HF-LPT220 Low Power WiFi Module User Manual

HF-LPT220

Low Power WiFi Module User Manual

V 1.2

Overview of Characteristic

Support IEEE802.11b/g/n Wireless Standards

Based on Self-developed High Cost Effective SOC

Support UART/GPIO Data Communication Interface

Support Work As STA/AP Mode

Support Smart Link Function (APP program provide)

Support Wireless and Remote Firmware Upgrade Function

Support WPS Function(Reserved)

Support Internal/External Pin Antenna Option

Single +3.3V Power Supply

Smallest Size: 22mm x 13.5mm x 3.8mm , SMT17 Package

FCC/CE Certificated

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 1 -

HF-LPT220 Low Power WiFi Module User Manual

FCC STATEMENT :

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may cause

undesired operation.

Warning: Changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates

uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of

the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

Consult the dealer or an experienced radio/TV technician for help.

FCC Radiation Exposure Statement:

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled

environment. This equipment should be installed and operated with minimum distance 20cm

between the radiator & your body.

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 2 -

HF-LPT220 Low Power WiFi Module User Manual

FCC INFORMATION (additional)

OEM INTEGRATION INSTRUCTIONS:

This device is intended only for OEM integrators under the following conditions: The module must

be installed in the host equipment such that 20 cm is maintained between the antenna and users,

and the transmitter module may not be co-located with any other transmitter or antenna. The

module shall be only used with the internal antenna(s) that has been originally tested and

certified with this module. As long as 3 conditions above are met, further transmitter test will not

be required. However, the OEM integrator is still responsible for testing their end-product for any

additional compliance requirements required with this module installed (for example, digital

device emissions, PC peripheral requirements, etc.).

Validity of using the module certification:

In the event that these conditions cannot be met (for example certain laptop configurations or colocation with another transmitter), then the FCC authorization for this module in combination with

the host equipment is no longer considered valid and the FCC ID of the module cannot be used

on the final product. In these circumstances, the OEM integrator will be responsible for reevaluating the end product (including the transmitter) and obtaining a separate FCC authorization.

End product labeling:

This transmitter module is authorized only for use in device where the antenna may be installed

such that 20 cm may be maintained between the antenna and users. The final end product

must be labeled in a visible area with the following: “Contains FCC ID: 2ACSV-HF-LPT220”.

Information that must be placed in the end user manual:

The OEM integrator has to be aware not to provide information to the end user regarding how to

install or remove this RF module in the user's manual of the end product which integrates this

module. The end user manual shall include all required regulatory information/warning as show in

this manual.

This device must be kept away from all persons by 20cm or more and installations using less

distance, or installations using antennas with gain greater than that with which this was Certified will

require additional approvals.

Antenna Specification:

Type: SMD Antenna

Model: HF-LPT220

Brand: High-Flying

Gain: 0.8

dBi

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 3 -

HF-LPT220 Low Power WiFi Module User Manual

TABLE OF CONTENTS

LIST OF FIGURES ............................................................................................................................. 8

LIST OF TABLES ................................ ................................................................ ............................... 9

HISTORY.......................................................................................................................................... 10

1. PRODUCT OVERVIEW.......................................................................................................... 11

1.1. General Description ................................ ................................................................ .......... 11

1.1.1 Device Features ........................................................................................................... 11

1.1.2 Device Paremeters....................................................................................................... 12

1.1.3 Key Application ............................................................................................................ 12

1.2. Hardware Introduction ................................ ................................................................ ...... 13

1.2.1. Pins Definition .............................................................................................................. 13

1.2.2. Electrical Characteristics .............................................................................................. 14

1.2.3. Mechanical Size ........................................................................................................... 15

1.2.4. On-board Chip Antenna ............................................................................................... 15

1.2.5. External Antenna ......................................................................................................... 16

1.2.6. Evaluation Kit ............................................................................................................... 16

1.2.7. Order Information ......................................................................................................... 18

1.2.8. Hardware Typical Application ....................................................................................... 18

2. FUNCTIONAL DESCRIPTION .............................................................................................. 20

2.1. Wireless Networking ......................................................................................................... 20

2.1.1. Basic Wireless Network Based On AP (Infrastructure) .................................................. 20

2.1.2. Wireless Network Based On AP+STA .......................................................................... 20

2.2. Work Mode : Transparent Transmission Mode ................................................................ 21

2.3. UART Frame Scheme(Reserved) ...................................................................................... 21

2.3.1. UART Free-Frame ....................................................................................................... 21

2.3.2. UART Auto-Frame ................................................................................................ ....... 22

2.4. Encryption ................................................................................................ ......................... 22

2.5. Parameters Configuration ................................................................................................ 22

2.6. Firmware Update(Reserved, See Appendix C) ............................................................ 22

2.7. SOCKET B Function.......................................................................................................... 23

2.8. Multi-TCP Link Connection(Reserved) ............................................................................. 24

3. OPERATION GUIDELINE...................................................................................................... 25

3.1. Configuration .................................................................................................................... 25

3.2. Usage Introduction ........................................................................................................... 25

3.2.1. Software Debug Tools ................................................................................................ .. 25

3.2.2. Network Connection ..................................................................................................... 25

3.2.3. Default Parameter Setting ................................ ................................ ............................ 26

3.2.4. Module Debug ............................................................................................................. 26

3.3. Typical Application Examples .......................................................................................... 27

3.3.1. Wireless Control Application ......................................................................................... 27

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 4 -

HF-LPT220 Low Power WiFi Module User Manual

3.3.2. Remote Management Application ................................................................................. 28

3.3.3. Transparent Serial Port Application ................................ ................................ .............. 28

4. AT+INSTRUCTION INTRODUCTION ................................................................................... 29

4.1. Configuration Mode .......................................................................................................... 29

4.1.1. Switch to Configuration Mode ....................................................................................... 29

4.2. AT+Instruction Set Overview ............................................................................................ 30

4.2.1. Instruction Syntax Format............................................................................................. 30

4.2.2. AT+Instruction Set ....................................................................................................... 31

4.2.2.1. AT+E ........................................................................................................................ 33

4.2.2.2. AT+WMODE............................................................................................................. 34

4.2.2.3. AT+ENTM ................................................................................................................ 34

4.2.2.4. AT+TMODE .............................................................................................................. 34

4.2.2.5. AT+MID ................................................................ .................................................... 34

4.2.2.6. AT+VER ................................................................................................................... 35

4.2.2.7. AT+LVER ................................ ................................ ................................................. 35

4.2.2.8. AT+FWSZ ................................................................................................................ 35

4.2.2.9. AT+RELD ................................................................................................................. 35

4.2.2.10. AT+FCLR .............................................................................................................. 35

4.2.2.11. AT+Z..................................................................................................................... 36

4.2.2.12. AT+H ................................ ................................................................ .................... 36

4.2.2.13. AT+CFGTF ........................................................................................................... 36

4.2.2.14. AT+UART ................................ ................................ ............................................. 36

4.2.2.15. AT+UARTF ........................................................................................................... 37

4.2.2.16. AT+UARTFT ......................................................................................................... 37

4.2.2.17. AT+UARTFL ......................................................................................................... 37

4.2.2.18. AT+UARTTE ......................................................................................................... 38

4.2.2.19. AT+SEND ............................................................................................................. 38

4.2.2.20. AT+RECV ............................................................................................................. 38

4.2.2.21. AT+PING ................................................................ .............................................. 38

4.2.2.22. AT+NETP ............................................................................................................. 39

4.2.2.23. AT+MAXSK........................................................................................................... 39

4.2.2.24. AT+TCPLK............................................................................................................ 40

4.2.2.25. AT+TCPTO ................................ ................................................................ ........... 40

4.2.2.26. AT+TCPDIS .......................................................................................................... 40

4.2.2.27. AT+SOCKB........................................................................................................... 41

4.2.2.28. AT+TCPDISB ........................................................................................................ 41

4.2.2.29. AT+TCPTOB ......................................................................................................... 41

4.2.2.30. AT+TCPLKB ......................................................................................................... 42

4.2.2.31. AT+SNDB ............................................................................................................. 42

4.2.2.32. AT+RCVB ............................................................................................................. 42

4.2.2.33. AT+WSSSID ................................................................ ......................................... 43

4.2.2.34. AT+WSKEY .......................................................................................................... 43

4.2.2.35. AT+WANN ............................................................................................................ 43

4.2.2.36. AT+WSMAC ......................................................................................................... 44

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 5 -

HF-LPT220 Low Power WiFi Module User Manual

4.2.2.37. AT+WSLK ............................................................................................................. 44

4.2.2.38. AT+WSLQ............................................................................................................. 44

4.2.2.39. AT+WSCAN .......................................................................................................... 45

4.2.2.40. AT+WSDNS .......................................................................................................... 45

4.2.2.41. AT+LANN ............................................................................................................. 45

4.2.2.42. AT+WAP ............................................................................................................... 45

4.2.2.43. AT+WAKEY .......................................................................................................... 46

4.2.2.44. AT+WAMAC ......................................................................................................... 46

4.2.2.45. AT+WADHCP ................................................................ ....................................... 46

4.2.2.46. AT+WADMN ......................................................................................................... 47

4.2.2.47. AT+WALK ............................................................................................................. 47

4.2.2.48. AT+WALKIND ....................................................................................................... 47

4.2.2.49. AT+WAPMXSTA ................................................................................................... 48

4.2.2.50. AT+OTA................................................................................................................ 48

4.2.2.51. AT+UPURL ........................................................................................................... 48

4.2.2.52. AT+UPFILE........................................................................................................... 48

4.2.2.53. AT+LOGSW .......................................................................................................... 49

4.2.2.54. AT+LOGPORT ...................................................................................................... 49

4.2.2.55. AT+UPST ............................................................................................................. 49

4.2.2.56. AT+DISPS ............................................................................................................ 50

4.2.2.57. AT+NTPRF ........................................................................................................... 50

4.2.2.58. AT+NTPEN ........................................................................................................... 50

4.2.2.59. AT+NTPTM ........................................................................................................... 51

4.2.2.60. AT+NTPSER ......................................................................................................... 51

4.2.2.61. AT+WRMID........................................................................................................... 51

4.2.2.62. AT+RLDEN ........................................................................................................... 51

4.2.2.63. AT+ASWD ............................................................................................................ 52

4.2.2.64. AT+MDCH ............................................................................................................ 52

4.2.2.65. AT+TXPWR .......................................................................................................... 52

4.2.2.66. AT+SMTLK ........................................................................................................... 53

4.2.2.67. AT+SMTLKVER ................................ ................................................................ .... 53

4.2.2.68. AT+WPS ............................................................................................................... 53

4.2.2.69. AT+WPSBTNEN ................................................................................................... 54

4.2.2.70. AT+LPTIO ............................................................................................................. 54

4.2.2.71. AT+WIFI ............................................................................................................... 54

4.2.2.72. AT+SMEM ............................................................................................................ 55

4.2.2.73. AT+NDBGL ........................................................................................................... 55

5. PACKAGE INFORMATION ................................................................................................... 56

5.1. Recommended Reflow Profile .......................................................................................... 56

5.2. Device Handling Instruction (Module IC SMT Preparation) ............................................. 56

5.3. Shipping Information ........................................................................................................ 57

APPENDIX A: HW REFERENCE DESIGN .................................................................................. 58

APPENDIX B: HTTP PROTOCOL TRANSFER .......................................................................... 59

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 6 -

HF-LPT220 Low Power WiFi Module User Manual

B.1. HTTP AT command(Reserved) ............................................................................................ 59

B.1.1. AT+HTTPURL.............................................................................................................. 59

B.1.2. AT+HTTPTP ................................................................................................................ 59

