Page 1

Purchasing

Copy

Dept

HIGH

LEAD

GC0518-MC/GC0518-MC-D

High Speed Needle

And

Bar

Automatic

Feed Lockstitcher With Edge

Thread

Cutter

Trimmer

Instruction Manual

Parts

SHANGHAI

HUIGONG

N0.3

Catalog

SEWING

MACHINE

FACTORY

Page 2

l.

PRECAUTIONS

2.

MAIN

3

INSTALLING

4.

ADJUSTMENT

5

LUBRICATION

6

CONDITION

7.

LUBRICATION

ADJUSTMENT

8

9.

REGULAR

l

0.

WINDING

ll

REPLACE

12.

THREADING

13.

SET

14

ADJUSTING

15.

16.

17.

18.

19.

20.

CLOTH

21

22.

SPECIFICATIONS

STITCH

UPPER

LOWER

ADJUSTMENT

ADJUSTMENT

INSTALLING

THROAT PLATE

OTHER

BEFORE

THE

BELT..

OF

NEEDLE

..

OF

OIL

LUBRICATION

ADJUSTMENT..

OF

OIL

CLEANING

ADJUSTMENT

NEEDLES

.

LENGTH

THE

THREAD

THREAD

THREAD

CUTTING

REPLACEMENT

TENSION

TENSION

OF

FEED

OF

THREAD

OF

THE

COVER.

KNIFE

STARTING

..............

PUMP

..........

....

AND

..

DOG

NEDDLE

..

PARTS ..

OPERATION

.

BAR

STOP

..

.....

.

.

............

REVERSE

TENSION

..

TRIMMER

.

INCLINATION

PLATE .

CONTENTS

......................

.

...............

POSITION

FEEDING

..

MECHANISM

.........

..

.

.

.

..

.

.........

.

.......

.

.......

.

........

.

.........

.........

.

........

.

......

.

.........

.

.........

.

.......

.

.........

.

..........

.

..

. . .. 7

.........

.

......

.

.........

.

.......

.

.

....

....

2

2

.3

. 3

.4

4

.4

.4

. 5

. 5

5

6

6

6

7

7

8

9

9

9

l 0

-]-

Page 3

1.

PRECAUTIONS

1)

Safety Precautions:

(

1)

When turning the

and the area around the balance wheel.

(2)

Power must

(3) Power must

the machine, or when replacing.

be

be

BEFORE

power

turned

off

turned

off

STARTING

on, keep your hands and fingers away from the area around/under the needle

when the machine

when tilting the machine head, installing or removing the

is

OPERATION

not in use, or when the operator leaves the

"V"

seat

belt, adjusting

(4) Avoid placing fingers, hairs,

or motor when the machine

(5) Do not insert fingers into the thread take-up cover, under/around the needle, or balance wheel

is

machine

(6)

If

a belt cover, finger guard, eye guard are installed, do

devices.

2)

Precautions before Starting Operation:

(1) 1 f the machine's oil

(2)

If

the machine

( 3) When a new sewing machine is first turned on, verify the rotational direction

the power

wheel)

(4) Verify the voltage and (single or three) phase with those given on the machine nameplate.

in operation.

pan

is

lubricated

on.

(The balance wheel should rotate counter-clockwise when viewed from the balance

bars

etc., near the balance wheel,

is

in operation.

has an oil sump, never operate the machine before filling

by

a drop oiler, never operate the machine before lubricating.

"V"

belt, bobbin winder balance wheel,

not

operate the machine without these safety

it.

of

the balance wheel with

3) Precautions for Operating Conditions:

(

1)

Avoid using the machine

]0\ver)

(2) Avoid using the machine in dusty conditions.

at

abnormally high temperature (

35

OC

or higher) or low temperature ( 5

when

OC

the

or

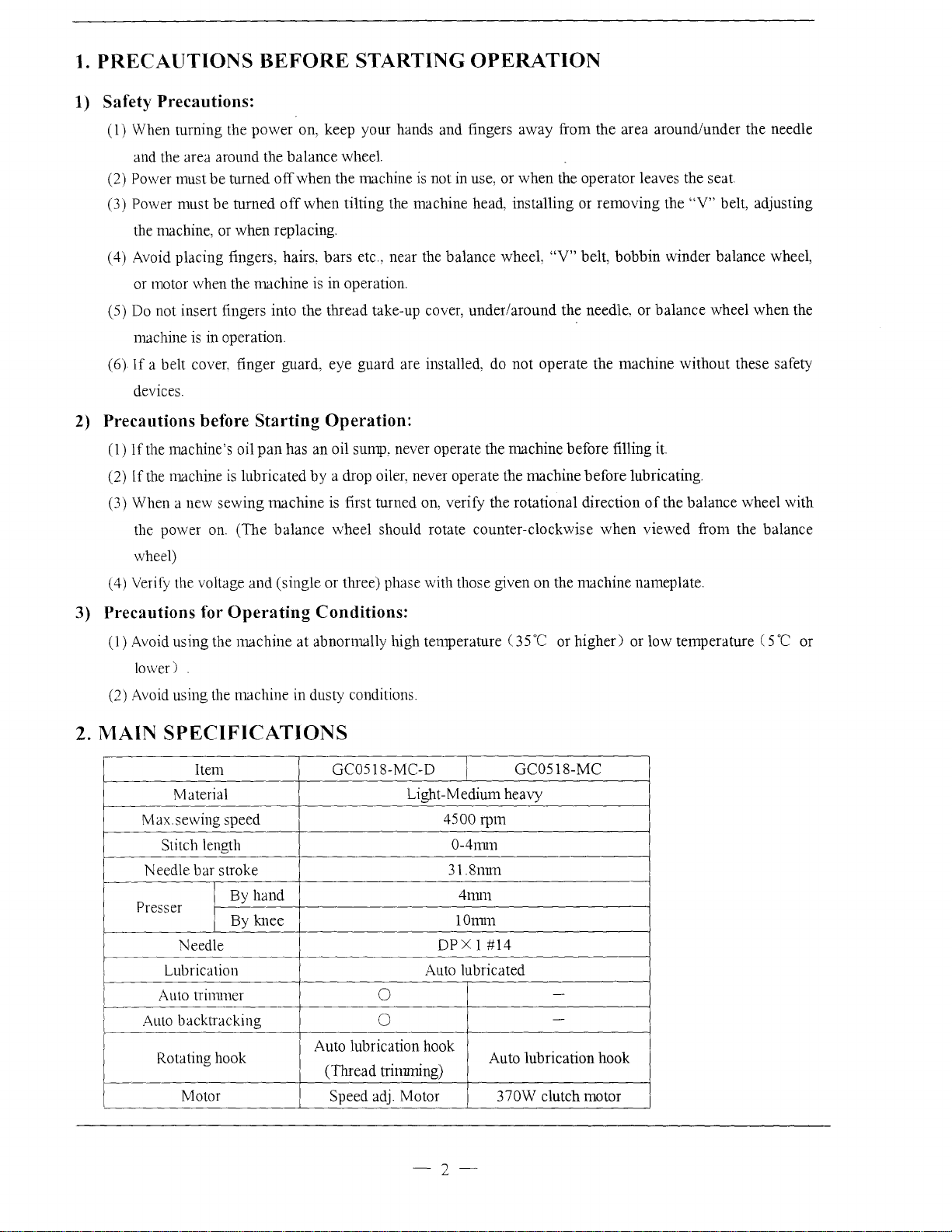

2. MAIN SPECIFICATIONS

Item

Material

Max. sewing speed

Stitch length

Needle bar stroke

Presser

Needle

Lubrication

Auto

Auto backtracking

Rotating hook

Motor Speed adj. Motor

By hand

By knee

trinnner

GC0518-MC-D

Auto lubrication hook

(Thread trinuning)

Light-Mediw11 heavy

4500 rpm

0-4111111

31.8nun

4nun

lOnm1

DPX1#14

Auto lubricated

0

0

-2-

GC0518-MC

-

-

Auto lubrication hook

370W clutch motor

Page 4

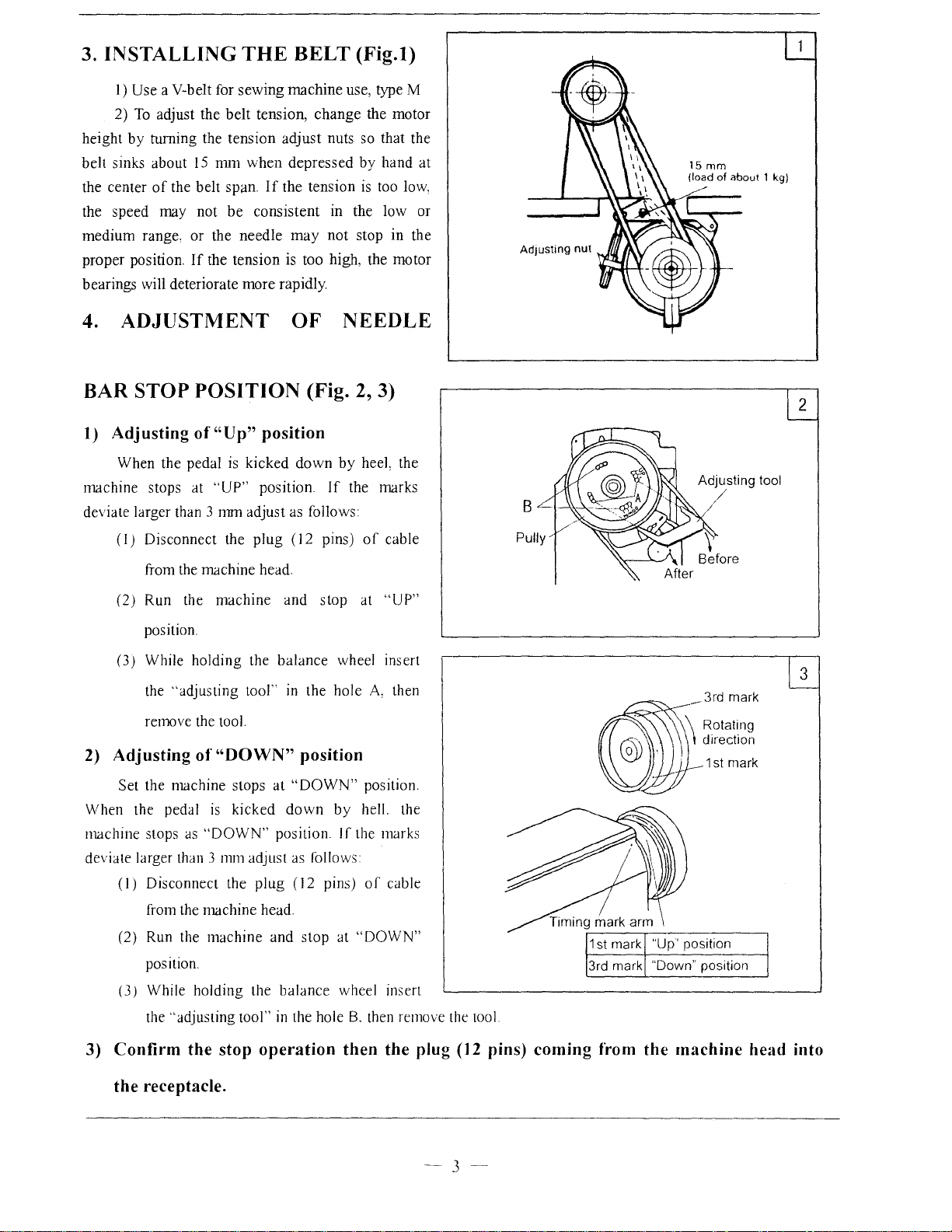

3. INSTALLING

1)

Use a V-belt for

2)

To

adjust the

by

height

belt sinks about

the center

the speed may not

medium

proper position.

bearings will deteriorate

turning the tension

of

the belt span.

range, or the

belt

15

nm1

be

If

the tension is too high, the motor

THE

sewing

when

needle

more

BELT

machine use, type M

tension,

adjust

depressed

If

the tension

consistent in the low or

may

rapidly.

