NX Blowers

80446693

Revision B

August 2013

Installation, Operation and Maintenance

EN

Installation, Operation and Maintenance

ES

Instalación, operación y mantenimiento

FR

Installation, fonctionnement et entretien

DE

Installation, Betrieb und Wartung

IT

Installazione, funzionamento e manutenzione

Save These Instructions

Authorized Hibon Distributor, Service & Repair Facility

120 – 10293 276 ST, Acheson, Alberta, Canada T7X 6A5

80.962.1827 F: 780.962.1830 E: sales@fraserwoods.ca

T: 7

www.fraserwoods.ca

EN

www.fraserwoods.ca

DECLARATION OF INCORPORATION

(as dened by the EU Machinery Directive 2006/42/EC Appendix II 1B)

DÉCLARATION D’INCORPORATION

(comme dénie par la directive européenne 2006/42/CE appendice II 1B relative aux machines)

WE, / NOUS,

INGERSOLL RAND AIR SOLUTIONS HIBON

Declare that, under our sole responsibility, the partly completed machinery:

Déclarons que, sous notre seule responsabilité, la presque-machine :

Description : Air Positive Displacement Blower Air End

Year of Manufacturing : 2013

Model Serial Number

NX 2 From 14151171 To 14159999

NX 3 From 14160901 To 14169999

NX 5 From 14170104 To 14179999

NX 8 From 15151260 To 15159999

NX 12 From 15170891 To 15179999

NX 18 From 16150103 To 16159999

NX 26 From 16170996 To 16179999

Has been designed, manufactured and tested in accordance with the requirements of directive 2006/42/EC and the relevant technical

documentation is compiled in accordance with annex VII B:

A été concue, fabriquée et testée en accord avec les exigences de la directive 2006/42/CE et que le dossier technique relatif a été

construit en accord avec l’annexe VII B:

This partly completed machinery must not be put in service until the nal machinery into which is to be incorporated has been

declared in conformity with the provisions of this directive

Cette presque-machine ne doit pas être mise en service tant que l’ensemble dans lequel elle doit être intégrée n’a pas été déclaré

conforme aux dispositions de la directive ci-dessus

The partly completed machinery to which this declaration relates is also in conformity with the following principal standards /

normative:

La Presque-machine à laquelle se réfère cette déclaration est également conforme aux principaux standards et normes suivants:

EN 1012-1 EN 1012-2 EN ISO 12100:2010

We undertake to transmit, in response to a reasoned request by national authorities, relevant information on the partly completed

machinery to which this declaration relates.

Nous nous engageons à transmettre, en réponse à une demande adéquatement motive des autorités nationales, les informations

appropriées concernant la Presque-machine à laquelle se réfère cette déclaration.

st

Wasquehal, 01

June 2013

Judicaël DE MEYERE

The signer of this Declaration of Incorporation is also the person authorized to compile the relevant technical documentation.

Le signataire de cette Déclaration d’Incorporation est aussi la personne autorisée à élaborer le dossier technique approprié.

EN-2 80446693 Rev. B

CONTENTS

www.fraserwoods.ca

1. INTRODUCTION .................................... 4

EN

4. OPERATION ....................................... 19

1.1 Scope and denitions ............................... 4

1.2 Description .........................................4

1.2.1 Introduction .......................................4

•

1.2.2 Principle of operation ..............................4

•

1.3 Applications ........................................ 4

2. TECHNICAL DATA ................................... 6

2.1 Operating and storage conditions ...................6

2.2 Mechanical data ....................................6

2.3 Performance ........................................6

2.4 Noise and vibration data ............................8

2.5 Lubrication data ....................................9

2.6 Materials of construction ............................9

2.7 Item Numbers......................................10

2.8 Connections .......................................12

3. INSTALLATION ....................................15

3.1 Installation safety ..................................15

3.2 System design and safety ...........................15

•

3.2.1 General requirements .............................15

•

3.2.2 System safety .....................................15

3.3 Unpack and inspect ................................16

3.4 Prepare, locate and connect the blower .............16

•

3.4.1 Introduction ......................................16

•

3.4.2 Prepare, locate and connect blowers installed

directly in your system ..................................16

•

3.4.3 Prepare, locate and connect a blower supported

by mounting feet .......................................17

3.5 Fill the blower with oil ..............................17

3.6 Fit the drive/transmission...........................17

3.7 Check the direction of rotation .....................18

3.8 Commissioning the blower .........................18

4.1 General operational safety ..........................19

4.2 Start-up ............................................19

4.3 Shut-down .........................................19

5. MAINTENANCE .................................... 20

5.1 Safety information .................................20

5.2 Maintenance plan ..................................20

5.3 Check the oil levels .................................20

5.3.1 Inspect the oil-level sight-glasses ..................20

•

5.3.2 Drive Head Plate ..................................20

•

5.3.3 Non-drive Head Plate ..............................21

•

5.4 Inspect the system installation ......................21

5.5 Change the oil .....................................21

•

5.5.1 Drive Head Plate ..................................21

•

5.5.2 Non-drive Head Plate .............................21

5.6 Overhaul the blower ...............................21

5.7 Fault nding .......................................22

6. STORAGE AND DISPOSAL .......................... 24

6.1 Storage ............................................24

•

6.1.1 Preparation .......................................24

•

6.1.2 Long-term storage ................................24

6.2 Disposal ...........................................24

7. SERVICE AND SPARES .............................. 25

7.1 Introduction .......................................25

7.2 Service .............................................25

7.3 Spares and repair kits ...............................25

RETURN OF Ingersoll Rand EQUIPMENT -

PROCEDURE ......................................... 26

RETURN OF Ingersoll Rand EQUIPMENT -

DECLARATION .......................................27

80446693 Rev. B EN-3

EN

www.fraserwoods.ca

1.1 Scope and denitions

1. INTRODUCTION

1.2 Description

This manual provides installation, operation and maintenance

instructions for the Ingersoll Rand NX Blowers, which may be

abbreviated to “blowers” in the remainder of this manual. You

must use the blowers as specied in this manual.

Read this manual before you install and operate your blower.

Important safety information is highlighted as WARNING and

CAUTION instructions; you must obey these instructions. The

use of WARNINGS and CAUTIONS is dened below.

WARNING

Warnings are given where failure to observe the

instruction could result in injury or death to people.

Cautions are given where failure to observe the

instruction could result in damage to the equipment,

associated equipment and process.

The identication and rating plate (Figure 1, item 13) provides

specic details about the blower, such as its Item Number and

so on.

The following warning symbols may be tted to the blower or

associated equipment:

1.2.1 Introduction

•

Refer to Figure 1.The NX blowers are positive displacement

blowers, which incorporate two three-lobe rotors (8). One

of the rotors is driven by the drive shaft (5).The other rotor is

maintained in the correct phase relation by timing gears.The

timing gears and the bearings on the rotors and drive shaft

are lubricated by oil in the drive end cover (4) and non-drive

end cover (12).

The blowers are supplied in ‘bareshaft’ form. You must

connect your own coupling or belt drive system (see Section

3.6) to the drive shaft (5) in order to operate the blower.

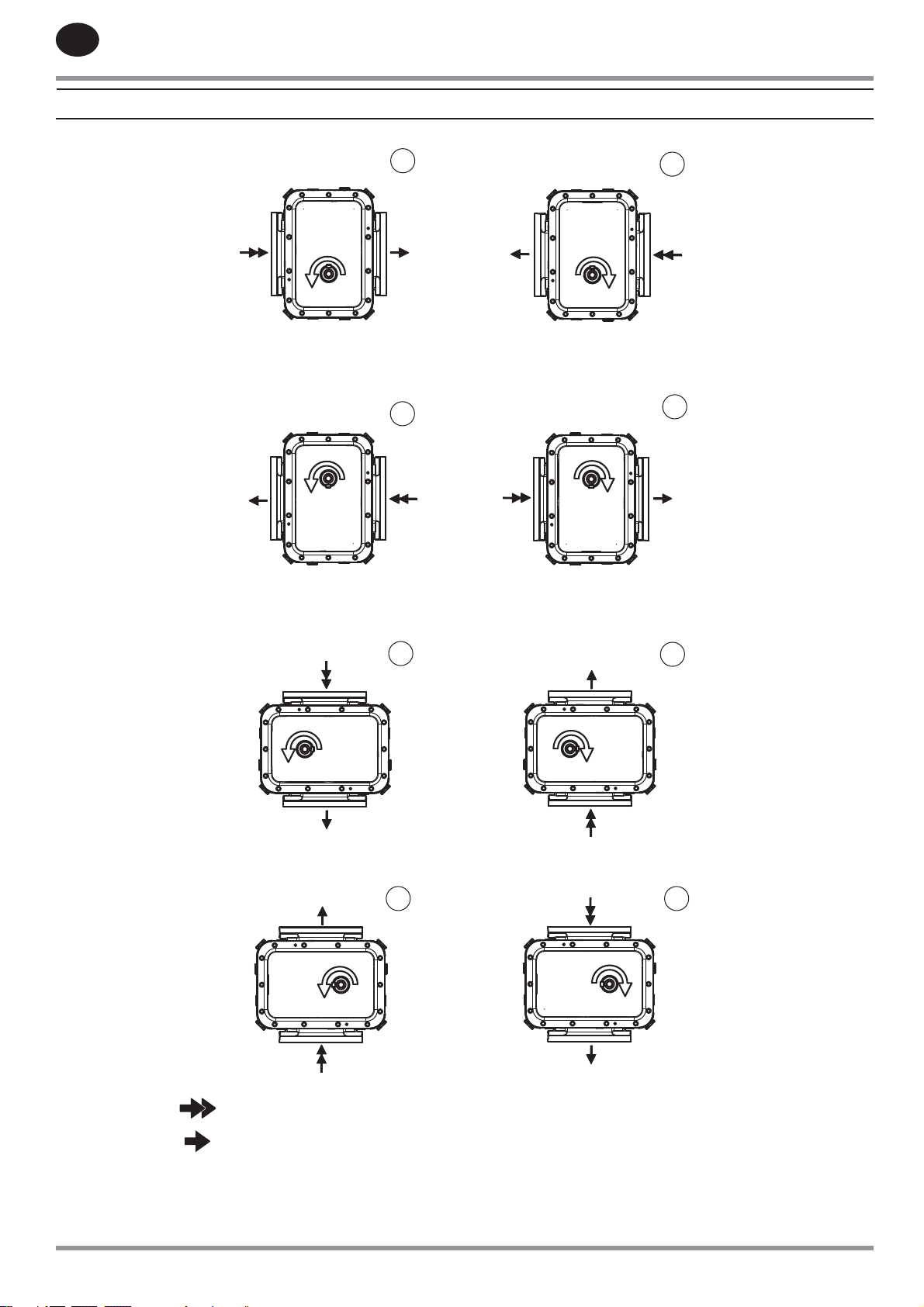

The blowers are available in eight dierent positions

depending:

Flow direction

•

Shaft position

•

Direction of rotation

•

Refer to Section 2.7 and gure 2 for the Item Numbers of the

dierent blower versions.

