Highlead GC0518 User Manual

Purchasing

Copy

Dept

HIGH

GC0518

HIGH SPEED NEEDLE BAR FEED

WITH

Instruction

AUTOMATIC THREAD

LEAD

SERIES

Manual

LOCKSTITCHER

TRIMMER

Parts

SHANGHAI

HUIGONG

N0.3

Catalog

SEWING

MACHINE

FACTORY

CONTENTS

1.

PRECAUTIONS BEFORE STARTING OPERATION

2. MAIN SPECIFICATIONS

3. INSTALLING

ADJUSTMENT OF NEEDLE BAR STOP POSITION

4.

LUBRICATION

5.

CONDITION OF

6.

7. LUBRICATION ADJUSTMENT

8. ADJUSTMENT OF

9.

REGULAR

THE

..........................................................................................................

OIL

CLEANINp

10. WINDING ADJUSTMENT

11. REPLACE NEEDLES

THREADING

12.

13.

SET STITCH LENGTH

ADJUSTING THE THREAD TENSION

14.

15. UPPER THREAD TENSION

LOWER THREAD TENSION

16.

ADJUSTMENT OF FEED DOG INCLINATION

17.

18. ADJUSTMENT OF THREAD

PARTS

A.

B.

C.

D. ROTATING

CATALOG

ARM BED AND IT'S ACCESSORIES

UP

SHAF'f MECHANISM

FEEDING NEEDLE MECHANISM

E. STITCH

F.

PltESSElt F'OOT.,MEC.HANISM

G

KNIFE~CTUATINGI'ECHANISM

.•

H.

WIPEil MECHANISM

............................................................................................................

BOOK

.

1"··

L~GTH

• • ~ '!'

<·

•. : --,:"

REGULATOR MECHANISM

;·

::;,...-.~---~

I. TOUCH BACK MECHANISM

J. OIL LUBRICATION MECHANISM

K.

ACCESSORIES;

.........................................................................................................

..............................................................................................

BELT

.............................................................................................

LUBRICATION

..............................................................................

....................................................................................

OIL

PUMP

.......................................................................................

.............................................................................................

.............................................................................................

...................................................................................................

AND

REVERSE FEEDING

...........................................................................

..........................................................................................

.......................................................................................

TRIMMER

MECHANISM

................................................................................

..............................................................................................

.................................................................................

SHAFT MECHANISM

......................................................................

.....................................................................................

...............................................................................

................................................................................................

.......................................................................................

................................................................................

.........................................................

.........................................................

............................................................

..................................................................

......................................................

...............................................................

2

2

3

3

4

4

4

4

5

5

5

6

6

6

7

7

7

8

9

12

l5

17

20

23

25

28

30

33

35

-1-

1.

PRECAUTIONS

1)

Safety Precautions:

(

1)

When turning the power on, keep your hands and fingers away from the area around/under the needle

and the area around the balance wheel.

(2) Power must

(3) Power must

the machine, or when replacing.

(

4)

Avoid placing fingers, hairs, bars etc., near the balance wheel,

or motor when the machine is in operation.

(5) Do not insert fingers into the thread take-up cover, under/around the needle, or balance wheel when the

be

be

BEFORE

turned off when the machine is not in use, or when the operator leaves the seat.

turned

off

when tilting the machine head, installing or removing the

STARTING

OPERATION

"V"

belt, bobbin winder balance wheeL

"V"

belt, adjusting

machine

(6)

If

devices.

2)

Precautions before

(1)

If

(2)

If

(3) When a new sewing machine is first turned on, verifY the rotational direction

the power

( 4)

VerifY

3) Precautions for

(1) Avoid using the machine at abnormally high temperature ( 3 5

lower) .

(2) Avoid using the machine in dusty conditions.

2.

MAIN

Item

Material

Max. sewing speed

Max. Stitch length

Needle

Presser

Touchback mechanism

Trimming mechanism

Reversing mechanism

bar

Needle

Lubrication

Rotating hook

Motor

is

in operation.

a belt cover, finger guard, eye guard are installed,

Starting

the machine's oil

the machine is lubricated

on.

(The balance wheel should rotate counter-clockwise when viewed from the balance wheel)

the voltage and (single or three) phase with those given on the machine nameplate.

pan

Operating

Operation:

has

an

oil sump, never operate the machine before filling

by

a drop oiler, never operate the machine before lubricating.

Conditions:

do

not operate the machine without these safety

OC

or higher) or low temperature ( 5

SPECIFICATIONS

GC0518 GC0518-H GC0518-B GC0518A-D3

Light-Medium heavy Heavy

3000rpm

5mm

35mm

DPX5

#22

5mm

11

automatism

5000rpm

4mm

31.8

DBX

mm

stroke

By hand

By knee

5000rpm 3500rpm

4mm

31.8

mm

DBX

1#14

Auto lubrication hook Big hook

5mm

33mm

DPX5

370W clutch motor

#18

it.

of

the balance wheel with

GC0518-H-D

Light-Medium heavy

3500rpm 3000rpm

5mm

mm

1 #14

33mm

DPX5#18

•

•

Auto lubrication hook

(Thread trimming)

