Highland H9G12S1, H9G09S1 User Manual

INSTALLATION, MAINTENANCE AND US E

INSTRUCTIONS FO R FREESTANDING

COOKERS

H9G09S1, H9I09S1 & H9G12S1

FREESTANDING COOKERS

READ THE INSTRUCTION BOOKLET BEFORE INSTALLING AND USING THE

APPLIANCE.

The manufacturer will not be responsible for any damage to property or to persons caused by

incorrect installation or improper use of the appliance.

The manufacturer is not responsible for any inaccurac ies, due to print ing or trans cription er rors, contain ed in

this booklet. In addition, the appearance of the figures reported is also purely indicative.

The manufacturer reserves the right to make changes to its products when considered necessary and useful,

without affecting the essential safety and operating characteristics.

3100150

1

2 YEAR CUSTOMER CARE WARRANTY

Congratulations on your new purchase and thank you for choosing HIGHLAND.

All Highland domestic appliances come with a 2 year parts and labour warranty. Highland will correct, free of charge, any

defects in material or workmanship for the period of 2 years, subject to the terms of our warranty stated below. At

Highland we place great importance on customer satisfaction and that is why we have established a dedicated and

experienced customer support team that you can rely on.

Should you ever need to make a warranty related enquiry about your Highland product simply call

+61 3 9700 9100 to speak with our friendly customer service consultants. We suggest you have the following

information close at hand to make the process as easy as possible.

1. Model number of your appliance

2. Serial number of your appliance

3. A copy of your original purchase receipt

4. Address details of where the appliance is installed

This warranty will be null and void if the appliance is used for outdoor and commercial purposes. Some examples of

outdoor and commercial purposes include restaurants, cafés, schools, clubs, and alfresco areas with open walls or

hoods used above barbecues.

Please note: The benefits provided by this warranty are in addition to all other rights and remedies in respect to the

product which the consumer has under the Trades Practices Act 1974 and/or any other State and Territory Laws.

1. This warranty only applies for products installed by a qualified person and when provided with a certificate of

compliance in accordance with State/Territory laws.

2. This product must be used in accordance with the manufacturer’s instructions. This warranty does not apply

should the defect in or failure of the product be attributable to misuse, abuse, accident or non-observation of the

manufactures instructions on the part of the user. Highland Appliances does not accept liability for any direct or

consequential loss, damage or other expense caused by or arising out of any failure to install or use the product

in accordance with the manufacturer’s instructions.

3. The warranty does not cover failures due to normal wear and tear with reasonable use or consumable

components such as globes, filters, etc.

4. Highland Appliances, at its own discretion may replace or repair any defective component(s) to affect a repair

due to any faulty workmanship and material. The warranty does not cover breakage of outer glass panels

attributed to external damage.

5. The warranty provided is a “Repair Warranty” and in an extreme event if a repair cannot take place, a

replacement will be provided of an equivalent current model where the balance of the warranty period from the

original date of purchase will take effect.

6. This warranty is immediately void if the serial or model number label is removed, defaced, serviced or repaired

by an unauthorised/unqualified personal or used for industrial/commercial purposes.

7. Warranty will be only provided when a proof of the original purchase is presented to an authorised dealer or

reseller before or at the time of service.

8. This warranty does not cover any corrosion or defect as a result of the product being installed in an environment

in which the appliance is not protected from the weather.

9. It is the responsibility of the customer to ensure the appliance is easily accessible for a service technician to

carry out required repairs. Any obstruction prohibiting access to the product by building materials of any kind will

be required to be removed and reinstalled by the customer.

10. Labour in excess of 1 hour is not covered by the warranty.

11. This warranty covers the first 50km travelled by a repair technician to the appliance location and return. Any

travel in excess of 50 km each way is not covered by the warranty.

Highland has a service network in all metropolitan areas and most regional areas. Where the warranty claim has

been made outside a radius of 50km from any store where the product can be purchased, the customer is

responsible for the cost of delivery to the nearest service agent or the travel cost for a technician to travel to a

location outside the 50km radius.

YOUR STATUTORY RIGHTS

Highland Products fully assures all customers that our goods come with guarantees that cannot be excluded under the

Australian Consumer Law. You are entitled to have the goods repaired or replaced if the goods fail to be of acceptable

quality and the failure does not amount to a major failure.

You are also entitled to a replacement or refund for a major failure and for compensation for any other reasonably

foreseeable loss or damage. The benefits under Highland’s warranty are in addition to other rights you have at law in

relation to the Appliances or services to which the warranty relates.

2

CONTENTS:

