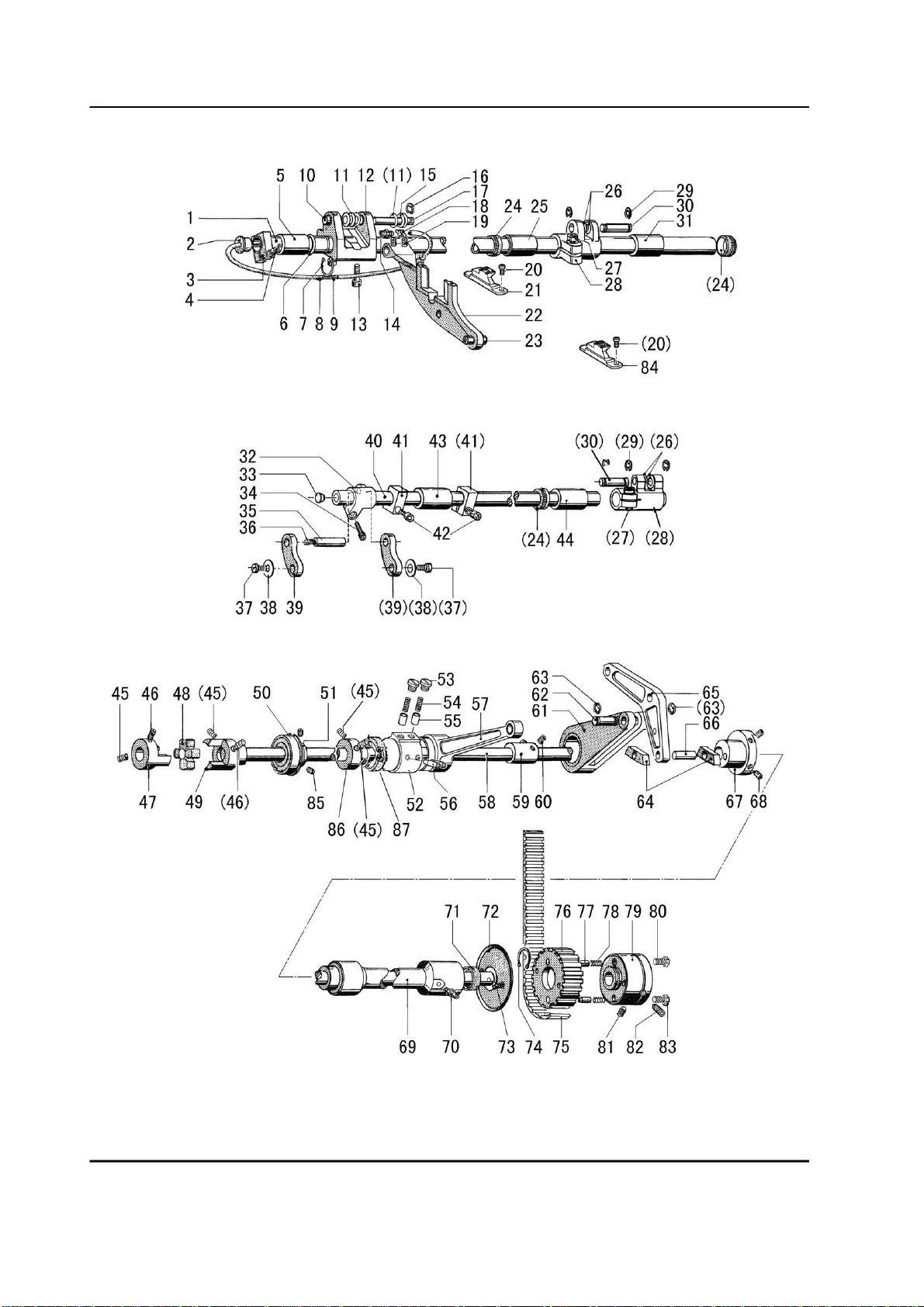

G.FEEDING AND FEED LIFTING & ROTATING HOOK SHAFT MECHANISM

— 40 —

2

~-=·

·

~~~

3

-----=

4

-------'

~"7'-=:~~='\

37

38

39

~.-(

~

20)

84

47

49 (46)

69

70

73

74

75

81

Page 42

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

G01 HE20I68001 Feed shaft 1 1

G02 HF959G8001 Rubber cap 1 1

G03 HF965G8001 Adjusting shaft collar 1 1

G04 H415040120 Bolt 1 1 M4×12

G05 HF927E8001 Bushing(L) 1 1

G06 HF931I8001 Thurst ring 1 1

G07 HF930I8001

C-type retaining ring

1 1

G08 HF941I8001 Tube 1 1

G09 HF942I8001 Oil wick 1 1

G10 HF937I8001 Bushing 4 4

G11 HF945I8001 Washer 3 3

G12 HF935I8001 Feed arm(L) 1 1

G13 HF936I8001 Bolt(L) 2 2

G14 HF956G8001 Oil joint 1 1

G15 HF946I8001 Spring 2 2

G16 H007013050 E-type retaining ring 5 1 1

G17 HF944I8001 Pin 1 1

G18 HF939I8001 Tube support 1 1

G19 HF948I8001 Bolt 2 2

G20 HF951I8001 Screw 2 2

G21 HF950I8001 Feed dog 1

G22 HF949I8001 Feed bracket 1 1

G23 HF953I8001 Pin 1 1

G24 HF929I8001 Oil seal 3 3

G25 HF924E8002 Feed shaft bushing(L) 1 1

G26 HF927I8001 Washer 4 4

G27 H415060120 Bolt(R) 2 2 M6×12

G28 HF923I8001 Feed shaft arm(R) 2 2

G29 H007013050 E-type retaining ring 5 4 4

G30 HF926I8001 Pin 2 2

G31 HF924E8001 Feed shaft bushing(R) 2 2

G32 HF957I8001 Feed connecting arm(L) 1 1

G33 HA719B0707 Rubber cap 1 1

G34 H415050160 Bolt 1 1 M5×16

G35 HF958I8001 Pin(L) 1 1

G36 HF961I8001 Oil wick 1 1

G37 H401030080 Bolt 2 2

G38 HF954I8001 Washer 2 2

G39 HF952I8001 Feed link 2 2

G40 HE20I78001 Shaft 1 1

G41 HF965G8001 Adjusting shaft collar 2 2

G42 H415040120 Bolt 2 2 M4×12

G43 HF927E8001 Bushing(L) 1 1

G.FEEDING AND FEED LIFTING & ROTATING HOOK SHAFT MECHANISM

— 41 —

Page 43

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

G44 HF924E8001 Bushing(R) 1 1

G45 H428060100 Bolt 3 3 M6×10

G46 H429060100 Bolt 1 1 M6×10

G47 HF975J8001 Coupling claw(L) 1 1

G48 HF978J8001 Toothed wreath 1 1

G49 HF977J8001 Coupling craw(R) 1 1

G50 H3205J0662 Ball bearing 2 2

G51 HB42D61081 Bushing 1 1

G52 HF987I8003 Bushing 1 1

G53 HF992I8001 Bolt 1 1

G54 H34412C110 Plunger spring 2 2

G55 HF966I8001 Plunger 2 2

G56 HA110E0672 Oil feeding pipe 2 2

G57 HF971I7101 Feed rod 1 1

G58 HE20I58001 Lower shaft 1 1

G59 HF963I8001 Feed cam 1 1

G60 H428060050 Bolt 2 2 M6×5

