Hi-Flame Alpha Inset AL357i Instruction Manual

Instruction Manual

Model AL357i Alpha Inset

The

ALPHA

Collection

Multi Fuel and Wood Burning

Non-Boiler Inset Stove

Published August 2012

Please note This appliance has been independently

CE tested and approved for the burning of wood

and multi fuels and must, at all times, be used in

accordance with these instructions to ensure safe and

efficient operation.

You will need to refer to the serial number of your

stove should you ever need to make a claim under

the Alpha Warranty. You will find the serial number,

beginning with AL, on the CE plate at the rear of the

stove as well as on the lid of the outer packaging.

Write the date the stove was delivered to you below

as this is likely to differ from the purchase date.

- -

Ref: AL357i / UK-NI-ROI / V1.01-08-12

www.alphastoves.com

CONTENTS

Standard Features

Technical Data

Important Safety Advice

Installation Regulations

Buildings Insurance

Health & Safety

Packing List

Assembling the Stove

Removing the Baffle Plate

Smoke Control Areas

Recommended Fuels

Prohibited Fuels

Understanding Fuel Types

Burning Wood Logs

Burning

Overnight Burning

Removing Ash

Installation Check-list

Installation General Guidelines

Fitting Instructions

Commissioning

Important: First Fires

Trouble-shooting

Standing Down

Routine Checks

Routine Maintenance

Alpha Warranty

Spare Parts

Annual Service

Service Record

Mineral Fuels

Page

10

11

11

12

13

15

17

17

18

20

20

20

22

22

23

23

INTRODUCTION

Thank-you for purchasing the

3

3

4

4

4

4

5

5

6

7

7

8

8

9

Alpha Inset stove. We are confident

that it will warm your home even on

the coldest winter days and provide

you with many years of pleasurable

heat.

Before you install or operate your

inset stove however, please read this

booklet which contains important

safety advice as well as instructions

which will help you make the most of

your new stove.

All users of this stove should be aware

of the contents of this handbook. If

other people are going to operate the

stove then please keep this booklet

handy so that it can always be quickly

referred to.

Never let anyone use the stove who is

unfamiliar with its correct operation.

PLEASE NOTE

This instruction manual is also used for a number

of other inset stove models in the Hi-Flame product

range and therefore some of the stove photographs

and diagrams used, which are used for guidance

purposes only, may differ slightly from your new

Alpha Inset stove. However, the principles illustrated

here remain the same.

Hi-Flame Fireplace (UK) L

2

imited

TECHNICAL DATA

General Specification

Model Name

Model Number

Dimensions (mm): Facia H605 W490 D95

Dimensions (mm): Firebox Ext H

Net Weight 83 kg

Gross Weight (packed)

Alpha Inset

AL357i

515 W380 D175

95 kg

IMPORTANT

In the interests of safety please read these

instructions carefully before installing or

operating your new stove. Even if you have

installed or operated stoves before, remember

manufacturer’s requirements can vary and can

also change with updates to building

regulations. If you are installing this stove in a

UK Smoke Control Area the Alpha Inset can only

be fuelled with approved smokeless fuels – it

will be illegal to burn wood in it.

Data from CE Test EN13240

Fuel Mineral Fuel & Wood Logs

WOOD

Nominal Heat Output 4.9 kW

Test Duration (appro

Efficiency (net)

Mean CO Emission (at 13%) 0.15

Mean Flue Gas Temperature

Flue Gas Mass Flow 4.8 g/s

ANCIT (mineral fuel)

Nominal Heat Output (wood) 4.8 kW

Test Duration (appro

Efficiency (net)

Mean CO Emission (at 13%) 0.21

Mean Flue Gas Temperature

Flue Gas Mass Flow

Minimum Distance to Combustible Materials

Top (shelf)

Sides

Flue

Flue configuration

Flue pipe / liner diameter 150 mm (6”)

Minimum flue height

from base of stove 4500 mm (15’)

