Page 1

15370 Barranca Parkway

Irvine, CA 92618

MaxiProx® DFM Reader - 5375

INSTALLATION GUIDE

5375-901, Rev E.1

March 2012

© 2008-2012 HID Global Corporation. All rights reserved.

Page 2

Part No. 5375-901, Rev E.1 MaxiProx® Installation Guide

Contents

Contact .................................................................................................................................................... 3

1 System Overview ............................................................................................................................ 4

1.1 Operation ............................................................................................................................. 4

1.2 Parts List .............................................................................................................................. 4

1.3 Regulatory Approvals and Certif ic ati ons ............................................................................. 5

2 Installation Procedure .................................................................................................................... 5

2.1 Preparation .......................................................................................................................... 5

2.2 Mounting and Installation ..................................................................................................... 5

2.3 Mounting Applications.......................................................................................................... 5

2.4 Cable Preparation ................................................................................................................ 5

2.5 Install Cable ......................................................................................................................... 6

2.6 Cable Connections .............................................................................................................. 6

2.7 Dip Switch and Jumper Settings .......................................................................................... 7

2.8 Tamper Switch ..................................................................................................................... 9

2.9 Mounting .............................................................................................................................. 9

2.10 Power Supply ....................................................................................................................... 9

2.11 Auto-tune Operation ..........................................................................................................10

2.12 Reader Testing ..................................................................................................................10

2.13 Power-Up Tune ..................................................................................................................10

2.14 Periodic Auto-tune .............................................................................................................10

2.15 Supervisor Mode ................................................................................................................10

2.16 Install Cover .......................................................................................................................11

3 Installation Guidelines .................................................................................................................13

3.1 Power Supply .....................................................................................................................13

3.2 Installation near metal........................................................................................................13

3.3 Radio Frequency Interference ...........................................................................................13

3.4 Transponder Types............................................................................................................14

4 Application Notes .........................................................................................................................14

4.1 Wiegand Interface ..............................................................................................................14

4.2 Clock-and-Data Interface ...................................................................................................16

4.3 RS232 and RS422 Card Message Specification (Send Mode Only) ...............................19

List of Figures

Figure 1: MaxiProx Front View .................................................................................................................................... 11

Figure 2: MaxiProx interior view showing mounting hole locations ............................................................................. 12

Page 2 of 19 March 2012

© 2008 - 2012 HID Global Corporation. All rights reserved.

Page 3

MaxiProx® Installation Guide Part No. 5375-901, Rev E.1

List of Tables

Table 1: TB1 Connector Definition ................................................................................................................................ 7

Table 2: TB2 Connector Definition ................................................................................................................................ 7

Table 3: DIP Switch and Jumper Settings ..................................................................................................................... 7

Table 4: Interface Jumpers Description - P3 and P4 ..................................................................................................... 7

Table 5: Switch Description - SW2 ................................................................................................................................ 8

Table 6: Mode Chart ..................................................................................................................................................... 8

Table 7: Baud Rate Chart – RS232 and RS422 ............................................................................................................ 8

Table 8: Switch Description - SW5 ................................................................................................................................ 8

Table 9: Logic Levels .................................................................................................................................................. 15

Table 10: Data Pulses - Timing Parameters ............................................................................................................... 15

Table 11: Data Timing - Timing Chart ......................................................................................................................... 17

HID GLOBAL, HID, the HID logo and MaxiProx are the trademarks or registered trademarks of HID Global

Corporation, or its licensors, in the U.S. and other countries.

Contact

If you have questions or comments about MaxiProx, please contact us.

North America

15370 Barranca Parkway

Irvine, CA 92618

USA

Phone: 800 237 7769

Fax: 949 732 2120

Europe, Middle East and Africa

Phoenix Road

Haverhill, Suffolk CB9 7AE

England

Phone: +44 1440 714 850

Fax: +44 1440 714 840

Asia Pacific

19/F 625 King’s Road

North Point, Island East

Hong Kong

Phone: 852 3160 9800

Fax: 852 3160 4809

support.hidglobal.com

March 2012 Page 3 of 19

© 2008-2012 HID Global Corporation. All rights reserved.

Page 4

Part No. 5375-901, Rev E.1 MaxiProx® Installation Guide

1 System Overview

MaxiProx® is a self-contained proximity reader. The two-piece polycarbonate enclosure has an O-ring

that weather seals the enclosure pieces together and a cable fitting that seals the cable entry. The

water-resistant unit is designed for outdoor use. The enclosure is mountable on a single gang

electrical box. A bi-color LED an d audi ble tone provide user feedback. Configurable open collector data

outputs provide the data to the Host. Configurable DIP Switches and jumpers provide choice of data

interfaces between Wiegand, Clock-and-Data, RS 232 and RS422. The data interface is configured as

ordered from the factory, but can be changed in the field - please contact HID Technical Support for

assistance. A tamper switch can alert the Host when the enclosure is opened. Internal DIP Switches

and jumpers provide for configuration of the outputs, audible tone and LED control options. Installation

of the MaxiProx reader consists of mounting, connecting the cable to the Host and +12VDC or

+24VDC power, ve ri fy ing the DI P Switch and jumper settings, verifying Auto-tune, and verifying the

reading of a transponder.

1.1 Operation

Transponders (Proximity Cards or ProxKeys) are presented to the front of the MaxiProx. The LED is

red when ready to read a transponder. The LED turns green and the beeper sounds when the

transponder is read and the message is transmitted to the Host computer or interface panel. The

system is ready for another transponder as soon as the LED returns to red. There is an anti-passback

delay of about one and a half seconds before it will read the same card. The LED flash is typically 250

milliseconds long. The operation of the LED and beeper may be controlled by the Host, in which case

the actual operation will depend on the programmed timing of the Host.

