Page 1

Purchasing

Copy

Dept

HIGH

LEAD

GC0618-1/-SC/-D2/GC0518-1

Heavy Duty Compound Feed Lockstitch Sewing Machine

Instruction

Parts

SHANGHAI

HUIGONG

N0.3

Catalog

SEWING

Manual

MACHINE

FACTORY

Page 2

Page 3

1.

PRECAUTIONS

2.

MAlN SPECIFICATIONS

3.

PREPARATION AND LUBRICATION ..

4.

REPLACE

5.

WINDING

6.

WINDING

7.

REMOVING AND INSERTING

8.

THREADING........ . .......................

9.

REGULATING THE

10 ADJUSTMENT OF

ll.

ADJUSTING THE

12. STITCH LENGTH

13.

ADJUSTING

14.

RELATIVE POSITION OF THE FEED

15

THE POSITION OF

16.

TIMING THE

17

ADJUSTING THE

18. TIMING

19.

ADJUSTING THE

BETWEEN

BEFORE

NEEDLES

...

..

ADJUSTMENT

THREAD

THE

LIFT

ADJUSTMENTS

THE

HEIGHT

THE

NEEDLE

HEIGHT

THE

HEIGHT

STARTING OPERATION

................

......

PRESSURE

OF THE ALTERNATING

OF

NEEDLE

WITH FEED

OF THE

HOOK

OF THE

20. TIMING OF THE VIBRATING

21

ADJUSTMENT OF THE

CLEARANCE

COLLAR

22. ADJUSTING THE

23. ADJUSTMENT OF

24. ADJUSTMENT OF KNIFE

THREAD

NEEDLE

CONTROLLER

BAR STOP POSITION

ENGAGEMENT

CONTENTS

.

.

THE

BOBBIN

TENSIONS

ON

AND

THE

FEED

DOG

AND

THE

DOG

NEEDLE

AND

THE

PRESSER

PRESSER

BETWEEN

................

..................

.

.....

.

THE

MATERIAL.

PRESSER

REVERSING

DOG

....

TO

NEEDLE

NEEDLE

.......................

BAR

.....

NEEDLE

FEET

FOOT

..

FEED FORKED

SPRING

...

.

.

.

.............

FEET

LEVER

..

...........................

PLATE ... 7

HOLE OF THE

FEED

DOG

.....................

.

.....................

............................

CONNECTION

.....

.

AND FEED FORK

.

......................

..........

.

............

.

.

.....

.

.......

.

......

.

.....

.

........

.

........

.......

.

........

.....

. .. 6

. ... 7

.

...

.

2

2

.

.3

3

.4

.4

..4

5

5

. .6

6

. .6

8

..

10

7

8

8

9

9

9

9

~I~

Page 4

1.

PRECAUTIONS

1) Safety Precautions:

(

1)

When turning the power on, keep your hands and fingers away from the area around/under the needle

and the area around the balance wheel.

Power must

(2)

be

turned

BEFORE

off

when the machine

STARTING

is

not in use, or when the operator leaves the seat.

OPERATION

( 3) Power must

be

turned

off

when tilting the machine head, installing

or

removing the

"V"

belt, adjusting

the machine, or when replacing.

(4) Avoid placing fingers, hairs, bars etc., near the balance wheel,

"V"

belt,

bobbin

winder balance wheel,

or motor when the machine is in operation

(5) Do not insert fingers into the thread take-up cover, under/around the needle, or balance wheel when the

is

machine

(6)

If

a belt cover, finger guard, eye guard are installed, do not operate the machine without these safety

in operation.

devices.

2) Precautions before Starting Operation:

(I)

If

the machine's oil pan has an oil sump, never operate the machine before filling

(2)

If

the machine is lubricated by a drop oiler, never operate the machine before lubricating.

(3) When a new sewing machine is first turned on, verify the rotational direction

po\ver on. (The balance wheel should rotate counter-clockwise when viewed from the balance

the

it.

ofthe

balance wheel with

wheel)

(4)

Verify the voltage and (single or three) phase with those given

on

the machine nameplate.

3) Precautions for Operating Conditions:

(1) Avoid using the machine at abnormally high temperature (

J

lower

(2)

Avoid using the machine

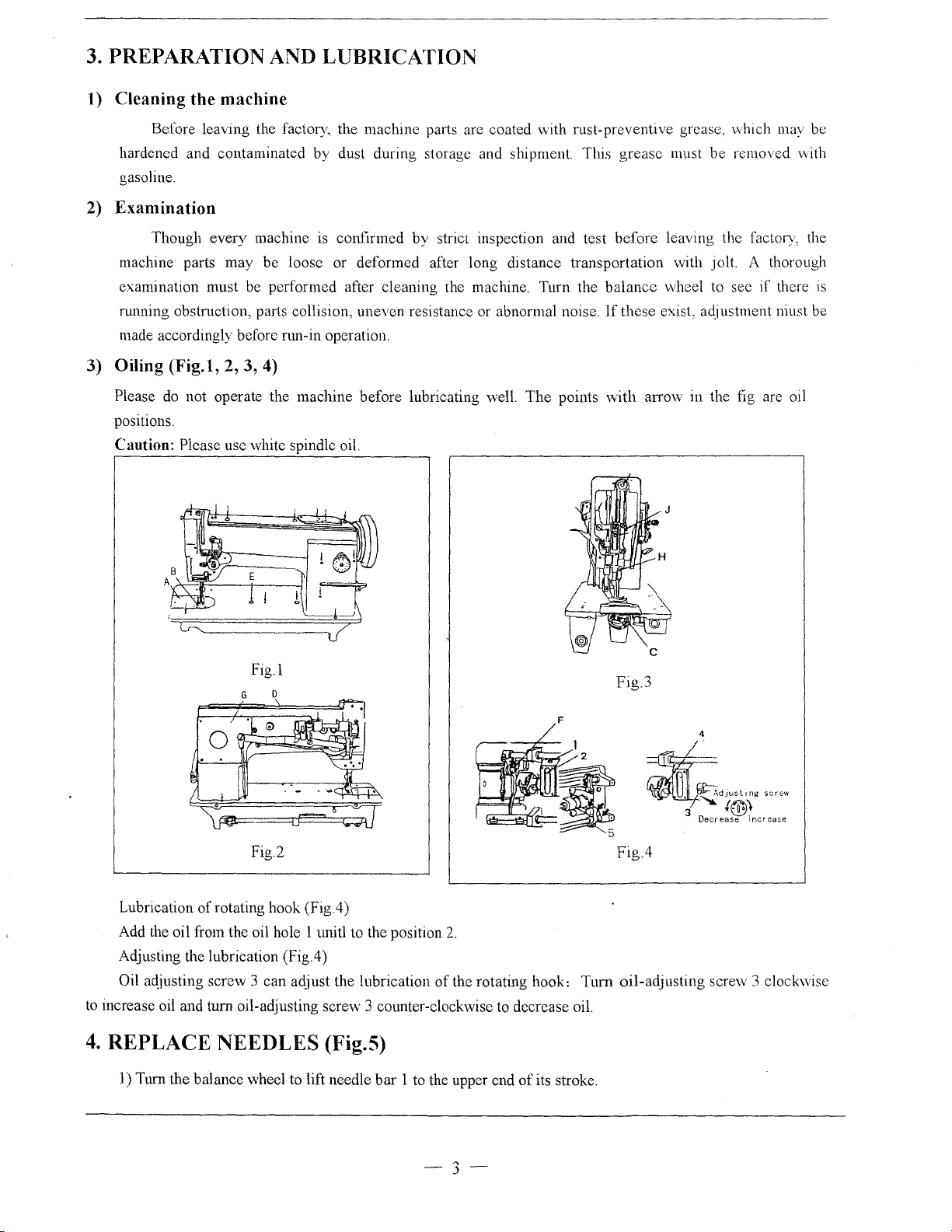

2. MAIN

SPECIFICATIONS

Item

Max. Sewing Speed L000 rpm

f----------''---'-----t-------------------------------·-·-··-··

f---------=----t--------------------------------------------

1 Take-up Lever Stroke

t-------------+-------------------------·------------

Stitch Length 0 I 0

in

dusty conditions

r;coo

1

1-1

1 J

r;r

:oo

1

1-1

1

sr:

J

Needle Bar Stroke

t-H--'~:.c.~gh:.::dc..::~:...:~:...:~:._~:..c~c_;~c::.~vs:...:ee:.::~....:1F-'~=-=oac...:.ti_n-+---------L-:J-III_m

Presser foot

lift By Knee

f--------__[__--=----t------------~----=---------------·

Rotating Hook

Lubrication

By

Hand H

t---=------+----------------:-;-----------------

Needle

Motor

Double Capacity Hook

370W Clutch Motor

I Large Hook

I

3S"C

or

r;r:oo

11-1

111111

71.

;,

111111

:l::J

111111

_________

111111

l~111111

Ill'~

17

LL;::

for

Manual

Speed adj. Motor

higher)

1

IlL

L~;::

Trimmer

or low temperature (

S"C

l

-------·

------

-------·.

---------

l_l__-

___

-~~----~=---~--~-~~

·-----··-·

-·--·--

~-Do~;blc

1 370W Clutch Motor

C'~l]~;~~J~lo()_<

-----

-·

-·-

-----

or

---

--

-2-

Page 5

3.

PREPARATION AND LUBRICATION

1)

Cleaning the machine

Before leaving the factory, the machine parts are coated with rust-preventive grease, which may be

hardened and contaminated by dust during storage and shipment. This grease must be removed

gasoline.

2) Examination

Though every machine is confirmed by strict inspection and test before leaving the factory, the

machine parts may be loose or deformed after long distance transportation with jolt. A thorough

exammation must be performed after cleaning the machine. Turn the balance wheel to sec

running obstmction, parts collision, uneven resistance or abnormal noise.

made accordingly before nm-in operation.

If

these exist, adjustment niust

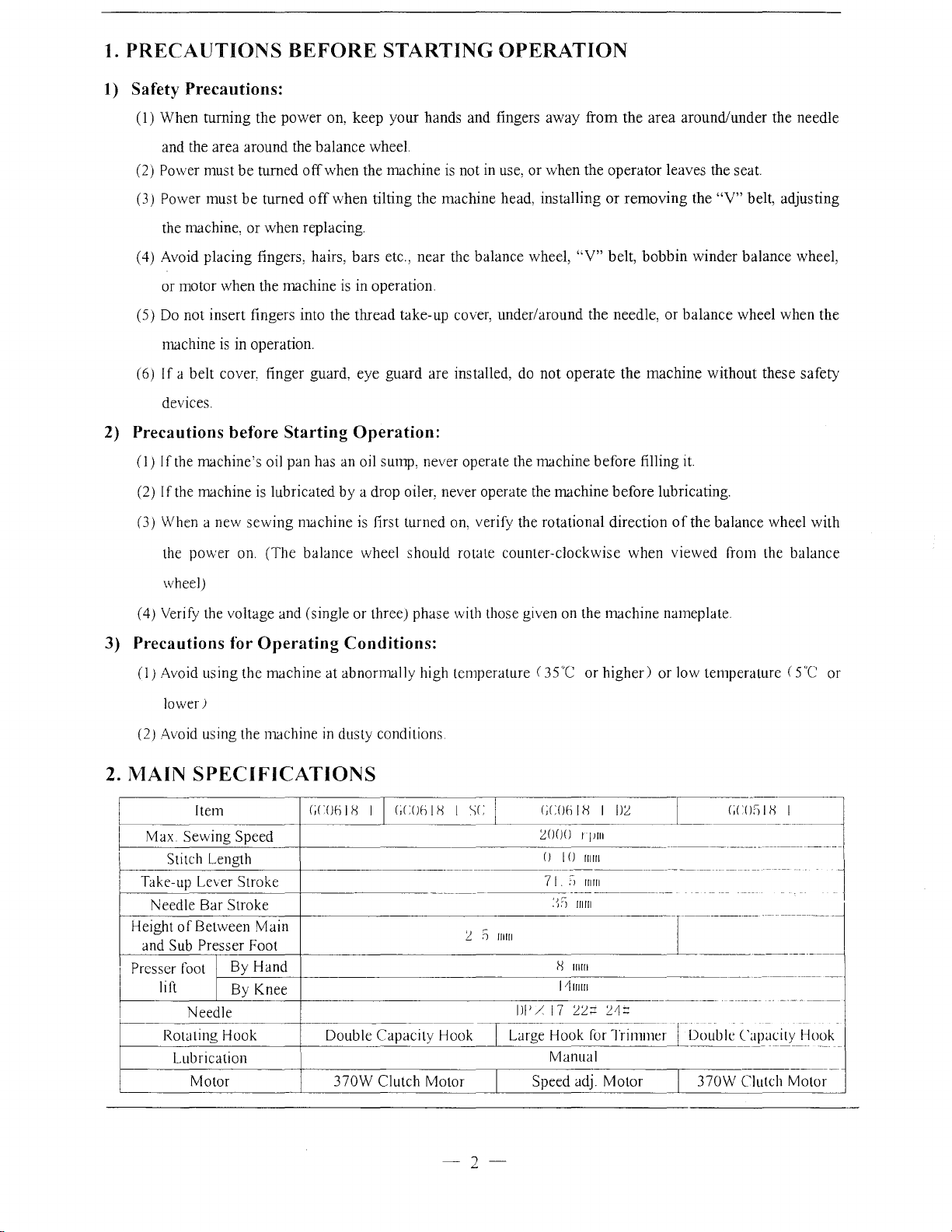

3) Oiling (Fig.l, 2, 3, 4)

if

vvith

there

is

be

Please

positions.