INSTALLER TECHNICAL MANUAL________________________________________________

pg.3

APPLIANCE MAINTENANCE _____________________________________________________

pg.6

INSTALLING A DUAL FUEL COOKER_____________________________________________

pg.8

GAS HOB_____________________________________________________________________

pg.14

TEPPANYAKI PLATE___________________________________________________________

pg.15

INDUCTION HOB_______________________________________________________________

pg.18

OVEN________________________________________________________________________

pg.19

USING THE AUTOMATIC PROGRAMMER___________________________________________

pg.25

OVEN TEMPERATURE GUIDE____________________________________________________

pg.28

CLEANING YOUR COOKER ______________________________________________________

pg.29

ACCESSORIES_________________________________________________________________

pg.34

TROUBLESHOOTING____________________________________________________________

pg.35

USEFUL TIPS___________________________________________________________________

pg.36

3

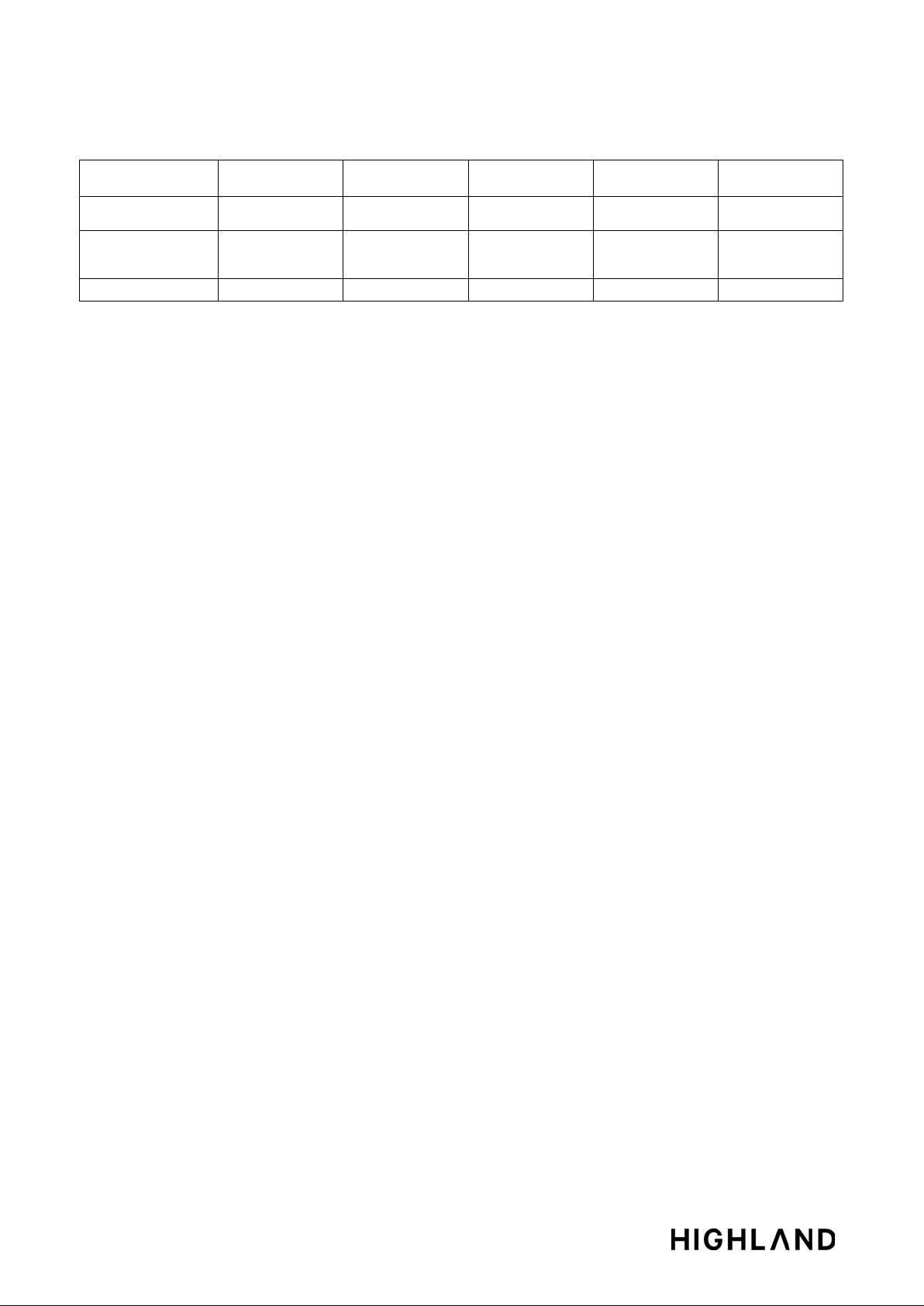

APPLIANCE DIMENSIONS

Back guard

height

H9G12S1

Gas

1,195 mm

600 mm

890-915 mm

60 mm

Model Hob Overall width Overall depth Overall height

H9G09S1 Gas

H9I09S1 Induction

895 mm 600 mm 890-915 mm 60 mm

895 mm 600 mm 890-915 mm 60 mm

THIS APPLIANCE HAS BEEN DESIGNED FOR NON-PROFESSIONAL DOMESTIC USE.

WARNING! If the surface is cracked, switch off the appliance to avoid the possibility of electric shock

The appliance an d its accessible parts become very hot durin g use. Care must be careful not to touch the

heating elements. Children under 16 years old must be kept away if not constantly supervised.

This appliance can be used by pers ons with reduce d physical, sens ory or menta l capabilities, pro vided that

they are supervised by someone who understands the use instructions and the risks involved.

Do not use steam cleaners for cleaning.

CAUTION! Make sure the app liance is sw itched of f bef ore r eplacing the bu lb to preve nt poss ibility of electr ic

shock.

WARNING! Use only the recommended and supplied food thermometer probe for this oven.

ATTENTION! The accessible parts can become hot during use. Keep children away from the appliance.

For glass doors: Do not use abrasive cleaning products or metal spatulas with sharp edges to clean the

glass of the oven door since this could scratch the surface and the glass could break.

If the power supply cord is damaged, it must be replaced by the manuf acturer, its service agent or similar

qualified person in order to avoid a hazard.

INSTALLER TECHNICAL MANUAL

INSTALLER INFORMATION

The installation, all adjustments, transformations and m aintenanc e list ed in this part of the manual must be

carried out only by qualified skilled personnel to the relevant Australian and New Zealand Standards.

