Page 1

15370 Barranca Parkway

Irvine, CA 92618-2215

USA

DTC4500 User Guide

P/N: L001444

Page 2

© 2010 HID Global Corporation All rights reserved

DTC4500 Card Printer/Encoder User Guide (Rev 1.0), © 2010 property of HID Global Corporation. All

rights reserved.

Exclusive permission is granted to authorized resellers of HID Global products to reproduce and

distribute this copyrighted document to authorized HID Global customers, who have signed a no

disclosure agreement regarding the restricted, proprietary use of said document.

The revision number for this document will be updated to reflect changes, corrections, updates and

enhancements to this document.

Revision Control

Date Document Title

Number

Revision 1.0 March 2010 DTC4500

Card Printer/Encoder User Guide

Trademarks and Disclaimers

HID, HID Global, and Fargo are the trademarks or registered trademarks of HID Global Corporation in

the U.S. and other countries.

The information contained in this document is provided AS IS without any warranty.

HID Global hereby disclaims all warranties and conditions with regard to the information contained

herein, including all implied warranties of merchantability, fitness for a particular purpose, title and noninfringement.

In no event shall HID Global be liable, whether in contract, tort or otherwise for any indirect, special or

consequential damages arising from the use of the information contained in this document.

Any questions regarding changes, corrections, updates or enhancements to this document should be

forwarded to:

Hid Global

Support Services

6533 Flying Cloud Drive

Eden Prairie, MN 55344 (USA)

(866)607-7339 Ext #6

FAX: (952) 946-8492

www.hidglobal.com

DTC4500 Card Printer/Encoder User Guide

2

Page 3

© 2010 HID Global Corporation All rights reserved

Table of Contents

DTC4500 User Guide______________________________________________________________________ 1

Section 1: Specifications ___________________________________________________________________ 5

Regulatory Compliances ___________________________________________________________________________5

Agency Listings__________________________________________________________________________________6

United States__________________________________________________________________________________6

Canada ______________________________________________________________________________________6

Safety Messages (review carefully)___________________________________________________________________7

Environmental Protection (China-RoHS) ______________________________________________________________ 8

Traditional Chinese RF Emissions and Safety Statements _______________________________________________ 8

Simplified Chinese _____________________________________________________________________________ 9

Technical Specifications __________________________________________________________________________ 10

Functional Specifications__________________________________________________________________________ 13

Printer Components: Print Ribbons _______________________________________________________________ 13

Ribbon Types/Count Table______________________________________________________________________14

Printer Components: Blank Cards ________________________________________________________________15

Section 2: Setup and Installation Procedures_________________________________________________ 16

Choosing a Good Location ________________________________________________________________________16

About Moisture Condensation ___________________________________________________________________16

Unpacking and Inspection_______________________________________________________________________ 16

Installing the Print Ribbon Cartridge (DTC4500) _______________________________________________________ 17

Installing the Ribbon___________________________________________________________________________17

Installing Blank Cards into the Card Hopper (DTC4500)_________________________________________________19

Using the Single and Dual Hopper ________________________________________________________________ 19

Setting the Card Size for CR79 and CR80_____________________________________________________________ 23

Connecting the Printer power ______________________________________________________________________27

Section 3: Print Driver Installation_________________________________________________________ 28

Driver Installation Instructions _____________________________________________________________________28

Section 4: Printer Preferences Tab Functions ________________________________________________ 29

|contextid=30 Using the Card tab __________________________________________________________________ 29

Using the Toolbox Options ________________________________________________________________________30

|contextid=150 Using the Configuration Tab __________________________________________________________ 31

|contextid=151 Selecting the Calibrate Laminator tab____________________________________________________ 32

Using the Event Monitoring Group Box ______________________________________________________________ 34

Reviewing the Ribbon Low message ______________________________________________________________ 34

|contextid=152 Selecting the Calibrate Ribbon tab ______________________________________________________35

|contextid=154 Selecting the Clean Printer tab _________________________________________________________37

|contextid=155 Selecting the Advanced Settings tab_____________________________________________________ 38

|contextid=40Using the Device Options tab ___________________________________________________________ 46

|contextid=50Using the Image Color tab______________________________________________________________ 49

|contextid=51Using the Image Calibrate tab ___________________________________________________________52

|contextid=70Using the Magnetic Encoding Tab________________________________________________________ 53

Using the Magnetic Encoding Tab – ISO Standards___________________________________________________ 54

Using the Magnetic Encoding Tab – Custom Encoding or Raw Binary Encoding Mode ______________________ 56

Reviewing the ISO Track Locations_______________________________________________________________57

Reviewing the Sample String ____________________________________________________________________ 58

Sending the Track Information ___________________________________________________________________59

Reviewing the ASCII Code and Character Table_____________________________________________________ 60

|contextid=80Using the Lamination tab ______________________________________________________________ 62

|contextid=90 Using the Overlay / Print Area tab _______________________________________________________ 62

DTC4500 Card Printer/Encoder User Guide

3

Page 4

© 2010 HID Global Corporation All rights reserved

|contextid=100Using the K Panel Resin tab ___________________________________________________________66

|contextid=120Using the Printer Info tab______________________________________________________________ 69

Section 5: Selecting the Fluorescent Panel Ribbon Type________________________________________ 70

Creating a Custom Fluorescent Image (using the YMCFKO Ribbon)_____________________________________ 70

Configuring Fluorescent Data (F-Panel for YMCFKO Ribbon) using the Application________________________72

Section 6: System Overview- Troubleshooting________________________________________________ 76

Reviewing the DTC4500 Sequence of Operations ______________________________________________________ 76

Reviewing the DTC4500 Sequence of Operations ____________________________________________________ 77

Section 7: Troubleshooting________________________________________________________________ 78

Printer Error Button and Display Message Table _______________________________________________________ 78

Using the Error Message Table_____________________________________________________________________80

Troubleshooting with the Error Message Table_________________________________________________________ 82

Printer Specific Tools (DTC4500)___________________________________________________________________ 92

Additional Printer Specific Tools (DTC4500) _______________________________________________________ 93

Section 8: Cleaning ______________________________________________________________________ 94

Safety Messages (review carefully) _______________________________________________________________ 94

DTC4500 Card Printer/Encoder Cleaning Kit _______________________________________________________ 95

Printhead Cleaning ____________________________________________________________________________96

Cleaning the Platen and the Card Feed Rollers_______________________________________________________ 97

Cleaning the Printer’s Interior____________________________________________________________________ 99

Cleaning the Printer’s Exterior ___________________________________________________________________ 99

Section 9: Firmware Upgrades____________________________________________________________ 100

Upgrade the Printer Firmware_____________________________________________________________________100

Section 10: HID Global Technical Support__________________________________________________ 103

Reading the Serial Numbers on a Fargo Printer _______________________________________________________ 104

Appendix A ____________________________________________________________________________ 105

Using the Defined Area Option____________________________________________________________________ 105

Configuring Fluorescent Data (F-Panel for YMCFKO Ribbon) using the Workbench _________________________ 106

DTC4500 Card Printer/Encoder User Guide

4

Page 5

© 2010 HID Global Corporation All rights reserved

Section 1: Specifications

The purpose of this section is to provide you with specific information on the Regulatory Compliances,

Agency Listings, Technical Specifications and Functional Specifications for the DTC4500 Card Printer

User Guide.

Regulatory Compliances

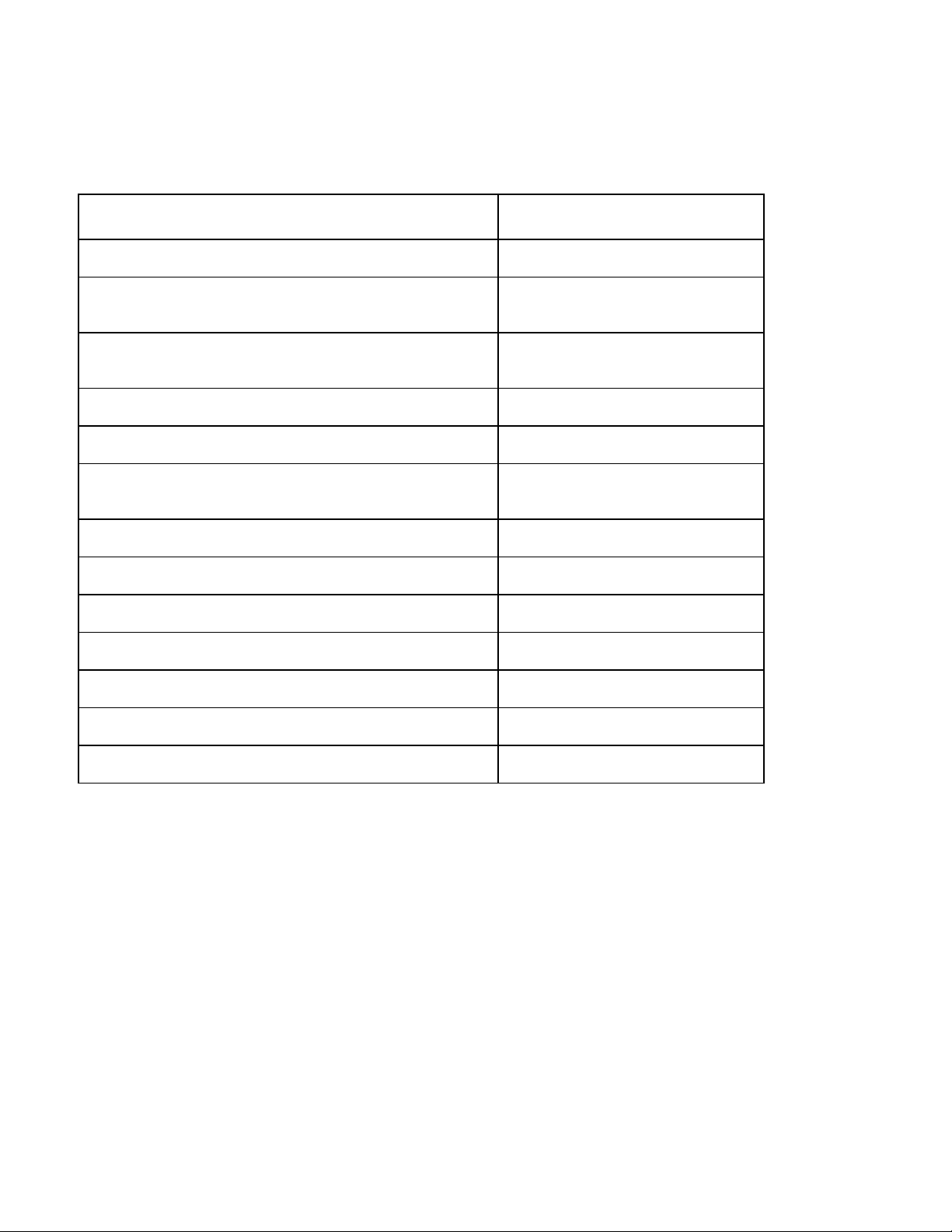

Term Description

CSA

(cUL)

FCC The Card Printer complies with the requirements in Part 15 of

EMC The Card Printer has been tested and complies with EN55022 /

UL The Card Printer is listed under UL IEC 60950-1 (2001)

The Printer manufacturer has been authorized by UL to

represent the Card Printer as CSA Certified under CSA

Standard C22.2 No. 60950-1-03.

File Number: E145118

the FCC rules for a Class A digital device.

CISPR 22 Class A: and EN55024 standards.

(Note: Based on the above testing, the Printer manufacturer

certifies that the Card Printer complies with current EMC

directive

placed the CE mark on the Card Printer.)

License Number: J99032510

INFORMATION TECHNOLOGY EQUIPMENT

(Note: This product is intended to be supplied by a Listed

Power Unit marked Class 2 and rated for 24 V dc, 3.7 to 5A.)

File Number: E145118

2004/108/EC of the European Community and has

Environmental Power supply Efficiency level IV, RoHS, China RoHS

DTC4500 Card Printer/Encoder User Guide

5

Page 6

© 2010 HID Global Corporation All rights reserved

Agency Listings

Term Description

Emissions

Standards

Safety Standards UL IEC 60950-1 (2001), CSA C22.2 No. 60950-1-03.

CE, FCCPart 15 Class A, CRC c1374, CISPR22 Class A,

EN55022, EN55024,

EN61000-3-2, EN61000-3-3,

United States

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference.

(2) This device must accept any interference received, including interference that may cause undesired

operation.

Note: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference; in which case, you will be required

to correct the interference at his own expense.

Reference the Safety Messages in this document.

Canada

This Class A digital apparatus complies with Canadian ICES-003.

C’et appareil numerique de la classe A est comforme a la norme NMB-003 du Canada.

