Page 1

Purchasing Dept

111

1 _c:

®

HIGHLEAD

GC1088 Series

Hig Speed Sing Needle

Industrial

Sewing

Machine

..

Y llllllallli..

Lockstitch

INSTRUCTION MANUAL

Page 2

BEFORE

l.

Never

with

2.

After

rotation.

the

the

as

3.

Do

4.

Confirm

are

the

OPERATION

operate

oil.

setting

needle

handwheel. (

observed from

not

use a

that

correct

motor nameplate.

the

up

To

check

down,

larger

the

by

checking them

machine

the

it,

and

The

the

voltage

unless

machine,check

turn

turn

the

handwheel should

handwheel

motor

pulley

and phase (

its

oil

the

the

handwheel

power switch

turn

side.)

for

against

pan has been

direction

by

hand

ON

while

observing

counterclockwise

the

first

single

the

ratings

one

or

3-phase)

filled

of

motor

to

bring

month.

shown

on

OPERATION

l.

Keep

your hands

switch

2.

Do

not

the

machine

3.

Be

sure

machine head

4.

When

an

off

the

5.

During

person'

belt,

bobbin winder

close

6.

If

or

any

7.

Don' t

to

your machine

any

of

PRECAUTIONS

ON

or

while

put your

is

to

turn

or

operator

power.

operation,

s head

them.

other

them

clean

protectors,

removed.

the

away

from

the

fingers

operating.

the

power

removing

leaves

be

careful

or

hands

or

Doing

is

provided

face

so

the

needle

machine

into

the

switch

the V belt.

from

the

not

to

come

motor. Also,do

maybe

with a belt

do

not

of

machine head

1

when

is

operating.

thread

OFF

machine,make

to

allow your

close

dangerous.

operate

you

turn

take-up

before

to

not

cover,

your machine

with

cover while

tilting

sure

or

the

handwheel, V

place

finger

thinner.

