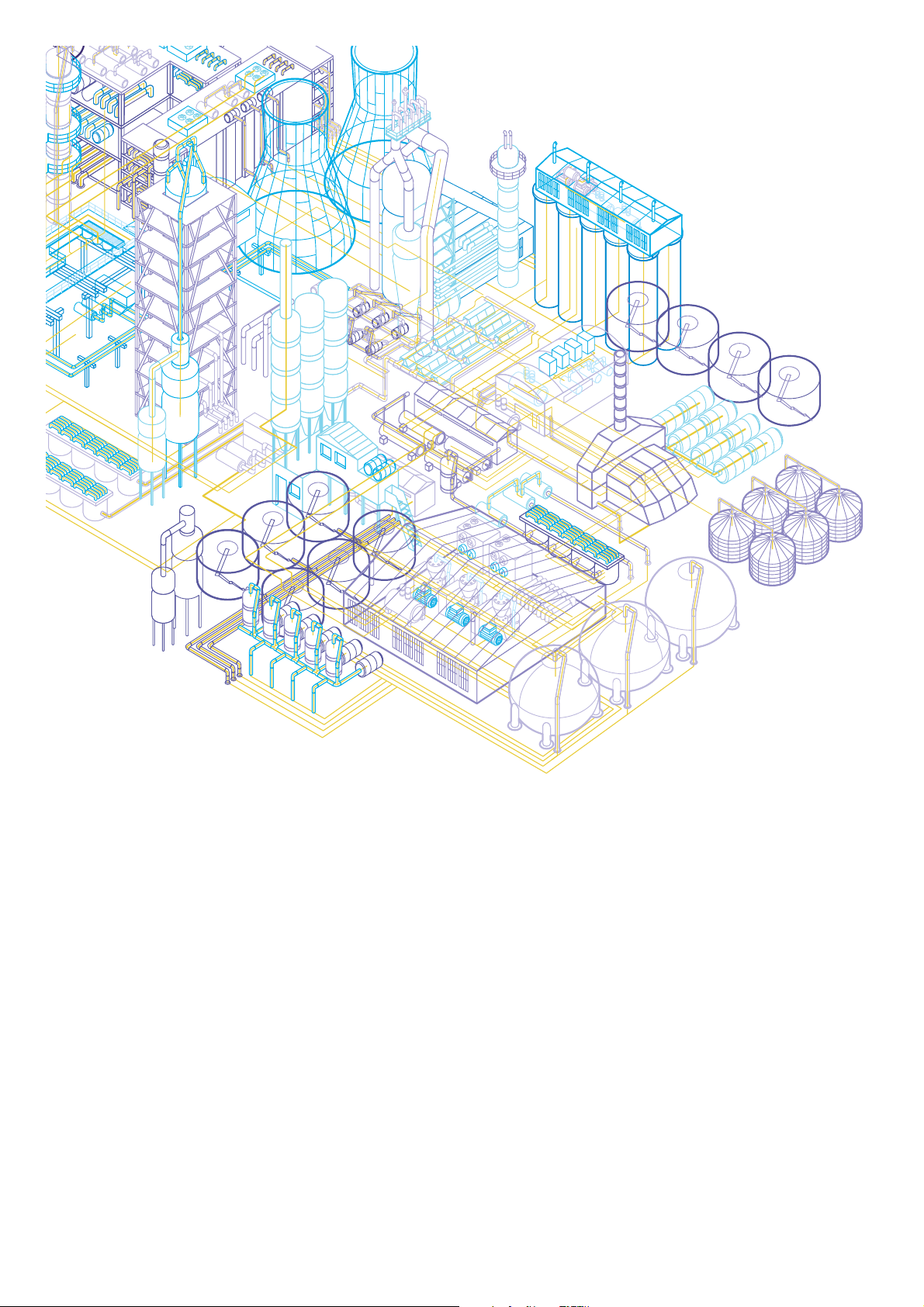

Hidden treasure

Drive data are a treasure trove of hidden information that can

help industries solve problems before they even happen

MICHAL ORKISZ, MACIEJ WNEK, PIEDER JOERG – As processes

become ever more complicated and margins thinner, minimizing downtime by ensuring that industrial machinery

operates correctly is as important as ever. Proper condition

monitoring of critical equipment can act as an early warning

system against impending problems. However, condition

monitoring is not used everywhere, often because of the

expense of installing proper sensors and cabling, especially

if the monitoring system needs to retrofi tted to existing

equipment. Another reason is that the task of selecting and

70 ABB review 1|10

interpreting the large quantities of data available in the most

effective way seems daunting as well as costly. ABB has

devised a way to easily access and process important data

without the burden of additional equipment, costs and

downtime. By extracting and processing data from existing

devices traditionally used in process industries, such as

drives, customers can prevent otherwise unforeseen problems from occurring and hence maximize the availability of

their machines.