Caution: Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

DTC4500 Card Printer/Encoder User Guide

6

Page 7

© 2010 HID Global Corporation All rights reserved

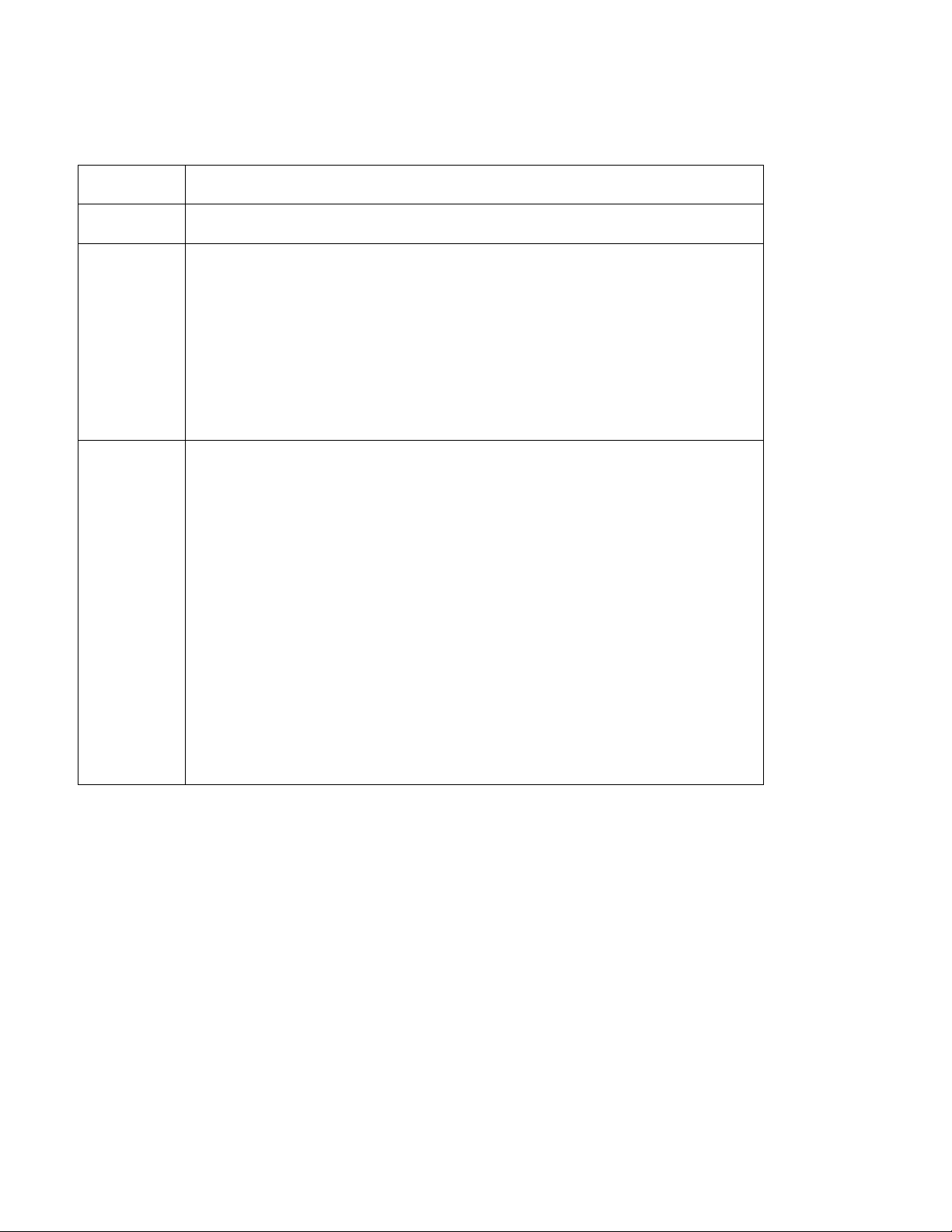

Safety Messages (review carefully)

Symbol

Danger:

Caution:

Critical Instructions for Safety purposes

Failure to follow these installation guidelines can result in death

or serious injury.

Information that raises potential safety issues is indicated by a

warning symbol (as shown to the left).

• To prevent personal injury, refer to the following safety

messages before performing an operation preceded by this

symbol.

• To prevent personal injury, always remove the power cord prior

to performing repair procedures, unless otherwise specified.

• To prevent personal injury, make sure only qualified personnel

perform these procedures.

This device is electrostatically sensitive. It may be damaged if

exposed to static electricity discharges.

Information that raises potential electrostatic safety issues is indicated

by a warning symbol (as shown to the left).

• To prevent equipment or media damage, refer to the following

safety messages before performing an operation preceded by this

symbol.

• To prevent equipment or media damage, observe all

established Electrostatic Discharge (ESD) procedures while

handling cables in or near the Circuit Board and Printhead

Assemblies.

• To prevent equipment or media damage, always wear an

appropriate personal grounding device (e.g., a high quality wrist

strap grounded to avoid potential damage).

• To prevent equipment or media damage, always remove the

Ribbon and Cards from the Printer before making any repairs,

unless otherwise specified.

• To prevent equipment or media damage, take jewelry off of

fingers and hands, as well as thoroughly clean hands to remove

oil and debris before working on the Printer.

DTC4500 Card Printer/Encoder User Guide

7

Page 8

© 2010 HID Global Corporation All rights reserved

Environmental Protection (China-RoHS)

Environmental Protection Use Period is based on the product being used in an office environment.

Traditional Chinese RF Emissions and Safety Statements

經型式認證合格之低功率射頻電機,非經許可,公司、商號或使用者均不得擅自變更頻率、加大功率或變更原設計之特

性及功能。低功率射頻電機之使用不得影響飛航安全及干擾合法通信;經發現有干擾現象時,應立即停用,並改善至無

干擾時方得繼續使用。前項合法通信,指依電信法規定作業之無線電通信。低功率射頻電機須忍受合法通信或工業、

科學及醫療用電波輻射性電機設備之干擾。

DTC4500 Card Printer/Encoder User Guide

8

Page 9

© 2010 HID Global Corporation All rights reserved

Simplified Chinese

如何使用本手册

实际上,DTC4500 证卡打印机用户指南

是一本整个证卡打印机的故障排除和服务手册。本手册旨在帮助安装人员和技术人员快速有效地查找相关

过程、组件和术语。安装人员或技术人员可根据自己的喜好,高效地使用本手册的电子文档或纸面文档。

安全消息(请仔细阅读)

符号 安全事项的重要说明

危险:

安全消息(请仔细阅读)

符号 安全事项的重要说明

小心:

如果不遵循这些安装指南进行操作,可能会导致重伤,甚至死亡。

可能引发安全问题的信息由警告符号(如左图所示)来表示。

为了确保人身安全,在执行前面带有此符号的操作之前,请先阅读下面

为了确保人身安全,除非另有规定,否则在执行维修过程前,始终应断

为了确保人身安全,只能由有资格的人员执行这些过程。

此设备为静电敏感设备。如果暴露在静电电流下,可能会损坏设备。

可能引发静电安全问题的信息由警告符号(如左图所示)来表示。

为了防止设备或介质受损,在执行前面带有此符号的操作之前,请先阅

为了防止设备或介质受损,请在处理电路板和打印头部件中或附近的

的安全消息。

开电源。

读下面的安全消息。

电缆时,遵守所有规定的静电放电 (ESD) 过程。

为了防止设备或介质受损,请始终佩带适当的个人接地设备(例如,已

接地避免出现潜在损坏的高质量腕带)。

为了防止设备或介质受损,除非另有规定,否则在执行任何维修过程前

,始终应将色带和证卡与打印机分离。

为了防止设备或介质受损,在操作打印机前,请取下手指和手上的珠宝

饰物,并将手上的油渍和污渍彻底清洗干净。

DTC4500 Card Printer/Encoder User Guide

9

Page 10

© 2010 HID Global Corporation All rights reserved

Technical Specifications

Term Function

Print resolution

• 300 x 300 dpi(11.8 dots/mm)

• Up to 16.7 million colors, Monochrome

Printer Memory 16MB RAM

Print Area CR-80 (3.375"L x 2.125"W / 85.6mmL x 54mmW)

Print Method Dye Sublimation/Resin Thermal Transfer

Printer Driver &

System

Requirements

• Windows XP, Server 2003 and 2008, Vista 32-bit and 64-bit

compliance, Linux distributions-Red Hat, open

• SUSE, SUSE Enterprise, Ubuntu, Fedora Core

• Mac OS X version 10.0 to 10.5

• x86 based PC or compatible, Windows 2000, Windows XP,

Windows 2003, 500MHz computer with 256MB of RAM or

higher, 500MB free hard disk space or higher

Fargo E-card

Software

Support with developed Fargo E-card Software Development Kit

(SDK).

Development Kit

DTC4500 Card Printer/Encoder User Guide

10

Page 11

© 2010 HID Global Corporation All rights reserved

Technical Specifications

Term Function

Connectivity

• Standard USB 2.0 (USB Standard with this option), including

single USB cable support for Omnikey 5121 and 5125

encoders

• Ethernet 10/100 option, including single Ethernet cable

support for Omnikey 5121 encoder (separate USB cable

required for encoding with the Omnikey 5125 encoder)

• Full bi-directional status messaging to the PC during the

encoding process

Print Speed Indicates the Ribbon type and the number of Ribbon panels

printed where Y=Yellow, M=Magenta, C=Cyan, K=Resin Black,

O=Overlay, F=Fluorescing Resin

• YMCKO= 24 seconds per card

• YMCKOK= 30 seconds per card

• Resin= 6 seconds per card

• Print speed indicates an approximate batch print speed and

is measured from the time a card feeds into the Printer to the

time it ejects from the Printer.

• Print speeds do not include encoding time or the time

needed for the PC to process the image.

• Process time is dependent on the size of the file, the CPU,

amount of RAM and the amount of available resources at the

time of the print.

DTC4500 Card Printer/Encoder User Guide

11

Page 12

© 2010 HID Global Corporation All rights reserved

Technical Specifications

Term Function

Card Size and

Types Supported

Printer Dimensions

• CR-80 (3.362"L x 2.114"W / 85.4mmL x 53.7mmW)

• CR-79 (3.303”L x 2.051”W / 83.7mmL x 51.9mmW

• 10 mil to 40 mil card thickness

• Re-writable card technologies (requires special rewritable

cards)

• PVC, Polyester cards with a polished PVC finish

DTC4500 :

• 14.4"(366 mm)L x 9.2"(234 mm)W x 9.8"(249 mm)H w/o

output bin

• 18.1"(460 mm)L x 9.2"(234 mm)W x 9.8"(249 mm)H w/

output bin

DTC4500 with Flipper (includes input Hopper):

• 18.7"(475 mm)L x 9.2"(234 mm)W x 9.8"(249 mm)H

DTC4500 without Flipper (includes input and output

Hoppers):

• 18.7"(475 mm)L x 9.2"(234 mm)W x 18.9"(480 mm)H

Environmental

Operation

Electrical

Encoding Options

Supported

• 20-80% Humidity

• 65° to 80° F / 18° to 27° C Temperature

• External power adapter: 100-240 VAC, 1.5 A max, output

24Vdc 3.75A

• 50 Hz/60 Hz Supply Frequency

• Efficiency level IV

• Omnikey 5121 (iClass, Mifare, Desfire)

• Omnikey 5125 (HID Prox,Indala)

• Contact Smart Card (requires Omnikey 5121 or 5125 )

• ISO Mag Encoding standard 7811, Parts 1-7. High or Low

Coercivity. (Raw Magnetic Encoding option)

• JIS II Mag Encoding

DTC4500 Card Printer/Encoder User Guide

12

Page 13

© 2010 HID Global Corporation All rights reserved

Functional Specifications

This Card Printer utilizes two different, yet closely related printing technologies to achieve its remarkable

direct-to-card print quality for dye-sublimation and resin thermal transfer.

Printer Components: Print Ribbons

The Card Printer utilizes both dye-sublimation and/or resin thermal transfer methods to print images

directly onto blank cards. Since the dye-sublimation and the resin thermal transfer print methods each

provide their own unique benefits, Print Ribbons are available in resin-only, dye-sublimation-only and

combination dye-sublimation/resin versions.

To make it easier to remember which Print Ribbons are which, a letter code has been developed to

indicate the type of Ribbon panels found on each Ribbon. This letter code is as follows:

= Dye-Sublimation Yellow Panel

= Dye-Sublimation Magenta Panel

= Dye-Sublimation Cyan Panel

= Resin Black Panel (Premium unless otherwise stated )

= Clear Protective Overlay Panel

= Ultra Violet Fluorescing Panel

DTC4500 Card Printer/Encoder User Guide

13

Page 14

© 2010 HID Global Corporation All rights reserved

Ribbon Types/Count Table

Ribbon type and count used in each Printer.

Ribbon DTC4500

YMCKO – Full Color/Resin Black/Overlay 500

YMCKO Half Panel – Full Color (1/2)/Resin

Black/Overlay

YMCFKO - Full Color/UV Fluorescing/Resin

Black/Overlay

YMCKK - Full Color/2 Resin Black 500

YMCKOK - Full Color/2 Resin Black/Overlay 500

YMCFKOK - Full Color/UV Fluorescing/2 Resin

Black/Overlay

K – Standard Resin 3000

K – Premium Resin 3000

Colored Resin 2000

Metallic Resin 2000

KO - Premium Black Resin/Overlay 1250

BO - Dye-Sub Black/Overlay 1250

850

500

400

None – Rewritable Supported

DTC4500 Card Printer/Encoder User Guide

14

Page 15

© 2010 HID Global Corporation All rights reserved

Printer Components: Blank Cards

Type Description

Card Size The Card Printer accepts standard CR-80 and CR-79 sized cards.

Card

Surface

UltraCard™

Brand

Cards

Suitable cards must have a polished PVC surface free of fingerprints, dust

or any other types of embedded contaminants. In addition, cards must

have a completely smooth, level surface in order for the Printer to achieve

consistent color coverage.

• Certain types of Proximity cards have an uneven surface that will

inhibit consistent color transfer.

• Certain types of smart card chips are raised slightly above the cards

surface which also results in poor color transfer.

The UltraCard product line, available exclusively as part of HID's Global's

Fargo brand secure card issuance solutions, has a long standing

reputation among dealers and end-Users for consistent quality in

construction.

