Highlead GC0068-1 User Manual

Purchasing

Copy

Dept

HIGH

LEAD

GG0068-1

High-Speed,l-Needle,Lockstitch, Zigzag Stitching Machine

Instruction Manual

Parts

SHANGHAI

HUIGONG

N0.3

Catalog

SEWING

MACHINE

FACTORY

CONTENTS

CONTENTS

1,

PRECAUTIONS BEFORE STARTING OPERATION

2,

MAIN SPECIFICATIONS

3,

PREPARATION

4,

REPLACE NEEDLES ..................................................................................................................................... 3

5,

WINDING THE BOBBIN THREAD ............................................................................................................. 3

6,

THREADING THE MACHINE HEAD ...........................••...........•...•....•...................................................... 4

7,

ADJUSTING THE STITCH LENGTH ..................•.......•...••.•.••......•.................................................•........... 5

8,

ADJUSTING THE HEIGHT

9,

ADJUSTING THE PRESSURE OF THE PRESSER

10, ADJUSTING THE THREAD TENSION ............................................................................................ 5

11, ADJUSTING THE BOBBIN THREAD TENSION

12, ADJUAT THE ZIGZAG WIDTH ................................................................................................................ 6

13, ADJUSTING THE DENSER STITCHING .............................................................................................. 7

......................................................................................................................

..... , .......................................................

...............................•....•..•..•..........•....•......................................

AND

LUBRICATION

OF

.....................•.........................•.....................•...•.•....

THE PRESSER .••.••.•.••••••••••..••.•.•........................•................................... 5

FOOT

................................................................

......................................................

!

2

2

2

5

6

14, ATTACHING I REMOVING THE HOOK ......................................•.....•.........•........................................ 7

15, ADJUST THE POSITION OF FEED DOG .............................................................................................. 7

16, ADJUSTING HEIGHT

17, ADJUSTING THE NEEDLE TO HOOK TIMING

18, ADJUSTING THE AMOUNT OF OIL

19, CHANGEOVER

20, PLACING A BOBBIN INTO THE BOBBIN CASE ................................................................................... 9

PARTS

CATALOG

...........................................................................................................

OF

THE NEEDLE BAR ..................................................................................... 8

AND

THE NEEDLE GUARD .............................. 8

IN

THE HOOK ............................................................................ 8

OF

STANDARD ZIGZAG ............................................................................................ 9

lO

-1-

1. PRECAUTIONS

1)

Safety Precautions

(

1)

When turning the power on, keep your hands and fingers away from the area around/under the needle

and the area around the balance wheel.

Power must be turned off when the machine is not in use, or when the operator leaves the seat.

(2)

Power must be turned off when tilting the machine head, installing or removing the

(3)

the machine, or when replacing.

(4) Avoid placing fingers, hairs, bars etc., near the balance wheel,

or motor when the machine is in operation.

(5) Do not insert fingers into the thread take-up cover, under/around the needle, or balance wheel when the

is

machine

(6) If a belt cover, finger guard, eye guard are installed, do not operate the machine without these safety

devices.

2)

Precautions before Starting Operation:

(

l)

If the machine's oil pan has an oil sump, never operate the machine before filling it.

(2) If the machine

(3) When a new sewing machine is first turned on, verify the rotational direction

the power on. (The balance wheel should rotate counter-clockwise when viewed from the balance wheel)

(4) Verify the voltage and (single or three) phase with those given on the machine nameplate.

in

BEFORE

operation.

is

lubricated by a drop oiler, never operate the machine before lubricating.

STARTING OPERATION

"V"

belt, bobbin winder balance wheel,

of

the balance wheel with

"V"

belt, adjusting

3)

Precautions for Operating Conditions:

(1) Avoid using the machine at abnormally high temperature (

lower) .

(2) Avoid using the machine in dusty conditions.

2.

MAIN SPECIFICATIONS

s

2-step

~

Max.sewing speed

Feed pitch

Zigzag width 5mm IOmm C Standard 8

Presser

Needle

Rotating hook Auto lubricated hook

Lubrication Auto lubricated

Motor 370W clutch motor

By hand

By knee IOmm

2.5mm

4500rpm

DPX5

35

5.5mm

9#-14#

·c

or higher) or low temperature ( 5

4-step

2mm

mm)