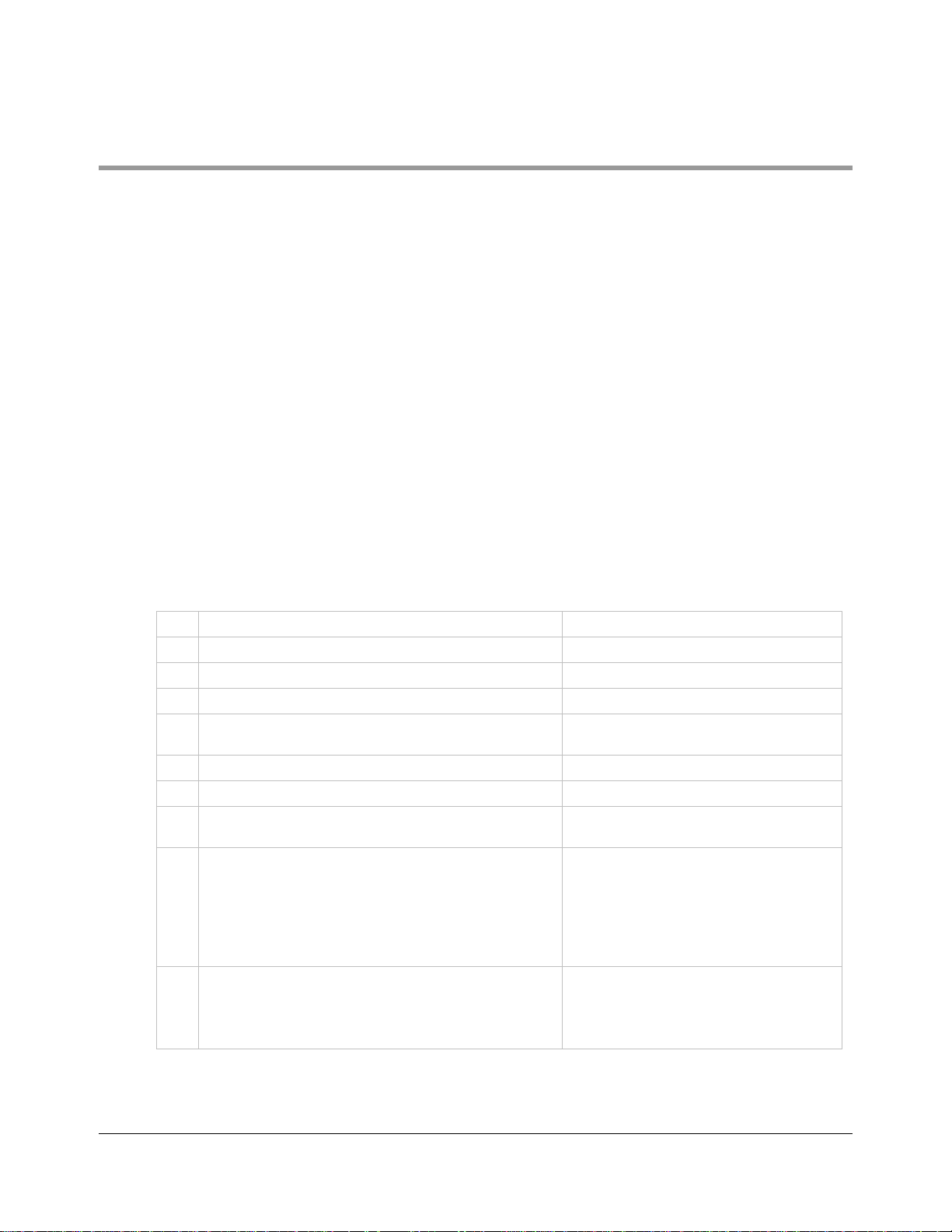

1.2 Parts List

1 MaxiProx reader Qty 1 (included)

2 Installation Manual Qty 1 (included)

3. Cable Fitting Qty 1 (included)

4 Label for front cover - HID logo Qty 1 (included)

#6-32 x 1" flat head screw, for upper-left base mount

5

screw

6 #6-32 x 1" black screw, for gang-box mounting Qty 2 (included)

7 #6-32 x .75" flat head screw, for front cover mount in g Qty 1 (included)

Cable, 5 conductor, 22 AWG (Alpha 1295 C or

8

equivalent)

9 Power Supply – 2.0 A, Linear or switching regulated

+12VDC Shunt Jumper – P2-1 to P2-2 for 12VDC

10

operation

Qty 1 (included)

See Install Cable

+24VDC, nominal (+21 TO 28.5VDC)

Factory Default – P2 Shunt Jumper

between P2 and P3 for 24V operation.

For Europe, use ALTRONIX SMP3

(USER SUPPLIED TRANSFORMER AND

BATTERY)

+12VDC, nominal (+11.6 to +20.9VDC)

For Europe , use ALTRONIX SMP3

(USER SUPPLIED TRANSFORMER AND

BATTERY)

Page 4 of 19 March 2012

© 2008 - 2012 HID Global Corporation. All rights reserved.

Page 5

MaxiProx® Installation Guide Part No. 5375-901, Rev E.1

1.3 Regulatory Approvals and Certifications

Underwriters Laborites listing CE Mark

FCC Certification European Declaration of Conformity

Foreign Countries EMC and/or Type Approvals

Pacemaker wearers should exercise caut ion

when in close proximity to this product.

2 Installation Procedure

2.1 Preparation

Determine an appropriate mounting position for the MaxiProx. Install an electrical box or drill the

appropriate mounting holes from inside the base with the cover removed for #6 fasteners. For optimum

performance, the reader should be mounted at least 4 inches away from any metallic surface 12-inch x

12-inch or larger. The Auto-tune feature au tomatically compensates for incidental metal such as

aluminum studs and conduit. The best method for installing the MaxiProx is by mounting the back of

the reader to the mounting surface. Accomplish side mounting with an adapter or spacer (customer

supplied) that mounts to the back of the reader.