• In addition to blank stock, the UltraCard line is available in a variety of

configurations for magnetic stripe, custom holograms and other

additional anti-counterfeiting feature

• UltraCard™ Premium is the preferred card for Direct-to-Card (DTC®)

applications that require a higher quality card. The UltraCard

Premium’s composite material construction provides for maximum

durability, flexibility and card life, with optimal resolution print quality

for lamination and fluorescent panel Ribbon printing applications.

• UltraCard™ PVC cards are medium-durability cards for a glossy,

photo quality finish. These cards are manufactured to ensure clean,

scratch-free cards for high-quality prints and extended Printhead life.

DTC4500 Card Printer/Encoder User Guide

15

Page 16

© 2010 HID Global Corporation All rights reserved

Section 2: Setup and Installation Procedures

This section describes the setup and installation for the DTC4500 Card Printer.

Choosing a Good Location

Follow these guidelines:

• Place the unit in a location with adequate air circulation to prevent internal heat build up.

• Use the Printer's dimensions as a guideline for the minimum clearances to the unit. (Note: Allow for

adequate clearance in front of the unit to accommodate the unit with its Covers open.)

• Do not install unit near heat sources such as radiators or air ducts or in a place subject to direct

sunlight, excessive dust, mechanical vibration or shock.

About Moisture Condensation

If the unit is brought directly from a cold to a warm location or is placed in a very damp room, moisture

may condense inside the unit. Should this occur, print quality may not be optimum.

Leave the unit turned Off in a warm, dry room for several hours before using. This will allow the moisture

to evaporate.

Caution: For safety purposes, Ethernet is not intended for a direct connection outside of the

building.

Unpacking and Inspection

While unpacking your Printer, inspect the carton to ensure that no damage has occurred during shipping.

Make sure that all supplied accessories are included with your unit.

Check that the following items are included:

• Power Supply

• US / EU Power Cable

• USB cable (2.0)

• Software Installation CD/User Guide

• User Guide

• Warranty Statement, Registration Card and Compliancy Document

DTC4500 Card Printer/Encoder User Guide

16

Page 17

© 2010 HID Global Corporation All rights reserved

Installing the Print Ribbon Cartridge (DTC4500)

Fargo Card Printers require highly specialized supplies to function properly.

• The Fargo DTC4500 Card Printer uses a one-piece, refill system.

• To maximize Printer life, reliability, printed card quality and durability, you must use only Fargo-

certified supplies.

• For this reason, your Fargo warranty is void, where not prohibited by law, if you use non-Fargo-

certified supplies.

• Printer cleaning is recommended with each Ribbon change to ensure quality printed cards.

• Resin-only Print Ribbons consist of a continuous roll of a single resin color. No protective overlay

panel (O) is provided since resin images do not require the protection of such an overlay.

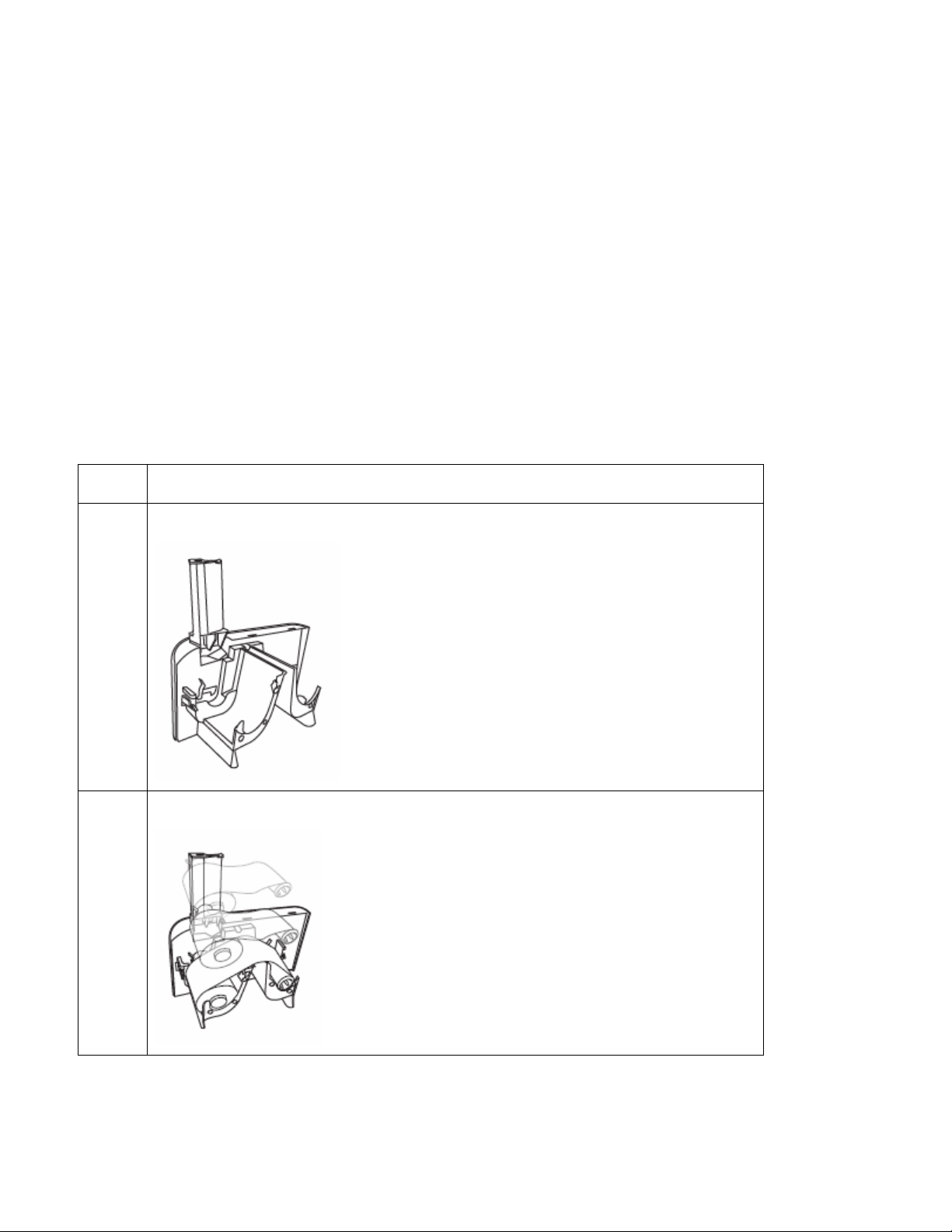

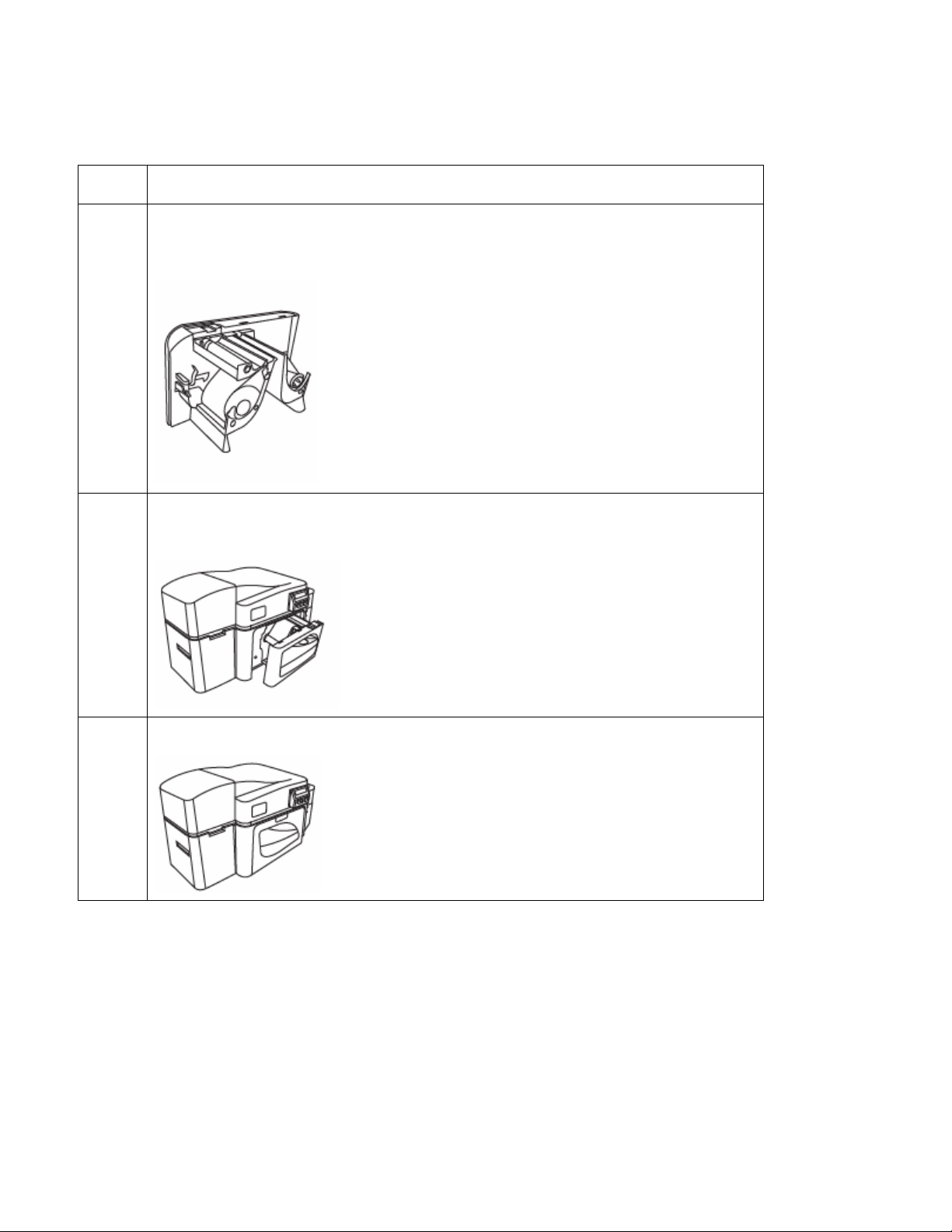

Installing the Ribbon

Step

1

2

Procedure

Lift up the Cleaning Roller Cover.

Load the Print Ribbon into the Print Ribbon Cartridge.

DTC4500 Card Printer/Encoder User Guide

17

Page 18

© 2010 HID Global Corporation All rights reserved

Installing the Ribbon

Step Procedure

3

4

a. Close the Cleaning Roller Cover.

b. Insert the new Cleaning roller.

Load the Ribbon Cartridge into the Printer.

5

Close the Front Cover.

DTC4500 Card Printer/Encoder User Guide

18

Page 19

© 2010 HID Global Corporation All rights reserved

Installing Blank Cards into the Card Hopper (DTC4500)

Using the Single and Dual Hopper

Caution: Do not run the cards with a contaminated, dull or uneven surface through the

Printer.

Step

1

Procedure

Pre-instruction.

• Printing onto such cards will ultimately lead to poor print quality and will

greatly reduce the life of the Printhead. Card Types include PVC or PVC

finish.

• Cards eject into the Output Hopper or Reject Hopper.

• Each Hopper holds 100 cards.

• The DTC4500 is available with two (2) Hopper configurations: Single and

Dual Hopper

• Certain types of smart card chips are raised slightly above the cards

surface which may result in poor color transfer. Design the card with white

space surrounding the chip. (Note: The Fargo DTC4500 Printer is capable

of printing single load cards and multiple feed cards (batch mode).)

• To print using single feed, simply remove all cards from the Card Hopper,

leave the Card Hopper door closed and place a card in the single Feed

Card Slot (which can be used repeatedly).

• Again, the cards should be loaded with the print side down and (if

applicable) the magnetic strip up and towards the front of the Printer.

DTC4500 Card Printer/Encoder User Guide

19

Page 20

© 2010 HID Global Corporation All rights reserved

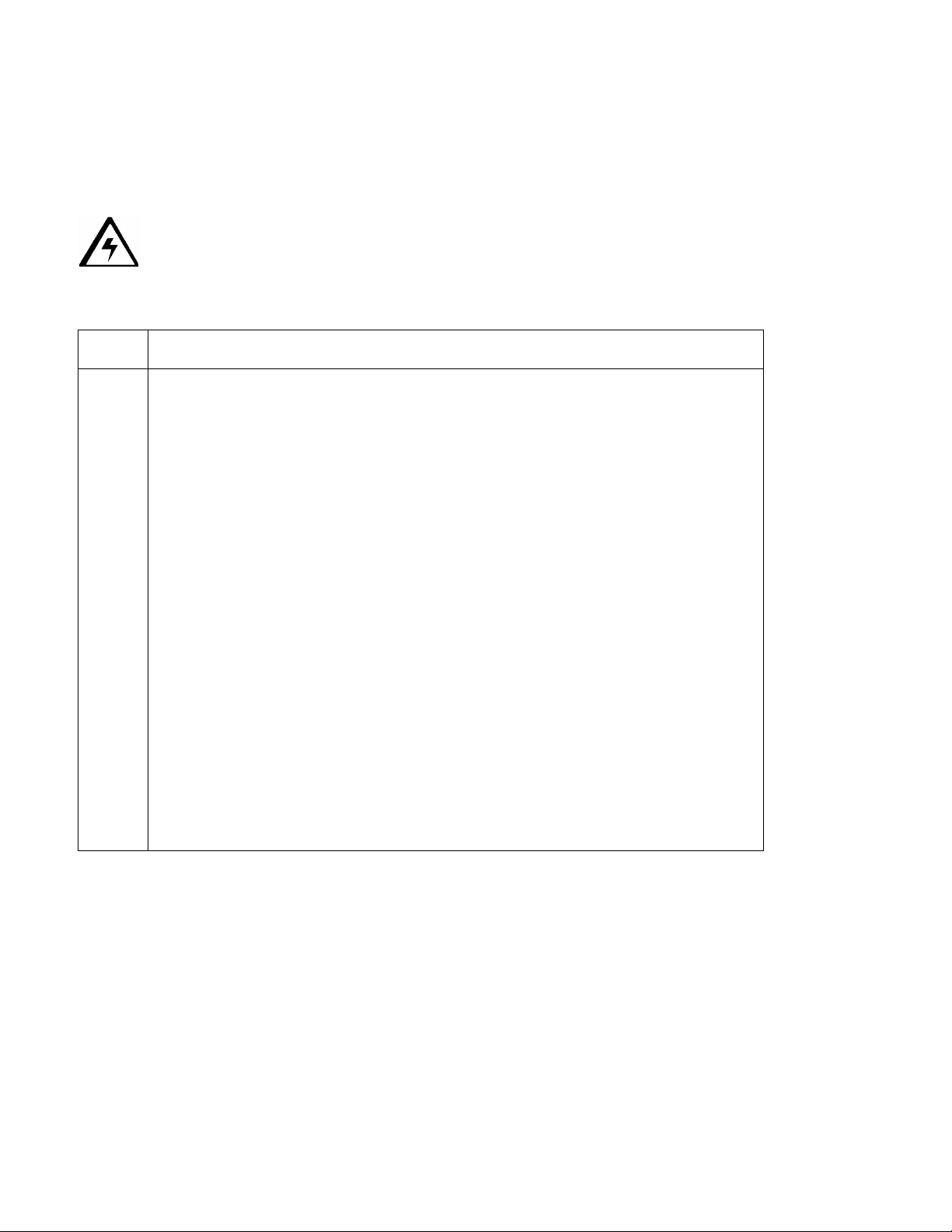

Using the Single and Dual Hopper

Step

2

3

Procedure

Open the Card Hopper Cover.