1.2.2 Principle of operation

•

During operation, the inlet gas stream to be pumped/

compressed enters the blower at the inlet (2).

Warning – refer to accompanying

documentation.

Warning – hot surfaces.

Ear defenders must be worn.

The units used throughout this manual conform to the SI

international system of units of measurement.

Equivalent values in imperial units are also included.

As the two contra-rotating rotors turn, the inlet gas is trapped in

the chambers formed between the rotors and the blower-body,

and is eventually forced out of the blower at the outlet (3).

1.3 Applications

All of the NX blowers are suitable for pressure or vacuum

operation.

The blowers are suitable for pumping/compressing ambient

air, and non-ammable gases, gas mixtures and dusts.

The blowers are not suitable for pumping/compressing

ammable or pyrophoric gases, gas mixtures and dusts.

The materials of construction of the blowers are specied in

Section 2.6. Before you use the blower, you must ensure that

these materials are compatible with the gases and vapours

which you will pump/compress or which may exist in the

external atmosphere.

You must ensure that your blower is suitable for your

application.

If you have any doubts as to the suitability of the blower for

your application, contact your supplier or Ingersoll Rand for

advice.

EN-4 80446693 Rev. B

1. INTRODUCTION

www.fraserwoods.ca

EN

15a

1

16

3

2

6

10

17

11

12

13a

14

13b

8

A

4

5

15b

B

7

9

Figure 1 – Components of the NX blower

1. Lifting lugs

2. Inlet

3. Outlet (behind blower)

4. Drive end cover

5. Drive shaft

6. Oil level sight glass (drive head plate)

7. Drive end oil drain plug

8. Rotors

9. Mounting feet

10. Nondrive end oil drain plug (behind blower)

11. Oil level sight glass (non drive head plate)

18

19

6, 11

12. Nondrive end cover

13a. Identication and rating plate (vertical position)

13b. Identication and rating plate (horizontal position)

14. Head plate bolts

15a. Direction of rotation arrow (vertical position)

15b. Direction of rotation arrow (horizontal position)

16. Oil ller plug (drive head plate)

17. Oil ller plug (non drive head plate)

18. Maximum oil level

19. Minimum oil level

80446693 Rev. B EN-5

EN

www.fraserwoods.ca

2.1 Operating and storage conditions

2. TECHNICAL DATA

2.3 Performance

Ambient operating temperature range

Ambient storage temperature range

Maximum ambient operating

humidity

Maximum operating altitude 3000 m, 9842 ft

Maximum particle size (in pumped/

compressed gases)

Maximum dust to gas ratio (in

pumped/compressed gases)

Table 1 – Operating and storage conditions

For operating data above the values indicated in table 1,

please contact Ingersoll Rand.

-20 to 40 °C,

-4 to 104 °F

-20 to 80 °C,

-4 to 176 °F

90%

25 µm,

0.00098 inch

200 mg/m ,

0.25 oz ft

2.2 Mechanical data

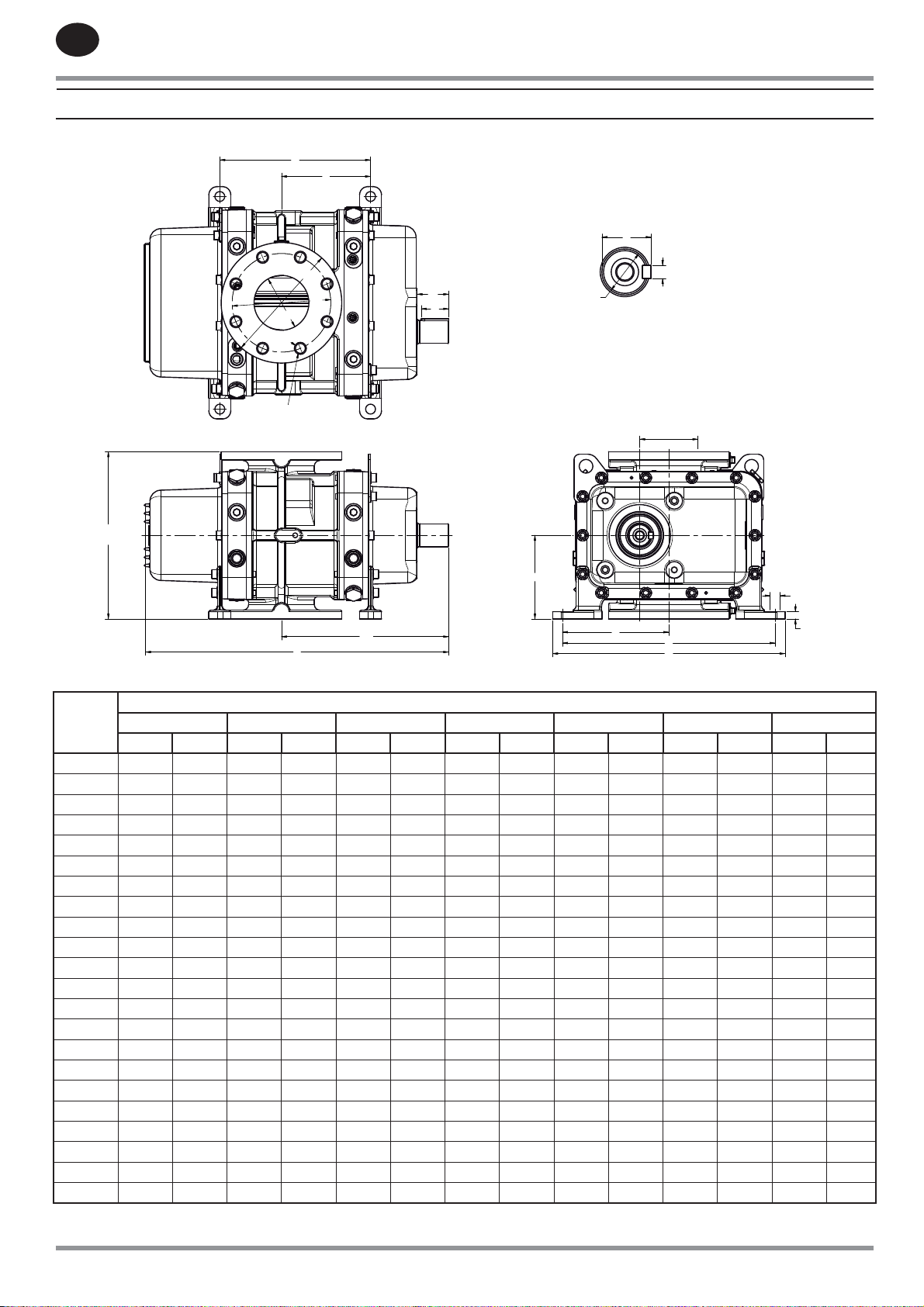

Dimensions

Left and Right Hand blowers See Figure 3

Top and Bottom Shaft

blowers

NX 2 NX 3 NX 5 NX 8 NX 12 NX 18 NX 26

Mass

114 kg 129 kg 147 kg 211 kg 255 kg 421 kg 498 kg

251 lbs 284 lbs 324 lbs 465 lbs 562 lbs 928 lbs 1098 lbs

Table 2 – Mechanical data

See Figure 4

Notes: The “given pressures” specied in Tables 4 and 5 are the

dierential pressures across the blower (that is, the dierential

pressures between the blower inlet and outlet)

The “r.p.m/r min¯ “ rotation speeds specied in Tables 4

and 5 are provided for information only, to identify blower

performance at the specied speed. During operation, the

rotation speed of the blowers need not be limited to these

specied speeds.

The maximum vacuum values given in Table 3 are for a ow

through the blower.

All of the throughput and power values given in Table 3 have a

tolerance of ± 5%.

You must not exceed these values, otherwise the blower may

be damaged and/or seize.

