Purchasing

Copy

Dept

HIGH

GC0388-D/GC0388

HEAVY DUTY

LOCKSTITCHER

LEAD

TOP

WITH

TRIMMER

AND

AUTOMATIC THREAD

BOTTOM

,

FEED

Instruction

Manual

Parts Catalog

SHANGHAI HUIGONG

N0.3

SEWING MACHINE FACTORY

CONTENTS

!.Instruction Manual

1,

SAFETY PRECAUTIONS

2,

PRECAUTIONS BEFORE STARTING OPERATION

3,

PRECAUTIONS

4,

SPECIFICATIONS

5,

POWER

6,

CONNECTION OF CONTROL

7,

INSTALLING THE BELT

8,

ADJUSTMENT OF NEEDLE

9,

INSTALLING THE

10,

LUBRICATION

11,

CONDITION OF OIL LUBRICATION

12,

ADJUSTMENT OF

13,

ADJUSTMENT

14,

PERIODICAL CLEANING

15,

HANDLING INSTRUCTIONS (MOTOR AND CONTROL BOX)

16,

INSTALLATION OF BELT COVER.

17,

HOW TO WIND THE

18,

HOW TO ATTACH A

19,

HOW TO ROUTE

20,

ADJUSTMENT OF STITCH LENGTH AND REVERSE SEWING

21,

ADJUSTING THE

22,

UPPER THREAD TENSION

23,

LOWER THREAD TENSION

24,

ADJUSTMENT OF PRESSER PRESSURE

25,

FEED DOG HEIGHT

26,

ADJUSTMENT OF

27,

ADJUSTMENT OF STITCH LENGTH AND FORWARD/BACKWARD

28,

PRESSER BAR LIFTER.

29,

ADJUSTMENT OF WALKING FOOT AND PRESSER FOOT

30,

ADJUSTMENT OF

31,

ADJUSTMENT OF

CABlE

FOR

.........................................................................................................

CONNECTION

KNEE

............................................................................................................

OF

....................................

OPERATING CONDITIONS

.......................................................................................

BOX

....................................................................................

.................................................................................................

BAR

STOP POSITION

LIFTER

THE

HOOK

OIL PUMP

LOWER

NEEDLE

THE

UPPER THREAD

THREAD

....................................................................................................

FEED

DOG INCLINATION

...............................................................................................

FEED

TIMING

THREAD

......................................................................................

.................................................................................

LUBRICATION

.........................................................................................

..............................................................................................

....................................................................................

THREAD

.......................................................................................

TENSION

...........................................................................................

..........................................................................................

TRIMMER MECHANISM

............................................................................

...........................................................................

.............................................................................

.........................................................................

...................................................................................

:

...........................................................

...............................................................

..................................................................

................................................................

...................................................................

...................................................................

........................................................

................................................

..............................................

......................................

.................................................

3

3

3

.4

.4

5

6

6

7

7

7

8

8

8

9

9

1 0

10

11

11

11

12

12

12

13

13

13

14

14

16

16

2.Parts Catalog

A. ARM BED AND ITS ACCESSORIES

B.

SEWING MECHANISM

C.

SEWING MECHANISM & FEED ROCK LOWER SHAFT

D.

STITCH LENGTH MECHANISM

................................................................................................

E UPPER FEED ROCK SHAFT MECHANISM

F.

UPPER FEED LIFTING

G. PRESSER FOOT MECHANISM

H.

KNIFE ACTUATING MECHANISM

ROCK

.............................................................................

.......................................................

.....................................................................................

........................................................................

SHAFT MECHANISM

.......................................................................................

..................................................................................

...........................................................

-1-

r20

.23

26

29

32

34

37

39

I. TOUCH

J.

OIL

LUBRICATION

K.

ACCESSORIES

BACK

& DETECTOR MECHANISM

MECHANISM

...........................................................................................................

.................................................................................

.....................................................................

42

.44

46

-2-

1...

Safety precautions :

1 ) When turning the power on, keep your hands and fingers away from the area around/under the needle and

the area around the pulley.

2)

Power must be turned

3)

Power must

machine, or when replacing.

4)

Avoid placing fingers, hairs, bars etc., near the pulley, "V" belt, bobbin winder pulley, or motor when

the machine is in operation.

5)

Do

not insert fingers into the thread take-up cover, under/around the needle, or pulley when the machine

in operation.

6)

If

a belt cover, finger guard, eye guard are installed,

devices.

2

...

Precautions before

I)

Never operate the machine before filling the machine's oil pan.

2)

When a new sewing machine

on.

3)

Verity the voltage and phase (single or three) with those given on the machine nameplate.

be

turned

off

when the machine is not in use, or when the operator leaves the seat.

off

when tilting the machine head, installing or removing the

do

not operate the machine without these safety

starting

is

operation:

first turned

on,

verity the rotational direction

"V"

of

the pulley with the power

belt, adjusting the

is

3....

Precautions for operating conditions:

I ) Avoid using the machine at abnormally high temperatures ( 3 5

lower) .

2)

Avoid using the machine in dusty conditions.

OC

or higher) or low temperatures ( 5

OC

or

-3-

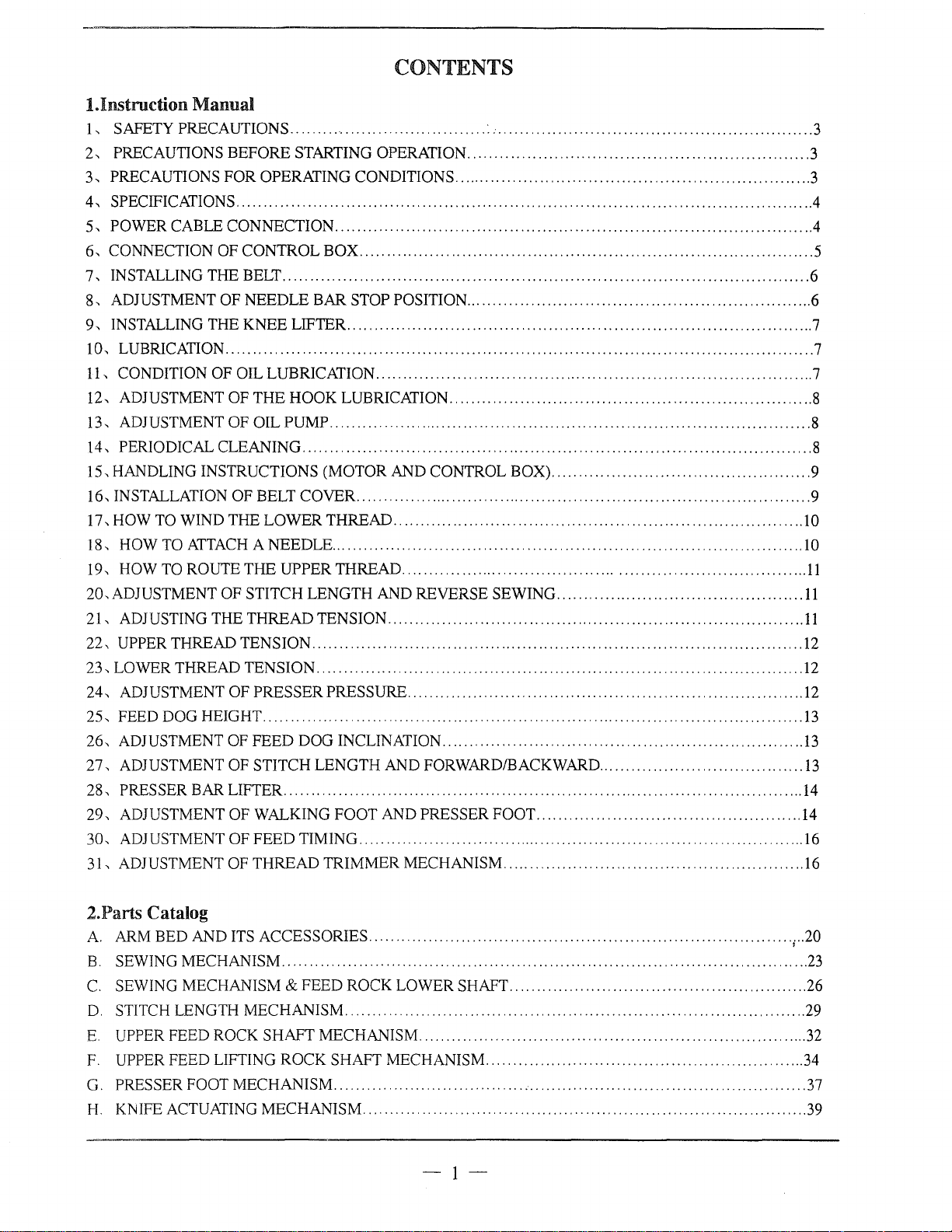

4,

Specifications:

s

Material weight Heavy

Max. sewing speed 2,000 rpm

Stitch length

Needle

Thread take-up

Alternating movement

Walking foot alternate

operating system

Feed dog height I.Omm

Needle

foot stroke

Lubrication system

Thread trimmer

Touch back

bar

stroke

Pn~sser

Hook

kver

stroke

By hand

By knee 16.0 mm

GC0388-D GC0388

0-8.0mm

38.0mm

73.0mm

2.0-5.0 mm

Dial

DPX17

6.0mm

Fully rotating Fully rotating

automatic lubrication automatic

Large Large

0

22#

lubrication, (for thread trimmer),

Automatic

X

0

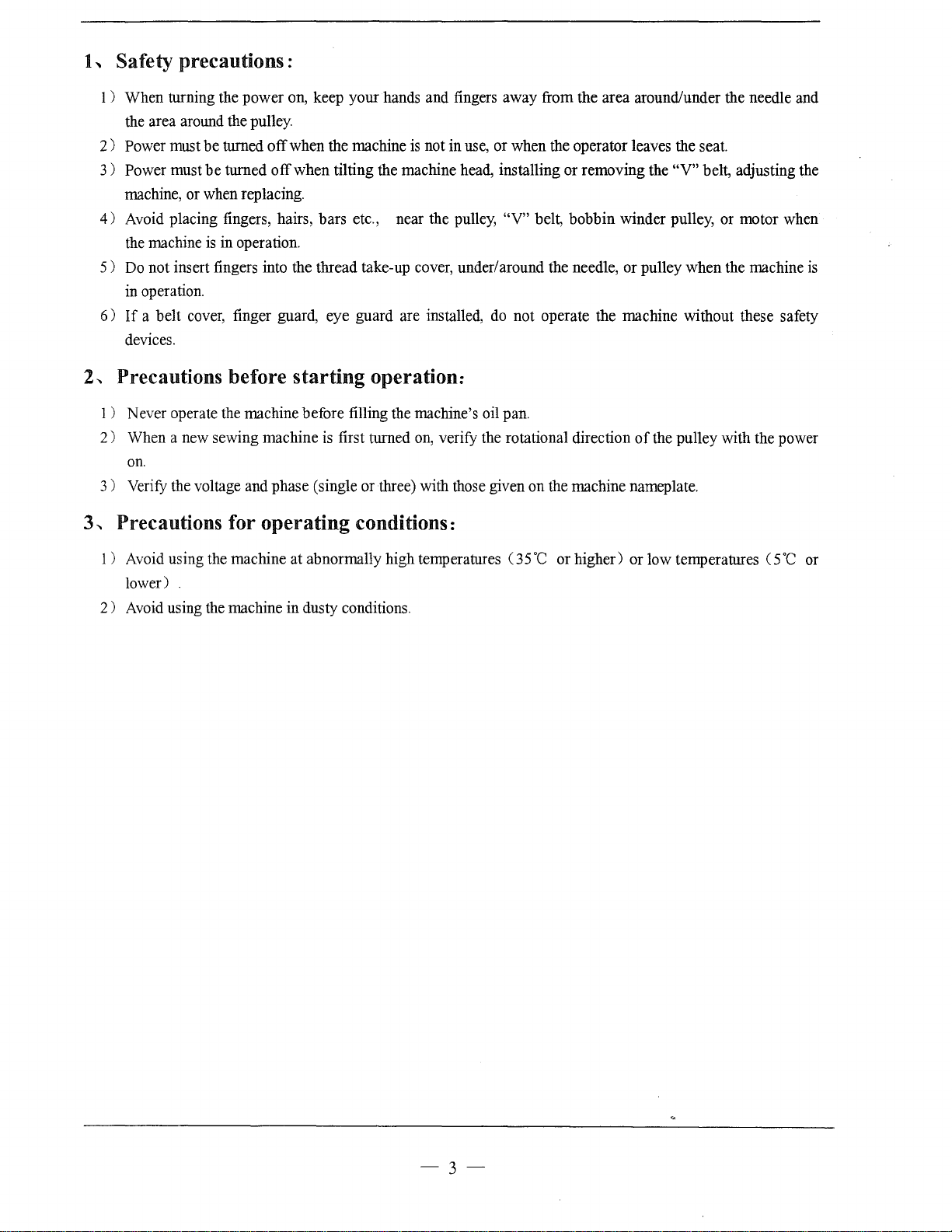

5,

Power cable connection:

1)

Connection to power supply:

Each connector(plug) should be completely set in the corresponding receptacle

checking the connector shape and mating direction.

