Page 1

HIGH

LEAD

GA2688-L

Long

Arm

Compound-Feed

Extral

Cylindrical Bed

Heavy Duty

Instruction Manual

Parts

Catalog

SHANGHAI HUIGONG

N0.3

SEWING MACHINE FACTORY

Page 2

1,

I'I~IT~l

~~r

1 J

(

2)

(

:1)

2,

VIAT\J

:1,

PREP.~RATION

4,

REPLACE

0,

111\DINGOFBOBBINTHREAD

fi,

:\D.Tl

(I)

(2)

C

:1)

7,

THRE:\DI"'G

i'L

I!I~Wl'v 1 ~c;

Y,

.\DJl'STI"iG

10,

11,

TIONS

SCi

f

~;tv

Precautions

Precautions

BEFORE

Precautions

before

for

SPECIFICATION

FOR

OPERATION

NEEDLES · .....

STMENT

In

case

OF

of

THE

uneven

Windingaruountofthread

Winding

strength

........................

AND

INSERTING

THE

THREAD

.\DWSTMENT

.\DJLSTMENT

OF

PRESSER

OF

WALKING

---

STARTING

.; · · · · · ·

OPERATION

;-.

· · · · · · · · · · •

Starting

Operating

Conditions

•·····•··•··•·••··

CONTENT

......................................................

.-.

· ·· · · · · · · · · · · · · · ·· · ·· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 2

Operation

·•·••·•··•··•··•··•·•·•••··•··•··

·····································································

························•············································

---

······•··•··

···•····•

·····•···

..........................................................................................

···

......

•· · •·

· · · ·•· ·

......

··· ··· •··

......

•·· ··· ·· · ··· ···

•·

· ··· ···

...

•·

· ··· ··· ·

.............................................................................................

BOBBIN

WINDER

winding

•·

· · .. ··· ·· ·•··

.........

··· ... ··

....

··· ... · .. · .. · ·· · .. ·

....

.......................................................................................

..........................................................................................

...................................................................................................

··· ···

THE

TENSION

FOOT

FOOT

.......................................

BOBBIN

..............................................................................

.......................................................................................

PRESSURE

AND

.........

PRESSER

• ·

....... • ....

FOOT

...............................................................

· •

··· ···

.....................

.....

•·

· · · · .. · • .. · .. • · • · · · .. · · • · • · · •

···

............

•··

..................

.....

··•··· ··· •·· ... 4

· · .. •··

...........

•··

...............

..........

··· 2

2

2

2

3

4

· •·· 4

4

4

4

4

5

5

· ·.. 5

6

12,

ADjt:STMENT

1

:1,

FEED

14,

ADJUSTING

:l,

l S

I

DOG

I·\JG

HEIGHT

OF

THE

OF

THE

HAND

STITCH

.....

· ... ·

HEIGHT

WHEEL

LENGTH

AND

..... · ........

OF

THE

• .. · · ·

......

FORWARD/BACKWARD

·•·

............

NEEDLE

· .. · ·

BAR

........ · ....

•··

.................................

..................

· .. •

SEWING

..........

.............................. · ........

· · · · · · · .. · .. • · ·

··

...............................

• · · · · ·

.. · ....

· .. · .. · · · · · · ·

.... · .... · ......

.........

· .. ·

..............

•··

...

· · · · · · 6

· · ..

·..

6

6

7

-1-

Page 3

1.

PRECAUTIONS

1)

Safety Precautions:

(I)

When turning the power on, keep your hands and fingers away from the area around/under the needle

and the area around the balance wheel.

Power must

(2)

be

BEFORE

turned

off

STARTING OPERATION

when the machine is not in use, or when the operator leaves the seat.

Power must

(3)

the machine, or when replacing.

( 4) Avoid placing fingers, hairs, bars etc., near the balance wheel,

or motor when the machine is in operation.

Do

(5)

(

not insert fingers into the thread take-up cover, under/around the needle, or balance wheel when the

machine

6)

If

a belt cover, finger guard, eye guard are installed, do not operate

devices.

be

turned

is

in operation.

off

when tilting the machine head, installing

"V"

2) Precautions before Starting O.veration:

(I)

If

the machine's oil pan has an oil sump, never operate the machine before filling

(2)

lfthe

machine

(3) When a new sewing machine is first turned on, verify the rotational direction

the power on. (The balance wheel should rotate counter-clockwise

wheel)

( 4) Verify

the

is

lubricated

voltage and (single or three) phase with those given on the machine nameplate.

by

a drop oiler, never operate the machine before lubricating.

or

removing the

belt, bobbin winder balance wheel,

the

machine without these safety

ofthe

when

viewed from the balance

"V"

belt, adjusting

it.

balance wheel with

3) Precautions for Operating Conditions:

(I)

Avoid using the machine

lower) .

(2) Avoid using the machine in dusty conditions.

at

abnormally high temperature (

2 ~ MAIN SPECIFICATIONS

Max. Speed

Needle

Needle Bar Stroke

Thread Take-up Lever Stroke

Stitch Length

By

Hand

Presser-Foot Stroke

By Knee

35

800 rpm

DYX3

56

nnn

96

nnn

11

nnn

13

nnn

20nnn

·c

or higher) or low temperature ( 5

26#

·c

or

-2-

Page 4

3-..

PREPARATION

FOR

OPERATION

1 ) Cleaning the machine

Before leaving the factory, the machine parts are coated with rust-preventive grease, which may be

by

hardened and contaminated

2)

Examination

dust during storage and shipment. This grease must

be

removed with gasoline.

Though every machine

parts may be loose

performed after cleaning the machine. Turn the balance wheel

collision, uneven resistance or abnormal noise.

operation.

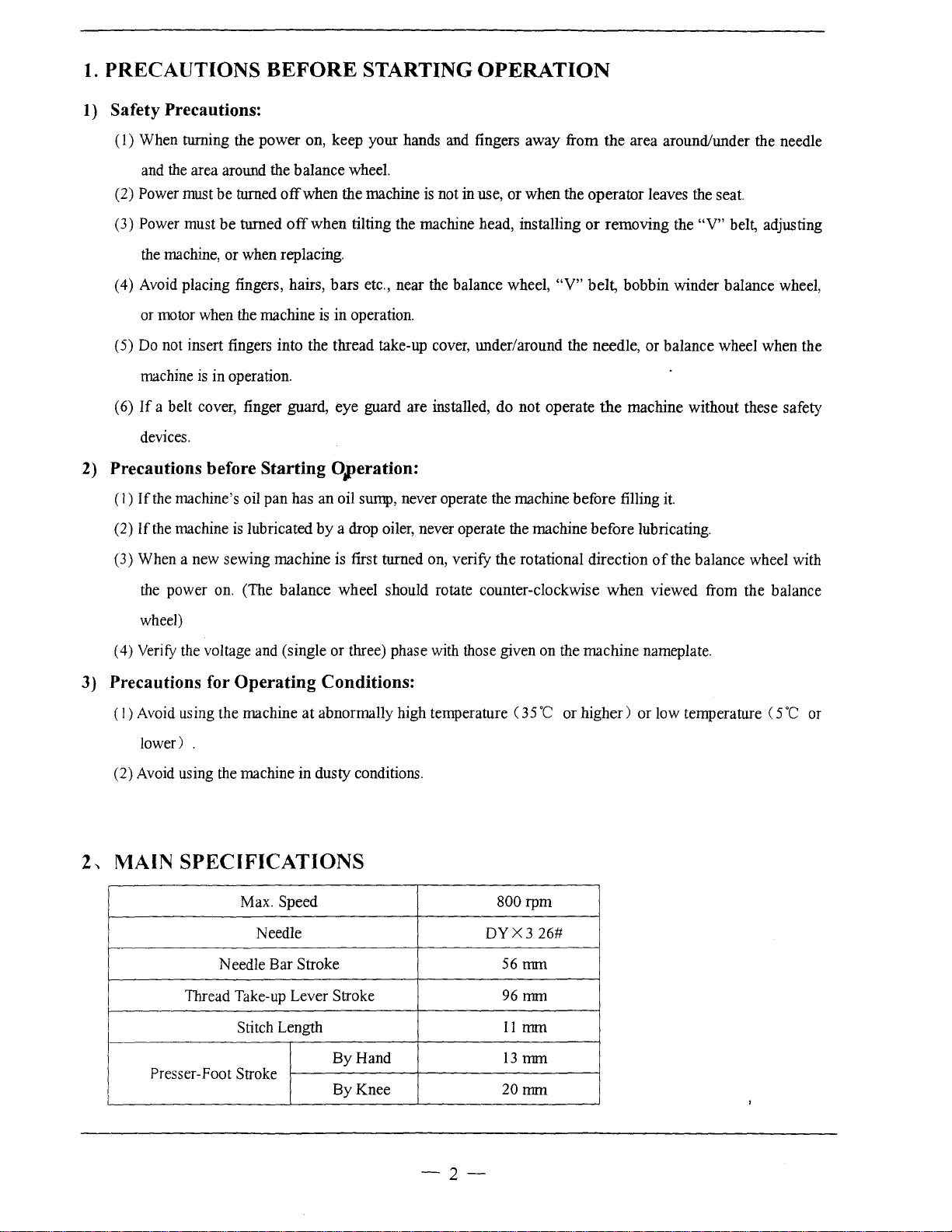

3)