5

1100 mbar, 1.1 x 10

(NX 2)

“Maximum dierential

pressure (inlet/outlet)”

Pressure performance See table 4

Rotational speed range See table 4

Nominal shaft power See table 4

“Maximum absorbed

shaft power (pressure

operation)”

Table 3 – Performance data

1050 mbar, 1,05 x 10

(NX 3, NX 8, NX 18)

1000 mbar, 1.0 x 10

(NX 5, NX 12, NX 26)

19 kW, 25,5 hp (NX 2)

29 kW, 38,9 hp (NX 3)

44 kW, 60,3 hp (NX 5)

54 kW, 72,4 hp (NX 8)

83 kW, 111,3 hp (NX 12)

104 kW, 139,5 hp (NX 18)

120 kW, 161,2 hp (NX 26)

Pa, 825 Torr

5

Pa, 787 Torr

5

Pa, 750 Torr

EN-6 80446693 Rev. B

Blower

www.fraserwoods.ca

NX 2

(617 m/h)

NX 3

(1028 m/h)

NX 5

(1570 m/h)

NX 8

(1952 m/h)

NX 12

(2823 m/h)

EN

2. TECHNICAL DATA

Throughput (m/h) and absorbed power (kW) at given pressure at 1013 mbar

and 20°C

rpm/

r.min¯

2000 167 2,5 143 3,6 124 5 - - - - - - 400 § 128 2,9

3000 281 3,7 255 5,4 234 7,6 220 9,2 208 10,8 - - 500≠ 209 5,4

4000 396 4,9 367 7,2 344 10,1 329 12,2 315 14,4 311 15,1 500≠ 316 7,2

5000 510 6,1 479 9 454 12,6 437 15,3 422 18 417 18,9 500≠ 424 9

2000 304 3,9 270 6,1 243 8,6 - - - - - - 400§ 248 4,9

3000 499 5,9 461 9,2 430 12,9 410 15,6 391 18,4 - - 500≠ 393 9,2

4000 694 7,9 652 12,2 618 17,1 595 20,8 574 24,5 568 25,7 500≠ 576 12,2

4900 870 9,7 824 15 786 21 761 25,5 739 30 - - 500≠ 759 15,3

2000 493 6 447 9,5 409 13,4 384 16,2 - - - - 400§ 416 7,6

3000 797 8,9 743 14,3 699 20 671 24,3 644 28,6 - - 500≠ 647 14,3

4000 1100 11,9 1039 19,1 990 26,7 958 32,4 928 38,2 - - 500≠ 931 19,2

4800 1343 14,3 1277 22,9 1223 32,1 1187 38,9 - - - - 500≠ 1214 23,8

1500 558 7,2 502 10,8 456 15,2 - - - - - - 400§ 465 8,7

2300 957 11 901 16,6 855 23,3 825 28,3 797 33,3 - - 500≠ 799 16,6

3100 1356 14,8 1299 22,4 1253 31,4 1223 38,1 1195 44,8 1186 47,1 500≠ 1197 22,4

3900 1756 18,7 1698 28,2 1652 39,5 1621 47,9 1593 56,4 - - 500≠ 1596 28,2

1500 890 11,3 825 16,1 772 22,5 738 27,4 - - - - 400§ 782 12,9

2300 1483 17,3 1417 24,7 1364 34,5 1329 42 1297 49,4 - - 500≠ 1299 24,7

3050 2039 22,9 1972 32,7 1919 45,8 1883 55,6 1851 65,4 - - 500≠ 1854 32,7

3800 2594 28,5 2528 40,8 2473 57,1 2438 69,3 - - - - 500≠ 2408 40,8

300 mbar 500 mbar 700 mbar 850 mbar 1000 mbar 1050 mbar

3 x 10 Pa 5 x 10 Pa 7 x 10 Pa 8.5 x 10 Pa 10 x 10 Pa 10.5 x 10 Pa

m/h kW m/h kW m/h kW m/h kW m/h kW m/h kW mbar m/h kW

Maximum vacuum

§ = 4 x 10 Pa ≠ = 5 x 10Pa

80446693 Rev. B EN-7

EN

www.fraserwoods.ca

2. TECHNICAL DATA

Blower

NX 2

(363 CFM)

NX 3

(605 CFM)

NX 5

(924 CFM)

NX 8

(1149 CFM)

NX 12

(1661 CFM)

Throughput (cfm) and absorbed power (h.p.) at given pressure at 14,7 psi

rpm/

r.min¯

2000 98 3,4 84 4,8 73 6,7 - -----11,8 75 3,9

3000 165 5,0 150 7,2 138 10,2 129 12,3 122 14,5 - - 14,9 123 7,2

4000 233 6,6 216 9,7 202 13,5 194 16,4 185 19,3 183 20,2 14,9 186 9,7

5000 300 8,2 282 12,1 267 16,9 257 20,5 248 24,1 245 25,3 14,9 250 12,1

2000 179 5,2 159 8,2 143 11,5 ------11,8 146 6,6

3000 294 7,9 271 12,3 253 17,3 241 20,9 230 24,7 - - 14,9 231 12,3

4000 408 10,6 384 16,4 364 22,9 350 27,9 338 32,8 334 34,5 14,9 339 16,4

4900 512 13,0 485 20,1 463 28,2 448 34,2 435 40,2 - - 14,9 447 20,5

2000 290 8,0 263 12,7 241 18,0 226 21,7 - - - - 11,8 245 10,2

3000 469 11,9 437 19,2 411 26,8 395 32,6 379 38,3 - - 14,9 381 19,2

4000 647 16,0 612 25,6 583 35,8 564 43,4 546 51,2 - - 14,9 548 25,7

4800 790 19,2 752 30,7 720 43,0 699 52,1 - - - - 14,9 715 31,9

1500 326 9,8 293 15 266 21,1 ------11,8 274 11,7

2300 561 15,1 528 23,1 500 32,3 480 40 469 44,6 - - 14,9 470 22,3

3100 796 20,3 762 31,1 735 43,5 715 53,9 703 60,1 700 62,2 14,9 705 30,0

3900 1031 25,5 997 39,1 969 54,7 949 67,8 938 75,6 - - 14,9 939 37,8

1500 522 15,3 483 22,3 451 31,2 428 38,7 - - - - 11,8 460 17,3

2300 871 23,5 831 34,2 799 47,9 776 59,3 763 66,2 - - 14,9 765 33,1

3050 1198 31,1 1158 45,4 1126 63,5 1102 78,7 1090 87,7 - - 14,9 1091 43,8

3800 1525 38,8 1485 56,5 1452 79,2 1429 98 ----14,9 1417 54,7

4,5 psi 7,5 psi 10,5 psi 13 psi 14,5 psi 15 psi

CFM hp CFM hp CFM hp CFM hp CFM hp CFM hp

and 68°F

Maximum

vacuum

inch

hg

CFM hp

Table 4 – Pressure performance data

2.4 Noise and vibration data

Note: The noise and vibration data values given below are maximum values. The actual values are given according to our test

bench and will depend on the installation and the operating conditions.

Noise level

Vibration

level

NX 2 NX 3 NX 5 NX 8 NX 12 NX 18 NX 26

93 94 95 98 102 99 102

4,5 mm.s- 4,5 mm.s- 4,5 mm.s- 5,5 mm.s- 5,5 mm.s- 6,5 mm.s- 6,5 mm.s-

0,18 inch.s- 0,18 inch.s- 0,18 inch.s- 0,22 inch.s- 0,22 inch.s- 0,26 inch.s- 0,26 inch.s-

Table 5 – Noise and vibration data

EN-8 80446693 Rev. B

2. TECHNICAL DATA

www.fraserwoods.ca

EN

2.5 Lubrication data

On standard applications, you can use an oil which complies

with the ‘standard use’ specication given in Table 6. You must

use an oil which complies with the ‘special use’ specication in

Table 6:

If you use the blower with an acoustic enclosure.

•

If you use the blower in ambient temperatures of 0 ° C

•

(32 ° F) or below.

If you use the blower with a power input that exceeds 2 / 3

•

of the maximum power input (see Table 3).

NX 2 NX 3 NX 5 NX 8 NX 12 NX 18 NX 26

Drive end cover

Non-drive end cover

0,83 litres 0,83 litres 0,83 litres 1,50 litres 1,50 litres 2,41 litres 2,41 litres

0,22 US gal 0,22 US gal 0,22 US gal 0,40 US gal 0,40 US gal 0,64 US gal 0,64 US gal

1,12 litres 1,12 litres 1,12 litres 2,10 litres 2,10 litres 3,84 litres 3,84 litres

0.30 US gal 0.30 US gal 0.30 US gal 0.55 US gal 0.55 US gal 1.01 US gal 1.01 US gal

Table 7 – Left and Right Hand blower oil capacities

Parameter Standard use Special use

Density (at 15 °C,

59 °F)

Mean pour point 21 °C (70 °F) 45 °C (113 °F)

Mean ash point 224 °C (435 °F) 260 °C (500 °F)

Viscosity: at 20 °C

(68 °F)

at 40 °C (104 °F)

at 100 °C (212 °F)

Mean viscosity

index

Recommended oil Hibon Lub Contact factory

Table 6 – Lubricating oil specications

0.89 0.86

8.09 x 10¯ m s¯

(809 cSt)

2.2 x 10¯ m s¯

(220 cSt)

1.8 x 10¯ m s¯

(18 cSt)

93 149

6.04 x 10¯ m s¯

(640 cSt)

2.18 x 10¯ m s¯

(218 cSt)

2.7 x 10¯ m s¯

(27 cSt)

NX 2 NX 3 NX 5 NX 8 NX 12 NX 18 NX 26

Drive end cover

Non-drive end cover

0,5 litres 0,5 litres 0,5 litres 0,9 litres 0,9 litres 1,45 litres 1,45 litres

0,13 US gal 0,13 US gal 0,13 US gal 0,24 US gal 0,24 US gal 0,38 US gal 0,38 US gal

0,75 litres 0,75 litres 0,75 litres 1,30 litres 1,30 litres 2,3 litres 2,3 litres

0,20 US gal 0,20 US gal 0,20 US gal 0,34 US gal 0,34 US gal 0,61 US gal 0,61 US gal

2.6 Materials of construction

Head Plates and End

Covers

Casings

Rotors

Bearings 100Cr6 steel

Piston rings Cast iron

Piston rings holder C 45E Steel

Gaskets Klingerit® C4430

O-rings Nitrile

EN GJL 200 grey cast iron

EN GJL 200 grey cast iron

(NX 2, NX 3, NX 5, NX 8, NX 12)

EN GJL 250 grey cast iron

(NX 18, NX 26)