·c

or

3. PREPARATION AND LUBRICATION

-2-

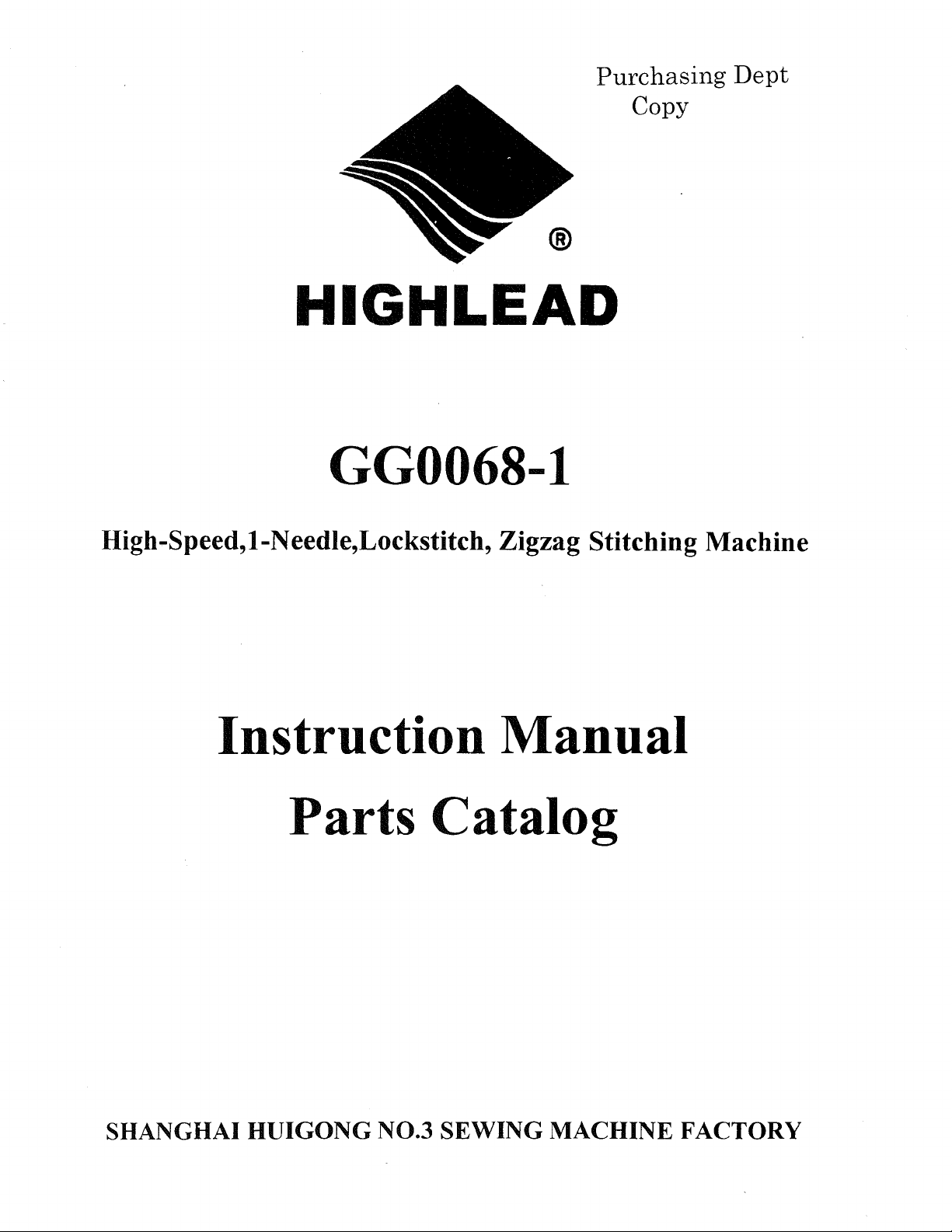

1) Cleaning the machine

Before leaving the factory, the machine

parts are coated with rust-preventive grease,

which may be hardened and contaminated by

dust during storage and shipment. This grease

must be removed with gasoline.

2)

Examination

Though every machine is confirmed by

strict inspection and test before leaving the

factory, the machine parts may be loose or

deformed after long distance transportation with

jolt. A thorough examination must be performed

after cleaning the machine. Turn the balance

wheel to see if there

parts collision, uneven resistance or abnormal

noise. If these exist, adjustment must be made

accordingly before run-in operation.

is

running obstruction,

3) Oiling (Fig.l)

(I)

Required amount

Line (A) on the oil reservoir: Max.

Line (B) on the oil reservoir: Min.

If oil level goes down under line B, oil cannot be

distributed to each part

parts a seizure.

(2) Replenishing

of

oil

Oil level

Oil level

of

the machine, thus causing the

A

.t

I

!

2

B

18

Always use only No.

for high speed sewing. Be sure to replenish oil to

line A before starting operation.

(3) Replacing oil

To

replace oil, remove screw (C) to drain oil.

After completely draining

reservoir and securely tighten screw (C), then fill

the reservoir with fresh oil.

4.

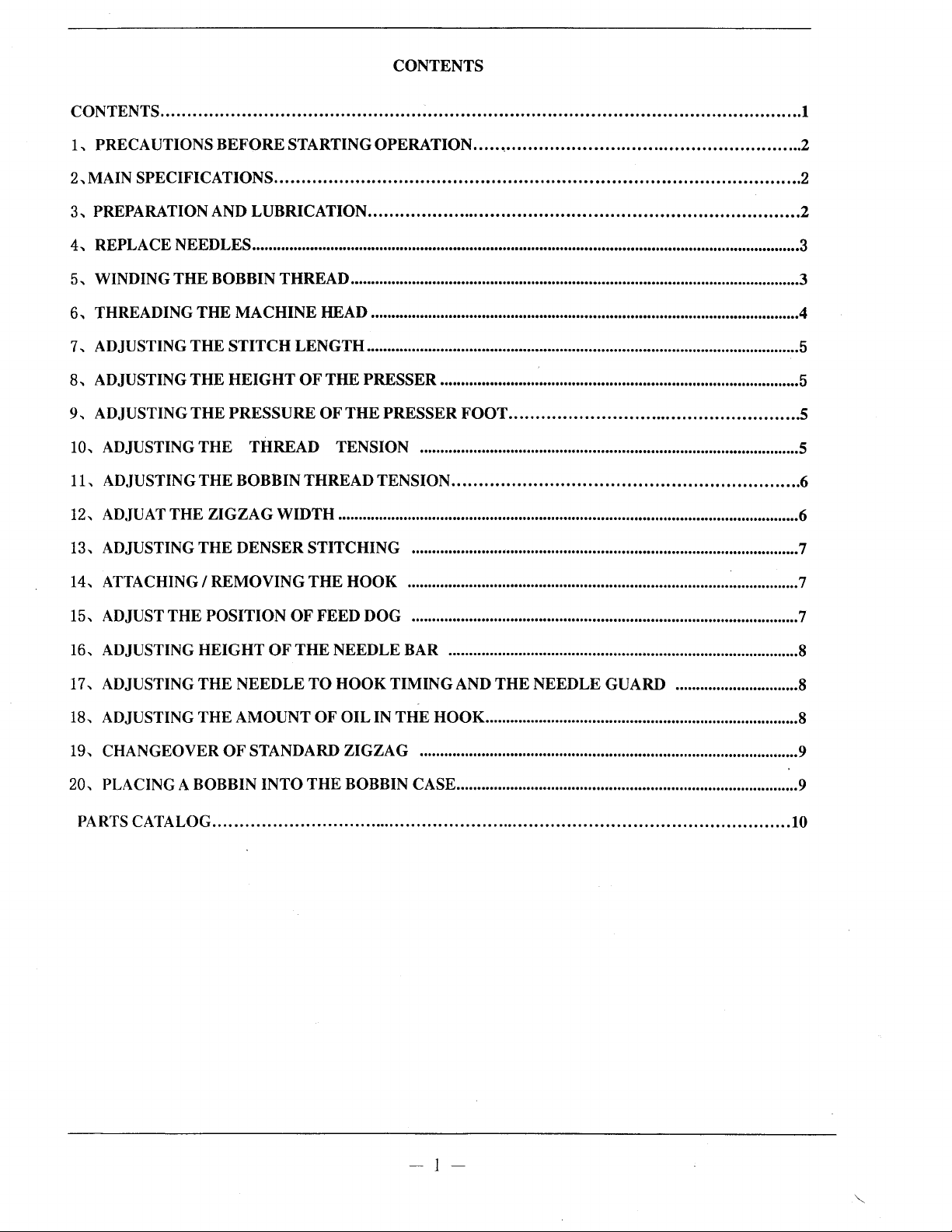

REPLACE NEEDLES (Fig.2)

Tum the handwheel by hand to raise the

needle bar

clamp screw

long groove B on the needle

toward

the needle har

will go

5,

to

the highest pointo Loosen the needle

(1),

hold the needle @ so that the

you" Insert the needle deep into the hole

in

the direction

no

further" Securely tighten the screw

WINDING

THE

special machine oil

off

oil, clean the oil

is

facing exactly

of

of

the arrow until it

CDo

BOBBIN THREAD (Fig.3,

3

4)