G61 HF919I7101 Lowe feed connecting rod assy 1 1

G62 HF926I8001 Pin 1 1

G63 H007013050 E-tpye retaining ring 5 2 2

G64 HF959H8001 Slide block 2 2

G65 HF925I8001 Back sylinder connection 1 1

G66 HF960H8001 Pin 1 1

G67 HF917I8001 Lower feed cam 1 1

G68 H428060080 Bolt 2 2 M6×8

G69 HF990I8001 Bushing(R) 1 1

G70 HF956G8001 Oil joint 1 1

G71 HF991I8001 Sealing ring 1 1

G72 HF915I8001 Disk 1 1

G73 HF916I8001 Stunk screw 2 2

G74 H007009220 Retainer ring 1 1

G75 HE20I88001 Toothed belt 1 1

G76 HF908I8001 Belt pulley(D) 1 1

G77 HF911I8001 Piston 2 2

G78 H3404D0658 Presser spring 2 2

G79 HF910I8001 Body 1 1

G80 H431060120 Adjusting screw 2 2 M6×12

G81 H431080120 Bolt 1 1 M8×12

G82 H430080120 Bolt 1 1 M8×12

G83 H003002060 Nut 2 2 M6

G84 HG006I8001 Feed dog 1

G85 H431040040 Screw 2 2 M4×4

G86 HE21I47101 Collar ASSY 1 1

G87 HF988I8001 Oil seal 1 1

G.FEEDING AND FEED LIFTING & ROTATING HOOK SHAFT MECHANISM

— 42 —

Page 44

H.HOOK SADDLE MECHANISM (RIGHT)

— 43 —

20

L

© 74

'----------·

73

~

~

71

72

Page 45

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

H01 H402025060 Screw 2 2 M2.5×6

H02 HF910J8001 Thread holding spring 1 1

H03 HF908J8001 Fixed knife 1 1

H04 H402025060 Screw 2 2 M2.5×6

H05 HE40J68001 Fixed knife support bracket 1 1

H06 H415050250 Bolt 2 2 M5×25

H07 H005005050 Washer 2 2

H08 HF989J8001 Washer 5 5

H09 HF991J8001 Oil drip ring 1 1

H10 HF997J8001 Bolt 2 2

H11 HF995J8001 Shaft 1 1

H12 HF92AJ8001 Oil wick 1 1

H13 H424050250 Bolt 1 1 M5×25

H14 HF981J8001 Hook shaft 1 1

H15 HF992J8001 Washer 1 1

H16 HF984J8001 Ball bearing 3 3

H17 HF983J8001 Gear 1 1

H18 H431050050 Bolt 2 2 M5×5

H19 HF946J8001 Pin(L) 1 1

H20 HF964J8001 Oil seal 2 2

H21 HF966J8001 Bolt 3 3

H22 HF965J8001 Screw 3 3

H23 HF962J8001 Lower shaft holder 1 1

H24 HF960J8001 O ring 1 1 GB/T 3452.1 38.5×1.8

H25 HF963J8001 Ball bearing 2 2

H26 H403030080 Screw 4 4

H27 HF969J8001 Lower shaft gear 1 1

H28 HF970J8001 Washer 1 1

H29 HF967J8001 Driving shaft 1 1

H30 HF973J8001 collar 1 1

H31 H415060160 Bolt 1 1 M6×20

H32 HF971J8001 Shaft 1

H33 HF956G8001 Oil feeding pipe(S) 1 1

H34 HF949J8001 Tube 1 1

H35 HF945J8001 Horizontal hook base 1 1

H36 095018 Wave washer 1 1

H37 HF990J8001 Lubrication shaft 1 1

H38 H007007260 Retainer ring 1 1

H39 HF956J8001 Bushing 1 1

H40 HF947J8001 Oil feeding pipe(M) 2 2

