Purchasing

Copy

Dept

HIGH

GC1988-MD

Single Needle High Speed Dry

Thread

LEAD

Lubricated

Trimmer

Lockstitcher

With

Instruction

SHANGHAI

Parts

HUIGONG

N0.3

Manual

Catalog

SEWING

MACHINE FACTORY

----- CONTENTS -----

1. PRECAUTIONS

1) Safety precautions ···························································································································1

2) Precaution before

3)

Precaution for

2.

PREPARETION

Adjustment

3.

PRECAUTIONS

1)

Lubrication

2) Adjustment

3) Periodical cleaning .......................................................................................................................... 3

4)

Precaution for position detector····································································································· 4

5) Installing the belt cover··············································································································

4.

HOW

TO USE

I)

How to

2) Threading········································································································································· 5

3) Ad.iusting of stitch length & reverse lever

4) Adjustment

5) Adjusting

6) Adjusting

7)

Adjustment

8) Adjustment of lower

BEFORE

Operating

BEFORE

of

needle

FOR

STARTING OPERATION ..................................................................... 1

Starting

Operation··························································································· 1

Conditions ···························································································· 1

START

bar

STARTING

TO

OPERATE··········································································· 2

stop position························································································· 2

TO

OPERATE··········································································· 2

···································································································································· 2

of

the

THE

attach

of

of

the

of

amount

MACHINE·········································································································· 4

needle······················································································································· 4

the

thread

pressure

thread

upper

of

oil for hook····················································································· 3

..

································· .. ·············································· 5

guide····································································································· 6

of

presser

foot····························································································· 6

tension·········································································································· 6

thread

thread

tension····································· ......................................................... 7

tension .............................................................................................. 7

...

··

4

9)

Thread

10) How to wind the lower

11) Ad.iustment

12) Adjustment

13) Adjustment

14)

Ad.i

15) Adjustment

5.

SPECIFICATIONS

6.

PARTS CATALOG ..............................................................................................................................

A)

A1·m

B) Sewing mechanism ························································································································17

C)

Feeding

D) Stitch

E)

Presser foot mechanism ................................................................................................................ 27

F)

Knife

G)

Touch

H)

Wiper

I) Oil lubrication mechanism··········································································································· 37

.J) Accessories····································································································································· 39

wiper (for machine equipped with

ustment

thread

offeed

of

offeed

of

of

dog height and inclination·············································································9

remaining needle

timing·····································································································

forward/backward

knife engagement .................................................................................................

on the bobbiw····························· .................................................. 8

thread

stitch length ......................................................................... ! 0

thread

length

wiper)························································· 8

after

thread

trimming

...................................... 9

······························································································································12

bed & Its accessories ............................................................................................................

and

feed lifting &

regulator

actuating

back

mechanism··········································································································

mechanism··········································································································

mechanism & Detector mechanism

Rotating

hook shaft mechanism ·····················································13

..

······························································ .........

mechanism··························································································································35

..

·····10

11

13

13

23

29

33

1.

PRECAUTIONS BEFORE STARTING OPERATION

1)

Safety precautions

(

1)

When turning the power on, keep your hands and fingers away from the area around/under the needle

and the area around the pulley.

(2) Power must

(3) The power must

adjusting the machine, or when replacing.

( 4) Avoid placing fingers, hairs bars etc. nears the pulley,

the machine

(5) Do not insert fingers into the thread take-up cover, under/round the needle, or pulley when the ma-

chine

(6)

If

a belt cover. finger guard, and/or eye guard are installed, do not operate the machine without these

safety devices.

be

is

is

in operation.

turned

off

when the machine

be

turned

operation. Injury could result.

off

before tilting the machine head, installing or removing the "V" belt,

is

not used,.

"V"

belt, bobbin winder pulley, or motor when

2) Precaution before Starting Operation

(1)

If

the machine's oil pan has an oil

(2)

If

the machine

( 3) When a new sewing machine

power

on.

(The pulley should rotate counterclockwise when viewed from the pulley.)

is

lubricated

sun1p,

never operate the machine before filling it.

by

a drop oiler, never operate the machine before lubricating.

is

first turned

on,

verify the rotational direction

of

the pulley with the

(4) Verify the voltage and (single or three) phase with those given on the machine nameplate.

3) Precaution for Operating Conditions

(1) Avoid using the machine at abnormally high ten1perature (35

or lower). Otherwise, machine failure may result.

(2) Avoid using the machine in dusty conditions.

