Page 1

Customer

Copy

HIGHLEAD

GC20528 series

Service

Twin-Needle High Speed Split Needle

Sewing Machine

Instruction Manual

Parts

Catalog

Bar

Lockstitch

SHANGHAI HUIGONG

N0.3

SEWING MACHINE FACTORY

Page 2

CONTENTS

PRECAUTIONS

PREPARATION

1.

Power

cable connection

2.

Connection

3.

Adjustment

CAUTIONS

1.

Oiling

(I)

2.

Oiling (2) -------------------------------4

3.

Oiling condition --------------------4

4.

Adjustment

5.

Cautions

BEFORE

FOR

of

control

of

needle

ON

USE

of

oiling

on operation

STARTING

OPERATION

-------------------------------------- 1

OPERATION

----------------------------------------------2

box

----------------------------------------3

bar

stop

1 -

to

rotating

position

hook

--------------------------------------3

---------------------------------------4

--------------------------------------

-------------------------------------5

OPERATION

1.

Installation

2.

Winding

3.

Selection·ofthread --6

4.

Threading

5.

Adjustment

6.

Setting

7.

Adjusting

8.

Threading

9.

Tension

10.

Balance

11.

Needle

12.

Adjustment

13.

Timing

14.

Adjustment

15.

Relationship

16.

Relationship

17.

Relationship

18.

Installation

19.

Adjustment

20.

Adjustment

21.

Sharpening

of

needles---------

of

bobbin

of

needle

offeed (stitch)

of

bobbin

of

needle

of

bobbin

adjustment

of

thread

thread

tension

of

presser

between

rotating

of

feed

between

between

between

of

movable

of

thread

of

meshing

of

fixed

------------------------------------------

thread ----------------------------------6

threads ------------6

length

and

stitch

reversing

-----------------------------7

thread

guide

threads

of

bobbin

tension

dog

--....-------------

-----------------

foot

p~essure

hook

height-------------------'---------------------------rotating

hook.motion

needle

knife-----------------------------------------------

trimmer

pressure

knife

__________

----------------------------------------7

------threads

motion

hook

motion

cam

and

needle

motion

and

of

movable

and

opener

and

---------------------------

feed

motion

dog

knife

(touch-back) --------------------------- 7

------------------8

---------------8

---------------·---------------------8

----8

-------------------9

motion----------------------------------------9

take-up

lever

motion

----------------------

motion

and

------------

fixed

knife

_,______

------------------------

--------------

--- 1 1

------

5

5

10

10

11

12

13

14

14

22.

Adjustment

23.

Wiper

for

change

adjustment --------------

of

needle

gage-----------------

SPECIFICATIONS

PARTS

1.

2.

3.

CATALOG

Arm

bed

its

Thread

Arm

tension regulator

shaft & presser

accessories----------·-------

mechanism-------------------------------·

foot

mechanism

-------

----------

15

16

17

18

20

23

Page 3

4.

Needle bar rocking motion mechanism

5.

Stitch regulator mechanism

-------------------------------------------------------

-------------------------------------------------------------------

26

28

6. Lower shaft & feed rock shaft mechanism

7.

Hook saddle mechanism

8.

Knife

mechanism(

9. Knife mechanism ( = )

I 0. Touch back mechanism & detector mechanism

11.

Wiper mechanism

12.

Oil lubrication mechanism

13.

Accessories

GAUGE

PARTS

------------------------------------------------------------------------------------

LIAT

-----------------------------------------------------------------------

- )

-·---

-----------------------------------------------------------------------

-------------------------------------------------

--------------------------------------------------------------------

-----------------------------------------------------------

-------------------------------------------------------------------------

----------------------------------------------------

--------------------:--------------------------

·--------------------------

30

33

36

3 8

41

43

45

48

51

Page 4

PRECAUTIONS BEFORES STARING OPERATION

1.

Safety precautions

I) When turning the power on, keep your hands and fingers away from the area around/under

the needle and the area around the pulley.

off

2) Power must be turned

3) The power must be turned

belt, adjusting the machine, or when replacing.

4) Avoid placing fingers, hairs, bars etc. near the pulley,

when the machine is operation. Injury could result.

5) Do not insert fingers into the thread take-up cover, under/round the needle, or pulley when

the machine is in operation.

If

a belt cover, finger guard, and/or eye guard are installed, do not operate the machine without

6)

these safety devices.

2.

Precaution before Starting Operation

when the machine

off

before tilting the machine head, installing or removing the

is

not used, or when the operator leaves his/her seat.

"V"

belt, bobbin winder pulley, or motor

"V"

I) If the machine's oil pan has an oil sump, never operate the machine before filling

2)

If

the machine is lubricated by a drop oiler, never operate the machine before lubricating.

is

3) When a new sewing machine

power on. (the pulley should rotate counterclockwise when viewed from the pulley.)

4)

Verify

the voltage and (single or three) phase with these given on the motor nameplate.

first turned on, verify the rotational direction

it.

of

the pulley with the

3. Precaution for Operating Conditions

I) Avoid using the machine at abnormally high temperature (35°C or higher) or low temperature (S°Cor

lower). Otherwise, machine failure may result.

in

2) Avoid using the machine

Avoid using the machine

welder and others,

is

dusty conditions.

in

areas where too much electrical noise, resulted from the high-frequency

generated.

-1-

Page 5

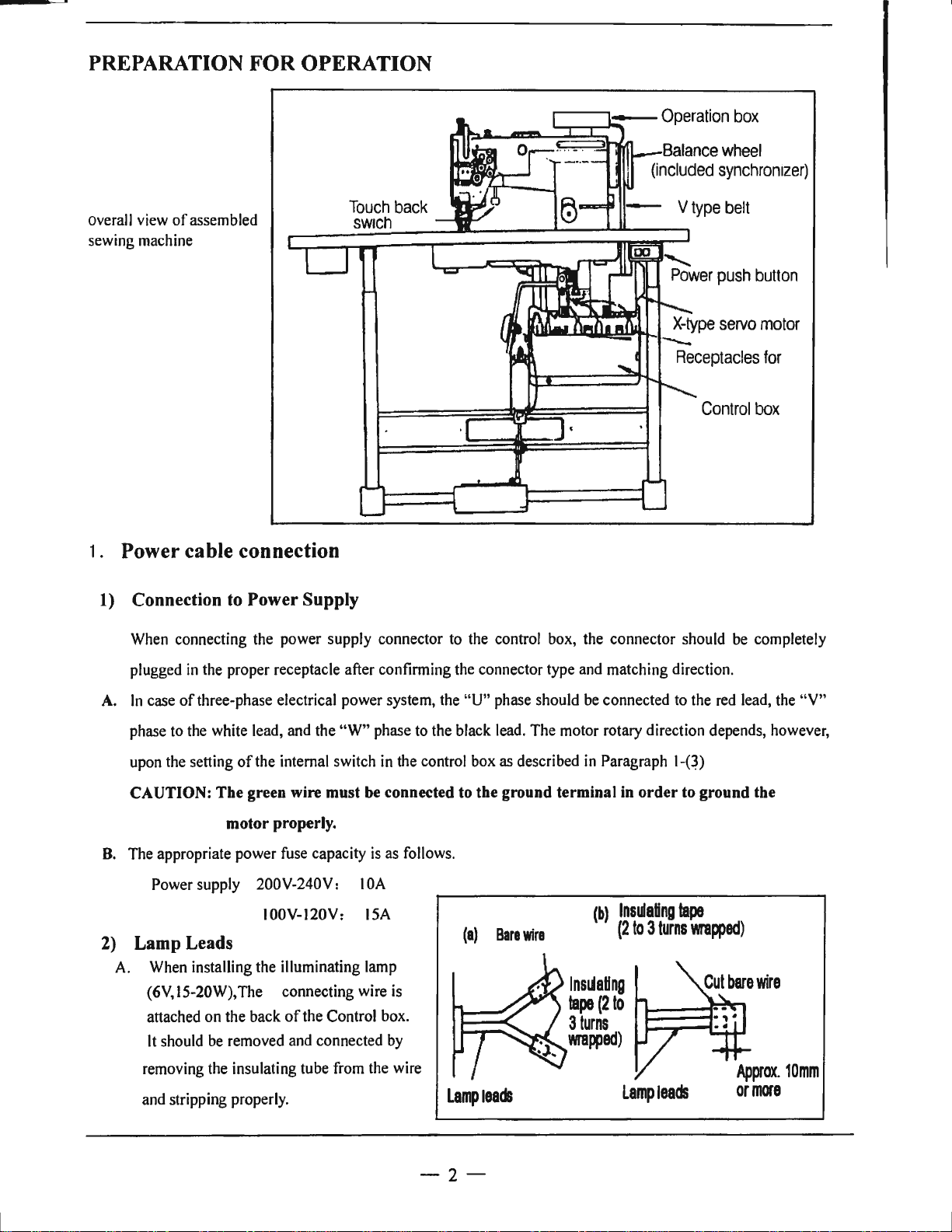

PREPARATION

FOR

OPERATION

overall view

sewing machine

of

assembled

1. Power cable connection

1)

Connection

to

Power Supply

!:-.:--::~:?n.Jr'P,._-Balance

(included

1------r----1:.-:...-:...-:...-_-_-_-

_-

_-

_---r_,

wheel

synchronizer)

Control

box

When connecting the power supply connector to the control box, the connector should be completely

plugged

A.

In

phase to the white lead, and the

upon the setting

CAUTION: The green wire must be connected

B.

The appropriate power fuse capacity

2) Lamp Leads

A. When installing the illuminating lamp

in

the proper receptacle after confinning the connector type and matching direction.

case

of

three-phase electrical power system, the

"W"

phase to the black lead. The motor rotary direction depends, however,

of

the internal switch in the control box as described

motor properly.

is

as follows.

Power supply 200V-240V: I 0A

I00V-120V: ISA

(6V,15-20W),The connecting wire is

attached

It

removing the insulating tube from the wire

and stripping properly.

on

the back

should be removed and connected by

of

the Control box.

"U"

phase should be connected to the red lead, the "V"

to

the ground terminal

(a)

Bare

wire

Lampteads

in

Paragraph

in

order

(b)

Insulating

(2

to 3 turns

lnsldattng

tape

(2

to

3

turns

wrapped)

Lamp

1-P)

to

tape

wrapped)

leads

ground the

- 2 -

Page 6

The

wire

connections should

be,

then, insulated

by

wrapping insulating tape

on

the wires.

CAUTION: The power switch must be Turned

B.

When

the

illumin.ating

shown

control

CAUTION: The illuminating lamp must not be connected with any heater, such as a foot warmer

in

box

the

will

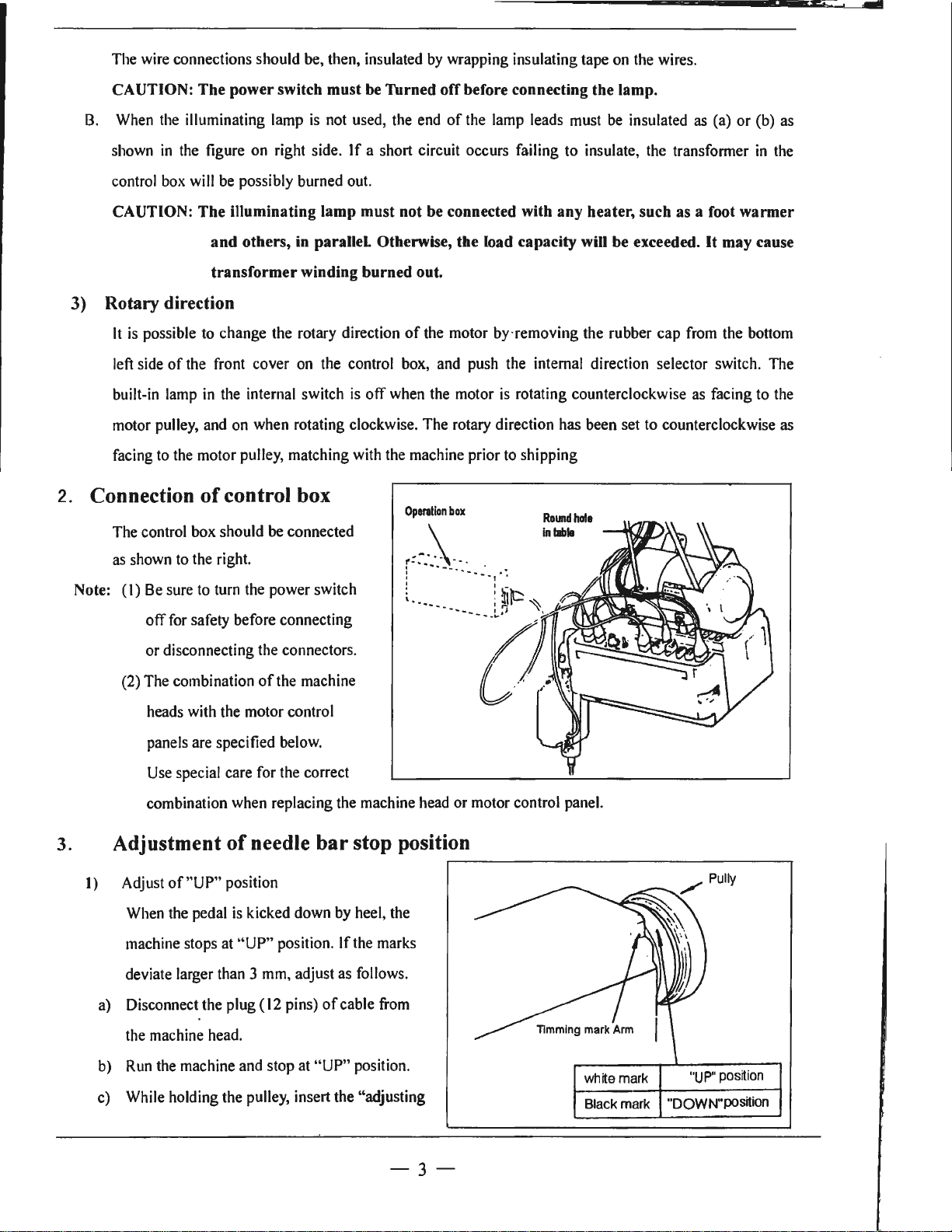

3) Rotary direction

It

is

possible

left

side

of

the

built-in

motor

facing

lamp

pulley,

to

the

motor pulley, matching

2. Connection

The control box should

lamp

is

not

used,

the

figure

on

right side. If a short circuit occurs failing

be

possibly burned

and others,

transformer winding burned out.

