Highlead GC188-M-D User Manual

----

'

®

HIGHLEAD

GC188-M-D

(WjJ!~-fJL

ftffllJitm~.

~14l¥*

~

SHANGHAI HUIGONG

~

- I

N0.3

..

~

SEWING MACHINE FACTORY

m

~

~

r

'Z:C"i~.

~fflhl~~o

·z:c:tU~Hi

1-;T

f2.~

'j;

T

12.~

~~fljj

~f:ilHs

~~~M~fflhl~~~~.

1

f{)}JQ

iH?f

L

fJl

ft,

~

SAFETY

{I'fr.:~-i.

J~

1111

OPERATION

iftlir\tJl~ntr,

MEl'~

~?f.

tJJ;

~~~~A~$Mo

in,

INSTRUCTION

.!.'xi111'T1£f*~ffllf'i:.

t1,{1iil:

f,[n

T

i~

n)]

o

~f~~

Lftz

1W,

ilfiAti-I~J~

In order

operating machine or exchanging parts and making maintenance.

I

&.

1.

2.

3.

to

operate machine safety, please read the INSTRUCITON

To make you kown well, explain the

~l:f-t~:u)

l="-1

I\

/\

warning

A

1-;

~flL

'h

ficm,

'hTm~A~~M.

Figure

CAUl

ON

Mrw~ng

parts

may

r_.ause

8

~'~

'""

~~~

trW

nJJ

·-·~

n~l,ec

creanH".g

etc

JU7~

'Z:C:'f'::?~i"i:R~J~~

tt~U!'l~1:t&.

Jr.

A

~IJ8£,

Jf~lJt~di'fJL~o

~

.1J

g:p

Motion section, Be cautious

of

"")

injuries

WARNING

X

i:f

!~JtH~l

tE

~

~#

m~t~~M~~~~m.

f:r

rl'Ti

machine's warning marks as follows:

~?f.r*J

Meaning

'

ill:flY:rJ'J<i~~~lt

--.

]'f[W:

~

if

~J)

_[

ft

MARK

-=Hi~

t1fTn1%

1J

t£

OF

SAFETY

{t:'V:;i&-MwdtM,

2i

ifliffJ'fr.:~tr:Kt~GZ

fr.

irr~

~~~Wfflm~~~c

MANUAL

If

not, it will cause personal injuries.

t~?f.tffiR

warning

~

DEVICE

irHJiliA

Jt

t':k

~

~

carefully before installing,

Mark

m

7r.

Showing right rotation

direction

$2~~i':

tl::!Lt.

fif:.

:ff

5ff!i)_JtOJ

c

~

Ffr-1-~Eill1'TMHto

f,[rJ8('&~--

fff

i,R

i*J

Meaning

JE

flfil

ntr

~

~:J

~J'!J

'fr.:

;g

JJ

rtJ

it't~'te

~[i:J]t?s'~

l. In order to avoid the accident occuring which caused by the deficits

make sure the safety device at itis right position. for

plate.

2.

Before operation, make sure the removed safety device has

3.

Keep the warning marks clean and clear.

example

been

• I

of

the belt, the finger guard and the safety

installed

safety device. before operation,

wen

and ascertain itis effects.

---------

1.

H~Jti

llt~i'3HJLst,

,

2.

{'Effl

I>~~tjJ

n;.

U~~t~il.iHSti"'il~o

3.

llt~~mB~~oom~~~~~~-g~mo

4.

f:'l':mllt~f>JJVltP~i'3JtJLZ9Jf'f:4

'ff(.Y~~g,JJ

5.

llt~fjjffifl

6.

11':m~t3JffiS;f,

7.

~Z:'±T1H¥f/£8J,

7-

HJlrr,

7-29!~TFLt't.

7-3

fi;ti~

7-4 I

ft

7

-sff

8.

UHJL U 2Utt

~ll?¥f

lJt

m~

~'rr,

BL

±m

Jiff

m

~

ir

ff

:k flil1)}

tJlz

EB

£,;giJ1i'TtJJ?;SirrrrYJ

-fW,

if11~li#:;t,:

Jl-_

f:'l':Jti

o

~~:i]:±ii;i)l\i'f~i*ft

~i)(Jt~~~JJ!P~lH~o

fl&Ht:k!lj.l:~;t~ff:k,

5t~

~~3{-tJt

HdJ!;P,

kAT

~

.1tst.

~

ft-t&.

!:'x

~

ff _ _[

fn:Jj

i¥f~ffl'

~it{'f

jt·.

*

E&

mEt~

tJUtl3.

ll3t

il5

fT

m~*~~~

El

0'~

:!£:zts:~~tiHffio

fifJTI

i5?,A]

ts:fr

fAJ

r'BJiff:;fH§'lf:;

1

•

fifTifB'~~~set~a~~¥https://manualmachine.com/EBitl:li:o

X

AD'L*f*f'f:o

~W:Fft!WJi~tw~o

fP1EJ~Jt'E~Bt

~'ft.

P;Jb5c

0

7t~~-

Jiff

B;f

a

~~

i1fJ

iff~§'~~

a

:i!:ftl:t.

1LZ.€

-JI}:lttfr

i*tfiiA~FH¥f

!Pft~.

o

~

-------

f-t,

[fi]

Rt

fl¥5-

lltfrr:ffJ

&1f~~~!EB'~~~~

st~.

~~

¥1J

f!J-'i'f~~~Bto

Hz

ltt.t

at,

~xAJ.hJH'XBt,

i5?,AJj

=j~~-~1*

0ZJL

I 9.

ft

ll:J{j

c:r-

~

HHJ

7fT~

o

f'i

;

I

I

II.

1

12.

13.

~-

1 16.

'-----------------·-----------~-

*:~tJHJLm

-·

J11Z(t~

?:if

1J

X~!!JJ

~JfJL

'JJ

rt

r tUf,

M:tffi

i5f

}d0Jtl

fttJ~.

fl:ti*

TI'fl

fJlErJ

~

~1JITUO'J{i;tlW:.

?f1Y.:k2:~.

·,tz

"]\.

i~H,

~

t.f

tJHJL

c9::iTI.

Eh

5Z:iliJII

0

\ffir

F~C!.C':\t:Jmt-1>

4

rt

/c{

i

Jf:k:®

;m~

fJJ;B'~

1}

!'

Hu

~

m

'4=#

~*=ito

0

E8

~:ct~!'liJII~m:tR*

A~

*:i!Hr

i1f:_fi;tJii:

iidfa2~EB~ftst,

lrf]

ll;t

i~

B'J

A*~

o

E8

~'&'H~B'~

Jt~tt*

0Z

0Z

:rt

::f~

r.'li

~Uc'f'Ntffl

~L

~

iW-

trii

A.Bt~x~***fr

AM.~~*Fi'.l

-t:JJiiff2~HdR3Vl

~:55iUM

*

·.12:'

Jvi

.8J~

fjt~lf,J§"

F}

i1Ur5P(ri]Enltli

iu

~

±!PJ

o

~~~

ru

ffiLL

tPt§'* F Jltfr a

-JI}Jltff

r::

o

f.tm

a

1.

1:7Tfl1JJJ::.tz:j:_fH!R~$m.

~

9:.

f§

r*J

EfJ

4=

14

0

1.

1:7Tfl1Jll::.A~$M:i'fJ£j:_,

i':

i'fJ

:tk

:$ r

~

w~

g,JHJl

2.

:i:JT

fl1J

11::.

:f&:'ffA,fJlHI'fJA~$i!it,

-~~w~.

3.

1:7

Tfl1J

ll::.A~$M:I¥J£j:_,

~HJl

ft

i'fJ

4.

1:7

T

~JJ

JtA~$M:i'fJ£j:_,

s.

H~m•~~.

re¥•:i!I~~o

6. jg T

fl1J

ll::.A

v%~W.

ffl

ili:

o

~~~m~~~o:i:7Tfl1Jll::.¥~~m~.

~$M:i¥J£j:_,

~:f~rrH7t~mi'fJ;tki$r.

~:f~if~r~Wfl1J~--

o

~g,JJm~whttps://manualmachine.com/F~~-f-m.

~~.

ili:f~re*®M~mHkOOo

tr7f~mtat

~t~JJtfl~~~~:f~re¥tr7l~~tl~tttff7~-r*Jo

7l~ff'J~g,JJf}l~:]S@J

l;J_&~g,JJf}l~~~,

JJiU-!Effii':Bt.

¥o

7.

1J

T

ll7J

11:-_

*~i'fJ~ilJ:@:bX:A5t$M:.

Bt,

m---J:E:*=Mftmlo

8.

~ffl

f§J

~Rl!;~Bt,

i!IX.

~ii~:f~75i2:kftmo

9.

1:7Tfl1Jll::.FM!Et!.$M:.

10.

:1;;

T

fl1J

JtfM!Et!.

fPrn±t~9:.4=flf:,

~~JJfJl

~

l1::.1!;~7CF"

~rftmt~tti'fJ;tk?$,

n~ff!J~g,])f}lBt.

if

o

:1;;

T

~:f~~~~g,JJfflo

tttftmi'fJflll!J:Bt,

tr7t~9:.~itr.&FM!m

¥mfl1J~H~~~~

!k:tt.