(

1)

When a three-phase motor is used, connect

phase to the black lead. Motor rotation direction depends

Bare

wire

Lamp leads

Fig.l

''U"

phase to the red lead,

on

the intemal switch setting in the control box.

Insulating tape

(wrap 2 - 3 turns)

Lamp

leads

Fig.2.

of

the control box after

"V"

phase to the white lead,

more

"W"

-4-

Note:

The

green

wire

must

be

connected

motor.

(

2)

The appropriate power fuse capacity is as follows:

Three-phase power source:

Single-phase power source: 100-120V: 15A

2)

Lamp leads

(

1)

When installing a work lamp

control box, strip the wire and connect them appropriately insulating the connections using insulating tape.

Note:

The

power

(

2)

When a work lamp is not used, the lamp lead ends must

that the two leads do not shortcircuit.

Note:

The

work

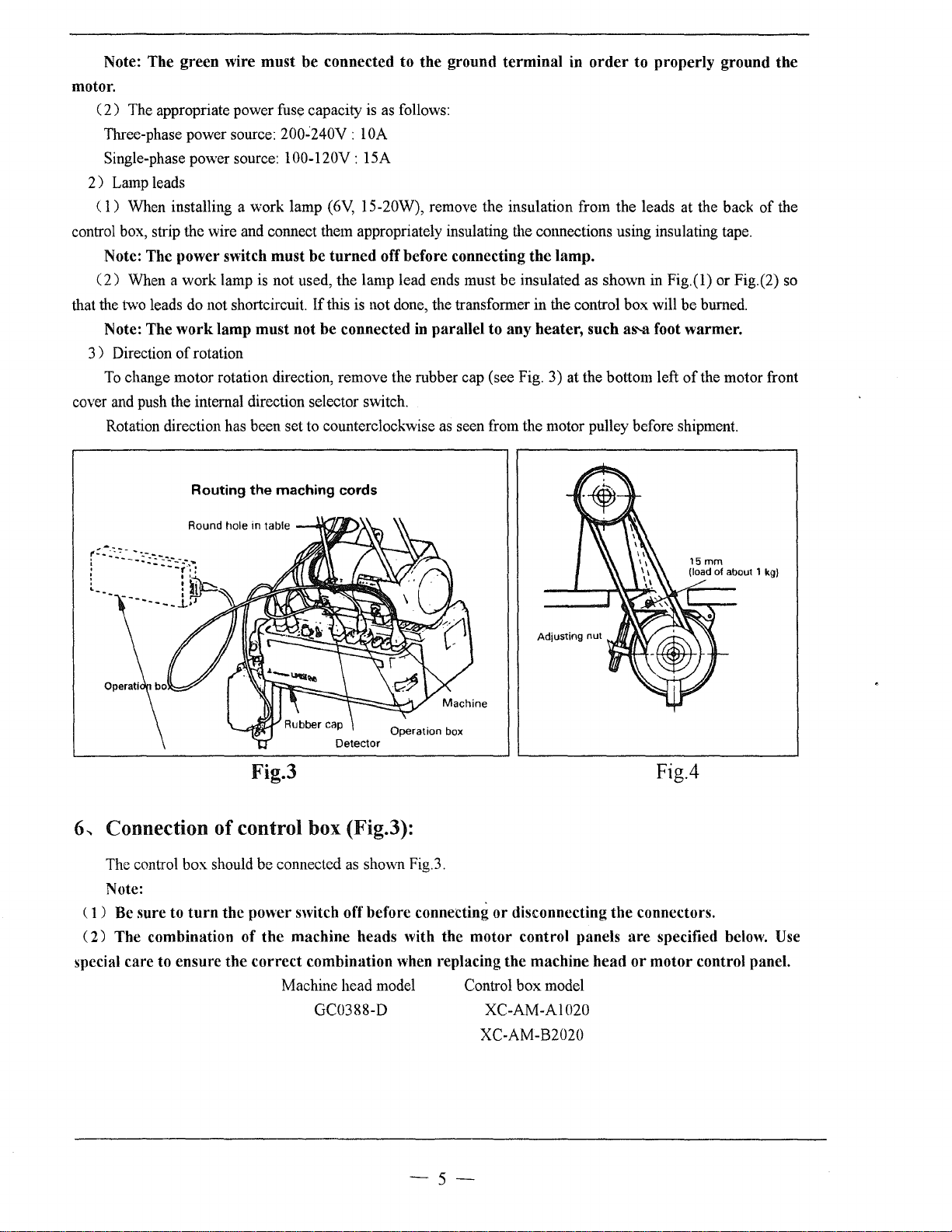

3 ) Direction

To

change motor rotation direction, remove the rubber cap (see Fig. 3) at the bottom left

cover and push the internal direction selector switch.

Rotation direction has been set to counterclockwise as seen from the motor pulley before shipment.

of

switch

lamp

rotation

200~240V

(6V,

must

be

turned

If

this is not done, the transformer in the control box will

must

not

be

: 1

connected in

to

the

ground

OA

15-20W), remove the insulation from the leads at the back

off

before

connecting

parallel

terminal

be

insulated as shown

to

any

the

lamp.

heater,

in

order

such

to

properly

in

Fig.(l) or Fig.(2) so

be

a!l"-3

foot

warmer.

of

ground

burned.

the motor front

of

the

the

Routing

Round

tlole

the

in

table

maching

cords

Fig.3

...

Connection of control box (Fig.3):

6

The control box should be connected

Note:

( 1 ) Be

(

special

sure

to

2)

The combination

care

to

ensure

turn

the

the

power

switch off

of

the

machine

correct

combination

Machine head model Control box model

GC0388-D

as

shown Fig.3.

before

heads

when replacing

connecting

with

the

or

disconnecting

motor

control

the

machine

XC-AM-Al020

XC-AM-B2020

the

panels

head

Fig.4

connectors.

are

specified below. Use

or

motor

control panel.

-5-

7

..

Installing the belt (Fig.4):

1)

Use a V-belt for sewing machine use, type

2)

To

adjust the belt tension, change the motor height by turning the tension adjust nuts so that the belt

15mm

sinks about

If the tension is too low, the speed may not be consistent in the low or medium range, or the needle

not stop in the proper position.

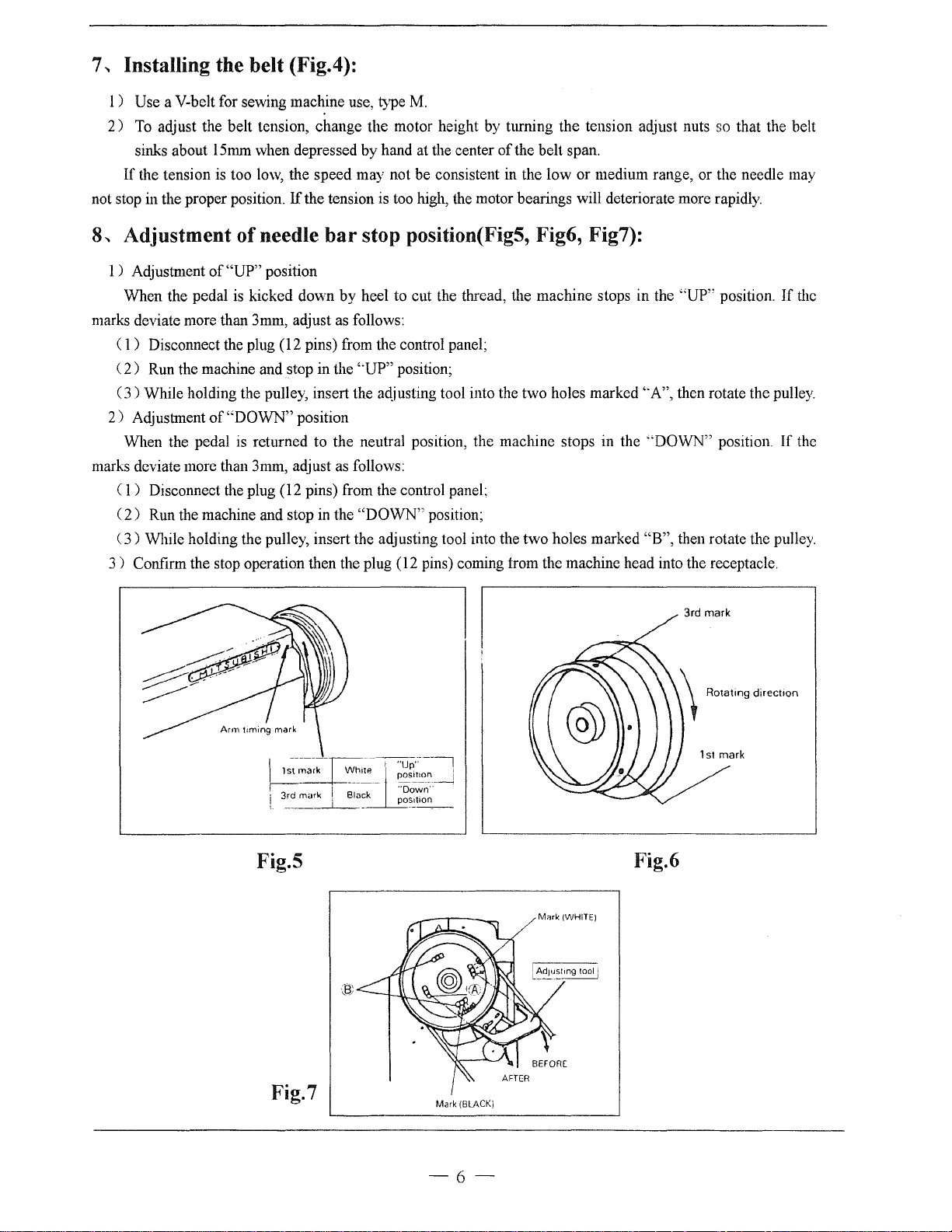

8

..

Adjustment

when depressed by hand at the center

lf

the tension is too high, the motor bearings will deteriorate more rapidly.

of

needle

bar

stop position(Fig5, Fig6, Fig7):

M.

of

the belt span.

may

1 ) Adjustment

When the pedal is kicked down

marks deviate more than 3mm, adjust

( 1 ) Disconnect the plug (12 pins) from the control panel;

2)

Run

(

(3)

While holding the pulley, insert the adjusting tool into the two holes marked '"A", then rotate the pulley.

2)

Adjustment

When the pedal is returned to the neutral position, the machine stops

marks deviate more than 3mm, adjust

1)

Disconnect the plug (12 pins) from the control panel:

(

2)

Run the machine and stop

(

3)

While holding the pulley, insert the adjusting tool into the two holes marked

(

3)

Confirm the stop operation then the plug (12 pins) coming from the machine head into the receptacle.

of

"UP"

position

by

heel to cut the thread, the machine stops in the

as

follows:

the machine and stop in the '·UP" position;

of

"DOWN"

position

as

in

the

follows:

"DOWN"

position;

"UP"

in

the "DOWN" position.

"B",

then rotate the pulley.

3rd mark

position.

If

If

the

the

I

.:

•.

:;~

I

' 1

i

3rd

marl< ,

L

_____

___l__

w.,;;_f

Black

;;;~:'

··oown··

poSition

-----

Fig.5

/Mork

(WHITE)

Fig.7

Mark (BLACK)

