Page 1

Installation Manual - 5375-900 Rev 06

MaxiProx Reader 5375A

__________________________________________________________________________________________________________

HID Corporation, 9292 Jeronimo Road, Irvine, CA 92618-1905, USA •Tel: (949) 598-1600, (800) 237-7769, Fax: (949) 598-1690

http://www.hidcorp.com MaxiProx Reader Installation Manual 5375-900 REV 06

Page

i

Page 2

CONTENTS

CHAPTER 1 MAXIPROX SYSTEM OVERVIEW ............................................................................................................1

1.1 O

1.2 P

1.3 R

PERATION......................................................................................................................................................................1

ARTS LIST......................................................................................................................................................................1

EGULATORY APPROVALS AND CERTIFICATIONS ............................................................................................................1

CHAPTER 2 INSTALLATION PROCEDURE...................................................................................................................2

2.1 P

2.2 M

2.3 M

2.4 C

2.5 I

2.6 C

2.7 C

2.8 D

2.9 T

2.10 M

2.11 P

2.12 A

2.13 R

2.14 P

2.15 P

2.16 S

2.17 I

REPARATION..................................................................................................................................................................2

OUNTING AND INSTA LLATION.......................................................................................................................................2

OUNTING APPLICATIONS...............................................................................................................................................2

ABLE PREPARATION ......................................................................................................................................................2

NSTALL CABLE...............................................................................................................................................................2

ABLE NOTES..................................................................................................................................................................2

ABLE CONNECTIONS......................................................................................................................................................3

IPSWITCH AND JUMPER SETTINGS .................................................................................................................................4

AMPER SWITCH .............................................................................................................................................................5

OUNTING ......................................................................................................................................................................5

OWER SUPPLY................................................................................................................................................................6

UTOTUNE OPERATION...................................................................................................................................................6

EADER TESTING ............................................................................................................................................................6

OWER-UP TUNE.............................................................................................................................................................6

ERIODIC AUTOTUNE.......................................................................................................................................................6

UPERVISOR MODE .........................................................................................................................................................6

NSTALL COVER...............................................................................................................................................................6

CHAPTER 3 INSTALLATION NOTES AND GUIDELINES...........................................................................................9

3.1 P

3.2 I

3.3 R

3.4 T

OWER SUPPLY................................................................................................................................................................9

NSTALLATION NEAR METAL ...........................................................................................................................................9

ADIO FREQUENCY INTERFERENCE.................................................................................................................................9

RANSPONDER TYPES ...................................................................................................................................................10

CHAPTER 4 APPLICATION NOTES...............................................................................................................................11

4.1 WIEGAND INTERFACE DESCRIPTION..............................................................................................................................11

4.1.1 Wiegand Message Format....................................................................................................................................11

4.1.2 Output Specification .............................................................................................................................................11

4.1.3 Signal Levels.........................................................................................................................................................12

4.1.4 Data Pulses...........................................................................................................................................................12

4.1.5 Example Output....................................................................................................................................................12

4.2 CLOCK AND DATA INTERFACE DESCRIPTION.................................................................................................................13

4.2.1 Clock and Data Message Format.........................................................................................................................13

4.2.2 Data Timing..........................................................................................................................................................13

4.2.3 Output signal Levels.............................................................................................................................................14

4.2.4 Bit structure..........................................................................................................................................................14

4.2.5 Bit Stream.............................................................................................................................................................15

4.2.6 Output Specification .............................................................................................................................................16

4.3 RS232/RS422 C

__________________________________________________________________________________________________________

HID Corporation, 9292 Jeronimo Road, Irvine, CA 92618-1905, USA •Tel: (949) 598-1600, (800) 237-7769, Fax: (949) 598-1690

http://www.hidcorp.com MaxiProx Reader Installation Manual 5375-900 REV 06

ARD MESSAGE SPECIFICATION (SEND MODE ONLY) ...........................................................................16

ii

Page

Page 3

FIGURES

FIGURE 1: MAXIPROX FRONT VIEW ...............................................................................................................................................7

F

IGURE 2: MAXIPR OX INSIDE VIEW SHOWING MOUNTING HOLE LOCATIONS ...................................................................................8

F

IGURE 3: DATA PULSES - TIMING PARAMETERS .........................................................................................................................12

F

IGURE 4: DATA TIMING - TIMING CHART....................................................................................................................................14

