Page 1

9292 Jeronimo Road

Irvine, CA 92618-1905

Quick Installation Guide

V2000 READER INTERFACE / ACCESS

CONTROLLER

PROPRIETARY INFORMATION. This document contains proprietary information which may not be duplicated,

published or disclosed to others, or used for any purpose without written permission from HID Corporation. 2004

© HID Corporation. All rights reserved.

Document Version 1.0

August 12, 2005

Document Number 6080-906B

Page 2

VertX V2000 (CS) Quick Installation Guide

Contents

Introduction ......................................................................................................................................................... 3

Parts List.......................................................................................................................................................3

Product Specifications .................................................................................................................................. 3

Cable Specifications ..................................................................................................................................... 3

Overview ......................................................................................................................................................... 4

Step 1 Preparations................................................................................................................................................ 5

1.1 What you need before getting started ............................................................................................. 5

1.2 V2000............................................................................................................................................... 5

Step 2 Hardware Installation .................................................................................................................................5

2.1 Mounting Instructions....................................................................................................................... 5

2.2 Wiring VertX..................................................................................................................................... 6

Step 3 Communications Configuration................................................................................................................ 9

3.1 Firewall Configuration...................................................................................................................... 9

3.2 Computer to VertX Controller Connection..................................................................................... 11

3.3 Windows TCP/IP Configuration..................................................................................................... 11

3.4 How to Edit Configuration Files ..................................................................................................... 14

3.5 DHCP TCP/IP Addressing.............................................................................................................16

3.6 Static TCP/IP Addressing ..............................................................................................................19

Step 4 Reboot and Test with the Central Station .............................................................................................. 22

4.1 Calibrate Input................................................................................................................................ 22

Central Station Automation Provider Instructions............................................................................................. 23

Dice Corporation.........................................................................................................................................23

GE MAS...................................................................................................................................................... 24

Bold Technologies ...................................................................................................................................... 24

Contact Information............................................................................................................................................... 24

Pre-Installation Checklist...................................................................................................................................... 26

August 2005 Page 2 of 23

2005 © HID Corporation. All rights reserved.

Page 3

VertX V2000 (CS) Quick Installation Guide

Introduction

VertX™ CS is the first family of access controllers designed specifically for alarm dealers for direct

connection to central stations. Because it was designed with central station in mind, VertX CS works with

software from leading central station automation providers, including Bold Technologies, DICE and

GE MAS.

The V2000 is designed to control two sets of door devices (such as two-doors, two-readers, associated

contacts and relays) as well as manage communications with the central station automated software.

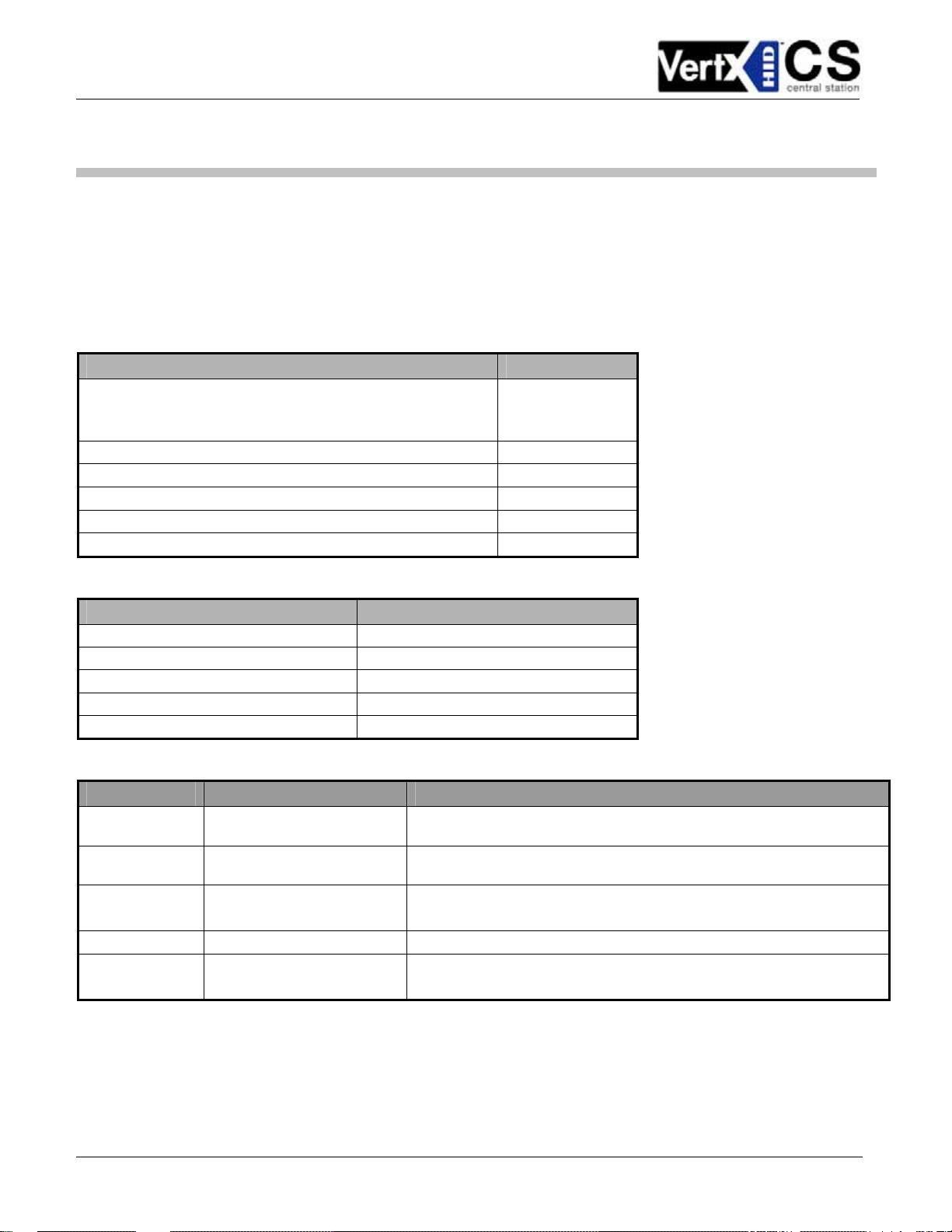

Parts List

Description Quantity

VertX™ V2000 Reader Interface/Access Controller

Note: The V2000 controller has a plastic base and is covered

with a Plastic or Mylar cover.