ndustries are constantly under pressure to reduce costs while increasing

service and productivity. The most ef-

I

fective way of fulfi lling these aims is for

managers to know the state of their equipment – in particular the critical components – at all times and to use this information to quickly identify and rectify faults

before they spread to other parts of the

process

system helps predict the reliability of

equipment and the risk of failure. With so

much to gain, why is it that condition

monitoring is not used everywhere? One

reason is that existing equipment is often

already retrofi tted with a monitoring system and the installation of additional sensors and cabling could prove both complicated and expensive. Another reason

concerns the interpretation of results. In

many cases it may not be clear how to

use a set of data that gives information

about one aspect of a process to provide

information about another. For example,

determining the fractal dimension of a

certain phenomenon may be fairly straightforward but relating it to the condition of a

machine may not be so obvious.

Most processes use devices that are capable of collecting and producing relevant signals, which, if harvested and processed correctly, can also be used for

diagnostic purposes. Among others, one

such example is ABB’s family of ACS

variable-speed drives, which are often

[1]. A good condition monitoring

used to power critical equipment. The

drives are based on powerful controllers

that consume and provide tens, if not

hundreds, of signals with sub-millisecond

resolution.

To be useful for condition monitoring,

data needs to be obtained from the drive

inverter in one form or another. Internally

the signals – which include measured

and computed values such as speed,

frequency, torque, flux, current, power

and temperature, as well as parameters

such as configurable drive settings – are

stored in a regularly updated memory

table. Data can be retrieved from this table as OPC

ed into hardware data loggers.

Data loggers are programmable buffers

capable of storing values from several

selected variables concurrently with a

specified sampling rate, generally one

that is high enough to make the data

useful for spectral analysis. In normal operation, the newest data overwrites the

oldest until the loggers are triggered by

certain events, such as the occurrence

of a fault or an alarm, a selected variable

signal crossing a specified threshold or a

software command. As the buffers are

circular, some data

prior to and after

the trigger can be

retained. ABB’s

DriveMonitor

➔ 1 can read

tem

the contents of a

drive’s hardware

data logger. It consists of a hardware

module in the form

of an industrial PC and a software layer

that automatically collects and analyzes

drive signals and parameters

Data enhancement

Because the resolution has already been

determined and preprocessing has been

performed, drive signals are generally

available in a form not easily applicable

to diagnostic evaluation. It is therefore

necessary to employ a suite of “tricks” to

transform the data so that it becomes

useful for diagnostics.

True to their name, variable-speed drives

dynamically change the frequency of the

current supplied to the motor. The direct

torque control (DTC) method employed

in the drive produces a non-deterministic

1

values or they can be load-

Most processes use devices

TM

sys-

that are capable of collecting

and producing relevant signals which can be used for

diagnostic purposes.

[2].

1 ABB‘s DriveMonitor

switching pattern, so there is no such

thing as a constant switching frequency.

This makes the straightforward application of spectral analysis methods somewhat challenging. Because individual

spectra contain many hard-to-predict

components collected one after another,

the averaging of many spectra using

point-by-point averaging, for example, is

essential to obtain a “clean” spectrum.

In general, signals currently available

from the ACS drive are used primarily for

control purposes. Therefore some of the

preprocessing needed for condition

monitoring signals is missing. One such

process is anti-aliasing filtering. Data

points are sampled or computed at rates

up to 40 kHz, but can only be accessed

at lower rates (eg, by keeping every 40th

data point). In signal processing it is typical that frequencies above the so-called

Nyquist frequency – defined as half the

sampling rate – should be filtered out

prior to signal sampling. Skipping this

step means the peaks from the higher

frequencies will appear in the lower part

of the spectrum, making it very hard to

interpret. For example, signals containing frequencies of 400 Hz, 600 Hz,

Footnote

1 OPC stands for object linking and embedding

(OLE) for process control and represents an

industry standard that specifies the communication of real-time data between devices from

different manufacturers.

TM

71Hidden treasure

1.4 kHz and 1.6 kHz that are sampled at

1 kHz all produce the same aliased spectrum with a peak at 400 Hz.

When it comes to monitoring drive-induced changes in the output frequency,

the high frequencies are important. Because they were not filtered out by the

anti-aliasing filter combined with the fact

that the drive’s output frequency is rarely

constant means they can be recovered.