~:f~re¥tr1it

~~~~~n:f~

Jiii~:f~~tt

~iEP~w-fPV%~W

fl1J

ll::.~:>'~i'fJ~ilJ:@:IJX:A5t$

~7t:kM,fJlHftmt7f:ko

::&~R

.

Ill•

IMPORTANT

SAFETY

INSTRUCTIONS-----

Puttmg

sewing

Technical

1

2

3

4 All

5

6

7 For the

8 !f

11

12

In

14

L

------------------------------

sewing

systems

mach1nes will be bu1lt into,

serv1ce

Observe

Read

keep

Use

spec1f1ed

Th1s

For

7-1

7 2

7-3

7-4

7-5

swallow

Tamper1ng w;th the l;ve

Repair

personnel

General

Repa,r

the

Whe11e•;er yot;

Before

the a;;

Ex1stmg res1dual a;r

Except1ons to

cinily

Per~od;cally

all

this

the

safety

machine

your

For

For

guide

For

When

When

you

should

and

audit

making

con1pressor

skilled

the

the

Instruction

mach

devices

safety

personal

following.

threading

replac1ng

etc

repair

lea·o;ng the

us;ng

any

remodel;ng

Only

ma;ntenance

mamtenance

and

clean

into

for

those

bas1c

safety

instructions,

Manual

me

after

1t

must

dev;ces

shall

be

operated

protection,

turn

off

needle(s),

pnrt!s)

work

working

clutch

motors

allow

011.

grease,

of

such

l;qu;d

and

spare

parts

and

guidance

f1nd a failure

rep;cm

and

has

pressure

th1s

are

only

personnel

tile

mach111e

operation

have

sew1ng

of

to be

systems

measures.

includmg,

so

that you

has

been

ascertained

be in pos;l!on

is

not

allowed

by appropri13tely-tramed

we

recommend

the

power

looper.

of

needle.

place

w1thout

etc.

by

mistake.

parts

ana

dev1ces,

ad;ustment

designated

mspection

works

of

electr~cal

specially

of

any

of

mallltenance

detached

after

adJliStments

throughout

is

prohibited

conformed

is

also

prohibited

Including,

but

not

!1m1ted

may

read

that

when

thP

that

sw;tch or

spreader

presser

or wr1en \he

use

works

works

skilled

electr~ca'

d1sconnect1ng

disconnect

etc.

font

applying

with

the

1mmed1ately

regardless

must

by JLJKican

have

components

personnel

components.

works

on the

from the

and

oerfon1ance

tne

period

until

it

has

with

the

but

not

to

this

1!

at

it

conforms

rnachme

you

and

throCJt

working

brake.

machine

wash

of

only

be

be

to

be

mach

machine

the

a;r

of

been

ascertained

safety

regulations

lim1ted to the

Instruction

anyt,me

wear

replacing

plate

it

used

done

when

with

is

ready

for

operators.

safety

the

power

bobbin.

looper,

place

IS

has

to be

and

devices

the

contacted

whether

done

shall

and

compressor

checks

use

the

by

appropriately

for

repairs.

by

appropriately

be

1mmed1ately

me

equ;pped

the

compressed

done

unattended.

conducted

following

Manual

necessary

safety

work

glasses.

plug

spreader,

wa;ted

to

machine

from

by

that the

in

your

county

ones,

before

rules/standards

or

in

operation

of

the

m'lch1ne

feed

until

the

motor

come

in

contact

areas

and

consult a med;cal

is

powered.

trained

tra1ned

by

qualified

stop

the

mach;ne

with

pneumatiC

a;r

supply

the

machine

appropriately

sewing

whenever

ycu

use

val1d m

The

from

dog

needle

stopped

with

is proh1b1ted

technic;ans

personnel

electric

parts

has

has

trained

systems

you

the

machine.

operast;on

the

receptacle

guard.

totally

your

technic,ans

such

to be

to be

expelled

technicians

in

use

your

eyes

doctor.

or

spec;ally

as

an

cut

off

which

these

the

machine.

In

addition,

country

w1thout the

folder

cloth

or

skm

skilled

or

air

cylinder

or

spe-

or

unde

15

Ground;ng

111

an

An

appropr~ate

to a grounded

17 The mach1ne IS only allovved to be used for the purpose

18. Remodel or mod;fy the

Fa!!Shi Co Ltd assun1es to

L

19

Warn1ng

tile

n'acllllle

env,ror:ment

power

receptacle

h111ts

CJre

Danger

IS

always

necessary

tllat

IS

free

from strong no1se

plug

has

tr' be attacherl

mach111e

marked

of

111

accordance

responstbtltty

w1tr1

the

two

InJury to operator or service staff

for the

sources

1

r'

---

w1th

for darnage

shown

symbols

normal

tlw

mach1ne by

llltellded

the safety rules/standards while tak;ng all the effect1ve safety measures.

caused

operat;on

such

by

of

the

as

h1gh

frequency

electr~c

techr:1c1an.;;

Other used are not ill lowed

renrodeltng

Items requ1ring speCial attent1on

I\

mach111e

or modtftcat1on of the mach:ne

The

welder

Power

-----------------'

macll111e

pluq

has

llas

to be

to be

operated

connected

1

B

1

To

avoid

touch the

FOR SAFE OPERATION

electrical

components

shock

hazards,

mounted

neither

inside

open

the

electrical

the

cover

box.

of

the

electrical

box

for

the

motor

nor

A

1

To

avoid

safety

2.

To

prevent

head and

In

addition.

To

avo1d

3.

switch

To

avoid

4

1s

1n operat1on

The hook

5.

to hands. be

add1t1on

To

avo1d

6.

tilmg/ralsmg the

To

avo1d

7

machine

If

your

8

machine

turn

OFF the

personal

devices

or

machine

removed

possible

clothes

place

personal

operate

personalmjury.

rotates

at a high

sure

be sure to

poss1b!e

machine

possible

when

tilting the

is

IS at rest.

power

never

inJury.

personal

away

from

nothing

inJury,

never

the

machine

never

to

keep

turn

OFF

persona!

accidents

machine

equipped

To

avoid

to the

operate

inJuries

the

handwheel, V belt

around

your

head

them.

put

put

speed

while

hands

the

power

inJunes, be

because

head

with a

possible

machine

your

your

servo-motor.

the

machine

caused

hand

fingers

the

machine

away

from

to the

careful

of

abrupt

or

removing

accidents

by

being

and

under

the

into

the

the

machine

not

to

start

of

the

motor

due

to

with

any

caught

the

needle

thread

is in

operation,

vicinity

when

allow

the

the belt

does

abrupt

of

the

in

the

motor

while the

when

take-CJp

of

the

replacing

your

fingers

machine,

cover

not

start

belt cover,

machine,

you turn

To

hook

turn

and the V belt.

produce

of

the

machine

cover

prevent

during

the

bobbin.

1n

the

OFF

noise

machine,

keep

"ON"

while

machine

the

finger

guard

or

your

tingers,

is

operation

the

power

the

machine

poss1ble inJury

operation.

power

while

be

sure

In

when

to the

the

to

I

I

To

9

the

To

10

turn OFF the

avo1d

electr1cal

power

prevent

supply

possible

power

stwck

removed

accidents

switch

hazards.

because

in

prior

never

operate

of

electric

to the

connection/disconnection

. v •

the

shock

sewmg

or

mach

me

damaged

w1th

electncal

of the

the

ground

components(s)

power

plug

w1re

for

§

~

Contents

Operation Manual · · · · · · · · · · · · · · · · · · · · · · · · · · ·

'2J:{Lf:tf*

Parts

Book

GC

188-M-D~(r:j:l

Model

L

tJl)t)till

Arm

Bed

2.

_t~.

3. rrff.

4.

fff-4.

s .

1:J

6.

J!H5Hll

M~rt:7t~fi

Main

Shaft

~

Needle

f'~rt:5Hfi

Presser

rt;

5Hll

Hook

Priving

Feed

Mechanism

.. · .. · .. · .. · .. · .. · .. ·

JJN ffl)

GC

188-M-D

{4

components

(For

ft

& Thread

rt:

71-~11

f-t

Bar

& Thread

f't

& Tension Release

Take-up

Tension

14

Shaft

Components

ft

Cornponents

Medium

....................................................................................

Bar

··

· · · · · · · · · · · · · · · · · · · · · · · · · .. · .. ·

.. · ..

· .. ·

.. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · ..

Heavy

Components

Components

Components

..............

.. · ..... · ..... · ..... · .....

Materials)

..... · ...........

.........................................................

..........................

· .. · .. · .. · .. · .. ·

.. · ..

· .. · .. ·

· .. ·

..

· .. · .. · .. ·

.............................................

· .. ·

..........................

·

.....

........... · ..... · ........................

· · · · .. · · .. ·

.......

· .. ·

........ · ....................

..

· .. ·

..

· .. ·

.. · .. · .. · .. · .. · ..

· .. ·

.............. · .....

..

· .. · .. · .. · 1

· .. ·

·

.........

25

26

26

28

30

· 32

34

· 36

7.

illH~li-71-tllfl

Feed

Regulating Components

s .

lj'J

rt;

7HJH4

Thread

9 .

t£:

Wiper

10.

il-~¥ff

Lubrication

lL

i'ltlftt.

Oil

12.

tJL

Machine

tJL

Machine

13.

tJL

Machine

Trimmer

rt;

57'-

ffi f't

Components

5HtH~

~ttlffW-117ttllfi

Reservoir

*

~ttf!f:c

1)

Head

Components ·

.. · ·

Components

& Knee Lifter

Accessories(

.......... · .. · ............ · ....... · .. · ..... · ..... · ...... · .... · ...... · .. · .. · ..........

1JfH't(2)

Head

Accessories(2)

~.

f1

f&.

Stand.

rtr

1

~

,)-f!Ht

Tabk

& Electric

..............

.... · .. · ..

..

· ·

.. · ....

· ...... ·

Components

1)

.. · ..

· ·

....

...........................

Appliance

· ·

......................

· .. ·

.. · ..

.. · ..

· ·

· .. ·

.. · ..

Components

·

...... · .... · ....................

· .. ·

..

· ·

....

· .. ·

.. · ..

· ·

....

· .. · .. · .. · ·

....

· ·

....

· ·

.... · ..

· ·

..

· .. ·

....

.........................................................

· .. ·

..

· ·

....

· .. · .. · .. · .. · .. · .. · ·

···

.............................................

...............

· .. · ·

....

··· · ·

.... · ..

....

· ·

· ·

....

···

...............

· .. · .. ·

....

· .. ·

· ·

..

..

· ·

..

· ..

....

· .. · 38

· .. · 40

· 42

·..

44

46

· 48

50

52

fF

$%I

l'fJ

51~

~:rw:

BEFORE OPERATION

~

&~'---

IX

~

J&,

A 7

~JJ

JttJH~~l~i~tdf11=~t~1JJ,

iw

Ml

i)Jm

l'

r_m

§I

0

A CAUTION:

To

avoid

malfunction

1_

iffi~

r*J

*:!Joiffi~::ftiUf:$

2-

fil~±E~

3_

tt~-~$,

4

~~~Mfll~~__t_M~~lli&ffim~~~~

1 _ Never operate the machine unless its oil pan has been filled with oil.