Single Hopper Dual Hopper

Press the Card Hopper Load Lever down until the Card Tray locks into place.

DTC4500 Card Printer/Encoder User Guide

20

Page 21

© 2010 HID Global Corporation All rights reserved

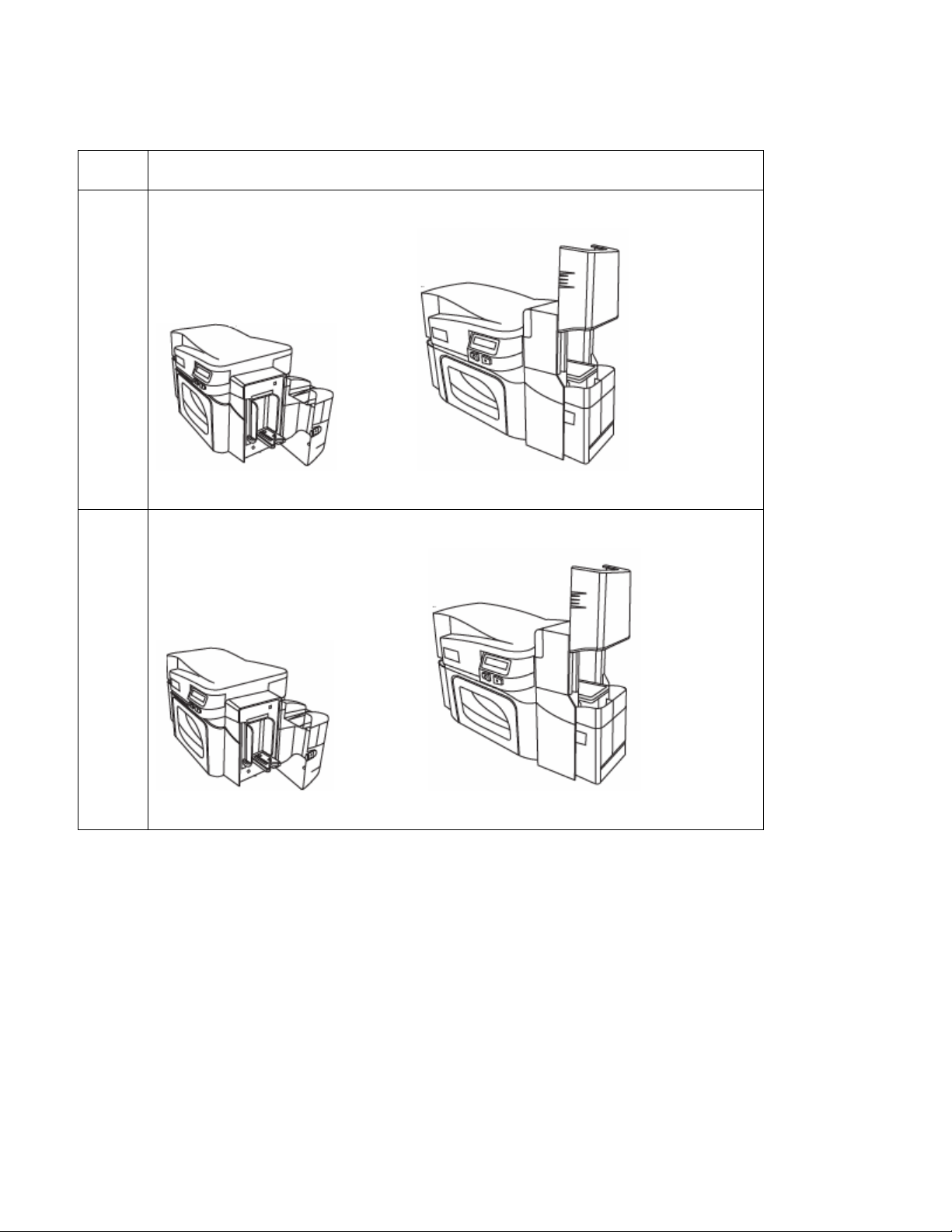

Using the Single and Dual Hopper

Step

4

Procedure

Load up to 100 cards into the Hopper with the print side down. (Note: If using

cards with a magnetic stripe, the magnetic stripe should be loaded with the

stripe up and to the front of the Printer.)

Display: Card loaded into the upper Hopper of DTC4500 Single Hopper

Display: Cards loaded into lower Hopper of DTC4500 Dual Hopper

DTC4500 Card Printer/Encoder User Guide

21

Page 22

© 2010 HID Global Corporation All rights reserved

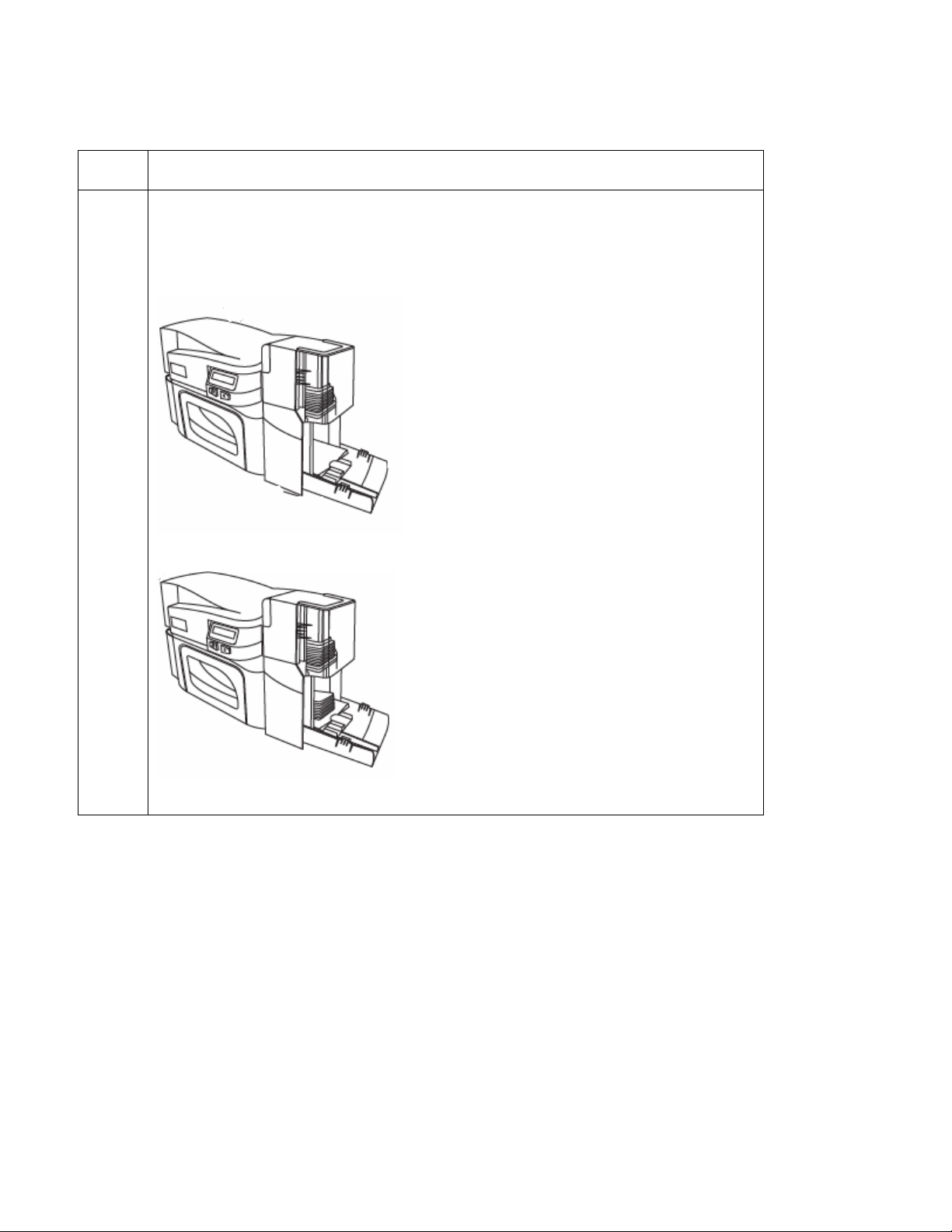

Using the Single and Dual Hopper

Step

5

Procedure

Close the Card Hopper Cover to release the lever to the printing position.

DTC4500 Card Printer/Encoder User Guide

22

Page 23

© 2010 HID Global Corporation All rights reserved

Setting the Card Size for CR79 and CR80

Follow this procedure in the Printer and in the Printer Driver to setup the card size.

