Page 1

GC20618-1E

Heavy Duty Compound Feed Lockstitch

Sewing Machine With Edge Binder

Instruction Manual

Parts Catalog

Page 2

CONTENTS

PRECAUTIONS BEFORE STARTING OPERATION ---------------------------------------------- 1

PREPARATION FOR OPERATION

1. Power cable connection -------------------------------------------------------------------------------------------- 2

2. C

onnection of control box -----------------------------------------------------------------------------------------

CAUTIONS ON USE

1. Oiling (1) -------------------------------------------------------------------------------------------------------------- 3

2. O

iling (2) --------------------------------------------------------------------------------------------------------------

3. O

iling condition -----------------------------------------------------------------------------------------------------djustment of oiling to rotating hook ---------------------------------------------------------------------------

4. A

autions on operation -----------------------------------------------------------------------------------------------

5. C

OPERATION

1. Installation of needles ----------------------------------------------------------------------------------------------- 4

2. W

3. T

4. S

5. T

6. Tension adjustment of bobbin threads --------------------------------------------------------------------------- 6

7. B

8. N

9. A

10. T

11. Adjustment of feed dog height ------------------------------------------------------------------------------------ 7

12. R

13. R

14. R

15. S

16. Upper feed adjustment (needle side) ---------------------------------------------------------------------------- 10

17. O

inding of bobbin thread ------------------------------------------------------------------------------------------

hreading of needle threads ---------------------------------------------------------------------------------------

etting of bobbin ---------------------------------------------------------------------------------------------------hreading of bobbin threads ---------------------------------------------------------------------------------------

alance of thread tension -----------------------------------------------------------------------------------------eedle thread tension ----------------------------------------------------------------------------------------------djustment of presser foot pressure ------------------------------------------------------------------------------

iming between rotating hook motion and needle motion ---------------------------------------------------

elationship between rotating hook motion and take-up lever motion -----------------------------------elationship between hook motion and opener motion -----------------------------------------------------elationship between needle motion and feed dog motion --------------------------------------------------

afety clutch device -------------------------------------------------------------------------------------------------

utside presser foot and inside presser vertical stroke adjustment ----------------------------------------

3

3

4

4

4

5

5

6

6

6

6

7

7

8

8

8

9

10

SPECIFICATIONS ------------------------------------------------------------------------------------------------- 10

Page 3

PRECAUTIONS BEFORE STARTING OPERATION

1. Safety precautions

1) When turning the power on, keep your hands and fingers away from the area around/under the

needle and the area around the pulley

ower must be turned off when the machine is not used, or when the operator leaves his/her seat.

2) P

3) The power must be turned off before tilting the machine head, installing or removing the “V” belt,

djusting the machine, or when replacing.

a

4) Avoid placing fingers, hairs, bars etc. near the pulley, “V” belt, bobbin winder pulley, or motor

when the machine is operation. Injury could result

o not insert fingers into the thread take-up cover, under/round the needle, or pulley when the

5) D

machine is in operati

6) I

f a belt cover, finger guard, and/or eye guard are installed, do not operate the machine without

these safety devices.

on.

.

.

2. Precaution before Starting Operation

f the machine’s oil pan has an oil sump, never operate the machine before filling it.

1) I

2) If the machine is lubricated by a drop oiler, never operate the machine before lubricating.

3) When a new sewing machine is first turned on, verify the rotational direction of the pulley wit

the power on. (the pulley should rotate counterclockwise when viewed from the pulley.)

h

4) Verify the voltage and (single or three) phase with those given on the motor nameplate.

3. Precaution for Operating Conditions

1) Avoid using the machine at abnormally high temperature (35℃ or higher) or low temperature

(5℃or lower). Otherwise, machine failure may result.

2) Avoid using the machine in dusty conditions.

void using the machine in areas where too much electrical noise, resulted from the

3) A

high-frequency welder and others, is gener

ated.

— 1 —

Page 4

PREPARATION FOR OPERATION

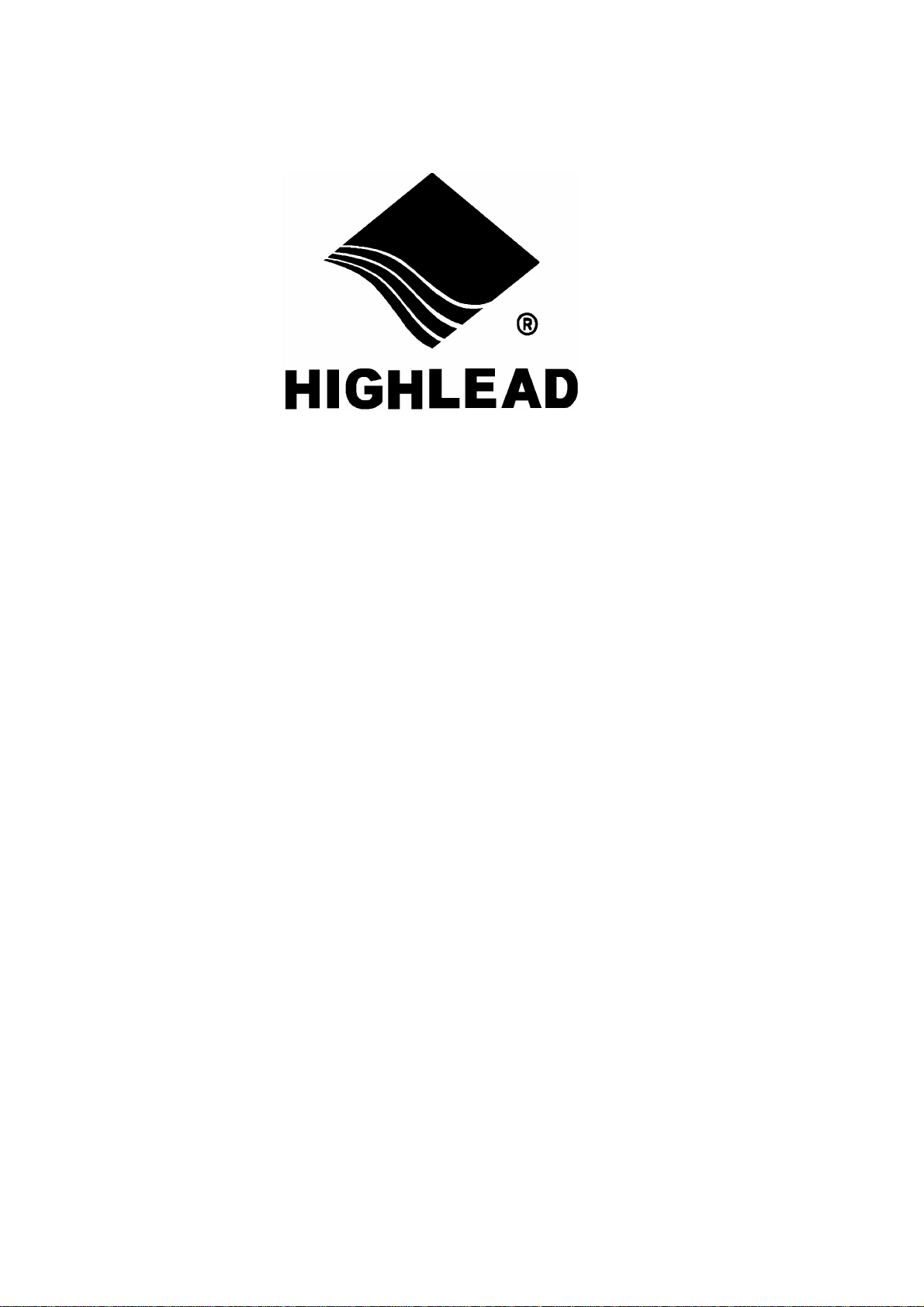

Overall view of assembled

sewing machine

1. Power cable connection

1) Connection to Power Supply

When connecting the power supply connector to the control box, the connector should be completely

plugged in the proper receptacle after confirming the connector type and matching direction.

A. In case of three-phase electrical power system, the “U” phase should be connected to the red lead

he “V” phase to the white lead, and the “W” phase to the black lead. The motor rotary direction

t

depends, however , upon the setting of the internal switch in the control box as described in

Paragraph 1-(3)

CAUTION: The green wire must be connected to the ground terminal in order to ground

the motor properly.

B

he appropriate power fuse capacity is as follows. Power supply 200V-240V: 10A

. T

100V-120V: 15A

2) Lamp Leads

A.

When installing the illuminating lamp(6V,15-20W),The connecting wire is attached on the back of

the Control box. It should be

removed and connected by

removing the insulating tube

from the wire and stripping

properly. The wire connections

,

should be, then, insulated by

wrapping insulating tape on the wires.

CAUTION: The power switch must be Turned off before connecting the lamp.

B. When the illuminating lamp is not used, the end of the lamp leads must be insulated as (a) or (b) as

— 2 —

Page 5

shown in the figure on right side. If a short circuit occurs failing to insulate, the transformer in the

control box will be possibly burned out.

CAUTION: The illuminating lamp must not be connected with any heater, such as a foot

warmer and others, in parallel. Otherwise, the load capacity will be exceeded.

It may cause transformer winding burned out.

3) Rotary direction

I

t is possible to change the rotary direction of the motor by removing the rubber cap from the

bottom left side of the front cover on the control box, and push the internal direction selector switch.

The built-in lamp in the internal switch is off when the motor is rotating counterclockwise as facing

to the motor pulley, and on when rotating clockwise. The rotary direction has been set t

counterclockwise as facing to the motor pulley, matching with the machine prior to shipping.