This recovery process is illustrated in

The individual true spectrum containing

the original and aliased peaks, as computed from the measured data, is shown

➔ 2a. The x-axis is scaled so that the

in

output frequency is 1. This spectrum is

“unfolded” by appending copies of itself

(alternating between reversed and

straight) along multiples of the Nyquist

frequency. A number of unfolded spectra

for varying output frequencies are then

averaged so that previously aliased

peaks are returned to their original

➔ 2b.

place

Variable-speed drives are generally used

in applications where a process parameter needs to be controlled. The drive

changes the output frequency in response to an external request (eg, to

pump more water) or because of process

changes (eg, more load on a conveyor

belt increases the slip of an asynchronous motor) or perhaps because of a

combination of both. While traditional

spectral analysis methods assume constant frequency, frequency variations can

be handled using one of two approaches: selecting constant frequency moments or rescaling the time axis.

The first approach takes advantage of

the fact that data is available in large

quantities at any time. Most of it can actually be ignored in favor of keeping only

a few “good” data sets. The trick, however, is knowing what to keep and what

to throw away. A good criterion for selecting a suitable data set is that the output frequency should not change appreciably during the measurement, and only

a set of conditions that occur regularly in

the process should be considered for selection.

Sometimes the operating-point variations are so frequent that it is impossible

to find such a stretch of data for any

length of time. In such cases, the solu-

➔ 2.

tion is to convert

the data domain

from time to another quantity, such

as the electric field

2

angle.

To aid in

this transformation, various measurements can be

collected from the

drive inverter in

parallel with the

original signal. The

instantaneous value of the output

frequency

such measurement. This frequency is then integrated to yield

the angle of the

stator electric field,

which then replaces the original xvalue of each data

point. Further normalization can be

applied to the yvalues.

This transformation results in an x-axis

that is no longer equispaced and therefore the fast fourier transform (FFT) spectral approach cannot be used. Instead,

the Lomb periodogram method is employed [3]. This process, as applied to

one of the phase currents of a hoist machine, is illustrated in

nal with pronounced frequency and amplitude variability is shown in

RMS current value reported by the inverter is given in

stantaneous frequency is plotted in

The stator electric fi eld angle is shown

➔ 3d and its shape follows the trend

in

that the higher the frequency, the faster

the rate the angle increases. The regular

sinusoid shown by the solid mustard-colored waveform line in

the original current signal is normalized

(using point-by-point averaging) by the

RMS current value and its x-axis respaced

to refl ect the angle. This in turn leads to a

spectrum that is represented by a singlefrequency peak (solid line in

the raw data spectrum, shown by the

dotted line, is not represented by a singlefrequency peak.

Different transformations can be applied

depending on the information required.

3

is one

➔ 3b and the measured in-

2 An individual electric-torque spectrum

1.5

1.0

0.5

Torque (kNm)

0

0 5 10 15 20 25 30 35

2a With aliased peaks

1.5

1.0

0.5

Torque (kNm)

0

0 5 10 15 20 25 30 35

2b With an averaged “unfolded” spectrum

➔ 3. The original sig-

➔ 3a. The

➔ 3c.

➔ 3e results when

➔ 3f), while

Frequency (orders)

Frequency (orders)

The frequency

variations associated with variable-speed drives

can be handled

by either selecting constant frequency moments

or rescaling the

time axis.

72 ABB review 1|10

3 Normalization and transformation of variable frequency (and amplitude) current

2,000

1,000

¶

Current (A)

-1,000

-2,000

0 2 4 6 8 10 0 2 4 6 8 10 0 2 4 6 8 10

3a Original signal

15

10

5

Stator electric field angle (revs)

0

0 2 4 6 8 10

3d Integrated frequency (angle)

Time (s) Time (s) Time (s)

Time (s)

1,200

1,000

800

RMS current (A)

600

400

3b RMS current

2

1

0

-1

Normalized current

-2

0 2 4 6 8 10 12 14

3e Transformed signal

Angle (revs)

3.0

2.5

2.0

1.5

Frequency (Hz)

1.0

0.5

3c Instantaneous frequency

1.0

0.8

0.6

0.4

Normalized current

0.2

0

0 0.5 1.0 1.5 2.0 2.5 3.0

Angular frequency (orders)

3f Spectrum (raw signal is dotted;

transformed is solid)

For example, suppose engineers want to

know if certain motor defects such as imbalance, misalignment and bearing faults

are present. Rather than measuring the

instantaneous value of the output frequency, a motor speed signal may be acquired. After an analogous transformation, the x-axis represents the shaft angle,

which in turn facilities the search for motor defects related to the rotating speed.