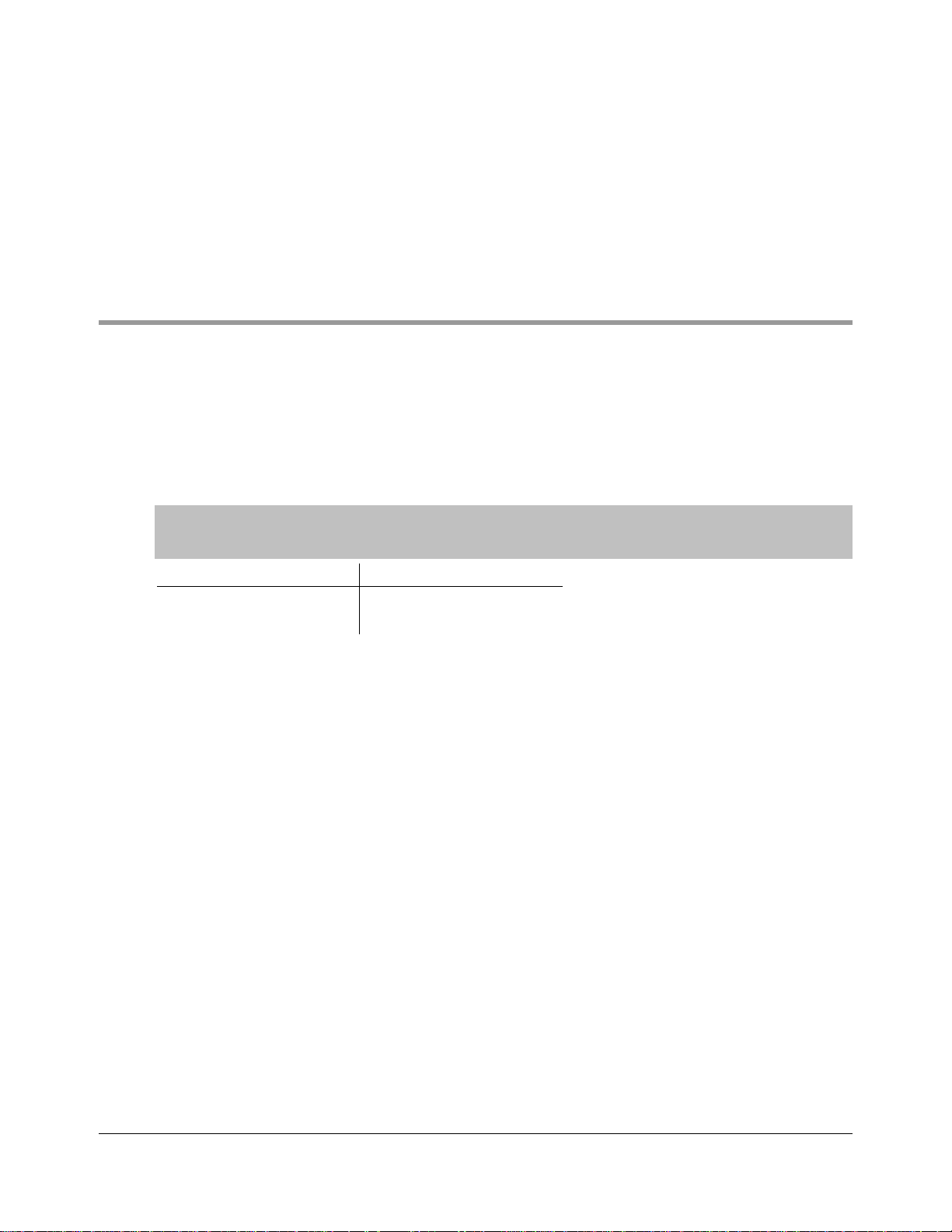

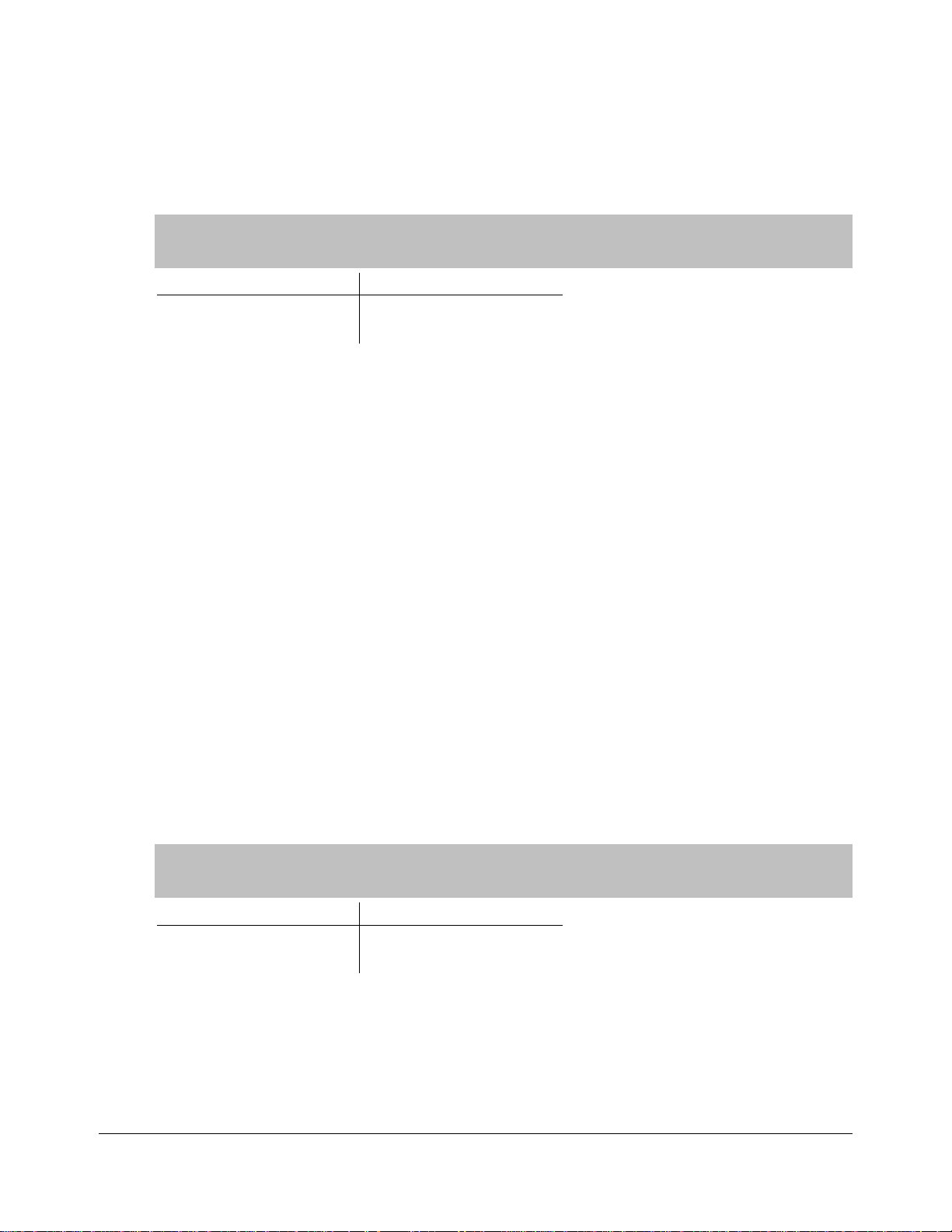

CAUTION: The P2 shunt jumper is factory installed in the 24VDC position. Failure to install the

P2 shunt jumper in the correct position will permanently damage the MaxiProx unit. The

following states the P2 shunt jumper installation.

Power Supply Voltage Jumper Position

+24 VDC (21-28.5VDC) P2 across pin 2 and 3

+12 VDC (11.6-20.9VDC) P2 across pin 1 and 2

2.2 Mounting and Installation

• When fastening the MaxiProx to the mounting surface, do not use a metallic fastener larger than a

#6 screw.

• Avoid mounting the MaxiProx closer than 1 meter (40-inches) to another MaxiProx.

2.3 Mounting Applications

• Mount the MaxiProx to a gooseneck that is 1½-inch in diameter with a 4-inch diameter-mounting

flange without degradation of read range. Mount the flange to a non-metallic adapter that will ease

the installation of the MaxiProx to the flange. The read range will not be affected.

• The MaxiProx may be mounted to a 12-inch x 12-inch or larger metal plate with a 4-inch spacer

used to separate the reader from the plate.

• A crylic, Plexiglas, Lexan (polycarbonate) or other suitable plastics may be found in ½-inch to 1-

inch stock. Mounting adapters may be fabricated from these materials that would be sturdy and not

affect the performance of the MaxiProx. Plastic J-boxes can also be used.

2.4 Cable Preparation

Prepare the cable by cutting the cable jacket back 2 inches and strip the wires 1/4-inch. Tinning the

wires is not required.

March 2012 Page 5 of 19

© 2008-2012 HID Global Corporation. All rights reserved.