-6-

Fig.6

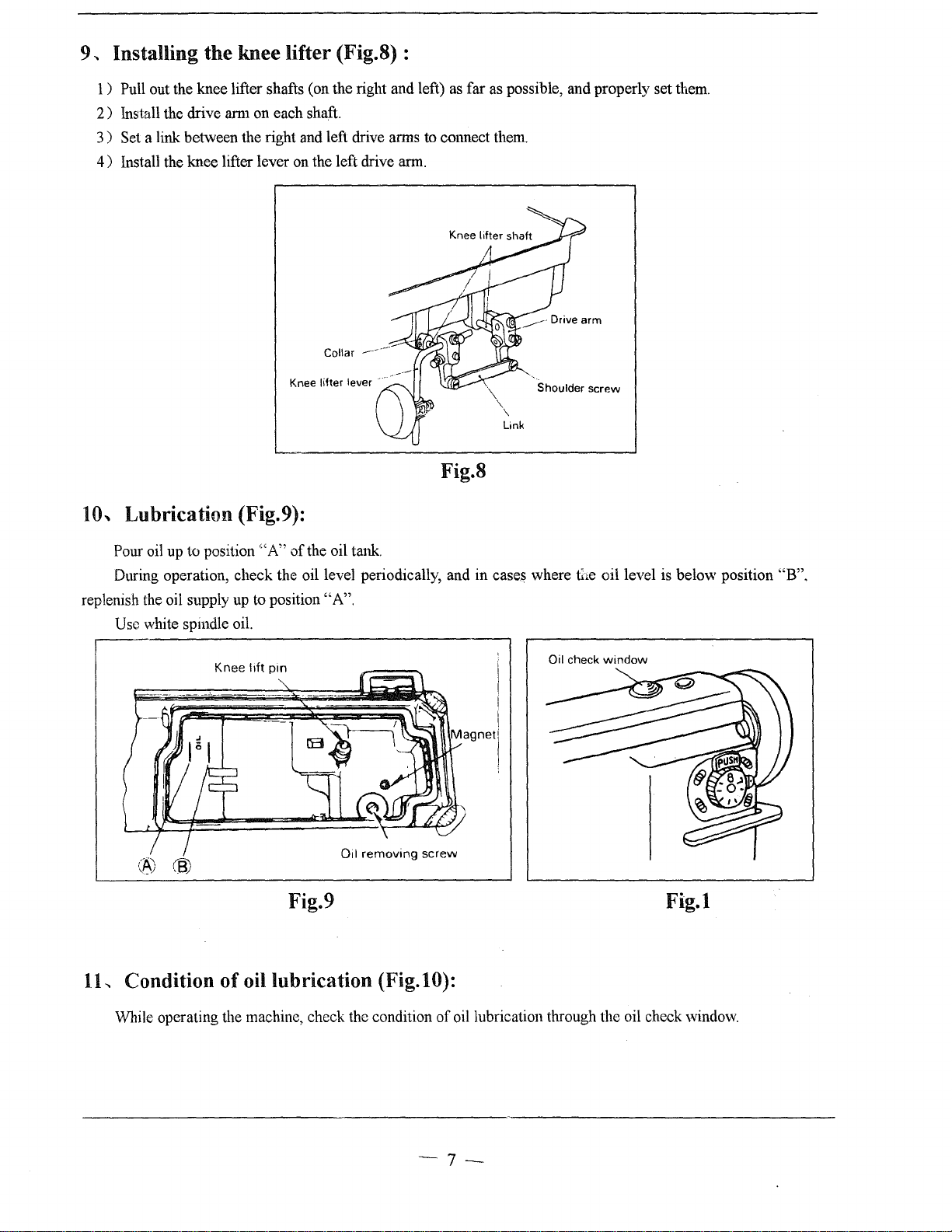

9

._

Installing the knee lifter (Fig.8) :

1)

Pull out the knee lifter shafts (on the right and left)

2)

Install the drive arm on each shaft.

3 ) Set a link between the right and left drive arms to cmmect them.

4)

Install the knee lifter lever on the left drive arm.

Collar ---··--

as

far as possible, and properly set them.

Knee lifter lever

····

Fig.8

10..

Lubrication (Fig.9):

Pour oil up to position

During operation, check the oil level periodically, and in cases where

replenish the oil supply up to position

Usc white spmdle oil.

"A"

of

the oil tank.

"A".

Shoulder screw

Link

t};e

Oil check

oil level is below position "B".

window

(~)

®

removing

screw

Oil

Fig.9

1L

Condition of oil lubrication (Fig.lO):

While operating the machine, check the condition

of

oil lubrication through the oil check window.

-7-

Fig.l

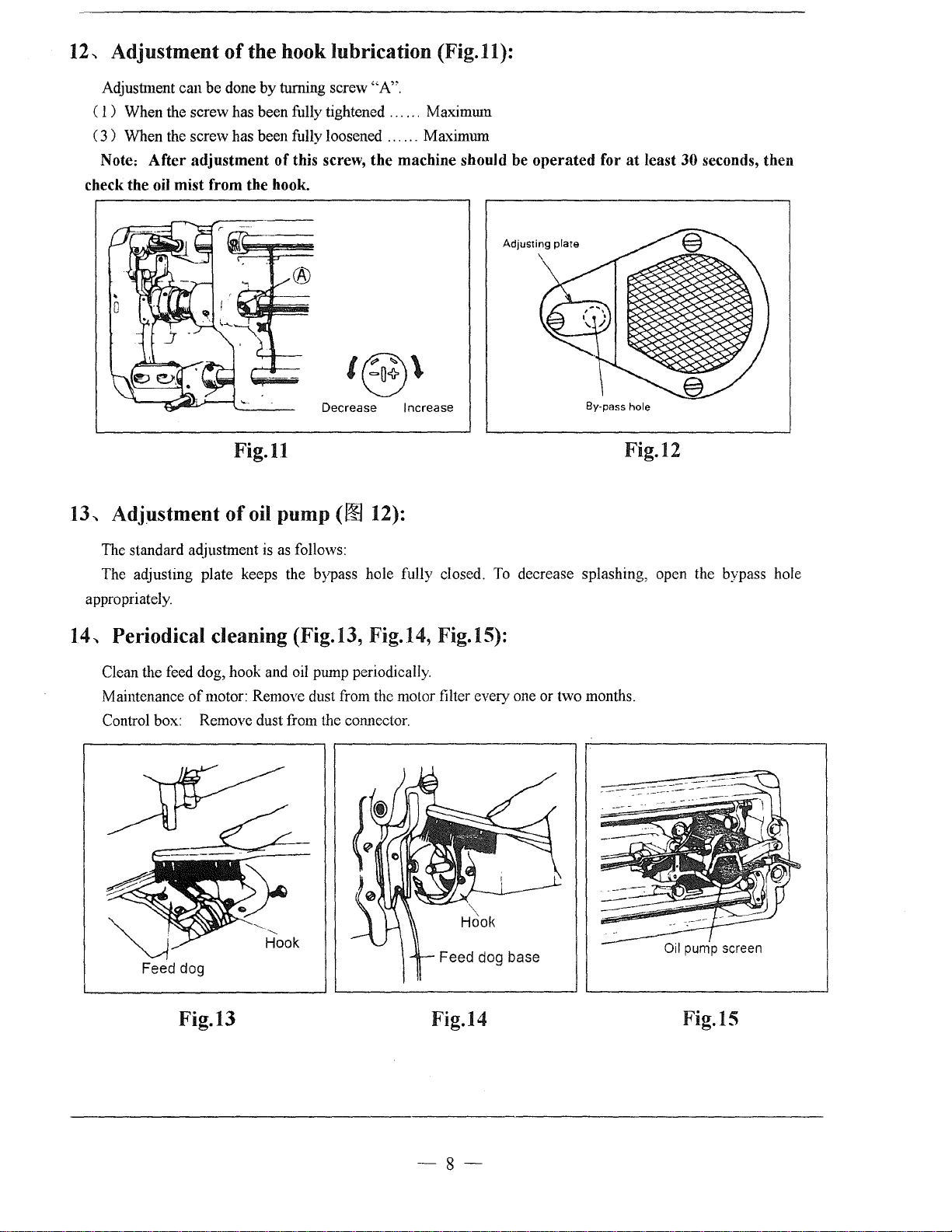

12-.

Adjustment

of

the hook lubrication (Fig.11):

Adjustment can be done

C I ) When the screw has been fully tightened . . . . . . Maximmn

3)

When the screw has been fully loosened

C

Note: After adjustment of this screw, the machine should be operated for

oil

check the

mist from the hook.

by

turning screw "A".

Decrease Increase

......

MaximUll1

Adjusting plate

Fig.11

13-.

Adjustment

of

oil pump

(00

12):

at

By·pass hole

Fig.12

least 30 seconds, then

The standard aqjustment is as follows:

The adjusting plate keeps the bypass hole fully closed.

appropriately.

14-.

Periodical

Clean the feed dog, hook and oil pmnp periodically.

Maintenance

Control box: Remove dust from the connector.

Feed

deaning

of

motor: Remoye dust from the motor filter every one or two months.

dog

(Fig.13, Fig.14, Fig.15):

"-

Hook

Hook

Feed

To

decrease splashing, open the bypass hole

dog

base

Fig.13 Fig.14

-8-

Fig.15

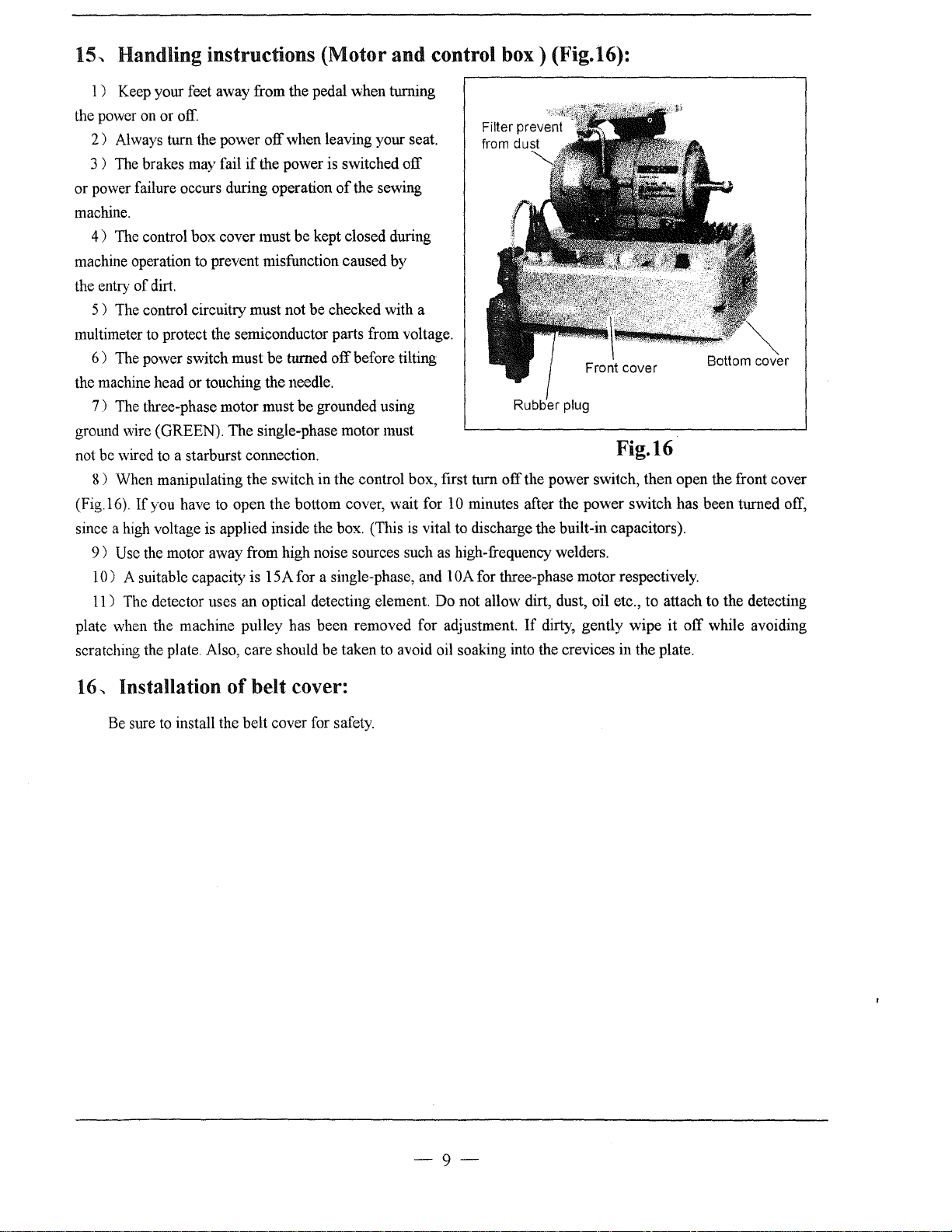

15-.

Handling instructions (Motor and control

1 ) Keep your feet away from the pedal when turning

the power on or off.

2)

Always turn the power off when leaving your seat.

3 )

The

brakes may fail

or power failure occurs during operation

machine.

4)

The control box cover must be kept closed during

machine operation to prevent misfunction caused by

the entry

multimeter to protect the semiconductor parts from voltage.

the machine head or touching the needle.

ground wire (GREEN). The single-phase motor must

not be wired to a starburst com1ection.

(Fig.l6).

since a high voltage is applied inside the box. (This

plate when the machine pulley has been removed for adjustment.

scratching the plate. Also, care should

of

dirt.

5 ) The control circuitry must not

6)

The power switch must be turned off before tilting

7)

The three-phase motor must be grounded using

8 ) When manipulating the switch in the control box, first turn

If

you have to open the bottom cover, wait for

9)

Usc the motor away from high noise sources such as high-frequency welders.

10)

A suitable capacity is 15A for a single-phase, and lOA for three-phase motor respectively.

11) The detector uses an optical detecting element. Do not allow dirt, dust, oil etc., to attach to the detecting

if

the power is switched off

of

the sewing

be

checked with a

be

taken to avoid oil soaking into the crevices in the plate.

10

is

vital to discharge the built-in capacitors).

box)

(Fig.16):

Rubber plug

Fig.16

off

the power switch, then open the front cover

minutes after the power switch has been turned off,

If

dirty, gently wipe

it

off while avoiding

16...

Installation of belt cover:

Be sure

to

install the belt cover for safety.