(Fig.l)

change

the motor

nuts so that the

by

hand at

is

too low,

not

stop in the

4. ADJUSTMENT

BAR

1) Adjusting

machine stops at

deviate larger than 3 mm adjust as follows

2) Adjusting

When the pedal

machine stops

deviate larger than 3

STOP POSITION (Fig. 2, 3)

of"

Up" position

When the pedal is

"UP"

(l)

Disconnect the

fTom

the machine head

(2) Run the

position.

(3)

While holding the

the ''adjusting

remove the tool.

Set the machine stops

(I)

Disconnect the

machine

of

"DOWN" position

is

kicked

as

"DOWN"

111111

OF

kicked

tool''

adjust as follows

position.

plug

(12 pins)

and

balance

in

at

"DOWN"

down

position

plug

(

down

If

stop

the hole

12

pins)

by

wheel insert

by

If

NEEDLE

heel, the

the marks

of

cable

at

"UP"

A,

then

position.

hell. the

the marks

of

cable

B

Adjusting tool

/

_3rd

mark

\ Rotating

I\

direction

.---1 st

mark

2

3

from the machine head.

(2) Run the

position.

(3) While holding the balance wheel insert

the

3) Confirm the stop operation then the plug

machine

"adjusting tool"

and

in

stop

the hole

at

"DOWN"

8,

then remove the tool

(1

2 pins) coming from the machine head into

the receptacle.

-3-

Page 5

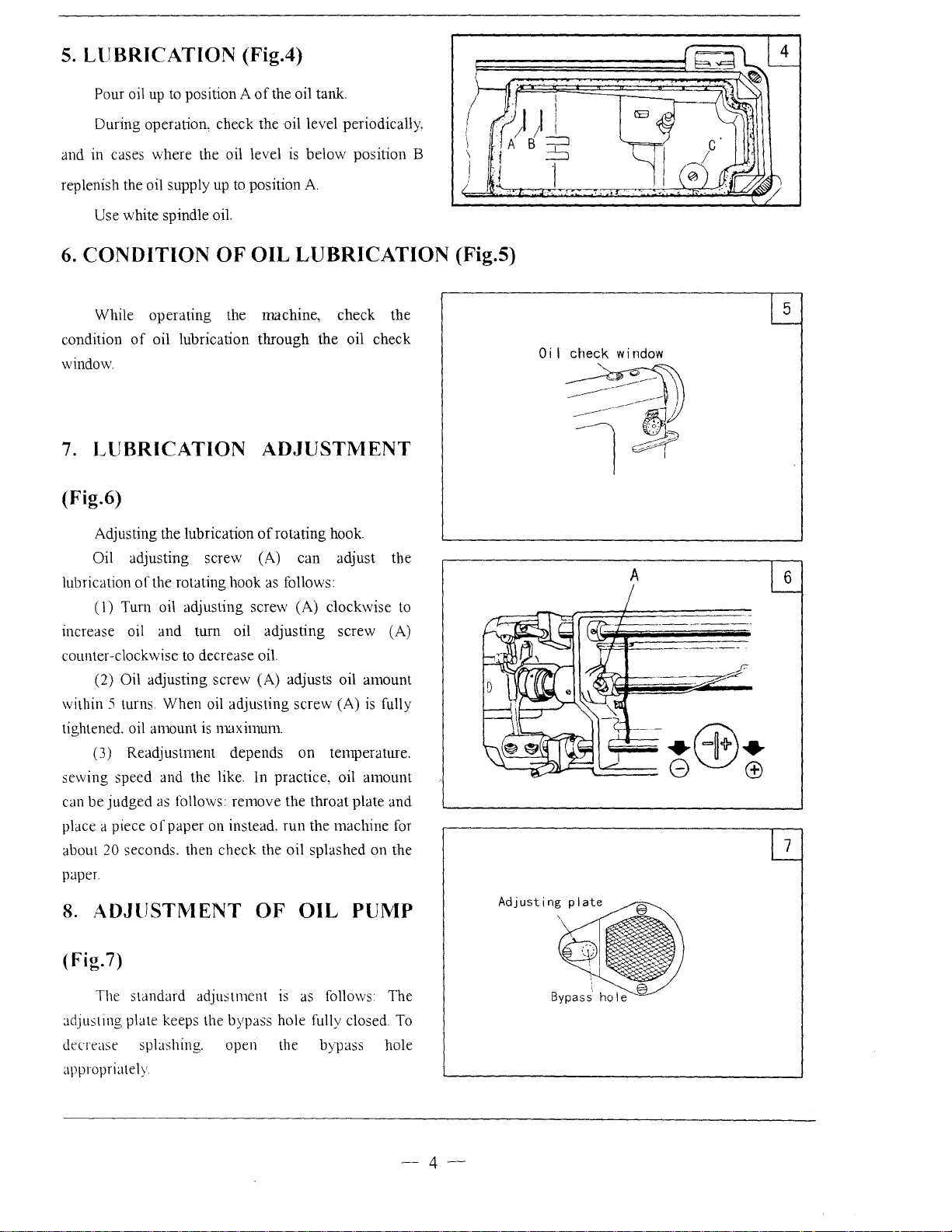

5.

LUBRICATION (Fig.4)

Pour oil up to position A

During operation, check the oil level periodically,

and in cases where the oil level

replenish the oil supply up to position

Use white spindle oil.

6.

CONDITION

While operating the machine, check the

condition

window.

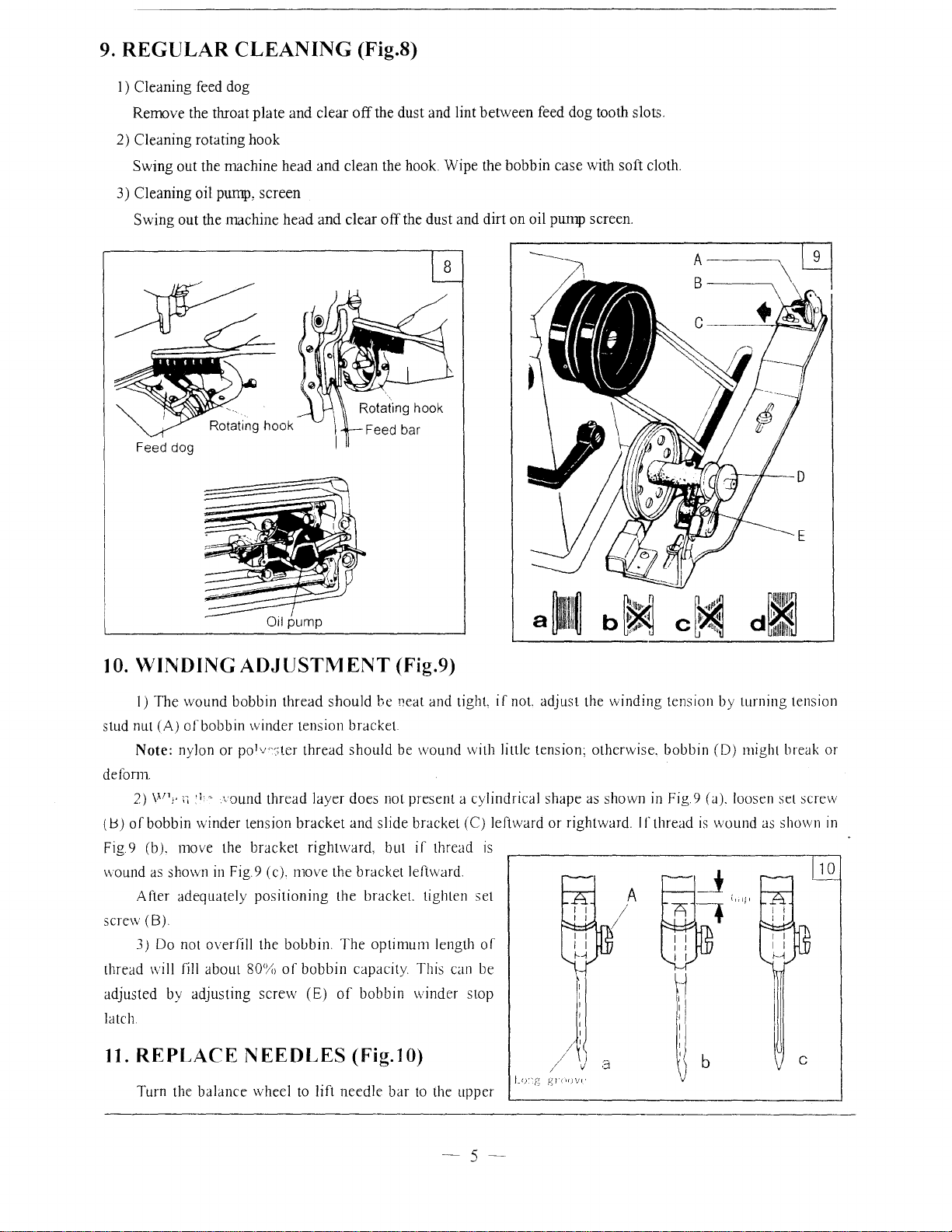

7.

of

oil lubrication through the oil check

LUBRICATION

of

the oil tank.

is

below position B

A.

OF

OIL

LUBRICATION

ADJUSTMENT

(Fig.6)

Adjusting the lubrication

Oil adjusting screw (A) can adjust the

of

lubrication

(

1)

increase oil and

counter-clockwise

(2)

within

tightened. oil amount

(3) Readjustment depends

sewing speed and the like. In practice, oil amount

can

be

place a piece

about

20 seconds. then check the oil splashed on the

paper

the rotating hook as follows:

Tum oil adjusting screw (A) clockwise to

tum

to

decrease oil.

Oil adjusting screw (A) adjusts oil amount

5 turns When oil adjusting screw (A)

is

judged

as follows: remove the throat plate

of

paper on instead,

of

rotating hook.

oil adjusting screw (A)

is

maximum.

on

temperature.

run

the machine for

fully

and

(Fig.S)

Oi

I check

----------~-----~

~~

window

l-Jf

A

6

7

8.