Page 6

Part No. 5375-901, Rev E.1 MaxiProx® Installation Guide

Power Supply Voltage

Jumper Position

2.5 Install Cable

Route the interface cable from the MaxiProx to the Host. Connect the MaxiProx DC power input to the

Host or external power supply. Either +12VDC or +24VDC can be used.

CAUTION: The P2 shunt jumper is factory installed in the 24VDC position. Failure to install the

P2 shunt jumper in the correct position will permanently damage the MaxiProx unit. The

following states the P2 shunt jumper installation.

Power Supply Voltage Jumper Position

+24 VDC (21-28.5VDC) P2 across pin 2 and 3

+12 VDC (11.6-20.9VDC) P2 across pin 1 and 2

Notes

• For Wiegand interface cable the maximum length is 500 feet (150m), 50 feet (15m) for RS232, and

4000 feet (1200m) for RS422.

• When using 5 conductor cable, the power supply and Host must have a common ground (voltage

reference).

• 7-Conductor cable is required when using the Hold function or if the ground for the MaxiProx power

supply is not common with the ground of the Host. TB2 terminal 3, Data Return, is to be connected

to the ground of the Host. (Alpha 1296 C or equivalent).

• 7-Conductor cable is required when the Hold function is used, and the power supply and Host

"ground" are separate. (Alpha 1297 C or equivalent).

• A 22 AWG twisted pair, shielded, stranded cable (Belden 9330 or equivalent) is often required for

the tamper switch. Follow the recommendations of the manufacturer of the Host system. If the

tamper input is a supervised input, the "end-of-line" resistor may be mounted in the enclosure

between TB1-4 and TB1-5.

• The inner diameter of the cable fitting will accommodate a cable with an outer diameter of up to

.260-inches.

2.6 Cable Connections

Install the cable fitting on the rear of the MaxiProx. Feed the cable through the cable fitting. Connect

the wires to the terminal strip with the minimum length necessary. Do not leave extra loops of wire

inside the reader housing. Connect the reader to the Host according to the terminal descriptions in the

dimension diagram. Tighten the fitting to secure the cable. Connect the drain line of the shield to

terminal TB1 Pin 2 (Power Supply Shield). If it is bare, cover it with heat shrink or tape to avoid short

circuits to the other wires. Connect the opposite end of the drain line to the negative terminal and the

frame connection of the power supply.

CAUTION: The P2 shunt jumper is factory installed in the 24VDC position. Failure to install the

P2 shunt jumper in the correct position will permanently damage the MaxiProx unit. The

following states the P2 shunt jumper installation.

+24 VDC (21-28.5VDC) P2 across pin 2 and 3

+12 VDC (11.6-20.9VDC) P2 across pin 1 and 2

Page 6 of 19 March 2012

© 2008 - 2012 HID Global Corporation. All rights reserved.

Page 7

MaxiProx® Installation Guide Part No. 5375-901, Rev E.1

Table 1: TB1 Connector Definition

1 2 3 4 5

+DC

Red Drain Black --- ---

Table 2: TB2 Connector Definition

1 2 3 4 5 6 7 8 9

DATA 0

DATA/TD/RX+

Green White Orange Brown Yellow Blue

Shield

Ground

DATA 1

CLK/RD/RX

Ground

DATA

RTN

Tamper

Common

GREEN

LED

Tamper

Select

RED

LED

BEEPER HOLD/

CARD

PRESENT

TX+

RS422

Note: On TB2, pins 1, 2 and 7 have multiple purposes, depending on the configured reader interface.

In the above table, the first description is for Wiegand, the second for Clock-and-Data, the third for

RS232, and the fourth is for RS422.

2.7 Dip Switch and Jumper Settings

TXRS422

Verify the default settings according to the model ordered, or set the DIP Switches and Jumper

positions according to the following.

Table 3: DIP Switch and Jumper Settings

Switch Default Description

1. Interface mode 1 On See Table 6: Mode Chart

2. Interface mode 2 On See Table 6: Mode Chart

3. Interface mode 3 On See Table 6: Mode Chart

4. Beeper control On/Off On

5. Green LED flash Off

6. Single/Dual external LED Off Off - single line LED control. On - dual line LED control.

7. Serial Baud 1 control Off See Table 7: Baud Rate Chart – RS232 and RS422

8. Serial Baud 2 control Off See Table 7: Baud Rate Chart – RS232 and RS422

Table 4: Interface Jumpers Descri ptio n - P3 and P4

P3 and P4 1-2 See Table 6: Mode Chart

On - beep after valid card read. Off - no beep after valid

card read.

Off - flash after valid card read. On - no flash after valid

card read.

March 2012 Page 7 of 19

© 2008-2012 HID Global Corporation. All rights reserved.

Page 8

Part No. 5375-901, Rev E.1 MaxiProx® Installation Guide

Table 5: Switch Description - SW2

Switch Default Description

1. Serial Baud 3 control On See Table 7: Baud Rate Chart – RS232 and RS422

2. Note address 0 N/A Unused

3. Note address 1 N/A Unused

4. Note address 2 N/A Unused

5. Note address 3 N/A Unused

6. Note address 4 N/A Unused

7. Unused

8. Unused

Table 6: Mode Chart

Mode SW1-1 SW1-2 SW1-3 SW5-3 SW5-4 SW5-5

Wiegand ON ON ON NA NA NA 1-2

Clock-and-Data OFF ON ON NA NA NA 1-2

RS232 ON OFF ON NA OFF OFF 2-3

RS422

terminated

RS422 unterm. OFF OFF ON OFF OFF OFF 2-3

Table 7: Baud Rate Chart – RS232 and RS422

BAUD SW1-7 SW1-8 SW2-1

9600 ON ON ON

4800 OFF ON ON

2400 ON OFF ON

1200 OFF OFF ON

Table 8: Switch Description - SW5

Switch Default Description

1. Data Isolation 1 On See 1 below

2. Data Isolation 0 On See 1 below

3. RS422 Terminating Resistor On See 5 below

4. Serial Hardware line setting 1 Off See 6 below

5. Serial Hardware line setting 2 Off See 7 below

OFF OFF ON ON OFF OFF 2-3

P3 & P4

Jumpers

1. Open Collector Data Outputs SW5-1&2 when using Wiegand or Clock & Data Interface.

Configure the data outputs so the MaxiProx is electrically isolated from the Host pull-up resistors.

The default (standard) configuration is non-isolated outputs; switches SW5-1 & 2 are ON.

Note: When configuring the outputs as isolated, use separat e pow e r s up pli e s fo r the Ma x iP rox an d

Host. These switches are unused when in RS232 or RS422 mode.

Page 8 of 19 March 2012

© 2008 - 2012 HID Global Corporation. All rights reserved.

Page 9

MaxiProx® Installation Guide Part No. 5375-901, Rev E.1

2. Beeper Contr ol SW1-4: Enable or disable the on-board beeper. When enabled, the beeper tone

sounds when the LED is green. SW1-4 in the ON position enables the beeper (the default).