Step Procedure

1 Open the front door and locate the slide bar.

DTC4500 Card Printer/Encoder User Guide

23

Page 24

© 2010 HID Global Corporation All rights reserved

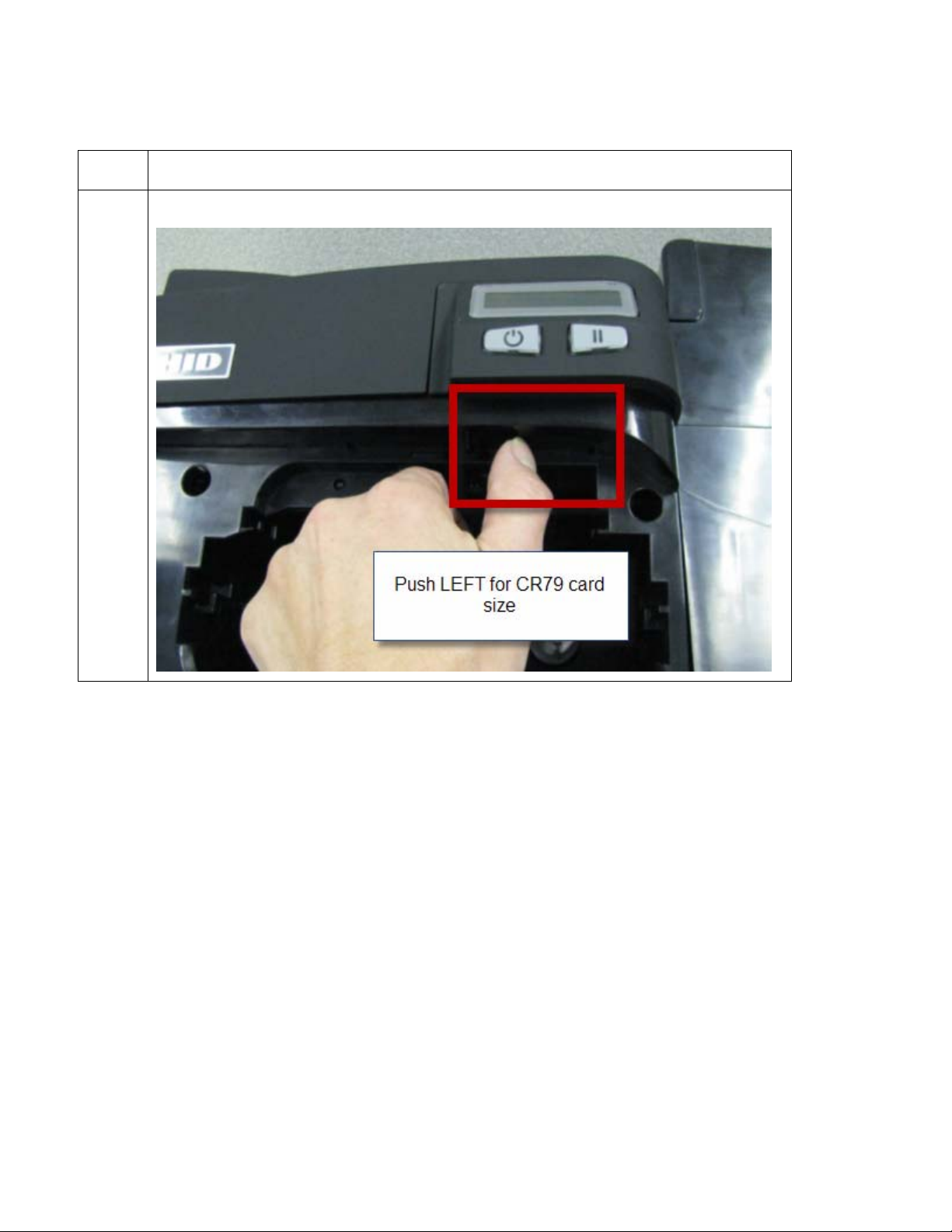

Setting the Card Size for CR79 and CR80

Step Procedure

2 If using the CR79 card, push the slide bar to the LEFT.

DTC4500 Card Printer/Encoder User Guide

24

Page 25

© 2010 HID Global Corporation All rights reserved

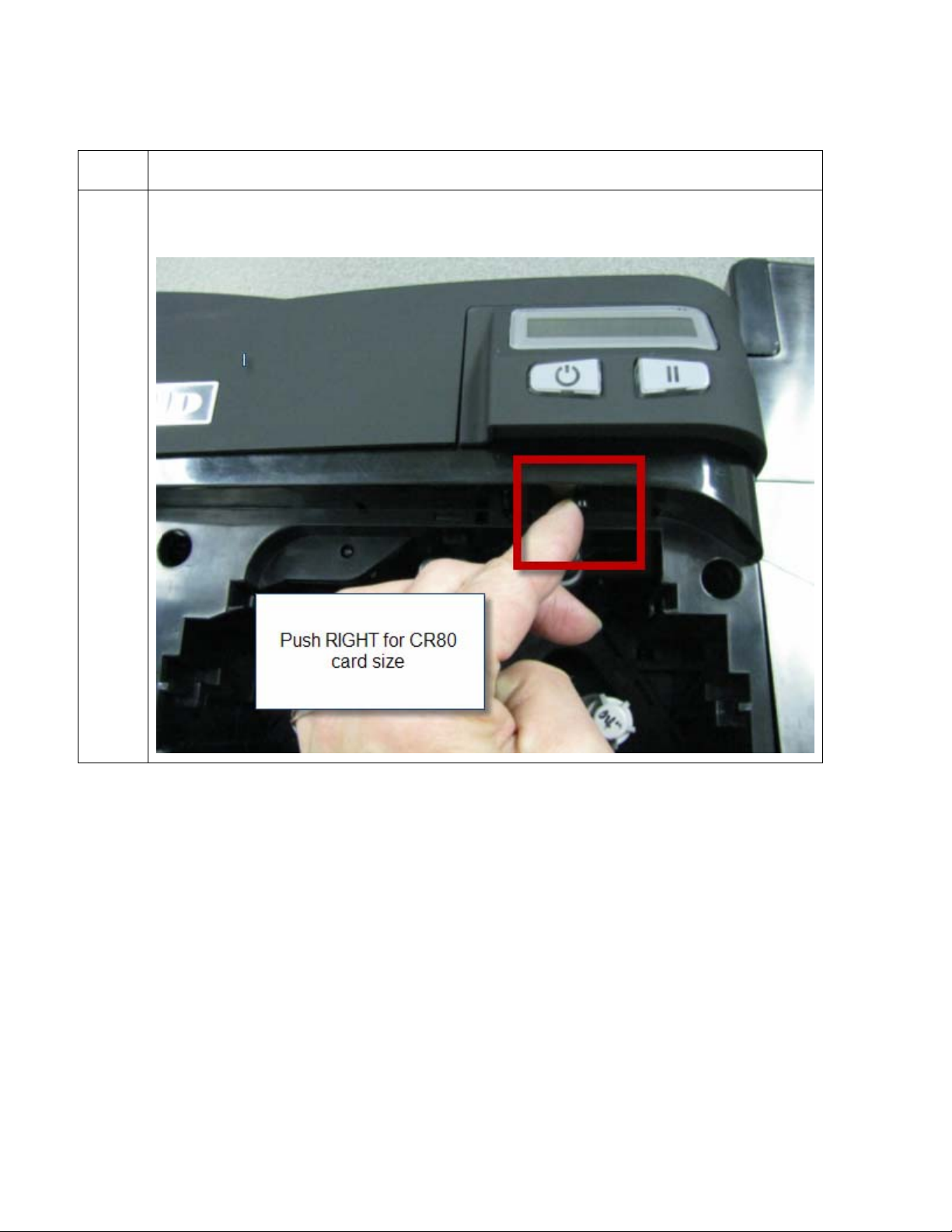

Setting the Card Size for CR79 and CR80

Step Procedure

3 If using the CR80 card, push the slide bar to the RIGHT.

DTC4500 Card Printer/Encoder User Guide

25

Page 26

© 2010 HID Global Corporation All rights reserved

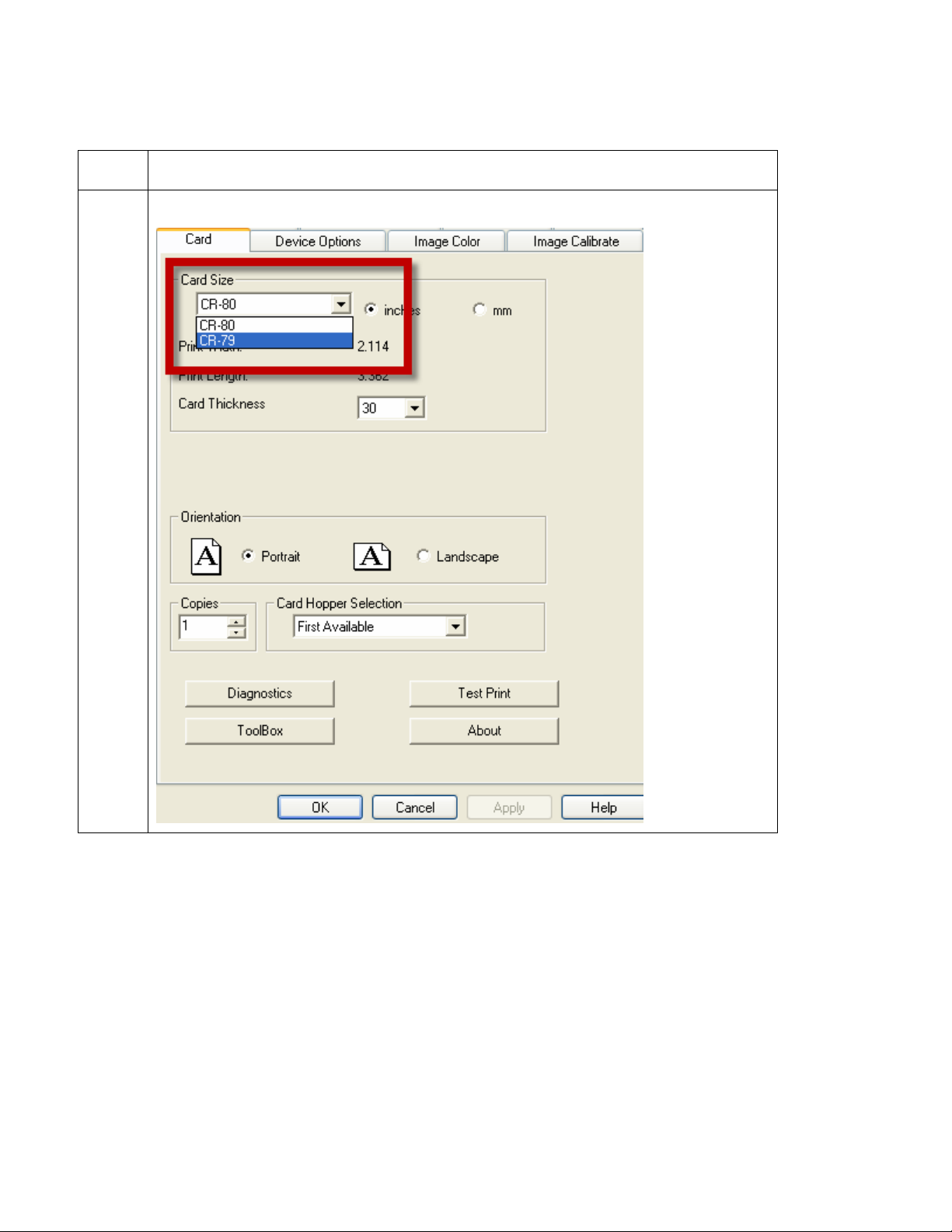

Setting the Card Size for CR79 and CR80

Step Procedure

4 From the Driver Printing Preferences, select the correct card size.

DTC4500 Card Printer/Encoder User Guide

26

Page 27

© 2010 HID Global Corporation All rights reserved

Connecting the Printer power

Follow this procedure. (Note: Do not connect the Printer’s USB cable until prompted during the Printer

Driver installation.)

Step Procedure

1 Plug the AC adapter power cable into the back of the Printer.

2 Plug the wall power cable into the AC power adapter. This display shows

Printer from behind with AC power cable.

3 Plug the wall power cable into a standard 110VAC power outlet.

4 Press the left ON/Off Button to power up the printer.

DTC4500 Card Printer/Encoder User Guide

27

Page 28

© 2010 HID Global Corporation All rights reserved

Section 3: Print Driver Installation

This section describes the Printer Driver installation requirements and standard procedures.

Requirements are listed below. The DTC4500 Print Driver supports the following:

• Vista, 32 bit Windows OS,

• Windows XP

• Server 2003

• Vista, 64 bit Windows OS

• Linux OS (Ubuntu7.10, Red Hat Enterprise Desktop 5, Fecora Core 7 & 8, openSUSE 10.3 , open

NOVELL SUSE 10.). Contact HID/Fargo Technical Support for the driver.

Driver Installation Instructions

Start the installation process by inserting the Driver CD into the computer. Then, follow the Installaware

Wizard screen prompts.

• Select 32 bit Windows or 64 bit Windows to start the installation.

• Select the Fargo Workbench Utility Program to install this program.

• Specific versions of Windows require Administrator rights.

• From the Printer & Faxes folder, open the Printing Preferences to setup the Driver after it has been

installed.

• Printing Preferences need to be setup after the Driver has been installed. Each TAB is shown in the

next section.

• Use the drop down arrows to select the correct options for each printing preference.

DTC4500 Card Printer/Encoder User Guide

28

Page 29

© 2010 HID Global Corporation All rights reserved

Section 4: Printer Preferences Tab Functions

This section provides an overview of the Printer Driver preferences tab.

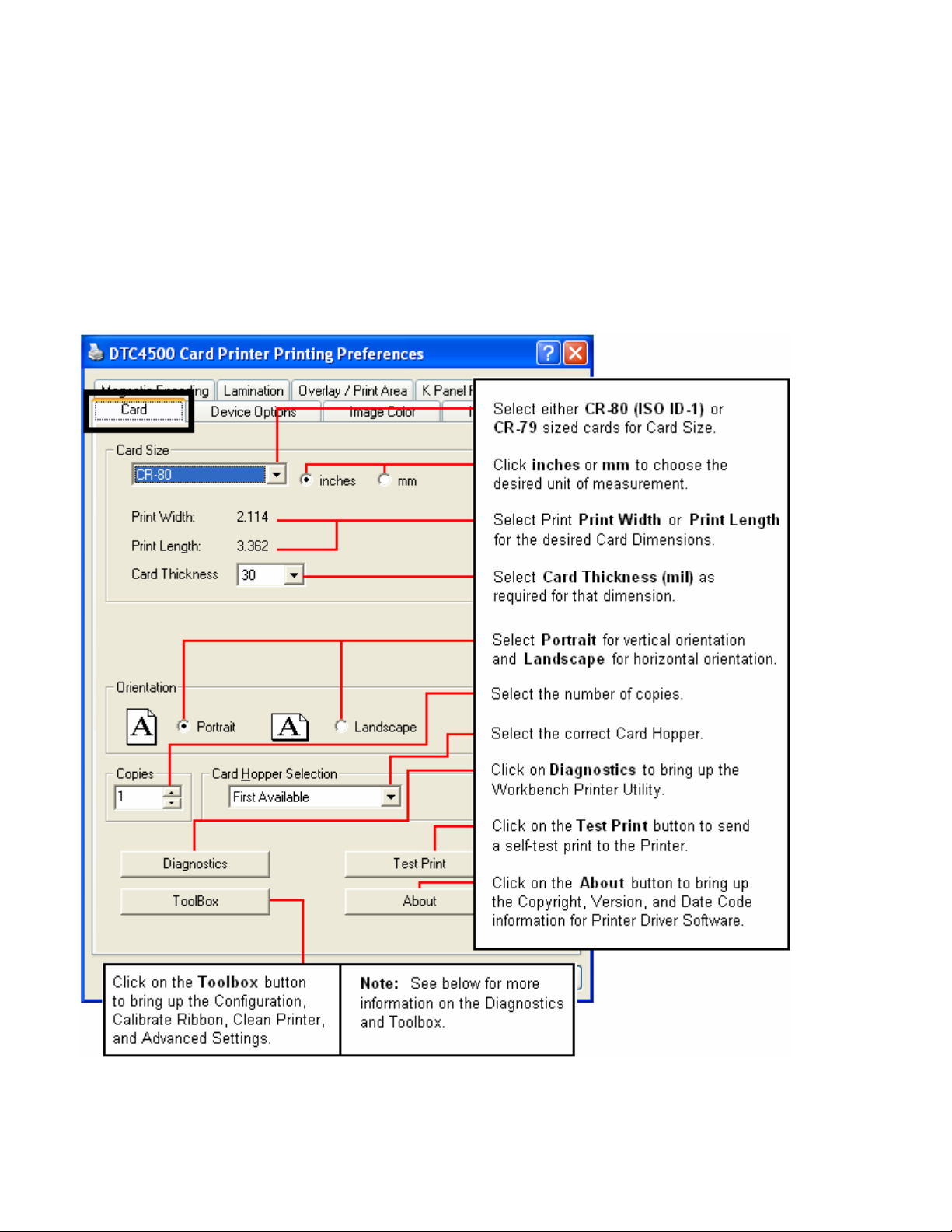

|contextid=30 Using the Card tab

Click on the Card tab to bring up the window (shown below). Refer to the Help file for the Fargo

Workbench Utility Program and User Guide.