B.1.3. AT+HTTPPH ................................................................................................................ 59

B.1.4. AT+HTTPCN................................................................................................................ 60

B.1.5. AT+HTTPUA ................................................................................................................ 60

B.1.6. AT+HTTPDT ................................................................................................................ 60

B.2. HTTP Example ..................................................................................................................... 60

C.3. Sending HTTP Raw Data in Throughput Mode(Recommend) ............................................ 61

C.4. Sending HTTP Request By AT Command(Reserved) ........................................................ 62

APPENDIX D:REFERENCES ....................................................................................................... 64

D.1.High-Flying Mass Production Tool .................................................................................... 64

D.2.SmartLink APP V7 Config Tool.......................................................................................... 64

D.3.EVK Quick Start Guide....................................................................................................... 64

C.4.Module Upgrade ................................................................................................................. 64

D.4.SDK Download ................................................................................................................... 64

APPENDIX E: CONTACT INFORMATION .................................................................................. 65

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 7 -

HF-LPT220 Low Power WiFi Module User Manual

LIST OF FIGURES

HF-LPT220 Pins Map........................................................................................................................ 13

Figure 1. HF-LPT220 Mechanical Dimension .................................................................................. 15

Figure 2. HF-LPT220 PCB Symbol Size ......................................................................................... 15

Figure 3. Suggested Module Placement Region ............................................................................. 16

Figure 4. HF-LPT220 Evaluation Kit ............................................................................................... 17

Figure 5. HF-LPT220 Order InformationTypical Application............................................................. 18

Figure 6. HF-LPT220 Hardware Typical Application ........................................................................ 18

Figure 7. HF-LPT220 Basic Wireless Network Structure ................................................................. 20

Figure 8. HF-LPT220 STA Network Structure ................................................................ ................. 20

Figure 9. Socket B function demo ................................................................................................... 24

Figure 10. Multi-TCP Link Data Transmition Structure ................................................................... 24

Figure 11. STA Interface Debug Connection ................................................................................. 25

Figure 12. AP Interface Debug Connection ................................................................................... 26

Figure 13. “CommTools” Serial Debug Tools................................................................................. 26

Figure 14. “TCPUDPDbg” Tools Create Connection ...................................................................... 26

Figure 15. “TCPUDPDbg” Tools Setting ........................................................................................ 27

Figure 16. “TCPUDPDbg” Tools Connection ................................................................................. 27

Figure 17. Wireless Control Application ......................................................................................... 27

Figure 18. Remote Management Application ................................................................................. 28

Figure 19. Transparent Serial Port Application .............................................................................. 28

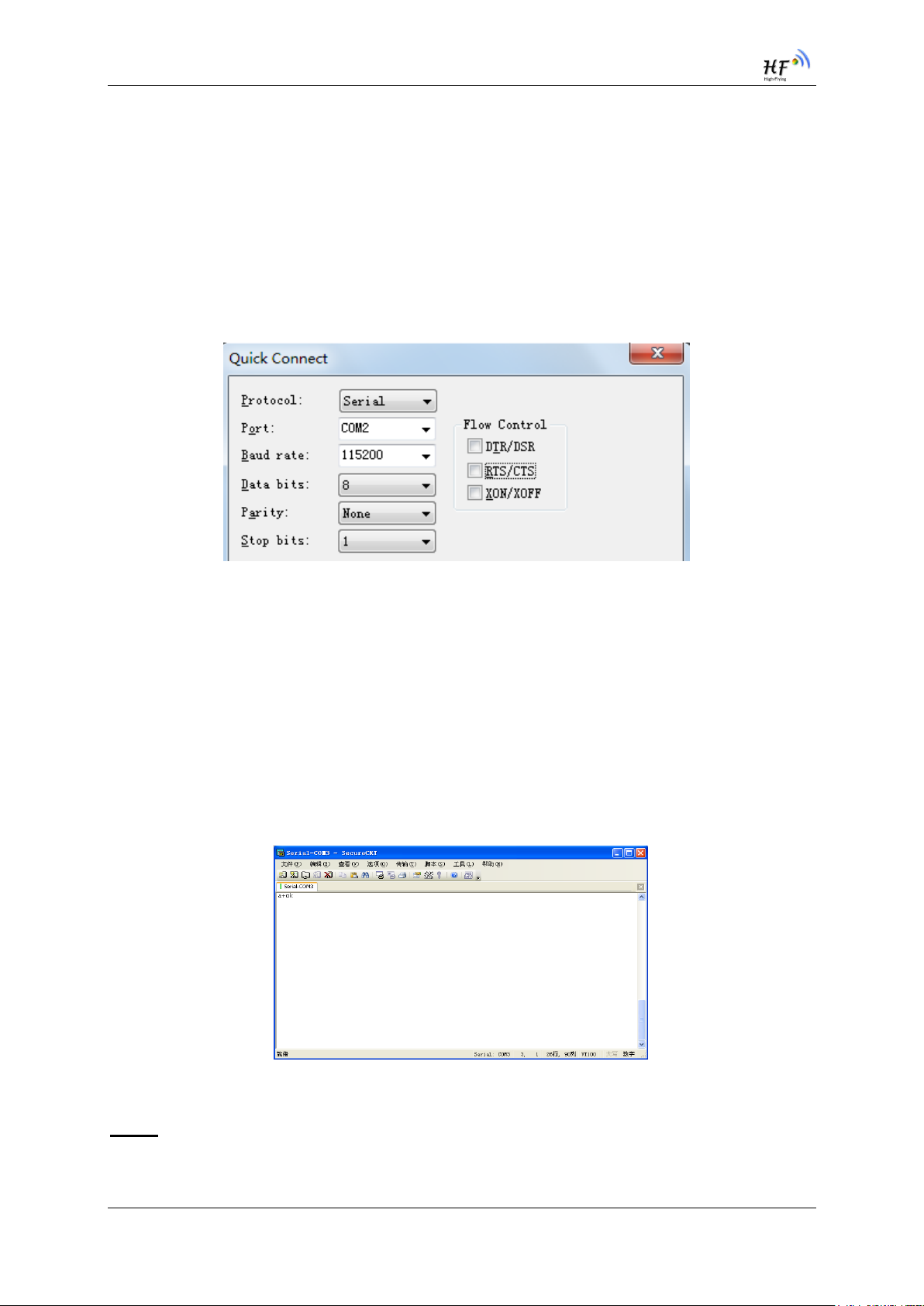

Figure 20. HF-LPT220 Default UART Port Parameters.................................................................. 29

Figure 21. Switch to Configuration Mode ....................................................................................... 29

Figure 22. ”AT+H” Instruction for Help ........................................................................................... 30

Figure 23. Reflow Soldering Profile ............................................................................................... 56

Figure 24. Shipping Information .................................................................................................... 57

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 8 -

HF-LPT220 Low Power WiFi Module User Manual

LIST OF TABLES

Table 1 HF-LPT220 Module Technical Specifications ................................................................ .... 12

Table 2 HF-LPT220 Pins Definition ............................................................................................... 13

Table 3 HF-LPT220 External Antenna Parameters ........................................................................ 16

Table 4 HF-LPT220 Evaluation Kit Interface Description................................................................ 17

Table 8 HF-LPT220 Web Access Default Setting........................................................................... 25

Table 9 Error Code Describtion ..................................................................................................... 31

Table 10 AT+Instruction Set List.................................................................................................... 31

Table 11 Reflow Soldering Parameter ............................................................................................. 56

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 9 -

HF-LPT220 Low Power WiFi Module User Manual

HISTORY

Ed. V1.0 01-05-2016 First Version.

Ed. V1.1 01-29-2015 Update AT command supported by 2.0.03 version firmware. Add support for

AT+E、AT+SOCKB、AT+TCPDISB、AT+TCPTOB、AT+TCPLKB、AT+WALK、AT+WALKIND

command. Correct the AT+NETP command description.

Ed. V1.2 03-14-2015 Update AT command supported by 2.0.04 version firmware. Add

support for AT+MAXSK、AT+WAPMXSTA command. Update AT+NETP、AT+UART command. All

the reserved function is not supported yet. See appendix C to get new firmware.

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 10 -

HF-LPT220 Low Power WiFi Module User Manual

1. PRODUCT OVERVIEW

1.1. General Description

The HF-LPT220 is a fully self-contained small form-factor, single stream, 802.11b/g/n Wi-Fi module,

which provide a wireless interface to any equipment with a Serial interface for data transfer.HFLPT220 integrate MAC, baseband processor, RF transceiver with power amplifier in hardware and all

Wi-Fi protocol and configuration functionality and networking stack, in embedded firmware to make a

fully self-contained 802.11b/g/n Wi-Fi solution for a variety of applications.

The HF-LPT220 employs the world's lowest power consumption embedded architecture. It has been

optimized for all kinds of client applications in the home automation, smart grid, handheld device,

personal medical application and industrial control that have lower data rates, and transmit or receive

data on an infrequent basis.

The HF-LPT220 integrates all Wi-Fi functionality into a low-profile, 22x13.5x 3.8mm SMT module

package that can be easily mounted on main PCB with application specific circuits. Also, module

provides built-in antenna, external pad antenna option.

1.1.1 Device Features

Single stream Wi-Fi @ 2.4 GHz with support for WEP security mode as well as WPA/WPA2

Based on Self-developed High Cost Performance SOC

Includes all the protocol and configuration functions for Wi-Fi connectivity.

Support STA/AP Mode

Support Smart Link Function

Support Wireless and Remote Firmware Upgrade Function

Integrated chip antenna, antenna connector options.

Compact surface mount module 22mm x 13.5mm x 3.8mm, SMT17 Package

Single supply – 3.3V operation.

CE/FCC Certified.

RoHS compliant.