Lubrication

When a new sewing machine

long time

is

used again, replenish a suitable amount

or

is

confirmed by strict inspection and test before leaving the factory, the machine

deformed after long distance transportation with jolt. A thorough examination must

If

these exist, adjustment must

(Fig.l.L

Fig.1.2-.. Fig.1.3)

is

used

for

the first time, or sewing machine left out

of

oil

to

the portions indicated by arrow in below figure.

to

see

0

if

there

is

running obstruction, parts

be

made accordingly before run-in

of

use for considerably

1.

be

3

CAUTION:

4)

lubricated

CAUTION:

according

Please

Always

use

keep

white

the

spindle

presser

oil.

foot

Testing

In

order

to

get the best working situation, run the sewing machine in a low speed

fully.

Then increase the speed

Before

The needle used by this sewing machine

to

the

using

sewing thread.

the

(the

to

the need

following

sewing thread should be able

lifted

one.

procedures,

is

DY

before

X 3

attempting

be

sure

26#.

During operation, proper needle can be chosen

to

pass the pinhole.)

-3-

to

turn

a

dry

run.

for

about 1 month after

the

power

switch

off.

Page 5

4.

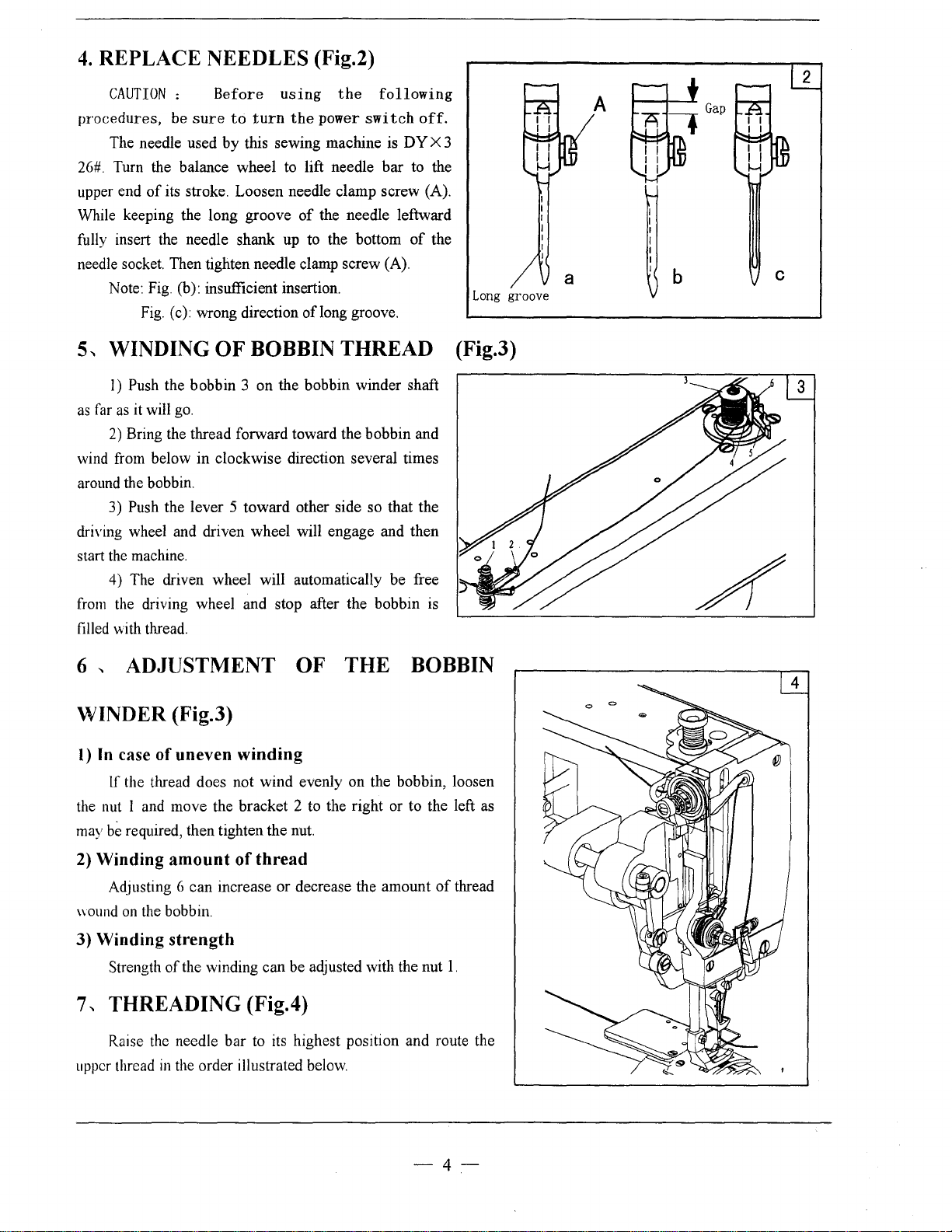

REPLACE NEEDLES (Fig.2)

CAUTION

procedures,

The needle used

26#.

Turn the balance wheel to lift needle

upper end

While keeping the long groove

fully insert the needle shank up to the bottom

needle socket. Then tighten needle clamp screw (A).

5-.

as

far

wind from below in clockwise direction several times

around the bobbin.

driYing

start the machine.

from

filled with thread.

of

its stroke. Loosen needle clamp screw (A).

Note: Fig. (b): insufficient insertion.

Fig. (c): wrong direction oflong groove.