the

power

the

to

turn

any

other

anything

guard

with

Page 3

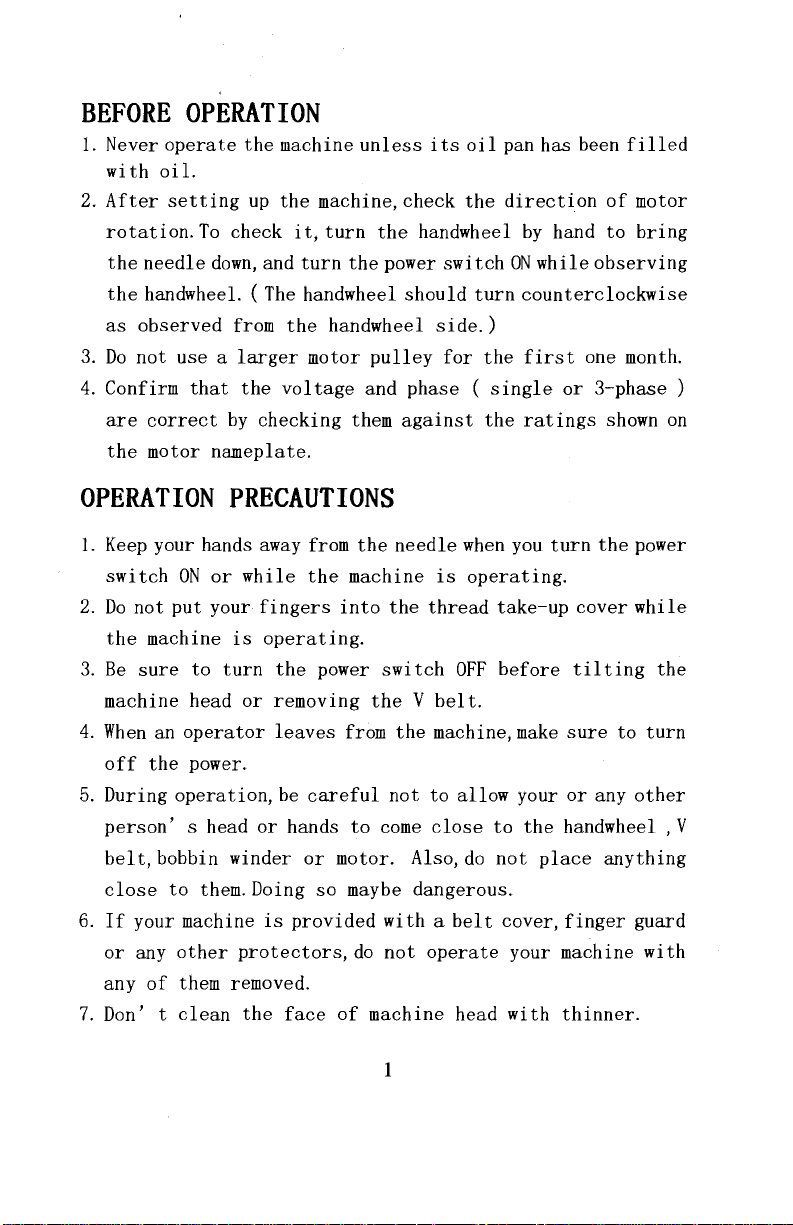

1.

INSTALLATION

*

Installing

1)

The

oil

table

2)

nails®

side

@

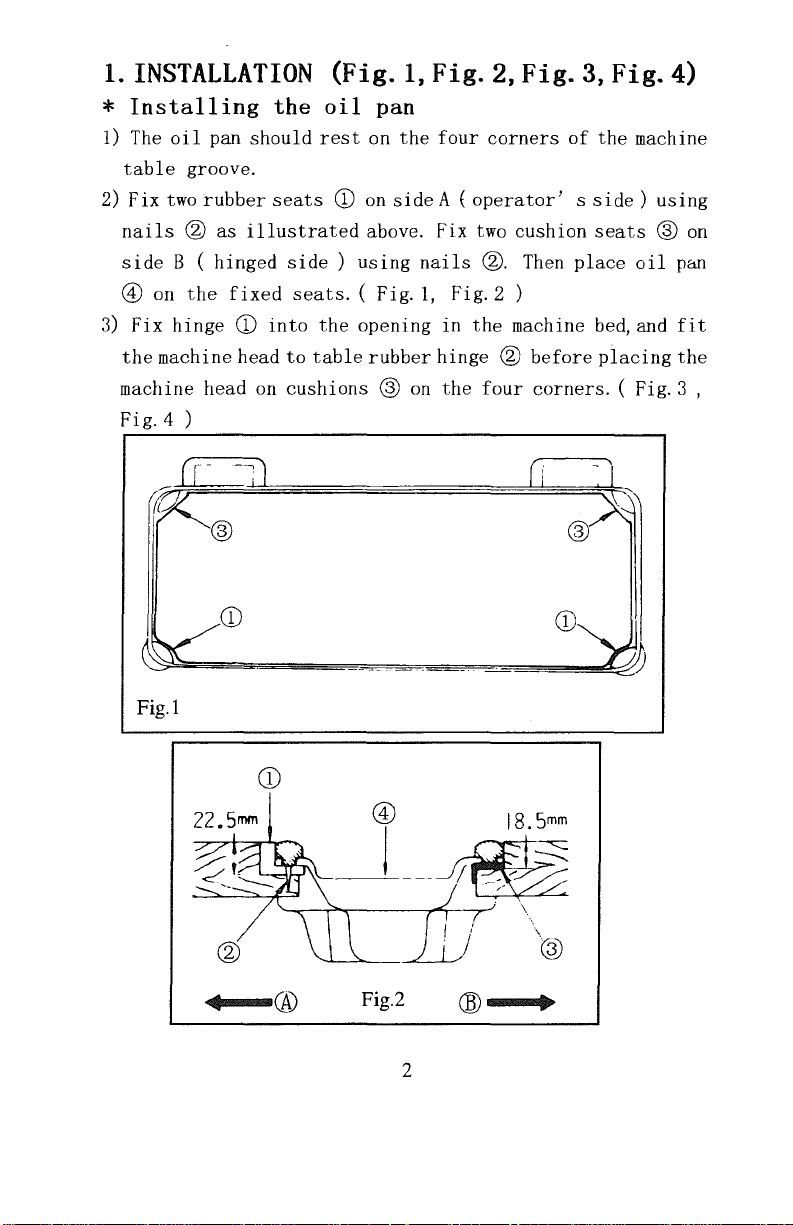

3)

the

machine head

Fig. 4 )

groove.

Fix

two

B ( hinged

on

the

Fix hinge

machine head

pan should

rubber

as

illustrated

fixed

CD

into

on

the

seats

® ®

(Fig.

oil

pan

rest

on

CD

on

above. Fix

side)

seats.

to

cushions @

the

table

using

( Fig.

opening

rubber

l,Fig.2,Fig.3,Fig.4)

the

four

side

nails®·

1,

on

corners

A (

operator' s side)

two

Fig. 2 )

in

the

hinge ®

the

four

of

the

machine

cushion

Then

machine bed, and

before

corners.

seats@

place

placing

oil

( Fig. 3 ,

(i

using

on

pan

fit

the

Fig.I

CD

@

CD

G)

-~.-~

Fig.2

--~-----·

@

I

...

