HIGHADVENTURE BEAMER 3, BEAMER 3 LIGHT Owner's Manual

2

This manual must be read before you install the reserve!

This manual tells you how to use your reserve correctly. If you have any questions about using the reserve you

should contact High Adventure direct for an answer.

If you need a professional to pack or repair your reserve please contact your dealer or High Adventure.

INHALT

Safety information ................................................................................................................................ 3

Technical Data ...................................................................................................................................... 3

intended purpose ................................................................................................................................. 4

operating limits ..................................................................................................................................... 4

documents you should have ................................................................................................................. 4

How to use the reserve ........................................................................................................................ 4

care and maintenance .......................................................................................................................... 4

storing ................................................................................................................................................... 5

Packing and checking intervals ............................................................................................................. 5

if damage is found ................................................................................................................................ 5

Repairs .................................................................................................................................................. 5

packing and installing instructions ....................................................................................................... 6

Installing in a harness reserve compartment ..................................................................................... 23

compatibility test ................................................................................................................................ 24

preflight check .................................................................................................................................... 24

3

SAFETY INFORMATION

This paraglider reserve must not be used for parachuting, free-falling or base jumping!

The user of this reserve system does so at his own risk. The manufacturer cannot be held responsible for any damage to persons or property that may arise from the use of this reserve system. Flying behaviour can be negatively

affected when the parachute is wet (after a landing in water).

Deployment system warning: this parachute system has been tested and found compliant using the original manufacturer's inner container. Use of any other inner container may produce different results, including failures.

It is essential that this reserve parachute is correctly installed in the harness and a compatibility test then carried

out by a suitably qualified person. Safe operation can only be guaranteed if the reserve has been installed correctly.

TECHNICAL DATA

(*) Extended Weight Range

Although the EN/LTF flight tests showed a 3,7 m/sec descent rate at 100 Kg, our own experience also tells us that

highly loaded Rogallos, like conventional reserve parachutes, can lead to mirror flying or down-planing when combined with the paraglider. This mainly happens with very stable and collapse resistant school gliders, or in very

steady throwing conditions such as training openings over water. The EN/LTF practical tests are always carried out

in separated configuration - without the troublesome paraglider. When developing our Rogallo reserve parachutes

we focus a lot of attention on the overall functioning spectrum, above all in connected condition (when the paraglider is not cut away).

Despite the positive flight tests at more than 100kg we recommend that the extended weight range is only for use

by experienced “Rogallo pilots”, or in conjunction with a reliable cut-away system.

Manufacturer High Adventure AG

Wiesenbergstrasse 10

CH-6383 Dallenwil

Switzerland

Beamer 3 Beamer 3 light Beamer 3 S Beamer 3 light S

Area: 41.75 m² 41.75 m² 35.47 m² 35.47 m²

Weight: 1785 g 1370 g 1590 g 1180 g

Weight including inner container: 1835 g 1420 g 1640 g 1230 g

Volume: 4959 ccm 3837 ccm 4432 ccm 3324 ccm

No. of panels: 18 18 16 16

Max. Load: 130 kg 130 kg 90 (100)* kg 90 (100)* kg

Inspection ID: EP/RG 073.2013 EP/RG 101.2013 EP/RG 102.2013 EP/RG 104.2013

4

INTENDED PURPOSE

Manually deployed emergency parachute for solo paraglider pilots.

OPERATING LIMITS

Maximum deployment speed: 115 km/h (32 m/s)

Packing interval: every 6 months; and each repacking should be recorded in the reserve packing record.

Inspection: We recommend that a full inspection is carried out every 24 months. This inspection should be record-

ed in the repacking record.

Certified operating life: 12 years, extended to 14 years by inspections every 12 months.

Caution: the certified life depends very much on the style of use and quality of care of your Beamer 3 (acro, test

openings etc. can significantly reduce the reserve’s life). The Beamer 3 light is not suitable for use in the acro discipline.

DOCUMENTS YOU SHOULD HAVE

• Owner’s manual

• Repacking and check record

HOW TO USE THE RESERVE

In an emergency give the reserve handle a determined pull. This will open the outer container and release the

inner container. Throw the inner container (the reserve is inside) far away with an energetic swinging action, letting go of the reserve handle at the same time (it is fixed to the inner container – its job is over)!