Wood Fuel Requirements

Wood Logs: Moisture content

Maximum Log Length 250 mm

x) 1.02 hrs

75.2%

302ºC

x) 3.99 hrs

68.3%

312ºC

6.3 g/s

600 mm

250 mm

top only

<20%

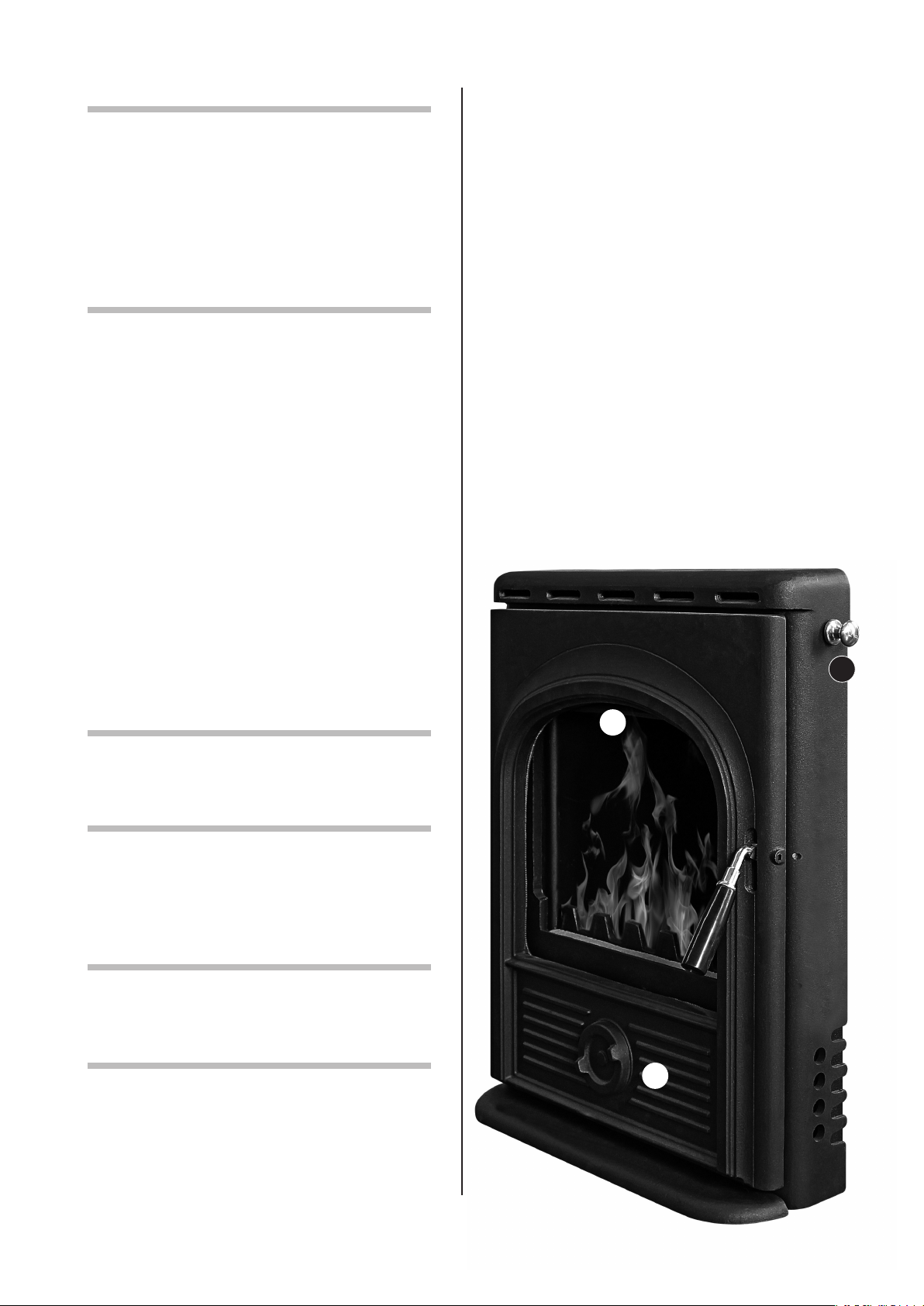

STANDARD FEATURES

1 Primary Air Control Air which enters under the

grate for multi fuel burning and to help get a wood

fire started

2 Secondary Air Control Air which enters at the top

of the fire chamber to ensure a cleaner burn and

effective wood burning (pull out to open)

3 Airwash System Part of the secondary air control

system which diverts hot air down along the front of

the glass to burn off unwanted sooty particulates and

help keep it clean

2

3

1

3

IMPORTANT SAFETY ADVICE

• Ensure that an approved carbon monoxide detector

(BS EN50291:2001) is fitted in the same room as the

stove. It should be powered by a battery designed for

the working life of the alarm. Please note this is now a

requirement under UK Building Regulations.