Caution: Please use white spindle oil.

do

not operate the machine before lubricating well. The points

Fig.l

with

arrO\v

in the fig are oil

Fig.3

F

~~"'""''"'

~

4

3

Decrease

,,,.

1~\

lncrea.s.e

Fig.2

Lubrication

Add the oil from the oil hole 1 1llitl to the position

Adjusting the lubrication (Fig.4)

Oil aqjusting screw 3 can aqjust the lubrication

to

increase oil and tum oil-adjusting screw 3 cmmter-clockwise to decrease oil.

4.

REPLACE NEEDLES (Fig.5)

1)

Tum the balance wheel to lift needle bar 1 to the upper end

of

rotating hook (Fig.4)

2.

of

the rotating hook:

of

its stroke.

3

Fig.4

Tum

oil-adjusting screw 3 clockwise

Page 6

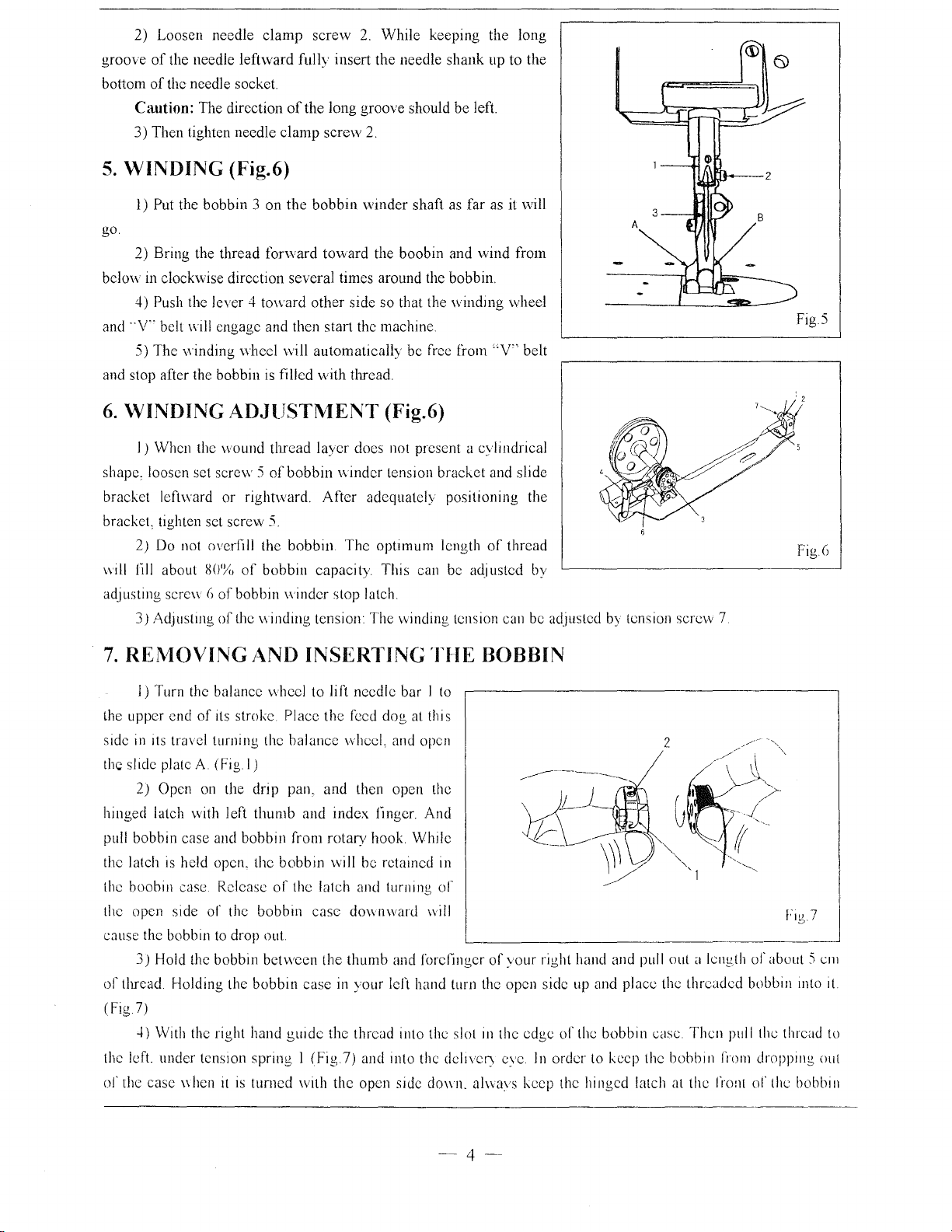

2)

Loosen needle clamp screw

of

groove

bottom

5.

go.

below

and

and stop after the bobbin

6.

shape, loosen set

bracket left ward or rightward. After adequately positioning the

bracket, tighten set screw

mil

adjusting sere\\

the needle leftward fully insert the needle shank up to the

of

the needle socket.

Caution: The direction

J)

Then tighten needle clamp screw

WINDING

l)

Put the bobbin J on the bobbin winder shaft

2) Bring the thread forward toward the boobin and wind from

in

clockwise direction several times around the bobbin.

4) Push the lever 4 toward other side so that the winding wheel

··v··

belt will engage and then start the machine

5) The v\inding \\heel

WINDING

I)

When the \vound thread layer does not present a cylindrical

2)

Do

not overfill the bobbin The optimum length

fill

about

J)

Adjustmg

(Fig.6)

ADJlJST~1ENT

screvv 5 of

80'%

()of bobbin winder stop latch

of

the winding tension: The winding tension can

of

the long groove should be left.

vvill

is

filled with thread.

bobbin winder tension bracket and slide

5.

of

bobbin capacity This can

2.

While keeping the long

2.

as

far

automatically be free from

(Fig.6)

be

adjusted by

as

"V"

of

it will

belt

thread

be

adjusted

by

tension screw 7

FigS

Fig.o

7.

RE!\10VING

I)

Turn the balance wheel to lift needle bar I

the upper end

in

side

the slide plate

hinged latch with left thumb and index finger And

pull bobbin case and bobbin from rotary

the latch

the boobin case. Release

the open side of the bobbin case downward will

cause the bobbin

of

(Fig

Its

2)

3) Hold the bobbin bet

thread Holding the bobbin case

7)

-n

the left. under tension spring l (Fig

or

the case \\hen

of

travel turnmg the balance wheeL and open

A (Fig

Open

on

is

held open. the bobbin will be retained

\Vith

the

AND

its

stroke Place the feed dog

I)

the drip pan, and then open the

to

drop out.

right hand

it

is

tumcd with the open side

INSERTING

hook. While

of

the latch and tuming

vvcen

the thumb and forefinger of your right hand and pull out a length

in

your left hand turn the open side

gwde

the thread into the slot

7)

and into the dciiVef) eve.

at

THE

to

this

In

of

do\\11.

BOBBIN

L__

__________________

up

and place the threaded bobbin lllto

Ill

the edge

alwavs keep the hinged latch

or

the bobbin case. Then pull the thread

In

order

to

keep the bobbin

2

at

!'rom

the front

Fig7

_

or

about 5

dropping out

or

the

bobbin

em

It

to

--

4

--

Page 7

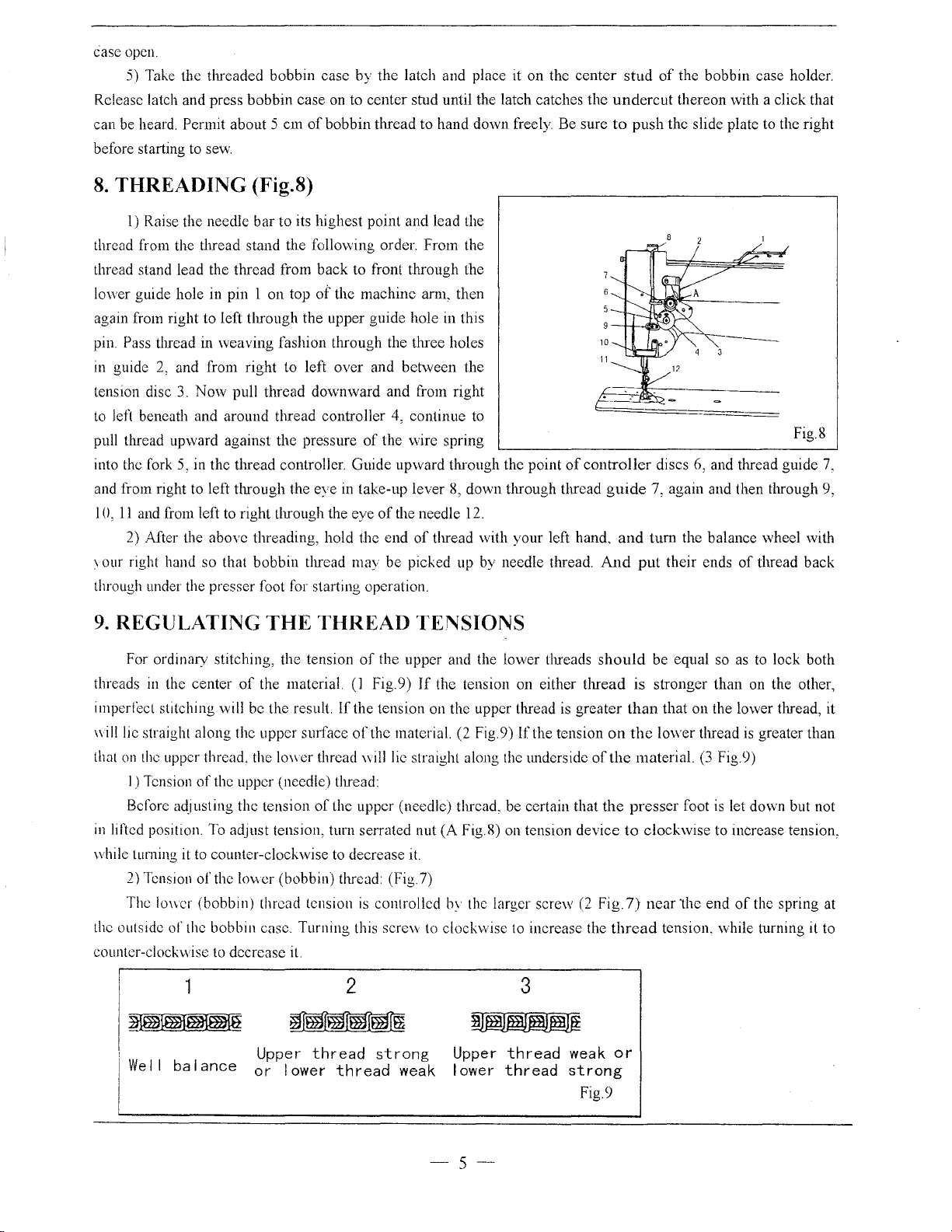

case open.