The inner container is designed so that the lines stretch out first, followed by the reserve canopy. This makes sure

the canopy does not open too soon, and this minimises the risk of the reserve becoming tangled up with the paraglider, the pilot, or anything else nearby (e.g. another flying machine if there has been a collision etc). For a fast

reserve opening the inner container needs enough speed after the pilot has thrown it. In general one can say: the

faster the throwing speed the faster will the reserve pay out and open.

The reserve inner container opens after it has been thrown. The strong throw, and/or the available airflow,

stretches out the lines, then the canopy, and the reserve will open.

When the reserve is fully open height above ground should first be assessed. If there is plenty of height available

the possibility of disabling the paraglider should be considered so as to minimise the problem of paraglider and

reserve scissoring (racing each other to the ground). If there’s not enough height for this the pilot should concentrate on the ground coming up and prepare for touchdown.

CARE AND MAINTENANCE

The Beamer 3 has been designed for high loads and extreme demands. Especially long-lived materials have been

chosen accordingly. To a great extent, however, the lifespan depends on the care and attention of the user and we

recommend that the reserve is regularly inspected for signs of wear - and that if any damage is found the Beamer

3 should be immediately returned for repair to High Adventure, or a workshop authorised by High Adventure.

5

Pay special attention to the following advice:

• Do not leave the reserve out in the sun (UV radiation) unnecessarily.

• A wet or damp reserve should be completely unpacked and allowed to dry inside at room temperature, or

outside in the shade.

• Do not expose a packed reserve to large temperature changes, and do make sure it gets enough air circu-

lation in cars and building so that condensation does not form.

• Deal with the reserve carefully on the ground after an opening, or during SIV training.

• After contact with seawater the reserve must be thoroughly rinsed with fresh water.

• Only clean the reserve with fresh water, and a little neutral soap if required. Never use solvents.

Caution: Chemicals, cleaning agents, insects, stains etc. can affect the strength of the parts as much as physical

abuse.

STORING

Do not store the reserve anywhere near oils, fats, acids and dyes. It should be stored in a well ventilated, dry

space. Reserves that are not to be used for a long time should be stored unpacked.

PACKING AND CHECKING INTERVALS

The reserve must be aired every 6 months and repacked in accordance with the packing instructions. This will

ensure a reliable and fast opening every time. If the reserve gets wet, damp, or has been exposed to extreme heat

it must be aired straight away and repacked.

If the reserve is thrown in an emergency or during SIV training it should be inspected by the manufacturer or an

authorised service centre. The reserve should also be thoroughly checked by a qualified person if it gets overloaded (e.g. tree landing).

IF DAMAGE IS FOUND

If damage is discovered during a check the reserve should be sent to High Adventure for repair. This applies to any

damage where you cannot be certain that the reserve is still airworthy. Repairs must only be done by the manufacturer!

REPAIR S

Basically you are not allowed to repair a reserve yourself. The various seams and the lines are made with great

precision. Only the manufacturer or an authorised service organisation may do repairs, using original materials.

6

PACKING AND INSTALLING INSTRUCTIONS

Before packing the reserve must be visually checked by the packer. Then the reserve should be aired in a humidity

of 60 – 65 % for 24 hours. Packing should be done on a packing table if possible, or at least on a clean static-free

surface.

Equipment needed for packing

• Line separator. Only the centre slot will be used.

• Several shot bags. The reserve is not tensioned from both ends: these are very useful – have enough.

• Elastic bands (must be new for every packing - original elastic bands are available from High Adventure)

• Packing tools for putting the reserve in the harness

We strongly recommend that a trained and qualified person does the packing.

Fixing to the harness

The Beamer 3 can be stowed in a front container or a harness reserve compartment.

The reserve risers marked “L” & “R” will be fixed on the relevant left and right (in the direction of flight) hand sides

of the harness on the main carabiners (front container) or shoulder harness loops.