3. LED Control SW1-5: The LED flashes after a valid card read. Control by both the MaxiProx and

Host, or Host only. SW1-5 in the OFF position selects flash green after valid card read (the

default).

4. LED Mode SW1-6: Single/Dual Mode. With SW1-6 OFF (defau lt ) it i s in Si ngle Mode. The LED is

normally red, until internal or host control turns it green (only a single control line is necessary). If

ON, it is in Dual Mode, and the LED is normally off (two control lines are necessary for host

control of red and green).

5. SW5-3 Terminating Resistor: Some RS422 connections require that the RX- line be terminated

with a resistor to RX+. If SW5-3 is in the OFF position, there is no terminating resistor on RX-. If

SW5-3 is ON, then a 120-ohm resistor is connected between RX+ and RX-.

6. SW5-4 Line Setting 1: Use SW5-4 to configure the reader's interface configuration. SW5-4

should be in the OFF position for RS232 or RS422 operation.

7. SW5-5 Line Setting 2: Use SW5-5 to configure the reader's interface configuration. SW5-5

should be in the OFF position for RS232 or RS422 operation.

2.8 Tamper Switch

Connect the tamper switch to the Host, if provided by the Host. When the cover is removed, the

tamper switch is released. The switch contacts available on TB1 Pins 4 and 5 and are either "normally

open" or "normally closed" dependent upon the position of the jumper on P1. Install the jumper to

connect pins 1 and 2 if you need the "normally open" contacts. Select the 2-3 position if you need the

"normally closed" contacts. "Normally closed" refers to the condition of the switch when the case is

open. The contacts are rated for 50 mA at 30 VDC.

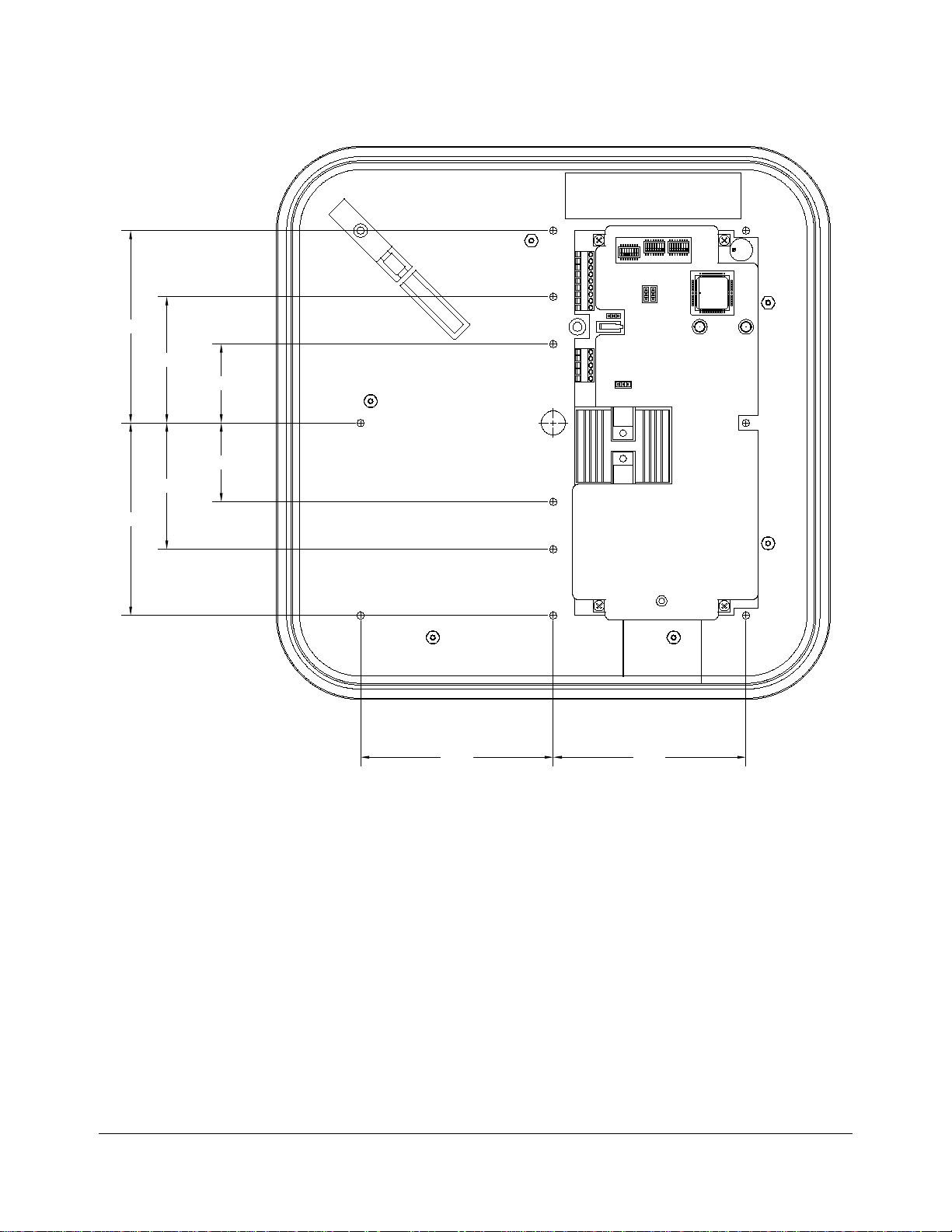

2.9 Mounting

Mount the base of the MaxiProx that holds the electronics to the surface using the holes located on the

base of the reader. There are 12 recessed holes for mounting. The holes are not through holes and

require drilling before mounting. Chose the appropriate holes to be used and drill with a 5/32 (.156)

inch bit. Use #6 screws only. (See Figure 2 MaxiProx interior view showing mounting hole locations,

page 12).

2.10 Power Supply

The MaxiProx reader can be operated over the full range of 11.6-28.5VDC. Current requirements are

200-mA average and 700 mA peak at 12 VDC input. At 24 VDC (21 to 28.5 VDC) input the average

current is 260 mA and peak is 1.2 A. A linear or switching regulated supply rated at 2.0 A is

recommended. Noise from devices such as computer monitors, and arc welders can reduce the read

range or make the unit inoperable. Keep these devices at least 10 ft away from the reader. With the

MaxiProx and powe r sup ply w i re d t oget he r , apply power to the reader.

CAUTION: The P2 shunt jumper is factory installed in the 24VDC position. Failure to install the

P2 shunt jumper in the correct position will permanently damage the MaxiProx unit. The

following states the P2 shunt jumper installation.

Power Supply Voltage Jumper Position

+24 VDC (21-28.5VDC) P2 across pin 2 and 3

+12 VDC (11.6-20.9VDC) P2 across pin 1 and 2

March 2012 Page 9 of 19

© 2008-2012 HID Global Corporation. All rights reserved.