2.

After setting up the machine, check the direction

handwheel by hand

observing the handwheel. (The handwheel should turn counterclockwise as observed

from the handwheel side.)

3.

Do

4

Conf1rm

against the ratings shown

Si,

J-l-__t*'f::91'ffiiJlH~

::f~mffl*R~~~Mfll~~~

not use a larger motor pulley for the first one month.

that the voltage and phase (single or 3-phase) are correct by checking them

and

damage

to

bring the needle down. and turn the power switch ON while

on

of

the

machine,

loJ

B

7J

~

SiH1:J

the motor nameplate.

loL

confirm

i!~,

the

following

::f

titfilJ$~

of

motor rotation.

To

check

it,

turn the

1~ffl

7i~$IYY:

OPERATION

&~,---1

..

PRECAUTIONS

~

A

T~JJJt~ji--~~M@PX:~$~.

iw

*

t*

~1m

f6

{!}

ill1:r

c

~~~~--I

8 WARNING:

Turn OFF

sewing machrne

1

m~~~H*~fil~±E~s-1.

2

tll~±E~Si,

3.

fil~gM&m=m~~s-1.

4

~~~~Hm~s-1.

5

tll~~$~WHBJ.

tJl

6

~m~~~.

1

::f~m~~*~~~~n~m~M~*oo

8.

~AA~~fll~~~~.

1.

Keep your hands away from the needle when you turn the power switch ON or while the

machine

2.

Do

not put your fingers into the thread take-up cover while the machine is operating.

3.

Be sure

belt.

4.

When

5.

During operation, be careful not to allow your or any other person's head or hands to come

close

to

6

If your machine

operate your machine with any

7.

Don't clean the face of machine head with thinner.

8

Penrlically clear dust and lint from the machine, and do the maintenance work

an

to

them. Doing so may be dangerous.