5) Take the tlu·eaded bobbin case

Release latch and press

can be heard.

before starting to sew.

8.

THREADING

l)

thread from the thread stand the

thread stand lead the thread from

lower guide hole in pin 1 on top

again from right to left

pin.

Pass thread in weaving fashion through the three holes

in guide

tension disc

to left beneath and around thread controller

pull thread upward against the pressure

into the fork

and from right to left through the eye in take-up lever

I 0,

ll

2)

\our

right hand so that bobbin thread may be picked up by needle thread.

through under the presser foot for starting operation.

Permit about 5

Raise the needle bar

2, and from right

3.

Now

5, in the thread controller. Guide upward through the point

and from left to right through the eye

.ASter

the above threading, hold the end

bobbin

case on to center stud until the latch catches

em

of

(Fig.8)

to

its highest point and lead the

tlu·ough the upper guide hole in this

to

left over and

pull thread downward and from right

by

the latch and place it on the

bobbin

follovving order. From the

back

of

thread

to

to front through the

the machine

of

am1,

between

4, continue to

the wire spring Fig.8

of

the needle 12.

of

thread with your left hand.

hand down freely. Be sure

then

the

8,

down through thread

center

the

10

of

controller

And

stud

of

the bobbin case holder.

undercut

to

guide

and

thereon with a click that

push

the slide plate to the right

discs 6, and thread guide

7, again and then through 9,

tum

the balance wheel with

put

their ends

of

thread back

7,

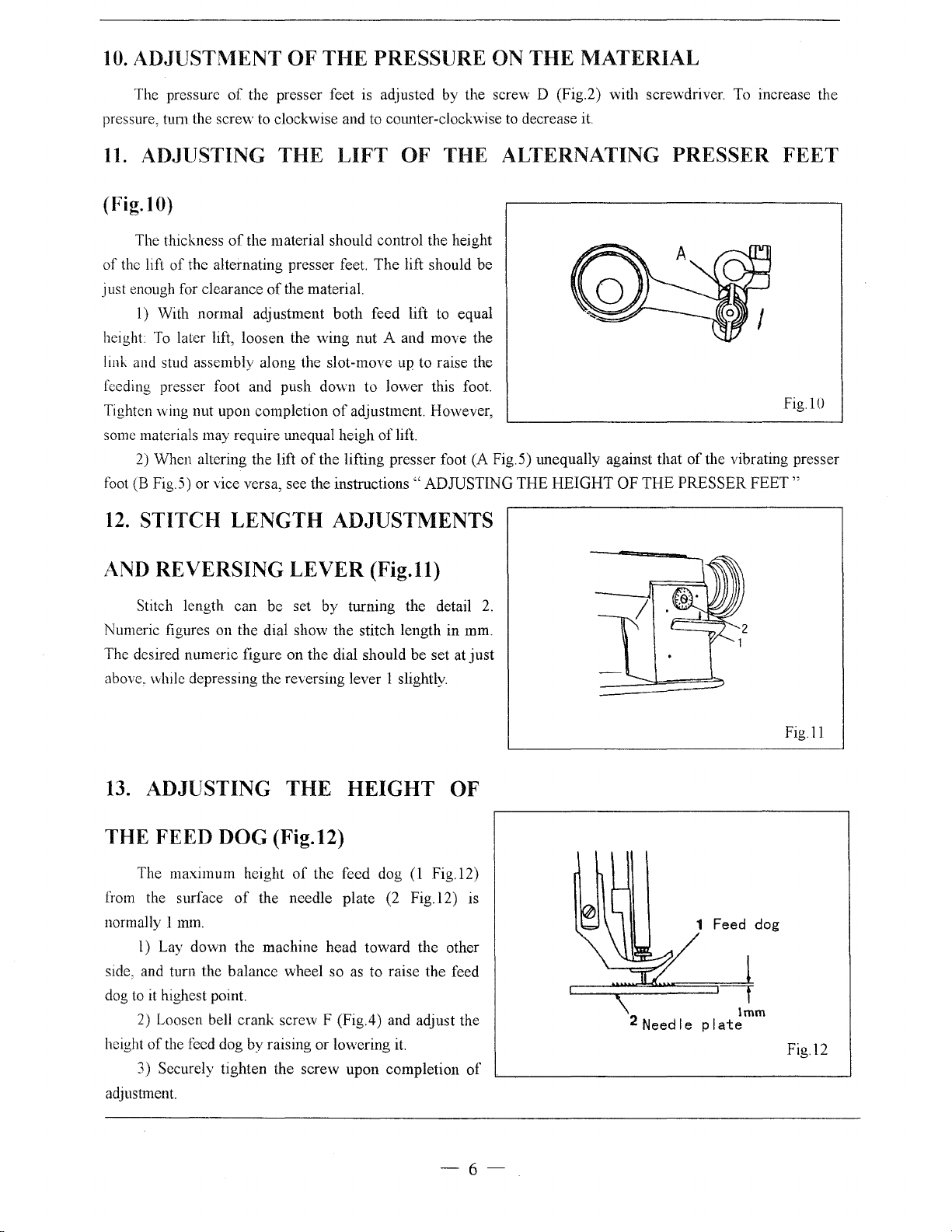

9.

REGULATING

For ordinary stitching, the tension

threads

imperfect stitching will be the result.

will lie straight along the upper surface

thot

in

while tuming it to counter-clockwise to decrease it.

the outside

counter-clockwise to decrease it.

in

the center

on

the upper thread_ the lO\\er thread will lie straight along the underside

I) Tension

Before

lifted position. To adjust tension, turn serrated nut

2) Tension

The 10\\er (bobbin) threod tension

of

the upper (needle) thread:

ad_i

usting the tension

of

the lower (bobbin) threod (Fig 7)

or

the bobbin case. Turning this screw to clockwise to increase the

THE

of

the material. (J Fig. 9)

THREAD

of

If

the tension on the upper thread is

of

of

the upper (needle) thread, be certain that

is

the upper and the lower threads

the material. (2 Fig.9)

controlled

2

~

1 Upper

j

We

II

ba I

ance

or

thread

I ower

strong

thread

weak

TENSIONS

If

the tension on either

If

(A

Fig.

S)

on tension

hy

the larger screw

3

Upper

lower

thread

thread

thread

greater

the tension

of

device

(2

weak

strong

Fig.9

should

is

than

on

the

the

the

presser

to

Fig.

7)

thread

or

be equal so as to lock both

stronger than on the other,

that on the lower thread, it

lower

thread

is

greater than

material.

clockwise

neor"thc

(3

Fig.9)

foot

is

let down but not

to increase tension,

end

of

the spring at

tension. while turning it to

-5-

Page 8

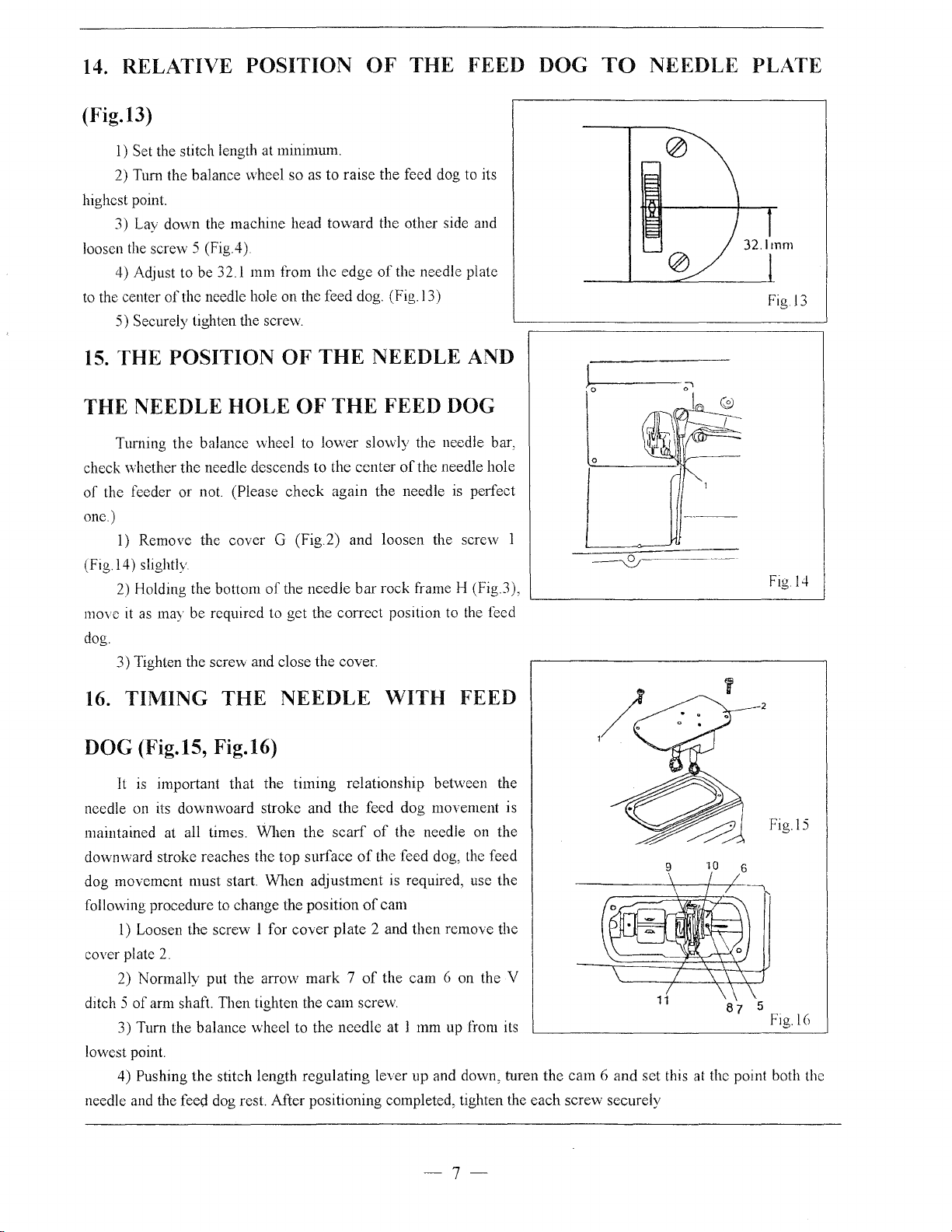

10.

ADJUSTl\1ENT

OF

THE

PRESSURE ON

THE

MATERIAL

The pressure

pressure, tum the

11.

ADJUSTING

of

the presser feet is adjusted by the screw D (Fig.2) with screwdriver. To increase the

scre"v to clockwise and to cmmter-clockwise to decrease it.

THE

LIFT

OF THE ALTERNATING PRESSER

(Fig. I 0)

The thickness

of

the lift

just

height

llllk and stud assembly along the slot-move up

feeding presser foot and

Tighten

some

foot (B Fig.5) or vice versa, see the

12.

of

enough for clearance

1) With normal adjustment

To later lift,

\Ving

materials may require unequal heigh

2) When altering the lift

STITCH

of

the material should control the height

the alternating presser feet.

of

the material.

both

loosen

nut upon completion

LENGTH

the

push

of

wing

nut

down

of

adjustment. However, Fig.l 0

the

lifting presser foot

instructions"

ADJUSTMENTS

The

feed lift to equal

A and

to

lower

of

lift.

lift should

move

to

raise the

this foot.