• External surfaces including the fire chamber door

and operating handles, windows and stove bodywork

will become extremely hot. Always use the tool

provided and avoid touching these parts of the stove

without proper protection, such as heat-resistant

gloves or other protective aids.

• Potentially combustible material or objects such as

soft furnishings should never be left on or near any

of the stove’s hot surfaces. Ensure that wood supplies

and log baskets are kept at a safe distance from the

stove. See Minimum Distance to Combustibles page 3

• Never leave children unattended in the room where

your stove is being operated. Ensure that children are

aware of the potential danger and make sure that

they keep clear of the stove when it is in operation.

Where children, the elderly or the infirm are present

always use an approved safety fireguard (BS6539) to

prevent accidental contact with the stove.

• This stove should not be fitted in a room with an

extractor fan (eg kitchen) as this will adversely effect

the air quality in the room and could be dangerous for

the room’s occupants. It will also starve the stove of

combustion air and reduce the stove’s efficiency.

• To ensure your safety make sure that your stove’s

installation complies with all local, national and

European building regulations’ ventilation requirements.

Low energy houses have their own particular

requirements and should be strictly adhered to.

• Do not use flammable liquids to ignite the fire. In

the confined space of the stove’s fire chamber there is

a real potential to cause a life-threatening flash flame

or explosion.

• Never over-fire the stove. If any external parts of

your stove glow red during operation then immediate

action should be taken to reduce the supply

of combustion air to the fire chamber through the

Primary and Secondary air controls which should

quickly limit the intensity of the fire.

• This stove is CE approved and tested to EU EN13240

standards in the United Kingdom by Kiwa GasTec at

CRE of Stoke Orchard, Gloucestershire. Alterations to

its construction could be potentially dangerous and

will also render your product warranty void.

• Do not use aerosol products in the vicinity of the

stove when it is in use.

• Check and clean the stove’s flue way and the top

of the baffle plate regularly to help avoid potential

blockages.

• Clean your chimney regularly

.

INSTALLATION REGULATIONS

You must ensure that your stove is installed by a

recognised competent person who is appropriately

qualified in the installation of stoves and that the

installation complies with all local, national and

European building regulations.

In the UK we strongly recommend using a Hetas

registered installer (www.hetas.co.uk) and in Ireland

a registered installer from INFO – the Irish

Nationwide Fireplace Organisation (www.fireplace.ie).

For further information please consult:

England & Wales

Building Regulations Document J (revised October

2010) – Combustion Appliances and Fuel Storage

Systems www.planningportal.gov.uk

Scotland

Building Standards (2001) Domestic

www.sbsa.gov.uk

Northern Ireland

The Building Regulations (Northern Ireland) 2000 /

Amendment 2006 / Amendment No 2 2006

www.buildingcontrol-ni.com

Isle of Man

Building Regulations (2007) – Isle of Man

www.gov.im

Republic of Ireland

Approved Document J – Heat Producing Appliances

www.environ.ie

Other Information Points

For additional useful information and links to the

government websites above, including informative

downloads, visit www.soliftec.com.

The Solid Fuel Association website is also a very good

source of practical information and downloads

www.solidfuel.co.uk.

The British Flue and Chimney Manufacturers

Association website, accessed through

www.feta.co.uk/bfcma, produces an authoritative and

informative download Yellow Guide to solid fuel flues

and chimneys.

BUILDINGS INSURANCE

It is a requirement by some building insurance

companies to inform them of the installation of a new

fixed heating appliance and a relevant certificate of

compliance produced.

HEALTH & SAFETY

During the installation of this stove and any related

building works you must comply with any current

Health & Safety at Work regulations. Always use

protective gloves and use the tool when adjusting the

air controls. When using fire cement always follow the

manufacturers instructions.