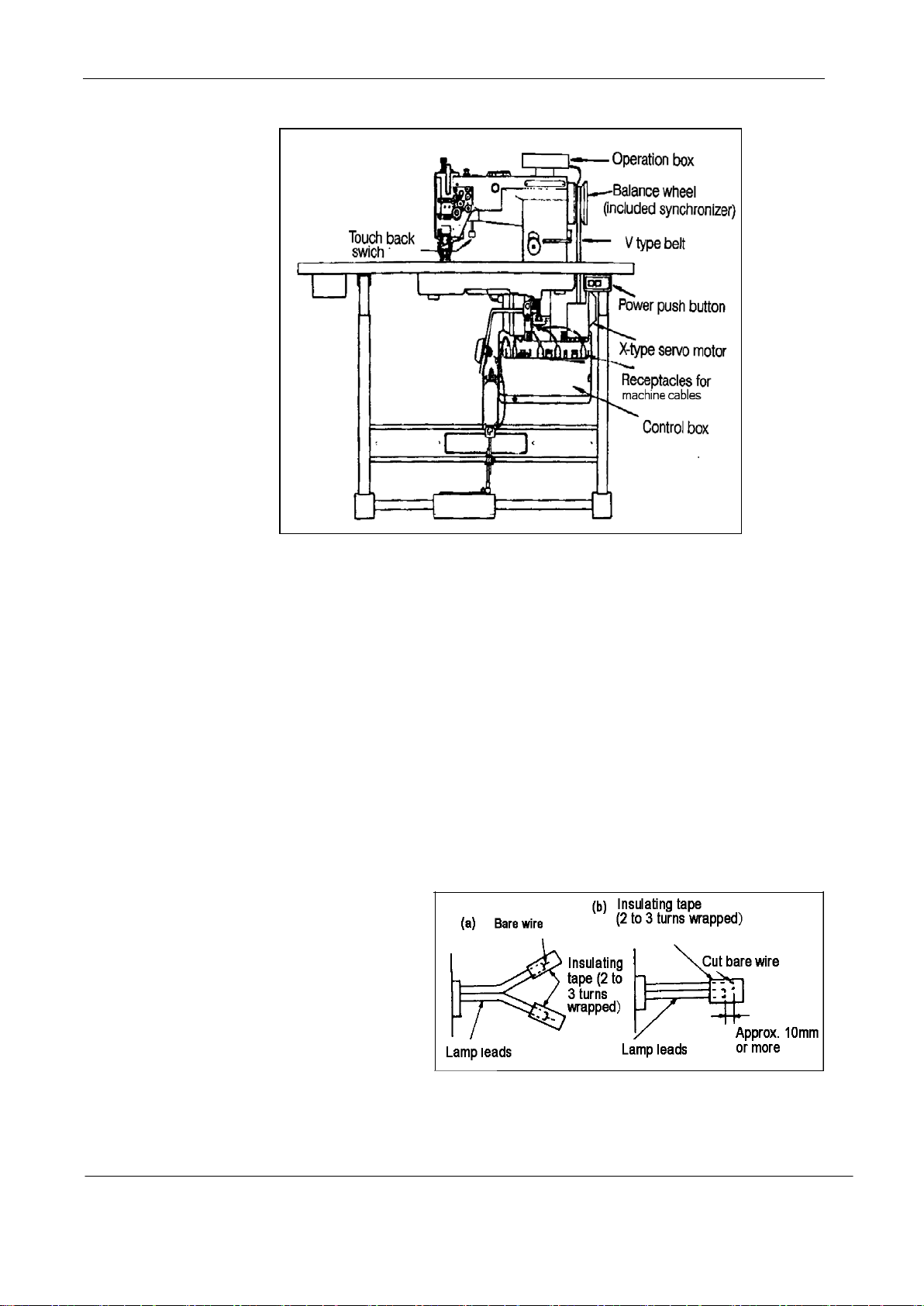

2. Connection of control box

The control box should be connected

as shown to the right.

Note: (1) Be sure to turn the power switch

off for safety before connecting

or disconnecting the connectors.

(2) The combination of the machine

heads with the motor control

panels are specified below.

Use special care for the correct

combination when replacing the machine head or motor control panel

CAUTIONS ON USE

o

.

1. Oiling (1) Fill the oil reservoir with oil up to “H”

mark.Oil level should be periodically checked. If oil level

is found below “L” level replenish oil to “H” level .

For oil, Use white spindle oil

.

2. Oiling (2) When a new sewing machine is used for the first time, or sewing machine left out of use

for considerably long time is used again, replenish a suitable amount of oil to the portions

indicated by arrow in the below figure.

— 3 —

Page 6

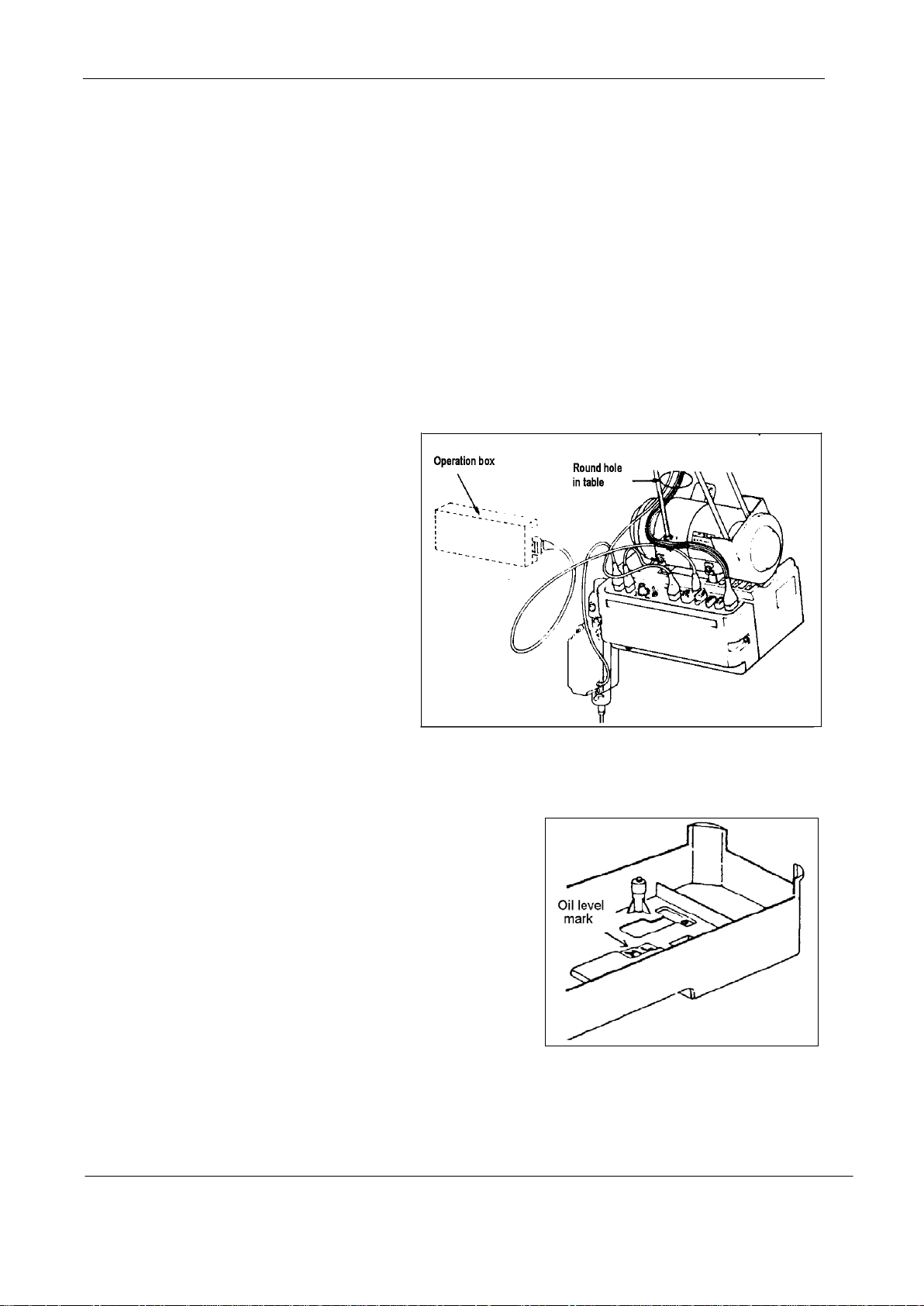

3.

Oiling condition

See dripping of oil through the oil window to check oiling condition during operation.

4. Adjustment of oiling to rotating hook

5. Cautions on operation

a) When the power is turned on or off, keep foot away from the pedal.

b) It should be noted that the brake may not work when the power is interrupted or power failure occurs

during sewing machine operation.

c) Since dust in the control box might cause malfunction or control troubles, be sure to keep the control

box cover close during operation.

d) Do not apply a multimeter to the control circuit for checking; otherwise voltage of multimeter might

damage semiconductor components in the circuit.

