Page 1

Purchasing

Copy

Dept

HIGH

LEAD

GC0318-1A/GC0318-1H/GC0318-1B

TOP

AND

BOTTOM

SEWING MACHINE

FEED

LOCKSTITCH

Instruction Manual

Parts

SHANGHAI HUIGONG

N0.3

Catalog

SEWING MACHINE FACTORY

Page 2

Page 3

CONTENTS

l.lnstruction Manual

1.

MAIN SPECIFICATIONS

2.

INSTALL THE MOTOR

3.

CONNECT THE CLUTCH LEVER WITH THE PEDAL

PREPARATION AND LUBRICATION

4

5.

REPLACE NEEDLES

6.

NEEDLE, THREAD AND MATERIAL TO

7.

RUN-IN OPERATION

8.

THREADING

9.

WINDING ADJUSTMENT

0.

SET STITCH LENGTH AND REVERSE FEEDING

I

11.

POSITION PRESSER BAR

12.

ADJUST THE PRESSURE OF PRESSER

ADJUST THREAD TENSION

I3.

ADJUST THREAD TAKE-UP SPRING

I4.

15.

ADJUST THREAD GUIDE AND THREAD TENSION

16.

TIME NEEDLE TO ROTAING

I

7.

REPLACE ROTATING HOOK.

18.

ADJUST THE HEIGHT OF FEED

19.

ADJUST THE POSITION OF FEED

20. TIME FEED MOTION TO

21. ADJUST OPENING TIME OF THE TENSION DISCS

22. LUBRICATION ADJUSTMENT

23. REGULAR CLEANING

...............................................................................................................

.................................................................................................

...................................................................................................

.................................................................................

......................................................................................................

BE

SEWN

....................................................................................................

...............................................................................................

.................................................................

...............................................................................................

EOOT

.....................................................................

...........................................................................................

................................................................................

HOOK

.........................................................................................

NEEDLE

.................................................................................................

................................................................................

DOG

..............................................................................

DOG

...........................................................................

MOTION

.......................................................................................

.....................................................................

............................................................

..............................................................

............................................................

............................................................

2

2

2

3

3

4

.4

5

6

7

7

8

8

9

10

11

12

12

13

13

14

15

16

2.Parts Catalog

A ARM BED AND ITS ACCESSORIES

B.

NEEDLE BAR AND TAKE-UP, ARM SHAFT AND VERTICAL

C.

STITCH REGULATOR MECHANISM

D.

FEEDING AND FEED LIFTING MECHANISM

E.

PRESSER FOOT MECHANISM

F.

PRESSER LIFTING, FEEDING MECHANISM

G LUBRICATION MECHANISM

H.

OIL RESERVOIR AND OTHER ACCESSORIES

...................................................................................

..................................................................................

.......................................................................

..........................................................................................

......................................................................

........................................................................................

.....................................................................

-1-

SHAFT

MECHANISM

....................

17

20

23

25

27

29

32

34

Page 4

1. MAIN SPECIFICATIONS

Item

Max.

Needle

Presser

sewing

Stitch

fool

speed

Needle

bar

stroke

Lubrication

length

lift

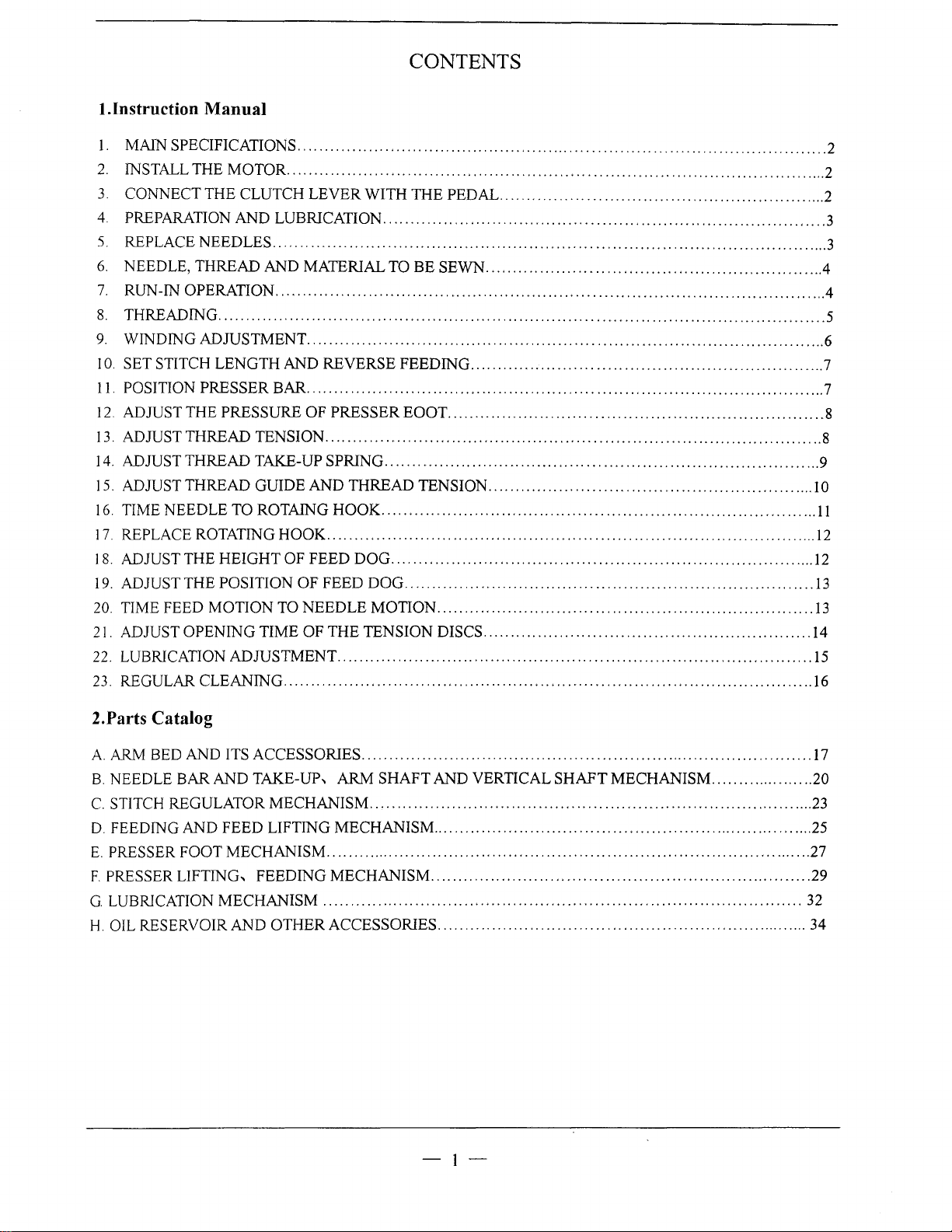

2.INSTALL THE

Align

Motor

rightward.

Pulley

( spm)

(mm)

C mm)

by

hand

(mm)

by

knee

(mm)

MOTOR ( Fig.l

Groove

( B )

and

GC0318-1A

2000

t:l t:l

18

DPX

Automatic

17

-22

35

0-10 0-5

6 6 6

13 13

)

Balance

Wheel

Groove

GC0318-1H

2000

DPX5

Automatic

( A )

14

35

by

GC0318-1B

2000

t:l t:l

moving

DPX

17

35

Automatic

0-10

13

the

motor

Fig.

25

leftward

1

or

L-----C

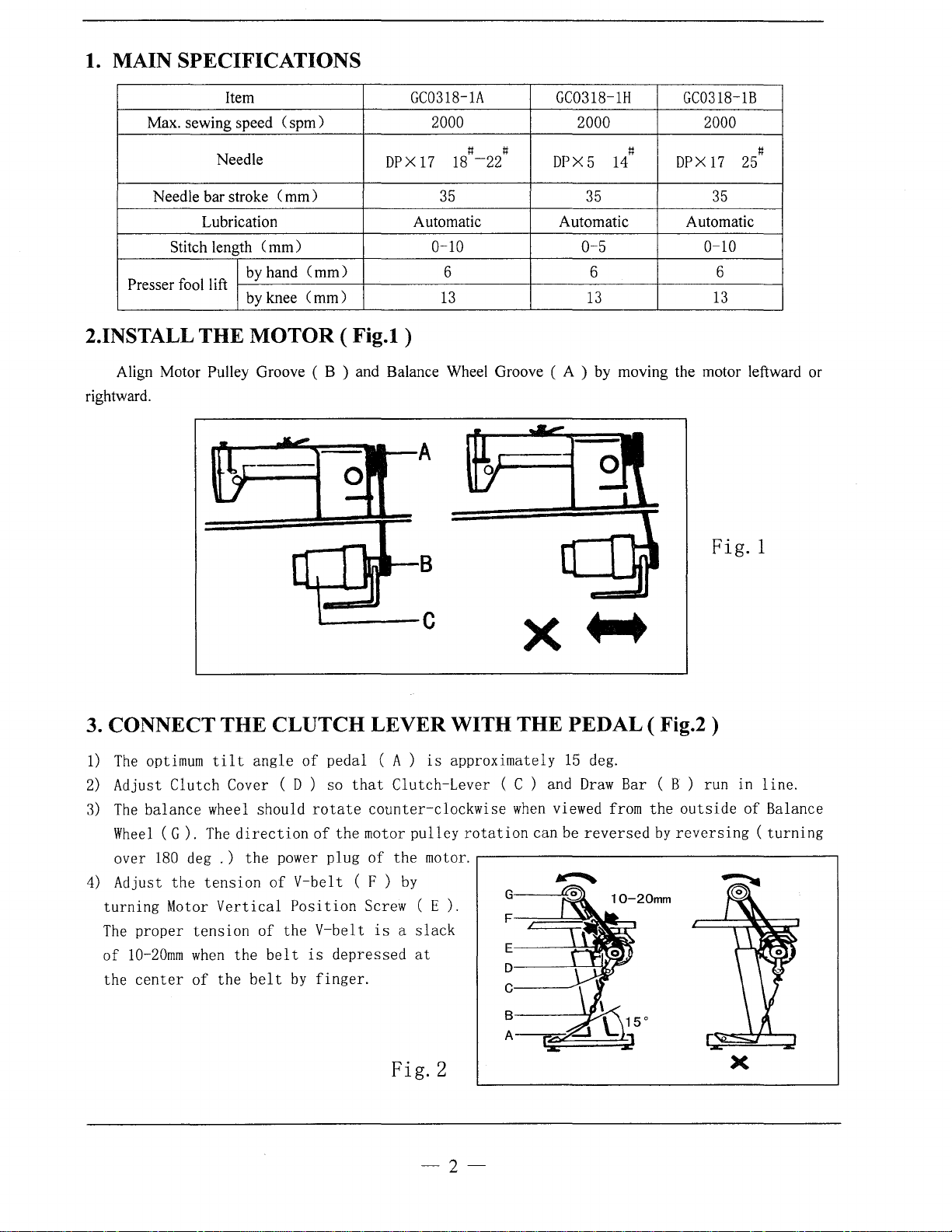

3. CONNECT THE CLUTCH LEVER WITH THE

1)

The

optimum

2)

Adjust Clutch Cover ( D )

3)

The

balance wheel should

Wheel

over

4)

Adjust the

turning

The

of

the

(G).