'Speed adj. Motor

•

OC

or

GC0518-B-D

Heavy

5mm

35mm

DPX5

#22

Big hook

-2-

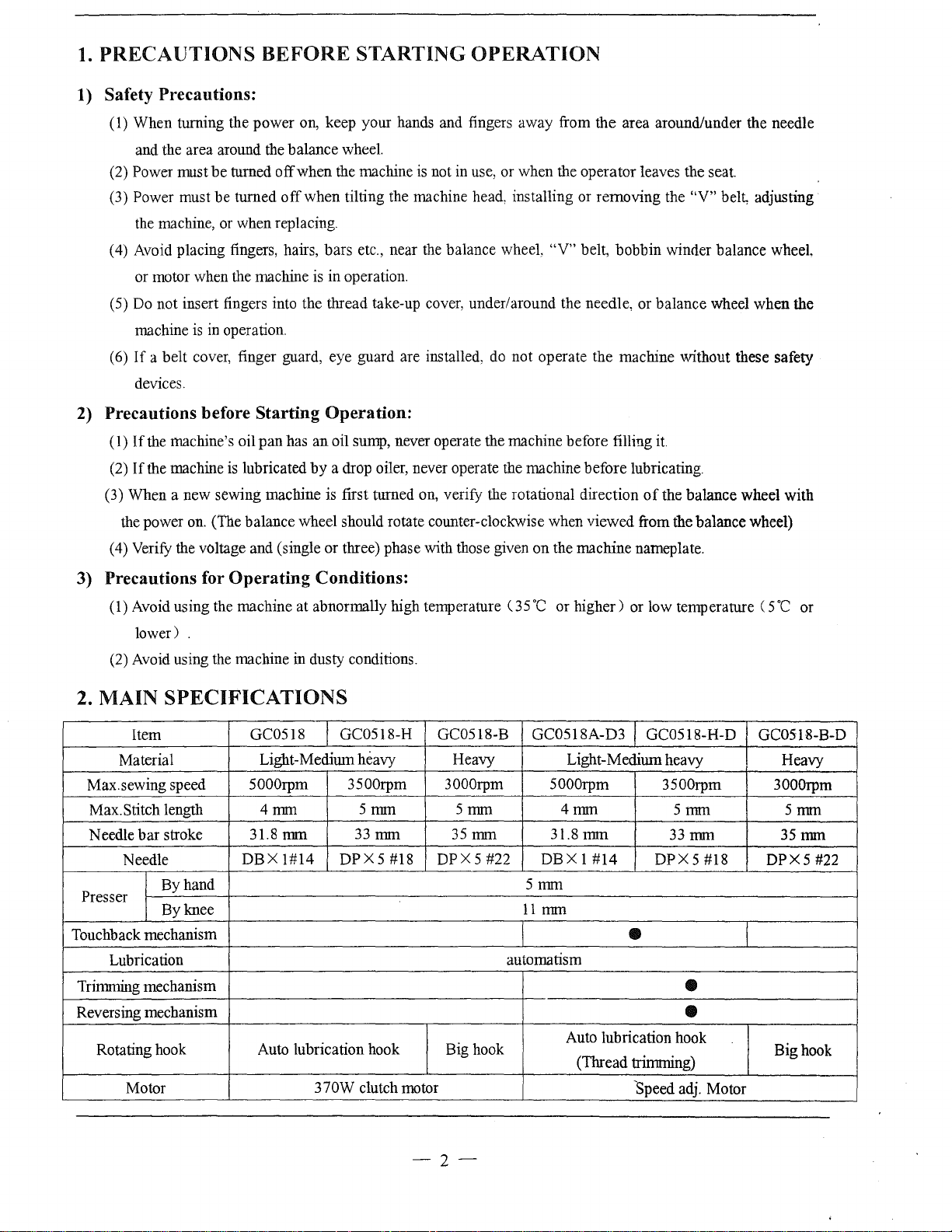

3. INSTALLING

1)

Use a V-belt for sewing machine use, type M

To

adjust the belt tension, change the motor

2)

by

height

sinks about

center

speed may not be consistent in the low or medium

range, or

If

deteriorate more rapidly.

4.

turning the tension adjust nuts so that the belt

15

nun when depressed

of

the belt span.

the

needle may not stop in the proper position.

the tension

is

ADJUSTMENT

THE

If

too high, the motor bearings will

BELT

the tension is too

OF

NEEDLE

(Fig.l)