- Lithium Battery 1

- Mounting screws 4

- 2.2K EOL resistors 8

- Quick Installation Guide 1

- Installation Wiring Diagram Example 1

1

Product Specifications

Description Specification

Power Supply 12-16VDC

Maximum current at 12VDC per V2000 1 Amp

Average operating current at 12VDC

Operating temperature range 32°-122°F (0°-50°C)

Humidity 5% to 95% non-condensing

625 mA (with two R40 iCLASS Readers)

Cable Specifications

Cable Type Length Specification

Input Circuits * 500 feet (150 m)

Output Circuits * 500 feet (150 m)

Wiegand

Ethernet 328 feet (100 m) Cat5, Cat5E, and Cat6

Power Supply

+12 VDC IN

500 feet (150 m) to reader ALPHA 1299C, 22AWG, 9-conductor, stranded, overall shield.

---- Refer to your Power Supply Installation Guide.

* Minimum wire gauge depends on cable length and current requirements.

2-conductor, shielded, using ALPHA 1292C (22AWG) or Alpha 2421C

(18AWG), or equivalent.

2-conductor, using ALPHA 1172C (22AWG) or Alpha 1897C (18AWG), or

equivalent.

Fewer conductors needed if all control lines are not used.

August 2005 Page 3 of 23

2005 © HID Corporation. All rights reserved.

Page 4

VertX V2000 (CS) Quick Installation Guide

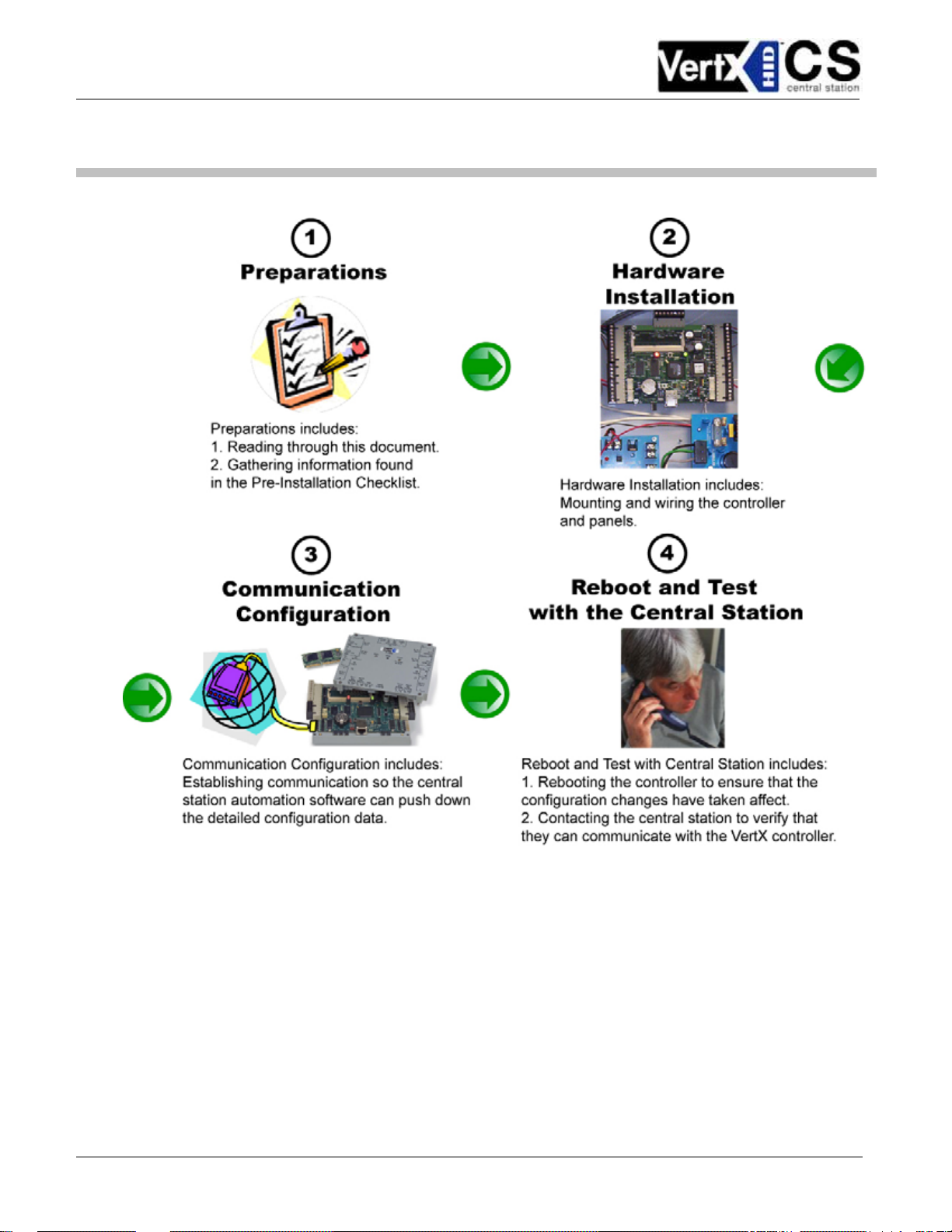

Overview

The following outlines what is required to install the V2000.

August 2005 Page 4 of 23

2005 © HID Corporation. All rights reserved.

Page 5

VertX V2000 (CS) Quick Installation Guide

Step 1 Preparations

1.1 What you need before getting started

Prior to starting the installation, please completely read this guide.

CAUTION: The V2000 is sensitive to Electrostatic Discharges (ESD). Observe precautions while handling the

circuit board assembly by using proper grounding straps and handling precautions at all times.

1.2 V2000

1. Remove the plastic or Mylar cover.

2. Verify the battery is installed. If the battery is not

installed, complete these steps:

a. Remove the button cell battery from the accessory kit.

b. Install the button cell battery (+ side up) in the battery

holder, BT1.

c. Verify that the battery jumper is in the ON position (or

OUT position on old covers), P10 (V2000), pins 2-3.

d. Replace the plastic or Mylar cover.

Step 2 Hardware Installation

2.1 Mounting Instructions

1. The V2000 should always be mounted in a secure area.

2. Mount the V2000 using the four mounting screws (provided) or other appropriate fasteners.

Place the fasteners in the corner holes of the base.

3. The V2000 can be stacked with or without the cover. Do not remove the plastic base. Make

sure you position the V2000 in such a way as to provide room for wiring, air flow and cable

runs.

August 2005 Page 5 of 23

2005 © HID Corporation. All rights reserved.

Page 6

VertX V2000 (CS) Quick Installation Guide

2.2 Wiring VertX

CAUTION: Connectors on the V2000 sides are positioned to be mirror images and are not

interchangeable once the installation is complete. Therefore, you cannot unplug the connector from

one side of the board and plug it into the corresponding connector on the other side of the board.