Page 10

Part No. 5375-901, Rev E.1 MaxiProx® Installation Guide

2.11 Auto-tune Operation

The MaxiProx is tuned correctly when the Auto-tune LED is green. If the LED is red, use a spacer to

position the reader at minimum of 4 inches away from metal in the mounting surface.

2.12 Reader Testing

Apply Power to the reader and the LED will display a sequence of flashes and beeps, indicating the

LED control mode. Two flashes of green and two beeps followed by a short delay, then one additional

flash (beep), is the correct sequence for "Green Flash/Beep on valid read” (SW1-5 off). Three initial

green flashes and beeps followed by a pause and then one additional beep indicate no Green

Flash/Beep on valid read (SW1-5 on).

2.13 Power-Up Tune

Following this initial power up sequence the reader will perform power-up Auto-tune. It will beep and

turn the access LED amber for ~1 second to indicate that a power-up tune test is about to begin. It will

then attempt to tune. If it successfully tunes, it will give two quick beeps and a green on the access

and tune LED's to indicate the reader is tuned. If unsuccessfu l , the uni t will gi v e a sin gl e 1 .5 -second

beep with a red on the access and tune LED’s. If Auto-tune is not successful, the installer should

check for large areas of metal less than 4 inches from the back of the unit.

2.14 Periodic Auto-tune

Periodic Auto-tune retunes every 1-minute.

2.15 Supervisor Mode

During idle periods in normal operation, a periodic supervisor 1-byte transmission is sent to the host

controller over the Wiegand interface every 1 minute. Supervisor Mode is only available in Wiegand

Interface Mode.

Page 10 of 19 March 2012

© 2008 - 2012 HID Global Corporation. All rights reserved.

Page 11

MaxiProx® Installation Guide Part No. 5375-901, Rev E.1

11.800

+/ - .03

2.16 Install Cover

Replace the top cover and top cover screw. Make sure that the Auto-tune indicator LED remains in a

steady green state. If the LED is red, remove the cover and re-mount the unit using a non-metallic

spacer to position it further away from the mounting surface. Reinstall the cover, verify Auto-tune, and

install the fro nt lab el ov e r the to p cov e r screw and th e Auto-tune indicator lens.

Figure 1: MaxiProx Front View

March 2012 Page 11 of 19

© 2008-2012 HID Global Corporation. All rights reserved.

Page 12

Part No. 5375-901, Rev E.1 MaxiProx® Installation Guide

HIGH VOLTAGE

- CAUTION -

TB1-1 +DC

TB1-2 SHIELD

TB1-3 GROUND

TB1-4 TAMPER COMMON

TB1-5 TAMPER SELECT

TB2-1 DATA0/DATA/TD/RX+

TB2-2 DATA 1/CLK/RD/RX-

TB2-3 DATA RTN

TB2-4 GREEN LED

TB2-5 RED LED

TB2-6 BEEPER

TB2-7 HOLD/CARD PRESENT

TB2-9

TX+TB2-8

TX-

1 3

P2

5

1

TB1

9

1

TB2

P1

1 3

P4

3

1 1

3

P3

SHUNT PINS 2 AND 3+21-28.5 VDC (DEFAULT)

SHUNT PINS 1 AND 2+11-20 VDC

SW1SW2SW5

SW5-1

SW5-2

SW5-3

SW5-4

SW5-5

SW5-6

SW5-7

SW5-8

DATA 1 ISOLATION

DATA 0 ISOLATION

RS422 TERM RESISTOR

RS 232/422 LINE 1

RS 232/422 LINE 2

NOT USED

NOT USED

NOT USED

SW2-1

SW2-2

SW2-3

SW2-4

SW2-5

SW2-6

SW2-7

SW2-8

SERIAL BAUD 3

NODE ADDRESS 0

NODE ADDRESS 1

NODE ADDRESS 2

NODE ADDRESS 3

NODE ADDRESS 4

NOT USED

NOT USED

SW1-1

SW1-2

SW1-3

SW1-4

SW1-5

SW1-6

SW1-7

SW1-8

INTF. MODE 1

INTF. MODE 2

INTF. MODE 3

BEEPER

LED FLASH

LED MODE

SERIAL BAUD 1

SERIAL BAUD 2

1 81 81 8

1.64

2.625

4.000

2.625

4.000

1.64

4.000 4.000

- CAUTION -

Figure 2: MaxiProx interior view showing mounting hole locations

Page 12 of 19 March 2012

© 2008 - 2012 HID Global Corporation. All rights reserved.

Page 13

MaxiProx® Installation Guide Part No. 5375-901, Rev E.1

3 Installation Guidelines

3.1 Power Supply

The recommended power supply is 12 or 24VDC, nominal, 2.0A current rating, linear or switching

regulated. The MaxiProx cycles through varying power stages and has a peak current demand of

approximately 1.2A when in long range read mode. Average current consumption is about 260mA.

Failure to provide an adequate current capacity power supply will result in reduced read range.

CAUTION: The P2 shunt jumper is factory installed in the 24VDC position. Failure to install the

P2 shunt jumper in the correct position will permanently damage the MaxiProx unit. The

following states the P2 shunt jumper installation.

Power Supply Voltage Jumper Position

+24 VDC (21-28.5VDC) P2 across pin 2 and 3

+12 VDC (11.6-20.9VDC) P2 across pin 1 and 2

The use of a Power Switching Supply is not recommended for two reasons:

1. This type of supply does not provide adequate response to rapid transient current loads and also

generates radio frequency (RF) interference in the same band that the reader receives data and;

2. The power supply may generate noise that is large enough to be transmitted or conducted to the

MaxiProx that interferes with the reception of a card signal. Some switching power supplies are

not able to provide adequate regulation to the MaxiProx reader.

3.2 Installation near metal

Read range will be reduced if located on metal surfaces or in the vicinity of metal objects. The amount

of reduction will be a factor of the amount of metal and the distance the reader is from the metal. Metal

near the reader absorbs energy from the reader excite field and affects the signal being received from

the card by re-directing excite field transmissions into the receiver circuitry. Moving the reader away

from the metal objects reduces energy loss.

Try to limit the amount of metallic materials installed near the MaxiProx. Use a plastic electrical box if

possible. Avoid installing conduit and other metal hardware within 2-inches of the back of the reader or

closer than 4-inches from large metal surfaces. The typical read distance specification (24-29 inches at

21-28.5 VDC or 21-26 inches at 12 VDC) refers to operation without metal in the vicinity of the reader.

The read distance will be reduced if metal is installed nearby.

The MaxiProx generates a magnetic field on all sides of the reader. Any metal that conducts electricity,

especially metal that contains iron, steel or copper will interfere with the field and reduce the effective

read range (this will happen even if the metal is behind the reader). It helps to put a non-metallic spacer

between the reader and the metal object.