TABLES

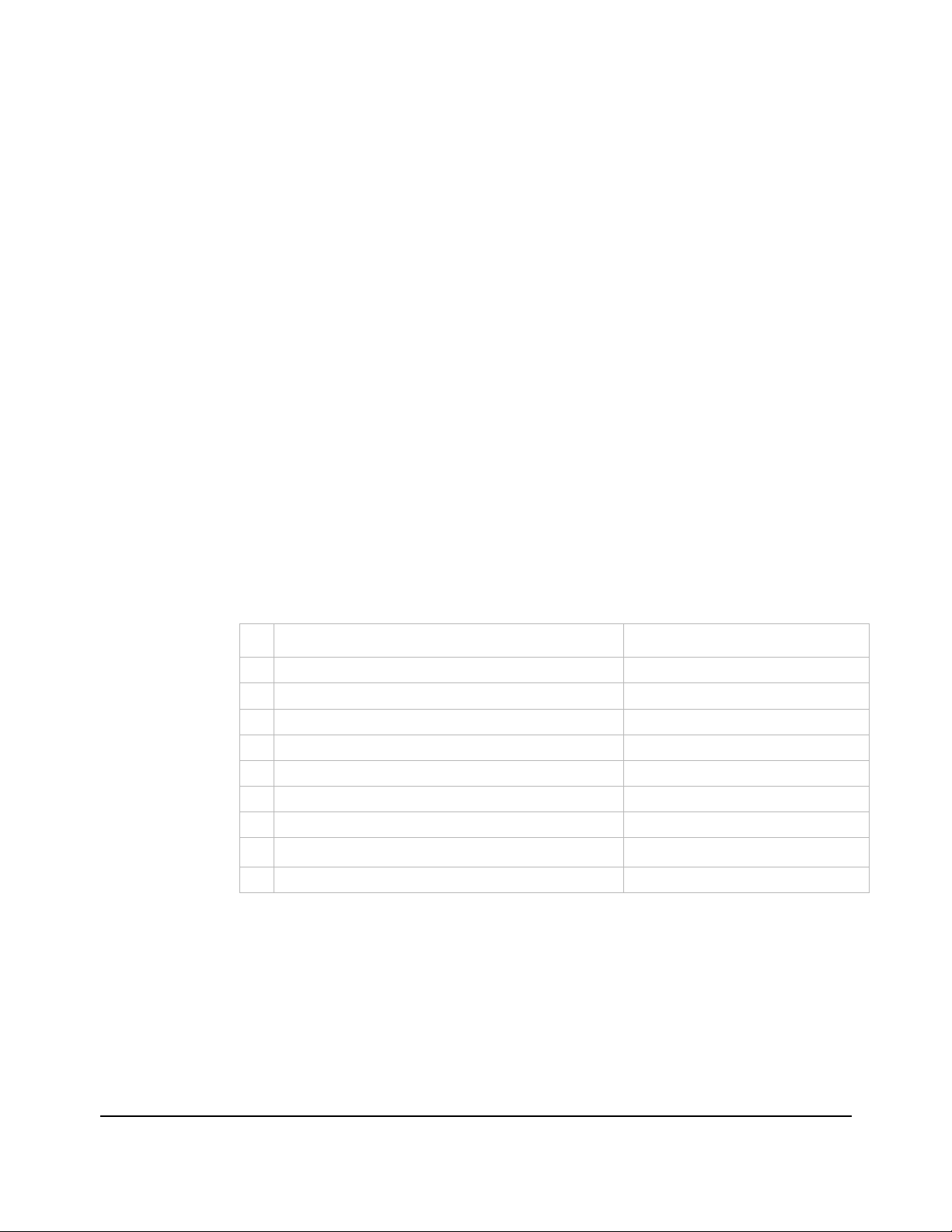

TABLE 1: TB1 CONNECTOR DEFINITION ........................................................................................................................................3

T

ABLE 2: TB2 CONNECTOR DEFINITION ........................................................................................................................................3

T

ABLE 3: DIPSWITCH AND JUMPER SETTINGS ...............................................................................................................................4

T

ABLE 4: INTERFACE JUMPERS DESCRIPTION - P3 AND P4.............................................................................................................4

T

ABLE 5: SWITCH DESCRIPTION - SW2..........................................................................................................................................4

T

ABLE 6: MODE CHART .................................................................................................................................................................4

T

ABLE 7: BAUD RATE CHART – RS232 AND RS422 ......................................................................................................................4

T

ABLE 8: SWITCH DESCRIPTION - SW5..........................................................................................................................................5

T

ABLE 9: LOGIC LEVELS ..............................................................................................................................................................12

__________________________________________________________________________________________________________

HID Corporation, 9292 Jeronimo Road, Irvine, CA 92618-1905, USA •Tel: (949) 598-1600, (800) 237-7769, Fax: (949) 598-1690

http://www.hidcorp.com MaxiProx Reader Installation Manual 5375-900 REV 06

Page

iii

Page 4

Chapter 1 MaxiProx System Ov erview

The MaxiProx Reader is a self-contained proximity Reader. The two piece polycarbonate enclosure has an

O-ring that weather seals the enclosure pieces together and a cable fitting that seals the cable entry. The

water-resistant unit is designed for outdoor use. The enclosure is mountable on a single gang electrical box.

A bi-color LED and audible tone provide user feedback. Configurable open collector data outputs provide

the data to the Host. Configurable DIPswitches and jumpers provide choice of data interfaces between

Wiegand,

but can be changed in the field - please contact

alert the Host when the enclosu re is opened.

the outputs, audible tone and LED control options. Installation of the MaxiProx Reader consists of

mounting, connecting the cable to the Host and +12VDC or +24VDC power, verifying the DIPswitch and

jumper settings, verifying Autotune, and verifying the reading of a transponder.

1.1

1.1 Operation

1.1 1.1

Transponders (Proximity Cards or ProxKeys) are presented to the front of the MaxiProx. The LED is red

when ready to read a tran s pon der. The L ED tu rn s green an d th e beeper s oun ds when the transponder is read

and the message is transmitted to the Host computer or interface panel. The system is ready for another

transponder as soon as the LED returns to

seconds before it will read the same card. The LED flash is typically 250 milliseconds long. The operation of

the LED and beeper may be controlled by the Host, in which case the actual operation will depend on the

programmed ti m in g of the H ost.

Clock and Data, RS 232 and RS422. The data interface is conf ig u red as ordered from the factory,

HID Technical Support for assistan ce. A tamper switch can

Internal DIP switches and jumpers provide for configuration of

Operation

OperationOperation

red. There is an anti-passback delay of about one and a half

1.2

1.2 Parts List

Parts List

1.2 1.2

Parts ListParts List

MaxiProx Reader Qty 1 (included)

1.

2. Installation Manual Qty 1 (included)

3. Cable Fitting Qty 1 (included)

4. Label for front cover - HID logo Qty 1 (included)

5. #6-32 x 1" flat head screw, for upper-left base mount screw Qty 1 (included)

6. #6-32 x 1" black screw, for gang-box mounting Qty 2 (included)

7. #6-32 x .75" flat head screw, for front cover mounting Qty 1 (included)

8. Cable, 5 conductor, 22 AWG (Alpha 1295 C or equivalent) See cable notes

9. Power Supply – 2.0 A linear regulated

10. +12VDC Shunt Jumper – P2-1 to P2-2 for 12VDC operation +12VDC, nominal (+11VDC to +20VDC)

1.3

1.3 Regulatory Approvals and Certifications

Regulatory Approvals and Certifications

1.3 1.3

Regulatory Approvals and CertificationsRegulatory Approvals and Certifications

+24VDC, nominal (+21 to +28.5VDC)

Factory Default – No P2 Shunt J umper

Underwriters Laboratories listing

FCC Certification

Foreign Countries EMC an d/or Ty pe Approv als

CE Mark

European Declaration of Conform ity

__________________________________________________________________________________________________________

HID Corporation, 9292 Jeronimo Road, Irvine, CA 92618-1905, USA •Tel: (949) 598-1600, (800) 237-7769, Fax: (949) 598-1690

http://www.hidcorp.com MaxiProx Reader Installation Manual 5375-900 REV 06

Page

1

Page 5

Chapter 2 Installation Procedure

2.1

2.1 Preparation

Preparation

2.1 2.1

PreparationPreparation

Determine an appropriate mounting position for the MaxiProx. Install an electrical box or drill the

appropriate mounting holes from inside the base with the cover removed for #6 fasteners. For optimum

performance, the Reader should be mounted at least 4 inches away from any metallic surface 12-inch x 12inch or larger. The Autotune feature automatically compensates for incidental metal such as aluminum studs

and conduit. The best method for installing the MaxiProx is by mounting the back of the Reader to the

mounting surface. Side mounting is usually accomplished with an adapter or spacer (customer supplied) that

mounts to the back of the Reader.