4

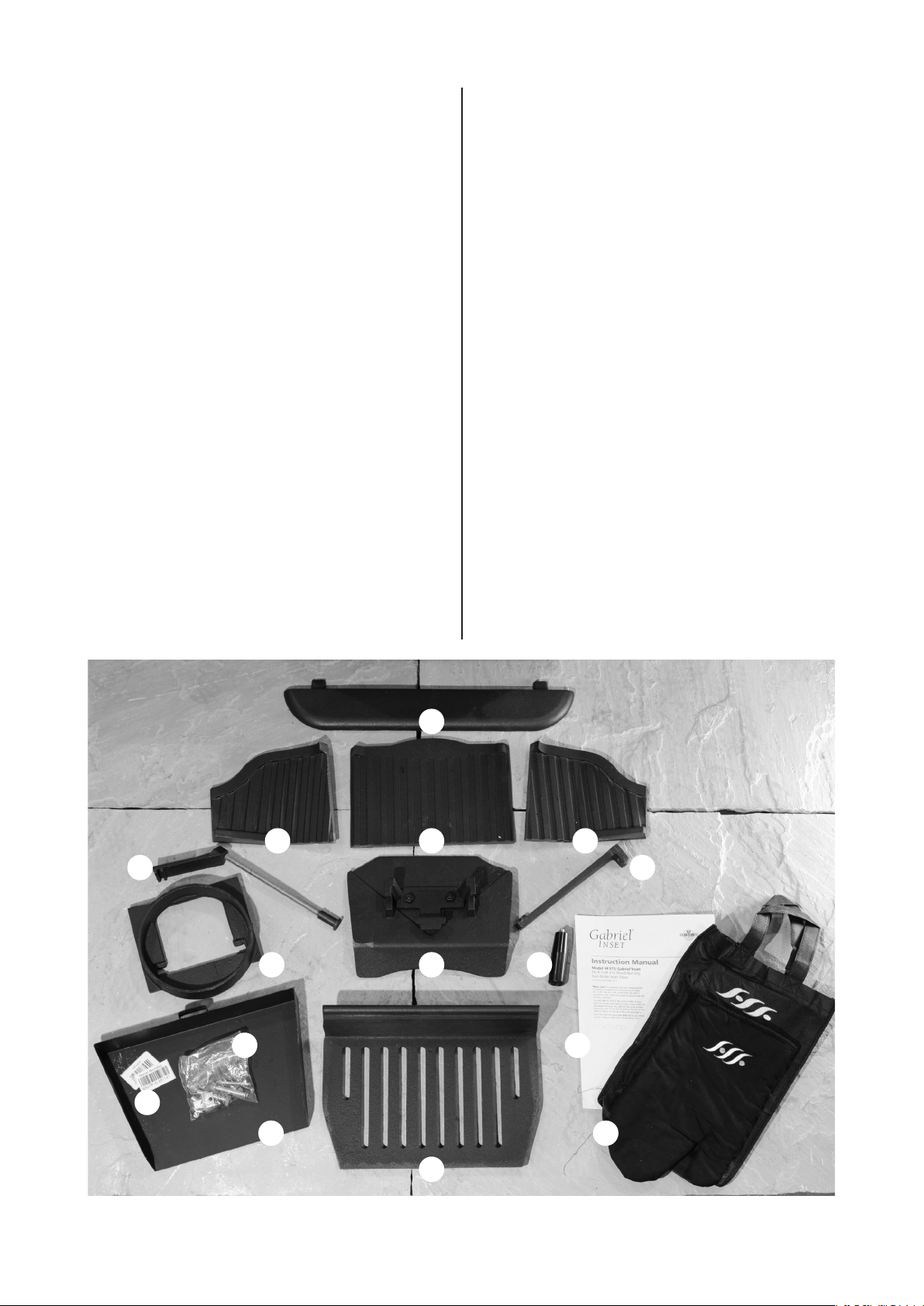

PACKING LIST

As soon as you receive your new stove please check

that you have a full set of components as set out in

the list below. In the unlikely event of a shortage,

please report this immediately to the dealer you

bought the stove from. Never attempt to operate the

stove with missing or damaged components.