3.3 Radio Frequency Interference

Motors and electronic devices generate RF noise that may interfere with the reception of the signal

from a transponder. The affect of RF noise is typically a reduction of read range. The MaxiProx is

susceptible to RF interference, as are all devices that receive RF signals. The read range is affected by

the amount of interference (noise) in the area. Common sources of RF interference are power supplies,

electrical and electronic equipment, some types of lighting, computers and monitors, motors and

generators. Moving the reader to a location known to be free of interference and testing read range

there will help to isolate RF interference as a factor in low read range situations.

The MaxiProx should not be mounted within six feet of any monitors (VDTs or CRTs) because the scan

frequencies of most monitors include frequencies that may interfere with the signal received from the

access control cards.

March 2012 Page 13 of 19

© 2008-2012 HID Global Corporation. All rights reserved.

Page 14

Part No. 5375-901, Rev E.1 MaxiProx® Installation Guide

3.4 Transponder Types

The type of transponder used affects the read range of the MaxiProx. The various styles of HID cards

and transponders use different types of antennas. The antenna type will determine the read range for

that type of transponder. The Vehicle ID tag provides the longest read range at 32-36 inches; the

ProxCard II is 24-29 inches. The IsoProx / DuoProx is 17-20 inches. The ProxKey reads at a distance

of 15-17 inches.

Note: The above are recommended installation procedures. All local, state and national electrical

codes have precedence.

4 Application Notes

The Application Notes section includes information about Wiegand, Clock-and-Data, and RS232/RS422

Card Message specification.

4.1 Wiegand Interface

The following outlines the MaxiProx Wiegand Interface.

4.1.1 Message Format

In the Wiegand format, the ID card is programmed with a specific bit pattern and the reader acquires

the data, checks the customer code and generally sends out the same bit pattern as previously

programmed on the card. Consult factory for variations to this method. A 26 bit Wiegand format will be

used in the examples below.

The 26 bits of transmission from the reader to the panel consists of two parity bits and 24 code bits.

The bits are transmitted in the order described. The first bit transmitted is the first parity bit, P1; it is

even parity calculated over the first 12 code bits. The last bit transmitted is the second parity bit, P2; it

is odd parity cal cul at ed ov er t he la st 12 cod e bi t s :

Code Format

1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2

1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 6

P1 C C C C C C C C C C C C C C C C C C C C C C C C P2

Parity Format

1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2

1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 6

P1 E E E E E E E E E E E E

O O O O O O O O O O O O P2

• P1: First, or even parity bit

• C: Code bits

• P2: Second, or odd parity bit

• E: Bits for calculation of even parity

• O: Bits for calculation of odd parity

Data format within the 24 code bits which includes the portioning of the bit, the designation of the Most

Significant Bit (MSB) or the Least Significant Bit (LSB) shall be subject to definition by the panel and

reader manufacturers and may remain proprietary.

Page 14 of 19 March 2012

© 2008 - 2012 HID Global Corporation. All rights reserved.

Page 15

MaxiProx® Installation Guide Part No. 5375-901, Rev E.1

Voltage

Data Outputs (Data0 and Data1)

Control Inputs (LED’s, Hold, Beeper)

Levels

Minimum

Maximum

Minimum

Maximum

Data One

Data Zero

Tpw Tpw

Tpw TpiTpi

Voh

Voh

Vol

Vol

4.1.2 Output Specification

The specifications of voltage, current, power and timing are from the perspective of the reader. A

common signal ground is defined as a voltage reference that is common to both the reader and the

control panel. The voltages for the data outputs are referenced from the power supply ground located

at the reader. The voltage measured for the power to the reader is referenced from the power supplyreturn connection location at the reader, not at the source of the power.

The voltage, current, and timing of the data pulses are measured at the reader in reference to the

power supply / sign al ground at the reader. The voltage, current and timing of a signal driving an

auxiliary input device on a reader is measured at the control panel that is controlling the input device

(with reference to the signal ground at the panel).

4.1.3 Signal Levels

The Data One, Data Zero, and LED Control conductors connect signals between the reader and the

panel. The logic levels are defined as follows:

Table 9: Logic Levels

Voh 3.5V 5.5V 3.5V 5.5V

Vol 0.0V 0.5V 0.0V 0.5V

Ioh 0.0mA 5.0mA -1.0mA 0.0mA

Iol -25.0mA 0.0mA 0.0mA 25.0mA

4.1.4 Data Pulses

The Data One and Data Zero signals are normally held at a logic high level until the reader is ready to

send a data stream. The reader places asynchronous low pulses on the appropriate data lines to

transmit the data stream to the panel. The following timing parameters shall be observed:

Table 10: Data Pulses - Timing Parameters

• Tpw Pulse Width Time - 30uS (mini mum) t o 50u S (max i mu m)

• Tpi Pulse Interval Time - 1.8mS ( minimum) t o 2.2mS (ma x imum)

March 2012 Page 15 of 19

© 2008-2012 HID Global Corporation. All rights reserved.

Page 16

Part No. 5375-901, Rev E.1 MaxiProx® Installation Guide

4.1.5 Example Output

The following is an example of an ID card with the number of “816” decimal, which will be output by the

MaxiProx reader, the number “02004CA0661” hex.

Note: The customer code is never transmitted or displayed.

sentinel parity parity

customer code 10 zeros bit even facility code card number odd

[0 0 0 0 0 0 1] [0 0 0 0 0 0 0 0 0 0] [1] [0] [0 1 1 0 0 1 0 1] [0 0 0 0 0 0 1 1 0 0 1 1 0 0 0 0] [1]

| 0 | 2 | 0 | 0 | 4 | C | A | 0 | 6 | 6 | 1

Wiegand Output | 0 | C | A | 0 | 6 | 6 | 1

Hex code numbers [ 6 | 5 ][ 0 | 3 | 3 | 0 ]

Decimal conversion [ 101 ][ 0816 ]

4.2 Clock-and-Data Interface

The following sections outline the MaxiProx Clock-and-Data Interface.

4.2.1 Message Format

The Clock-and-Data interface consists of three signals, Card Present, Data and Strobe/Clock. The

interface is a serial data stream, which is controlled with a clock/strobe that indicates when data is

valid. All sig na l s ar e qui e scen t hi gh . Card Present goes low when data is about to be sent and

remains low until the whole data stream is completed. Data is the signal that determines the “ones”

and “zeros”. Strobe/Clock is the signal that indicates when data is valid for each cycle.

The Track 2 message format is a stream of binary bits that are grouped into HEX characters. The

message starts with leading zeros, followed by a start sentinel, data, end sentinel, LRC and trailing

zeros. Each HEX character has error correction in the form of a parity bit. Each character consists of

five bits. The maximum number of characters for a magnetic strip card encoded on Track 2 are 40, this

product will output less than 40 characters. The data consists only of BCD digits, the remaining HEX

digits, A to F, are used for the start and end sentinel, data separators and control. Only hex B and F are

used, A, C D and E are not used. The message will consist of a minimum of 210 bits.