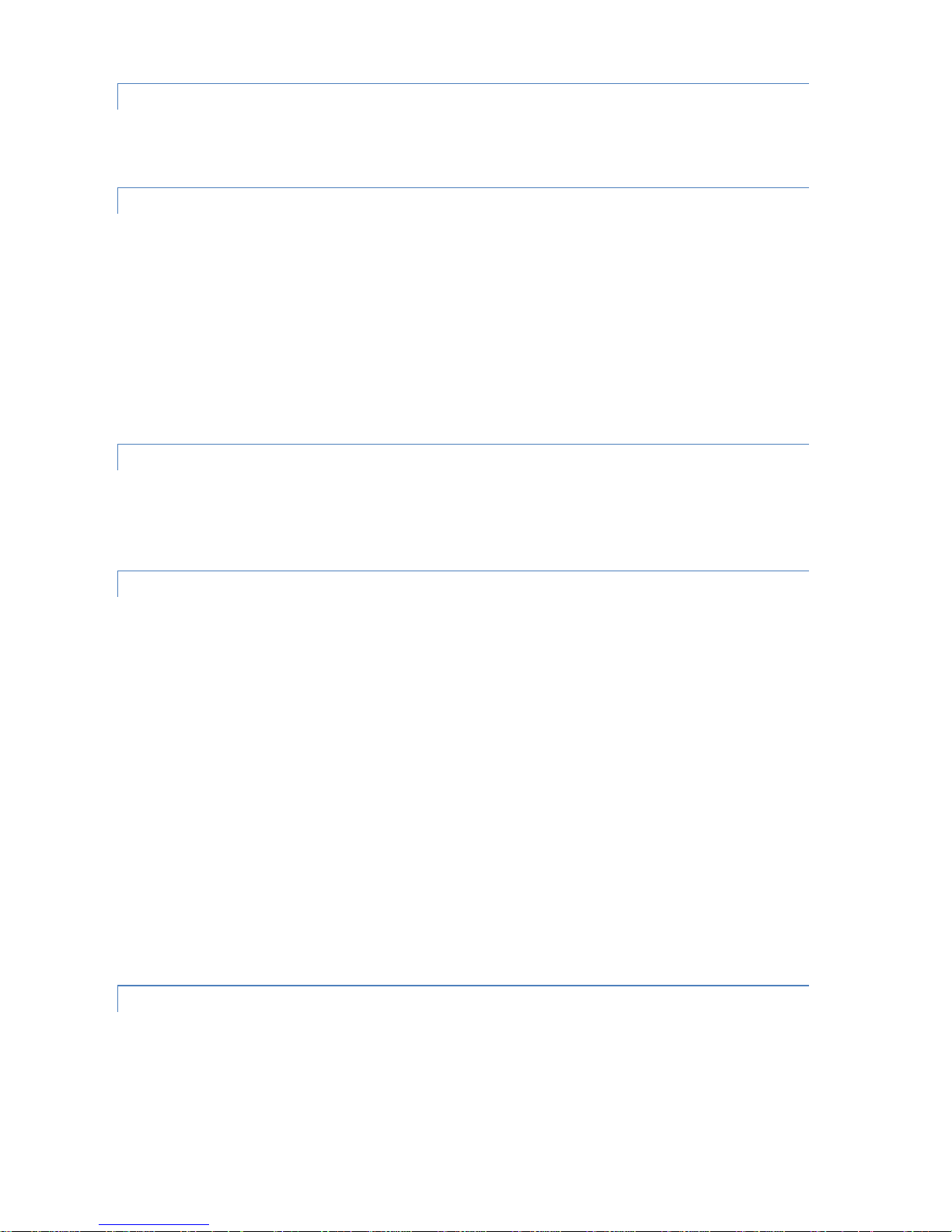

Pic. 1 Attachment on main carabiners

Pic. 2 Shoulder harness attachment

Note: The “L” & “R” markings on the reserve risers face rearwards relative to the direction of flight (similar to the

paraglider riser attachment). The riser colours may be different, but the L and R indications apply.