- 3

--

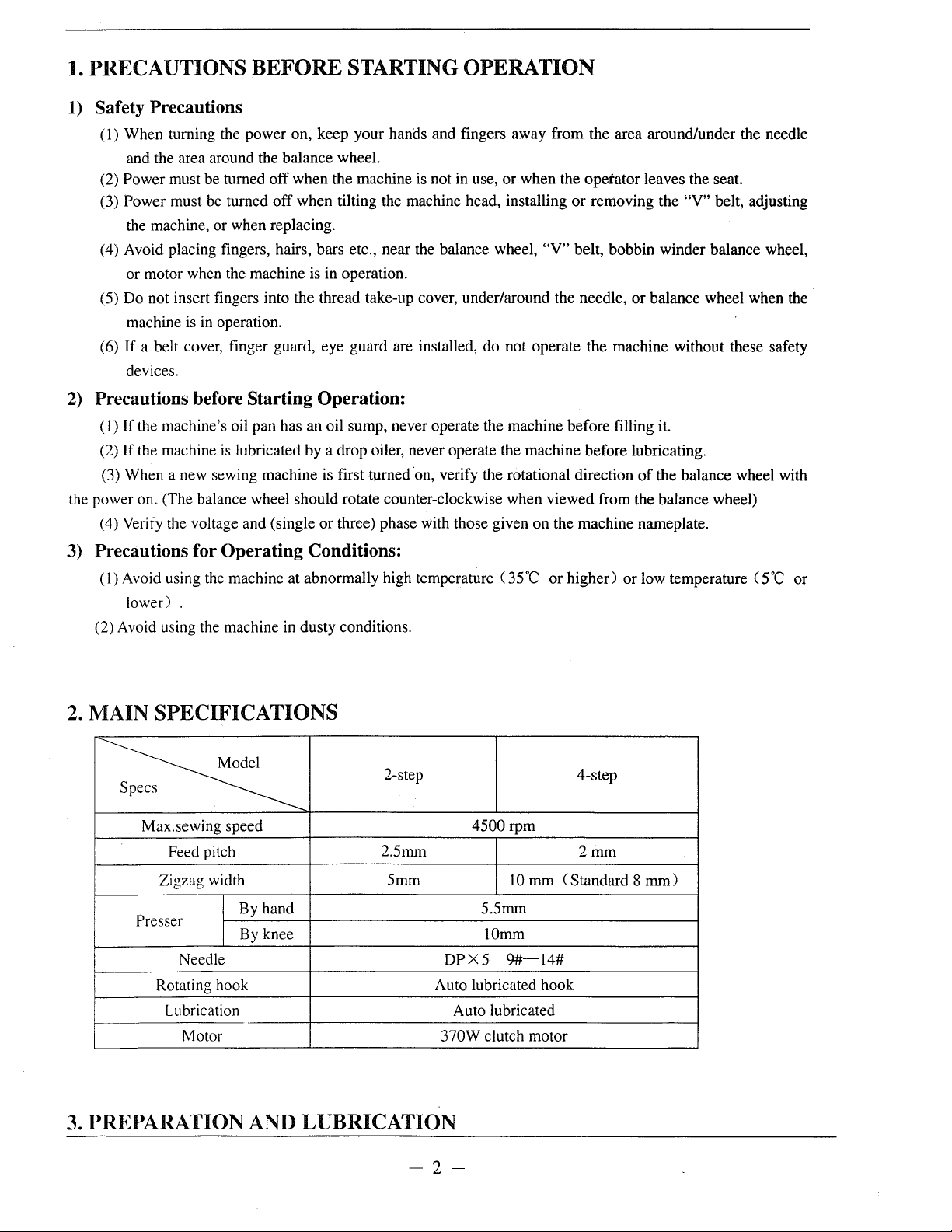

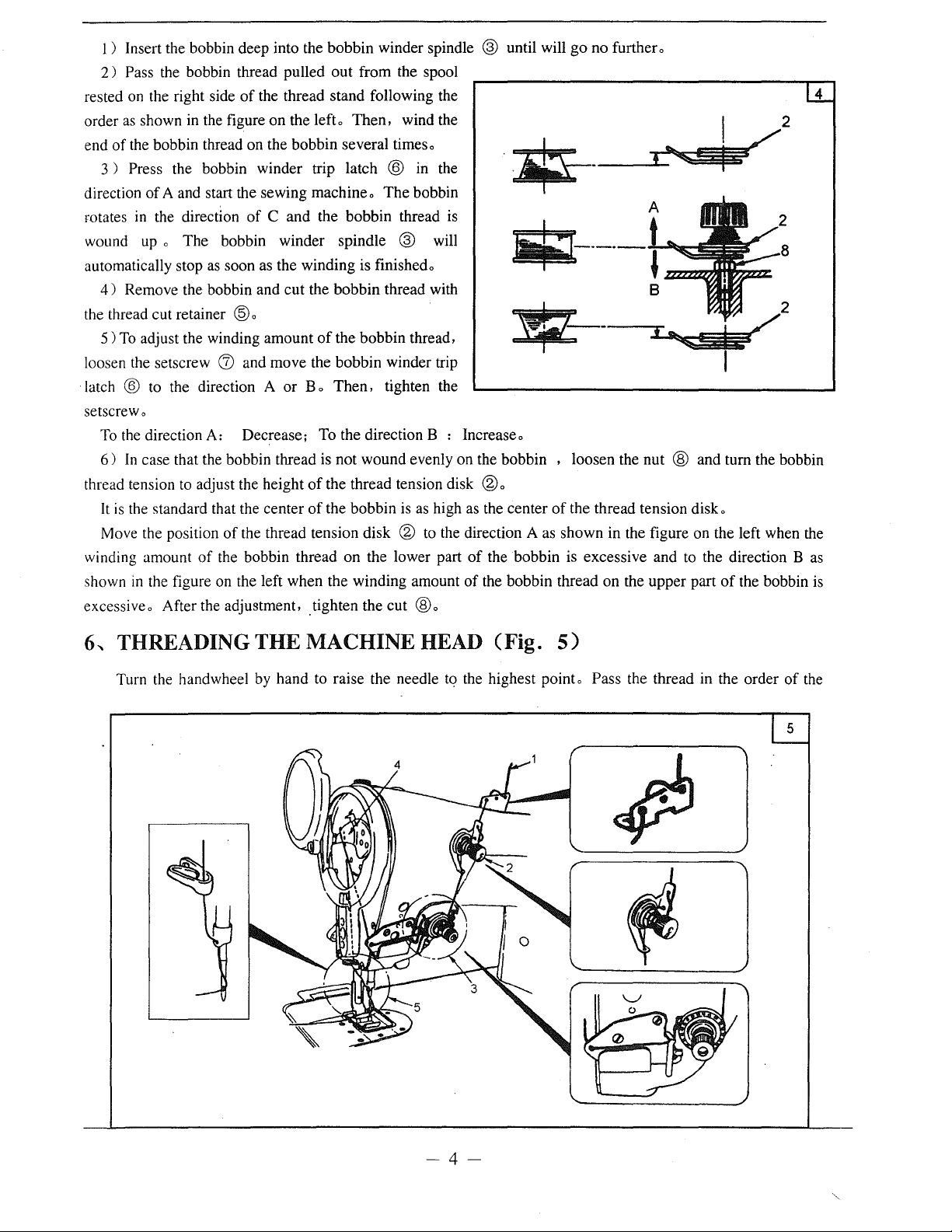

1 ) Insert the bobbin deep into the bobbin winder spindle ® until will

2)

