Hi-Flame GloFire 905 Installation And Operating Instructions Manual

GloFire 905

Installation and Operating Instructions

Henan Hi-Flame Metal Co. Ltd., 71 Welai Rd., Zhengzhou, China 450008

Save These Instructions

Tested to UL 1482 by Intertek

U.S EPA Phase II Certified Stove

Please read this entire manual before you install and use your new room

heater. Failure to follow instructions may result in property damage, bodily

injury, or even death.

Safety Notices

When this room heater is not properly installed, a house fire may result. To reduce the

risk of fire, follow the installation instructions. Contact local building, fire officials, or

authority having jurisdiction about restrictions, permit and installation inspection

requirements in your area.

DO NOT INSTALL IN A MOBILE HOME.

DO NOT USE CHEMICALS OR FLUIDS TO START THE FIRE.

DO NOT BURN GARBAGE OR FLAMMABLE FLUIDS SUCH AS GASOLINE, NAPHTHA OR

ENGINE OIL.

HOT WHILE IN OPERATION. KEEP CHILDREN, CLOTHING AND FURNITURE AWAY.

CONTACT MAY CAUSE SKIN BURNS.

Do not tamper with or use the spin draft air control in the fuel loading door. Using this

control will cause an overtiring condition.

Page 1

INSTALLATION

Assembling the GloFire 905

1. Open the door and unfasten the wire on the fire fence. It is used to ensure that the

fire glass does not break during transportation.

2. Take the packet containing the spare parts and screws from the ash pan.

3. Fix the flue collar on the outlet which you selected by using the M6*20 flat

crosshead screw. Ensure all seals are secure to prevent air leakage. If you choose

the rear flue outlet, remove the flue cover before fixing the flue collar.