OPERATION

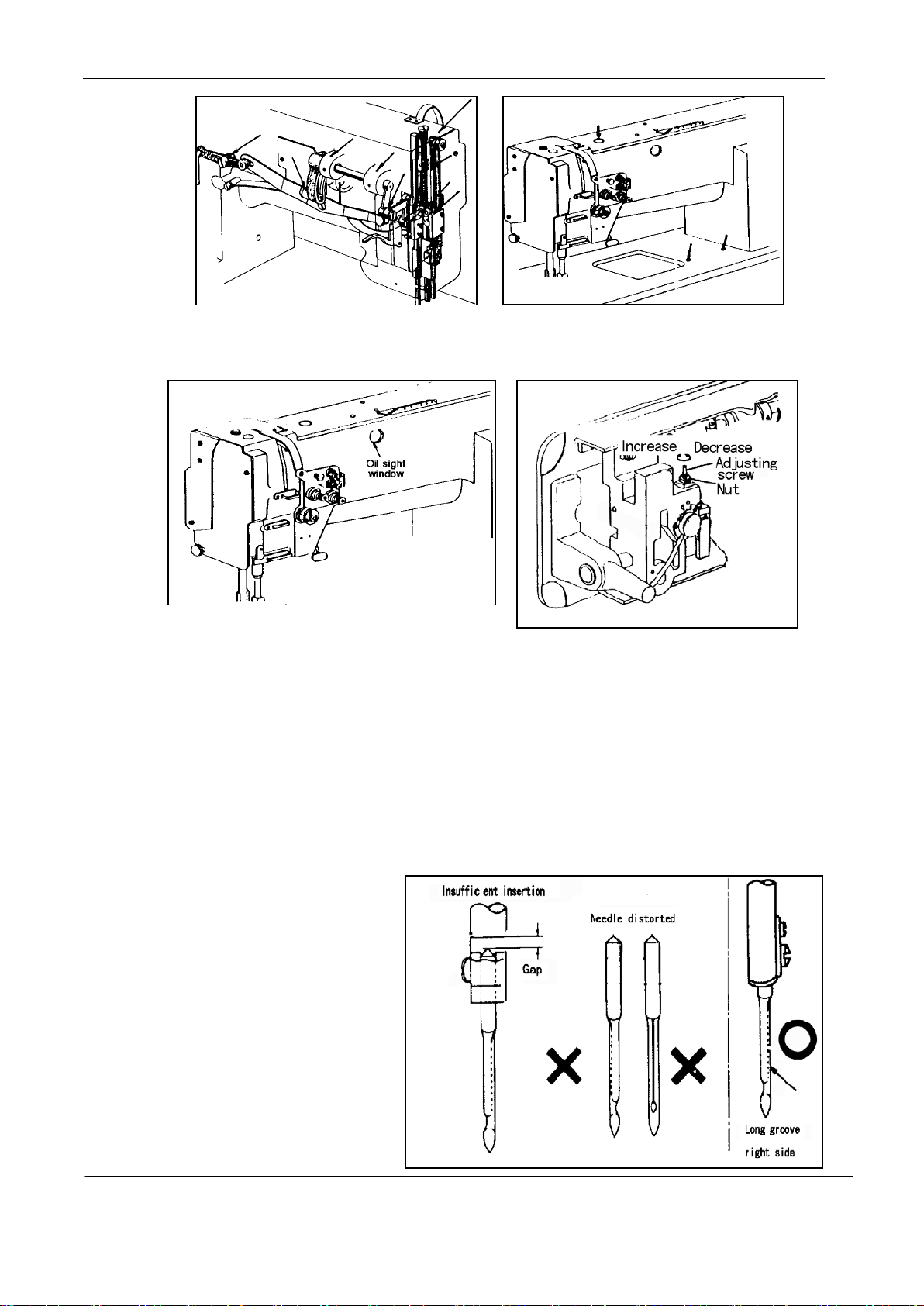

1. Installation of needles

Note: Before installing the needles,

be sure to turn off the power.

— 4 —

Page 7

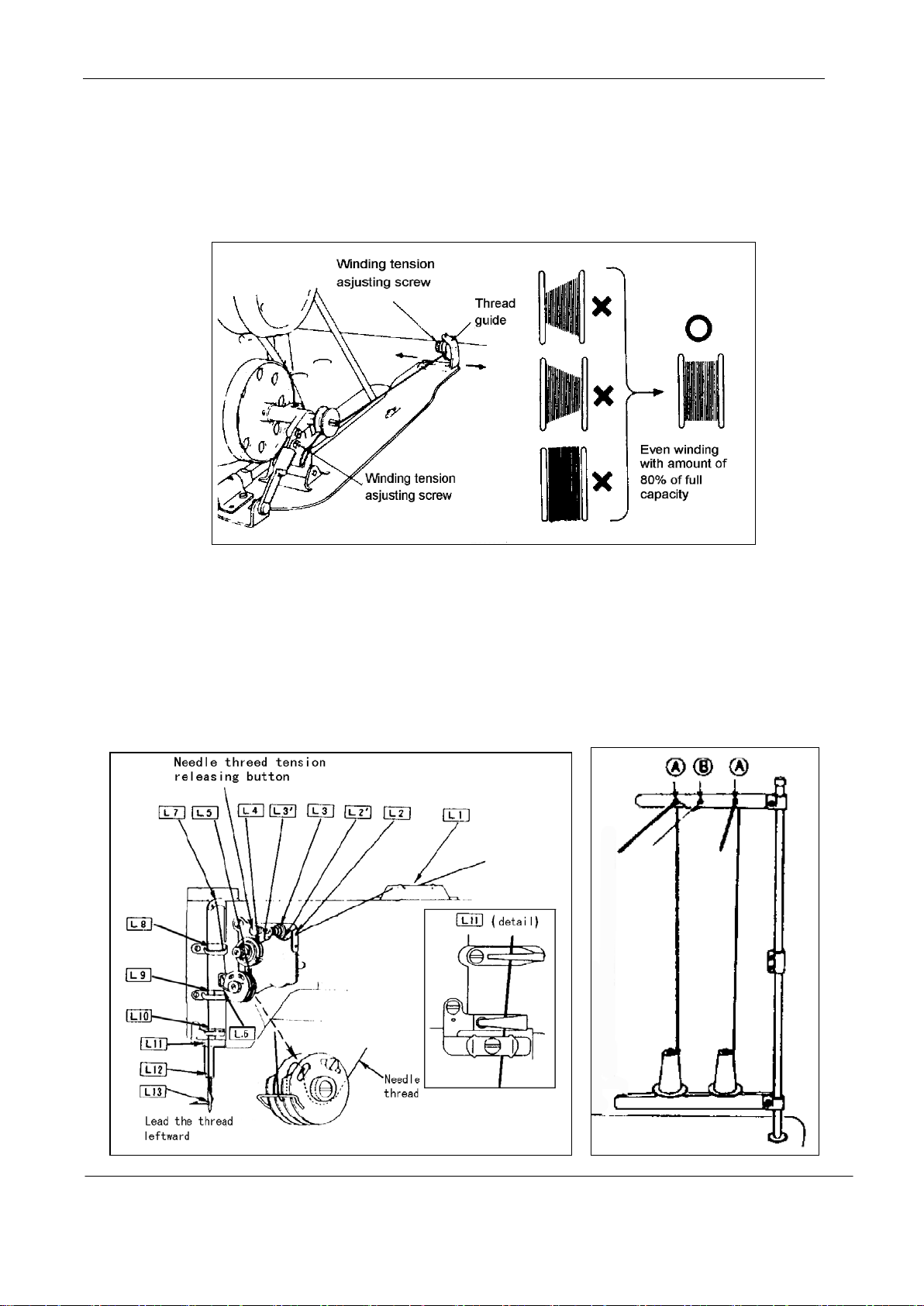

2. Winding of bobbin thread

Note: When bobbin thread is wound, keep the presser foot lifted. Adjustment:

Tension of wound thread Slack winding is recommended for polyester threadand nylon thread.

Conically wound thread Move the thread guide toward smaller diameter of wound thread layer.

Length of wound thread Loosen the thread length adjusting screw to increase length of thread and

tighten the screw to decrease length of thread.

.

3. Threading of needle threads

a) Pass each needle thread through thread guide A

Note: When thin slippery thread (polyester Thread or filament thread, for example) is used pass the

thread through thread guide B as well

ith the take-up lever located at the upper most position, pass each needle thread in the order

b) W

shown in the following figure.

Note: Pressing the upper thread loosening button shown in the figure below opens the saucer of the

upper thread tension adjuster, and the upperthread can easily pulled out.

.

— 5 —

Page 8

4. Setting of bobbin

a) Pulling out 5cm thread tail from the bobbin.

b) Hold the bobbin so that the bobbin thread is would in right direction and put it into the hook.

5. Threading of bobbin threads

a) Put the hook into the bobbin case and press down the latch ①. The thread end should be left on

the bed .

b) While holding the needle Thread by left hand, rotate the hand-wheel one turn by right hand.

By pulling up the needle thread, as shown in the figure, the bobbin thread will be lifte

Each combination of bobbin thread and needle thread should be aligned and led backward.

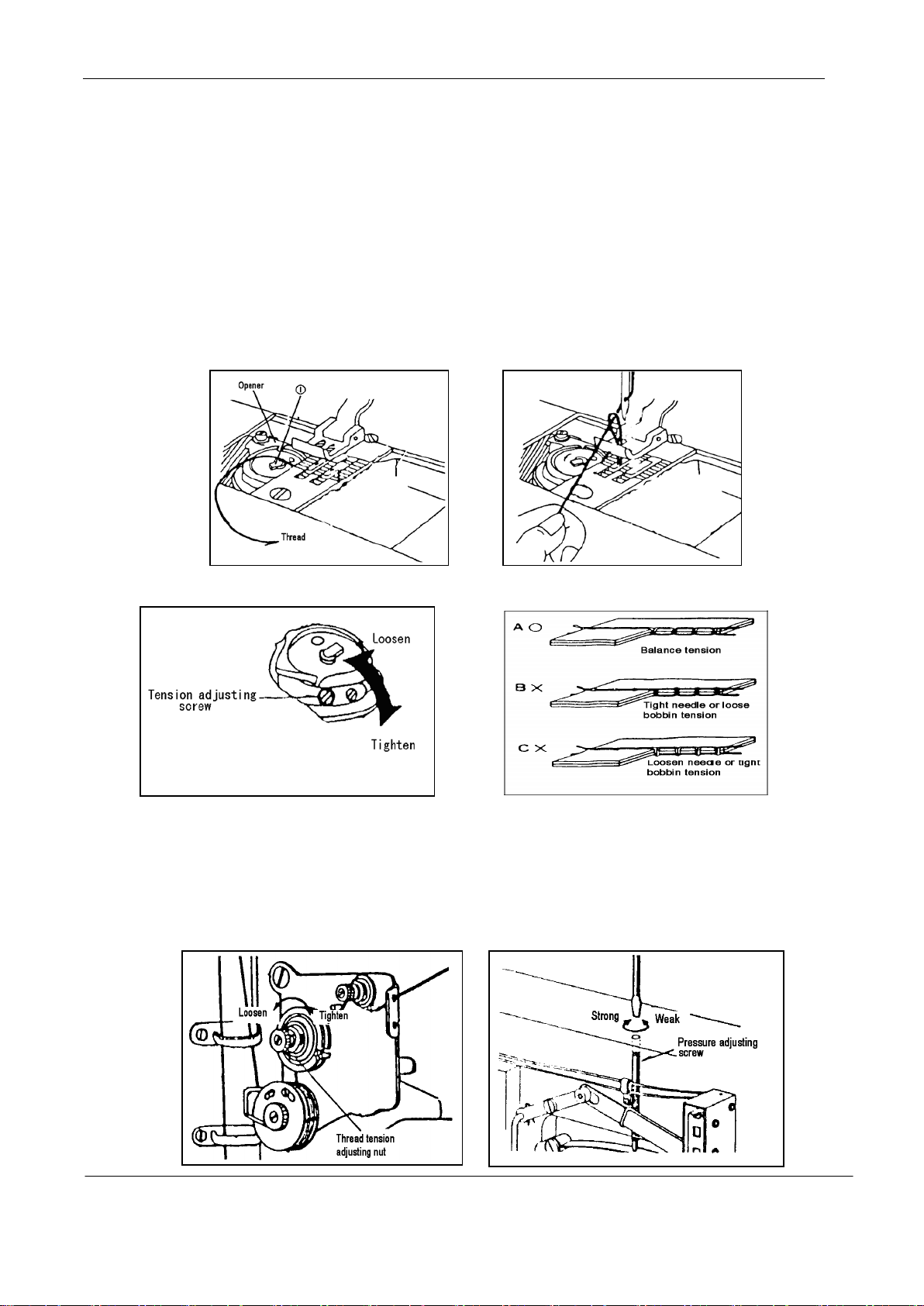

6. Tension adjustment of bobbin threads 7. Balance of thread tension

d.