EN GJS 400-15 spheroidal graphite

cast iron

Table 8 – Top and Bottom Shaft blower oil capacities

Table 9 – Construction materials data

80446693 Rev. B EN-9

EN

www.fraserwoods.ca

2.7 Item Numbers

2. TECHNICAL DATA

A

T

A

I

O

T

N

O

R

T

A

I

O

T

N

O

R

C

T

A

I

O

T

N

O

R

T

A

I

O

T

N

O

R

B

D

E

T

A

I

O

T

N

O

R

GH

T

A

I

O

T

N

O

R

Inlet gas stream

Discharge (outlet) Gas stream

F

T

A

I

O

T

N

O

R

T

A

I

O

T

N

O

R

Note: Refer to Table 10 for the item numbers

of blowers with the congurations shown in

the gure

EN-10 80446693 Rev. B

Figure 2 – Ordering congurations

2. TECHNICAL DATA

www.fraserwoods.ca

EN

Blower

model

NX 2

NX 3

NX 5

NX 8

NX 12

NX 18

NX 26

Shaft

position

Bottom Anticlockwise F014150110 47005012 F0141501101 47005020 A

Bottom Clockwise F014150111 47005038 F0141501111 47005046 B

Top Anticlockwise F014150120 47005053 F0141501201 47005061 C

Top Clockwise F014150121 47005079 F0141501211 47005087 D

Left Anticlockwise F014150100 47004973 F0141501001 47004981 E

Left Clockwise F014150101 47004999 F0141501011 47005004 F

Right Anticlockwise F014150130 47005095 F0141501301 47005103 G

Right Clockwise F014150131 47005111 F0141501311 47005129 H

Bottom Anticlockwise F014160110 47005178 F0141601101 47005186 A

Bottom Clockwise F014160111 47005194 F0141601111 47005202 B

Top Anticlockwise F014160120 47005210 F0141601201 47005228 C

Top Clockwise F014160121 47005236 F0141601211 47005244 D

Left Anticlockwise F014160100 47005137 F0141601001 47005145 E

Left Clockwise F014160101 47005152 F0141601011 47005160 F

Right Anticlockwise F014160130 47005251 F0141601301 47005269 G

Right Clockwise F014160131 47005277 F0141601311 47005285 H

Bottom Anticlockwise F014170110 47005335 F0141701101 47005343 A

Bottom Clockwise F014170111 47005350 F0141701111 47005368 B

Top Anticlockwise F014170120 47005376 F0141701201 47005384 C

Top Clockwise F014170121 47005392 F0141701211 47005400 D

Left Anticlockwise F014170100 47005293 F0141701001 47005301 E

Left Clockwise F014170101 47005319 F0141701011 47005327 F

Right Anticlockwise F014170130 47005418 F0141701301 47005426 G

Right Clockwise F014170131 47005434 F0141701311 47005442 H

Bottom Anticlockwise F015100110 47001235 F0151001101 47001243 A

Bottom Clockwise F015100111 47001250 F0151001111 47001268 B

Top Anticlockwise F015100120 47001276 F0151001201 47001284 C

Top Clockwise F015100121 47001292 F0151001211 47001300 D

Left Anticlockwise F015150100 47001318 F0151501001 47001326 E

Left Clockwise F015150101 47001334 F0151501011 47001342 F

Right Anticlockwise F015150130 47001359 F0151501301 47001367 G

Right Clockwise F015150131 47001375 F0151501311 47001383 H

Bottom Anticlockwise F015120110 47001391 F0151201101 47001409 A

Bottom Clockwise F015120111 47001417 F0151201111 47001425 B

Top Anticlockwise F015120120 47001433 F0151201201 47001441 C

Top Clockwise F015120121 47001458 F0151201211 47001466 D

Left Anticlockwise F015170100 47001474 F0151701001 47001482 E

Left Clockwise F015170101 47001490 F0151701011 47001508 F

Right Anticlockwise F015170130 47001516 F0151701301 47001524 G

Right Clockwise F015170131 47001532 F0151701311 47001540 H

Bottom Anticlockwise F016150110 47005855 F0161501101 47005863 A

Bottom Clockwise F016150111 47005871 F0161501111 47005889 B

Top Anticlockwise F016150120 47005897 F0161501201 47005905 C

Top Clockwise F016150121 47005913 F0161501211 47005921 D

Left Anticlockwise F016150100 47005814 F0161501001 47005822 E

Left Clockwise F016150101 47005830 F0161501011 47005848 F

Right Anticlockwise F016150130 47005939 F0161501301 47005947 G

Right Clockwise F016150131 47005954 F0161501311 47005962 H

Bottom Anticlockwise F016170110 47006010 F0161701101 47006028 A

Bottom Clockwise F016170111 47006036 F0161701111 47006044 B

Top Anticlockwise F016170120 47006051 F0161701201 47006069 C

Top Clockwise F016170121 47006077 F0161701211 47006085 D

Left Anticlockwise F016170100 47005970 F0161701001 47005988 E

Left Clockwise F016170101 47005996 F0161701011 47006002 F

Right Anticlockwise F016170130 47006093 F0161701301 47006101 G

Right Clockwise F016170131 47006119 F0161701311 47006127 H

Rotation

direction

Without Feet With Feet

Table 10 - Item Numbers

Standard blowers

Item Number

“Conguration:

See Figure 2”