to

change the rotary direction

front cover

in

the

internal switch

and

on

of

control box

in

on

when

rotating clockwise. The

be

connected

out.

parallel. Otherwise, the load capacity will be exceeded. It may cause

of

the

control

is

with

off

when

the

box,

machine prior

off

before connecting the lamp.

end

of

the

lamp

leads

must

be

insulated

to

insulate,

the

the motor by· removing the rubber cap

and

push

the

internal direction selector switch.

the

motor

is

rotating counterclockwise

rotary

direction

to

has

shipping

Roundhola

In

labla

been set

to

as

(a) or

(b)

transformer

from

as

the

facing

in

bottom

to

counterclockwise

as

the

The

the

as

3.

as

shown

Note:

(I)

(2)

Adjustment

1)

Adjust of"UP" position

When

machine stops

deviate larger

a)

Disconnect the plug (

to

the

right.

Be

sure

to

turn

for

safety before connecting

off

or disconnecting

The

combination

heads

with

the

panels

are

specified

Use

special care

combination

when

of

the

pedal

is

at

"UP" position. If

than 3 mm,

the

power switch

the

connectors.

of

the

machine

motor control

below.

for

the

correct

replacing

the

machine

head

needle bar stop position

kicked down

12

pins)

adjust

of

by

heel,

the

as

follows.

cable

the

marks

from

or motor control panel.

the

b)

c)

machine

Run

While

the

head.

machine

holding the

and

pulley,

stop

at

"UP" position.

insert the "adjusting

-3-

wh

lte

mark

Black mark

"UP"

position

"DOWN"position

Page 7

tool" in the hole" A", then remove the tool.

2) Adjust

When the pedal is "Neutral" the machine stops at

5 mm, adjust

a) Disconnect the plug ( 12 pins)

the machine head

b) Run the machine and stop at

c) While holding the pulley, insert the "adjusting

3)

Confirm the stop operation, then set the plug (

pings) coming from the machine head into the

of

"Down"

tool"

in

the hole "B", then remove the tool.

receptacle.

as

follows.

position

of

"Down"

CAUTIONS ON USE

1.

Oiling (1)

Fill the oil reservoir with oil up to

Oil level should be periodically checked.

"L"

level is fottnd below

level replenish oil to

cable from

position.

"H"

mark.

If

oil

12

"Down

@

" position.

If

the marks deviate large than

"H"

level .

For oil, Use white spindle

2. Oiling (2)

When a new sewing machine is used for the first time,

considerably long time is used again, replenish a suitable amount

arrow

in

the below figure

oill.

--~~:.~

....

····

c-..

~ ·

·~

or

sewing machine left

of

oil to the portions indicated by

out

of

use for

3. Oiling condition

(I)

See

dripping

of

oil during operation through the oil sight window to check oiling condition in the

- 4 -

Quantit y of

oll

:2 - 3

drop•

Page 8

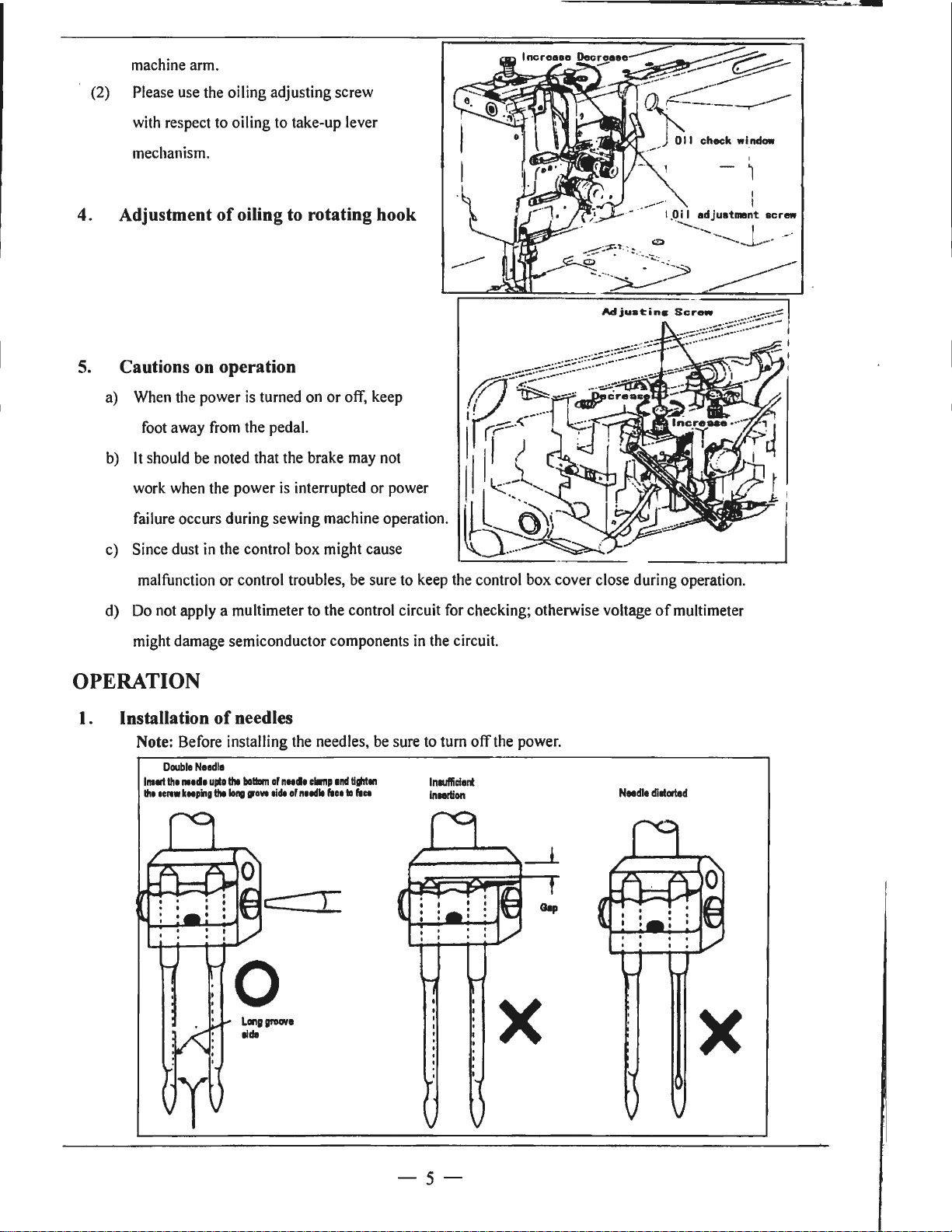

(2)

machine

Please

with

mechanism.

arm.

use

respect

the oiling adjusting screw

to

oiling

to

take-up lever

Adjustment

4.

Cautions on operation

5.

a)

When

the

power

foot

away

b)

It

should

work

failure

c)

Since dust

malfunction or control troubles,

d)

Do

might

be

when

occurs during sewing machine operation.

in

not

apply a multimeter

damage semiconductor components

of

oiling to rotating hook

is

turned

on

or

off,

from

the

pedal.

noted

that the brake

the power

the

is

interrupted or power

control box might cause

may

be

to

the control circuit

keep

not

sure

to

keep

in

the

the

control box cover close during operation.

for

checking; otherwise voltage

circuit.

of

multimeter

OPERATION

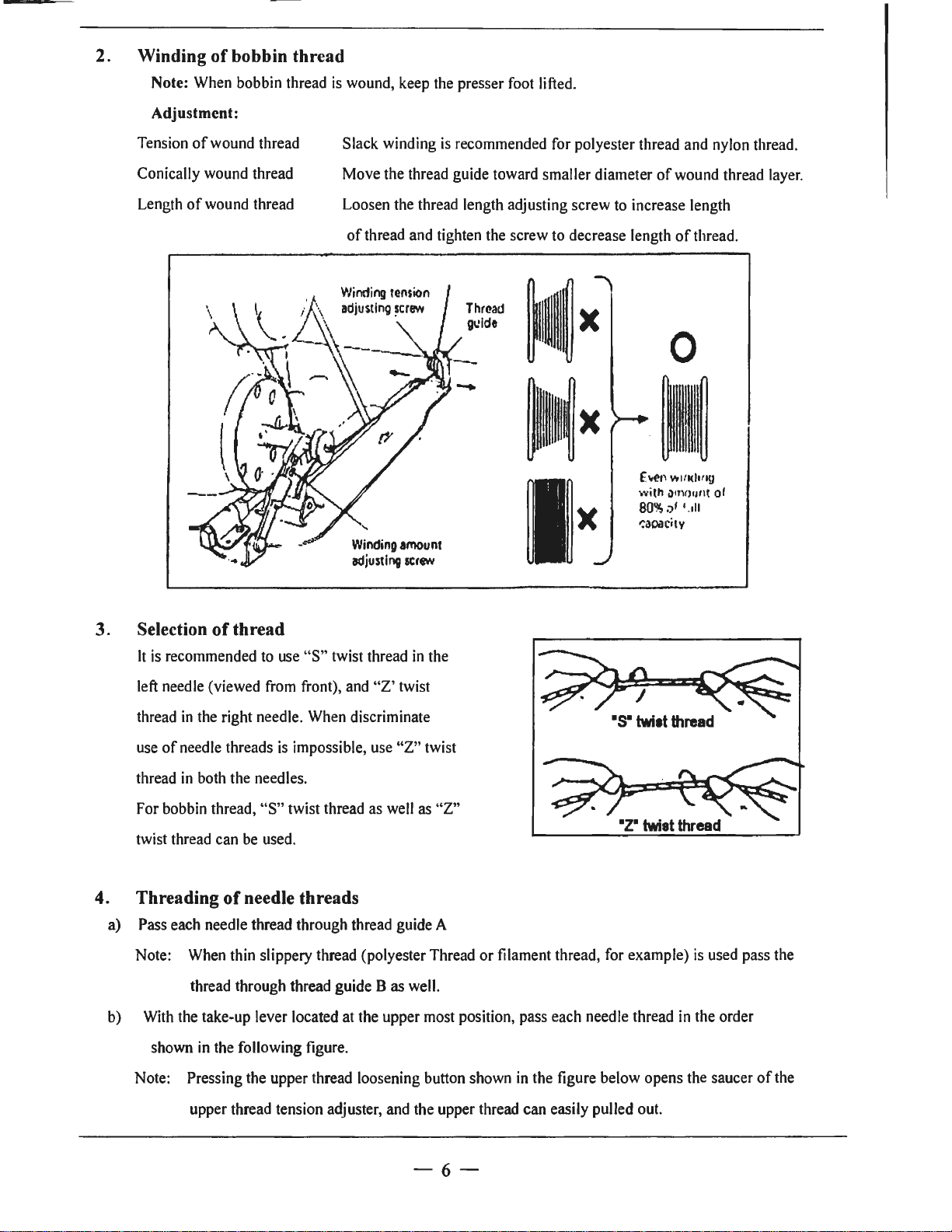

l.

Installation

Note: Before installing

Double

lnalll

th1

1111d1

Iha

ICIIW

kNping

of

Needle

uplo

Iha

needles

the

bollllm

of

··"

nNdl

aide

lo,w

0

LOl'IDIJl'DCIH

Iida

the

of

n11dll

needles,

clamp

1ml

l'IH

tli,iten

lo

l'ICI

be

sure

to

turn off

lnlllfficienl

Inmon

the

power.