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 11 -

HF-LPT220 Low Power WiFi Module User Manual

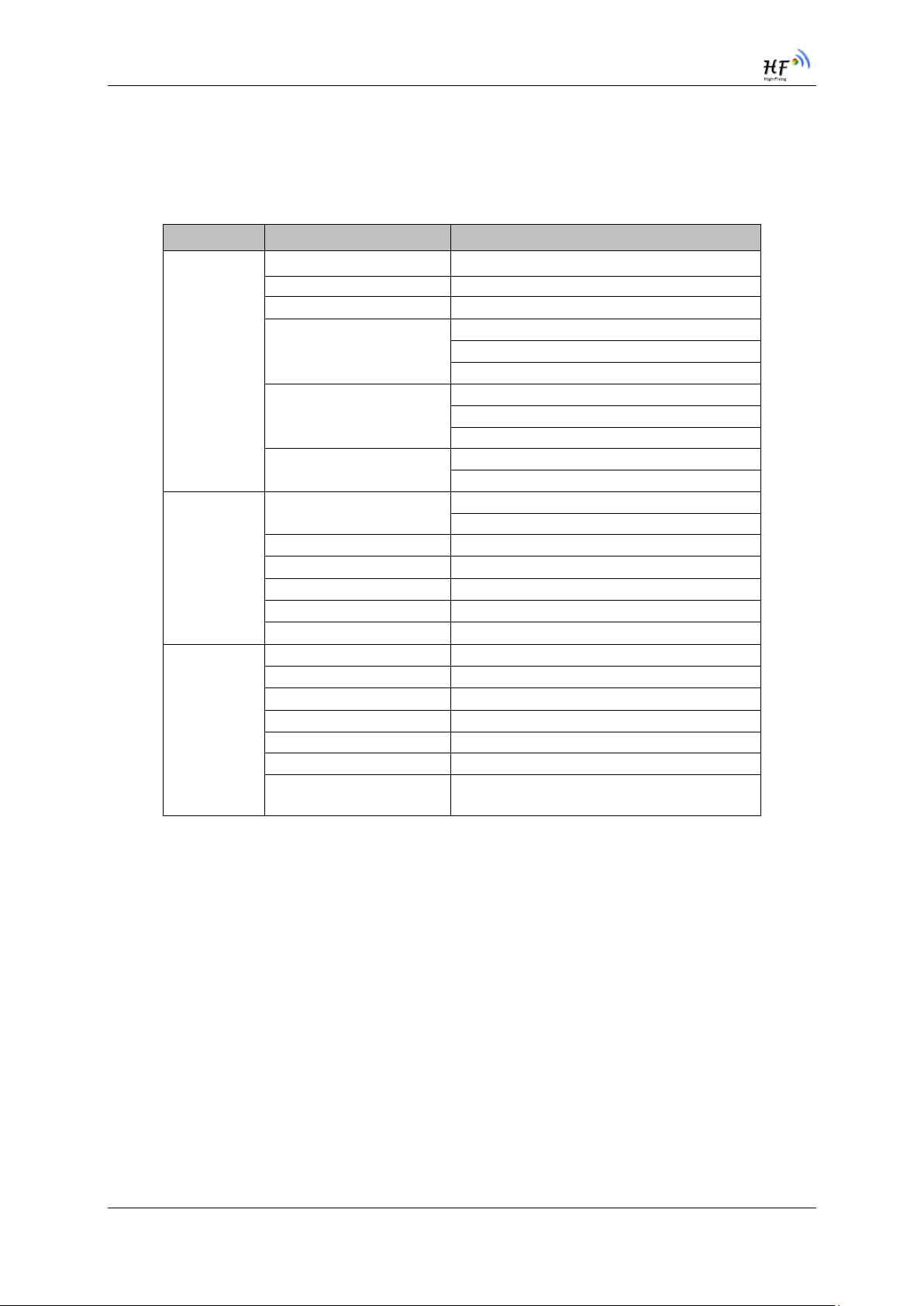

1.1.2 Device Paremeters

Table 1 HF-LPT220 Module Technical Specifications

Class Item Parameters

Certification FCC/CE

Wireless standard 802.11 b/g/n

Frequency range 2.412GHz-2.462GHz

Wireless

Parameters

Hardware

Parameters

Software

Parameters

Transmit Power

Receiver Sensitivity

Antenna Option

Data Interface

Operating Voltage 2.95~3.6V

Operating Current

Operating Temp.

Storage Temp.

Dimensions and Size 22mm×13.5mm×3.8mm

Network Type STA /AP

Security Mechanisms WEP/WPA-PSK/WPA2-PSK

Encryption WEP64/WEP128/TKIP/AES

Update Firmware Local Wireless, Remote

Customization Support SDK for application develop

Network Protocol IPv4, TCP/UDP/HTTP

User Configuration

802.11b: +16 +/-2dBm (@11Mbps)

802.11g: +14 +/-2dBm (@54Mbps)

802.11n: +13 +/-2dBm (@HT20, MCS7)

802.11b: -93 dBm (@11Mbps ,CCK)

802.11g: -85 dBm (@54Mbps, OFDM)

802.11n: -82 dBm (@HT20, MCS7)

External: Pad interface

Internal:On-board Chip antenna

UART

GPIO

Average. ~30mA, Peak: 280mA

-20℃- 85℃

-40℃- 125℃

AT+instruction set. Android/ iOS

Smart Link APP tools

1.1.3 Key Application

Remote equipment monitoring

Asset tracking and telemetry

Security

Industrial sensors and controls

Home automation

Medical devices

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 12 -

HF-LPT220 Low Power WiFi Module User Manual

1.2. Hardware Introduction

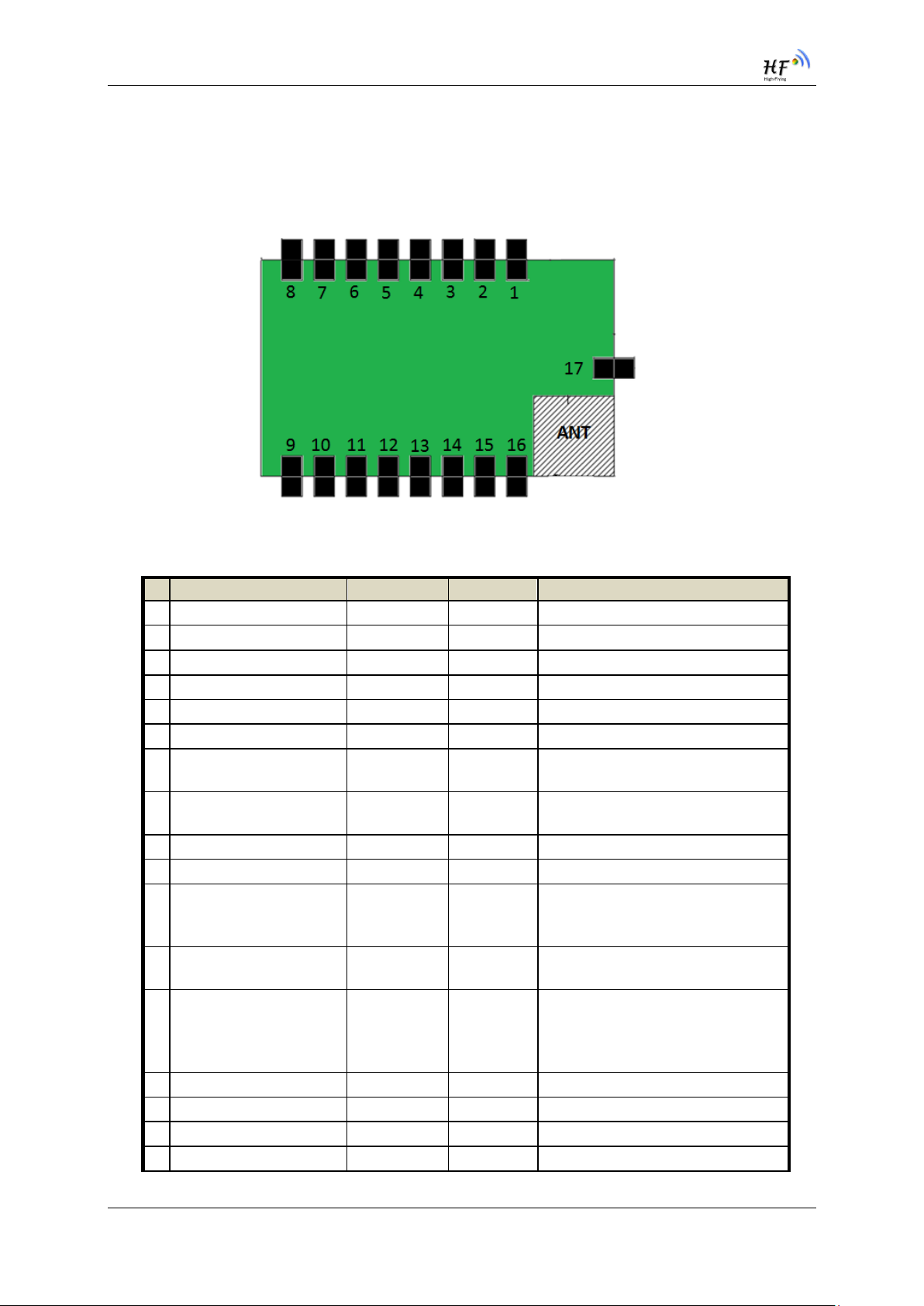

1.2.1. Pins Definition

HF-LPT220 Pins Map

Table 2 HF-LPT220 Pins Definition

Pin Describtion Net Name Signal Type

1 N.C No connect

2 N.C No connect

3 N.C No connect

4 PWM/GPIO GPIO_8 I/O,PU GPIO_8

5 UART0 UART0_TX O,PU GPIO_20

6 UART0 UART0_RX I GPIO_19

7 UART0 UART0_CTS I/O GPIO6/UART1_RXD

UART1 Debug Information Input

8 UART0 UART0_RTS I/O GPIO5/UART1_TXD

UART1 Debug Information Output

9 GPIO GPIO_1 I/O,PU GPIO1

10 Module Reset EXT_RESETn I,PU “Low” effective reset input.

11 Module Boot Up Indicator nReady O “0” – Boot-up OK;

12 Multi-Function nReload I,PU

13 Wi-Fi Status nLink O “0” – Wi-Fi connect to router

14 GPIO18 GPIO18 I/O GPIO_18

15 +3.3V Power DVDD Power

16 Ground GND Power

17 2.4GHz Antenna PAD Ant_2.4G O 50ohm Impendence

Detailed functions see <Notes>

“1” – Wi-Fi unconncted;

Detailed functions see <Notes>

Comments

“1” – Boot-up No OK;

GPIO_3

GPIO_2

GPIO_15

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 13 -

HF-LPT220 Low Power WiFi Module User Manual

<Notes>

When bootup, module PIN4/5/9 must be high.

I — Input;O — Output

PU—Internal 4.7K Resistor Pull Up;PD—Internal Pull Down; I/O: Digital I/O; Power—

Power Supply

nReload Pin (Button) function:

1. When this pin is set to “low” during module boot up, the module will enter wireless

firmware and config upgrade mode. This mode is used for customer manufacture.

(See Appendix C to download software tools for customer batch configuration and

upgrade firmware during mass production)

2. After module is powered up, short press this button ( “Low” < 2s ) to make the

module go into “Smart Link “ config mode, waiting for APP to set password and

other information. (See Appendix C to download SmartLink APP)

3. After module is powered up, long press this button ( “Low” >= 4s ) to make the

module recover to factory setting.

High-Flying strongly suggest customer fan out this pin to connector or button for

“Manufacture” and “ Smart Link” application.

nLink Pin (LED) function:

1. At wireless firmware and config upgrade mode , this LED used to indicate configure

and upgrade status.

2. At “Smart Link “ config mode, this LED used to indicate APP to finish setting.

3. At normal mode, it’s Wi-Fi link status indicator

High-Flying strongly suggest customer fan out this pin to LED.