~

2

j

®

CD

18.5mm

\.

\~)

Iii

Page 4

®

>"---~

Fig.3

Fig.4

@

@

>~

@

CD

3

Page 5

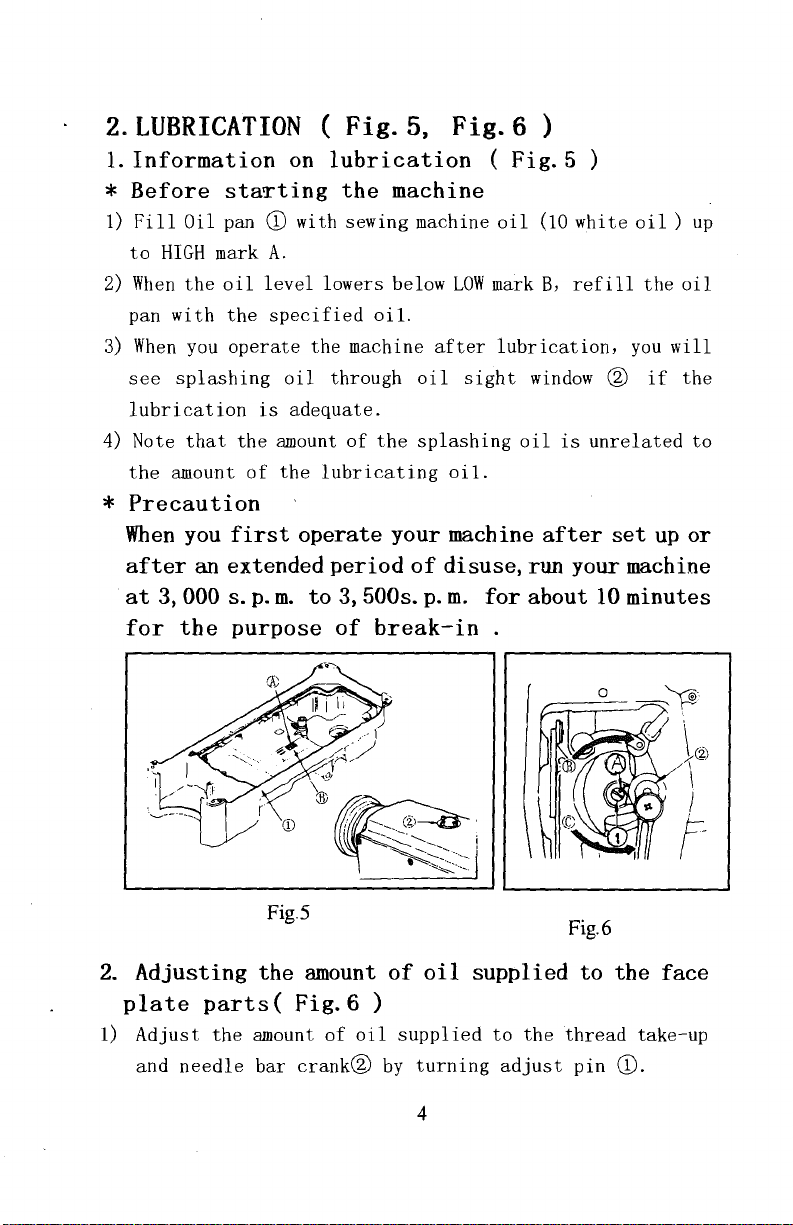

2.LUBRICATION ( Fig.5,

1.

Information

*

Before

1)

Fill

Oil

to

HIGH

2)

When

the

pan

with

3)

When

you

see

splashing

lubrication

4)

Note

that

the

amount

*

Precaution

When

you

after

at

for

an

3, 000 s.

the

staTting

pan

mark

oil

the

operate

extended

on

CD

with sewing machine

A.

level

specified

oil

is

adequate.

the

amount

of

the

first

operate your machine

p.

m.

to

purpose

lubrication

the

machine

lowers below

oil.

the machine

through

of

the

lubricating

period

3,

of

of

500s.

break-in.