80446693 Rev. B EN-11

EN

www.fraserwoods.ca

2.8 Connections

2. TECHNICAL DATA

A

a

T

ø R

ø r

ø DN

ø S

n : number of holes

E

L1

L

W

V

h

Z

Y

EA / GC

4 x ø P

F

B

D

G

Figure 3 - Left and Right Hand blower dimensions

Dimensions

“Figure

3 Key”

NX 2 NX 3 NX 5 NX 8 NX 12 NX 18 NX 26

mm inch mm inch mm inch mm inch mm inch mm inch mm inch

A 205 8.07 275 10.83 370 14.57 355 13.98 476 18.74 444 17.48 589 23.19

a 102.5 4.04 162.5 6.40 213 8.39 208 8.19 278 10.94 222 8.74 339.5 13.37

B 388 15.28 388 15.28 388 15.28 475 18.70 475 18.70 586 23.07 586 23.07

D 424 16.69 424 16.69 424 16.69 515 20.28 515 20.28 626 24.65 626 24.65

E 305 12.01 305 12.01 305 12.01 370 14.57 370 14.57 450 17.72 450 17.72

EA/GC 106 4.17 106 4.17 106 4.17 135 5.31 135 5.31 173 6.81 173 6.81

F 194 7.64 194 7.64 194 7.64 238 9.37 238 9.37 293 11.54 293 11.54

G 13 0.51 13 0.51 13 0.51 13 0.51 13 0.51 15 0.59 15 0.59

h 152.5 6.00 152.5 6.00 152.5 6.00 185 7.28 185 7.28 225 8.86 225 8.86

L 485 19.09 555 21.85 650 25.59 671 26.42 791 31.14 848 33.39 993.2 39.10

L1 245 9.65 305 12.01 356 14.02 385 15.16 454 17.87 441 17.36 559 22.01

T 45 1.77 45 1.77 45 1.77 51.5 2.03 51.5 2.03 69 2.72 69 2.72

V 50 1.97 50 1.97 50 1.97 70 2.76 70 2.76 90 3.54 90 3.54

W 60 2.36 57 2.24 58 2.28 81 3.19 80 3.15 102 4.02 102.2 4.02

Y 12 0.47 12 0.47 12 0.47 14 0.55 14 0.55 18 0.71 18 0.71

ØZ* 42 1.65 42 1.65 42 1.65 48 1.89 48 1.89 65 2.56 65 2.56

ØR 200 7.87 220 8.66 220 8.66 250 9.84 285 11.22 340 13.39 340 13.39

Ør 160 6.30 180 7.09 180 7.09 210 8.27 240 9.45 295 11.61 295 11.61

ØDN 80 3.15 100 3.94 100 3.94 125 4.92 150 5.91 200 7.87 200 7.87

ØP 18 0.71 18 0.71 18 0.71 18 0.71 18 0.71 22 0.87 22 0.87

ØS 18 0.71 18 0.71 18 0.71 18 0.71 22 0.87 22 0.87 22 0.87

n 8 0.31 8 0.31 8 0.31 8 0.31 8 0.31 8 0.31 8 0.31

* Fitting tolerance range : m6

Table 11 - Left and Right hand blower dimensions

EN-12 80446693 Rev. B

EN

www.fraserwoods.ca

2. TECHNICAL DATA

E

H

EA / GC

h

Ø DN

X

4 x Ø P

F

B

D

G

Ø S

Ø r

Ø R

n : number of holes

W

V

F

Detail F

Y

A

a

L

L1

T

Z

Figure 4 -Top and Bottom Shaft blower dimensions

80446693 Rev. B EN-13

EN

www.fraserwoods.ca

2. TECHNICAL DATA

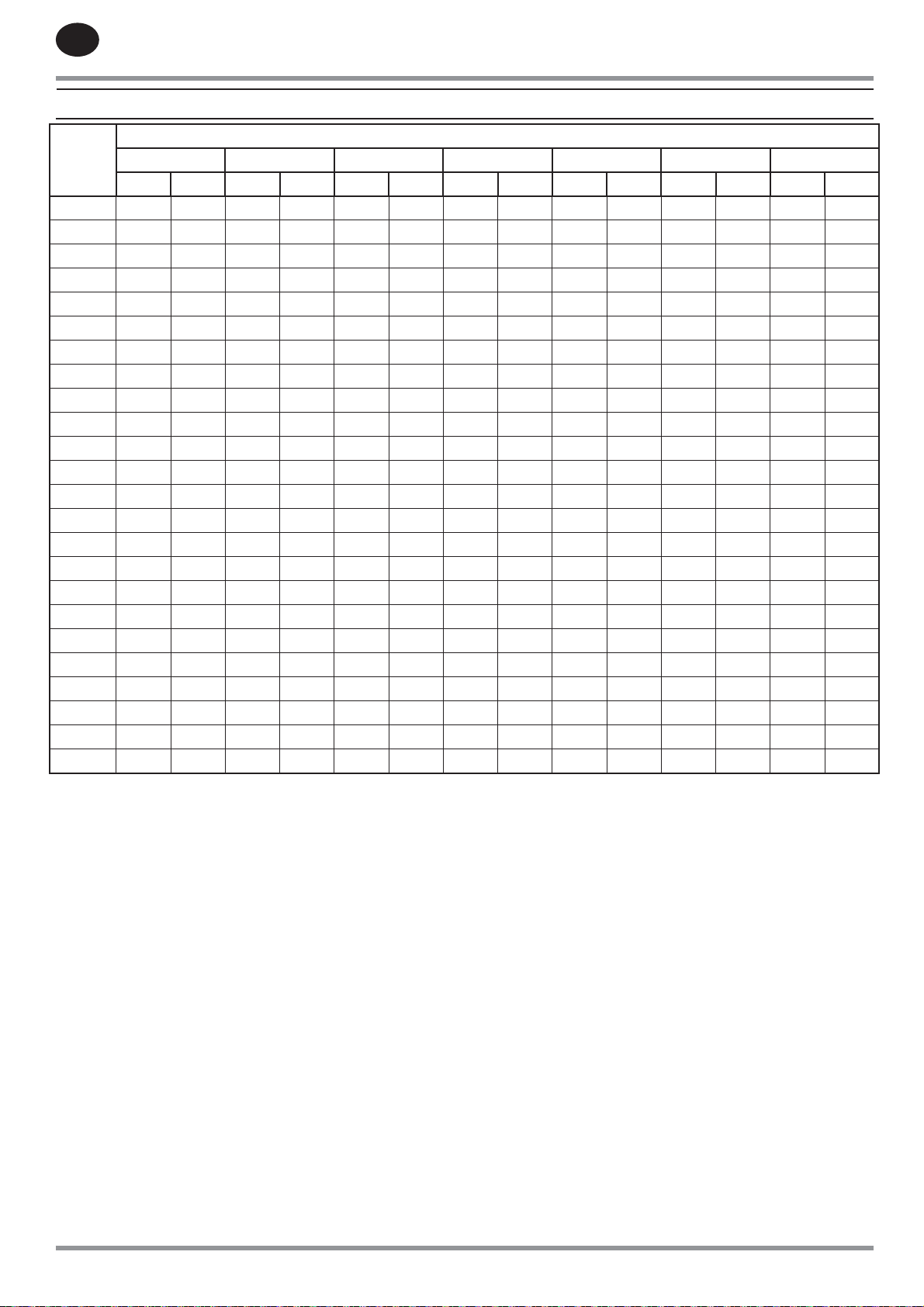

Dimensions

“Figure

4 Key”

A 205 8.07 275 10.83 370 14.57 355 13.98 476 18.74 444 17.48 589 23.19

a 102.5 4.04 162.5 6.40 213 8.39 208 8.19 278 10.94 222 8.74 339.5 13.37

B 284 11.18 284 11.18 284 11.18 336 13.23 336 13.23 414 16.30 414 16.30

D 320 12.60 320 12.60 320 12.60 376 14.80 376 14.80 454 17.87 454 17.87

E 305 12.01 305 12.01 305 12.01 370 14.57 370 14.57 450 17.72 450 17.72

EA/GC 106 4.17 106 4.17 106 4.17 135 5.31 135 5.31 173 6.81 173 6.81

F 142 5.59 142 5.59 142 5.59 168 6.61 168 6.61 207 8.15 207 8.15

G 13 0.51 13 0.51 13 0.51 13 0.51 13 0.51 15 0.59 15 0.59

H 152.5 6.00 152.5 6.00 152.5 6.00 185 7.28 185 7.28 225 8.86 225 8.86

h 151.5 5.96 151.5 5.96 151.5 5.96 187 7.36 187 7.36 224.5 8.84 224.5 8.84

L 485 19.09 555 21.85 650 25.59 671 26.42 791 31.14 848 33.39 993.2 39.10

L1 245 9.65 305 12.01 356 14.02 385 15.16 454 17.87 441 17.36 559 22.01

T 45 1.77 45 1.77 45 1.77 51.5 2.03 51.5 2.03 69 2.72 69 2.72

V 50 1.97 50 1.97 50 1.97 70 2.76 70 2.76 90 3.54 90 3.54

W 60 2.36 57 2.24 58 2.28 81 3.19 80 3.15 102 4.02 102.2 4.02

X 404.5 15.93 404.5 15.93 404.5 15.93 499 19.65 499 19.65 589 23.19 589 23.19

Y 12 0.47 12 0.47 12 0.47 14 0.55 14 0.55 18 0.71 18 0.71

ØZ* 42 1.65 42 1.65 42 1.65 48 1.89 48 1.89 65 2.56 65 2.56

ØR 200 7.87 220 8.66 250 9.84 250 9.84 285 11.22 340 13.39 340 13.39

Ør 160 6.30 180 7.09 210 8.27 210 8.27 240 9.45 295 11.61 295 11.61

ØDN 80 3.15 100 3.94 125 4.92 125 4.92 150 5.91 200 7.87 200 7.87

ØP 18 0.71 18 0.71 18 0.71 18 0.71 18 0.71 22 0.87 22 0.87

ØS 18 0.71 18 0.71 18 0.71 18 0.71 22 0.87 22 0.87 22 0.87

n 8 0.31 8 0.31 8 0.31 8 0.31 8 0.31 8 0.31 8 0.31

NX 2 NX 3 NX 5 NX 8 NX 12 NX 18 NX 26

mm inch mm inch mm inch mm inch mm inch mm inch mm inch

* Fitting tolerance range: m6 unless otherwise stated above.

Table 12 -Top and Bottom Shaft blower dimensions

EN-14 80446693 Rev. B

3. INSTALLATION

www.fraserwoods.ca

Ingersoll Rand will accept no liability or warranty

claims if your installation includes any modications

or additions to the blower without the prior written

approval of Ingersoll Rand, or if the blower is incorrectly

installed.

3.1 Installation safety

WARNING

Obey the safety instructions listed below and take note

of appropriate precautions when you install the blower.

•

A suitably trained and supervised technician must install

the blower.

Ensure that debris and dust does not get into the blower or

•

the system pipelines when you install the blower.

Check that all of the required components and tools are

•

available and of the correct type before you start to install

the blower.

Use suitable new gaskets/seals to connect the blower into

•

your system. Do not re-use old gaskets/seals.

If you will t the blower into an existing system, disconnect

•

the power from the drive system before you start

installation, so that the drive system cannot be operated

accidentally.

3.2 System design and safety

WARNING

Ensure that the maximum dierential pressure across

the blower specied in section 2.2 cannot be exceeded.

If it is, the drive will trip and the blower will stop. Obey

the safety instructions listed below when you design

and build your system:

3.2.1 General requirements

•

Your system must be suitably designed for correct operation

of the blower. Note that:

You must design a suitable pipeline to t the blower inlet/

•

outlet connections. refer to Section 2.8 and to Figures 3

and 4 for the dimensions of the blower connections.

Your system design must ensure that, when the blower

•

is in its nal operating location, you can see the oil-level

sight-glasses and can access the oil ller and drain plugs.

•

Your system must incorporate a suitable mounting

platform: see Section 3.4 for more details.

The blower must be suciently level for correct operation:

•

see Section 3.4 for more details.

There must be at least 150 mm (6 inches) of free space

•

around the blower, for adequate cooling-air circulation.

EN

The gases which enter the blower must not contain solid

•

particulates larger than 25 m (9.84 x 10-5 inch) in size and

must not contain more than 200 mg/m3 (1.37 x 10

of dust. Incorporate suitable lters to prevent the ingress

of solids into the blower.

The temperature of the gases which enter the blower must

•

not exceed the temperature rating of the blower.

3.2.2 System safety

•

Your system design must ensure that the blower cannot

•

be operated with the inlet or discharge (outlet) pipelines

obstructed.

•

Ensure that the blower cannot operate with the incorrect

direction of rotation (see Section 3.7).

We also recommend that your system incorporates an

•

emergency stop facility which, once activated, must be

manually reset before the blower can be operated again.

•

Your system must incorporate non-return valves (check

valves), to prevent reverse rotation of the blower when it is

switched o.

•

Your system must incorporate a pressure relief valve in the

outlet pipeline (for pressure operation) and/or incorporate

a vacuum relief valve in the inlet pipeline (for vacuum

operation), to ensure that the design capability of the

blower cannot be exceeded during operation. The relief

valve(s) must be suitably rated/sized for the performance

of the blower.

•

We recommend that you incorporate silencers, to

attenuate the pulsations in the inlet/outlet gas streams.

If required, install your own acoustic enclosure around

•

the blower or ensure that people wear suitable protective

equipment (such as ear defenders) when they are close

to the operating blower (See section 2.4). If you install an

acoustic enclosure, ensure that there is sucient space for

cooling-air ow around the blower. See above

Your design must ensure that people are protected from

•

accidental contact with the blower or the outlet pipelines.

During blower operation, the temperature of the blower

and the outlet pipelines will be above 70 °C (158 °F). If

necessary, t suitable guards.

Your design must ensure that materials or substances

•

which are ammable at temperatures of 70 °C (158 °F) or

above are not close to, or in contact with, the hot blower or

outlet pipelines.

If you pump/compress ammable or toxic gases, you must

•

take suitable precautions to prevent the discharge of the

gases to the surrounding atmosphere.

Note: Filters, pressure/vacuum relief valves, non-return (check)

valves, acoustic enclosures and silencers are available from

Ingersoll Rand: contact your supplier or Ingersoll Rand for

advice.