2.2

2.2 Mounting and Installation

Mounting and Installation

2.2 2.2

Mounting and InstallationMounting and Installation

When fastening the MaxiProx to the mounting surface, do not use a metallic fastener larger than a #6

screw.

Avoid moun tin g th e Maxi Prox clos er than 1 m eter (40- in ches ) to anoth er Max iProx.

2.3

2.3 Mounting Applications

Mounting Applications

2.3 2.3

Mounting ApplicationsMounting Applications

The MaxiProx may be mounted to a gooseneck that is 1½-inch in diameter with a 4-inch diameter-

mounting flange without degradation of read range. The flange should be mounted to a non-metallic

adapter that will ease the installation of the MaxiProx to the flang e. The read range w ill not be aff ected.

The MaxiProx may be mounted to a 12-inch x 12-inch or larger metal plate with a 4-inch spacer used to

separate the Reader from the plate.

Acrylic, Plexiglas, Lexan (polycarbonate) or other suitable plastics may be found in ½-inch to 1-inch

stock. Mounting adapters may be fabricated from these materials that would be sturdy and not affect the

performance of the Max iProx. Plastic J-box es can als o be used.

2.4

2.4 Cable Preparation

Cable Preparation

2.4 2.4

Cable PreparationCable Preparation

Prepare the cable by cutting the cable jacket back 2 inches and strip the wires 1/4-inch. Tinning the wires is

not required.

2.5

2.5 Install Cable

Install Cable

2.5 2.5

Install CableInstall Cable

Route the interface cable from the Maxi Prox to the Host. C onnect th e MaxiProx DC pow er in put to the Host

or external power su pply . Eit her +12VDC or +24VDC can be us ed.

CAUTION!

The shunt jumper P2 is not installed as the factory default for +24VDC operat ion. If the jumper i s in the +12

VDC position and +21 to +28.5 VDC is applied, circuit damage can result.

2.6

2.6 Cable Notes

Cable Notes

2.6 2.6

Cable NotesCable Notes

For Wiegand interface cable the maximum length is 500 feet (150m), 50 feet (15m) for RS232, and 4000

feet (1200m) for RS 422.

When using 5 conductor cable, the power supply and Host must have a common ground (voltage

reference).

__________________________________________________________________________________________________________

HID Corporation, 9292 Jeronimo Road, Irvine, CA 92618-1905, USA •Tel: (949) 598-1600, (800) 237-7769, Fax: (949) 598-1690

http://www.hidcorp.com MaxiProx Reader Installation Manual 5375-900 REV 06

Page

2

Page 6

7-Conductor cable is required when using the Hol d function or if the ground for the M axiProx's po wer

supply is not common with the ground of the Host. TB2 terminal 3, Data Return, is to be connected to the

ground of the Hos t. (A lpha 1296 C or equiv alen t).

7-Conductor cable is required when the

Hold function is used, and the power supply and Host "ground"

are separate. (Alpha 1297 C or equi vale nt).

A 22 AWG twisted pair, shielded, stranded cable (Belden 9330 or equivalent) is often required for the

tamper switch. Follow the recomm endations of the manufactu rer of th e Host sy stem. If the tamper input is

a supervised input, the "end-of -lin e" resistor m ay be m oun ted in th e enclosu re betw een TB1-4 and TB1-5.

The inner diameter of the cable fitting will accommodate a cable with an outer diameter of up to .260-

inches.

2.7

2.7 Cable Connections

Cable Connections

2.7 2.7

Cable ConnectionsCable Connections

Install the cable fitting on the rea r of the MaxiProx. Feed the cable through the cable fitting. Conne ct the

wires to the terminal strip with the minimum length necessary. Do not leave extra loops of wire inside the

Reader housing. Connect the Reader to the Host according to the terminal descriptions in the dimension

diagram. Tighten the fitting to secure the cable. Connect the drain line of the shield to terminal TB1 Pin 2

(Power Supply Shield). If it is bare, cover it with heat sh rin k or tape to avoid short circuits to the other wires.

The opposite end of the drain line should be connected to the negative terminal and the frame connection of

the power suppl y .

CAUTION!

The shunt jumper P2 is not installed as the factory default for +24VDC operat ion. If the jumper i s in the +12

VDC position and +21 to +28.5 VDC is applied, circuit damage can result.

Table 1: TB1 Connector Definition

12345

+DC Shield Ground Ground

Red Drain Black --- ---

Tamper

Common

Tamper

Select

Table 2: TB2 Connector Definition

123456789

DATA 0

DATA/TD/RX

Green White Orange Brown Yellow Blue

Note

On TB2, pins 1, 2 and 7 have mult iple purposes , depending on t he int erface that the Reader is configured for.

In the table above, the firs t des cript ion i s f or Wiegand, the second for Cl ock and Data, the t hird for RS 232, and

the fourth is for RS422.

+

CLK/RD/RX-

DATA 1

DATA RTN GREEN LED RED LED BEEPER

HOLD/

CARD PRESENT

TX+

RS422

RS422

TX-

__________________________________________________________________________________________________________

HID Corporation, 9292 Jeronimo Road, Irvine, CA 92618-1905, USA •Tel: (949) 598-1600, (800) 237-7769, Fax: (949) 598-1690

http://www.hidcorp.com MaxiProx Reader Installation Manual 5375-900 REV 06

Page

3

Page 7

2.8

2.8 DipSwitch and Jumper Settings

DipSwitch and Jumper Settings

2.8 2.8

DipSwitch and Jumper Settings DipSwitch and Jumper Settings

Verify the default settings according to the model ordered, or set the DIPswitches and Jumper positions

according to the followin g.