Improper installation may cause damage to persons, animals or property, for which the manufacture will not

be held responsible. The appliance safety or automatic adjustment devices may be changed during the

service life of the system only by the manufacturer or by the duly authorised supplier.

4

INSTALLING THE COOKER

After having removed the various loose parts from the internal and external packing, make sure that the cooker is not damaged. In case of doubt, do not use the appliance and contact the Highland service department.

Keep all the dangerous packing parts (polystyrene foam, bags, cardboard, staples, etc.) away from children.

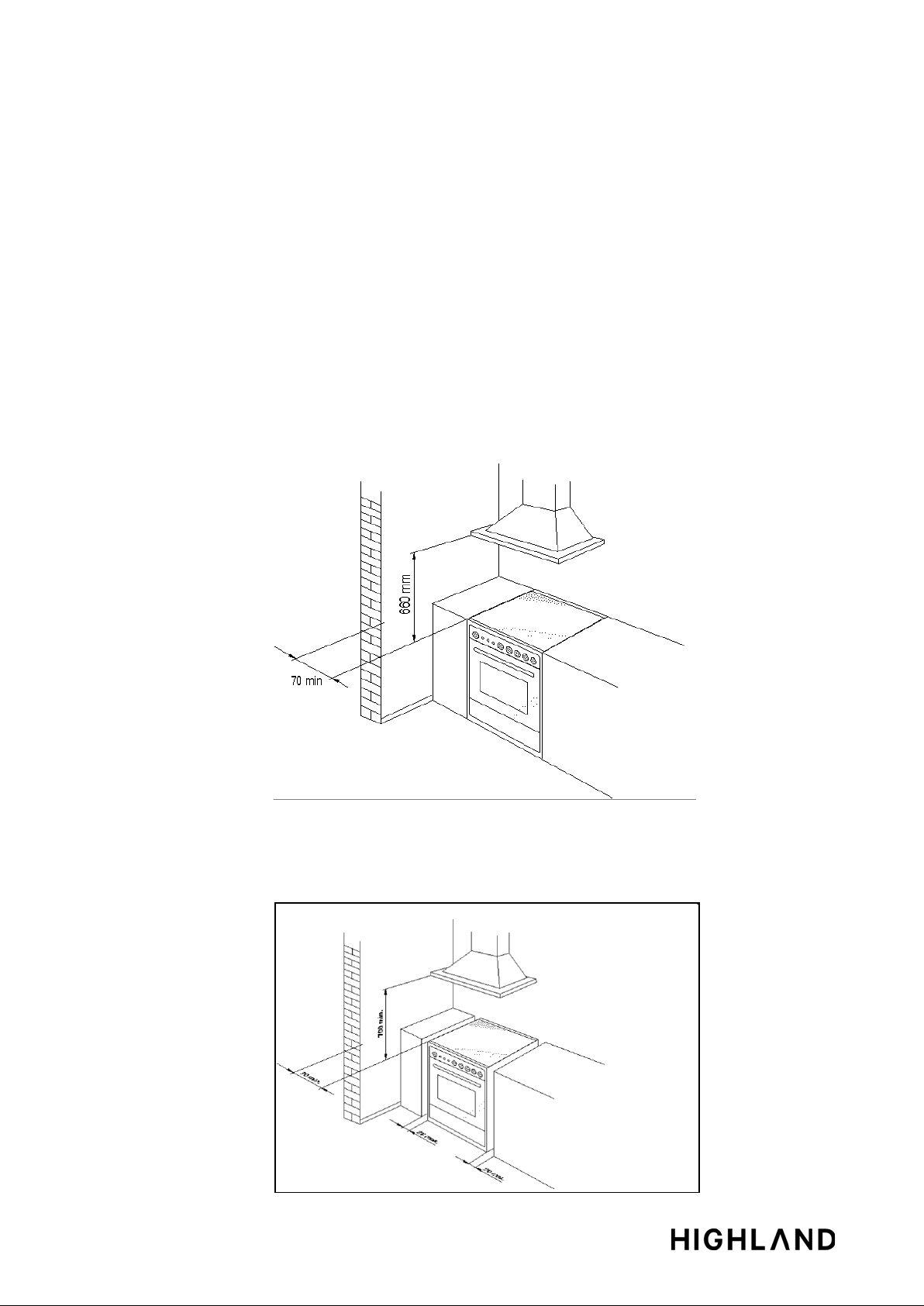

The appliance can be installed as a freestanding unit, next to a wall at a distance of less than 20 mm

(Fig.1B, Class 1 Installation) or inserted between two walls (see Fig.1A, Class 2 Subclass 1 Installation). A

single sidewall that exceeds the height of the work surface is possible. This must be at a minimum distance

of 70 mm from the edge of the cooker (see Fig.1B, Class 1 Installation). Any walls of the adjacent furniture

pieces and the wall behind the cooker must be made with heat-resistant materials. For the installation of the

rangehood above induction freestanding cooker please refer to Fig.1A, a minimum distance of 660 mm is

required. For the installation of the rangehood above the gas/electric cooker please refer to Fig.1B, a

minimum distance between the burner cap and the base of the rangehood must be 700 mm.

Fig.1A

Fig.1B

5

ATTENTION: IMPORTANT WARNINGS

APPLIANCE MAINTEN ANCE

FOR COOKERS RESTING ON A BASE - ATTENTION: If the cooker rests on a base, take the

measurements necessary to prevent the cooker from sliding along the support base.

FOR COOKERS WITH ELECTRIC OVENS

The unit becomes hot during use. Do not touch the heating elements inside the oven.

ATTENTION: The accessible parts can become hot during use. Keep children away from the appliance.