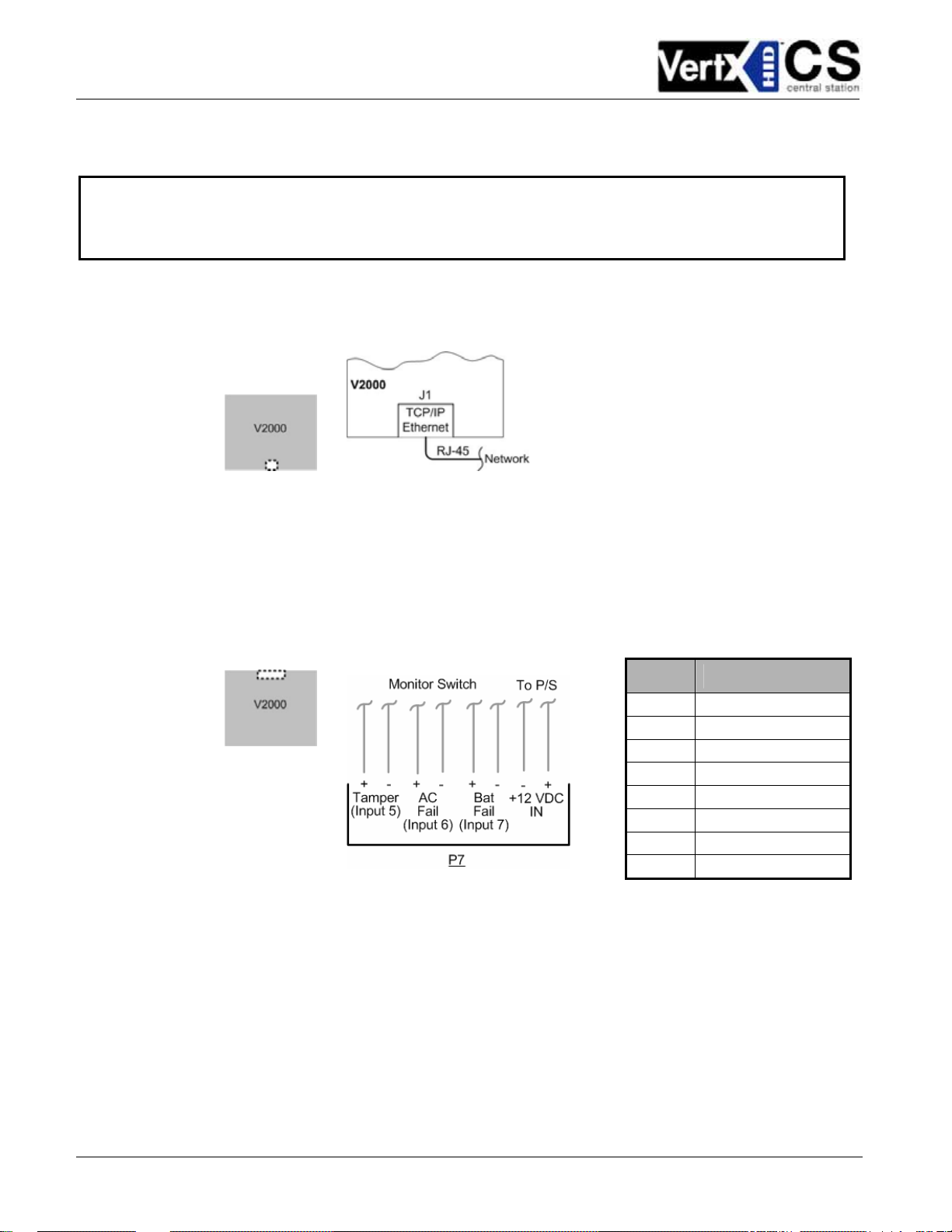

1. Network Connection: Connect the V2000 to the network using a standard Cat5 network

patch cable. Connect one end of the Cat 5 network patch cable to the J1 (RJ-45) connector

on the V2000 and the other end to the network connection point (network jack, hub, switch, or

router) on your site.

2. Power and Alarm input connections: Connect power by providing 12VDC to the P7

connector. +12VDC goes to Pin 1 and Ground on Pin 2. The Bat Fail, AC Fail, and Tamper

switch inputs are wired as shown in the table. Connect the Bat Fail and AC Fail inputs to

battery low/failure and AC failure contacts provided on the power supply. Connect the Tamper

input to a tamper switch on the enclosure.

Pin # P7

1 +12VDC

2 Ground

3 Bat Fail 4 Bat Fail +

5 AC Fail 6 AC Fail +

7 Tamper 8 Tamper +

August 2005 Page 6 of 23

2005 © HID Corporation. All rights reserved.