H41 H402030040 Bolt 1 1 M3×4

H42 H415040080 Bolt(short) 6 6 M4×8

H43 H415040120 Bolt(long) 3 3 M4×12

H.HOOK SADDLE MECHANISM (RIGHT)

— 44 —

Page 46

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

H44 H415030060 Bolt 2 2 M3×6

H45 H005004030 Washer 2 2

H46 HE40J88001 Driving knife 1 1

H47 HF913J8001 Driving knife shaft 1 1

H48 HE41J28001 Opener 1 1

H49 HF90HJ8001 Screw 2 2

H50 HF90AJ8001 Oil wick 1 1

H51 HF999J8001 Adjusting pin 1 1

H52 HF90BJ8001 Adjusting guide rail 1 1

H53 HF90DJ8001 Opener shaft 1 1

H54 HF996J8001 Bearing 1 1

H55 HE41J18001 Opener setting bracket 1 1

H56 HF90EJ8001 Pin 1 1

H57 HF917J8001 Bushing 1 1

H58 H007013040 E-type retaining ring 1 1

H59 HF950J8001 Oil wick 1 1

H60 HF919J8001 Bushing 1 1

H61 HF91CJ7101 Gear base assy 1 1

H62 H431050060 Bolt 2 2 M5×6

H63 H005014060 Belleville spring washer 1 1

H64 HF91IJ8001 Nut 1 1

H65 HF91JJ8001 Hexagonal nut 1 1

H66 HF91AJ8001 Gear 1 1

H67 H431050050 Bolt 2 2 M5×5

H68 HF954J8001 Sheet packing 1 1

H69 HF953J8001 Cover 1 1

H70 HF958J8001 Oil seal 1 1

H71 HF942J8001 Thread trimmer cam 1 1

H72 H415040080 Bolt 3 3 M4×8

H73 HE41J07101 Horizontal hook 1 1

H74 HE41J38001 Bobbin 1 1

H75 HF931J8001 Driving knife arm(S) 1 1

H76 H415040120 Bolt 1 1 M4×12

H77 HF934J8001 Pin 2 2

H78 H007013040 E-type retaining ring 2 2

H79 HF933J8001 Driving knife connection 1 1

H80 HF928J8001 Solinoid setting bracket 1 1

H81 H415040080 Bolt 1 1 M4×8

H82 HF937J8001 Driving knife arm(L) 1 1

H83 HF940J8001 Roller 1 1

H84 H007013030 E-type retaining ring 1 1

H85 H415040120 Bolt 1 1 M4×12

H86 HF920J8001 collar 2 2

H.HOOK SADDLE MECHANISM (RIGHT)

— 45 —

Page 47

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

H87 H428050050 Bolt 2 2 M5×5

H88 HF922J8001 Solinoid setting plate 1 1

H89 H005018060 Washer 1 1

H90 H415060120 Bolt 1 1 M6×12

H91 H415040100 Bolt 2 2 M4×10

H92 HF939J8001 Pin 1 1

H93 HF926J7101 Thread trimmer solinoid 1 1

H94 H415060220 Bolt 2 2 M6×22

H95 HF92BJ8001 Spacer 1 1

H96 HF92CJ8001 Eccentric collar 1 1

H.HOOK SADDLE MECHANISM (RIGHT)

— 46 —

Page 48

I.HOOK SADDLE MECHANISM (LEFT)

— 47 —

1

2

3

4

___s;:D

5

6

7

(5)

(?)--~16

8

--L-11

9~

23

24

39

40

41

42

43

44

45

46

~

~57

"61

56

58

59

60

62

63

64

65

66

67

(40)

68

69

'

' '

....