X

Needle

dillorled

X

-5-

Page 9

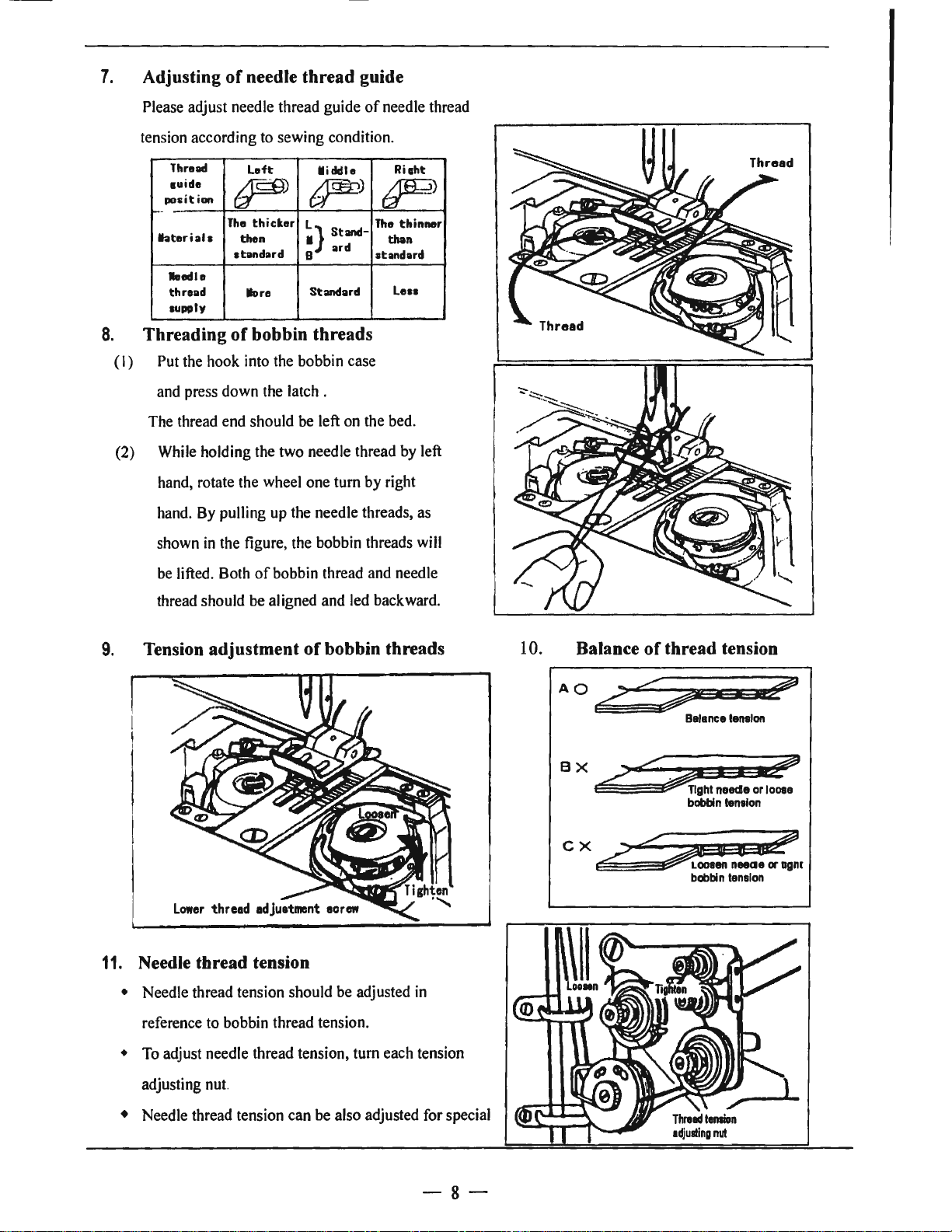

2. Winding

of

bobbin thread

Note: When bobbin thread

Adjustment:

Tension

Conically wound thread

Length

of

wound thread

of

wound thread

is

wound, keep the presser foot lifted.

Slack winding

Move the thread guide toward smaller diameter

Loosen the thread length adjusting screw to increase length

of

thread and tighten the screw to decrease length

Winding

adjustlnv

amount

screw

is

recommended for polyester thread and nylon thread.

of

wound thread layer.

of

thread .

;;~

~~

~

)(

!~

x

f.

It(?!\

Vt

with il

tn<

80%

:,I •.

-:aoacitv

lfl<llf

>•mt

1II

~x

l!J

of

3. Selection

It

is

left needle (viewed from front), and

thread

use

of

thread

For bobbin thread,

twist thread can be used.

4. Threading

a) Pass each needle thread through thread guide A

Note: When thin slippery thread (polyester Thread

b) With the take-up lever located at the upper most position, pass each needle thread

shown

Note: Pressing the upper thread loosening button shown

of

thread

recommended to use

in

the right needle. When discriminate

needle threads

in

both the needles.

of

needle threads

thread through thread guide B as well.

in

the following figure.

"S"

twist thread

is

impossible, use

"S"

twist thread as well as

"Z'

in

twist

"Z"

the

twist

"Z"

or

filament thread, for example)

in

the figure below opens the saucer

is

used pass the

in

the order

of

the

upper thread tension adjuster, and the upper thread can easily pulled out.

-6-

Page 10

@@

@@@

Needle

thread tension releasing button

IL9)

I

···-.

......

..

_

5. Adjustment

Note:

To

make

setting

Touch-back button

Stitching goes

direction

when

f11dlongth

Mtting

k

~

-----·- ·-·-

of

feed (stitch) length and stitch reversing (touch back)

feed

(stitch) length smaller, depress

dial

to

a desired position

..

. Direction

on

in

reversed direction while

the

button

dial

is

released.

of

stitching

-----~------------~

the

feed

reverse lever and set the

can

be

the

reversed

button

by

depressing this button.

is

held

down, and returns

I

I

"\

feed

to

forward

------------·

_ .----

length

6. Setting

leading

(I)

Pulling out thread

bobbin case.

(2)

Threading following ( I

(3)

Put

hook

(4)

Press

(5)

Leading

of

the

the

bobbin case

shaft.

the

bobbin bar.

the

bobbin

lower thread

lower thread over

and

from

side

)-(5)

to

rotating hook, then replace

install

A,

then

bed

the

install

plate .

bobbin

the

-7-

Page 11

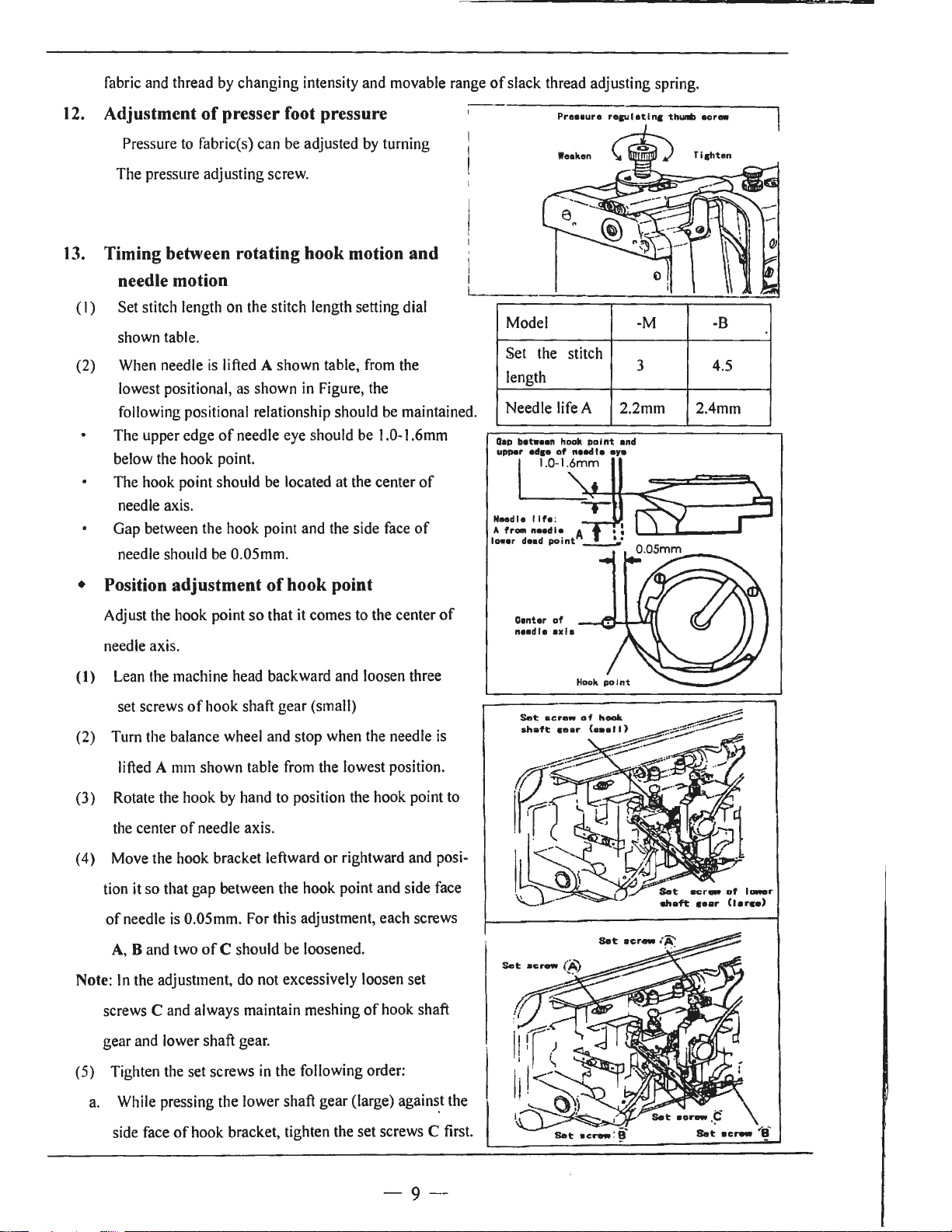

7.

Adjusting

of

needle thread guide

Please adjust needle thread guide

tension according to sewing condition.

8.

(I)

(2)

Thread

1uide

posit

ion

~-

hteriah

•edte

thread

supply

Threading

Put the hook into the bobbin case

and press down the latch .

The thread end should be left on the bed.

While holding the two needle thread by left

hand, rotate the wheel one

hand. By pulling up the needle threads, as

shown

Left

r)

The

thicker

then

standard

lore

of

bobbin threads

in

the figure, the bobbin threads will

~}

8

M

iddle

~)

Standard

Standard

tum

of

needle thread

Ri1ht

~)

The

thinner

than

atandard

Lesa

by right

be lifted. Both

thread should be aligned and led backward.

Tension adjustment

9.

11.

Needle thread tension

• Needle thread tension should be adjusted

reference to bobbin thread tension.

of

bobbin thread and needle

of

bobbin threads

in

10.

AO

BX~

cx.2~r

Balance

of

thread tension

r2:::,

'

::hi

12>

Balance

I

neade

bobbin

bobbin

tension

I~

or

lenelon

tension

~

loose

•

To

adjust needle thread tension, tum each tension

adjusting nut.

• Needle thread tension can be also adjusted for special

-8-

Page 12

fabric and thread by changing intensity and movable range

12.

Adjustment

of

presser foot pressure

Pressure to fabric(s) can be adjusted by turning

The pressure adjusting screw.

13.

Timing between rotating hook motion and

needle motion

(I)

Set stitch length on the stitch length setting dial

shown table .

(2) When needle

lowest positional, as shown

following positional relationship should be maintained.

The upper edge

below the hook point.

The hook point should be located at the center

needle axis.

Gap between the hook point and the side face

needle should be 0.05mm.

is

lifted A shown table, from the

in

Figure, the

of

needle eye should be 1.0-I .6mm

of

of

of

slack thread adjusting spring.

Preeaure

Model -M

Set the

length

Needle life A

Oap

betwHn

hook po i

eds•

upper

of

stitch

nalld

reau I at

Inc

thunib

3 4.5

2.2mm 2.4mm

nt

and

I•

•Y•

•crew

-B

LJ~m'-11+--c:;5:::;c:=:==~

,-

Neadlo I lfe:

• Position adjustment

Adjust the hook point so that it comes to the center

of

hook point

of

needle axis.

(I)

Lean the machine head backward and loosen three

of

set screws

(2) Turn the balance wheel and stop when the needle

lifted A

hook shaft gear (small)

mm

shown table from the lowest position.

is

(3) Rotate the hook by hand to position the hook point to

of

the center

(4) Move the hook bracket leftward

needle axis.

or

rightward and posi-

tion it so that gap between the hook point and side face

of

needle is 0.05mm. For this adjustment, each screws

A, B and two

Note:

In

screws

the adjustment, do not excessively loosen set

C and always maintain meshing

of

C should be loosened.

of

hook shaft

Oenter

neadl•

Set:

of

axla

screw

of

hook

gear and lower shaft gear.

in

(5) Tighten the set screws

the following order:

a. While pressing the lower shaft gear (large) agains_t the

of

side face

hook bracket, tighten the set screws C first.

- 9

--

Set:

aor-

Set:

.