Pass the bobbin thread pulled

of

rested on the right side

as

order

end

direction

rotates

wound up o The bobbin winder spindle

automatically stop

the thread cut retainer

loosen the setscrew

latch

setscrewo

thread tension to adjust the height

winding amount

shown

excessiveo After the

shown in the figure on the left o

of

the bobbin thread on the bobbin several timeso

Press the bobbin winder trip latch ® in the

3 )

of

A and start the sewing machineo

in

the direction

as

4)

Remove the bobbin and cut the bobbin thread with

5)

To

adjust the winding amount

® to the direction A

To

the direction A: Decrease; To the direction B : Increaseo

6)

In

case that the bobbin thread is not wound evenly on the bobbin , loosen the nut @ and turn the bobbin

It

is

the standard that the center

Move the position

of

in

the figure on the left when the winding amount

the thread stand following the

of

C and the bobbin thread is

soon as the winding is finishedo

®o

(J)

and move the bobbin winder trip

or

of

the thread tension disk ® to the direction A as shown in the figure on the left when the

the bobbin thread on the lower part

adju~tment,

out

from the spool

Then,

wind the

The

bobbin

® will

of

the bobbin thread,

B o

Then,

of

the thread tension disk ® o

of

the bobbin is

.tighten the cut

tighten the

as

high as the center

®o

of

the bobbin is excessive and to the direction B

of

the bobbin thread on the upper part

go

no further o

of

the thread tension disk o

of

the bobbin is

4

as

6-.

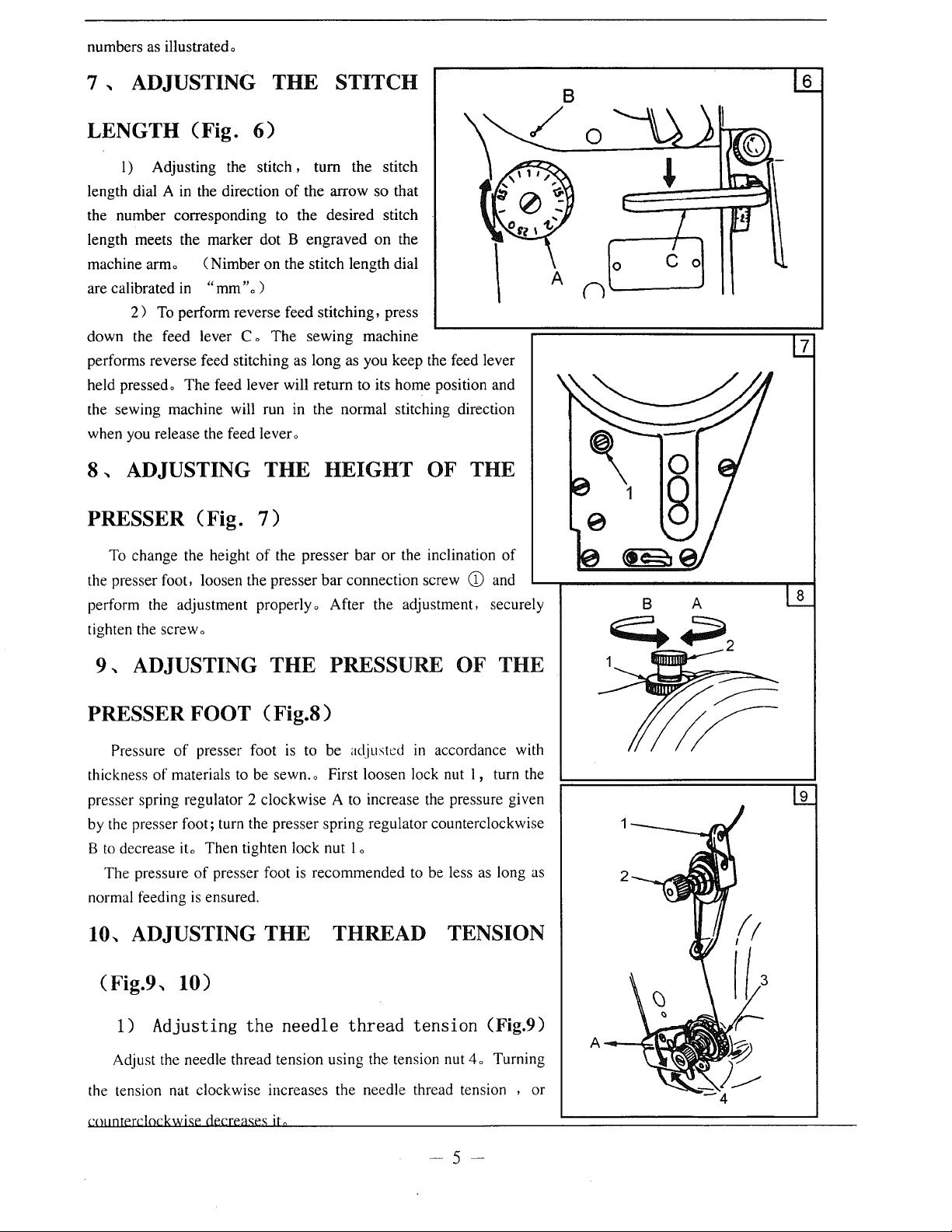

THREADINGTHEMACHINEHEAD (Fig.

Turn the handwheel by hand to raise the needle tq the highest pointe Pass the thread in the order

5)

of

the

-4-

numbers as illustratedo

7 , ADJUSTING

LENGTH (Fig.