....

(40)

'

'

' '

71',

72

73

74

75

76

77

78

81

86 87

..................

' '

'

...

'

.............. , ....

(5) (4)

~~'-::'_,

J,.

92

82

\

93

88

83

94

89

90

79

80

(35)

91

(90)

Page 49

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

I01 HG013J8001 Link lever 1

I02 HF920J8001 collar 1

I03 H428050050 Bolt 1 M5×5

I04 H007013040 E-type stop ring 4 6

I05 HF934J8001 Pin 4

I06 HG012J8001 Thread trimmer arm(S) 1

I07 H415040120 Bolt 2 M4×12

I08 HF939J8001 Pin 1

I09 H007013030 E-type stop ring 4 1

I10 H415060220 Bolt 2 M6×22

I11 HF92BJ8001 Spacer 1

I12 HF92CJ8001 Eccentric collar 1

I13 HG017J8001 Driving knife connection 1

I14 HF919J8001 Bushing 1

I15 HG016J8001 Crack 1

I16 HF937J8001 Thread trimmer arm(L) 1

I17 HF940J8001 Roller 1

I18 HG021J8001 Driving shaft mandril 1

I19 H415030060 Bolt 2 M3×6

I20 H005004030 Washer 2

I21 HE40J88001 Driving knife 1

I22 HF913J8001 Driving knife shaft 1

I23 H415050250 Bolt 2 M5×25

I24 H005005050 Washer 2

I25 HE40J68001 Fixed knife support bracket 1

I26 HF90HJ8001 Screw 2

I27 HE41J28001 Opener 1

I28 HE41J18001 Opener setting bracket 1

I29 HF90EJ8001 Pin 1

I30 HF90DJ8001 Opener shaft 1

I31 HF996J8001 Bearing 1

I32 HG008J8001 Oil wick 1

I33 HG007J8001 Oil joint 1

I34 HF917J8001 Bushing 1

I35 HF964J8001 Oil seal 2

I36 HF973J8001 Collar 1

I37 H415060200 Bolt 1 M6×20

I38 HG006J8001 Horizontal hook base 1

I39 HF919J8001 Bushing 1

I40 HF984J8001 Bearing 3

I41 HF91CJ7101 Gear base assy 1

I42 095018 Wave washer 1

I43 H005014060 Belleville spring washer 1

I.HOOK SADDLE MECHANISM (LEFT)

— 48 —

Page 50

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

I44 HF91IJ8001 Adjusting block 1

I45 HF91JJ8001 Hexagonal nut 1

I46 HF91AJ8001 Driving gear 1

I47 HF947J8001 Oil joint(M) 2

I48 H415040080 Bolt(short) 6 M4×8

I49 H415040120 Bolt(long) 3 M4×12

I50 HF958J8001 Oil seal 1

I51 HF942J8001 Thread trimmer cam 1

I52 H415040080 Bolt 3 M4×8

I53 H402025060 Screw 2 M2.5×6

I54 HF910J8001 Thread holding spring 1

I55 H402025060 Screw 2 M2.5×6

I56 HF908J8001 Fixed knife 1

I57 HF989J8001 Uncork washer 5

I58 HF991J8001 Hook support 1

I59 HF90AJ8001 Oil wick 1

I60 HF999J8001 Adjusting pin 1

I61 HF90BJ8001 Adjusting guide rail 1

I62 HF997J8001 Bolt 2

I63 HF995J8001 Shaft 1

I64 HF92AJ8001 Oil wick 1