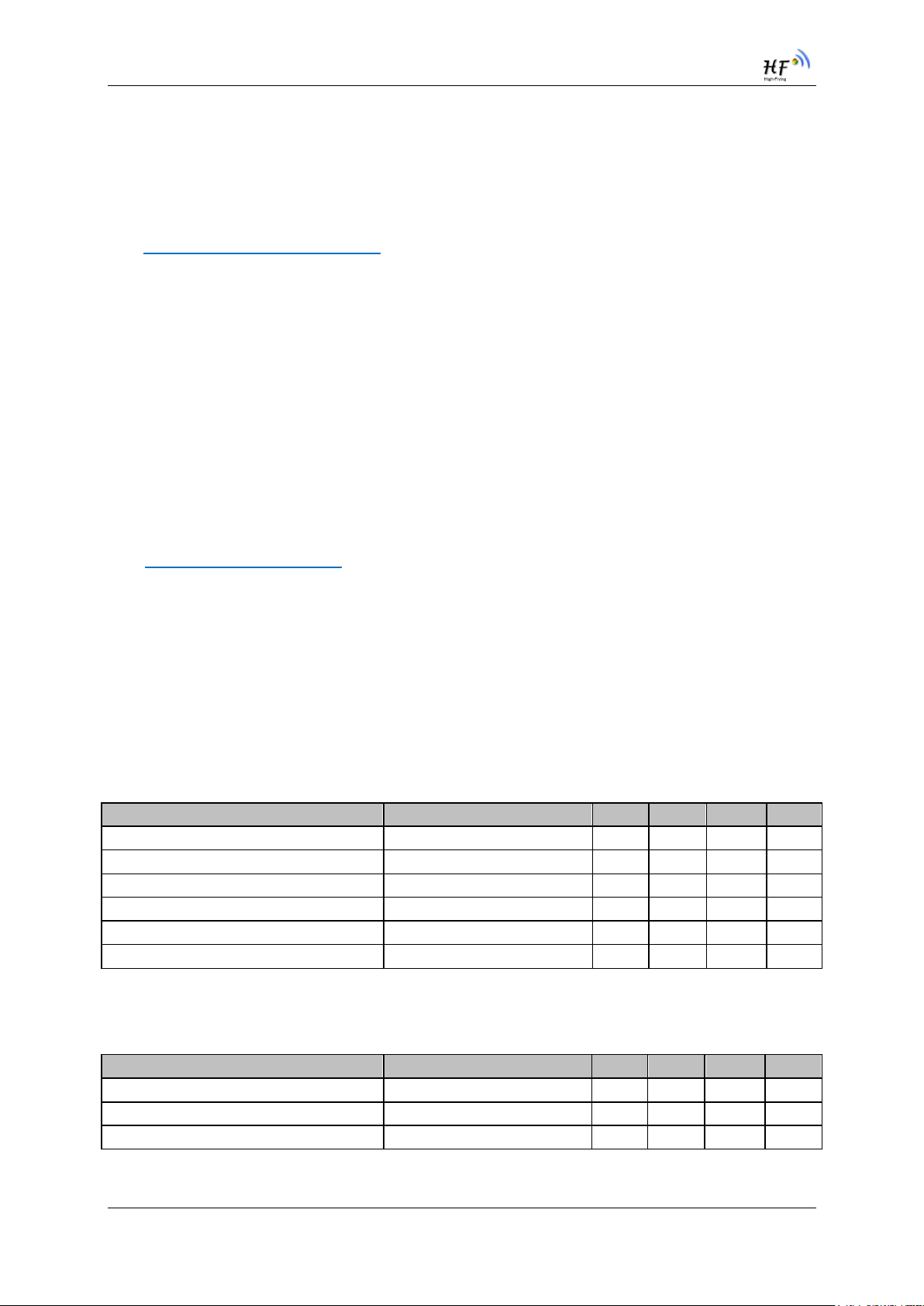

1.2.2. Electrical Characteristics

Absolute Maximum Ratings:

Parameter Condition Min. Typ. Max. Unit

Storage temperature range -40 125 °C

Maximum soldering temperature IPC/JEDEC J-STD-020 260 °C

Supply voltage 0 3.6 V

Voltage on any I/O pin 0 3.6 V

ESD (Human Body Model HBM) TAMB=25°C 2.5 KV

ESD (MM) TAMB=25°C 0.25 KV

Power Supply & Power Consumption:

Parameter Condition Min. Typ. Max. Unit

Operating Supply voltage 2.95 3.3 3.6 V

Supply current, peak Continuous Tx 280 mA

Supply current, IEEE PS DTIM=100ms 30 mA

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 14 -

HF-LPT220 Low Power WiFi Module User Manual

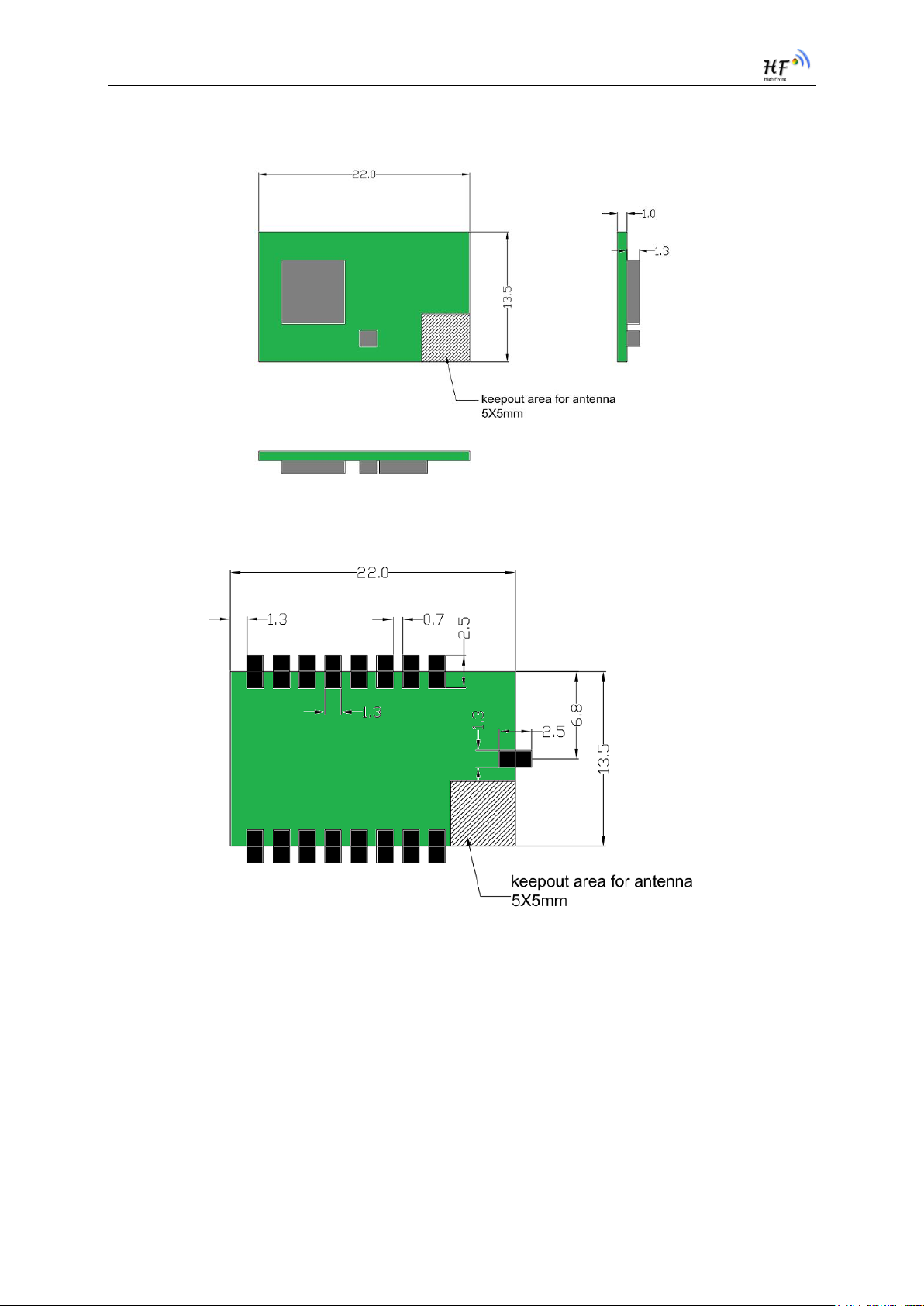

1.2.3. Mechanical Size

HF-LPT220 modules physical size (Unit: mm) as follows:

Figure 1. HF-LPT220 Mechanical Dimension

HF-LPT220 Module PCB symbol size (mm) as follows:

Figure 2. HF-LPT220 PCB Symbol Size

1.2.4. On-board Chip Antenna

HF-LPT220 module support internal on-board chip antenna option. When customer select internal

antenna, you shall comply with following antenna design rules and module location suggestions:

For customer PCB, RED color region (5x5mm) can’t put componet or paste GND net;

Antenna must away from metal or high components at least 10mm;

Antenna can’t be shieldedby any meal enclosure; All cover, include plastic, shall away from

antenna at least 10mm;

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 15 -

HF-LPT220 Low Power WiFi Module User Manual

Item

Parameters

Frequency range

2.4~2.5GHz

Impedance

50 Ohm

VSWR

2 (Max)

Return Loss

-10dB (Max)

Connector Type

I-PEX or populate directly

Figure 3. Suggested Module Placement Region

High-Flying suggest HF-LPT220 module better locate in following region at customer board, which to

reduce the effect to antenna and wireless signal, and better consult High-Flying technical people when

you structure your module placement and PCB layout.

1.2.5. External Antenna

HF-LPT220 module supports internal antenna and external antenna(I-PEX or SMA) option for user

dedicated application.

If user select external antenna, HF-LPT220 modules must be connected to the 2.4G antenna

according to IEEE 802.11b/g/n standards.

The antenna parameters required as follows:

Table 3 HF-LPT220 External Antenna Parameters

1.2.6. Evaluation Kit

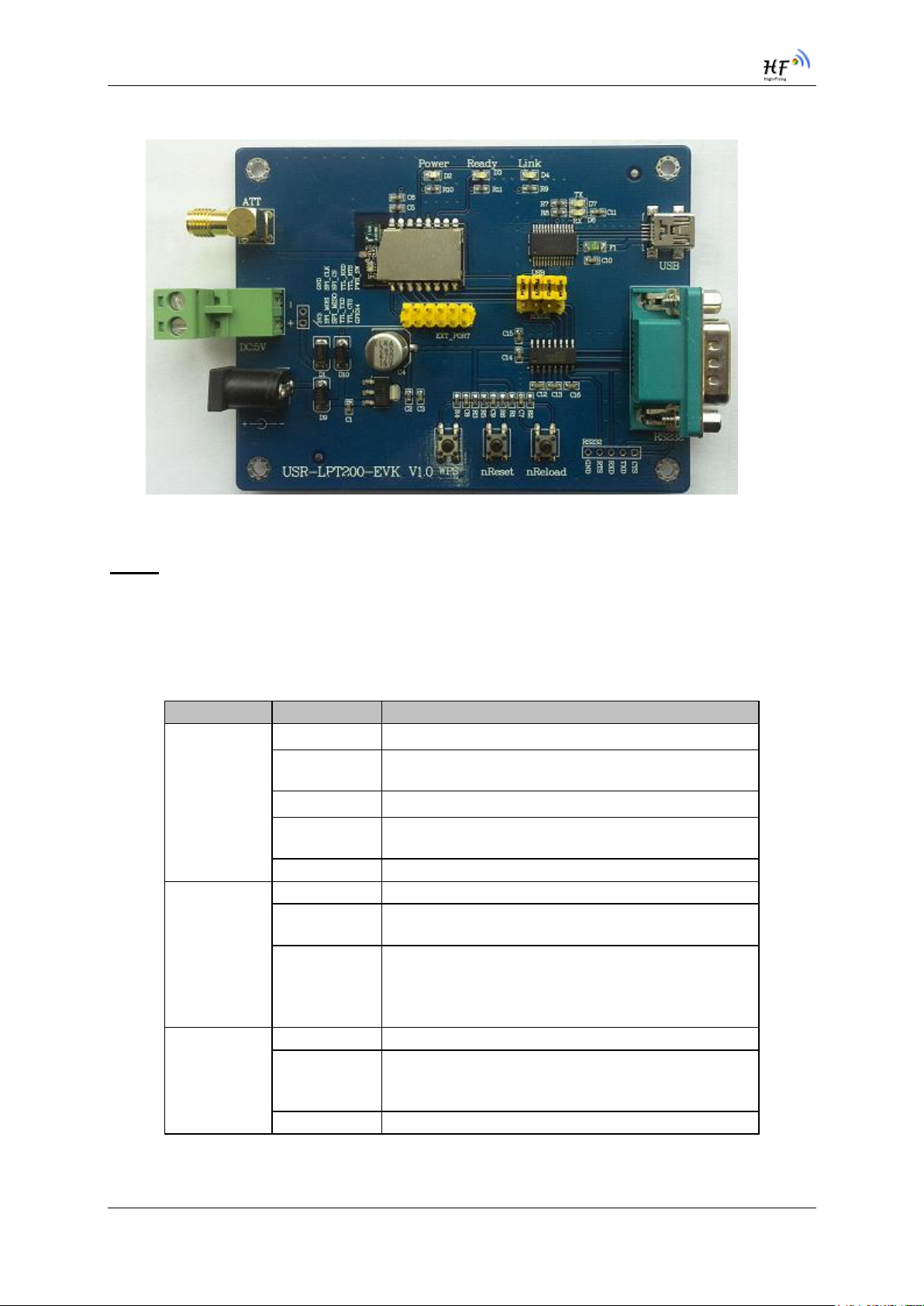

High-Flying provides the evaluation kit to promote user to familiar the product and develop the detailed

application. The evaluation kit shown as below, user can connect to HF-LPT220 module with the RS232 UART, USB (Internal USB to UART convetor) or Wireless interface to configure the parameters,

manage the module or do the some functional tests.