¢'

\

•c~

...-

e·

Page 13

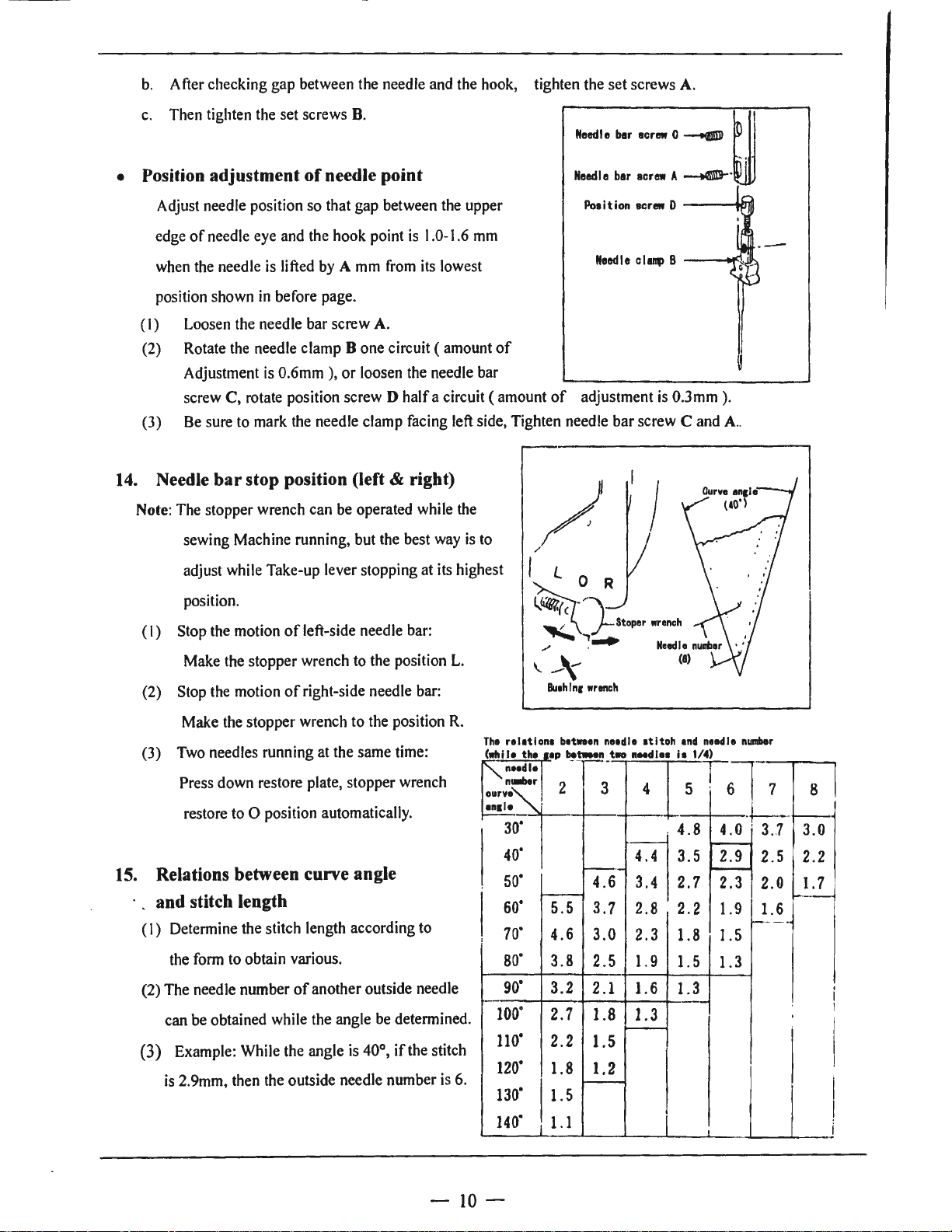

b.

After checking gap between the needle and the hook,

c.

Then tighten the set screws

• Position adjustment

Adjust needle position so that gap between the upper

of

edge

when the needle

needle eye and the hook point

is

of

lifted

B.

needle point

by A mm

from its lowest

is

1.0-1.6

mm

tighten the set screws

•

...

,.

'"

"'· 0 --

Needle

bar

acrew

A.

A__......~

~!

11

--

position shown

(I)

Loosen the needle bar screw A.

(2) Rotate the needle clamp B one circuit ( amount

Adjustment is 0.6mm ), or loosen the needle bar

screw C, rotate position screw D half a circuit ( amount

Be

(3)

14.

Needle bar stop position (left & right)

Note: The stopper wrench can be operated while the

(I)

(2) Stop the motion

(3) Two needles running at the same time:

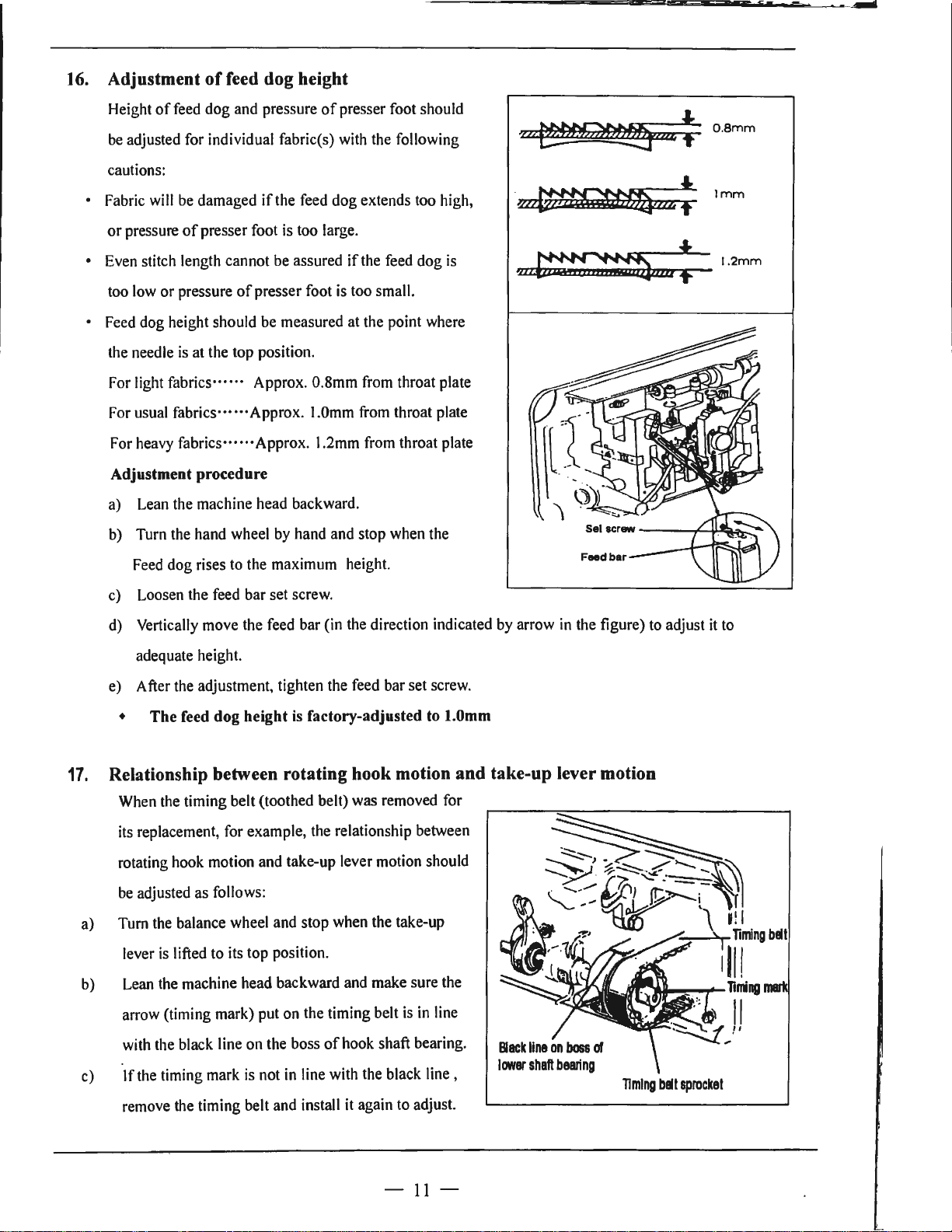

15.

Relations between curve angle

sure to mark the needle clamp facing left side, Tighten needle bar screw C and A

sewing Machine running, but the best way

adjust while Take-up lever stopping at its highest

position.

Stop the motion

Make the stopper wrench to the position

Make the stopper wrench to the position

Press down restore plate, stopper wrench

restore to O position automatically.

in

before page.

of

left-side needle bar:

of

right-side needle bar:

and stitch length

(I)

Determine the stitch length according to

the form to obtain various.

of

(2) The needle number

can be obtained while the angle be determined.

(3) Example: While the angle is 40°,

is

2.9mm, then the outside needle number is 6.

another outside needle

if

the stitch

of

is

to

L.

R.

The

(while the

~

ourv:"'

anal•

40·

so·

so·

I

10·

80"

90·

100"

no·

120·

130·

of

adjustment

/

/

is

';

0.3

mm

I .

~\~

•

:;,;.,_ \ j--Stoper

.,,

;

_,.

\.

-\'

Bu,h

Inc

wrench

relation,

needle j

n_,.r

30·

b1tnen

••P

2 3

.._

5.5

4.6

3.8

3.2

2.7

2.2

1.8

1.5

ba~'!

...._

>---

needle

__

4.6

3.7

3.0

2.5

2. l

1.8

1.5

1.2

wrench

Needle nunier

(8)

atitoh

and

two

naedl11

4 5

_

:::f:

2.8

2.3

1.9

1.6 1.3

nHdle

i•

1/4)

2.7

2.

2

1.8 1.5

1.

5 1.3

1.3

----

).

..

.

number

6

4.0

----

2.9

I---

2.3

1.

9

L---·

7

3 .. 7

2.5

2.0

1.6

.,_..

8

3.0

2.2

l.

__

_

7

140"

I 1.1

-IO-

.

Page 14

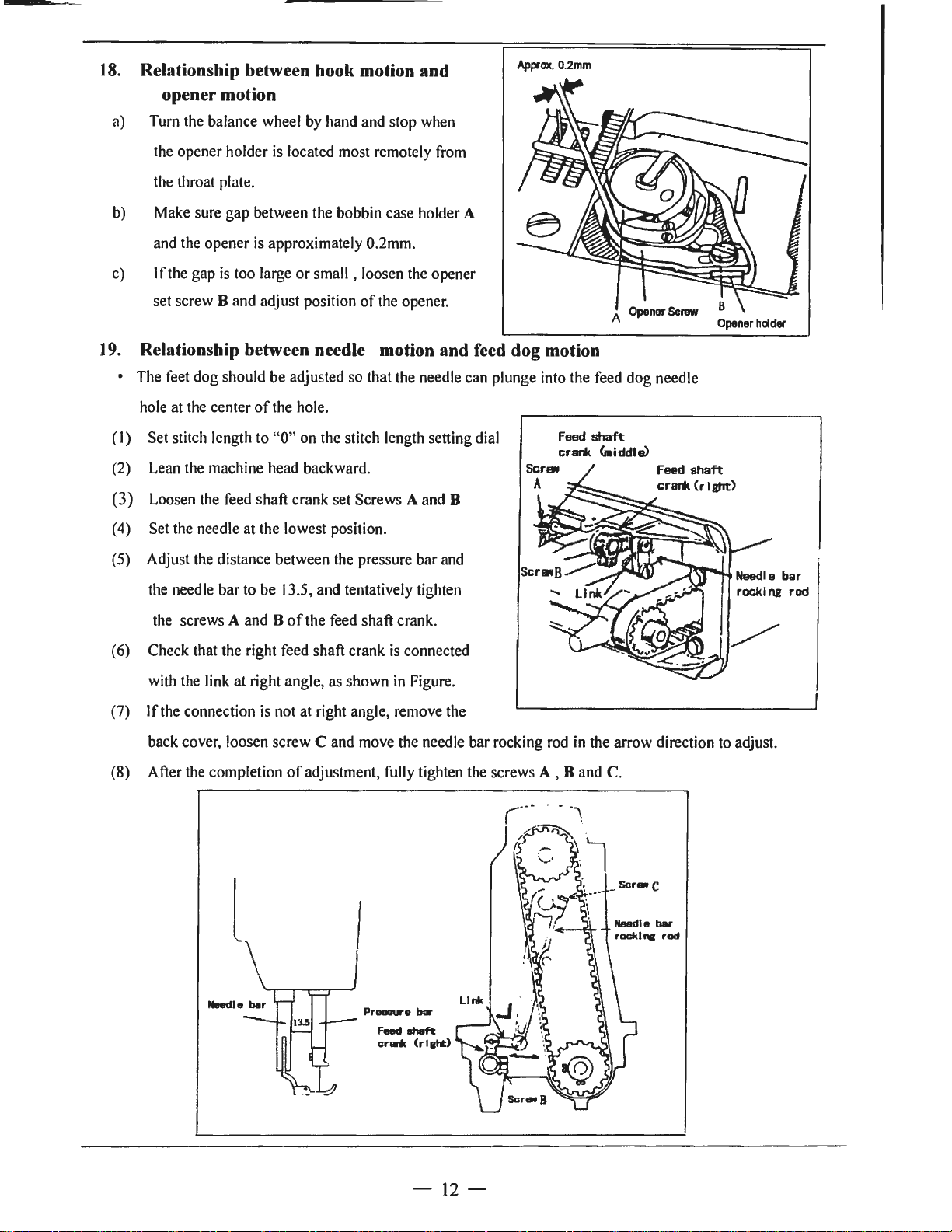

16.