180

proper tension of the V-belt

10-20mm

center

deg

Motor

when

of the

tilt

angle

The

direction

. ) the

tension

Vertical

the

belt

of

pedal (

so

that

rotate

of

power

of V-bel t ( F )

Position

belt

is

by

finger.

counter-clockwise

the motor pulley

plug

of

Screw ( E ).

is

depressed

A)

is

approximately

Clutch-Lever ( C )

when

rotation

the

motor.,--------------------,

by

a slack

at

can

Fig.2

and

viewed

PEDAL

15

deg.

Draw

Bar

from

be

reversed

( Fig.2 )

( B ) run in line.

the

outside

by

reversing

of Balance

(turning

X

-2-

Page 5

4.

PREPARATION

I)

Cleaning the machine

Before leaving the factory, the machine parts are coated with rust-preventive grease,

hardened and contaminated

2) Examination

Though every machine is confirmed by strict inspection and test before leaving

parts may be loose

performed after cleaning the machine. Turn the balance wheel to see

collision, uneven resistance or abnormal noise.

operation.

3) Oiling

(I)

Required amount

Line (

A)

Line ( B ) on the oil reservoir: Min. oil level.

lf

oil level goes down under line ( B ),

oil cannot be distributed to each

thus causing the parts a seizure.

(2) Replenishing

Always use only

for

high speed sewing.

Line ( A ) before starting operation.

(3) Replacing oil

To

replace oil,

securely tighten Screw ( C ), then fill the reservoir with fresh oil.

or

on the oil reservoir: Max. oil level.

remove

AND

by

deformed after long distance transportation with jolt. A thorough examination must be

of

oil.

No.l8

special machine oil

Be

sure to replenish oil

LUBRICATION (

dust during storage and shipment. This grease

If

these exist, adjustment

part

of

the machine,

Fig.3)

must

A B

to

must

be removed with gasoline.

if

there is running obstruction, parts

be

made

Fig.3

Screw

( C ) to drain oil. After completely draining

off

oil, clean the oil reservoir and

which

the

factory, the machine

accordingly before run-in

may be

c

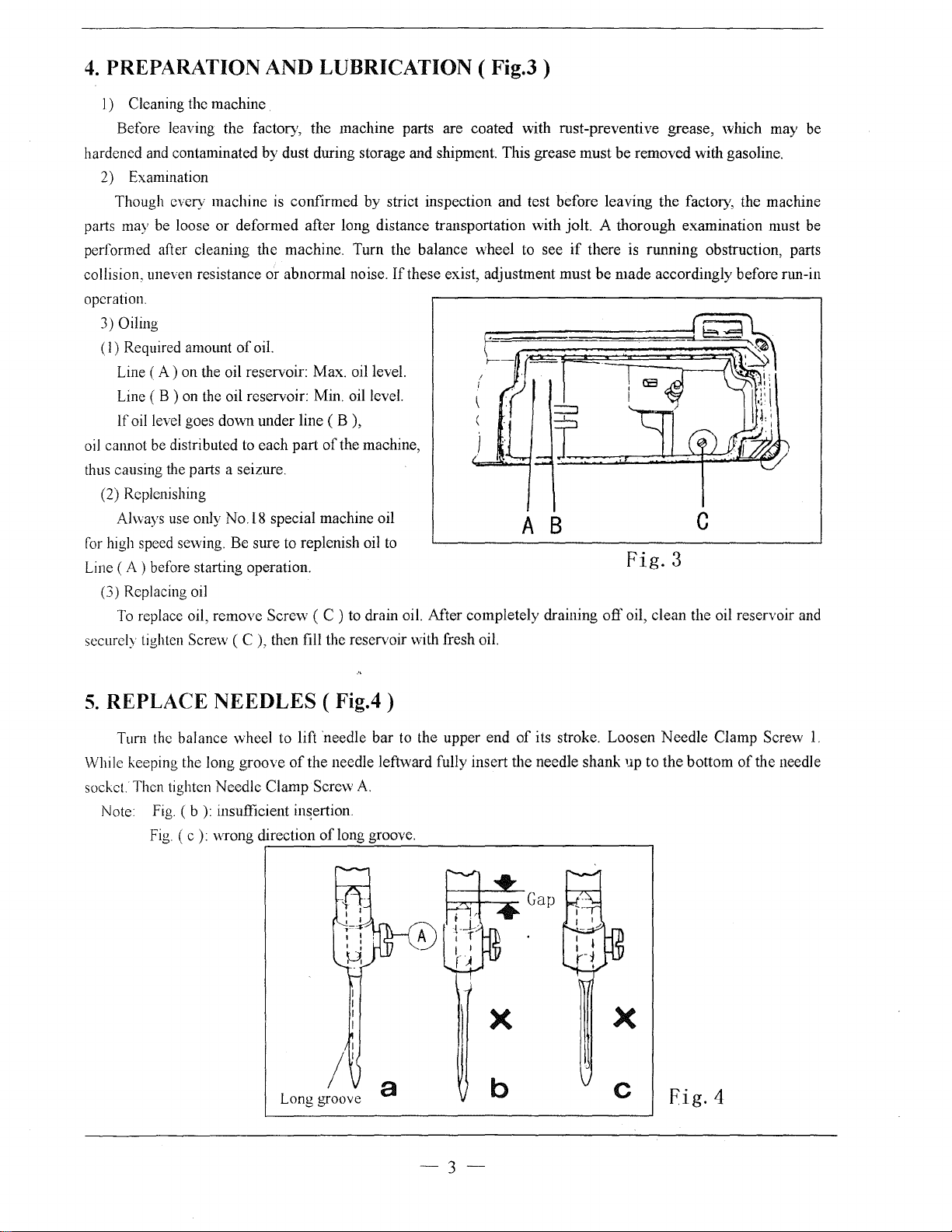

5.

REPLACE NEEDLES (

Tum the balance wheel

While keeping the long

socket Then tighten Needle Clamp Screw

Note Fig. ( b

Fig.

):

insufficient

(c):

\vrong direction

to

groove

Long groove

Fig.4)

lift needle

of

the

needle leftward fully insert the needle shank

in~ertion.

oflong

bar

to the upper end

A.

groove.

of

its stroke. Loosen Needle Clamp Screw

up

to

the

bottom

of

the needle

Fig.4

1.

-3-

Page 6

6.

NEEDLE,

THREAD

AND MATERIAL

TO

BE SEWN

Needle Size

No.l4

No.l6

No.22 Medium leather, Canvas

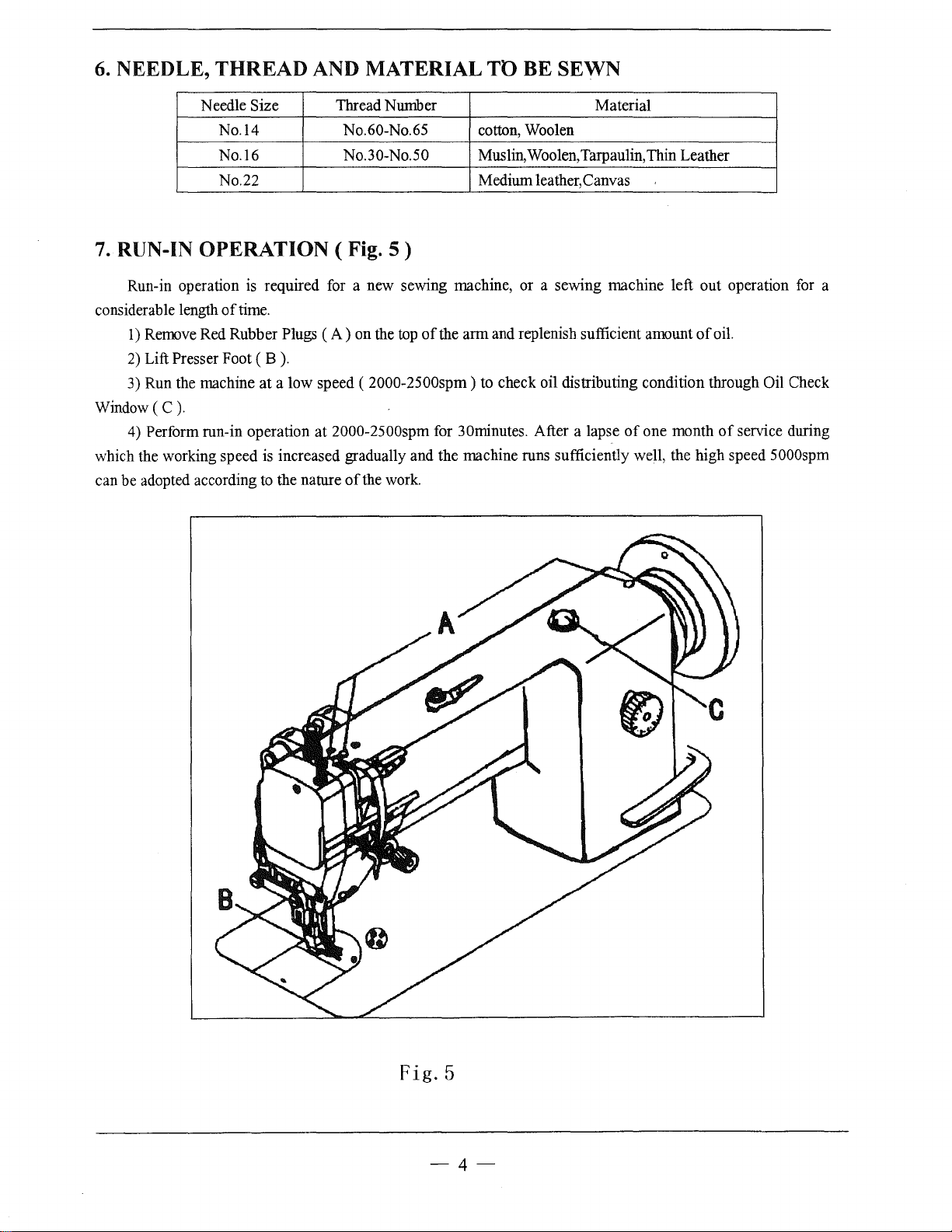

7.

RUN-IN

Run-in operation is required for a new sewing machine, or a sewing machine left out operation for a

considerable length

1)

Remove Red Rubber Plugs

2)

Lift Presser Foot ( B

3)

Run the machine

Window

4) Perform run-in operation at 2000-2500spm for 30minutes. After a lapse

which the working speed is increased gradually and the machine runs sufficiently well, the high speed

can be adopted according

OPERATION

of

(C).

time.

).

at

a low speed ( 2000-2500spm) to check oil distributing condition through Oil Check

to

the nature

Thread Number Material

No.60-No.65 cotton, Woolen

No.30-No.50 Muslin, Woolen, Tarpaulin, Thin Leather

(Fig.

(A)

on the

of

the work.