"C

or higher) or low temperatures

(5

"C

-1-

2. PREPARETION BEFORE START TO OPERATE

CD

BEFORE

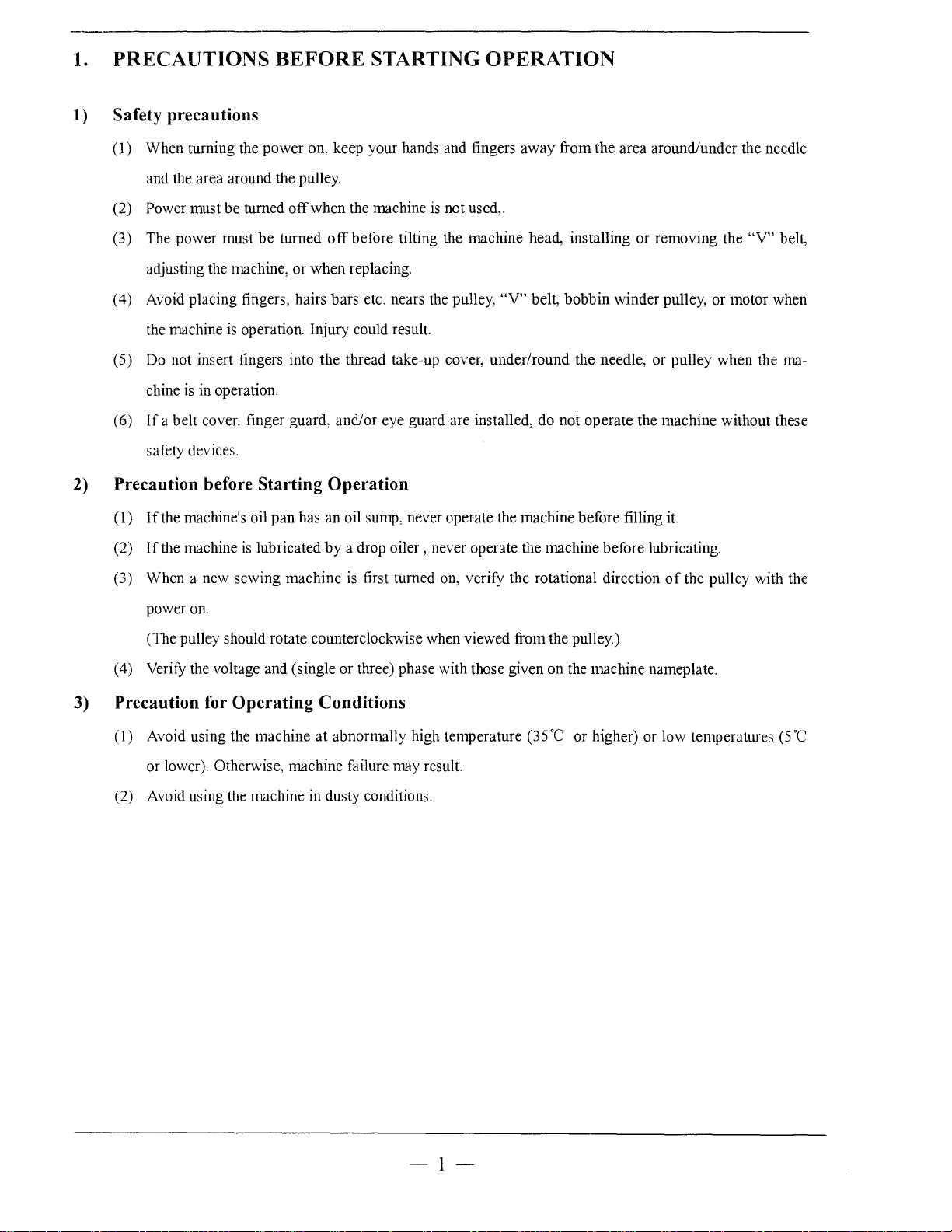

Adjustment

1)

Adjust

When the

chine stops

larger than

(1) Disconnect

machine head.

(2) Run the machine and stop at

(3) While holding the pulley insert the "adjusting

tool" in the hole

2) Adjust

When the pedal

"DOWN" position.

1)

Disconnect the

3nnn adjust as follows the machine head.

of

needle

of

"UP"

pedal

at

"UP" position.

3nnn

the

plug

of

"DOWN"

plug ( 12

bar stop position

position

is

kicked down by heel, the

If

the marks deviate

adjust

as

follows.

(12 pins)

CD

, then remove the tool.

of

cable from the

"UP"

position.

position

is

Neutral the machine stops

If

the marks deviate larger

pins)

of

cable from thun

ma-

as

2) Run the machine and stop at "DOWN" position.

3) While holding the pulley insert the "adjusting

tool" in the hole ® . then remove the

3)

Confirm the

pins) coming from the machine head into the

Tirn1ng

mark

Ann

"up"

position

"DOWN" position

receptacle.

3. PRECAUTIONS FOR STARTING TO OPERATE

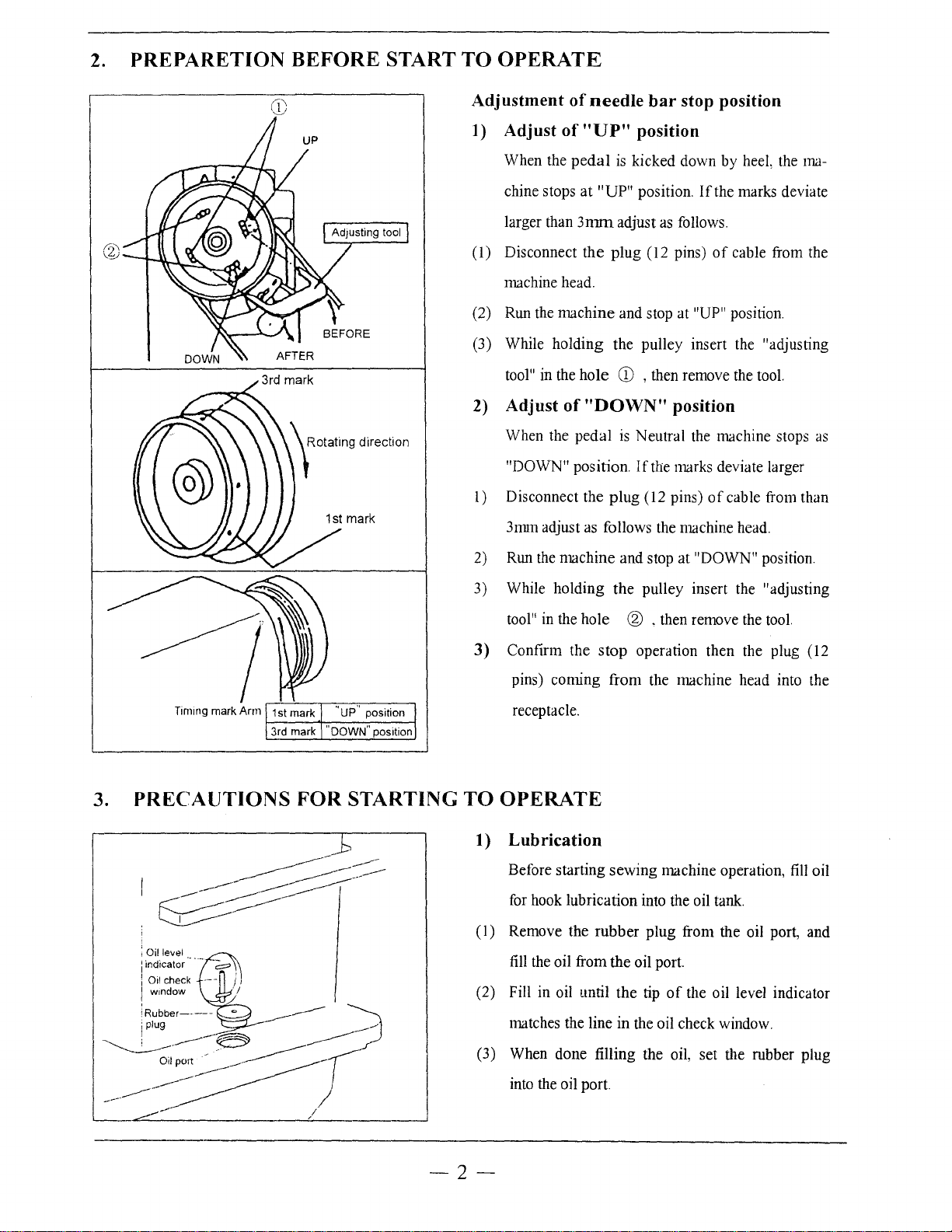

1) Lubrication

Before starting sewing machine operation, fill oil

for hook lubrication into the oil tank.

(

1)

Remove the rubber plug from the oil port, and

fill the oil from the oil port.

(2) Fill in oil until the tip

stop

operation then the plug (12

of

the oil level indicator

tool.

matches the line in the oil check window.

(3) When done filling the oil, set the rubber plug

into the oil port.

-2-

-l

( 4)

If

the tip

of

the

oil level indicator drops below

the line

replenish the oil .

2)

Adjustment

hook

turn the oil

Oil level adjustment screw amount

Decrease (en)\ Increase

3) Periodical cleaning

a.

Machine

(

1)

Remove the throat plate and clean the feed dog.