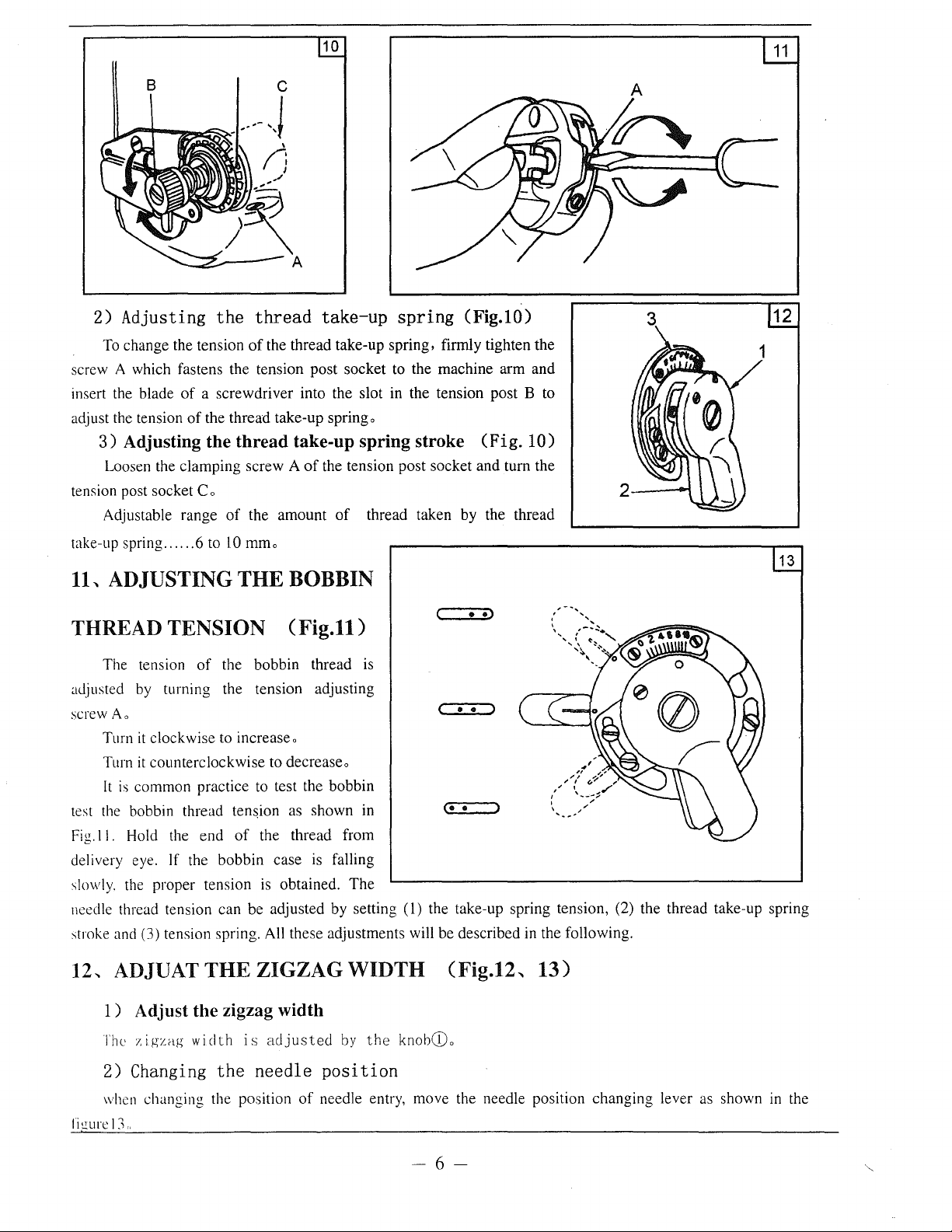

I) Adjusting the stitch , turn the stitch

length dial A in the direction

the number corresponding to the desired stitch

length meets the marker dot B engraved on the

machine armo ( Nimber on the stitch length dial

are calibrated in

2)

To

down the feed lever C o

performs reverse feed stitching as long as you keep the feed lever

held pressedo The feed lever will return to its home position and

the sewing machine will run in the normal stitching direction

when you release the feed lever o

8,

ADJUSTING

"mm

perform reverse feed stitching, press

PRESSER (Fig.

"o

6)

)

7)

THE

of

the arrow so that

The

sewing machine

THE

HEIGHT

STITCH

OF THE

A

6

0

(l'------J

7

To change the height

the presser foot, loosen the presser

perform the adjustment properly o After the adjustment, securely

tighten the screw o

9,

ADJUSTING

of

the presser bar or the inclination

bar

connection screw

THE

PRESSURE

CD

OF

of

and

THE

PRESSER FOOT ( Fig.S)

Pressure

thickness

presser spring regulator 2 clockwise A to increase the pressure given

by the presser foot; turn the presser spring regulator counterclockwise

B

to

decrease

The pressure

normal feeding

10,

(Fig.9,

of

presser foot

of

materials to be sewn. o First loosen lock nut I , turn the

ito

Then tighten lock nut 1 o

of

presser foot

is

ensured.

ADJUSTING

is

to be adjusted

is

recommended to be less as long as

THE

in

accordance with

THREAD TENSION

10)

8

9

1) Adjusting

Adjust the needle thread tension using the tension nut

the tension nat clockwise increases the needle thread tension , or

coJmterc!ockwise

the

decreases

needle

ita

thread

tension

4o

(Fig.9)