Brake handle position

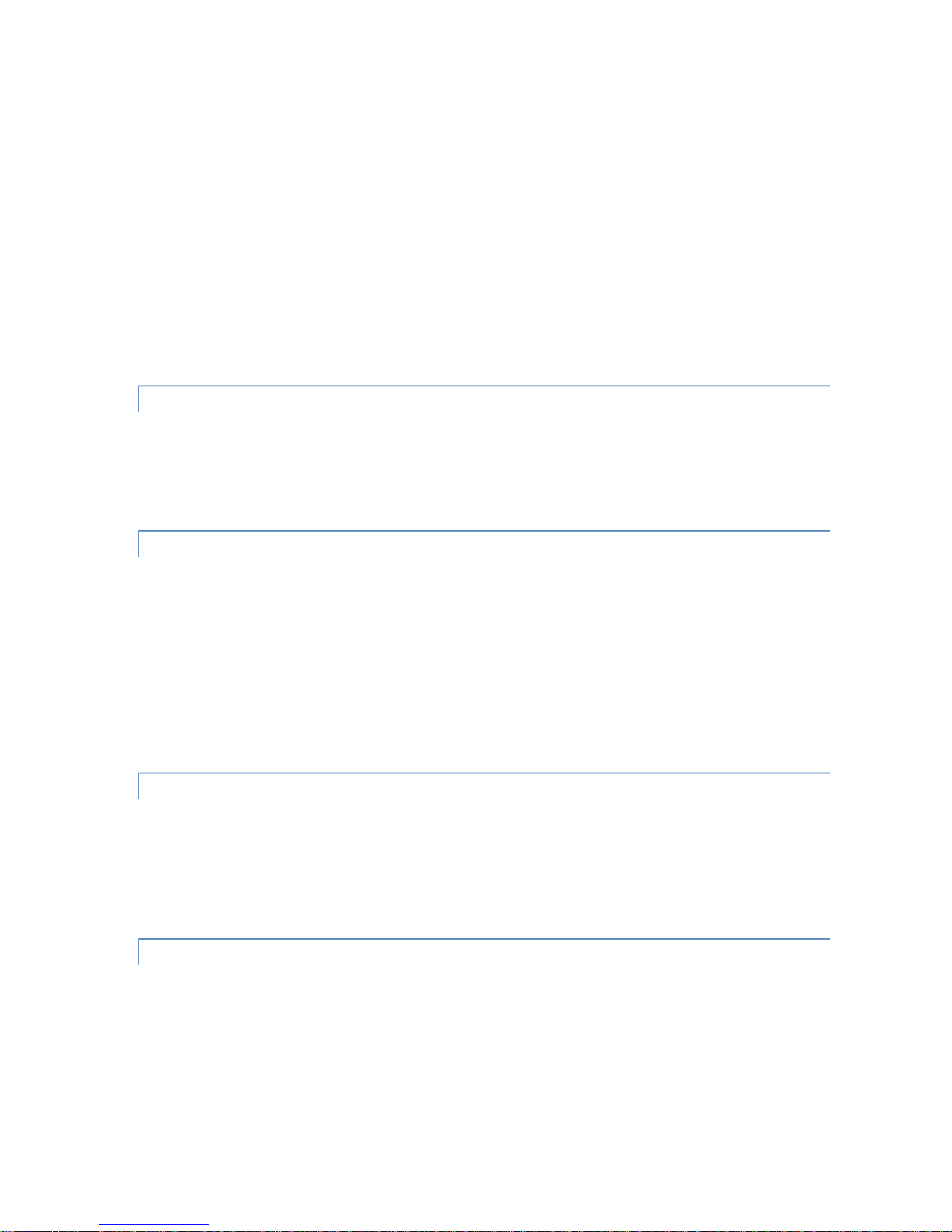

Reserve riser extensions are needed for front container mounting to get the brake handles in the right position

(See Pics 1 & 2). The riser extensions (optional accessory - Pic. 3) are looped through the ends of the risers and

secured with O-rings (Pics. 4-11). This arrangement has been dynamically load tested.

7

Pic. 3

Art. Nr. 000345 extensions for

Beamer 3 Dyneema risers &

Art. Nr. 000140 O-Ring 22mm

Pic. 4

Pic. 5

Pic. 6

Pic. 7

Pic. 8

Pic. 9 O-Ring 2 turns

Pic. 10

Pic. 11

8

Reserve/Harness connections

Pic. 12

Art. Nr. 000136 Maillon Rapide

Ref. MRDI06.0 – Stainless (INOX)

Art. Nr. 000140 O-Ring 22mm &

Art. Nr. 000141 O-Ring 32mm

Pic. 13

Art. Nr. 000137 Maillon Rapide

Ref. MRNI06.0 – Stainless (INOX)

Art. Nr. 000140 O-Ring 22mm

Caution: Minimum safe load

2,250kg per quicklink!