Page 7

VertX V2000 (CS) Quick Installation Guide

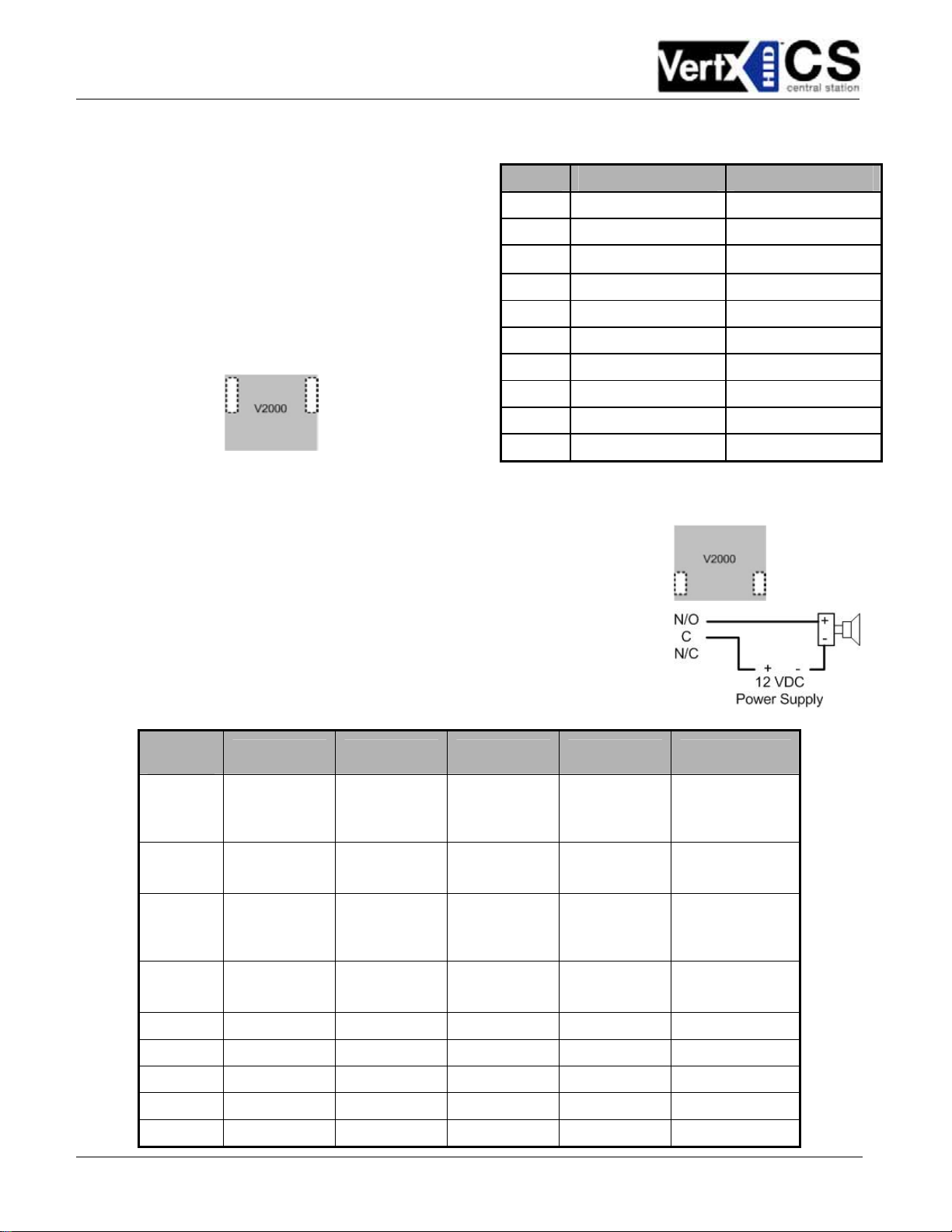

3. Reader Connections: Connect

Wiegand or clock-and-data interfaces

using the connection table shown. You

can connect up to 10 signal lines for

the reader. Use as many signal lines

as are required for your reader

interface.

Note: Connect the data return line to

the same ground as the reader power,

if the reader is not powered by the

VertX controller’s 12VDC.

Pin # V2000 P1 V2000 P4

1 Reader Power Shield Ground

2 Ground Hold

3

4 Data 1 / Clock Red LED

5 Data Return Green LED

6 Green LED Data Return

7 Red LED Data 1 / Clock

8 Beeper Data 0 / Data

9 Hold Ground

Data 0 / Data Beeper

10 Shield Ground Reader Power

4. Output Connections – All Output connections are used for

general purpose controls. The following table shows where the

various outputs are located among the various VertX types. Pin

numbers shown use the convention “NO/C/NC”. For example,

Output 1, V2000: P3 Pin1 is NO (Normally Open) and Pin 2 is

C (Common) and Pin 3 is NC (Normally Closed).

Note: Relay contacts are rated for 2Amps @ 30VDC.

Output

number

1

2

3

4

5

6

7

8

9

V2000 V1000 V100 V200 V300

P3 Pins 1/2/3

Strike (lock)

Relay 1

P3 Pins 4/5/6

Aux Relay 1

P6 Pins 6/5/4

Strike (lock)

Relay 2

P6 Pins 3/2/1

Aux Relay 2

P14 Pins 2/3/4

P11 Pins 6/5/4

P3 Pins 1/2/3

Strike (lock)

Relay 1

P3 Pins 4/5/6

Aux Relay 1

P6 Pins 6/5/4

Strike (lock)

Relay 2

P6 Pins 3/2/1

Aux Relay 2

P3 Pins 2/3/4 P1 Pins 1/2/3

P6 Pins 3/2/1 P1 Pins 4/5/6

P1 Pins 7/8/9

P2 Pins 1/2/3

P4 Pins 9/8/7

P4 Pins 6/5/4

P4 Pins 3/2/1

P2 Pins 4/5/6

P2 Pins 7/8/9

August 2005 Page 7 of 23

2005 © HID Corporation. All rights reserved.

Page 8

VertX V2000 (CS) Quick Installation Guide

Output

number

10

11

12

V2000 V1000 V100 V200 V300

P5 Pins 9/8/7

P5 Pins 6/5/4

P5 Pins 3/2/1

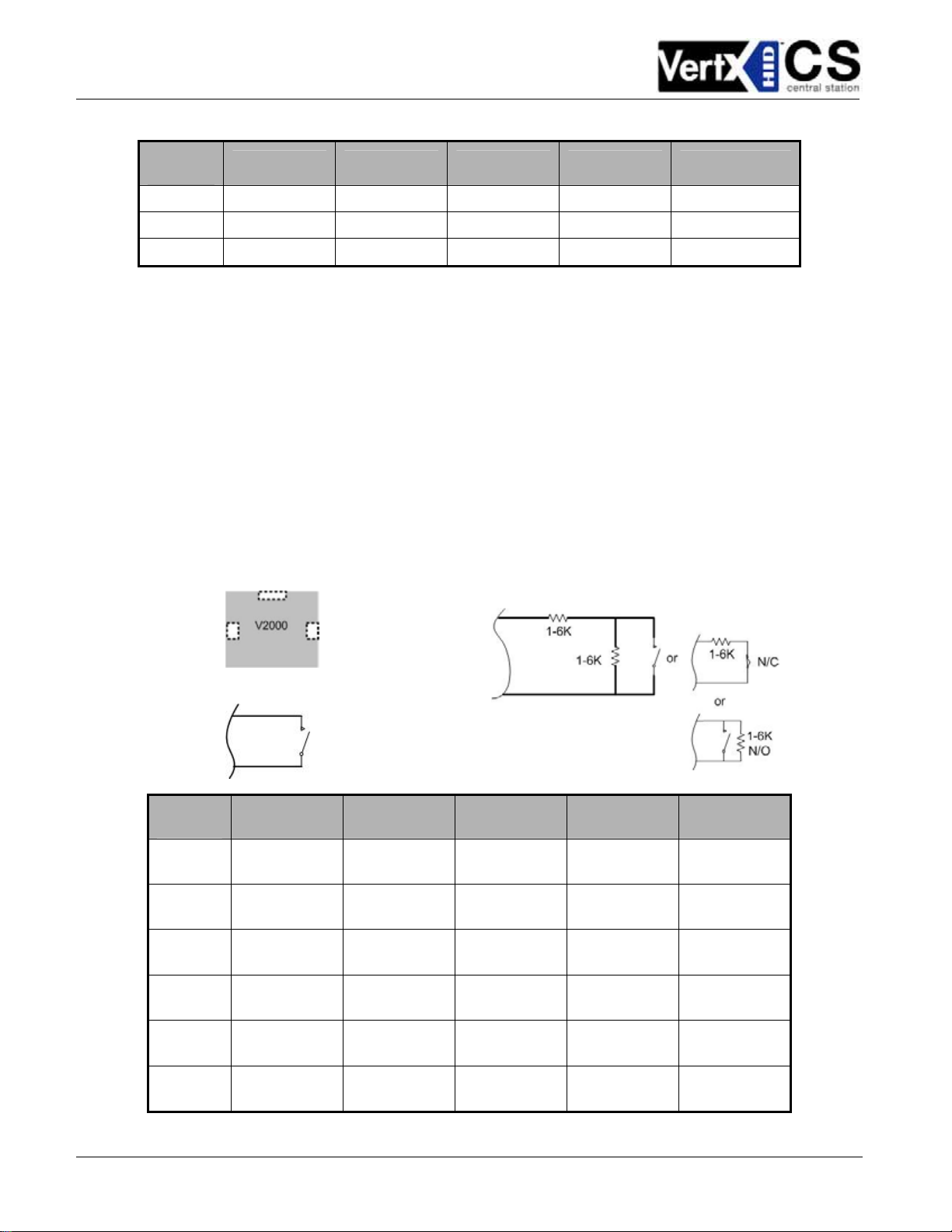

5. Input Connections – Input connections are used for a combination of specific functions such

as Request-to-Exit (REX), Door monitor, etc. They can also be used as general purpose

monitoring. Connect one side of the switch or contact to the + (plus) lead and the other to the