(2) Assembling is to

screw

tightening

screw driver.

in

he

oil

check window during operation,

of

level

of

oil for hook.

by

2 to 3rotations

them

evenly

the

amount

adjustment screw, and adjust

be

made

by

by

by

use

of

oil for

screwing in the

hand at first, then

of

a long size

Feed dog

(3) Lay down the machine head and clean the hook

and inner

b.

Maintenance

Remove dust from the motor filter every one or

two month.

filter clogged with lint or dust. the motor might

overheat)

c.

Control box

Remove dust from the connector

tor covered

ated.)

bobbin

(lf

with

case.

of

motor

operation

dust. machine might misoper-

is

continued with the

(If

the connec-

-3-

4) Precaution for position

detector

(1) A light type detection element

tector plate sewing machine pulley

with a soft cloth while taking care not

of

ances

(2)

If

locked completely, the motor

the motor from burning (The motor may not be switched

curred.) The operation

been repaired. The above also takes place when the detector has become faulty or any wire has been broken.

the detector plate.

the

position detector connector has been disconnected, the belt has

is

is

used in the detector. Thus, take care

is

removed for adjustments, etc.

to

scratch the detector plate. Do

is

automatically switched

restored

to

normal by switching the power off, and then on after the fault

not

to

adhere dust or oil on the de-

If

dust or oil does adhere, wipe off

not

allow oil

been

removed, or the machine has

off

off

f

in a predetermined period

if

incomplete lock-up or overload has

to

seep into the clear-

of

time

5) Installing the belt cover

(I)

machine side Install the belt cover for safety purposes. Refer

cessones.

for

(2) motor side

4.

HOW

Install the belt cover

TO

USE

THE

MACHINE

safety purposes.

to

the instructions enclosed with the

to

prevent

ochas

ac-

Long groove

left

Use

DB

X 1

or

DA

X 1 needle. According to fabric &

1

Sizeo

fNeedle

#9

------··--

#11

#14

#16

-------·

---------

..

_.

~;~;--

L

.... _ ..

____

·---·--

...

____

No.

#100

#80

1--

#60

#50

i #40

_L

ofthread

lO

#80

to

#60

to

#50

to

#30

to

#20

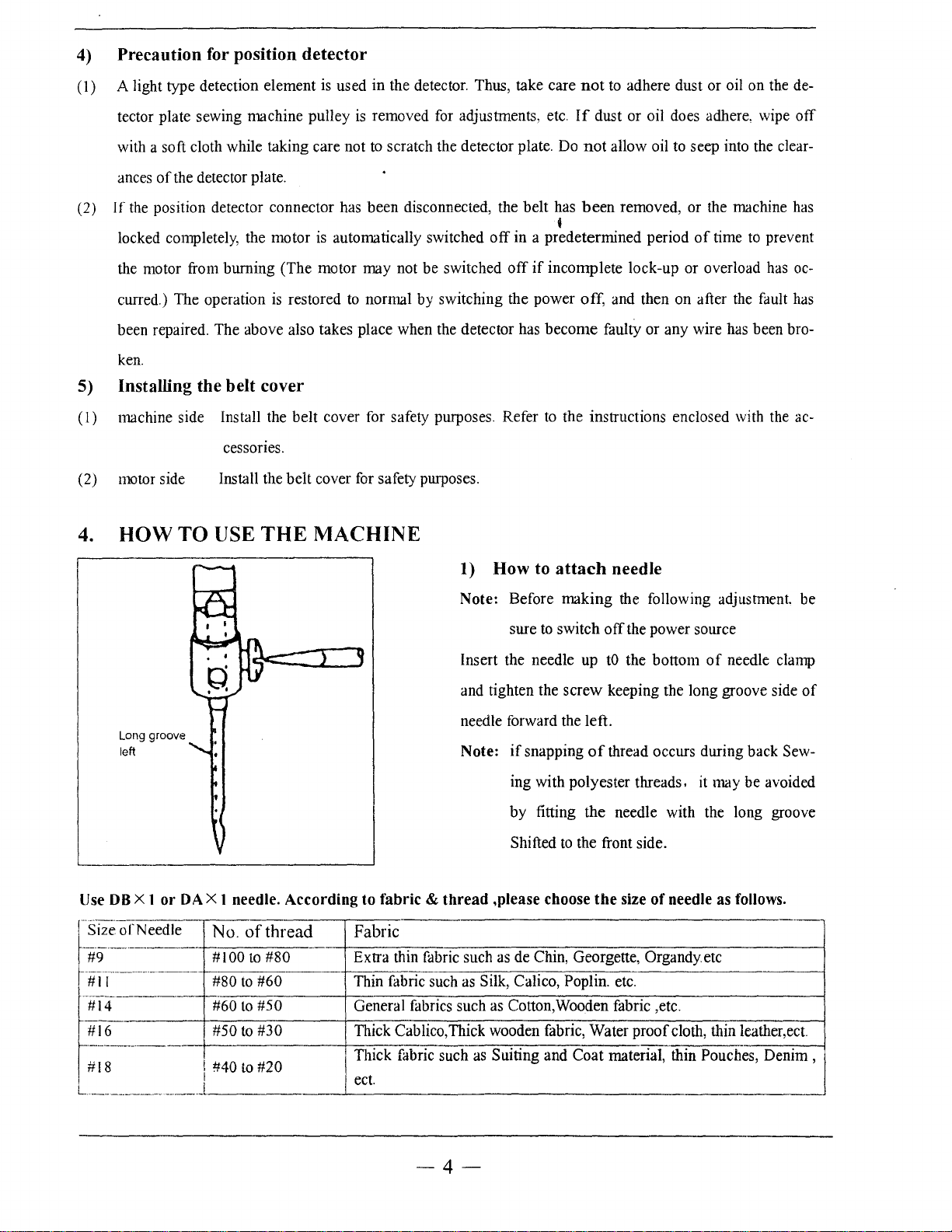

1) How to

Note: Before making the following adjustment. be

sure

Insert the needle up

and tighten the screw keeping the long groove side

needle forward the left.

Note:

thread

,please choose

attach

to

switch

if

snapping

ing with polyester threads,

by fitting the needle with the long groove

Shifted

to

needle

off

the power source

tO

the bottom

of

thread occurs during back Sew-

the front side.

the

size

of

of

it

needle as follows.

Fabric

-·

Extra thin fabric such

Thin fabric such

General fabrics such

Thick Cablico, Thick wooden fabric, Water proof cloth, thin leather,ect.