-5

lb/ft3)

80446693 Rev. B EN-15

EN

www.fraserwoods.ca

3. INSTALLATION

3.3 Unpack and inspect

WARNING

Use suitable lifting equipment to move the blower.

If you do not, you can injure yourself or damage the

blower. Refer to Section 2.2 for the mass of the blower.

Note that the blowers are supplied with either lifting bolts

tted (as shown in Figure 1) or with lifting lugs tted. Where

necessary in Sections 3.4.2 or 3.4.3, attach your lifting

equipment to these lifting bolts/lugs.

3.4.2 Prepare, locate and connect blowers

•

installed directly in your system

1. Use a suitable fork-lift truck or pallet truck to move the

blower, on its pallet, close to where you will install it.

2. Remove all packing materials and protective covers

and check the blower. If the blower is damaged, notify

your supplier and the carrier in writing within two

days; state the Item Number of the blower together

with your order number and your supplier’s invoice

number. Retain all packing materials for inspection. Do

not use the blower if it is damaged.

3. Check that you have received the items. If any item is

missing, notify your supplier in writing within two days

4. Look at the blower rating and identication plate

(Figure 1, item 13) and check that the blower is suitable

for use in your system. If the blower is not suitable

for use in your system, do not continue to install the

blower: contact your Supplier or

Ingersoll Rand.

If the blower is not to be used immediately, replace the

protective covers. Store the blower in suitable conditions, as

described in Section 6.1.

3.4 Prepare, locate and connect the blower

3.4.1 Introduction

•

Take note of the following when you locate the blower and

connect it into your system:

For optimum performance, ensure that the system

•

pipelines connected to the blower are as short as possible.

Support your system pipelines and other components, to

•

prevent loading of the inlet and outlet ports on the blower.

Incorporate exible components in your system, to

•

minimise noise and vibration.

Where necessary, use gaskets/seals which are compatible

•

with the gases which will be pumped/compressed, and

with the operating conditions.

The leak tightness of your system connections must be in

•

accordance with the requirements of your applications.

Note that blowers can be:

Installed directly in your system. You must ensure that your

•

system pipelines can support the blower. Prepare, locate

and connect blower as described in Section 3.4.2.

Supported by mounting feet; prepare, locate and connect

•

blowers as described in Section 3.4.3.

•

WARNING

Use suitable lifting equipment to move the blower.

If you do not, you can injure yourself or damage the

blower. Refer to Section 2.2 for the mass of the blower.

Note: The following procedure assumes that your system inlet

pipeline will support the blower. If your blower will be supported

by your system outlet pipeline, reverse Steps 4 and 5 below.

Use the following procedure to prepare, locate and connect

blower:

1. Use a suitable cleaning solution (such as alcohol or

white spirit) to clean the rotors:

Moisten a suitable clean, lint-free cloth with the

•

cleaning solution.

Clean the rotors (Figure 1, item 8) which are visible

•

through the inlet port.

Turn the blower drive shaft as necessary to access the

•

other rotors.

2. Refer to Figure 1. Attach suitable lifting equipment to

the blower, then use the lifting equipment to move the

blower to its required operating location.

3. While it is supported by the lifting equipment, adjust

the position of the blower so that the blower inlet and

outlet are correctly aligned with the connections in

your system inlet and outlet pipelines.

4. Fit a suitable gasket/seal* to the blower inlet (Figure 1,

item 2), then use the correct number and size of bolts

to connect the blower inlet ange to your system inlet

pipeline.

5. Fit a suitable gasket/seal* to your system outlet

pipeline, then use the correct number and size of bolts

to connect the blower outlet ange to your system

outlet pipeline.

6. Disconnect your lifting equipment from the blower.

*Note: Gaskets are available from Ingersoll Rand:

Contact your supplier or Ingersoll Rand for advice

EN-16 80446693 Rev. B

3. INSTALLATION

www.fraserwoods.ca

3.4.3 Prepare, locate and connect a blower

•

supported by mounting feet

WARNING

Use suitable lifting equipment to move the blower.

If you do not, you can injure yourself or damage the

blower. Refer to Section 2.2 for the mass of the blower.

EN

3.5 Fill the blower with oil

Ensure that you use the correct grade of oil and that

the oil levels in the blower are correct. If you do not, the

blower will probably be damaged during operation, or

its performance may be aected.

You must provide a rm, level platform for the blower. Ensure

that the operating location is clean and free from debris and

oil.

You must ensure that when the blower is in its required

operating location, all of the mounting feet (1, 2 or 4,

depending on the blower model) are at on the mounting

platform to within 0.1 mm.m ¯ (0.0013 inch.ft ¯ ).

Use the following procedure to prepare, locate and connect

the blower:

1. Refer to Figure 1. Attach suitable lifting equipment to

the four lifting-bolts (1), then use the lifting equipment

to move the blower to its required operating location.

2. Disconnect your lifting equipment from the blower. If

required, remove the lifting-bolts from the blower.

3. Fit suitable bolts through the xing holes in the

mounting feet (Figure 1, items 9), to secure the blower

in position.

4. Clean the rotors: refer to Step 1 of Section 3.4.2.

5. Use a suitable gasket/seal* to connect your inlet

pipeline to the blower inlet (Figure 1, item 2).

6. Use a suitable gasket/seal* to connect your outlet

pipeline to the blower outlet (Figure 1, item 3).

1. Drain the protective oil from the drive end and nondrive end covers: refer to Section 5.5.

2. Refer to Figure 1. Fill the drive end cover (4) with oil:

refer to Section 5.5.1.

3. Fill the non-drive end cover (12) with oil: refer to

Section 5.5.2.

3.6 Fit the drive/transmission

WARNING

You must t suitable guards to protect people from

rotating/moving parts.

Your drive and transmission system design must ensure

that the maximum blower rotational speeds specied in

Section 2.3 cannot be exceeded, otherwise the blower

will be damaged, or may not operate correctly.

You must use a suitable coupling or a belt drive and

transmission system to connect your drive to the blower.

Your drive and transmission system design must ensure that

the radial and axial loadings on the blower drive shaft are as

low as possible.

*Note: Gaskets are available from Ingersoll Rand:

Contact your supplier or Ingersoll Rand for advice

Minimum pully diameter for specied dierential pressure : mm (inch)

Blower

NX 2 100 (3.94) 100 (3.94) 100 (3.94) 100 (3.94) 100 (3.94) 112 (4.41) 112 (4.41) 125 (4.92)

NX 3 100 (3.94) 100 (3.94) 100 (3.94) 112 (4.41) 112 (4.41) 125 (4.92) 125 (4.92) 150 (5.90)

NX 5 125 (4.92) 125 (4.92) 125 (4.92) 150 (5.90) 150 (5.90) 160 (6.30) 170 (6.69) 180 (7.09)

NX 8 140 (5.51) 140 (5.51) 150 (5.90) 160 (6.30) 170 (6.69) 180 (7.09) 180 (7.09) 200 (7.87)

NX 12 170 (6.69) 170 (6.69) 180 (7.09) 200 (7.87) 212 (8.35) 212 (8.35) 224 (8.82) 224 (8.82)

NX 18 150 (5.90) 150 (5.90) 160 (6.30) 170 (6.69) 180 (7.09) 200 (7.87) 200 (7.87) 224 (8.82)

NX 26 170 (6.69) 170 (6.69) 180 (7.09) 200 (7.87) 212 (8.35) 212 (8.35) 224 (8.82) 250 (9.84)

“300 mbar

3 x 10 Pa

4,35 psi”

“400 mbar

4 x 10 Pa

5,8 psi”

Table 13 - Minimum drive shaft pulley diameters

“500 mbar

5 x 10 Pa

7,25 psi”

Note: For this, the blower pulley diameter must be above

diameters specied in Table 13, linear speed of belts should not

exceed 31 m/s and transmission safety factor should be between

1,4 and 1,7.

Connect the components of the drive and transmission

system to the blower drive shaft (Figure 1, item 5) as

described in the manufacturer’s instructions supplied with

the components.

“600 mbar

6 x 10 Pa

8,7 psi”

“700 mbar

7 x 10 Pa

10,15 psi”

“800 mbar

8 x 10 Pa

11,6 psi”

“900 mbar

9 x 10 Pa

13,05 psi”

“1000

mbar

1 x 10 Pa

14,5 psi”

80446693 Rev. B EN-17

EN

www.fraserwoods.ca

3.7 Check the direction of rotation

3. INSTALLATION

3.8 Commissioning the blower

WARNING

If you remove a guard during the following procedure,

ensure that you do not corne into contact with the shaft,

the coupling/belt or the drive system when you operate

the blower.

If you do, you may be injured by the rotating

components.

Ensure that the blower rotates in the correct direction. If

it does not, your system will not operate correctly.

After you have connected the drive/transmission, check the

direction of rotation of the blower as follows:

1. Ensure that isolation valves in the blower inlet and

outlet pipelines are in the correct ‘open’ positions.

2. If necessary (that is, to make it easier to see the blower

drive shaft), temporarily remove guard over the drive

coupling or belt.

3. Refer to Figure 1. Watch the blower drive shaft (5) while

you start up the blower (refer to Section 4.2), then

shut down the blower (refer to Section 4.3) after two

seconds.

4. Check that the blower drive shaft (5) rotated correctly

in the expected direction. (This depends on your

application and installation conguration: see Figure 1

item 15a or b)

5. If the direction of rotation was incorrect:

Check the installation of the drive and transmission

•

system and recongure as appropriate.

Perform the direction of rotation check from Step 2

•

again, to ensure that the blower now rotates in the

correct direction.

After you have installed the blower, use the following

procedure to commission it and prepare it for subsequent

operation:

1. Ensure that isolation valves in the blower inlet and

outlet pipelines are in the correct ‘open’ positions.

2. Ensure that all other components in the system

pipelines (such as lters) have been correctly installed

and congured for operation.

3. Engage your drive and transmission system to start the

blower.