8. Needle thread tension

Needle thread tension should be adjusted in reference to bobbin thread tension.

·

·To adjust needle thread tension, turn each tension adjusting nut

·N

eedle thread tension can be also adjusted for special fabric and thread by changing intensity a

ovable range of slack thread adjusting spring.

m

— 6 —

.

nd

Page 9

9. Adjustment of presser foot pressure

Pressure to fabric(s) can be adjusted by turning the pressure adjusting screw.

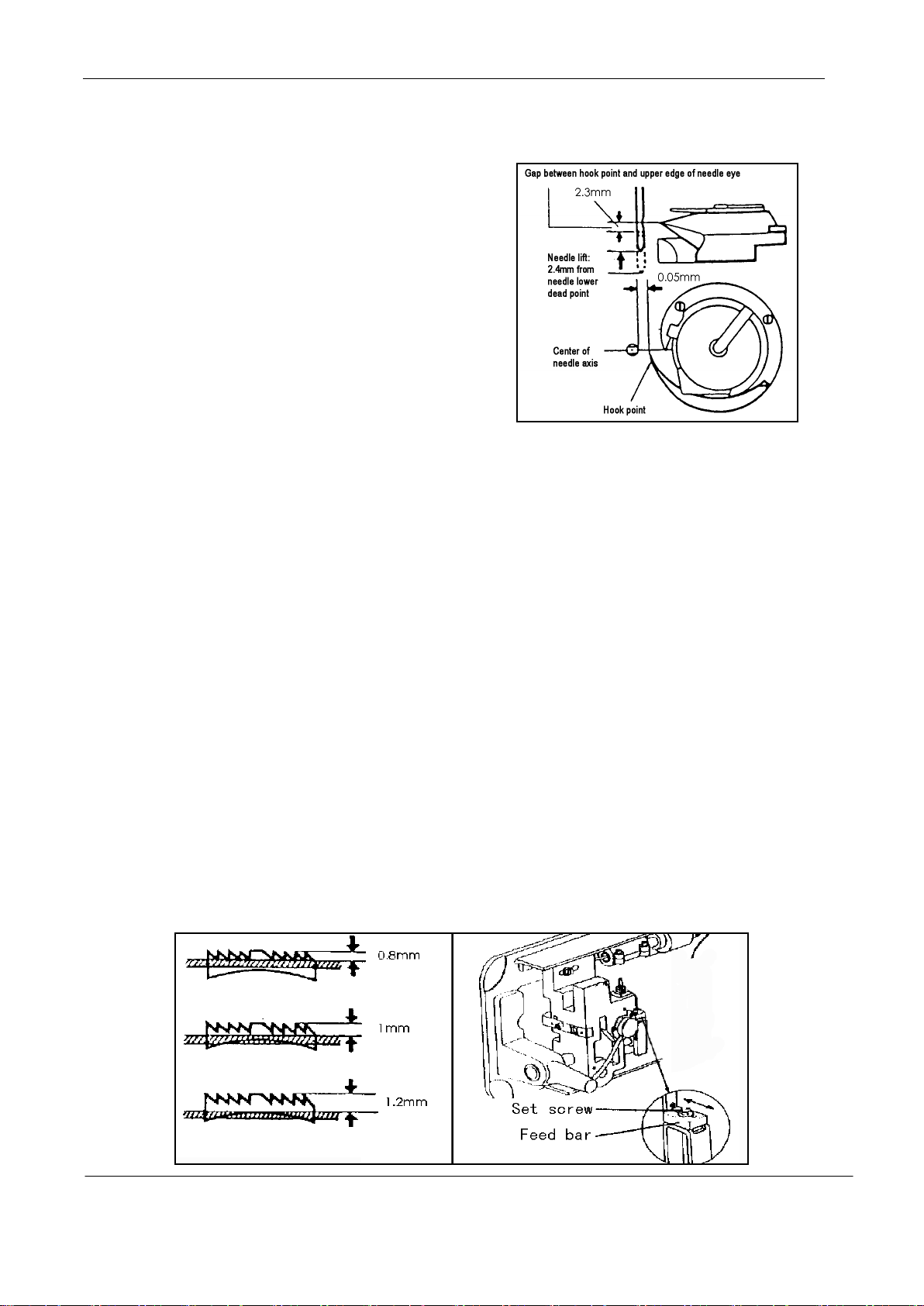

10. Timing between rotating hook motion and

needle motion

(1) Set feed length (stitch length) to “6” on the feed

etting dial.

s

(2) When needle is lifted 2.4mm from the lower dea

poi

nt, as shown in Figure, the following positiona

elationship should be maintained.

r

· The upper edge of needle eye should be 2.3mm

below the hook point

The hook point should be located at the center of needle axis.

·

· Gap between the hook point and the side face of needle s hould be 0.05mm

.

d

l

.

11. Adjustment of feed dog height

Height of feed dog and pressure of presser foot shouldbe adjusted for individual fabric(s) with the

following cautions:

· Fabric will be damaged if the feed dog extends too high,or pressure of presser foot is too large

· Even stitch length cannot be assured if the feed dog is too low or pressure of presser foot is too small.

· Feed dog height should be measured at the point where the needle is at the top position.

For light fabrics …… Approx. 0.8mm from throat plate

For usual fabrics …… Approx. 1.0mm from throat plate

For heavy fabrics …… Approx. 1.2mm from throat plate

.

Adjustment procedure

a) Lean the machine head backward.

b) Turn the hand wheel by hand and stop when the feed dog rises to the maximum height.

c

) Loosen the feed bar set screw.

d) V

e) After the adjustment, tighten the feed bar set screw.

ertically move the feed bar (in the direction indicated by arrow in the figure) to adjust it to

adequate height

The feed dog height is factory-adjusted to 1.2mm

.

— 7 —

Page 10

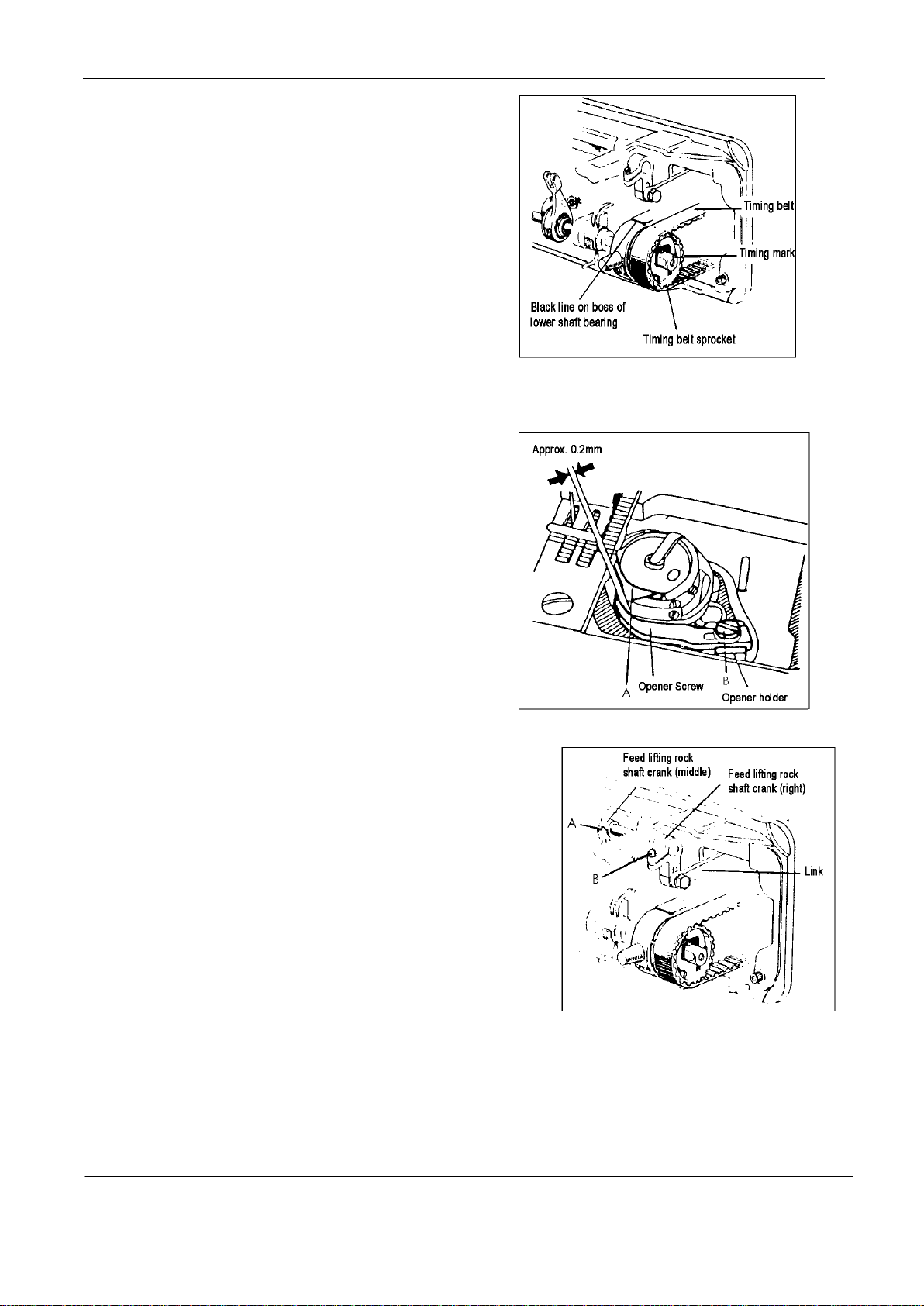

12. Relationship between rotating hook

motion and take-up lever motion

When the timing belt (toothed belt) was removed for

its replacement, for example, the relationship between

rotating hook motion and take-up lever motion should

be adjusted as follows:

a) Turn the balance wheel and stop when the take-up

lever is lifted to its upper dead point.

b) Lean the machine head backward and make sure the

arrow (timing mark) put on the timing belt is in line with the black line on the boss of lower shaft bearing.

c) If the timing mark is not in line with the black line ,remove the timing belt and install it again to

adjust.