Thick fabric s ch

I

ect.

u

as

de Chin, Georgette, Organdy.etc

as

Silk, Calico, Poplin. etc.

as

Cotton,Wooden fabric ,etc.

as

Suitin

and Coat

g

materia(thin

Pouch-es

needle clamp

of

may be avoided

--

Denim

'j

-4-

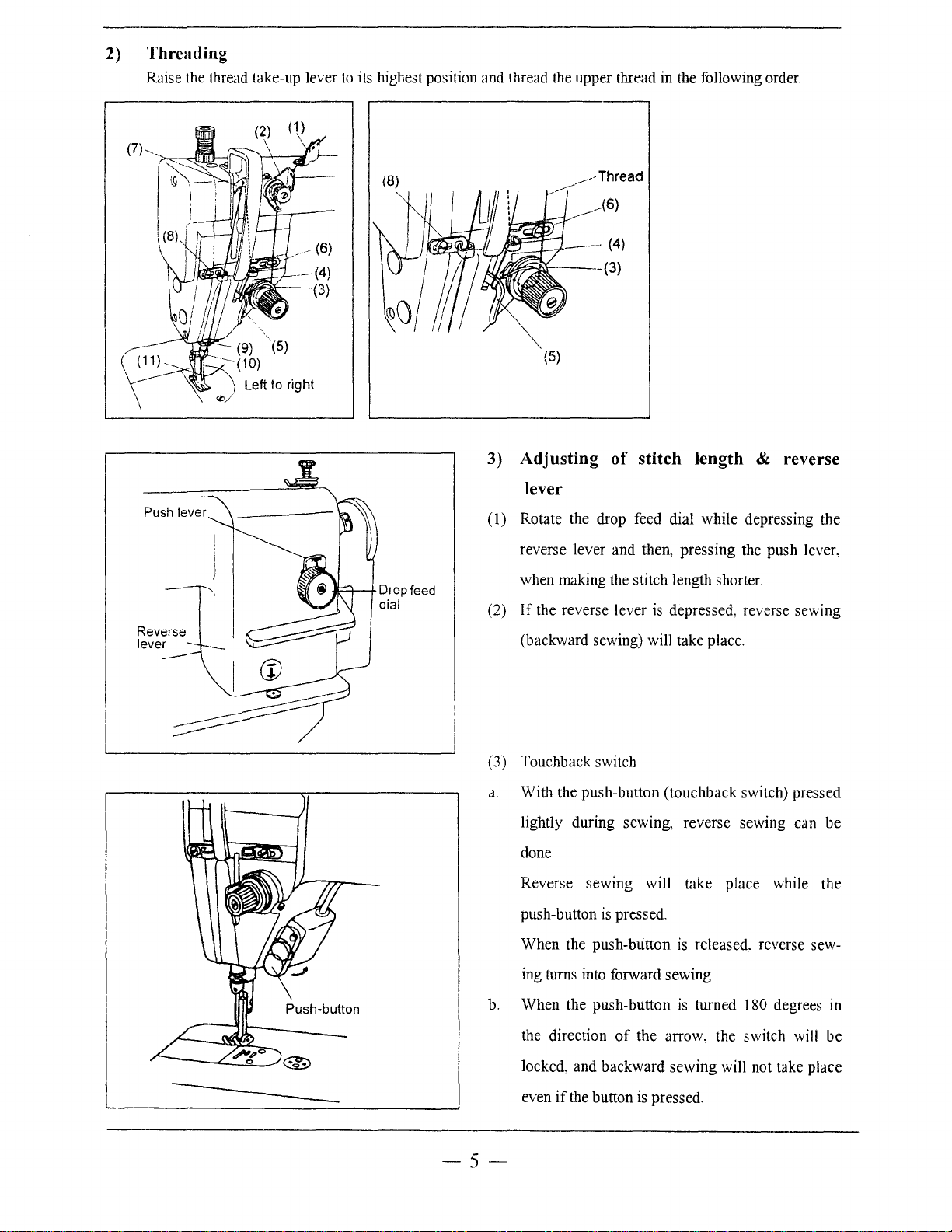

2) Threading

Raise the thread take-up lever

to

its highest position and thread the upper thread in the following order.

(8)

Push lever

Left

(5)

to

right

~~-:1/_

Drop feed

dial

"lf2---+-l----·-·

/ffm.~ir-----(3)

(5)

3) Adjusting

(4)

of

stitch length & reverse

lever

(1) Rotate the drop feed dial while depressing the

reverse lever and then, pressing the push lever,

when making the stitch length shorter.

If

(2)

the reverse lever

(backward sewing) will take place.

is

depressed, reverse sewing

-----

(3) Touchback switch

a.

With the push-button (touchback switch) pressed

lightly during sewing, reverse sewing can be

done.

Reverse sewmg will take place while the

push-button

When the push-button

ing turns into forward sewing.

b. When the push-button

the direction

locked, and backward sewing will not take place

if

even

the button is pressed.

-5-

is

pressed.