by

hand at the

low,

BAR

the

STOP

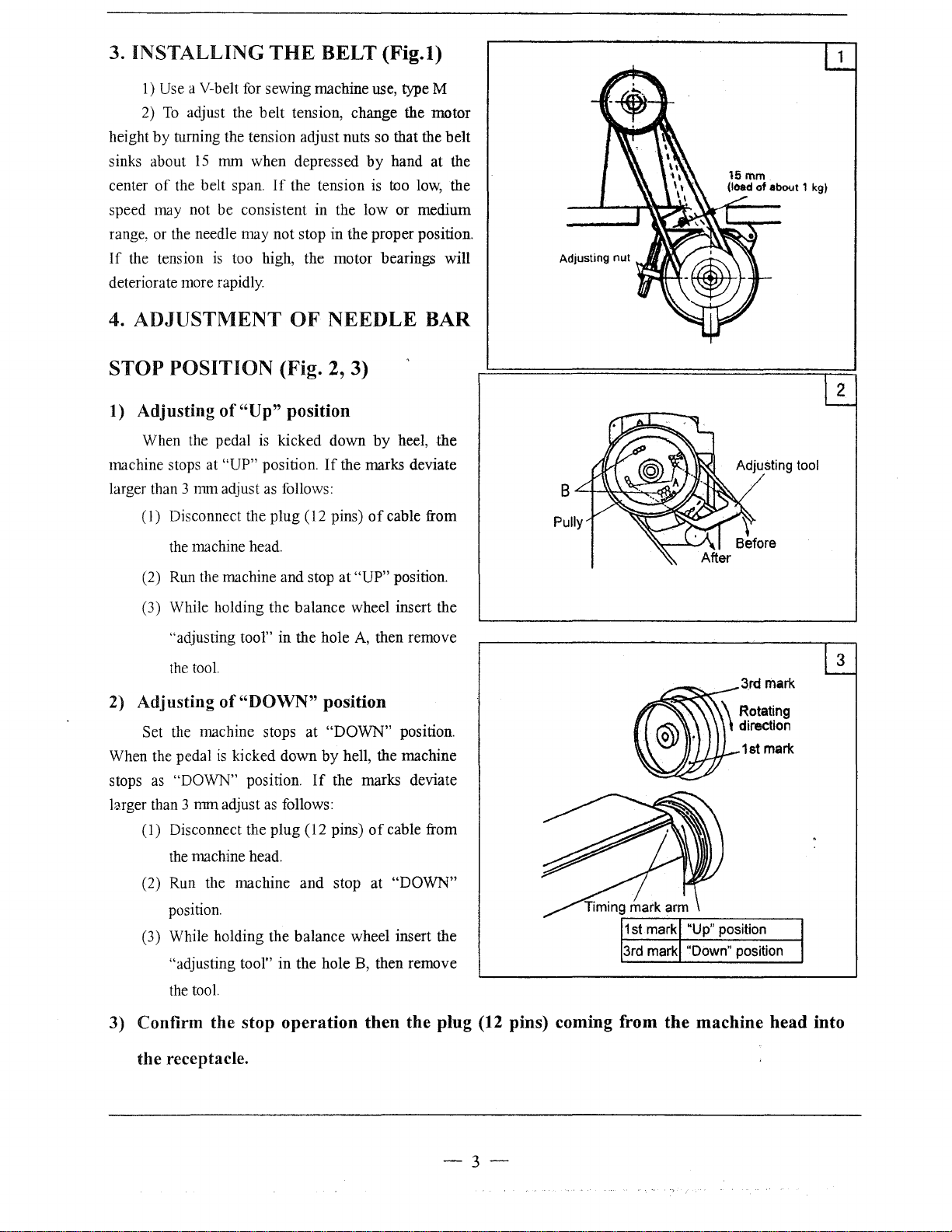

1) Adjusting

machine stops at

larger than 3

2)

When the pedal

stops

larger than 3 mm adjust

POSITION

of

When the pedal

"UP" position.

mm

adjust

(I)

Disconnect the plug (

the

machine head.

Run

(2)

(3) While holding the balance wheel insert the

Adjusting

Set the machine stops at "DOWN" position.

as

(1) Disconnect the plug (12 pins)

the machine and stop at "UP" position.

"adjusting tool" in the hole

the

tool.

of

is

kicked down

"DOWN" position.

(Fig. 2, 3)

"Up"

position

is

kicked down

as

follows:

"DOWN"

as

follows:

by

If

the marks deviate

12

pins)

of

A,

then remove

position

by

hell, the machine

If

the marks deviate

of

heel, the

Adjusting tool

cable from

3

3rd mark

cable from

the machine head.

(2) Run the machine and stop at

position.

(3) While holding the balance wheel insert the

"adjusting tool" in the hole

the

tool.

3) Confirm the stop

operation

"DOWN"

B,

then remove

then

the plug (12 pins) coming from

the receptacle.

-3-

the

machine

head

into

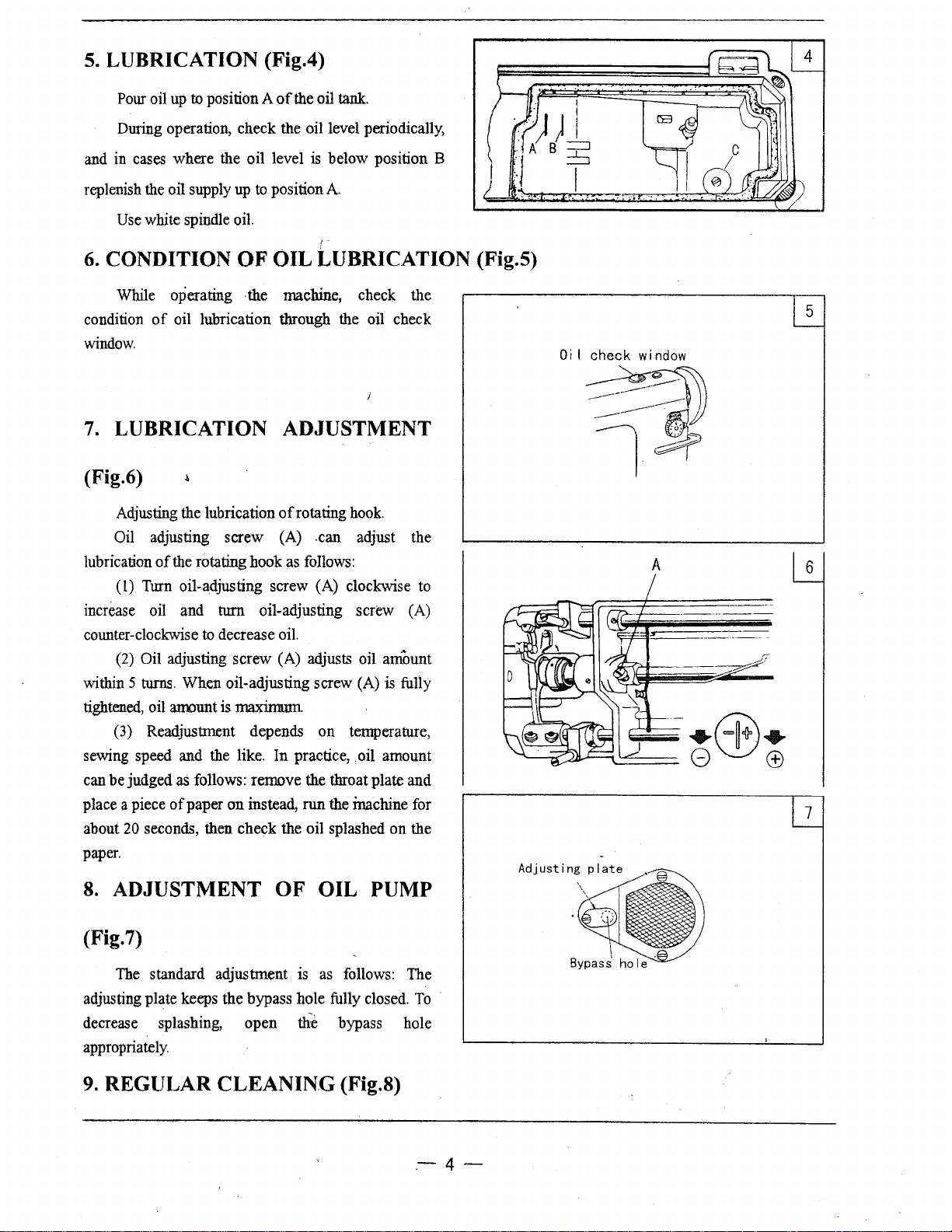

5. LUBRICATION (Fig.4)

Pour oil

During operation, check the oil level periodically,

and in cases where the oil level

replenish the oil supply

Use

6. CONDITION

While operating ·the machine, check the

condition

window.

up

to position A

white spindle

of

oil lubrication through the oil check

of

the oil

tank.

is

below position B

up

to

position

oil

OF

OIL LUBRICATION (Fig.5)

A.

