Page 1

®

audiovias.com

Studio ColoR

Automated Wash Luminaire

User’s Manual

.

P/N 60600061 Version 3.0

High End Systems Inc.

2105 Gracy Farms Lane

Austin, Texas U.S.A.

Page 2

© High End Systems, Inc. 1996-2004, All Rights Reserved

Information and Specifications in this document are subject to change with out notice. High End Systems, Inc.

assumes no responsibility or liability for any errors or inaccuracies that may appear in this manual.

Unlawful reproduction or distribution in any manner without the written permission of High End Systems is strictly

forbidden.

Trademarks used in this text: Ecodome is a trademark, Cyberlight, Lightwave Research, Lithopatterns,

and Studio Color are registered trademarks of High End Systems Inc.; Motorola is a registered trademark of

Motorola Inc.; Philips is a registered trademark of Philips Corporation.

Other trademarks and trade names such as Rosco, Lee, and 409 may be used in this document to ref er to either

the entities claiming the marks and names or their products. High End Systems discl aims any proprietary interest

in trademarks and trade names owned by others.

Studio Color uses one or more of the following patents: US 4,962,687; US 5,078,039; UK 2,043,769; US

5,331,822; US 5,402,326; US D 372550; UK 2292896; US D365165; US 5,430,629; US D360,404; US 5,455,748;

0475082; US 5,506,762; M9604224.9; US 5,515,254; US D370080; UK 2.291,814; US 5,545.951; UK 2055842;

UK 2,292,530; UK 2294909; UK 2292896; MR 8621996; and US 5,580,164.

Additional patents pending.

June 22, 2004

Studio Color User’s Manual

P/N 60600061 Rev. C

Printed in the U.S.A.

M.D.T.

.

Page 3

Declaration of Conformity

according to ISO/IEC Guide 22 and EN45104

Manufacturer’s name: High End Systems

Manufacturer’s address: 2105 Gracy Farms Lane

Austin, Texas 78758

U.S.A.

Distributor’s name: High End Systems Inc.

Distributor’s address: 2105 Gracy Farms Lane

Austin, Texas 78758

U.S.A.

Declares that the product

Product Name: Studio Color

Product Number: Studio Color 575-M

Studio Color 575-S

Product Options: All

conforms to the following EEC directives:

73/23/EEC, as amended by 93/68/EEC

89/336/EEC, as amended by 92/31/EEC and 93/68/EEC

Equipment referred to in this declaration of conformity first manufactured in 1996 in compliance with

the following standards:

Safety: EN 60598-1 : 1993

EN 60598-2-17 : 1989

A1-A3 : 1993

EMC: EN 55022, Class A ITE 1987

IEC 801-2, 1991 Level 2 (4/8 kV)

IEC 801-3, Draft 5 Level 2 (3 V/m) 1991

IEC 801-4, 1988 Level 2 (1 kV/0.5 kV)

U.S.A., June 22, 2004

Lanny Derryberry, Compliance Engineer

Page 4

IMPORTANT SAFETY INFORMATION

INSTRUCTIONS PERTAINING TO CONTINUED PROTECTION AGAINST FIRE, ELECTRIC

SHOCK, EXPOSURE TO EXCESSIVE UV RADIATION, AND INJURY TO PERSONS ARE

FOUND IN APPENDIX D.

READ ALL CAUTIONS AND WARNINGS PRIOR TO ASSEMBLY, MOUNTING, AND OPERATING THIS EQUIPMENT.

IMPORTANT: INFORMATIONS DE SÉCURITÉ

INSTRUCTIONS RELATIVES À UNE PROTECTION CONTINUE CONTRE L' INCENDIE, LE

CHOC ÉLECTRIQUE, L' EXPOSITION AUX RADIATIONS ULTRAVIOLETTES EXCESSIVES,

ET CONTRE DES BLESSURES POSSIBLES SUR DES INDIVIDUS SE TROUVENT DANS

L'APPENDICE D.

PRIÈRE DE LIRE TOUTES LES PRÉCAUTIONS ET LES AVERTISSEMENTS AVANT D'ASSEMBLER, DE MONTER, ET DE FAIRE FONCTIONNER CET ÉQUIPEMENT.

WICHTIGE SICHERHEITSHINWEISE

DIE NACHSTEHENDEN HINWEISE BETREFFEN DEN SCHUTZ GEGEN BRAND, ELEKTRISCHEN SCHLAG, ÜBERHÖHTE UV-STRAHLUNG SOWIE VERLETZUNGEN. SIE BEFINDEN SICH IN APPENDIX D.

LESEN SIE ALLE WARNUNGEN SORGFÄLTIG, BEVOR SIE DAS GERÄT ZUSAMMENBAUEN, INSTALLIEREN UND BENUTZEN!

INFORMACIÓN IMPORTANTE DE SEGURIDAD

SE ENCUENTRAN EN EL APÉNDICE D LAS INSTRUCCIONES CONCERNIENTES A LA PROTECCIÓN CONTINUA CONTRA INCENDIO, CHOQUE ELÉCTRICO, EXPOSICIÓN EXCESIVA

A RAYOS ULTRAVIOLETAS Y LESIONES A PERSONAS.

POR FAVOR LEA TODAS LAS PRECAUCIÓNS Y LAS ADVERTENCIAS ANTES DE ENSAMBLAR, MONTAR Y OPERAR ESTE EQUIPO.

INFORMAZIONI IMPORTANTI DI SICUREZZA

ISTRUZIONI PERTINENTI LA PROTEZIONE CONTRO IL FUOCO, LE SCOSSE ELETTRICHE,

L' ECCESSIVA ESPOSIZIONE AI RAGGI ULTRAVIOLETTI I DANNI ALLE PERSONE SI TRO

VANO NEL APPENDICE D.

LEGGERE TUTTI GLI AVVERMENTI PRIMA DI MONTARE E USARE QUESTO APPARECCHIO.

FCC Statement

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

-

Page 5

Warranty Information

Limited Warranty

Unless otherwise stated, your product is covered by a two year parts and labor limited warranty.

Dichroic filters and Lithopatterns™ are not guaranteed against breakage or scratches to coating. It is the

owner's responsibility to furnish receipts or invoices for verification of purchase, date, and dealer or

distributor. If purchase date cannot be provided, date of manufacture will be used to determine warranty

period.

Returning an Item Under Warranty for Repair

It is necessary to obtain a Return Authorization Number (RA#) from your dealer/point of purchase

BEFORE any units are returned for repair. The manufacturer will make the final determination as to

whether or not the unit is covered by warranty. Lamps are covered by the lamp manufacturer's warranty.

Any Product unit or parts returned to High End Systems must be packaged in a suitable manner to

ensure the protection of such Product unit or parts, and such package shall be clearly and prominently

marked to indicate that the package contains returned Product units or parts and with a Return

Authorization (RA#) number. Accompany all returned Product units or parts with a written explanation

of the alleged problem or malfunction.

Please note: Freight Damage Claims are invalid for fixtures shipped in non-factory boxes and packing

materials.

Freight

All shipping will be paid by the purchaser. Items under warranty shall have return shipping paid by the

manufacturer only in the Continental United States. Under no circumstances will freight collect

shipments be accepted. Prepaid shipping does not include rush expediting such as air freight. Air freight

can be sent customer collect in the Continental United States.

REPAIR OR REPLACEMENT AS PROVIDED FOR UNDER THIS WARRANTY IS THE

EXCLUSIVE REMEDY OF THE CONSUMER. HIGH END SYSTEMS, INC. MAKES NO

WARRANTIES, EXPRESSED OR IMPLIED, WITH RESPECT TO ANY PRODUCT, AND HIGH

END SPECIFICALLY DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. HIGH END SHALL NOT BE LIABLE FOR ANY INDIRECT,

INCIDENTAL, OR CONSEQUENTIAL DAMAGE, INCLUDING LOST PROFITS, SUSTAINED

OR INCURRED IN CONNECTION WITH ANY PRODUCT OR CAUSED BY PRODUCT

DEFECTS OR THE PARTIAL OR TOTAL FAILURE OF ANY PRODUCT REGARDLESS OF THE

FORM OF ACTION, WHETHER IN CONTRACT, TORT, (INCLUDING NEGLIGENCE), STRICT

LIABILITY, OR OTHERWISE, AND WHETHER OR NOT SUCH DAMAGE WAS FORESEEN OR

UNFORESEEN.

Warranty is void if the product is misused, damaged, modified in any way, or for unauthorized repairs or

parts. This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state.

Page 6

Page 7

Studio Color

Table Of Contents

Introduction................................................................................................. I-1

About This Manual............................................................................................. I-1

Caution and Warning Symbols .....................................................................I-2

Safety Instructions......................................................................................... I-2

Studio Color 575-S Features............................................................................... I-3

Studio Color 575-M Features ............................................................................. I-4

System Overview................................................................................................ I-5

MSR 575/2 and MSD 575 Lamps................................................................. I-5

Color Mixing and Capabilities...................................................................... I-5

Beam Shaping ...............................................................................................I-5

Full Mechanical Dimming ............................................................................I-6

Automatic Voltage Selection ........................................................................I-6

Power Factor Correction ............................................................................... I-6

Cooling..........................................................................................................I-6

DMX Control ................................................................................................I-6

Stepper Motors.............................................................................................. I-6

Optical Encoders ........................................................................................... I-7

Lamp Power Options..................................................................................... I-7

Automatic Power-Saving Mode.................................................................... I-7

Ease of Maintenance ..................................................................................... I-7

Safety............................................................................................................. I-7

Specifications...................................................................................................... I-8

Models...........................................................................................................I-8

Mechanical .................................................................................................... I-8

Electrical .....................................................................................................I-10

Lamp ........................................................................................................... I-11

Communication........................................................................................... I-11

Compliance....................................................................................................... I-11

Available Controllers........................................................................................ I-11

Accessories ....................................................................................................... I-12

Front and Side Panels ....................................................................................... I-13

Chapter 1 Installation and Setup............................................................... 1-1

Unpack Studio Color ......................................................................................... 1-1

Save the Shipping Materials......................................................................... 1-1

Inspect the Contents ..................................................................................... 1-1

Road Cases......................................................................................................... 1-2

Minimum Material Requirements................................................................ 1-2

Construction Requirements.......................................................................... 1-2

Before You Begin Installation........................................................................... 1-4

Table of Contents TOC-i

Page 8

Power Requirements........................................................................................... 1-4