is

released. reverse sew-

is

turned 180 degrees in

of

the arrow. the switch will be

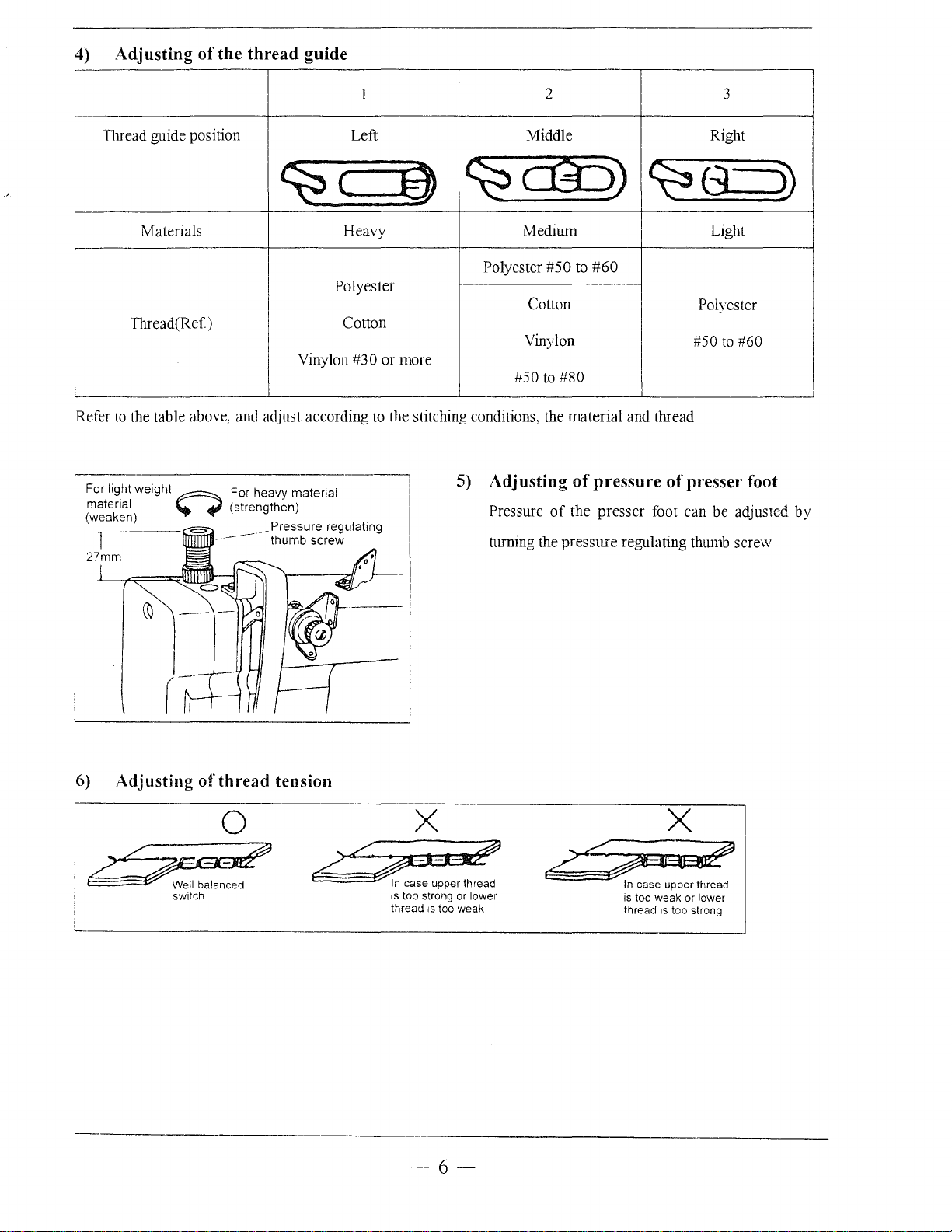

4) Adjusting

Thread guide position Left Middle Right

of

the thread guide

1 2 3

Refer

~

Materials Heavy Medium Light

Polyester

Thread(Ref)

to

the table above, and adjust according

Cotton

Vinylon #30 or more

~

to

the stitching conditions, the material and thread

c

~c@:))

Polyester #50

Cotton

Vinyl on

#50

5)

Adjusting

Pressure

turning the pressure regulating

to

#60

to

#SO

of

pressure

of

the presser foot can be adjusted by

~8

of

Polyester

#50

to

#60

presser foot

thm11b

screw

~

I

6)

Adjusting

r-

~~

~

of

thread tension

0

Well balanced

switch is too strong or lower

c~

X X

thread IS too weak

~~

l

-6-

In case upper thread

is too weak or lower

thread IS too strong

----------------------------------------------------------------------------------

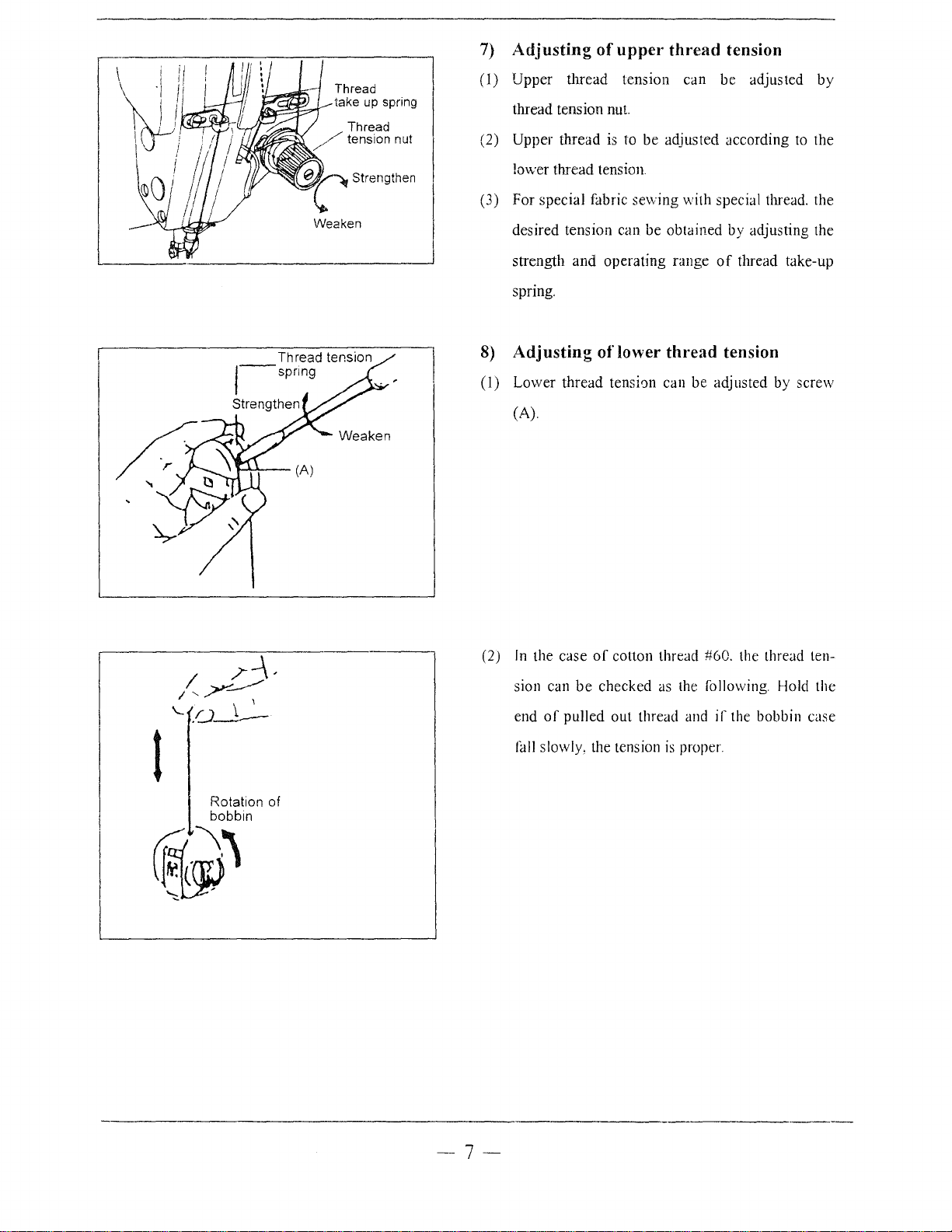

Thread tension

~--spring

Strengthen

Thread

tension

nut

Strengthen

7) Adjusting

(1)

Upper

thread tension nut.

(2)

Upper thread is to

lower thread tension.

(3) For special fabric se\ving with special thread. the

desired tension can

strength

spring.

8)

Adjusting

(I)

Lower

(A).

of

upper thread tension

thread

and

operating range

of

thread

tension can

tension can

be

adjusted <Jccording to the

be

obtained

be

adjusted

by

adjusting the

of

thread take-up

lower thread tension

be

adjusted by screw

by

,-----------------~----------------,

I

_,r-\,

/ " 7-------

~

.a--.-l--

,

1

Rotation

bobbin

of

~'

(2)

In

the case

sion can

end

fall slowly, the tension

of

be

pulled

of

cotton thread #60. the thread ten-

checked as the following Hold the

out

tl1reac!

and

if

the bobbin case

is

proper.