-9-

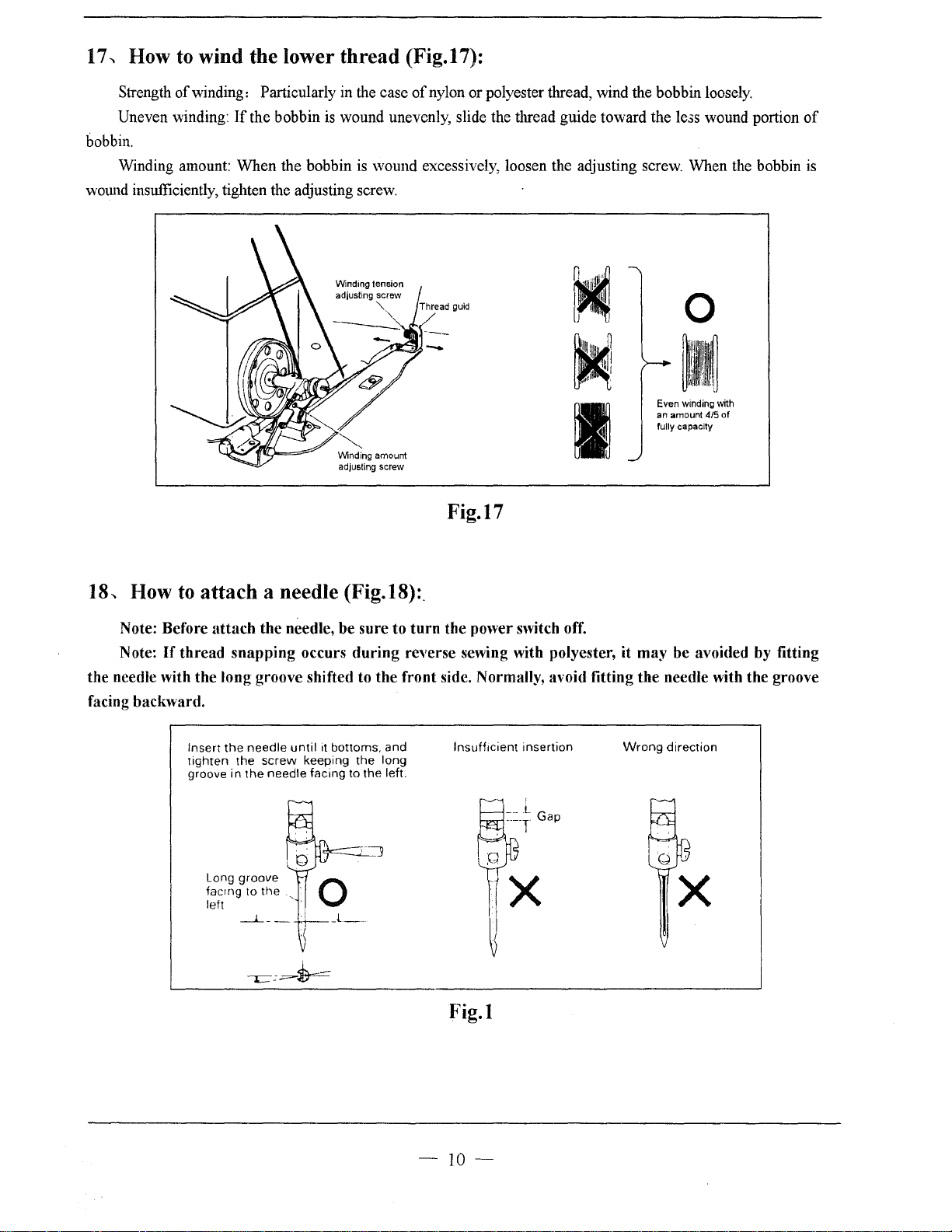

17...

How to wind the lower

thread

(Fig.17):

Strength

Uneven winding:

bobbin.

Winding amount:

wmmd insufficiently, tighten the adjusting screw.

of

winding: Particularly in the case

If

the bobbin is wound unevenly, slide the thread guide toward the le.;s wound portion

When

the bobbin is wound excessively, loosen the adjusting screw. When the bobbin

Winding tension

adjusting screw

Winding amount

adjusting screw

"-

of

nylon or polyester thread, wind the bobbin loosely.

Thread guid

0

Even winding with

an amount 4/5

fully capacity

I

Fig.17

of

is

of

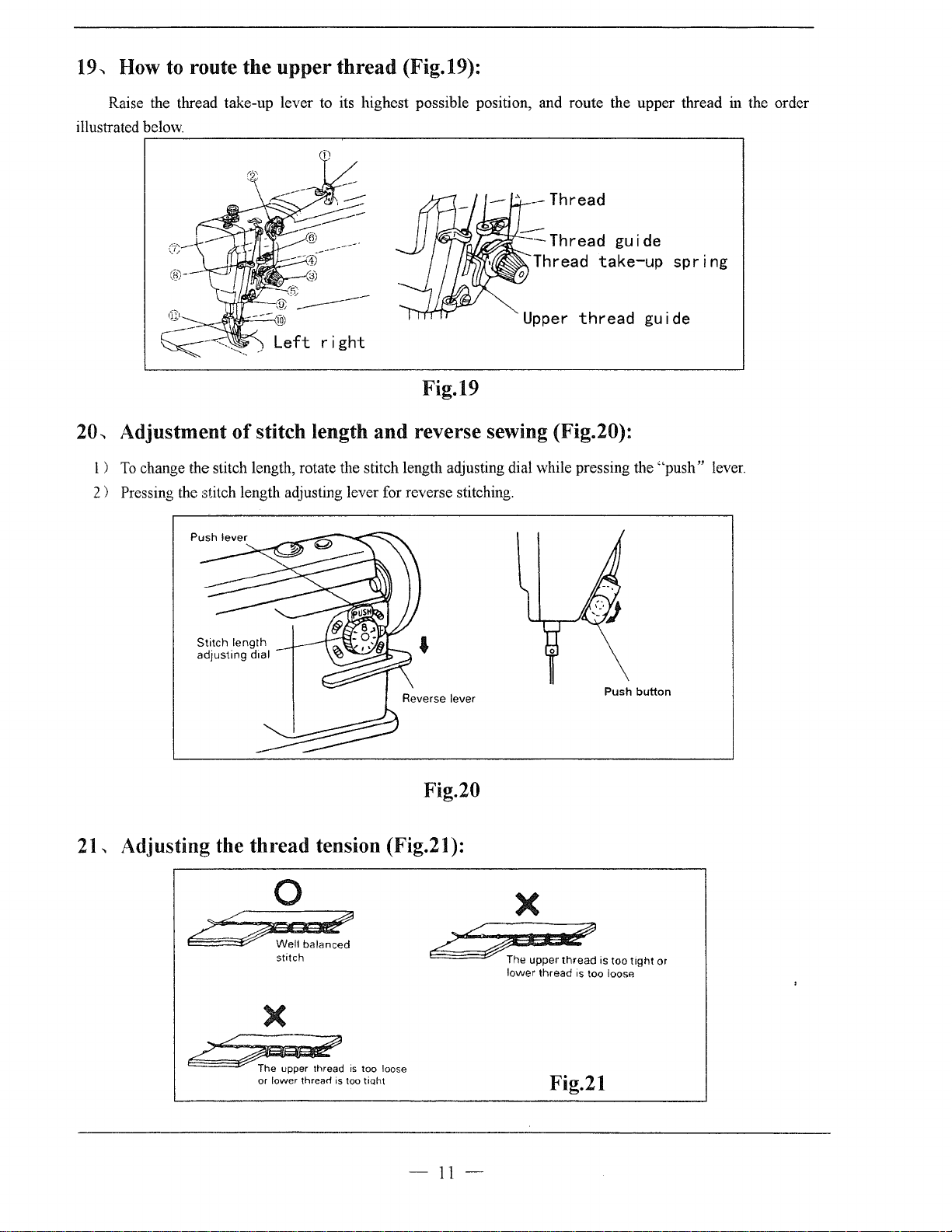

18

...

How

Note: Before attach the needle, be sure to

Note:

to

attach

If

thread snapping occurs during reverse sewing with polyester, it may be avoided by fitting

a needle (Fig.18):.

turn

the power switch off.

the needle with the long groove shifted to the front side. Normally, avoid fitting the needle with the groove

facing backward.

Insert

the

tighten

groove in

needle

the

the

Long groove

facrng to

left ·

_j_

until

screw

needle facing to the left.

the

__

it bottoms. and

keeping

,

the

long

lnsuffrcient insertion

Wrong

direction

X

Fig.l

-

10-

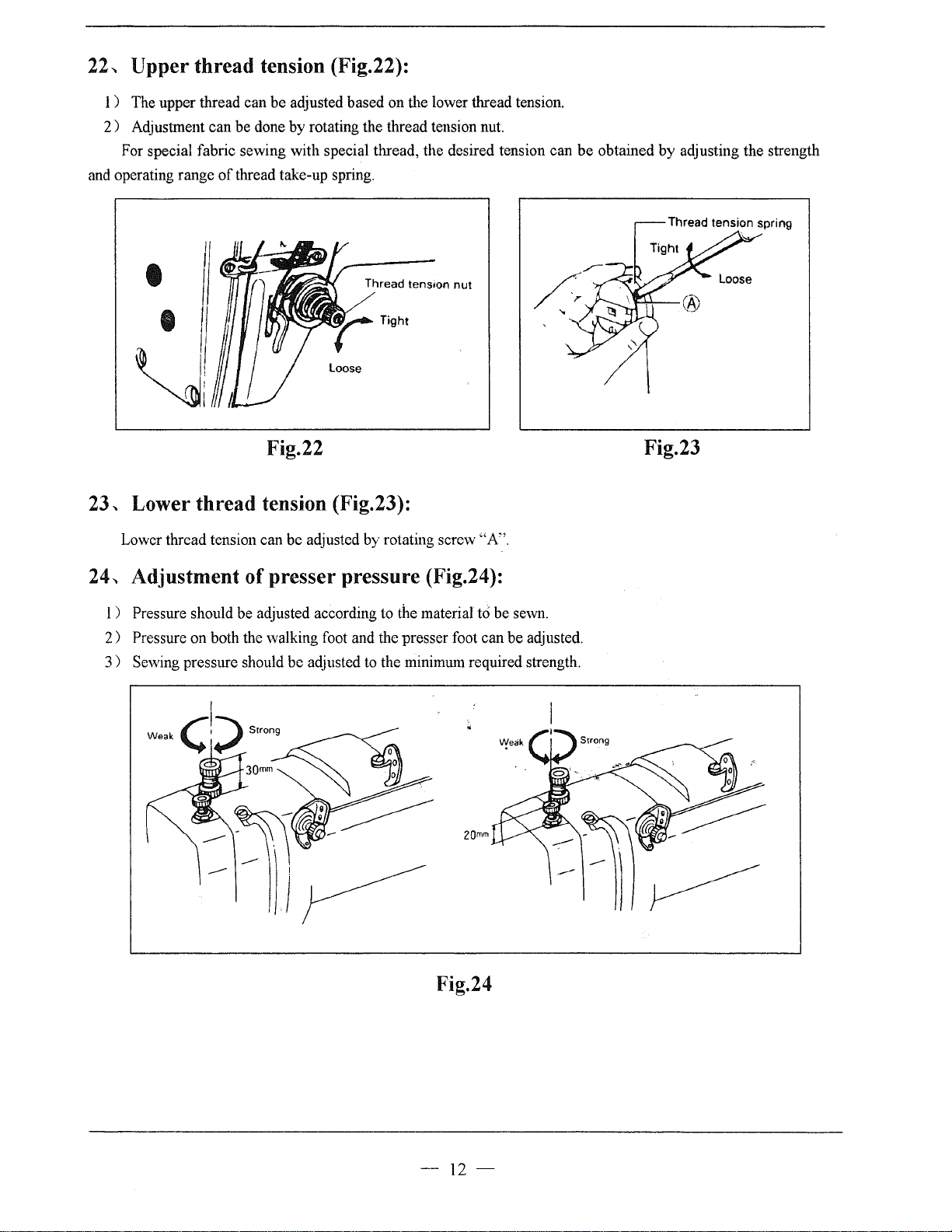

19.,

How to route the

Raise the thread take-up lever to its highest possible position, and route the upper thread in the order

illustrated below.

upper

thread

(Fig.19):

Thread

Thread guide

Thread

take-up

spring

Fig.19

20.,

Adjustment

l )

To

change the stitch length, rotate the stitch length adjusting dial while pressing the

2 ) Pressing the stitch length adjusting lever for reverse stitching.

of

Stitch

length

adjusting

stitch length

dtal

-

and

reverse sewing (Fig.20):

Upper

thread

Push button

guide

"push"

lever.

Fig.20

21.,

Adjusting the

/~

~Well

thread

0

balanced

stitch

tension (Fig.21

£/;J#!

1

):

~

X

ca~

The

upper

lower

thread

thread

X

2:2~.

he upper thread

or lower threarl

IS

is

too tioht

too loose

Fig.21

-

11-

is too

is

too

loosP.

tight

or

22

...

Upper

1 ) The upper thread can be adjusted based on the lower thread tension.

2 ) Adjustment can be done

For special fabric sewing with special thread, the desired tension can

and operating range

thread tension (Fig.22):

by

rotating the thread tension nut.

of

thread take-up spring.

be

obtained by adjusting the strength

Thread tens1on

loose

nut

Fig.22

23-.