7. LUBRICATION ADJUSTMENT

(Fig.6)

Adjusting the lubrication

Oil adjusting screw (A) .can adjust the

of

lubrication

(1)

increase oil and

counter-clockwise

(2)

within

tightened, oil

(3)

sewing speed and the like. In practice,

can be judged as follows: remove the throat plate and

place a piece

20

about

paper.

the rotating hook as follows:

Turn oil-adjusting screw (A) clockwise

turn

to decrease oil.

Oil adjusting screw (A) adjusts oil amount

5 turns. When oil-adjusting screw (A)

atrount

Readjustment depends on temperature,

of

seconds, then check the oil splashed on the

is

paper on instead, run the inachine for

of

rotating

oil-adjusting screw (A)

maxinnnn

hook.

. oil amount

is

to

fully

Oi

I check

window

~

l-~

A

6

7

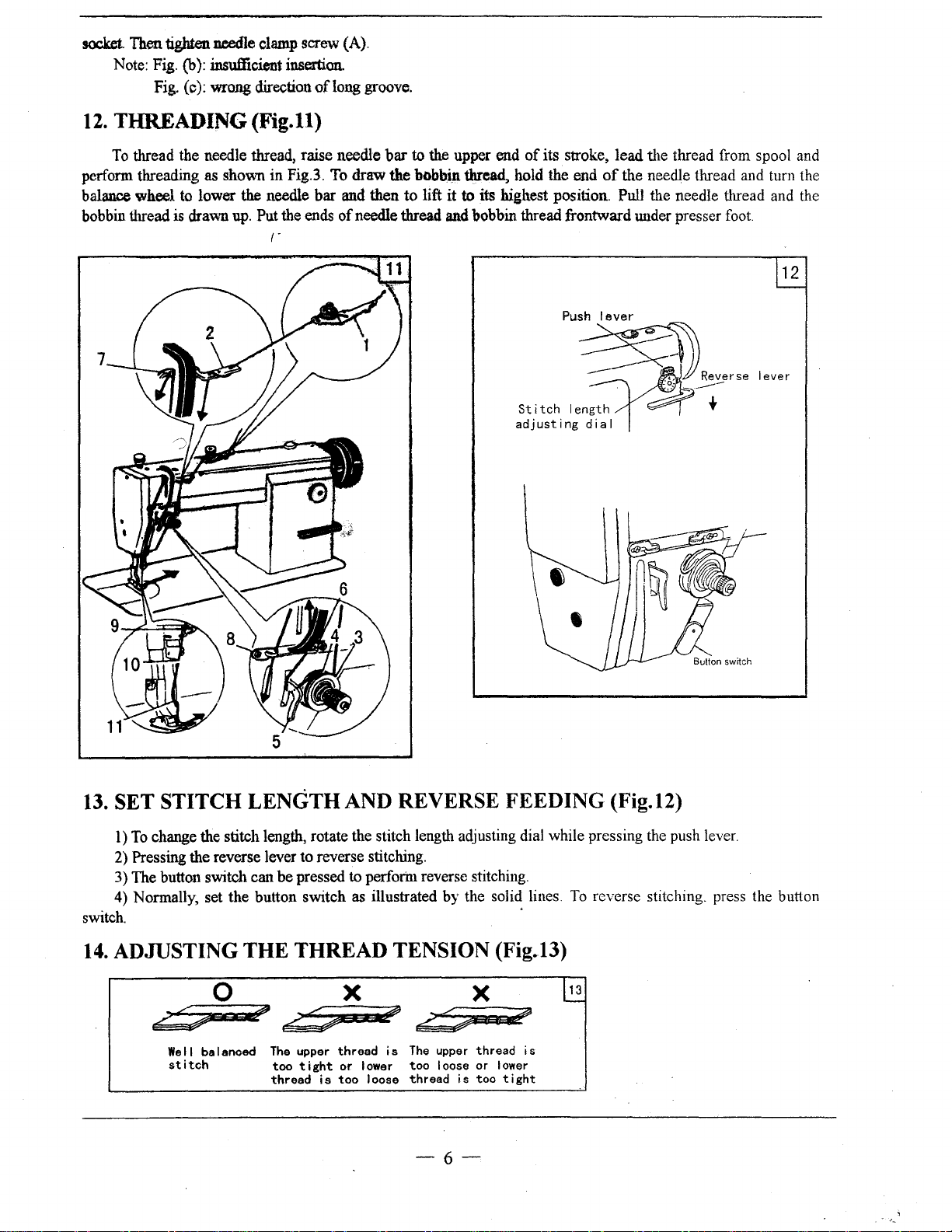

8. ADJUSTMENT OF OIL PUMP

(Fig.7)

The standard adjustment is

adjusting plate keeps the bypass hole fully closed.

decrease splashing, open

appropriately.

9.

REGULAR CLEANING (Fig.8)

as

the

bypass hole

follows: The

To

.-4-

1)

Cleaning feed dog

Remove the throat plate and clear off the dust and lint between feed dog tooth slots.

2)

Cleaning rotating hook

Swing out the machine head and clean the hook. Wipe the bobbin case with soft cloth.

3)

Cleaning oil pump, screen

Swing out the machine head and clear off the dust and dirt on oil pump screen.