Fig.6)

(

oil

LOW

mark

after

oil

splashing

p.

lubrication,

sight

oi

1.

disuse,

m.

for

Fig.5)

(10

B,

window

oil

is

after

run

about

white

refill

oil)

the

you

@

if

unrelated

set

up

up

oil

will

the

to

or

your machine

10

minutes

2.

Adjusting

plate

1)

Adjust

and

parts(

the

needle

Fig.5

the

Fig.6)

amount

bar

crank@

amount

of

oil

of

oil

supplied

by

turning

4

supplied

to

adjust

the

Fig.6

to

thread

pin

the

take-up

CD.

face

Page 6

2) The minimum amount

brought

pin

3) The

brought

crank

3.

ADJUSTING

close

in

direction

maximum

to

by

turning

to

amount

the

position

THE

needle

of

oil

is

reached

bar

crank

B.

of

oil

is

reached

just

opposite

the

adjust

AMOUNT

OF

pin

OIL

when

marker

® by

turning

when

marker

from

in

direction

SUPPLIED

the

dot A is

the

adjust

dot A is

needle

C.

TO

bar

THE

HOOK ( Fig.7

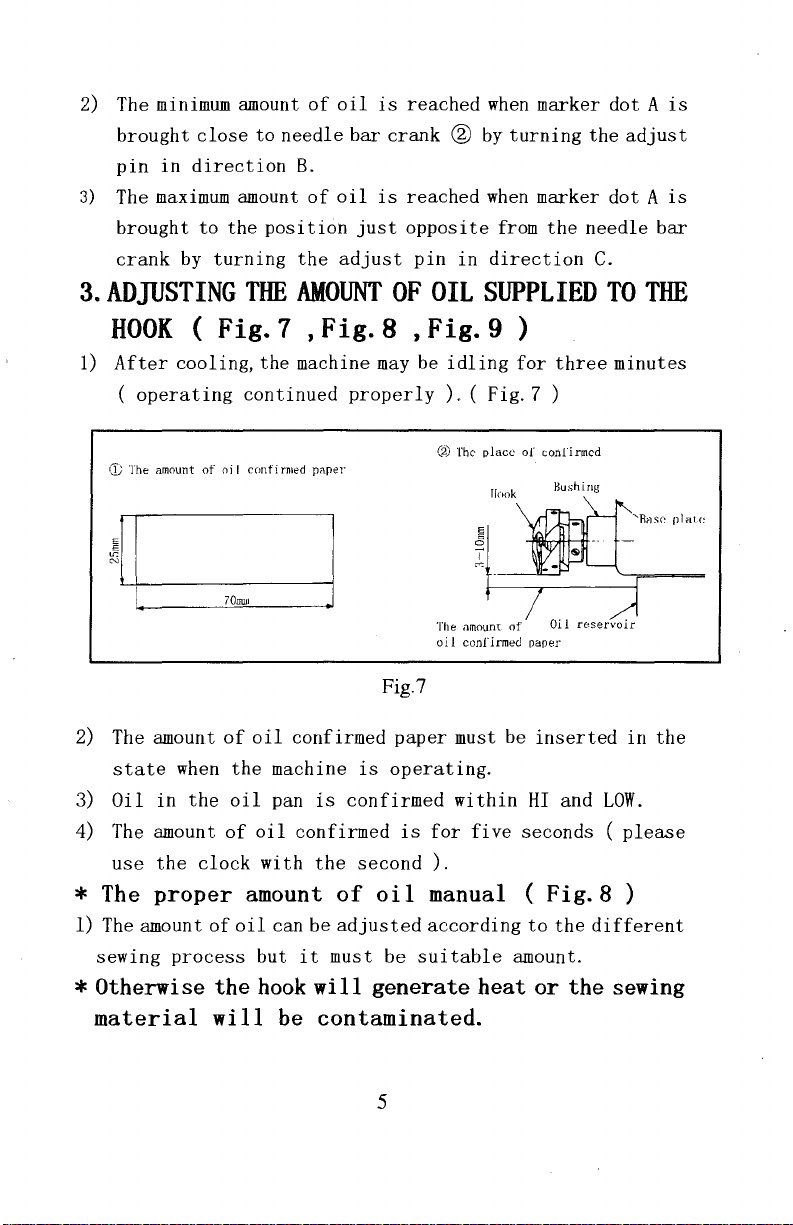

1)

After

Cf;

2) The amount

state

3)

Oil

4) The amount

use

*

The

1) The amount

sewing

cooling,

(

operating

The amount

in

the

of

when

the

clock

oi I cnnfi

of

the

oil

of

proper amount

of

oil

process

* Otherwise the

material

will

,Fig.8

the

machine

continued

rmed

pnper

oil

confirmed

machine

pan

is

oil

confirmed

with

the

can be

but

it

hook

will

be contaminated.

may

properly

Fig.7

paper

is

operating.

confirmed

is

second).

of

oil

adjusted

must

be

generate heat or the sewing

,Fig.9)

be

idling

). ( Fig.