Lower

Lower thread tension can be adjusted by rotating scre\v "A".

24

...

Adjustment of presser pressure (Fig.24):

1 ) Pressure should be adjusted according to the material to be sewn.

2)

Pressure on both the walking foot and the presser foot can be adjusted.

3)

Sewing pressure should be adjusted to the minimum required strength.

thread

tension (Fig.23):

Fig.23

2Qmm

Fig.24

-

12-

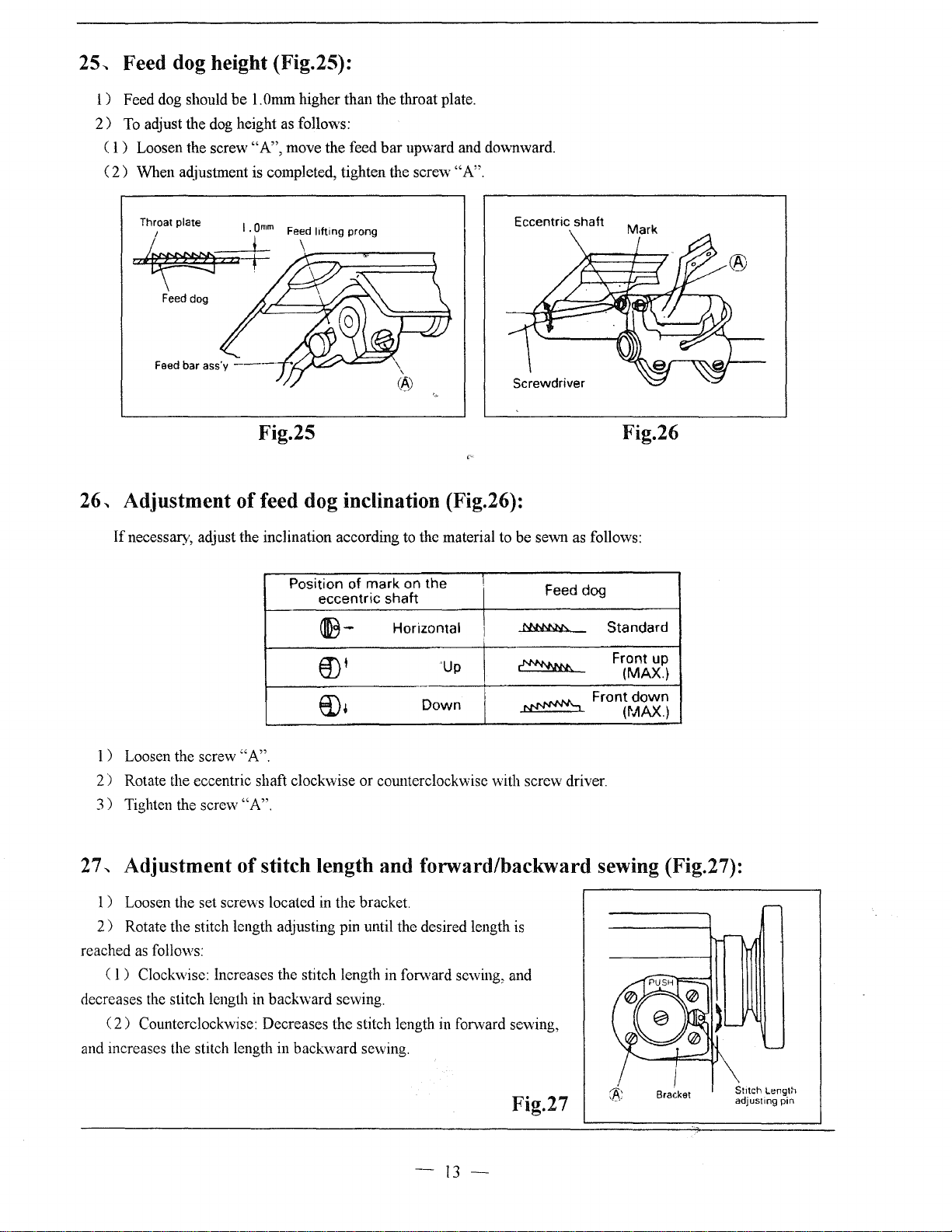

25-.

Feed dog height (Fig.25):

l)

Feed dog should

2)

To

adjust the

( 1 ) Loosen the screw

(

2)

When aqjustment is completed, tighten the screw "A".

be

l.Omm higher than the throat plate.

dog

height as follows:

"A",

move the feed

bar

upward and do""nward.

Throat plate

"~"'T

Feed dog

26" Adjustment

If

necessary, adjust the inclination according to the material to be sewn as follows:

.

Qmm

1

Feed

lifting

prong

\

Fig.25

of

feed dog inclination (Fig.26):

Position of mark on the

eccentric

~-

€D'

ED•

shaft

Horizontal

'Up

Down

Eccentric shaft

I

I

~

I

~

I

~

I

Feed dog

Front

Fig.26

Standard

Front up

(MAX.)

down

(MAX.)

1 ) Loosen the screw "A".

2 ) Rotate the eccentric shaft clockwise or counterclockwise with screw driver.

3)

Tighten the scre\v "A".

27" Adjustment of stitch length and forward/backward sewing (Fig.27):

1 ) Loosen the set screws located

2 ) Rotate the stitch length adjusting pin until the desired length

reached

decreases the stitch length in backward sewing.

and increases the stitch length in backward sewing.

as

follows:

(

l)

Clockwise: Increases the stitch length

(

2)

Counterclockwise: Decreases the stitch length in forward sewing,

in

the bracket.

in

forward sewing, and

is

Bracket

Fig.27

-

13-

'

St1tch

Lengt~l

adjusting pin

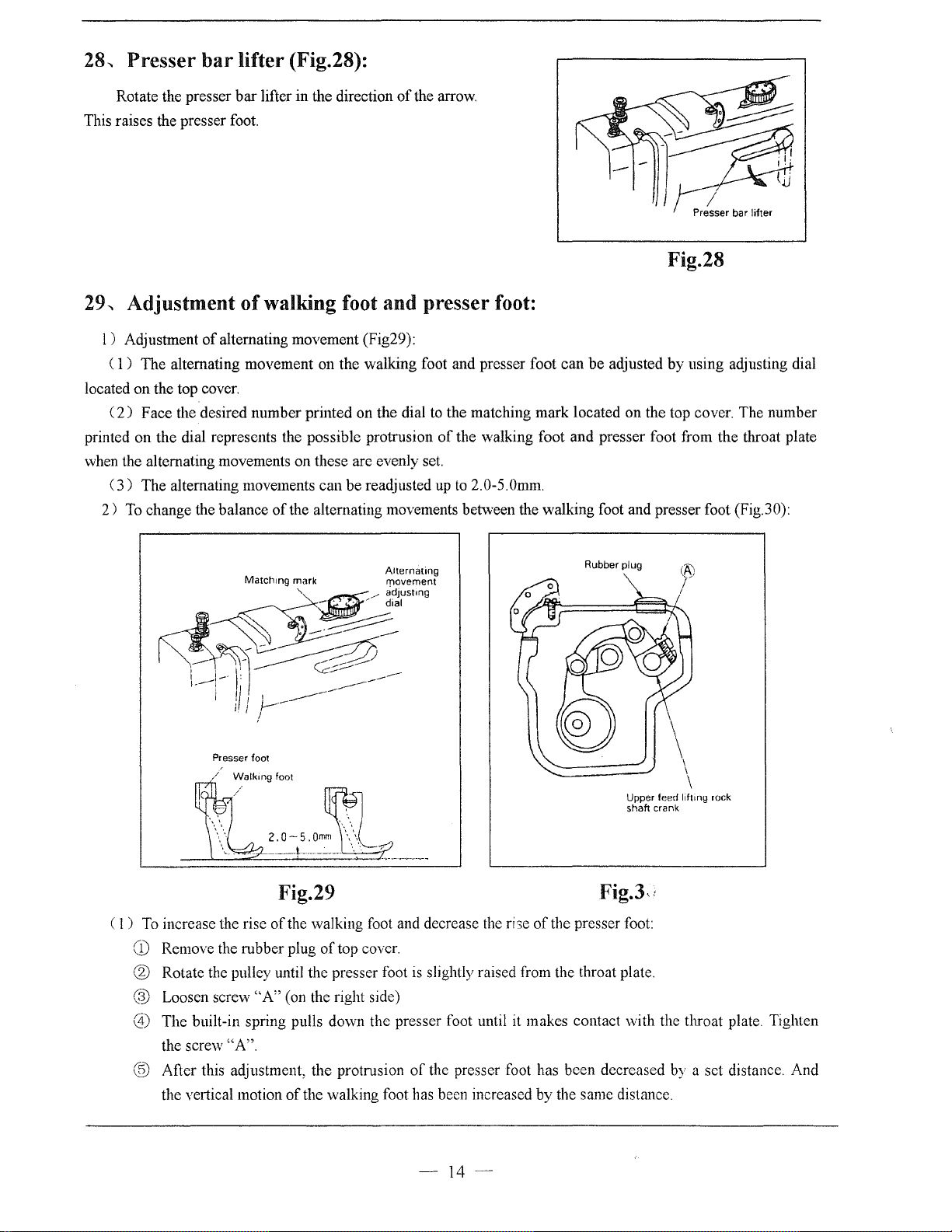

28.,

Presser

bar

lifter (Fig.28):

Rotate the presser

This raises the presser foot.

29.,

Adjustment

l)

Adjustment

( 1 ) The alternating movement on the walking foot and presser foot can

located on the top cover.

(

2)

Face the desired number printed on the dial

printed on the dial represents the possible protrusion

when the alternating movements on these arc evenly set.

(

3)

The alternating movements can

2)

To

change the balance

bar

lifter in the direction

of

walking foot and presser foot:

of

alternating movement (Fig29):

be

readjusted

of

the alternating movements between the walking foot and presser foot (Fig.30):

of

the arrow.

to

the matching mark located on the top cover. The number

of

the walking foot and presser foot from the throat plate

up

to

2.

0-5.

Omm.