– (minus) lead. The following table shows where the inputs are located among the different

VertX units. Pin numbers shown on the cover use the convention +/–.

The default REX switch configuration is normally open (NO) unsupervised (no EOL resistors),

while the default door switch (DS) configuration is Normally Closed (NC) unsupervised (no

EOL resistors). All other input points are defaulted for NO switches and are unsupervised (no

EOL resistors).

Any input can be configured as a supervised input. They can be configured for resistors of 1K

– 6K Ohm. The setup of supervised inputs should be done during configuration of the VertX

units via the central station automation software (host) or by using the Calibrate Input tool, see

section 4.1 Calibrate Input.

Example: Input 1, V1000 is: P14 Pin1 is + and Pin 2 is -.

Supervised inputs can be configured for:

Input

number

1

2

3

4

5

6

All default inputs will be:

V2000 V1000 V100 V200 V300

P2 Pins 1/2

Door Monitor

P2 Pins 3/4

REX input

P5 Pins 4/3

Door Monitor

P5 Pins 2/1

Rex Input

P7 Pins 8/7

Tamper

P7 Pins 6/5

AC Fail

P14 Pins 1/2

P11 Pins 4/3

P7 Pins 8/7

Tamper

P7 Pins 6/5

AC Fail

P7 Pins 4/3

Batt Fail

P2 Pins 1/2

Door Monitor

P2 Pins 3/4

REX input

P5 Pins 4/3

Door Monitor

P5 Pins 2/1

Rex Input

P7 Pins 8/7

Tamper

P7 Pins 6/5

AC Fail

P1 Pins 1/2 P6 Pins 2/1

P1 Pins 3/4 P3 Pins 1/2

P1 Pins 5/6

P1 Pins 7/8

P1 Pins 9/10 P7 Pins 4/3

P2 Pins 1/2

P7 Pins 8/7

Tamper

P7 Pins 6/5

AC Fail

Batt Fail

August 2005 Page 8 of 23

2005 © HID Corporation. All rights reserved.

Page 9

VertX V2000 (CS) Quick Installation Guide

Input

number

7

8 P2 Pins 5/6

9 P4 Pins 10/9

10 P4 Pins 8/7

11 P4 Pins 6/5

12 P4 Pins 4/3

13 P4 Pins 2/1

14 P5 Pins 6/5

15 P5 Pins 4/3

16 P5 Pins 2/1

17

18

19

V2000 V1000 V100 V200 V300

P7 Pins 4/3

Batt Fail

P7 Pins 4/3

Batt Fail

P2 Pins 3/4

P7 Pins 8/7

Tamper

P7 Pins 6/5

AC Fail

P7 Pins 4/3

Batt Fail

Step 3 Communications Configuration

This section describes the communications configuration.

There are two methods of communication possible on a V2000:

• Error! Reference source not found.

• Static TCP/IP Addressing

Follow only the communication instructions that relates to your sites specific installation.

3.1 Firewall Configuration

If the VertX controller is being installed were it communicates through a firewall, then the firewall must be

configured to allow TCP data transfer on the specified port(s).

The port(s) that must be opened on the firewall for the VertX controller are the “

listen_port” specified in the CommCfg configuration file (The Setup Host Communication screen will

“

take you to the Edit Configuration Files screen. The configuration files described in this section will enable

DHCP TCP/IP host communications. See sections 3.2, 3.3, and 3.4 for instructions on how to start.

Select a file from the list the appropriate configuration file and click Edit File. If you need to clear the

selection, click Clear Selection.

While following these instructions edit the circled areas shown.

Note: In addition to these configuration file edits, you may be interested in changing the “hostname”. See

/mnt/flash/etc/conf.d/hostname for instructions on changing the host name.

connection_port” and

/mnt/flash/TaskConfig/CommCfg) as well as the Pre-Installation Checklist

.

If you are not familiar with configuring a firewall for the network, contact the Network/IT administrator or

manager.

August 2005 Page 9 of 23

2005 © HID Corporation. All rights reserved.

Page 10

VertX V2000 (CS) Quick Installation Guide

CAUTION: If the firewall is not configured properly the controller will not be able to communicate with the

host.

August 2005 Page 10 of 23

2005 © HID Corporation. All rights reserved.

Page 11

VertX V2000 (CS) Quick Installation Guide

3.2 Computer to VertX Controller Connection

Note: This step is necessary if you are configuring your communications for DHCP or Static TCP/IP.

3.2.1 Hardware Requirements

The following outlines the hardware requirements for configuring a static TCP/IP connection.

• Computer with administration rights and a Internet browser, Internet Explorer 5.0 (or greater), or

equivalent.

• Ethernet cable

• Optional Hub – Required if primary communication channel is Ethernet.

Connect the computer to the VertX controller using an Ethernet cable.

3.3 Windows TCP/IP Configuration

Prior to proceeding, document your Network Connections settings, in order to change your settings back to

their original configuration.

CAUTION: During the timeframe in which you have changed the TCP/IP settings on your computer,

you will not have access to the Internet or E-mail.

Depending on your operating system, follow one of the listed procedures.

• Windows XP Computers

• Windows 2000 Computers

•

August 2005 Page 11 of 23

2005 © HID Corporation. All rights reserved.

Page 12

VertX V2000 (CS) Quick Installation Guide

Windows Millennium Computers

3.3.1 Windows XP Computers

1. Set the computer IP address.

2. Click the Windows Start menu > Settings > Network Connections. The Network

Connections screen displays.

3. Double-click

Local Area Connection. The Local Area Connection Status dialog

displays.

4. Click Properties. The Local Area Connection Properties dialog displays.

5. Within the This connection uses the following items: window, click Internet Protocol

(TCP/IP), and click Properties. The Internet Protocol (TCP/IP) Properties dialog displays.