Line Cord Cap Construction............................................................................... 1-5

Data Cable Construction .................................................................................... 1-5

Terminator Construction .................................................................................... 1-6

Lamp Installation................................................................................................ 1-7

Fixture Mounting................................................................................................ 1-9

Floor Mounting.............................................................................................1-9

Truss Mounting...........................................................................................1-10

Data Cabling..................................................................................................... 1-11

DMX Starting Channel..................................................................................... 1-12

Setting the Starting Channel by Fixture Number........................................1-12

Setting the Starting Channel by DMX Channel Number ...........................1-13

Patching DMX Controllers .........................................................................1-14

DMX Control of Functions .............................................................................. 1-15

Chapter 2 Operation................................................................................... 2-1

Overview ............................................................................................................ 2-1

MSpeed............................................................................................................... 2-1

Pan and Tilt ........................................................................................................ 2-2

Dimming............................................................................................................. 2-3

Strobe Effects ..................................................................................................... 2-3

Color Mixing...................................................................................................... 2-3

Fixed Color Wheel........................................................................................2-3

Subtractive Color Wheels .............................................................................2-3

Color Functions.................................................................................................. 2-4

Double Rotation of Color Mixing Wheels....................................................2-4

Enable MSpeed On Color Functions ............................................................2-4

Forward Color Spins and Synchronized Color Mix Sequences ...................2-4

Reverse Color Spins and Random Color Mix Cycling.................................2-4

Color Lock and Quickest Path......................................................................2-4

Beam Shaping..................................................................................................... 2-5

Remote Shutdown .............................................................................................. 2-5

Remote Homing and Lamp Restrike.................................................................. 2-5

Chapter 3 Menu System............................................................................. 3-1

Overview ............................................................................................................ 3-1

Menu Map .......................................................................................................... 3-2

Address Menu..................................................................................................... 3-5

Information Menu............................................................................................... 3-6

TOC-ii Studio Color User’s Manual

Setting the Starting Channel .........................................................................3-5

Viewing Lamp Hours....................................................................................3-6

Viewing Lamp Strikes ..................................................................................3-6

Viewing System Version Number ................................................................3-6

Resetting Lamp Hours ..................................................................................3-7

Page 9

Viewing Total Fixture Hours ....................................................................... 3-7

Resetting Fixture Hours ............................................................................... 3-7

Viewing the Current Internal Temperature.................................................. 3-7

Viewing the Minimum Internal Temperature .............................................. 3-8

Viewing the Maximum Internal Temperature.............................................. 3-8

Resetting Temperature Readings ................................................................. 3-8

Viewing DMX Errors and Function Values................................................. 3-9

Viewing DMX Data by Channel Number.................................................. 3-10

Viewing Supplemental Fixture Data.......................................................... 3-10

Test Menu ........................................................................................................ 3-11

Manually Homing the Fixture.................................................................... 3-11

Moving the Fixture to Setup Position ........................................................ 3-11

Self Tests.................................................................................................... 3-12

Changing Functions ................................................................................... 3-12

Changing Boot Codes ................................................................................ 3-12

Mode Menu...................................................................................................... 3-13

Selecting Operational Mode 1.................................................................... 3-13

Selecting Operational Mode 2.................................................................... 3-13

Cross-Loading Fixtures.............................................................................. 3-13

Set Menu.......................................................................................................... 3-14

Turning On and Off Factory Presets .......................................................... 3-14

Setting the Starting Channel by DMX Channel or by Fixture Number..... 3-14

Setting Display Output............................................................................... 3-14

Inverting Pan .............................................................................................. 3-15

Inverting Tilt .............................................................................................. 3-15

Swapping Pan and Tilt ............................................................................... 3-15

Setting Fixture Shutdown Time ................................................................. 3-16

Setting the Lamp Power............................................................................. 3-16

Calibrating Pan........................................................................................... 3-17

Calibrating Tilt........................................................................................... 3-17

Appendix A Troubleshooting and Maintenance ..................................... A-1

Overview............................................................................................................ A-1

Before You Begin.............................................................................................. A-1

Support Checklist............................................................................................... A-1

Acquiring Help .................................................................................................. A-2

Troubleshooting................................................................................................. A-2

Display Error Messages ...............................................................................A-3

General Troubleshooting..............................................................................A-8

Upload Troubleshooting.............................................................................A-10

Onboard Self-Tests.....................................................................................A-11

Testing DMX Data.....................................................................................A-11

Maintenance..................................................................................................... A-12

Table of Contents TOC-iii

Page 10

Replacing the Lamp...................................................................................A-12

Cleaning.....................................................................................................A-12

Exterior............................................................................................... A-12

Lens Interior ....................................................................................... A-13

Software Updates.......................................................................................A-14

Upload Dongle ................................................................................... A-16

Another Studio Color ......................................................................... A-16

Appendix B Accessory Installation .......................................................... B-1

Overview ........................................................................................................... B-1

Dichroic Glass Installation ................................................................................ B-2

Accessory Lens Installation............................................................................... B-7

Light Snoot........................................................................................................ B-8

Appendix C Supplemental Information .................................................. C-1

Color Matching.................................................................................................. C-1

Converting DMX Values to MSpeed Times ..................................................... C-5

Appendix D Important Safety Information............................................. D-1

Appendice D Importantes Informations Sur La Sécurité ................................. D-2

Anhang D Wichtige Hinweise Für Ihre Sicherheit ........................................... D-3

Apéndice D Información Importante De Seguridad.......................................... D-4

Appendice D Importanti Informazioni Di Sicurezza ........................................ D-5

Appendiks D Vigtig Sikkerhedsinformation..................................................... D-6

Index........................................................................................................... IX-1

List of Figures

Side View Dimensions ....................................................................................... I-8

Front Panel ....................................................................................................... I-13

Side Panels ....................................................................................................... I-14

Road Case Construction Overhead View ...........................................................1-2

Road Case Construction Side View ...................................................................1-3

Data Cable Construction ....................................................................................1-5

Terminator Construction ....................................................................................1-6

Removing the Lamp Access Cap .......................................................................1-7

Installing the Lamp .............................................................................................1-8

Floor Installation ................................................................................................1-9

Attaching Mounting Hardware .........................................................................1-10

Safety Cable Installation ..................................................................................1-10

Data In and Data Out Connectors .....................................................................1-11

Daisy Chaining Fixtures ...................................................................................1-11

Using the Front Panel .......................................................................................1-12

MSpeed Values ...................................................................................................2-2

Fixture Menu ......................................................................................................3-1

TOC-iv Studio Color User’s Manual

Page 11

Removing the Bezel .........................................................................................A-13

Device Code Upload Dialogue Box ................................................................A-14

Device Upload Status Information Window ....................................................A-15

Removing the Bezel ...........................................................................................B-2

Stepper Drive Cable Removal ...........................................................................B-3

Removing the Strobe Plate ................................................................................B-4

Locating the Color Wheel ..................................................................................B-4

Color Wheel and Factory Index Positions .........................................................B-5

Removing the Dichroic Glass ............................................................................B-5

Lens Removal ....................................................................................................B-7

Installing the Light Snoot (Exploded View) ......................................................B-8

Installed Light Snoot ..........................................................................................B-9

List of Tables

Breaker Requirements ....................................................................................... 1-4

DMX Starting Channel .................................................................................... 1-14

DMX Control ................................................................................................... 1-15

Display Error Messages .....................................................................................A-3

General Troubleshooting ...................................................................................A-8

Upload Troubleshooting ..................................................................................A-10

Color Matching .................................................................................................C-1

DMX Values to MSpeed Times ........................................................................C-5

Table of Contents TOC-v

Page 12

TOC-vi Studio Color User’s Manual

Page 13

Introduction

Congratulations on your purchase of the Studio Color® Automated Wash

Luminaire from High End Systems®.

About This Manual

This manual provides the means to setup and operate Studio Color. This

manual is organized in the following sections:

Introduction—introduces you to this manual, provides hardware

specifications, and technical support information.

Chapter 1 Installation and Setup—explains how to install and setup Studio

Color.

Chapter 2 Operation—explains the functionality and operation of the fixture

in detail.

Introduction

Chapter 3 Menu System—provides information on using the menu system

and its functions.

Appendix A Troubleshooting and Maintenance—provides directions for

troubleshooting problems, maintenance, and uploading software.

Appendix B Accessory Installation—provides information on installing

approved accessories.

Appendix C Supplemental Information—provides information on how to

color mix common gel colors and contains a reference chart for DMX values to

MSpeed times.

Appendix D Important Safety Information—provides safety information in

English, French, German, Spanish, Italian, and Danish.

Index—provides easy access to relevant topics and words.

Introduction I-1

Page 14

Caution and Warning Symbols

The following international symbols appear in margins throughout this manual to

highlight caution and warning messages.

Caution: This symbol appears adjacent to Caution messages. Ignoring

these messages could result damage to equipment.

Warning: This symbol appears adjacent to High Voltage Warning

messages. Ignoring these messages could result in serious personal injury.

This symbol indicates the minimum distance to a lighted object is 1 meter.

This symbol indicates eye protection is required.

This symbol indicates a hot surface.

This symbol indicates an explosion hazard.

Safety Instructions

• Heed all caution and warning messages throughout this manual and the

documentation that accompanies your fixtures.

• Servicing must be conducted by the manufacturer or other qualified service

personnel.

• Avoid allowing liquids in any form to come in contact with the fixture.

I-2 Studio Color User’s Manual

Page 15

Studio Color 575-S Features

• Automatic voltage selection for electronics, lamp, and motors at 50-60 Hz for all

international voltages

• Full power factor correction

• Convection cooled for quiet operation

• Utilizes stepper motors throughout

• All functions are controllable via DMX-512 protocol

• Subtractive color mixing system plus six position fixed color wheel (100 million

color permutations)

• 6200° K color temperature using the MSR 575/2 lamp and 5600° K using the MSD

575. The color correction filter fitted in the color wheel changes the MSR 575/2’s

color temperature to 3100° K and the MSD 575’s color temperature to 2800° K.

Virtually infinite up/down color correction is also available through the use of the

three variable subtractive color wheels.

Introduction

• Partial colors, color spins, synchronized color sequences, and random color

sequences are available for effects

• The 8° to 22° selectable beam angle may be further user shaped to variable

horizontal or vertical positioning through the use of proprietary secondary effects

lens systems.