DTC4500 Card Printer/Encoder User Guide

29

Page 30

© 2010 HID Global Corporation All rights reserved

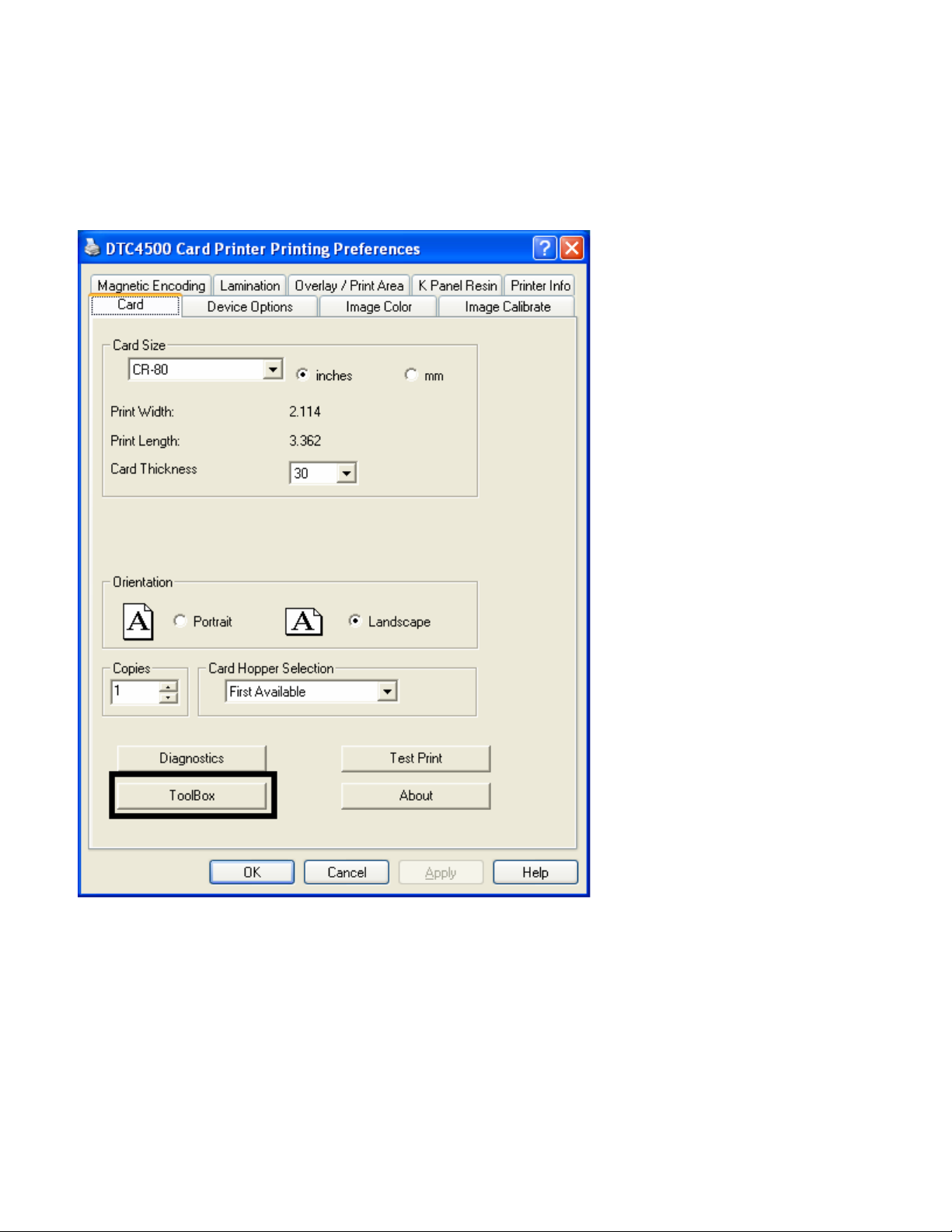

Using the Toolbox Options

DTC4500 Card Printer/Encoder User Guide

30

Page 31

© 2010 HID Global Corporation All rights reserved

|contextid=150 Using the Configuration Tab

This option is used to show the currently installed Optional Printer features, Event Monitoring, to set the

Printer Driver language and Printer LCD Display language.

• To switch between languages, select the desired language and reboot the driver.

DTC4500 Card Printer/Encoder User Guide

31

Page 32

© 2010 HID Global Corporation All rights reserved

|contextid=151 Selecting the Calibrate Laminator tab

The Calibrate Laminator tab is active when the Laminator is automatically detected or when the

Laminator is manually checked (as a Printer Feature on the Configuration tab). If the Laminator is not

detected and not manually checked, the tab is active; however, all functions are grayed out.

• Calibrate button: Sends calibrate Laminator command to Printer. Follow the instruction on the page

for setting up the Printer.

• Help button: Launches help specific to this tab.

Step Procedure

1 Select the Calibrate Laminator tab.

a. Ensure that the Cartridges are out of the Laminator.

b. Ensure the Laminator Cover is closed.

c. Click on the Calibrate button. (Note: The Printer’s LCD will display

CALIBRATE PASSED. Error Message Calibration Failed may be

solved by manually increasing the sensor calibration number to 13 of

higher under the Advanced Settings tab. Do not use the AUTO calibrate

function.)

d. Click on the OK button on the LCD display to complete the procedure.

DTC4500 Card Printer/Encoder User Guide

32

Page 33

© 2010 HID Global Corporation All rights reserved

Selecting the Calibrate Laminator tab

DTC4500 Card Printer/Encoder User Guide

33

Page 34

© 2010 HID Global Corporation All rights reserved

Using the Event Monitoring Group Box

This Event Monitoring group box displays the Low Supplies (Ribbon, Laminate and Film).

• The default setting is checked. If checked, the Ribbon Low message box is displayed with every

print job when Printer reports low Ribbon to the Driver.

• Do not show this message again: The check box allows the User to suppress message per Driver

instance. Default = unchecked.

Reviewing the Ribbon Low message

Display – Ribbon Low dialog

DTC4500 Card Printer/Encoder User Guide

34

Page 35

© 2010 HID Global Corporation All rights reserved

|contextid=152 Selecting the Calibrate Ribbon tab

The two buttons for the Calibrate Ribbon tab are described below.

• Calibrate button: Sends the Calibrate Ribbon Command to Printer. Follow the instructions below to

set up the Printer.

• Help button: Launches help specific to this tab.

Step Procedure

1 Select the Calibrate Ribbon tab.

a. Ensure that the Ribbon Cartridge is removed.

b. Ensure the Printer’s Cover is closed.

c. Click on the Calibrate button. (Note: The Printer’s LCD will display

CALIBRATE PASSED.)

d. Click on the OK button on the LCD display to complete the procedure.

DTC4500 Card Printer/Encoder User Guide

35

Page 36

© 2010 HID Global Corporation All rights reserved

Selecting the Calibrate Ribbon tab

DTC4500 Card Printer/Encoder User Guide

36

Page 37

© 2010 HID Global Corporation All rights reserved

|contextid=154 Selecting the Clean Printer tab

The button for the Clean Printer tab is described below.

• Clean Button: Launches cleaning routine. Follow the instruction on the page for setting up the

Printer.

• Help button: Launches help that is specific to this tab.

• Also see Cleaning the Printer

for full instructions.

DTC4500 Card Printer/Encoder User Guide

37

Page 38

© 2010 HID Global Corporation All rights reserved

|contextid=155 Selecting the Advanced Settings tab

Use the Advanced Settings tab for adjusting the internal Printer settings, which are customized for

every Printer at the factory and saved directly within the Printer's memory. (Note: You can select the

Restore Defaults to restore the internal default settings.)

Selecting the Advanced Settings tab

These change values for Firmware settings. See below.

• Setting Column: Displays label for setting

• Default Column: Displays default value for setting

• Current Column: Displays current value for setting

• Change the value by clicking on the value to activate spin control or type.

• Apply Button: Applies changed values.

• Restore Defaults Button: Restores default values.

DTC4500 Card Printer/Encoder User Guide

38

Page 39

© 2010 HID Global Corporation All rights reserved

Selecting the Advanced Settings tab

Example:

DTC4500 Card Printer/Encoder User Guide

39

Page 40

© 2010 HID Global Corporation All rights reserved

Selecting the Advanced Settings tab

Setting Option

Image Darkness

Mag Top of Form

Use this option to set the overall darkness of the printed

image by increasing or decreasing the amount of heat

(used by the Printhead when printing).

Caution: If the value is set too high, the

Ribbon may jam or even break.

Use this option to shift the starting point where the Printer

begins to encode the magnetic track data on the card’s

Magnetic Stripe.

Caution: If the negative value is set too

high, the Printer may start encoding before the Magnetic

Stripe reaches the encoding head.

• Maximum adjustment range is +/- 80.

• Each increment equals .01”.

Sleep Delay

The Sleep Time setting adjusts the number of minutes of

inactivity before the Printer enters a low power sleep

state.

DTC4500 Card Printer/Encoder User Guide

40

Page 41

© 2010 HID Global Corporation All rights reserved

Selecting the Advanced Settings tab

Setting Option

Print Top of Form

Print End of Form

Print Left of Form

Use this option to adjust the length-wise or horizontal

position of the printed image on the card (so it appears to

be centered).

Caution: If the negative value is set too

high, the Print Ribbon may break.

Use this option to reduce or increase the overall printable

area; this is done in order to optimize edge to edge

printing toward the trailing edge of the card.

• Maximum adjustment range is +/- 200.

• Each increment equals .01”.

Use this option to adjust the vertical position of the printed

image on the card; so it appears centered.

• Maximum Adjustment Range is +/- 127.

• Each increment equals .01”.

Cleaning Rate

Use this option to adjust the number of cards printed

before the Printer displays a message indicating cleaning

is needed.

• The default value is 3000 cards.

DTC4500 Card Printer/Encoder User Guide

41

Page 42

© 2010 HID Global Corporation All rights reserved

Selecting the Advanced Settings tab

Setting Option

Ribbon Calibrate Green

Ribbon Green LED Level

Ribbon Calibrate Green

Ribbon Blue LED Level

Ribbon Print Tension

This is a calibration driven value and should not be

adjusted.

(Note: This is factory set and should not be changed

unless directed by a technician.)

This is a calibration driven value and should not be

adjusted.

(Note: This is factory set and should not be changed

unless directed by a technician.)

This is a calibration driven value and should not be

adjusted.

(Note: This is factory set and should not be changed

unless directed by a technician.)

This is a calibration driven value and should not be

adjusted.

(Note: This is factory set and should not be changed

unless directed by a technician.)

Use the Ribbon Tension option to increase or

decreases the amount of tension (drag) on the Ribbon

during printing.

Flipper Home Offset

This is a calibration driven value and should not be

adjusted. If the Flipper unit is replaced and has not been

calibrated this value may need to be adjusted.

(Note: This is factory set and should not be changed

unless directed by a technician.)

DTC4500 Card Printer/Encoder User Guide

42

Page 43

© 2010 HID Global Corporation All rights reserved

Selecting the Advanced Settings tab

Setting Option

Flipper Lam Height

Offset

Mag HI-Co Voltage Offset

Mag Lo-Co Voltage

Offset

OLED Contrast

(display contrast)

Resin Heat Adjust

This is a calibration driven value and should not be

adjusted. If the Flipper unit is replaced and has not been

calibrated this value may need to be adjusted.

(Note: This is factory set and should not be changed

unless directed by a technician.)

This option changes the voltage going the magnetic head.

(Note: This is factory set and should not be changed

unless directed by a technician.)

This option changes the voltage going the magnetic head.

(Note: This is factory set and should not be changed

unless directed by a technician.)

Use this option to increase or decrease the contrast of the

printer OLED (if applicable).

Use this adjustment for Black resin text and barcodes

appear faded or too light/dark.

Adjust the Resin Heat, Front (K) or the Resin Head, Back

(K) as needed.

• Move the slider to the left to cause less heat to be

used in the printing process, causing resin images to

be lighter or less saturated.

OR

• Move the slider to the right to (a) cause more heat to

be used or (b) cause the resin image to be darker or

more saturated.

(Note: This control can be helpful for fine-tuning the

transfer of resin text and bar codes.)

DTC4500 Card Printer/Encoder User Guide

43

Page 44

© 2010 HID Global Corporation All rights reserved

Selecting the Advanced Settings tab

Setting Option

Head Resistance

Head Home Offset

Head Contact Offset

Erase Heat Offset

This is factory set. If the main board or the Printhead is

replaced then adjust this number.

Locate the Printhead Setting Number on the bottom of the

Printhead.

The number reads R=XXXX.

This is a calibration driven value and should not be

adjusted. If the Printhead assembly is replaced then this

value may need to be adjusted.

(Note: This is factory set and should not be changed

unless directed by a technician.)

This is a calibration driven value and should not be

adjusted. If the Printhead assembly is replaced then this

value may need to be adjusted.

(Note: This is factory set and should not be changed

unless directed by a technician.)

Adjust the Erase temperature for the rewriteable cards as

needed.

• Increase the Current Setting to cause more heat to

be used in the erasing process.