Pic. 12

Pic. 13

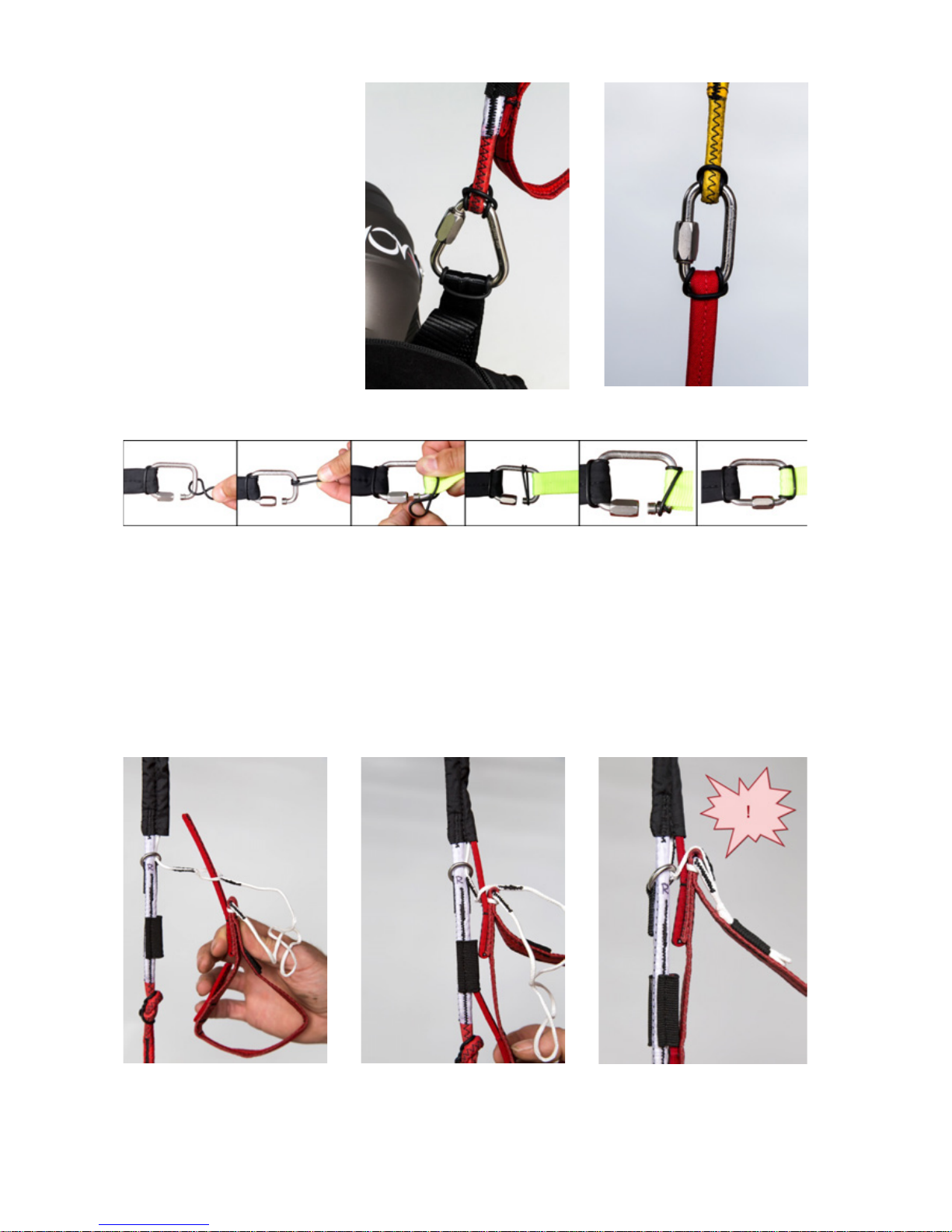

Preparing the braked opening configuration

Our pre-braking concept gives the Beamer 3 two flight phases. The canopy opens in its braked condition. This

means that the Beamer 3 flies with very little forward speed at first. When the pilot takes the brake handles this

braked position is released and the Beamer takes up its proper gliding flight.

The braked opening setting must be set before packing. When the brake handles are fixed in their correct positions the brake lines are shortened on the Beamer 3 / Beamer 3 light by approx. 42 cm and around 25 cm on the

Beamers in small size. There is a loop in the brake line at this distance. The brake handle stick goes through this

loop (Pic. 14).

Pic. 14

Pic. 15

Pic. 16 Stow the brake stick out-

side the metal ring!

Stow the extra length of brake line in the elastic loop on the brake handle (Pic. 16).

Loading...

Loading...