Product Information

A This Instruction Booklet and Warranty Card

B Stove Serial Number

Stove Components

C Handle Cover and Handle Cover Securing Bolt

D Locking Bolt and Retaining Clamp for top fixing

E Outer Flue Spigot / Plate

F Ash Lip

G Screw and Anchor for base fixing

H Fire Grate and integral Log Bar (in place)

I Cast Iron Firebricks – Left, Right and Back (in place)

J Baffle Plate (Located inside roof of fire chamber)

Equipment

K Shaped Ash Pan

L Operating Tool

Tool Bag

M Safety Mitten

G Spare Glass Retaining Clips

G Spare Glass Retaining Clip Screws

G Allen key (for door hinges)

M Spare Door Rope Seal

ASSEMBLING THE STOVE

Your new inset stove is extremely heavy. Always

handle with care and make sure that you have

additional strong help when you move it.

The door and door handle, should never be used to

grip the stove as they could be damaged from

supporting the stove’s weight. Items, such as the cast

iron fire bricks, fire grate and baffle plate can all be

easily removed to help reduce the weight. Under no

circumstances should the door be removed as this will

invalidate your Alpha Warranty.

Always lift the stove to finally position it.

Alternatively it may be possible to place the stove on

heavy duty plastic sheeting or thick floor covering to

slide the stove into position, being careful not to

damage any finished floor or decorative hearth

surfaces with trapped grit or building debris.

• Unpack Remove your new stove from its recyclable

packaging. Retain this until the stove is installed and is

fully operational. Unfasten retaining wires and remove

any components, including those inside the ash pan,

from inside the stove.

• Inspect Please inspect the stove to check that it

has not been damaged in transit – never attempt to

install a stove which has been damaged. If damage is

suspected then report this immediately to your stove

dealer.

D

F

I

I

I

L

C

A

G

E

J

B

K

M

H

5

• Check List Study the Packing List on page 5 and

make sure that you have received all of the

components listed before proceeding. Some

components are contained within the ash pan or will

already be fitted to the stove.

• Baffle Plate Check the position of the baffle plate

(sometimes known as the throat plate) inside the

‘roof’ of the stove to ensure that it has not moved

during transit. This is a heavy metal plate which directs

flames and helps retain heat inside the stove.

C

A

A

• Handle Assembly Thread the split washer along

the handle bolt. Feed the bolt and washer through the

handle grip. Use a Phillips crosshead screwdriver to

attach the assembled grip to the door handle clamp

mechanism on the door, being careful not to

over-tighten.

Your inset stove is now ready for installation.