Presser bar lifter

Fig.28

be

adjusted by using adjusting dial

Match1ng

mark movement

,c-,~~~'"""

~~~~~;;;b

I

.---1-

II'

I .

i ! i

~---------

1.

t I

Presser foot

~,,,,,

I •

\

'.

\\

~-~-~--~--~-

( 1 )

To

increase the rise

CD

Remove the rubber plug

® Rotate the pulley until the presser foot

® Loosen screw

0)

The built-in spring pulls down the presser foot until it makes contact

the screw "A".

@ After this adjustment, the protrusion

the vertical motion

2

0-5

Fig.29

of

the walking foot and decrease the

"A"

(on the right side)

of

--~----

]L

' \

Qmm

\\

\:·

of

top cover.

the walking foot has been increased by the same distance.

Alternating

7?_

is

of

Rubber plug

Upper feed

shah crank

liftmg

rock

Fig.J,,

ri

;e

ofthe

presser foot:

slightly raised from the throat plate.

vvith

the throat plate. Tighten

the presser foot has been decreased by a set distance. And

-

14-

C

2)

As

a contrary case ( 1) , to decrease the rise

of

the walking foot and increase the rise

follows:

Fist, rotate the pulley until the walking foot

Finally, tighten screw "A". This decreases the rise

3)

Installing the feed regulator bracket (Fig.31

Note:

If

the feed regulator bracket

is

slightly raised from the throat plate. Next, loosen screw "A".

of

the walking foot.

):

is

poorly positioned, the resultant alternating movements may be

too short or long, causing defective machine operation.

C 1 ) Set the clearance between special screw

located on the regulator stud and the side wall

machine arm to 26.5mm as Fig.31.

2)

With the feed regulator stud held as explained

(

1)

is step (

above, adjust the feed regulator bracket.

This adjustment should insure a clearance

of

pin

"B"

between the periphery

located on the feed

regulator bracket and the top cover motmting face

located on the arm. Tighten screw

"C".

of

"A"

of

the

12mm

of

presser foot

r-------------------------------------~

Feed regulator bracket

as

4)

Feed pitch adjustment

of

The ratio

the upper feed amount

to the lower feed amount

to

1:

1.

However, the walking foot feeding an10unt can be

of

walking foot (Fig.32):

(of

the \valking foot)

(of

the feed dog) has been adjusted

increased or decreased depending on the operating conditions..

Loosen the nut located on the upper feed rock shaft

of

crank (left), and shift to adjust the position

the pivot

bracket upward or downward.

Upper

position~Fecd

Lower

position~

pitch-Small

Feed

pitch-Large

Nut

Fig.31

---

Fig.32

Upper feed rock

crank (Left)

shah

-

15--

30

...

Adjustment of feed timing (Fig.33):

1 ) The standard position

feed cam and eccentric feed lifting

of

the eccentric

can1

are

illustrated to Fig.33

2)

Open the top cover,properly slide the

eccentric ring to adjust the position.

3 ) eccentric feed

by

removing the rubber plug located on the

cam can also

be

adjusted

top cover. In the latter case, however, the

built-in bevel gear is concealed; care should

be taken when adjusting.

31,

Adjustment

1)

The thread trimmer mechanism illustrated as Fig.34.

of

thread

trimmer

1

st

screw

Upper eccentric feed

lifting cam

Upper

Top cover

mechanism:

shaft

Bevel gear for

upper

Rubber

Fig.33

plug

shaft

Eccentric

feed cam

Thread guide ,

Fixed blade ,

Movable knrfe (ref!)

,,_,_

Knrfe drrvrng

crank

[_~_')I~_

y

I

I

Knrfe driving

shaft

base

unit_]

Cam follower

crank (1)

Twist spring

Colla\\

Thread trrmmer

cam

\

Cam follower

crank (2)

Fig.34

\

\\

Drive lever

L

Thread

..

------

',

, Stopper

Stopper

plate

trimmer

·-------·--------··-------··-

Flexrble wrre

Twrst sprrng

solenoid

unit

j

-16-

2)

Relation between the fixed blade and movable knife (left) edge:

C

1)

The standard position is illustrated as Fig.35.

(2)

The distance between the fixed blade and movable knife is 0.3mm.

(3)

The correct position

of

fixed blade bracket or fixed blade

®

I

r-..-----+---

(knife edge)

can

be

adjusted according to Fig.35.

0.

3mm

Movable knife (left)

1

l----11

3)

Knife driving shaft:

(

1)

The standard position is illustrated as Fig.36.

(

2)

When assembling, the knife driving shaft must first be put through the drive arm.

C

3)

Cam follower crank 1 must be positioned as illustrated

the knife driving shaft.

0

Fixed blade

bracket

unit

( 4 ) The stopper must be secured on the recess in such a

smoothly rotates in the shaft direction.

Coil

spring

Cam follower

1 Cam

crank

\

Fixed

Fig.35

follower

0

0

blade

to

the right, and secured on the recess located on

way

that the knife driving shaft

crank 2

is

snug and

Bush1ng

\ J

87.5mm

~-

-----------

Knife

shaft

driving

','\

Stopper

Fig.36

4)

Installing the thread trimmer solenoid unit (Fig.3

( I ) Operation stroke

a.

Standard operation stroke is 6.0mm.

b.

This stroke can be adjusted by using nut ''A".

( 2 ) Installing the unit:

a.

The unit can be mounted by using screws

b.

Clearance

stopper nut

c.

In

such a situation, activating the solenoid should create a clearance

of

the thread trinm1er solenoid:

of

l.Omm must be insured between the driving lever and cam follower crank 2 with

"A"

made contact with solenoid.

-

7):

"B"

17-

and "C".

of

0.5mm between cam

follower crank 1 and 2. This situation is standard. To

bracket in the direction

mm

6

5)

Installing the thread trimming

(

1)

Face the 2nd timing

(

2)

With the thread

contact with the roller. Then, secure the cam.

(3)

With the thread trimmer solenoid deactivated, allow the

position. This should create a clearance

standard.

trimmer

of

the arrow as illustrated,

cam

(Fig.38):

mark

"A"

(GREEN)

solenoid activated, rotate the thread trimmer

of

Matching

meet

this standard, slide

if

adjustment is needed.

the

®@

Cam follower

crank 2

follower

Cam

crank 1

mounting

bracket

o.smm

Fig.37

located on the pulley to the matching mark on the arm.

cam

forward until the

cam

follower crank 2 to return to its original

0.5mm-l.Omm

mark

between

A

the

cam

and roller end .This distance

\

solenoid mounting

cam

makes

is

Thread

trimmer

cam

follwer

\

\

\

0

\\

'-.....___

----~

Hook

shaft

0.

6mm

//"

Roller~----~.de

~

)Q/

crank

2/-.?~

\,

Knife

~

~

·

)!

u!

driving

0.

5-1.

cam

,~-'ljr·

·----Ju.

lht__

..

Omm

~

:

w~p

shaft

Fig.38

-

18-

6)

Adjustment

1)

Position

(

of

knife engagement (Fig.39):

of

movable knife (left) and fixed blade:

See the Fig.39, the standard distances from the needle center are 7.5mm and 5mm from the movable knife

(left) and fixed blade respectively:

of

( 2 ) Adjustment

knife engagement:

With the solenoid activated, turn on the machine. This rotates the thread trimming cam which rotates the

movable knife (left) When the movable knife (left) has

moved to its farthest distance, the standard

the blade

by

is

1.5mm-2.0mm. The engagement can be adjusted

properly mounting the drive arm.

3)

Adjustment

(

a.

If

a thread is poorly cut, particularly

of

knife engagement pressure:

engagement

w·hen

it

is

of

thick,

Movable

knife (left) 7.

' '

Smm · Smm

Fixed blade

/@

1

slightly increase the engaging pressure. This should solve the

problem.

b.

The engaging pressure can be adjusted in this way:

Loosen lock nut

"B"

and adjust it

by

using adjusting screw "A".

Knife driving crank

I

.5-2

.Qmm

Fixed blade

r;fJ

Movable

Movable knife (left)

knife (left)

Fixed blade

Fig.39

-19-

A.ARM BED AND ITS ACCESSORIES

-20-

A.ARM BED AND ITS ACCESSORIES

Fig.

No.

AOl

A02 HA300B2110 Rubber plug

A03

A04

A05 H6029B8001

A06 HA307B0673

A07 HA700F2100

A08 H6017B8001

A09 H6022B8001

AlO

All

A12 H6025B8001

A13

Al4

Al5

Al6

A17

Al8

A19

A20

A21

A22

A23

A24 HA300B2100

A25

A26 HA100B2220 Leg

A27

A28 HA710B0672

A29 HA112B0693 Thread tension disc

A30 HA710B0673 Thread tension stud

A31

A32

A33 HA600B2050 Thread guide

A34

A35

A36

A37

A38

A39 HA500C2060 Thread guide

A40 HA115B7011

A41

A42

A43

Part No.

Description

HA300B2090 Rubber plug

HA300B2170

H6028B8001

Screw

Arm side cover

Gasket for

arm

side cover

Rubber plug

Screw

Thread guide

Coil spring for upper feed lifting

H6023B8001

H431040060

Stopper pin for upper feed lifting

Set

screw

Dial for upper feed lifting

H6026B8001

HA309B0069

HAlllG0683

H6015B8001

H6016B8001

H6030B8001

H6031B8001

H6032B8001

Plate for upper feed lifting

Oil

check window

Screw

Top cover

Gasket for top cover

Rubber plug

Rubber plug

Rubber plug

H6020B8001 Upper feed lifting regulator

HA600C2020 Thread take-up cover

HA100B2110 Set screw

Rubber plug

H005008060 Spring washer

HA710B0671

Pre-tension adjusting nut

Thread tension spring

HA710B0674 Thread guide

HA106B0676 Screw

screw

HA300B2080

Set

HA300B2130 Screw

H2000B2040 Cloth guide plate

HA307B0674 Rubber plug

HA114I0674

Screw

0-ring

HA310B0703

HA806B0671

Thread tension regulator bushing

Thread take-up spring

H6037B8001 Thread releasing pin

cam

Ci

00

I

00

00

('")

00

('")

0

~

4

1

0

u

0

4

<1>

8.8

1

<1>

5.7

Remarks

4 4

1 1

1

1

3

3

<1>

11.8

1 1

SM11/64(40)x7

1 1

1

1

1

1

2 2

GB/T80M4x6

1 1

1 1

1 1

8 8

SM11/64(40)xl2

1 1

1

1

2

2

1

1

1

1

1

1

1

1

1 1

SMll/64(40)x5.5

1 1

3

3

1 1

GB/T936

3

3

SM11/64(40)

1 1

2 2

1 1

SM11/64(40)x31

1 1

2

2 SM9/64(

40)x6

1 1

1 1

2

SM15/64(28)x6.8

2 SM11/64(40)x5.5

1 1

1 1

1 1 SM9/64(40)x4.5

1 1

1 1

SIS

1 1

1 1

1 1

-21-

A.ARM BED AND ITS ACCESSORIES

Fig.

No.

A44

A4S

A46

A47

A48 HA11SB7010 Thumb nut revolution stopper

A49

ASO

• ASl

AS2 HA124B0713 Screw

AS3

AS4

ASS

AS6

AS7

ASS

AS9

A60 H6008B8001 Arm 1

A61

A61

A62

A63

A64

Part

No.

HA806B0673 Thread tension stud

HA310B070S Thread tension disc

HA310B0702 Thread tension releasing disc

H2206B0671 Thread tension spring

HA310B0701 Thumb nut

HA11SB0708

HA607B0671 Thread guide

HA124B0712

H6812B8001 Slide plate

HASOOB2030

H2000B20SO

HA700B2030

HS341B8001

H6013B8001

H6010B8001 Bed

H6406B8001 Bed

H6409B8001 Arm bed cover

H6410B8001 Gasket for

HA300B2160 Screw

Screw

Plate spring for slide plate

Needle plate

Screw

Screw

Screw

Face plate

arm