Feed dog

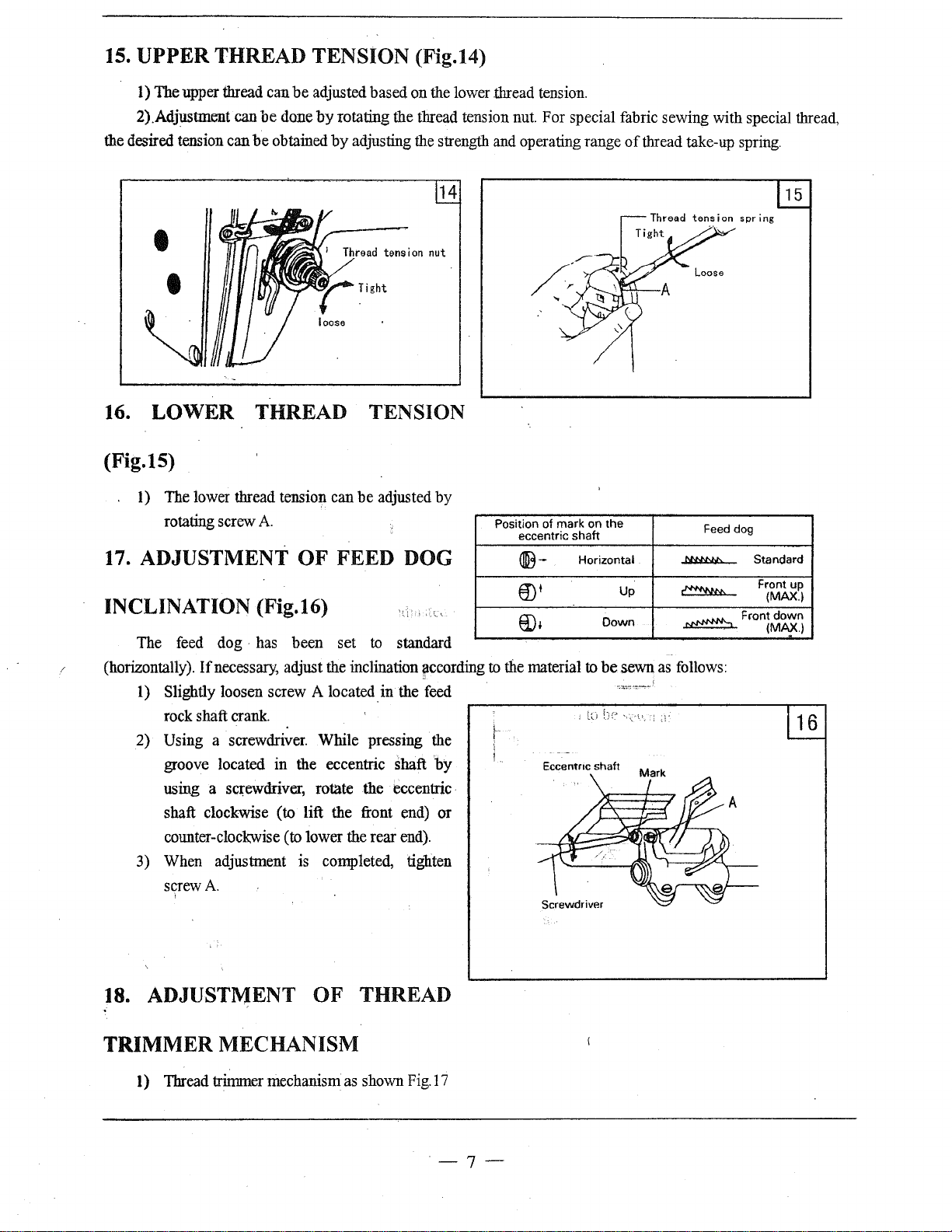

10.

WINDING

1)

The wound bobbin thread should

stud nut (A) ofbobbin winder tension bracket.

Note: nylon or polyester thread should

deform

2) When the wound thread layer does not present a cylindrical shape

of

bobbin winder tension bracket and slide bracket (C)

(B)

leftward or rightward.

(b), move the bracket rightward,

shown

in

Fig.9 (c), move the bracket leftward.

After adequately positioning the bracket, tighten set

screw (B).

3)

Do

not overfill the bobbin. The optimum length

thread will fill about 80%

adjusted by adjusting screw (E)

latch.

11.

REPLACE

Turn the balance wheel

While keeping the long groove

ADJUSTMENT

be

If

thread

is

wound

but

of

bobbin capacity. This can be

NEEDLES

to

lift needle bar

of

the needle leftward fully insert the needle shank up

as

if

thread

of

bobbin winder stop

(Fig.10)

(Fig.9)

neat and tight

be

wound with little tension; otherwise, bobbin (D) might break or

shown in Fig.9

is

wound

to

the upper end

if

as

of

not, adjust the winding tension by turning tension

as

shown in Fig.9 (a), loosen set screw

10

A

of

the needle

c

Long

a

groove

of

its stroke. Loosen needle clamp screw (A).

b

to

the bottom

-5-

socket.

perform threading

balance wheel to lower

bobbin thread

Then tighten needle clamp screw (A).

Fig.

Note:

12.

THREADING (Fig.ll)

To

thread the needle thread, raise needle

(b): insufficient

Fig.

(c):

wrong

as

is

drawn

shown in Fig.3. To draw the

the

up.

insertion.

direction

needle bar and then to lift it to its highest position. Pull the needle thread and the

Put the ends

r·

oflong

of

groove.

bar

to the upper end

bobb.in

needle thread

of

its stroke, lead the thread from spool and

thread, hold the end

and

bobbin thread frontward under presser foot

of

the needle thread and turn the

12

Push

lever

Stitoh

adjusting

13.

SET STITCH LENGTH AND REVERSE FEEDING (Fig.12)

1)

To

change the stitch length, rotate the stitch length adjusting dial while pressing the push lever.

2)

Pressing the reverse lever to reverse stitching.

3) The button switch

4)

Normally, set the button switch

switch.

can be pressed to perforin reverse stitching.

as

illustrated by the solid lines.

·

le~~~''''

:~ahl

To

reverse stitching. press the button

i

''"''

~

14.

ADJUSTING

THE

THREAD TENSION (Fig.l3)

0 X X 13

.?%&

Well

st i toh

;#'

balanced

~

The upper

too

tight

thread

thread

or

is

too I oose

I ower

?*

-&::~

is

The

upper

too I oose

thread

is

thread

or

too

-6-

is

I ower

tight

-

··-

15.

UPPER

THREAD TENSION (Fig.14)

1) The upper thread can

2).Adjustment can

the desired tension can

16.