Table 3: DIPSwitch and Jumper Settings

Switch Default Description

1. Interface mode 1 On See mode chart table 6 below

2. Interface mode 2 On See mode chart table 6 below

3. Interface mode 3 On See mode chart table 6 below

4. Beeper control On/Off On On - beep after valid card read. Off - no beep after valid card read.

5. Green LED flash Off Off - flash after valid card read. On - no flash after valid card read.

6. Single/Dual external LED Off Off - single line LED control. On - dual line LED control.

7. Serial Baud 1 control Off See baud rate chart below.

8. Serial Baud 2 control Off See Baud rate chart below.

Table 4: Interface Jumpers Description - P3 and P4

P3 and P4 1-2 See mode chart table 6 below

Table 5: Switch Description - SW2

Switch Default Description

1. Serial Baud 3 control On See baud rate table 7 below

2. Note address 0 N/A Unused

3. Note address 1 N/A Unused

4. Note address 2 N/A Unused

5. Note address 3 N/A Unused

6. Note address 4 N/A Unused

7. Unused

8. Unused

Table 6: Mode Chart

Mode SW1-1 SW1-2 SW1-3 SW5-3 SW5-4 SW5-5

Wiegand ON ON ON NA NA NA 1-2

Clock & Data OFF ON ON NA NA NA 1-2

RS232 ON OFF ON NA OFF OFF 2-3

RS422

terminated

RS422

unterm.

OFF OFF ON ON OFF OFF 2-3

OFF OFF ON OFF OFF OFF 2-3

P3 & P4

Jumpers

Table 7: Baud Rate Chart – RS232 and RS422

BAUD SW1-7 SW1-8 SW2-1

9600 ON ON ON

4800 OFF ON ON

2400 ON OFF ON

1200 OFF OFF ON

__________________________________________________________________________________________________________

HID Corporation, 9292 Jeronimo Road, Irvine, CA 92618-1905, USA •Tel: (949) 598-1600, (800) 237-7769, Fax: (949) 598-1690

http://www.hidcorp.com MaxiProx Reader Installation Manual 5375-900 REV 06

Page

4

Page 8

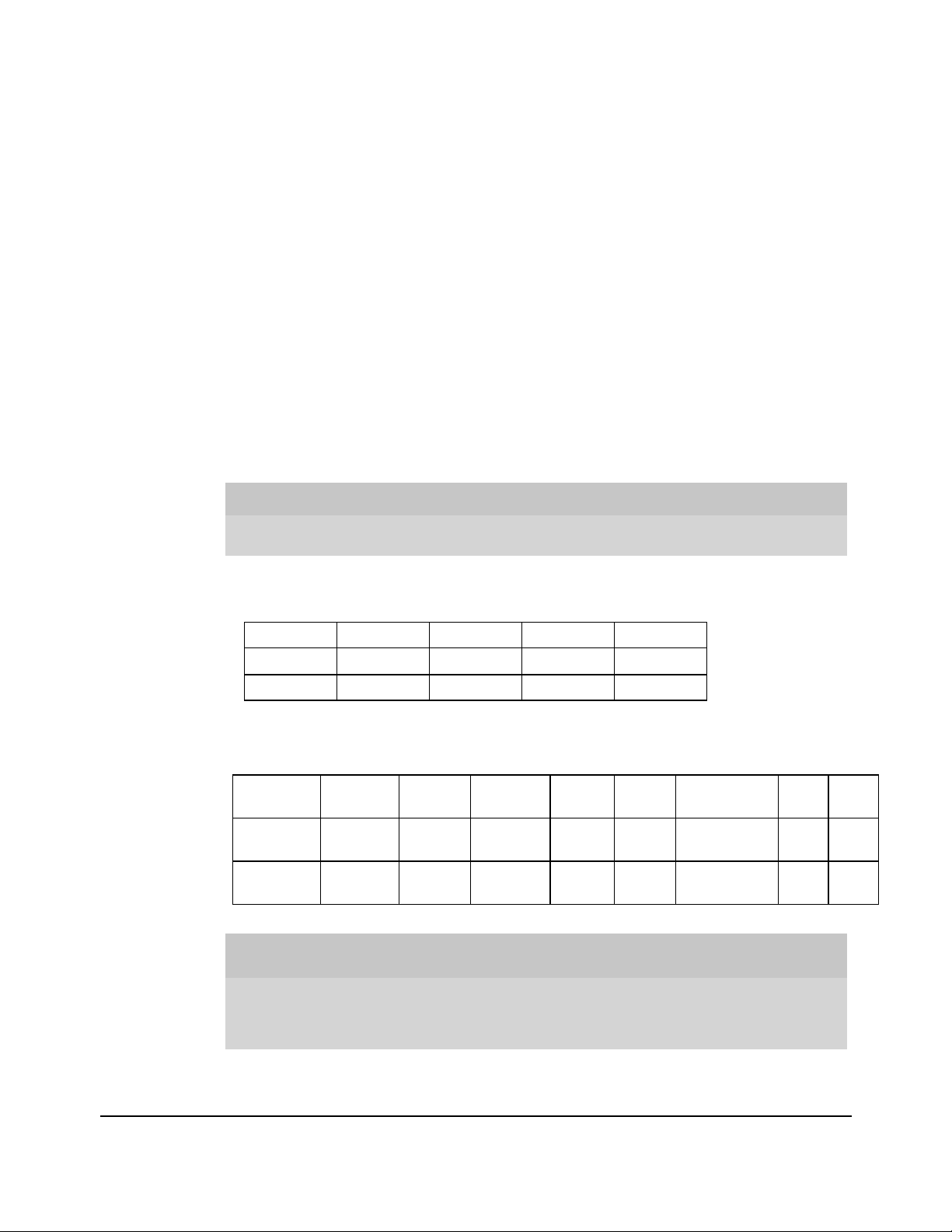

Table 8: Switch Description - SW5

Switch Default Description

1. Data Isolation 1 On See 1 below

2. Data Isolation 0 On See 1 below

3. RS422 Terminating Resistor On See 5 below

4. Serial Hardware line setting 1 Off See 6 below

5. Serial Hardware line setting 2 Off See 7 below

1. Open Collector Data Outputs SW5-1&2 when using Wiegand or Clock & Data Interface. The data

outputs may be configured so the MaxiProx is electrically isolated from the Host pull-up resistors. The

default (standard) configuration is non-isolated outputs, switches SW5-1 & 2 are

Note

When the outputs are configured as isolated, s eparate power supplies should be used for the MaxiProx and

Host. These switches are unused when in RS232 or RS422 mode.

ON.