4. Operate the blower, with no gas load, for at least 15

minutes. During this time:

Monitor the external surfaces of the blower and check

•

for ‘hot spots’ (that means, areas which are unusually

hot).

•

If any hot spots persist at the end of the 15 minutes,

contact your supplier or Ingersoll Rand for advice.

5. Continue to operate the blower with a representative

gas load, and check that it operates correctly and

provides the required performance. If necessary, refer

to Section 5.7 if any fault conditions occur.

6. Disengage your drive and transmission system to stop

the blower.

7. Wait until you can hear that the blower has stopped

before you close any isolation valves in the blower inlet

and outlet pipelines.

The blower is now ready for normal operation.

6. If you have removed the guard over the drive coupling

or belt (as in Step 1 above), ret the guard.

EN-18 80446693 Rev. B

4. OPERATION

www.fraserwoods.ca

WARNING

Ingersoll Rand will accept no liability or warranty

claims if your blower is used on applications or in a

way prohibited in this manual, or not specied in this

manual.

EN

4.2 Start-up

Ensure that the oil levels in the blower are correct. If you

do not, the blower will probably be damaged during

operation, or its performance may be aected.

4.1 General operational safety

WARNING

Obey the safety instructions and precautions listed

below. If you do not, there may be a risk of injury or

death to people, or damage to the blower.

Do not expose any part of your body to vacuum. If you do,

•

you may be injured.

Do not operate the blower when the cooling-air ow

•

around the blower is restricted (see Section 3.2). If you do,

the blower may overheat.

Do not operate the blower with the blower inlet or outlet

•

ports open to the atmosphere. If you do, your ngers or

other parts of your body or clothing may get trapped, and

you may be injured by the rotating mechanisms in the

blower.

Do not operate the blower with the guards removed from

•

the blower drive shaft, the coupling/belt or the drive

system. If you do, your ngers or other parts of your body

or clothing may get trapped, and you may be injured by

the rotating components.

Never disconnect any of the connecting pipelines (for

•

example, the pipeline connected to the inlet) when the

blower is operating.

Prevent accidental contact with the hot blower, and do

•

not place ammable materials on the blower. During

operation, the temperature of external parts of the blower

can exceed 70° C (158° F).

Do not attempt to use the blower to pump/compress

•

liquids. The blowers are not designed for this application.

Where necessary (for example, if you have not tted an

•

acoustic enclosure), wear suitable ear defenders. The

blower can be noisy during operation (refer to Section 2.4).

During pressure operation, prevent accidental contact with

•

the discharged (outlet) gas stream. This gas stream will be

at high pressure and will be hot and cause burn injury.

1. Ensure that any isolation valves in the blower inlet and

outlet pipelines are in the correct ‘open’ positions.

2. Check the oil-levels in the blower: refer to Section 5.3.

3. Engage your drive and transmission system to start the

blower.

You can now use the blower as required in your application.

4.3 Shut-down

1. Disengage the drive and transmission system to stop

the blower.

2. Wait until you can hear that the blower has stopped

before you close any isolation valves in the blower inlet

and outlet pipelines.

80446693 Rev. B EN-19

EN

www.fraserwoods.ca

5. MAINTENANCE

5.1 Safety information

WARNING

Obey the safety instructions given below and take note

of appropriate precautions. If you do not, you can cause

injury to people and damage to equipment.

A suitably trained and supervised technician must

•

maintain the blower. Obey your local and national safety

requirements.

•

Ensure that the maintenance technician is familiar with

the safety procedures which relate to the gases pumped/

compressed by the system in which the blower is installed.

•

Allow the blower to cool to a safe temperature before you

start maintenance work.

•

Isolate the blower from the drive system so that it cannot

be operated accidentally.

Recheck the blower rotation direction (see Section 3.7) if

•

the drive and transmission system has been disconnected

and then reconnected.

•

Take care to protect the inlet/outlet port sealing faces from

damage.

Do not re-use seals/gaskets if they are damaged.

•

Check the tightness of the system connections after

•

maintenance work is complete if you have connected

or disconnected any suction inlet or discharge (outlet)/

injection joints. The tightness of the system connections

must be in accordance with the requirements of your

applications.

5.2 Maintenance plan

The plan in Table 14 details the maintenance operations

required to maintain the blower in normal operation.

Instructions for each operation are given in the section

shown.

Operation Frequency

Check the oil levels

Inspect the system installation

Change the oil

Overhaul the blower

Weekly

Monthly

See Section 5.2

4 yearly

Refer to

Section

5.3

5.4

5.5

5.6

After blower installation, the oil must be changed after 200

hours of running.

Table 14 – Maintenance plan

5.3 Check the oil levels

Ensure that you use the correct grade of oil and that

the oil levels in the blower are correct. If you do not, the

blower will probably be damaged during operation, or

its performance may be aected.

5.3.1 Inspect the oil-level sight-glasses

•

1. Refer to Figure 1. Look at the oil-level sight-glass (6) on

the drive head plate (4):

If the sight-glass is dirty, use a suitable cloth to wipe it

•

clean.

If the sight-glass is damaged (that is, scratched,

•

cracked or corroded), or if there are signs of oil

leakage from the sight-glass, you must replace it:

contact your supplier or Ingersoll Rand.

2. Look at the oil-level sight-glass (11) on the non-drive

head plate (12):

If the sight-glass is dirty, use a suitable cloth to wipe it

•

clean.

If the sight-glass is damaged (that is, scratched,

•

cracked or corroded), or if there are signs of oil

leakage from the sight-glass, you must replace it:

contact your supplier or Ingersoll Rand.

Note that:

If you use a mineral oil in the blower: you must change the

•

oil every 2000 hours of operation or once a year.

If you use a synthetic oil in the blower, you must change

•

the oil every 12 months.

If you use a Hibon Lube in the blower and you operate the

•

blower with a discharge (outlet) temperature above 120 ˚ C

(248 ˚ F), you must change the oil every 12 months.

If you use a Hibon Lube in the blower and you operate the

•

blower with a discharge (outlet) temperature below 120 ˚ C

(248 ˚ F), you must change the oil every two years.

When you maintain the blower, use Ingersoll Rand spares:

refer to Section 7.3.

EN-20 80446693 Rev. B

5.3.2 Drive Head Plate

•

1. Refer to Figure 1, detail B. Look at the oil level in the

sight-glass (6) on the drive head plate (4):

If the oil level is below the minimum level mark (19),

•

continue at Step 2 to add more oil.

If the oil level is above the maximum level mark (18),

•

drain oil from the blower until the level is correct: refer

to Section 5.5.

2. Refer to Figure 1. Remove the oil ller-plug (16) from

the ller port on the top of the drive head plate (4).

3. For new oil of the correct type (see Section 2.6)

through the ller port and into the head plate until

the oil-level reaches the maximum level mark (detail B,

item 18). If the oil level goes above the maximum level

mark (18), drain oil from the blower until the level is

correct: refer to Section 5.5.

4. Ret the oil ller-plug (16) to the ller port on the top

of the drive head plate (4).

5.3.3 Non-drive Head Plate

www.fraserwoods.ca

•

5. MAINTENANCE

5.5.1 Drive Head Plate

•

EN

1. Refer to Figure 1, detail B. Look at the oil level in the

sight-glass (11) on the non-drive head plate (12):

If the oil level is below the minimum level mark (19),

•

continue at Step 2 to add more oil.

If the oil level is above the maximum level mark (18),

•

drain oil from the blower until the level is correct: refer

to Section 5.5.

2. Refer to Figure 1. Remove the oil ller-plug (17) from

the ller port on the top of the non-drive head plate

(12).

3. For new oil of the correct type (see Section 2.6)

through the ller port and into the head plate until

the oil-level reaches the maximum level mark (detail B,

item 18). If the oil level goes above the maximum level

mark (18), drain oil from the blower until the level is

correct: refer to Section 5.5.

4. Ret the oil ller-plug (17) to the ller port on the top

of the non-drive head plate (12).

5.4 Inspect the system installation

Note: Where possible, we recommend that you investigate the

cause of any damage or corrosion, and implement corrective

measures to prevent any future damage of components.

Use the following procedure to inspect the system

connections:

1. Inspect all of the system pipelines and connections

and check that they are not damaged or corroded and

that they are suciently leak-tight. Repair or replace

any damaged or corroded component and seal any

leak found.

2. Inspect the drive/transmission system and

adjust, repair or replace as necessary: refer to the

manufacturer’s instructions supplied with your drive/

transmission system.

5.5 Change the oil

Ensure that you use the correct grade of oil and that

the oil levels in the blower are correct. If you do not, the

blower will probably be damaged during operation, or

its performance may be aected.

1. Refer to Figure 1. Remove the oil ller-plug (16) from

the ller port on the top of the drive head plate (4).

2. Refer to Figure 1. Place a suitable container under the

drain plug (7) on the drive head plate. The container

must have a maximum capacity as specied in Table 7

or Table 8.

3. Remove the oil drain plug (7) from the end cover,

and allow the oil to drain from the end cover into the

container.

4. Ret the oil drain plug (7) to the drive head plate (4).

5. Dispose of the oil: refer to Section 6.2.

6. Fill the drive end cover with new oil of the correct type

and grade: refer to Section 5.3.1.

•

5.5.2 Non-drive Head Plate

1. Refer to Figure 1. Remove the oil ller-plug (17) from

the ller port on the top of the nondrive head plate

(12).

2. Refer to Figure 1. Place a suitable container under

the drain plug (10) on the non-drive head plate. The

container must have a maximum capacity as specied

in Table 7 or Table 8.

3. Remove the oil drain plug (10) from the end cover,

and allow the oil to drain from the head plate into the

container.

4. Ret the oil drain plug (10) to the non-drive head plate

(12).

5. Dispose of the oil: refer to Section 6.2.

6. Fill the non-drive end cover with new oil of the correct

type and grade: refer to Section 5.3.2.