Diagnostic opportunities

Converted drive data can be analyzed

using two general methodologies that reveal different and important diagnostic

information. These methodologies are:

– Point-to-point variability within one

signal

– Signal-to-signal correlations

Point-to-point variability can be analyzed

via spectral analysis in which periodic

components are represented as peaks in

the spectrum while various system defects or conditions can manifest themselves as spectral features with different

frequencies. Signal-to-signal correlations, on the other hand, give information

about the operating point and any associated anomalies.

Other methods use acquired knowledge

about the normal behavior of a machine

or process, and any observed deviations

are immediately indicated. Irrespective of

which method is

used, their under-

4 A fragment of the torque-signal spectrum from a rolling mill.

On the horizontal axis, one equals the output frequency.

lying purpose is

more or less the

same – to produce

key performance

indicators (KPIs)

that give adequate

information about,

for example, the

health of a machine, process ro-

0.4

0.3

0.2

Torque (kNm)

0.1

0

0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

F

Rot

bustness or supply

quality. The conclusions can also

be helpful in uncovering the root cause

of a problem once it has been identified.

Spectral analysis

Drives equipped with an active rectifi er

unit can use the spectra of supply voltages and currents to yield valuable information about the quality of the power

supply. Phase currents and voltages that

are measured concurrently enable engineers to check for possible unbalances,

phase shifts, harmonic distortions, etc.

Similarly, looking at the harmonic content

of the output current is a means of verifying the quality of the motor’s power supply. The drive provides information relevant to the motor (such as frequency,

torque, power, RMS current and fl ux) and

to the inverter operation (such as internal

DC voltage levels, speed error and switch-

“X”

2·F

Rot

2·“X”

Frequency (orders)

ing frequency). In fact the spectral analysis of data supplied by a drive is capable

of revealing more than is uncovered by

the “classical” analysis of electrical or vibration signals.

An example of an averaged torque spectrum from a rolling mill is shown in

➔ 4.

The horizontal axis is scaled so that the

output frequency equals 1. There are two

peaks related to the rotating frequency,

. In addition, a family of peaks exists

F

Rot

at an interharmonic frequency of “X” =

0.7742 (37.86 Hz) and 2“X” (1.5484), and

Footnotes

2 These domains are equivalent when the

frequency is constant.

3 The frequency the drive establishes on the

output current. The drive controls this frequency

so it knows its exact value.

73Hidden treasure

this likely corresponds to a resonance

frequency in the driven equipment. This

is an interesting piece of diagnostic information since such resonances accelerate equipment wear, which in turn could

negatively impact certain process quality

issues, such as the uniformity of rolled

metal thickness.

Transient phenomena

Spectral analysis also helps to reveal the

presence of transient phenomena in drive

data. As well as stationary oscillatory

components in the signals, other more

temporary events may also be present

that are indicators of potential problems.

For example, the raw torque signal from a

rolling mill, measured over the course of

4s is shown in

➔ 5a. Some form of ring-

ing, which lasts roughly half a second, is

evident after approximately 3s. The spectrum of this ringing fragment is given

in

➔ 5b where a 10 Hz frequency compo-

nent and its harmonics are obvious. The

source of this oscillation is unknown but

the spectrum has highlighted a potential

problem that needs to be investigated.

5 Transient phenomena in a torque signal.

35

Torque (kNm)

Time (days)

2.0

1.5

1.0

0.5

0

0 10 20 30 40 50 60 70

Frequency (Hz)

30

25

Torque (kNm)

20

0 1 2 3 4

5a The raw waveform with ringing 5b Spectrum of the ringing fragment

6 Time evolution of the torque/speed ratio (τ/n2) for a fan

Time (s)

0.87

0.85

0.83

0.81

Arb. units

0.79

0.77

0.75

0 1 2 3 4 5 6 7

The spectral analysis of data from

a drive is capable

of revealing more

than is uncovered

by the “classical”

analysis of electrical or vibration

signals.

While it is impractical to continuously collect high-frequency data, the periodic collection and examination of such signals

signifi cantly improves the chance of detecting unwanted temporary occurrences.

Operating-point tracking

Concurrently tracking operating-point

quantities (such as current, torque,

speed, power and frequency) in drive

data is an example of the signal-to-signal

correlation methodology mentioned previously. Analyzing the relationships between certain quantities can shed light

on both the operation of the machine

and the state of the process. The rela-

tionship between torque and speed,

governed by the fan laws, is a good example of a process-dependent relationship.