I65 H424050300 Bolt 1 M5×30

I66 HF992J8001 Spacer 1

I67 HF981J8001 Hook shaft 1

I68 HF983J8001 Driven gear 1

I69 H431050050 Bolt 2 M5×5

I70 HG014J8001 Arm adjusting pin 1

I71 HF990J8001 Lubrication shaft 1

I72 H415050060 Bolt 2 M5×6

I73 H007007260 Retainer ring 1

I74 H431050050 Bolt 2 M5×5

I75 HF956J8001 Bushing 1

I76 HF954J8001 Sheet pack 1

I77 HG010J8001 Cover(L) 1

I78 H402030040 Bolt 1 M3×4

I79 HE41J07101 Horizontal hook assy 1

I80 HE41J38001 Bobbin 1

I81 HF967J8001 Driving shaft 1

I82 HF963J8001 Boll bushing 2

I83 HF962J8001 Lower shaft holder 1

I84 HF965J8001 Screw 3

I85 HF966J8001 Bolt 3

I86 HF970J8001 Washer 1

I.HOOK SADDLE MECHANISM (LEFT)

— 49 —

Page 51

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

I87 HF969J8001 Driving gear 1

I88 H403030080 Screw 4

I89 HF960J8001 O-ring 1 GB/T 3452.1 38.5×1.8

I90 H415040100 Bolt 4 M4×10

I91 HF926J7101 Thread trimmer solenoid 1

I92 HG019J8001 Solenoid setting bracket 1

I93 H415040080 Bolt 1 M4×8

I94 HG020J8001 Solenoid setting plate 1

I.HOOK SADDLE MECHANISM (LEFT)

— 50 —

Page 52

J.OIL LUBRICATION MECHANISM

— 51 —

13 14

20

4

3

5

6

~

10

11

Page 53

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

J01 H401050080 Bolt 1 1 M5×8

J02 H005018050 Spacer 1 1

J03 HF909K8001 Oil wick support 1 1

J04 HF917K8001 Oil joint 1 1

J05 HF908K8001 Tube guide 1 1

J06 HF906K8001 Felt 1 1

J08 HE20K58001 Oil tube 1 1 φ 3×φ 5×1150

J09 HE21K88001 Oil tube 1 1 φ 7×φ 5×950

J10 HF914K8001 Felt 1 1

J11 HE21K58001 Oil wick 1 1 φ 4×1000

J12 HE21K38001 Oil tube 1 1 φ 7×φ 5×900

J13 HF948K8001 Pipe 1 1

J14 HF950K8001 Oil tube 1 1 φ 3×φ 5×25

J15 HF949K8001 Hose 1 1 φ 3×φ 5×210

J16 HF936K8001 Oil pipe 1 1 φ 3×φ 5×60

J17 HF959K8001 Oil window 1 1

J18 HE25K78001 Oil pipe 1 1 φ 3×φ 5×970

J19 HF919K8001 Spring 1 1

J20 HF962K8001 Tape 1 1

J21 HA04042160 Screw 2 2

J22 HF960K8001 Guard plate 1 1

J23 HF956K7101 Valve 1 1

J24 HF955K8001 Main oil pipe 1 1 φ 3×φ 5×110

J25 HF920K8001 Oil joint 2 4

J26 HF921K8001 Oil pipe 1 1 φ 7×φ 5×25

J27 HF922K8001 Oil pipe 1 1 φ 7×φ 5×120

J28 HF938K8001 Oil joint 1 1

J29 HF939K8001 Oil pipe 1 1 φ 7×φ 5×140

J30 HF951K8001 Oil pipe setting plate 1 1

J31 H3200K0170 Oil wick setting plate 2 1

J32 H415040100 Screw 2 2 M4×10

J33 H005001040 Washer 2 2

J34 H3210K0671 T-joint 3 3