ADJUSTMENT

OF

OIL

PUMP

(Fig. 7)

The standard adjustment

Jdjusting plate keeps the bypass hole fully closed. To

decrease

appropriately

spbshing.

open the bypass hole

is

as follows The

-4-

Page 6

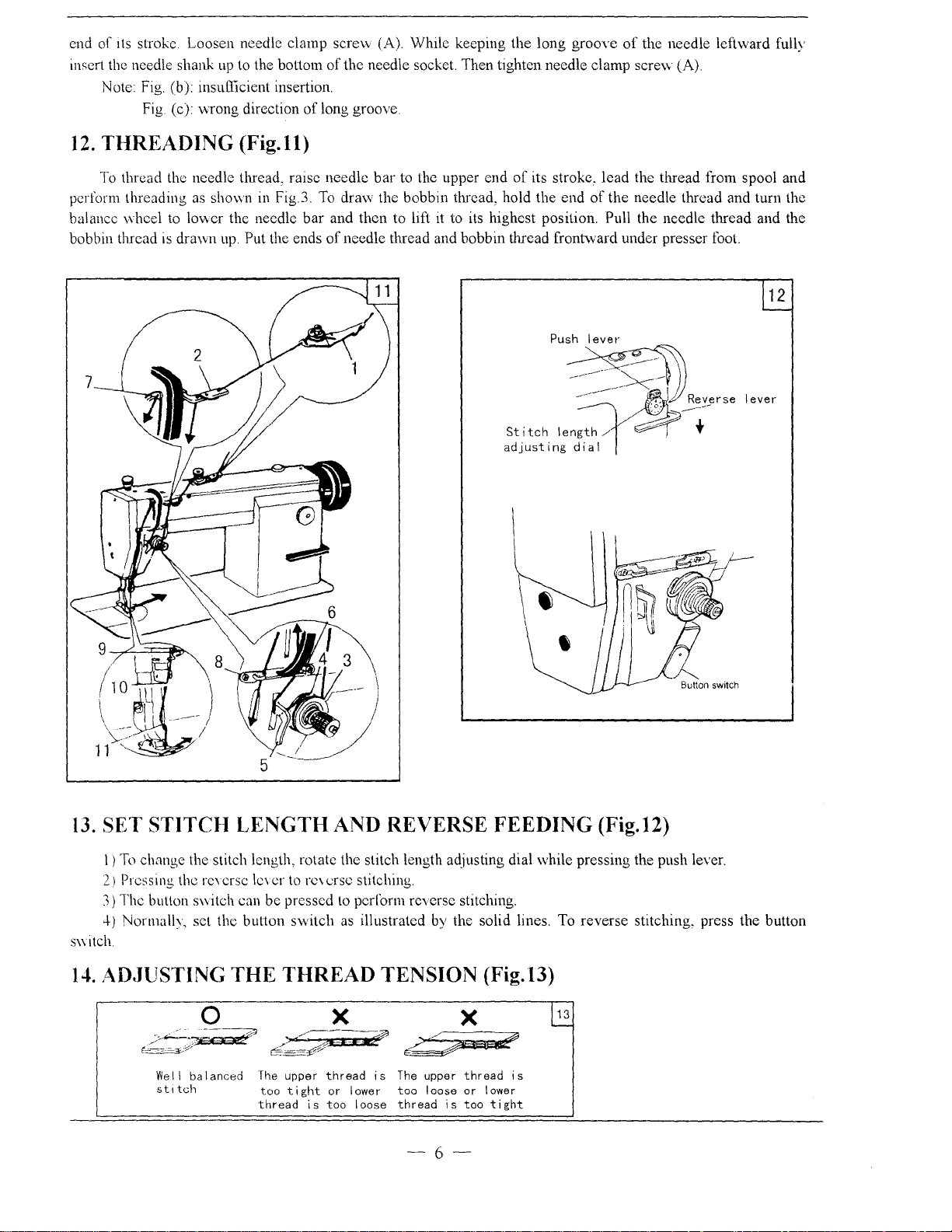

9.

REGULAR

I) Cleaning feed dog

Remove the throat plate and clear off the dust and lint between feed dog tooth slots.

2)

Cleaning rotating hook

Swing out the machine head and clean

3)

Cleaning oil

Swing out the machine head and clear off the dust and dirt on oil

Feed dog

CLEANING

pump,

screen

(Fig.S)

the

hook. Wipe the bobbin case with soft cloth.

plll11p

screen.

A----,

B---__,

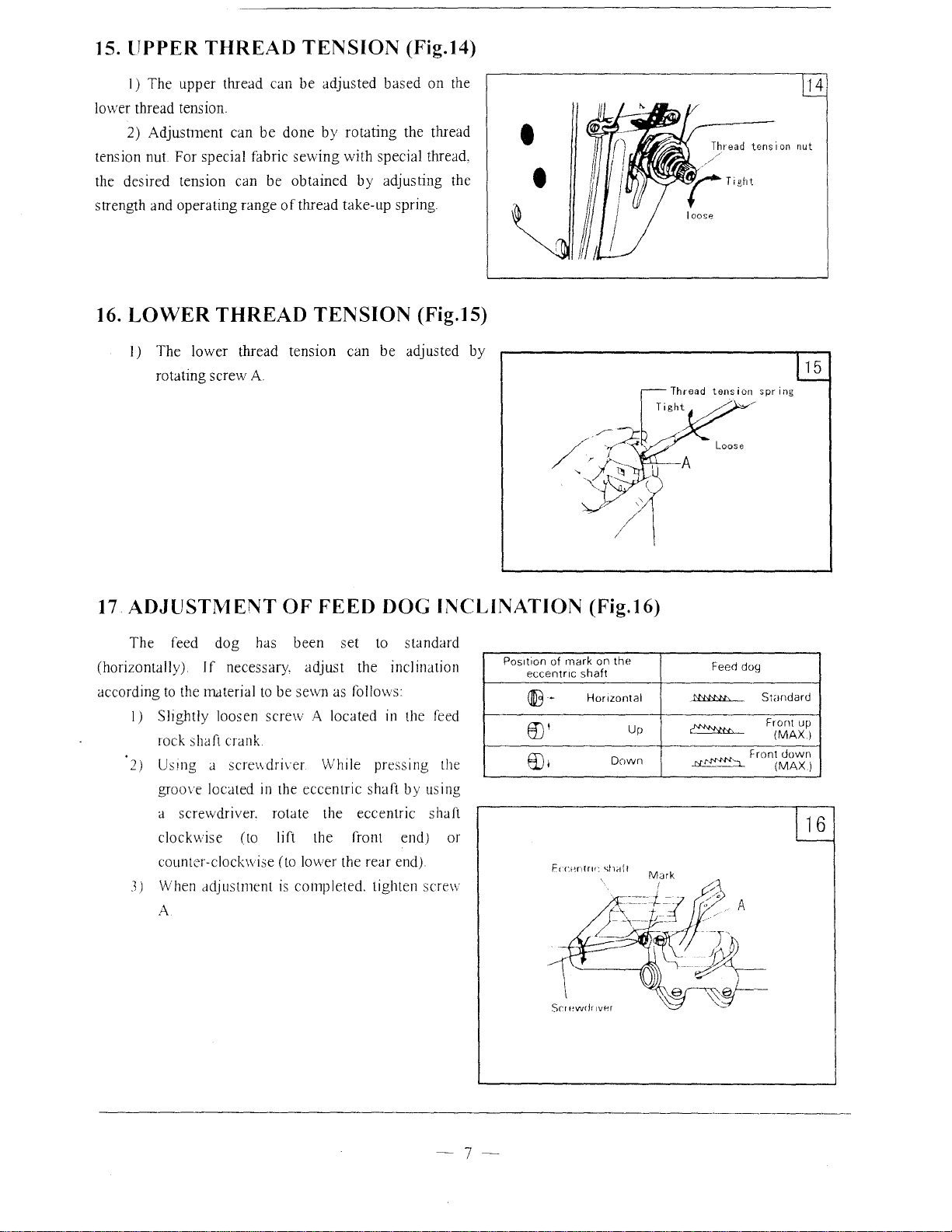

10.

WINDING

I) The wound bobbin thread should be Peat and tight.

nut

(A)

stud

Note: nylon or pol.r:;ter thread should be wound with little tension; otherwise. bobbin (D) might break or

defom1.

2)

(1:5)

of

Fig 9 (b). move the bracket rightward, but

\\Ound

After adequately positioning the bracket. tighten set

screw (B)

3)

thread

adjusted by adjusting screw (E)

latch

ofbobbin winder tension bracket.

vn;.

~~

bobbin winder tension bracket and slide bracket

as

shmvn

Do

not

\Viii

fill

ADJUSTMENT

·1

o vound thread layer does not present a cylindrical shape

in

Fig 9 (c). move the bracket leftward.

overfill the boubin. The optimum length

about

80'%

of

bobbin capacity This

of

(Fig.9)

(C)

if

thread

bobbin winder stop

can

is

of

be

if

not.

adjust the winding tension by turning tension

leftward or rightward. If thread

as

I

~

shown

in

Fig 9 (a). loosen set screw

is

wound

as

E

shown

in

10

11.

REPLACE N EEOLES

Turn the balance wheel

to

(Fig.1 0)

lift needle bar

to

the upper

)J

-s-

a

Page 7

end

of

1ts

stroke Loosen needle clamp screw (A). While keeping the long groove

insert the needle shank

Note Fig (b):

Fig (c) wrong direction

12.

THREADING

To

thread the needle tlu·ead, raise needle

perform threading as

balance wheel to lower the needle

bobbin thread is drawn

up

to the bottom

insu!llcient insertion.

(Fig.ll)

shown

in

up.

Put the ends

Fig.3.

of

the needle leftw·ard fully

of

the needle socket. Then tighten needle clamp

of

long groove

bar

to the upper end

To

draw the bobbin thread, hold the end

bar

and then to lift it to its highest position. Pull the needle thread and the

of

needle thread and bobbin thread front\vard under presser foot.

of

its stroke, lead the thread from spool and

scre'v\

(A)

of

the needle thread and turn the

'"~

12

-~~-----·~Reverse

Stitch

adj

13.

SET STITCH LENGTH AND REVERSE FEEDING (Fig.12)

len~,~~-

ust

i ng

Ji~l

lever

/I

I)

To

change the stitch length, rotate the stitch length adjusting dial while pressing the push lever.

2)

Press

1ng

the reYcrse lc\

3)

The button switch can be pressed to perl'orm reverse stitching.

4)

Normally, set the button switch as illustrated

S\Yitch

14.

AD.JUSTING THE

0

Wei I balanced

st1tch

cr

to rc\ crsc stitching.

THREAD

X

The

upper

tight

thread

or

is

too I oose

too

thread

TENSION

is

lower

The upper

too

thread

by

the solid lines. To reverse stitching, press the button

(Fig.l3)

13

is

loose

is

X

thread

or

too

lower

tight

-6-

Page 8

15.

UPPER

1)

The

10\ver thread tension.

2)

Adjustment

tension

the desired tension can

strength and operating range

16.

nut

LOWER

I)

The

rotating screw A

THREAD

upper

thread

can

be

For special fabric

be

THREAD

lower thread

TENSION

can

be

adjusted

done

by

rotating

sewing

obtained

of

with

by

thread take-up spring.

TENSION

tension

can

(Fig.14)

based

on

the

the thread

special thread,

adjusting the

(Fig.15)

be

adjusted

by

•

•

Thread

tension

~UHl~IA.~

//~/

14

nut

17

ADJUSTMENT

The

feed

(horizontally)

according

to

the material to

1)

Sllghtly loosen

rock shaft crank

2)

Usmg a scre\\driver

groove

a screwdriver. rotate the eccentric shaft

clockwise (to lift the front end) or

counter-clockwise (to lower the

3) When adjustment

A

dog

If

necessary,

located

OF

FEED

has

been

be

screw A located

in

the

is

set

adjust

sewn as follows:

While pressing the

eccentric

completed.

DOG

to

the inclination

in the feed

shaft

rear

tighten screw

INCLINATION

standard

by

using

end).