FOR GLASS DOORS

Do not use abrasive cleani ng products or metal spatulas with sharp edges to c lean the oven door’s glass

since this could scratc h the sur fac e and the glass c ould break . Do not sit cooking trays/dishes onto the g lass

surface of the oven, whether hot or cold as this could cause the glass chip and break.

DO NOT USE STEAM CLEANERS TO CLEAN THE APPLIANCE.

REPLACING PARTS

Before performing any maintenance operation, disconnect the appliance from the gas supply and electricity network. To replace parts such as knobs and burners, just remove them from the seats without disassembling any part of the cooker.

To replace the oven bulb, just unscrew the protection cap that projects out inside the oven Fig.2.

Fig.2

WARNING! Before replacing the bulb, disconnect the appliance from the electric power supply.

WARNING! The power cord supplied with the appliance is connected to that appliance with an X type

connection (in compliance with standards EN 60335-1, EN 60335-2-6 and subsequent amendments) for

which it can be installed without the use of special tools, with the same type of cord as the one installed.

If the power cord becomes worn or damaged, replace it based on the information reported in types of power cords paragraph.

WARNING! If the power cord is replaced, the installer shall ensure that the ground cable is longer than the

phase cables and also shall comply with the warnings regarding the electric connection. To replace the

power cable, lift the terminal board’s cover and replace the cable. To access the terminal board in cookers

with a 3x2.5 mm² cable, the back panel on the rear of the appliance must be removed. The power cord

should be replaced only by qualified personnel.

Before disposing of the packaging, please ensure you have removed all the components.

The up-stand is packed separate and is taped to the back of the cooker. Other components can be found

inside the ovens. All packaging and covering films must be removed before the installation can commence.

6

USE OF THE APPLIANCE

WARNING! Do not use aerosols in the vicinity of this appliance while it is in operation.

WARNING! Do not use or store flammable materials in or near this appliance.

WARNING! Do not place articles on or against this appliance.

WARNING! Do not modify this appliance

7

INSTALLING THE COOKER

MCB size for

cooker circuit

Gas hob + Teppanyaki

plate

IMPORTANT

All electric cookers should be installed by a qualified electrician in accordance with AS/NZS3000 wiring

regulations and local electricity provider rules. The gas connection should be installed by a qualified plumber

in accordance with AS/NZS5601 .1 Gas Installations Part 1: General Installations, and AS/NZS5601.2 Gas

Installations Part 2: LP Gas installations in caravans and boats for non-propulsive purposes. Consideration

of the installation of the freestanding will need to comply with building regulations, local government and

council authorities. Failure to install the appliance correctly will render the warranty null and void.

WARNING! The connec tion to the g as network must onl y use metal flex ible pipes that conform to Australia n

Standard AS/NZS 5601.1.

Freestanding cookers are heavy and should be handled by two people. Never lift or drag a range by the oven handles as damage may occur and will render the warranty null and void.

Note: Pictures and graphics in this manual cover different models and may vary in minor details from your cooker.

RATING OF SERVICES

The rating plate is visible in the storage area of the cooker and is also stated below. Before connecting the

cooker, check that the requirements on the rating plate correspond with those of the electrical system and

gas supply (where applicable). Ensure that the electrical system and isolating switches have a suitable

capacity to carry the maximum power as indicated on the rating plate. This chart can be used as a guide to

the electrical supply ratings.

Table No.1.

Cooker model Type

90 cm single oven Gas hob 16 AMP MCB 16 AMP FUSE H05RR-F or H05VV-F 3X1,5 mm²

*90 cm single oven Induction hob 32/40 AMP MCB 32/40 AMP FUSE H07RN-F 3X4 mm²

120 cm twin oven

* With diversity factor applied

POSITIONING

The cooker may be installed in a kitchen or open-plan kitchen diner but not in a room containing a bath or shower. The cooker should be positioned in an area with good light and free from draughts.

Any shelf or unit of combustible material should be at least 650 mm above the hotplate. In addition an area of 75 mm wide on either side and behind the hotplate must be clear of any combustible materials. Units must not overhang over the hob.

When setting the cooker height, ensure the top of the cooker is at least 10 mm higher than the level of the benchtop. It is recommended that a 2.5 mm gap be allowed on each side so that the cooker may be moved if necessary.

The worktop or kitchen cabinets must not protrude beyond the height of the cooker hotplate frame.

VENTILATION

Your appliance is not connected to a combustion products evacuation device. The room in which it is to be

installed must have an air supply in accordance with national standards . The room must have an opening

window or equivalent, and some rooms may require a permanent vent in addition to the opening window.

General guidelines: The cooker must not be installed in a bedsit room of 20 m³ or less. If the cooker is

installed in a room with a volume of less than 5 m³, then a vent with an effective area of 100 cm³ is required.

dedicated

32 AMP MCB 30 AMP FUSE H07RN-F 3X4 mm²

Fuse rates The cable on cooker

8

If it is installed in a room with a volume of between 5 m³ and 10 m³, then an air vent with an effective area

50 cm³ is necessary. If there are other fuel burning appliances in the room, please consult national standards

for guidance.

GAS CONNECTION

IMPORTANT: THIS APPLIANCE MUST BE INSTALLED BY AN AUTHORISED PERSON.

WARNING! The appliance utilizes a threaded 1/2” BSP external thread gas cylindrical male fitting according

to UNI-ISO228-1.

Gas inlet (mm) Nat gas Gas inlet (mm) LPG

From RH rear side: 35 mm From RH rear side: 35 mm

Up from floor: 590 mm Up from floor: 675 mm

Fig.3.