6. Select the Use the following IP address

radio button. This action will enable the

fields IP address, Subnet mask and

Default gateway. Use the space bar to

tab between fields, the tab key will not

work.

7. Enter the IP address 10.19.4.130. If the

VertX board’s IP address is different than

what is shown, the computer IP address

must be modified accordingly. The two IP

addresses need to be in line with each

other and separated by one digit (for

example: 10.19.4.130 is one digit greater

than 10.19.4.129).

8. Enter the Subnet mask: 255.255.0.0.

9. Enter the Default gateway: 10.19.0.1.

10. Click OK.

11. Click Close to complete the computer

configuration.

12. Restart your computer.

3.3.2 Windows 2000 Computers

1. Go to the Network screen by clicking the Start button. Click Settings and then Control

Panel. From there, double-click the Network Connections icon.

2. Select the Local Area Connection icon for the applicable Ethernet adapter (usually it is the

first Local Area Connection listed). Double-click the Local Area Connection. Click the

Properties button.

3. Select Internet Protocol (TCP/IP), and click the Properties button.

4. Select the Use the following IP address radio button. This action will enable the fields IP

address, Subnet mask and Default gateway. Use the space bar to tab between fields, the

tab key will not work.

August 2005 Page 12 of 23

2005 © HID Corporation. All rights reserved.

Page 13

VertX V2000 (CS) Quick Installation Guide

5. Enter the IP address 10.19.4.130. If the VertX board’s IP address is different than what is

shown, the computer IP address must be modified accordingly. The two IP addresses need to

be in line with each other and separated by one digit (for example: 10.19.4.130 is one digit

greater than 10.19.4.129).

6. Enter the Subnet mask: 255.255.0.0.

7. Enter the Default gateway: 10.19.0.1.

8. Click OK.

9. Click the OK button again to complete the computer configuration.

10. Restart your computer.

August 2005 Page 13 of 23

2005 © HID Corporation. All rights reserved.

Page 14

VertX V2000 (CS) Quick Installation Guide

3.3.3 Windows Millennium Computers

1. Go to the Network screen by clicking the Start button. Click Settings and then Control

Panel. From there, double-click the Network icon.

2. On the Configuration tab, select the TCP/IP line for the applicable Ethernet adapter. Do not

choose a TCP/IP entry whose name mentions DUN, PPPoE, VPN, or AOL. If the word TCP/IP

appears by itself, select that line. Click the Properties button.

3. Click the IP Address tab and select Use the following IP address. Enter the IP address

10.19.4.130.

4. Now click the Gateway tab to enter the Installed Gateway content. Enter the Default

Gateway 10.10.0.1. Click the OK button.

5. Click OK again. Windows may ask you for the original Windows installation disk or additional

files. Supply them by pointing to the correct file location, e.g., D:\win98, D:\win9x,

c:\windows\options\cabs, etc. (if “D” is the letter of your CD-ROM drive).

6. Restart your computer.

3.4 How to Edit Configuration Files

Before configuring a VertX controller to communicate through DHCP or Static TCP/IP Addressing, learning

the following conventions is necessary.

First, you must become familiar with editing conventions to successfully configure the VertX controller.

3.4.1 Conventions

The rules described are basic guidelines for editing the configuration files successfully.

• Lines beginning with “#” are comments and are ignored.

o The term “uncomment” means that you should remove the “#” symbol from the referenced line in

the configuration file.

o The term “comment” means to add a “#” symbol to the referenced line in the configuration file.

• White spaces must be space characters, and not tabs.

• In the Installer Tools, do not uncheck Convert CRLF to LF (found at the top of the Edit screen). This

checkbox ensures that Carriage Returns are converted correctly to line feeds for the VertX Controller.

CAUTION: Currently there is minimal error checking on configuration parameter data. If errors occur

during startup, you must verify that all configuration data is within valid ranges.

3.4.2 Accessing the Installer Tools

When configuring for a DHCP or Static TCP/IP connection, access the Installer Tools to edit the

configuration files.

1. Open your Internet Browser.

2. Enter the URL of the controller into the Address field.

• Static TCP/IP Communication,

• DHCP TCP/IP Communication,

Assigned VertX IP/InstallerTools.html

VertX_Controller.yourdomain.suffix/InstallerTools.html

Note: The URL is case sensitive and must be entered precisely as shown.

August 2005 Page 14 of 23

2005 © HID Corporation. All rights reserved.

Page 15

VertX V2000 (CS) Quick Installation Guide

3. Click

. The Installer Tools menu will display.

3.4.3 Accessing the Installer Tools

When configuring for a DHCP or Static TCP/IP connection, access the Installer Tools to edit the

configuration files.

1. Open your Internet Browser.

2. Enter the URL of the controller into the Address field.

• Static TCP/IP Communication,

• DHCP TCP/IP Communication,

Assigned VertX IP/InstallerTools.html

VertX_Controller.yourdomain.suffix/InstallerTools.html

Note: The URL is case sensitive and must be entered precisely as shown.

August 2005 Page 15 of 23

2005 © HID Corporation. All rights reserved.

Page 16

VertX V2000 (CS) Quick Installation Guide

3. Click

. The Installer Tools menu will display.

3.5 DHCP TCP/IP Addressing

The VertX controller’s default communication configuration is DHCP addressing. When a DHCP address is

not provided, the controller will default to a static IP address of 10.19.4.129. When the controller successfully

obtains an IP address from a DHCP server, the V1000 communications will use the controller’s hostname.

The default hostname of a V2000 is “VertX_Controller.” Access the controller by completing the following

steps:

1. Connect an Ethernet cable from the controller connecting it to the computer or Ethernet Hub. See

Error! Reference source not found. Error! Reference source not found..

2. Open your Internet Browser.

3. Enter the URL of the controller into the Address field.

The default DHCP URL is VertX_Controller.yourdomain.suffix/InstallerTools.html.

Domain names identify one or more IP addresses. For example, the domain name microsoft.com represents

about a dozen IP addresses. Domain names are used in URLs to identify particular Web pages. Every

domain name has a suffix, examples of a suffix include .com, .net, .org etc.

Note: If access to the controller is not successful, use the default static IP address (10.19.4.129).

CAUTION: For the DHCP communications to function properly the network must have a functioning DNS

(Domain Name Server) or you will be unable to communicate with the controller.

The following configuration files require editing to enable DHCP.

The Setup Host Communication screen will take you to the Edit Configuration Files screen. The

configuration files described in this section will enable DHCP TCP/IP host communications. See sections 3.2,

3.3, and 3.4 for instructions on how to start.

Select a file from the list the appropriate configuration file and click Edit File. If you need to clear the

selection, click Clear Selection.

While following these instructions edit the circled areas shown.

August 2005 Page 16 of 23

2005 © HID Corporation. All rights reserved.