4. Fix the black handle on the stainless steel door catch with the M8*90 bolt.

5. Keep the rest of the screws and Allen wrench for future use.

Page 2

Floor Protector

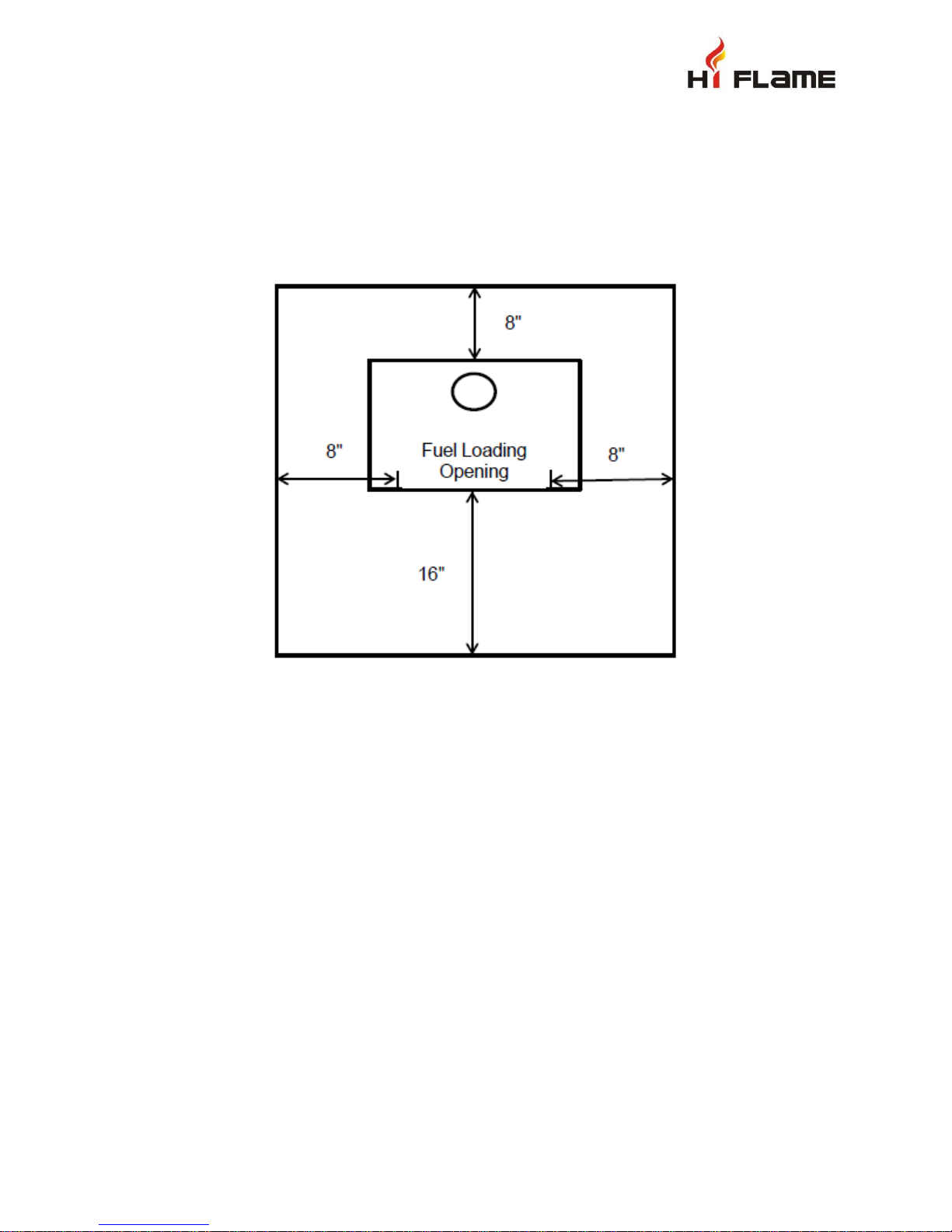

If the stove is to be installed on a combustible floor, it must be placed on an approved

1” (25mm) non-combustible hearth pad with k = 0.42 (BTU)(in)/(ft2)(hr)(oF). The floor

protector must extend 8” beyond each side of the flue loading and ash removal opening

and 16” to the front.

In a rear vent installation the floor protection must also extend under the stovepipe and

a minimum of 2” (50mm) beyond either side of the pipe.

Page 3

How to determine if alternate floor protection materials are acceptable.

893.075.0

84.0

11

xT

k

R

431.042.0

rick

R x

b

431.0125.0

29.0

1

R x

board mineral

T

k

1

R

T

12xK

1

R

Btu

)F

o

)(hr)(

2

(ft

R

12xK

)F

o

)(hr)(

2

ft(

(Btu)(in)

k

)F

o

)(hr)(

2

ft(

(Btu)(ft)

K

k

1

)in)(Btu(

)Fo)(hr)(

2

(ft

r

All floor protection must be non-combustible (i.e., metals, brick, stone, mineral fiber boards,

etc.). Any organic materials (i.e., plastics, wood paper products, etc.) are combustible and

must not be used. The floor protection specified includes some form of thermal designation

such as R-value (thermal resistance) or k-factor (thermal conductivity).

PROCEDURE:

1. Convert specification to R-value:

i. R-value given - no conversion needed.

ii. k-factor is given with a required thickness (T) in inches:

iii. K-factor is given with a required thickness (T) in inches:

iv. r-factor is given with a required thickness (T) in inches: R = r x T

2. Determine the R-value of the proposed alternate floor protector.

i. Use the formula in step (1) to convert values not expressed as “R”.

ii. For multiple layers, add R-values of each layer to determine overall R-value.

3. If the overall R-value of the system is greater than the R-value of the specified floor

protector, the alternate is acceptable.

EXAMPLE: The specified floor protector should be 3/4-inch thick material with a k-factor of

0.84. The proposed alternate is 4” brick with an r-factor of 0.2 over 1/8” mineral board with a

k-factor of 0.29.

Step (a): Use formula above to convert specification to R-value.

Step (b): Calculate R of proposed system.

4” brick of r = 0.2, therefore:

1/8” mineral board of k = 0.29, therefore

R

total

= R

brick

+ R

Step (c): Compare proposed system R

system R

is greater than required, the system is acceptable.

total

DEFINITIONS:

mineral board

= 0.8 + 0.431 = 1.231

of 1.231 to specified R of 0.893. Since proposed

total

Page 4

Loading...

Loading...