Turning

-5-

10

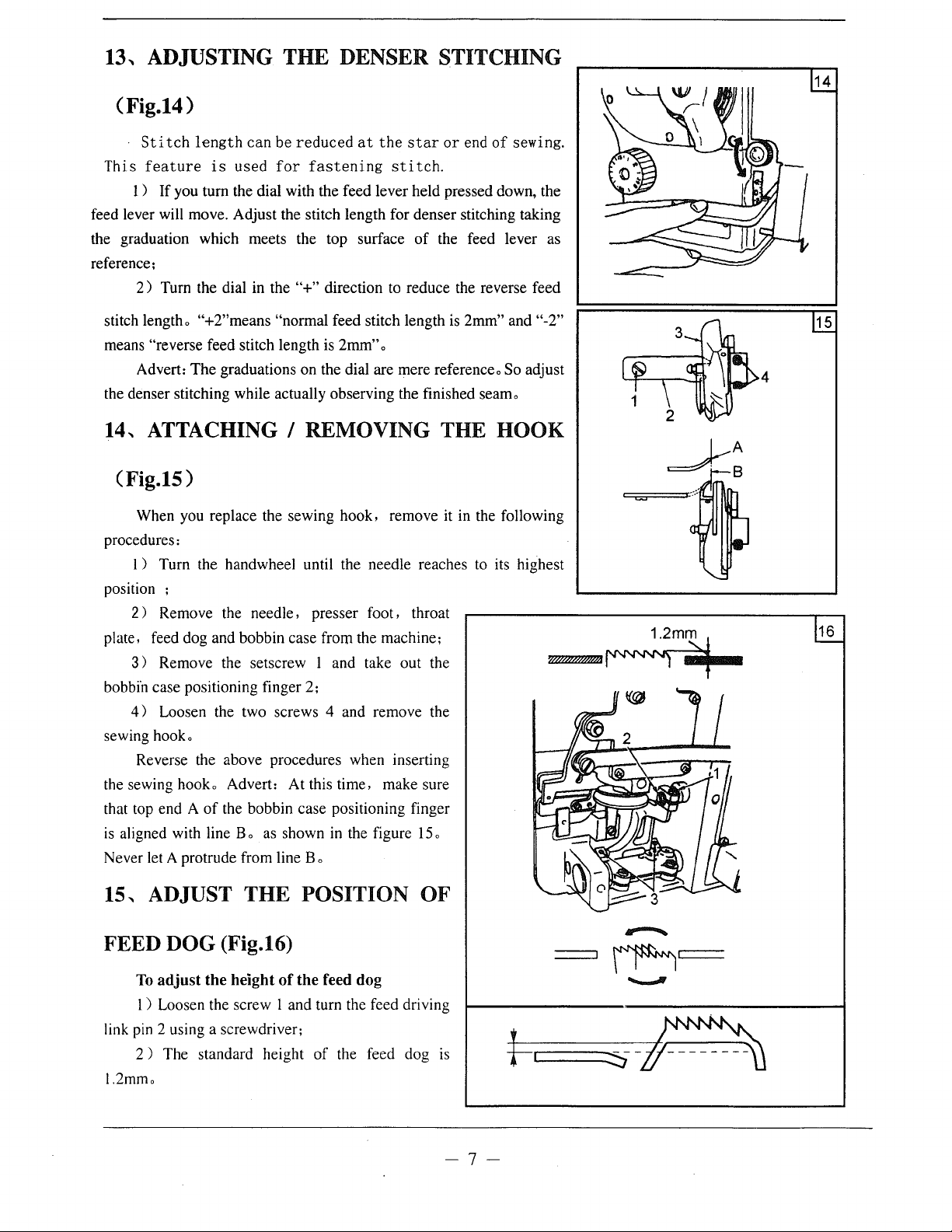

2)

Adjusting

To change the tension

screw A which fastens the tension post socket to the machine

insert the blade

adjust the tension

3)

Adjusting the

Loosen the clamping screw A

tension post socket Co

Adjustable range

take-up spring ..

11,.

ADJUSTING

the

thread

of

the thread take-up spring, firmly tighten the

of

a screwdriver into the slot in the tension post B to

of

the thread take-up spring o

thread

of

the amount

00

••

6 to 10 mmo

THE

take-up

take-up

of

the tension post socket and turn the

of

spring

spring

thread taken by the thread

stroke (Fig.

(Fig.lO)

BOBBIN

( •

·>

arm

and

10)

2--~

THREAD TENSION (Fig.11)

The tension

aJjusted by turning the tension adjusting

screw

Ao

Turn

it

Turn

it

It

is

common practice to test the bobbin

test the bobbin thread

Fig.!

I.

Hold the

delivery eye. If the

slowly. the proper tension

needle thread tension can be adjusted by setting

stroke and (3) tension spring. All these adjustments will be described in the following.

of

the bobbin thread is

clockwise to increaseo

counterclockwise to decreaseo

ten~ion

end

of

bobbin

as shown in

the thread from

case

is falling

is

obtained.

The

( . .

(-.=•.....;:•:..---J

(I)

the take-up spring tension, (2) the thread take-up spring

3

12

---=-~

13

12,.

ADJUAT

1)

Adjust the zigzag width

The

1.igzag

2) Changing

when changing the position

ri~ure

13'

THE

width

the

ZIGZAG WIDTH (Fig.12,.

is

adjusted

needle

by

the

knobCDo

position

of

needle entry, move the needle position

13)

-6-

changing

lever as shown in the

13, ADJUSTING THE DENSER STITCHING

(Fig.14)

14

Stitch

This

feature

1 )

feed lever will move. Adjust the stitch length for denser stitching taking

the graduation which meets the top surface

reference;

2)

stitch lengtho

means "reverse feed stitch length is 2mm" o

Advert: The graduations on the dial are mere referenceo So adjust

the denser stitching while actually observing the finished seamo

length

If

you tum the dial with the feed lever held pressed down, the

Tum the dial in the

"+2"means "normal feed stitch length

is

can

used

be

reduced

for

"+"

at

the

star

or

end

of

sewing.

fastening

direction to reduce the reverse feed

stitch.

of

the feed lever as

is

2mm" and "-2"

14, ATTACHING I REMOVING THE HOOK

(Fig.15)

When you replace the sewing hook, remove it in the following

procedures:

I ) Tum the handwheel until the needle reaches to its highest

position ;

2 ) Remove the needle , presser foot, throat

plate, feed dog and bobbin case from the machine;

3 ) Remove the setscrew 1 and take out the

bobbi'n case positioning finger 2;

4)

Loosen the two screws 4 and remove the

sewing hooko

Reverse the above procedures when inserting

the sewing hook o Advert: At this time, make sure

of

that top end A

is

aligned with line B o as shown in the figure

Never let A protrude from line B o

the bobbin case positioning finger

15

o

W!!/d/d/d!AJ~

1.2mm

15

4

16

15, ADJUST THE POSITION OF

FEED DOG (Fig.16)

To

adjust

I ) Loosen the screw I and tum the feed driving

link pin 2 using a screwdriver;