Page 17

VertX V2000 (CS) Quick Installation Guide

Note: In addition to these configuration file edits, you may be interested in changing the “hostname”. See

/mnt/flash/etc/conf.d/hostname for instructions on changing the host name.

• /mnt/flash/TaskConfig/CommCfg

• /mnt/flash/TaskConfig/CommHosts

August 2005 Page 17 of 23

2005 © HID Corporation. All rights reserved.

Page 18

VertX V2000 (CS) Quick Installation Guide

3.5.1 Configuration File Edits

The Setup Host Communication screen will take you to the Edit Configuration Files screen. The

configuration files described in this section will enable DHCP TCP/IP host communications. See sections 3.2,

3.3, and 3.4 for instructions on how to start.

Select a file from the list the appropriate configuration file and click Edit File. If you need to clear the

selection, click Clear Selection.

While following these instructions edit the circled areas shown.

Note: In addition to these configuration file edits, you may be interested in changing the “hostname”. See

/mnt/flash/etc/conf.d/hostname for instructions on changing the host name.

3.5.1.1 /mnt/flash/TaskConfig/CommCfg

From the Edit Configuration Files screen, then edit the

file.

/mnt/flash/TaskConfig/CommCfg configuration

1. Select

/mnt/flash/TaskConfig/CommCfg from the list.

2. Click Edit File. The Edit File window will display.

3. Enter the appropriate configuration data, see the Pre-Installation Checklist – Ref #4, page 23

VertX controller to communicate to the host.

Example:

#

# commtask configuration parameters

# -----------------------------------------------------# Connect to host on startup (1=>yes)

connect_on_start 1

# If contacted by a host, maintain connection without callback (1=>yes)

maintain_host_connection 0

# Call the host machine on this port

connection_port 4070

# Listen on this port for host connection requests

listen_port 4050

# If a connect attempt fails, wait this interval (~secs)

# before attempting to connect to the next host in CommHosts

reconnect_interval 15

# If no messages are received from the host within this interval (~min)

# then disconnect. (timeout = 0 => no timeout, continuous connection)

timeout 0

# Encrypt host communications (0=no, 1=yes)

use_encryption 0

# If a response to a host request is not received within this time (~secs),

, for the

August 2005 Page 18 of 23

2005 © HID Corporation. All rights reserved.

Page 19

VertX V2000 (CS) Quick Installation Guide

# then disconnect.

message_response_time 20

3.5.1.2 /mnt/flash/TaskConfig/CommHosts

Finally, edit the

/mnt/flash/TaskConfig/CommHost configuration file to communicate with the central

station automation software (host).

This is the last configuration file requiring edits for Ethernet setup.

1. From the Edit Configuration Files screen, select

/mnt/flash/TaskConfig/CommHost from

the list.

2. Click Edit File. The Edit File window will display.

For Static TCP/IP configuration edit the first two lines (lines 1 and 2 shown in the example).

Change “

host(s) in which you are working. See the Pre-Installation Checklist – Ref #5, page 23

10.19.4.130” and/or “VertXProductionTest” to include the IP Address or host name of the

.

Example of Ethernet primary only:

# commtask connection file

# cmid WaitTime MaxPings Username Script IPAddress(or Hostname) CommChannel(1-3)

1 1 2 * * 10.19.4.130 1

2 1 2 * * VertXProductionTest 1

#3 20 4 router1 Router 10.10.10.2 2

#4 20 4 modem1 Modem 10.19.4.131 2

3.6 Static TCP/IP Addressing

The following outlines hardware requirements and provides a detailed configuration procedure to aid you in

connecting to the V2000 through the static TCP/IP addressing configuration only.

See sections 3.2, 3.3, and 3.4 for instructions on how to start.

3.6.1 Configuration File Edits

The Setup Host Communication screen will take you to the Edit Configuration Files screen. The

configuration files available for editing will enable TCP/IP Static host communications using the Static TCP/IP

addressing communications method.

Select a file from the list and click Edit File. If you need to clear the selection, click Clear Selection.

While following these instructions edit the circled areas shown.

3.6.1.1 /mnt/flash/etc/conf.d/net.eth0

First, edit the

Modify the following lines to match the controller’s specified configuration.

See the Pre-Installation Checklist – Ref #1, page 23

August 2005 Page 19 of 23

/mnt/flash/etc/conf.d/net.eth0 configuration file.

1. Select

/mnt/flash/etc/conf.d/net.eth0 from the list.

2. Click Edit File. The Edit File window will display.

.

1. IP (Controller’s IP Address).

2. NETMASK (Subnet Mask).

3. Gateway (Network Gateway).

2005 © HID Corporation. All rights reserved.

Page 20

VertX V2000 (CS) Quick Installation Guide

Example:

# Network configuration:

# Valid boot protocols are "dhcp" (anything else implies "none").

# DHCP is configured to fail after a single server connection attempt,

# we will then revert to the statically configured address.

BOOTPROTO="dhcp"

DHCP_CLIENT="/bin/dhclient -1 -cf /etc/conf.d/dhclient.conf -lf /etc/dhclient.leases"

# Valid media types are "auto", "10baseT-HD", "10baseT-FD", "100baseTX-HD",

# "100baseTX-FD" and "" (nothing).

MEDIA="auto"

# If you are using DHCP the following variables will not be used.

IP="10.19.4.129"

NETMASK="255.0.0.0"

BROADCAST="10.255.255.255"

GATEWAY="10.19.0.1"

If using static

TCP/IP, change the

“

dhcp” to “none”.

3.6.1.2 /mnt/flash/etc/conf.d/hostname

From the Edit Configuration Files screen, continue by editing the

/mnt/flash/etc/conf.d/hostname

configuration file.

1. Select

/mnt/flash/etc/conf.d/hostname from the list.

2. Click Edit File. The Edit File window will display.

3. Modify the “

Hostname” (shown in the example as “V1000_Demo”) with the specified Hostname.

See the Pre-Installation Checklist – Ref #2, page 23

Example:

HOSTNAME="V1000_Demo"

3.6.1.3 /mnt/flash/etc/resolv.conf.def

Next, from the Edit Configuration Files screen edit the

file.

1. Select

/mnt/flash/etc/resolv.conf.def from the list.

2. Click Edit File. The Edit File window will display.

3. Modify the “

aaitg.com”, “10.7.2.220” and “10.7.2.221” values with the specified DNS IP

addresses.

See the Pre-Installation Checklist – Ref #3, page 23

Example:

search aaitg.com\000

nameserver 10.7.2.220

nameserver 10.7.2.221

.

/mnt/flash/etc/resolv.conf.def configuration

.

August 2005 Page 20 of 23

2005 © HID Corporation. All rights reserved.