5)

top

of

the arm and replenish sufficient amount

of

one month

of

oil.

of

service during

5000spm

Fig. 5

-4-

Page 7

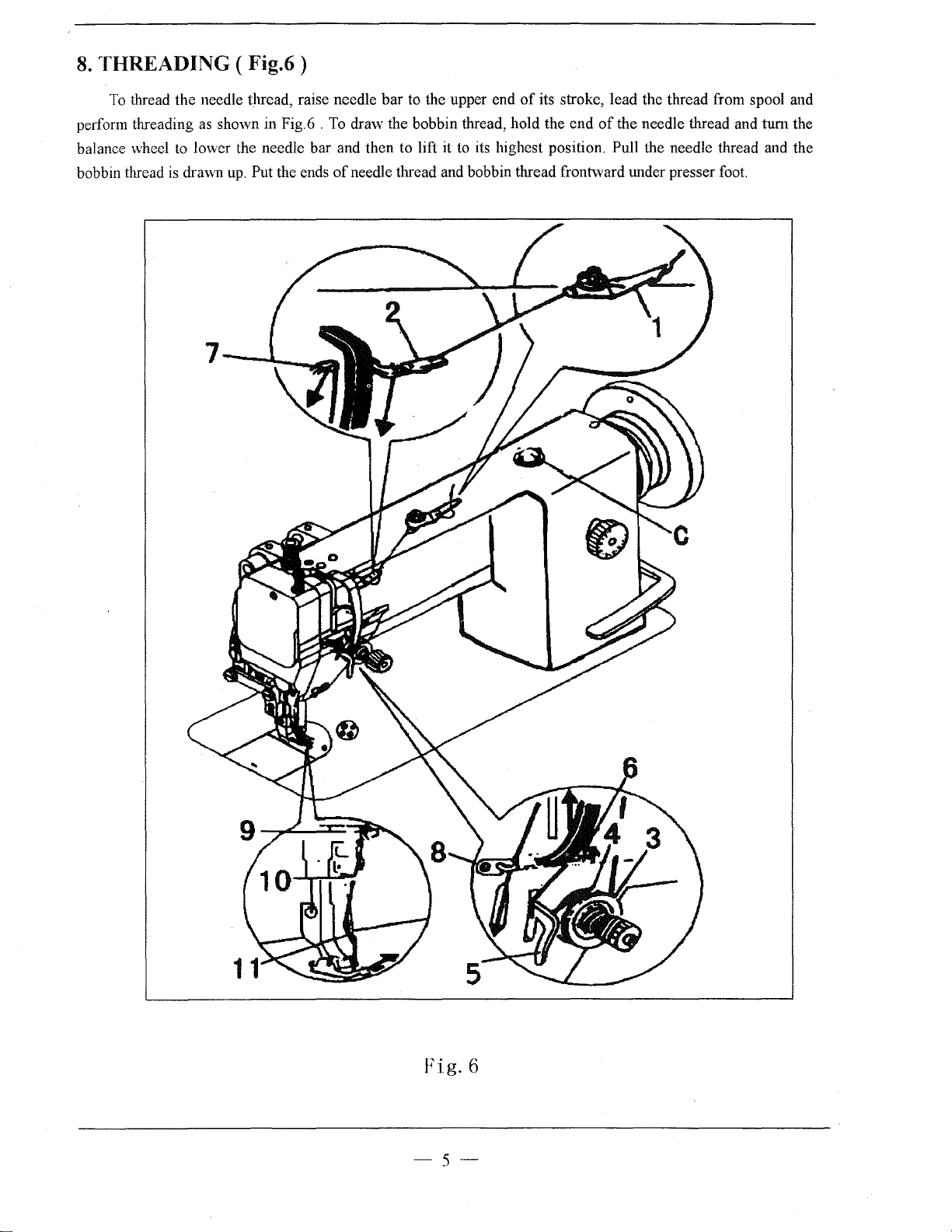

8.

THREADING (

To

thread the needle thread, raise needle bar to the upper end

perform threading

balance wheel

bobbin thread is drawn

as

to

lower the needle bar and then to lift it

Fig.6)

shown in Fig.6 .

up.

Put the ends

of

its stroke, lead the thread from spool and

To

dra\V

the bobbin thread, hold the end

to

its

highest position. Pull the needle thread and the

of

needle thread and bobbin thread frontward under presser foot.

of

the needle thread and turn the

'.

6

;lg.

l

-5-

Page 8

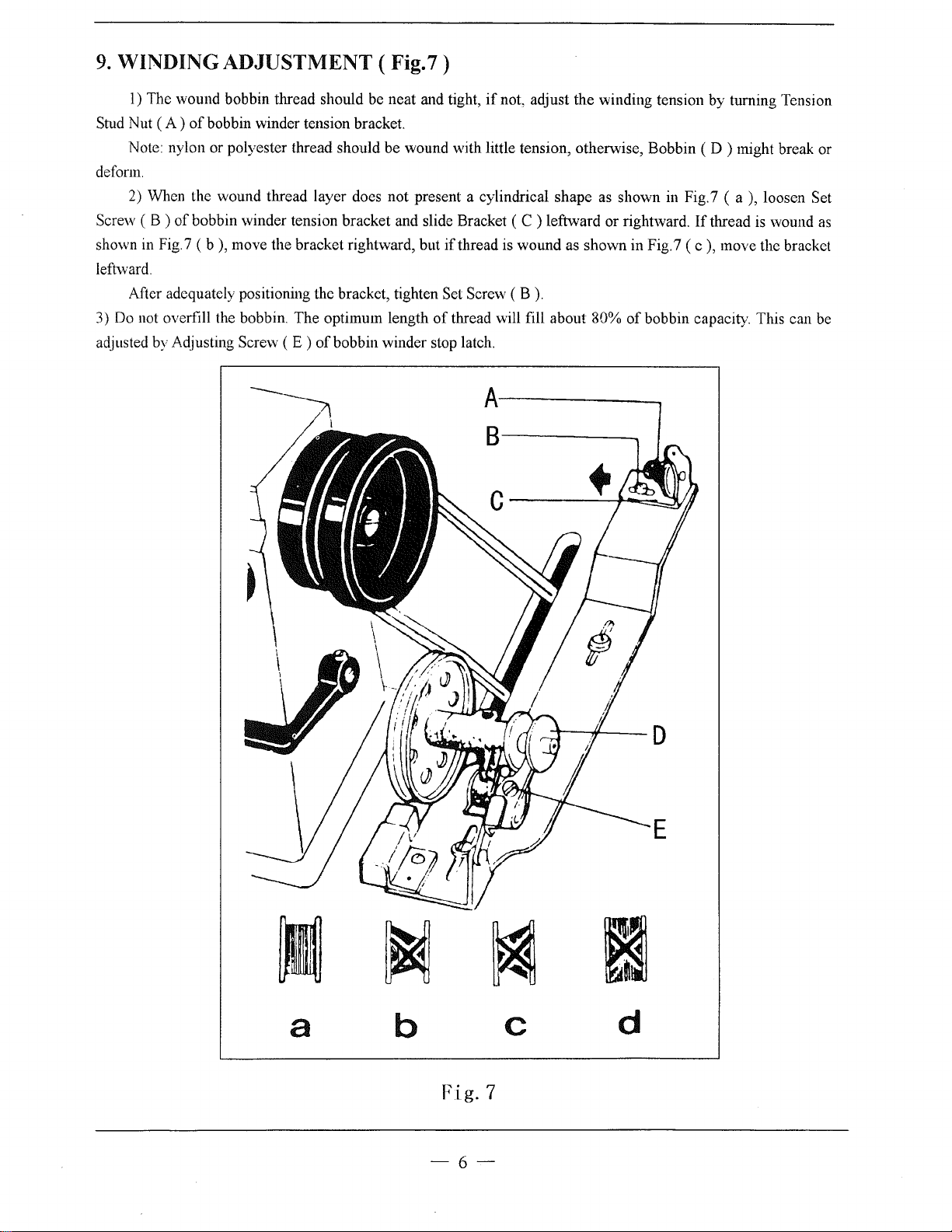

9.

WINDING ADJUSTMENT (

1)

The wound bobbin thread should be neat and tight,

Stud Nut

deform.

Screw

shown in

leftward.

3)

adjusted

(A)

of

bobbin winder tension bracket.

Note: nylon or polyester thread should be wound with little tension, otherwise, Bobbin ( D ) might break or

2)

When the wound thread layer does not present a cylindrical shape as shown

( B )

of

bobbin winder tension bracket and slide Bracket ( C ) leftward or rightward.

Fig.

7 ( b

),

move the bracket rightward, but

After adequately positioning the bracket, tighten

Do

not overfill the bobbin. The optimum length

by

Adjusting Screw

(E)

of

bobbin winder stop latch.

Fig.7)

if

Set Screw

of

if

not, adjust the winding tension by turning Tension

thread is wound

(B).

thread will fill about 80%

as

shown in Fig. 7

in

Fig.7 (

(c),

of

bobbin capacity. This can be

a),

If

thread

is

move the bracket

loosen Set

wound

as

~

~

-

a

b

Fig.

-6-

c

7

m

d

Page 9

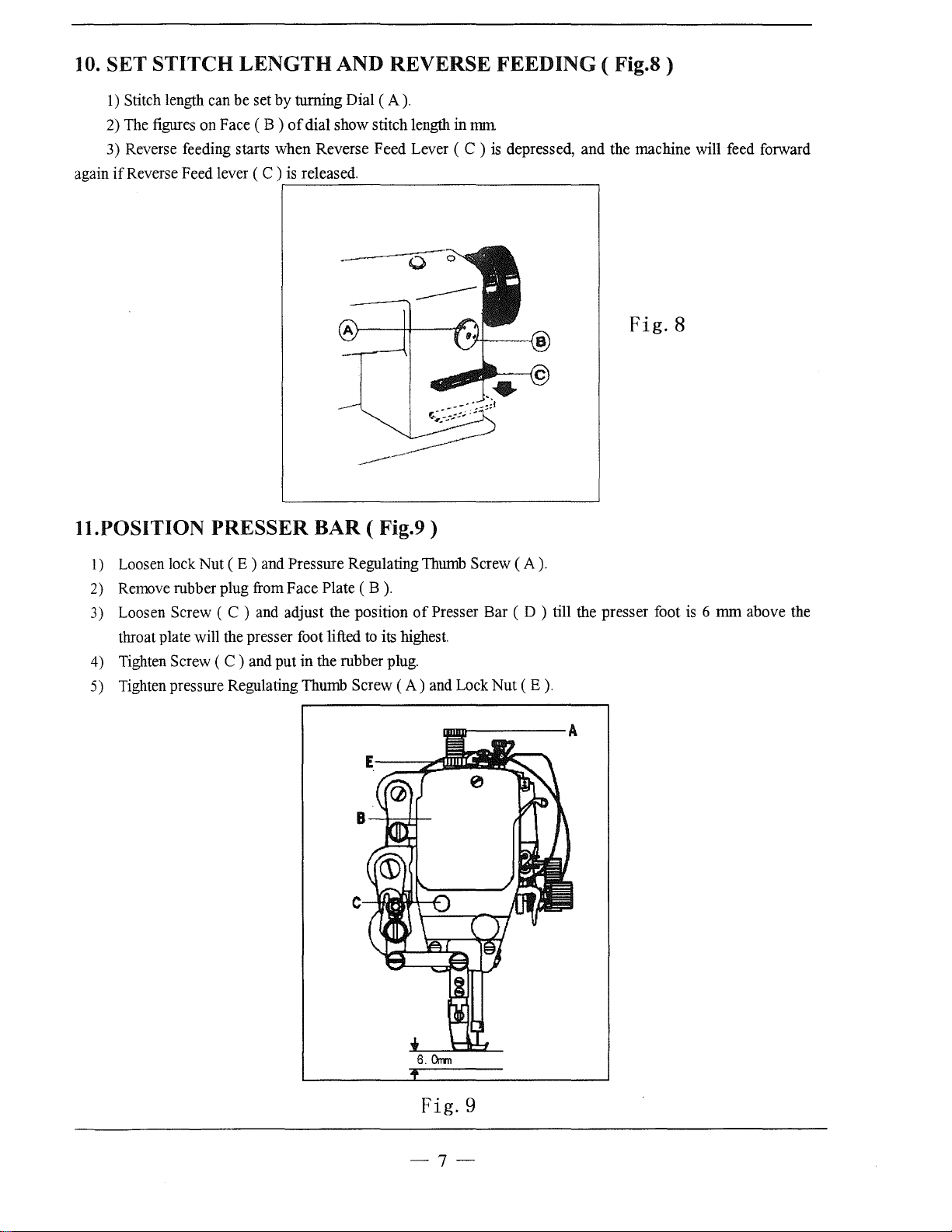

10.