--

7--

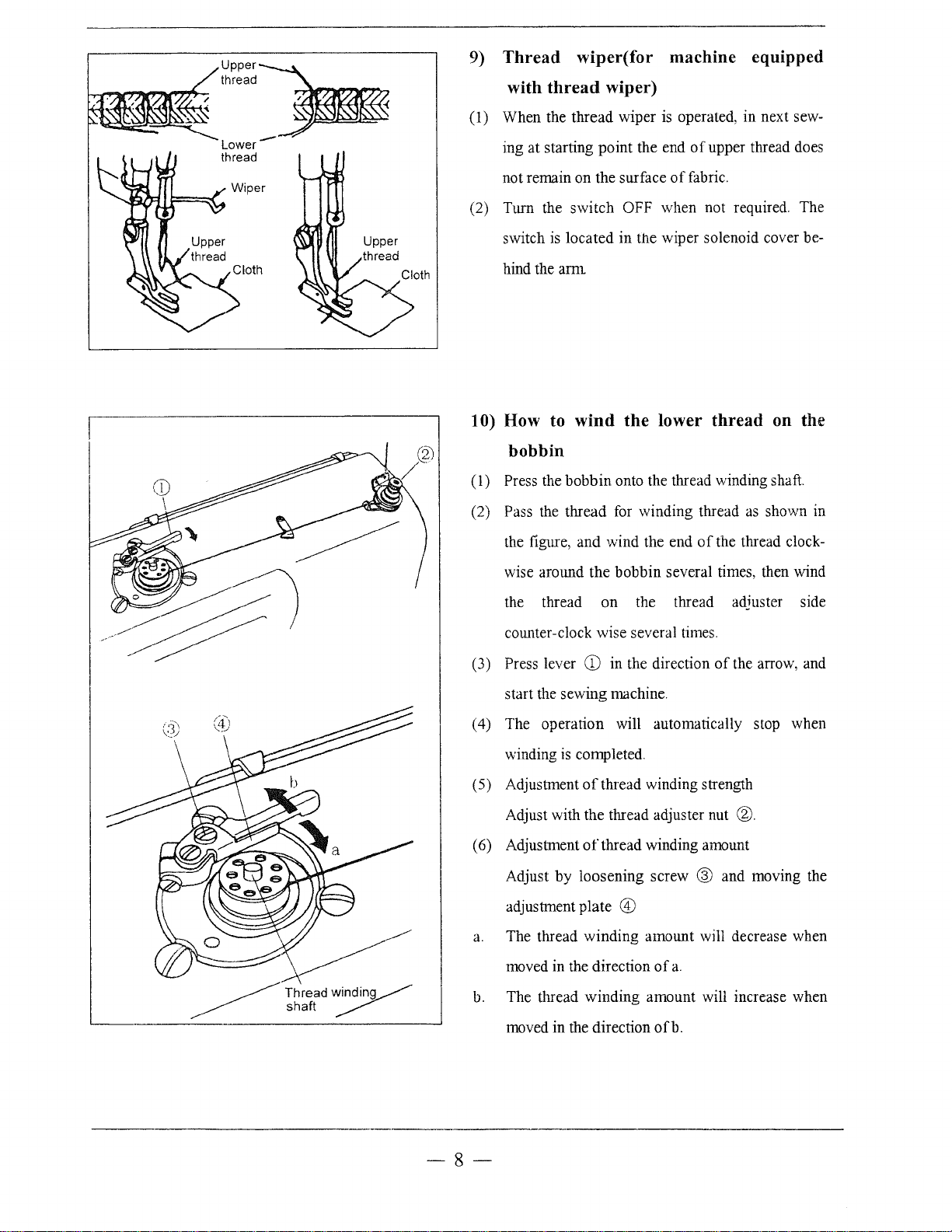

9) Thread wiper(for machine equipped

with thread wiper)

(1) When the thread wiper is operated, in next sew-

ing at starting point the end

not remain on the surface

(2) Turn the switch

switch is located in the wiper solenoid cover behind the

arn1.

OFF when not required. The

ofupper

of

fabric.