13. Relationship between hook motion

and opener motion

a) Turn the balance wheel by hand and stop when

the opener holder is located most remotely from

the throat plate.

b) Make sure gap between the bobbin case holder A

and the opener is approximately 0.2mm.

c) If the gap is too large or small , loosen the opener

holder set screw B and adjust position of the opener.

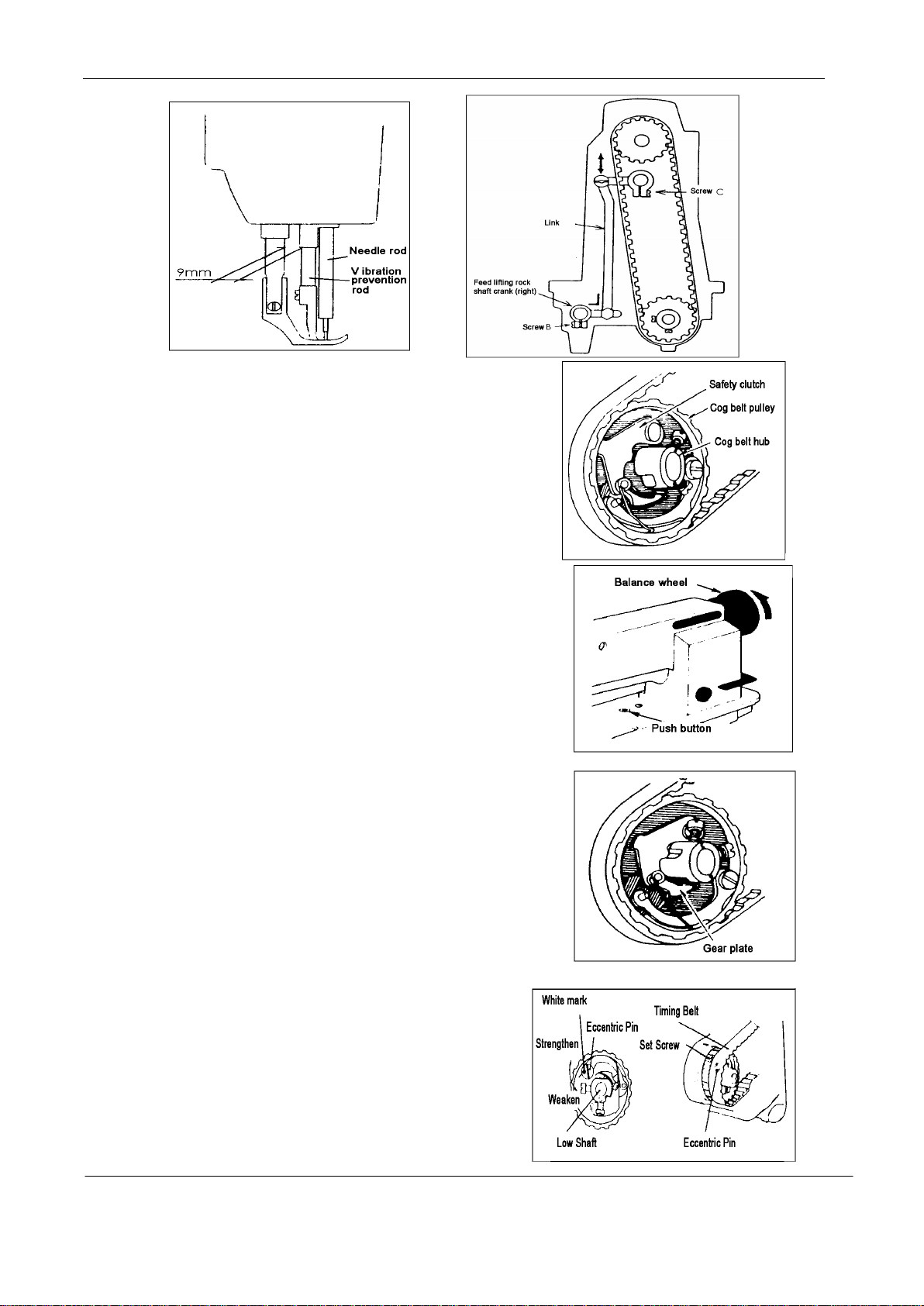

14. Relationship between needle motion and feed dog motion

a) Set feed length to “0” on the feed setting dial

b) Lean the machine head backward.

c) Loosen the feed lifting rock shaft crank set screws A and B.

d) Set the needle at the lowest position.

e) Adjust the distance between presser rod and vibrati

prevention rod to 9mm and temporarily tighten the feed

lifting rock shaft crank set screws A and B

f) Check that the right feed lifting rock shaft crank is

connected with the link at right angle, as shown in Figure.

g) If the connection is not at right angle, remove the back cover, loosen screw C and move the right link

.

on

to connect the right feed lifting rock shaft with the link at right angle.

h) After the completion of adjustment, fully tighten the screws A , B and C.

At this time make certain that needle can enter the feed dog needle hole at the center of the hole.

— 8 —

Page 11

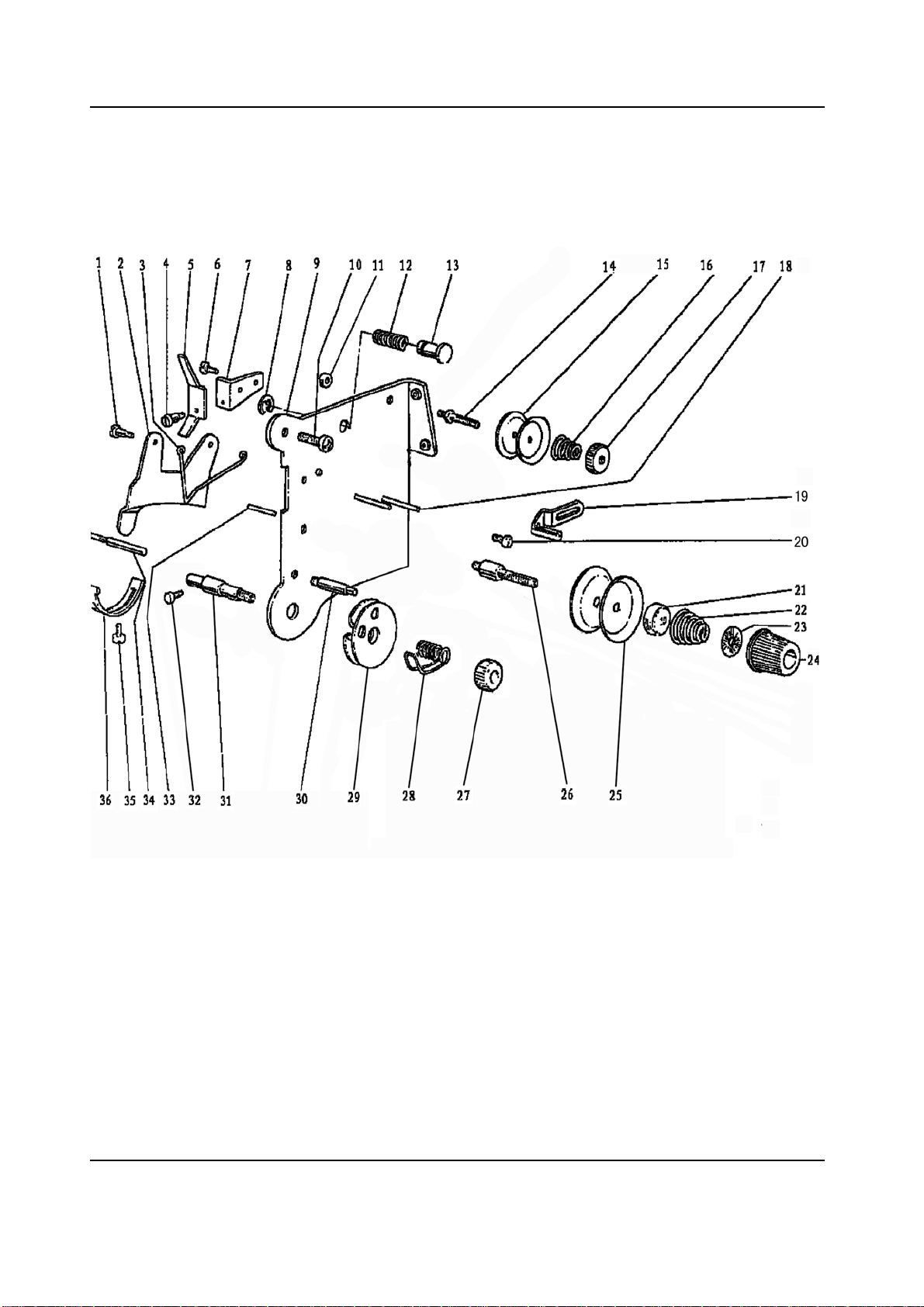

15. Safety clutch device:

Safety clutch device is installed to prevent the hook

and cog belt from damage in case the thread is

caught into the hook when the machine is loaded

abnormally during operation.

(1) Function of safety clutch.

a) When the safety clutch acts, the cog belt pulley will be

unloaded. then the rotation of hook shaft will stop.

The arm shaft only will rotate. Stop the operation of machine.

b) Clean the thread thoroughly which is caught into the hook.

c) Turn the cog belt hub by hand, and check whether the hook

Shaft rotates lightly and properly, place the clutch device

as follows.

(2) How to set the safety clutch.

a) While pressing down the push button on the opposite side

of bed by left hand, turn the balance wheel slowly by

right hand away from you as shown in the figure.

b) The balance wheel will stop by the gear plate,

but turn the balance wheel more firmly.

c) Release the push button.

d) As shown in the Figure, the safety clutch device is set.

(3) Force applied to the safety clutch.

a) The force applied to the safety clutch is the

smallest when the white mark of the eccentric pin faces

the center of the lower shaft. The force proportionally

increases as the white mark faces the outside.

— 9 —

Page 12

b) To adjust the force slide the timing belt, loosen the set screw, and turn the eccentric pin.