(Fig.16)

Pos1tion of rnark on

eccentnc

aB-

shaft

Honzontal

[)'

[),

the

Up

Down

Feed dog

t'NN,U,

~

J:i.!~'J

Standard

Front

Front up

(MAX)

down

(MAX)

-7-

Page 9

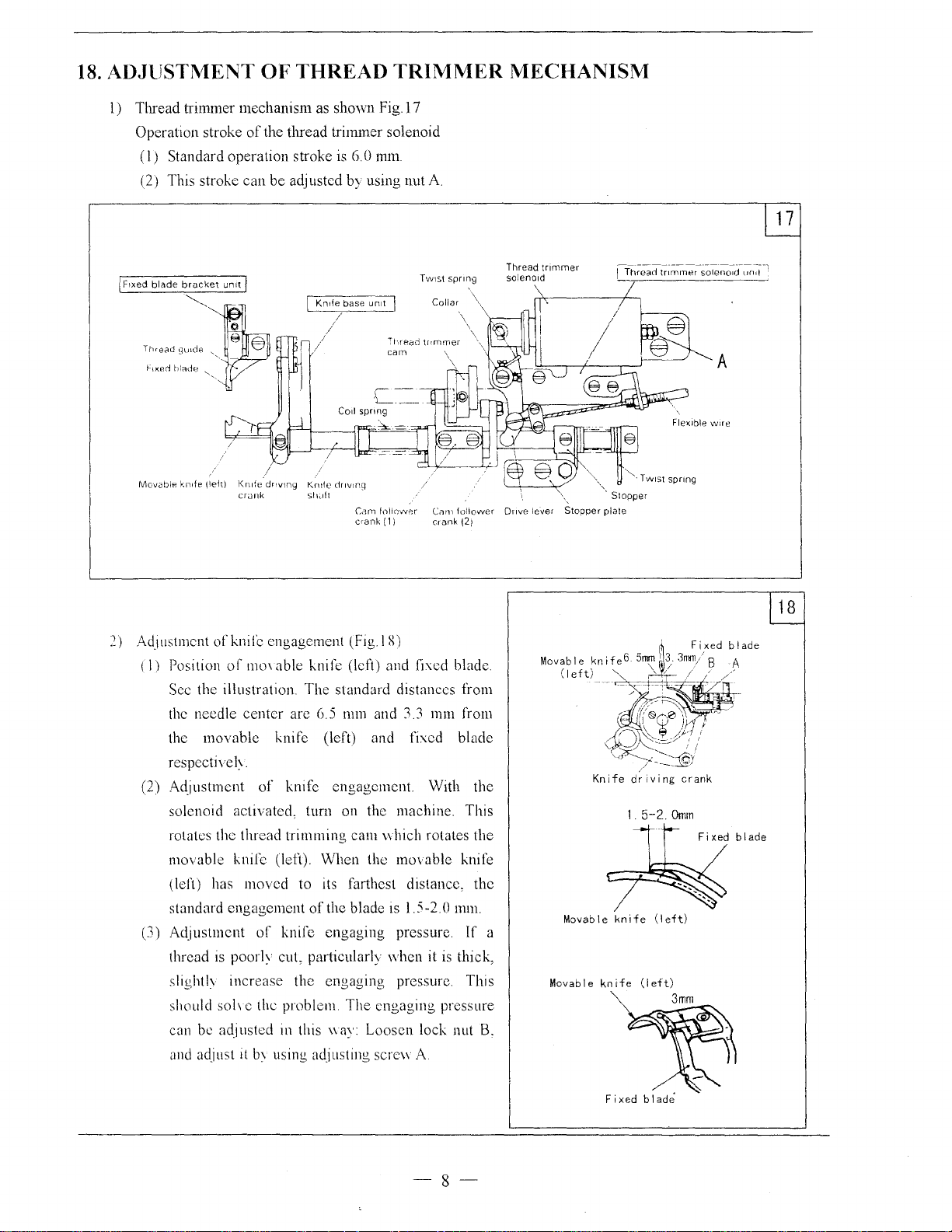

18.

ADJUSTI\1ENT

1)

Thread trimmer mechanism as shown

Operation stroke

(I)

Standard operation stroke is

(2) This stroke can be adjusted by using nut A

I FIXed

blade

bracket

~'

Thcead

gu1cle

hxerl

hi;:Hie "'-,

Movable

knde

OF

of

the thread tri1mner solenoid

un11/

),

~

§

·,

\left)

Knde

cr<Jnk

THREAD

Kn1fe base un1t I

/

/

drtvlng

Krn1e cinvrng

Shed!

TRIMMER

J\;1ECHANISM

Fig.l7

6.

0

mm

1 Thread

trnl1rner

solenotd

Twrs1

spnng

/

Collar

ur1d

I

A

Flexible

wtre

"'

"...TWISt

spnng

C:am

crank

follower

(1

I

(;:tl11

crank

follower

(21

Dr~ve

lever

Stopper

',.

plate

Stopper

2)

AdJustment

(I)

Position

Sec the illustration. The standard distances from

the needle

the

respective!~.

(2) Adjustment

solenoid activated, turn on the machine. This

rotates the thread trimming

movable

(left) has

standard engagement

(3) Adjustment

thread

slighth

should

can be adjusted in this

and adjust

of

knife engagement

of

mm

able knife (left) nnd fixed blade.

center

are 6.5 nnn and 3.3 mm from

movable

knife (left) and fixed blade

of

knife

knife (left).

moved

is

poorly cuL pmiicularly

to its farthest distance, the

of

knife engaging pressure.

(fig I R)

engagement

cam\\

When

of

the blade

With the

hich rotates the

the movable knife

1s

1.5-2 0 mm.

when

it

increase the engaging pressure. This

soh

c the problem

The

engaging pressure

\\ay: Loosen lock nut

it

b\ using adjusting sere\\

A.

is

If

thick,

B.

18

1.

5-2.0mrn

Fixed blade

a

Movable

Movable

knife

knife

(left)

(left)

3mm

-8-

Fixed

blade

Page 10

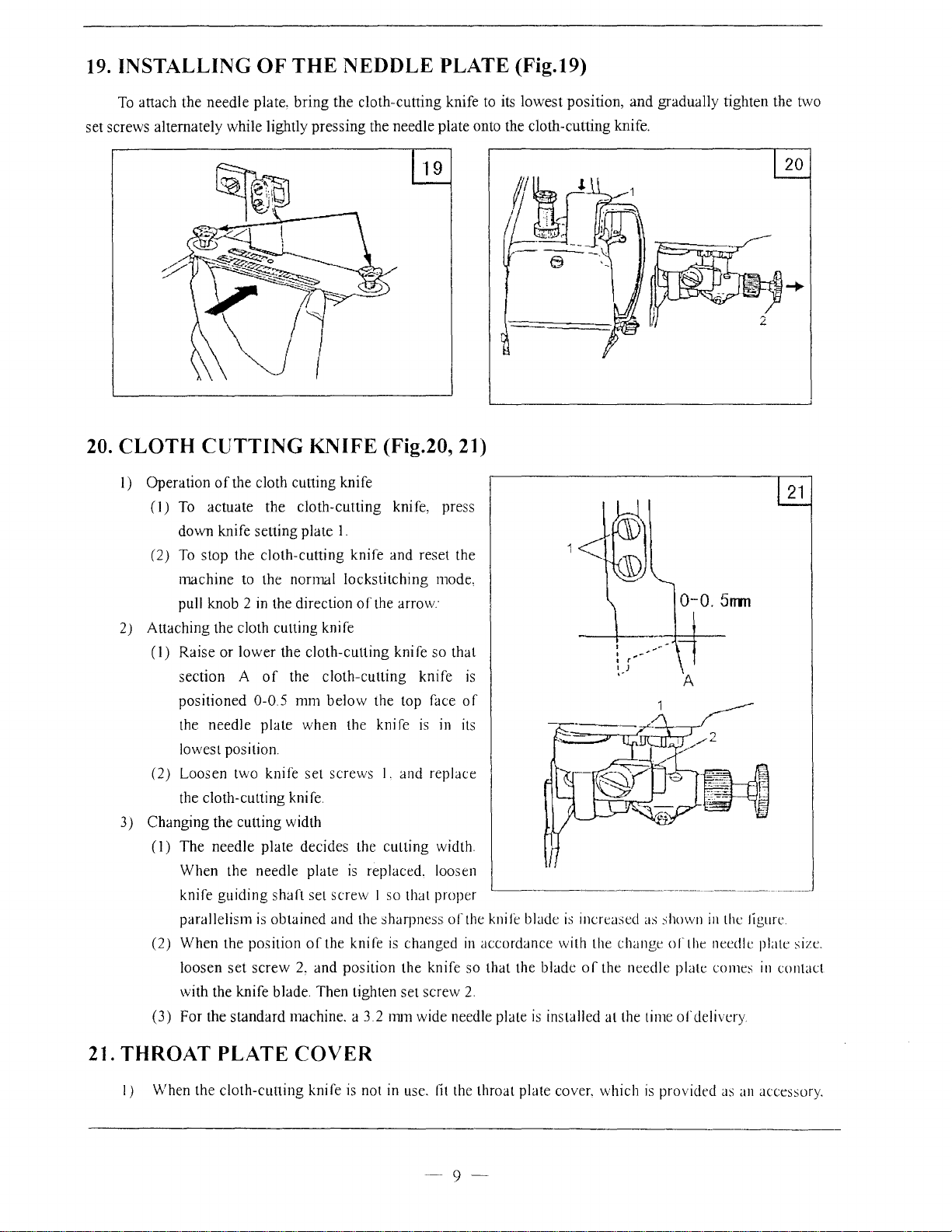

19. INSTALLING

To

attach the

set screws alternately while lightly

needle

OF

plate,

THE

bring

NEDDLE

the cloth-cutting knife to

pressing

the needle plate onto the cloth-cutting knife.

PLATE (Fig.19)

its

lowest

position,

and

gradually tighten the two

20. CLOTH

l)

Operation

(I)

(2)

2) Attaching the cloth cutting knife

(I)

(2)

3) Changing the cutting width

(I)

(2) When the position

(3) For the standard machine. a 3 2

CUTTING

of

the cloth cutting knife

To actuate the

down knife setting plate

To

stop the cloth-cutting knife and reset the

machine

pull knob 2

Raise

section A

positioned

the

lowest position.

Loosen two knife set screws I. and replace

the cloth-cutting knife.

The

When the needle plate

knife

parallelism

loosen

with the knife blade. Then tighten

to the normal lockstitching mode,

in

the direction

or

lower

of

0-0.5

needle

needle

guiding

is

set

screw

plate

plate

shaft

obtained and the sharpness

KNIFE (Fig.20, 21)

cloth-cutting

1.

the cloth-cutting knife so that

the

cloth-cutting

mm

below

when the knife

decides the cutting width.

set

screw

ofthe

2,

and position the knife so that the blade

knife, press

of

the arrow·

knife

the top face

is

is

replaced. loosen

I so that proper

knife

is

changed

set

screw

mm

wide needle plate

is

of

in its

'-------------~-----------~~---------------

of

the knife blade

in

accordance with the

2.

is

installed

is

increased as shown

change

of

the

needle

at

the time

in

the ligure

of

the needle plate size.

platt

of

delivery

comes

in

contact

21. THROAT PLATE

I) When the

cloth-cuning

COVER

knife

is

not in use.

fit

the throat plate cover. which

-9-

is

provided as an accessory.