Adjustment

of

feed dog height

Height

be

cautions:

• Fabric will be damaged

or

• Even stitch length cannot be assured

too low

• Feed dog height should be measured at the point where

the needle

For light fabrics······ Approx. 0.8mm from throat plate

For usual

a) Lean the machine head backward.

b)

of

feed dog and pressure

adjusted for individual fabric(s) with the following

if

pressure

For heavy fabriCS"""Approx. 1.2mm from throat plate

Adjustment procedure

Turn the hand wheel by hand and stop when the

of

presser foot

or

pressure

is

fabrics·"·"Approx.

of

presser foot is too small.

at the top position.

of

presser foot should

the feed dog extends too high,

is

too large.

if

the feed dog

1.0mm from throat plate

is

?U~mz

·~

-U~/lll:

04

! 0 .

!

8mm

1mm

1.2mm

Feed dog rises to the maximum height.

c) Loosen the feed bar set screw.

d) Vertically move the feed bar (in the direction indicated by arrow

adequate height.

e) After the adjustment, tighten the feed bar set screw.

• The feed dog height

17.

Relationship between rotating hook motion and take-up lever motion

When the timing belt (toothed belt) was removed for

its replacement, for example, the relationship between

rotating hook motion and take-up lever motion should

be

adjusted as follows:

a) Turn the balance wheel and stop when the take-up

lever

is

lifted to its top position.

b)

Lean the machine head backward and make sure the

arrow (timing mark) put on the timing belt

is

factory-adjusted to 1.0mm

is

in

line

in

the figure) to adjust

it

to

with the black line on the boss

c) If the timing mark

remove the timing belt and install it again to adjust.

is

not

of

hook shaft bearing.

in

line with the black

line,

-

11

-

Timing

belt

sprocket

Page 15

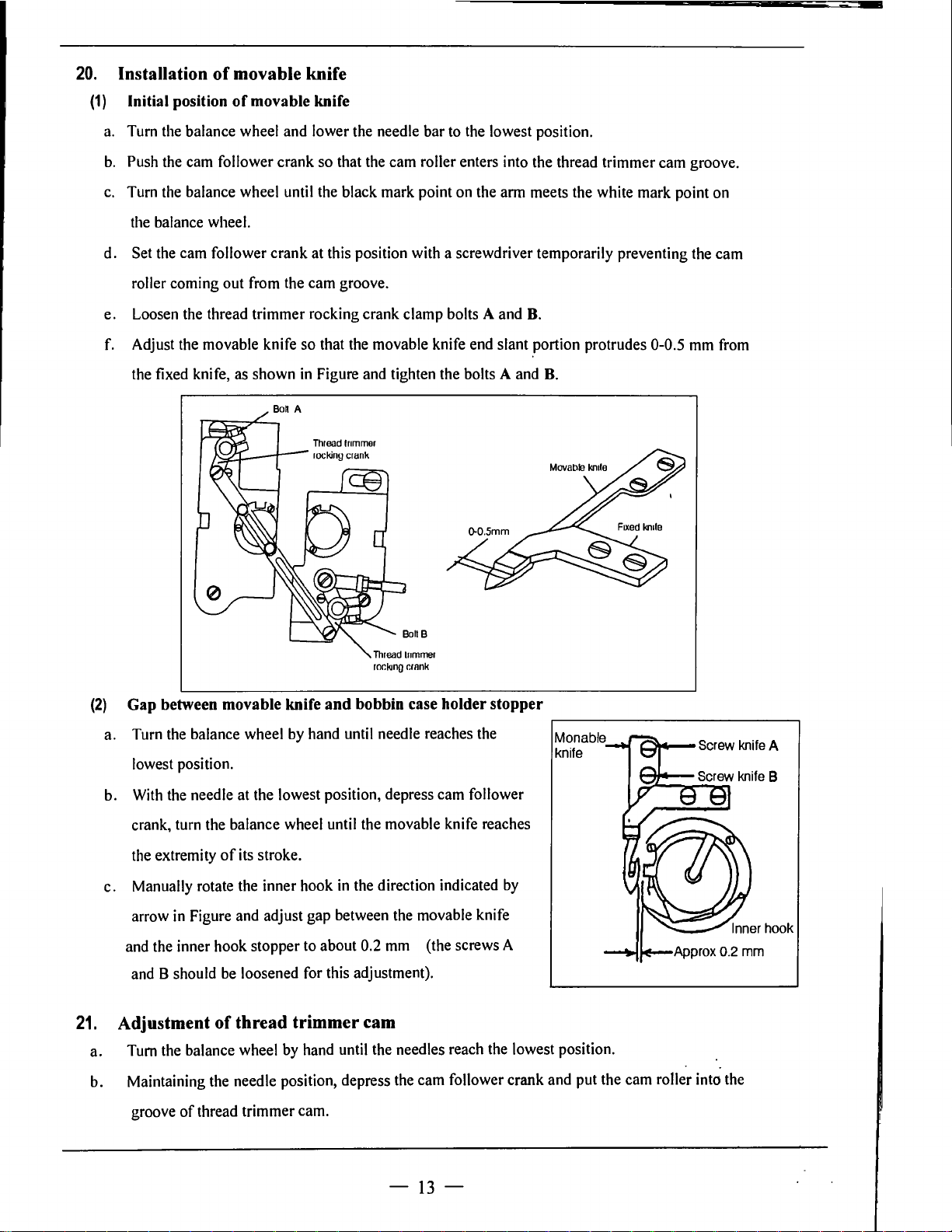

18.

Relationship between hook motion and

opener motion

Approx.

0.2mm

a) Turn the balance wheel

the opener holder

by

hand and stop when

is

located most remotely from

the throat plate.

b) Make sure gap between the bobbin case holder

and the opener

c)

If

the gap

set screw

19.

Relationship between needle motion and feed dog motion

is

is

too large

Band

adjust position

approximately 0.2mm.

or

small , loosen the opener

of

the opener.

A

A

Opener

• The feet dog should be adjusted so that the needle can plunge into the feed dog needle

hole at the center

(I)

Set stitch length to "O" on the stitch length setting dial

of

the hole.

Feed

crri

shaft

<middle)

(2) Lean the machine head backward.

(3) Loosen the feed shaft crank set Screws A and B

(4) Set the needle at the lowest position.

(5) Adjust the distance between the pressure bar and

Screw

Feed

crar* (rlafrt)

Opener

shaft

hdder

the needle bar to be 13.5, and tentatively tighten

the screws

A and B

(6) Check that the right feed shaft crank

with the link at right angle, as shown

If

(7)

the connection

of

the feed shaft crank.

is

connected

in

Figure.

is

not at right angle, remove the

back cover, loosen screw C and move the needle bar rocking rod

of

(8) After the completion

adjustment, fully tighten the screws A , Band C.

Pressure

Feed

crlrit

bar

shaft

(rllht)

in

the arrow direction

to

adjust.

-

12

-

Page 16

20.

(1)

a.

b.

c.

d.

Installation

Initial position

Turn

the

balance wheel

Push

the

cam

Turn

the

balance wheel

the

balance wheel.

Set

the

cam

of

movable knife

of

movable knife

and

follower crank

until

follower crank

lower

the

so

that

the

the black

at

this position

needle bar

cam

mark

to

the

lowest position.

roller enters into the thread trimmer

point

on

the

arm

meets the white mark point

with

a screwdriver temporarily preventing the

cam

groove.

on

cam

roller coming out

e.

Loosen

f.

Adjust

the

(2)

Gap between movable knife and bobbin case holder stopper

a.

Turn

lowest

the

the

fixed

knife,

the

balance wheel

position.

from

the

cam

groove.

thread trimmer rocking crank clamp bolts A

movable knife

as

shown

so

that the movable knife

in

Figure

and

tighten the bolts A

Thread

lr1mmer

rocking

crank

ror.kmg

by

hand

until

needle reaches

r.rnnk

and

B.

end

slant portion protrudes 0-0.5

and

B.

the

~-----------~

Monable

knife

mm

from

b.

With

the

needle

at

c.

21.

Adjustment

a.

b.

the lowest position, depress

turn

crank,

the

extremity

Manually

arrow

and

the

and

8 should

Tum

the

the balance

of

rotate the inner hook

in

Figure

and

inner hook stopper

be

of

thread trimmer cam

balance wheel

wheel

its

stroke.

adjust

loosened

by

until

the

in

the

gap

between

to

about

0.2

for

this adjustment).

hand

until

the needles

movable

direction indicated

mm

Maintaining the needle position, depress the

groove

of

thread trimmer

cam.

-

cam

the

movable

(the screws A

cam

13

follower

knife

reaches

by

knife

reach

the

lowest position.

follower crank

-

and

put the

cam

roller

into

the

Page 17

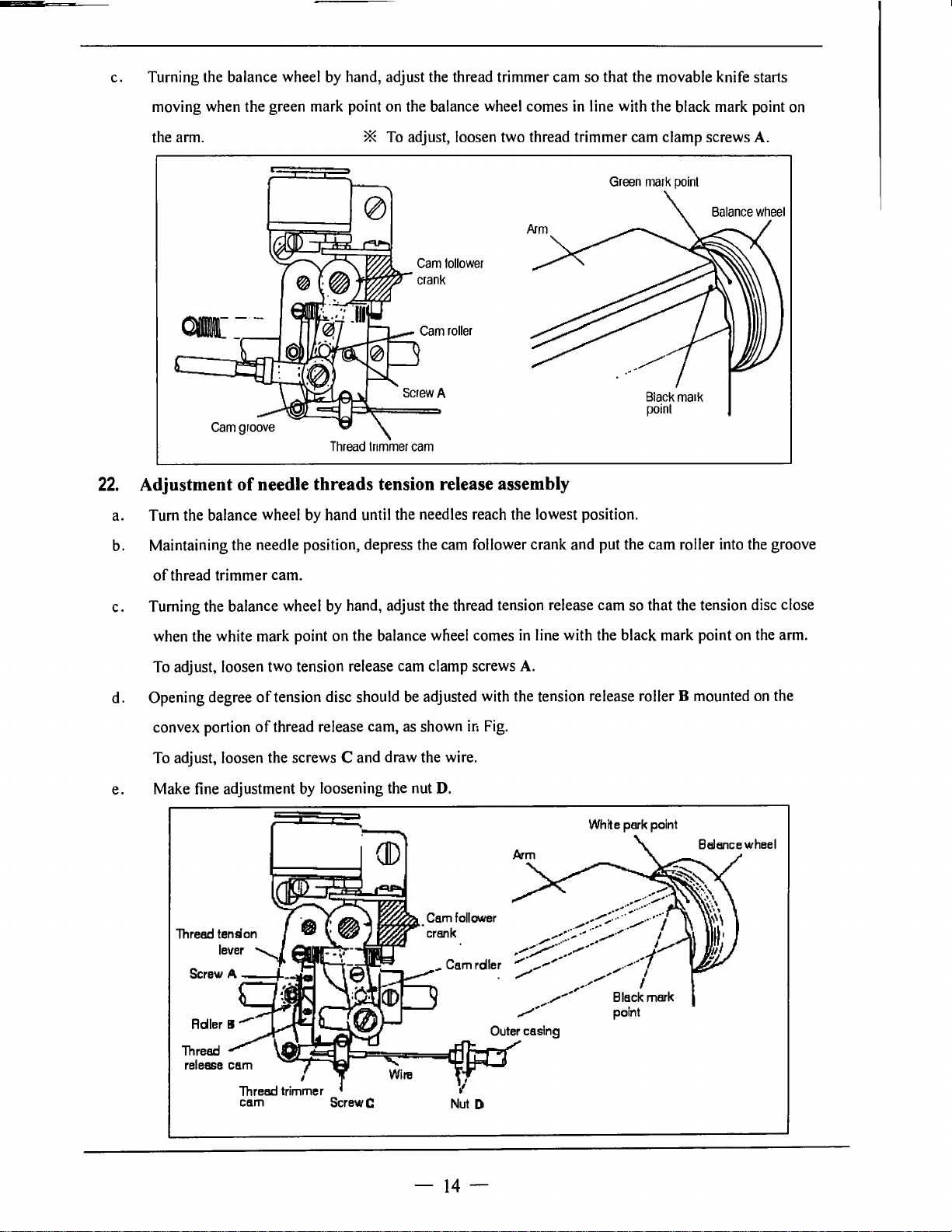

c. Turning the balance wheel by hand, adjust the thread trimmer cam so that the movable knife starts

moving when the green mark point on the balance wheel comes in line with the black mark point on

the arm.

QI[-

22.