J35 HF942K8001 Hose 1 1 φ 3×φ 5×21

J36 HF947K8001 Hose 1 1 φ 3×φ 5×30

J37 HF946K8001 Oil wick 1 1 φ 3×φ 5×30

J38 HF943K8001 Oil pipe plate assy 1 1

J39 HF92FJ7101 Wire assy 1 1

J40 HF927K7101 Oil hose assy 1 1

J41 HF963K7101 Filter pot assy 2 2

J42 HE22K98001 Oil pipe 1 1 φ 3×φ 5×700

J43 HF930K8001 Support spring 1 2

J.OIL LUBRICATION MECHANISM

— 52 —

Page 54

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

J44 HF923K8001 Oil pipe 1 1

J46 HE22K48001 Oil pipe 1 2 φ 7×φ 5×400

J47 HE22K58001 Oil pipe 1 1 φ 7×φ 5×410

J48 HF926K8001 Support spring 2 2

J49 HF932K8001 Felt part 1 1

J50 HA300I2040 Cable tie 1 1

J51 HF934K8001 Oil pipe 1 1 φ 3×φ 5×250

J52 HF937K8001 Oil pipe 1 1 φ 3×φ 5×600

J53 HG006K8001 Oil pipe 3 φ 7×φ 5×100

J54 HG005K8001 Oil pipe 1 φ 7×φ 5×60

J55 HF922K8001 Oil pipe 1 φ 7×φ 5×120

J56 HE23K08001 Oil pipe 1 1

J58 HE25K98001 Tube support 1 1

J59 H415050080 Screw 1 1

J.OIL LUBRICATION MECHANISM

— 53 —

Page 55

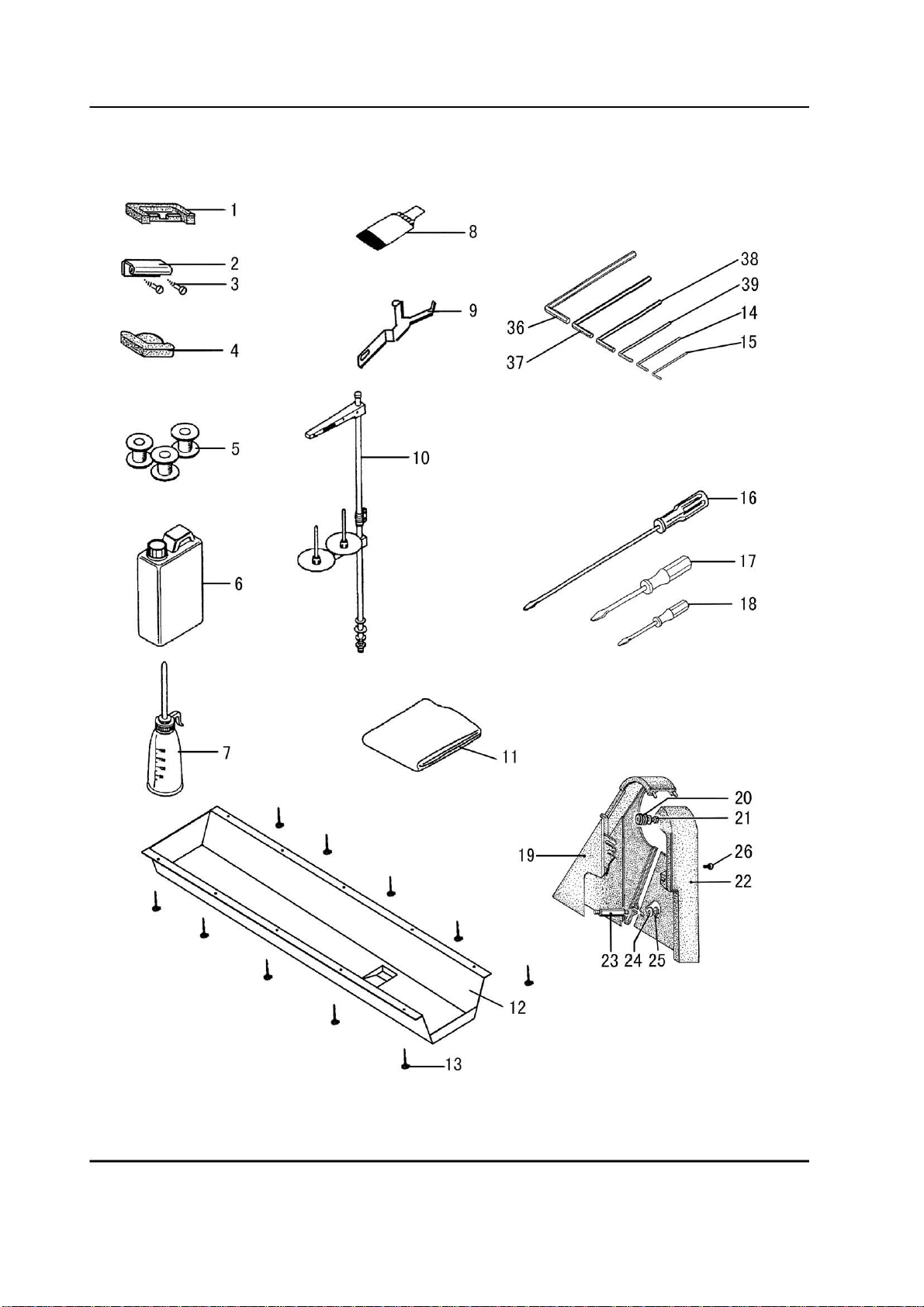

K.ACCESSORIES

— 54 —

.

~

1

· .

4

~5

6

10

12

L-13

Page 56

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

K01 HA307J0671 Hinge support 2 2

K02 HF914L8001 Hinge 2 2

K03 H411060100 Screw 4 4

K04 HF905L8001 Head cushion 2 2

K05 HE41J38001 Bobbin 2 4

K06 HA100J2170 Oil tank 1 1

K07 H2004O0069 Oiler 1 1

K08 JZDP1700G2301 Neddle 4 DP×17 #23

K08 JZDP1700G2302 Neddle 6 DP×17 #23

K09 HF913L8001 Detector setting plate 1 1

K10 HA200J2030 Cotton stand assy 1

K10 H3200L0120 Cotton stand assy 1

K11 HA100J2180 Cover 1 1

K12 HE20L48001 Oil plate 1 1

K13 H801050200

Screw

10 10

K14 HB00001025 Hexagonal wrench (2.5) 1 1

K15 HB00001015 Hexagonal wrench (1.5) 1 1

K16 HA300J2070 Screw driver(L) 1 1

K17 HA300J2200 Screw driver(M) 1 1

K18 HA300J2210 Screw driver(S) 1 1

K19 HF908L8001 Belt guard(R) 1 1

K20 HF915L8001 Rubber washer 1 1

K21 H401060120 Bolt 1 1

K22 HF907L8001 Belt guard(L) 1 1

K23 HF911L8001 Bolt 1 1

K24 H005001060 Washer 1 1

K25 H7316E8001 Nut 1 1

K36 HB00001060 Hexagonal wrench (6) 1 1

K37 HB00001050 Hexagonal wrench (5) 1 1

K38 HB00001040 Hexagonal wrench (4) 1 1

K39 HB00001030 Hexagonal wrench (3) 1 1

K.ACCESSORIES

— 55 —

Page 57

L.PNEUMATIC CONTROL UNIT

— 56 —

7

(4

)---"0

6

-------

d

c

(19)

-----

24-------

--+

v

~-

·

-

~=

-----4

~---2

13-----...