(2)

The

place

Hnok

The amount

oil

confirmed

must

within

for

five

manual (

according

suitable

for

three

minutes

7 )

of

conrirmcd

Hushing

'Rr1s1"~

of

Oil

re:servoir

paper

be

inserted

HI

and

seconds ( please

in

LOW.

Fig.8)

to

the

different

amount.

plat<:

the

5

Page 7

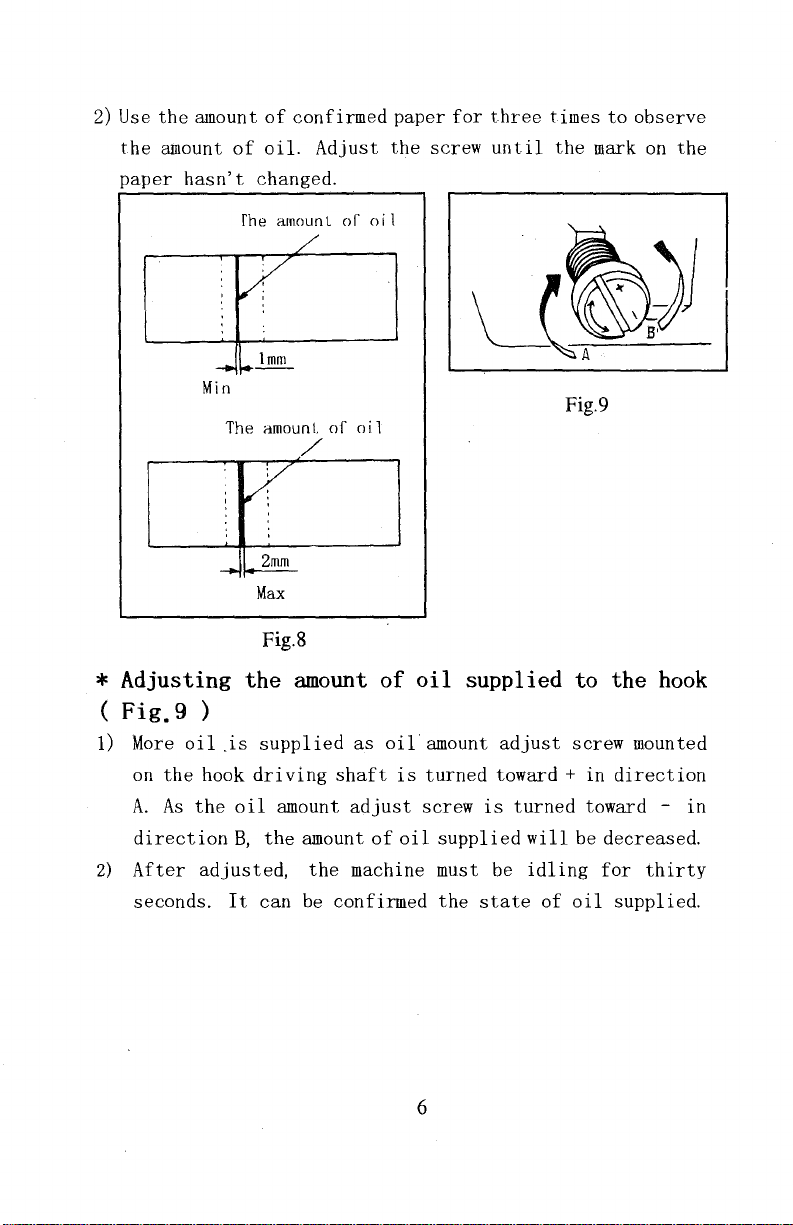

2) Use

the

paper

the

amount

amount

hasn't

Min

of

confirmed

of

oil.

changed.

fhe

amounl

1mm

The amounl

Max

Fig.8

Adjust

of

of

oil

oil

paper

the

for

screw

three

until

times

the

Fig.9

to

observe

mark on

the

* Adjusting

(

Fig.9)

1) More

on

the

A.