Page 11

onto the throat plate, and press A portion from above.

2)

The throat plate cover

is

now securely fixed. and the hole

22

u

for

the waste cloth

is

closed.

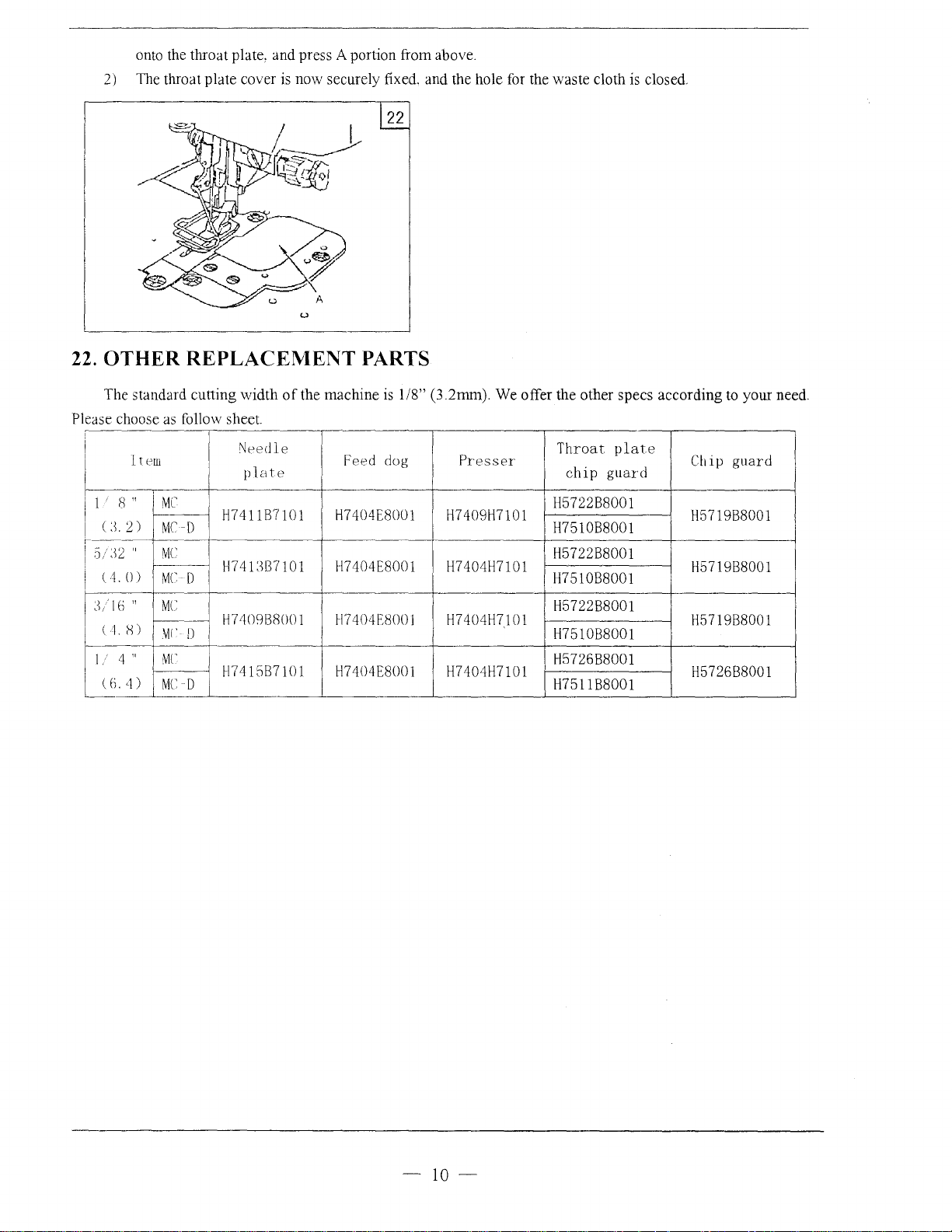

22. OTHER

The standard cutting width

Please choose

I

I

I

ltew

REPLACEMENT

as

follow sheet.

I

4 "

4)

..

MC

MC-D

MC

MC

D

MC

'vH'

D

~JC

MC

D

11

. 8 "

1 u. 2)

'

I

-:

l2 "

I

::J.

•

i

(!.())

I

r~~(i

l (

1H)

I/

(

(i.

of

the machine

NPedle

plate

J-1741187101

1-1741387101

J-17409138001

f-1741587101

PARTS

is

1/8" (3.2mm). We offer the other specs according to your need.

Feed dog

H7404E8001

H7404E8001

H7404E800J

H7404E8001

Presser

J-174091-17101

J-174041-17101

f-174041-17101

H7404H7101

Throat

chip

H572288001

J-1751088001

J-1572288001

J-1751088001

J-1572288001

f-1751088001

J-1572688001

J-1751188001

plate

guard

Chip guard

J-1571988001

J-1571988001

J-1571988001

H572688001

-

10-

Page 12

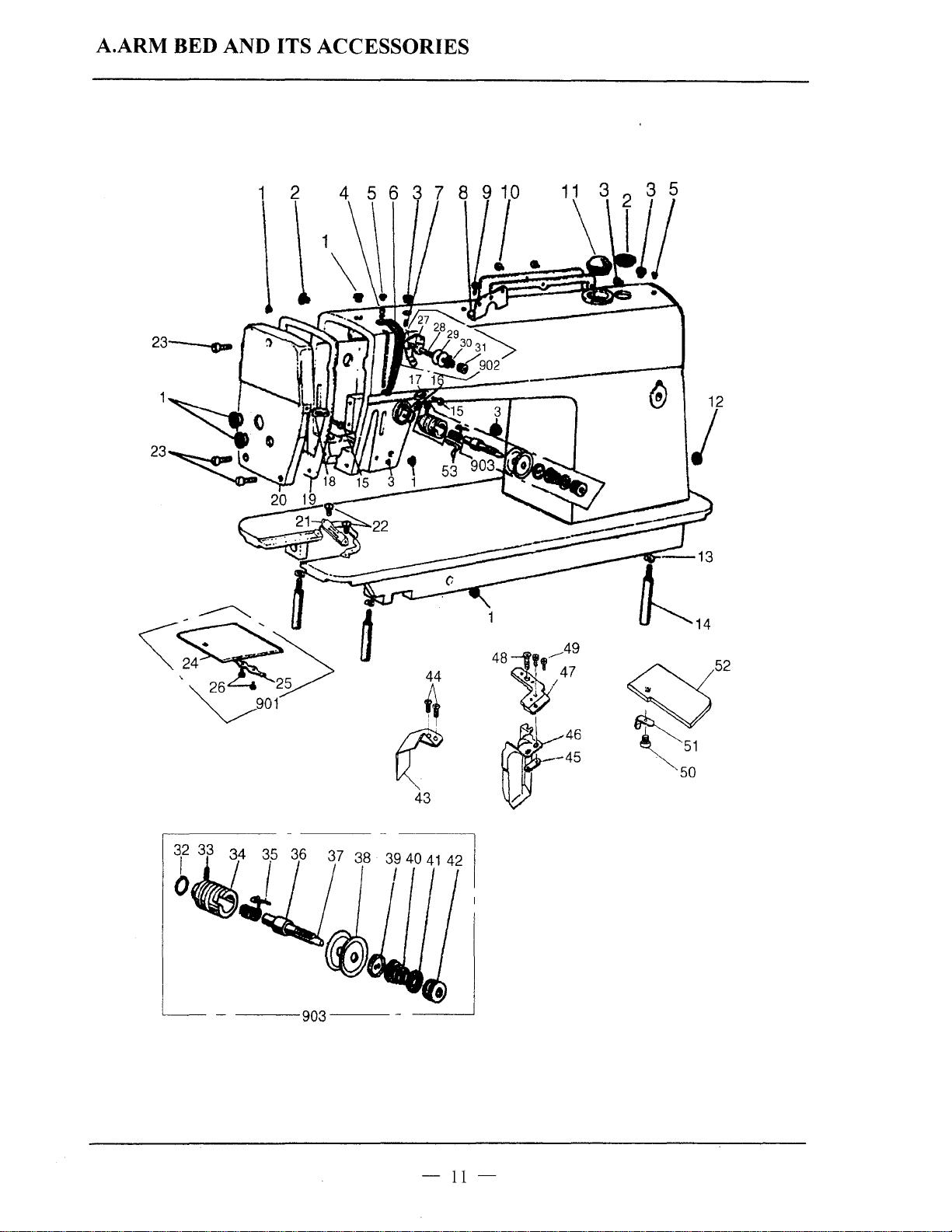

A.ARM BED AND ITS ACCESSORIES

1 2

23----o-

44

#

fZ

43

GJ

48~--A9

0

,,

47

•. I

)

~46

~

45

12

/

-

11-

Page 13

A.ARM BED AND ITS ACCESSORIES

Fig.

No.

A01

A02

A03

A04 HA300C2030

A05

A06

A07 HA100B2110

A08

A09

A10

All

Al2

Al3

Al4

Al5

Al6

A17

i\18

Al9

A20

A21

A22

i\23

A24

i\25

i\2(,

A27

i\28

A2<J

A3ll

/\31

i\32

/\33

A34

i\35

i\3(1

/\37

/\38

A3<J

i\40

A41

.'\42

A-13

Part No.

HA307B0674

HA307B0673 Rubber plug 2 2

HA300B2090

HA30082110

HA300C2020

HA700B2050

HA700B2060

HA300B2170

Hl210B0067

HA300B2100

H005008060 Spring washer

HA100B2220

HA106B0676

HA300B2080

HA100B2140

HA106B0675

H3010B0682

H5912mWOl

H741087101

HA30082190

HA300B2160

HA12480711

Hi\32480711

IIA124B0713

HA71080674

HA710B0673

I lA 11280693

I

lA 71080672

IIA71080671

IIA115B7011

HA11580708

IIA31 080703

I II\ 11580706

1-1/\11580701

HA11580709

IIA31 080705

I

!J'\31

OI30702

IL<\111580703

l-IA115I37010

I

IA31

OB070

!1571

<JB8()()

Rubber plug 6 6

Rubber plug

Set screw 1 1

Rubber plug

Thread take-up cover 1 1

Set screw

Thread guide

Set screw

Set screw

Oil

check window

Rubber plug

Leg

Set screw

Set screw

Thread guide

Thread guide

Face plate gasket

Face plate

Needle plate

Set

screw

Set

screw

Slide plate

Slide plate spring

Set screw

Pre-tension

Screw type tension stud

Disk for

Spring for pre-tension

Nut for pre-tension

0-ring

Set

screw

Thread tension regulating bushing

Tlu·ead

Thread tension stud

Thread tension releasing pin

Thread tension disc

Thread releasing disc

Thread ten::;ion spring

Stop disc

Thumb nut

1

1 Chip guide piate

thread guide

pre-tension

take-up spring

Description

u

~

00

-

'fl

u

0

5 5

2 2

1

1 1

1 1

6

1

1 1

3 3

3

2

1

1 1

1 1

1

1 1

1 1

2 2

3

1 1

1 1

2

1 1

1

2

I I

1

1 1

1 1

1

1 1

1 1

1

2 2

1 1

1 1

1

1 1

1 1

Q

c)

~

00

-0

'fl

0

u

0

SM11/64(40)x8

SM11/64(40)x5.5

1

SM11!64(40)x8

SM11/64(40)x9

6

1

GB/T93 6

3

SM9/64(40)x6

2

SM15/64(28)x6.8

1

1

SM11/64(40)x4.5

SM11/64(40)xlo

3

SM3/32(56)x2.2

2

SM1!/64(40)

I

2

SM1!/64(40)

1

SM9/64(40)x6

1

SM!/4(40)

1

1

Remarks

-12-

Page 14

A.ARM BED AND ITS ACCESSORIES

Q

u

I

~

00

......