11

~~

_

8----~

______,

'-'---

------1

,,

-

14

16

20

17

1

0

2

23

27

52

28

57

56

50

44

54

35

34

55

46 47

25

58

38

42

30

37

35

3659

43

e

b

~

28 29

39

X@

~

52

~

~

0 0

g

49

38

(24)

45

26

31

28

27

38

Page 58

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

L01 HF930M8001

Connecting box base

1 1

L02 HF924M8002 PCB board 1 1

L03 HF932M8001

Connecting box screw

2 2

L04 H409040160

Screw

2 2

L05 H415030120

Screw

2 2

L06 HF931M8001

Connecting box cover

1 1

L07 HF922E8001

Rheostat

1 1

L08 HE20E57101

Rheostat wire assy

1 1

L09 HE20C57101

Tension release solenoid

1 1

L10 HF92IJ8001

Wire joint

4 4

L11 HF926J7101

Trimming solenoid

1 2

L12 HF92HJ8001

Wire joint

4 6

L13 HF92EJ8001 H type wire joint 1 1

L14 HF934M8001

Button set frame

1 1

L15 HF933M8001

Button set board

1 1

L16 HF937M8001

Button with light

3 3

L17 HF937M8002

Button without light

2 2

L18 HE20M57101

Button wire assy

1 1

L19 H415040060

Screw

4 4

L20 HF940M8001

Plotting

5 5

L22 HF929M7101

Count to alarm wire assy

1 1

L23 HF925M7102

Control box wire assy

1 1

L24 HE20M97101

Reset button assy

1 1

L25 HF917M8001

Solenoid valve set board

1 1

L26 HF941M8001

Solenoid valve cover

1 1

L27 H409040100

Screw

4 4

L28 H005001040 Washer 8 8

L29 H005008040 Spring washer 4 4

L30 HF906M7101 Solenoid valve assy 1 1

L31 HF927M7101 Solenoid valve wire assy 1 1

L32 H4915N8001

Filter with regulator

1 1

L33 H4923N8001 Bracket 1 1

L34 HF912M8001

Wire joint

2 2

L35 H4921N8001

Wire joint

2 2

L36 H4918N8001

Solenoid valve

3 3

L37 H4924N8001

Exhaust muffler

6 6

L38 HF959M8001

Wire joint

9 9

L39 HG00B88001

Screw

2 2

L40 H005008040 Spring washer 2 2

L41 H005001040 Washer 2 2

L42 H4917N8001

Wire joint

1 1

L43 HF958M8001

Windpipe

3 3

L44 HF915M8001

Windpipe