5.6 Overhaul the blower

The blower must be regularly overhauled, as specied in Table

14. As part of the overhaul, the bearings in the blower must

be replaced.

We recommend that you contact your supplier or

Ingersoll Rand to arrange for an overhaul of the blower.

You must take care about the oil temperature. Please

wait at least two hours after the last running of the

blower to empty the oil casings to let the oil cool -down.

80446693 Rev. B EN-21

WARNING

EN

www.fraserwoods.ca

5. MAINTENANCE

5.7 Fault nding

A guide to fault conditions and their possible causes is provided in Table 15 to assist you in basic fault nding.

If you are unable to rectify a fault when you use this guide, call your supplier or your nearest Ingersoll Rand Service Centre for

advice.

Note: If you have been approved to carry out strip-down, repair and reassembly of your blower, refer to the Service Manual supplied

separately for detailed procedures.

Symptom Check Actions

Check the rotor clearances and adjust as

necessary.

Check the required operating conditions and

specied performance of the blower (see

Section 2).

Strip down, clean and repair the blower as

necessary.

Check that your drive and transmission

system is operating correctly, and that it is

correctly tted to the blower: refer to Section

3.6 and to the manufacturer’s instructions.

Check the rotor clearances and adjust as

necessary.

Check the clearances and adjust as necessary.

Clean the rotors and rotor housing, then

check the rotor clearances and adjust as

necessary.

Check that your system design complies with

the requirements of Section 3.2, and that the

blower is suitable for use in your application.

Check the oil levels (refer to Section 5.3) or

drain the blower and ll with the correct

grade of oil (refer to Section 5.5).

Contact your supplier or Ingersoll Rand for

advice.

Ensure that there is sucient clearance

around the blower to provide for free

circulation of ambient cooling air.

If you have tted an acoustic enclosure

around the blower:

The blower will not start, or

seizes during operation.

The blower is noisy during

operation.

The blower overheats.

Are the rotors touching ?

Has the blower been overloaded ?

Has debris or foreign material entered the

blower ?

Is the drive/transmission system faulty ?

Are the rotors touching ?

Are the gear and/or bearing clearances

incorrect ?

Are the rotors unbalanced ?

Is the inlet lter blocked ? Clean or replace the lter.

Is the dierential pressure across the

blower too high ?

Is an oil level too high, or has the incorrect

grade of oil been used ?

Are the rotor or rotor/casing clearances

incorrect ?

Is there inadequate clearance around the

blower ?

The blower overheats

(continued).

There is oil in the gas stream

from the blower.

EN-22 80446693 Rev. B

Does your enclosure provide inadequate

cooling ?

Is an oil level too high ?

Have the sealing rings failed ?

Ensure that the enclosure cooling vents/

louvres are unobstructed.

Ensure that the enclosure cooling/extraction

fan is operating correctly.

Ensure that there is sucient clearance for

cooling air ow around the blower: refer to

Section 3.2.

Check the oil levels and if necessary drain oil

from the blower: refer to Section 5.3.

Contact your supplier or Ingersoll Rand for

advice.

Symptom Check Actions

www.fraserwoods.ca

There is a low volume ow

through the blower.

Absorbed power is too high.

The blower rotates in reverse

direction when you stop it.

- -

5. MAINTENANCE

Is the inlet lter blocked ? Clean or replace the lter.

Is the blower worn or damaged ?

Is the blower unsuitable for your

application ?

Is the blower unsuitable for your

application ?

Is the inlet lter blocked ? Clean or replace the lter.

Is the nonreturn valve defective ?

Table 15 – Fault nding

Contact your supplier or Ingersoll Rand for

advice.

If necessary, redesign your system to

comply with the capabilities of the blower,

or t a dierent blower which provides the

necessary performance.

If necessary, redesign your system to

comply with the capabilities of the blower,

or t a dierent blower which provides the

necessary performance.

If you have tted a nonreturn valve in your

outlet pipeline, check that the nonreturn

valve operates correctly. Repair or replace as

necessary.

If you have made the checks/actions as

described above and you still cannot identify

the cause of a fault, or if you cannot rectify a

fault, contact your supplier or

Ingersoll Rand for advice.

EN

80446693 Rev. B EN-23

EN

www.fraserwoods.ca

6.1 Storage

6.1.1 Preparation

•

6. STORAGE AND DISPOSAL

During storage, every 6 weeks or less, turn the blower drive

shaft by hand through a quarter of a revolution, to turn the

blower and prevent seizure or degradation of the bearings.

WARNING

Use suitable lifting equipment to move the blower.

If you do not, you can injure yourself or damage the

blower. Refer to Section 2.2 for the mass of the blower.

1. Shut down the blower as described in Section 4.3.

2. If necessary, disconnect the drive and transmission

system from the blower drive shaft: refer to the

manufacturer’s instructions supplied with your

transmission system.

3. If necessary, purge your system and the blower with

dry air, and disconnect the blower from your system

pipelines.

4. Place and secure protective covers over the blower

inlet and outlet connections.

5. Use suitable lifting equipment to move the blower to

its storage area.

6. If you will store the blower for longer than six weeks,

refer to the requirements in Section 6.1.2.

7. Store the blower in clean, dry conditions in a wellventilated place that is free from vibration or shocks.

•

6.1.2 Long-term storage

WARNING

When driveshaft of the blower (refer item 5 Figure 1) is

manually rotated, keep away from anges (items 2 and

3 gure 1) your ngers or other parts of your body or

clothing may get trapped, and you may be injured by

the rotating components.

WARNING

Use suitable lifting equipment to move the blower.

If you do not, you can injure yourself or damage the

blower. Refer to Section 2.2 for the mass of the blower.

If the blower is to be stored for longer than six weeks:

External components Internal components

Rust Ban 324 (Esso)

V Product 9703 (Shell)

Mobilarma 778 (Mobil)

Table 16 – Suitable protective oils

When required for use after storage:

1. Drain the protective oil from the drive end and nondrive end covers, then ll the end covers with new oil:

refer to Section 5.5.

2. Use a suitable cleaning solution (such as alcohol or

white spirit) to clean the rotors:

Moisten a suitable clean, lint-free cloth with the

•

cleaning solution.

Clean the rotors which are visible through the inlet

•

port.

Turn the blower drive shaft as necessary to access the

•

other rotors.

3. Prepare and install the blower as described in

Section 3.

Mobilarma 523/524 (Mobil)

Esso Lub MZ 20E/20 (Esso)

Ensis Motor Oil 20 (Shell)

6.2 Disposal

WARNING

Ensure that you wear the appropriate Personal

Protective Equipment (PPE) when you handle

contaminated oil or contaminated components.

Safely dispose of the blower, used oil, cleaning materials, and

any components in accordance with all local and national

safety and environmental requirements.

Take particular care with the following:

Used oil that has been contaminated with dangerous

•

substances.

Components that have been contaminated with

•

dangerous substances.

1. Drain the oil from the drive end and non-drive end

covers: refer to Section 5.5.

2. Fill the drive end and non-drive end covers with a

suitable protective oil (see Table 16): use the method in

Section 5.3.

3. Turn the blower drive shaft by hand through three

or four revolutions, to turn the blower and prevent

seizure.

4. Spray a suitable protective oil (see Table 16) through

the inlet and into the blower.

5. If required, spray a suitable protective oil (see Table

16) on the outer surfaces of the blower, to inhibit

corrosion.

EN-24 80446693 Rev. B

7.1 Introduction

EN

7. SERVICE AND SPARES

7.2 Service

Ingersoll Rand products, spares and accessories are available

from Ingersoll Rand companies in Belgium, Brazil, China,

France, Germany, Israel, Italy, Japan, Korea, Singapore, United

Kingdom, U.S.A and a world-wide network of distributors. The

majority of these centres employ Service Engineers who have

undergone comprehensive Ingersoll Rand training courses.

Order spare parts and accessories from your nearest

Ingersoll Rand company or distributor. When you order, state

for each part required:

Model and Item Number of your equipment

•

Serial number

•

Item Number and description of part.

•

Ingersoll Rand products are supported by a world-wide

network of Ingersoll Rand Service Centres. Each Service

Centre oers a wide range of options including; service

exchange; repair; rebuild and testing to factory specications.

Equipment which has been serviced, repaired or rebuilt is

returned with a full warranty.

Your local Service Centre can also provide Ingersoll Rand

engineers to support on-site maintenance, service or repair of

your equipment.

For more information about service options, contact your

nearest Service Centre or other Ingersoll Rand company.

7.3 Spares and repair kits

The spares and repair kits available for the blowers are shown in Tables 17 and 18.

Spare Item Number

Hibon Lube: 2 litres (0.53 US gal)

Hibon Lube: 5 litres (1.32 US gal)

Table 17 – Spares Item Numbers

Blower

NX 2 R014210100 47002407 R014092100 47002449 P148502042 47004692

NX 3 R014210100 47002407 R014092100 47002449 P148502042 47004692

NX 5 R014210100 47002407 R014092100 47002449 P148502042 47004692

NX 8 R015210100 47002258 R015092100 47002266 P158502042 47004957

NX 12 R015210100 47002258 R015092100 47002266 P158502042 47004957

NX 18 R016210100 47003348 R016092100 47003355 P168502042 47004700

NX 26 R016210100 47003348 R016092100 47003355 P168502042 47004700

Standard maintenance kit Piston Ring Holder Kit Gears

Hibon number CCN Hibon number CCN Hibon number CCN

Table 18 – Repair Kits Item Numbers

LUB0000002

LUB0000005

Authorized Hibon Distributor, Service & Repair Facility

120 – 10293 276 ST, Acheson, Alberta, Canada T7X 6A5

T: 7

80.962.1827 F: 780.962.1830 E: sales@fraserwoods.ca

www.fraserwoods.ca

80446693 Rev. B EN-25

Loading...

Loading...