<rl

0

u

0

1 1

2 2

1

I

2

SM118(44)x3.4

SM1/8(44)x3.4

1

1

1

u

Fig.

No.

Part No. Description

~

00

......

<rl

0

g

A44 H5727B8001 Screw 2 2 SM118(44)x3.4

A45 H5720B8001 Clip plate

A46

H5722B8001

H7510B8001 Chip funnel 1

A46

A47

H5723B8001 Chip funnel plate 1 1

HA300B2190 Screw 2 2

A48

H5727B8001 Screw 2

A49

A 50 H5720I8001

A51

H5721I8001 Spring for chip funnel cover 1 1

H5727B8001 Screw

A52

H3000B2130 Tirread guide 1

A53

A901 HA324B0071

A902 HA710B0067 Pre-tension thread complete

H30!3B0070 Tirread

A903

Chip funnel 1

Chip funnel cover 1 1

Slide plate complete 1 1

tension complete 1

Remarks

-

13-

Page 15

5

6

11

12 13

14

15

16

20

34

18

19

21

14

22

23 24

25

I

L~

I

,,,

Page 16

B.NEEDLE BAR AND THREAD TAKE-UP MECHANISM

Q

u

u

Fig.

No.

801 H5709C8001 Needle

802

803

804

805

806

807

808

809

810

811 HA104D0652 Rubber

812

813

813

814

815

816

817

818

819

820

821

822

1323

824

1325

826

B27

B28

132S)

830

B31

B32

1333

834

835

1335

836

837

838

839

840

841

Part No.

bar

H5710C8001 Thread guide

HAIOOC2170 Needle

HAIOOC2160 Needle I I

HA7311C606

HAIOOC2070

HAIOOC2060

H5705C7101

HA307C0662

HAIOOC2200 Slide block

HAIOOD2030

H5711C7101

H7504C7101

1-IA I OOC2020

HAIOOD2040

I-IAI08G0066

HAI05D0662

HAII3D2112

I-IAII3D2122

HA112D3012

H30211Cl06

H30211C406 Washer

HA7311C306

HA300D2020

HA306D0066

H30211C206

HA7311C506

HAI12D3013

fiAIOOD2110

HAI13D0691

HAIOOD21

IIA113D2222

HA113D2212

HA108C0663

HA710R0651

HA307D0671

I-L<\110D0672

HA700R0030

HA700ROOIO

HA700R0020

HA700R0040

HA700R0050

lO

clamp

Set

screw

Set

screw

Set

screw

bar

Needle

Set

Arm

Arm

Arm

Set screw

Arm

Collar for

Set screw

Bevel

Bevel

C-type ring

Feed and feed liiling eccentric

Set screw

Arm

Oil

Needle bearing

Crank rod for feed rock

Crank rod for feed lifting rock shalt

Vertical shall hushing (upper)

Vertical shaft

Vertical shalt bushing (lower)

Bevel

Bevel

Set

Driver

Driver

Set

Spacer 1

Speed

Speed

Spacer 2

Support spring

crank complete

screw

plug

shaft

bushing

shaft

shaft

shaft bushing (middle)

arm

gear

for

gear

for vertical shafl(upper)

shall hushing (right)

seal

gear

for vertical sha!t(luwer)

gear

for hook shalt

screw

screw

command

command

screw

shan

arm

disc 1

disc 2

(left)

shall

Description

shan

~

00

~

0

"'

C)

I I

I

I I

I I

I I

1 I

1 1

2

I I

2

1 1

1

4 4

I I

1 1

2 2

1 1

I I

1 1

1 1

1

3

1 1

1 1

1 1

1 1

1

1 1

1 1

1 1

1

1 1

8

1

2

~

00

~

0

"' u

u

C)

I

SMI/8(44)x4.5

SMll/64(40)xJ2

SMli4(40)x6

2

2

1

SM15/64(28)x

SM1/4(40)x4

I

SM9/64(40)x7

3

1

1

SMl/4(40)x7

8

1

SM 15/64(28)X

2

2

1

I

1

1

Remarks

10

12

-

15-

Page 17

B.NEEDLE BAR AND THREAD TAKE-UP MECHANISM

Cl

I

u

~

00

~

If)

0

~

1 G8/T894.1

SM11164(40)x8

3

1

1

Fig.

No.

842

843

844

845

846

847

848

8904

8905

8906

Part No.

HA700R0060

H007009300 C-type ring

HA300C2030 Set screw

HA703R0066 Detector bracket supporter

HA703R0067

HA700ROOOO

HA703R0065

HA104C0065

HA113D4021

HA113D4022

Washer 1

Washer 1

Driver complete

Detector complete 1

Needle

bar

Bevel gear for

Bevel gear for hook shaft complete

u

~

00

Description

link and thread take-up lever complete 1 1

arm

shaft complete

~

If)

0

u

C)

1 1

1 1

Remarks

30

-16-

Page 18

1

------------.

21

22

23

12

13

14 15

16

10

11

38

37

36

35

Page 19

C.NEEDLE BAR FEEDING MECHANISM

Fig.

No.

COl

C02

C03

C04 H3012D0693

cos

C06

C07 H7404D8001

C08

C09

C10

C11

Cl2

Cl3

C14

C15

C16

C17

C18

C19

C20

C21

C22

C23

C24

C25

C26

C27

C28

C29

C30

C31

C32

C33

C34

C35

C36

C37

C38

Part No. Description

HA304G0656 Set screw

H3012D0691

HA100B2110 Set screw 2 2

H3012D0692 Needle bar vibrating lever link pin 1 1

H5904D7101

H7405D8001

H3000D2160 Set

H3000D2170

HA300C2030 Set screw

H3000D2020

H3000D2030

H30612D113

H005005050

HA304G0656 Set screw

H3000D2110 Needle bearing

HA104G0654 Set screw

H005004040 Washer

H3000D2130

HA100B2110 Set screw

H3010D0672

H3010D0671 Rock shaft

H3009D0662

HA104G0012

H3009D0661

HA100B2110

HA105D0662

H3011D0681

H3010D0673

H3010D0674 Washer

H007009120

H3000B2110

H3000D2050

H3004D0651

HA304G0656

H30611D713

H3000D2040

Needle bar vibrating lever

Needle bar vibrating lever link

Needle bar support complete 1 1

Gasket for needle bar support 1 1

Fitting plate for gasket 1 1

screw 2 2

Needle bar support guide bracket 1 1

Needle bar support bushing 1 1

Needle clamp screw

Guide bracket for needle bar slide block

Washer

Felt

Rock shaft bushing (left)

Rock shaft driving crank pin

screw

Set

Rock shaft driving crank

screw

Set

screw

Set

Collar for rock shaft

Rock

shan

bushing (right)

C-type ring

Rubber plug

Crank rod for feed rock shaft

Feed rock

Set

Set screw

Eccentric

screw

shan

shan

driving crank

~

I

00

.-

Of')

0

g

1

1 1

1

2 2

1 1

1 1

1 1

1 1

1 1

1

1 1

1 1

2 2

1

1

1

1 1

1 1

1

2

1

1 1

1

1 1

1

1

1

1

1

1

Cl

I

u

::;E

I

00

..-

Of')

0

g

1 SM3/16(28)x

SM11/64(40)x5.5

1

SM9/64(

SM11/64(40)x8

SM11/64(40)x4.35

GBfr95

SM3/16(28)x15

SM1/8(44)x6

1

GBfr848 4

SM11/64(40)x5.5

1

1

1

SM3/16(28)x12

SM11/64(40)x5.5

1

SM1/4(40)x4

2

1

1

GBfr894.1 12

1

1

1

SM3/16(28)x15

1

SM1/8(44)x3. 9

1

1

40)x4. 5

5

Remarks

15

-18-

Page 20

11

2

3 4

12 13

-

:..c

5

161

~

~"

17

6

~

18

19 20

21

48

43

31

9

41

46 40

44

35 36

37

38 39

7

Page 21

D.ROT A TING

Fig.

No.

DOl

D02

D03

D04

DOS

D06 HA104G0011

Part

No.

HAI04G0656

H30311El06

HAI04G0654 Set

H7404E8001

HA705J0654

HOOK

Washer

Feed bar I 1

screw 2 2

Feed dog 1 1

for feed bar crank (eccentric) 1

Shaft

Feed rock shaft crank 1 1

D07 HA!04G0012 Set screw

HA300G2050

D08

H007009150

D09

DIO HA100G2040

HA7311C706 Feed rock shaft crank (right)

Dll

HA706CIIB2

Dl2

HA7311C806 Set screw

D13

Dl4

HA7311C606

HA305E0662 Set

DIS

Dl6

H3005E0066

HA700E2060

D17

1)]8

HA300E2050

))]'_)

HAIOOE2150 Set screw

])20

ll3004E0065

)

)21

HA104EOOI1

))22

11Al111E204

))23

I

fA

700E2030 Oil seal

IIA 704B0(>54 I look shall hushing (left)

I

>24

))25

11/\3041~0(>5

7041

IIA

I l25

I

!2(>

II A 71

0 I

Iii\

I

>27

>2X

I

>2'!

I

))\()

I

l31

IJ\2

I

!.\I

I J\4

7101

));\

7041l0(>53

I l.\305 I

lii\3i!5i·i!(>(>2 Set screw

11\3111·1)(>71

llo\ I

Ill

11.\31101·:2

11\.11)())'211

I l I 5 lli\31Jill•2040

II.\

I

>31,

/J\7

I

!.IX

I><'>

I

>411

>41

I

>4'

I

/114/·0(>54

II.\

/I)()(

//.\311(>1

I

J.\3115t

1/A/IJIII

II.\

/IIIII

I lA/

IIt

Feed rock shaft 1 1

C-type ring

Feed

rock shafl bushing 1 1

Feed rock shaft crank pin

Set screw

screw

Rotating hook complete

Bobbin

Rotating hook positioner

Bohhin case complete

Filter complete

Filter

Rotating hook shall

I

Rotating hook shall

~0(>5

I

t

~tWJ

I

·:om2

Thread

Set screw

immer

Rotating hook shall bushing (middle)

Collar

Ill!·

'00(>(>

rotating hook shaft

Rotating hook shall bushing (right)

I lil pipe

I

~i!i>72

J()() Plunger

()

l)lunger spring

I luiLk plate

ll>r

Set serew

i2070

1/ingc pin

Feed lilling

ill01>7

i1Jr,r,3

l'ccd lilling mck shall

Feed I ill ing rock shall bushing

i2/211

\Vashcr

i2130

i()(,X3

Sct scrcw

SHAFT MECHANISM

Description

cam

rotating hook shall

rm:k

shall crank (right)

u

~

I

00

~

<r)

0

u

c.J

I 1

4

2

1

I 1

2 2

1 1

I I

I I

I I

I I

1

1 1

I 1

1 1

1 1

I 1

1

1 1

1 I

l 1

I

1 I

I

l I

l l

l l

I

l l

I I

I I

I

Cl

I

u

~

00

-

<r)

0

u

c.J

SM118(44)x6

1

SM3/16(28)x12

4

GB/T894.1

2

1

SMI1164(40)x7

SM11!64(40)x12

SM15/64(28)x4.5

SMII/64(40)xJO

I

1

1

SM114(40)x10

2

I

15/M(2~)x4.5

SM

1

1

SMI5/M(2X)x10

l

SM11/64(40)x12

1

Remarks

15

-20-

Page 22

D.ROTATING HOOK SHAFT MECHANISM

Cl

C)

u

~

Fig.