The bits of a character are in the order 1248P, where parity is odd over the four bits. The LRC is the

Xoring of the message, starting with the start sentinel and ending with the end sentinel. The LRC does

not include the parity bits of the characters in the Xoring. LRC does include its own odd parity bit that

covers the four bits that are the result of the Xoring.

<leading zeros><Start Sentinel><data><data>........<data><End sentinel><LRC><trailing zero>

Customer code 0,1, 63, 72 and 73 (existing customer codes) cards will be read and output in the Track 2

format. The data on these cards will be packed into the Track 2 format in segments of three bits, so

the character does not exceed a BCD seven.

Page 16 of 19 March 2012

© 2008 - 2012 HID Global Corporation. All rights reserved.

Page 17

MaxiProx® Installation Guide Part No. 5375-901, Rev E.1

1

0 0 0

1

1 1

0 0 0 0 0

1 1 1 1

0 0 0 0

bit time strobe width

card present

data

clock/

strobe

1st valid bit

Note: the first 25 bits and trailing bits are zeros, not shown above.

4.2.2 Data Timing

The outputs, Card Present, Data and Strobe are low going signals and the following timing chart

describes the timing.

Table 11: Data Timing - Timing Chart

• bit time = 1.5ms (default)

• strobe width = bit time/3 (33% of bit time), default = 500us

• Clock/Strobe is valid 1.5ms (one clock cycle, min) after card present is asserted

• Data is valid 10us (min) before the negative edge of clock/strobe

• Card Present returns to the high-level 50 ms (max) after the last clock/strobe.

The above timing is representative of a magnetic stripe card traveling at 8.9 inches per second. The

timing is to be adjustable for cards traveling at 4 inches per second to 20 inches per second. This

relates to bit times of 3.3 ms and 666us, respectively. There are 75 bits per inch on Track 2.

4.2.3 Output signal Levels

Inputs: low threshold = 0.8 volts high threshold = 3.5 volts

4.2.4 Bit structure

The reader will read an 1849 or compatible chip that is encoded with 44 bits of data. The data will be

programmed in accordance with ProxGuard formatting. The data will be packed into the ABA/ISO

Track 2 message format in accordance with the following rules based on customer code:

Case 1:

Customer Code = 0, 1, 63, 72, 73 or other, will have t he data ou tp ut as fo ll ows.

The output is in the Track 2 character format but the bits are packed in sets of three bits (octal):

ccc CCCC a bcd efg hij klm nop qrs tuv wxy zAB CDE FGH IJK

Where cccCCCC is the customer code, abc...IJK is the programmed data on the card.

1248p 1248p 1248p1248p 1248p1248p 1248p1248p1248p1248p 1248p1248p1248p 1248p 1248p 1248p 1248p1248p1248p

<B> c000p Ccc0p CCC0p a000p dcb0p gfe0p jih0p mlk0p pon0p srq0p vut0p yxw0p BAz0p EDC0p HGF0p KJI0p <F><LRC>

March 2012 Page 17 of 19

© 2008-2012 HID Global Corporation. All rights reserved.

Page 18

Part No. 5375-901, Rev E.1 MaxiProx® Installation Guide

Case 2:

Customer Code = 74 are structured as follows:

421 8421 8421 8421 8421 8421 8421 8421 8421 8421 8421

CCC CCCC 1 aaaa bbbb cccc dddd eeee ffff gggg hhhh iiii

CCC CCCC - Customer code

1 - fixed bit “1”

aaaa - Most significant nibble of message

bbbb - Second MSN

cccc - next nibble

hhhh - least significant nibble of message

iiii - LRC of nibbles aaaa to hhhh, start (B) and end sentinel (F) (xor of the nibbles or the even parity of the

respective column)

The output from the reader will look like the following:

1248p 1248p 1248p 1248p 1248p 1248p 1248p 1248p 1248p 1248p 1248p

<B> <aaaap> <bbbbp> <ccccp> <ddddp> <eeeep> <ffffp> <ggggp> <hhhhp> <F> <iiiip>

start data a data b data c data d data e data f data g data h end LRC

The message structure follows the ISO/ABA Track 2 standard. The first character is a start sentinel: B

(hex), which is followed by data. After the data there is an end sentinel: F (hex), followed by an LRC.

The LRC is the xoring of the message in accordance to the bit position. Each character has an odd

parity bit that covers bit 1 to bit 4 of the nibble.

A typical message:

B 1 2 3 F LRC the bits broken down:

1248p 1248p 1248p 1248p 1248p 1248p

11010 10000 01000 11001 11111 00101

B 1 2 3 F 4

start < data > end LRC

4.2.5 Bit Stream

The bit stream will consist of 25 leading zeros, the message and fill with zeros until the end of the

message. The message will consist of a minimum of 210 bits.

Example

00000000000000000000000000 11010 10000 01000 11001 11111 00100 00000000000000...000000

B 1 2 3 F LRC

4.2.6 Output Specification

Vol = 0.8 V

Voh = 3.5 V

sink = 25 ma

source = 5 ma

Page 18 of 19 March 2012

© 2008 - 2012 HID Global Corporation. All rights reserved.

Page 19

MaxiProx® Installation Guide Part No. 5375-901, Rev E.1

4.3 RS232 and RS422 Card Message Specification (Send Mode Only)

When Access Cards (transponders) are presented to the MaxiProx reader, the reader sends a

message. The message is in the following format:

CCDDDDDDDDDDXX<CR><LF>

^ First character sent

All characters C, D and X are ASCII encoded, hexadecimal digits. (i.e., the hex value 7 is sent as an

ASCII character 7 or the hex value E is sent as an ASCII character E).

The CC field is reserved for use by HID Global Corporation. The valid values are 00 through 7F.

The DDDDDDDDDD field is the transponders (Access Card) data. The valid values are 0000000000 through

1FFFFFFFFF (ASCII).

The XX field is a computed checksum. The checksum is calculated by first grouping the message data

into the pairs CC DD DD DD DD DD. Each pair of characters represents one byte of data. Then each pair of

characters is converted from ASCII to their respective hex values. At this point, the 6 bytes are added

together. The checksum is equal to the least significant 8 bits of the result.

<CR> is the ASCII code for a carriage return. (0D hex)

<LF> is the ASCII code for a line feed. (0A hex)

For example, if the MaxiProx reads a transponder (Access Card) that contains the value CC=00 and

DDDDDDDDDD=01234ABCDE, the reader will report the ASCII message 0001234ABCDE08<CR><LF>.

Note: Each of the characters is ASCII encoded. The actual bytes (hex value) that are sent to the host

are:

<30><30><30><31><32><33><34><41><42><43><44><45><30><38><0D><0A>

The checksum was computed by adding 00 + 01 + 23 + 4A + BC + DE = 208 hex. The checksum is the least

significant 8 bits of this result or 08 hex. The communications settings are 9600-75Hz BAUD, 8 bits, 1

stop bit, no parity.

March 2012 Page 19 of 19

© 2008-2012 HID Global Corporation. All rights reserved.

Loading...

Loading...