Description

bed cover

Q

00

00

(<)

0

~

1

2

1

1

1

1

1

1

2

1

1

1

2

2

1

1

1

00

00

(<)

0

Remarks

~

1 SM1/4(40)x49

2

1

1

1

1

1 SM9/64(40)x6

1

SM3/32(S6)x2.2

2

1

1

1

SM11/64(40)x8.8S

2

SM11/64(40)x20

2

1 SM11/64(40)x26

1

1

1

1

1

1

SM11/64(40)xl2

s

-22-

B.SEWING

MECHANISM

24

3 -

4

5

.1)

"'

6~

7

11

39

40

'1

43

-23-

B.SEWING MECHANISM

Fig.

No.

BOI

B02 H2009B0067 Needle

B03

B04 H6006C8001 Needle bar bushing (lower)

BOS

B06

B07

B08

B09 HA700H2040

BlO

B

BIZ HA300C2030 Screw

Bl3

Bl4

BIS

Bl6

Bl7

Bl8

Bl9

B20 H6011C8001 Upper shaft bushing (upper)

B21

B22 H6016C8001 Upper feed rock crank (left)

B23

B24

B25 HA3411D308

B26

B27

B28 HA112D3012

B29 H6020C8001

B30 H6019C8001

B31

B32

B33

B34

B35 HA113D2112 Upper shaft gear

B36 HAII3D2122 Vertical shaft gear (upper)

B37

B38

B39 H6022C8001 Vertical shaft

B40 HA600D2010 Vertical shaft bushing (lower)

B41

B42 HA113D2212

1343

Part No. Description

HA300B2090 Rubber plug

bar

bushing (upper)

H6005C8001

H2000G2020 Thread guide

H2000G2030

HA100C2170 Set

HA100C2020 Screw

HA804H0651

11

H6007C7101 Thread take-up lever assay

HA100C2200 Slide block

H2205C0661

HA307C0662 Set screw

H6023C8001 Needle bar crank

HAIOOC2060 Screw

HA705C0662

HA100C2070 Set screw

H6013C8001 Upper feed lifting cam

H6015C8001 Balance weight

HA100D2040 Upper shaft bushing (middle)

HA108G0661

HA105D0662 Screw

H6018C8001 Upper feed lifting cam (rigbt)

H6021C8001 Upper shaft bushing (right)

HA306D0066 Oil seal

HA108C0663 Screw

HAIOOD2110 Vertical shaft hushing (upper)

HA 1

(X)C2020

HA113D2222 Vertical shaft gear (lower)

HA

104DOo52 Ruhher plug

Needle bar

Needle

screw

Felt

shade cap

Oil

Needle bar connecting link guide

0-ring

Screw

Collar for upper shaft

C-type retaining ring

Crank rock

Upper feed rock crank (right)

Screw

Lower shaft gear

Q

00

I

00

00

("'")

00

("'")

0

0

~

~

1 1

1

1

1 1

1

1

1 1

1

1 1 SM1/8(44)x4.5

1

1

DPxl7

1

SM15/64(28)x10

1

1

#22

1 1

1 1

2

2 SM11/64(40)x8

1

1

1 1

2 2

SM1/4(40)x6

1 1

1

1 SM9/32(28)xl3

1

1

1

1 SM9/32(28)xl4

1

1

1

1

1

1

1 1

1 1

1 1 SM 15/64(28)x7

1 1

2 2 SM1/4(40)x4

1 1

1

1

1

1

1

20

1

1

1

1

1

8 8 SM1/4(40)x7

1 1

I I

1 1

2 2

1

SM15/o4(28)xl u

1

1 I

1 1

1 1

I I

Remarks

-24-

B.SEWING MECHANISM

Fig.

No.

B44

B45

B46

Part No.

Description

H6010C8001 Upper shaft

HA704C0653

Felt

HA7121Cl04 Oil amount adjusting pin assay

Q

I

00

00

("<")

0

~

1

1

1

00

00

("I")

0

~

1

1

1

Remarks

-25-

C.FEEDING AND FEED

3 .

~

4

LIFTING & LOWER

SHAFT MECHANISM

14

15

12 13

\~

(/

11

~

~

~

-..........

rJ

~-

25

23

48

27 28

47

r§\~/)

Y/!J--44

~

45

-26-

C.SEWING MECHANISM & FEED ROCK

Fig.

No.

COl

C02

C03 HA104G0011 Feed rock shaft crank 1 1

C04 HA104G0012 Screw

cos

C06 HA104G0654

C07 H6005D8001 Feed dog 1 1

C08 HA705J0021 Feed bar assay 1

C09 Hl204D0651

C10 HA111G0683 Screw 1 1 SM11/64(40)x12

C11

C12

C13

C14 H6012D8001 Upper feed rock shaft 1 1

Cl5

C16

C17 HA800F2020

Cl8

Cl9

C20 H6006D8001 Feed rock shaft 1 1

C21

C22 HA105D0662 Screw

C23 HA100G2040

C24 H007009150 C-type.retaining ring 1

C25

C25 HA600E2080 Bobbin case 1

C26 HA600E2060 Bobbin 1 1

C27 HA100E2150 Screw 1 1 SM11/64(40)xl0

C28

C29 H2200C2050 Rotating hook 1

C29

C30

C31

C32 HA 700E2030

C32

C33

C33 H6404D8001 Bushing for hook shaft (left) 1

C34

C35

C3G

C37

C38

C39

Part

No.

HA300C2030 Screw 1 1 SM11/64(40)x8

HA705J0654

HA104G0656

H6010D8001

HA300C2030

H6011D8001

H4722G8001 Square block 2 2

HA113F0684 Screw 1

H6008D8001 Feed rock shaft crank (right) 1 1

H6009D8001

HA105D0661

HA900E2030

H2100E2010

HAGOoE0066

HAllllE104

HA1111E204 Oil felt for hook shaft 1

HA106E0071 Oil

HA 704BOo54 Bushing for hook shaft (left) 1

HA704B0653

H6015D80lll

HA305E06o2

HA305E0661

HA311E067l

HA 1

OOC2020

Shaft for feed

Washer 1 1

Screw

Feed lifting rock shaft fork

Upper feed rock shaft 1

Screw 1 1

Connecting

Screw

Pin

Collar

Bushing for feed rock shaft

Bobbin case

Hook positioner

Rotating hook

Screw 1

Oil

Bushing for hook shaft (middle) 1 1

Hook shaft 1 1

Screw 2

Collar for hook shaft 1

Bushing for hook shaft (right)

Screw

rod

for feed rock shaft

seal

seal

Description

bar

(eccentric) 1 1

for upper feed 1 1

LOWER

Q

I

00

00

("')

0

~

2

2 2 SM1/8(44)x6

1 1

1 1

1 1

2 2

4

1

1

1 1

1

1 1

1

SHAFT

00

00

("')

0

u

0

2

1

1

1

4 SM1/4(40)x4

1

1

1

1

1

1

2

1

1

Remarks

SM3/16(28)x 12

SMll/64(

SM15/64(28)x8.5

SM

GBIT894.1

SM3/16(32)x9.7

SM15/64(28)x4.5

SM15/64(28)xl0

40)x8

15/64(28)x 13.5

15

-27-

C.SEWING MECHASISM & FEED ROCK LOWER SHAFT

0

00

oO

Fig.

No.

C40

C41

C42

C43

Part

No.

HA300E2100

Plunger

HA300E2110 Coil spring

HA300E2040

Guide plate

HA104F0654 Screw

DescriptiOn

C44 HA705K0661 Feed lifting rock shaft crank (right)

C45

HA104G0012

C46

HA100G2070 Pin

C47

H6013D8001 Feed lifting rock shaft

C48

HA!OOG2120 Bushing for feed lifting shaft

C49

HA100G2130 Washer

Screw

C50 HA710E0692 Screw

C51 HA710E0691 Thread trirmner

cam

00

(")

0

~

1

1

1

1

1

2

1

1

1

1

2

1

00

(")

0

u

0

1

1

1

SM15/64(28)x10

I

1

2 SM3116(28)xl2

1

1

1

1

SM1!4(40)xl0

Remarks

-28-

D.STITCH

REGULATOR

MECHANISM

5

\

49 '

\M

,p

\

~6

48

______.o

47 45

-29-

D.STITCH LENGTH MECHANISM

Fig.

No.

DOl

D02 HA10SD0662

D03

D04 HA100B2110 Screw

DOS

D06 H6007E8001 Bracket pin

D07 H6008E8001 Pin

DOS

D09

DlO

D11

D12

D13

D14 HA3411D308

DIS

D16

D17

D18

D19

D20 H6009E8001 Feed regulator

D21

D22

D23

D24

D2S

D26

D27

D28

D29

D30 HA720F0681 Screw

D31

D32

D33 HA7421F120 Dial

D34

D3S

D36

D37 HA113F0683 Screw

D38 HA104F06S4

D39

D40 HA100F2110 Spring washer

D41

D42 HA113F3022

D43

Part No.

HA108G0661 Collar for reverse

Screw

HA100G2040

HA100C2020 Screw

H6006E8001 Reverse bar

H4723G8001

HA300C2030 Screw

HA700B2120 Rubber plug

HA100F2040

HA704B06SS

H6012E8001 Washer

H007013040 E-type ring

H6010E8001 Link

H6013E8001

HA113F0684

H6018E8001

HC01360

H601SE8001 Bracket

HA100E21SO Screw

HA100F2090 Spring for stopper pin

HA700F2030 Stopper pin

HA113F3022

H6017E8001 Feed regulator pin

HA109F0674

HA720F0687 Coil spring

HA720F0683 Stopper pin releasing lever

H220SD0661

HA720F068S Bushing

HA720F0686

HA309F0671

H3008F0671 Feed reversing lever shaft

H6020E7101

Bushing for reverse bar

Guide plate

Pin

Bushing for feed regulator

Screw

Pin

Screw

Spring,retainer

0-ring

0-ring

0-ring

bar

Plate

for stitch length

Screw

Screw

Feed reversing lever

0-ring

Crank for feed reversing lever

Description

bar

0

00

00

00

("')

00

("')

0

0

u

d

~

1 1

2

1 1

1 1 SM11/64(40)xS.5

1

1 1

1 1

1 1

2 2

6 6 SM11/64(28)x8

1 1

1 1

1

1

2

2 2

1 1

2 2

1

1 1

1 1

1 1 GB34S2.1 36

1 1

4 4 SM11164(40)x10

1 1

1 1

1

1 1

1 1

1 1

1 1

1

1 1

1

1 1

1 1

1 1 SM3116 (28)x6

2 2

1 1

1 1

1

1 1

1 1

SM1/4(40)x4

2

SM 1S/64(28)x

1

1

1 SM1S/64(28)x7

2

GBff896

SM1S/64(28)x8.5

1

1

1

1

SM3/l6(28)x

SM1S/64(28)xl0

1

Remarks

4

18

10

.S

-30-

D.STITCH LENGTH MECHANISM

Fig.

No.

D44

D45

D46

D47

D48

D49

D50

Part No. Description

HA100F2130 Screw

H6023E8001

HA800F2010

HA800F2020 Screw 1

HA806C0675

HA806C0674

H6011E8001

Spring

Spring holder 1

Spring holder 1

Coil spring 1

Link for reserve feed

0

00

00

("')

0

~

1

1 1

1

00

00

("')

0

~

SM15/64(28)x 14.5

1

1

SM15/64(28)xl3.5

1

1

1

Remarks

-31-

E.UPPER FEED

ROCK

SHAFT

'IECHA~ISM

2

1?

15

13

21

22 23

-32-

E.TOP FEED MECHANISM

Fig.

No.

EO!

E02

E03

E04

E05

E06

E07

E08

E09

ElO

Ell

E12

E13

E14

E!5

E!6

E!7

E!8

E!9

E20

E21

E22

E23

Part

No.

H6006F8001 Upper feed rock shaft crank (left)

H6017F8001 Screw

HA!OOB2110

H6008F8001

H2013N0067

H2013J0065

H2121I0065

H6007F8001

HA!08GD66!

HA105D0662 Screw

H6018F800!

H6013F800! Upper feed rock shaft crank (right)

H2010J0066 Nut

H6014F800! Feed driver connecting rod

H2012N0066

HA3411D308 Screw

H6010F8001 Hinge pin

H6015F800! Feed connecting lever

H2004J0662 Screw

H6016F8001

H2004J0067 Screw

HA100I2050 Spring washer

H2004J066! Feed

Screw

Bushing for upper feed rock shaft crank

Nut

Washer

Feed connecting slick block

Upper feed rock shaft

Collar

0-ring

Screw

Walking foot connecting rod

arm

Description

M

I

2

2

2

1

1

1

1

1

2

1

1

1

1

1

1

I 1

1

2

1

2

2

1

H

1

2

SM15/64(28)x!8

2 SM11/64(40)x5.5

2

1 SM1/4X24

6

1

1

1

1

SM114(40)x4

2

1

1

1 SM9/32X28

1

1 SM9/32(28)x7

1

SM15/64(28)x7

1

SM114(40)x5

2

1

2

SM9/64(40)x7

2

3.5

1

Remarks

-33-

F.

UPPER FEED

3

1

LIFTING

ROCK

SHAFT MECHANISM

18

17

,.~37

38

4i

46 45

1--35

®

36

i--39

k40

1~k·

~

~

.

tt--------'42

47 44 48

-34-

F. UPPER FEED LIFTING

Fig.

No.

Part No.

ROCK

Description

SHAFT MECHANISM

Q

00

I

00

00

(")

00

(")

0

0

u

~

CJ

Remarks

H6005G8001

FOl

F02 HAIOOB2110 Screw

H6006G8001

F03

F04 H6007G8001

FOS

H6009G8001 Upper feed lifting rock crank

F06

HA800F2020

F07

H6010G8001 Upper

H6011G8001

F08

F09

H6039G8001

H6013G8001 Upper

FlO

HA7311C606 Screw

F11

H6014G8001

F12

F13

H6015G8001 Crank for upper feed lifting rock crank

Fl4

H007009100 C-type ring

F15 H6016G8001 Pin

Fl6

H6020G8001

HAIOOG2040 Bushing for upper feed shaft

F17

Fl8

H6019G8001 Upper feed regulator shaft

Fl9

H6021G8001 Spring

HA108G0661

F20

F21

HA105D0662 Screw

H2004J0662 Screw

F22

F23

H6023G8001 Link for feed lifting rock shaft

H007013060 E-type ring

F24

H6022G8001 Pin

F25

H6024G8001

F26

F27

H6027G8001 Link

H6028G8001 Pin

F28

F29 H6029G800 1 Stud screw

F30 H6030G8001 Bell crank support

F31

H6040G8001

F32

H6031G8001 Bell crank support shaft

F33

HA110D0672 Screw

HA300B2110

F34

H201010065 Thumb screw

F35

H20lOJOOo6

F3o

H0032G8001 Presser regulating bracket

F37

F38

HA300C2030 Sere\\

Ho038G800 1 Spting

F39

F40

H6034G7101

F41

H6037G8001

F42

Ho036G8001

F43 H603

3CT800

Upper

feed lifting rock shaft

Bushing for upper feed lifting rock shaft (left)

Bushing for upper feed lifting rock shaft (right)

Screw

feed lifting rock crank shaft