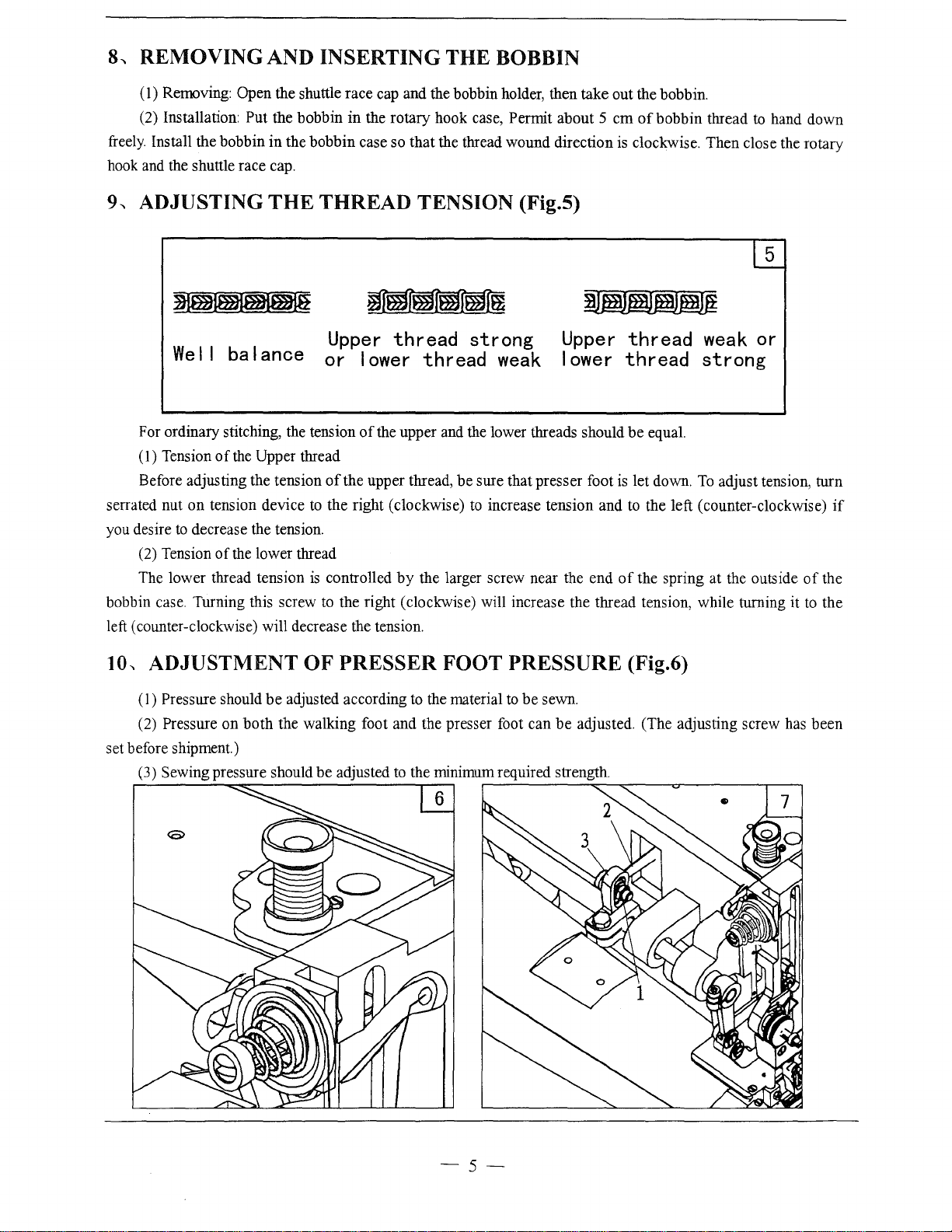

WINDING

I) Push the bobbin 3 on the bobbin winder shaft

as

it will

2)

Bring the thread forward toward the bobbin and

3) Push the lever 5 toward other side so that the

wheel and driven wheel will engage and then

4) The driven wheel will automatically

the driving wheel and stop after the bobbin is

:

be

go.

Before

sure

to

by

OF

using

turn

this sewing machine is DY X 3

BOBBIN

the

following

the

power

switch

bar

of

the needle leftward

THREAD

be

off.

to the

of

free

the

(Fig.3)

Long

groove

A

b

2

c

6

-.

ADJUSTMENT OF THE BOBBIN

WINDER (Fig.3)

I)

In

case

of

uneven

lf

the thread does not wind evenly on the bobbin, loosen

the nut I and move the bracket 2 to the right or to the left as

may

be

required, then tighten the nut.

2) Winding

Adjusting 6 can increase or decrease the amount

\\OUnd

on

the bobbin.

amount

3) Winding strength

Strength

7..

THREADING (Fig.4)

Raise the needle bar to its highest position and route the

upper thread

of

the winding can be adjusted with the nut

in

the order illustrated below.

winding

of

thread

of

thread

1.

-4-

Page 6

8...

REMOVING AND INSERTING

(

1)

Removing: Open the shuttle race cap and the bobbin holder, then take out the bobbin.

(2) Installation:

freely.

Install the bobbin in the bobbin case so that the thread wound direction is clockwise. Then close the rotary

hook

and

the shuttle race cap.

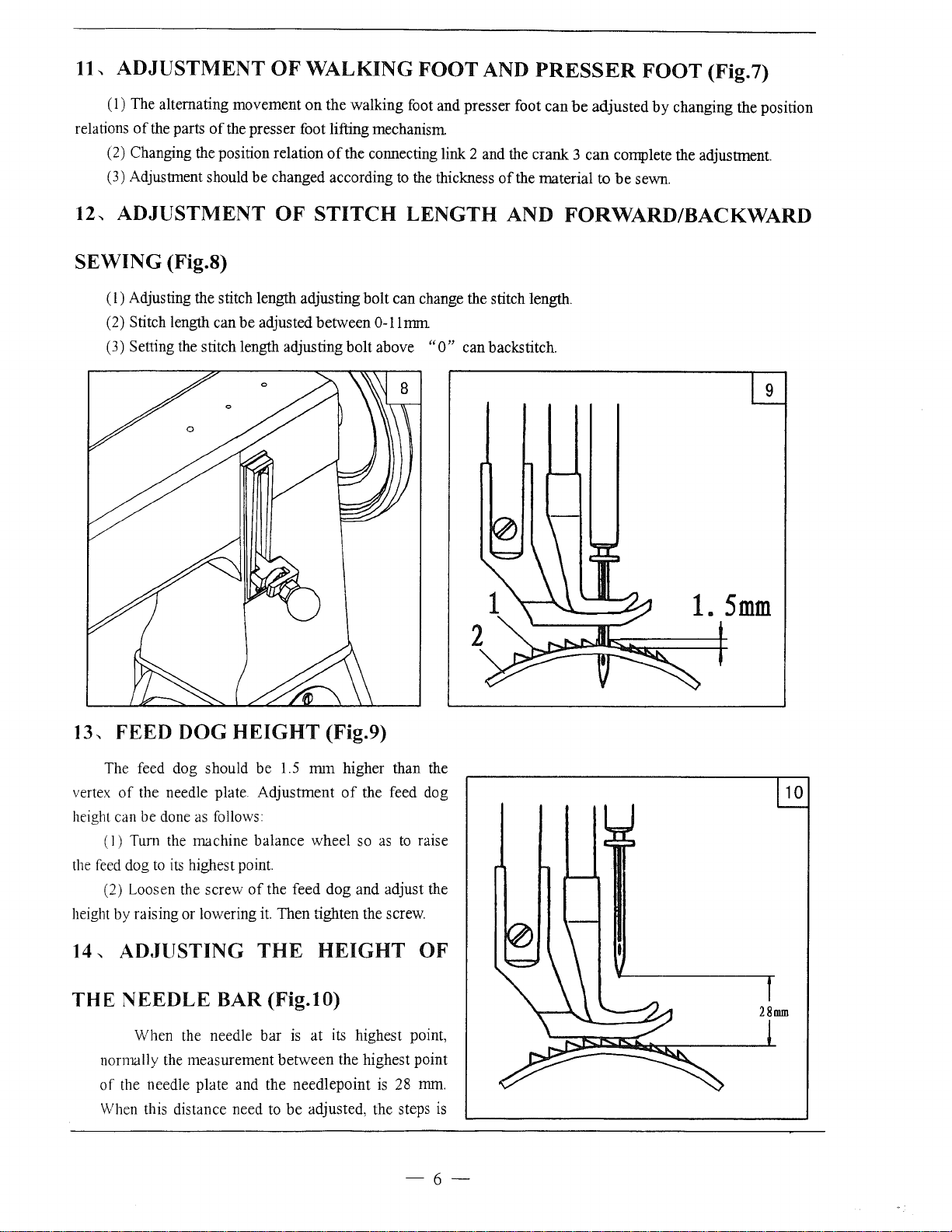

9

...

ADJUSTING

Put the bobbin

THE

in

the rotary hook case, Permit about 5 em

THREAD TENSION (Fig.5)

THE

BOBBIN

of

bobbin thread to hand down

5

I ance

For ordinary stitching, the tension

(1) Tension

Before adjusting the tension

serrated nut

you desire

(2) Tension

The lower thread tension

bobbin case. Turning this screw

left (counter -clockwise) will decrease the tension.

10-.

ADJUSTMENT

(I)

Pressure should

Pressure on both the walking foot and the presser foot can

(2)

set before shipment.)