As

direction

2)

After

seconds.

oil

is

hook

the

oil

B,

adjusted,

It

the

amount

supplied

driving

amount

the

can

of

as

oil

shaft

amount

the

be

confirmed

is

adjust

of

oil

machine must be

oil

supplied to the

amount

turned

screw

supplied

the

6

adjust

toward+

is

turned

state

will

idling

of

screw

in

direction

toward -

be

decreased.

for

oil

supplied.

hook

mounted

in

thirty

Page 8

4.ATTACHING

*

Turn

the

the

needle.

A

needle

size

material

1)

Turn

point

2) Loosen

A

3)

Insert

will

4)

Securely

5) Check

to

of

according

the

of

screw

facing

the

go on

that

the

left

used.

handwheel

THE

motor power

DBX 1 14

to

its

stroke.

@, and

exactly

needle

further.

tighten

long

in

NEEDLE

#

should

the

count

until

hold

to

the

in

the

screw

groove C

direction

OFF

before

be used.

the

needle

needle

right

direction

@.

of

D.

(Fig.IO)

starting

Select a proper

of

thread

bar

CD

with

in

direction

of

the

needle

-@

and

reaches

its

the

arrow

is

facing

to

attach

the

type

the

highest

indented

B.

until

exactly

needle

of

part

it

®

.......::___~--

__

.----

©

Fig.to

7

Page 9

5.

SETTING

(

Fig.

1)

Hold

directed

bobbin

2)

Pass

in

direction

tension

3) Cheek

when

THE

11

)

the

bobbin

to

the

into

the

the

thread

B.

spring

that

the

bobbin

thread C is

BOBBIN

in a way

left

as

bobbin

through

By

so

doing,

and

come

rotates

pulled.

INTO

that

observed

case.

thread

the

out

slit

thread

from

in

the

THE

the

thread

from you,

A,

and

will

notch

direction

BOBBIN

open end

and

set

pull

the

pass

under

B.

of

the

CASE

is

the

thread

the

arrow

Fig.11

8

Page 10

6.

THREADING THE MACHINE HEAD( Fig.12 )

Fig.12

7.ADJUSTING

1)

Turn

stitch

and

align

arm.

2) The

3)

dial

When

you want

length

direction

dial

THE

length

the

desired

calibration

to

CD

of

the

STITCH

dial

CD

number

is

decrease

while

arrow.

pressing

LENGTH

in

the

to

marker

in

millimeters.

the

stitch

direction

dot

length,

feed

lever

( Fig.

of

the

A on

the

turn

@

13)

arrow,

machine

stitch

in

the

9

Page 11

8.THREAD

TENSION

I.adjusting

1) Adjust

CD

2)

As

thread

3)

As

the

the

according

you

turn

tension

you

turn

tension

2.Adjusting

1)

As

you

turn

direction C ),

2)

As

you

turn

The

bobbin

( Fig.

the

needle

needle

nut

screw ® counterclockwise (

thread

to

CD

will

nut

will

the

tension

the

thread

the

sewing

clockwise (

increase.

CD

counterclockwise

decrease.

bobbin

adjust

bobbin

tension

14)

thread

tension

specifications.

thread

thread

will

tension

using

in

direction

tension

screw ® clockwise (

tension

decrease.

tension

(indirection

in

adjust

A),

the needle

will

increase.

direction

nut

B ),

in

D ) ,

10

Fig.14

\ \

\

''{_

'\

Page 12

9.THREAD

1.

Changing

1) Loosen

2)

As

you

the

3)

As

you

the

2. Changing

1) Loosen

2) Loosen

3)

As

you

the

4)

As

you

the

TAKE-UP

setscrew

turn

stroke

turn

stroke

the

setscrew

setscrew@,

turn

pressure

turn

pressure

the

stroke

tension

of

the

the

will

pressure

tension

will

the

post

will

SPRING

of

( Fig.

thread

®·

post @ clockwise ( in

thread

knob

be

®,

take-up

counterclockwise ( in

decreased.

of

and

take

and

remove

post

@

be

increased.

counterclockwise ( in

be

decreased.

spring

thread

out

tension

clockwise ( in

take-up

will

take-up

tension

15)

spring

direction

be

direction

spring

asm. ®·

post@.

direction

direction

® @

CD:

A ) ,

increased.