ADJUSTING

be

the

(A

Fig.5) tmequally against

THE

HEIGHT

OF

that

THE

of

the vibrating

PRESSER

FEET

presser

FEET"

AND

Numeric figures

The desired numeric figure

above, while depressing the reversing lever 1 slightly.

13.

REVERSING

Stitch length

on

can

the

ADJUSTING

LEVER

be

set

by

dial show the stitch length

on

the

THE

(Fig.ll)

turning the detail

dial should

be

HEIGHT

set

THE FEED DOG (Fig.l2)

The

maximum

from the surface

normally l mm.

l)

Lay

down

side, and turn the balance wheel so as

dog to it highest point.

2) Loosen bell

height

of

the feed dog

3) Securely tighten the

adjustment.

height

of

the

crank

of

the

feed

dog

the

needle

machine

screw F (Fig.4) and adjust the

by

raising

head

or

screw

plate

toward

to

lowering it.

upon

(1

Fig.l2)

(2

Fig.l2)

the

raise

the

completion

in

mm.

at

just

OF

is

other

feed

of

2.

2 Need I e

1 Feed dog

lmm

pI

ate

Fig.ll

Fig.l2

-6-

Page 9

14. RELATIVE POSITION

OF

THE FEED DOG

(Fig.13)

1)

Set the stitch length

2) Tum the balance wheel so as to

highest point.

3) Lay down the machine head toward the other side and

screvv

loosen the

4) Adjust to be 32.1 mm from the edge

to

the center

5) Securely tighten the screw.

15.

THE POSITION OF

5 (Fig.4)

of

the needle hole on the feed dog. (Fig.l3)

at

minimum.

raise the feed dog to its

of

the needle plate

THE

NEEDLE AND

TO

NEEDLE PLATE

Figl3

THE NEEDLE

Turning the balance wheel to lower slowly the needle bar,

check whether the needle descends to the center

of

the feeder or

one)

1)

Remove the cover G (Fig.2) and loosen the screw 1

(Fig 14) slightly.

2)

Holding the bottom

move

it

as

may be required to get the correct position to the feed

dog.

3) Tighten the

16. TIMING THE

HOLE OF THE FEED DOG

of

the needle hole

not

(Please check again the needle

of

the needle

screw and close the cover.

NEEDLE

bar

rock frame H (Fig 3),

WITH FEED

is

perfect

DOG (Fig.15, Fig.16)

It

is

important that the timing relationship between the

needle on its downwoard stroke and the feed dog movement is

maintained at all times. When the

downward stroke reaches the top surface

dog movement must start. When adjustment is required, usc the

following procedure to change the position

l)

Loosen the screw l for cover plate 2 and then remove the

cover plate

ditch 5

lowest point.

needle and the feed dog rest. After positioning completed, tighten the each screw securely

2.

2) Normally put the arrow mark 7

of

arm shaft. Then tighten the cam

3) Tum the balance wheel to the needle at l mm up from its

Pushing the stitch length regulating lever up and down, turen the cam 6 and set this at the point both the

4)

scarf

of

the needle on the

of

the feed dog, the feed

of

cam

of

the cam 6 on the V

screw

87

Figl4

Fig.l5

5

Fig.l(J

-7-

Page 10

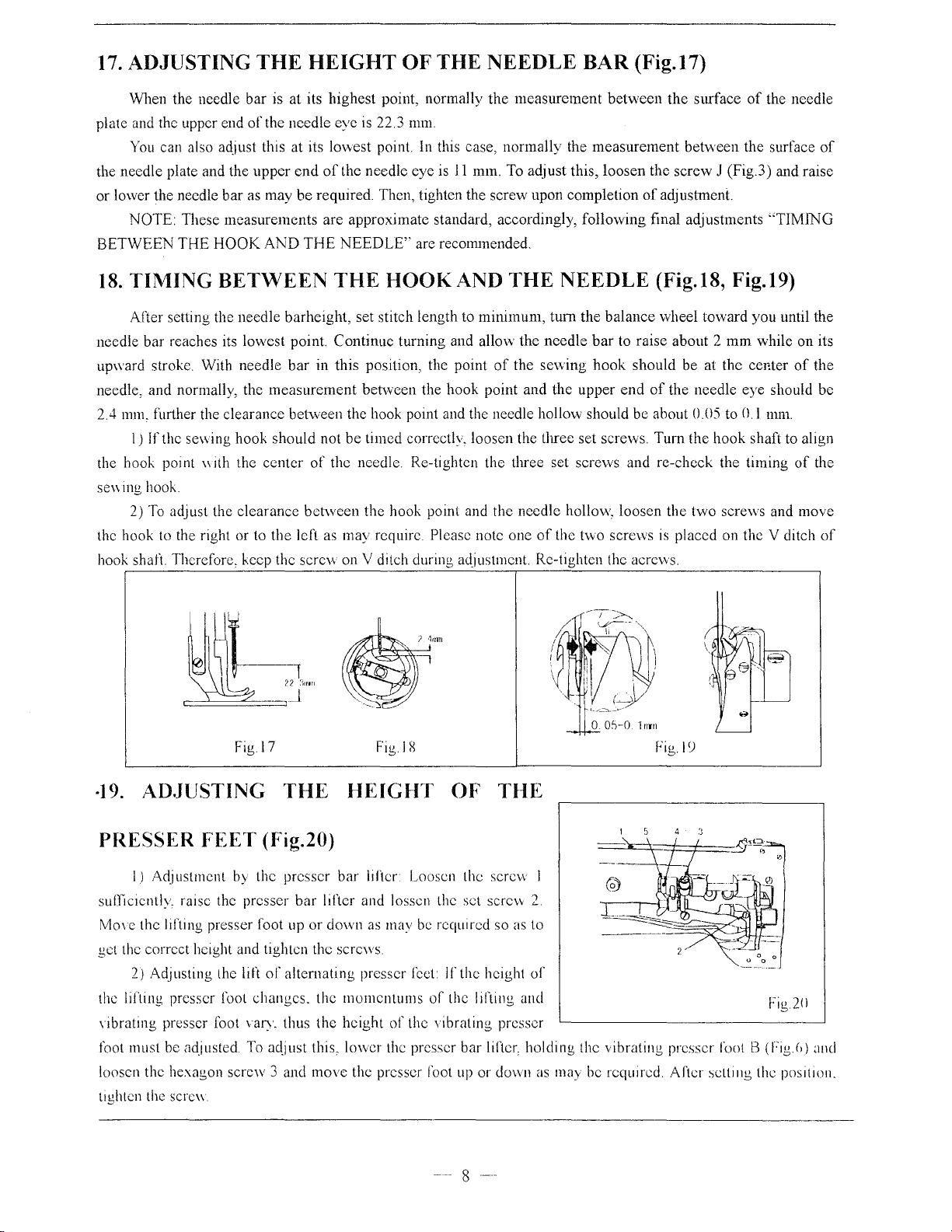

17. ADJUSTING

THE

HEIGHT

OF

THE

NEEDLE

BAR

(Fig.17)

When the needle bar is at its highest point, normally

of

plate and the upper end

You

can also adjust this at its lmvest point. In this case, normally the

the needle plate and the

or

low·er the needle

NOTE: These

BETWEEN

18.

TIMING

After setting the needle barheight, set stitch length to

needle bar reaches its lowest point.

upward stroke. With needle

needle, and normally, the

2.4

111111,

the hook point

se\\ ing hook

2)

the hook to the right

hook

THE

HOOK

BETWEEN

further the clearance between the hook point and the needle hollow should

1)

If the sewing hook

"ith

To

adjust the clearance

shari

Therefore, keep the screw on V ditch during adjustment. Re-tighten the acrc\vs.

the needle eye

upper

end

bar

as may

measurements

the

or

be

AND

THE

bar

measurement

should

center

to

the

left as may require Please note one

of

between

is

22.3

of

the needle eye is

required. Then, tighten the screw upon completion

are approximate standard, accordingly, following final adjustments

NEEDLE''

THE

Continue

in this position, the point

not

the needle. Re-tighten the three set screws and re-check the timing

HOOK AND THE

turning and allow the

benveen the hook point and the

be

timed correctly, loosen the three set screws. Turn the

the hook point and the needle hollow, loosen the

the

mm.

11

mm. To adjust this, loosen the

are recmmnended.

minimum,

of

measurement

NEEDLE

tum

the balance wheel to\vard you until the

the

needle

se\\ing

of

the

bar

upper

t\vO

between

measurement

the

of

adjustment.

(Fig.18, Fig.l9)

to raise about 2

hook

should

end

of

the needle eye should

be

about

screws

is

surface

between the surface

screw

be

0.05

two

placed on the V ditch

of

the needle

J (Fig.3) and raise

"TIMING

mm

while

on

at the center

to

0.1

hook

screws and move

of

mm.

shaft to align

of

of

its

the

be

the

of

Fig l

C)

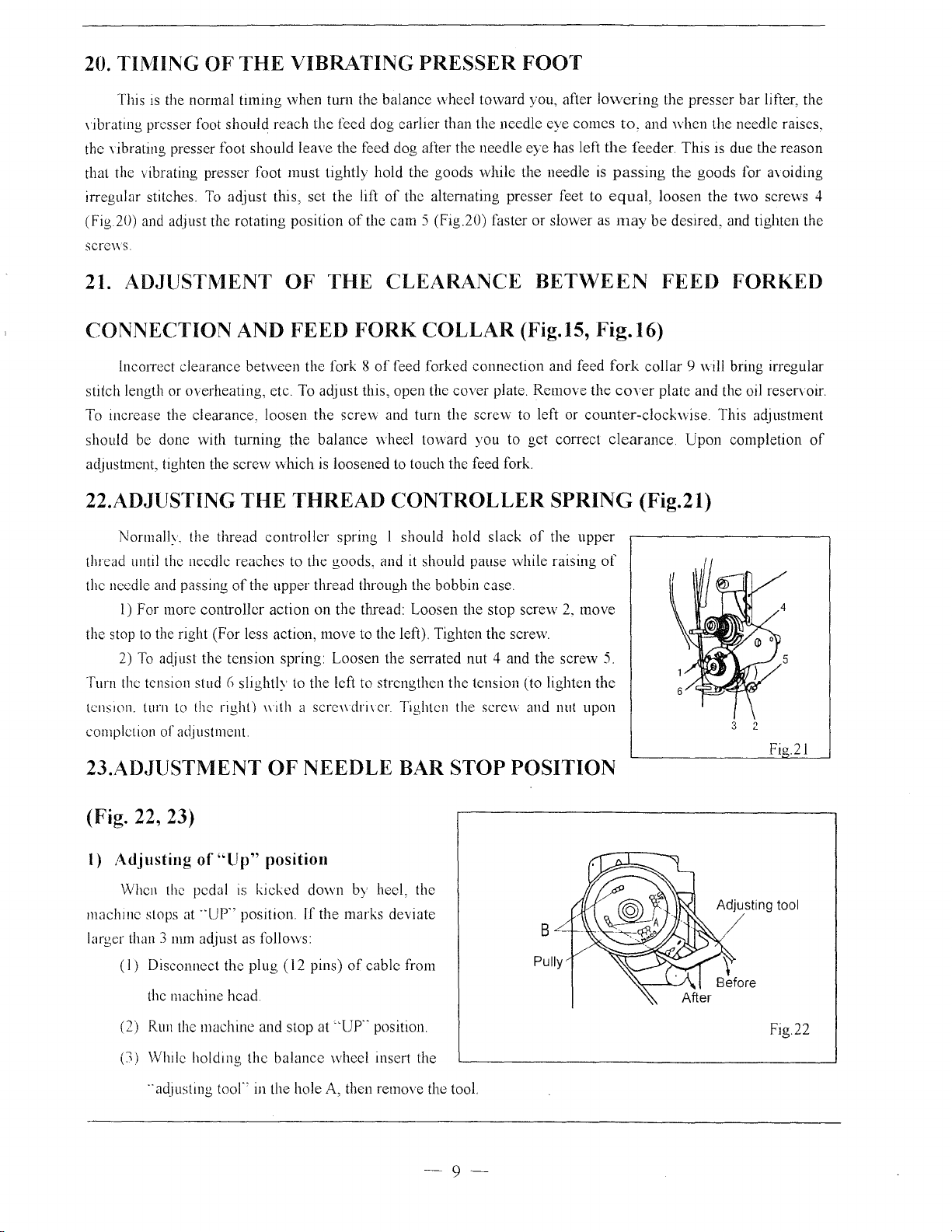

·19.