Sewing pressure should be adjusted

(3)

of

the

Upper thread

on

tension device

to

decrease the tension.

of

the lower thread

be

or

of

the upper thread, be sure that presser foot

to

the right (clockwise)

is

controlled

to

the right (clockwise) will increase the thread tension, while turning it

OF

PRESSER

adjusted according to the material to

We

Upper

I I

ba

thread

lower

of

the upper and the lower threads should

by

to

the minimum required strength .

strong

thread

the larger screw near the end

FOOT

weak

to

increase tension and

PRESSURE (Fig.6)

.---------~~~--~~-------.--~

be

Upper

lower

sewn.

be

adjusted. (The adjusting screw has been

thread

thread

be

equal.

is

let down.

to

the left (counter-clockwise)

of

the spring at the outside

weak

or

strong

To

adjust tension, turn

of

to

if

the

the

-s-

Page 7

11"

ADJUSTMENT

OF

WALKING

FOOT

AND

PRESSER

FOOT

(Fig. 7)

(1) The alternating movement

relations

12.,

SEWING

of

the parts

(2) Changing the position relation

(3) Adjustment should be changed according

of

the presser foot lifting mechanism

ADJUSTMENT

(Fig.S)

(

1)

Adjusting the stitch length adjusting bolt can change the stitch length.

(2) Stitch length can be adjusted between

(3) Setting the stitch length adjusting bolt above

on

OF

the walking foot and presser foot can

of

STITCH

be

the connecting link 2 and the crank 3

to

the thickness

LENGTH

0-11

nnn

"0"

of

the material to

AND FORWARD/BACKWARD

can backstitch.

adjusted

can

by

changing the position

complete the adjustment.

be

sewn.

13, FEED DOG

The feed dog should be

vertex

of

the needle plate. Adjustment

height can be done

(I) Tum the machine balance wheel so

the

feed

dog

to

its

(2) Loosen the screw

height by raising or lowering

14

._

ADJUSTING

THE

NEEDLE

When the needle bar

normally the measurement between the highest point

of

the needle plate and the needlepoint

When this distance need to

HEIGHT

as

follows:

highest point.

of

the feed dog and adjust the

it.

THE

BAR (Fig.10)

(Fig.9)

1.5

mm

higher than the

of

the feed dog

as

Then tighten the screw.

HEIGHT

is

at its highest point,

is

be

adjusted, the steps

to

28

10

raise

OF

mm.

is

-6-

Page 8

as follows:

(

1)

Take down the face plate, adjust the needle

(2) Loosen the screw

(3) Adjust the needle

( 4) Tighten the screw.

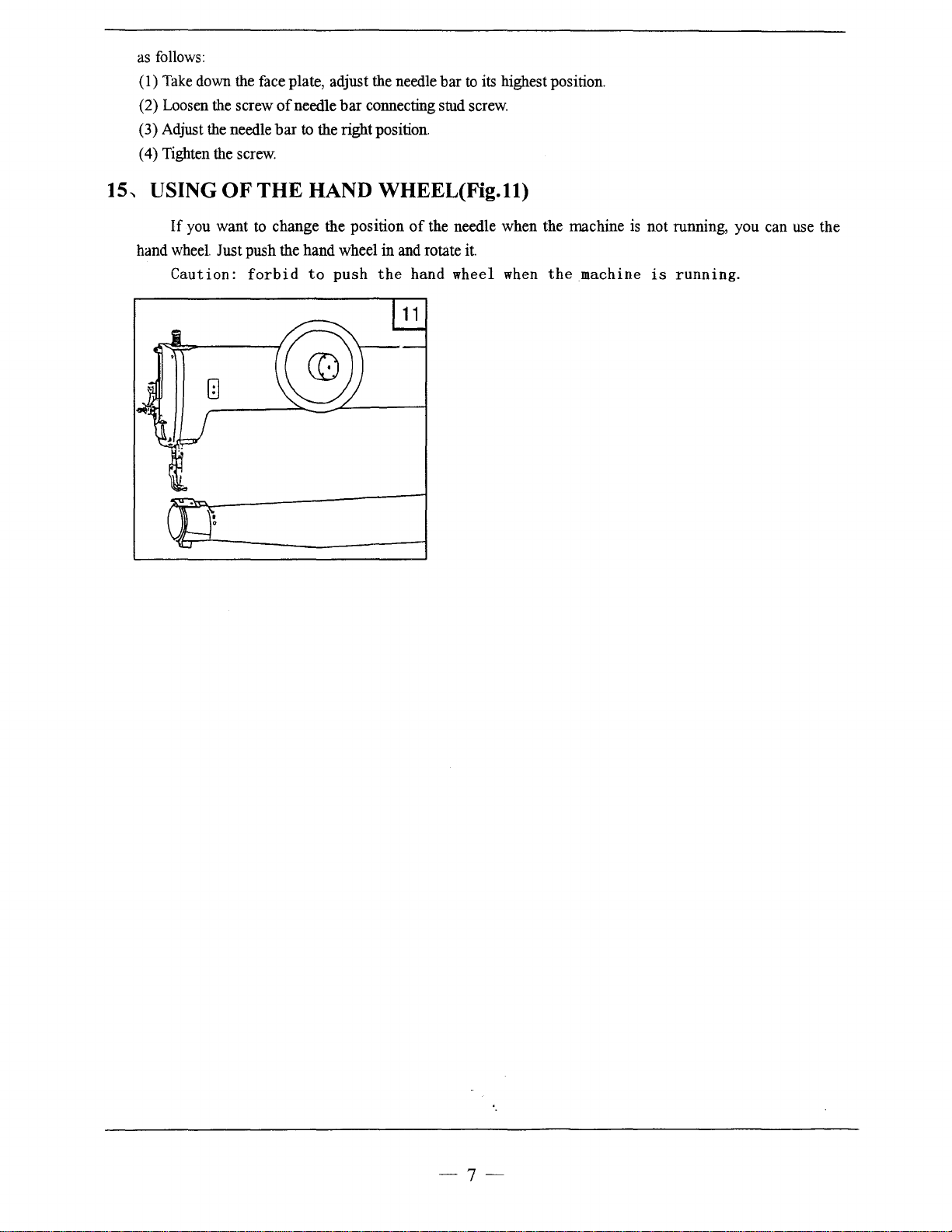

15-.

USING

If

hand wheel Just push the hand wheel in and rotate

OF

you want to change the position

Caution:

of

needle

bar

connecting stud screw.

bar

to

the right position.

THE HAND WHEEL(Fig.ll)

forbid

to

push

the

bar

to

its highest position.

of

the needle when the machine is not running, you can use the

it.

hand wheel

when

the

machine

is

running.