OR

• Decrease the Current Setting to cause less heat to be

used in the erasing process.

(Note: Erase Temp Offset provides user ability to control

the Printhead heat level when the Erase Operation is

performed. Appropriate heat levels should be applied for

the proper erase process. This setting should be adjusted

for proper erasure.)

DTC4500 Card Printer/Encoder User Guide

44

Page 45

© 2010 HID Global Corporation All rights reserved

Selecting the Advanced Settings tab

Setting Option

Write Heat Offset

Adjust the Write temperature for the rewriteable cards as

needed.

• Increase the Current Setting to cause more heat to

be used in the printing process of a rewritable card.

OR

• Decrease the Current Setting to cause less heat to be

used in the printing process of a rewritable card.

(Note: Write Heat Offset provides user ability to control

the Printhead heat level when the Write Operation is

performed. Appropriate heat levels should be applied for

the proper writing process.)

DTC4500 Card Printer/Encoder User Guide

45

Page 46

© 2010 HID Global Corporation All rights reserved

|contextid=40Using the Device Options tab

Click on the Device Option tab to bring up the window (shown below).

DTC4500 Card Printer/Encoder User Guide

46

Page 47

© 2010 HID Global Corporation All rights reserved

Using the Device Options tab

DTC4500 Card Printer/Encoder User Guide

47

Page 48

© 2010 HID Global Corporation All rights reserved

Using the Device Options tab

DTC4500 Card Printer/Encoder User Guide

48

Page 49

© 2010 HID Global Corporation All rights reserved

|contextid=50Using the Image Color tab

Click on the Image Color option tab to bring up the window (shown below).

DTC4500 Card Printer/Encoder User Guide

49

Page 50

© 2010 HID Global Corporation All rights reserved

Using the Image Color tab

DTC4500 Card Printer/Encoder User Guide

50

Page 51

© 2010 HID Global Corporation All rights reserved

Using the Image Color tab

DTC4500 Card Printer/Encoder User Guide

51

Page 52

© 2010 HID Global Corporation All rights reserved

|contextid=51Using the Image Calibrate tab

Use the Image Calibrate tab to control the position of the printable area in relation to the card.

DTC4500 Card Printer/Encoder User Guide

52

Page 53

© 2010 HID Global Corporation All rights reserved

|contextid=70Using the Magnetic Encoding Tab

Select the Magnetic Encoding tab to display options for controlling the Magnetic Stripe encoding

process.You should use these options only if the Printer has an optional Magnetic Stripe Encoding

Module installed.

DTC4500 Card Printer/Encoder User Guide

53

Page 54

© 2010 HID Global Corporation All rights reserved

Using the Magnetic Encoding Tab – ISO Standards

You can change the encoding mode and coercivity setting or modify the ISO standards for Tracks 1, 2

and 3. This can be done by correctly modifying these Magnetic Encoding options.

Window TAB Procedure Procedure (continued)

If you select ISO

Encoding, you send

down a formatted set of

characters.

If you select Custom

Encoding, all options

are active.

If you select Raw

Binary Encoding, you

send down a raw binary

string rather than a

formatted set of

characters.

This selection activates the

track tabs. However, all

functions on the Track tabs

are inactive or gray and

display ISO defaults, which

are the defaults listed for each

track below. The Shift Data

Left check box remains

unchecked and inactive.

The Default is ISO Encoding.

(Note: The defaults are the

same as the ISO Encoding

defaults.)

All functions on the Magnetic

Track Options tabs are active.

The Coercivity dropdown

function is active and the

Shift Data Left checkbox is

not active.

All functions on the Magnetic

Track Options tabs are

inactive except for Bit

Density.

DTC4500 Card Printer/Encoder User Guide

54

Page 55

© 2010 HID Global Corporation All rights reserved

Using the Magnetic Encoding Tab – ISO Standards

Window TAB Procedure Procedure (continued)

If you select JIS II

Encoding, specific

standards are used.

This selection disables all the

Magnetic Track Options tabs.

It also disables the Coercivity

dropdown function and Shift

Data Left checkbox option.

Select the Coercivity

option (Oersted) to use

the Magnetic Stripe type

that matches the card

type.

The default Coercivity is 600 Oe.

• High Coercivity to Super

Coercivity = 2750-4000

Oersted

• Fargo’s High Coercivity

UltraCard IIIs are 2750 Oe

• Medium Coercivity=600

Oersted

• Low Coercivity = 300

Oersted

Select this option to shift

the recorded magnetic

data to the left-hand

This is useful in situations that

require cards to be readable

with insert type readers.

side of the card's

Magnetic Stripe.

Select the Magnetic

Track Selection option

to specify which track is

to be configured through

the Magnetic Track

Options.

DTC4500 Card Printer/Encoder User Guide

This applies if the application

being used

requires

customization of the standard

ISO encoding process.

55

Page 56

© 2010 HID Global Corporation All rights reserved

Using the Magnetic Encoding Tab – Custom Encoding or Raw Binary Encoding Mode

You can change the Magnetic Track options for Tracks 1, 2 and 3 when using the Custom Encoding or

Raw Binary Encoding Mode. These options are not availabe for ISO or JIS II encoding.

Window TAB Procedure Procedure (continued)

Select 4 Bits to change the bits

per character to 4 BPC. (Note:

This is the default for Track 3).

Select 5 Bits to change the bits

per character to 5 BPC. (Note:

This is the default for Tracks 2

and 3).

Select NULL to change the

ASCII Offset to NULL.

Select SPACE to change the

ASCII Offset to SPACE. (Note:

This is the default for Track 1.)

Select 75 BPI to change the bits

per inch to 75 BPI. (Note: This

is the default for Track 2.)

Select 128 BPI to change the

bits per inch to 128 BPI.

Select 7 Bits to change the

bits per character to 7 BPC.

(Note: This is the default for

Track 1).

Select 8 Bits to change the

bits per character to 8 BPC.

Select ZERO to change the

ASCII Offset to ZERO. (Note:

This is the default for Tracks 2

and 3.)

Select 210 BPI to change the

bits per inch to 210 BPI.

(Note: This is the default for

Tracks 1 and 3.)

Select Custom BPI, which

enables the custom BPI text

box. (Note: The lower limit is

75 and upper limit is 210.)

DTC4500 Card Printer/Encoder User Guide

56

Page 57

© 2010 HID Global Corporation All rights reserved

Using the Magnetic Encoding Tab – Custom Encoding or Raw Binary Encoding Mode

Window TAB Procedure Procedure (continued)

Select No LRC to change the

LRC Generation to none.

Select Even Parity to change

the LRC Generation to Even

Parity. (Note: This is the default

for all tracks.)

Select No Parity to change the

Character Parity to none.

Select Even Parity to change

the Character Parity to Even

Parity.

Reverse Bit Order is used to

reverse the character bits and is

used for the encryption of data

in specific programs

Select Odd Parity to change

the LRC Generation to Odd

Parity.

Select Odd Parity to change

the Character Parity to Odd

Parity. (Note: This is the

default for all tracks.)

Add Leading Zeros is used to

add a set number of leading

zeros to the magnetic string in

order to move the starting

point of the encoded data in

specific programs for

encryption of data.

Reviewing the ISO Track Locations

The magnetic Encoding Module encodes onto tracks in accordance with an ISO 7811-2 Magnetic Stripe.

For track locations, review the display below.

0.223" 0.353" 0.493"

TRACK1 0.110"

0.130"

TRACK2 0.110"

0.140"

TRACK3 0.110"

DTC4500 Card Printer/Encoder User Guide

57

Page 58

© 2010 HID Global Corporation All rights reserved

Reviewing the Sample String

• Track 1: ~1%JULIEANDERSON^1234567890?

• Track 2: ~2;1234567890987654321?

• Track 3: ~3;1234567890987654321?

Track

Track 1

Track 2

Track 3

Start

Sentinel

End

Sentinel

Field

Separator

% ? ^

; ? =

; ? =

Valid Characters

ASCII 32-95

(See the table below.)

ASCII 48-63

(See the table below.)

ASCII 48-63

(See the table below.)

Maximum

Number of

Characters

78

39

106

DTC4500 Card Printer/Encoder User Guide

58

Page 59

© 2010 HID Global Corporation All rights reserved

Sending the Track Information

Magnetic track data is sent in the form of text strings from the application software to the Printer Driver.

• In order for the Printer Driver to differentiate between Magnetic Track data and the rest of the

printable objects, specific characters must be added to the magnetic data to be encoded.

• These specify the data that is to be encoded, the tracks to encode and mark the start and stop of the

data string. In some cases, these specific characters are automatically added to the string of track

data by ID software applications.

• In most cases, the user must carefully add these characters to the string of Magnetic Track data. If

these characters are not added to the track data, the text intended for the Magnetic Track will appear

as printed text on the card. To avoid this, track information must be entered as described below.

Step Procedure

1 When entering track data, the ~ (tilde) character is entered first, followed by the

track number (1, 2 or 3) on which the data should encode. This is followed by

the data to be encoded.

• The first character of this data string must be the track's specific Start

Sentinel (SS) and the last character must be the specific End Sentinel

(ES).

• The characters or data in between the SS and ES can include all of the

valid characters specific to each track.

• The number of these characters, however, is limited by each track's

maximum character capacity.

• When segmenting track data, the appropriate Field Separator (FS) must be

used. The table below shows the SS, ES, FS and the valid characters

defined for each track.

DTC4500 Card Printer/Encoder User Guide

59

Page 60

© 2010 HID Global Corporation All rights reserved

Reviewing the ASCII Code and Character Table

ASCII Code Character ASCII Code Character ASCII

Character

Code

32 space 56 8 80 P

33 ! 57 9 81 Q

34

58 : 82 R

35 # 59 ; 83 S

36 $ 60 < 84 T

37 % 61 = 85 U

38 and 62 > 86 V

39 ' 63 ? 87 W

40 ( 64 @ 88 X

41 ) 65 A 89 Y

42 * 66 B 90 Z

43 + 67 C 91 [

44 ' 68 D 92 \

45 - 69 E 93 ]

DTC4500 Card Printer/Encoder User Guide

60

Page 61

© 2010 HID Global Corporation All rights reserved

Reviewing the ASCII Code and Character Table

ASCII Code Character ASCII Code Character ASCII

Character

Code

46 . 70 F 94 ^

47 / 71 G 95 _

48 0 72 H

49 1 73 I

50 2 74 J

51 3 75 K

52 4 76 L

53 5 77 M

54 6 78 N

55 7 79 O

DTC4500 Card Printer/Encoder User Guide

61

Page 62

© 2010 HID Global Corporation All rights reserved

|contextid=80Using the Lamination tab

Use the Image Calibrate tab to control the position of the printable area in relation to the card.

|contextid=90 Using the Overlay / Print Area tab

This option is helpful if, for example, you would like to omit the printing or block out the overlay for a

signature or printing around a card's smart chip or Magnetic Stripe. Refer to Using the Defined Area

Option for a specific procedure that relates to this tab.

DTC4500 Card Printer/Encoder User Guide

62

Page 63

© 2010 HID Global Corporation All rights reserved

DTC4500 Card Printer/Encoder User Guide

63

Page 64

© 2010 HID Global Corporation All rights reserved

Using the Overlay / Print Area tab

DTC4500 Card Printer/Encoder User Guide

64

Page 65

© 2010 HID Global Corporation All rights reserved

Using the Overlay / Print Area tab

DTC4500 Card Printer/Encoder User Guide

65

Page 66

© 2010 HID Global Corporation All rights reserved

|contextid=100Using the K Panel Resin tab

Use this tab to control where the resin black (K) Panel of a full-color Ribbon is printed. Refer to Using the

Defined Area Option for a specific procedure that relates to this tab.

DTC4500 Card Printer/Encoder User Guide

66

Page 67

© 2010 HID Global Corporation All rights reserved

Using the K Panel Resin tab

DTC4500 Card Printer/Encoder User Guide

67

Page 68

© 2010 HID Global Corporation All rights reserved

Using the K Panel Resin tab

DTC4500 Card Printer/Encoder User Guide

68

Page 69

© 2010 HID Global Corporation All rights reserved

|contextid=120Using the Printer Info tab

Use the options on this tab to view information about the Ribbon, Laminate, Card Count, Printer Serial #,

Firmware version, and Reorder Media #’s installed in the Printer.

DTC4500 Card Printer/Encoder User Guide

69

Page 70

© 2010 HID Global Corporation All rights reserved

Section 5: Selecting the Fluorescent Panel Ribbon Type

The YMCFKO/YMCFKOK Ribbon is an economical way to add a fully customizable, incremental level of

security to your photo identification cards.

• Process: This process allows you to configure the data that is printed with the fluorescent panel of

an YMCFKO/YMCFKOK Ribbon. (Note: Any software program may be used to print the special

florescent panel of the Ribbon to a card once the Driver and Workbench are set up correctly.)

• Ribbons: These Ribbons contain a yellow (Y), magenta (M), cyan (C), and resin black (K) panels to

create a full color over-the-edge printing identification card. In addition, the Ribbon contains a dyebased fluorescing panel (F) which will allow you to print a standard or one-to-one personalized

grayscale fluorescing image that is completely invisible until exposed to ultraviolet light.

Creating a Custom Fluorescent Image (using the YMCFKO Ribbon)

There are three (3) methods used to accomplish the creation of a custom fluorescent image when using

the YMCFKO Ribbon.

• First Method: The first method uses the Fargo Workbench Printer Utility to create a static image that

will be applied automatically to each card sent to the Printer. Refer to the Help file for the Fargo

Workbench Utility Program and User Guide or to Appendix A for Configuring Fluorescent Data

(F-Panel for YMCFKO Ribbon) using the Workbench.