ADJUSTING

Figl7

THE

Fig.! X

HEIGHT OF THE

PRESSER FEET (Fig.20)

l)

Adj

ustmcnt by the presser

suffiCiently, raise the presser

Mm

e the lifting presser foot up or down as may be required so as to

get the correct height and tighten the screws.

2) Adjusting the lift

the lifhng presser foot changes. the momentums

nbrating

foot must be adjusted To a4just this, 10\ver the presser bar lilicr, holding the vibrating presser foot B (Fig.()) and

loosen the hexagon screw 3 and move the presser foot up or

tighten the sere\\

presser foot vary. thus the height

of

altcmating

bar

lifter Loosen the screw l

bar

lifter and lassen the set screw 2

presser f'cct

of

lf

the height

of

the l1fting and

the vibrating presser

--

8

--

dovvn

of

Fig 20

as

nwy he required. After setting the position.

Page 11

20. TIJ\1ING OF THE VIBRATING PRESSER FOOT

This is the normal

, ibrating presser foot

the

vibrating presser foot

that the vibrating presser

irregular stitches.

(Fig 20) and adjust the rotating

screws

21. ADJUSTJ\1ENT

CONNECTION

lnconect

stitch length

To tnerease the clearance, loosen the

should be done with

adjustment, tighten the

clearance

or

overheating, etc. To

22.ADJUSTING

Normally. the thread

thread until the needle reaches to the goods, and

the needle and passing

l)

For more

the stop to the right

2)

To

adjust the

Turn the tension stud G slightly to the left to strengthen the tension (to lighten

tension. turn to the right)

completion

of

adjustment

23.ADJUSTMENT

timing

should

should

foot

To

adjust

AND

between

tuming

screw

THE

of

the

controller

(For

less action,

tension

when

tum

the

balance

reach

the reed

leave the feed dog after the

must

this, set the lift

position

OF

FEED

the fork 8

adjust

the

balance

which

is loosened to touch the feed fork.

dog

tightly

of

hold

of

the

THE CLEARANCE

FORK

of

this,

screw

and turn the scrcvv to left or

wheel

THREAD

controller

upper

action

spring:

\\ith a scre\\dri\er.

OF

spring I should hold slack

thread through the bobbin case.

on

the

thread:

move

to the left). Tighten the screw.

Loosen

the serrated nut 4 and the

NEEDLE BAR STOP POSITION

wheel

toward

earlier than the

the

goods

the alternating

cam

5 (Fig.20) faster

COLLAR

feed forked

open

the

toward

needle

while

connection

cover

plate.

you

needle

eye

the

presser

(Fig.15,

to

CONTROLLER

it

should pause

Loosen

Tighten the sere\\ and nut

the

stop

while

screw

you, after

eye

comes

has left

needle

feet to

or

slower as

BETWEEN

and feed

Remove

get

correct

SPRING

of

the

upper

raising

2.

move

screw

lowering

the

is

passing

equal,

may

to,

feeder

the

presser

and

when

This is due the

the

loosen

be

desired, and tighten the

FEED FORKED

Fig.l6)

fork

collar

9 will bring irregular

the

coyer

plate

and

counter-clockwise.

clearance.

Upon

(Fig.21)

of

5.

the

upon

bar

lifter, the

the needle raises,

reason

goods

for aYoiding

the

two

screws 4

the oil reservoir.

This adjustment

completion

3 2

Fio.2]

of

(Fig. 22, 23)

l)

Adjusting

When the pedal is

machme

larger than 3 nun adjust as follows:

stops at --up·' position.

(I)

Disconnect the

the machine

(2) Run the machine and stop at

(:I) While

..

of"

holding

adJusting

Up" position

kicked

plug ( 12

head

the

toor'

in the hole A, then remove the tool.

down

lf

the marks deviate

pins)

''UP

balance

wheel

by heel, the

of

cable

..

position

insert the

from

Pully

-9-

Adjusting

tool

Fig.22

Page 12

2) Adjusting

of

Set the machine stops at

When the pedal

machine stops as

is

"DOWN"

deviate larger than 3

(I)

Disconnect the

"DOWN~~

position

"DOWN"

kicked

down

position.

mm

adjust as follows:

plug

(12 pins)

position.

by

helL the

If

the marks

of

cable

3rd mark

\ Rotating

\ direction

\

1st mark

from the machine

(2)

Run the

machine

position.

(3) While holding the

"adjusting tool" in the hole B, then

the

head

and stop at

balance

"DOWN"

Fig.23

wheel insert

remove the tool.

3)

Confirm the stop operation then the plug (12 pins) coming from the machine head into

the receptacle.

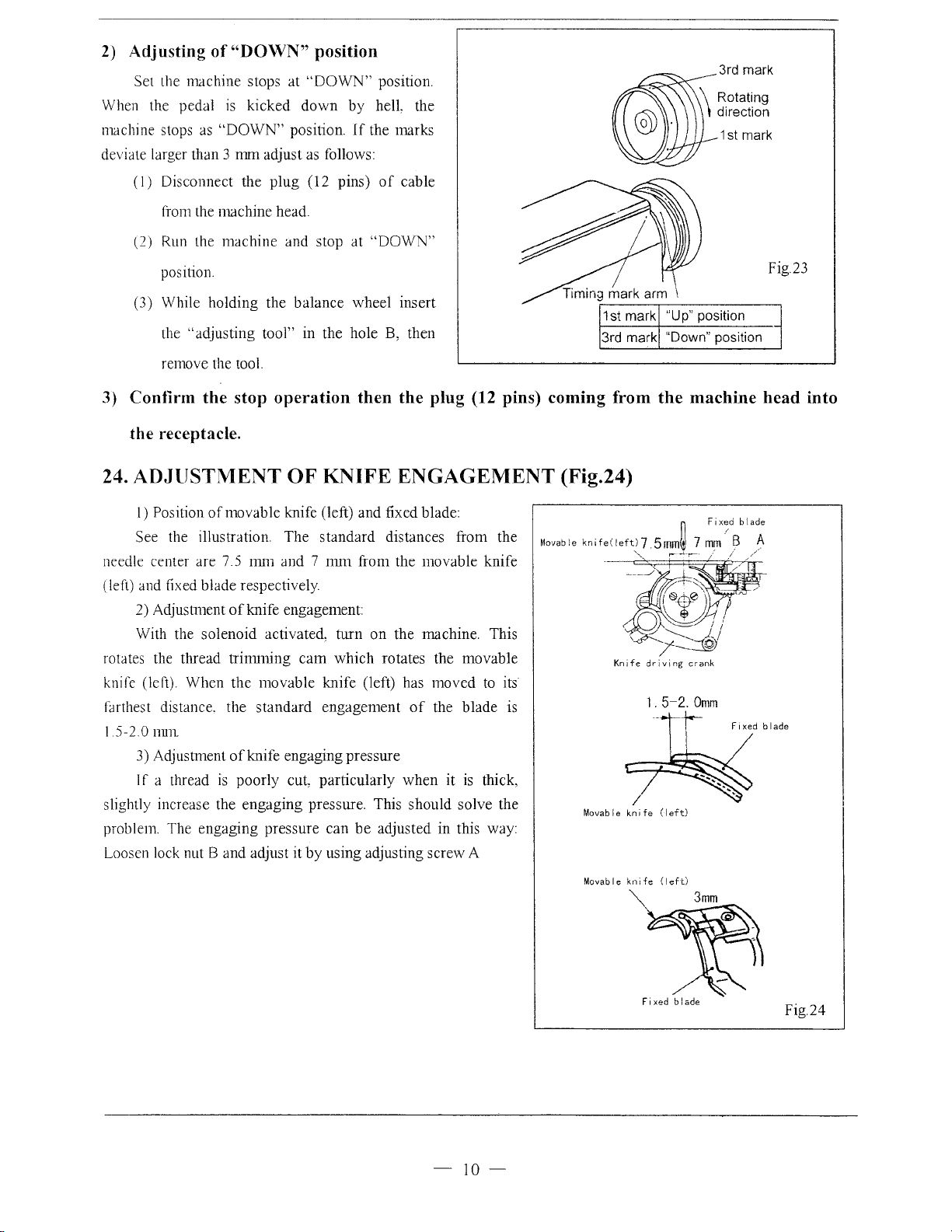

24. ADJUSTMENT OF KNIFE ENGAGEMENT (Fig.24)

I)

Position

See the illustration

needle center are 7 5

(left) and fixed blade respectively

2) Adjustment

With the

rotates the thread

knife (left). When the movable knife (left) has

farthest distance. the

5-2.0

I

nnn

3) Adjustment

If

a thread

slightly increase the

problem

Loosen lock nut

of

movable knife (left) and fixed blade:

The

standard

nm1

and 7

nun

of

knife engagement:

solenoid

is

activated, turn

trinuning

of

knife engaging pressure

poorly

engaging

cam

standard

engagement

cut, particularly

pressure. This should solve the

which

The engaging pressure can

B and adjust it

by

using adjusting screw A

distances from the

from the movable knife

on

the machine. This

rotates the movable

moved

of

the

when

be

adjusted in this way:

to

blade

it is thick,

its

is

Movable

knife(leftl7

Movable

n

Fixed

.5rnm~

7

r-

(left)

---l--:--· /

mm

"...,_

knife

b I a

1

B A

//

de

-10-

Movable

knife

""'

Fixed

(left)

3mm

b I

ade

Fig.24

Page 13

A.ARM BED AND ITS ACCESSORIES

53

4""-.

~

~'

3

52

0

0

171

0

18~

16

-11-

Page 14

A.ARM BED AND

Fig.

No.

A01

A02 HA06030080 Screw

A03 H2020M0069 Felt

A04 H2020M0067

AOS

A06

A07 H2020M0068 Oil wick

A08 H2400J2010 Oil cap

A09 H2400J2020

A10

All

A12 HA124B0711 Slide plate

Al3

Al4

Al5

A16

Al6

Al7

A18

A19

A20 H3108B0691

A21

A22

A23

A24

A25

A26

A27

A2g

A29

A30 H3100G2230

A30 H4200G2010

A30

A31

A32

A33

A34

A35

A36

A37

A38

A39

A40 H3111B0703

Part

No.

H3115B0721

Ann

Felt

H2020M0066

Ann

H2020M0068 Oil

Oiling

H3106B0671.

HA300B2170

Face plate 1 1

Screw

HA124B0713 Screw

HA124B0712 Slide plate spring

H2000B2050 Screw 2 2

H3100B2090 Needle plate 1 1 1

H4500B2020 Needle plate 1

H005008060 Spring washer 1 1

H2009B0653

Leg

H3108B0692 Felt 1 1

Thread guide

HA500C2070

Screw

HA300B2130 Screw 2 2

H2000B2040 Cloth guide plate 1 1 I

HAI06B0676 Screw

HAI06B0675 Thread guide 1 1 I

H2400B2080

H2400B2070 Thread guide 1 I

.

H2000M0090

Screw

Oil

H2000M0080 Felt

Thread tension releasing pin

Thread tension releasing pin(long)

H420002020

H2504C6510

H3111B0704

H31611B311

HA300B2080

H3111B0702

H3221B6819

Thread tension releasing pin( short)

Screw

Tension releasing lever

Screw

Screw

Thread controller spring

Thread controller spring stop

H324giBC21 Screw

H2504C0654

Thread guide

H2504C0658 Nut

Ser

ITS

ACCESSORIES

.......

I

00

.......