SET

2) The figures on Face ( B )

3) Reverse feeding starts

again

STITCH

1)

Stitch length can

if

Reverse Feed lever

LENGTH

be

set

by

turning

of

dial

when

(C)

is released.

~--------------------------~

AND REVERSE

Dial ( A).

show

stitch length

Reverse Feed Lever ( C ) is depressed,

FEEDING

in

nnn

( Fig.S)

and

the machine will feed forward

Fig.8

11.POSITION

1)

Loosen lock

2) Remove rubber plug from

3) Loosen Screw ( C ) and adjust the position

throat plate will the presser foot lifted to its highest.

4) Tighten

5) Tighten pressure Regulating Thumb

PRESSER

Nut ( E)

Screw

(C)

BAR ( Fig.9)

and Pressure Regulating Thumb Screw

Face

Plate ( B

and

put

in

the rubber plug.

Screw

).

of

(A)

Presser

and Lock

(A).

Bar

( D ) till the presser foot is 6

Nut

(E).

mm

above the

Fig.9

-7-

Page 10

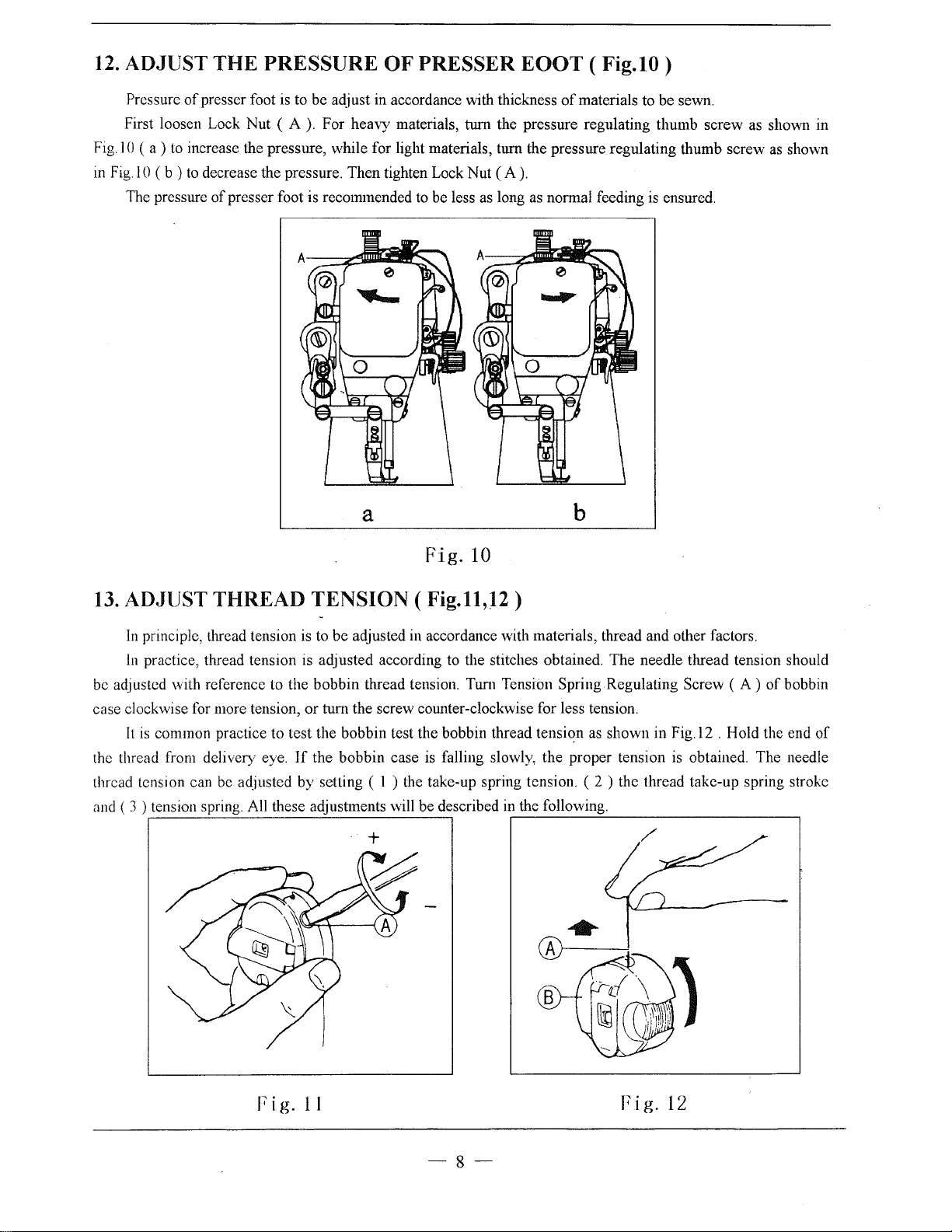

12.

ADJUST

THE

PRESSURE

OF

PRESSER

EOOT

(

Fig.lO)

Pressure

First loosen Lock Nut ( A

Fig.!

0 (

in Fig.l 0 ( b )

The pressure

of

presser foot is to be adjust in accordance with thickness

a)

to

increase the pressure, while for light materials, turn the pressure regulating thumb screw

to

decrease the pressure. Then tighten Lock Nut

of

presser foot is recommended to

of

materials to be sewn.

).

For heavy materials, turn the pressure regulating thumb screw as shown in

as

shovvn

(A).

be

a

less as long as normal feeding

b

is

ensured.

Fig.

10

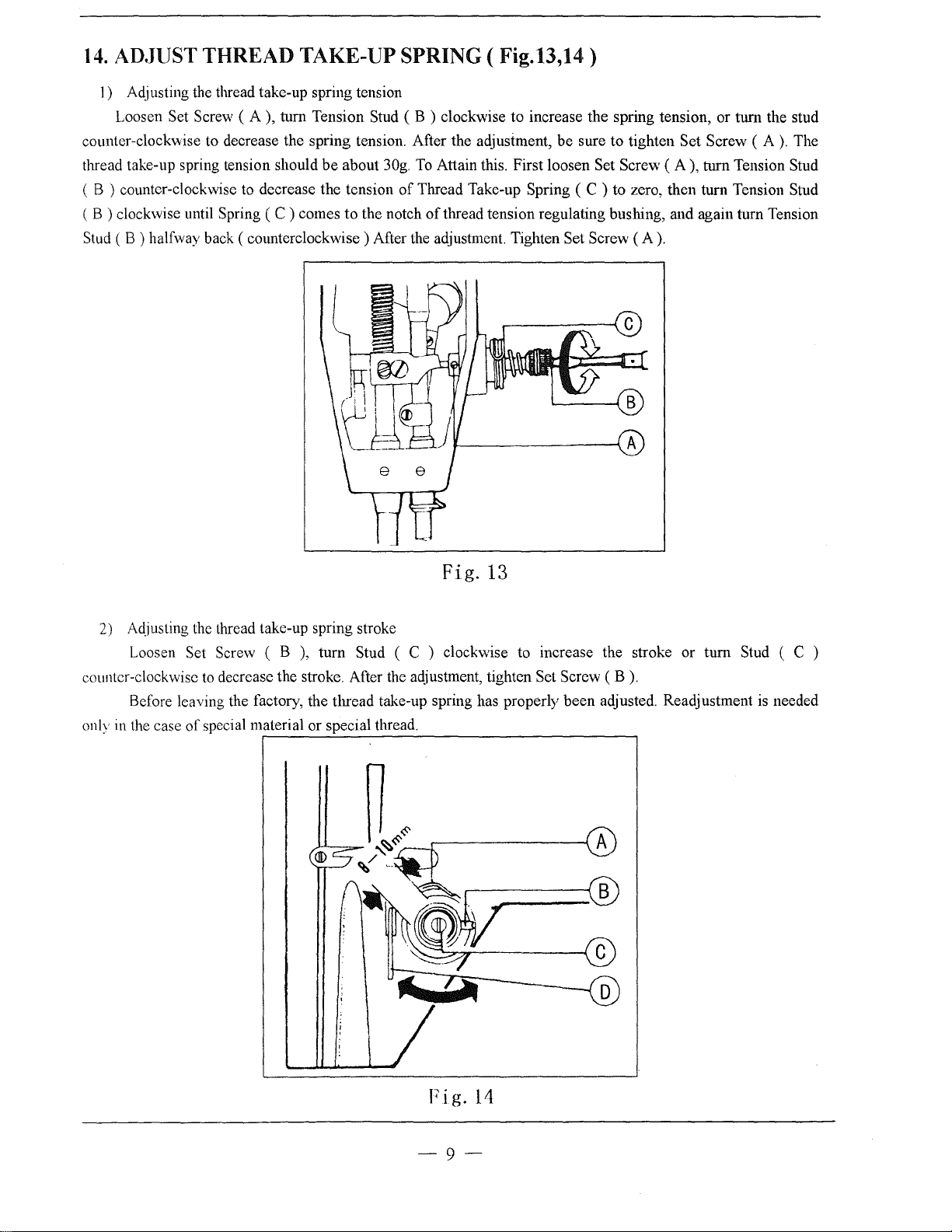

13.

ADJUST THREAD TENSION ( Fig.11,12)

In

principle, thread tension is to be adjusted in accordance with materials, thread and other factors.

In

practice, thread tension

be adjusted

case clockwise for more tension, or tum the screw counter-clockwise for less tension.

the thread from delivery eye.

thread tension can

and ( 3 ) tension spring. All these adjustments will be described in the following .

with reference to the bobbin thread tension. Tum Tension Spring Regulating Screw (

It

is

common practice to test the bobbin test the bobbin thread tension as shown in

be

adjusted by setting ( 1 ) the take-up spring tension. ( 2 ) the thread take-up spring stroke

is

adjusted according to the stitches obtained. The needle thread tension should

If

the bobbin case is falling slowly, the proper tension is obtained. The needle

.-------~~------------------~

/

Fig.l2

A)

of

bobbin

. Hold the end

of

Fig.

11

--8-

Fig.

12

Page 11

14.

AD.JUST THREAD TAKE-UP SPRING (

1)

Adjusting the thread take-up spring tension

Loosen Set Screw ( A ), turn Tension Stud ( B ) clockwise to increase the spring tension, or turn the stud

counter-clockwise

thread take-up spring tension should

( B ) counter-clockwise

( B ) clockwise until Spring (

Stud ( B ) halfway back ( counterclockwise ) After

to

decrease the spring tension. After the adjustment, be sure to tighten Set Screw (

be

about 30g.

to

decrease the tension

C ) comes

to

the notch

To

Attain this. First loosen Set Screw

of

Thread Take-up Spring ( C ) to zero, then tum Tension Stud

of

thread tension regulating bushing, and again turn Tension

the

adjustment. Tighten Set Screw

Fig.l3,14)

(A).