B ) ,

CD:

A ) ,

B),

CD

Fig.15

IO.HAND

1)

To

lifter

2) The

3) The

hand

LIFTER

stop

CD

presser

presser

lifter

the

in

machine

direction

foot

foot

will

CD

is

(Fig.

with

will

go

turned

16)

A.

go up

back

down

11

its

presserfoot

about

to

its

original

in

direction

5.5mm

up,

and

stop.

position

B.

turn

hand

when

Page 13

4)

Using

foot

Fig.16

the

lift

knee

of

about

lifter

10mm

, you can

and a maximum

get

the

lift

standard

of

about

presser

13mm.

11.PRESSER

1) Loosen

clockwise

be

2)

As

(

decreased.

3)

After

4)

For

spring

GC1088-H

nut

increased.

you

turn

in

direction

adjustment,

general

regulator

@.

(indirection

the

it

FOOT

fabrics,

is

PRESSURE

As

you

presser

B

),

tighten

is

7kg.)

turn

spring

the

the

29

presser

A),

the

presser

nut

standard

to

( Fig.

spring

presser

regulator

foot

17)

foot

counterclockwise

pressure

@.

height

32mm(5kg). (For

of

regulator

pressure

will

the

presser

the

..

---

-

CD

will

be

model

Fig.17

12

Page 14

12.ADJUSTING

1)

Loosen two

properly

setscrews.

2)

To

obtain

dropping

dog

with

the

throat

3)

To

advance

material

of

the

4)

To

delay

tightness,move

direction

*

If

moving

will

setscrews

position

the

standard

from

the

the

top

plate.

the

feed,

move

arrow.

the

feed

from

the feed

be break .

CD

THE

® and ® on

the

throat

of

the

feed

the

timing

the

feed

the

arrow.

eccentric

FEED

timing

feed

TIMING ( Fig.18)

eccentric

feed

timing,when

plate , align

hole

on

in

eccentric

in

eccentric

cam.

the

order

order

cam

feed

Then

needle

cam

to

cam

to

eccentric

retighten

the

the

top

and

to

prevent

in

the

increase

in

the

far,the

Standard

cam

feed

of

the

the

direction

opposite

needle

CD,

the

dog

is

feed

top

of

uneven

stitch

Fig.18

13

Page 15

13.HEIGHT

1)

The

feed

dog

the

throat

GC1088-A,

GC1088-H,0.95mm

2)

If

the

sewing

0.

7mm

3)

To

adjust

(1) Loosen

(2)

(3)

*

Precaution

If

the

be

abraded

it

feed

light-weight

to

0.8mm)

Move

the

Securely

screw

OF

THE

is

factory-adjusted

plate

juts

to

dog

juts

out

the

height

screw®

feed

bar

tighten

is

tighten

.

a. Feed dog

FEED

surface

out

1.05mm.

too

much,

materials

of

the

of

crank

up

or

screw®·

too

DOG

so

0.8mm

0.

7mm

puckering

. (

Recommended

feed

dog:

CD.

down

to

securely,

b.

Throat

( Fig.

that

it

to

0.9mm.For

to

0.8mm.For

may

make

the

plate

19)

juts

out

from

the

the

result

protrusion:

adjustment.

crank

when

will

CC1088-M

0.

75-0.85mm

~~,;;-

b

GC1088-A

702J~~

GC1088-H

702Jr~~~

Fig.19

14

o.

7-0.Smm

b

0.95-1.

b

05mm

Page 16

14.

NEEDLE-TO-HOOK

RELATIONSHIP ( Fig.

1.Adjust the timing between

as

follows:

1) Turn

*

Adjusting

2)

the

lowest

When

needle

bushing@,

When

it,

point

using

bar®

using

then

handwheel

of

the

needle

the

with

then

the

needle

tighten

to

its

stroke,and

bar

needle

the

tighten

setscrew

bring

height"

of

DB X 1,

bottom

setscrew(!).

of

DAX

(!).

the

the

1,

align

needle

needle

loosen

align

end

of

and

bar

setscrew(!).

marker

needle

marker

~®

20 )

the

hook

down

to

the

line

A on

bar

lower

line B with

©

®

*

Adjusting

When

3)

setscrews,

the

bushing

line D with

using

needle

@.

Fig.20

position

the

needle

turn

the

bar ® with

When

using

the

bottom

of

the

hook

of

handwheel,

the

the

end

of

15

DB X 1,

and

bottom

needle

needle

loosen

align

end

of

of

DAX

bar

,'.

-~---®

' \

' . '

' '

\ 0 }

' ,

' ,

...

___

.....