3. Beeper Control SW1-4: The on-board beeper may be enabled or disabled. When enabled, the beeper

tone is sounded when the LED is green. SW1-4 in the

2. LED Control SW1-5: The LED flash after valid card read can be controlled by both the MaxiProx and

Host, or Host only. S W1-5 in the

OFF position selects flash green after valid card read (the default).

ON position enables the beeper (the default).

4. LED Mode SW1-6: Single/Dual Mode. With SW1-6 OFF (default) it is in Single Mode. The LED is

normally red, until internal or host control turns it green (only a single control line is necessary). If

ON, it

is in Dual Mode, and the LED is normally off (two control lines are necessary for host control of red and

green).

5. SW5-3 Terminating Resistor: Some RS422 connections require that the RX- line be terminated with

a resistor to RX+. If SW5-3 is in the

ON, then a 120-ohm res ist or is con nected between RX+ and RX- .

6. SW5-4 Line Setting 1: SW5-4 is u sed to con figu re the Reader' s in terface con fig uration. SW5-4 sh ould

be in the

7. SW5-5 Line Setting 2: SW5-5 is u sed to con figu re the Reader' s in terface con fig uration. SW5-5 should

be in the

2.9

2.9 Tamper Switch

2.9 2.9

OFF position for RS232 or RS422 operation.

OFF position for RS232 or RS422 operation.

Tamper Switch

Tamper SwitchTamper Switch

OFF position, there is no terminating resistor on RX-. If SW5-3 is

Connect the tamper switch to the Host, if provided by the Host. When the cover is removed, the tamper

switch is released. The switch contacts available on TB1 Pins 4 and 5 and are either "normally open" or

"normally closed" dependent upon the position of the jum per on P1. Install the jum per to connect pin s 1 and

2 if you need the "normally open" contacts. Select the 2-3 position if you need the "normally closed"

contacts. "Normally closed" refers to the condition of the switch when the case is open. The contacts are

rated for 50 mA at 30 VD C.

2.10

2.10 Mounting

Mounting

2.10 2.10

MountingMounting

Mount the base of the MaxiProx that holds the electronics to the surface using the holes located on the base

of the Reader. There are 12 recessed holes for mounting. The holes are not through holes and require drilling

before mounting. Chose the appropriate holes to be used and drill with a 5/32 (.156) inch bit. Use #6 screws

only. (See figure 2).

__________________________________________________________________________________________________________

HID Corporation, 9292 Jeronimo Road, Irvine, CA 92618-1905, USA •Tel: (949) 598-1600, (800) 237-7769, Fax: (949) 598-1690

http://www.hidcorp.com MaxiProx Reader Installation Manual 5375-900 REV 06

Page

5

Page 9

2.11

2.11 Power Supply

Power Supply

2.11 2.11

Power SupplyPower Supply

The MaxiProx Reader can be operated over the full range of 11-28.5VDC. Current requirements are 200

mA average and 700 mA peak at 12 VDC input. At 24 VDC (21 to 28.5 VDC) input the average current is

260 mA and peak is 1.2 A. A linear regulated supply rated at 2.0 A is recommended. Noise from devices

such as switching power supplies, computer monitors, and arc welders can reduce the read range or mak e th e

unit inoperable. Keep these devices at least 10 ft away from the Reader. With the MaxiProx and power

supply wired tog ether, apply power to the Reader.

CAUTION!

The shunt jumper P2 is not installed as the factory default for +24VDC operat ion. If the jumper i s in the +12

VDC position and +21 to +28.5 VDC is applied, circuit damage can result.

2.12

2.12 Autotune Operation

Autotune Operation

2.12 2.12

Autotune OperationAutotune Operation

The MaxiProx is tuned correctly when the autotune LED is green. If the LED is red, use a spacer to

position the Reader at minimum of 4 inches away from metal in the mounting surf ace.

2.13

2.13 Reader Testing

Reader Testing

2.13 2.13

Reader Testing Reader Testing

Apply Power to the Reader and the LED will display a sequence of flashes and beeps, indicating the LED

control mode. Two flashes of green and two beeps followed by a short delay, then one additional flash

(beep), is the correct sequence for "Green Flash/Beep on valid read” (SW1-5 off). Three initial green flashes

and beeps followed by a pause and then one additional beep indicate no Green Flash/Beep on valid read

(SW1-5 on).

2.14

2.14 Power-Up Tune

Power-Up Tune

2.14 2.14

Power-Up TunePower-Up Tune

Following this initial power up sequence the Reader will perform power-up Autotune. It will beep and turn

the access LED amber for ~1 second to indicate that a power-up tune test is about to begin. It will then

attempt to tune. If it successfully tunes, it will give two quick beeps and a

LED's to indicate the Reader is tuned. If unsuccessful, the unit will give a single 1.5-second beep with a

on the access and tune LED’s. If Autotune is not successful, the installer should check for large areas of

metal less than 4 inches from the back of th e unit.

2.15

2.15 Periodic Autotune

Periodic Autotune

2.15 2.15

Periodic AutotunePeriodic Autotune

Periodic Autotune retunes every 1 minute.

2.16

2.16 Supervisor Mode

Supervisor Mode

2.16 2.16

Supervisor ModeSupervisor Mode

During idle periods in normal operation, a periodic supervisor 1 byte transmission is sent to the host

controller over the Wiegand interface every 1 minute. Supervisor Mode is only available in Wiegand

Interface Mode.

2.17

2.17 Install Cover

Install Cover

2.17 2.17

Install CoverInstall Cover

Replace the top cover and top cover screw. Make sure that the autotune indicator LED remains in a steady

green state. If the LED is red, remove the cover and re-mount the unit using a n on- metallic spacer to position

it further aw ay from the mounting surf ace. Rein s tall th e cov er, v erif y autotune, and install the front label over

the top cover screw and the au totun e indicator lens .

green on the access and tune

red

__________________________________________________________________________________________________________

HID Corporation, 9292 Jeronimo Road, Irvine, CA 92618-1905, USA •Tel: (949) 598-1600, (800) 237-7769, Fax: (949) 598-1690

http://www.hidcorp.com MaxiProx Reader Installation Manual 5375-900 REV 06

Page

6

Page 10

Figure 1: MaxiProx Front View

__________________________________________________________________________________________________________

HID Corporation, 9292 Jeronimo Road, Irvine, CA 92618-1905, USA •Tel: (949) 598-1600, (800) 237-7769, Fax: (949) 598-1690

http://www.hidcorp.com MaxiProx Reader Installation Manual 5375-900 REV 06

Page

7

Page 11

Figure 2: MaxiProx interior view showing mounting hole locations

__________________________________________________________________________________________________________

HID Corporation, 9292 Jeronimo Road, Irvine, CA 92618-1905, USA •Tel: (949) 598-1600, (800) 237-7769, Fax: (949) 598-1690

http://www.hidcorp.com MaxiProx Reader Installation Manual 5375-900 REV 06

Page

8

Page 12

Chapter 3 Installation Notes and Guidelines

3.1

3.1 Power Supply

Power Supply

3.1 3.1

Power SupplyPower Supply

The recommended power supply is 12 or 24VDC, nominal, 2.0A current rating, linear regulated. The

MaxiProx cycles thro ugh varying p ower st age s and has a p ea k cur re nt d emand o f ap pr o ximate ly 1.2 A when

in long range read mode. Average current consumption is about 260mA.

current capacity power supply will result in reduced read range.