-7-

Page 9

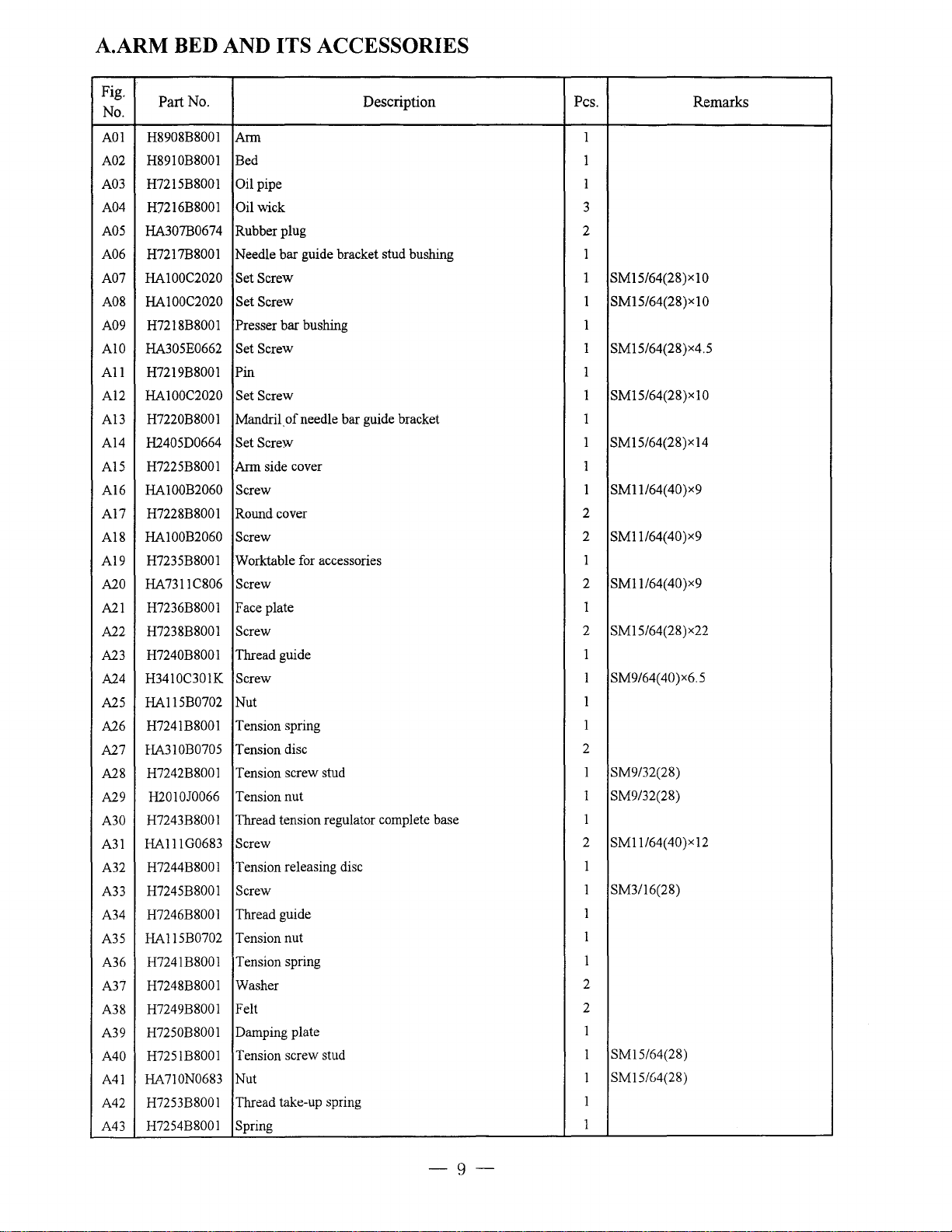

A.ARM BED AND ITS ACCESSORIES

25

/

(j)/'

26

2728

https://manualmachine.com/I

~/

31

~/24

/w..

31

--w

36

!

29 / f)

33 1

I

48

46

23

.......

,_

'·

32

-8-

2

18

Page 10

A.ARM BED AND ITS ACCESSORIES

Fig.

No.

A01

A02 H8910B8001 Bed 1

A03 H7215B8001

A04 H7216B8001

A05 HA307B0674 Rubber plug 2

A06 H7217B8001 Needle

A07 HA100C2020 Set Screw

A08 HA100C2020 Set Screw 1

A09 H7218B8001 Presser

A10 HA305E0662 Set Screw

All

Al2

Al3

A14

A15

A16

A17

A18

A19

A20

A21

A22

A23

A24

A25

A26

A27

A28

A29

A30

A31

A32

A33

A34

A35

A36

A37

A38

A39

A40

A41

A42

A43

Part No.

H8908B8001

H7219B8001 Pin

HA100C2020

H7220B8001

H2405D0664 Set Screw

H7225B8001 Ann side cover 1

HA100B2060

H7228B8001 Round cover

HA100B2060 Screw

H7235B8001 Worktable for accessories

HA7311C806 Screw

H7236B8001 Face plate

H7238B8001 Screw

H7240B8001 Thread guide

H3410C301K Screw

HA115B0702 Nut

H7241B8001 Tension spring

HA310B0705 Tension disc

H7242B8001

H2010J0066

H7243B8001

HA111G0683 Screw

H7244B8001

H7245B8001 Screw

H7246B8001 Thread guide

HA115B0702

H7241B8001

H7248B8001

H7249B8001 Felt

H7250B8001

H7251B8001

HA710N0683 Nut

H7253B8001

H7254B8001 Spring

Ann

pipe

Oil

wick

Oil

bar

guide bracket stud bushing 1

bar

bushing

Set Screw

Mandril.

Screw

Tension screw stud

Tension nut

Thread tension regulator complete base

Tension releasing disc

Tension nut

Tension spring

Washer

Damping plate

Tension screw stud

Thread take-up spring

of

needle bar guide bracket

Description

Pes.

Remarks

1

1

3

1 SM15/64(28)x10

SM15/64(28)xl0

1

1 SM15/64(28)x4.5

1

1 SM15/64(28)x10

1

1 SM15/64(28)x14

SM11/64(40)x9

1

2

2 SM11/64(40)x9

1

2 SM1l/64(40)x9

1

SM15/64(28) x22

2

1

SM9/64(40)x6.5

1

1

1

2

1 SM9/32(28)

1 SM9/32(28)

1

2 SM11/64(40)x12

1

1 SM3/16(28)

1

1

1

2

2

1

SM15/64(28)

1

SM15/G4(28)

1

1

1

-9-

Page 11

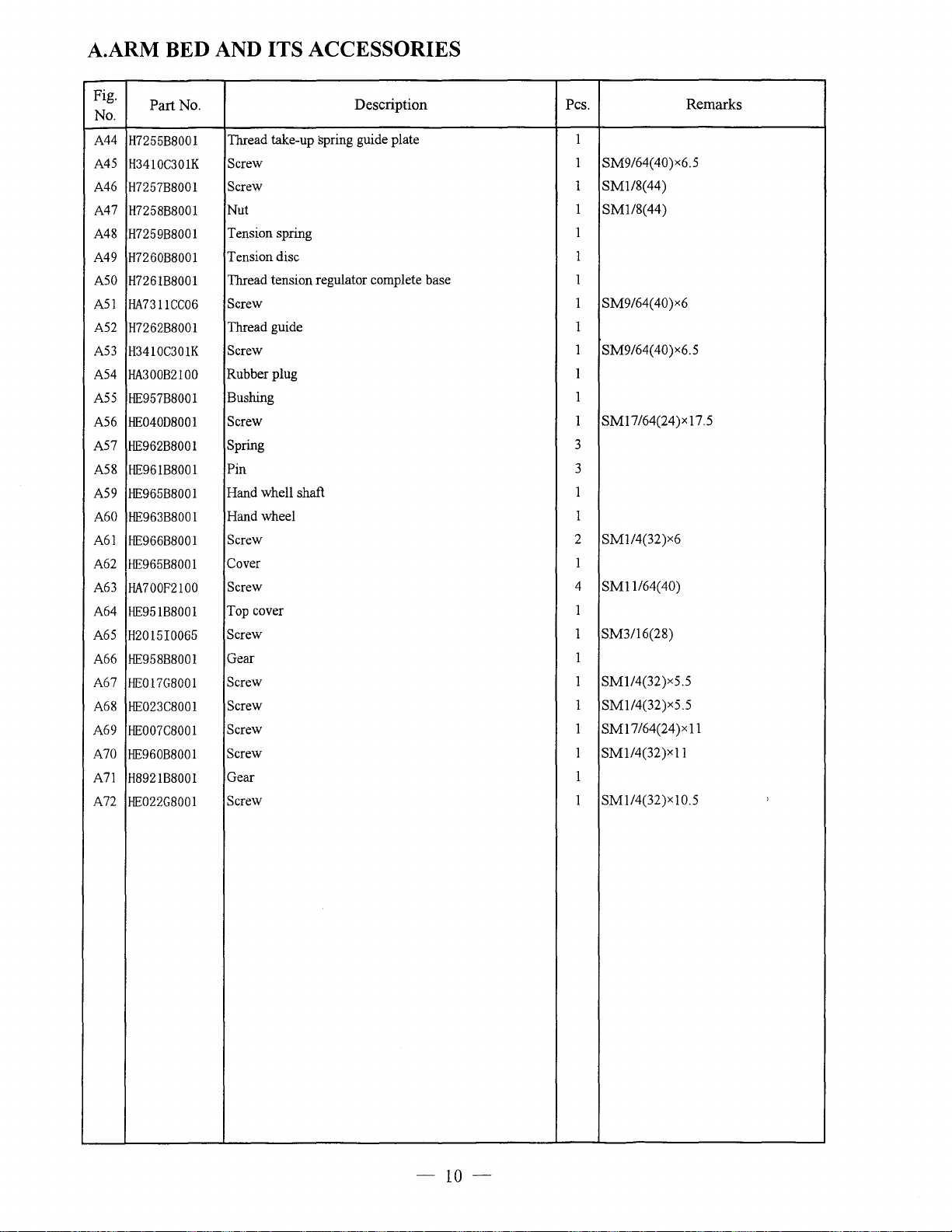

A.ARM BED AND ITS ACCESSORIES

Fig.

No.

A44

A45

A46

A47

A48

A49

ASO

A51

A 52

A53

Part

No.