• Variable frost

• Moving yoke achieves up to 370° pan and 240° tilt. Control accuracy is 11.6"

(sec.) (0.0032°).

• Optical encoders self-correct pan and tilt positions

• Accessory PAR type lenses are available in VNSP, NSP, WFL, MFL, and XWFL

PAR beams

• 15-segment four character alpha-numeric LED display shows data, status, and

internal diagnostic features

• LED indicators are provided to analyze power and data conditions

• Easy, quick, lamp replacement

• Integral AC power switch/breaker

• Integral floor mountable design with carrying handles. Mountable with standard

installation hardware.

• Smooth iris dimming

• Shutter providing instant blackout, strobe effects, and random strobe effects

• Flicker-free light output

• Lamp power reduction for special applications

• Automatic power-saving mode when the shutter is closed

• Remote fixture shutdown

• Enhanced lamp life

Introduction I-3

Page 16

Studio Color 575-M Features

• Robust magnetic ballast power supply for operation at 50 or 60 Hz at 208 or 230

volts

• Power factor correction

• Utilizes stepper motors throughout

• Convection cooled for quiet operation

• All functions are controllable via DMX-512 protocol

• Subtractive color mixing system plus six position fixed color wheel (100 million

color permutations)

• 6200° K color temperature using the MSR 575/2 lamp and 5600° K using the MSD

575. The color correction filter fitted in the color wheel changes the MSR 575/2’s

color temperature to 3100° K and the MSD 575’s color temperature to 2800° K.

Virtually infinite up/down color correction is also available through the use of the

three variable subtractive color wheels.

• Partial colors, color spins, synchronized color sequences, and random color

sequences are available for effects

• The 8° to 22° selectable beam angle may be further user shaped to variable

horizontal or vertical positioning through the use of proprietary secondary effects

lens systems

• Variable frost

• Moving yoke achieves up to 370° pan and 240° tilt. Positioning accuracy is 19.8"

(sec.) (0.0055°).

• Accessory PAR type lenses are available in VNSP, NSP, MFL, WFL, and XWFL

PAR beams

• 15-segment four character alpha-numeric LED display shows data, status, and

internal diagnostic features

• LED indicators are provided to analyze power and data conditions

• Easy, quick, lamp replacement

• Integral AC power switch/breaker

• Integral floor mountable design with carrying handles. Mountable with standard

installation hardware.

• Smooth iris dimming

• Shutter provides instant blackout, strobe effects, and random strobe effects

I-4 Studio Color User’s Manual

Page 17

System Overview

The following subsections provide a basic overview of the Studio Color

features.

MSR 575/2 and MSD 575 Lamps

Studio Color utilizes custom lamps which are critical to the achievement of a full

range of color permutations for the fixture. The MSR 575/2 provides a high color

rendering index and high color temperature of 6200° K.

An optional MSD 575 lamp is available for architectural applications. It has a

color temperature of 5600° K and offers extended lamp life.

Color Mixing and Capabilities

Color range is achieved through the use of two systems, a fixed color wheel and

three subtractive color wheels. The fixed color wheel contains six user selectable

filters. Custom color filters may be selected and ordered from High End Systems'

dichroic color filter selection and easily installed by the user in the fixed color

wheel.

Introduction

When the fixed color wheel is used in combination with the subtractive color

mixing gradient dichroic color wheels, over 100 million colors can be achieved.

Proprietary dichroic subtractive color mixing wheels employ computer generated

color distribution for uniform color of the beam and the most seamless three-color

mixing available. The coloration of the three filters (CYM) is optimized in High

End Systems' dichroic labs to provide the widest range of color available from

subtractive color mixing. A color correcting dichroic is fitted in the fixture's color

wheel to correct color temperature to 3100° K with the MSR 575/2 and 2800° K

with the MSD.

Special color functions allow MSpeed to control all color systems, color spins of

the fixed color wheel, random color combinations, double rotation of the

subtractive color wheels, and quickest path to the desired color.

Beam Shaping

An exclusive variable beam profiling effect is achieved through selectable lens and

frost systems. The standard beam angle selection is from 8° to 22°, which may be

further shaped through a secondary effects lens system. The beam retains full light

output while being profiled. This delivers virtually unlimited beam shaping in both

the horizontal and vertical planes. Additionally, a variable frost effect provides

progressive beam diffusion enhancement. These features deliver dynamic control

of beam shape, offering new features never before available in a traditional wash

fixture.

Introduction I-5

Page 18

Full Mechanical Dimming

The dimming system is optimized to provide extremely uniform dimming of the

beam. A dimming iris provides complete dimming without changing the color

temperature.

Automatic Voltage Selection

Studio Color 575-S features integral proprietary switching power supplies for the

on-board electronics packages and the lamp power supply. The fixture

automatically operates on all voltages between 100 V.A.C. and 250 V.A.C. at 50

to 60 hertz without changing a power tap, the lamp, or making any adjustments.

Power Factor Correction

Both Studio Color models are power factor corrected. The lamp's power supply is

also power factor corrected to optimize the light source's efficiency and deliver

maximized power economy.

Cooling

Studio Color is convection cooled and uses no fans. Careful optical design

provides a reduction of 65% heat between the lamp chamber and the optical

section.

DMX Control

Full control over all operating parameters of Studio Color is achieved via 16

channels of DMX-512 protocol. This includes 16-bit pan and tilt positioning

accuracy over the 370° x 240° range of movement, 8-bit accuracy for color wheels,

effects wheels, and 8-bit dimming. A full function alpha-numeric display provides

the ability to comfortably program the address channel, mode, offset, and other

functions of the fixture in easy to view characters. A full set of diagnostic

functions are available through the menu system. All parameters are controlled by

a built-in Motorola® 68340 microprocessor. Operating software can be uploaded

from the Lightwave Research Upload Dongle, the Wholehog III, Lighting Console,

or from another fixture, thus keeping the fixtures constantly updated with the latest

software version.

Stepper Motors

All motors are digitally controlled steppers, providing precision control and very

long life. The pan and tilt motors are special high torque stepper motors offering

40% greater torque than comparable steppers. All mechanical movements are

achieved via belt drives, insuring high reliability and very smooth, quiet

performance.

I-6 Studio Color User’s Manual

Page 19

Optical Encoders

The Studio Color 575-S utilizes optical encoders for the pan and tilt systems. The

encoders automatically correct position if a fixture is jolted from a programmed

position.

Lamp Power Options

For special applications, lamp power in the Studio Color 575-S can be reduced to

250 watts. This feature decreases light output, decreases heat, and saves power.

Automatic Power-Saving Mode

The Studio Color 575-S provides an automatic power-saving mode. When the

shutter is closed, lamp power decreases to 250 watts. When the shutter is reopened,

the lamp instantly returns to full power.

Introduction

Ease of Maintenance

Studio Color has been designed for the professional user. All electronics, motors,

and drive systems are easily accessible. Access to all color wheels, color motors,

and effects motors is provided via a removable impact resistance, high temperature

polymer front bezel. This front bezel is removable in seconds through two quick

release latches. All processor and power supplies are accessible by opening the

electronics housing and removing complete modules. Changing the lamp is quick

(typically less than 30 seconds) and convenient, being accessed through the rear of

the fixture via two access screws. The lamp assembly retains optimum lamp

alignment during movement and replacement.

Safety

The lamp cover is secured through a wiring harness for additional safety. Multipoint grounding is provided throughout for complete assurance of safe operation.

The bezel is secured to the unit by an additional safety cable. The fixture and all

electronics comply with current UL, CE, and CSA safety standards for

professional lighting fixtures.

Introduction I-7

Page 20

Specifications

Models

Studio Color 575-S

Studio Color 575-M

Mechanical

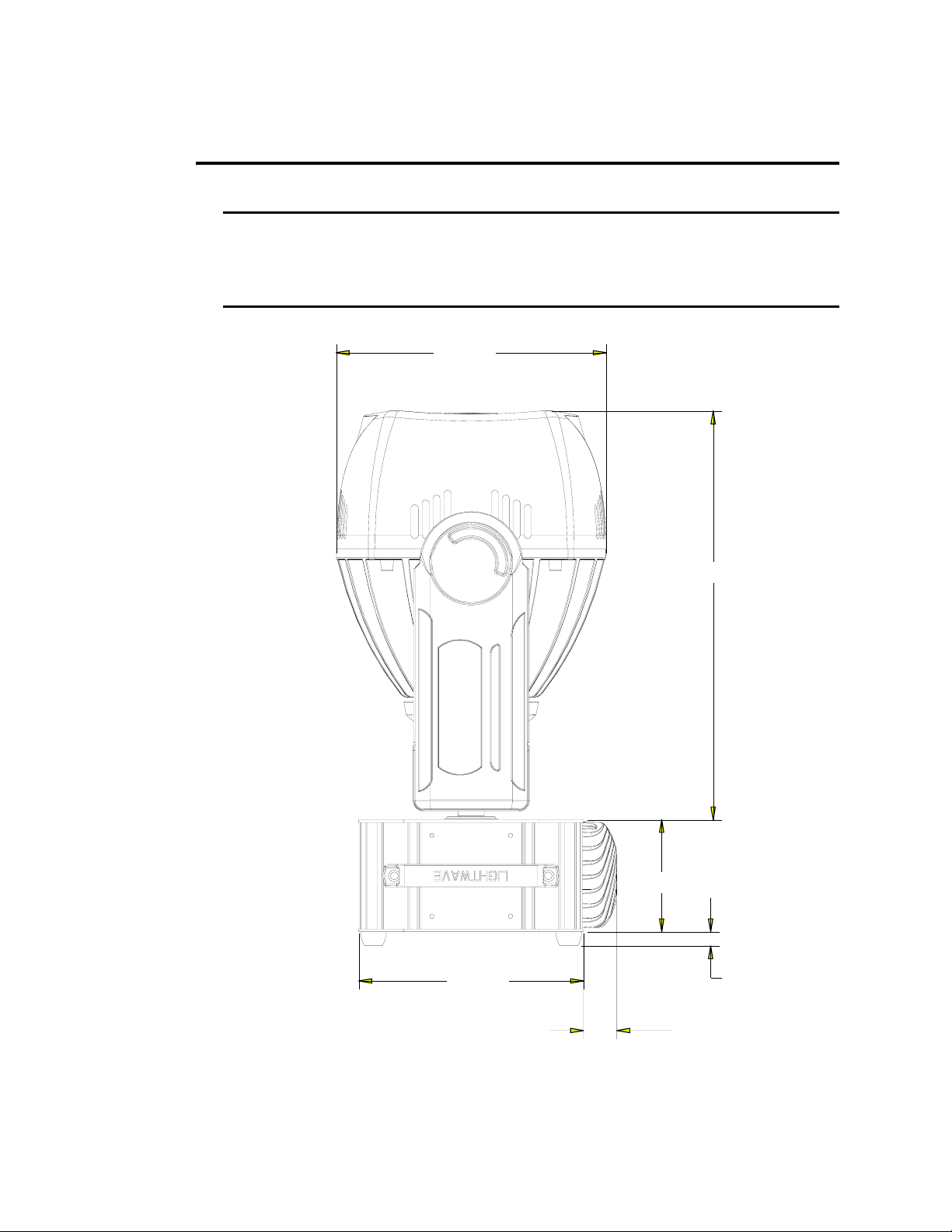

Dimensions:

305.05 mm

(12.01 in.)