thread does

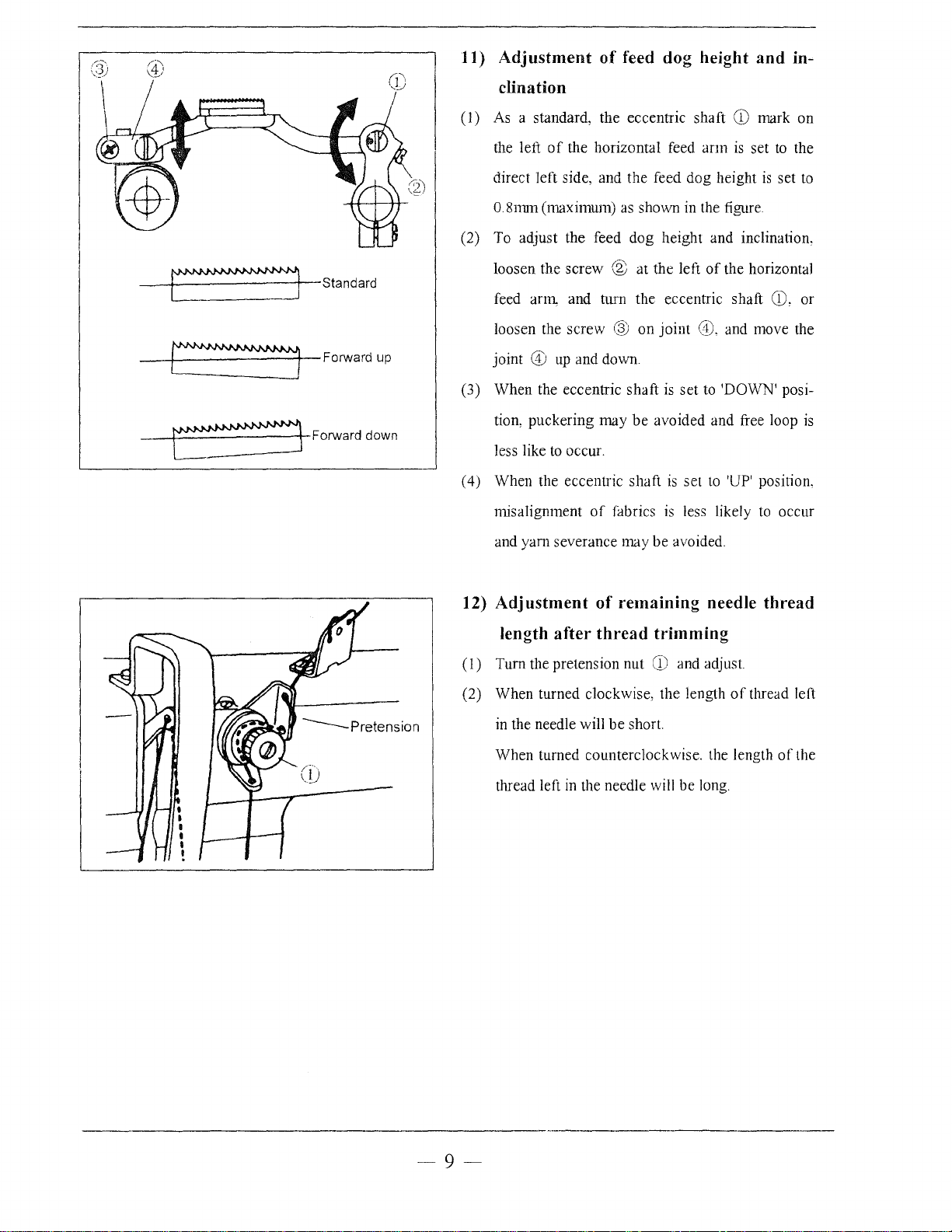

1 0) How to wind the lower thread on the

bobbin

(1) Press the bobbin onto the thread winding shaft.

(2)

Pass the thread for winding thread

the figure, and wind the end

arotmd the bobbin several times, then wind

wise

of

as

shown in

the thread clock-

'---------

~Thread

~

winding~

shaft

~

the thread on the thread adjuster side

counter-clock wise several times.

3)

Press lever

(

start the sewing machine.

( 4) The operation will automatically stop when

winding

(5) Adjustment

Adjust with the thread adjuster nut

( 6) Adjustment

Adjust

adjustment plate

a.

The thread winding amount will decrease when

moved in the direction

b.

The thread winding amount will increase when

moved in the direction

CD

in the direction

is

completed.

of

thread winding strength

of

thread winding amount

by

loosening screw ® and moving the

of

the arrow, and

@.

@

of

a.

ofb.

-8-

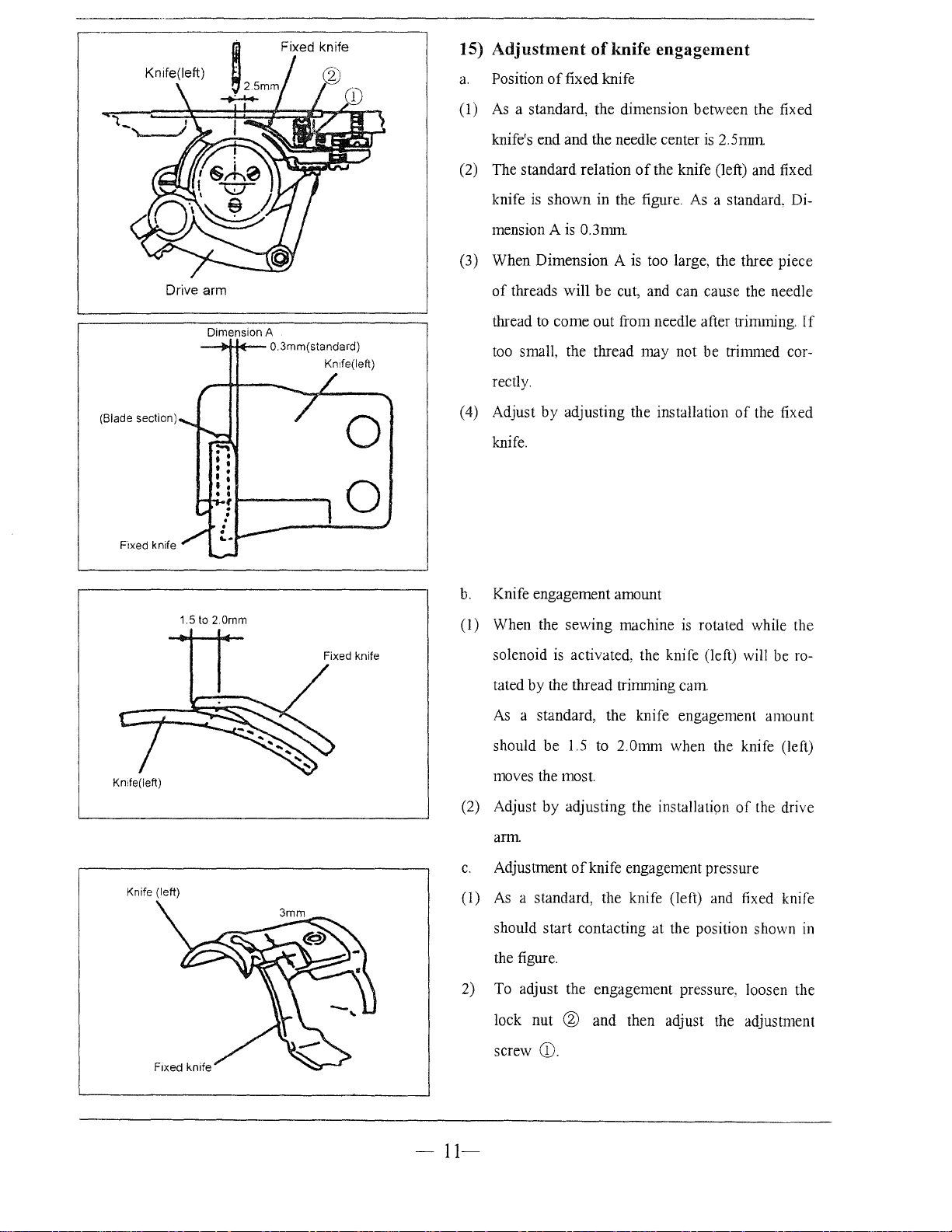

11) Adjustment

clination

of

feed dog height and in-

r.=::J

Standard

t::::=J Forward up

~

Forward down

(1) As a standard, the eccentric shaft

the left

direct left side, and the feed dog height

O.Snnn (maximwn) as shown in the figure.

(2) To adjust the feed dog height and inclination,

loosen the screw

feed arm, and turn the eccentric shaft

loosen the screw

joint

(3) When the eccentric shaft is set to

tion, puckering may

less like

(4) When the eccentric shaft

misalignment

and

of

the horizontal feed

@

up

and down.

to

occur.

of

yam

severance may

® at the left

®

on

joint

be

avoided and free loop is

is

set

fabrics

is

be

avoided.

less likely

CD

ann

is

set

of

the horizontal

@,

and move the

'DOWN' posi-

to

'UP' position,

mark on

to

the

is

set to

CD,

or

to

occur

12) Adjustment

of

remaining needle thread

length after thread trimming

(I)

Tum the pretension nut

(2) When turned clockwise, the length

in

the needle will

When turned counterclockwise. the length

in

thread left

the needle will be long.

be

CD

short.

and adjust

of

thread lelt

of

the

-9-

Adjustment

13)

of

feed timing

l

Adjust

(1)

feed eccentric ring.

(2)

As

when the

linear with

tric ring.