2 ) The standard height

1.2mmo

the height

of

the feed dog

of

the feed dog is

-7-

Inclination

so that it becomes horizontal when it rises above tha top surface

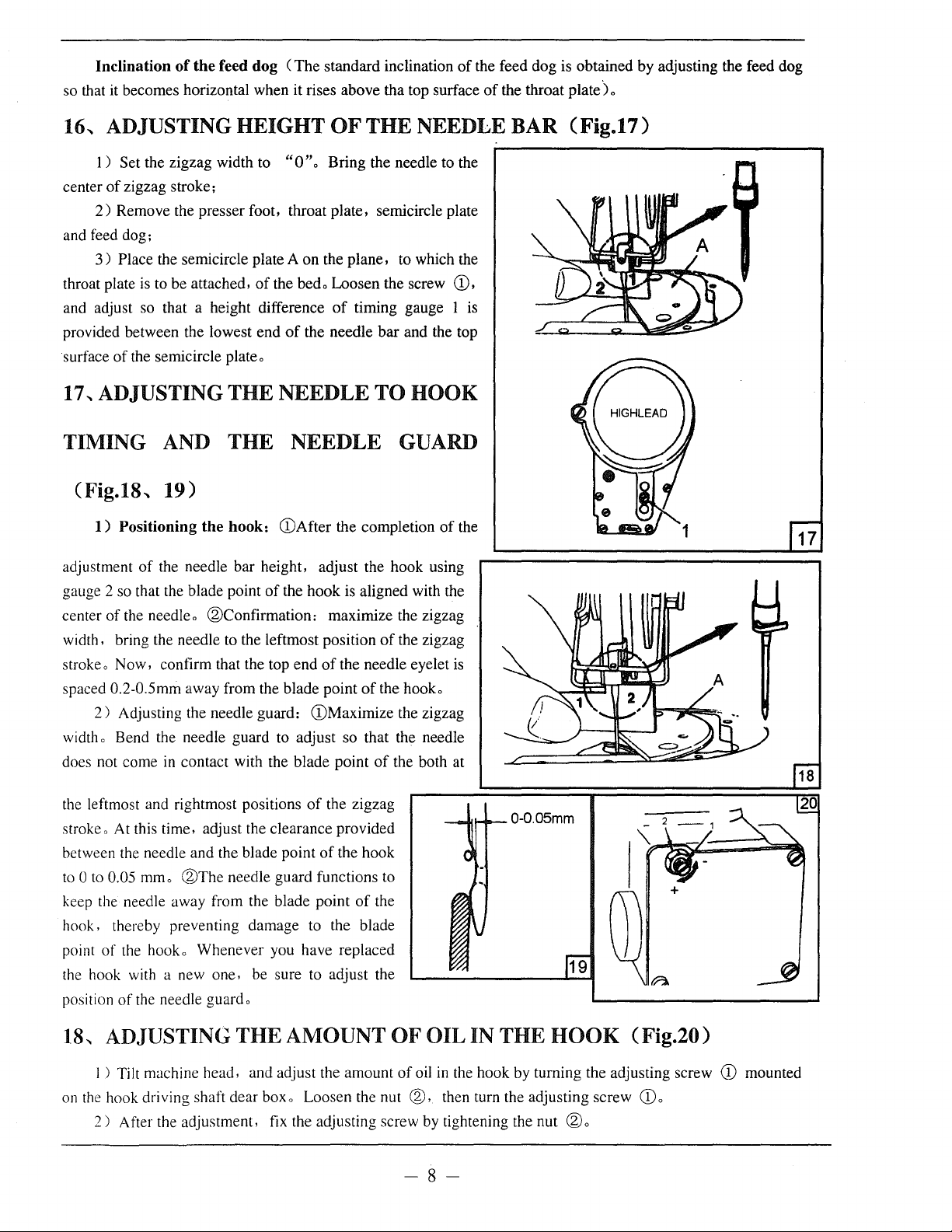

16-.

ADJUSTING HEIGHT

of

the

feed

dog

(The

standard inclination

OF

THE NEEDLE BAR (Fig.17)

of

the feed dog is obtained by adjusting the feed dog

of

the throat

plate)

o

1 ) Set the zigzag width to

of

center

and feed dog;

throat plate

and adjust so that a height difference

provided between the lowest end

surface

17

TIMING

zigzag stroke;

2)

Remove the presser foot, throat plate, semicircle plate

Place the semicircle plate A on the plane, to which the

3 )

is

to be attached,

of

the semicircle plate o

..

ADJUSTING THE NEEDLE TO HOOK

AND

THE NEEDLE GUARD

"0

"o

Bring the needle to the

of

the bedo Loosen the screw (D,

of

timing gauge 1 is

of

the needle bar and the top

(Fig.18-. 19)

1)

Positioning

adjustment

gauge 2 so that the blade point

center

width, bring the needle to the leftmost position

stroke o Now, confirm that the top end

spaced 0.2-0.Smm away from the blade point

width o Bend the needle guard to adjust so that the needle

does not come

of

of

the needleo

2)

Adjusting the needle guard: (!)Maximize the zigzag

the

hook:

the needle bar height, adjust the hook using

®Confirmation:

in

contact with the blade point

(DAfter the completion

of

the hook is aligned with the

maximize the zigzag

of

the zigzag

of

the needle eyelet

of

the hooko

of

the both at

of

is

the

of

the leftmost and rightmost positions

stroke o At this time, adjust the clearance provided

between the needle and the blade point

to 0 to

keep the needle away from the blade point

hook, thereby preventing damage to the blade

point

the hook with a new one. be sure to adjust the

position

18-.

on

0.05

mmo

®The

needle guard functions to

of

the hooko Whenever you have replaced

of

the needle guardo

ADJUSTING THE AMOUNT OF OIL IN THE

I ) Tilt machine head, and adjust the amount

the

hook driving shaft dear boxo Loosen the nut

2)

After the adjustment, fix the adjusting screw by tightening the nut

the zigzag

of

the hook

of

the

HOOK

of

oil in the hook by turning the adjusting screw

@,

then turn the adjusting screw

-8-

®o

(Fig.20)