The velocity pressure difference at the

Δ

output

density

p is proportional to the gas

ρ

and the square of the output

velocity V:

Δ

p = ρ⋅V2/2

Power P is equal to the pressure difference times the volumetric flow rate Q:

Δ

p⋅Q

P =

but it can also be expressed as a prod-

τ

uct of torque

τ

⋅n

P =

and rotating speed n:

In normal operation under constant

geometry, both Q and V are proportional to n, thus:

τ

= C⋅ρ⋅n2

where the constant C depends on the

fan’s geometry.

τ

It follows that the ratio

/n2 refl ects the

density of the gas and the fan’s geometry,

which rarely changes.

In ➔ 6 this ratio for a drive-powered fan

over a period of several days is plotted. The

oscillations (with a period of one day) refl ect

the daily variations in temperature and thus

the density of the pumped air. High density

(cold temperature) occurs at night while

low density (warmer temperature) is evident

during the day. The drive data alone enables the evolution of process variables,

such as inlet temperature, to be tracked. In

addition, comparing this data with values

from the control system (temperatures in

this case) can lead to the detection of any

unexpected discrepancies.

Tracking the operating point is possible

without having to employ any additional

hardware – the data is already available

in the drive. The analyzed data can be

presented directly or further analyzed by

using the principal component analysis

(PCA) technique described below.

Cyclic process analysis

Some processes powered by a variablespeed drive are cyclic in nature. A rolling

mill application is one such example

where torque and current abruptly jump

or increase as a slab is loaded onto the

rolls and then suddenly decrease as the

74 ABB review 1|10

7 A typical rolling mill torque profile

40

30

20

Torque (kNm)

10

0

-1.0 -0.5 0 0.5

Time (s)

7a Examples of torque up and down profiles 7b The two clusters represent torque increases

50

40

30

20

10

0

-10

principal component

-20

nd

2

-30

-40

-40 -20 0 20 40 60

1st principal component

and decreases

ABB’s medium-voltage AC drive

ACS 1000

Drives are but one

example of useful

diagnostic data

providers. Other

examples include

motor control

centers, protection

relays and intelligent fuses.

slab leaves. These jumps can be analyzed to detect any process instabilities

or divergence from normal behavior that

may be an indication of equipment wear

or material variations.

In order to extract only the most essential information, high-resolution data

gathered around torque jumps is processed using the PCA methodology

[4].

This technique reduces multidimensional

data sets to lower dimensions for analysis. These lower dimensions condense

the set-to-set variability. Typical rolling

mill torque profiles are shown in

Each profile in

➔ 7a, corresponding to

➔ 7.

one jump, is reduced to a single point as

shown in

➔ 7b. Jumps – or points – that

tend to cluster within certain boundaries

generally indicate the process is operating normally while those outside could

signify a problem. The full data set can

be saved for further examination at a

later stage or, if the analysis takes place

in real-time, more data can be collected.

Healthy machines, healthy processes

In today’s competitive world, unplanned

downtime can be disastrous for a company. That is why industries are constantly striving to maximize the availability of their machines. To do this

effectively, some form of condition monitoring needs to be in place so that maintenance can be scheduled or actions

taken to avoid the consequences of failure before it occurs. Condition monitoring is increasing in importance as engineering processes become more

automated and manpower is reduced.

The benefits of condition monitoring

need not come at the expense of having

to install additional equipment. Often the

data provided by devices for one purpose in a process can be used to satisfy

another at no extra cost. As an important

part of an industrial process, ABB drives

have access to and generate large quantities of data, which, when properly processed, can be used for condition monitoring and diagnostics. Drives are but

one example of useful diagnostic data

providers. Other examples include motor

control centers, protection relays and intelligent fuses. As well as being data providers, these devices are capable of using their onboard computational power

for analyses.

Michal Orkisz

ABB Corporate Research

Krakow, Poland

michal.orkisz@pl.abb.com

Maciej Wnek

ABB Low Voltage Products

Turgi, Switzerland

maciej.wnek@ch.abb.com

Pieder Joerg

ABB Discrete Automation and Motion

Turgi, Switzerland

pieder.joerg@ch.abb.com

References

[1] Mitchell, J. S. (2002). Physical Asset

Management Handbook (185). Clarion

Technical Publishers, United States.

[2] Wnek, M., Nowak, J., Orkisz, M., Budyn, M.,

Legnani, S. (2006). Efficient use of process and

diagnostic data for the lifecycle management.

Proceedings of Euromaintenance and 3rd World

Congress on Maintenance (73– 78). Basel,

Switzerland.

[3] Press, W.H., Flannery, B.P., Teukolsky, S.A.,

Vetterling, W.T. (1986). Numerical Recipes:

The Art of Scientific Computing. Cambridge

University Press.

[4] Jolliffe, I.T. (2002). Principal Component

Analysis. Springer.

75Hidden treasure

Loading...

Loading...