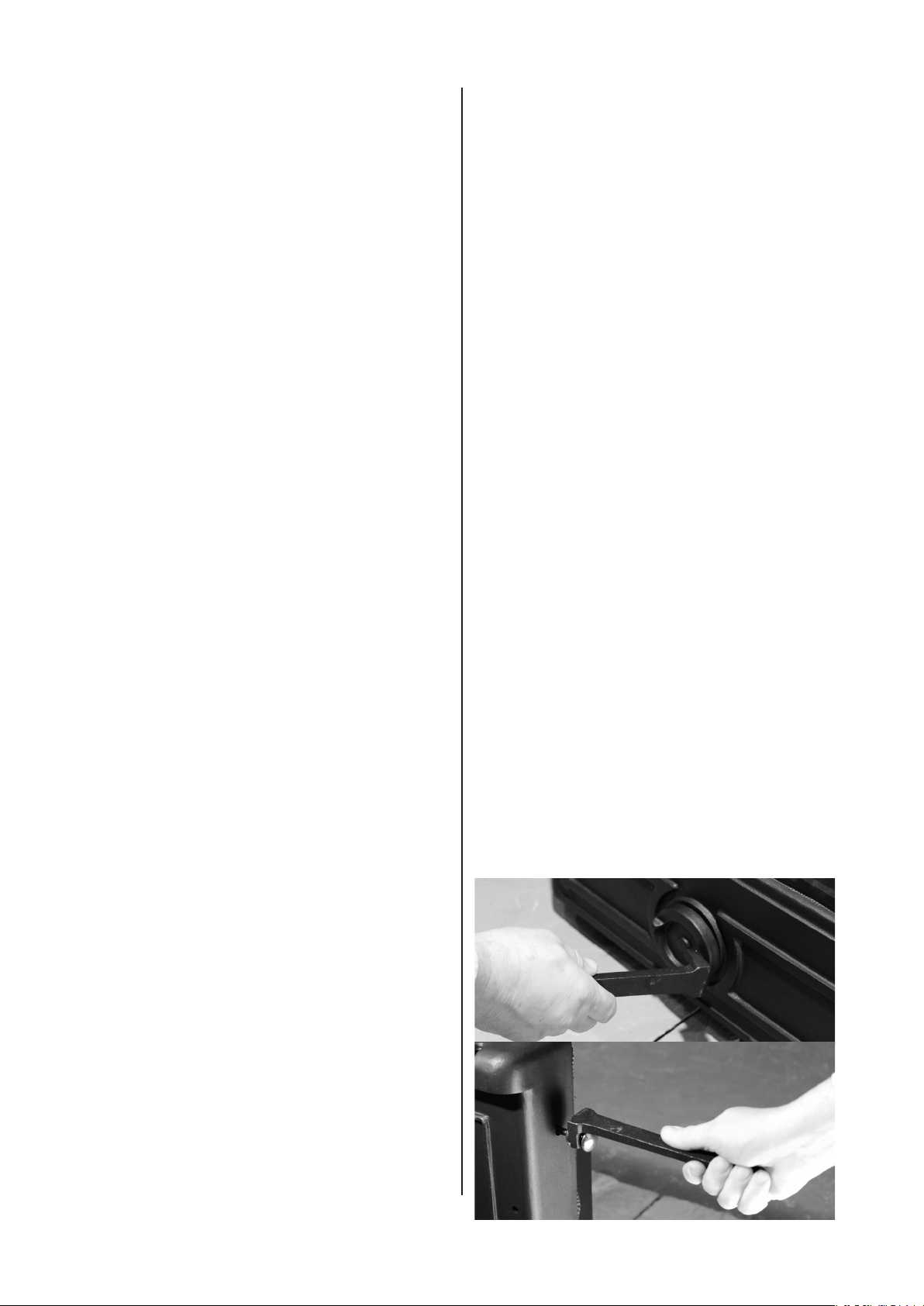

REMOVING THE BAFFLE PLATE

Regular checking of the baffle plate will ensure that

the stove’s flueway stays clear of soot as well as its

continued safe and efficient operation. If you have

never owned a stove before it is important to

understand how critical this aspect of operating a

stove is. As stated previously it is best to familiarise

yourself with this before the stove is installed. With

the Alpha Inset there are no fixing brackets, bolts or

fire bricks to remove – simply put your hand inside the

‘roof’ of the fire chamber and push upwards. This will

release the plate which should then be pulled

forward and dropped down inside the stove ready for

inspection and cleaning.

It is best to fully familiarise yourself with the baffle

plate’s correct location by practising removing it and

re-fitting it prior to the stove’s installation as you will

need to regularly check the top of this plate and the

access to the flue way to avoid potential soot build up

and blockages. Once you know how to do this it is a

very easy operation. See right

• Flue spigot plate To maximise efficiency the

AL357i inset stove has been designed to work best in

conjunction with a 150mm (6”) flexible flue liner

connected to the purpose-designed spigot / plate

housed on top of the stove. To avoid soot build-up

on the stove bodywork, which could potentially ignite

and cause a chimney fire, we therefore we strongly

recommend that a liner is always used. Should it not

be possible to fit a liner then the householder should

ensure that the chimney is regularly swept and if

possible the stove removed at the same time so that

the top can be thoroughly cleaned.

• Ash Lip The ash lip is simply fitted to the installed

stove by positioning it at the front and pushing it

underneath to make a snug fit. It can then be easily

removed for cleaning the hearth.

B

To replace the baffle simply reverse the operation

– ensuring that the two positioning lugs (A) slide into

the retaining brackets (B) on the left and right sides

of the flueway aperture. The plate should be pushed

all the way to the back of the stove so that the final

central positioning lug (C) fits in the bracket (D).