GAS REGULATOR

Gas connection is via ½” compression. Connect the cooker to the gas supply and check for gas soundness.

IF USING A FLEXIBLE CONNECTION

This appliance is approved for connection with a Flexible Hose, which complies with AS/NZS 1869 (AGA

Approved), 10 mm ID, class B or D, between 1-1.2m long. Connection shall be in compliance with AS 5601,

clause 5.12.1.8. When installing the hose restrain device, the appliance anchor point is the rear panel

securing.

IF USING A FIXED COPPER PIPE CONNECTION

The gas connection to the freestanding cooker must be connected to the gas supply with upstream

connection of an isolation valve in accordance with the respective valid regulations. We recommend that the

isolation valve be fitted prior to the cooker to enable isolation of the cooker from the gas supply. The valve

must be easily accessible at all times. To find out the factory set gas type, see label at rear of cooker.

The gas connection is via 1/2" compression. Connect the cooker to the gas supply and check for gas soundness. NEVER use a naked flame to check for gas leaks.

ELECTRICAL CONNECTION

The electric connection must comply with Australian Standard AS/NZS 3000, current legal standards and

regulations.

Before making the connection, check that:

- The system electric al rating and the c urrent outlets ar e adequate for the m aximum power out put of

the appliance (see the rating plate applied to back of the cooker).

9

- The outlet or the system is equipped with an efficient ground connection in accordance with Australian standards, legal standards and regulations. The company will not be responsible for the non-compliance with these inst ruc tio ns .

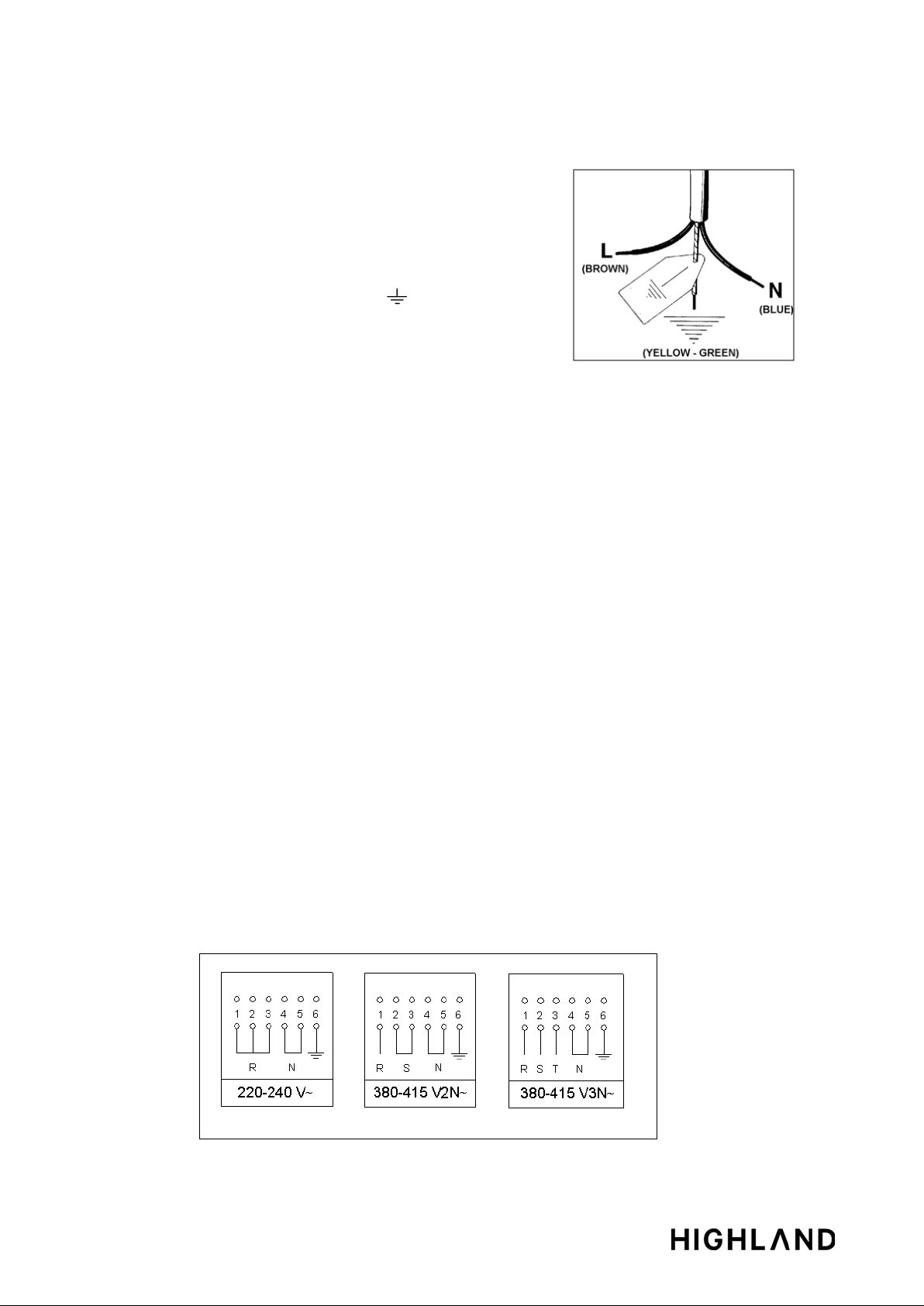

Letter L (phase) = brown wire;

Letter N (neutral) = blue wire;

Ground symbol

= green-yellow wire;

- The power cord must be positioned so that an over temperature of 75 K will not be reached at any point.