461.77 mm

(18.18 in.)

¹Note: the 575-S has a proprietary heat sink which extends the fixture depth by

37.84 mm (1.49 in.).

I-8 Studio Color User’s Manual

Studio Color

126.49 mm

(4.98 in.)

254 mm

(10.00 in.)

Figure 1. Side View Dimensions

37.84 mm¹

(1.49 in.)

15.74 mm

(.62 in.)

Page 21

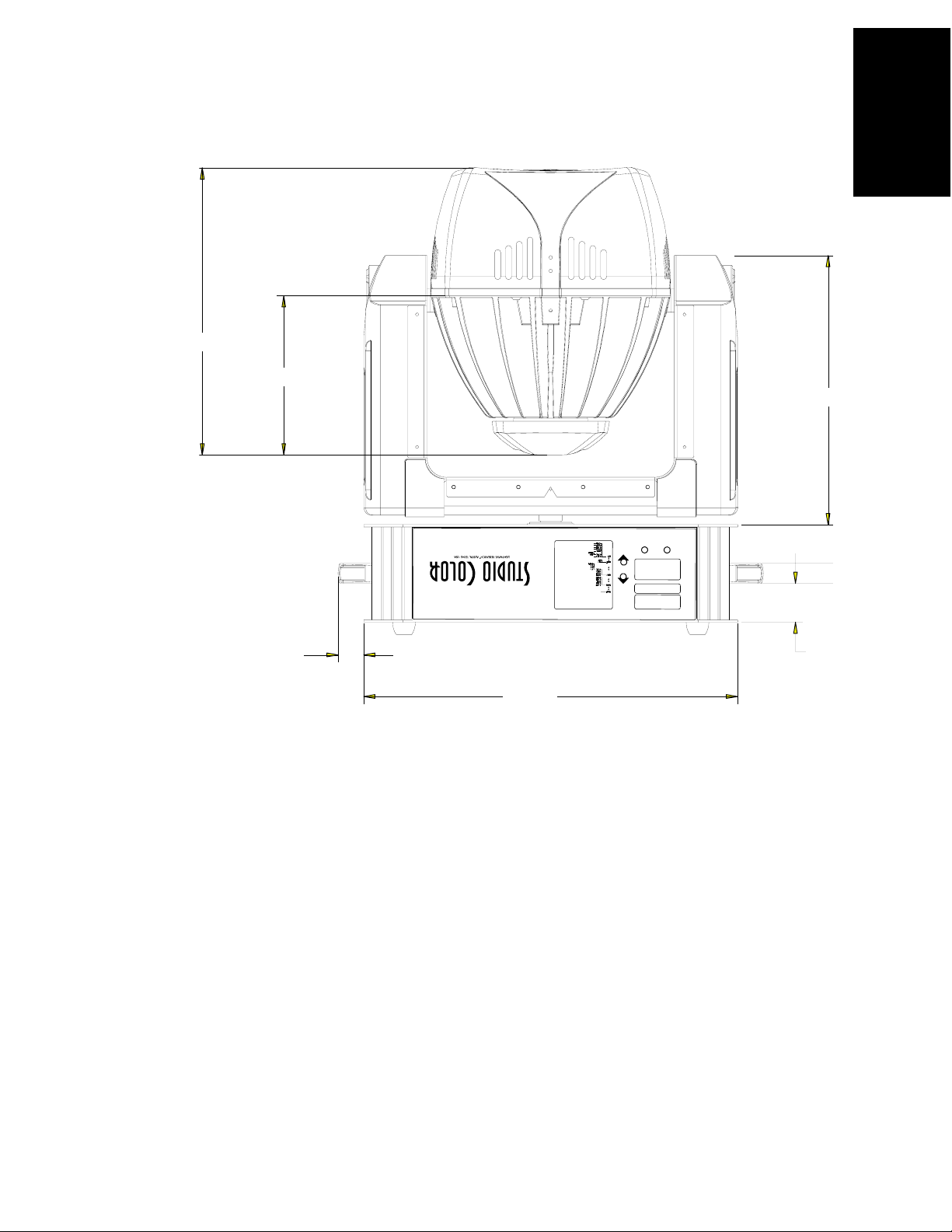

371.60 mm

(14.63 in.)

205.99 mm

(8.11 in.)

348.23 mm

(13.71 in.)

Introduction

R

E

E

T

n

e

N

t

,

e

s

t

h

t

u

h

i

s

t

n

m

o

e

¯

-

w

o

d

t

R

T

N

E

E

t

n

e

h

,

p

a

w

l

s

t

t

-

i

n

a

f

o

p

f

/

n

o

t

t

n

r

u

o

¯

-

R

T

E

N

E

t

,

n

e

h

t

r

e

v

f

o

t

f

/

n

o

t

t

i

l

n

r

u

o

¯

i

t

n

-

R

T

E

N

E

n

e

h

t

,

t

r

e

i

n

v

n

a

f

o

p

f

/

n

o

t

n

r

u

t

o

¯

-

R

E

T

N

n

l

e

p

h

a

f

o

E

y

t

,

i

d

f

s

/

n

o

t

t

n

r

u

o

¯

-

f

#

s

e

t

r

d

d

a

i

e

r

u

s

o

x

b

R

t

y

T

E

N

E

l

e

n

n

a

h

c

X

s

e

r

d

d

a

s

o

M

b

R

t

y

D

T

E

N

E

R

T

N

f

n

E

e

e

h

l

u

E

a

t

,

t

s

/

t

n

o

d

y

r

o

o

n

c

a

f

r

u

¯

f

-

f

t

E

R

E

N

T

2

#

e

d

o

i

g

n

m

t

a

s

r

e

p

o

t

l

o

e

R

c

e

t

E

T

N

E

1

#

e

d

o

i

g

n

m

t

a

s

r

e

p

o

t

l

o

e

R

c

e

t

T

N

E

E

E

N

T

E

R

3

#

r

o

t

o

m

t

t

s

e

o

R

t

T

N

E

E

2

#

r

o

t

o

m

t

t

E

s

e

o

R

t

T

N

E

1

#

r

o

t

o

m

t

t

s

e

o

R

E

t

T

N

E

s

l

e

t

t

t

f

s

t

r

e

a

s

t

o

R

E

T

N

E

i

s

i

n

o

t

e

e

e

s

o

p

t

s

p

t

u

o

R

E

E

T

N

e

r

u

t

f

i

e

x

m

o

h

t

o

R

E

T

N

E

N

T

E

R

E

o

s

r

u

t

e

r

u

t

o

e

e

h

t

f

a

l

s

i

t

x

o

R

E

T

N

E

s

r

u

o

h

p

l

t

m

e

a

s

e

r

t

o

R

E

E

T

N

#

i

n

o

s

r

e

v

m

e

t

s

y

s

e

e

s

t

o

R

E

T

N

E

s

e

i

k

r

p

t

l

s

m

a

#

e

e

s

t

o

R

E

T

N

E

s

r

u

o

p

h

l

m

a

e

e

s

t

o

R

E

T

N

E

E

R

N

T

E

R

E

T

N

s

e

d

t

E

i

t

o

d

e

n

r

e

s

h

s

e

a

,

r

d

d

¯

-

E

R

N

T

E

t

n

r

l

o

n

o

.

a

d

e

t

p

u

U

k

y

e

.

o

t

u

t

e

h

h

g

k

y

e

c

o

r

e

e

d

t

t

f

r

d

i

i

l

a

n

i

e

a

o

m

o

n

i

n

o

x

f

t

r

s

u

e

e

o

r

e

l

R

e

r

u

r

f

a

e

a

f

m

h

u

s

t

n

m

o

t

N

E

n

s

t

e

u

,

M

p

i

e

o

m

h

u

r

s

s

h

r

v

p

e

e

e

o

t

t

k

c

g

a

b

o

o

e

.

n

e

a

e

r

T

g

t

h

n

a

c

u

o

n

r

e

m

y

e

t

r

t

k

n

e

o

e

a

R

E

T

N

E

.

h

r

s

e

P

t

e

s

s

e

i

c

c

i

o

u

f

d

h

n

f

r

e

m

e

e

t

n

t

o

h

l

r

l

r

o

c

t

o

s

p

r

s

d

P

l

s

e

e

a

t

e

m

y

s

d

.

i

e

s

h

e

y

i

i

¯

k

t

u

i

l

n

u

f

t

e

t

i

r

h

n

s

e

m

t

U

N

E

M

l

d

o

a

s

d

h

n

s

,

r

s

r

e

e

u

p

k

e

y

h

s

n

s

e

d

c

u

u

e

l

t

n

o

n

k

a

T

m

c

s

o

a

c

s

e

33.27 mm

(1.31 in.)

M

T

484.63 mm

(19.08 in.)

Weight

575-S: 25.85 kg (57 pounds)

575-M: 30.68 kg (67.5 pounds)

N

R

T

E

E

N

U

E

M

R

e

c

e

i

v

e

r

T

i

s

t

m

a

n

5

V

L

a

m

p

o

r

o

M

t

50.54 mm

(1.99 in.)

Introduction I-9

Page 22

Electrical

Studio Color 575-S

Rated voltage: 100–230 V.A.C.¹

Rated current: 7.0 A @ 100 V/60 Hz.,

3.0 A @ 230 V/50 Hz.

Rated power: 700 W max.

Rated frequency: 50/60 Hz.