Adjustment

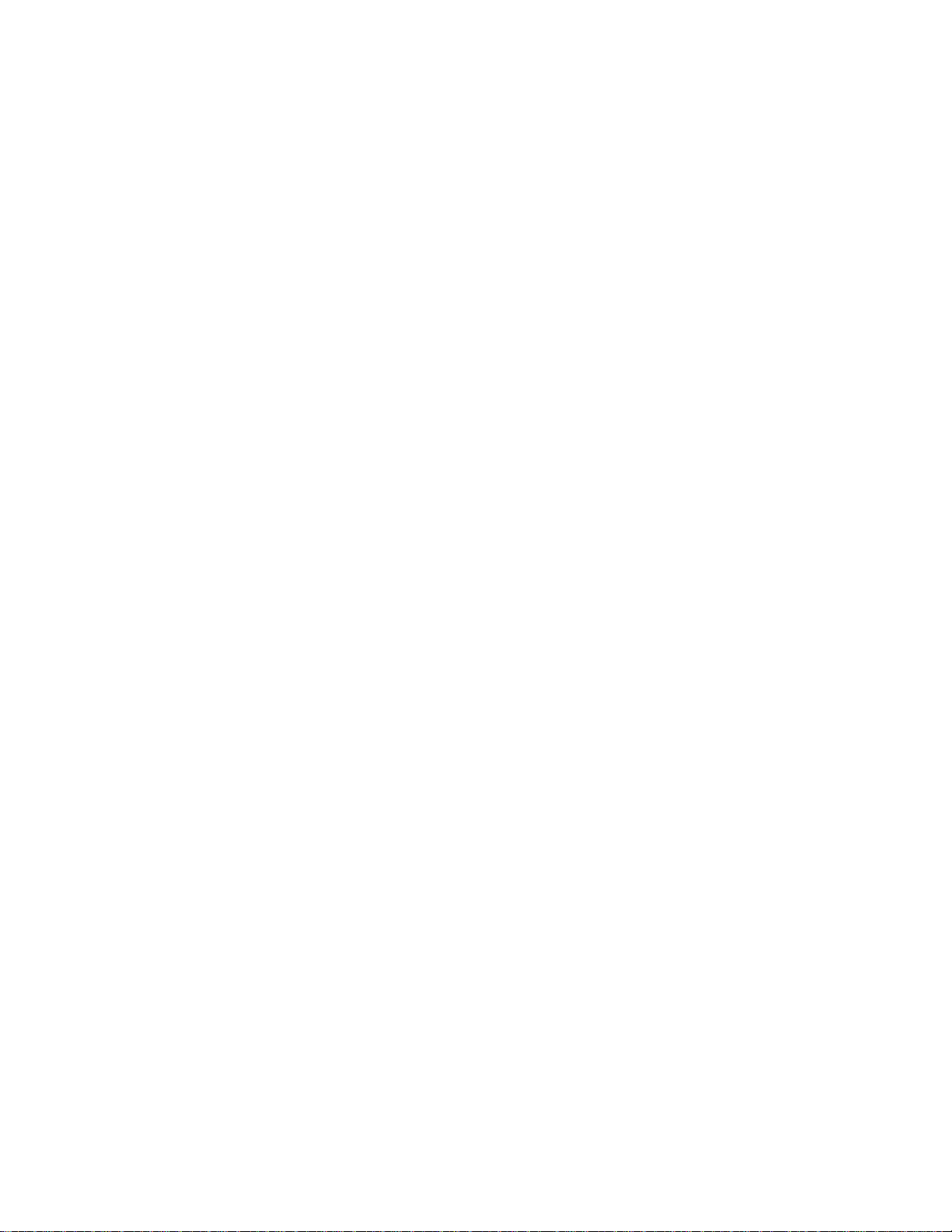

a. Turn the balance wheel by hand until the needles reach the lowest position.

b. Maintaining the needle position, depress the cam follower crank and put the cam roller into the groove

of

thread trimmer cam.

·-

of

needle threads tension release assembly

* To adjust, loosen two thread trimmer cam clamp screws A.

Green

mark

point

Cam

follower

Black

maik

point

Thread

trimmer

cam

c.

Turning the balance wheel by hand, adjust the thread tension release cam so that the tension disc close

when the white mark point on the balance wlieel comes

To adjust, loosen two tension release cam clamp screws

d. Opening degree

convex portion

To adjust, loosen the screws

e.

Make fine adjustment by loosening the nut

of

tension disc should be adjusted with the tension release roller B mounted on the

of

thread release cam, as shown

C and draw the wire.

in

D.

Fig.

in

line with the black mark point on the arm.

A.

White

park

point

(II)

,

Thre&I

trimmer

cam

ScrewC

-

14

-

Page 18

23.

Adjustment

a.

Loosen the fixed knife bracket clamp bolt A.

b.

Turn the vertical positi~n adjusting screw B to adjust meshing pressure and then righter the hexagon

of

meshing pressure

of

movable knife and fixed knife

socket head cap screw

Note: Since excess pressure causes large

torque to the thread trimming mechanism

and trimming failure, adjust it so that

thread can be trimmed with minimum

pressure.

c. Move the movable knife and check that

the thread can be sharply trimmed.

24.

Sharpening

When the knives dull, the fixed should

be sharpened as illustrated

it

Since

replace it with a new one when it dulls.

of

is

very difficult to sharpen the movable knife,

A.

fixed knife

in

Fig.

Fixed

br-acker-

Hexacon

cap

scr-ew A

knife

socket

head

Ver-ti

cal

position

adjustinc

scr-ew B

25.

Adjustment for change

(I)

Replace the throat plate, feed dog and needle clamp.

(Since the throat plate and feed dog are special parts designed for thread trimming machine, be sure

to

use those specified by us.)

(2) Lean the machine head backward.

(3) Loosen two connecting link clamp bolts

(4) Remove the spring M.

(5) Loosen the hook bracket clamp screws A and

(6) When the needles and hooks have been adjusted, install the spring

(7) Contact the rocking cranks C and D to the stopper pins E and F and tighten the connecting link

clamp bolt

(8) Turn the balance wheel

(9) Loosen the nuts G and

( I

0)

Depress the cam follower crank Kand adjust the connecting rod L

smoothly enter the groove

J.

of

needle gage

J.

Band

adjust gap between each needle and hook.

by

band until the needles reach the lowest position.

H.

of

thread trimmer cam

..

Then tighten the nuts G and

M.

so

that the cam roller can

H.

(

11)

Adjustment

i.

Push the cam follower crank K so that the cam roller enters into the cam groove.

ii.

Turn the connecting rod

of

the cam groove and the cam roller

Land

adjust the clearance between the cam roller and the cam

-

15

-

Page 19

groove surface N as small as possible, and tighten the nuts G and ff.

111.

Push the cam follower crank K again and check that the cam roller enters into the thread

trimmer cam groove smoothly.

Screw

A

Connecting

link

Bolt J

Stopper

pm

--

F Thread trimmer

rockinA crank

D

Screw B

Lower

shalt

26. Wiper adjustment

a)

Run the machine then stop at

b)

Loosen the screw C ,then adjust the base block so that the line A and the line Bare

the same plane, then tighten the screw C.

c). Loosen the screw F, then adjust the wiper move so as the E clearance

Tighten the screw

F.

"up"

Lower

of

Arm

position.

plane

is

2mm, then

.,---t--,O

Screw

~2mm

Wiper

-

16-

Page 20

SPECIFICATIONS

Model

Application

Max. sewing

speed

Stitch length

Needle-bar stroke

Presser-foot stroke

Needle No.

Rotating hook

GC20528

Light to medium heavy material

-M

GC20528-M

3500rpm

0

,.._,

5mm

13mm by Leg

DP

X 5

11

#-14#

Standard

vertical-axis

hook

with

self-lubrication

Auto lubrication Large

hook (Thread

trimming)

-D

32mm

GC20528

-B

Medium heavy material

3000rpm

0

-----

7mm

by

hand

DP

X 5 18#-22#

hook

with

bobbin

thread full-rotating)

pull-back

GC20528

7mm

(Horizontal

-B-D

.,

Large

Auto trimmer

Thread take-up

lever

Stitch adjusting

system

Lubrication system

Motor

Standard

Needle

gauge

Special

--

Clutch

370W

motor

3.2

.J

Slide

Dial

Automatic lubrication

Servo motor

550W

6.4mm

4.

8 8

lever

Clutch

--

370W

9.5

motor

12.

.J

Servo motor

550W

7mm

- 17 -

Page 21

A.ARM

BED

1

AND

ITS

(I)

2 3 4 5 6 7 8 9

ACCESSORIES

10

11

(9)

15

16

17

(I)

35

34

33·

32

(9)

1

-

18

-

Page 22

A.ARM BED AND ITS ACCESSORIES

Fig.

No.

Part No.

A0I H3200B2l90 Rubber plug

1-

14715B8001

A0I

A02

1-12400B2080

H2400B2060 Spacer I I

J\03

A04

1-13200B2060 Oil guard plate I I I

J\05

H2400B2050

1-13200B2070

A06

J\07

H3000O2l60 Screw 2 2

A08

11409060080

A09

I-IA300C2030

AI0 H3200B2030

All

1-13200B2050

All

H4717B8001

Al2

1-13200K0210

Al3

l-13200K0220

Al4

H3200B2040

Al5

H2000B20l0

Al6

I-IA70082060 Screw 2 2 2 2 SMI

1-12400B2100 Thread guide

Al7

J\18

H2000M0080 Cap 2

Al9

114913B800I Supporter I

J\20 l-1491288001

A21

1-1320082170

A22

H320082160 Slide plate I I I I

A23

1-13200132080

A24

11321W0066

A25

113200B2l00 Screw I

J\26 1-149158800 I

A27 1-14914B8001

A28

1-14911B8001

A29

I-IJ\30082190 Screw I I I I

A30

1-1320082120

Rubber plug

Screw 2

Oil guard plate

Thread guide

Screw

Screw

Side cover (left)

Thread take-up cover

Thread take-up cover

Thumb screw I

Special nut

Side cover (right)

Rubber plug

Screw 2 2

Screw I I I

Thread guide (middle)

Thread guide (complete)

Cover

Screw 4 4 SM9/64( 40)x6

Cover I

Screw I

A3I H3400K0020 Cover

A32

H2004J0067

H3406K065I Oil guard plate

A33

A34

H3406K0652

A35

M3400L0030

A35

H3406L0065

J\36 HA73I IC606

H3400L0070 Shaft supporter

A37

J\37

1-13410L0065

A38

H602030200

A39

H200012080 Screw

Screw

Felt

Face plate

Face plate

Screw 2

Shaft supporter

Pin 2 2

Description

Q

Q

~

I

00

N

lf"I

0

N

u

0

5

co

00

'

N

lf"I

0

N

u

0

5

~

00

N

lf"I

0

N

u

0

I

O?

00

N

lf"I

0

N

u

0

black

5 5 gray

2

2

I

I

I

I

I I

I

I

2

I I I I

15

15

11

I I I I

I

I

I

I I

I

I

I

I

I

I I

SMJ/

2

I

I

I

SM9/64 (40)

2

GB(f8 I 8 M6x8

SMI 1/64

11

black

gray

I

I

MIOx33

MI0

I

I I I I

I I I

I

2

2 2

I

SMl/4

SM I 3/64(32)x4

I

I I I I

I I I

I

SM9/64(40)x6.5

I

I

I

I

SMI

I

I

I I I I

2

2

I

I

I I black

I I

I

2 2

I

I

2 2 2

I

I

I

2

I

I

l

I

I

I

I

I

2

l

SM9/64 (

SM9/64

gray

SMI

GBrrl

SMI

Remarks

16 (28

)

(40)

x8.5

1/64 (40)

(24)

1/64 (40)

36)

C

40)

1/64

(40)

17

3x20

1/64

(40)

II

x6.5

x8

x8

x9

x8

x6.5

x7

xt2

x8

-

19

-

Page 23

B.

THREAD

TENSION

REGULATOR

MECHANISM

1 2 3 4 5 6 7 8 9

10

11

12 13

14

15 16

17

18 19

21

22

26

27

28

29

30

I

49

48

47

46 45

44

43

42

41

40

39 38

I

..

,'

I

37

-

20-

36 35

34 33 32

31

Page 24

B.THREAD TENSION REGULATOR MECHANISM

:g

al

I

I

00

00

N

N

Fig.

No.

801

802

B03

B04

B05

B06

807

B08

B09

BIO

Bil

B12

B13

B14

B15

B16

817

818

B19

B21

Part No.