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 16 -

HF-LPT220 Low Power WiFi Module User Manual

Function

Name

Description

External

Interface

RS232

Main data/command RS-232 interface

USB

UART to USB debug interface. (For PC without

RS232, need load driver). Can be Power input.

DC5-18V

DC jack for power in, 5~18V input.

EXT PORT

HF-LPT220 GPIO function extend interface

connector

JMP

4Pin USB or RS232 Jumper. Left jump select USB.

LED

Power

3.3V Power Indicator

nLink

nLink -WiFi LINK Indicator

See 1.2.1

nReady

nReady – Module Bootup Ready Indicator

On (“low”)- Module bootup OK;

Off (“high”)- Mouule botup failed;

Twinkle- Remote Upgrade Ongoing;

Button

nReset

Used to reset the module.

nReload

Restore factory default configuration after push this

pin more than 4s.

See 1.2.1

WPS

WPS Button

Figure 4. HF-LPT220 Evaluation Kit

Notes: User need download USB to UART port driver from High-Flying web or contact with technical

support people for more detail.

The external interface description for evaluation kit as follows:

Table 4 HF-LPT220 Evaluation Kit Interface Description

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 17 -

HF-LPT220 Low Power WiFi Module User Manual

1.2.7. Order Information

Base on customer detailed requirement, HF-LPT220 series modules provide different variants and

physical type for detailed application.

Figure 5. HF-LPT220 Order InformationTypical Application

1.2.8. Hardware Typical Application

Figure 6. HF-LPT220 Hardware Typical Application

Notes:

nReset- Module hardware reset signal. Input. Logics “0” effective.

There is pull-up resister internal and no external pull-up required. When module power up or some

issue happened, MCU need assert nRST signal “0” at least 10ms, then set” 1” to keep module fully

reset.

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 18 -

HF-LPT220 Low Power WiFi Module User Manual

nLink- Module WIFI connection status indication. Output.

(This pin is recommend to connect to LED, indicate status when the module in wireless

upgrade mode)

When module connects to AP (AP associated), this pin will output “0”. This signal used to judge if

module already at WiFi connection status. Thers is pull-up resister internal and no external pull-up

required. If nLink function not required, can leave this pin open.

nReady- Module boot up ready signal. Output. Logics “0” effective.

The module will output “0” after normal boot up. This signal used to judge if module finish boot up and

ready for application or working at normal mode. If nReady function not required, can leave this pin

open.

nReload- Module restore to factory default configuration.Input. Logics “0” effective.

(This pin is recommend to connect to button, is used to enter wireless upgrade mode)

User can de-assert nReload signal “0” more than 4s through button or MCU pin, then release, module

will restore to factory default configuration and re-start boot up process.. If nReload function not

required, can leave this pin open.

UART0_TXD/RXD- UART port data transmit and receive signal.

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 19 -

HF-LPT220 Low Power WiFi Module User Manual

2. FUNCTIONAL DESCRIPTION

2.1. Wireless Networking

HF-LPT220 module can be configured as both wireless STA and AP base on network type. Logically

there are two interfaces in HF-LPT220. One is for STA, and another is for AP. When HF-LPT220

works as AP, other STA equipments are able to connect to HF-LPT220 module directly. Wireless

Networking with HF-LPT220 is very flexible.

Notes:

AP: that is the wireless Access Point, the founder of a wireless network and the centre of the network

nodes. The wireless router we use at home or in office may be an AP.

STA: short for Station, each terminal connects to a wireless network (such as laptops, PDA and other

networking devices) can be called with a STA device.

2.1.1. Basic Wireless Network Based On AP (Infrastructure)

Infrastructure: it’s also called basic network. It built by AP and many STAs which join in.

The characters of network of this type are that AP is the centre, and all communication between STAs

is transmitted through the AP. The figure following shows such type of networking.

Figure 7. HF-LPT220 Basic Wireless Network Structure

2.1.2. Wireless Network Based On AP+STA

HF-LPT220 module support STA network mode.,

Figure 8. HF-LPT220 STA Network Structure

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 20 -

HF-LPT220 Low Power WiFi Module User Manual

2.2. Work Mode : Transparent Transmission Mode

HF-LPT220 module support serial interface transparent transmission mode. The benefit of this mode

is achieves a plug and play serial data port, and reduces user complexity furthest. In this mode, user

should only configure the necessary parameters. After power on, module can automatically connect to

the default wireless network and server.

As in this mode, the module's serial port always work in the transparent transmission mode, so users

only need to think of it as a virtual serial cable, and send and receive data as using a simple serial. In

other words, the serial cable of users’ original serial devices is directly replaced with the module; user

devices can be easy for wireless data transmission without any changes.

The transparent transmission mode can fully compatible with user’s original software platform and

reduce the software development effort for integrate wireless data transmission.

The parameters which need to configure include:

Wireless Network Parameters

Wireless Network Name(SSID)

Security Mode

Encryption Key

TCP/UDP Linking Parameters

Protocol Type

Link Type(Server or Client)

Target Port ID Number

Target Port IP Address

Serial Port Parameters

Baud Rate

Data Bit

Parity (Check) Bit

Stop Bit

Hardware Flow Control

2.3. UART Frame Scheme(Reserved)

2.3.1. UART Free-Frame

HF-LPT220 support UART free-frame function. If user select open this function, module will check the

intervals between any two bytes when reciving UART data. If this interval time exceeds defined value

(50ms default), HF-LPT220 will think it as the end of one frame and transfer this free-frame to WiFi

port, or HF-LPT220 will receive UART data untill 1000 bytes, then transfer 1000 bytes frame to WiFi

port.

HF-LPT220’s default interval time is 50ms. User can also set this interval to fast (10ms) through AT

command. But user have to consider if user MCU can send UART data with 10ms interval ,or the

UART data may be divide as fragment.

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 21 -

HF-LPT220 Low Power WiFi Module User Manual

Through AT command: AT+UARTTE=fash/normal, user can set the interval time: fast (10ms) and

normal (50ms).

2.3.2. UART Auto-Frame

HF-LPT220 support UART auto-frame function. If user select open this function and setting auto-frame

trigger length and auto-frame trigger time parameters, then module will auto framing the data which

received from UART port and transmitting to the network as pre-defined data structure.

Auto-frame trigger length: The fixed data length that module used to transmitting to the

network.

Auto-frame trigger time: After the trigger time, if UART port received data can’t reach auto-

frame trigger length, then module will transmitting available data to the network and bypass

the auto-frame trigger length condition.

Detailed UART auto-frame function can refer to AT+instruction set “UARTF/UARTFT/UARTFL”

introduction.

2.4. Encryption

Encryption is a method of scrambling a message that makes it unreadable to unwanted parties,

adding a degree of secure communications. There are different protocols for providing encryption, and

the HF-LPT220 module supports following:

WEP

WPA-PSK/TKIP

WPA-PSK/AES

WPA2-PSK/TKIP

WPA2-PSK/AES

2.5. Parameters Configuration

HF-LPT220 module supports two methods to configuration parameters: Web Accessing and

AT+instruction set.

Web accessing means users can configure parameters through Web browser. When HF-LPT220

module connected to wireless network, parameters configuration is done on a PC connected to the

same wireless network.

AT+instruction set configuration means user configure parameters through serial interface command.

Refer to “AT+instruction set” chapter for more detail.

2.6. Firmware Update(Reserved, See Appendix C)

HF-LPT220 module supports two on-line upgrade methods:

Webpage Wi-Fi Upgrade

Remote Upgrade

Webpage based Wi-Fiupgrade,please refer to 3.1.8 firmware upgrade page , user can upload

firmware file from PC to HF-LPT220.

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 22 -

HF-LPT220 Low Power WiFi Module User Manual

HF-LPT220 module also support upgrade from remote HTTP server, keep module connects to AP

router before execute remote HTTP upgrade. Remote upgrade have two methods: Direct Download

and Upgrade, Configure File Based Upgrade.

Configure File Based Upgrade

AT+UPURL command to set the remote directory which the configuration file located, such as

AT+UPURL=http://www.hi-flying.com/!admin/down/

Notes: The last ’/’ can’t be remove

AT+UPFILE command to set the configuration file name, such as AT+UPFILE=config.txt

AT+UPST command to start remote Application upgrade. After excuate this command, the module will

firstly download configuration file (“config.txt”), then download the upgrade file base on the URL

address listed in the configure file.

General “config.txt” file format as following example:

[URL]=http://10.10.100.100:80/lpb.bin

[URL]= the URL address of Application.

Direct Download and Upgrade

AT+UPURL command to set the remote directory and file name, such as:

AT+UPURL=http://www.hi-flying.com/!admin/down/,lpb.bin

After excuate this command, the module will directly download the “lpb.bin” file from remote directory

and start upgrade Application.

Notes: please contact with high-flying technical people before upgrade firmware, or maybe damage

the module and can’t work again.

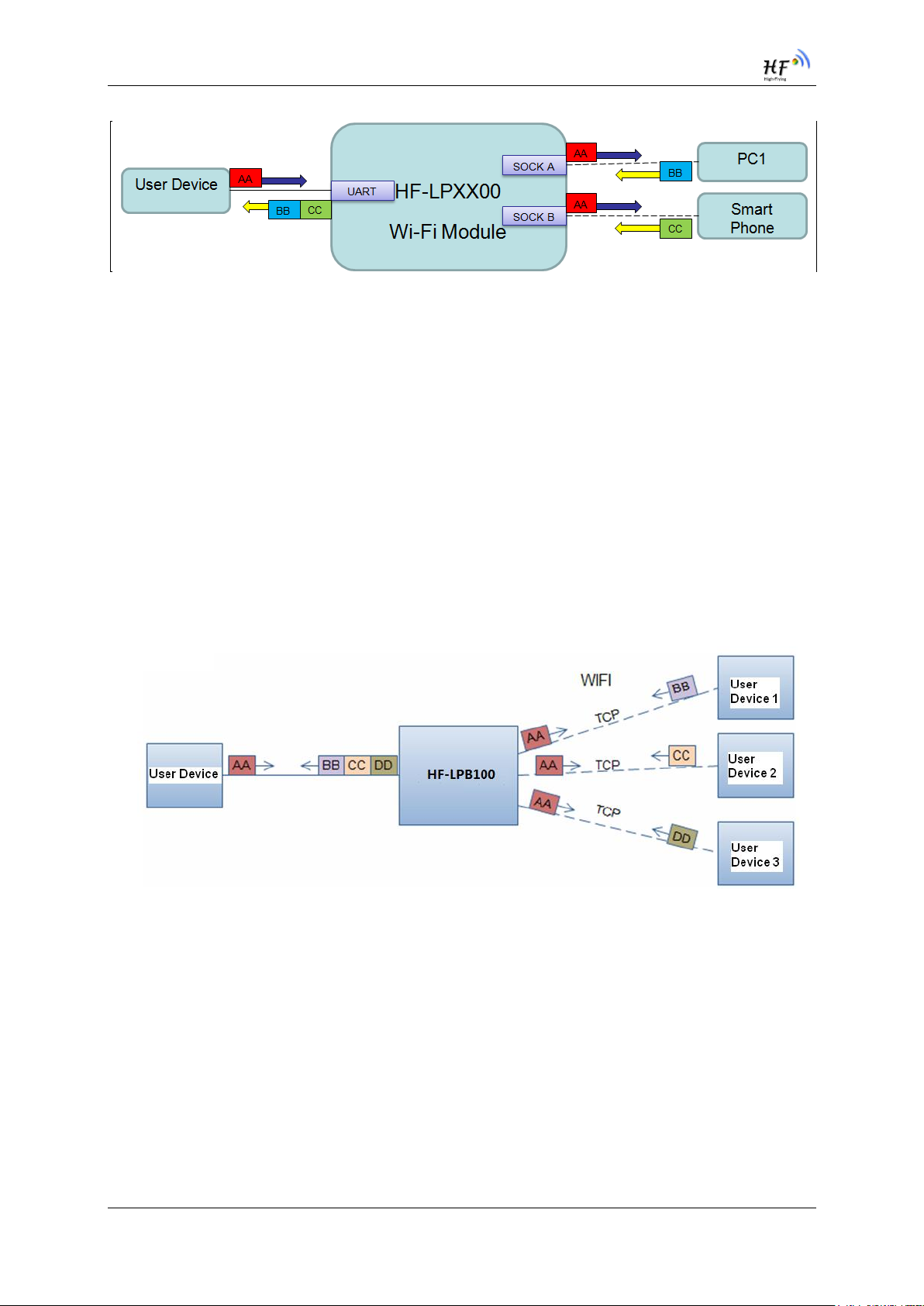

2.7. SOCKET B Function

HF-LPT220 support double socket communication.