Max. ambient temperature, Ta: 40° C (104° F)

Max. exterior surface temperature: 140° C (284° F)

Power factor: 0.96 @ 230 V/50 Hz.,

1.0 @ 100 V/60 Hz.

Max. winding temperature, Tw: 130° C (266° F)

Max. capacitor temperature, Tc: 85° C (185° F)

Studio Color 575-M

Rated voltage: 208/230¹ V.A . C .

Rated frequency: 50/60 Hz.

Rated current: 3.2 A @ 208 V/60 Hz.,

3.0 A @ 230 V/50 Hz.

Rated power: 700 W max.

Max. ambient temperature, Ta: 40° C (104° F)

Max. exterior surface temperature: 140° C (284° F)

Power factor: 0.90 @ 60 Hz., 0.864 @ 50 Hz.

Max. winding temperature, Tw: 130° C (266° F)

Max. capacitor temperature, Tc: 100° C (212° F)

¹

Note: fixtures can operate with international 200, 240 and 250 V.A.C. supplies.

575-M fixtures must be re-tapped for some voltages. To retap 575-M

fixtures, contact your authorized dealer or High End Systems Service

Department.

I-10 Studio Color User’s Manual

Page 23

Lamp

Lamp type: Use only M Series, GX 9.5 base, 575

watt, metal halide type lamp

MSR 575/2 color temperature: 6200° Kelvin

MSD 575 color temperature: 5600° Kelvin

WARNING: Use only the lamps purchased from High End Systems. These lamps

were specifically designed for use in Studio Color.

Communication

Protocol: USITT DMX-512

Start code: 00h

Maximum load: 32 fixtures per DMX link

Required channels: 16

Introduction

Termination: 120 Ω

Compliance

Studio Color 575-M and 575-S are compliant to the following standards:

• UL 1572

• CSA 22.2 Number 9

• EN 60598-1 : 1993

• EN 60598-2-17 : 1989 A1-A3 : 1993

• EN 55022, Class A ITE

• IEC 801-2, 1991 Level 2 (4/8 kV)

• IEC 801-3, Draft 5 Level 2 (3 V/m)

• IEC 801-4, 1988 Level 2 (1 kV/0.5 kV)

• FCC-Class A digital device

Available Controllers

The following controllers from Lightwave Research® may be used to operate

Studio Color:

Wholehog III Lighting Console

Hog2 PC controller

Additionally, most DMX-512 controllers may be used to operate Studio Color.

Introduction I-11

Page 24

Accessories

The following items are currently available for Studio Color:

Accessory effect lenses (set of five) 99090029

Cheeseborough clamp 55040014

Color mixing assembly 80430044

Dark blue color filter 80510061

Orange color filter 80510060

Color corrector filter (full) 80510159

Purple color filter 80510063

Blue color filter 80510116

Green color filter 80510117

Indigo color filter 80510114

Magenta color filter 80510118

Yellow color filter 80510119

10-foot heavy duty data cable w/ Neutrik XLRs 55050005

25-foot heavy duty data cable w/Neutrik XLRs 55050006

50-foot heavy duty data cable w/ Neutrik XLRs 55050007

100-foot heavy duty data cable w/ Neutrik XLRs 55050008

Lightwave Research Upload Dongle 26040002

Ecodome™ 115 V (575-S only) 28010001

Ecodome 208/230 V 28010002

Keal Road Case for one fixture 26070000

Keal Road Case for two fixtures 26070001

Light snoot (fresnel light shield) 99190012

Philips MSR 575/2 lamp 55030045

Philips MSD 575 lamp 55030050

Safety cable 12040001

Studio Color User’s Manual 60600061

Studio Color Quick Reference Card 60600082

Notes: additional custom color filters are available from High End Systems. For

special applications, all Studio Color models are available in white. Contact

your authorized dealer or distributor for ordering information.

I-12 Studio Color User’s Manual

Page 25

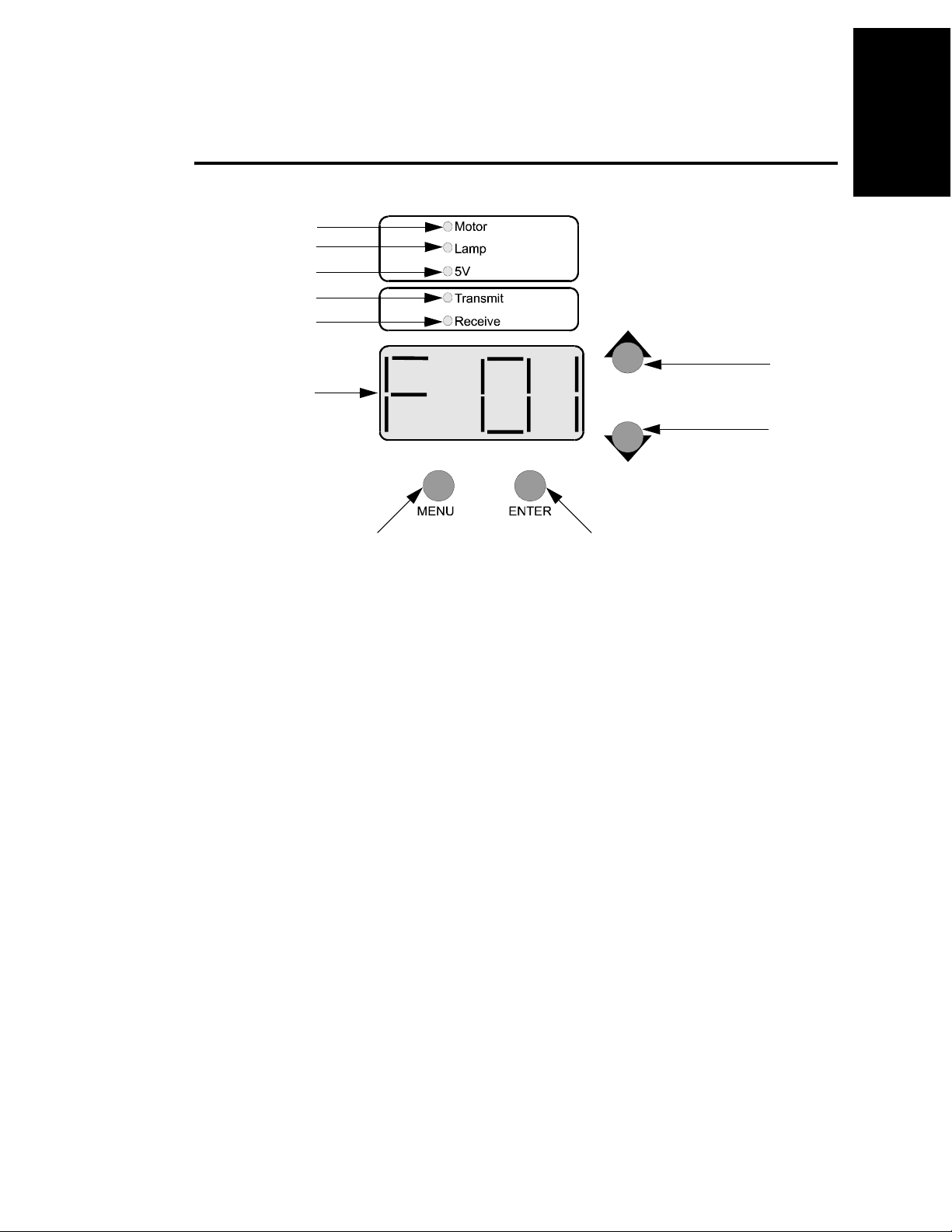

Front and Side Panels

A

B

C

D

E

F

Introduction

J

I

GH

Figure 2. Front Panel

A- Motor power supply indicator. This LED is on when the motor power supply has the

proper voltage.

B- Lamp power supply indicator¹. This LED is on when the lamp is on, off if the lamp

is turned off, or flashing if there is a malfunction.

C- 5V supply indicator. This LED is on when the logic board is being supplied with +5

volts.

D- Transmit data indicator. This LED is on when the fixture is the bus master (not the

controller).

E- Receive data indicator. This LED reflects the state of the received data.

F- 15-segment four character alpha-numeric LED display. The display provides data,

status, and internal diagnostic features.

G- <MENU> button. This button recalls the menu system and backs out of the current

field.

H- <ENTER> button. This button enters the current field.

I- Down arrow button. This button scrolls downward through data fields.

J- Up arrow button. This button scrolls upward through data fields.

¹Note: the 575-M LED will always remain on.