No.

D43 H3009E0068

D44

D45

D46

D47

D48

D49

D50 HA104G0658 Hinge pin nut 1 1 SM3/16(32)

D51

Part No.

Feed lifting rock shaft crank (left)

HA108G0066

HA105D0662

HAIOOC2020 Set screw 2 2 SM15/64(28)x

HA112G0070 Feed bar link 1

HA100G2100

HAI04G0659 Hinge pin I I

HA300C2030 Set screw 1 1 SM11/64(40)x8

Collar for Feed lifting rock shaft

Set screw 4 4 SM1/4(40)x4

Set screw

Description

I

00

~

......

00

V")

......

V")

0

0

g

g

1 1

2 2

1

2 2 SM9/64(40)x6.5

Remarks

10

-21-

Page 23

E.STITCH REGULATOR MECHANISM

1 2

6 7 8 9

38 39

50

40

41

I ! I

42

i

46/

51

35

1817

16

~~-~~~

\

31

30

48

23

\r'

·.

··\

29 28

49 24

~

27

22

25 23

21

20

-22-

Page 24

E.STITCH REGULATOR MECHANISM

Fig.

No.

EO!

EO!

E02

E02 H3000F20!0

E03

E03

E04

E05

E06

E07

E08 HAIOOF2040

E09

EIO

Ell

Ell

E12

E12

E13

E14

E15

E16

E17

E17

E18

E19

E20

E21

E22

E23

E24

E25

E26

E27

E28

E29

E30

E31

E31

E32

E33

E34

E35

E36

Part No. Description

H!204E0651

H3000F2070

HA73!1C406

H1204E065I Feed regulator I

H3005F0651 Feed regulator I

H3000F2090

H007013040

H2204D0652 Pin

HA704B0655 Feed regulator bushing

HA700B2120

HA1!3F0684

HA115F0692 Spring for reverse feed lever crank

H3009F0663

HA115F0069

H3009F0066

Hf

113F3022

HAIOOF2110

HAI13F0683

HA309F0671

HA113F3021

H3008F0671

HAIOOF2130

HA800F2020

HA706C!IBI

HA706C!191

HA706C!192

HAIIIG0683

HA7311CE06

HA700C2040

H2000H2020

HA73!!CG06

HA7311CD06

HA73!1CC06

HA700C2050

HA7311CF06

H3000F2080

HA104F0654

HAI09F0674

HAIOOF2090

HAIOOF2140

HA700F2030

Connecting rod stud

Connecting rod stud I

Feed connecting link I

Feed connecting link I

Reverse feed link

Washer I I

Hinge pin for feed regulator

Rubber plug

Set screw

Spring for reverse feed lever crank I

Reverse feed lever crank

Reverse feed lever crank

0-ring

Washer

Set screw

Reverse feed lever

Reverse feed lever pin

Reverse feed lever pin

Set screw

Set screw

Link stud

Link (short)

Link (long)

Set screw

Link stud

Feed regulator shaft (right)

Set screw

Stitch length adjusting crank

Set screw

Set screw

Feed regulator shaft (left)

Link stud

Link stud

Set screw

0-ring

Spring for stopper pin

Spring holder

Stopper pin

u

~

I

00

..-

V")

0

g

I

I I

I I

I

I I

I

1

I 1

I

I I

I I

1

I I

1

I

2

2

3 3

1

I

2

I

I

I I

I

I

2

I

I

I I

I

Q

I

u

~

00

..-

V")

0

g

I

GB/T896 4

1

SM15/64(28)x8.5

I

1

I

SM3/16(28)x6.5

I

SMI5/64(28)

SMI5/64(28)x 13.5

I

I

2

2

SM!li64(40)x12

I

I

SM15/64(28)x14

2

I

SM9/64(40)x8.5

I

SM9/64(40)x6.5

I

I

SMI5/64(28)x!O

2

I

I

I

Remarks

-23-

Page 25

E.STITCH REGULATOR MECHANISM

u

;:;s

Fig.

No.

E37

E38

E39 HA7421F120 Dial 1 1

E40

E41

E42

E43

E44

E45

E46

E47

E48

E49

E50

Part No.

HA720F0681

HA720F0683 Stopper pin releasing lever

HA720F0684

HA720F0685 Bushing for dial screw

HA720F0686 Dial screw

HA720F0687 Coil spring 1

HAJOOC2190

HA7311CI06 Spring holder

H.A.7311CJ06

HA7311C706 Feed rock shaft bushing 1 1

HA7311C806

HA7311C606

HA706C11B2 Link stud 1 1

Feed regulator screw

Stitch length indicating plate

Set screw

Spring for feed regulator crank

Set screw 2

Set screw 2

Description

bar

I

00

V)

-

u

0

1 1

1 1

1

1

1 1

1

Cl

u

~

00

V)

-0

0

g

1

I

1

SM9/64(40)x8

2

1

I

SM11!64(40)x7

2

SM11164(40)x

2

Remarks

12

-24-

Page 26

F.PRESSER

FOOT

MECHANISM

25

24

23

22

17

15

14

13

2'

21

...

9

10

L9t8J

22

'\

1

8

3 1

7 6

5

1

12

11

-25-

Page 27

F.PRESSER FOOT MECHANISM

u

Fig.

No.

Part

No.

Description

~

00

~

.,.,

0

g

HA107H0663

F01

F02 HA107H0662 Set screw 2 2

F03 HA100H2050 Set screw 1 1

F04 HA306H0067 Knee lifter lever (right) 1 1

HA306H0671

F05

HA100H2080

F06

F07 HA110H0672

F08 HA100H2050 Set screw 1 1

HA305H6611 Tension releasing

F09

FlO HA7311Il06

H7404H7101 Presser foot complete 1 1

F11

HA100H2150

F12

HA704B0651 Presser bar bushing 1 1

F13

HA300H2110 Presser bar 1 1

F14

HA705I0661 Presser

F15

HA300H2080

F16

H7408H8001 Presser

F17

FUl HA100B2110

HA3411D308

Fl9

H3004G0651 Presser

F20

F21

HA300H2050

HAI07H0662

F22

HAIOOH2120

F23

HA309H0681

1'24

HAI17H0692 Lock nut

F25

F908 Hi\706!2011

Knee lifter rod 1 1

Knee lifter connecting rod 1 1

Pin for spring

Spring

for knee lifter lever

cam

Knee lifter lever (left) 1 1

screw 1 1

Set

bar

lifting

cam

Oil

seal for presser bar litling cam 1 1

bar

lifter

screw

Set

Set screw 1 1

bar litling bracket I

Presser

bar spring 1 1

Set

screw 1 1

Presser

bar guide 1 1

Pressure

Presser

regulating thumb screw 1 1

bar litling lever complete 1

1

1 1

1 1

1

1

1

1 1

0

u

~

00

~

.,.,

0

u

tJ

SM3/16(28)x3.5

SM15/64(28)x13.5

1

SM15/64(28)x135

SM9/64(40)x11

1

1

SM11/64(40)x5.5

1

SM 15/64(28)

1

SM3/16(28)x3.5

1

Remarks

x7

-26-

Page 28

G.KNIFE

2~

MECHA

1

NISM

7 6 5

~

1

-27------------

~

Page 29

G.KNIFE MECHANISM

Fig.

No.

GO!

G02

G03

G04

G05

G06

G07

G08

009

010

011

012

013

014

015

016

017

018

019

0:.?.0

021

022

023

0:.?.4

025

U26

U27

()28

02<)

ll30

l

ll32

l

l

l i35

l

037

()38

l

l

Part

No.

H7405F8001

H7406F8001

H7407F8001

1-13200!2030

HA104J6510

H5707F8001 Spring

HA104F0654

HAIOOE2150

HA100C2170

H5709F8001

H5710F8001 Knife

H5711F8001

H5733F8001

H5712F8001

H7409F8001

l-1005004050

H5735F8001

H5715F8001

H5716F8001

1-1007013015 Stop ring

H5717F8001

H5718F8001 Pin

H5719F~W01

H5720F8001

H5721F8001

HA104C0659

H5722F80lll

I-I5723F800 I

1130211 C206

1!5724F8001 Knife

115

i31

133

134

13(,

i3<J

140

725F800 I

l-15726HOOI Pin

115727F8001

IIA100C2l<JO

l!A

I OOC2200 Slide

115728F8001

H5729F8001

H5730F8001

115731F8001

115732F8001

Knife

positioning

Screw

Spring

Washer

Nut

Screw

Screw

Screw

Washer

Knife

holder

Screw

Knife

driving

Guide

stud

for

Washer

Screw

Knife driving

Spring

Knife release

Knife

driving

Bushing

Knife

driving

Screw

Knite

driving

Knite driving

needle

Knite

cam

plate

Thrust

Slide

block

Screw

block

Knob

Nut

Cap

Spring

K.nite

driving

block

knife

rod

lever

rod

stud

stud

rod

bearing

guide

block

Description

plate

Asm.

driving

clutch

pin

clutch

pin

connection

stud

guide

u

~

oO

V)

-

0

g

1 1

2 2

2

2 2

2 2

1 1

1 1

1 1

2 2

1 1

1 1

1 1

1

1 1

1

2 2

2 2

1

1 1

2

1

1

1

1

1

1

I

1

1 1

1 1

1 1

1

1 1

2

1 1

1 1

2 2

1

1 1

I 1

Cl

I

u

~

I

00

V)

-

0

g

SM9/64(40)x5

2

SM

15/64(28)

SM

15/64(28) X 10

SM11164(40)x9.5

SM1/8(44)x4.5

SM11/64(40)x8

1

1

GB!f848

SM3/16(28)x9

1

GB!f896

2

1

1

1

1

1

SM9/64(40)x6

1

1

1

1

SM!1/64(40)x8

2

1

Remarks

5

1.5

-28-

Page 30

61

60

18

7-----

---CG~-

~

~-5

3

4

40

39

54

38

37

36

34

15

35

7

32

33

Page 31

H.

THREAD TRIMMER MECHANISM

Fig.

No.

Part No.