Page 21

VertX V2000 (CS) Quick Installation Guide

3.6.1.4 /mnt/flash/TaskConfig/CommCfg

From the Edit Configuration Files screen, edit the

/mnt/flash/TaskConfig/CommCfg configuration file.

1. Select

/mnt/flash/TaskConfig/CommCfg from the list.

2. Click Edit File. The Edit File window will display.

3. Enter the appropriate configuration data, see the Pre-Installation Checklist – Ref #4, page

23, for the VertX controller to communicate to the Host.

Example:

#

# commtask configuration parameters

# -----------------------------------------------------# Connect to host on startup (1=>yes)

connect_on_start 1

# If contacted by a host, maintain connection without callback (1=>yes)

maintain_host_connection 0

# Call the host machine on this port

connection_port 4070

# Listen on this port for host connection requests

listen_port 4050

# If a connect attempt fails, wait this interval (~secs)

# before attempting to connect to the next host in CommHosts

reconnect_interval 15

# If no messages are received from the host within this interval (~min)

# then disconnect. (timeout = 0 => no timeout, continuous connection)

timeout 0

# Encrypt host communications (0=no, 1=yes)

use_encryption 0

# If a response to a host request is not received within this time (~secs),

# then disconnect.

message_response_time 20

3.6.1.5 /mnt/flash/TaskConfig/CommHosts

From the Edit Configuration Files screen, edit the

/mnt/flash/TaskConfig/CommHost configuration file to

communicate with the central station automation software (host).

This is the last configuration file requiring edits for Ethernet setup.

1. Select

/mnt/flash/TaskConfig/CommHost from the list.

2. Click Edit File. The Edit File window will display.

August 2005 Page 21 of 23

2005 © HID Corporation. All rights reserved.

Page 22

VertX V2000 (CS) Quick Installation Guide

Change “10.19.4.130” and/or “VertXProductionTest” to include the IP Address or Hostname of the

Host(s) in which you are working. See the Pre-Installation Checklist – Ref #5, page 23

.

Example of Ethernet primary only:

# commtask connection file

# cmid WaitTime MaxPings Username Script IPAddress(or Hostname) CommChannel(1-3)

1 1 2 * * 10.19.4.130 1

2 1 2 * * VertXProductionTest 1

#3 20 4 router1 Router 10.10.10.2 2

#4 20 4 modem1 Modem 10.19.4.131 2

3.6.1.6 Reconfigure to the original Windows TCP/IP Settings

As discussed in 3.3 Windows TCP/IP Configuration, return your computers TCP/IP settings to their original

configuration.

Step 4 Reboot and Test with the Central Station

NOTE: Dependant on the central station automation software that is being utilized, proceed to Central

Station Automation Provider Instructions on page 23 before continuing with Step 4 Reboot and Test with the

Central Station.

Now that the V2000 is installed and configured.

1. Reboot the controller by removing and reconnecting the power supply to the controller. The

controller should be functional within 20-60 seconds.

2. Contact the central station to test communications.

4.1 Calibrate Input

The Calibrate Input tool is available for calibrating the input devices through the Installer Tools.

CAUTION: Only use the Calibrate Input tool if instructed to use it by the central station.

1. Find the Installer tools by opening a browser and entering the controllers URL into the

Address field. See the Pre-Installation Checklist – Ref #5, page 23

2. Enter the following URL depending on your communication configuration:

• Static TCP/IP Communication,

• DHCP TCP/IP Communication,

VertX_Controller.yourdomain.suffix/InstallerTools.html

3. Select Calibrate Input

4. If more information is required, click Installer Tools Documentation.

Assigned VertX IP/InstallerTools.html

.

August 2005 Page 22 of 23

2005 © HID Corporation. All rights reserved.

Page 23

VertX V2000 (CS) Quick Installation Guide

Central Station Automation Provider Instructions

Dice Corporation

Perform the following steps if the central station uses Dice software.

1. Open your Internet Browser.

2. Enter the V2000 URL into the Address field. The URL is gathered from the central station.

See the Pre-Installation Checklist – Ref #5, page 23

3. Click

.

.

4. Click Edit Configuration Files

5. From the Edit Configuration Files screen, click Here I am. Then, click Edit File to modify the

file.

6. From within the Here I am configuration file, on the third line, change 0 to 60.

BEFORE

AFTER

7. Click Save File, when complete and the change will become activated once the controller is

rebooted.

8. Close the browser window(s) when completed.

Continue to Step 4 Reboot and Test with the Central Station.

August 2005 Page 23 of 23

2005 © HID Corporation. All rights reserved.

Page 24

VertX V2000 (CS) Quick Installation Guide

GE MAS

If using GE Monitoring Automation Systems (MAS) as a central station automation software, no additional

steps are necessary for configuring the V1000 controller.

Bold Technologies

If using Bold Technologies as a central station automation software, no additional steps are necessary for

configuring the V1000 controller.

Contact Information

HID Corporation

Web Site http://www.hidcorp.com

Main Phone (949) 598-1600

Sales (800) 210-4744

Technical Support (800) 237-7769

929274 Jeronimo Road, Irvine, CA 92618-1905

Fax (949) 598-1698

August 2005 Page 24 of 23

2005 © HID Corporation. All rights reserved.

Page 25

VertX V2000 (CS) Quick Installation Guide

All National and local Electrical codes apply.

• This equipment is intended to be powered from a limited power source output of a

previously certified power supply.

• Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

Class A Digital Devices

FCC Compliance Statement: This equipment has been tested and found to comply with the limits for a

Class. A digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

Class B Digital Devices

FCC Compliance Statement: This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to the limits for a Class B digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined

by turning the equipment off and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

August 2005 Page 25 of 23

2005 © HID Corporation. All rights reserved.

Page 26

VertX V2000 (CS) Quick Installation Guide

Pre-Installation Checklist

Hardware

Name Source Part Number

Ethernet Cable

Computer with Web Browser

Hub (Optional)

AC Electrical Outlet or Surge Protector (Optional)

Configuration Data

Doc

Ref

File Name/Data Configuration Data Collected Data

Bootproto (for DHCP)

IP Address

1 /mnt/flash/etc/conf.d/net.eth0

Netmask

Gateway

2 /mnt/flash/etc/conf.d/hostname Hostname

Domain Name for Search

3 /mnt/flash/etc/resolv.conf.def

DNS IP Address (Primary)

DNS IP Address (Secondary)

Connect_on_start

Maintain_host_connection

Connection_port

Listen_port

4 /mnt/flash/TaskConfig/CommCfg

Reconnect_interval

Timeout

Use_encryption

Message_response_time

Host Name (“john.abc.com”)

5 /mnt/flash/TaskConfig/CommHost

Host IP Address

Connection Type(s)

August 2005 Page 26 of 23

2005 © HID Corporation. All rights reserved.

Loading...

Loading...