the

power

before startrng the work so as to prevent accrednts

~~~~$~H~~M

~~

1~-'¥

:t§1$A~t~:fft.PS!

-~~m~~fil**

~~m~~~

i!~::f

M~~.

is

operating.

to

turn the power switch OFF before tilting the machine head or removing the V

operator leaves form the machine. mack sure to turn off the power.

the handwheel. V belt. bobbin winder or motor. Also, do not place anything close

ft

ilifiilJ

~~M~~~~~s-1-

~~.

is

provided with a belt cover, finger guard or any other protectors, do not

A.~~~~~.:J.,0HE16J3t~~ili:__t$-t;

~~.

of

r*J

~~HMfil~

~B~WI~

them removed.

caused

·-v··

H~~~.

by

abrupt

start

m~$'t:f!J

of

the

~M

1.

;f:Jl~~~~(f!j1

1. INSTALLATION (Fig.1, Fig.2, Fig.3,

*

5Eil:&~~:

1 )

XIJ

1l

B:

tlm

R I

f'F

2)

~n

Li-1

ffr

;r,

,

i-1t

~LR

m

NJ

t-t

2-Hr

C£l

IQJ

3)

?J

tJL

-'k

iit:tc~CD!Ji

iJ,HH~@_L

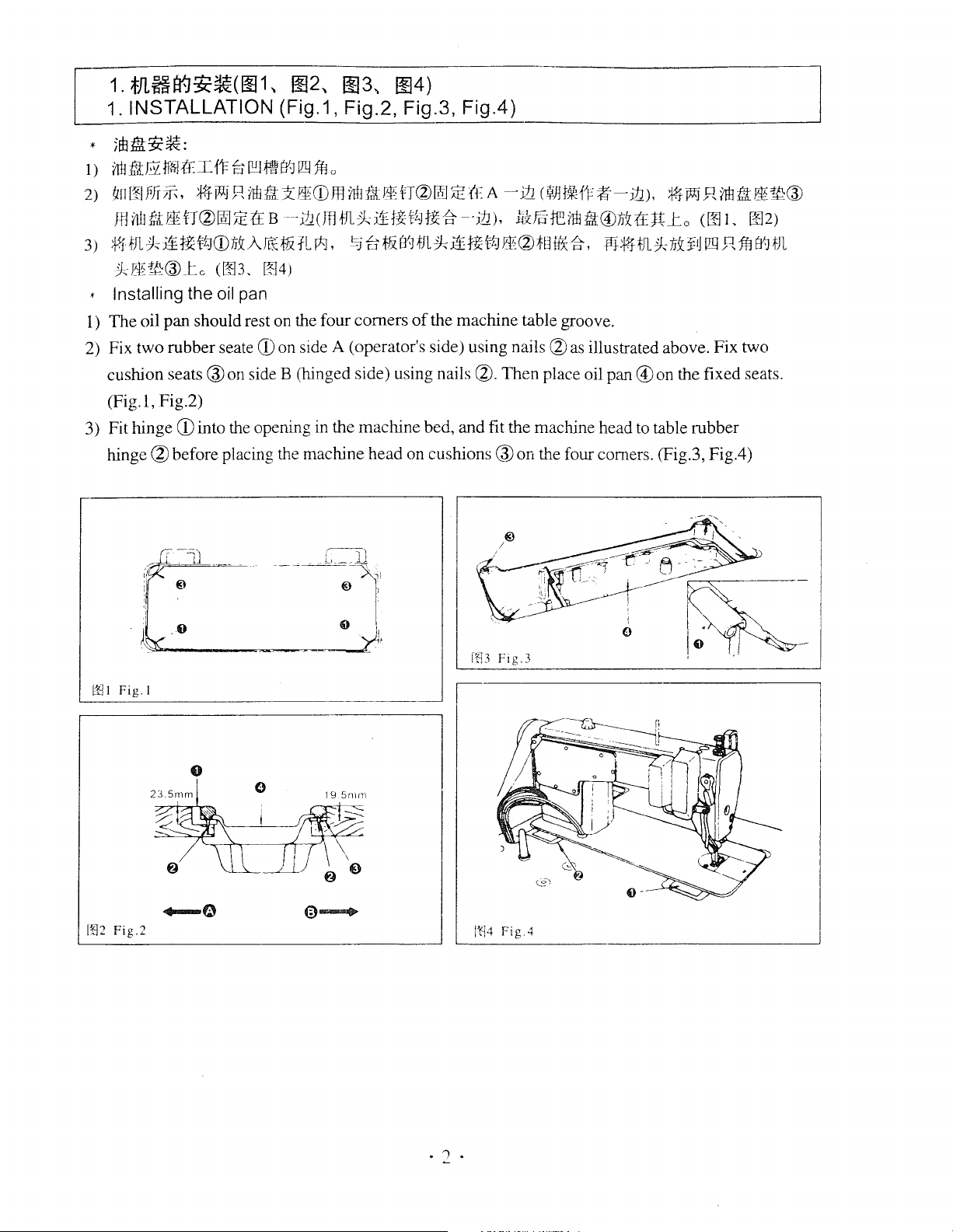

" Installing the oil pan

1)

The oil pan should rest on the four corners

(003,

fl

5E

~

[li] ilt

XlJ

1l

tr:

s -

Am;

~4)

~2~

8'~

[liJ

1M

:7.:

NKD

-:ill

Ofl

f&

fL

I7'J,

~3~

a

JiHEh

fnt

+JL

:J-;-

ii

'=J

iJ

~4)

[~

H

tt

,f&(J~J

Fig.4)

C£l

Rtl

1£

1r

A

-~

.iti

C

~JmHt:

r£J

t§<

g.

--

jti).

.ttl

f8·

re

tfl-*

iiffl~

of

the machine table groove.

ffi(£}-f@

itt

:%';-

~

X~J

:m:

®

g.,

¥}¥-f

jti),

nz

tr:

J.Lto

tfl

:J.;

¥.t

M"

.R

coo

1iJ¥'1

R1l

XlJ

ft

1 ,

f!.

ftJ

ffiHf':@

oo

2)

81

tJl

2) Fix two rubber seate

cushion seats

(Fig.l, Fig.2)

3) Fit hinge

hinge~

. )

,\~

llll

Fig.l

®on

CD

into the opening

before placing the machine head on

.0

CD

on side A (operator's side) using

side B (hinged side) using

in

the machine bed, and fit the machine head

--~

C1

).

ll

@ '

1

0 I

nails~-

cushions®

nails~

Then place oil pan

on the four corners. (Fig.3, Fig.4)

rm

Fig.3

as

illustrated above. Fix two

@on

to

the fixed seats.

table rubber

~

' '

[f]2

Fig.2

.

[tj4

Fig.4

')

.

1.

m~Et-Jii!Ji~(oos,

1.

LUBRICATION (Fig.5, Fig.6)

1

i1IJ

?i!H~

~

: (

00

5)

*

7f$M:

1)

rtJ

lEB

fttCD

1*J

1JD~f~J

2)

'~

)rtJ

ITiJ

f~-TLOWi~5B.

3 l

!Jo

;m

16,

-Tfi9J

:fll

~.

-+

l

Zf:

f

~i~ffJ

?rtl

it

~H/'

*

il~:

f~

ffl

m

tJl

~

9.t

::g--t~JiJJ

~tli¥l:@B'ti:iE~,

2 .

1m]

iJ

mJ

fi~

iffi ~ : (

1 l

~UJJidlliifliliJ

2)

i-llliitWliJ

3)

illl

!:iflil1H~

3

1m]

::p

J

·JJf

1

2)

~S

ilB

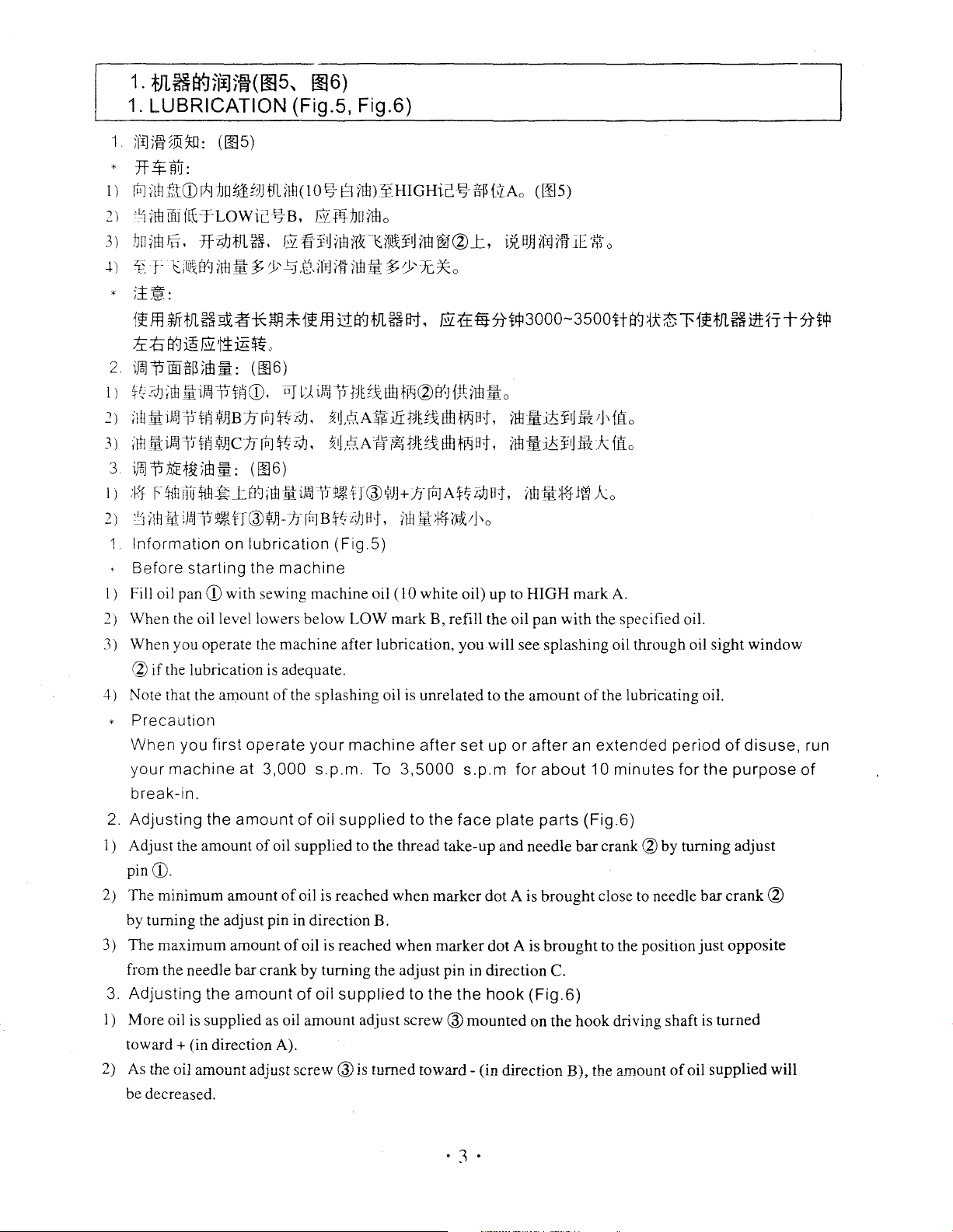

Information

,

Before

1)

Fill oil pan

2) When the oil level lowers

3) When you operate the machine after lubrication,

(J)

4)

Note that the amount

~

Precaution

When

your

break-in.

2.

Adjusting

1) Adjust the

pinQ)_

2) The

by turning the adjust pin in direction B.

3)

The

from the needle bar crank

3.

Adjusting

1)

More oil is supplied as oil

toward+

2) As the oil

be decreased.

t~

mEt~

iffi

F:

IWl

rliJ

~

M:

ifWiJ-P,.~

starting

CD

if

the lubrication is adequate.

you

machine

the

amount

minimum

maximum

the

(in direction A).

amount

006)

MCD.

-'W.JB}J

rtJ

~JJCJJ

rtJ

~:

(

00

-~

_t

8~

H®-'M-/i

on

lubrication

the