CAUTION!

The shunt jumper P2 is not installed as the factory default for +24VDC operat ion. If the jumper i s in the +12

VDC position and +21 to +28.5 VDC is applied, circuit damage can result.

The use of a Power Switch ing Su pply is not recom m en ded for tw o reason s:

(1) This type of supply does not provide adequate response to rapid transient current loads and also

generates radio frequency (RF) interf erence in th e sam e ban d that the Reader receiv es data an d;

(2) The power supply may generate noise that is large enough to be transmitted or conducted to the

MaxiProx that interferes with the reception of a card signal. Some switching power supplies are not able

to provide adequate regulation to the Maxi Prox Reader.

3.2

3.2 Installation near Metal

Installation near Metal

3.2 3.2

Installation near MetalInstallation near Metal

Failure to provide an adequate

Read range will be reduced if located on metal surfaces or in the vicinity of metal objects. The amount of

reduction will be a factor of the amount of metal and the distance the Reader is from the metal. Metal near

the Reader absorbs energy f rom the Reader ex cite field an d aff ects th e sign al being received from the card by

re-directing excite field transmissions into the receiver circuitry. Moving the Reader away from the metal

objects reduces energy loss .

Try to limit the amount of metallic materials installed near the MaxiProx. Use a plastic electrical box if

possible. Avoid installing conduit and other metal hardware within 2-inches of the back of the Reader or

closer than 4-inches from large metal surfaces. The typical read distance specification (24-29 inches at 21-

28.5 VDC or 21-26 inches at 12 VDC) refers to operation without metal in the vicinity of the Reader. The

read distance will be reduced if metal is installed nearby.

The MaxiProx generates a magnetic field on all sides of the Reader. Any metal that conducts electricity,

especially metal that contains iron, steel or copper will interfere with the field and reduce the effective read

range (this will happen even if the metal is behind the Reader). It helps to put a non-metallic spacer between

the Reader and the metal object.

3.3

3.3 Radio Frequency Interference

Radio Frequency Interference

3.3 3.3

Radio Frequency InterferenceRadio Frequency Interference

Motors and electronic devices generate RF noise that may interfere with the reception of the signal from a

transponder. The affect of RF n oise is typically a reduction of read rang e. The Maxi Prox is s u sceptible to R F

interference, as are all devices that receive RF signals. The read range is affected by the amount of

interference (noise) in the area. Common sources of RF interference are power supplies, electrical and

electronic eq uipment, some types of lighting, co mputers and monitors, motors and genera tors. Moving the

Reader to a location known to be free of interference and testing read range there will help to isolate RF

interference as a factor in low read rang e situation s.

__________________________________________________________________________________________________________

HID Corporation, 9292 Jeronimo Road, Irvine, CA 92618-1905, USA •Tel: (949) 598-1600, (800) 237-7769, Fax: (949) 598-1690

http://www.hidcorp.com MaxiProx Reader Installation Manual 5375-900 REV 06

Page

9

Page 13

The MaxiProx should not be mounted within six feet of any monitors (VDTs or CRTs) because the scan

frequencies of most mo nitors include frequencies that may interfere with the signal received from the access

control cards.

3.4

3.4 Transponder Types

Transponder Types

3.4 3.4

Transponder TypesTransponder Types

The type of transponder used affects the read range of the MaxiProx. The various styles of HID cards and

transponders use different types of antennas. The antenna type will determine the read range for that type of

transponder. The Vehicle ID tag provides the longest read range at 32-36 inches; the ProxCard II is 24-29

inches. The IsoProx/DuoProx is 17-20 in ches. The ProxKey reads at a distan ce of 15- 17 inches .

Note

The above are recommended installation procedures. All local, state and national electrical codes have

precedence.

__________________________________________________________________________________________________________

HID Corporation, 9292 Jeronimo Road, Irvine, CA 92618-1905, USA •Tel: (949) 598-1600, (800) 237-7769, Fax: (949) 598-1690

http://www.hidcorp.com MaxiProx Reader Installation Manual 5375-900 REV 06

Page

10

Page 14

Chapter 4 Application Notes

4.1

4.1 Wiegand Interface Description

Wiegand Interface Description

4.1 4.1

Wiegand Interface DescriptionWiegand Interface Description

4.1.1 Wiegand Message Format

In the Wiegand format, the ID card is programmed with a specific bit pattern and the Reader acquires the

data, checks the customer code and generally sends out the same bit pattern as previously programmed on

the card. Consult factory for variations to this meth od. A 26 bit Wiegand format will be used in the examples

below.

The 26 bits of transmission from the Reader to the panel consists of two parity bits and 24 code bits. The

bits are transmitted in the order described. The first bit transmitted is the first parity bit, P1; it is even parity

calculated over the first 12 code bits. The last bit transmitted is the second parity bit, P2; it is odd parity

calculated over the last 12 code bits:

Code Format

12345678901234567890123456

P1CCCCCCCCCCCCCCCCCCCCCCCCP2

11111111112222222

Parity Format

11111111112222222

12345678901234567890123456

P1EEEEEEEEEEEE

OOOOOOOOOOOOP2

P1: First, or even parity bit

C: Code bits

P2: Second, or odd parity bit

E: Bits for calculation of even parity

O: Bits for calculation of odd parity

Data format within the 24 code bits which includes the portioning of the bit, the designation of the Most

Significant Bit (MSB)

or the Least Significant Bit (LSB) shall be subject to definition by the panel and

Reader manufactu rers and m ay rem ain proprietary .