H7255B8001

H3410C301K

H7257B8001

H7258B8001

H7259B8001

H7260B8001

H7261B8001

HA7311CC06

H7262B8001

H3410C301K

A 54 HA300B2100

A55

HE957B8001

HE040D8001

A56

A57

HE962B8001

A58

HE961B8001

A59

HE965B8001

A60 HE963B8001

A61

HE966B8001

A62

HE965B8001

A63

HA700F2100

A64

HE951B8001

A65

H2015I0065

A66

HE958B8001

A67

HE017G8001

A68 HE023C8001

A69

HE007C8001

A70 HE960B8001

A71

H8921B8001

A72

HE022G8001

Description

Thread take-up spring guide plate

Screw

Screw

Nut

Tension spring

Tension

Thread

Screw

Thread guide 1

Screw

Rubber

Bushing

Screw

Spring

Pin

Hand

Hand

Screw

Cover

Screw

Top cover

Screw

Gear

Screw

Screw

Screw

Screw

Gear

Screw

disc

tension

plug

whell

wheel

regulator complete base 1

shaft

Pes.

1

SM9/64(

1

1

SM1/8(44)

1

SMl/8(44)

1

1

SM9/64(

1

1

SM9/64(

1

1

SMI7/64(24)x17.5

1

3

3

1

1

SM1/4(32)x6

2

1

4

SMll/64(40)

1

SM3/16(28)

1

1

SMI/4(32)x5.5

1

SM1/4(32)x5.5

1

SM17

1

1

1

1

/64(24 )x

SM114(32)x11

SM1/4(32)x10.5

Remarks

40)x6.5

40)x6

40)x6.5

11

'

-10-

Page 12

B.NEEDLE BAR AND THREAD TAKE-UP MECHANISM

16

\d

~~

13 12

21~

-11-

Page 13

B.NEEDLE BAR AND THREAD TAKE-UP MECHANISM

Fig.

No.

B01

B02

B03

B04

B05

B06

B07

B08 H7210C8001

B09

B10 H4933K8001

Bll

B12

B13

B14 H7213C8001

B15

B16

B17

B18

B19

B20

B21

B22

B23

B24

B25

B26

B27

B28

B29

B30

B31

B32

B33

B34

B35

B36

B37 H7212B8001

B38

B39 H7211B8001

B40

Part

No.

H7204C8001

H7205C8001

H7206C8001

H8905C8001

HA108G0661

HA105D0662

H7209C8001

H403060120

H602040450

H7211C8001

H7212C8001

H7214C8001

H2010]0066

H007013050

H7215C8001

H2010]0066

H7216C8001

H7217C8001

H7218C8001

H7219C8001

HA700F2100

H7220C8001

H7222C8001

H7223C8001

H7224C8001

H7225C8001

H3208G0676

HA111G0683

H7226C8001

H415060140

H7213B8001

H2405D0664

H7214B8001

H2405D0664

H2405D0664

Description

Pulley

Screw

Screw

Arm

shaft

Collar

Set Screw

Thread take-up cam

Needle

bar

connecting base

Screw

Set

Screw

Pin

Thread take-up lever

Screw

Roller

Roller

pin

Nut

Retaining ring-E type

Needle bar connecting

Nut

Needle bar connecting

Needle bar connecting stud

Set Screw

Needle bar

Screw

Needle

Needle

bar

guide bracket

Needle bar guide bracket

Oil

wick

Needle

bar

guide bracket plate

Screw

Screw

Needle bar guide bracket plate base

Screw

Bushing

Set

Screw

Felt

Bushing

Set Screw

Bushing

Set Screw

link

link

link

screw

pin

screw

Pes. Remarks

1

SM5116(24)x19

1

SM5!16(24 )x 19

1

1

1

2

SM1/4(40)x6

1

1

GBff68

2

2 SM114(40)x10

GBff117

1

1

SM5116(24 )x7. 5

1

1

1

SM9/32(28)

1

GBff896

1

SM9/32(28)x11.5

1

SM9/32(28)

1

1

1

SM1/4(40)x4.5

2

1

SM11/64(40)x7

1

DY*3

1

1

1

1

1

SM15/64(28)x10.5

1

SM11/64(40)x12

1

1

GBff70.1

1

1

SM15/64(28)x14

1

3

1

SM15/64(28)x14

1

1

SM15/64(28)x14

1

M6x12

4x45

5

26#

M6x14

,

-12-

Page 14

C.LOWER SHAFT MECHANISM

19

20 \

\~

I/\/

0

40

---7

36

-

13-

~

\

\

31

Page 15

C.LOWER SHAFT MECHANISM

Fig.

No.

COl

C02

C03

C04

cos

C06

C07

cos

C09

C!O

Cll

C12

C13

C14

C15

C16

C17

Cl8

C!9

C20

C21

C22

C23

C24

C25

C26

C27

C28

C29 11722708001

C30 H602040180

C3!

C32 11722908001

C33

C34

C35

C36

C37 H72340800l

C38

C39

C40

C41

C42

C43

Part No. Description

8720408001

8720508001

8720608001

8415060250

H4728H8001

8723708001

8720708001

H2000B2050

8720808001

H720908001

H721008001

H721108001

H72!308001

H721408001

H721508001

H72!608001

H2000M0120

H721808001

H72!908001

H722008001

H722208001

H415080200

H722308001

H722408001

H2010J0066

H890508001

HA108G0661

H723908001

H722808001

H7230D8001

11723108001

H723208001

11723308001

1-1723508001

1-1723608001

1-1723488001

HA3411D308

HAlOOC2020

H7230B8001

Pes.

Eccentric 1

Set Srew

pin

Screw

Washer

Bearing 1

Eccentric cover

Screw

Crank

connecting rod 1

connecting

Crank

Pin

Screw

Shuttle shaft

Plate

Plate

Screw

Nut

Inside Shaft

Oil

wick

Rivet

Lower shaft crank

Screw

Shuttle shaft slide block

Screw

Nut

Lower shaft

Collar

Set Screw

Shuttle driver

Pin

Bobbin

Shuttle race body

Shuttle race back ring

Screw

Spring

Shuttle race cap

Screw

Spring

Screw

Bushing

Set Screw

Set Screw

Bushing

rod

pin

SM15/64(28)x12

1

2

GBff70.1

2

2

K43x48x17(N1N)

1

2

SM11/64(

1

1

SM3/16(32)x18

1

I

1

1

SM11/64(40)

2

SM11/64(40)

2

I

I

I

I

GB/T70.1

1

I

1

SM9/32(28)

1

1

1

SM1/4(

2

1

GBff117

I

1

1

1

SM3/16(32)

2

2

1

2

SMl/8(44)

2

SM3/32(56)

2

1

SM15/64(28)x7

1

SM15/64(28)x

1

1

Remarks

M6x25

40)x9

M8x20

40)x3.5

4x18

10

-14-

Page 16

C.LOWER SHAFT MECHANISM

Fig.

No.

C44

C45

C46

C47

C48

Part No.

H2405D0664

H7229B8001

H2405D0664

H7240D8001

H7228D8001

Description

Set Screw

Bushing 1

Set Screw

Shuttle hook complete

Bobbin

Pes.

SM15/64(28)x

1

SM15/64(28)x14

1

KSP-204N C

1

1

Remarks

14

-fti:)C)

-15-

Page 17

D.FEEDING

MECHANISM

45

38

40 39

\ \

~~

0'

~"

52

40

.

51

24

I 25

J~

49

50

/¥~

~

26

)5

24

16-

-

Page 18

D.FEEDING MECHANISM

Fig.

No.

DOl

D02

D03

D04

DOS

D06

D07

DOS

D09

DIO

Dll

D12

Dl3

Dl4

DIS

D16

Dl7

DIS

D19

D20

D21

D22

D23

D24

D2S

D26

D27

D28

D29

D30

D31

D32

D33

D34

D35

D36

D37

D3S

D39

D40

D41

D42

D43

Part

No.