Introduction I-13

Page 26

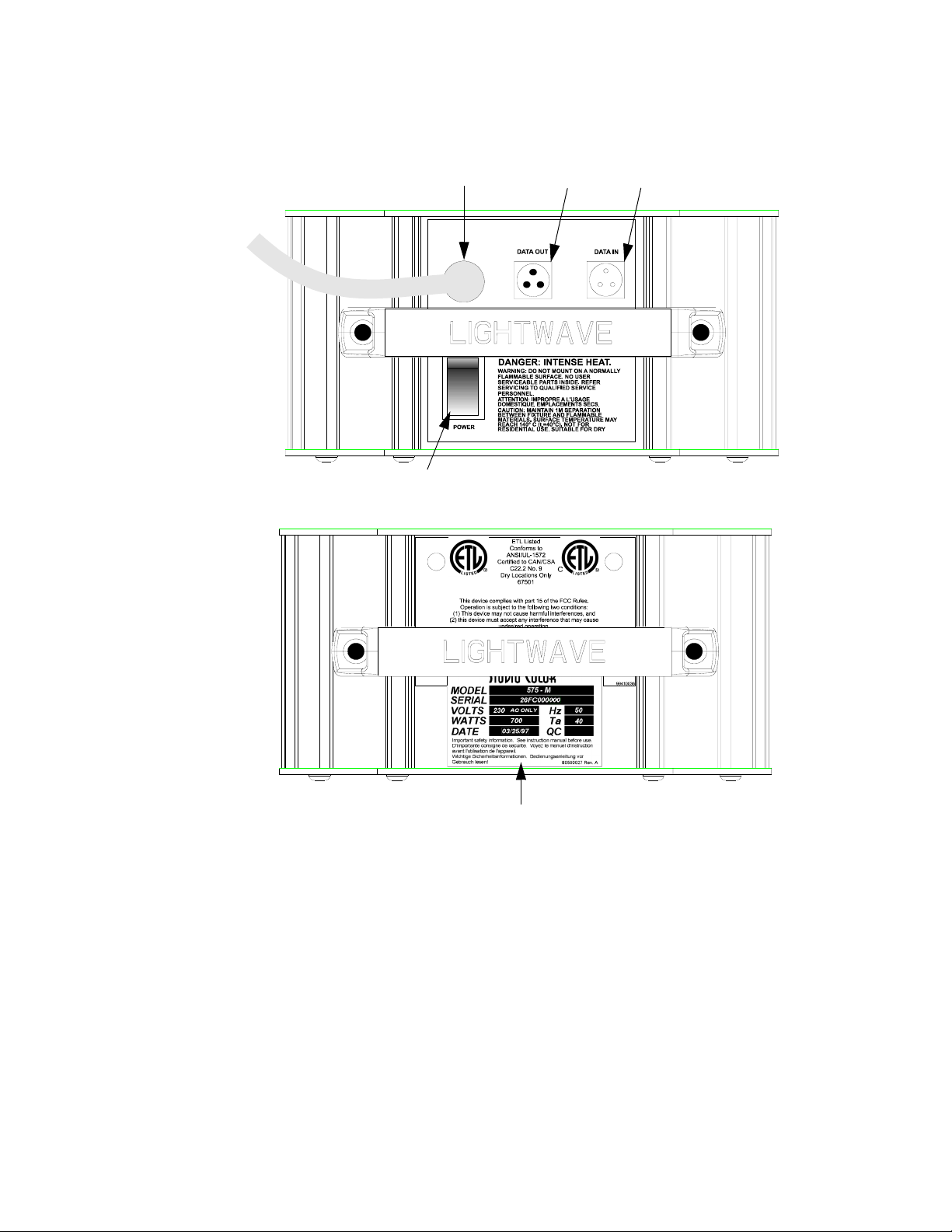

KLM

N

K- Line cord.

L- Data Out connector.

M- Data In connector.

N- Breaker/power switch.

O- QC/rating label.

I-14 Studio Color User’s Manual

O

Figure 3. Side Panels

Page 27

Chapter 1 Installation and Setup

In this chapter you will:

S unpack Studio Color (1-1)

S construct a road case (1-2)

S construct line cord caps (1-5)

S learn the power requirements (1-5)

S construct data cables (1-5)

S construct terminators (1-6)

S install the lamp (1-7)

S mount the fixture (1-9)

S connect data cables (1-11)

S set the starting address (1-12)

S patch fixtures into the controller (1-14)

S configure your DMX controller to control Studio Color (1-15)

Unpack Studio Color

1

Introduction

Installation and

Setup

In this section you unpack your Studio Color and verify that it arrived complete

and without any damage.

Save the Shipping Materials

Do not discard the shipping carton and packing materials. The carton and packing

materials are specifically designed to protect the fixture during transport.

If you ever need to return a product for repair or maintenance, you must return it in

its original shipping carton and packing materials. You will be billed for a new

shipping carton and new packing materials if you return your Studio Color in a

non-factory shipping carton with non-factory packing materials.

Note: Before returning anything to the factory, be sure to call your High End

Systems Dealer/Distributor for a Return Authorization Number. The factory

can not accept any goods shipped without an RA number.

Inspect the Contents

The carton contains the following:

• Studio Color fixture

• Philips MSR 575/2 or MSD 575 series lamp

• Studio Color User’s Manual

• Studio Color Quick Reference Card

Chapter 1 Installation and Setup 1-1

Page 28

Road Cases

If Studio Color fixtures will be transported after they are unpacked from their

original shipping box, a professional road case is strongly recommended. Road

cases must be purchased from High End Systems or constructed according to

the information in this section.

Minimum Material Requirements

Use the following materials to construct the road case:

• 3/4-inch pressed plywood

• 4 pound poly-ethylene foam

• steel or aluminum rivets

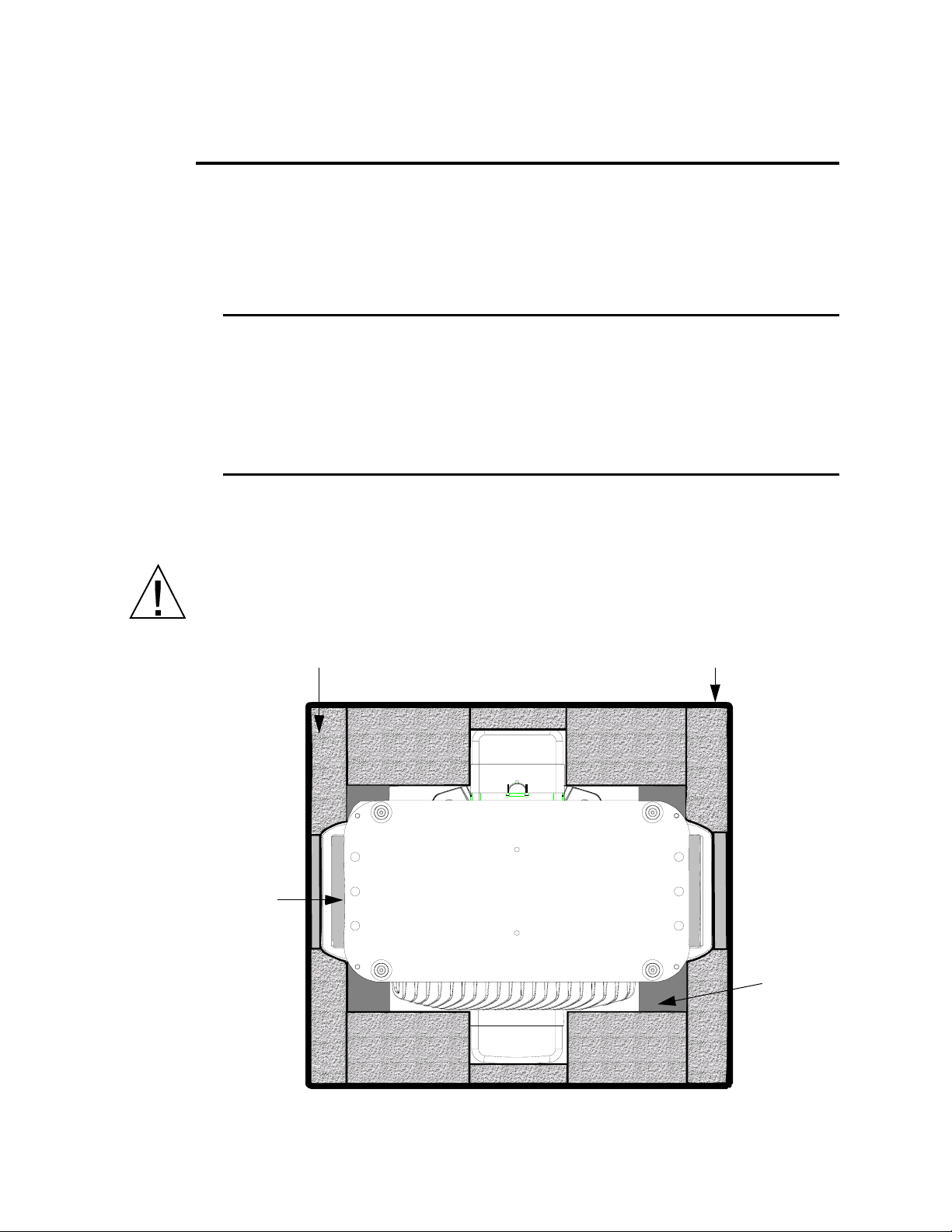

Construction Requirements

The road case must be constructed in a manner that supports the base and the

handles with the head pointed down and the yoke rotated 90°. Refer to Figure 1.1

and Figure 1.2.

Caution: For 575-S fixtures, allow a small gap in the foam around the heat sink to

ensure that the foam is not damaged by the heat from the fixture.

foam

foam over wood

supporting handles

fixture base

case exterior

foam over wood

supporting base

1-2 Studio Color User’s Manual

Figure 1.1. Road Case Construction Overhead View

Page 29

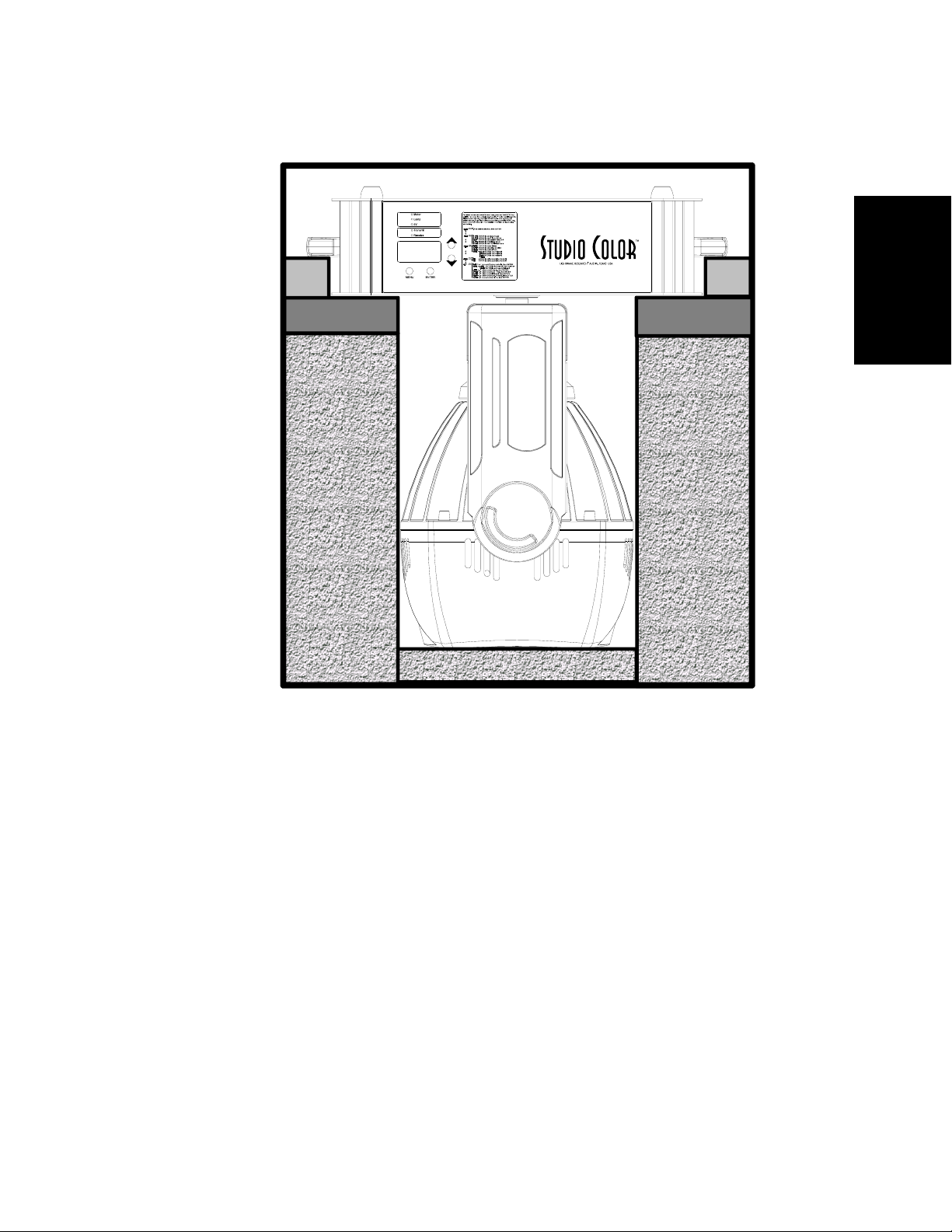

Studio Color

1

Introduction

Installation and

Setup

Figure 1.2. Road Case Construction Side View

Chapter 1 Installation and Setup 1-3

Page 30

Before You Begin Installation

Warning: Before you begin the installation read the following safety precautions.