Model

GC20618-1E

Application

Heavy material

Max. sewing speed

1800rpm

Thread take-up lever stroke

74.5mm

Needle-bar stroke

36mm

Presser-foot stroke

16mm by Leg 8mm by hand

Needle No.

DP×17 18#-23#

Lubrication system

Automatic lubrication

Motor

Clutch motor 370W

c) After the adjustment, make sure to fasten the set screw.

16. Upper feed adjustment (Needle side)

If the uneven feeding occurs according to the fabric,

Adjust the long hole of the horizontal feed shaft crank

(right) to adjust the upper feed length. (How to adjust)

a) Loosen the special bolt.

ove the special bolt upward to decrease upper feed.

b) M

c) Move the special bolt downward to increase the upper feed. The upper feed and the lower f

t

heoretically becomes equal at the reference line on the horizontal feed shaft crank.

d) Securely tighten the special bolt after adjustment.

17. Outside presser foot and inside presser vertical stroke adjustment

When fabric with large elasticity is sewn, or when thickness of fabric changes, the vertical stroke

(movable range) of the presser feet should be adjusted as follows:

Adjustment

a) Loosen the special bolt.

b) The vertical strokes of the presser feet becom

m

aximum when the crank rod is moved upward and set

c) T

he vertical strokes becomes minimum when the nut

is moved downward and set.

d) A

fter the adjustment, fully tighten the special bolt.

The vertical strokes of the presser feet can be adjusted within a range from 6mm to 2mm.

e

.

SPECIFICATIONS

eed

Stitch length

Vertical stroke of upper feed

Edge binder 8mm(Standard)

— 10 —

0~10mm

2~6mm

Page 13

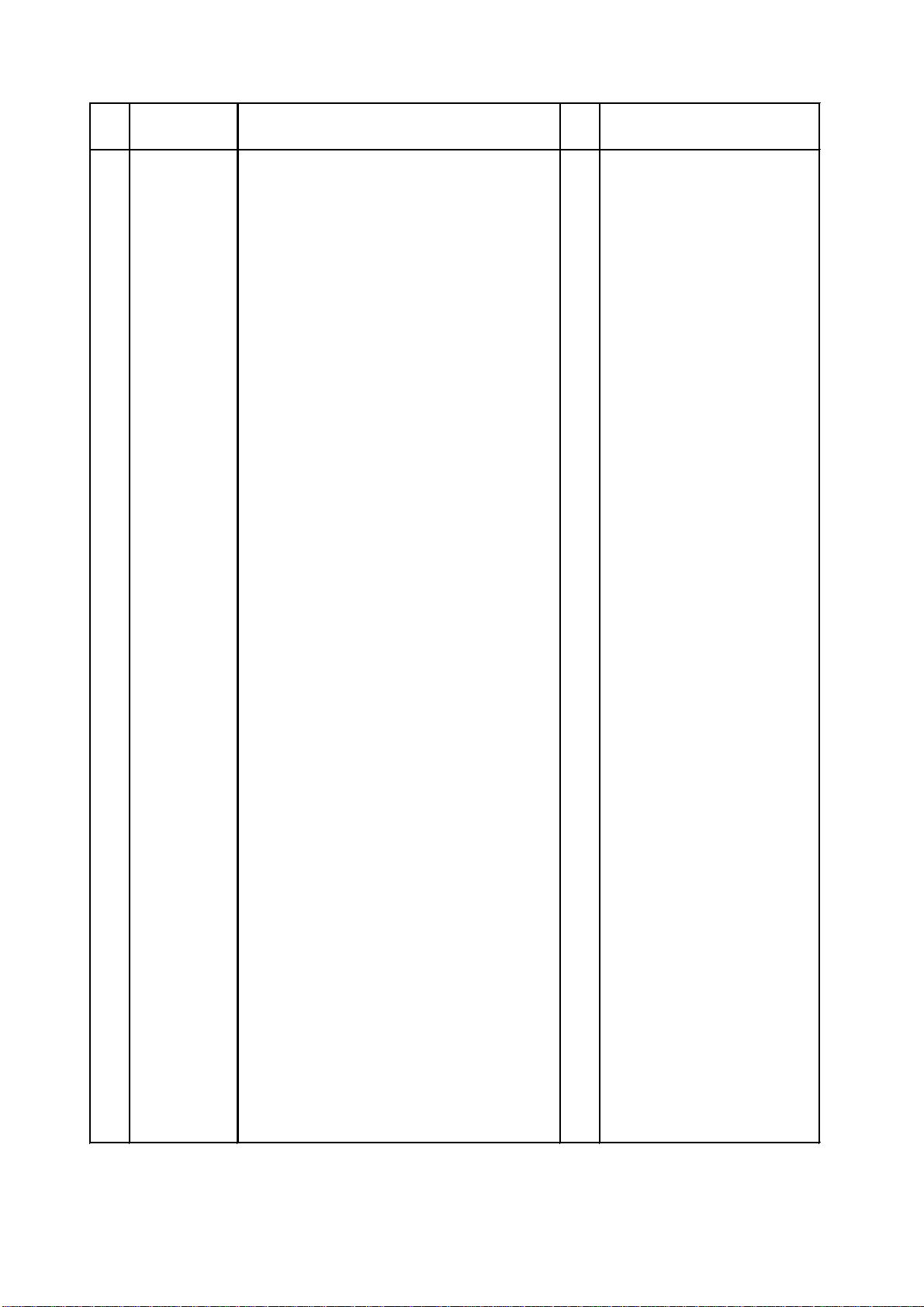

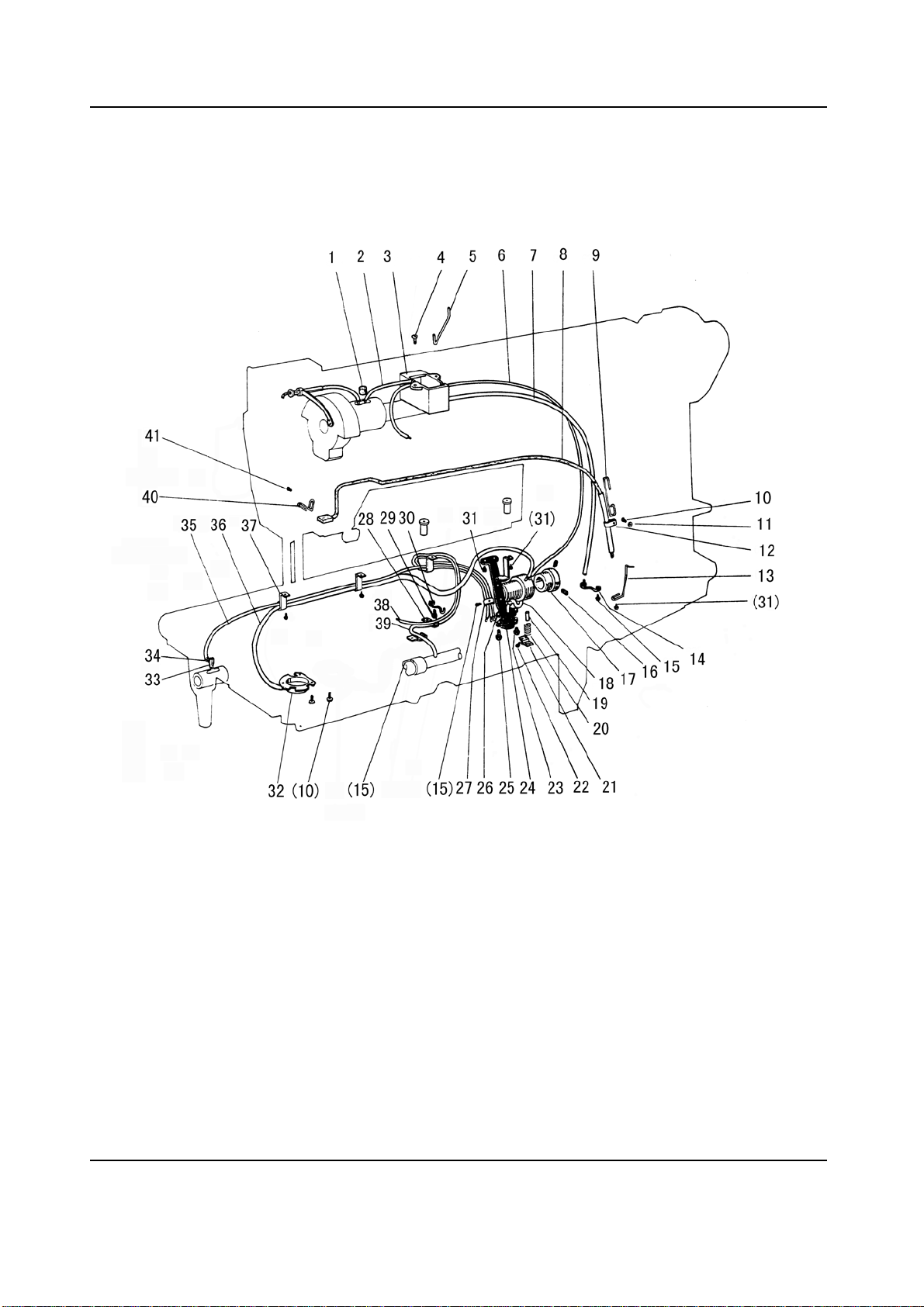

A.ARM BED AND ITS ACCESSORIES

— 11 —

Page 14

A.ARM BED AND ITS ACCESSORIES

Fig.

No.