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 23 -

HF-LPT220 Low Power WiFi Module User Manual

Figure 9. Socket B function demo

2.8. Multi-TCP Link Connection(Reserved)

When HF-LPT220 module configured as TCP Server, it supports Multi-TCP link connection, and

maximum 5 TCP clients permitted to connect to HF-LPT220 module. User can realize multi-TCP link

connection at each work mode.

Multi-TCP link connection will work as following structure:

Upstream: All dates from different TCP connection or client will be transmitted to the serial port as a

sequence.

Downstream: All data from serial port (user) will be replicate and broadcast to every TCP connection

or client.

Detailed multi-TCP link data transmission structure as following figure:

Figure 10. Multi-TCP Link Data Transmition Structure

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 24 -

HF-LPT220 Low Power WiFi Module User Manual

Parameters

Default Setting

SSID

HF-LPT220

IP Address

10.10.100.254

Subnet Mask

255.255.255.0

3. OPERATION GUIDELINE

3.1. Configuration

When first use HF-LPT220 modules, user may need some configuration. User can connect to HFLPT220 module’s wireless interface with following default setting information and configure the module

through laptop.

Table 8 HF-LPT220 Web Access Default Setting

3.2. Usage Introduction

3.2.1. Software Debug Tools

High-Flying use two common software tools debugging and applying HF-LPT220 module.

(User can also select other tools used to debug serial port).

Serial Debugging Software: ComTools

Ethernet Debugging Software: TCPUDPDbg

3.2.2. Network Connection

User can select two methods to connect HF-LPT220 module base on dedicated application.

Use HF-LPT220 STA interface. HF-LPT220 and debug PC2 connect to a wireless AP,

another PC1 (or user device) connect to HF-LPT220 module with serial port:

Figure 11. STA Interface Debug Connection

Use HF-LPT220 AP interface. Debug PC2 connect to HF-LPT220 through wireless

connection, another PC1 (or user device) connect to HF-LPT220 module with serial port.

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 25 -

HF-LPT220 Low Power WiFi Module User Manual

Figure 12. AP Interface Debug Connection

3.2.3. Default Parameter Setting

Default SSID: HF-LPB100;

Deault security mode: open,none;

User UART parameter setting:115200,8,1,None;

Default network parameter setting:TCP,Server,8899,10.10.100.254;

Module IP address: dhcp,0.0.0.0,0.0.0.0,0.0.0.0;

3.2.4. Module Debug

PC1 open “CommTools” program, setting the same serial port parameters with HF-LPT220 module

and open serial port connection.

Figure 13. “CommTools” Serial Debug Tools

PC2 open “TCPUDPDbg” program, and create a new connection. If HF-LPT220 configured as Server

mode, “TCPUDPDbg” Tools shall create “Client “mode connection. Or otherwise, create a “Server”

mode connection.

Figure 14. “TCPUDPDbg” Tools Create Connection

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 26 -

HF-LPT220 Low Power WiFi Module User Manual

Then setting the TCP/UDP connection parameters. Default as following:

Figure 15. “TCPUDPDbg” Tools Setting

Then, click “Create” button to create a connection.

Figure 16. “TCPUDPDbg” Tools Connection

Now, in transparent transmission mode, data can be transferred from “CommTools” program to

“TCPUDPDbg” program, or in reverse. You can see data in receiver side will keep same as in sender

side.

3.3. Typical Application Examples

3.3.1. Wireless Control Application

Figure 17. Wireless Control Application

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 27 -

HF-LPT220 Low Power WiFi Module User Manual

For this wireless control application, HF-LPT220 works as AP mode. Module’s serial port connects to

user device. So, control agent (Smart phone for this example) can manage and control the user device

through the wireless connection with HF-LPT220 module.

3.3.2. Remote Management Application

Figure 18. Remote Management Application

For this remote management application, HF-LPT220 works as STA mode and connects to Internet

through wireless AP. Module configured as TCP Client and communicates with remote TCP server at

Internet. Module’s serial port connects to user device.

So, user device’s data or sampling information can send to remote TCP server for storage or

processing. Also remote TCP server can send command to control and manage the user device

through the wireless network.

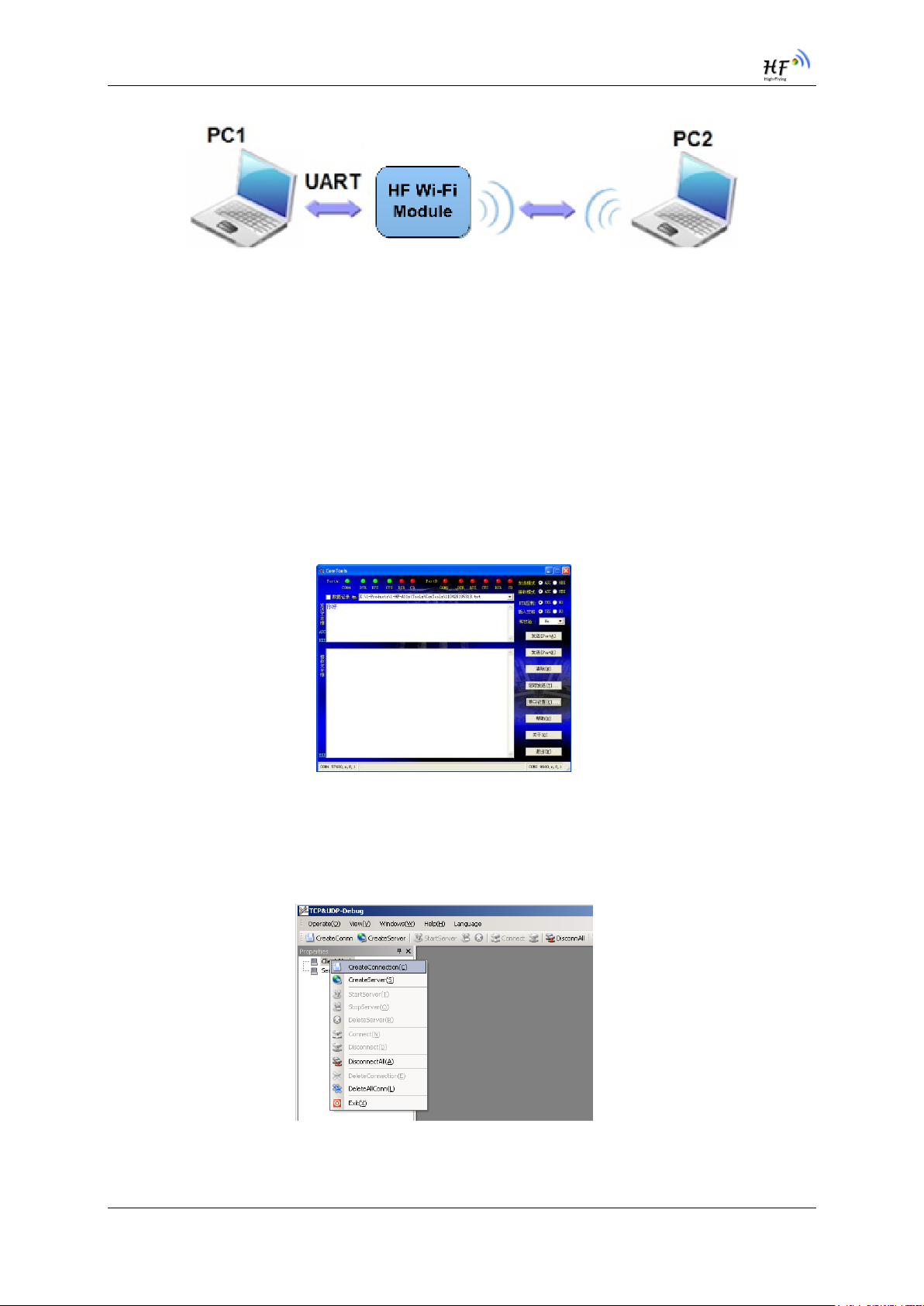

3.3.3. Transparent Serial Port Application

For this transparent serial port application, two HF-LPB100 modules connect as below figures to build

up a transparent serial port connection. One HF-LPB100 works as AP mode, another HF-LPB100

works as STA mode. Make the STA device connects to AP.

Figure 19. Transparent Serial Port Application

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 28 -

HF-LPT220 Low Power WiFi Module User Manual

4. AT+INSTRUCTION INTRODUCTION

4.1. Configuration Mode

When HF-LPT220 power up, it will default works as transparent transmission mode, then user can

switch to configuration mode by serial port command. HF-LPT220 UART default parameters setting as

below figure.

Figure 20. HF-LPT220 Default UART Port Parameters

In configuration mode, user can setting the module through AT+instruction set, which cover all web

page setting function.

4.1.1. Switch to Configuration Mode

Two steps to finish switching from transparent transmission mode to configuration mode.

UART input “+++”, after module receive “+++”, and feedback “a” as confirmation.

UART input “a”, after module receive “a” and feedback “+ok” to go into

AT+instruction set configuration mode.

Figure 21. Switch to Configuration Mode

Notes:

1. When user input “+++” (No “Enter” key required), the UART port will display feedback information

“a”, and not display input information”+++” as above UART display.

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 29 -

HF-LPT220 Low Power WiFi Module User Manual

2. Any other input or wrong step to UART port will cause the module still works as original mode

(transparent transmission).

3. “+++” and “a” should be input in a certain period of time to make the module switch to configuration

mode. Like the following sequence.