LOWER

be

adjusted based on the lower .thread tension.

be

done

by

rotating the thread tension nut. For special fabric sewing with special thread,

be

obtained

by

adjusting the strength and operating range

THREAD TENSION

(Fig.15)

.

I)

The lower thread tension can

rotating screw A

17. ADJUSTMENT

OF

be

FEED DOG

INCLINATION (Fig.16)

The feed

(horizontally).

1) Slightly loosen screw

rock shaft crank.

Using a screwdriver. While pressing the

2)

groove located in the eccentric

using a screwdriver, rotate the eccentric

shaft clockwise

coliD.ter-clockwise (to lower the rear end).

3) When adjustment is completed, tighten

screw A

dog·

has been set

If

necessary, adjust the inclination jiccording

to

A located in the feed

(to lift the front end) or

I

14

t~nsion

nut

adjusted by

standard

shaft

by

Position of mark on

eccentric shaft

®-

Horizontal

€D'

8)1

to

the material

Eccentnc

to

shaft

of

thread take-up spring.

the

MrNy,f.

as

follows:

~

~

Up

Down

be

sewn

Feed dog

Frontdown

Standard

Front up

(MAX.l

(MAX.)

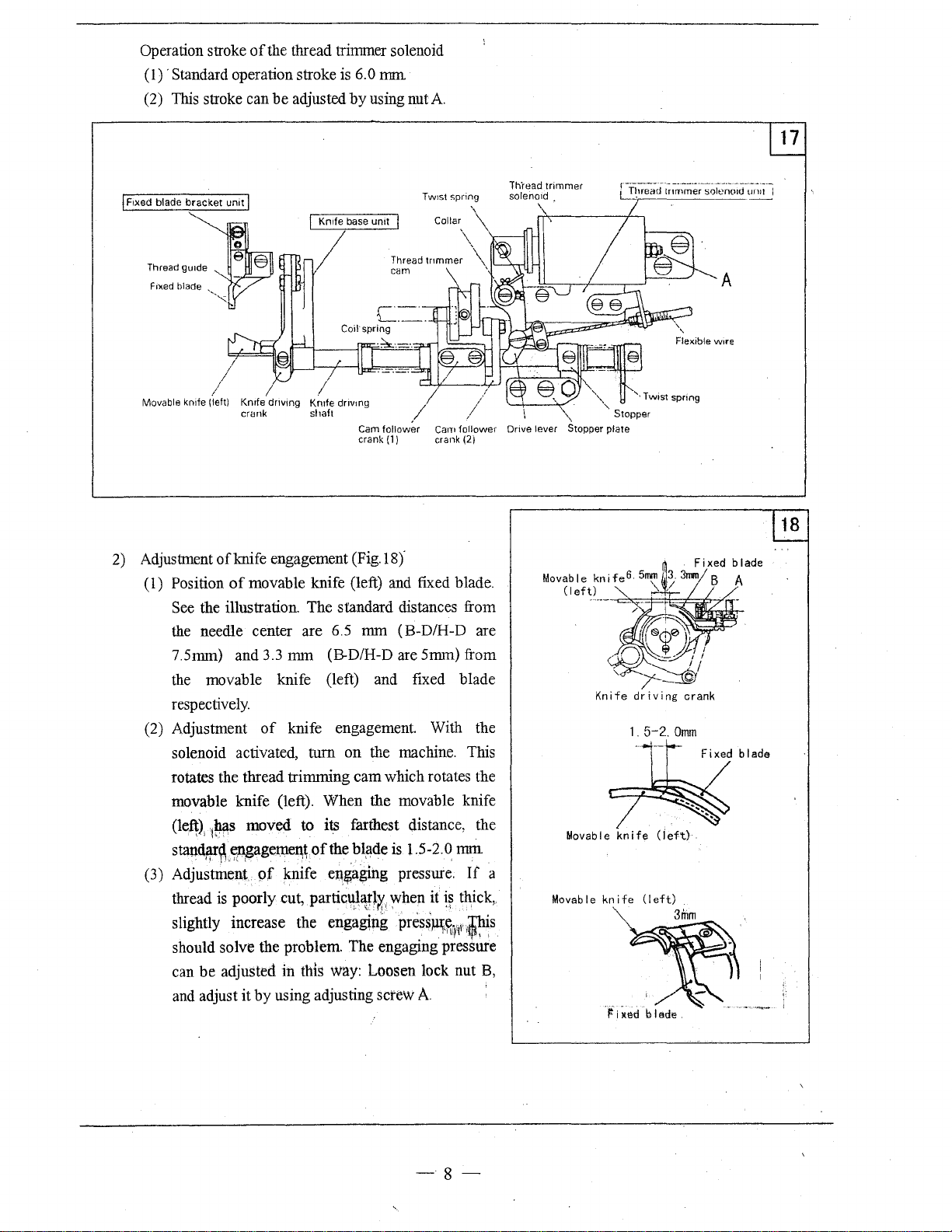

18. ADJUSTMENT

TRIMMER

1)

Thread trinnner mechanism as shown

MECHANISM

OF

THREAD

Fig.

I 7

·-7-

Operation stroke

(1)

·Standard operation stroke is 6.0

(2)

This

of

the thread trimmer solenoid

stroke can be adjusted

I Knrfe base

mm

by

using nut A

unit

r---

-----~--

-----------

------

Thread

trimmer

spring

Twrst

Collar

I

solenord

t_!~uead

tnrnrner

solenoid

--·-----~

-~.!_.1

Thread

glllde

Frxed blade

Movable knife (left)

2)

Adjustment

(

1)

'•,,,

/

/

Knrfe

crank

of

knife engagement (Fig.18)'

Position

See

the

of

the illustration. The standard distances from

needle center are 6.5 mm (B-D/H-D are

7.5mm) and

the

movable knife (left) and fixed blade

respectively.

(2) Adjustment

solenoid activated, turn on the machine. This

rotates the thread trimming cam which rotates the

movable knife (left). When the movable knife

(leff),

p.ts

1

standf!.r~,~gagerne~\

(3) Adjustment of knife

thread

is

poorly cut, partict¥¥lX,

slightly increase the engaging

should solve the problem. The engaging pressure

can be adjusted in this

and

adjust it by using adjusting screw A

I

driving

I

Krnfe

shaft

dr~vmg

cam

Cam

crank (1) crank (2)

,/

follower

Cam

follower

movable knife (left) and fixed blade.