H7205E800l

H7206E800l

H7207E8001

H2000B2050

H7208E8001

H7209E8001

H2010J0066

H7210E8001

H7211E800l

H415050140

H7212E8001

H7213E8001

HA104G0012

H7211D8001

H7214E800l

H7215E8001

H7216E8001

HE00001032

H7217E8001

H003008080

H7218E8001

H415060200

H7219E8001

H007013080

H8904E8001

HA!08G0661

H7239D8001

H7221E8001

H7222E8001

H7223E8001

H2013N0067

H7225E8001

H7226E8001

HA700F2100

H7219E8001

H007013080

H7227E8001

H7228E8001

H7239D8001

H7229E8001

H57!1G8001

H7230E8001

Description

Feed cam 1

Set Screw

Feed cam cover 1

Screw 2

Feed forked connection

Feed forked connection crank pin

Nut 1 SM9/32(2S)

Stitch length connecting link 1

Stitch length connecting link crank

Screw

Stitch length adjusting pin

Damping plate 1

Screw 2

Screw

Stitch length adjusting bolt

Stitch length limited plate 1

Nut

Metal ball 1

Spring

Plastic ball 1

Nut 1 GBff6172.1 MS

Feed driving rock shaft crank

Screw 2 GBfr70.1 M6x20

Feed driving rock shaft crank pin 2

Retaining ring-E type 2 GBfrS96 S

Feed driving rock shaft

Collar 1

Set Screw

Crank pin 1

Feed driving connecting link

Feed driving connecting link crank pin 1

Nut

Feed dog base 1

Feed dog 1

Screw

Feed lifting rock shaft crank pin

Retaining ring-E type 1 GBffS96 8

Feed lifting rock

Collar

Set

Screw

Feed dog base limited plate

Screw 2

Needle plate 1

shaH 1

pin

Pes.

SM1S/64(2S)x6

2

SM11/64(40)x9

1

1

1

1

GBfr70.1

MSxJ4

1

SM3/16(2S)x12

SM3/16(32)xJS

1

1

1

GBff30S 3.17S

1

JBff7271.1 MSx32

1

1

2 SM1/4(40)x3.S

1

1 SM1/4(24)

1 SM11/64(40)x7

I

1

2 SM1/4( 40)x3.5

1

SM!l/64(40)x6

Remarks

~~

-17-

Page 19

D.FEEDING MECHANISM

Fig.

No.

D44

D45 H7232E8001

D46 HA104F0654

D47

D48

D49

D50

D51

D52

Part

No.

H7231E8001

H7232B8001

HA100C2020

H7231B8001

HA3411D308

H7233B8001

H2405D0664

Description

Screw

Stitch length indicating plate

Screw

Bushing

Set Screw

Bushing 1

Set Screw 1

Bushing

Set Screw

Pes.

SM3/16(28)x9.5

2

1

SM15/64(28)x9

2

1

SM15/64(28)x

1

SM15/64(28)x7

1

SM15/64(28)x 14

1

Remarks

10

-

18-

Page 20

E.

UPPER SHAFT & PRESSER FOOT MECHANISM

7

~

8

20

21

19-------

6

5

11

22~

~

/~

fo

16

;!

5

8

4

13

-19-

Page 21

E.PRESSER FOOT MECHANISM

Fig.

No.

EOl H7204F8001

E02

E03

E04

E05 H7207F8001

E06 H7208F8001

E07 H7209F8001

E08 H7210F8001

E09

ElO

Ell

El2

El3

El4

E15

El6

El7

El8

E19

E20

E21

E22 H609030180

Part

No.

H7205F8001

HA710P0673

H7206F8001

H7211F8001

HA719B0709

H7212F8001

H7213F8001

H7214F8001

H7215F8001

H7217F8001

H7218C8001

H7219F8001

H7220F8001

H7221F8001

H7222F8001

Presser foot

Screw

Nut

Finger guard

Presser

bar

Presser

bar

spring

Thumb screw

Nut

Walking foot

Screw

Presser

bar

Screw

Presser

bar

lifting shaft

Washer

Collar

Set Screw

Plastic ball

Bolt

Presser

bar

guide bracket

Connecting rod

Screw

Pin

Description

Pes.

1

SM9/64(40)x14

1

SM9/64(40)

1

1

1

1

SMS/8(28)

1

SMS/8(28)

1

1

SM11/64(4Q)x7

1

1

SM9/64(40)

1

1

1

1

SM1/4(40)x4.5

2

JBm271.1

1

1

1

1

SMl/4(40)

1

GB!f879.1 3x18

1

Remarks

M6x20

-20-

Page 22

F. UPPER FEED LIFTING

7

~:

------

27

28

""

ROCK

---

9

~

SHAFT MECHANISM

4---_

I

I

L_

2 -

25

--

26

~

___

_

--?

/

3

'1

10

~

14

-21-

Page 23

F.

UPPER FEED LIFTING ROCK SHAFT MECHANISM

Fig.

No.

F01 H7204G8001

F02 HA307C0066

F03

F04 H7206G8001

FOS

F06

F07

F08

F09

FlO

F11

F12

F13

F14

F15

F16

F17

F18

F19

F2ll

F21

F22

F23

F24

F25

F26

F27

Fn

Part No.

H7205G8001

H7207G8001

H7208G8001

H7209G8001

H7210G8001

H7211G8001

H7212G8001

H415060140

H7213G8001

H7214G8001

11007013080

H7215G8001

H7214G8001

H7216G8001

HA104G0012

H7217G8001

H7221G8001

H7218G8001

H7219G800l

HA700B2060

H7220G800l

H7221B800l

HA3411D308

H7222B80lll

HA34llD308

Description

Presser foot lifting eccentric

Set

Screw

Eccentric connecting

Screw

Washer

Nut

Adjusting

Screw

Presser

Presser foot lifting shaft

Screw

Presser

Screw

Retaining ring-E type

Presser foot lifting lever

Screw

Presser

Screw

Roller

Bearing

Screw

Roller

Screw

Walking foot lifting connecting

Bushing

Set

Bushing

Set

crank

foot lifting shaft

foot lifting connecting

foot lifting lever

base

plate

Screw

Screw

link

crank

base

link

link

Pes.

1

SM114(40)x6

2

1

1

1

SM11/32(28)

1

1

SMS/16(18)

1

1

1

GBff70.1

1

1

2

GBff896

4

1

2

1

SM3116(28)x12

2

1

ISO

1

SM15/64(28)

1

1

SM3116(32)x8

2

1

1

SM15/64(28)x7

1

1

SM15/64(28)x7

1

Remarks

M6x14

8

K7

-22-

Page 24

G.NEEDLE BAR

19

20 \

ROCKING

8

\

MOTION

MECHANISM

9

\

13~

\o

\

18

~~

15

J'

18

I

17

1

-23-

Page 25

G.NEEDLE BAR ROCKING MOTION MECHANISM

Fig.

No.

GO!

G02 H7219E8001

G03 H007013080

G04 H7206H8001

G05

G06 H7208H8001

G07

G08 H8904H8001

G09 H7210H8001

G10 HA105D0662

G11 H7211H8001

G12 HA105D0662

G13

G14

GIS

Gl6

Gl7

G18

Gl9

G20

G21

G22

Part No.

H7204H8001

H7207H8001

H7210G8001

HA100C2070

H7212H8001

H7214G8001

H007013080

H7213H8001

H7214H8001

H7224B8001

HA3411D308

H7223B8001

HA3411D308

Description

Needle bar rocking connecting link

Screw

Retaining ring-E type

Adjusting crank

Adjusting crank base

Screw

Screw

Needle bar rock shaft

Collar

Set Screw

Needle bar rocking crank

Set Screw

Screw

Needle bar rocking connecting link

Screw

Retaining ring-E type

Screw base

Screw

Bushing

Set Screw

Bushing

Set Screw

Pes.

1

1

GB!T896

1

1

1

SM5/16(18)x24

1

SM5/16(18)x18

1

1

2

SM1/4(

4

1

SM1/4(40)x4.5

1

SM9/32(28)

1

1

2

GB!T896

2

1

SMll/64(

3

1

SM15/64(28)x7

1

1

SM15/64(28)x7

1

Remarks

8

40)x4.5

8

40)x4.5

-24-

Page 26

H.KNEE LIFTER MECHANISM

4

1

2

3

7

21

~1~

16~y

i

20

17

13

ft~llitl~lliJJ!IJ

f?.f!itlfj

IJ

-25-

Page 27

H.KNEE LIFTER MECHANISM

Fig.

No.

HOI

H02

H03

H04 H4910N8001

HOS

H06

H07

H08 H4921N8001

H09

HlO H8908I8001

Hll

Hl2

Hl3

H14

H15

Hl6

Hl7

Hl8

Hl9

H20

H21

H22

H23

H24

Part

No.