0

the

three

marker

needle

1,

align

lower

bushing

',

line

bar

hook

Bon

lower

marker

@.

Page 17

4)

After

making

align

Provide a clearance

and

*

Precaution

If

will

hook

the

hoo~

the

clearance

be abraded.

over.

* Note

that

the

replacing

very

machine

type

of

the

blade

then

type

the

hook,

of

original

adjustments

point®

of

0.04mm

securely,

is

too

If

it

is

of

hook

shall

the hook

assemblage.

mentioned

with

the

to

0.

tighten

small,the

too

big,

to

be

substituted

be

in

installed

in

the

above

center

lIIlIIl.

the

it

between

hook

tip

will

of

needle@.

the

setscrews.

of

the

lead

needle

to

for,

conformity with

in

the

sewing

steps

hook

skip

when

the

15.ADJUSTING

(

Fig.

1)

2)

Loosen

the

angle

After

21 )

setscrew

adjustment,securely

of

THE

the

HEIGHT

CD,

and

adjust

presser

OF

the

foot.

tighten

16

THE

presser

the

CD

Fig.21

PRESSER

bar

height

setscrew.

BAR

and

Page 18

16.ADJ(JSTING

{

Fig.22)

1)

When

sewing

to

the

left

2)

3)

pulled

When

to

pulled

When

with

sewing

the

the

the

out

right

out

marker

center

THE

heavy-weight

in

direction A to

by

the

light-weight

in

direction B to

by

the

line

\

\

~\

Fig.22

thread

thread

of

't

\

\

THREAD

materials,move

take-up.

materials,move

take-up.

C on

the

the

screw,

•@

~-CD

increase

decrease

thread

it

is

®-

TAKE-UP

thread

the

length

thread

the

length

guide

standard.

CD

of

of

is

STROKE

guide

guide

CD

thread

CD

thread

aligned

17.

INSTALLING

WINDER

1.

Installing

1)

Drill

machine

2)

Insert

Install

3)

middle

4)

Install

5) Using

cover

{Fig.23,Fig.24,Fig.25)

four

table.

support

the

of

the

the

® on

screw

THE

Procudure

wooden

CD

front

the

the

hol~

back

belt

belt

@, @

support

BELT

screw

in

the

and

COVER

guide

tapped

cover®,

cover ® at C and

washer

the

tighting

17

holes

hole

get

® ,

AND

A,

B,

C and D

in

the

handwheel

fix

torque

THE

the

arm.

D.

the

front

for

BOBBIN

in

the

in

the

be 1 t

the

screw

Page 19

6)

7)

8)

@

is

Fix

the

Move

touches

0.

5-lmm,

Fix

bobbin

about

30

kgf • cm,

cover.

the

back

belt

the

front

fix

it

winder @ at A and B using

cover

belt

using

for

cover@,

the

the

screw®

®

wooden

backward

then

screws

is

move

the

about

until

and

wooden

25

kgf • cm.

its

further

washers.

47

rubber

more

screws.

Fig.23

©

©

\

63.5

75. 5

Unit:mm

®

Fig.24

18

Fig.25

Page 20

18.ADJUSTING

(

Fig.26,Fig.27)

1) The

2)

3)

standard

knee

lifter

You

can

lifter

GC1088-A

When

you have

be

sure

position

adjust

adjust

that

Fig.26

THE

height

is

10mm.

the

screw(D. ( The

type

)

adjusted

the

does

not

HEIGHT

of

presser

the

bottom

hit

the

presser

foot

presser

end

of

presser

OF

lift

max.

lift

foot

needle

foot@.

---<)

THE

foot

up

to

shoule

1 i

bar

KNEE

lifted

13mm

using

be

ft

to

over

®

in

its

LIFTER

using

9mm

10mm

lowest

the

knee

for

,

Fig.27

19

Page 21

19.SPECIFICATIONS

Application

Sewing speed

Stitch

Presser

length

foot

(by knee

Needle

Lubricating

lift

lifter)

oil

GC1088-M

For

medium-weight

materials

Max.

'Max.

10mm

13mm

#

5500s.

(standard)

DBX

9-18

p.m

5mm

(max)

1

#

GC1088-A

For For

light-weight

materials

Max.4000s.p.m

Max.

4mm

9mm

(max)

DAXl

# #

9-

11

10

white

oil

GC1088-H

heavy-weight

materials

Max.

3500s.p.m

Max.

5mm

10mm

(standard)

13mm

(max)

DBX

1

#

#

20-

23

20

Loading...

Loading...