with sewing machine oil ( l 0 white oil) up to

first

operate

at

3,000

amount

of

amount

amount

amount

adjust screw

006)

ffl)IB(l

015-

8

irtl)

¥HIGHic-'%

fl-fl}hUtalo

GZ

:~-

:fu

?1±J

~-\S

~ru

ta1

-tJ

,t2,J~fll1hrtl

*

fi

ffl

~lJ

U

iJ,'iJ

~z;i).

~~:;iJ.

6)

i!E

J:

ifW¥I

itJB~iJJHJ,

machine

below

of

the splashing oil is

your

s.p.m.

of

oil

oil supplied to the thread

of

oil is

of

oil is reached when

by

turning the adjust pin in direction C.

of

oil

amount

it

g;

~,

!C::ko

i181

tll

~

a1,

P"

Jjttx

illJ

MCl!Ef-JffJjffi

~~L8All

~~L8AcJf'fr'*WE~

~~

(Fig.5)

supplied

reached

supplied

@is

ill

H ®

~JJ

+

i!ll

LOW

mark

machine

To

3,5000

when

adjust

screw®

turned

Jjtt~

JT

~;j4fi!£;J\o

unrelated

after

to

to

toward-

w

B

illJ

Bil

~J

A$~

B, refill the oil pan

the

take-up

marker

marker

the the

tfll

f_ll:Ao

Cl!

_t.

tt

&7H~

il:o

j:j;l:j

B•j,

j:j;l:]Bt,

4iJ

U t,

you

will

to the

set

up

s.p.m

face

plate

and

dot

dot A is

hook

mounted

(in direction

(

~5)

i5t

BJH~fl

l'fl

.iE

-~~

o

3000-

im

il:~ilj

?!Eil::il5¥H&k

iUl

HIGH

see splashing oil through oil sight

or

for

A is

it

;j4t

with

amount

after

about

parts

needle

brought

brought

(Fig.6)

on the

B),

3500H

i&

1j\

81

Ulo

:JX

~

fflo

J~

A a

mark

A.

the specified oil.

of

the lubricating oil.

an

extended

10

minutes

(Fig.6)

bar

crank

(J)

by turning adjust

close to needle bar

to the position

hook

driving shaft is

the amount

l'

fifll

period

for

the

just

of

oil supplied will

~

li!1f

window

of

disuse,

purpose

crank

opposite

turned

-t-

:5ti~

run

of

ClJ

. l .

~

, I

~5

Fig.5

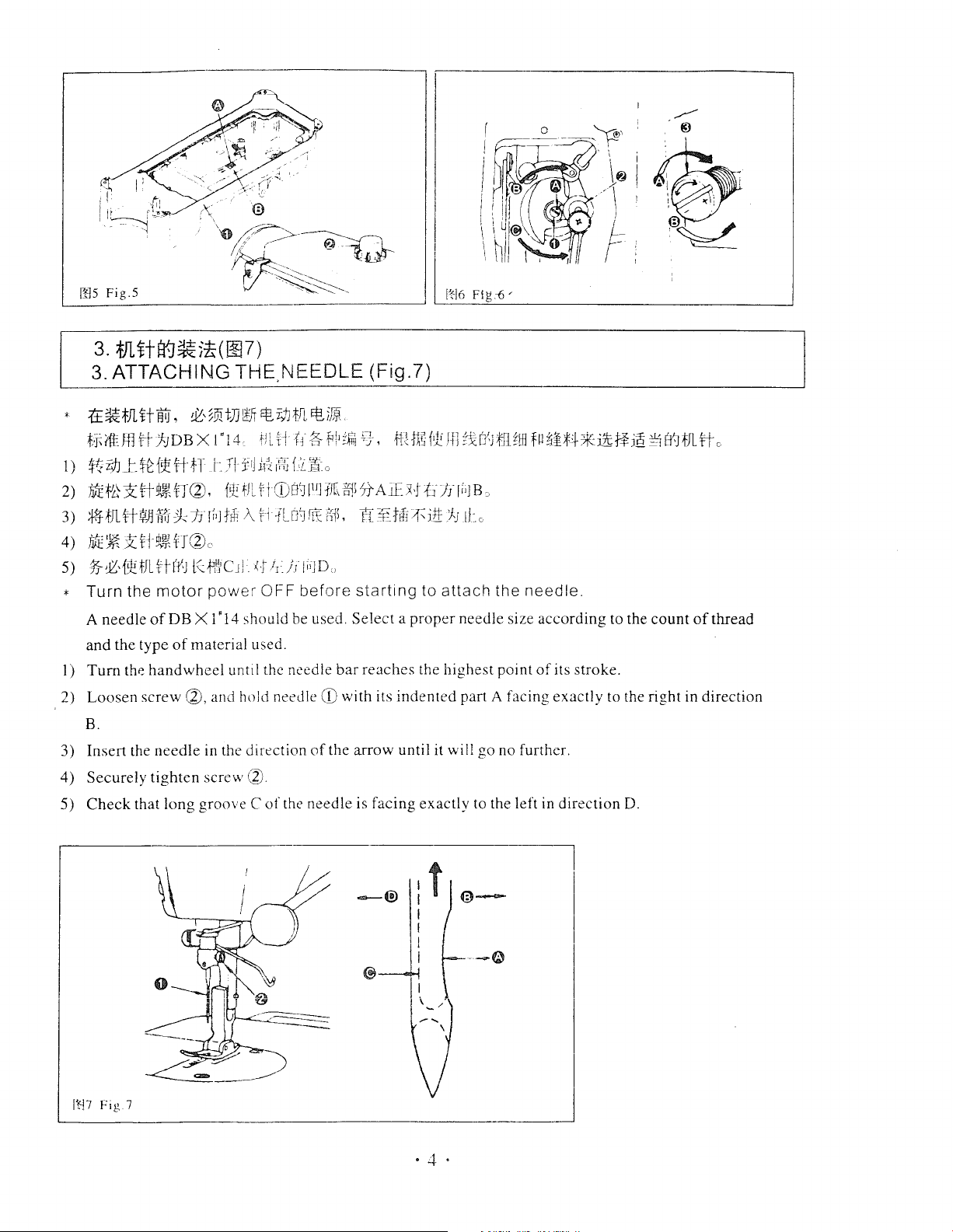

3.

:fllltl¥1*it(!!J7)

3.

ATTACHING

"

ti

~

tfl H

WJ,

ti;lftHH-t-

1)

~iJJJJ't{~hH

2)

Nitt

3)

~tJLl'rWJrifi:Y~1ni,JM~

4)

NE~

5)

fi£·f:1::tJL

*

Turn

7-JDB

3tftt~

:tl'i

HaJ,

5\.~HaJ,

ft(Y,J

the

motor

THE.NEEDLE (Fig.7)

&<uHJJ

l(f,~'CJ]

151

~

z:,-+1

tn

~

iP¥

X

1"1

r

ijfrJNo:r\;~

H~

power

H),

f!L

HCfJ8~

A

I11HIC

o~r{l({jil.

/r}r!r,JDu

OFF

before

ffll5t

'r},

ttHit~ftl!

A.i.Ex·J

rL~f':tJi~~jJ11J

starting

t.1

Jifr,JB"

to

attach

Hl

:1:r1'·J

ll:.o

{flfHl

the

fu

~i;ff3!E::i21fijEi

needle.

3

C-tltfl

ft

o

A needle

and

1)

Tum

2)

Loosen

B.

3)

Insert

Securely

4)

5)

Check

of

the type

the

hand

screw

the

needle

tighten

that

DB

X 1

of

material

wheel

aJ,

and hold needle

in the direction

screw

long

groove C of

'14

should he used.

used.

until the needle

W

the

Select a proper

bar

CD

with its

of

the

arrow

needle

is

needle

reaches

facing

the

highest

indented

until it will go no further.

part A facing

exactly

to the left in

size

point

according

of

its stroke.

exactly

direction

to the

count

of

thread

to the right in direction

D.

lt17

Fig

7

.

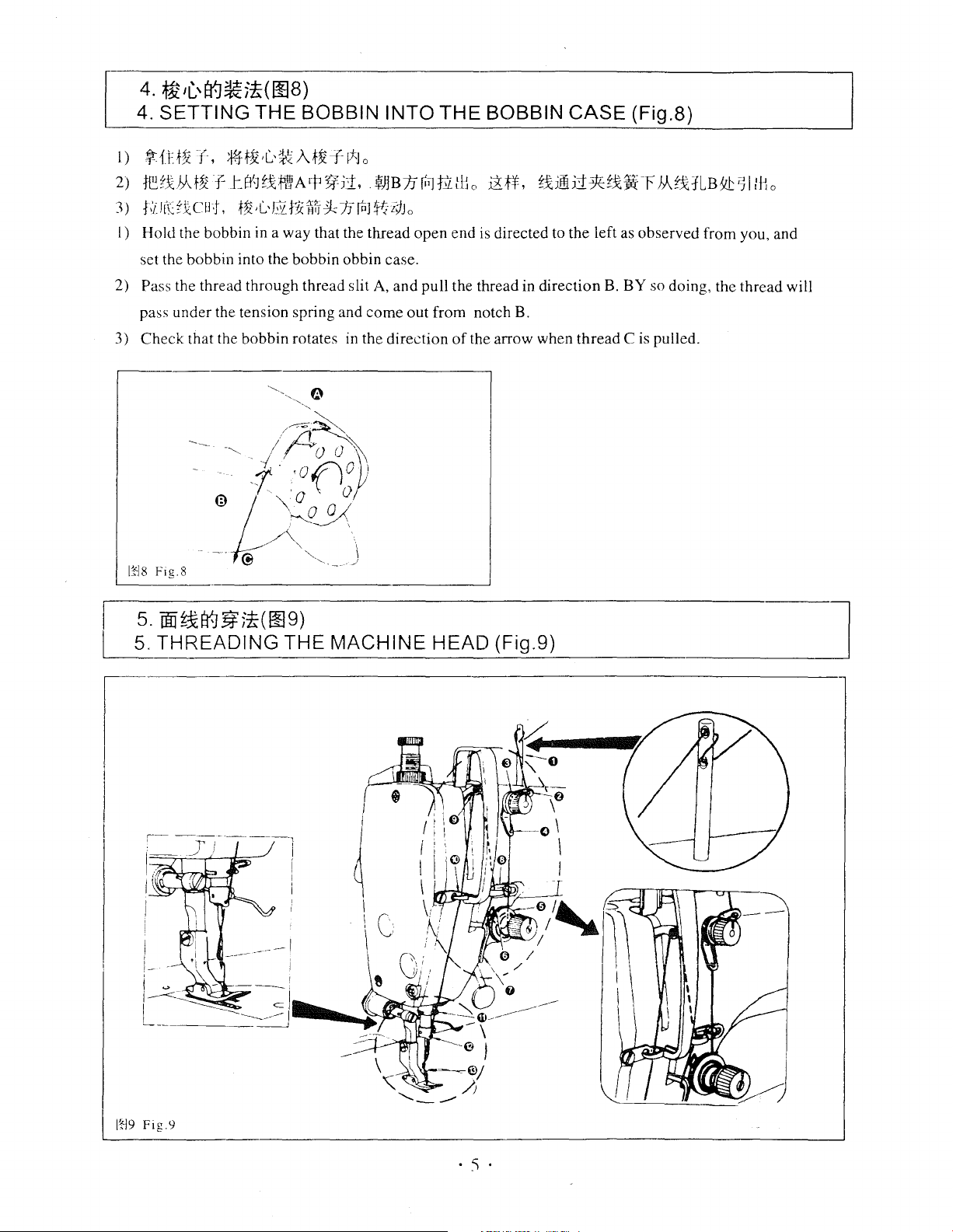

4.

4.

~'L'fn~i!(I!J8)

4.

SETTING

I)

*1H~

2)

1ett.MJ~

3) j,'fi((fj(CUJ,

I) Hold the bobbin in a

set the bobbin into the bobbin obbin case.

(,

THE

BOBBIN INTO

:J%-f&'L'~Af~-f~*Jo

f

J:.8'~~f-WArp