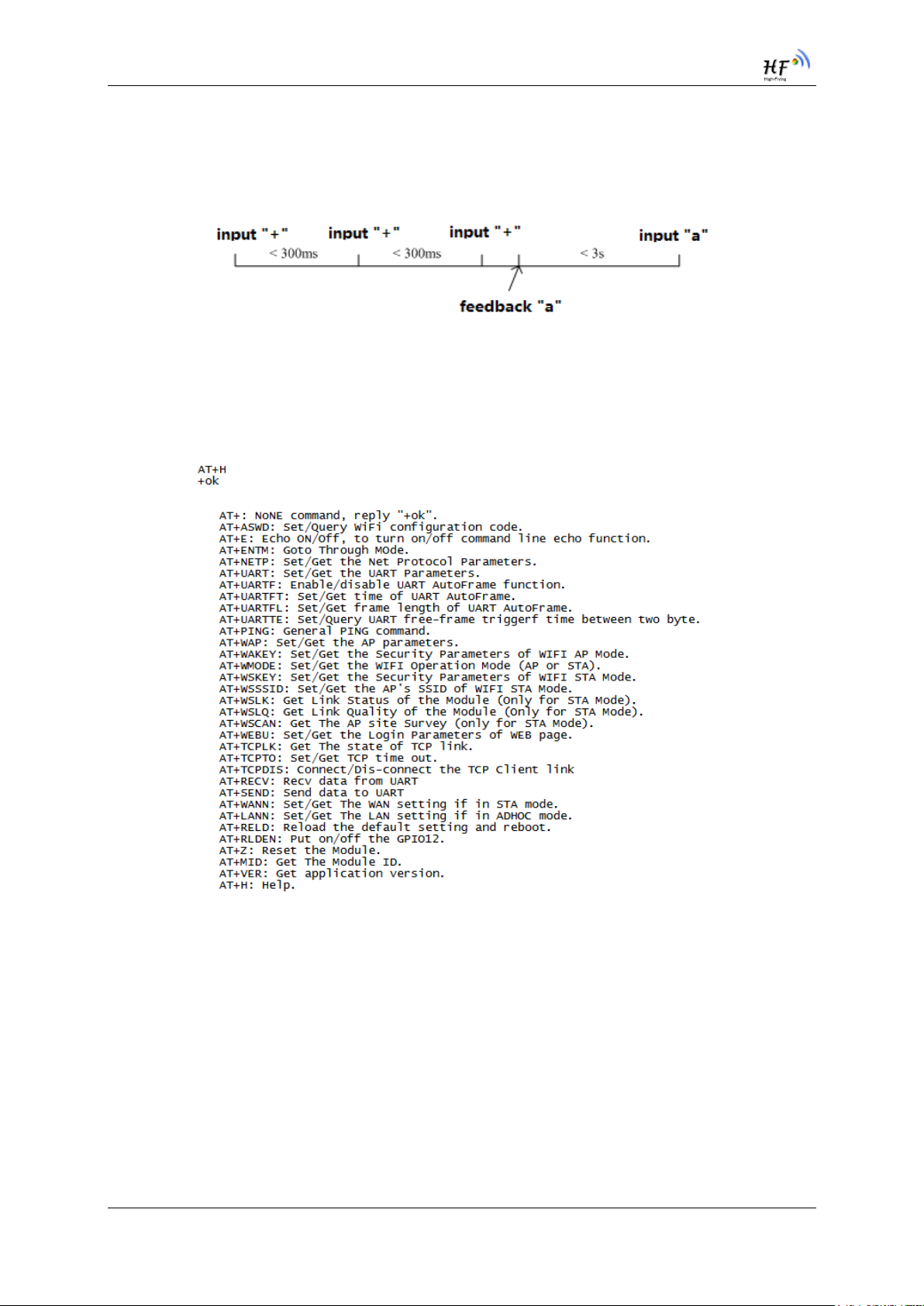

4.2. AT+Instruction Set Overview

User can input AT+Instruction through hyper terminal or other serial debug terminal, also can program

the AT+Instruction to script. User can also input “AT+H” to list all AT+Instruction and description to

start.

Figure 22. ”AT+H” Instruction for Help

4.2.1. Instruction Syntax Format

AT+Instruction protocol is based on the instruction of ASCII command style, the description of syntax

format as follow.

Format Description

< >: Means the parts must be included

[ ]: Means the optional part

Command Message

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 30 -

HF-LPT220 Low Power WiFi Module User Manual

Error Code

Description

-1

Invalid Command Format

-2

Invalid Command

-3

Invalid Operation Symbol

-4

Invalid Parameter

-5

Operation Not Permitted

Instruction

Description

<null>

NULL

Managment Instruction Set

E

Open/Close show back function

WMODE

Set/Query Wi-Fi work mode (AP/STA)

ENTM

Set module into transparent transition mode

TMODE

Set/Query module data transfer mode

AT+<CMD>[op][para-1,para-2,para-3,para-4…]<CR>

AT+: Prefix of command message;

CMD: Command string;

[op]: Symbol of command operator,

“=” : The command requires parameters input;

“NULL”: Query the current command parameters setting;

[para-n]: Parameters input for setting if required;

<CR>:”Enter” Key, it’s 0x0a or 0x0d in ASCII;

Notes: When input AT+Instruction, “AT+<CMD>” character will display capital letter automatic and

other parts will not change as you input.

Response Message

+<RSP>[op] [para-1,para-2,para-3,para-4…]<CR><LF><CR><LF>

+: Prefix of response message;

RSP: Response string;

“ok” : Success

“ERR”: Failure

[op] : =

[para-n]: Parameters if query command or Error code when error happened;

<CR>: ASCII 0x0d;

<LF>: ASCIII 0x0a;

Error Code

Table 9 Error Code Describtion

4.2.2. AT+Instruction Set

Table 10 AT+Instruction Set List

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 31 -

HF-LPT220 Low Power WiFi Module User Manual

Instruction

Description

MID

Query module ID information

VER

Query module software version information

LVER

Query module detailed software version

FWSZ

Query Wi-Fi driver size

RELD

Restore to factory default setting

FCLR

Erase factory setting

Z

Re-start module

H

Help

Configure Parameters Instruction Set

CFGTF

Copy User Parameters to Factory Default Parameters

UART Instruction Set

UART

Set/Query serial port parameters

UARTFT

Open/Close UART auto-frame function

UARTFT

Set/Query UART auto-frame trigger time

UARTFL

Set/Query UART auto-frame trigger length

UARTTE

Set/Query UART free-frame triggerf time between two bytes

Command Mode Set

SEND

Send Data at Command Mode

RECV

Receive Data at Command Mode

Network Instruction Set

PING

Network ”Ping” Instruction

NETP

Set/Query network protocol parameters

MAXSK

Set/Query TCP Client connection number

TCPLK

Query if TCP link already build-up

TCPTO

Set/Query TCP timeout

TCPDIS

Open/Close TCP link

SOCKB

Set/Query SOCKB parameters

TCPDISB

Open/Close SOCKB TCP link

TCPTOB

Set/Query SOCKB TCP timeout

TCPLKB

Query if SOCKB TCP link already build-up

SNDB

Send data to SOCKB in Command Mode

RCVB

Receive data from SOCKB in Command Mode

Wi-Fi STA Instruction Set (Effective when module works as STA)

WSKEY

Set/Query STA security parameters

WSSSID

Set/Query associated AP SSID parameters

WANN

Set/Query STA’s network parameters

WSMAC

Set/Query STA’s MAC address

WSLK

Query STA Wi-Fi link status

WSLQ

Query STA Wi-Fi signal strength

WSCAN

Scan AP

WSDNS

Set/Query STA’s Static DNS server address

Wi-Fi AP Instruction Set (Effective when module works as AP)

LANN

Set/Query AP’s network parameters

WAP

Set/Query AP Wi-Fi parameters

WAKEY

Set/Query AP security parameters

WAMAC

Set/Query AP MAC address

WADHCP

Set/Query AP DHCP Server status

WADMN

Set/Query AP webpage domain name

WALK

Query MAC address of STA device connecting to module AP

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 32 -

HF-LPT220 Low Power WiFi Module User Manual

Instruction

Description

WALKIND

Enable/Disable indication of connection status.

WAPMXSTA

Set/Query max STA devices supported for AP.

Remote Upgrade Instruction Set

OTA

Upgrade Firmware

UPURL

Set/Query remote upgrade URL address

UPFILE

Set/Query remote upgrade configure file name

LOGSW

Open/Close remote upgrade log

LOGPORT

Set/Query UDP port of remote upgrade log

UPST

Start remote Application upgrade

Power Management Instruction Set

DISPS

Set/Query power save parameters

Network Time Set

NTPRF

Set/Query time calibration interval

NTPEN

Enable/Disable time calibration function

NTPTM

Query time

NTPSER

Set/Query NTP server IP

Others Instruction Set

WRMID

Set module ID

RLDEN

Set/Query GPIO45 status

ASWD

Set/Query WiFi configuration code

MDCH

Set Wi-Fi Auto Switch Function

TXPWR

Set/Query Wi-Fi Transmit Power

SMTLK

Start SmartLink function

SMTLKVER

Set/Query SmartLink version

WPS

Start WPS function

WPSTNEN

Enable/Disable GPIO 15 WPS function

LPTIO

nRead/nLink/WPS function mapping

WIFI

Enable/Disable Wi-Fi

SMEM

Query RAM status

NDBGL

Set UART debug information

Note: Some AT is not supported yet(The above AT command with line through). It will

be updated for later firmware.

4.2.2.1. AT+E

Function: Open/Close show back function;

Format:

Set Operation

AT+E=<status><CR>

+ok<CR><LF><CR><LF>

Parameters:

status: Echo status

on: Open echo

off: Close echo

When HF-LPB120 module firstly switch from transparent transmission to configuration mode, show

back status is open, input “AT+E” to close show back function, input“AT+E” again to open show back

function.

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 33 -

HF-LPT220 Low Power WiFi Module User Manual

4.2.2.2. AT+WMODE

Function: Set/Query Wi-Fi work mode. Setting is valid after reset;

Format:

Query Operation

AT+WMODE<CR>

+ok=<mode><CR><LF><CR><LF>

Set Operation

AT+WMODE=<mode><CR>

+ok<CR><LF><CR><LF>

Parameters:

mode:Wi-Fi work mode

AP

STA

APSTA

4.2.2.3. AT+ENTM

Function: Set module into transparent transmition mode;

Format:

AT+ENTM<CR>

+ok<CR><LF><CR><LF>

When operate this command, module switch from configuration mode to transparent transmission

mode.

4.2.2.4. AT+TMODE

Function: Set/Query module data transfer mode. Setting is valid after reset.

Format:

Query Operation

AT+TMODE<CR>

+ok=<tmode><CR><LF><CR><LF>

Set Operation

AT+TMODE=<tmode><CR>

+ok<CR><LF><CR><LF>

Parameters:

tmode: data transfer mode, include:

throughput: throughput mode

cmd: command mode

pwm: PWM/GPIO mode

4.2.2.5. AT+MID

Function: Query module ID information;

Format:

Query Operation

AT+MID<CR>

+ok=<module_id><CR><LF><CR><LF>

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 34 -

HF-LPT220 Low Power WiFi Module User Manual

Parameters:

module_id: Module ID information;

HF-LPB120;

Notes: User can set this parameter through AT+WRMID.

4.2.2.6. AT+VER

Function: Query module software version information;

Format:

Query Operation

AT+VER<CR>

+ok=<ver><CR><LF><CR><LF>

Parameters:

ver: Module software version information;

4.2.2.7. AT+LVER

Function: Query module detailed software version information;

Format:

Query Operation

AT+LVER<CR>

+ok=<ver><CR><LF><CR><LF>

Parameters:

ver: Module software detailed version information;

4.2.2.8. AT+FWSZ

Function: Query Wi-Fi driver size;

Format:

Query Operation

AT+FWSZ<CR>

+ok=<size,version><CR><LF><CR><LF>

Parametewrs:

size: Wi-Fi driver size.(Byte)

version: Wi-Fi driver version

4.2.2.9. AT+RELD

Function: module restore to factory default setting;

Format:

Set Operation

AT+RELD<CR>

+ok=rebooting…<CR><LF><CR><LF>

When operate this command, module will restore to factory default setting and reboot.