• Second Method: The second method (described below) allows the creation of the fluorescent panel

image directly from the badge application software. (Note: You can now print a unique fluorescent

image, such as the card holder’s picture on each card.)

• Third Method: The third method is described in the Asure ID 2009 Software User Guide. See the

procedure relating to the Fluorescent Panel Ribbon. For more information about Asure ID 2009,

please visit our website at http://www.hidglobal.com/cardIssuance/idSoftware.php

DTC4500 Card Printer/Encoder User Guide

70

Page 71

© 2010 HID Global Corporation All rights reserved

Creating a Custom Fluorescent Image (using the YMCFKO Ribbon)

DTC4500 Card Printer/Encoder User Guide

71

Page 72

© 2010 HID Global Corporation All rights reserved

Configuring Fluorescent Data (F-Panel for YMCFKO Ribbon) using the Application

This process creates a fluorescent image on your card using a simple text string command in your badge

application.

Step Procedure

1 Creating Fluorescent Text: Create a new text box in your badge application.

2 Type the TEXT that you want to appear as fluorescent and put a ~T before

the start of the text with no space after the ~T. The text will start on the card

where the ~T begins. (see Display A below)

DTC4500 Card Printer/Encoder User Guide

72

Page 73

© 2010 HID Global Corporation All rights reserved

Configuring Fluorescent Data (F-Panel for YMCFKO Ribbon) using the Application

Step Procedure

3 Creating a Fluorescent Image: In a separate drawing program, create the

image that you wish to fluoresce. (See Display C below.)

4 Create the IMAGE in the actual size that you want it to appear on the card,

and save it as a Grayscale or 1 - bit bmp file on the root c:\ directory.

• Do not put spaces in the file name.

5 Create a new text box in your badge application, and type ~I followed by the

address of your image (see Display A below). The top left of your image will

start at the top left of your text box.

DTC4500 Card Printer/Encoder User Guide

73

Page 74

© 2010 HID Global Corporation All rights reserved

Configuring Fluorescent Data (F-Panel for YMCFKO Ribbon) using the Application

Step Procedure

6 Set up the Printer Driver preferences. Refer to Step 8-10 below.

7 Printer will print the fluorescent BMP IMAGE at the ~I position on the card.

Printer will print the fluorescent TEXT at the ~T position on the card. (See

Display B below)

BMP Image located at c:\globe.bmp

8 Set the Ribbon for YMCFKO in the Printing Preferences. ( Note: The Detect

Supplies at Print Time button may also be used.)

9 Check Dual Pass if you would like to print the F-Panel on a separate panel of

HDP film from the YMC image.

You should use:

The default Dual Pass option if the fluorescent image is used in places where

other dye is used.

OR

Any time the Invert F-Panel Image option is selected.

DTC4500 Card Printer/Encoder User Guide

74

Page 75

© 2010 HID Global Corporation All rights reserved

Configuring Fluorescent Data (F-Panel for YMCFKO Ribbon) using the Application

Step Procedure

10 Check Invert F-Panel Image to create a negative of the fluorescent image.

See below.

• This refers to the ability to cause light or white areas of the image to

fluoresce and dark colors to remain dark on the printed card when exposed

to a UV light.

• This was requested because the fluorescent dye color is bright when black

light is applied to it.

By default, the dark areas of the image will fluoresce on the card and the

lighter or white areas will have no dye applied. (Note: This may improve the

look of the person’s image if used for the Logo.)

DTC4500 Card Printer/Encoder User Guide

75

Page 76

© 2010 HID Global Corporation All rights reserved

Section 6: System Overview- Troubleshooting

Reviewing the DTC4500 Sequence of Operations

Knowing the sequence of the Printer operation will help troubleshoot the printer.

Step Process

1 The File information is received from PC.

2 Printer checks the installed Ribbon type stored in memory against the Ribbon

type command that was sent from the Printer. If Ribbon type does not match,

the Pause button on the right will begin flashing.

3 The Print Stepper Motor engage.

4 The Card Feed Sensor detects leading edge of card, the Headlift Stepper then

engages to disengage the input lever.

5 The card feeds through for the alignment pass.

6 The Card Feed Stepper Motor engages to queue card for magnetic encoding

(if applicable).

7 The Encoding data is written to the card (if applicable).

8 The Magnetic Encoder verifies while the Stepper reverses the card (if

applicable).

9 The Print Ribbon Drive engages (if not already at the yellow Panel).

10 The Print Ribbon Sensor looks for the Yellow Panel. (Note: The Print Ribbon

Encoder detects number of revolutions, required to use an entire color Panel.)

11 The Print Stepper Motor engages.

12 The Card Feed Sensor detects the leading edge of card.

DTC4500 Card Printer/Encoder User Guide

76

Page 77

© 2010 HID Global Corporation All rights reserved

Reviewing the DTC4500 Sequence of Operations

Step Process

13 The Print Stepper Motor queues card to the middle of the platen Roller. All

Stop.

14 The Print Headlift Motor engages to the print position.

15 The Print Cover Sensor checks for closed state.

16 The Print Stepper Motor engages.

17 The Ribbon Drive Motor engages.

18 The Image data is burned by the Printhead until the image data is depleted. All

Stop.

19 The Thermistor engages the Printhead Cooling Fan to maintain proper

operating temperature.

20 The Headlift Motor engages to the queue position.

21 The Print Stepper Motor engages.

22 The Print Ribbon Drive engages.

23 After Ribbon advances a few Encoder clicks, assume the Ribbon is free of

card. All stop.

24 Repeat Steps 9 through 22 for the appropriate number of color/overlay Panels.

25 Either the Card is ejected from the singled-sided Printer or the Card Feed

Stepper engages to queue the card for the Flipper Table for the dual-sided

Printer.

26 All Stop.

DTC4500 Card Printer/Encoder User Guide

77

Page 78

© 2010 HID Global Corporation All rights reserved

Section 7: Troubleshooting

Printer Error Button and Display Message Table

Both the DTC4500 use the Button messages rather than the Display Message system.

Step Procedure

1

All Printers have two (2) buttons, one for ON/Off (LEFT) and one for Pause (II)

(RIGHT).

2 The ON/Off button is blue when the Printer is ON. When the Printer enters the

Sleep Mode, the LED is dimmed but still ON.

3 The Pause (II) button will be illuminated blue when the Printer is capable of

accepting a printjob and does not have an error.

• This LED will continue to stay on while the Printer prints as long as there is

no error.

• This LED will also be dimmed when the Printer goes into sleep mode.

4 When an error occurs, the Pause button will no longer be illuminated blue, but

will blink red.

DTC4500 Card Printer/Encoder User Guide

78

Page 79

© 2010 HID Global Corporation All rights reserved

Printer Error Button and Display Message Table

Both the DTC4500 use the Button messages rather than the Display Message system.

Step Procedure

5 Press the ON/Off button when Printer is in an error state to cause the action to

be cancelled. (Note: If no other error occurs, then the Pause button will

illuminate its blue LED.)

6

Press the Pause button when Printer is in an error state to cause the Printer to

retry. (Note: It will illuminate its blue LED and retry the failed action.)

7

When downloading an upgrade file, both blue LED’s will blink. If the unit is a

DTC1000:

• You have been advised that the upgrade is in process.

8

If a language (other then English) is currently selected:

• You can press and hold the Pause button during the power-up sequence to

change the language back to English.

9

When no LCD Display is available, press or hold the buttons to access certain

Internal Test jobs. See below.

• To print a card with the Printer Settings, press the Pause button and hold for

4+ seconds when the Printer is ready and idle.

• To print the alignment or the Self Test, press the ON/OFF button then

immediately press the Pause button.

DTC4500 Card Printer/Encoder User Guide

79

Page 80

© 2010 HID Global Corporation All rights reserved

Using the Error Message Table

This section provides the troubleshooting table for the error message. The DTC4500 has a display that

will show the Printer error messages.

• When an error occurs in the Printer, the PC will show the error message on screen with solutions.

• The display will blink in the location needing attention. Those locations include the Printer, Input

Hopper, Magnetic Encoder, Flipper, Card Path, Ribbon, and Data/Communication error device.

Each table uses a 3- column presentation to present a specific or Printer error message, its cause and its

solution.

• This allows the troubleshooter to identify the error and its cause, and then perform the procedure

(provided in the solution column).

• This standard mode of identifying the problem and its solution should provide an efficient method of

troubleshooting this Printer.

• If you encounter problems beyond the capabilities of these the error message table, you should

contact Technical Support. Refer to: Section 10: HID Global Technical Support

DTC4500 Card Printer/Encoder User Guide

80

Page 81

© 2010 HID Global Corporation All rights reserved

Using the Error Message Table

Error Message Cause Solution

# 81

Unable to Feed

The Printer is unable to

feed a card from the

Card Hopper.

Check the following, then press the

Pause button to continue.

• Verify the card thickness setting is

set to the thickness of your cards.

• Verify the Cleaning roller is properly

installed on the Ribbon Cartridge.

• Check for card slippage. If

necessary, run the Printer cleaning

routine.

• Verify that your cards are within the

perimeters accepted card size range.

• Verify the cards are not sticking

together.

DTC4500 Card Printer/Encoder User Guide

81

Page 82

© 2010 HID Global Corporation All rights reserved

Troubleshooting with the Error Message Table

Error Message Cause Solution

# 2

Head Move Error

# 3

Headlift Error

|contextid=201

# 8

Head Sensor Error

|contextid=200

# 9

Reboot Required

# 25

Ribbon not Installed

|contextid=232

This is a problem with the

Printhead Lift.

The Printhead

Temperature Sensor is not

functioning or is not

connected properly.

OR

The Printhead is not

cooling properly.

Unspecified system error

detected by the Printer

Firmware.

A Ribbon is not installed in

the Printer.

Reset the Printer and try again.

• If this problem persists, call for

technical assistance.

Reset the Printer and try again.

• If the problem persists, call for

technical assistance.

Reset the Printer and try again.

• If this problem persists, call for

technical assistance.

Install a Ribbon and retry.

DTC4500 Card Printer/Encoder User Guide

82

Page 83

© 2010 HID Global Corporation All rights reserved

Troubleshooting with the Error Message Table

Error Message Cause Solution

# 30

Mag Verify Error

|contextid=251

|contextid=252

# 31

No Mag Module

|contextid=250

# 38

# 39

# 40

EEPROM Corrupt

EEPROM Read

Error

Magnetic encoding

verification failure.

You are trying to send

encoding data, but the

Printer is not configured

with this Encoder type.

EEPROM restored with

factory default values.

• Try encoding with a different

card.

• Verify cards have the Magnetic

Stripe.

• Replace the Magnetic Encoding

Module.

• Ensure that no encoding data is

being sent with the print job and

reprint the card.

• Install a Magnetic Encoding

Module.

If changes were made in the

Advanced Setting Tab in the Printer

Driver, click the Default button to

reset these numbers.

• Reset the Printer and try again. If

this problem persists, call for

technical assistance.

DTC4500 Card Printer/Encoder User Guide

83

Page 84

© 2010 HID Global Corporation All rights reserved

Troubleshooting with the Error Message Table

Error Message Cause Solution

# 44

Flipper Jam/ Home

Error

|contextid=220

# 45

No Flip Module

|contextid=221

# 48

Check Lam Power

|contextid=281

# 52

Lam Generic Error

|contextid=280

A card has become

jammed in the Printer’s

Flipper Table.

The Flipper failed to

position properly while

aligning a card or flipping a

card.

Request to print on 2

nd

side

of card, but no Flipper is

installed.

Lam is connected but not

powered.

Laminator firmware error

Clear any cards in the Flipper Table

using the buttons to move the card

out. Resume printing.

• Reset the Printer and retry. If

problem persists call for technical

assistance.

If a Flipper Module is present,

ensure that the Print Both Sides

option in the Printer Driver is set

correctly.

• Install a Flipper module.

Power off the Printer, power the

Laminator, and then power on the

Printer. A damaged Flipper board,

E-Card board, or EEPROM could

potentially result in this same error.

Cycle power and try again.

• If this problem persists call for

technical assistance.

DTC4500 Card Printer/Encoder User Guide

84

Page 85

© 2010 HID Global Corporation All rights reserved

Troubleshooting with the Error Message Table

Error Message Cause Solution

# 53

Lam Card Jam

# 63

Lam Tag Error

|contextid=286

# 64

# 65

# 66

Reboot Required

# 68

Card in Printer

# 70

Multiple Feed

|contextid=211

A jam occurred

somewhere between the

Printer and the laminator

There is no material

loaded in the laminator

Unspecified system error

detected by the Printer

Firmware.

A card is jammed in the

Print Station or card

flipping area of the Printer.

Multiple cards were fed

into the Printer.

Open covers and clear the

obstruction/jam

Load material into the Laminator

Reset the Printer and try again.

• If this problem persists, call for

technical assistance.

Clear the jam and press the the

Pause button.

Verify the card thickness is set to

the thickness of your cards, then

press the Pause button.

• Check for card slippage. If

necessary, run the Printer

cleaning routine

DTC4500 Card Printer/Encoder User Guide

• Verify the Cleaning roller is

properly installed on the Ribbon

Cartridge.

• Verify the cards are not sticking

together.

85

Page 86

© 2010 HID Global Corporation All rights reserved

Troubleshooting with the Error Message Table

Error Message Cause Solution

# 81

Unable to Feed

|contextid=214

|contextid=210

# 82

Mag Jam

|contextid=216

The Printer is unable to

feed a card from the Card

Hopper.

A card is jammed Magnetic

station

Check the following, then press the

Pause button to continue.