4.1.2

Output Specification

The specifications of voltage, current, power and timing are from the perspective of the Reader. A common

signal ground is def i n ed as a v oltag e ref eren ce th at is common to both the Reader and the control panel. The

voltages for the data outputs are referenced from the power supply ground located at the Reader. The

voltage measured for the power to the Reader is referenced from the power supply - return conn ection location

at the Reader, not at the source of the pow er.

__________________________________________________________________________________________________________

HID Corporation, 9292 Jeronimo Road, Irvine, CA 92618-1905, USA •Tel: (949) 598-1600, (800) 237-7769, Fax: (949) 598-1690

http://www.hidcorp.com MaxiProx Reader Installation Manual 5375-900 REV 06

Page

11

Page 15

The voltage, current, and timing of the data pulses are measured at the Reader in reference to the power

supply/signal ground at the Reader. The voltage, current and timing of a signal driving an auxiliary input

device on a Reader is measured at the control panel that is controlling the input device (with reference to the

signal ground at the panel).

4.1.3

Signal Levels

The Data One, Data Zero, and LED Control conductors connect signals between the Reader and the panel.

The logic levels are defined as follow s:

Table 9: Logic Levels

Voltage Data Outputs (Data0 and Data1) Control Inputs (LED’s, Hold, Beeper)

Levels Minimum Maximum Minimum Maximum

Voh 3.5V 5.5V 3.5V 5.5V

Vol 0.0V 0.5V 0.0V 0.5V

Ioh 0.0mA 5.0mA -1.0mA 0.0mA

Iol -25.0mA 0.0mA 0.0mA 25.0mA

4.1.4 Data Pulses

The Data One and Data Zero signals are norm ally held at a logic h igh lev el until th e Reader is ready to send

a data stream. The Reader places asynchronous low pulses on the appropriate data lines to transmit the data

stream to the panel. The following tim ing param eters shall be observed:

Figure 3: Data Pulses - Timing Parameters

Data One

Voh

Vol

Tpw Tpw

Data Zero

Voh

Vol

Tpw TpiTpi

Tpw Pulse Width Time - 30uS (minimum ) to 50uS (m axim um )

Tpi Pulse Interval Time - 1.8mS (m inim um ) to 2.2mS (m ax im um )

4.1.5 Example Output

The following is an example of an ID card with the number of “816” decimal, which will be output by the

MaxiProx Reader, the num ber “02004CA0661” hex.

__________________________________________________________________________________________________________

HID Corporation, 9292 Jeronimo Road, Irvine, CA 92618-1905, USA •Tel: (949) 598-1600, (800) 237-7769, Fax: (949) 598-1690

http://www.hidcorp.com MaxiProx Reader Installation Manual 5375-900 REV 06

Page

12

Page 16

Note

The customer code is never transmitted or displayed.

customer code 10 zeros bit even facility code card number odd

sentinel parity parity

[0 0 0 0 0 0 1] [0 0 0 0 0 0 0 0 0 0] [1] [0] [0 1 1 0 0 1 0 1] [0 0 0 0 0 0 1 1 0 0 1 1 0 0 0 0] [1]

| 0 | 2 | 0 | 0 | 4 | C | A | 0 | 6 | 6 | 1 |

Wiegand Output | 0 | C | A | 0 | 6 | 6 | 1 |

Hex code numbers [ 6 | 5 ][ 0 | 3 | 3 | 0 ]

Decimal conversion [ 101 ][ 0816 ]

4.2

4.2 Clock and Data Interface Description

Clock and Data Interface Description

4.2 4.2

Clock and Data Interface DescriptionClock and Data Interface Description

4.2.1 Clock and Data Message Format

The Clock and Data interface consists of three si gnals , Card Present, Data and Strobe/C lock. The interf ace is

a serial data stream, which is controlled with a clock/strobe that indicates when data is valid. All signals are

quiescent high. Card Present goes low when data is about to be sent and remains low until the whole data

stream is completed. Data is the signal that determines the “ones” and “zeros”. Strobe/Clock is the signal

that indicates when data is v alid for each cy cle.

The Track 2 message format is a stream of binary bits that are grouped into HEX characters. The message

starts with leading zeros, followed by a start sentinel, data, end sentinel, LRC and trailing zeros. Each HEX

character has error correction in the form of a parity bit. Each character consists of five bits. The maximum

number of characters for a magnetic strip card encoded on Track 2 are 40, this product will output less than

40 characters. The data consists only of BCD digits, the remaining HEX digits, A to F, are used for the start

and end sentinel, data separators and control. Only hex B and F are used, A, C D and E are not used. The

message w ill consis t of a m in im um of 210 bits.

The bits of a character are in the order 1248P, where parity is odd over the four bits. The LRC is the Xoring

of the message, starting with the start sentinel and ending with the end sentinel. The LRC does not include

the parity bits of the characters in the Xoring. LRC does include its own odd parity bit that covers the four

bits that are the result of the Xoring.

<leading zeros><Start Sentinel><data><data>........<data><End sentinel><LRC><trailing zero>

Customer code 0,1, 63, 72 and 73 (existing customer codes) cards will be read and output in the Track 2

format. The data on these cards will be packed into the Track 2 format in segments of three bits, so the

character does not exceed a BCD seven.

4.2.2

Data Timing

The outputs, Card Present, Data and Strobe are low going signals and the following timing chart describes

the timing.

__________________________________________________________________________________________________________

HID Corporation, 9292 Jeronimo Road, Irvine, CA 92618-1905, USA •Tel: (949) 598-1600, (800) 237-7769, Fax: (949) 598-1690

http://www.hidcorp.com MaxiProx Reader Installation Manual 5375-900 REV 06

Page

13

Page 17

Figure 4: Data Timing - Timing Chart

g

card present

data

clock/

strobe

Note: the first 25 bits and trailin

000

1st valid bit

00000

1

11

bit time strobe width

bits are zeros, not shown above.

1111

0000

1

bit time = 1.5ms (default)

strobe width = bit tim e/ 3 (33% of bi t tim e), def au lt = 500u s

Clock/Strobe is valid 1.5ms (one clock cy cle, m in) after card pres ent is as serted

Data is valid 10us (min) before the negative edge of clock/strobe

Card Present returns to the high level 50 m s (m ax) af ter the last clock/strobe.