The view of the

fitted baffle

from the top

(outside)

A

B

A

C

D

6

UK SMOKE CONTROL AREAS

The Clean Air Act 1993 and Smoke Control Areas

Under the Clean Air Act local authorities may declare

the whole or part of the district of the Authority to

be a Smoke Control Area. It is an offence to burn an

‘unauthorised fuel’ (ie non-smokeless fuel) in a Smoke

Control Area. It is a legal requirement that fuels burnt

or obtained for use in Smoke Control Areas have been

‘authorised’ and officially designated “Smokeless

Fuels’. Wood log are not classified as a Smokeless

Fuel and therefore should not be burned in the Alpha

Inset stove if it is located in a building within a Smoke

Control Area. In such a case you must only use an

Approved Smokeless Fuel.

Further information on the requirements of the Clean

Air Act can be found here:

www.smokecontrol.defra.gov.uk.

Your local authority is responsible for implementing

the Clean Air Act 1993 including designation and

supervision of Smoke Control Areas and you can

contact them for details of Clean Air Act requirements.

Even if you don’t live in a Smoke Control Area it is

still the householder’s legal responsibility not to cause

nuisance smoke. Your inset stove therefore should,

at all times, be operated in accordance with these

instructions which have been written to help you

minimise the amount of smoke produced from your

stove.

RECOMMENDED FUELS

Please note If you live in a UK Smoke Control Area

you must only burn approved smokeless fuels. The

following fuels are approved by Alpha for use in the

AL357i inset stove:

• Wood Logs Only ever use dried, fully seasoned

chopped wood logs with a moisture content of less

than 20%.

Wood which is well seasoned makes a distinctive

‘clack’ rather than a dull ‘thud’ when knocked

together. It will also feel much lighter than an

unseasoned log. Other indicators include bark peeling

away and cracking and splitting around the outside.

Ideally wood should be seasoned outdoors for

between 18 to 24 months – the harder the wood

then the longer the seasoning. It should be stacked

off the ground with plenty of space between the logs

to allow air movement and with the top covered to

keep rain and snow out. Seasoned wood will give

you approximately 50% more heat output than the

equivalent unseasoned log.

Most types of hardwood, for instance

regarded as the best), Birch, Beech, Oak and Elm can

be used. However, avoid woods with a high resin

content. As a rule of thumb, the heavier the wood,

then the greater the heat output and the longer burn

Ash (generally

time – the time between refills. All of this is providing

it is fully seasoned wood.

Never use wet or unseasoned (green) wood as this will

cause nuisance smoke and a very disappointing fire.

Its use could quickly result in the build up of soot and

creosote which, because of the higher temperatures

of stove flue gases, could easily cause a flue or

chimney fire. In addition, burning wet wood creates

other environmental problems, a less efficient fuel

economy and can eventually clog your flue system

and cowl. It will also reduce the effectiveness of the

stove’s Airwash system thus causing staining and

blackening of the glass.

Wet or unseasoned would produces the following

poor performance:

• Hard to light fires

• Fires that are difficult to keep going or to keep

burning well

• Smoky fires with fewer flames which are also of a

dull orange colour

• Increased dense grey / blue smoke from the chimney

• Shorter burn times

• Low heat output

• Dirty glass and firebricks

• Excessive and rapid creosote build-up in the flue

system and chimney

• Unpleasant smoky smells both inside and sometimes

outside the house

Manufactured or finished wood products, such as

plywood and chipboard, must also be strictly avoided

because of the high chemical adhesive content used

in their production which will also leave harmful

residue inside the stove and flue system.

For more information about wood fuel visit the DEFRA

funded National Energy Foundation website

Logpile at www.nef.org.uk/logpile.

• Peat or ‘Tu

alternative and provides a similar calorific heat output

to wood. It’s also clean and easy to handle with low

atmospheric emissions. However, you must ensure

that the peat is kept thoroughly dry as it absorbs and

retains unwanted moisture very easily.

Peat has traditionally been used as a heating fuel in

both Scotland and Ireland and you can find out more

by visiting these suppliers’ useful websites – �www.

peatheat.co.uk (Scotland) and www.bnm.ie/fuels

(Ireland).