1 1

L.PNEUMATIC CONTROL UNIT

— 57 —

Page 59

Fig.

No.

Part No. Description

GC20688-1BDL

GC20688-2BDL

Remarks

L45 HF914M8002

Windpipe

1 1

L46 HF914M8003

Windpipe

1 1

L47 HF914M8001

Windpipe

1 1

L48 HF914M8004

Windpipe

2 2

L49 HE21M48001

Windpipe

2 2

L50 HF905M8001 Air source units 1 1

L52 H003002040 Nut 8 8

L53 H005001040 Washer 1 1

L54 HZ11040120

Screw

2 2

L55 H801050200

Screw

4 4

L56 H4919N8001

Wire joint

1 1

L57 H4914N8001

Wire joint

1 1

L58 HF960M8001

Screw plug

1 1

L59 HG119M8001

Wire joint(Y)

2 2

L60 HF937E8001

Wire joint

1 1

L.PNEUMATIC CONTROL UNIT

— 58 —

Page 60

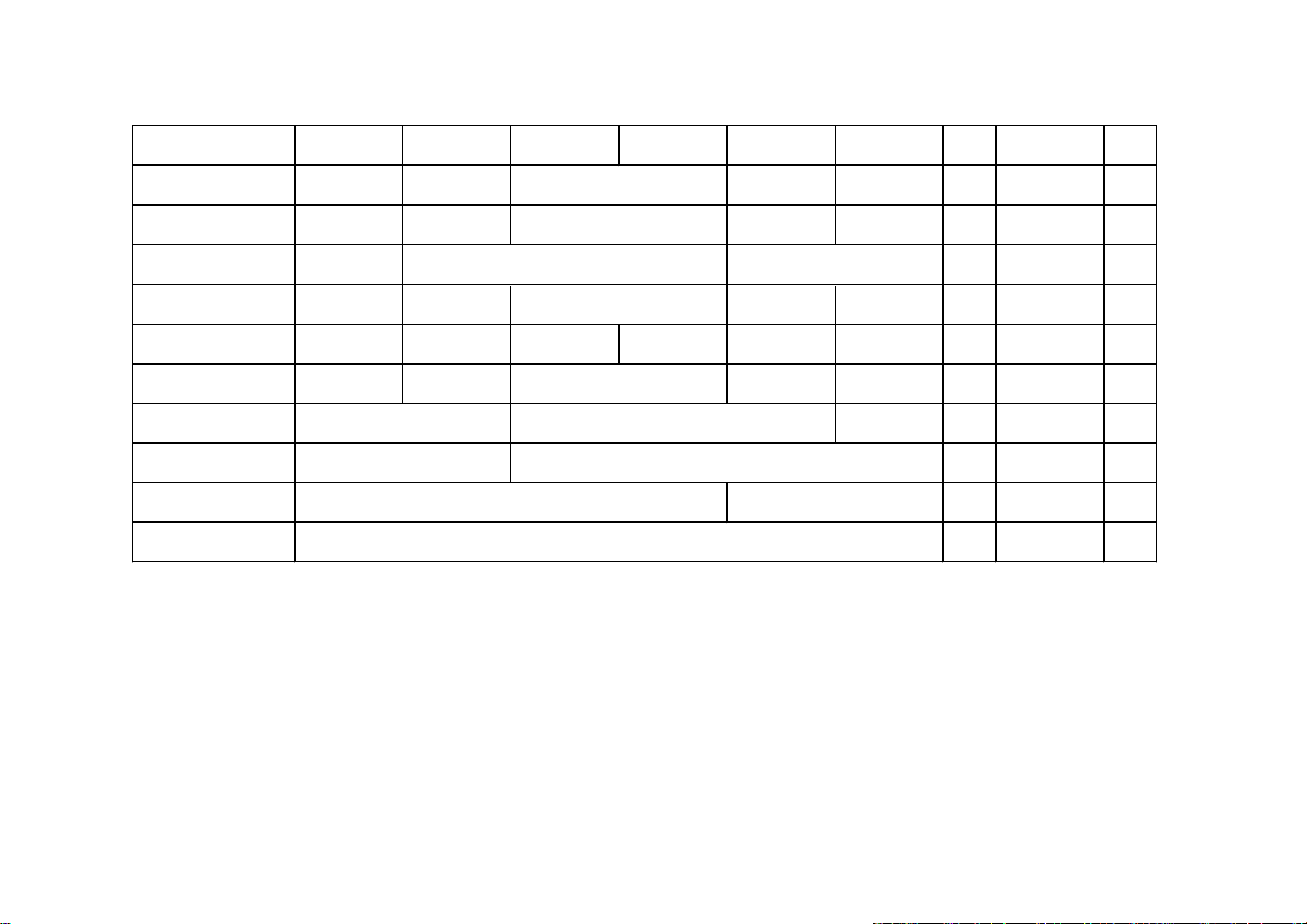

Needle gauge

3.2mm 6.4mm 8mm 8mm 10mm 12mm Pcs. 16mm Pcs.

Needle bar connecting stud

HG017G8001 HG019G8001 HG010G8001 HG013G8001 1 HG015G8001 1

Outer presser foot

HG021F8001 HG025F8001 HG013F8001 HG016F8001 1 HG018F8001 1

Finger gusrd HG022F8001 1 HG019F8001 1

Inner presser foot

HG023F8001 HG026F8001 HG009F8001 HG010F8001 1 HG011F8001 1

Feed dog

HG010I8001 HG011I8001 HG006I8001 HG006I8002 HG007I8001 HG008I8001 1 HG009I8001 1

Needle plate

HG014B8001 HG015B8001 HG008B8001 HG009B8001 1 HG010B8001 1

Slide Plate left

HG013B8001 1 HG011B8001 1

Slide Plate right

1 HG012B8001 1

Thread guide

1 HF971G8001 2

Screw

1 HF972G8001 2

HG007B8001

HG007G8001

HG011G8001

HG008G8001

HF980B8001

HG005B8001

HF981B8001

HG006B8001

GAUGE PARTS LIST

HG006G8001

HG005F8001

HG006F8001

HG014F8001

HG008F8001

Page 61

ADD: 1418, Yishan Road, Shanghai, China

Zip Code: 201103

Overseas Business: TEL: 86-21-64853303 FAX: 86-21-64854304

E-mail:highlead@online.sh.cn http://www.highlead.com.cn

The description covered in this manual is subject to change for improvement of the commodity without notice

2008.5. Printed

SHANGHAI HUIGONG NO.3 SEWING MACHINE FACTORY

Loading...

Loading...