Description

cover( right)

'D

0

u

0

1 1 1

2 2 2 2

1 1 1

2 2 2

oil box( right)

wick

1 1

1 1 1

1 1

1 1

felt 1 1

2 2 2 2

1 1 1

2 2 2 2 SM3/32(56)x2.2

1 1 1

1 1

1 1

1 1 1

1 I I 1

I

cap I I 1

2 2 2

I I

2 2 2

I

I

1

I

1 I I

I I I

I

I

screw

1

N

u

(/).

Q

I I

....... .......

I

00

.......

'D

0 0

u u

0

I

00

.......

'D

0

1

1

1

1

1

2

1

1

1

I

2

I I

1

1

I

I I

I I

I

1

I

I

I I

I I

1 1

,......

I

00

.......

.,..,

0

u

0

Remarks

1

1

2

1

1

1

1

1

1

SM11/64(40)x9

1

1

2 SM11/64(40)x6.5

1

1

I

1

1 SM9/64( 40)x5

SM11/64(40)x5.5

2

I

SM9/64(40)x6

I

I SM3/16(28)x

13

1

1

2

I

2

I

I

SMI5/64(28)x6.8

I

I

1

I

I

1

SM3/32(56)x6

1

-

12-

Page 15

A.ARM BED AND ITS ACCESSORIES

u

(fJ

I I

I

-

Fig.

No.

A41 HA115B7010 Stop disc 1 1 1

A42

A43

A44

A45

A46

A47 H31611B211

A48 HA7311C606 Screw 1 1 1

A49

ASO

A51

A52

A53

A53

A

A54

A

A56

A57 H3100B2060

A58

A

A59

A60 H2000M0180

A61

A62

A63

A64

A65

A66

Part

No.

HA607B0068 Tension releasing spring 1

H2504C0657 Thread tension releasing plate

H2504C0656 Thread tension disc 2 2 2

H2504C0121

HA310B0701 Nut

H3100B2070 Thread guide 1 1 1

H31611Blll

H2504C0013 Thread tension stud 1 1 1

HA300B2170 Screw

H4205l0661

H3107B0681

54

H2000B2010 Rubber plug 1

HA307E0674 Rubber plug 1 1

55

HA300B2170 Screw 5 5 5

HA300B2160 Screw

H2400B2100 Thread guide 1 1

H4206B0066 Thread tension complete 1

58

HA700B2060 Screw 2 2

H2000M0190 Sealing washer 1 1 1

H2000M0200 Gland 1 1 1

HA300B2170 Screw 5 5

H2400B2050 Oil guard 1 1 1

H2400B2060

H3111B0705 Plate spring 1 1 I

Thread tension releasing pin

Pin

Tension bracket 1

Arm

side plate 1

Arm side plate 1

Thread take-up lever cover

Oil

window

Plate for oil guard

Description

00

\0

-

0

u

0

I I

-

00

\0

-

0 0

u

0 0

1

1 1 1

1 1

1 1

1 1 1

1 1

2 2

1

1 1 1

1 1 1

1 1

1 1

I

N

0

-

00

\0

-

u

1

1

1

2

1

5

I

-

00

lr)

-

0

u

0

1

1

1

2

1

1

1

1

1

1

1

SM11/64(40)x9

2

1

1

5

SM11164(40)x10

1

1

1

2

1

1

1

SM11!64(40)x9

5

1

1

1

Remarks

-13-

Page 16

B.ARM SHAFT MECHANISM

22

23

24

16

21

------

,-

1 18

20

I

I

I

:

19

I/

r#f

I

\_-----

32

~"

~----~--·

34

\

-

_3_3_~--

--~---

---

41

.--

4

~

---

14

~-

15

I

I

I

I

I

\

I

I

..-'

-

14-

Page 17

B.ARM SHAFT MECHANISM

Fig.

No.

BOl

802

803

804

805

806

B07

808

809

BlO

Ell

812

813

814

Bl5

816

817

818

819

B20

821

822

823

824

825

825

826

826

827·

828

829

830

830

831

832

832

833

834

835

836

837

838

839

Part No.

H3100C2110

H2009B0743 Felt

H31133Bl04

HA100C2020

H31122B204

HA105D0662

HA.105D0661

HA113D2112

HA108D0663 Set screw

HA112D3012 C-type ring

H3100E2010

HA3411D208 Slide block

HA.3411D308

H2000C2040

HAll

OD0672

H3100C2070 Hinge pin

H2009B0732

HA300B2110 Rubber plug

H3100C2050 Oil wick

H3100C2030 Oil

HAIOOC2020

H3100C2020 Hinge pin

H3100C2010

H3100C2040

H4200C2060

H3100C2060

HA100C2070

H4206C800l

H3100C2130

H3100C2080

HA105D0662

HA.l08C0663

HA307C0662

H3100C2120

H4204C0651

H3100C2090

H409050140

H2017M0067

H2017M0065

H31122BI04

H2009B0731

HAIOOC2020

H20ll!C206

Ann

shaft

Ann

shaft bushing(left) 1 1 1

Screw

Ann

shaft bushing(middle) 1

Screw

Ann

shaft

bevel gear for

Feed and feed lifting eccentric

Screw

Balance wheel

Screv:

Ann

shaft bushing(right)

wick

Screw

Thread take-up lever

lever

Slide

Needle bar cormecting stud

Needle

bar

screw

Set

Screw

Ann

shaft oil packing stop screw

wick

Oil

Screw

Set screw

screw

Set

wick

Oil

Needle

bar

Needle bar

Screw

Bevel gear cover( up-backward)

Bevel gear cover(up-foreward)

Felt

Felt

Screw

Felt

Description

collar

arm

shaft

cormecting stud

crank

crank

N

u

r/1

Ci

I I

I

-

00

- -

00

\C;

-

0

\C; \C;

- -

u

0 0

0

u u

0

1 1 1

1

1 1 1

2 2 2

1 1 1

1 1 1

8

1 1

1 1 1

1 1

2 2 2

1 1

, ,

"'

1 1 1

1 1 1

1

1 1 1

1 1 1

I

00

0

1

1

8 8

"-

1 1

I

1

1

1

1

1 1 1 I

I I

1 I 1

I

1 1 1

1 I

I I 1

1

1 I 1

I

1 1 I 1

I

2 2 2 2

I I

1 1

1 1

1 1

I 1 1 I

I 1

I

I I

I

1

1 I

1

2

I

I 1

1

1

1

1 I

1 I

I

-

00

lr)

-

0

u

0

1

1

1

SM15/64(28)xlO

1

1

SMl/4

2

1

1

SM114(40)x7

8

1

1

1

2

1

Siv1 i 5/

2

1

1

1

1

1

SMI5/64(28)x!O

I

1

I

SM9/32

I

SM9/32

I

1

SMl/4

SMl/4

1

SMl/4

I

1

1

SM 15/64(28)x

Remarks

(40)

64(28)x

(28)

(28)

(40)

(40)

(40)

x4

i 2

X4

x7

x6

10

-15-

Page 18

B.ARM SHAFT MECHANISM

I

-

Fig.

No.

B40 H20111C106 Oiling felt presser pin 1 1

B41

B41

Part No. Description

HA100C2060

H4204C0652 Screw

Screw

00

\D

-

0

u

0

1 1 1 SM9/32

N

u

C/J

0

I I

I I

-

-

00

00

\D

\D

-

-

0 0

u u

0

0

I

-

00

lr>

-

0

u

0

1

1

1

SM9/32

Remarks

(28)

X12

(28)

X\2

-16-

:

I

Page 19

C.ROTATING

HOOK

SHAFT MECHANISM

4

\$\

~

8

~

22

25

n.·

--u

~

~--21

m--20

18

___

15

13

~~ y ~

~~14

'---.._1

0

\

12

27 28

26

-17-

Page 20

C.ROTA TING HOOK SHAFT MECHANISM

I

-

Fig.

No.

CO!

CO!

CO!

C02

C02 Hl!OOE2010 Bobbin

C03 H2200C20SO Rotating hook complete

C03 H3!00D2160 Rotating hook complete

C03 H2300E2010

C04 H2000M0070

cos

cos

C06

C07 H2009B0772

C08 H2000M0060

C09

C09 H3!00D20SO

C09

CIO

CIO

Cll

Cll

Cl2

Cl3

Cl4

CIS

Cl6

Cl7

.CI8

Cl9

C20

C21

C22

C23

C24

C25

C26

C27

C28

C29

C30

C31

C32

C33

Part No.

HA900E2030

H3!00D2170 Bobbin case complete

HA600E2080 Bobbin case complete

HA600E2060 Bobbin I

H4200D20!0 Rotating hook positioner

HA600E2040 Rotating hook positioner

HAIOOE21SO Screw

H2200C2030

H2000E2030

H2009B0751

H31!8SB104

H2009B0711 Felt

H3118SB204

H2000I2080

HA113D2212

HA108C0663

HA113D2222

H2009B0711 Felt

HAIOOC2020

H2009B0721

H3104D06SI

H2009B071

HAIOOC2020

H31

196B104

HAI08C0663

HAl

13D2122

H2009B0712

H2018M0066

HA300B2110

H4090SOI40

H2018M006S

H2008M006S

H2008M0066

H2008M0067

HA300B2170

Bobbin case complete

Rotating hook complete

for oil adjusting screw I

Spring

Hook shaft bushing(left)

adjusting screw

Oil

Rotating hook shaft

Rotating hook shaft(left)

Rotating hook shaft

Hook shaft bushing(right)

Hook shaft bushing(right)

Felt

Screw

Bevel gear for hook shaft

screw

Set

Bevel gear for vertical shaft(lower)

Screw

Vertical shaft bushing(lower)

Vertical shaft

Felt

I

Screw

Vertical shaft bushing(up)

screw

Set

Bevel gear for vertical

wick

Oil

Bevel gear cover(lower-backward)

Rubber plug

Screw

Bevel gear cover(lower-foreward)

pipe

Oil

Felt

Oiling felt spring

Screw

Description

shaft(up)

00

\J:)

-

0 0

u

0

I

I

I I

I

I I

I I

I I

I I

1

I

4

I

I

I

I

I

I

I

I

2

I

2

I

2

I

I

I

I

I

I

N

u

r./J

a

I

I

I

I

-

-

00

00

\J:)

\J:)

-

-

0

0

u u

0 0

I

I

I

1

I

I

I I

I

I

I

1

I

I

I

I

I

I

I

I I I

4

4

I 1 I

I I I

I I

I

I

I

I

I

I

I I

I

I

2 2

I I

2 2

I I

2 2

I I

I

I

I I

I I

I I

I I

I

-

00

1£)

-

u

0

I

I

I

SM!l/64(40)x!O

I

I

I

SMII/64(40)x~U

I

SMl/4

4

SM I S/64(2X)x I 0

I

I

I

I

SM 15/M(2X)x I 0

I

I

SMI/4

2

I

2

I

2

M5xl4

I

I

I

I

I

SMII/64(40)x'J

I

Remarks

(40)

(40)

x7

x7

-

18-

Page 21

C.ROT A TING

Fig.

No.

C34

C35

C36

C37

C37

C38

C38

C39

C39

C40 H2000I2080

C41

C42

C43

C44

C45

C46

C47 H3100D2100 Pin I

C48 B3100D2150 Fork 1

C4'.!

cso

('51

Part

No.

H3100D2060 Push button

H3100D2090 Push

H007013035 Stop ring

H312ID8001 Ratchet wheel I

H3!00D2080

HA307C0662 Screw 2

HAIOOC2090

HA704B0653

H3104B0074

H3106D0066 Safety clutch complete

H3100D2020

H3100D2130

H3100D2140 Screw

H3100D2120 Positioner

HAIOOC2090

H415050120 Screw I

HA.810E0691 Thread trimming eccentric

HAX10E06'.!2 Screw

HOOK

button

Hook

shaft lock ratchet

Screw

Hook

shaft bushing( middle) I

Hook

shaft bushing(rniddle) complete

screw

Set

Hook

shaft(right)

Positioner

Screw

SHAFT MECHANISM

Description

spring

-

00

\D

-

0

u

C)

I

N

u

(/J

0

I I

I I

-

-

00 00

-

\D

\D

-

0 0

u u

C)

C)

I

1

1

1

2

I

1

I

1

I

1

I

2 SM15/64

I

2

I

-

00

<n

-

0

u

C)

SMl/4

SMIS/64

SM11164(40)x8.5

M5xl2

Remarks

(40)

x6

(28)

(28)

x4.5

x4.S

-19-

Page 22

D.STITCH

REGULATOR

MECHANISM

-20-

Page 23

D.STITCH

Fig.