Description

()

~

00

.-

on

0

g

Cl

u

~

00

.-

on

0

g

Remarks

HA713N0070 Flexible wire

HOI

Thread

HA713N0701

H02

HA712N0698

H03

HA712N0695

H04

HA712N0697

H05

HA712N0696 Collar for

H06

HA710N0683

H07

HA712N6910 Flexible wire support plate

H08

HA712N0699

H09

HA712N6911

HlO

HA712N6912

H11

HA712N6913

H12

H003002050

H13

HA7511N212 Solenoid

H14

HA700N0080 Set screw

H15

HA712N0692

H16

HS900!1406

H17

HA7641B319

H18

HA7121N604

H22

HA7121NI04

H23

HA7121N404

H24

HA7121N304 Set screw

H25

H2(i

H3000H2030

11A

H27

1!2X

[

[2()

1130

1131

[[32

1133

r

134

1135

I

f3(,

1137

lf3X

1139

1140

1141

1142

r

143

lf44

1145

114(J

7121 N704 Nut

I IA

7221

N206

HA7221NIO(,

!lA

706N0663 Nut

IIA70'JN0671

HA700NOIIO

IIA715N0711

I lA 7 ION06X2

I

fA

7 411 N I I 0

f lA 700N0040

I fA700N0050

11750XIXOOI

I

175()(,1XOO

IIA

71

IIA7111N404

IIA7111N304 Nut

IIA719B7011

I

!75071XOO

!IA704NIII4

HA704NIII3

I

I I N204

I

trimmer

Thread

trimmer

Stud

screw

Trimmer

Stopper

Set screw

Flexible wire

Set screw

Wire

Wire

Thread

P-type

Terminal pin

Set screw

Bracket for fixed

Thread

Fixed blade

Crank

C'rank roller

Stopper

Coil spring

Collar

Lever stopper plate

Screw

Coil

Bushing

Knife

Knife holding

Set screw

Rod

Set screw

Knit~

Set screw

Washer

driving

stud

nut

holder

nut

bracket

trimmer

screw

tinger

screw

block

with

spring (leH)

driving

driving

complete

driving lever

driving

lever

screw

presser

solenoid

blade

screw

shall

bracket

crank

lever 1

spring

stud

saddle

1

1

1

1

1

1

SM

15/64(28)

1

SM11/64(40)x4

1

I

SM118(44)x7

2

1

2

GB/T6170

1

SM15/64(28)x12

4

1

M4x6

3

2

SM9/64(40)x8.5

1

1

1

SM9/64(40)x5

1

I

SM9/64(40)

I

I

1

SM3/16(28)

I

1

I

1

1

SM

I

1

1

1

I

2

I

2

I

I

3

1

15/64(28)x23

SM11!64(40)x6.2

SMII/64(40)

SMI1!64(40)x11

SMI/8(44)x5.2

M5

A

-30-

Page 32

H.THREAD

Fig.

No.

H47 HA704N1112 Knife holding bracket saddle (left)

H48

H49 HA7111N704

HSO

H51

H52

H53

H54 HA7311CH06

H55 HA113F0684 Set screw 2 SM15/64(28)x8.5

H56

H57 HA7311C606 Set screw 2

H58

H58

H59

H59

H60 HA300B2170

H61

H909 HA712N0069

Part

HA7111N804

HA300C2030 Set screw

HA7311CC06

HA100E2150 Screw

H007013040 Washer

HA105D0662

H5904H7101 Thread tension releasing bracket complete I

H5905H8001 Thread tension releasing bracket 1

HAIOOH2060 Thread tension releasing pin

H3000H2080 Thread tension releasing pin 1

HA708P0668

TRIMMER

No.

Movable knife (left) 1

Set screw

Set screw

Set screw

screw

Set

Screw

Cord holder

Solenoid bracket complete 1

MECHANISM

Description

Q

u

u

~

00

~

00

V)

-

V)

0

-

0

g

u

C)

1

2 SM11/64(40)x5.5

6

2 SM9/64(40)x6.5

1

2

1

1

1

1

1

Remarks

SM11/64(40)x8

SM11/64(40)x10

GB/T896 4

SM9/64(40)x8

SM114(40)x4

SM11164(40)x12

SM11/64(40)x9

-31-

Page 33

I.

TOUCH BACK AND

DETECTOR

MECHANISM

25

4 5

. I f

~li~~

9

27

1

-32-

13

Page 34

I.

TOUCH BACK AND DETECTOR MECHANISM

Fig.

No.

IOl

J02 HA700Q0030 Cord holder

I03

!04

105

106

I07

I07 HA108B0681

I08

I08 HA108B0682

!09

110

Ill

112

113

!14

!15

Il6

117

118

!19

12(;

!21

!22

!23

!24

!25

!26

!27

!28

!29

130

Part No. Description

HA300B2170 Screw

H2611E8001 Solenoid

HA712Q0693 Tie-in

HA700Q0010 Pin

H2206I0672

H2609E0671

H2609E0672

HA712N069l

H2204G0651 Screw

H2204G0652 Stop ring

HA705Q0065

HA700Q0050

HN00B2170

H5911J800l

HA7221P508

HA70400657 Rubber plug

HA70400659 Screw

HA.

70400654

H2205I0661

HA70400021 Touch switch complete

H007013030

HA70400653 Spring

HA7641B319

HA7641B319

HA300C2030

H007013040 Stop ring

HA70406510

HA70400655

HA70400658

Wasl~er

Arm

side cover 1

Arm side cover

Gasket for

Gasket for

Link stud 1

Ground wire assy.

Cord holder 1

Screw 2

Bracket for touch switch 1

Screw

Plate spring

Bracket for touch switch

E-type ring

Cord assy.

Terminal pin

Screw

Screw

Micro switch

Insulator seet

arm

side cover

arm

side cover 1

-

u

::'E

I

00

......

V)

0

g

1

0

u

~

00

......

V)

0

g

4

3

1

1

1

1

1

SM15/64(28)x7

1

1

1

SM11!64(40)x9

M3x5

2

1

M2x4

1

1

1

1

GB/T896 3

2

1

3

5

SM11/64(40)x8

4

GB/T896 4

2

M2x8

2

1

1

""'

Remarks

-33-

Page 35

J.OIL LUBRICATION MECHANISM

')

1

L.

,,__ _ _,...5

,

___

_,~

G

22

8

15

9

14

13

'

-34-

Page 36

J.OIL LUBRICATION MECHANISM

Fig.

No.

Part No. Description

u

:::2

ob

.-

V1

0

g

~

u

:::2

ob

.-

V1

0

g

Remarks

101

HA100H2150

102 H3004L0065

H3000L0020 Oil filter holder 1 1

103

H3006L0065 Oil return tube complete 1 1

104

HA116I0068

105

106 HA11610682

HA100I2010

107

HA100I2090 Set screw

108

HA100I2030 Set screw

109

HA300I2050 Set screw

110

HA100I2050

Ill

HA100I2070

112

J13

HA111I0065

HA700L0030

114

115

HA100I2020

HA707L0065

116

HA11310661

117

HA300I2030

118

HA300E2030

119

HA100E2060

.120

HA305G0664

121

H3000E2050 Oil wick

122

123

HA300C2030

H3000L0030

124

Screw

Oil

wick fitting plate complete 1 1

Arm

shaft oil tube complete 1 1

Arm

shaft oil tube connector

pump

Oil

Spring washer 1 1

Oil

adjusting plate 1 1

Oil pump screen complete

Oil

pump fitting plate

pump impeller

Oil

Oil

pipe for hook shaft complete

Oil pipe for hook shaft connector

Oil

return tube holder

adjusting screw

Oil

adjusting spring

Oil

Oil wick

screw

Set

Oil

pipe holder

2 2

1 1

1

3 3

1 1 SM1!8(44)x6.5

3 3

1 1

1 1

1

1 1

1 1

1

1 1

1 1

1

1 1

1

1

SM9/64(40)xll

1

SM11164(40)X13

SM1/8(44)x13

1

1

15/64x28/12

1

SM11/64(40)x8

1

1

-35-

Page 37

K.ACCESSORIES

44 9

~

~~rr~--2

7

•

~5

•

43

~

12~

11~

L~4~~

19

42

~3

~4

13

47

-----------

.

,_

__

,

~51

50

-36-

Page 38

K.ACCESSORIES

Fig.

No.

Part

No. Description

u

:::E

'

00

~

0

"'

g

Q

u

~

00

.-

"'

0

g

Remarks

KOl

HA100J2120

K02

HA704S0653 Hexagon socket screw key 2 1 1

K03

HA300J2230 Washer

K04

H801045200 Wood screw

KOS

HA300J2200 Screw

K06

HA300J2210

K07

HA704S0654

K08

HA100J2110 Oil

K09

HA307J0067 Hinge with rubber cushion

K10

HA300J2050

K11

HA300J2060 Head cushion (small)

K12

HA305J0666 Belt cover

K13

K14

HA300J2280

K15

HA300J2250

HA305J0662 Belt cover complete

Kl6

H003002040 Nut

Kl7

HA305J0665 Belt cover

Kl8

HA707S0068 Thread stand complete

Kl9

HA706S0067

K20

HA300J2190

K21

HA300J2130

K22

HA106J0661

K23

HA104J0654

K24

HA104J0653

K25

HA104J0652

K26

HA104J0655

K27

HA300J2160

K28

HA104J0657

K29

HA104J0658

K30

HA104J6510 Nut

K31

HA104J0659 Set screw

K32

H007013090 E-type ring

K33

H5703I7101

K34

H7504K7101

K34

HA106J0663

K35

HA300J2180

K36

HA106J0662

K37

HA106J0667

K38

HA106J0666

K39

HA106J0665

K40

HA106J0668

K41

HA300J2170 Oil tank

K42

Magnet block

Hexagon socket screw key 3

driver (Size M)

screw driver (Size S)

Speed

command disc adjusting plate 1

with oiler

Head cushion (large) 2 2

Set

screw

Screw

Bobbin winder complete

Head cover

driver (Size L)

Screw

Knee lifter lifting rod

Gasket for oil reservoir (small)

Seal

washer

Oil drain screw

Gasket for oil reservoir (large)

Knee lifter shaft

Knee lifter spring

Knee lifter

Oil reservoir

Oil reservoir

Knee lifter coupling joint

Bolt

Knee lifter bell crank

Screw

Gasket for Knee lifter plate

Knee lifter plate

Pad for knee plate

1 1

1 1

4

4

4 4 GB/T99 4.5x20

1

1

1

1

1 1

1

1

2 2

1 1

2 2 SM15/64(28)x8

1 1

1 1

1 I GB/T6170 M4

'

1

1 1

1 1

1 1

1 1

1 I

1 1

1 1

1 1

1 1

1 1

1 I

1

2

2 2

1 1

1

1 1

2 2

1 1

1 1

1 1

1

1 1

1 1

M4xl2.5

1

SMS/16(28) X I 0

1

2

SMS/16(28)

SM15/64(28)x28

GB/T896 9

1

SM5!16(18)x16

SM15/64(28)X8

1

-37-

Page 39

K.ACCESSORIES

Fig.

No.

K43

K44

K45

K46

K47

K48

K49

K50

K51

K52

Part

No.

HA115B0706 Thread take-up spring 1

HA300J2310

HA700E2060

HA300B2170

H5709I8001

H801045200 Screw

H5704I8001

H5705I8001

H801045200 Screw

HA1JOD0672

Needle

Bobbin 4

Screw

Bracket 1

Waste material chure(large) 1

Waste material chure(small) 1

Screw 1

Description

u

~

00

...-<

0

"'

~

1

2

3

4

Q

u

~

00

.--<

0

"'

~

1

1

4

SM11!64(40)x8

2

1

GBfT99

3

1

1

GBfT99

4

SM15/64(28)x12

1

Remarks

4.5x20

4.5X20

I

-38-

Page 40

SHANGHAI HUIGONG

N0.3

SEWING MACHINE FACTORY

ADD: 1418, Yishan Road, Shanghai,

China

Zip Code: 201103

Overseas

Business:

TEL:

86-21-64853303 FAX: 86-21-64854304

E-mail:highlead@online.sh.cn http://www.highlead.com.cn

The

description covered

in

this

manual

is subject to change for improvement

of

the commodity without notice

2004.3. Printed

Loading...

Loading...