(3) When the eccentric ring is moved

tion

(4) When the eccentric ring is moved in the direc-

tion

14) Adjustment

by

changing the position

a standard, the vertical feed timing

screw

screw

of

a,

the vertical feed dog will rise earlier.

ofb,

the vertical feed dog will rise later.

CD

on

the bearing bushing is

@on

the vertical feed eccen-

of

forward/backward stitch

of

the vertical

in

Is

set to

the direc-

I

length

(1) Loosen

am1.

(2)

Tum

(3) The forward stitch length will increase and the

backward

tric shaft

( 4) The forward stitch length will decrease and the

backward

shaft

screw

CD

on

the right

the eccentric shaft @ and adjust.

length

@ is turned counterclockwise.

length

@

is

will decrease

will increase when the eccentric

turned clockwise.

of

the adjustment

when

the eccen-

-10-

---------------------------------------------------------------------------------

Drive arm

(Blade section)

Dimension A

-+f-1~-

0.3mm(standard)

Kn1fe(left)

0

15) Adjustment

a.

Position

(1)

As

a standard, the dimension between the fixed

knife's end and the needle center

(2) The standard relation

knife

is

mension A

(3) When Dimension A is too large, the three piece

of

threads will

thread

to

too

small, the thread may not be trimmed cor-

rectly.

(4) Adjust

knife.

by

of

knife engagement

of

fixed knife

is

2.5mm

of

the knife (left) and fixed

shown in the figure.

is

0.3nml

be

cut, and can cause the needle

come out from needle after trimming.

adjusting the installation

As

a standard, Di-

of

the fixed

If

Fixed knife

Kn1fe(left)

Knife (left)

1.5 to 2.0mm

0

Fixed knife

b.

Knife engagement amount

(

1)

When the sewing machine

solenoid

tated by the thread trinmling

As

should

moves the most.

(2) Adjust by adjusting the installation

is

activated, the knife (left) will be ro-

a standard, the knife engagement amount

be

1.5

to 2.0mm when the knife (left)

is

rotated while the

cam

arm

c.

Adjustment

(1)

As

a standard, the knife (left) and fixed knife

should start contacting at the position shown

the figure.

of

knife engagement pressure

of

the drive

in

2)

To

adjust the engagement pressure, loosen the

lock nut ® and then adjust the adjustment

screw

CD.

--

11--

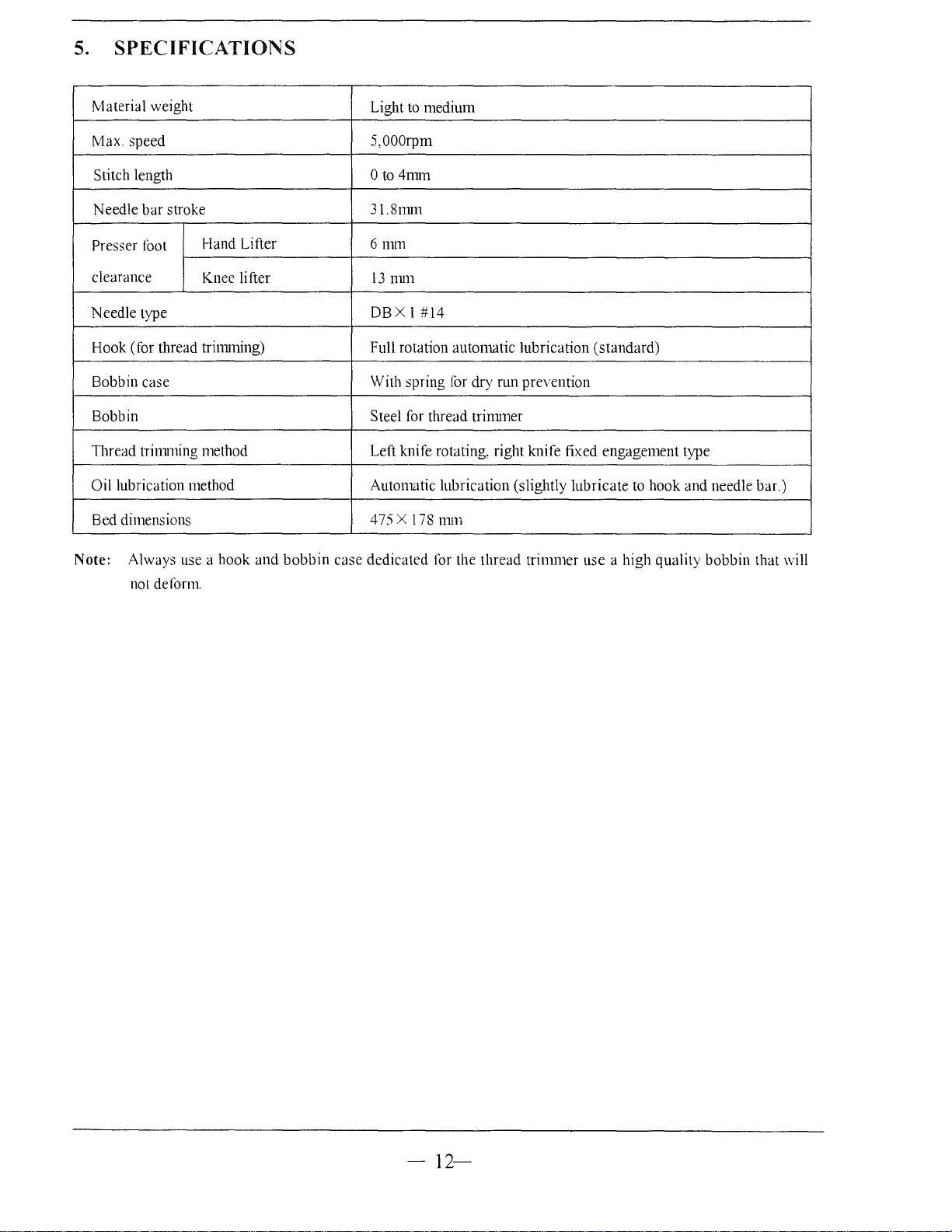

5. SPECIFICATIONS

Material weight

Max. speed

Stitch length

Needle

Presser foot

clearance

Needle type

Hook (for thread

Bobbin case

Bobbin

Thread trinm1ing method

Oil lubrication method Automatic lubrication (slightly lubricate

Bed dimensions

bar

stroke

Hand Lifter 6mm

Knee lifter

trilllining)

to

to

111111

4nnn

1 #14

for

178 mm

medium

for

dry

nm

thread trimmer

prevention

Light

5,000rpm

0

31.8nnn

13

DBX

Full rotation automatic lubrication (standard)

With spring

S tee!

Left knife rotating, right knife fixed engagement type

475X

to

hook and needle

bar)

Note: Always use a hook

not de

lorm

and

bobbin

case dedicated lor the thread trimmer use a high quality bobbin that will

-12-

Loading...

Loading...