H8906I8001

H005008100

H007013060

H8907I8001

H005008080

H4922N8001

H4923N8001

H801045200

HA300J2230

H402040120

H005008040

H005005040

H8909I8001

H4915N8001

H4918N8001

H4924N8001

H402040300

H003002040

H8910I8001

H4917N8001

Description

Cylinder

Nut

Spring Washer

Cylinder

E type ring

Swing

Spring

Tube Fitting

Timing valve

PUTube

Bracket for filtration and decompression

Screw

Washer

Screw

Spring

Washer

Tube Fitting

Valve for filtration

Solenoid Valve

Silencer

Screw

Nut

PUTube

Tube Fitting

bar

Pin

Washer

washer

and

decompression 1

Pes.

1

GB!f6173

1

GB!f93

1

MAL25x50

1

GB!f896

1

1

1

GB!f93

<l>

1

1

<l>

2

<l>6(1.6m)

1

GB!T99 4.5x20

2

2

GB!f67

2

4

GB!f93

GB!T95 4

8

<1>8-1/4"

3

DC24V

1

2

GB!f67

2

4

GB!f6170

1

<l>

<l>

2

Remarks

M10x1.25

10

6

8

6-118"

6-1/8"

M4x12

4

M4x30

M4

8(0.2m)

6-1/4"

-26-

Page 28

I.KNEE

LIFTER

MECHANISM

7

\

9

1

~

6

5 3

-27-

Page 29

I.KNEE LIFTER MECHANISM

Fig.

No.

I01

I02

I03

I04 HA300J2280

lOS

I06

I07 H7205I8001

I08

I09 H7210I8001

IlO

Ill

Il2

l13

I14

Part No.

H7204!8001

H7205I8001

H7206I8001

H7207I8001

H8904I8001

H7209I8001

H7211I8001

H7212I8001

H7214I8001

HA300J2280

H7213I8001

Description

Knee lifter lever

Screw

Knee lifter lever base

Screw

Screw

Knee lifter rod

Screw

Coil spring

Screw

Screw

Washer

Knee lifter lever connecting plate

Screw

Screw

Pes.

2

SM15/64(28)x6

1

1

SM15/64(28)x8

2

SM15/64(28)

1

1

SM15/64(28)x6

2

1

SM11/64(40)x6

1

SM11/64(40)x4.5

1

1

1

SM15/64(28)x8

2

SM1/4(40)x3.5

1

Remarks

-28-

Page 30

J.BOBBIN WINDER MECHANISM

0-------------

1

11-----.

/29

~/30

31

14

19

----

Jf~~

-----32

~33

22~

:~~

~

#',/

e~,

r 4

24

I

/

/20

{[JJ]J

~23

5

9

-29-

Page 31

J.BOBBIN WINDER MECHANISM

Fig.

No.

JOl

J02 H6707N8001

J03 H6708N8001

]04

JOS

J06 H6713N8001

J07

J08

]09

JlO

Jll

Jl2

Jl3

Jl4

JlS

Jl6

J17

]18

J19

J20

J2l

J22

J23

J24

J25

J26

127

J28

J29

130

J3]

132

133

Part

No.

H6706N8001

H7210J8001

H7213J8001

H6714N8001

H6715N8001

H007013050

H7205J8001

H6717N8001

H6718N8001

H6719N8001

H6720N8001

HA100H2150

H7206J8001

H3200B2100

H6722N8001

H6723N8001

H6731N8001

H6732N8001

H6724N8001

H6725N8001

H7005D800l

H4723D800l

H3107G0662

H7208J8001

HA310B0705

HAll5B0702

HAll5B7010

H3300B2040

H6662B8001

H003008040

Description

Bobbin winder plate

Pin

Pin

Bobbin winder crank shaft

Bobbin winder crank

Bushing

Pin

Bobbin winder spring

Retaining ring-E type

Bobbin

winder

shaft

Bobbin base

Driven wheel

Friction rubber band

Bobbin winder lever

Screw

Winding length limited plate

Screw

Washer

Pin

Set Screw

Set Screw

Spring

Bobbin winder cam

Driving wheel

Set Screw

Screw

Screw

Tension disc

Nut

Limited plate

Spring

Thread guide

Nut

Pes.

1

1

1

1

1

2

1

1

GBtr896

2

1

1

1

1

1

SM9/64(40)x11

1

1

1

1

1

M5x6

1

GBtr

2

1

1

1

SM15/64(28)

2

SM11/64(40)

3

1

2

1

1

1

1

GBtr6172.1

2

80

Remarks

5

M3x4

M4

-30-

Page 32

K.ACCESSORIES(-)

7 8 7

1

5

6

~~4

$~3

9

13

I

17

~~~

I I I

10

15

11

12

20

0

-31-

~

/'

22

19~

21

~

Page 33

K.ACCESSORIES(-)

Fig.

'No.

K01

K02

K03

K04

KOS

K06

K07

K08

K09 HA800F2020

K10

Kll

K12

K13

K14

K15

K16

K17

K18

K19

K20

K21

K22

Part No.

H7207K8001

H7208K8001

H605030400

H34411C410

H7209K8001

H3215K0693

H7210K800l

H7211K8001

HB00001050

HB00001040

HB00001030

HA300J2070

HA300J2200

HA300J2210

HJ02090110

HJ02100130

H7228D8001

H7220C8001

HA200]2030

H200400069

H8904K8001

Description

Silicon oil

Cover

Pin

Screw

Spring

Screw

Thread guide

Nut

Screw

Hexagon socket screw key

Hexagon socket screw key

Hexagon socket screw key

Screw driver (size L)

Screw driver (size

Screw driver

Spanner

Spanner

Bobbin

Needle

Thread stand assy

Oiler

Vinyl cover

box

M)

(sizeS)

Pes.

1

1

GBffll9.2

1

SM9/64( 40)x4

1

1

SM9/64(40)x5

1

2

SM3/32(56)

2

SM15/64(28)

1

GBff5356

1

GBff5356

1

GBff5356

1

1

1

1

GBff4388

1

GBff4388

1

4

4

1

1

1

Remarks

3x40

5

4

3

9x11

10x13

-32-

Page 34

L.ACCESSORIES(

1

=)

11

13

2 5

3~~~~

. '

,_

-..::::~---14

''

'1

~----15

1!!1

-----16

1

2~~

r\\

I~

6

!

I ! I

~

t

1\r

~

10

'\

I 8

I

I

I

I

l__,

17

-33-

Page 35

L.ACCESSORIES(

=)

Fig.

No.

L01

L02

L03

L04

L05

L06

L07

L08

L09

LIO

L11

Ll2

Ll3

Ll4

LIS

Ll6

Ll7

Ll8

Ll9

L20

L21

Part No. Description

H415060140

Hl03080250

H8918K8001

H8917K8001

H415080160

H8924K7101

H8920K8001

H8913K8001

H8924K7101

H8918K8001

H8910K8001

Hl25100900

H8915K8001

H429120250

H005001100

H003002100

H8912K8001

Hl03120500

H005008120

H8916K8001

H8911K8001

Screw

Screw

Short rod

Long rod I

Screw

Large pedal 1

Long steel tube 1

Steel tube base

Small pedal

Short steel tube 1

Bedplate 1

Screw 4

Flange

Set Screw 4

Washer 4

Nut

Connecting steel tube 1

Screw

Spring washer 4

Flange

Operation base 1

Pes

..

GB/T70.1 M6x14

8

GB/T5782 M8x25

4

I

· GB/T70.1

4

2

1

GB/T14M10x9o

1

GB/T78 M12x25

GB/T97.1

GB/T6170 M1 0

4

GB/T5782

4

GB/T93

1

Remarks

M8x16

10

M12x50

12

-34-

Page 36

SHANGHAI HUIGONG

N0.3

SEWING MACHINE FACTORY

ADD: 1418, Yishan Road, Shanghai,

China

Zip Code: 201103

Overseas

Business: TEL: 86-21-64853303 FAX: 86-21-64854304

E-mail:highlead@online.sh.cn http://www.highlead.com.cn

The description covered

in

this manual is subject to change for improvement

of

the conunodity without notice

2004.2.

Printed

Loading...

Loading...