1. Disconnect the fixture from power before removing the cover or changing the

lamp.

2. Allow the unit to cool for at least five minutes before removing cover or

accessing the lamp.

3. Wear protective gloves and goggles when working inside the unit.

Power Requirements

The following items must be used to provide power to Studio Color:

• 12 AWG stranded THHN or equivalent

• Branch Circuit Protection

• 20 A, high-surge thermal breakers (GE THQB, THQL, or equivalent). Refer to

Table 1.1.

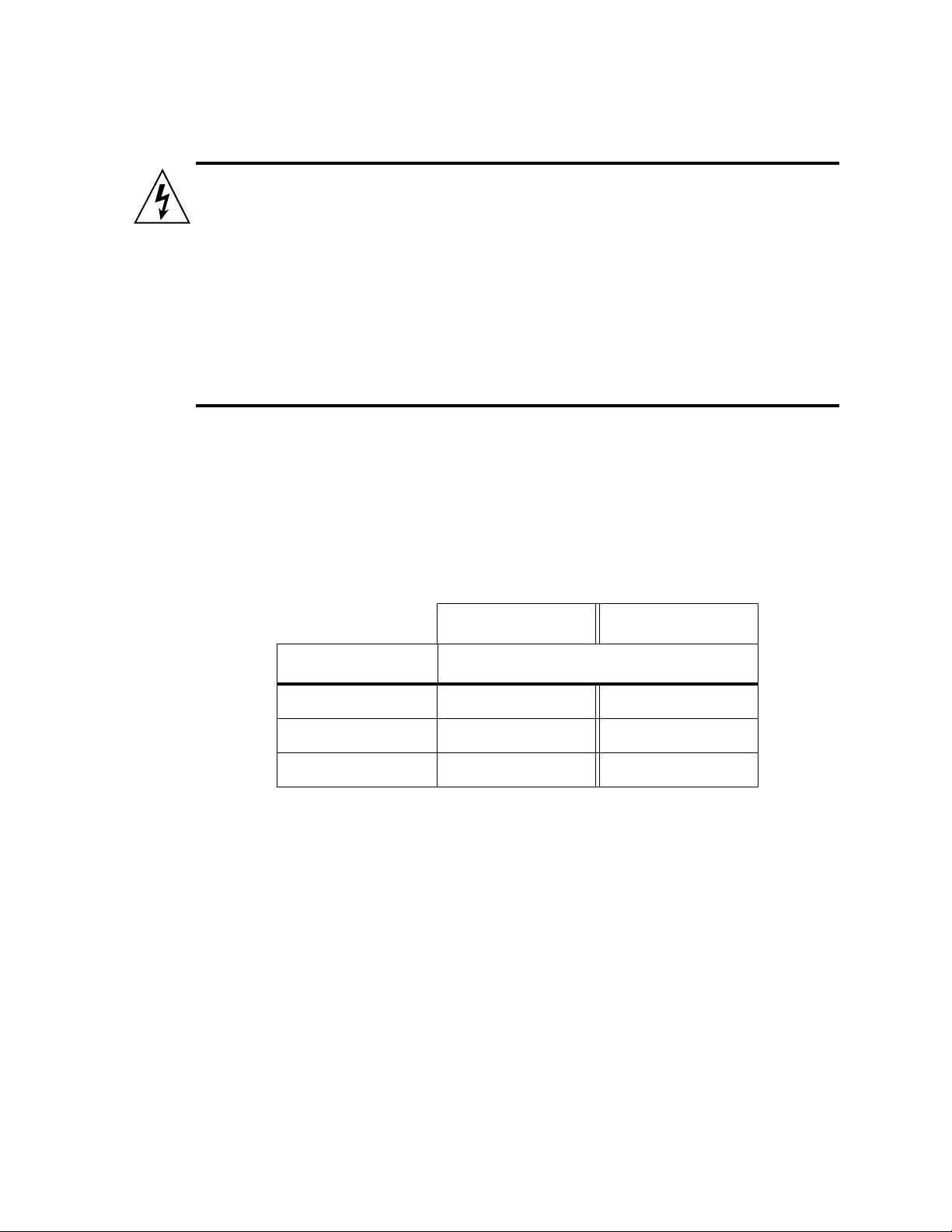

Table 1.1: Breaker Requirements

575-S 575-M

Voltage Number of Fixtures per 20 A Breaker

110 3 n/a

208 5 3

230 6 4

Note: do not use magnetic type circuit breakers.

1-4 Studio Color User’s Manual

Page 31

Line Cord Cap Construction

Studio Color is shipped without a line cord cap attached. Secure the line cord to

a line cord cap in accordance with the following code:

• green and yellow– earth

• blue– neutral

• brown– live

In the United States, use an integral cord grip that is rated either at 125 V 20 A

(NEMA 5-20) or 250 V 20 A (NEMA 6-20), depending on the available

supply.

In the United Kingdom, as the colours of the cores in the mains lead of this

equipment may not correspond with the coloured markings identifying the

terminals in your plug, proceed as follows:

• The core which is coloured green and yellow must be connected to the terminal in

the plug which is marked with the letter

green or green and yellow.

• The core which is coloured blue must be connected to the terminal which is

marked with the letter

• The core which is coloured brown must be connected to the terminal which is

marked with the letter

N or coloured black.

L or coloured red.

E or by the earth symbol, or coloured

1

Introduction

Installation and

Setup

WARNING: Class I equipment. This equipment must be earthed.

Data Cable Construction

Studio Color uses standard three-pin XLR connectors. You should construct

data cables using shielded, two conductor cable with male three-pin XLR

connectors at one end and a female three-pin XLR connectors on the other end.

You can use microphone cables if the pin connections are correct. Test each

cable with a volt-ohm meter for correct polarity and ensure that the negative

and positive pins are not grounded or shorted to the shield. Ensure that pin 1 is

shielded. Refer to

If your DMX controller uses five-pin data cables, you will need to construct or

purchase a five-pin to three-pin adapter.

Figure 1.3.

Figure 1.3. Data Cable Construction

Chapter 1 Installation and Setup 1-5

Page 32

Terminator Construction

DMX-512 protocol recommends terminating resistors be used on the last

fixture on the link. You will need the following items to construct a

terminator:

• Male three-pin XLR connector

• 120 Ω resistor (¼ watt minimum)

To construct a terminator, complete the following procedure:

1. Disassemble the male XLR connector.

2. Solder a 120 Ω resistor, minimum of ¼ watt, between pins 2 and 3.

Ω

0

2

1

2

1

3

Figure 1.4. Terminator Construction

3. Reassemble the XLR connector.

1-6 Studio Color User’s Manual

Page 33

Lamp Installation

You will need the following items to install or replace the lamp:

¼

inch hex wrench

•

• Philips MSR 575/2, MSD 575, or factory approved lamp

• Protective gloves

• Protective goggles

Note: do not mix lamp types! The MSR 575/2 and the MSD 575 have different color

temperatures and characteristics.

To install or replace the lamp, complete the following procedure:

1. Remove power from fixture. If the fixture has been in operation, allow it to

cool for at least five minutes before continuing.

2. Using the ¼-inch hex wrench, loosen the hex screws located at the rear of the

fixture and remove the lamp access cover. Refer to Figure 1.5.

1

Introduction

Installation and

Setup

Studio Color

Figure 1.5. Removing the Lamp Access Cap

3. Holding the lamp by its base, align the lamp leads to their female slots and

carefully push the lamp into the socket. Refer to

Warning: Do not touch the lamp with bare fingers. If the lamp is accidentally

touched, clean it immediately with a soft cloth and isopropyl alcohol

(C

O). An alcohol cloth is provided with each lamp.

3H8

Figure 1.6.

Chapter 1 Installation and Setup 1-7

Page 34

Figure 1.6. Installing the Lamp

4. Place lamp assembly back into the housing and tighten the hex screws.

Caution: Do not overtighten the hex screws.

Note: when a lamp is replaced, remember to reset the lamp hours as outlined in

“Resetting Lamp Hours” on page 3-7. If you are using a 575-M, reset the

fixture hours as outlined in “Resetting Fixture Hours” on page 3-7.

1-8 Studio Color User’s Manual

Page 35

Fixture Mounting

)

Studio Color may be mounted on the ground or at any angle on a truss.

Complete the instructions in the following subsections to mount the fixture

properly.

Caution: Keep flammable items at least 1 M away from fixture.

Floor Mounting

Complete the following procedure to mount a fixture on the floor:

1. Check to ensure that the rubber feet are installed on the base of the fixture

and place it on a flat surface. Refer to

Caution: Do not place the unit on a flat surface without the rubber feet installed.

Figure 1.7.