(A),

turn Tension Stud

A).

The

2)

Adjusting the thread take-up spring stroke

Loosen Set Screw ( B

counter-clockwise

Before leaving the factory, the thread take-up spring has properly been adjusted. Readjustment is needed

in

only

the case

to

decrease the stroke. After the adjustment, tighten Set Screw

of

special material or special thread .

.-----~-------------------------------,

Fig.

13

),

turn Stud ( C ) clockwise to increase the stroke or turn Stud ( C )

(B).

.-----------\

A

Fig.

14

--9-

Page 12

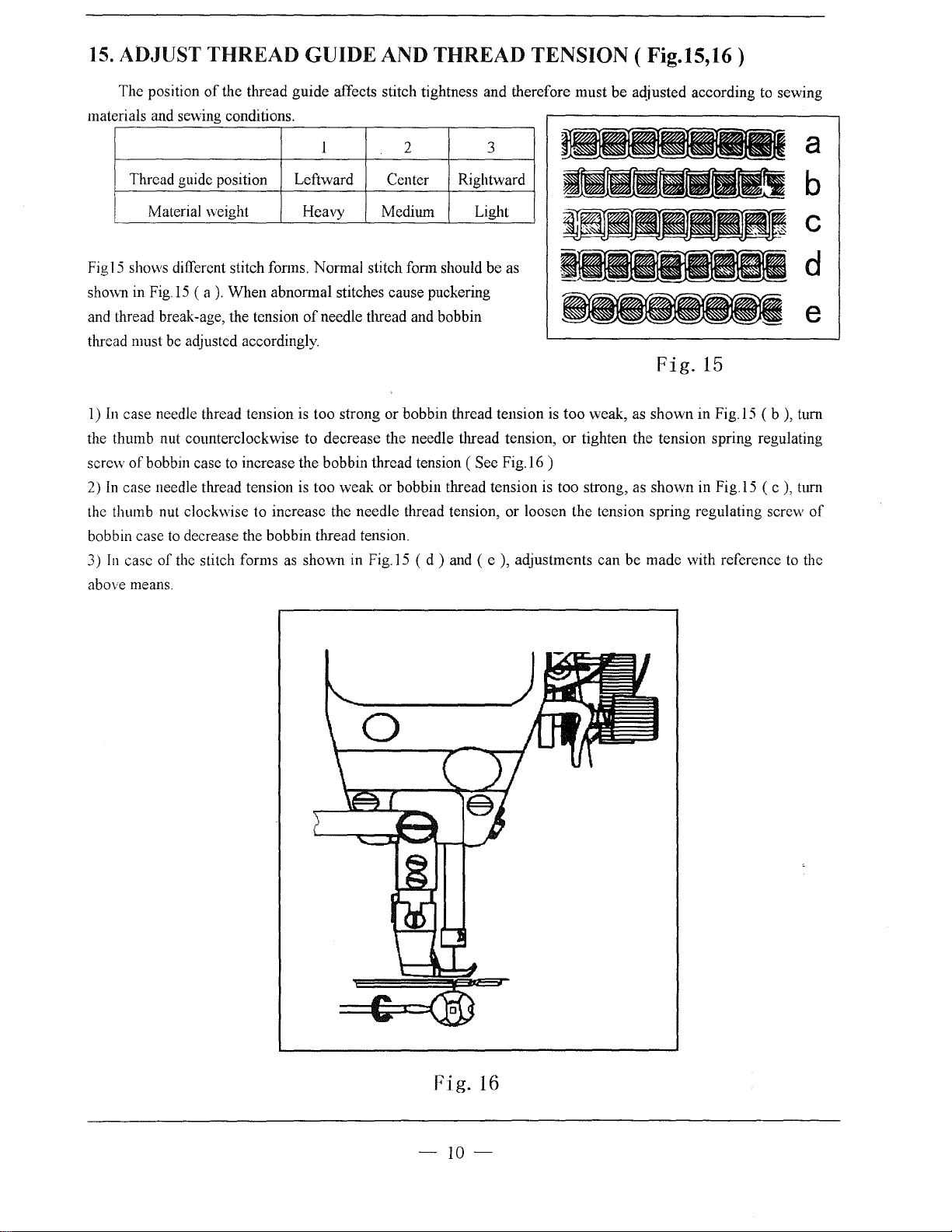

15.

ADJUST THREAD GUIDE AND THREAD TENSION (

Fig.15,16)

The position

materials and sewing conditions.

Thread guide position Leftward Center Rightward

Material weight

Fig

15

shows different stitch fonns. Normal stitch fonn should be as

shmvn in

and thread break-age, the tension

thread must

l)

the thumb nut counterclockwise to decrease the needle thread tension,

screw

2)

the thumb nut clockwise to increase the needle thread tension, or loosen the tension spring regulating screw

bobbin case

3)

above means.

Fig.

In

case needle thread tension is too strong or bobbin thread tension is too weak, as shown in

of

bobbin case

In

case needle thread tension is too weak or bobbin thread tension is too strong, as shown in Fig.

In

case

of

of

the thread guide affects stitch tightness and therefore must be adjusted according to sewing

1 2 3

Heavy Medium Light

IS

( a

).

When abnormal stitches cause puckering

of

needle thread and bobbin

be

adjusted accordingly.

to

increase the bobbin thread tension ( Sec Fig.16 )

to

decrease the bobbin thread tension.

the stitch forms

as

shown in Fig.

IS

Fig.

15

or

tighten the tension spring regulating

(

d)

and ( e ), adjustments can be made with reference

Fig.l5

IS

( b ), tum

( c ), turn

to

a

b

c

d

e

of

the

•

Fig.

16

-IO-

Page 13

16. TIME NEEDLE TO ROTAING HOOK ( Fig.17,18,19,20)

A. Adjusting the needle position

I) Turn balance wheel by hand to bring Needle Bar ( C ) to the lowest position

2) Remove rubber plug from Face

3) Loosen Set Screw

4)

Move

Needle

5) After the adjustment, tighten Set Screw ( B ) and put in the rubber plug. The standard needle timing ( See

Fig.l8 ) is

meanwhile align the Inner Surface (

down to its lowest position.

to align Timing

Bar

(B)

(C)

(See

Fig.l7)

Plate

(A).

of

needle bar adaptor.

vertically to adjust needle timing.

Mark

( B )

on

the needle bar and the bottom

E )

of

the hook and the center

of

its stroke.

of

Needle Bar Bushing ( A ) and

of

Needle Eye ( D ) when the needle bar gets

Fig.

17

B.

Adjusting the hook point timing

of

Timing

hook point timing ( See

is

lifted by 2.2mm from the lower end

upper end

When adjusting the hook point timing, also notice that the clearance between the bottom

and Hook

needle motion to rotating hook motion has a great effect on sewing performance. The standard

Fig.l9

) is to align Hook Point ( D ) and Needle Centerline ( C ) when Needle Bar ( B )

of

its stroke. Besides, Hook Point ( D ) should be

of

needle eye ( E

Point

(C)

).

should be approK 0.05mm ( See

Fig.20)

Fig.

18

0.05mm

1.0-l.Smm

of

needle notch

above the

Pi

g.

19

-

11-

Fig.20

Page 14

17. REPLACE ROTATING

HOOK

( Fig.21 )

l ) Lift needle bar to the highest position

2) Remove throat plate, take down needle and bobbin case.

Loos.en

3)

4) Loosen two Screws ( D )

5) Tum balance wheel to raise feed

avvay

6) Installing the hook can be done in reverse sequence. Note that Needle ( B ) and the convex surface

Hook Positioner

Screw ( C )

from feed bar.

(A)

of

hook positioner and take down Hook Positioner

of

rotating hook.

should align with a clearance

of

its stroke.

(A).

bar

to

its highest position, then take down the rotating hook by turning it

of

0.5-0. 7mm between them.

0.

5-0.

7mm

of

18. AD.JUST THE HEIGHT OF FEED

1 ) Tum balance wheel until feed dog

(A)

of

2) Loosen Screw

3) Move Feed Bar

dog.

The standard height

4) After the adjustment, be sure to tighten Screw

feed lifting rock shaft crank right ( Sec Fig.22,b )

(B)

in the direction shown

of

is

feed dog

lifted to its highest position from throat plate surface.

by

is

that the top

(A).

a b

Fig.22

Fig.

21

DOG

the arrow in Fig. 22

( Fig.22,23 )

(a)

to adjust the height

of

feed dog is 1 mm above Throat Plate Surface ( B )

w~-:

Vig.23

of

the feed

1.

Ornm

-12-

Page 15

19.

ADJUST THE POSITION OF FEED

DOG ( Fig.24,25)

The standard position

first tooth

I) Fully advance the feed dog tovvard the front end

2) Loosen Feed Rock

3) Move Feed Bar

4) After the adjustment, be sure to tighten

of

the fully advanced feed dog

of

feed dog is that the clearance behveen the front

Shaft Crank Screw

(B)

in the direction

Fig.

24

is 1 nm1,

(A).

shovvn

Screw

as shown in

of

the throat plate slot.

See Fig.25

by

the arrow in Fig.

(A).

Fig.24.

(b).

25

(a)

end

of

the throat plate slot and the

to

adjust the feed dog position.

b

Fig.

25

20. TIME FEED lVIOTION TO NEEDLE MOTION (

The standard timing

Plate Surface

I r

I J

2)

3)

(B)

feed

motion IS not timed to needle motion, adjust

RcmO\ c i\rm

Loosen Set Screws

Hold

feed and Feed Lifting Eccentric

.-\rm

Shan

ccccntnc

Oil Hole ( C ) aligns with the lower edge

of

feed motion to needle motion

when the point

Fig.

Side Cover .

(A

) and ( D )

of

26

Needle

of

is

that the top

(A)

reaches Throat Plate Surface

as

follows ( Sec Figs.27 and 28

feed and feed lifting eccentric.

(B)

and turn Balance Wheel

of

Reference Hole ( G )

of

Fig.26,27,28)

feed Dog ( C )

(B).

See

is

flush with Throat

Fig.26.

Fig.27

).

(E)

slowly until the upper edge

of

feed and feed lifting

of

-

13-

Page 16

4)

Leave a clearance

(

H),

then tighten Set Screws

of

0.3-0.Smm between Feed and Feed Lifting Eccentric ( B ) and Eccentric Sleeve

(A)

and

(D).

0.3-0.

5mm

(0\---

~'/

_..;

"·

Fig.28

21. ADJUST OPENING TIME OF THE TENSION DISCS (

within the presser foot lift range

I) Remove the rubber plug from the back

2) Move the tension releasing cam leftward for earlier opening or rightward for later opening.

the adjustment to put under the presser foot a block as thick

3) After the adjustment fully tighten Screw

of

2-7mm opening time

of

ann

and loosen

(A).

of

the tension discs can be adjusted as follows:

Screvv

(A)

of

knee lifter lever ( left

as

the presser foot lift.

Fig.29)

).

It

will facilitate

'-----Cam

Fig.29

-14-

Page 17

22. LUBRICATION ADJUSTMENT (

A.

Adjusting

ln ordinary operation, adjustment is ndt required for the oil pump.

check window

hole.

B.

Adjusting the lubrication

The lubrication

I)

Turn Oil Adjusting Screw ( A ) clockwise

counterclockwise to decrease oil.