- Do not use reductions, adapters or splitters since they might cause false contacts and lead to dangerous overheating.

When the connection is made directly to the electric network:

- Use a device that ensures disconnection from the mains in which the contacts are opened to a distance that permits complete disconnection according to the conditions for over-voltage category III.

- Remember that the ground wire must not be interrupted by the circuit-breaker.

- As an alternative, the electric connection can also be protected by a high-sensitivity residual current circuit-breaker.

- It is highly recommended to attach the special green-yellow groun d wir e to an eff icient ground system.

WARNING! If the power cord is replaced, the ground wire (yellow-green) connected to the terminal, should be longer than the other wires by about 2 cm.

WARNING! The power cord should be replaced only by qualified electrician.

TYPES OF POWER CORDS

The appliance is equipped with a terminal for the electric connection placed behind, which is accessible by

removing the posterior casing. The cookers that can also be connected to three-phase systems normally are

factory built for the single-phase 230V connection and are supplied with a power cord. Based on the

connection system used, install the power cord type indicated in table No.1.

To use the selected connection system change the jumpers on the terminal strip as indicated in the diagram

of Fig.4.

Fig.4.

10

ADAPTATION TO DIFFERENT TYPES OF GAS

(kPa)

Natural

1.0

0.92

Natural

1.0

1.17

Large

(Rapid)

Natural

U-LPG

1.0

2.75

1.55

0.98

11.5

11.6

inner 0.80

outer 2 x 1.30

inner 0.50

outer 2 x 0.73

Before performing any maintenance operation, disconnect the appliance from the gas supply and electricity

network.

REPLACING THE GAS NOZZLES TO OPERATE WITH ANOTHER TYPE OF GAS:

Follow the instructions below to change the burner nozzles on the work surface:

1. Isolate the appliance from the electric outlet to avoid any type of electric contact.

2. Remove the grids from the work surface.

3. Remove the burners.

4. Unscrew the nozzles using a 7 mm spanner, and replace them (Fig.5) with those needed for the new type of gas accordingly.

Fig.5.

WARNING! After completing the above-mentioned replacements, adjust the burners, as described in the

paragraph below. S eal any adjustm ent and pre-adj ustment devic es. Replace the existing rating pl ate with a

new one corresponding to the new gas adjustment. This rating plate is contained in the spare nozzle

bag.

Energy consumption

Burner Gas Type

Small

(Auxiliary)

Medium

(Semi-rapid)

Wok *

*The inner and outer wok operates from the same control knob. Please, note that the inner wok can operate on

its own a nd the inner and out can also operate together.

U-LPG

U-LPG

Natural 1.0

U-LPG 2.75

Pressure

2.75

2.75

Injector (mm) MJ/hr

4.3

0.56

0.73

4.0

6.7

7.0

18.0

16.8

Check correct operation of the ignition system and operation of burners individually and in combination.

Burner flames should be clear blue, with no yellow tipping. If the burners show any abnormality check that

burner heads are correctly located. Note: These burners have no aeration adjustment.