4.2.2.10. AT+FCLR

Function: Erase factory setting;

Format:

Query Operation

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 35 -

HF-LPT220 Low Power WiFi Module User Manual

AT+FCLR<CR>

+ok=<status><CR><LF><CR><LF>

4.2.2.11. AT+Z

Function: Re-start module;

Format:

AT+Z<CR>

4.2.2.12. AT+H

Function: Help;

Format:

Query Operation

AT+H<CR>

+ok=<command help><CR><LF><CR><LF>

Parameters:

command help: command introduction;

4.2.2.13. AT+CFGTF

Function: Copy User Parameters to Factory Default Parameters;

Format:

Query Operation

AT+CFGTF<CR>

+ok=<status><CR><LF><CR><LF>

Parameters:

status: feedback operation status;

4.2.2.14. AT+UART

Function: Set/Query serial port parameters. Setting is valid after reset.

Format:

Query Operation

AT+UART[=uart_num]<CR>

+ok=<baudrate,data_bits,stop_bit,parity,flowctrl><CR><LF><CR><LF>

Set Operation

AT+UART=<baudrate,data_bits,stop_bit,parity,flowctrl>[,uart_num]<CR>

+ok<CR><LF><CR><LF>

Parameters:

uart_num:UART Channel, the default is UART0.

0:UART0 Channel

1:UART1 Channel

baudrate:

1200,1800,2400,4800,9600,19200,38400,57600,115200,230400,

380400,460800,921600

data_bits:

8

stop_bits:

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 36 -

HF-LPT220 Low Power WiFi Module User Manual

1,2

parity:

NONE

EVEN

ODD

Flowctrl: (CTSRTS)

NFC: No hardware flow control

FC: hardware flow control

4.2.2.15. AT+UARTF

Function: Open/Close UART auto-frame function;

Format:

Query Operation

AT+UARTF<CR>

+ok=<para><CR><LF><CR><LF>

Set Operation

AT+UARTF=<para ><CR>

+ok<CR><LF><CR><LF>

Parameters:

para:

disable - Close auto-frame function;

enable - Open auto-frame function;

4.2.2.16. AT+UARTFT

Function: Set/Query UART auto-frame trigger time;

Format:

Query Operation

AT+UARTFT<CR>

+ok=<time><CR><LF><CR><LF>

Set Operation

AT+UARTFT=<time ><CR>

+ok<CR><LF><CR><LF>

Parameters:

time: Range 100 ~10000; Unit: ms. Auto-frame trigger time

4.2.2.17. AT+UARTFL

Function: Set/Query UART auto-frame trigger length;

Format:

Query Operation

AT+UARTFL<CR>

+ok=<len><CR><LF><CR><LF>

Set Operation

AT+UARTFL=<len ><CR>

+ok<CR><LF><CR><LF>

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 37 -

HF-LPT220 Low Power WiFi Module User Manual

Parameters:

len: Range 8 ~1000; Unit: Byte. Auto-frame trigger length;

4.2.2.18. AT+UARTTE

Function: Set/Query UART free-frame trigger time between two bytes;

Format:

Query Operation

AT+UARTTE<CR>

+ok=<mode><CR><LF><CR><LF>

Set Operation

AT+UARTTE=<mode><CR>

+ok<CR><LF><CR><LF>

Parameters:

mode:

fast: No free-frame trigger time, the uart data may be break into two fragment

normal: free-frame trigger time between two bytes is 50ms;

4.2.2.19. AT+SEND

Function: Send Data to SOCKA at Command Mode.

Format:

AT+SEND=<data_lenth><CR>

+ok<CR><LF><CR><LF>

Parameters:

data_lenth: Lenth of send data. Range: 0~1000 Byte

The UART port will wait 3 seconds for input after this command is sent OK. The data received

from UART port is sent to SOCKA. If the interval of two bytes is more than 10ms, the data will be

sent instantly.

4.2.2.20. AT+RECV

Function: Receive Data from SOCKA at Command Mode.

Format:

AT+RECV=<data_lenth,timeout><CR>

+ok=< data_lenth, data_content><CR><LF><CR><LF>

Parameters:

data_lenth: Lenth of receive data. Range: 0~1000 Byte

timeout: wait for timeout, 0~10 sec

data_content: contents of receive data.

If not receive any data in 3 second, then feedback +ok=0.

4.2.2.21. AT+PING

Function: Network “PING” Instruction.

Format:

Set Operation

AT+PING=<IP_address ><CR>

+ok=<sta><CR><LF><CR><LF>

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 38 -

HF-LPT220 Low Power WiFi Module User Manual

Parameters:

sta: feedback result

Success

Timeout

Unknown host

4.2.2.22. AT+NETP

Function: Set/Query network protocol parameters, Setting is valid after reset.

Format:

Query Operation

AT+NETP<CR>

+ok=<protocol,CS,port,IP><CR><LF><CR><LF>

Set Operation

AT+NETP=<protocol,CS,port,IP><CR>

+ok<CR><LF><CR><LF>

Parameters:

protocol:

TCP

UDP

CS: Network mode:

SERVER

CLIENT

Port: protocol port ID: Decimal digit and less than 65535

IP: Server’s IP address when module set as client

If set as UDP SERVER, the module will save the IP address and port of the latest UDP

packet received. The data will be sent to the saved IP address and port. If the module hasn’t

saved any IP address and port when power up. The data will be sent to the IP address and port

which is set by this command.

If set as UDP,CLIENT, the data will always be sent to the IP address and port set by this

command.

4.2.2.23. AT+MAXSK

Function:Set/ Query TCP Client connection number.

Format:

Query Operation

AT+MAXSK<CR>

+ok=<num><CR><LF><CR><LF>

Set Operation

AT+MAXSK=<num><CR>

+ok<CR><LF><CR><LF>

Parameters:

num: TCP Client connection number. Range: 1~5. 5 is the default value it means

when the module work in TCP server , it accepts max 5 TCP client connect to it.

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 39 -

HF-LPT220 Low Power WiFi Module User Manual

4.2.2.24. AT+TCPLK

Function: Query if TCP link already build-up;

Format:

AT+TCPLK<CR>

+ok=<sta><CR><LF><CR><LF>

Parameters:

sta.: if module already setup TCP link;

on: TCP link setup;

off: TCP link not setup;

4.2.2.25. AT+TCPTO

Function: Set/Query TCP timeout; Setting is valid after reset.

Format:

Query Operation

AT+TCPTO<CR>

+ok=<time><CR><LF><CR><LF>

Set Operation

AT+TCPTO=<time ><CR>

+ok<CR><LF><CR><LF>

Parameters:

time: TCP timeout time.

<= 600, (600s);

>=0, (0 means no timeout);

Default, 300s;

Module begin to count time when TCP channel don’t receive any data, clecherar time

counter when TCP channel receive any data. If the time counter reaches the TCPTO, the tcp

channel will be break. If the module work in TCP Client, it will connect the TCP server

instantly and when the module work in TCP Server, the TCP client device should make the

connection itself.

4.2.2.26. AT+TCPDIS

Function: Open/Close TCP link;

Format:

Query Opera

AT+TCPDIS<CR>

+ok=<sta><CR><LF><CR><LF>

Set Operation

AT+TCPDIS =<on/off><CR>

+ok<CR><LF><CR><LF>

Parameters:

When query, sta.: Feedback if TCP Client can be link,

On, TCP link close

off,TCP link on

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 40 -

HF-LPT220 Low Power WiFi Module User Manual

When setting, “off” means close TCP link. After finish this command, module disconnect TCP

link and not connect again. “On” means open TCP link. After finish this command, module re-

connect TCP server right away.

4.2.2.27. AT+SOCKB

Function: Set/Query SOCKB parameters. Setting is valid after reset.

Format:

Query Operation

AT+SOCKB<CR>

+ok=<protocol,port,IP><CR><LF><CR><LF>

Set Operation

AT+SOCKB=<protocol,port,IP><CR>

+ok<CR><LF><CR><LF>

Parameters:

Protocol: Protocol type:

TCP: Only for TCP Client

UDP: UDP Client

UDPS: UDP Server

Port: Protocol Port in decimal, less than 65535

IP: Destination IP address, domain name is support

If set as UDP SERVER, the module will save the IP address and port of the latest UDP

packet received. The data will be sent to the saved IP address and port. If the module hasn’t

saved any IP address and port when power up. The data will be sent to the IP address and

port which is set by this command.

If set as UDP,CLIENT, the data will always be sent to the IP address and port set by this

command.

4.2.2.28. AT+TCPDISB

Function: Open/Close SOCKB connection

Format:

Query Operation

AT+TCPDISB<CR>

+ok=<sta><CR><LF><CR><LF>

Set Operation

AT+TCPDISB =<on/off><CR>

+ok<CR><LF><CR><LF>

Parameters:

When setting, “off” means close TCP link. After finish this command, module disconnect TCP

link and not connect again. “On” means open TCP link. After finish this command, module reconnect TCP server right away.

4.2.2.29. AT+TCPTOB

Function: Set/Query Operation SOCKB TCP timeout. Setting is valid after reset.

Format:

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 41 -

HF-LPT220 Low Power WiFi Module User Manual

Query Operation

AT+TCPTOB<CR>

+ok=<time><CR><LF><CR><LF>

Set Operation

AT+TCPTOB=<time ><CR>

+ok<CR><LF><CR><LF>

Parameters

Time: TCP timeout

<= 600:600s

>=0:0 means no timeout

Default:300s

If the SOCKB TCP don't receive any data from TCP server for TCP tmeout setting, the

module will break and reconnect the TCP server. If it receive data from server, the timeout

counter will be clear.

4.2.2.30. AT+TCPLKB

Function:Query SOCKB connection status

Format:

AT+TCPLKB<CR>

+ok=<sta><CR><LF><CR><LF>

Parameters:

sta.: SOCKB connection status

on: TCP connected

off: TCP disconnected

4.2.2.31. AT+SNDB

Function: Send datas to SOCKB at Command Mode

Format:

AT+SNDB=<data_lenth ><CR>

+ok<CR><LF><CR><LF>

Parameters:

data_lenth: Lenth of send data. Range: 0~1000 Byte

The UART port will wait 3 seconds for input after this command is sent OK. The data received

from UART port is sent to SOCKB. If the interval of two bytes is more than 10ms, the data will be

sent instantly.

4.2.2.32. AT+RCVB

Function: Receive datas from SOCKB at Command Mode

Format:

AT+RCVB=<data_lenth><CR>

+ok=< data_lenth, data_content><CR><LF><CR><LF>

Parameters:

data_lenth: Lenth of receive data. Range: 0~1000 Byte

data_content: contents of receive data.

Shanghai High-Flying Electronics Technology Co., Ltd(www.hi-flying.com) - 42 -

HF-LPT220 Low Power WiFi Module User Manual

If not receive any data in 3 second, then feedback +ok=0.

4.2.2.33. AT+WSSSID

Function: Set/Query Wi-Fi associated AP SSID parameters. Setting is valid after reset.

Format:

Query Operation

AT+WSSSID<CR>

+ok=<ap’s ssid><CR><LF><CR><LF>

Set Operation

AT+WSSSID=<ap’s ssid ><CR>

+ok<CR><LF><CR><LF>

Parameters:

ap’s ssid: AP’s SSID (Within 32 character);

4.2.2.34. AT+WSKEY

Function: Set/Query STA security parameters. Setting is valid after reset.

Format:

Query Operation

AT+WSKEY<CR>

+ok=<auth,encry,key><CR><LF><CR><LF>

Set Operation

AT+WSKEY=< auth,encry,key><CR>

+ok<CR><LF><CR><LF>

Parameters:

auth: Authentication mode

OPEN

SHARED

WPAPSK

WPA2PSK