f~

,c_,J~

#jJ:,

t't<~~*

way

1J

that the

~J

!MB1J

f!;idJo

thread

THE

(l'J

:tL

tU

o

open

end is directed to

BOBBIN

i!:ff.

gx:@i1*fX'i:T

CASE

the

left as

(Fig.8)

JAttJLB~

observed

from you, and

'7 I Il-l

o

Pass the thread through thread slit A,

2)

under

pass

Check

3)

l!fl8

Fig.8

I

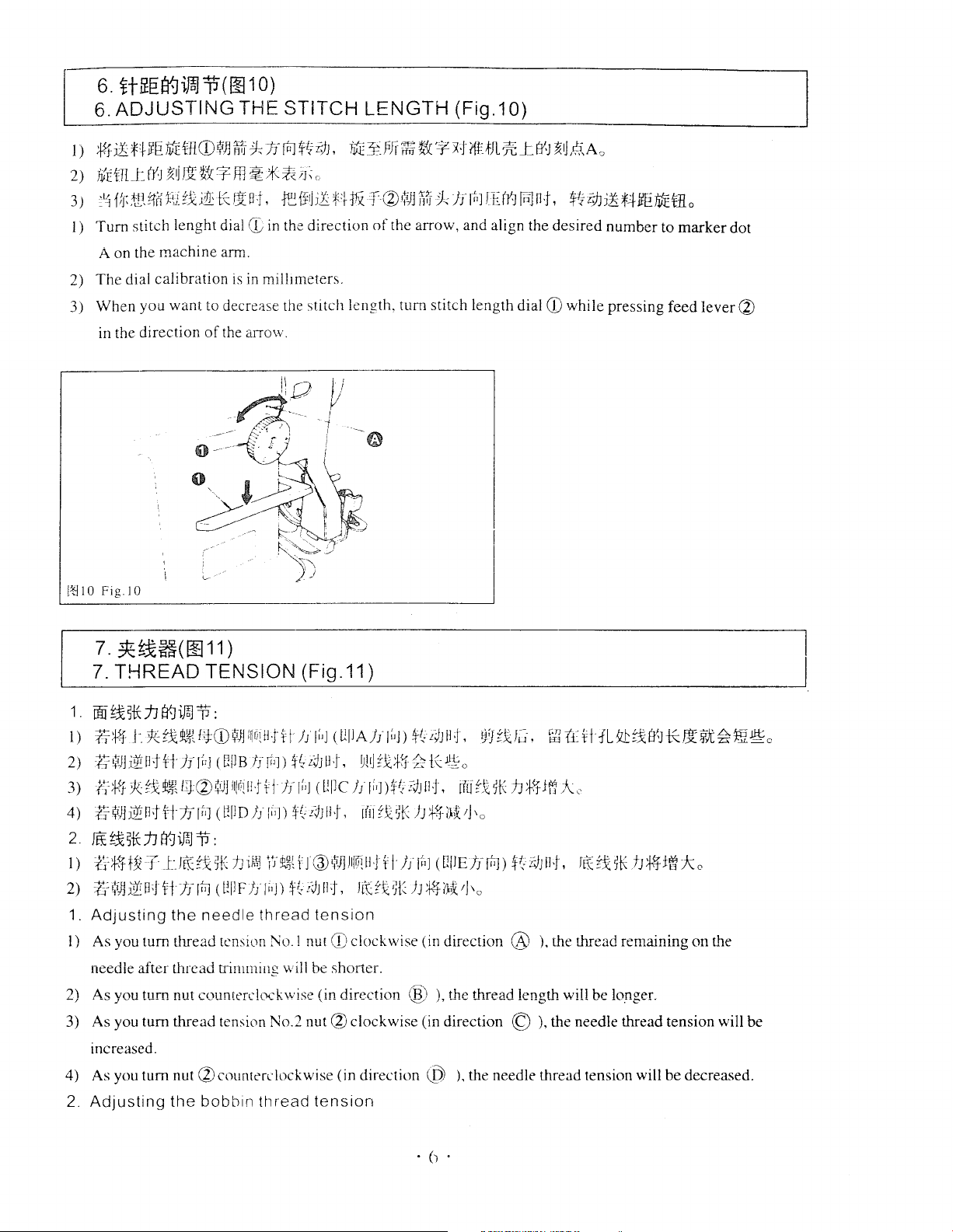

s.

1m~a15.Fit(009)

~~--5_.T

__

the tension spring and

that the

bobbin

rotates in the

H_R_E_A_D_I_N_G_T_H_E_M_A_C_H

I -

and

come

direction

pull the thread in

out

from

notch B.

of

the arrow when

direction

thread

B.

BY

so doing, the thread will

C is pulled.

]

__

I_N_E_H_E_A_D_(~F~ig~.9_)

________________

__

I

~

I

1119

Fig.9

. ') .

6.

lt

Jf!?:tf.JiFcJ

6.

ADJUSTING

1)

~ill

fl.~§:

:fjj'HHCD?JJ

2)

3 > '

1)

2)

3)

Jt'HILL

Tum

A on the

The

When

in the

(Y.J

~rj]JOlC¥

1

1

f!s:~J.t1(i

stitch

machine

dial

calibration

you

direction

HHbll:

lenght

want

~

(

00

1 0)

THE

M

:Y~

m

1t%

K:

13!

BJ,

dial

C1

arm.

is

in

to

decre:1se the

of

the arrO\v.

STITCH

IT

rtJ

tb9J,

:tUJ;

,,

11::

{'frJjh:'fHN.lC~)t:VJ

in

the

direction

milluneter~.

stitch

LENGTH

iitE3~?Jri¥fi

of

the

length.

v

I

tum

~

'j

(ifj

J-~

arrow,

stitch

(Fig.1 0)

x.J

l#~-fJl7Cs~8'0

)Jrt,J

1Eft0

and

align the

length

[r1]

dial

~~Jl~A"

n.J,

~jiJJizH4R§:MHllo

desired

CD

while

number

pressing

to

marker

feed

lever~

dot

1'810

Fig.l

0

7.

*~~(0011)

7.

THREAD

1 . ®

~stt

:1J

1)

*H

J-

1'~~.9;.~

2)

'f:'i•WJ&nHi

3)

f1:;f.(;

>}(ftP,.~

4)

:fi'?JJ&nJri-:trri,J

2 Iff

~

stt

:1J

I)

'{j:t.HY

2)

={:}:

1.

Adjusting

I)

As

needle

2) As you

3) As you

T J.·Jfttt

E;ijjJ1!

B;J

you

tum

after

tum

tum

TENSION (Fig.11)

81

ifcl

1J:

I'J:CD

?JJiifo!HJ

Jnf,J

c~llB

t:Jell4iJJ

81

ifcl

HJT

the

thread

thread

nut countnc!o<.:hvise (in

thread

i1[0!fi.fH

(l!PD}Jrt,n

1J

:

~K

:IJ

JfiJ

(l![JF};

needle

tension

trimming will be shorter.

tension No.2 nut

H

JJ

J;(<,J)

Hz9JilJ,

h

JI,J

ttz9Jfl·L

if~

i'i<l;.~

1

Jr'j)

H

thread

No.I

JI,J

(

(

UilC

UilA)f

JwJ)

vlutU:jZ,KJJ~o

h

H>?tt

rfilfl.dK

J®•:iJJJifiiUJ.j

tJJ

ilJ, l((f\:

tension

nut

CD

ell

1 I h

~K

clockwise

direction

clockwise

tU

zJJ

f!J,

Mtl:C,

iJJfiJ,

)J

@

rfutl.t

~K

JJ~-;;~,t;J,o

rt,J

C

UllEJTf~])

:f41P:H\o

(in direction @

),

Lhe

Lhread length will

(in direction ©

\iiH'±:

tr+itlrl

t~

A:,.

4J

n-t,

),

the thread

),

the needle thread tension will be

tl

fL

£tt\!:8'0

lt'sU1dK

be

longer.

trf4tf'?

remaining

-KOC~Jt~m.lltc

:ko

on the

increased.

4)

As

you

tum

nut

ell

2.

Adjusting

the

countnL·lockwise (in

bobbin

thread

direction

tension

©

),

the needle thread tension will

. () .

be

decreased.

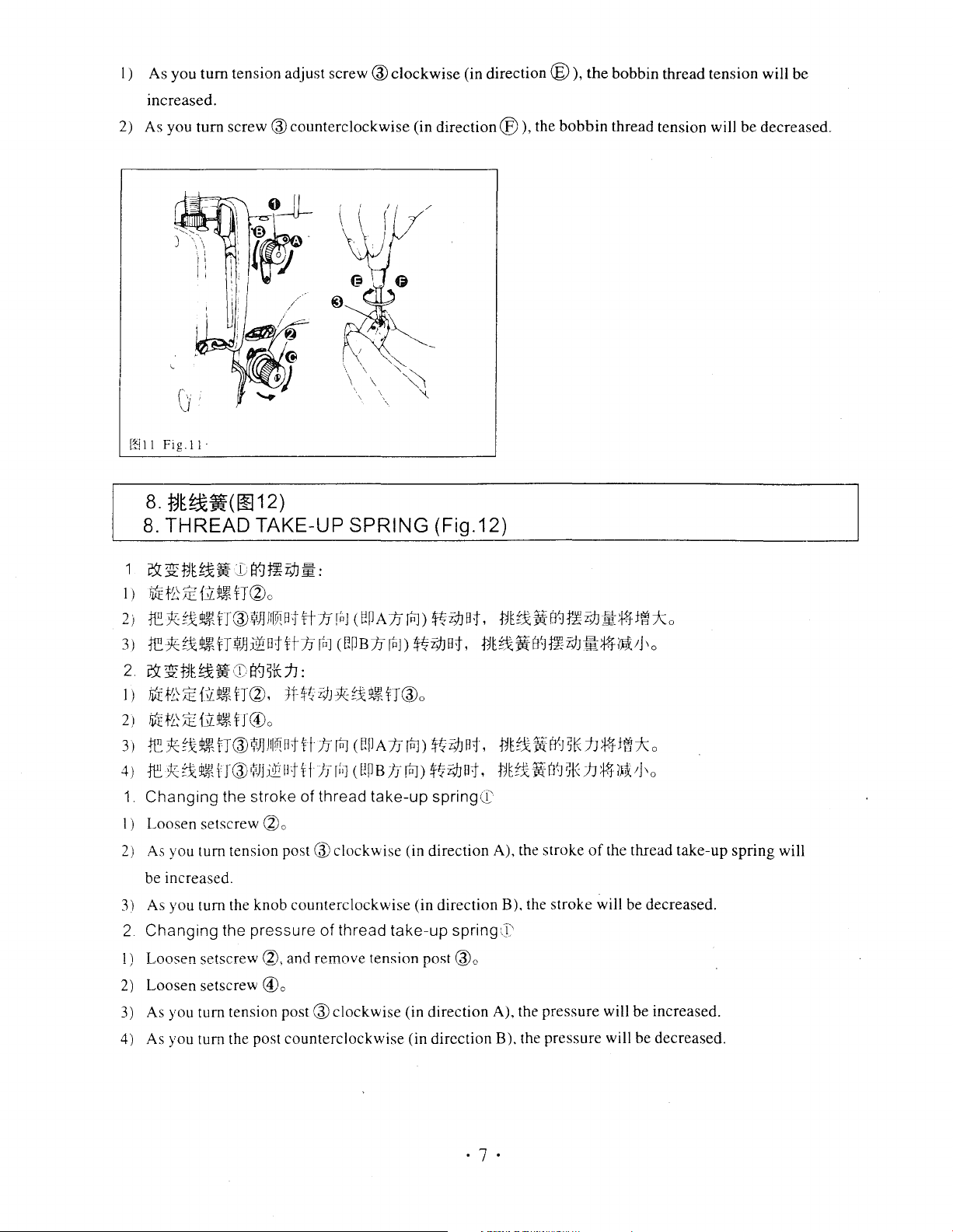

I) As you

increased.

2)

As you

l1lll

8.

8.

tum

Fig.ll

tension adjust

tum

screw®

screw®

counterclockwise (in

clockwise

j:jt~li(1!112)

THREAD TAKE-UP SPRING (Fig.12)

(in

direction®),

direction®),

the

the

bobbin

bobbin thread tension will be

thread tension will

be

decreased.

i&~:Ht~~