2)

Oil

tightened,

as

follows: remove the throat plate and place a piece

then check

oil

3) Readjustment depends on temperature, sewing speed and the like. In practice, oil amount can be judged

oil

pump.

vvhen

the machine runs at a low, speed ( approx.2000spm

of

the rotating hook can be adjusted by Oil Adjusting Screw

Adjusting Screw (

amount is maximum.

the

oil

splashed

on

of

rotating hook.

A)

adjusts

the paper.

oil

amount within 5 tums. When Oil Adjusting Screw (

Fig.30)

If

oil splashing does not occur in the oil

),

reduce the clearance

(A)

as follows:

to

increase oil and turn Oil Adjusting Screw ( A )

of

paper on instead, run the machine for about

of

the by-pass

A)

20

A

is fully

seconds,

Fig.30

-

15-

Page 18

23. REGULAR CLEANING ( Fig.31,32,33)

l)

Cleaning feed dog ( See Fig.31 )

Remove the throat plate and clear off the dust and lint between feed dog tooth slots.

Feed

dog

Feed

Fig.3l

2)

Cleaning rotating hook

Swing out the machine head and clean the hook. Wipe the bobbin case with soft cloth.

3) Cleaning oil pump, screen

Swing out the machine head and clear off the dust and dirt on oil pump screen.

(Sec

(See

Fig

Fig.33)

32)

~,.

1

lg.

Hook

bar

32

Screen

Fig.33

-16-

Page 19

A.