3.3

mm (B-D/H-D are 5mm) from

of

knife engagement. With the

moved to

i~

farthest distance, the

of

the bliide is 1.5-2.0

e~~aging

pressure.

~hen

press~~~f

way:

Loosen lock nut

it

i~

mill

If

thick,

,ir,is

11

Drive lever Stopper

a

B,

'\

Movab

Movable

',,

I e

Stopper

"

plate

knife

knife

'·Twist

1.

5-2.

( i

spring

Omm

eft)

Flexible

Fixed blade

A

w~re

-8-

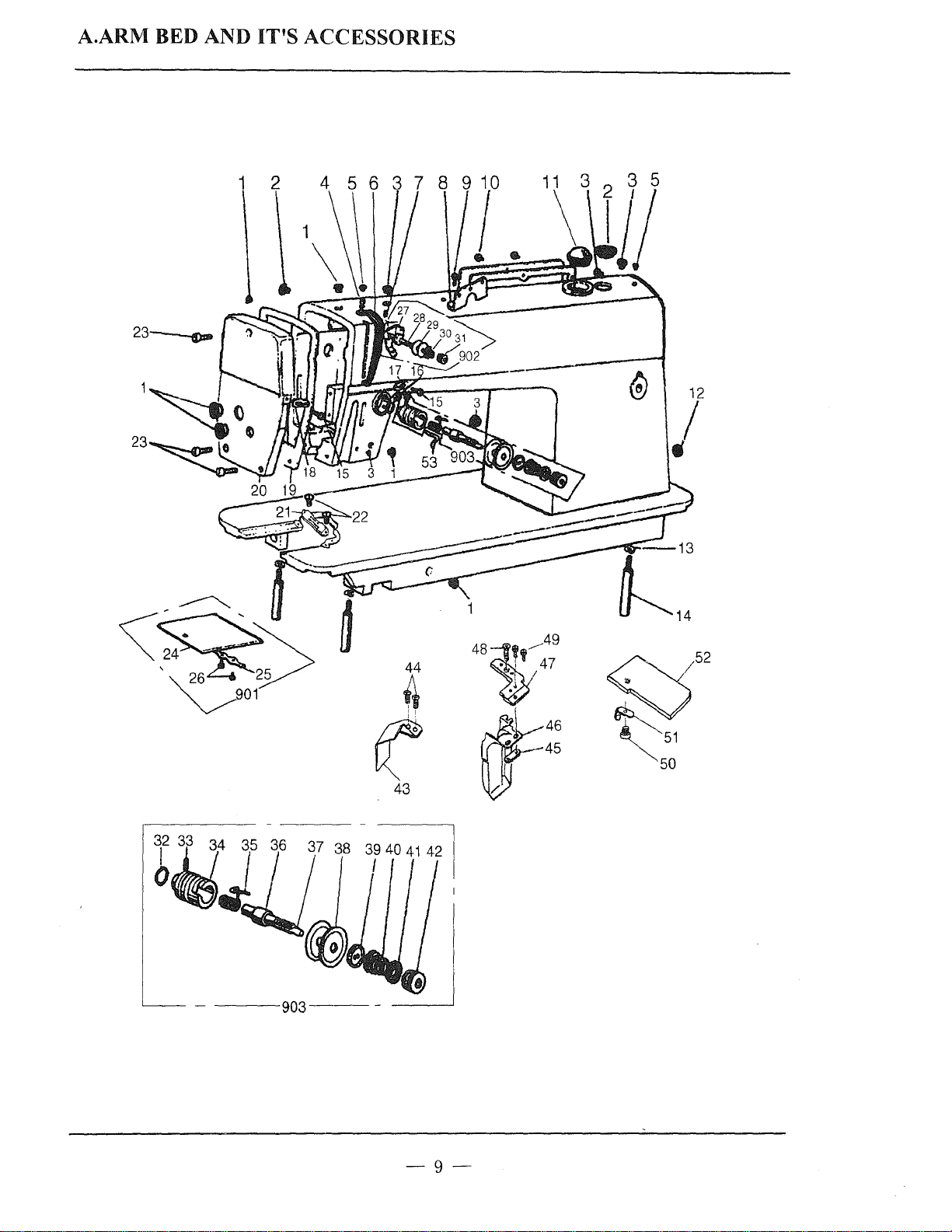

A.ARM BED AND

1 2

23~

IT'S

ACCESSORIES

12

/

44

4

~

43

<f;j52

~51

50

-9-

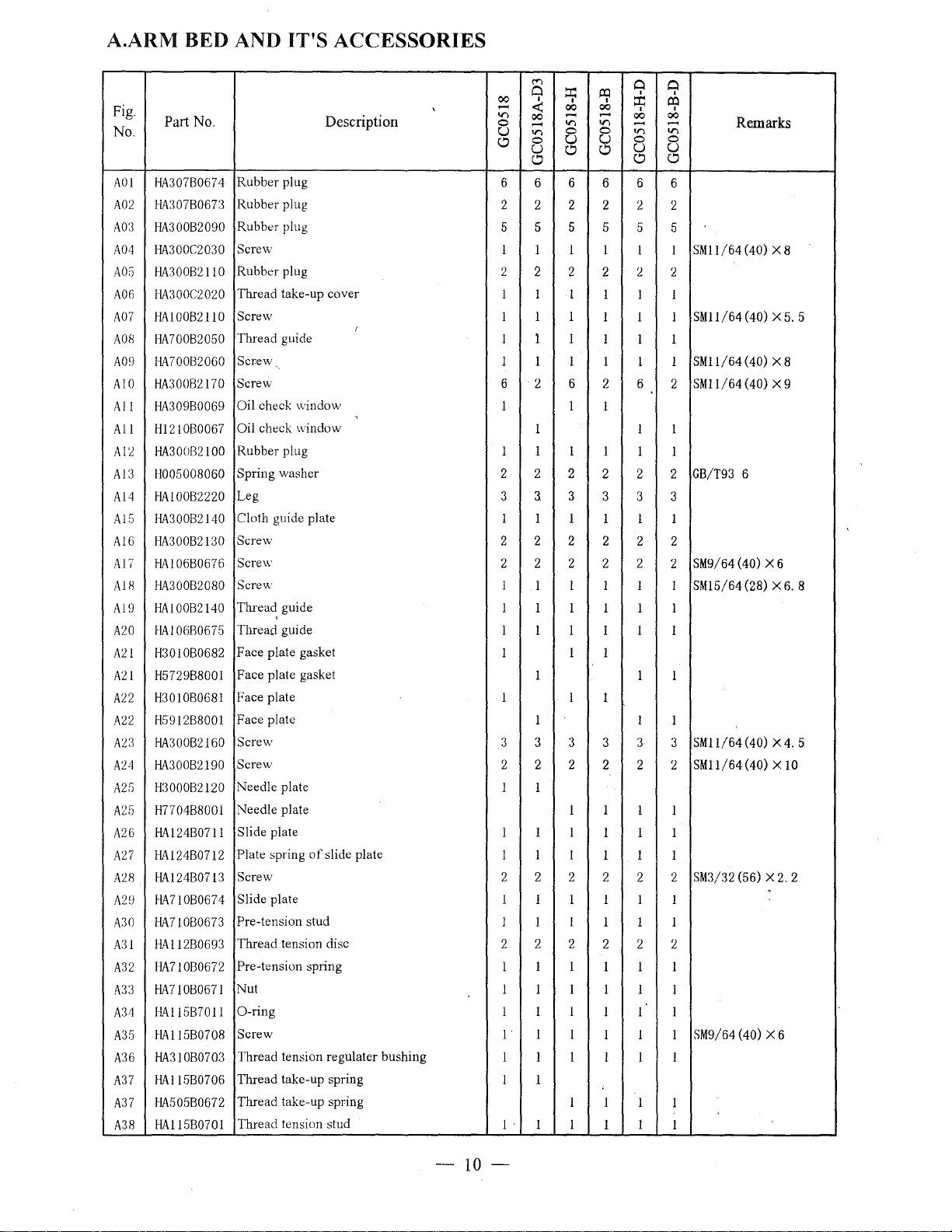

A.ARM BED AND

IT'S

ACCESSORIES

Fig.

No.

AOI

A02

A03

A04

A05

A06

A07

A

Oil

A09

AIO

All

All

A12

A13

A14

Al5

Al6

A17

A11l

Al9

A20

A21

A21

A22

A22

A23

A24

A25

A25

A26

A27

A28

A29

A30

A31

A32

A33

A34

A35

A36

A37

A37

A38

Part

No.

HA307B0674

HA307B0673

HA300B2090

HA300C2030

HA300B2110

HA300C2020

HAIOOB2110

HA70082050

HA700B2060

HA300B2170

HA30980069

Hl2IOB0067

HA300B2100

H005008060

HAIOOB2220

HA300B2140

HA300B2130

HAI06B0676

HA300B2080

HAIOOB2140

HA106B0675

H3010B0682

H5729B8001

H3010B0681

H5912B8001

HA300B2160

HA300B2190

H3000B2120

H770488001

HA124B07!1

HA124B0712

HA124B0713

HA710B0674

HA710B0673

HAI12B0693

HA710B0672

HA710B0671

HA115B7011

HAll5B0708

HA3!0B0703

HA115B0706

HA505B0672

HA115B0701

Description

Rubber plug

Rubber plug

Rubber plug

Screw

Rubber plug

Thread take-up cover

Screw

Thread guide

Screw

Screw