• Multi Fuels (Other than Wood or Peat)

cannot burn wood then we recommend burning a

smokeless alternative, such as smokeless nuggets, as

this is better for the stove and flue system as well as

the environment. Your stove is also approved to burn

coal – however, we do not recommend prolonged use

of bitumous house coal because of the excessive soot

it produces. There are many different brands of high

quality smokeless coal nuggets available in the UK and

rf’ Peat is an excellent cost-effective fuel

If you

7

Ireland. The most popular include Phurnacite, Taybrite,

Ancit and Homefire.

Your local fuel merchant will be able to advise you on

the best types of coals suitable for multi fuel stoves,

as well as natural mineral fuel alternatives such as

anthracites which burn cleanly. The following fuel

merchant’s website also has good descriptions of the

comparative benefits that the brands listed above

have to offer – www.coalproducts.co.uk.

You can also find out more by visiting the Hetas

website www.hetas.co.uk.

PROHIBITED FUELS

Never use your stove like an incinerator. Burning

prohibited ‘fuels’ in a Smoke Control Area is illegal.

Burning the following materials could also damage

your stove and flue system, rendering the product

warranties on the stove and flue system components

void.

• Petroleum Coke Never burn petroleum coke as this

burns at a very high temperature and its continued

use will almost certainly cause irreparable damage to

components such as the grate, baffle plate and fire

bars.

• Bituminous House Coal is not recommended

because it produces excessive soot deposits, which is

not good for the environment, and thus considerably

increases the need for frequent cleaning of the stove

and flue system.

• Household Rubbish Printed matter (excluding very

small amounts of newspaper for starting the fire),

plastic, rubber, lacquered or impregnated wood,

plywood, chipboard and household rubbish, such as

milk cartons, should also be avoided. During

combustion some of these materials may develop

substances which could be hazardous to your health

and be harmful to the environment.

• Flammable Liquids Never use methylated spirits,

petrol or other highly inflammable liquids for

lighting the fire as these could cause an explosion

in the confined spaces of the fire chamber.

burns best on a bed of its own embers and the ashes

shouldn’t need to be riddled. Again mineral fuels

differ because they need combustion air from below

the grate therefore needs to be riddled to keep the air

passage clear.

See the section below to help you understand how

to control the different types of combustion air that

wood and mineral fuels need.

Your new stove can burn very well, or very poorly,

depending on how you light the fire, how you refuel

the fire, and, of course, the type and quality of the

fuel that you are burning. A log moisture meter is a

cost-effective investment if you want to maximise the

efficiency of your stove and wood fuel.

Wear protective gloves when loading a burning stove

and place the fuel precisely where you want it in the

fire chamber by using heat-resistant tongs. Always

open the stove door gently to avoid unnecessary air

turbulence which could cause fly ash or small lighted

embers to be drawn from the fire chamber and

beyond the protective hearth.

The stove is not designed to be operated with the

door left open continuously – this will reduce its

operating efficiency and it will consume more fuel

very quickly and produce less heat.

CONTROLLING THE COMBUSTION AIR

Your Alpha Inset stove has two simple air controls:

1 Primary Air Control

in the centre at the base of the stove. Primary Air is

required when burning mineral fuels (and to quickly

aid the supply of air during the initial combustion of

wood). Turn it anti-clockwise to open and add air.

2 Secondary Air Control This is the silver control

knob on the right hand side of the stove – pull it out

to open the air supply. Secondary air is needed when

burning wood and is not needed when burning

mineral fuels (unless it is to maximise the air supply to

aid the initial combustion).

This is the large control knob

UNDERSTANDING HOW

DIFFERENT FUELS BURN

Wood and solid or mineral fuels (multi fuels) burn in

different ways and you will need to understand these

differences if you are a newcomer to wood burners

and multi fuel stoves.

Putting it simply, mineral fuels, such as coal or

smokeless nuggets, need a flow of combustion air

through the bottom grate which is known as Primary

Air, whereas wood fuel works much better when its

combustion air is taken from above the grate. This

source of air is known as Secondary Air. Wood always

8

Loading...

Loading...