1

Introduction

Installation and

Setup

Studio Color

rubber feet (4

Figure 1.7. Floor Installation

Chapter 1 Installation and Setup 1-9

Page 36

Truss Mounting

To mount the fixture on a truss, you will need the following equipment:

• (2) Safety cables

• (2) Cheeseborough clamps (recommended) or other mounting hardware

Complete the following procedure to mount the fixture to a truss:

1. Lay the fixture on its side and attach the mounting hardware to the

center holes on the base. Refer to

Figure 1.8

center holes

Figure 1.8. Attaching Mounting Hardware

2. Install the fixture on the truss and secure the mounting hardware.

3. Loop the safety cables through an outer hole on the base of the unit,

around the handle, and out the other outer hole. Refer to

Figure 1.9.

Figure 1.9. Safety Cable Installation

Caution: Do not place safety cables through the lower plate that connects to the

1-10 Studio Color User’s Manual

fixture yoke. Doing so may cause interference with the fixture’s pan

movement.

Page 37

Data Cabling

To connect the data cables, complete the following procedure:

1. Connect the data cable from the controller to the Data In connector on the side

of the fixture. Refer to

Figure 1.10.

Figure 1.10. Data In and Data Out Connectors

2. Daisy chain additional fixtures by connecting the Data Out connector to the

Data In connectors on subsequent fixtures. Refer to Figure 1.11.

1

Introduction

Installation and

Setup

DMX controller

to additional

fixtures

N

I

A

T

D

A

T

U

O

A

T

A

D

E

R

W

P

O

S

t

u

d

i

o

C

o

l

o

r

DATA INDATA OUT

POWER

S

t

u

d

i

o

C

o

l

o

r

DATA OUT

DATA IN

DATA LINK

OUT

MIDI

IN OUT

SERIAL PORT

PERSONALITY

RS-232

A

POWER

S

t

u

d

i

o

C

o

l

o

r

B

1 2 3 4

1 2 3 4 5 6 7 8

L

R

ANALOG INPUTS

STEREO

CAUTION

1-6

7-12

AUDIO

SLAVEMASTER

FUSE

INPUT

REMOTE

1.6 amp

ENABLE

Figure 1.11. Daisy Chaining Fixtures

3. Install a terminator in the Data Out connector of the last fixture on each DMX

link.

4. Connect AC mains (power) and turn on the breaker located next to the power

cord on the side of each fixture. Refer to

Figure 1.10.

5. The fixture(s) will home and run through a built in self-test.

Note: if any error messages are present on the display, refer to Troubleshooting in

Appendix A.

voltage

select

115

Chapter 1 Installation and Setup 1-11

Page 38

DMX Starting Channel

Use the following subsections to set the fixture DMX starting channel. Starting

channels may be set by fixture number (1-32) or DMX channel number (1-512). Either

way, each fixture uses 16 DMX channels.

Setting the Starting Channel by Fixture Number

To set the starting channel by fixture number, complete the following procedure:

1. Apply power to the fixture.

Note: to skip the homing process, simultaneously hold down the <MENU> and

ENTER> buttons immediately after applying power to the fixture.

<

2. Observe the display on the front of the fixture. Initially, it will display the

software version (

3. Press and hold the <MENU> button until the display changes to the AddR

field. Press the <ENTER> button to manipulate the address field. Refer to

Figure 1.12.

V xxx) and then the fixture number (F 01).

4. Using the up and down arrow keys on the front of the unit, set the desired

5. Press the <ENTER> key to store the appropriate fixture number. The

Note: if the <ENTER> key is not pressed, the unit will not store the starting

6. Press the <MENU> button to exit the menu.

1-12 Studio Color User’s Manual

Figure 1.12. Using the Front Panel

fixture number (

F 01 to F 32). The display will flash when it is moved

from the stored value.

display will stop flashing.

channel.

Page 39

Setting the Starting Channel by DMX Channel Number

To set the starting channel by DMX channel number, complete the following

procedure:

Caution: if an incorrect starting channel is given, channels could overlap and produce

unexpected results.

1. Apply power to the fixture.

2. Observe the display on the front of the fixture. Initially, it will display the

software version (

3. Press and hold the <MENU> button until the display changes to AddR.

Refer to

4. Use the up and down keys to move to the SET field. Press <ENTER> to

enter the

5. Use the up and down keys to move to the CHNL field. Press <ENTER> to

enter the CHNL field.

6. Use the up and down keys to move to the DMX field. Press <ENTER> to

enable the fixture to accept addressing by DMX channel.

7. Press the <MENU> key to back out to the AddR (address) field.

8. Using the up and down keys on the front of the unit, set an the starting

channel from (

channels per fixture. Refer to Table 1.2 “DMX Starting Channel” on page

1-14 for assistance. The display will flash when it is moved from the stored

value.

Figure 1.12.

SET field.

Vxxx) and then the fixture number (F 01).

C 001 to C512). Studio Color fixtures require 16 DMX

1

Introduction

Installation and

Setup

9. Press the <ENTER> key to store the appropriate starting channel. The

display will stop flashing. The fixture address is stored in ROM and retains

its value until the value is changed.

Note: if <ENTER> is not pressed, the unit will not store the starting channel.

10. Press and hold the <MENU> button to exit the menu.

Chapter 1 Installation and Setup 1-13

Page 40

Patching DMX Controllers

Use the following table to patch (set the correct starting address) DMX controllers.

If your starting channels are assigned by DMX channel number, set each starting

address by adding multiples of 16.

Table 1.2: DMX Starting Channel

Fixture

Number

1 1 9 129 17 257 25 385

2 17 10 145 18 273 26 401

3 33 11 161 19 289 27 417

4 49 12 177 20 305 28 433

5 65 13 193 21 321 29 449

6 81 14 209 22 337 30 465

7 97 15 225 23 353 31 481

8 113 16 241 24 369 32 497

DMX

Starting

Channel

Fixture

Number

DMX

Starting

Channel

Fixture

Number

DMX

Starting

Channel

Fixture

Number

DMX

Starting

Channel

1-14 Studio Color User’s Manual

Page 41

DMX Control of Functions

Studio Color may be controlled by either by 8- or 16-bit DMX controllers.

Chapter 2 discusses all Studio Color functions in detail. Use the following

table to control Studio Color functions via DMX.

Table 1.3: DMX Control

DMX

Chan.

1 Pan MSB coarse positioning, 8 bit;

2 Pan LSB fine positioning 0-255 0-100 00-ffh

3 Tilt MSB coarse positioning, 8 bit;

4 Tilt LSB fine positioning 0-255 0-100 00-ffh

Function Description Decimal

0-255 0-100 00-ffh

8-bit controllers use only high

byte

0-255 0-100 00-ffh

8-bit controllers use only high

byte

Fader

percent

Hex

1

Introduction

Installation and

Setup

Chapter 1 Installation and Setup 1-15

Page 42

Table 1.3: DMX Control

DMX

Chan.

5 Color

Function Description Decimal

functions

default- color wheel continuous

F1- allows the color mixing

wheels to make two com

plete rotations

F2- locks dim, color, and effect

systems to MSpeed

F3- enables forward color spins

on the fixed color wheel or

synchronized color mix

sequences

F4- enables reverse color spins

on the fixed color wheel or

random color mix cycling

from the subtractive color

wheels

F5- color wheel color lock and

quickest path

default

F3

F4

F5

F1

F1 and F3

F1 and F4

F1 and F5

F2

F2 and F3

F2 and F4

F2 and F5

F1 and F2

F1, F2, and F3

F1, F2, and F4

F1, F2, and F5

-

0

16

32

48

64

80

96

112

128

144

160

176

192

208

224

240

Fader

percent

0

8

14

20

26

33

39

45

51

58

64

70

76

83

89

95

Hex

00

10h

20h

30h

40h

50h

60h

70h

80h

90h

a0h

b0h

c0h

d0h

e0h

f0h

1-16 Studio Color User’s Manual

Page 43

Table 1.3: DMX Control

DMX

Chan.

6 Color

Function Description Decimal

wheel

default- continuously variable

pos 0 - open

pos 1 - CTO

pos 2 - pink

pos 3 - magenta

pos 4 - red

pos 5 - aqua

F3- variable forward spins/synchronized color mix sequences

spin stop

spin forward slowest

spin forward fastest

color mix sequence slowest

color mix sequence fastest

F4- variable reverse spins /random color mix cycling

spin stop

spin reverse slowest

spin reverse fastest

color mix cycle slowest

color mix cycle fastest

0 & 255

44

86

128

170

213

0-3

4

127

128

255

0-3

4

127

128

255

Fader

percent

0 & 100

17

34

50

66

83

0-1

2

48

50

100

0-1

2

48

50

100

Hex

00 & ffh

2ch

56h

80h

aah

d5h

00-03h

04h

7fh

80h

ffh

00-03h

04h

7fh

80h

ffh

1

Introduction

Installation and

Setup

F5- color lock and quickest path

pos 0 - open

pos 1 - CTO

pos 2 - pink

pos 3 - magenta

pos 4 - red

pos 5 - aqua

7 Cyan mix red subtractive

cyan in

cyan out

8 Magenta

mix

9 Yellow

mix

green subtractive

magenta in

magenta out

blue subtractive

yellow in

yellow out

0-43

44-85

86-127

128-169

170-212

213-255

0

255

0

255

0

255

0-17

18-33

34-50

51-66

67-83

84-100

0

100

0

100

0

100

0-2bh

2ch-55h

56h-79h

80h-a9h

aah-d4h

d5h-ffh

00h

ffh

00h

ffh

00h

ffh

Chapter 1 Installation and Setup 1-17

Page 44

Table 1.3: DMX Control

DMX

Chan.

10 Lens

11 Frost

12 Shutter closed

Function Description Decimal

full rotation, continuously vari-

wheel

(effects

wheel 1)

wheel

(effects

wheel 2)

able

open

wide angle filter

narrow horizontal shaping center

axis

wide vertical shaping center axis

full rotation, continuously

variable

open

frost

narrow vertical shaping center

axis

wide horizontal shaping center

axis

strobe slowest

strobe fastest

random strobe-low saturation

random strobe-high saturation

open

0 & 255

64

128

192

Fader

percent

0 & 100

25

50

75

Hex

00 & ffh

40h

80h

c0h

0 & 255

64

128

192

0-7

8

127

128

247

248-255

0 & 100

25

50

75

0-2

3

49

50

96

97-100

00 & ffh

40h

80h

c0h

00h-07h

08h

7fh

80h

f7h

f8h-ffh

13 Dimmer iris

closed

open

14 MSpeed movement speed