H32218681 l

H322183142

H3221B6812

I

H4705C8001

H4706C8001

HA7311C306

H4707C8001

H007013050

H322186820

HA300C2030

H4708C800I

H4709C8001

H322186810

H322180685

H322l80683

HAI

1280693

H322l80684

HA7l0B0671

H322180682

H322180687

821 H330680661

B22

HAI0680676

B23

HA3l080702

824

HAI

1580703

H330082040

B24

B25

HAI

l5B70IO

HA3IOB0701

B26

HA3l0B0705

B27

H322l868l6

B28

B29

H322l80689

H3221B0686

830

B31

H32481872I

B32

H324818621

H3248IBC21

833

B34

H3248IBB21

H32481892I

B35

H32481B521

B36

H32481B821

B37

B38

H32481BF2I

B39

H32481B321

840

H324818E2I

H3248l8221

841

B42

H324818D21

Description

Screw

Tension releasing plate

Tension releasing spring

Screw

Lever

Screw

Mounting plate

Stop ring

Mounting plate

Screw

Spring

Push button

Nut

Thread tension stud

Thread tension stud

Thread tension disk

Thread tension spring

Thumb nut

Pin

Thread guide

Thread

&_uide

Screw

Thread tension releasing plate

Thread tension spring

Thread tension spring

Thumb nut revolution stopper

Thumb nut complete

Thread tension disk

Pin

Thread tension stud

Thread tension stud

Thumb

nut

Take-up spring

guide

Screw

Stopper

Thread tension post

Screw

Bushing

Plate complete

Thread take-up spring

Plate

Thread

take-up spring l

Plate complete

. I

.,.,

.,.,

0

0

M

N

u

u

0

0

2

2

1

1

I 1

1

1 I

2 2 2

2

2

I 1 I I

I I

4

4 4

2

2

2 2 2

2

3 3 3 3

I

I 1

1 1

I

2

2

1 I

I 1

2

2

2 2 2 2

4 4 4

I

I

·1

1

I 1 1

1 1

1

1 1 1

1 1 I 1 SM9/64 C 40)

I 1

1 1

2

2

1

1

1

I

I I I 1

1 1 1

l

I I I 1

0

0

I

:g

00

N

.,.,

0

M

u

0

2 2

I

c::o

I

al:,

N

.,.,

0

N

u

0

SM9/64 ( 40)

1 1

1

1 I

1

I I

SM9/64 ( 40)

I

SM9/64

1 I

1 1 GBff896

1 1

2

I 1

I

I

SMI

2 2

I I

1/64

4

2

2

SM

11/64 ( 40

I

SM9/64

1

2 2

2

2

4

I I

I

I

I

SMl/4

I

I

1 I

1

I

2 2

SMl/8

1 1

1

I

l I

Remarks

(40)

5

(40)

(40)

(40)

(44)

x3

x4.2

><4

)

x6

x6

x3.9

.5

-

21

-

Page 25

B.THREAD TENSION REGULATOR MECHANISM

co

Fig.

No.

Part No.

Description

843 H324818421 Screw

844 H324818121

Thread tension stud

845 H2004J0067 Screw

846 H322186817

Pin I

847 H322186818 Tension releasing pin

848 H320082100 Screw

849 H322186819 Stopper

~

00

N

I/'\

0

N

u

0

I

I

00

N

I/'\

0

N

u

0

I

I I

I I I

I

I I I

I I I

I I I I

I I I

I I I I

0

I

~

I

00

N

I/'\

0

N

u

0

0

CQ

ob

N

I/'\

0

N

u

0

I SM9/64

I

SM9/64 (

SM9/64

I

Remarks

(40)

x2.9

40)

x7

(40)

x6.5

-

22-

Page 26

C.ARM

SHAFT

MECHANISM

44

43-------o

42-----..jjj

41~

40~-

35

1 2 3 4 5 6 7 8 9

•

10

11

12 13

14

15 16 17

18

19

20

1-------26

21

22

23

24

25

(27)

34

33

32

31

30

29

(17)

28

-

23

-

27

Page 27

C.ARM SHAFT MECHANISM

Fig.

No.

COi

CO2

C0J

C04

cos

C06

C07

cos

C09

CIO

CII

Cl2

Cl3

Cl4 H3200E2090

Cl5

Cl6

Cl7

Cl8

Cl9

C20

C21

C22

C23

C24

C25

C26

C27

C28

C29

C29

C30

C31

C32

C33

C34

C35

C36

C37

C38

C39

C40

C41

C42

Part No.

H3404BOOI

HAl05D0662 Screw

HA307C0662

HAI0OC2060

HAI00C2070

H2405D0664

H3204BO0I I Arm

H321

HAI07H0662 Screw

HAI0OH2050

H321

H321

H321

HAI00C2020 Screw

H3406B0671

H3205C0661

HAI

H3205CI021

HAI00F2130

H3205J0662

H3205J0661

HAI

H3204J0652

HAI

H3200C2030 Cog belt

HAI04F0654 Screw 3 3 3 3

H3207C0671

H3204C0651

H6906D8001

HA704B0651

H3200E20IO

H3200E2020

HAIO0C2020

H3207E066I Presser bar guide bracket I I

H3210E0683

H3210E0682

H3210E0681

H6904D8001

H3200E2060

H3208E0672

HAIO0B21

H3200E2100 Spring

I Crank

Set screw I I

Screw

Screw I

Set screw I I

shaft bushing (left)

I IBI04 Felt

Bolt

IE0691

IE0692 Spring

IE0693

13F0684

13F0684

Knee

lifter lever (right) 1 1

Knee

lifter connecting

Pin

Blance weight

Spring flange 3 3 3 3

Screw

Pulley(upper) 1

Screw I I 1 I

Ball

bearing I I

B'ushing

Screw

Pulley

l0D0672 Screw 2 2

Pulley(lower) I I I I

Ann shaft

Arm

shaft

Bushing

Presser bar I I I

Screw I I I I

Screw

Operation plate I I

Knee

lifter lever

Knee

lifter

Knee

lifter lever left

Presser bar lifting

Presser bar lifter

IO

Screw

Description

rod

left

rod

cam

1:0

~

00

N

V\

0

N

u

0

.

-

2 2 2 2 SMI

I

I

00

N

V\

0

N

u

0

I I

I 1 I 1

I I I I

I I I I

I 1

3

3

I I I 1

1 I I 1

I 1 I I

2

I

I I

2

I I

1

I

I 1 I I

I

I I

I I I I

I I I I

I

I

. I

I

3

3

2

I

I 1 I

2

I 1 1

I

I I I

I I I

I

~

~

00

N

~

.

V\

V\

~

g

g

1

I

I I

1

3 3

3

1

2

1

I I

I I

I

I

I

I

1

I

I

1

3

1

2

I

I

I

I

I

I

Remarks

SMl/4

(40)

SMl/4

(40)

SM9/32

SM9/32

SM15/64

SMJ/16

SMIS/64

<p5x28

SMl5/64

SM

SMl5/64

6204ZZNR/5K

SMIS/64

SM

SM

SMl/8(44)x9

SMl5/64

(28)

(28)

(28)

(28)

(28)

(28)

15/64

( 28)

(28)

(28)

15/64 ( 28

1-5/64

< 28) x

(28)

1/64

(40)

xJ.5

x7

xl4

xlJ

xl4

xJ.5

x6.7

xlO

><8.5

xJ4.5

xS.5

) x I 2

IO

x

10

x6.6

-

24-

Page 28

C.ARM SHAFI' MECH

Fig.

No.

C43

C44

Part

No.

HAIO0H2120

HA309H068I

Presser spring guide I I I I

Screw

ANISM

Description

C

Ill

::E

I

00

00

N

N

....

:g

0

N

N

u

u

0

0

I I I I

I

I

::E

I

00

N

....

0

N

u

0

C

.

Ill

I

00

N

....

0

a

0

SMl/2

Remarks

(28)

x49

-25-

-

Page 29

D.NEEDLE

BAR

ROCKING

MOTION

MECHANISM

1 2 3 4 5 6 7 8 9 10

11

16 17 18

19 (17) 20

21

22 23

12 13 14 15

-

26

-

Page 30

D.NEEDLE BAR ROCKING MOTION MECHANISM

Cl

co

=¥

Fig.

No.

DOI

002

003

D04

DOS

005

D06

D07

D08

Part No.

l-12405O0663

1-1240500662

1-12405D

Oil

wick

Needle bar crank pin

1122

Oil

wick

H32422CI08 Thread take-up guide bracket

1-1342118205

1-1350480651

HAI

10D0672

1-12405D1112

1-124211D305

lliread take-up lever

Thread take-up lever

Screw

Thread take-up link I I

Plug

Description

pin

00

N

0

"'

N

u

0

009 H3409C067I Connecting link I I

D10

HAI00l-12150

Oil

H3409C0672 Bushing I I

D12

H34l0C30IP Square block

D13

H3406C067I Connecting stud

D14

H3406C0672

015

1-1602040240

016

H3400C2050

D17

1-1320480652

D18

l-13406C0673

D19

H20l2N0652 Screw

D20

H3407C0661

021

1-1323110506

D22

H3231

H32311D406 Oil wick

023

1)24

H3407C0662

Screw I I

Needle bar rocking shaft crank

Pin

Washer

Bushing 2 2

Needle bar rocking shaft

Connecting crank

Nut

ID306 I linged screw

Rocking shalt connecting

rod

I

00

N

00

N

*

0

"'

N

0

"'

N

u

u

0

0

I I

I I

I I

I

I I

I I

I I I I

I I

I

3 3

3

I I

I

I

I I

I I

I I SM9/64(40)x

I I

I I

I

I I I I

I I

I

I I

I I

I

I I

I I

2 2

I

I I I

I I

I

I I I I

I I

I I

I I

I I

I

I I SM5/16(24)x26.2

I

I I

Cl

C!l

I

00

N

0

"'

N

u

0

I

q>3

80

ljl2.5><240

I

3 SMl5/

64 (28) ><

I

GB/Tl

17 4 24

I SMl/4(24)

I SMS/16(24)

I

Remarks

11

><

16

12

-

27

-

Page 31

E.NEEDLE

48--

47

48

BAR

45-----m

MECHANISM

6 7 8

44--.u.

43

42--<Cl

41--~

40::3.

39~

38

37

36

-f.1

:2:1

33~

32

~

I

31

30

29

2s

21

20

2s

24

23 22

21

20

19

,.

'

0

-

28-

Page 32

E.NEEDLE BAR MECHANISM

Fig.

No.

Part No.

E0I H3410C3025

E02

HA305E0662

H3248IBC21 Screw

E03

H3410C301J

E04

E0S

H3410C301O

E06

H3410C3023

E07

H3441

IC110

E08

H609030220 Pin

H007013070

E09

H3410C3022

EI0

H3410C301H Holder

El

I

E12

H3410C301Q Holder

El3 H3410C301L

E14

H3410C301E

HA703R0067

EIS

E16

H3410C30IK Screw

,

El7

H3410C30ID

EIS

H3215K0693

El9

H3410C301C Screw

E20

H3410C301B

E21

H3410C3015

E22

H3410C3019

E23

H3410C3018

E24

H3410C3017

E25

H3410C3016

E26

H3204D6513

E27

H3410C3014

E28

l-134411C310

E29

H3400C2020

E30

H320012030

I

13400C20

E31

E32

1-13204D0~8

E32

H3304D065I

E33

H324818521

H34412C710 Screw

1:34

1-134412C910

~3~

1-134412C410

P4

H3441

E

31

E38

E39

IC210 Needle bar

H3410Cl264

H3410C3011

E40 H3410Cl263

E41

H3410Cl265

E42

H3410Cl262 Nut

Bushing

Screw

Spring

Oil

wick

Oil

wick

Needle bar supporter

E-type stop ring

Needle bar supporter guide

Screw

Stopper

Washer

Guide plate

Screw

Needle bar supporter

Needle bar holder (right)

Set screw

Needle

bar

Needle bar holder (left)

Spacer

Felt

Needle bar holder

Bushing

Bolt

Washer

Needle bar guide

I 0

Needle DPx5#14

Needle DPxS#

Screw

Stopper

for

Spring

Triangle

Steel

ball

Stud

Spring 2

Description

pin

holding stopper

for

needle bar supporter 2 2

18

:

needle clamp

pin

0

~

00

N

on

0

N

u

C,

I

2 2

l I

'1l

00

N

on

0

N

u

C,

I

~

I

00

N

on

0

N

u

C,

I I I

2 2

I

I I I

I I

l

l

I I I

I I

I

I I I

I I I GB/f896 7

1

I I

I I

I I

2 2

I

I

I

I I

I I

I

I I I

I I I

I I

I I

I I

2 2

I I I

I I I

I I I

I I

I I

I I

I

2 2 2

2 2 2

I I

4 4

I I I I

I I

I

1 · I

I I I

I I

4 4

I I

2 2

I I

I I

2 2

2

4

2

2

I

4 4

2 2

2 2

2 2

2 2

12 12

2 2

I I

4

2 2

2 2

2

2

12 12

2 2

2 2 2

2 2

2 2 SMS/64(64)

Q

I

a:)

I

00

N

on

0

[l

C,

SM

SM9/64(40)x6

I

I

I

I

Remarks

l 5/l 6(28)x4.5

I GB/f879. l 3x22

SM9/64(40)x4

SM9/64(40)x6.5

SM9/64(40)x5

SM3/32(

I

I

44

)x4.2

2 SM9/64(40)x3 .5

2

SM

11/64(

I

I

40)x

2

SM

I

l/8(44)x3.5

SM

1/8(

44

)x6

Sq,2.5

I 2

-

29

Page 33

E.NEEDLE BAR MECHANISM

Fig.

No.

E43

E44

E45

Part No.