Oil check window

Oil check window

Rubber plug

Spring washer

Leg

Cloth guide plate

Screw

Screw

Screw

Thread, guide

Thread guide

Face plate gasket

Face plate gasket

Face plate

Face plate

Screw

Screw

Needle plate

Needle plate

Slide plate

Plate spring

Screw

Slide plate

Pre-tension stud

Thread tension disc

Pre-tension spring

Nut

0-ring

Screw

Thread tension regulater bushing

Thread take-up spring

Thread take-up spring

Thread tension stud

of

slide plate

I

.,

('<")

0

I

'

00

V)

-

0

u

Cl

6

2 2 2 2

~

00

<t:

00

V)

-

0

V)

-

0

u

u

Cl

Cl

6 6 6 6

5 5 5 5

1 1 1 l

2 2 2 2

"

"

I 1

1 1 l

I 1 1

1 1 I

1 I I I

6 2 6 2 6

1 1

0 0

I

l.l:l

I

00

.....

V)

0

~

l.l:l

::r:

I

00

00

.....

......

V)

V)

0

0

u u

Cl

Cl

I

I

6

2 2

5 5

I I SM11/64(40)

2

1

I 1 I

1 I 1

1 1

2

1

SMI1/64

SM11/64

SMII/64

Remarks

XB

(40) X 5.

(40)

X 8

(40)

X 9

5

1 1 l

1 I I

2 2

3

3.

I

I I I 1 I

2 2 2

2 2 2 2 2

I

I I I I I SM15/64(28) X6. 8

I 1 I

2 2 2 2

3

3 3 3

2 2 2

2

GB/T93

SM9/64

6

(40)

X 6

I I I 1 l l

1 I I I 1

1

1 1 1

1

1 1

1 1

3 3 3 3 3 3

2 2 2

1

2 2

1 1

I

SM11/64

SMII/64(40) X

2

(40) X 4.

10

5

1 1

I I

1 I 1

1 1 I

2 2 2 2

I I

1 I I

1 1 I

2 2

SM3/32

(56) X 2.

2

1 1 1 1 I 1

I 1 I I 1 1

2 2 2

1 1

l l 1 1 1

l 1

l 1 I

l I I

1

1

2

2 2

l l I

1 1 1

l I l

I I

I

1

SM9/64

(40)

X 6

1 I

I .

I 1

I 1 1

1

I

I

I

-10-

Loading...

Loading...