No.

DOl

D02

D03

D04 HA104F06S4

DOS

DOS

DOS

Part No. Description

HAI04F06SI Hinge pin

HA104F06S2

H3100E2170

H421!1E104 Feed regulator cam

H3IOOE2060

H4500E2010

REGULATOR

MECHANISM

Feed connecting link

Feed connecting link hinge pin 1

Screw

Feed regulator

Feed regulator

cam

cam

D06 HAI04F06S4 Screw 2

H2200D2030 Spring

D07

H2000F2030 Spring

D07

H2204D0651

D08

D09 H3!00E2230

H2006C0661

D09

HA700B2120

DIO

HA109F0671 Feed regulator screw

Dll

HA109F0674

Dl2

Dl3

Hll04F0651

H3!00E2070 Dial

Dl3

HA!09F0673 Screw

Dl4

HA!OOF2070

DIS

Dl6

Hi\IOOF2080

HA!OOF2090

Dl7

HA309F0671

Dl8

H2005F0065

Dl9

HA300C2030

D20

HA113F0683

D21

HA104F0654

D22

[)23

HAIOOF2110

H4205E0066

D24

H3111E0065

m4

H2204D0654 Spring

D25

ILA.806C067 5

D26

1)27

H007013040

D28 H2204D0652

[)29

H2204D0653

])30

HAIOOC2190

])31

H2405D0664

retainer

retainer I

Reverse link

Hinge pin for feed regulator 1

Hinge pin for feed regulator 1

Rubber plug 1 1 1 1

bar

0-ring

Dial 1

Rubber plug I I I 1

Stopper

Spring

pin

for stopper pin I I I

Reverse feed lever I I I 1

Reverse feed lever pin I I 1 1

Screw

Screw I I I I

Screw

Washer

Reverse feed lever crank complete I

Reverse teed lever crank complete

Spring retainer

Stop

ring

Pin

retainer

Spring

Screw

Screw

......

I

00

......

'-D

0

u

c.:J

I I

1

Ci

I I

......

......

I I

00

00

......

......

'-D

'-D

0 0

u u

c.:J

c.:J

1

1 1 1

N

u

(/1

I 1 1

1 1

1

1

1 1

2 2 2

1

1

1

1 1

1 1

1

1

I I

I

2 2

2

1

1 1

I I

I

I I

2

2

2

I I 1

I I I

I

I

I

I

I

2

I I

1

......

I

00

......

tn

0

u

c.:J

1

1 SM1S/64

1

SM1S/64

1

1

1

I SM3/16

1

I

2

SMII/64(40)x8

2

SMIS/64

I

SMII/64(

1

Remarks

(28)

x10

(28)

x10

(28)

x8

(28)

xJO

40)x8

-21-

Page 24

E.LOWER FEEDING MECHANISM

38

7

'

13-

16

·~~

17~~~----'

29

~

14

'

27

15

~

~

36

'

-22-

Page 25

E.LOWER FEEDING MECHANISM

Fig.

No.

EO!

E02

E03

E04 H3100E2110

E05 H3100E2120

E06 HA100C2020

E07 H2005L0065

E08

E10

Ell

El2

El2

El2

El3

El4

E15

El6

El7

El~

El9

E20

E2l H3!00E2040

E22

H23

E24

li25

E2(l

E27

E2X

E29

L30

li31

I

~32

L33

1·:34

I

~35

1;.3()

1~37

H3K

Part No.

H2009B0069

HA100C2020

HA304G0656 Screw

HA104G0012

H3116E0661

HA104G0654

H3100E2160

H4206E0671

H4500E2020

H3100E2140

H415050!20

H3100E2200

H3100E2190

HA305Gl012

H3100E2050

H3!00E2180 Nut I

H3!00E2!90

H3!00E2090

HAIOOG2070

I-IAI04F0654

H3100E2100

H2009B0069

IIAIOOC2020

1!2004K0065

l-1007009150 Stop

I !2UIIICI0(l

1!20IIIC206

I

131

OOE2030

IIA I

OOG2070

IIA30(lU0671

I

lA I OXU0(l6l

I

lA

I 05D0662

[ 1007013050

11AIOOG2130

Feed rock shaft bushing 2 2 2 2

Set

screw 2 2

Feed rock shaft crank

Feed bar shaft

Screw

Feed rock shaft

Screw

Feed bar

Screw

Feed dog 1

Feed dog

Feed dog

Feed lifting rock shaft crank(left) 1

Screw

Washer

Slide

block

Slide

block

Screw

Nut 2

Feed forked connection

Feed rock shall crank

Feed rock shall crank hinge pin

Screw

Screw

Feed litling rock shaft bushing 2

Screw

Feed lining rock shall

ring

Oiling

felt spring

Felt

Feed litling link

Feed rock shall crank hinge pin

Feed

titling rock shatl crank( right)

Feed rock shall collar

Set screw

Stop

ring

Washer

Description

shan

N

u

lZl

9

I

I

-

00

-

00

\0

-

0

\0 \0

-

u

0 0

t:l

u u

t:l

2 2 2 2

1 1 1 1

1 1 1 1

2

1 1 1 1

2 2 2 2

1 1 1 1

2 2 2 2

2,

2

1 1 1

1 1

I 1

1

1

2 2

1

1

1

3

1

2

1 I

2

1

I 1

1

I I

1 I

2

4 4

4

1

2

I

I

-

00

-

t:l

2

2 2 2

1

1

1 1 1

2 2

1 1

1 1

1 1 1

1 1 1

2 2

I 1 I

1 I

1

1

3 3

3

I 1

1

2 2

2

2

2

1 1

2 2

2

1 I

1

1 I

1

1

1

1

2

2

1

1

2 2

I

-

00

-

"'

0

u

t:l

SM 15/64(28)x

2

SM15/64(28)x

SM1/8(44)x6

1

M5x12

1

M4

M3

1

I

SM15/64

SM 15/64(28)x I 0

2

I

I

I

2

SM1/4(40)x4

4

1

2

Remarks

10

10

(28)

xJO

-23-

Page 26

F.NEEDLE BAR FEEDING MECHANISM

51-~

I

35

~~14

13

G)

22

®

46

®545

........

37

21

I

18

I

~

~

17

-24-

~

16

I

Page 27

F.NEEDLE BAR FEEDING MECHANISM

......

I

00

Fig.

No.

F01

F02

F03

F04

F05

F06

F07

F08

F09

F09

FlO

Fll

Fl2

Fl2

Fl3

Fl4

Fl5

Fl6

F17

F18

F19

F20

F21

F22

F23

F24

F24

F25

f-26

F27

F28

f-29

F30

F31

F32

F33

F34

F35

F36

F37

F38

F39

F40

Part No.

H3100F2010

H3100F2020

H3100F2030

HA700F2100 Screw

H3111F0651

H3100F2240

H3400C2020

H2000G2030

H3129F0693

HA500C2030

H3129F0691

HA100C2170

H3129F0692

H4500F2040 Needle bar complete 1

H3100F2270

H3406C0671

H602040240

HA100G2070 Hinge pin

H3132F0712

H3100F2310

H3100F2300

H3132F0711

H2010J0066 Nut

H3131F0703

H3126F0683

H4200F2010

H4500F2030

HAIOOC2020

H3100F2200

H3100F2220

HA7311CD06

H3100F2070

H3100F2060

H3100F2050

H3100F2040

H3100F2130

H005001060

H3100F2150

H3100F2170

H3100F2180

H3100F2160 Nut

H3115F0672

H31!5F0671 Screw

Crank link 1 1 1

Lifting bell crank

Link

Vibrating presser foot 1 1 1

Needle bar rack frame position bracket 1 1 1

Screw

Needle

Needle bar thread guide

Needle bar thread guide 1

Screw

Screw

Needle bar

Needle bar rock frame slide block

Needle bar rock frame slide block stud

Set

screw

Screw

Screw

Needle bar rock frame rock shaft crank connec

Needle bar rock frame rock shaft crank (right)

Needle bar rock frame rock shaft

Oil wick

Needle bar adaptor

Needle bar adaptor

Screw

Needle bar rock trame hinge stud

Needle bar rock frame

Screw

Vibrating presser bar

Vibrating presser

Vibrating presser

Screw

Screw

Washer

eccentric connecting collar

Litling

Litling eccentric connection

Needle bearing for

Lining eccentric connecting crank

Description

bar

extension spring

bar

extension

lithng

eccentric connectior

......

\0

0

u

CJ

1

1 1 1

1

1 1 1

1

1

1 1 1

1 1 1

1

1 1 1

1 1

1 1 1

1

1 1 1

1 1

1

I I 1

1 1 I

I I I I

1 1

I 1 1

1 1

I

I I 1

1 I 1

1

1 1

1 1

1 I 1

1 1 1

1 1 1

1 1 1

1 1

1 1

I

I 1

1

C'l

u

CZl

0

I I

......

00 00

......

\0

0

u

CJ CJ

I

I

-

\0

-

0

u

1

1

1

1

1 1 1

1

1

1

1

1

1

1

1

1

1

1

1

I

1

1 I

1

I

I

1

I

I

I

1 1

I

-

00

......

<r)

0

u

CJ

1

1

DPx17 22#

SM3/32(56)x2.5

1

SMl/8

1

1

1

1

1

1

1

I

I

1

SM15/64(28)xiO

Remarks

(44)

x4.5

-25-

Page 28

F.NEEDLE BAR FEEDING MECHANISM

Fig.

No.

F41

F42

F43

F44

F45

F46

F47

F48

F49

F50

F51

F52

F53

F54

Part

No. Description

H3100F2100 Lifting rock shaft bushing 2

H3112F0663 Lifting rock shaft 1

H3112F0661 Screw 1

H3112F0662

H3100F2330

H3131F0704

HA100B2110

H3100F2340 Guide for slide block

H3100F2350 Slide block 1

H3100F2360

HA105D0662

HA7311C306

H3100F2370 Stop plate

H3200I2030

Nut

Lifting eccentric 1

Needle bar rock frame rock shaft crank(left) 1

Set screw 2

Screw 2

Screw 2

Screw 2

Washer

C"l

u

r:Fl

Q

I I

I

-

00

\D

-

0

u

0

I I

-

-

00

00

\D

\D

-

-

0

0

u

u

0

0

2

1

1

1 1

1

1 1

1

2 2 SM11/64(40)x5.5

1

1

1

2 2 SM9/64(40)x7

2 2

2 2

1 1

1

1

1

2

1

1

1 1

1

1

1 1

-

00

lr'J

-

0

u

0

I

1

Remarks

-26-

Page 29

G.PRESSER FOOT MECHANISM

30

/28

1

\

I

~

2

I

!

I

I

~

'~:

~/27

.

24

·,.-·/

/26

@

/25

I

I

A

I

32

-27-

Page 30

G.PRESSER FOOT MECHANISM

Fig.

No.

GO!

002

003

004

005

006

007

008

009

GIO

Gll

Gl2

G13

G14

G14

G15

G16

G17

Gl8

Gl9

G20

G21

G22

G23

G24

G25

G26

G27

G28

G29

G30

G31

G32

G33

G34

G35

G36

G37

G38

G38

G39

Part No. Description

HA341!D308 Set screw

H3!00G2020 Presser bar position guide

HA!OOC2020 Set screw I I

H3104B0654 Presser bar bushing( upper) I I I

H2404I0034

H3106G0652

H3107G0661

H3107G0662 Screw

H3100G2070 Presser bar lifter

H3!00G2080 Screw I I I

H2404I0034 Screw

HAIOOC2020 Screw

H3!00G2120 Screw

H3100G2110

H4504G0065

H3!04B0656

H3113G067!