H34l0Cl261

H344l2C310

H34412C210

E46 H34412CI

E47

H344l2C5l0

E48

H344l2C810

Nut

Pin 2

Sleeve

10

Spring 2

Pin

Screw 2

Description

~

I

00

N

,r\

0

N

u

c.,

2

2

2

0

co

00

N

,r\

0

N

u

c.,

I

I

~

00

N

,r\

0

N

u

c.,

2 2 2

2

2 2

2 2 2

2 2 2

2 2 2

2

2 2

0

I

co

I

00

N

,r\

0

N

u

c.,

SM5/64(64)x6

M5.5x5

Remarks

-

30

-

Page 34

F.NEEDLE

BAR

CONTROL

MECHANISM

2 3 4 5 6 7 8 9

11

12

13

14

18

36 35 34 33 32 (4)

31

30 29 28 27 26 25 24 23

-

31

22

21

20

-

19

Page 35

F.NEEDLE

BAR

CONTROL MECHANISM

Ill

~

00

Fig

No

FOi

F02

F03

F04

F05

F06

F07

F08

F09

FIO

FIi

Fl2

Fl3

Fl4

FIS

Fl6

Fl7

FIS

Fl9

F20

F2I

F22

F23

F24

F2S

F26

F27

F28

F29

F30

F31

F32

F33

F34

FJS

F36

F37

F38

F39

F40

.

.

No.

H3400D2030

H3405D0663

H3400D2120

HA731

ICC06

H340SD0661

H0030S70SO

Screw 2 2 2

Ball

joint 2 2 2

Cover

Screw

Connecting

Nut 2

Description

rod

H3416D0692 Screw I I I

H3416D0691

HAI00821

H322186810

H34321D407

H609030180 Spring

H34321D207

H34321Dl07 Stop motion control

H3400LOOSO

Arm

IO

Blot I I I I

Nut

Shaft

pin

Pinching bushing I 1 I I

lever

Thread guide I I I I

H2004J0067 Screw 2 2 2 2

H3400D2060

H3407P067I

H3408D0681

Pipe I I

Pin

Pin

H3408D0686 Lever position plate I I

H3408D0682

H0070l3040 E

H3408D0684

H3408D068S

Spring I I I I

type

stopring

Lever

Pin

H3400D2100 Spring I I I I

HA300C2030

H3400D2090

H3400D2080

H3400D2I

H3410C3021

H3404D06S2

H3404D06S3

Screw 2 2 2

Plate

Pipe

IO

Screw

Cam

Guide

pin

Pin I I 1 I

H3404L06SJ Washer

H3404D06SS

H3404D06S7

H3404D06S6

H3404D06S8

H3404D06S4

H3404D06SI

H3404L06S2

Pin 2 2

Spring 2 2 2 2

Cap

screw 4

Spring 2 2 2

Pin 2 2 2

Guide

Bushing

00

N

on

0

N

u

0

'

'

N

on

0

N

u

0

I I I

2 2 2 2

I I I 1

2'

I I I

I

I

I

1 I

I 1 1

I I

I I I

I I I I

1 I 1

1 I 1 I

I

1 1

I

I

I I

1 I 1

I .

I I

I I I I

I I

4

I

I

I I I

Q

'

~

00

'

N

on

0

N

g

2 2

I I

1

1

1

I

I

I I

2 2

4

1

Q

'

Ill

00

'

N

on

0

N

u

0

SMl l/64(40)x9.5

2

2

JKM5

I

SM9/64(40)x6.5

MS

SMI 1/64(40)x6.6

I

I

SM

I S/64(28)x I 0

SMI 1/64(40)

I

I GB/f879.I

I

SMI

l/64(40)xl

I

I

I

I

GB/f896 4

I

SMI l/64(40)x8

2

I

I

SM9[64(40)x

I

I

SMS/16(28)x4

4

2

2

I

I

.

Remarks Part

Jxl8

1.4

12.5

-

32-

Page 36

G.STITCH

REGULATOR

MECHANISM

33

2

3 4

5

6 7 8

(7)

9

10

11

12

13 14

15

29

30

28

27

26

-

33

25

24 23

-

22

21

20

19

Page 37

G.STITCH REGULATOR MECHANISM

Fig.

No.

G0I

G02

G03

G04

G05

G06

G06

G07

G08 I IA

G09

GI0

GI0

Gil

Gl2

Gl3 IGl4

Gl5 H3216F0071 Reverse sewing lever (complete) 1

015

Gl6

Gl7

Gl8

Gl9

020

G21

G21

G22

G23

G24

G25

G26

G27

G27 H3304F

G28

G29

G30

G31

G32

G33

G34

G35

Part No.

M3204F0651

IIAI 13F0684

I 13200F2020

1-13206F0661

1-13206F0662

1-13200F2060

1-16904F8001

l-

13200F2

I I 0

I 00F2080

I-IA700F2030

1-13207F0671

l-14905G8001

I-IA800F2020

Feed regulator

Screw

Screw I I

Connecting

Eccentric shall

Reverse stitch shall I

Reverse stitch shall

Spring

Pin

Pin

Arm

Arm

Screw I I I I

Description

link

I 13207F0672 Screw

IAIO0F21

HAI

I0 Spring washer

13F0684 Screw

H4906G800I Reverse sewing lever

IH207F0673 Spring I 1

H3200F2050 Bracket for spring I

I-IA300C2030

I-IA720F0686

HA720F0685

H8504H8001

H9204F8001

HA7421Fl20

Screw

Screw

Bushing I I

Stitch length indicating plate

Stitch leng

th

indicating plate

Dial I I

HA720F0683 Stopper pin releasing lever I I

HA720F0687 Coil spring

HAI09F0671

HAI09F0673

Screw bar

Screw

H3213F0702 Dial

0651

Di

al

H3206F0662

H3210F0681

Bolt

Sc

rew

H32l0F0683 Stitch regulating crank lower

H3200F2080

Holding plate

of

reverse bar I

HA703R0067 Washer

H3212F0692

H3208G0672

1-13212F0691

Rev

erse bar

Square block 2 2 2

Guide plate

Cl

~

00

N

If'\

0

N

u

i:.,

ca

00

N

0

""'

N

u

i:.,

I

I

~

00

N

If'\

0

N

u

i:.,

I I I

2 2 2 2

I

I I

I

I

I

I

I

I I

I I

I

I

I

I I

I

I

I I

I I 1 1

I

I

2 2

I

I I

I

I

6

5

6

I I

I

I

I I I

I

I

I

1

1

1 I

1

2 2 2

1

I

I

2

I

I

I

I I

2

1 1

I I

I I

2 2

Cl

~

00

N

If'\

0

N

u

i:.,

I

SM

15/64 ( 28)

SM

I

I 5/64(28)x I 2

I

I

I

SMl5/64

SMl l/64(40)x8.5

SM

15/64

I

SM

5

11/64(40)•8

SMJ/16(28)"

I

I

I

SM3/6(28)x8

SM

l/4(40)x8

M5

2

·,6

I

2

Remarks

><8.5

(28)

xl6.5

( 28) x8.5

12

-

34

-

Page 38

H.

LOWER

SHAFT & FEED

ROCK

SHAFT

MECHANISM

49

48

2 3 4 5 6 7 8 9

26

27

28 29

LL

10

11

12

13

14

41

-

35

-

Page 39

H.LOWER SHAFT &

Fig.

No

1101

1-102

1-103

1-104

HOS

1-106

II07

1-108

1-109

Part No. Description

.

1-13213213104

1-132132B204

1-132001-12010

H3205H0655

1-132051-10654

1-132143B104

1--132132B204

1--132154B104

HA700F2l00

Lower shall bushing lcli

Oil

wick I I

Lower shall

Feed

lifting

Screw

Lower shaft bushing right I

Oil wick I

Lower shall bushing middle I

Screw

FEED

cam

ROCK

SHAFT

HI0 H3208G0674 Screw 2

MIi

1-132372G208

1-

112

H32372G408

Hl3

l-l32372G308

1-114

H32372GI08

1-114

H3305GI0I I

1-115

1-13231

HAIO0C2020 Screw I

Hl6

1-117

1-12405D0664

1-118

H3208G0675 Nut 2 2 2 2

1-119

H3208G0676 Screw

H20

H3208G0673 Connecting

H21

HAI05D0662

H22

H3208H0662

H23

H3208H0661

H24

H3200H2060

H25

HA73

I IC306

H3205GI

H26

H26

H4942H8001

H27

HS90131005 Screw

H3205G0662

1-128

H29

H32243G205

H2012N0652

H30

H31

H3407C0663

H3407C0664 Pin

H32

H242l

H33

1-134

1-13204B0656

H35

HAI08G0661 Collar

HAl05D0662

H36

H37

H3204G0651

H3204G0652 Felt

H38

H39

HAI00G2120

H40

HAI04G00l2

H41

H3205GI032

Washer I

Feed connecting

rod

Needle bearing I I I

feed

IGI08

Lever

Lever

Link

feed

connecting

connecting

cam

cam

Screw

rod

crank

Screw 2 2 2 2

Bushing I

Ball bearing

Bearing holder I

Screw 3 3

111

Feed bar I

Feed bar I I

Oil

wick

Feed

bar shaft I I

Screw 2 2 2 2

Feed

rock shaft crank

Oil

1D405

wick

Feed

rock shaft crank (right)

Screw

Feed

rock shaft I

Feed rock shaft bushing (left)

Screw 2

Feed

rock shaft Crank (left) I I

MECHANISM

a

~

O?

I

00

00

N

N

.,..,

'"

0

0

N

N

u

u

0

0

I I I I

I

I

I

3

3

2 2 2

I

I

I

3

3 3 3

I I

I I

I

I I

I

I I

I I I I

I

I I

2

2

4 4

2

2 2 2

I

2

I

~

I

00

N

.,..,

0

N

u

0

I I

I

I

I I

I I I

I I I

I I

I

I I I

3 3

I I

I

I I I

I

I I

I

I I

I I I

I I

I I

I I

I I I

I I

I

3 3

I

I

I I I

I

I

I

I I

I I

2 2

4 4

I I I

I I I

2 2

Cl

~

00

N

'"

0

N

u

0

I

I

SMl /4(40)

SMI

SM

K32x37

I

SM 15/

SM 15/

SM 1/4(24)

SM 15/64(28

SMl/4 (40) x6

I

6004ZZNR/5K

SM9/

M5

x5

I

I

SMl/4 (

I

SMl/4 (

SM3/16 (28

Remarks

l/

64(40)x7

1/4(24)•

xl3

64 ( 28

64 ( 28

64 (40

24

40

><

5

22

)x

) x7

) '

) Y4

) ~ 12

) x I 0

) x

14

14

16

- 36 -

Page 40

H.LOWER SHAFT & FEED ROCK SHAFT MECHANISM

Cl

Cl

i

O?

I

00

00

N

N

tr,

tr,

0

0

N

N

u

u

0

0

I I GBff97. I 6

I I

I

Fig

.

Part

No

.

1141

142 l-1320SG0662

11143

1-144

1-145

1146

1-147

1-148

1-149

1150

HSI

No.

H490SH8001

l-1320002030 Holder

1-132001-12040

H005001060 Washer

HS90131951

1-1003056030

1-132051-10651

1-132051-I06S2

1-132051-10653

1-1322110205

co

~

I

00

00

N

N

tr,

Description

tr,

0

N

u

0

0

N

u

0

Feed rock shaft Crank (lefl) I I

I

Oil wick

I I I

I I I I

Bolt

I I I I

I I

Screw

Nut

Feed bar connecting

Felt

Screw

Bolt

fork

I I I I

I I I I

I I I I

I

I

I I I

I I I I

Remarks

SM

15/64(28)x

M3

xl4

M3

SMl/8(44) x4

SM

1/8(

40) ><7

18

-

37

-

Page 41

I.HOOK

GC20528-B/D

SADDLE

MECHANISM

7

6

4

3

2

1

GC20528-M/B-D

7

____

_

8

9

10

29

33

-

38

-

Page 42

I.HOOK

Fig.

No.

IOI

IOI

IOI

IOI

I02

103

104

104

104

104

105

105

106

106

106

106

107

l07

107

107

108

109

110

111

111

112

112

113

114

115

115

116

117 I IA

118

118

119

119

120

121

122

123

124

125

Part No.

11320410651

I

1330410651

1-169041-18001

I

149061800

113207I0661

11320710066

1-

1340510652

1-1350012010

11850417101

H9304J7101

H69061-l8001

1-

149221800

1-12400\2020

1-

1330610067

H8505l8001 Bobbin

1193051800

1-1340610671

11350510651

1-1850618001

1-19306]8001

l-13204\0656

11321531504

H32153l204

11321531304

11331311204

1-1321531104

1-1331311104

1-1200410067

1-

1320012030

11220012020

113305\0066

11005008050

I 0400658 Nut

1-

1321211304

1-1331211204

1-1340410011

11331211104

1-1320410657

1-1321421204

IIA

I 05D0662

l-1321421104

H320410653

H2013J0065 Washer 2 2 2 2

SADDLE MECHANISM

Description

Hook saddle (right)

I look saddle (right) I

Hook saddle (right)

Hook

I

I Spring

I

saddle (right) I

Screw 2

Bushing 2

!-look

complete

Hook complete

Hook

complete

I-look

complete

Spring

Bobbin

Bobbin

Bobbin

Bobbin case

Bobbin case

Bobbin case

Bobbin case

Oil

wick