11

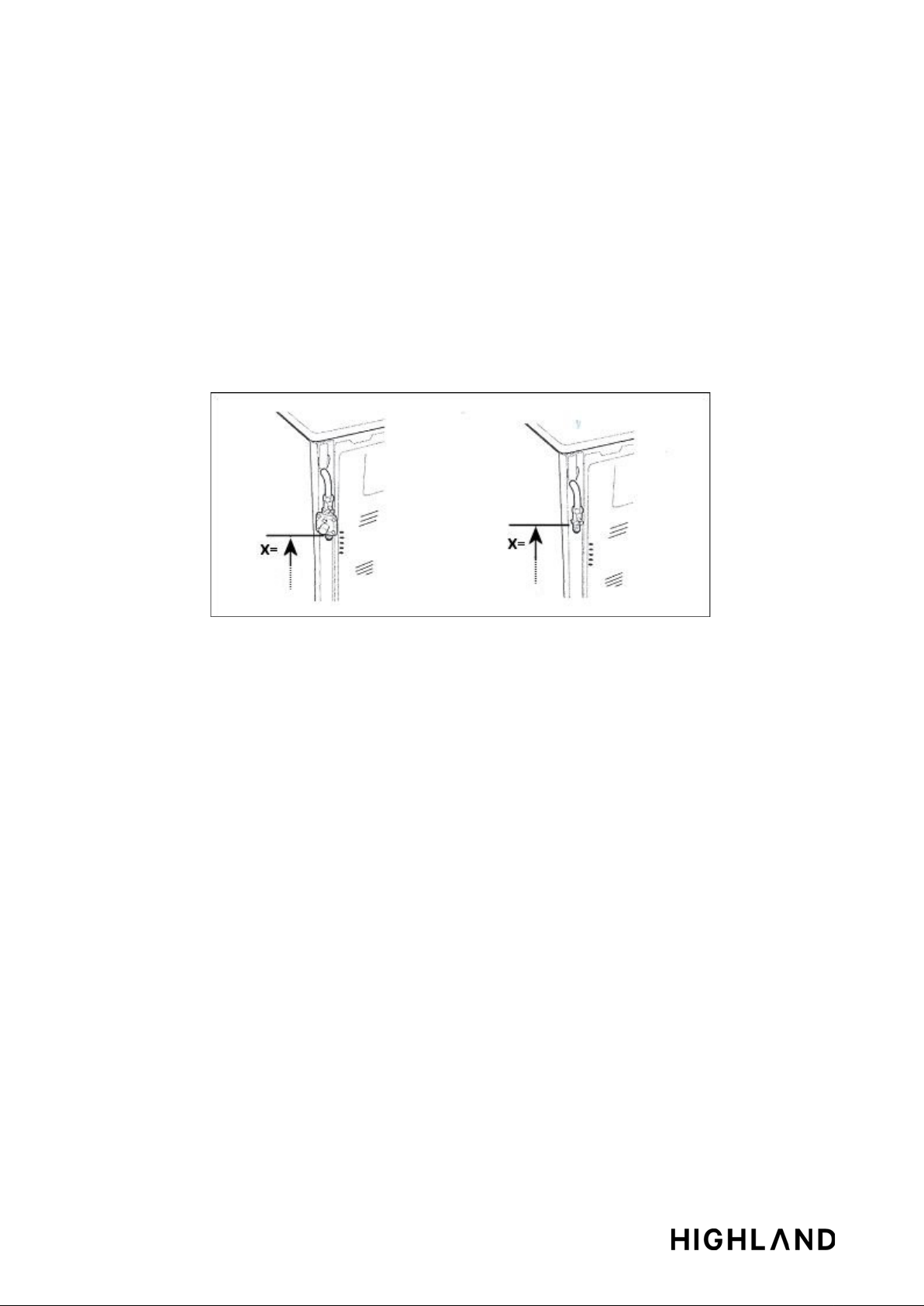

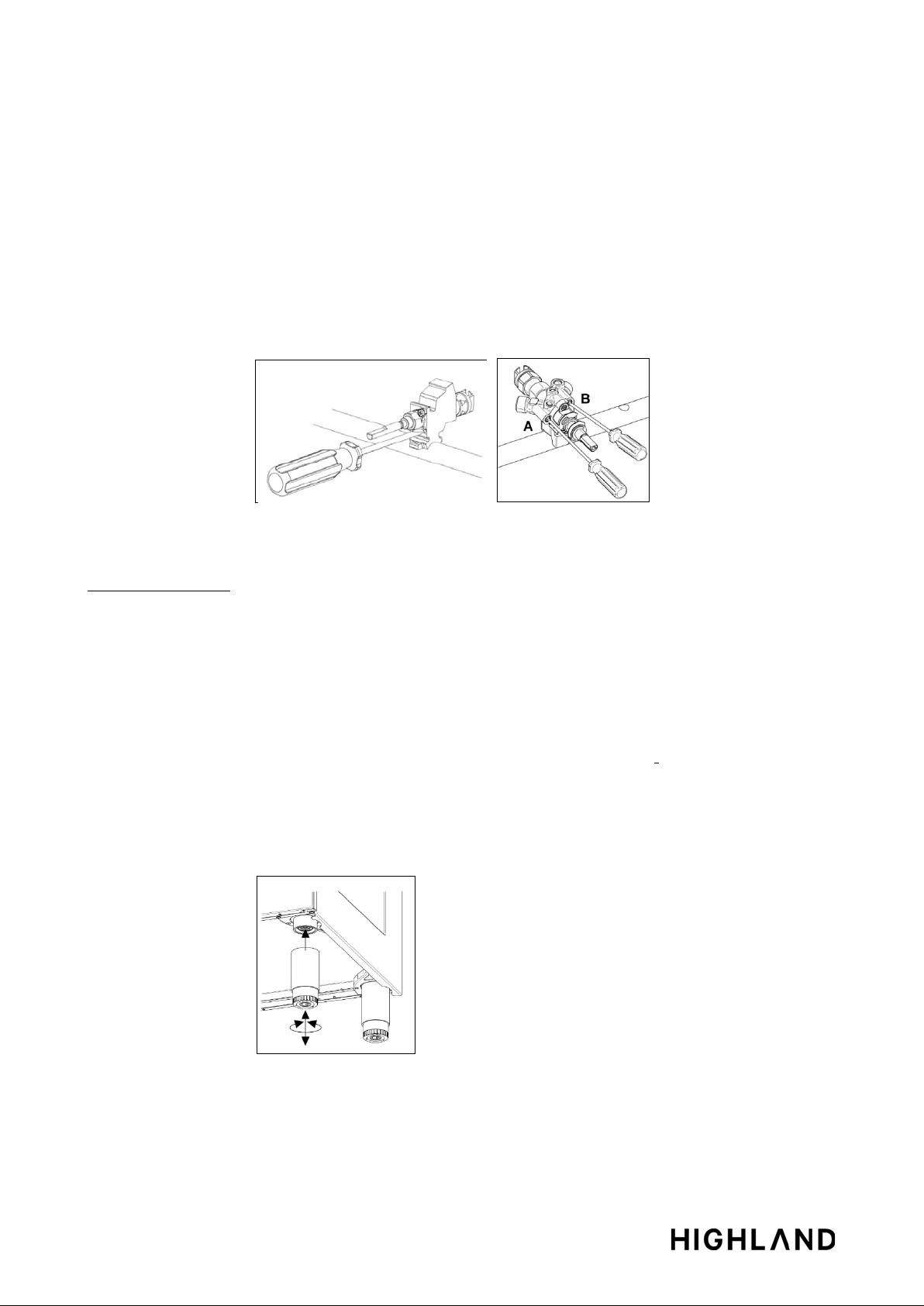

Burner "MINIMUM" adjustment:

Work surface burner adjustment: follow the instructions below to adjust the work surface burner minimum:

1. Light the burner and set the knob to the MINIMUM position (small flame).

2. Remove the knob of the valve that is press-fit on the rod of that valve.

3. Insert a small slotted screwdriver into the hole on the valve body (Fig.10A) and turn the choke screw to the right or left until the burner flame is adjusted to minimum.