ARM BED AND ITS

ACCESSORIES

5

47

36

~~~0

17

38

18

19

20

1112

36-6

48 49

50

•

$

40

41

42

43

33

29

28

-17-

23

3127

26

25

32

24

2

6

~)

Page 20

A.

ARM BED AND ITS ACCESSORIES

Fig.

A38

No.

A01

A01

A02

A02

A02

A03

A04

A05

A06

A07

A08

A09

A10

All

A12

A13

A14

Al5

A16

Al7

A18

A19

A20

A21

A22

A23

A24

A25

A26

A27

A28

A28

A29

A30

A31

A32

A33

A34

A35

A3ti

A37

A38

Part

No.

HM307B8001

HN208B8001

HM309B8001

HN207B8001

HN105B8001

H924025050

H005008060

H2005B0065

HA306B0674

HA607B0671

HA106B0676

HA700B2030

HA300B2170

H6028B8001

H6029B8001

H1210B0671

H6030B8001

HA112B0691

HA112B0692

HA112B0693

HA112B0694

H007013030

HA112B0695

HAlOOB2100

HAIOOB2110

HA115B0701

HA310B0701

HA505B0671

HA310B0702

HA310B0705

HA505B0672

HN106B8001

HA310B0703

HA115B0708

HAll5B0709

HA115B7010

HA115B7011

HA300B2080

HA600B2050

HA300B2090

HA300B2100

HA300B2ll0

HA300B2110

Description

Arm

Arm

Trade

mark

plate

Trade

mark

plate

Trade

mark

plate

rivet

Spring washer

Face

plate

Rubber plug (

Thread guide

Thread guide screw

Face

plate

Screw group

Arm

side

Gasket

Check

window

Rubber plug (

Screw type

Spring

Disc

for

Spacer

Stop

ring

Pre-tension

Three-hple

Set

screw

Thread

Oil

thumb

Thread

Thread

Thread

Thread take-up

Thread take-up

Thread

Set

screw

Thread

Stop

disc

Rubber

Set

screw

Thread guide

Rubber plug (

Rubber plug (

Red

rubber plug

Red

rubber plug (

<P

on

screw

cover

for

arm

<P

tension

for

pre-tension

pre-tension

for

pre-tension

thread

thread

tension

nut

tension

tension

tension

tension

tension

ring

at

<P

<P

11.

face

side

22

stud

spring

releasing

disc

spring

spring

regulating

releasing

arm

8.

27

8 )

)

guide

8 )

)

(

<P

<P

plate

cover

stud

guide

center

5.

7 )

5.

7 )

disc

bushing

pin

::c:

<T::

I I

-

CX) CX)

M M

-

0 0 0

u

0

1

1

6

3

1 1

3 3

1 1 1

1 1

2 2

4 4 4

1 1 1

1

1 1

1

1 l

1 1

2 2 2

1 1

1

1 1

I

1 1

1 1 1 SMI/4(40) X

1 I 1

I

1 l

2 2 2

1 l

1 1 1

l

I

1

1

1

1 1

2

1 1 l

2 2 2

2

-

,.....,

u

0

1

1

6

3

1

1

1

1

1

1

1

1

1

1

2

2

co

I

-

CX)

,.....,

M

u

0

1

1

6

GB/T827

GB/T

3

1

3

1 SM9/64(40) X6

SM11/64

2

1

1

1

SM11/64

1

1

l

1

GB/T

l

1

SM11/64

1

1

1

1

SM9/64

I

l

1

I

1

SM15/64

1

2

2

¢2.5X5

93

6

(40) X 20

(40) X 16

896

(40) X 5.

(40)

(28) X ti.

Remarks

3

5

17

X 4

8

-18-

Page 21

A.

ARM BED AND ITS ACCESSORIES

Fig.

No.

Part

No.

Description

X

<r:

...... ......

I I

00 00

......

......

M M

0

0

u u

C-'

c.!:>

o::l

......

I

00

......

M

0

u

c.!:>

Remarks

A39

A39

A39

A40

A41

A42

A43

A44

A45

A46

·HA307B0673

A47

A48

A49

A50

H2100B2120

H2900B2030

H6520B8001

HA300B2190

HA124B0711

HA124B0712

HA124B0713

HA100B2220

HA300B2140

HA300B2130

HA300B2160

H6409B8001

H6410B8001

Needle

Needle

Needle

Needle

Slide

Slide

plate

plate

plate

plate

plate

plate

Screw

Leg

Plate

for

Screw

Rubber plug

Screw

Arm

bed cover

Gasket

for

screw

spring

guide

arm

bed cover

1

2

1 1

1 1

2 2

3 3

1 1

2 2

1

5 5

1 1

1 1

1

1

2

2

SM11/64

(40) X 4.

5

1

1

SM3/32

2

(56) X 2.

2

3

1

2

SM11/64(40)

1

1

X5

5

1

1

-19-

Page 22

8. NEEDLE BAR AND TAKE-UP, ARM SHAFT AND

27

30 32

3 1

14

19

29

45

I

8 7

24

25

1111

12

VERTICAL

41

0

SHAFT

MECHANISM

·'

37

23

69~

70

d···.

r \ \

71

72

68

54

55 58

57 56

\'

62

-20-

Page 23

B.

NEEDLE BAR AND TAKE-UP, ARM SHAFT AND VERTICAL SHAFT MECHANISM

::I:

ex:~

,..... ,.....

00 00

,.....

0 0

u u

0 0

Remarks

Fig.

No.

Part

No.

Description

<

,.....

I I I

00

,..... ,.....

M M M

0

u

0

B01

801

802

802

803

804

B04

805

B06

807

808

809

810

811

812

Bl3

814

815

816

B17

B18

819

Bl9

820

821

821

821

822

823

824

825

826

827

828

829

830

831

832

833

B34

B35

836

837

H11111C104

HA3111C104

H11112C104

HA304C0012

HA104C0653

HA504C0651

HA104C0655

HA104C0656

HA304C0653

HA104C0658

HA104C0659

HA100C2020

HA307C0661

HA307C0662

HA100C2060

HA100C2070

HA100C2080

HA100C2100

HA300C2050

HA804B0652

HA500C2060

H2100C2010

HA700G2030

HA500C2030

H2000G2030

HA700G2040

H6524B8001

HA100C2170

HAIOOC2180

HA!OOC2190

HA100C2200

HA304D0651

HA104D0652

HA!08G066l

HA105D0662

HA100D2030

HA!OOD2040

HA100C2020

HA300D2020

HA306D0066

H2000C2040

HA110D0672

HA!OOD2080

Therad take-up

Therad

take-up

Thread take-up

Thread take-up

Hinge

pin

Thread take-up crank

Needle

bearing

Set screw

Needle

Needle

bar

bar

Screw

Set screw

Needle

bar

Set screw

Set

screw

Set screw

Needle

Felt

Red

Needle

bar

plug

rubber plug (

bar

Thread guide

Needle

Needle

bar

bar

Thread guide

Needle

Needle

lever

lever

lever

link

lever

link

(left-handed)

link

1 1

1

1 1

1

1 1

1

1

1 1

2 2

2

1

1

1 1 1

adaptor 1 1 1

1 1

1

1 1 SM15/64(28) X

1

crank

1 1

1

2

2

1 1 1

1 1 SM9/32/

1

bushing

(upper)

1

1

1 1 1

<P

8.

8)

bushing (lower)

for

needle

bar

bushing 1 1 1

1 1 1

1

l

1 1

1

for

needle

bar

1 1 1

1

1

Needle

Needle clamp screw 1

Guide

for

slide

block 1

Set screw 2

Slide

block 1

Arm

shaft

for

bushing

(<l>7.4X10)

(left)

bushing

(middle)

Rubber plug

Collar

Set

screw 2 2 2

Arm

shaft

Arln

shaft

Set screw 1

Arvn

Oil

shaft

seal

bushing

(right)

Balance wheel

Set

screw

1 1

1 1

2

1

1 1 1

2

2

1 1 1

1 1

1

1 1

1

1 1

1 1

1

1 1

1

1

1

')

2

Screw 1 1 1

SM9/64

1

SM9/64

SMl/4(40) X6

2

SM9/32

1

1

DPX

DPX5

DPX5

1

SM1/8

SM11/64

2

1

2

SM1/ 4 (40)

SM15/64

1

SM15/64(28) X

2

SM11/32

(40)

(40)

(28) X 13

(28) X 14

17

22tl

14tl

25tl

(44) X 4.

(40)

(28) X 10

(28) X 10

X 7

X 6

10

5

X 8

X 4

12

-21-

Page 24

B.

NEEDLE BAR AND

Fig.

No.

B38

B38

B39

B40

B40

B41

B42

B43

B43

B44

B45

B46

B47

B48

B49

B50

B51

B52

B53

B54

B55

B56

B57

B58

B59

B60

B61

B62

B63

B64

B65

B66

Bti7

B68

B68

B68

B69

B69

B70

B70

B71

B71

B72

B72

Part

No.

H38111D104

HA3411D108

HA3411D308

H38111D204

HA3411D208

HA112D3012

HA112D3013

H3800D2020

HA504D0651

H2IOOD20IO

HA113D2112

HA113D2122

HA108C0663

HA113D2212

HA113D2222

HA100D2110

HA600D2010

HA100C2020

HA904E0651

HA1111E104

HA1111E204

HA305E0661

HA305E0662

HA106E007l

HA100E2040

HA100E2050

HA100E2060

HA311E0671

HA110E0672

HA300E2100

HA300E2110

HA600E2020

HA104F0654

Hll05E0066

HA500E2030

H6519B8001

H2100E2010

HA300E2050

HA100E2150

HA100E2150

HA608E0067

HA300E2070

H1100E2010

HA100E2180

TAKE-UP~

ARM SHAFT AND VERTICAL SHAFT MECHANISM

Description

Feed and feed

Feed and feed

Set

screw

Eccentric

Eccentric

Retaining

Crank rod

lifting

lifting

sleeve

sleeve

ring

for

feed

lifting

Feed forked connection

Feed forked connection

Vertical

Bevel

Bevel

Set

Bevel

Bevel

Vertical

Vertical

Set

Rotating

Filter

gear

gear

screw

gear

gear

screw

screw

shaft

for

arm

for

vertical

for

hook

for

vertical

shaft

bushing(upper)

shaft

bushing(lower)

hook

shaft

shaft

shaft

Filter

Collar

Set

Oil

Hook

Oil

Spring

Hook

Oil

for

hook

screw

seal

for

shaft

bushing

adjusting

for

oil

shaft

bushing

pipe

for

shaft

rotating

screw

adjuster

hook

shaft

(left)

(right)

Plunger

Plunger

Guide

spring

plate

Screw

Rotating

Rotating

Rotating

Rotating

Rotating

hook

hook

hook

hook

hook

complete

complete

complete

positioner

positioner

Screw

Screw

Bobbin case

Bobbin case

Bobbin

Bobbin

eccentric

eccentric

rock

shaft(upper)

shaft(lower)

hook

shaft

bushing

shaft

::r:

co

.....

M

c..?

1

o::l

co

,.....;

M

c..?

I

Remarks

1

-<

,.....; ,.....; ,.....;

I I

co

,.....;

M

0 0 0

u u u

c..?

1

1

2

2

2

1 1

1

1

I

1

1

I

1

1 1

1

1

1

1

1

8

1

1 1

1

1

2

1

1 1 1

1

1

1

1

1

8

8 SMl/4(40)

1

1

1

1

1

1

1

2

2 SM15/64(28) X

1

1

SM3/16

X7

(32)

1 1 1

1 1 1

2 2

1 1

2 SM15/64(28) X4. 5

1

1 1 1

1 1 1

1 1

1

1 1

1

1

1

1

1

SM11/64(40) X28. 5

1

1

1 1 1

1 1 1

1 1 1 SM15/64(28) X

1

1

1

1 l

1

1 1 SMll/64

1

1

SM11/64(40) X

1

(40) X 13

1

1

1

1

10

X 9

10

13

-22-

Page 25

C.STITCH REGULATOR MECHANISM

'

.....

-

---

'

25 ;

r---

'

I

'

I

I

----

----

_

18

-23-

Page 26

C.STITCH REGULATOR MECHANISM

Fig.

No.

C05

C05

C06

C07

COB

C09

C10

C11

C12

C13

C13

C14

C15

C16

C17

C18

C19

C20

C21

C22

C23

C24

C24

C25

C26

C26

C27

C28

C29

C30

C3I

C32

C33

C34

C35

C36

COl

C02

C03

C04

Part

No.

HA104F0651

HA104F0652

HA104F0653

HA104F0654

H1000F2010

HA105F0661

HA104F0654

HA300F2020

HA100C2020

HA100F2040

HA700B2120

HA109F0671

HA109F0674

HA307F0661

H3100E2070

HA109F0673

HA300F2050

HA100F2080

HA100F2090

HA309F0671

HA113F3021

HA113F3022

HA113F0683

HA104F0654

HA!OOF2110

H2605E0661

HA115F0691

HA1511F115

HM306F8001

HA1511F215

HA115F0692

HA100F2130

HA100F2140

HA720F0685

HA720F0686

HM308F8001

HA720F068I

HA720F0687

HA720F0683

HA7421FI20

Hinge

pin

Feed connecting

Hinge

pin

for

Screw

Feed

regulator

Feed

regulator

Screw

Feed

regulator

Set

screw

Hinge

pin

for

Rubber plug

Feed

regulator

0-ring

Dial

Dial

Screw

Rubber plug

Stopper pin

Spring

Reverse feed

Reverse feed

0-ring

Screw

Screw

Washer

Reverse

Reverse

Slide

slide

slide

Spring

Screw

Bracket

Bushing

Screw

Plate

Screw

Coil

spring

Stopper pin

Dial

(<!>20X6)

for

stopper

lever

lever

feed crank 1

feed crank 1

block

pin

block

block

for

feed crank

spring

for

stitch

bar

releasing

Description

link

feed connecting

bushing

feed

regulator

screw

bar

pin

shaft

length

lever

link

::r::

...::

......

I

00

......

M

0 0 0

u u u

0 0 0

1 1 1

1

1 1 1

1 1 1

1

2

1

1 1 1 SM15/64(28) X

1

1 1 1

2

1

1 1 1

1

1

1

1

1 1 1 SM3/16(28) X6. 5

2

1

1 1 1

1

1

1

1

1

I

I

1

1 1

I

I 1

1:0

......

I I

-

00 00

M M

- -

1

1

2 2

1 1

1 1

1

2

1

1

1

1

1

1 1

1 1

2 2

1

1

1 1

1 I

I

1

SM15/64

1

SM15/64(28) X

<!>14X2.4

2

1

SM3/16

1

1

<!>9Xl.9

1

1

1

SMI5/64

I

I

I

I

I

1

Remarks

(28) X 10

(28)

X 8

(28)

X I 0

10

10

-24-

Page 27

D.FEEDING AND FEED LIFTING MECHANISM

\

\

15

9

·'?

26

~

37

25

-25-

Page 28

D.FEEDING AND FEED LIFTING MECHANISM

::t::

<:

......

......

Fig.

Part

No.

DOl

HA104G0011

D02

HA304G0656

003

H2004L0661

D04

HA104G0653

004

H2900G2010

D04

H6521B8001

D05

HA104G0654

006

Hll00G2040 Hinge

D07

HA100C2190

008

HA104G0656

D09

H2100G2060

DlO

H2100G2050

Dll

HA104F0654

Dl2

H2100G2010

013

H2100G2020

014

HA305E0662

016

H007009150

Dl6

HA108G0661

017

HA10500662

018

H2100G2030

019

HA104G0012

020

H2100G2040

021

HA305Gl011

022

HA305Gl012

D23

HA111G0683

024

HA310G3011

025

HA305G0664

026

H2100G2070

D27

HA200G2020

027

HA305G0663

028

HA100G2120

029

HA100C2020

030

H007009150

031

HA100G2130

HA108G0661

032

033

HA10500662

D34

HA306G0671

035

HA100G2070

o;5

HA104G0012

037

HA304G0655

No.

Feed rock

Screw

Feed

bar

Feed

dog

Feed

dog

Feed

dog

Screw

pin

Screw

Washer

Bushing

Bushing

Screw

Feed rock

Bushing

Set