I)

JLfE.jJ_0j£

2J

~1Uf:IJ\.~H@MJifDlBHt1J!~J

3)

1\::'ktf:IJ\.~Hif:Jli~StHJJrr,J

2.

22

~:Ht~~

J)

ti1f.f'_0f:E

2!

!W:.f'.0

IE

3! ~

*tx!J\.~

4!

-te

~

tt!J\.~

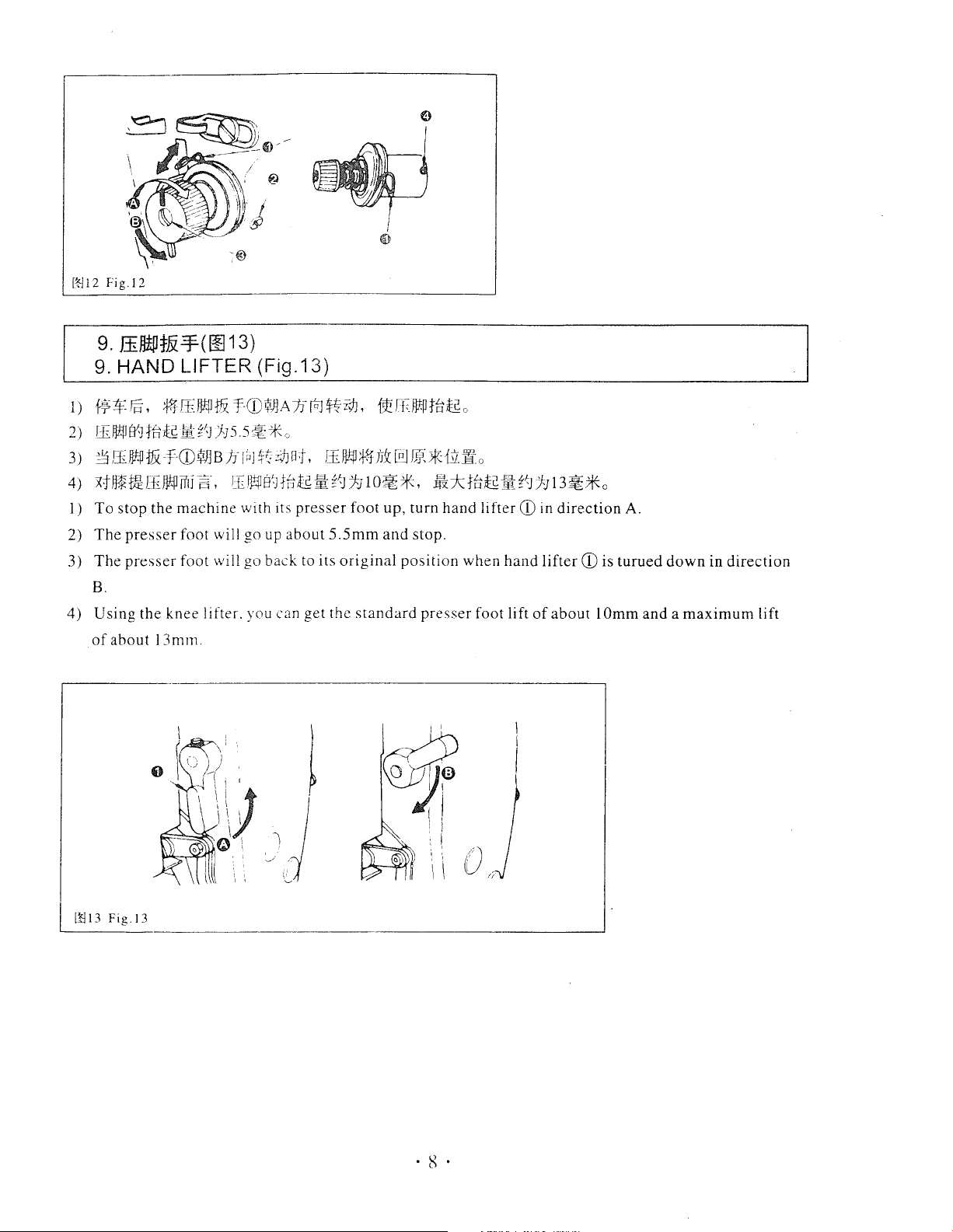

1.

Changing the stroke

I)

Loosen setscrew

2)

As

you

be increased.

3)

As you

2 Changing the pressure

! )

Loosen

2)

Loosen setscrew @o

3) As you

l!

81~M;:

{i[:IJ\.~

fTWo

t})

815¥:::tJ:

{\f:iJ\.lMJW,

fiLIJ\.~

H@o

JH~:i;tJ-;idf:IJ\.~

TT®'M!Illf!Ht111J

1

T@'i!Jiil!

lltH

of

C~PAiJrPJ)

C~PBiJ(riJ)

tJ@o

f1iJ

Cf.llA/J

JT

rt,J

(

~PB

thread take-up springCI.'

~ifJBt,

~ifJBt,

rPJ)

~ifJHi,

JT

f1iJ)

tvzJJot,

tj[fJJif81tlifJ_~;J-1t±~:Xa

tjt~jf81~4Jil;J-1tfPt;J\o

tjttl:~A'051\

Vtttj[(J'~

Wo

tum

tension

tum

the knob counterclockwise (in direction B). the stroke will be decreased.

setscrew

tum

tension

W,

post@

and

post®

clockwise (in direction A), the stroke

of

thread take-up

remove

tension post

clockwise (in direction A), the pressure will be increased.

spring'}'

®o

::fJ

;J-1t±~:Xo

~K h ;J-1ti,t~!J\a

of

the thread take-up

spring

will

4) As you

tum

the post counterclockwise (in direction B). the pressure will be decreased .

. 7 .

[!f]

12

Fig.

l 2

9.

ffM!Jt.&~(l!]13)

9.

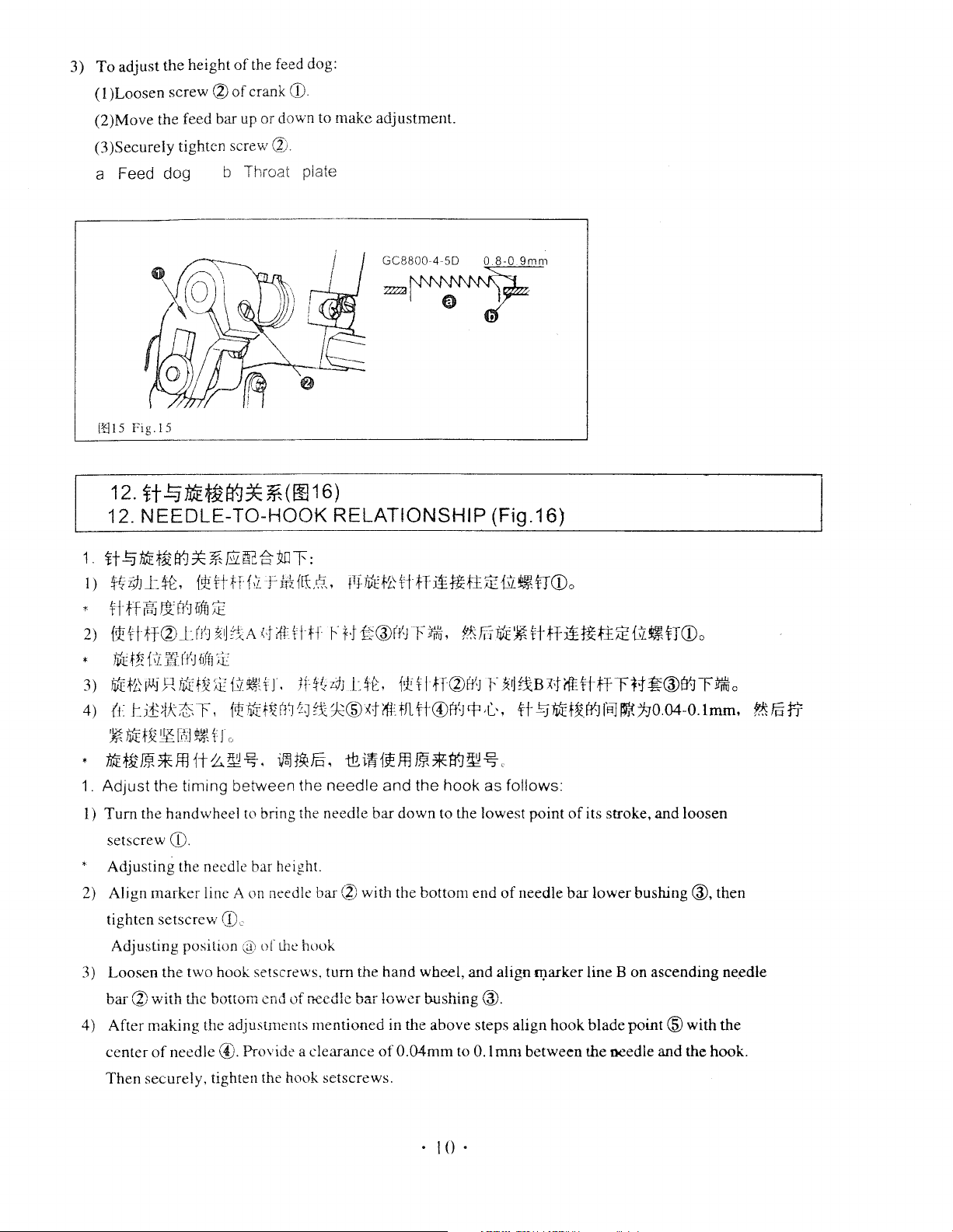

HAND LIFTER (Fig.13)

1)

f-}

:t:

fl§',

:PJ"

ffi

l}tp

t&

f-(l)

~JJA

/.)

f!~

11-lil

A,(l

f:L>-

t(.

'{

f~J

'I

c

"i

A{:

-

..1'.1)4Ji1'.,1n~IL-

3)

~

!£1ltP

iN

fCDWJB)]

4)

xtJJ*W:U~IltPITii

I)

To

stop

the

2)

The

presser

3)

The

presser

B.

4)

Using

the

knee

ofabout

13mm.

/'].!

§,

machine

foot

will

foot

will

lifter.

~1'-

...

.

·t_

·1''-<o

rs

J

t'f:QJ

U~~j!.jl8~J

with

go

up

go

back

you can

1i

flJ,

ff]g

its

presser

about

(oJ

~z9J,

LEW;ll;f-(f

ii

~'J

'h

foot

S.Smm

to

its

original

get

the

I

tD

{~

n~JJtMttf

il~

[r~

J;]Uk

f;J.i'!'o

101ft

;j<:,

J&j(

up,

turn

hand

and

stop.

position

standard

presser

o

tfltfit~~J

lifter

when

foot

CD

hand

lift

JJ

13~*o

in

direction

lifter

CD

of

about

lOmm

A.

is

turued

and a maximum

down

in

direction

lift

~

. I

!

0

1.

~\

//

I [I]!3

Fig.l3

. 8 .

1)

2)

3

4)

)

1 0.

J±Mil

J±

1J

10.

PRESSER

)'j;ff',0i)6J

JJ!rtJ

;rtl

~PJ

x-t

n;:!P,.~

£t(l),

cmlB/J(IlJ)

H~1---:

lJ

';[;,t!;>3:"'1UJ~-mi!J!D-M\

J1

l

fw.:

}'j'~

~OJ

~f&:tflNrm

§f.

ffJ

ifc]

T.i

( 0014)

FOOT

II@\

t~i0JI-:IJ!;jlifi'fl1J't~n,

:t.J;.'"J~

f:E)jtjl~1Y!P,.~HB'0f!Fi{E~f!it:l:729-32~*

PRESSURE

rtJ

c~nA:1f

UJ-~O

rPJ)

(Fig.14)

~i;.IJJl~)jtjliftj"iJ!FJHT'

ffjJ~{}Jt~~o

ffj)¥f±fl151lio

(50JT)

h::ba

1) Loosen

pressure will be increased.

2) As you turn the

decreased.

3) After adjustment, tighten nut

4)

For

nut~.

general fabrics, the standard height

As you turn

presser

spring

presser

spring regulator

regulator

Clla

CD

clockwise

counterclockwise (in

of

the presser spring

(in direction A), the

direction

regulator

B), the pressure will be

is 29 to 32

mm

presser

(5kg).

foot

ltl14

Fig

14

------------------------------------~

11.

~;f4~ffj~Ji(lfl15)

11.

HEIGHT