A01

A02

A03

A04

A05

A06

A07

A08

A09

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A22

A23

A24

A25

A26

A27

A28

A29

A30

A31

A32

A33

A34

A35

A36

A37

A38

A39

A40

Part No. Description Pcs. Remarks

HA300B2090

HA300B2170

H4716B8001

H4717B8001

H4715B8001

H4718B8001

H2000B2010

H4719B8001

HA700B2060

H2400B2100

HA307B0673

H2000M0080

HM41B98001

HN11B28001

HM41B88001

HN11B18001

HM32B47101

H3200I2030

H415040060

HN11B38001

H4722E8001

HA719B7011

HN10B88001

H5332B8001

HN10B98001

HA300B2190

H4732B8001

H4722B8001

H4723B8001

H4724B8001

H4725B8001

H3200B2100

H3000D2160

H4726B8001

H4727B8001

H2400B2080

H2400B2070

H4730B8001

H2400B2060

H3200B2060

Rubber plug 2

Screw 15 SM11/64(40)×8

Oil guard plate 1

Thread take-up cover 1

Rubber plug 1 φ13

Side cover (left) 1

Rubber plug 1 φ13

Side cover (right) 1

Screw 2 SM11/64(40)×8

Thread guide 1

Rubber plug 1

Cap 2

Screw 1

Screw 1

Lever 1

Single needle binders mounting plate 1

Single needle binders 1

Washer 2

Screw 2

Mounting plate 1

Washer 1

Screw 1

Side cover 1

Screw 3

Needle plate 1

Screw 2 SM11/64(40)×8

Slide plate 1

Screw 1 SM1/8(44)×3

Spring 1

late 1

P

Thread guide 1

Screw 1 SM9/64(40)×6.5

Screw 1 SM9/64(40)×6.5

Thread guide (middle) 1

Face plate 1

Screw 2 SM3/16(28)×11

Thread guide (upper) 1

Guide mounting plate 1

Plate for oil guard 1

Oil guard 1

— 12 —

Page 15

B.THREAD TENSION REGULATOR MECHANISM

— 13 —

Page 16

B.THREAD TENSION REGULATOR MECHANISM

Fig.

No.

B01

B02

B03

B04

B05

B06

B07

B08

B09

B10

B11

B12

B13

B14

B15

B16

B17

B18

B19

B20

B21

B22

B23

B24

B25

B26

B27

B28

B29

B30

B31

B32

B33

B34

B35

B36

Part No. Description Pcs. Remarks

H3221B6811

H3221B3142

H3221B6812

H4705C8001

H4706C8001

HA7311C306

H4707C8001

H007013050

H3221B6820

HA300C2030

H3221B6810

H4708C8001

H4709C8001

H3221B0683

HA112B0693

H3221B0684

HA710B0671

H3221B0682

H3306B0661

HA106B0676

HA310B0702

H4710C8001

HA115B7010

HA310B0701

HA310B0705

H3221B0686

H32481B721

H4713C8001

H32481BD21

H4804C8001

H4805C8001

H3230K0751

H3221B6817

H3221B6818

H3200B2100

H3221B6819

Screw 2 SM9/64(40)×3

Tension releasing pl ate 1

Tension releasing spring 1

Screw 1 SM9/64(40)×4.2

Lever 1

Screw 1 SM9/64(40)×4.5

Mounting plate 1

Stop ring 1 GB/T896 5

Mounting plate 1

Screw 2

Nut 1 SM11/64(40)

Spring 1

Push button 1

Thread tension stud 1

Thread tension disk 2

Thread tension spring 1

Thumb nut 1

Pin 2

Thread guide 1

Screw 1 SM9/64(40)×6

Thread tension rel eas ing plate 1

Thread tension spring 1

Thumb nut revolution stopper 1

Thumb nut complete 1

Thread tension disk 2

Thread tension stud 1

Thumb nut 1 SM1/4(40)

Thread take-up spring 1

P

late complete 1

Screw 1

Thread tension stud 1

Screw 1 SM11/64(40)×10

Pin 1

Tension releasing pin 1

Screw 1 SM9/64(40)×6.5

Stopper 1

— 14 —

Page 17

C. ARM SHAFT MECHANISM

— 15 —

Page 18

C.ARM SHAFT MECHANISM

Fig.

No.

C01

C02

C03

C04

C05

C06

C07

C08

C09

C10

C11

C12

C13

C14

C15

C16

C17

C18

C19

C20

C21

C22

C23

C24

C25

C26

C27

C28

C29

C30

C31

C32

Part No. Description Pcs. Remarks

HA307C0662

H4706D8001

HA105D0662

HA100C2060

HA100C2070

H32111B204

H4708D8001

H32111B104

H4709D8001

H3205C0661

HA113F0684

H3205C1021

HA100F2130

H3205J0662

H3205J0661

HA113F0684

HF60D58001

HA110D0672

H3200C2030

H4713D8001

H4714D8001

H4715D8001

H007013025

H4716D8001

H4717D8001

H4718D8001

H4719D8001

H4720D8001

H4721D8001

HA104F0654

H4722D8001

H4723D8001

Set screw 1 SM1/4(40)×7

Crank 1

Screw 1 SM1/4(40)×3.5

Set screw 1 SM9/32(28)×14

Screw 1 SM9/32(28)×13

Arm shaft bushing (left) 1

Screw 1 SM1/4(24)×13

Felt 1

Arm sha ft 1

Spring flange 3

Screw 1 SM15/64(28)×8.5

Belt pulley (upper) 1

Screw 1 SM15/64(28)×14.5

Bearing 1

Collar 1

Screw 2 SM15/64(28)×8.5

Pulley 1

Screw 2 SM11/64(28)×12

Cog belt 1

Spring plate 1

Pin 1

Link 1

E-type stop ring 1 GB/T896 2.5

Twist spring 1

Plate 1

Pin 1

te 1

Pla

Bushing 1

Screw 1 SM15/64(28)×10.5

Screw 1 SM15/64(28)×10

Belt pulley (lower) 1

Screw 2 SM15/64(28)×4.5

— 16 —

Page 19

D.UPPER SHAFT & PRESSER FOOT MECHANISM

— 17 —

Page 20

D.UPPER SHAFT & PRESSER FOOT MECHANISM

Fig.

No.

D01

D02

D03

D04

D05

D06

D07

D08

D09

D10

D11

D12

D13

D14

D15

D16

D17

D18

D19

D20

D21

D22

D23

D24

D25

D26

D27

D2

D29

D30

D31

D32

D33

D34

D35

D36

D37

D38

D39

D40

D41

D42

D43

Part No. Description Pcs. Remarks

Feed lifting rock shaft 1

Screw 2 SM1/4(24)×7

Bushing 2

Nut 1 M6×0.75

Lever 1

Screw 1 SM1/4(28)×16

Washer 1

Connecting rod 1

Bolt 1

Oil pipe & wick complete 1

Spring 1

C-type stop ring 1 GB/T894.1 25

Eccentric 1

Screw 2 SM1/4(40)×6

Screw 1 SM1/4(24)×14

Knee lifter lifting lever complete 1

Snap pin 1

Operation rod 1

Collar 1

Screw 1 SM11/64(40)×5.5

Screw 1 SM1/4(24)×17

Lever spring 1

Screw 1 SM15/64(28)×79

Twist spring 1

Knee lifting lever 1

Screw 1 SM1/4(24)×7

Nut

Screw 1 SM1/4(24)×19

Screw 2 SM11/64(40)×12

Guide 1

Bushing 1

Presser bar 1

Screw 1 SM1/8(44)×9

Spring bracket 1

Thread releasing plate 1

Screw 1 SM9/64(40)×8.5

Lifter lever 1

Spring 1

Bracket 1

Screw 1 SM11/64(40)×8.5

Bell crank 1

Support shaft 1

Roller 1

1

8

H4705E8001

H4706E8001

H4707E8001

HS91165206

H4709E8001

H3115F0671

H2013J0065

H2014J0066

H2000J2100

H4713E8001

H20111C106

H007009250

H4714E8001

HA307C0662

H4732E8001

H4735E8001

H4739E8001

H4738E8001

H4741E8001

H4742E8001

H3100G2170

H4730E8001

H4729E8001

H4727E8001

H4728E8001

H3100G2130

H4726E8001

H4725E8001

HA111G0683

H4723E8001

H4744E8001

H4754E8001

H3200E2020

H4746E8001

H4768E8001

H2404I0034

H4748E8001

H4767E8001

H4752E8001

H4749E8001

H4715E8001

H2004J0655

H4717E8001

— 18 —

Page 21

D.UPPER SHAFT & PRESSER FOOT MECHANISM

Fig.

No.

D44

D45

D46

D47

D48

D49

D50

D51

D52

Part No. Description Pcs. Remarks

H4718E8001

H2004J0662

H4719E8001

HA100E2150

H4722E8001

H4721E8001

H4753E8001

H4708D8001

HN10E48001

Screw 1 SM11/64(32)×6

Screw 1 SM1/4(40)×5

Link 1

Screw 2 SM11/64(40)×10

Washer 2

Bell crank guide 1

Screw 1 SM11/64(40)×14.5

Screw 2 SM1/4(24)×13

Lifting presser foot 1

— 19 —

Page 22

E.NEEDLE BAR & THREAD TAKE-UP LEVER MECHANISM

— 20 —

Page 23

E.NEEDLE BAR & THREAD TAKE-UP LEVER MECHANISM

Fig.

No.

E01

E02

E03

E04

E05

E06

E07

E08

E09

E10

E11

E12

E13

E14

E15

E16

E17

E18

E19

E20

E21

E22

E23

E24

E25

E26

E27

E28

E29

E30

E31

E32

E33

E34

E35

E36

E37

E38

E39

E40

E41

E42

E43

Part No. Description Pcs. Remarks

H24211DN05

H4706F8001

H4707F8001

HA100C2020

H24211DN05

H24211DM05

H4712F8001

H2405D1112

H24211D405

H24211D305

HA110D0672

H2405D0662

H4716F8001

H4717F8001

H4719F8001

H32111D304

H4721F8001

H3204D6513

H4722F8001

H32111D604

H4806F8001

H4725F8001

H3400C2020

H3200I2030

H3400C2010

H4726F8001

H4753E8001

H4728F8001

H4729F8001

H4730F8001

H3410C301P

H3406C0671

H3406C0672

H602040240

H4734F8001

H4736F8001

H3204B0652

H2012N0652

H3407C0661

H32311D506

H3407C0662

H32311D306

H32311D406

Oil wick 1

Needle bar guide bracket s tud 1

Screw 1 SM5/16(28)×10.4

Screw 1 SM15/64(28)×10

Oil wick 1

Thread take-up lever support stud 1

Thread take-up lever 1

Thread take-up slide brock 1

Oil wick 1

Plug 1

Screw 1 SM15/64(28)×12

Needle bar crank pin 1

Oil wick 1

Connecting link 1

Needle bar guide bracket 1

Screw 6 SM3/32(56)×4

Spacer 2

Felt 1

Needle bar holder 1

Screw 1 SM9/64(40)×8.5

Needle bar 1

Vibrating press er bar 1

Screw 1

Washer 1

Needle bar guide 1

Vibrating presser bar link 1

Screw 2 SM11/64(40)×17.5

Vibrating presser bar guide 1

S

pring 1

Vibrating presser spring guide 1

Square block 1

Crank pin 1 SM15/64(28)×10

Needle bar vibratin g crank (left) 1

Taper 1 GB/T117 4×24

Collar 1

Needle bar vibratin g shaft 1

Needle bar vibrating shaft bushing 2

Screw 1 SM1/4(24)×16

Needle bar vibratin g crank (right) 1

Nut 1

Connecting link 1

Screw 1 SM5/16(24)

Oil wick 1

— 21 —

Page 24

E.NEEDLE BAR & THREAD TAKE-UP LEVER MECHANISM

Fig.