screw

C-type

stop

Collar

Set screw

Feed rock

Screw

Hinge pin

Feed

lifting

Shaft

Screw

Eccentric

Oil

braid

Bushing

Feed

lifting

Feed

lifting

Bushing

Set

screw

C-type

stop

Washer

Collar

for

Screw

Feed

lifting

Hinge

pin

Screw

Oil

braid

shaft

for

for

for

shaft

for

shaft

sleeve

for

for

feed

Description

crank

feed

regulator

feed rock

feed rock

feed rock

ring

crank

rock

shaft

feed

lifting

rock

shaft

rock

shaft

feed

lifting

ring

lifting

rock

shaft

(left)

shaft(left)

shaft(right)

shaft

(right)

(left)

crank

rock

shaft(right

rock

shaft

shaft

rock

(right)

crank

I I

00

00

.......

.......

M

M

0

0

u

u

<:,:,

<:,:,

1

2

1

1 1

2

1

1

1 1 1

1 1

1 1

1 1 1

1 1 1

1

1 1 1

1 1 1

1 1 1

2 2 2

1

2

1

1

1

1

1 1 1

1 1

1 1

1 1

1 1

1

1

2 2

1 1

1 1

1

2

1

1

c:o

.......

I

00

.......

M

0

u

(.!)

1

1

2 2

1

1

SM3/16

(28) X 15

1

1

SMl/8

(44)

2

1 1

2

X 6

1 1 SMll/64(40)

SM15/64

1 1

SM15/64

(28) X 10

(28)

SMl/ 4 (40)

1

1

SM3/16

2 2

(28) X 12

1 1

1

1

1 1

1

SM11/64(40) X 12

1

1

1

1

1

1

2

SM!5/64

SM!/4

1

1

(28)

(40)

1

l

l

1

SM:3/lfi(2H) X 1:2

2

2

1 1

1 1

Remarks

X8

X 4

X 4

X l 0

X l

-26-

Page 29

E.

PRESSER

FOOT

MECHANISM

9

6

10

~·11

14

12

8~~·!

13~:

,,

t

...........

I

••

I •

I

'

I

I

I

I

I

I

I

I

I

I

I

I

....

..........

•,,,

~

..

,,

~,

15

:16

/

ill,

:

17 "

27~

~

...

~_,_,

24

-27-

Page 30

E.

PRESSER FOOT MECHANISM

Fig.

No.

EOl

E02

E03

E04

E05

E06

E07

E08

E09

E10

Ell

E12

E13

E14

E15

E16

E17

E18

E19

E20

E21

E22

E23

E24

E25

E26

E27

E27

E27

Part

No.

H2104H0651

HA100B2110

H2104H0661

HA300H2080

HA107H1011

HA305H6611

HA107H1013

HA107H0662

HA107H0663

HA100H2050

HA100H2060

HA110H0671

H3211E0692

HA100H2050

HA306H0671

HA720B0651

HA300H2090

H2000I2010

HM305H8001

HA3411D308

H1100H2020

H2005I0065

HA117H0692

HA100H2150

HA300H2120

HA100C2040

H3800H2020

H2900H2020

H6522B800l

Description

Presser

Set

Presser

Oil

Knee

Tension

screw

seal

lifter

bar

lifter

bar

lifting

fot

presser

lever

releasing

cam

bar

(left)

cam

Screw

Hinged screw

Knee

lifter

rod 1

Bolt

Tension

Knee

releasing

lifter

lever

pin

(right)

Spring

Bolt

for

knee

lifter

Knee

lifter

Pin

for

Presser

Presser

Presser

connecting

spring

bar

bushing 1

bar

bar

lifting

bracket

Set screw 1

Presser

Pressure

Lock

Set

Upper

nut

screw

thread

spring

regulating

guide

thumb

Screw

Presser

Presser

Presser

loot

complete

loot

complete

loot

complete 1

lever

rod

litting

screw

cam

<

..-<

I

()()

..-<

M

0

u

0

1 1

1 1

1 1

1 1

1

1

1 1

2

1

1

1

1

1

1

1

1

1

1 1

1 1

1

1 1

1

l

1

:J::

..-< ..-<

I I

()()

..-< ..-<

M M

0 0

u u

0 0

1

1

2

1

1

1

1 1

1

1 1

1 1

1

1

1

1

1

1

1

1

1

o:l

()()

1

1 SMll/64

1

8X

1.

1

9

1

1

SMll/64

1

SM3/16(28) X3. 5

2

1

SM15/64(28) X

1

1

1

SM15/64(28) X

1

1

1

1

SM15/64(28) X7

1

1

SMl/2

1

(28) X 43

1

SM9/64(40) X

1

1

1 SMll/64

Remarks

(40)

X 5

(40)

X 6

(40)

X 5

13

10

11

-28-

Page 31

F.

PRESSER LIFTING-. FEEDING MECHANISM

13

\

I

\

32

58~

~

~

/-

~

~

36

31

/

35

37

-29-

Page 32

F.

PRESSER LIFTING.. FEEDING MECHANISM

....::

.-

Fig.

No.

POl

F02

F03

F04

F05

F06

F07

FOB

F09

FlO

Fll

Fl2

Fl3

Fl4

Fl5

Fl6

Fl7

Fl8

Fl9

F20

F21

F22

F23

F24

F25

F26

F27

F28

F29

F30

F31

F32

F33

F34

F35

F36

F37

F38

F39

F40

F41

F42

F43

Part

No.

H2010]0065

H2010]0066

H2000]2060

H2009B0068

HA100B2110

H2011]0066

H2100I2010

H2012N0652

H2104I0065

H2000J2100

H2014J0652

H007009250

HA307C0662

H2013]0065

H0030020608

H2100I2020

H2004J0652

H2004J0653

H2100I2190

H2007J0066

H2004J0658

HA100H2150

H609025180

H2000J2020

H2000I2050

H2000J2030

H2004J0655

H2004J0662

H2011]0065

H602040200

H3209B0065

HA100B2110

H6013F8001

H6017F8001

H2010J0066

H2100I2030

H2012N0066

H2100I2060

H2121I0065

H2013N0069

H2008N0066

H2004J0654

H2004J0661

Description

Lifting

Lifting

Lifting

Presser

presser

presser

presser

lifting

Screw

Shaft

Presser

lifting

Set screw

Eccentric

Set

Eccentric

C-type

screw

stop

wheel rod

wheel

ring

Screw

Washer

Nut

Presser

Presser

feed

feed

crank

crank

Screw

Lifting

Presser

Lifting

presser

spring

presser

Screw

Pin

Lifting

presser

Screw

Lifting

presser

Feed crank guide

Screw

Presser

lifting

Pin

Presser

swing

shaft

Screw

Presser

swing

crank(right)

Screw

Lifting

Presser

presser

swing crank

Screw

Presser

Lifting

Lifting

Lock

Presser

Presser

swing

presser

presser

nut

rod

rod guide

shaft

adjusting

adjusting

bracket

shaft

shaft

link

spring

guide

guide

plate

spring

shaft

crank

bushing

adjusting

(right)

bushing

sway

crank

sway

crank

screw

nut

for

bushing

plate

guide

nut

shaft

spring

pin

(right)

rod

(left)

compl

00

.- .-

M

0

u

0

2

2 2 2

2

1 1 1

2 2 2 SMl/4(40) X6

2 2

2 2 2

1 1 1

:r::

o::l

.- .-

I I I

1 1 1

1 1 1

1

00

M

0 0

u u

0 0

1 1

00

.-

M

SM9/32

SM9/32

(28) X 35

(28)

2 2

2 2

1

1 1

1 1 1

1

1 1

M6

(0.

75) X 29

1

1 1

1

1

1

1

1

1

1

1 1

1 1

1 1

1

1 1

1 1

1 1

1 1

1 1

1 1

1

1 1

GB/T894. 1 25

GB/T6170

SM3/16

(28) X 12.

1

1

1

1 SM9/64(40) X

GB/T879. 1 2.

2

1 1

1

1

1

1

1

1

1 SM9/64(40) X

1 1

1 1

1 1

1 1

1 1

1

1

SMl/4(40)

GB/T117

SM11/64

1

1 1

1 1

1

1

1 1

1 1

1

1

1 SM1/4(24Xl9.

1

1

1

1

1

1

1

SM9/32(28)

SM9/32

(28) X 28

1 1 1 SM1/4(40)

1

1

1

1 1 1

Remarks

M6XO.

13

5 X

10

Xl5

4 X

20

(40) X 5.

7)

75

6

18

5

-30-

Page 33

F.

PRESSER LIFTING-. FEEDING MECHANISM

<r;

......

Fig.

No.

Part

No.

Description

00

...... ......

M

0

u

'-'

I

::c:

......

I I

00

M

0 0

u u

'-'

co

......

00

......

C')

'-'

Remarks

F44

H2004J0067

F45

H2100I2040

F45

H2900I2020

F45

H6525B8001

F46

H2000N0040

F47

H2000N0030

F48

HA111G0683

F49

H2008N0065

F50

H2013N0066

F51

H2100I2070

F52

H2013N0067

F53

H2013J0065

F54

H2013N0070

F55

H6507I8001

F56

HA100I2050

F57

H2004J0662

F58

H6018F8001

1-i

~,.q-o

f-5/

fbil

1rf

H~7~1

Screw

Out

presser

Out

presser

Out

presser

Space

for

Lifting

Screw

Screw

Lifting

Screw

Presser

Washer

Presser

Presser

Washer

Screw

o;feeJ rJ

~I

presser

presser

crank

swing

swing

~c.retAJ

presser

connecting

crank(left)

shaft

rod

plate

rod

plate

sway

crank guide

g/wft

pin

nut

if~

t

re{t;

2

2 2

1

2

1

2

1

1

1

1

1

1

1

1 1

1 1

1

I

I

1

1

1

2 2

1 1

2 2

1 1 SM1/4(40) X26

1

1

1 1

1 1

1 1

1 1

1

1

1

1 SM1/4(40) X

1 1

I

I

I

l

SM9/64

(40)

X 9

SM11/64(40) X 14.5

SM1/ 4 (40)

SM3/16

(32)

X 7

SM1/ 4 (24)

15

~

M.

(r

folf

(

J8-

)X.I'f

-31-

Page 34

G.

OIL LUBRICATION MECHANISM

11

12

('~-::

16_~£r·

:1

14

I

fr{----

.

---

~.

·;--.

~--

l-

----

-

---

I

'

15

_,

------~

----

~~_:---·~

[-....~

I '

~--

"~-:--::...=---

\

--

)

-

~---

,--

1

L_

---

_I

o_!'

-.

r-I

"

1-~

9

6--......

13

-----<:::-,

_...,.,Ull.....,.

r-----2

~~-3

\

...

-32-

8 7

4 5

4

Page 35

G.OIL LUBRICATION MECHANISM

Fig.

No.

GO!

G02

G03

G04

G05

G06

G07

G08

G09

GlO

Gll

G12

G14

G15

G16

Part

No.

HA100I2010

H6010I800l

HAlOOI2090

HA300I2050

HAlOOI2050

H6012I8001

HA100I2070

HA111I0065

HA100I2090

HA113I0066

HA304I0065

HA100I2020

HA305I066l

HA100I2150

HA300I2060

Oil

pump

Oil

pump

Screw

Screw

Spring

Oil

pump

Oil

adjusting

Oil

pump

Screw

Oil

pipe

Oil

braid

Screw

Oil

return

Felt

pipe

holder

washer

pouch

Description

body

impeller

fitting

plate

screen

for

hook

fitting

pipe

plate

complete

shaft

plate

...::

,...;

I

00

,...;

M

0 0

u

0

1 1

1

l

3 3

1 l

1 1

l 1

1 1

3 3

1

1 1

2 2

1

1 l

1 1

::z::

,...;

I

00

......

M

u

0

1

1

1

1

co

,...;

I

00

......

M

0

u

0

1

1

1

3

1

1

1

1

3

1

I

2

1

l

1

Remarks

-33-

Page 36

H.

OIL

RESERVOIR

AND

OTHER

ACCESSORIES

42

44~

5

4

23

./)

..

/

•"11

"726

''

---------1 4

~-15

19

24

25

'-:::.

27

23

6

~18

17

16

-34-

Page 37

H.

OIL RESERVOIR AND OTHER ACCESSORIES

<

......

Fig.

No.

Part

No.

Description

00

......

M M

0

u

(.!)

I I

::t:

co

......

......

00 00

......

......

M

0 0

u u

(.!)

(.!)

I

Remarks

H01

HOZ

H03

H04

H05

H06

H07

H08

H09

HlO

H11

H12

H13

H14

H15

H16

Hl7

H18

Hl9

H20

H21

H22

H23

H24

H25

H26

H27

H28

H29

H30

H31

H32

H33

H34

H35

H36

H37

H38

H39

H40

H41

H41

H41

HA304J0651

HA104J0652

HA104J0653

HA104J0654

HA104J0655

HA300}2160

HA104J0657

HA104J0658

HA104J0659

HA104J6510

HA110D0672

HA106}0661

HA106J0662

HA106J0663

HA300J2180

HA106J0665

HA106J0666

HA106}0667

HA106J0668

H801045200

HA300J2230

H200800068

HA300B2170

H200800671

HA300}2250

HA300}2280

H200800067

HA305J0665

HA110J0701

HA307J0671

HA300J2050

HA300J2060

HA100J2110

HA100J2120

HA300J2070

HA300J2200

HA300J2210

HA300J2220

HA100J2170

HA100J2180

H2000G2030

HA700G2040

HN504C8001

seservoir

Oil

drain

Oil

screw

Washer

Gasket

Gasket

Hinge

Backspring

Knee

for

for

pin

lifter

oil

oil

for

for

stop

reservoir

reservoir

knee

lifter

knee

bracket

Adjusting screw

Lock

nut

Screw

Knee

Knee

Joint

lifter

lifter

for

lifting

bell

knee

crank

lifter

Set screw

Knee

lifter

Bracket

Set

screw

Pad

for

for

knee

plate

knee

lifter

lifter

Screw

Washer

Belt

(upper)

Screw

Belt

mark

complrte

Screw

Screw

Belt

(lower)

Belt

complete

Hinge

of

machine head

Rubber

Rubber

socket

for

cushion(big)

hinge

Rubber cushion(small)

Oiler

Magnet

Screw

driver

(long)

Screw

driver

(medi

urn)

Screw

driver(short)

Double-end wrench

Oil

container

Vinyl cover

Needle

Needle

Needle

lifter

rod

bell

plate

(small)

(big}

crank

plate

1

1 1

1

1 1

1 1 1

1

1 1

1 1

1

1 1 1

1 1

1

1 1 1

2

2 2

2

2 2

1 1

1 1

1

2

1

1

1

1 1

2 2

1 1 SM5/16(28) X

1 1 1

1 1

1

4 4

4 4

1 1

6 6

1 1

1 1

2

1

1 1

2

1

1

4

4

1

6

1

1

2

1

1 1 1

1 1

1

2 2 2

2 2

2

2 2 2

2 2 2

1 1 1

1 1 1

1 1 1

1 1 1

1 1

1

1 1 1

1 1

1

1

1 1

4

4

4

SM15/64

SM15/64

SM15/64

GB/T99

SM11/64

M4X

12.

SM15/64

(28) X 28

(28) X 14.

16

(28)

X 8

4.

5 X

20

(40)

X 8

5

(28)

X 8

8

-35-

Page 38

H.

OIL RESERVOIR AND OTHER ACCESSORIES

-o::

.......

Fig.

No.

H42

H42

H43

H44

H44

Part

No.

HA905S0066

HA905S0067

HA200J2030

H1100E2010

HA100E2170

Description

Bobbin winder assy

Bobbin winder assy

Washer

Bobbin

Bobbin

I

00 00

....... .......

M M

0 0 0

u u u

0 0 0

1 1

1 1

3

::c:

.......

I I

1

3

c:l

.......

00

.......

M

1

3

Remarks

-36-

Page 39

Page 40

SHANGHAI HUIGONG

N0.3

SEWING MACHINE FACTORY

ADD: 1418, Yishan

Road,

Shanghai,

China

Zip Code: 201103

Overseas Business:

TEL:

86-21-64853303 FAX: 86-21-64854304

E-mail:highlead@online.sh.cn http://www.highlead.com.cn

The

description

covered

in

this

manual

is

subject

to

change

for

improvement

of

the

conmtodity without notice

2006.8.

Printed

Loading...

Loading...