H3!00G2090

H3109G0651

H3100G2050

H3107G0663

H3100G2150 Presser bar spring

H3100G2220 Screw

H3100G2170

H3!00G2160

H3!00G2240

H2000I2160 Nut

H2000I2150

H2000l2140 Screw

H3100G2140

H3100G2130

H3!28G0651

H2000I2200 Screw

H604050180 Pin

H3128G0652

H2000I2190

H2021I0068

H3109G0652

H3100G2210

H4206C8001

H609025180

Screw

bar position guide bracket 1 I I

Presser

Screw

Lifting presser foot I

Lifting presser foot complete I

Presser

bushing(lower)

Presser

bar spring bracket

Presser

bar

Tension release slide

Tension release spring

Presser

bar lifting bracket I

Screw

Screw

Knee lifter lifting lever connecting rod I

Knee lifter lifting lever connecting rod joint

Knee lifter lifting lever

Screw

Knee lifter bell crank base

Knee lifter bell crank

Spring for knee lifter bell crank

Roller

Guide for tension release slide

bar lifting bracket guide

Presser

bar

Presser

Spring pin

lifting bracket guide

C'l

u

Vl

I

I

-

00

\0

-

0

u

Cl

I I I

I I I

I I I

I I I

I I I

I I I

I I I

I I I

I I I

I I I

I I I

I I I

I

I I

I

I I I I

I

I

I

I

I

1

1

I

1

1

1

1

1

1

I

1

ct

I

- -

00 00

\0 \0

-

0

u u

Cl

I

-

0

Cl

I

I

I

I I

I I

I I

I I

I I

I I

I I

I I

I I

I

I I

1 1

1 I

I 1

1 1

1 1

1 1

1 1

1

1

1

1

I I

1

I

1

I

-

00

.,.,

-

0

u

Cl

I

I

I

I

I

I

I

I

I

I

I

SM9/64(40)x6

I

1

I

I

I

I

I

SMI/4(24)x20

I

I

I

I

I

1

I

1

1

1

1

1

1

1

I

Remarks

-28-

Page 31

H.KNIFE

MECHANISM

11

\

I

I

~

~

49

(17) ®-(11)

-29-

Page 32

H.KNIFE MECHANISM

.....

00

Fig.

No.

HOl

H02

H03 HA712N6910

Part No.

HA7511N112 Solenoid

HA712N0698

Thread trimmer driving lever

Flexible wire presser

Description

H04 HA712N0699 Screw

H05 HA712N6911 Flexible wire presser

H06 HA712N6912

H07

HA712N0695 Stud screw

H08

HA712N0697 Spring

Screw

H09 HA712N0696 Collar

HlO HA7311CC06 Screw

Hll

HA710N0683 Nut

Hl2

HA712N0692 Link stud

H007013040 Washer

Hl3

Hl4

HS90011406 Screw

Hl5

HA100E2150 Screw

HA7511N212 Solenoid bracket

Hl6

HA700N0080

Hl7

HA708P0668 Cord holder

Hl8

HA300B2170 Screw

Hl9

HA70400657

H20

H21

HA713N0070

H003002050 Nut

H22

H2208H0681 Flexible wire base

H23

HA7121N704 Nut 2

H24

HA7121N604 Screw 1

H25

HA7121N104 Bracket for fixed blade 1

H26

H22121H204 Thread fmger 1

H27

HA7311CH06 Screw

H28

HA7121N304

H29

H4204Hllll

H30

HA704Nllll

H31

HA7111N304

H32

HA904Nllll

H33

HA719B7011

H34

HA7111N604

H35

HA7111N204

H36

HA7111N404

H37

HA704Nlll4

H38

HA704Nlll3

H39

H2204H0651

H40

HA7111N704

H41

H2200H2020

H42

HA706N0663

H43

Screw

Rubber plug 1

Flexible wire complete

Screw 1

Fixed blade 1

Knife holding bracket saddle 1

Nut

Knife holding bracket saddle(left) 1

Screw

Knife driving crank

Screw

Link

Screw

Washer

Fixed blade

Screw

Driving

crank shaft

Nut

.....

1.0

0

u

C)

N

u

r./1

I

I

.....

I

00

.....

1.0

0

u

C)

Q

I

.....

I

00

.....

1.0

0

u

C)

.....

I

00

.....

on

0

u

C)

Remarks

1

1

1

1

SM11/64(40)x4

1

2

1

SM1/8(44)x7

1

1

2

1

1

2

3

M4x6

1 SM11/64(40)xlO

1

4

SM15/64(28)x

12

4

1

1

2

M5

1

SM9/64(40)

SM9/64(40)x8.5

1

2

1

SM9/64( 40)x8

SM9/64(

40)x5

SMll/64(40)

SM11164(40)x11.4

1

2

SM11/64(40)x6.2

1

3

SM1/8(44)x5.2

1

1

2

SM11164(40)x5.5

1

2

-30-

Page 33

H.KNIFE

Fig.

No.

HA7221NI06

H44

HA7221N206 Roller pin

H45

HAII3F0684 Screw

H46

HA700N0050

H47

HA700N0040 Spring

H48

HA710N0682 Lever stopper plate 1

H49

HSO

HA307C0662

H2206H0661 Stopper lever

H51

HA700N0110

H52

HA715ND711 Collar

H53

HA105D0662

H54

HA706N0664 Washer

HSS

H56 H2207H0671

H57

HA300C2030

H58 HA300I2040

HA300B2170

H59

HA7211N106 Crank 1

H60

H61

HA7211N206

H4205C0661

H62

H63 H4205C0662

H64 H4205C0663

H65 H4205C0664

HA104GQ654 Screw

H66

MECHANISM

Part No.

Roller 2

Spring cover 1

Screw

Coil spring I

Screw

Screw

Screw

Wire holder

Screw

Crank 2

Hinge pin bracket

Hinge pin

Pin

Spring

Description

-

00

\C)

-

0

u

0

I

N

u

VJ

0

I I

I I

-

-

00

00

\C)

\C)

- -

0 0

u u

0 0

2

2 SMI5/64(28)x8.5

2

I

-

00

tn

-

0

u

0

I

1

1

1

1

1

1

1

2

I

I

1

1

1

1

2

Remarks

-31-

Page 34

I.

TOUCH

BACK

AND

DETECTOR

MECHANISM

-32-

Page 35

I.

TOUCH

Fig.

No.

IO!

102 HA300B2170

I03

I04

lOS

I06

I07

I08

I09

IIO

Ill

Il2

113

I14

115

Il6

Il7

Il8

II'J

I20

121

!22

I23

I24

I2S

I2(i

127

12X

I2'J

130

131

132

133

134

135

13()

137

13:-<

IYJ

140

141

142

Part

No.

HA300I2040

H4204I0651

H411030060

HA70400657

HA70400659

HA70400654

H2205I0661

HA71610104

HA7641B319

HA70400021

H0070!3030

HA70400653

HA70406510

HA70400655

HA70400658

HA705Q0065

HA300C2030

HA708P0668

HA700Q0050

l-!220610673

H2609E0674

HA703R0065

HA.300C2030

I I007013040

I

lA

712N0692

I

12204CKlo51

I 12204l

!0652

I!A703ROO(,(i

HA

703R00(J7

11007009300

I

lA

700R00(,0

I

lA

700R0050

IIA 700R0040

IIA700R0020

IIA700R0030

IIA71HlROOIO

IIA1101)0h72

I12204lllCJ5

IIA700()0010 Pin

I

lA

7CA

I

£3319

I IA300B21

BACK

1

(,()

AND

Wire

holder

Screw

Switch

Screw

Rubber

Screw

Plate spring I

Switch

Switch

Tie-in

Touch

switch

Stop

ring

Spring

Screw

Micro

switch

Insulator seet 1

Ground

Screw

Cord

holder

Curd

holder

Solenoid

Washer

Detector

Screw

Washer

Link

stud

Screw

Stop ring

Detector

Washer

Stop

ring

Washer

Suppmier

Spacer

Speed

command

Spacer

Speed

command

Screw

Balance wheel

Tie-in

Screw

DETECTOR

Description

bracket

plug

bracket 1

wire 1

complete 1

wire assy.

complete

bracket supporter

spring

2

disc 2

I

disc I

MECHANISM

......

I

00

......

\0

0

u

(j

u

U')

I

......

I

00

......

\0

0

u

(j

N

0

I

......

I

00

......

\0

0

u

(j

I

2

I

2

I

2

2

2

1

2

1

I

2

4

1

I

I

I

4

2

I

I

1

1

I

1

1

1

I

I

2

I

2

I

1

I

3

......

I

00

......

Ill

0

u

(j

SM15/64(28)x 12

SM!l/64(40)x10

Remarks

-33-

Page 36

J.ACCESSORIES

~

/

r-

~

\

~

\

N

-34-

Page 37

J.ACCESSORIES

I

-

Fig.

No.

JOI

J02

J03

J04

JOS

J06

J07

J08

J09

JIO

J11

Jl2

Jl3

J14

Jl4

Jl5

116

117

118

119

120

121

122

123

124

125

12(>

127

12X

12')

no

131

132

133

Part

No.

HA300J2180 Vinyl cover 1 1 1 1

Bed

HA307J0067

H200400069

H2000G2030 Needle 1

HA300J2210

HA300J2200

H200400066

H200400065

H2207J0065

HA300J2070 Screw driver(large)

H801045200 Screw

HA300J2230 Washer

HA600E2060

Hl100E2010

HA100J2170 Spanner

HA200J2030 Thread stand

H3104H0065

HA905S0066 Bobbin winder nechanism

H200800070

HA300B2170

HA300B2170

H200800671

HA300J2250 Screw

I IA30012280

I JA300132170

Jf200800067 Belt cover(lower)

I !A30510665

I IA30012230 Washer

1180

I 045 200

11200400069 Oiler

llA60012030

113111

130702

IIA 704S0(J54

hinge connection 2 2 2 2

Oiler 1

Screw driver( small) 1

Screw driver( middle) 1 1 1 1

Rubber cushion( small)

Rubber cushion(large) 2

Oil pan assy.

Nail

Bobbin

Bobbin

Knee litler assy.

Belt cover

screw

Set

screw

Set

Belt cover with label

Screw

Screw

Belt cover assy.

Screw

Oiler

Thread tension spring

Speed

command disc adjusting plate

Description

00

\C)

-

0

u

C>

2 2

1 1 1 1

1 1

2

2 2 2 2

10 10 10

3

1 1

1 1 1 1

1 1 1 1

1

1

2 2 2 2

2

1 1 1 1

1

2 2 2 2

2

1

1

2

2

I

I

1 1

N

u

r/J.

0

I

I

I

-

00 00

\C) \C)

- -

0 0

u u

C> C>

2

3

I

-

1

1 1

1

1 1

1

1 1

2 2

2

2 2

1 1

2

3

1 1

1

1

1

1

2

2 2

1

I

2

2

1 1 1

1

1

2 2

2 2 2

1 1 1

1

1

1

I

I

-

00

on

-

0

u

C>

DPx17

4.5x20

2

10

3

BZ009

1

1

SM11/64(40)x8

SM11/64(40)x8

M4xl2.5

1

2

1

2

4.5x20

1

I

Remarks

22#

-35-

Page 38

Page 39

Page 40

SHANGHAI HUIGONG

N0.3

SEWING MACHINE FACTORY

ADD: 1418,

Yishan

Road, Shanghai,

China

Zip Code: 201103

Overseas

Business:

TEL:

86-21-64853303 FAX: 86-21-64854304

E-mail:highlead@online.sh.cn http://www.highlead.com.cn

The description covered

in

this

manual

is

subject

to

change for improvement

of

the commodity without notice

2004.3. Printed

Loading...

Loading...