CDo

CD

mounted

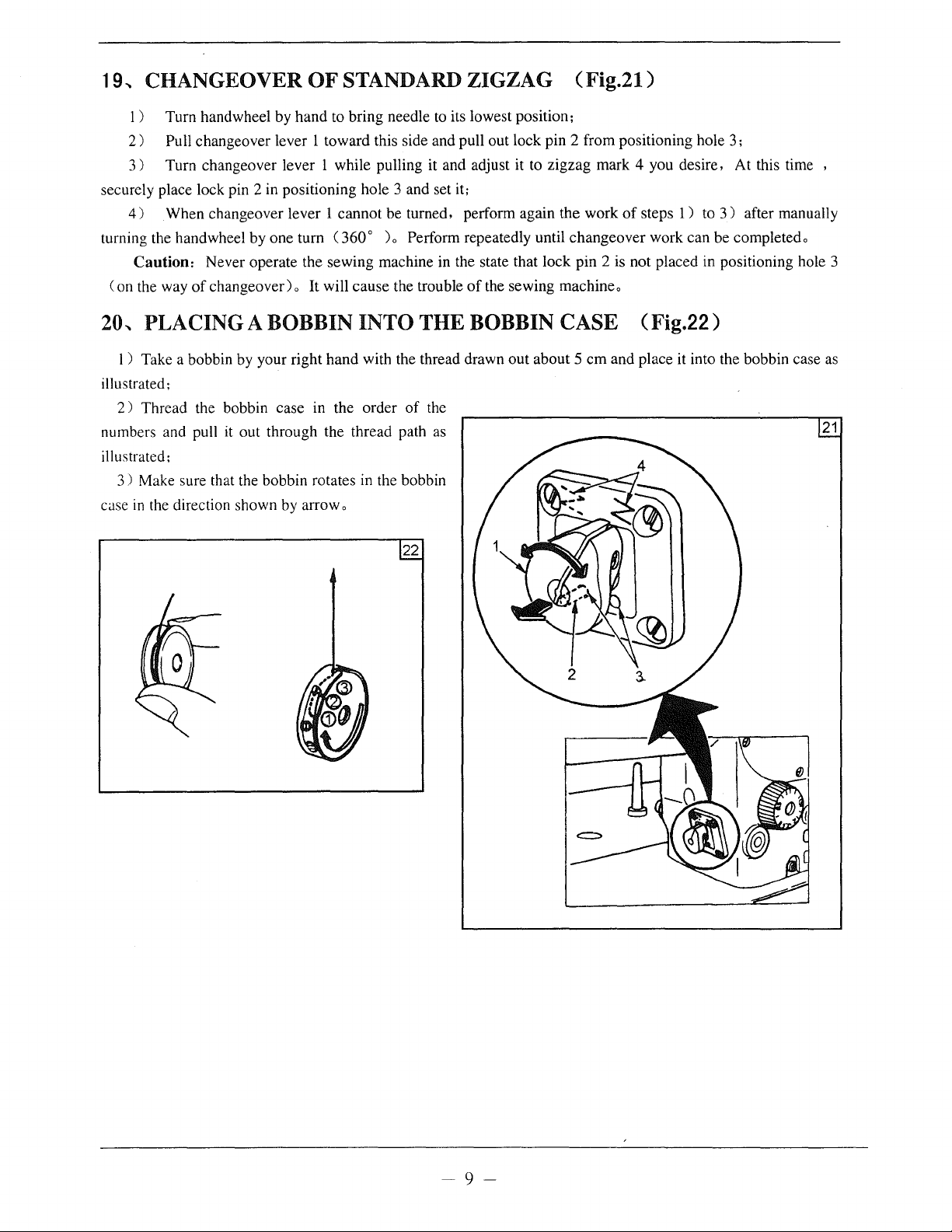

19,

CHANGEOVER

1)

Turn handwheel by

2)

Pull changeover lever 1

3)

Turn changeover lever 1 while pulling it and adjust it to

securely place lock pin 2 in positioning hole 3 and set it:

4)

When changeover lever 1

turning the handwheel by

Caution:

(on

the way

Never operate the sewing machine in the state that lock

of

changeover)

hand

one

turn C360o

o It will

OF

STANDARD ZIGZAG (Fig.21)

to bring needle to its lowest position;

toward

this side and pull out lock pin 2 from positioning hole 3;

zigzag

cannot

be turned, perform again

)o

Perform repeatedly until

cause

the trouble

of

the

changeover

pin

the sewing machineo

mark

4 you desire, At this time ,

work

of

steps 1 ) to 3 ) after manually

work

can

2 is not placed in positioning hole 3

20, PLACING A BOBBIN INTO THE BOBBIN CASE (Fig.22)

be completedo

1 ) Take a bobbin by your right

illustrated;

2)

Thread the bobbin case in the order

numbers and pull it out through the thread path as

illustrated:

3)

Make sure that the bobbin rotates in the bobbin

case

in

the direction shown by arrow o

hand

with the thread drawn

of

the

22

out

about 5

em

and place it into the bobbin case as

21

~9~

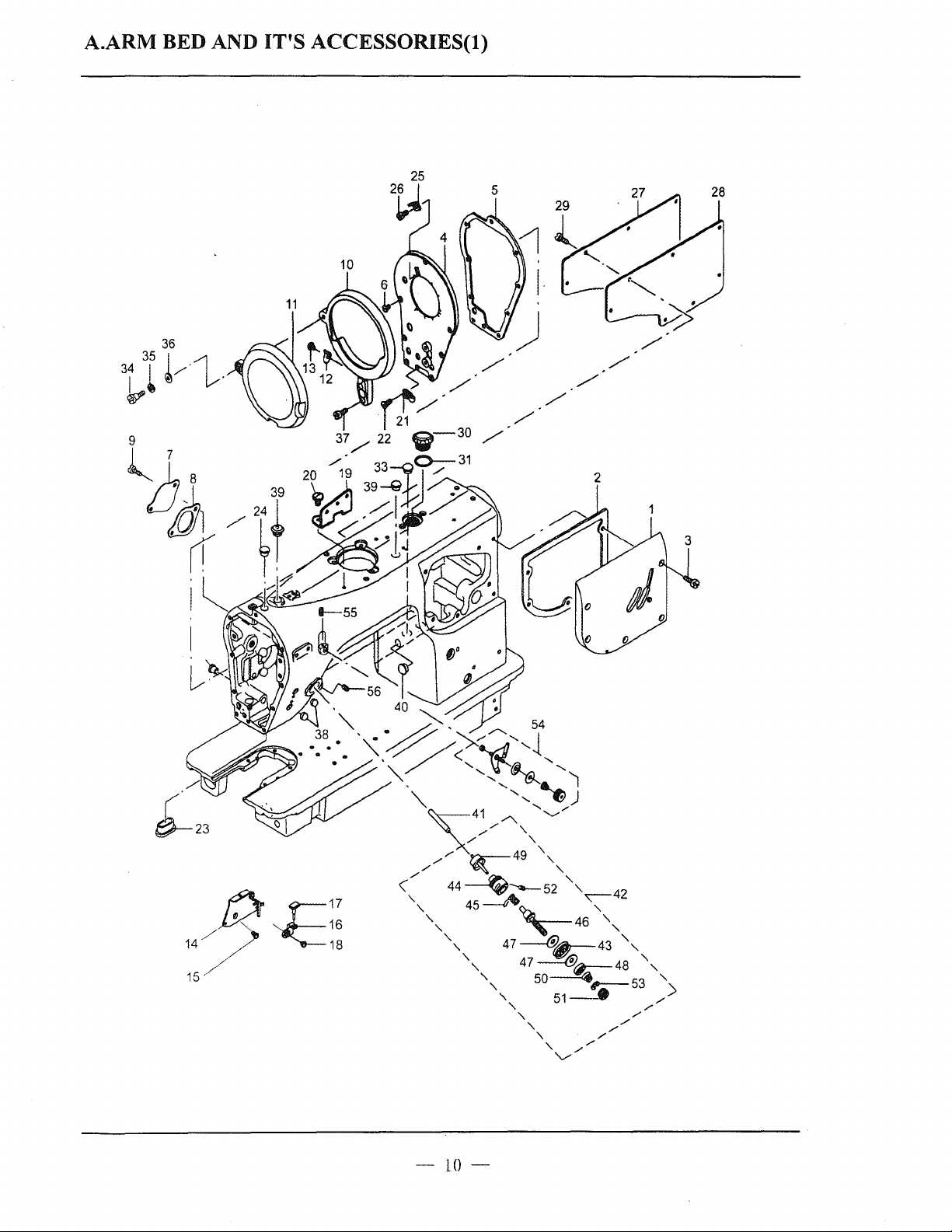

A.ARM BED AND

IT'S

ACCESSORIES(l)

-10-

Loading...

Loading...