I)

iE

H

:1~

Ci

2)

{-E~iW'Hfl'0'fl11x

3)

if~

1'i

i~

:f'~

CDhiit~tfl

~

t

-r

H~

®hii

~

rttl

A

~:f43f

I) The feed dog

2)

If

the feed dog

(Recommended

OF

THE

lt

Hf&

rt,i

lfJ0.8-0.9~*o

F,

~-(1-J

1~-J

IJ[:

'if~

x M

Rtl

MCDEtJ~~

:01

5f

~!

~~tt

fril~

M't~HClla

b

Ht.&

is

factory-adjusted so that

juts

out too muCh, puckering may result when

protrusion:

FEED

lzn:W.i!H

11·

0

0.7mm

DOG

5fi15t{1

't~

f:

J~o

it

to

0.8mm)

(Fig.15)

:U

i':

~n~:f:J-gM:a

juts

out from the throat plate surface

.

9.

cttt#.i!ft:f*

sewing

t!Hl:

0.8mm

light-weight materials.

0.7-0.8~*)

to

0.9mm.

3)

To

adjust

(I

)Loosen

the

screw

height

Ql

of

the feed dog:

of

crank

CD.

(2)Move

(3)Securely

a Feed dog b Throat plate

[t]15

12.

12.

1 .

tt

I)

~z;JJl~t£.

*

tl·-tf~

2)

f~rl

the

feed bar up

tighten screw(£;

Fig.15

lt

~Mf.if&a0:k*(l!l

or

down to

NEEDLE-TO-HOOK

!:J

1i1E

f~

81

~

~H0Jfe:;5

fri::rtfH,L_

ffl:8~Mi

HQ)J.fJ''J

2

trJrtA

:9Jl ~ :

F.Mflb7:.

~Jiff

HH

make

adjustment.

/:~

16)

RELATIONSHIP (F1g.16)

N~t'tHH:ii~tt5EtL~HCDo

~-Ht'®rt'~

fttff&,

~ffiJt't~Hff:ii~tt!Ei;iJ~HCDo

* iff

3)

!tft'trV-i

4)

{f

~fiJi

•

1i1E

f~

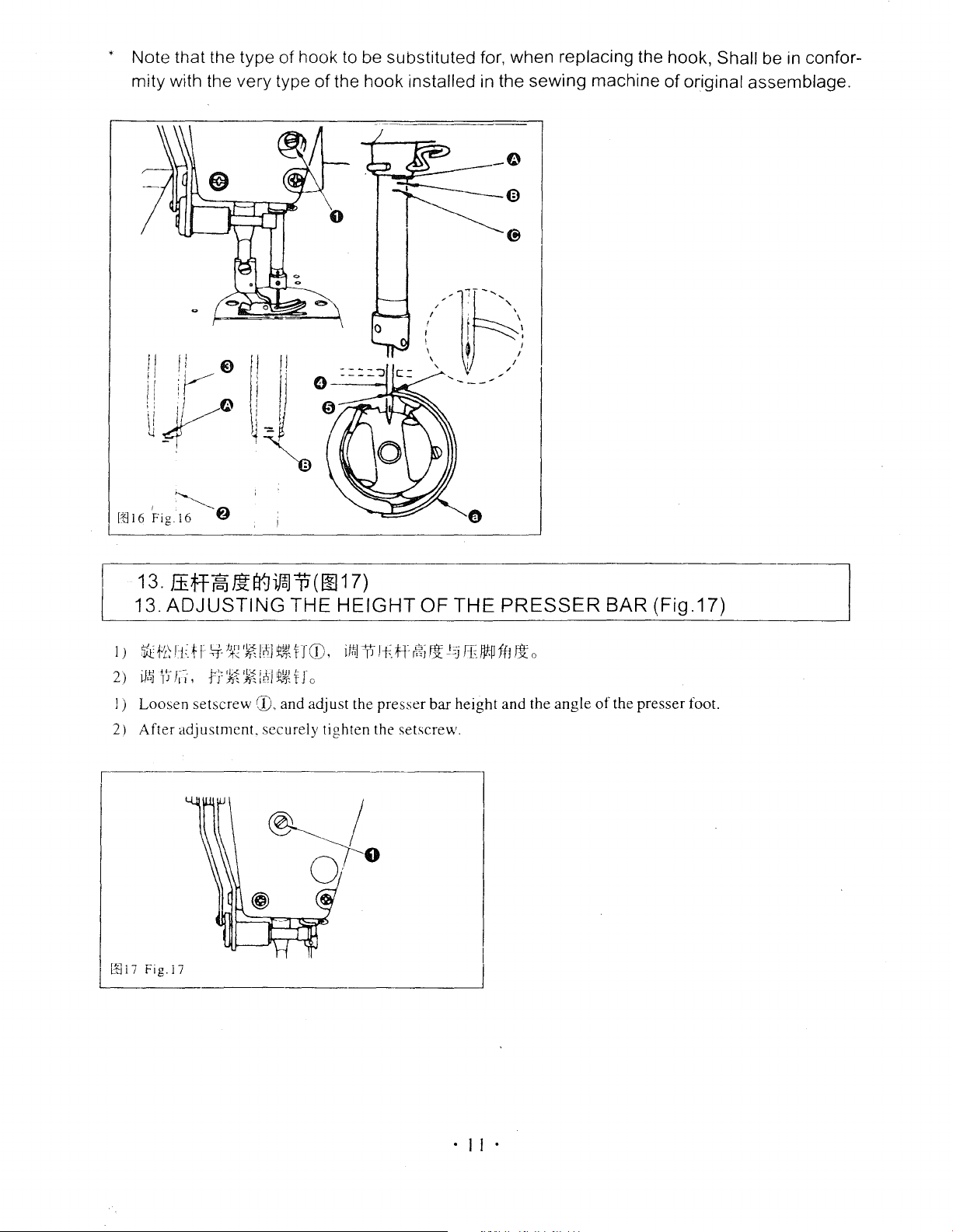

1.

Adjust

1)

Turn

setscrew

~

Adjusting

2)

Align

tighten

Adjusting

3)

Loosen

bar(£)

4)

After

center

Then

HH

-1:

i'N

t'~

Mfl

ii'

R

tifft3z!E

b£~7\~r,

t~

II£(;~!~'~

m * m 1 t

the timing between the

the

handwheel

f;J:~

H.

f't%:t~R~~0

t J

,,

~ ~

-s-

.

to bring the

CD.

the needle bar height.

marker

with

making

of

securely,

line A on needle

setscrew

position

the

two

tl1c

bottom end

the adjustments

needle@.

tighten the hook

CDc

of

hook setscrews. turn the

Provide a

ifal

Lhe

11

~

huok

of

t&zJJ

t.tt,

~

~(5)xtti1

g ,

mi.~

needle

needle

bar

Ql

needle

mentioned

clearance

setscrews.

He

and the

bar

with the

hand

bar

low·cr

in the

of

0.04mm

WH-tfQlffJ

tfl

rhV!i~

m

muMn

down

r:f:l·L·,

IDJ ~ ,

hook

to the lowest

bottom

wheel,

bushing®.

above

to 0.1

end

and

steps align

r:

~~J~Bx;ttfHt:fFfHg®tt-Jrttffifo

ri·

Ei1tftt~I¥JIRJ

as follows:

point

of

needle

align

IQarker line B on

hook

mm

between

of

bar

~t;0.04-0.lrnrn.

its stroke,

lower

blade

the needle

and

loosen

bushing®,

ascending

point®

and

with

the

~§rr

then

ne.edle

the

hook.

. I 0 .

* Note that the type of hook

mity with the very type

1

1

II

8

1

I~~

i I i r

:~ye

-I

I

!

I

\j

~~

II

I)

of

o

0

~

to

be substituted for, when replacing the hook, Shall be

the hook installed

in

the sewing machine

of

original assemblage.

in

confor-

I)

2)

l)

2)

I

L~i7

13.

ffff~JiEt-.JiJWT.i(!!l17)

13.

ADJUSTING

~

t'L~

u:

f F

'vi"·

il~ W ~~~

Loosen

After

adjustment.

Fig.i7

,

:f!'

setscrew

f#~

'M

~

~

THE

l~l

't~

HCD,

i6J

'tl«

H o

CD,

and

securely

HEIGHT

iMJ1J

adjust the

tighten the setscrew.

If. H

~i

presser

OF THE

f5t

~~]

bar

PRESSER

FEJltll

HJI3t

height

and

o

the

angle

BAR (Fig.17)

of

the

presser

foot.

· I I ·

Loading...

Loading...