Link

Screw

feed regulator bracket

Shaft for upper feed lifting rock shaft

Cam follower

Collar

Bell crank

Nut

Rubber plug

Nut

Spring guide bar assay

Bushing for walking foot guide link

Walking foot guide link

1

Spring guide bar holder

I

I

4

4

SMIII64(40)x5.5

I I

I 1

1 1

1

1

SM15/64(28)xl3.5

1 1

1 1

2 2

SM11/64(40)x3.8

1 1

4 4

1 1

1

1 1

1 1

I

2 2

I I

I I

I 1

2 2

2 2 SMI/4(40)x5

I 1

2 2

I I

1 1

I 1

I

I I

1 I

I 1

I I

I

1

1 I

1 1

1

2 2

1

1 1

I I

I

1 1

SM11/64(40)x15

1

GB/T894.1

1

SMI5/64(28)x10

SMI/4(40)x4

GB/T896 6

I

SM 15/64(28)x5

SMIS/64(28)

I

SM

15/64(28)x 12

1

SM9/32(28)x35

SM9/32(28)

1

SM11/64(40)x8

1

1

10

-35-

F. UPPER FEED LIFTING ROCK SHAFT MECHANISM

Q

00

I

00

Fig.

No.

Part No. Description

00

00

(<)

0

~

(<)

0

~

Remarks

F44 H2000I2050 Screw

F45

H2000N0040

HA111G0683

F46

F47

H2000N0030

F48

H2000N0010 Walking foot

Washer

Screw

Walking foot guide bracket

3 SM9/64( 40)x8

3

2 2

2 2 SM11/64(40)x12

1 1

1 1

-36-

G.PRESSER FOOT MECHANISM

5-1

6----®

7 8

2

12

1

\

\·~u

~/

25

26

~

20~

ll\~27

~28

J '

~~

\'T814

I;\

24

16

19

-37-

G.PRESSER FOOT MECHANISM

Fig.

No.

GOI

G02

G03

G04 HA3411D308

G05 H6022H8001 Thumb screw

G06

G07

GOS

G09 H6013H8001

GlO H6017H8001 Spring

Gll

Gl2

G13

G14

GIS

Gl6

Gl7

GIS

G19

G20

G21

G22 HA305H6611

G23

G24

G25

G26

G27 HA7311CH06 Screw

G28 H2205F0651

Part No.

HA700F2100

H6023H8001

H6027H8001

HA117H0692

H6020H8001 Presser

HA107H0662 Screw

HA100H2050 Stud bolt

H6016H8001

H6009H7101

HA305E0662 Screw

H6008H8001 Spring

H6007H8001

HA300H2080

H6006H8001

H6018H8001

HA107H1013 Screw

H6014H8001 Knee lifter lever (left)

HA100H2050 Stud bolt

H6037B8001 Thread releasing pin

H6019H8001 Presser

HA704B0651 Bushing for presser

Screw

Thread guide

bar

Presser

guide bracket

Screw

Nut

bar

spring

Knee lifter rod

Knee lifter lever

bar

lifting

Presser

Presser

bar

cam

lifting shaft

0-ring

bar

Presser

lifter

Knee lifter connecting rod

Tension releasing

cam

bar

foot

Presser

Description

bar

Cl

00

I

00

00

<:'")

00

<:'")

0

u

CJ

I

0

u

CJ

SMII/64(40)x7

I

Remarks

I I

I

I

1 I SM15/64(28)x7

I

1

SM112(28)x43

1

SMl/2(28)

I

1 I

2 2

1

I

1 1

SM3116(28)x3

1

1

SM15/64(28)x5.2

.5

1 I

I

1

2 2 SM15/64(28)x4.5

I

1

I

1

1

1

1

1

1

1

1

I SM11/64(40)x6.5

I I

1

1

1 I

SM 15/64(28)x6. 7

1 1

1 1

I 1

1 1 SM9/64(40)x8

1 1

-38-

H.UPPER FEED

ROCK

SHAFT MECHANISM

-39-

H.KNIFE ACTUATING MECHANISM

Fig.

No.

Part No. Description

Q

oO

00

("')

0

~

00

00

("')

0

~

Remarks

HOI

HA712N0698

H02 HA712N6910 Flexible wire holder

H03 HA712N0699

H04 HA712N6911 Flexible wire presser

H05 HA712N6912

HA712N0695

H06

H07 HA712N0697 Trimmer lever spring

H08 HA712N0696 Spring support collar

H09 HA7311CC06 Screw

HA100E2150

HlO

HA710N0683

Hll

H2208H0068 Thread trimmer solenoid

Hl2

HA700N0080 Screw

Hl3

Hl4

HA300C2030

HIS HA708P0668

Hl6

HA7641B319

H6005J8001 Flexible wire

Hl7

HA300H2080

Hl8

H6004J7101 Flexible wire assay 1

Hl9

H003003050

H20

H21

HA712N6913

HA7121N604

H22

HA7121N704

H23

HA7121Nl04 Bracket for fixed blade

H24

H22121H204 Thread guide

H25

H26 HA7311CH06

HA7121N304 Screw

H27

H28 H22121Hl04

H29

HA704Nllll

HA7111N304 Nut

H30

H31

HA704Nlll2

H32

HA7lllN504

H33

HA7111N604 Knife driving crank

H34 HA7111N204 Screw

HA7111N404

H35

HA704Nlll4

H36

HA704Nlll3

H37

H38

H2204H0651 Movable knife (left)

H39 HA7111N704

H40 H6006J8001 Knife driving shaft

H41

HA706N0066

HA700NOOSO

H42

H43

HA700N0040 Coil spring

Thread trimmer driving lever

Stud screw

Screw

Stud screw

Screw

Nut

Screw

Cord holder

Tenninal pin

0-ring

Nut

Holder

Screw

Nut

Screw

Fixed blade

Knife holding bracket saddle

Knife base (left)

Nut

Link

Screw

Thrust washer 1

Screw

Cam

follower crank assay

Bushing

1

1

1 SM11/64(40)x8

1

2 SM1/8(44)x7

1

1

1

2

1

1

1

4

7

1

2

1

1

2

1

1

1

1

1

1

1

1

1

2

1

1

1

2 SM11/64(40)x6.2

1

3

1

2 SM11/64(40)x7

1

1

1

1

SM9/64(40)x8.5

SM11/64(40)xl0

SM15/64(28)xl2

SMll/64(

GB/T6171

SM9/64(40)x8.5

SM9/64(40)

SM9/64(40)x8

SM9/64(40)x5

SM1/8(44)x6

40)x8

MS

-40-

H.KNIFE ACTUATING MECHANISM

Fig.

No.

H44 HA710N0682 Lever stopper plate

H45 HA113F0684

H46

H47

H48

H49 HA715N0071 Collar

HSO

Part No. Description

Screw

HA709N0671 Stopper

HA700NOIIO Coil spring

HA105D0662 Screw

HA7411NIIO

Screw

Q

ob

00

<:')

0

~

1

1

1

l

1

1

1

00

00

<:')

0

~

~·

SM

15/64(28)x 11.3

SM1/4(40)x4

SM15/64(28)x23

Remarks

-

~

-41-

I. TOUCH BACK &

DETECTOR

MECHANISM

-42-

I. TOUCH BACK &

Fig.

No.

IOl

!02

!03

104

!05

106

!07 H2205I0661

!08

!09

no

Ill

Il2

Il3

I14

I15

ll6

Il7

Il8

I19

120

121

122

123

124

I25

126

I27

128

129

130

131

132

I33

134

I35

I3o

137

138

138

Part No.

HA300B2160 Screw

H6005K8001

HA7221P508 Screw

HA70400657 Rubber plug

HA70400659 Screw

HA70400654

H6006K7101

HA7641B319

HA70400021 Push button

H007013030

HA70400065 Spring

HA70406510

HA70400655

HA70400658 Insulator set

HA705Q0065

HA708P0668 Cord holder

H6009K8001

H2006I0672

H6010K8001

HA300C2030

H6011K8001

H007013040

HA712N0692 Pin

H 60 12K800 1

H2204G0652 Rubber ring

HA 703R0065

HA703R0067 Washer

HA 703R006o Detector bracket suppmter

HAII1G0683

HA 700R0060 Washer

HA 700R0050 Supporter spring

HA 700R0040

HA 700R0020 Speed command

HA700R0030 Spacer A 2

HA

700ROO

HAllODOo72

H2204I0651 Pulley 1

H2000C2040

Bracket

Spring plate

Bracket for touch switch

Vinyl cap-tire cable for touch switch

Terminal pin (male)

E-type ring

Screw

Micro switch

Ground wire

Solenoid assay for touch back

Gasket

Arm side cover

Screw

Gasket

E-type ring

Stud screw

Detector bracket assay

C-type ring

Spacer

Speed comrmmd disc (down)

10

Screw

Pulley

DETECTOR

Description

B

elise

(up)

MECHANISM

q

00

00

("')

0

~

8

1

2

1

2

1

1

1

5

1

2

1

2

1

1

1

2

1

1

1

7

1

2

1

1

1

1

1

1

1 1

1

I

1

1

I

2 2

00

00

("')

0

~

SMll/64(

GB/T896 3

M2x8

SM11/64(40)x8

SM15/64(28)x12

1

Remarks

40)xl0

-43-

J.OIL

L

UBRICAT.

_

ai-=O_N

MECHANISM

_____

_

-44-

J.OIL

Fig.

No.

JOl H6019I8001

J02 HA700B2150 Oil felt

J03 H6019I8001 Oil wick

J04 H6016I8001 Upper shaft oil tube

J05 HA116I0682 Bushing

J06 H6006I8001 Oil pump

J07 HA100I2090 Screw

J08

J09 H6011I8001

JIO H6012I8001

Jll

J12

J13 HA100I2040 Screw

J14

J15 HA113I0661 Bushing

J16

J17

J18

J19

J20 HA300E2030

J21

J22

J23

J24

J25

J26

LUBRICATION MECHANISM

Part No. Description

Oil

wick

H6010I8001

HA100I2070

HA100I2050

HA111I0065 Oil pump filter

H6014I8001 Lower shaft oil tube

HA110E0672 Oil pipe for lower shaft bushing

H6018I8001 Oil return tube

HA300I2030

HA100E2060 Oil adjusting spring

HA305G0664 Oil wick

HA304G0655 Oil wick

HA300I2060 Oil felt holder

HA106B0676

H6009I8001 Oil wick holder

Rooter

Slider

Oil

pump cover

Oil

adjusting plate

Spring washer

return tube clip

Oil

Oil

adjusting screw

Screw

0

I

co

00

("1"1

0

~

1

1

1

1 1

1 1

1 1

3 3

1

1 1

1 1

1

1 1

3 3

1

1 1

1

1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

.-...~~'

co

00

("1"1

0

~

1

1

1

SM11/64(40)x13

1

1

3.5

SM1/8(44)x13

1

1

1

SM1/2(28)

SM15/64(28)x25.5

SM9/64(40)x6

Remarks

-45-

K.ACCESSORIES

1

~/

e ;6

~15

~14

L,::::..

13

~45

12

11

17

18

~/

~~5

6

10

~

j

11--46

II

;f---

47

':]

48~

49

50

-0--51

52---:

L:1

~

---

~

53

-46-

K.ACCESSOR!ES

-·-.,•c··

..

~----

Fig.

No.

KOI

K02

K03

K04 HA704S0653

K05

K06

!

K07 liA300J2200 Screw ci:iv '

I

K08 "

IC'~

K

Kll

Kl:'

K::; I dA307J0067

f:.:

K.S

K:

K17

K18

K19

K20

K21

K22 H6017L8001 Screw

K23 H6005L8001 Link

K24

K25

K26

K27

K28

K29 HA106J0668 Knee lifter cover

K30 HA106J0662 Knee lifter shaft

K31

K32

K33

K34

K35

K36

K37

K38

K39

K40

K41

K42

K43

Part No. Description

HA505B0672 Thread take-up spring

H2000G2030

H3200L0060

HA300J2230

H80104'\200

HP

100~221\J

:1.:·JOuJ2l60 iSpanner

I ,

10

HA 704SI16541 Speecl connnand disc adjusting disc

I HA100J2110

I HA600E2C60

1

I HA100J2090 Vibration preventing rubber (large)

I H3200L0030

6 HA100J2120 Magnet block

HA300J2370 Thread stand assay

E:\90550066 Bobbin winder assay

HA3u.JJ2170 Oil tank

HA100J218C

HA300J2070

H6006L8001 Knee lifter driving crank

HA106J0664 Bolt

HA106J0667 Bolt

HA106J0666 Knee lifter plate stopper

HA106J0665 Knee lifter plate

H6015L8001

HA104J0657 Coil spring

HA104J0658

HA100F2130

HA104J6510

HA104J0659 Set screw

H007013090 E-type ring

H6016L8001 Collar

HA100C2090 Screw

H6008L8001

HA104J0652 Screw

HA104J0653 Seal washer

H6(X19L8001

Needle

Socket wrench 3

Socket

wrmch

2

Washer for wood screw

Wood screw

(midr1.1.ej

;Sw

,,,,driver (small)

0

il with oiler

Bohr,i~

·"v'ith

Hinge

Vibration preventing rubher (small)

Cove1

Screw driver (larg.:)

Knee lifter shaft

Knee lifter

Screu1

Nut

Oil

Gasket for oil reservoir

rubber cushion

reservoir

Q

00

00

00

("')

00

("')

0

0

~

t>5

1 1

4 4

1

1 1

4 4

4

1

1 l

1 1

1 1

1 1

4 4

2 2

2 2

2 2

1

1 1 GXJ-2A

1

1 1

1 1

1 1

2 2

1 1

2 2

3

1 1

1 1

DPx17 #22

1

4

GB/T99

1

1

1

SM1/4(24)xl0.7

3 SM5!16(18)xl3

SM

15/64(28)x8

Remarks

45x20

1 1

1 1

1 1

2 2

1

1

1

1

1 1 SM15/64(28)x 14.5

2

2 SM15/64(28)

2 2

1 1

1 1

2 2 SM15/64(28)x45

1 1

1 1 SM5/16(28)x10

1 1

2

SM15/64(28)x28

GB/T896 9

2

-47-

K.ACCESSORIES

Fig.

No.

Part No.

~

Description

Q

I

00

00

('f")

0

25

00

00

('f")

0

25

Remarks

K44 HA106J0661

K45

HA600J2060

K46

HA600J2040 Screw

K47 HA600J2050 Drainage tube

K48

HA600J2030

Knee lifter lifting

Gasket

Oil

bottle

pi...'1

1 1

1 1

1 1

1 1

1 1

..

-48-

.

SHANGHAI HUIGONG

N0.3

SEWING MACHINE FACTORY

ADD: 1418, Yishan Road, Shanghai, China

Zip Code: 201103

Overseas Business: TEL: 86-21-64853303 FAX: 86-21-64854304

E-mail:highlead@online.sh.cn http://www.highlead.com.cn

The

description

covered

in this

manual

is

subject to change for

improvement

of

the commodity without notice

2004.1.

Printed

Loading...

Loading...