No.

E44

E45

E46

E47

E48

E49

Part No. Description Pcs. Remarks

H3129F0691

HA100C2170

H3129F0693

H4740F8001

HA700F2100

HN10F48001

Screw 1 SM3/32(56)×2.5

Screw 1 SM1/8(44)×4.5

Thread guide 1

Needle 1

Screw 1 SM11/64(40)×7

Presser loot complete 1

— 22 —

Page 25

F.LOWER SHAFT & FEED ROCK SHAFT MECHANISM

— 23 —

Page 26

F.LOWER SHAFT & FEED ROCK SHAFT MECHANISM

Fig.

No.

F01

F02

F03

F04

F05

F06

F07

F08

F09

F10

F11

F12

F13

F14

F15

F16

F17

F18

F19

F20

F21

F22

F23

F24

F25

F26

F27

F28

F29

F30

F31

F32

F33

F34

F35

F36

F37

F38

F39

F40

F41

F42

F43

Part No. Description Pcs. Remarks

H4706H8001

H4707H8001

HF60H48001

HN10H58001

HN10H68001

H4712H8001

H007013050

H4714H8001

HF60H78001

HF61H08001

H2405D0664

H4719H8001

HF62H48001

H007009260

HF60H97101

HF60H87101

H4722H7101

H4725H8001

HA105D0662

H3205H0654

H4723H8001

H4727H8001

HA7311C306

H4729H8001

H4728H8001

H003055060

H4731H8001

H2012N0652

HA100G2120

H4708D8001

HA108G0661

HA105D0662

H4736H8001

H2012N0652

HA304G0656

H3204G0651

H4740H8001

HA104G0012

H3205G1032

H3204G0031

H3200G2030

H3205G0662

HF62H68001

Lower shaft bushing (left) 1

Oil wick 1

Lower shaft 1

Feed eccentric cam 1

Screw 1 SM1/4(40)×4.3

Lower shaft bushing (right) 1

Stop ring 4 GB/T896 5

Spring 2

Push button 2

Stopper 1

Screw 4 SM15/64(28)×14

Bearing 1

Feed connecting rod 1

Stop ring 1

Feed ragulator comp 1

Feed connecting rod comp 1

Lower shaft bushing complete (middle) 1

Bushing 1

Screw 1 SM1/4(40)×4

Screw 1 SM1/4(40)×5

Ball bearing 1

Bearing holder 1

Screw 3 SM9/64(40)×7

Screw 1 M6

Washer 1

Nut 1 GB52008 M6

Feed connection crank (right) 1

Screw 1 SM1/4(24)×16

Feed rock shaft bushing 2

crew 2 SM1/4(24)×13

S

Collar 2

Screw 4 SM1/4(40)×4

Feed connection crank (middle) 1

Screw 1 SM1/4(24)×16

Screw 1 SM3/16(28)×15

Feed rock shaft 1

Felt 2

Screw 2 SM3/16(28)×12

Feed connectio n crank (left) 1

Oil wick 1

Clip 1

Oil wick 1

Shaft for feed connecting rod 1

— 24 —

Page 27

F.LOWER SHAFT & FEED ROCK SHAFT MECHANISM

Fig.

No.

F44

F45

F46

F47

F48

F49

F50

F51

F52

F53

F54

Part No. Description Pcs. Remarks

H32243G205

H3205G0662

H429050050

H4805H8001

HN10H87101

H32211G205

H3200H2040

H2013J0065

H3205H0653

H3205H0652

H4743H8001

Feed bar shaft 1

Oil wick 1

Bolt 1 GB/T78 M5×5

Feed bar 1

Feed dog 1

Bolt 2 SM1/8(40)×7

Screw 1 SM15/64(28)×17

Washer 1

Screw 1 SM1/8(44)×4

Felt 1

Feed bar forked connection 1

— 25 —

Page 28

G.HOOK SADDLE MECHANISM

— 26 —

Page 29

G.HOOK SADDLE MECHANISM

Fig.

No.

G01

G02

G03

G04

G05

G06

G07

G08

G09

G10

G11

G12

G13

G14

G15

G16

G17

G18

G19

G20

G21

G22

G23

G24

G25

G26

G27

G28

Part No. Description Pcs. Remarks

H3304I0651

H3207I0661

H3207I0662

H33121I104

H33121I204

H33131I204

H4708I7101

H3306I0067

H3204I0656

H32153I204

H32153I504

H33131I104

H005008050

HA104G0658

H2004J0067

H3200I2030

H3305I0066

H4707I8001

H4706I8001

H4708I8001

H4705I8001

H4709I8001

H3204I0653

H3204I0658

H3204I0659

H2013J0065

H3200I2050

H3204I0657

Hook saddle (left) 1

Screw 1 SM15/64(28)×22

Bushing 1

Hook shaft bushing (upper) 1

Washer 1

Link 1

Hook complete 1

Bobbin 1

Oil wick 2

Screw 1 SM3/16(32)×7.8

Opener bracket shaft 1

Opener bracket 1

Spring washer 1 GB/T93 5

Nut 1

Screw 1

Washer 1

Opener 1

Screw 3 SM1/4(40)×4

Hook driving gear (large) 1

Screw 1 SM1/4(40)×6.5

Hook driving gear (small) 1

Screw 1 SM1/4(40)×5

Hook shaft bushing (lower) 1

Screw 1

Nut 1

Washer 1

Screw 1 SM1/4(24)×23

Screw 1

SM3/16(

28)×14.5

— 27 —

Page 30

H.OIL LUBRICATION MECHANISM

— 28 —

Page 31

H.OIL LUBRICATION MECHANISM

Fig.

No.

H01

H02

H03

H04

H05

H06

H07

H08

H09

H10

H11

H12

H13

H14

H15

H16

H17

H18

H19

H20

H21

H22

H23

H24

H25

H26

H27

H28

H29

H30

H31

H32

H33

H34

H35

H36

H37

H38

H39

H40

H41

Part No. Description Pcs. Remarks

H32175B304

H4705J7101

H3204K0011

H411040160

H4707J8001

H4708J8001

H4709J8001

H4711J7101

H4713J8001

HA7311CC06

HA100I2050

H2000M0110

H4714J8001

H4715J8001

HA106B0676

H3230K0751

H4716J8001

H3215K0696

H1100I2070

H1100I2090

H1100I2110

H3204D6510

H3215K0693

H3215K0692

H3215K0694

H4718J7101

H3215K0695

H3200K0170

HA7311CC06

H3210K0674

HA100E2150

H3211K0068

H2000M0110

H3200K0180

H4735J8001

HM90M48001

H3200K0160

H4725J7101

H4728J7101

H4731J8001

HA300C2030

Felt 1

Oil pipe complete 1

Oil reservoir complete 1

Screw 2 GB/T819.1 M4×16

Holder 1

Oil pipe Ф3×1×400 1

Oil pipe Ф5×1×360 1

Oil reservoir complete 1

Holder 1

Screw 4 SM9/64(40)×6.5

Spring washer 1

Holder 1

Holder 1

Holder 1

Screw 8 SM9/64(40)×4.5

Screw 2

Bushing 1

Oil pipe 1

Pin 1

Spring 1

Spring holder 1

Screw 1 SM1/8(44)×4.5

Screw 1 SM9/64(40)×5

Filter 1

Screw 1 SM9/64(40)×7

Mounting plate complete 1

Holder 1

Holder 1

Screw 1 SM9

Holder 1

Screw 4 SM11/64(40)×9

Oil reservoir complete 1

Holder 3

Oil wick Ф2.5×35 3

Oil pipe 1

Oil pipe Ф3×1×535 1

Holder 3

Oil wick 1

Oil wick 1

Holder 1

Screw 1

/64(40)×6.5

— 29 —

Page 32

I.ACCESSORIES

— 30 —

Page 33

eat

I.ACCESSORIES

Fig.

No.

I01

I03

I05

I06

I07

I08

I09

I10

I11

I12

I13

I17

I18

I19

I22

I24

I27

I28

I29

I30

I31

I32

I33

I34

I35

I36

I37

I38

I39

I40

I41

I42

I43

I44

I45

I46

I47

Part No. Description Pcs. Remarks

H4740F8001

H3208L8001

H3306I0067

H3200L0050

H801045200

H4700K0020

H4700K0030

HA100J2110

HA100J2140

HA100J2150

H3207L0065

HA300J2170

HA200J2030

H3300L0040

HA300J2280

HH404I7101

HA100J2120

HA307J0067

HA300J2070

H3214L0067

H3214L2011

H3213L0662

HA104J0657

HA106J0664

HA104J6510

HA104J0659

H3213L0664

H007013090

HA104J0653

HA104J0652

H3213L0661

HA100J2180

H7323H8001

H7320H7101

H801055250

HA300J2230

H7326H8001

Needle DP×17-23 3

Socket wrench 1

Bobbin 2

Screw 2

Vibration preventing rubber 4 GB/T99 4.5×20

Vibration preventing rubber 2

Vibration preventing rubber 2

Oiler 1

Screw driver (middle) 1

Screw driver (small) 1

Thread a needle kit 1

Oil can 1

Cotton stand 1

Bobbin winder 1

Screw 2 SM11/64(28)×8

Belt cover complete 1

Magnet block for reservoi r 1

Hinge complete 2

Screw driver (large) 1

Small parts 1

Knee lifter pin 1

Knee lift shaft 1

Spring 1

Bolt 1

Nut 2

Screw 2

Knee lifter crank 1

E-type stop ring 1 GB/T896 9

Washer 1

Screw 1

Oil reservoir 1

Vinyl cover 1

Shelf 1

Plate complete 1

Screw 2

Washer 1

S

1

— 31 —

Page 34

2010.9. Printed

Loading...

Loading...