The above timing is representative of a magnetic stripe card traveling at 8.9 inches per second. The timing is

to be adjustable for cards traveling at 4 inches per second to 20 inches per second. This relates to bit times of

3.3 ms and 666us, respect ively . There are 75 bi ts per in ch on Track 2.

Output signal Levels

4.2.3

Inputs: low th reshol d = 0.8 volt s high thresh old = 3.5 v olts

4.2.4

Bit structure

The Reader will read an 1849 or compatible chip that is encoded with 44 bits of data. The data will be

programmed in accordance with ProxGuard formatting. The data will be packed into the A BA /ISO T rack 2

message form at in accordan ce w ith th e follow in g ru les based on cust om er code:

Case 1:

Customer Code = 0, 1, 63, 72, 73 or other, w ill hav e the data output as follow s.

The output is in the Track 2 character format but th e bits are pack ed in sets of three bits (octal):

ccc CCCC a bcd efg hij klm nop qrs tuv wxy zAB CDE FGH IJK

Where cccCCCC is the customer code, abc...IJK is the prog ram m ed data on the card.

__________________________________________________________________________________________________________

HID Corporation, 9292 Jeronimo Road, Irvine, CA 92618-1905, USA •Tel: (949) 598-1600, (800) 237-7769, Fax: (949) 598-1690

http://www.hidcorp.com MaxiProx Reader Installation Manual 5375-900 REV 06

Page

14

Page 18

1248p 1248p 1248p1248p 1248p1248p 1248p1248p1248p1248p 1248p1248p1248p 1248p 1248p 1248p 1248p1248p1248p

<B> c000p Ccc0p CCC0p a000p dcb0p gfe0p jih0p mlk0p pon0p srq0p vut0p yxw0p BAz0p EDC0p HGF0p KJI0p <F><LRC>

Case 2:

Customer Code = 74 are s tructu red as follow s :

421 8421 8421 8421 8421 8421 8421 8421 8421 8421 8421

CCC CCCC 1 aaaa bbbb cccc dddd eeee ffff gggg hhhh iiii

CCC CCCC - Customer code

1 - fixed bit “1”

aaaa - Most significant nibble of message

bbbb - Second MSN

cccc - next nibble

hhhh - least significant nibble of message

iiii - LRC of nibbles aaaa to hhhh, start (B) and end sentinel (F) (xor of the nibbles or the even parity of the respective

column)

The output from the Reader will look like the follow ing:

1248p 1248p 1248p 1248p 1248p 1248p 1248p 1248p 1248p 1248p 1248p

<B> <aaaap> <bbbbp> <ccccp> <ddddp> <eeeep> <ffffp> <ggggp> <hhhhp> <F> <iiiip>

start data a data b data c data d data e data f data g data h end LRC

The message structure follow s th e ISO/ABA Track 2 s tandard. The firs t character is a s tart sentin el: B (h ex ),

which is followed by data. A f ter th e data there is an end sentinel: F (hex), followed by an LRC. The LRC is

the xoring of the message in accordance to the bit position. Each character has an odd parity bit that covers

bit 1 to bit 4 of the ni bble.

A typical message:

B 1 2 3 F LRC the bits broken dow n:

1248p 1248p 1248p 1248p 1248p 1248p

11010 10000 01000 11001 11111 00101

B 1 2 3 F 4

start < data > end LRC

4.2.5 Bit Stream

__________________________________________________________________________________________________________

HID Corporation, 9292 Jeronimo Road, Irvine, CA 92618-1905, USA •Tel: (949) 598-1600, (800) 237-7769, Fax: (949) 598-1690

http://www.hidcorp.com MaxiProx Reader Installation Manual 5375-900 REV 06

Page

15

Page 19

The bit stream will consist of 25 leading zeros, the message and fill with zeros until the end of the message.

The message will con sist of a m ini m um of 210 bits .

Example

00000000000000000000000000 11010 10000 01000 11001 11111 00100 00000000000000...000000

B 1 2 3 F LRC

4.2.6 Output Specification

Vol = 0.8 V

Voh = 3.5 V

sink = 25 ma

source = 5 ma

4.3

4.3 RS232 and RS422 Card Message Specification (Send Mode Only)

RS232 and RS422 Card Message Specification (Send Mode Only)

4.3 4.3

RS232 and RS422 Card Message Specification (Send Mode Only)RS232 and RS422 Card Message Specification (Send Mode Only)

When Access Cards (transponders) are presented to the MaxiProx Reader, the Reader sends a message. The

message is in the following form at:

CCDDDDDDDDDDXX<CR><LF>

^ First character sent

All characters C, D and X are ASCII encoded, hexadecimal digits. (i.e., the hex value 7 is sent as an ASCII

character 7 or the hex value

The

CC field is reserved for use by HID Corporation . The valid valu es are 00 through 7F.

The

DDDDDDDDDD field is the transponders (Access Card) data. The valid values are 0000000000 through

1FFFFFFFFF (ASCII).

The

XX field is a computed checksum. The checksum is calculated by first grouping the mess ag e data in to th e

pairs

CC DD DD DD DD DD. Each pair of characters represents one byte of data. Then each pair of characters is

E is sent as an A SCII ch aracter E).

converted from ASCII to their respective hex values. At this point, the 6 bytes are added together. The

checksum is equal to the least significant 8 bits of the result.

<CR> is the ASCII code for a carriage return. (0D hex)

<LF> is the ASCII code for a line f eed. (0A hex)

For example, if the MaxiProx reads a transponder (Access Card) that contains the value

DDDDDDDDDD=01234ABCDE, the Reader will report the ASCII message 0001234ABCDE08<CR><LF>.

CC=00 and

Note that each of the characters is A SCII encoded. The actu al bytes (hex value) th at are sent to th e host are:

<30><30><30><31><32><33><34><41><42><43><44><45><30><38><0D><0A>

The checksum was computed by adding 00 + 01 + 23 + 4A + BC + DE = 208 hex. The checksum is the least

significant 8 bits of this result or 08 hex. The communications settings are 9600-75Hz BAUD, 8 bits, 1 stop

bit, no parity.

__________________________________________________________________________________________________________

HID Corporation, 9292 Jeronimo Road, Irvine, CA 92618-1905, USA •Tel: (949) 598-1600, (800) 237-7769, Fax: (949) 598-1690

http://www.hidcorp.com MaxiProx Reader Installation Manual 5375-900 REV 06

Page

16

Loading...

Loading...