4. For the gas valve of dual burner the choke valve is located on the valve body (fig. 10B), the A screw adjust the outer ring, the B screw adjust the inner ring.

Make sure that the flame does not go out when switching quickly from the MAXIMUM to the MINIMUM position.

Fig 10A Fig 10B

WARNING! The above-mentioned adjustment should be made only with natural gas burners, while those

operating with liquid gas the screw must be locked at the end in a clockwise direction.

Test the operation of the cooker before leaving.

It should be noted that PR Kitchen and Washroom Systems, the distributor of Highland Appliances cannot

accept any liability for direct or indirect damage caused by incorrect connection or improper installation.

When being repaired, the appliance must always be disconnected from the mains supply; if required, notif y

our customer service +61 (03) 9700 9100 or +64 (09) 964 0400.

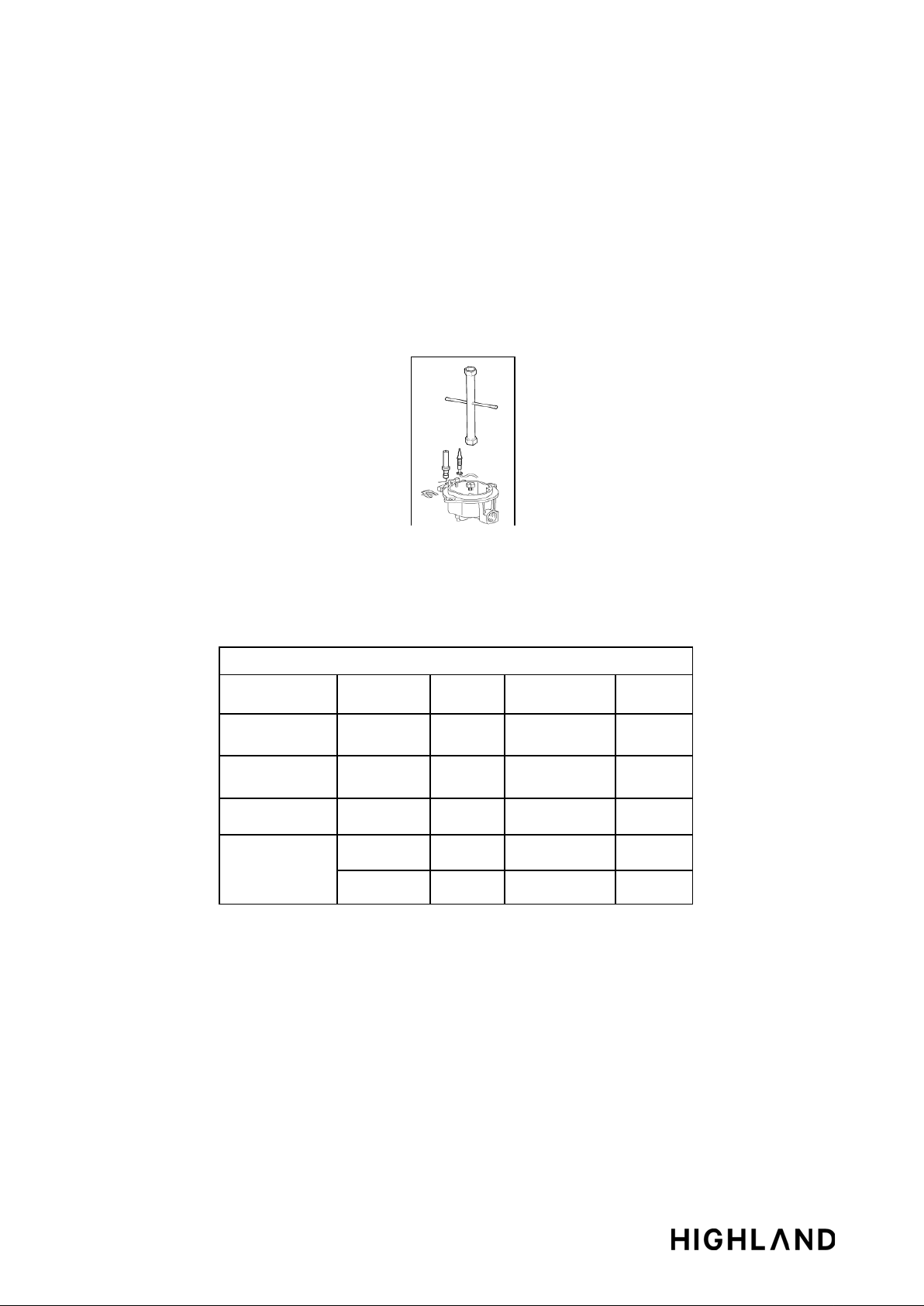

SUPPORT LEGS

4 support legs are supplied separately and are fitted on location to the four corners of the lower support frame (Fig.11)

After unpacking the cooker, lift it approximately 250 mm to fit the legs then gently lower the cooker to keep

undue strain from the legs. It is recommended to use a lifting device instead of tilting the unit. Transit

supports are left in situ. Each leg is firmly pushed over one of the transit supports. If the legs are not used

and the cooker is mounted onto a plinth, leave transit legs in position to allow for clearance.

Fig 11

UPSTAND INSTALLATION

The up-stand is packaged at the bottom rear of the cooker. The up-stand is fixed along the rear of the cooker

hob. Screw fixing points for locating the up-stand are at either end. Place the up-stand on the rear of the hob,

line up locating holes and secure with the screws supplied.

12

Loading...

Loading...