H&H Specialties 700 Installation Instructions

700 SERIES LIGHT-DUTY

CURVED TRACK

INSTALLATION INSTRUCTIONS

PLEASE READ INSTRUCTIONS THOROUGHLY

BEFORE BEGINNING.

The 700 Series Track is a light-duty I-beam style suitable for

curved or straight curtains up to 40 feet. This Series is for walkalong use only and cannot be rigged for cord operation. A 4'-0"

minimum is suggested for ease of operation and for optimum

life.

A. GENERAL INSTRUCTIONS

1. Before raising track into position, determine location of

hangers. Install end stop (709) at one end of the track.

2. Place track either on the floor or on sawhorses in the

configuration of the finished track. If track needs to be spliced,

please refer to the section on splices in "Special Instructions."

3. Install hangers (706 or 711) evenly along the entire run of the

track starting adjacent to the end. Refer to recommended

spacing provided. Additional hangers should be installed on

curves and others may be required due to site conditions.

4. The 700 Series may also be suspended with wire rope or

welded link chain. Use attachment method appropriate to

application and as determined by a qualified person.

5. For COMPLETE Tracks, one single carrier (701, 716, or

728) is provided per foot of track and one pair of master carriers

(702, 717, or 729) are provided, one for each end of curtain.

Install single and master carriers on track. Finally, install one

end stop (709) on open end of track to captivate single and

master carriers.

sections of track. If track must be spliced on a curve it is

necessary to interrupt the radius in that location with a short

straight section of track (4" minimum) to accommodate the

splice.

3. A drill fixture (707FX) is available from the factory to

facilitate field drilling of splices for the 700 Series track.

Pivot Devices: Pivot devices are not available from the factory

and are not to be used with the 700 Series Track. .

RECOMMENDED TRACK SUPPORT SPACING

Curtain Weight

Per Carrier (pounds)

The user is cautioned that H & H Specialties Inc. cannot guarantee the

accuracy of the data presented in this table for every situation. It is the

customer’s responsibility to determine the suitability of H & H

Specialties’ products for any given application, taking into account the

specific requirements, the environment of use, and any possible

peculiarities of the application.

Using 706 Clamp Hanger or

711 Ceiling Hanger (in feet)

706 Hanger 711 Ceiling

Clamp

244

334

433.5

6. The curtain may now be attached to the carriers.

B. CEILING MOUNT INSTALLATION

1. After laying out the track, use a plumb line or laser to locate

positions of the ceiling hangers relative to the track. Use

appropriate attachment methods for the individual job

conditions. Before installing ceiling hangers (711) make sure

that the ceiling is parallel to the floor. Shims may need to be

installed to compensate for irregularities.

2. After the hangers are installed, raise the track in sections and

attach to the ceiling hangers. In many cases, ceiling hangers can

be installed onto the track, then raised to the ceiling for

mounting of the hanger.

3. Install single and master carriers per the above.

C. MISCELLANEOUS

Splices:

1. In order to have a smooth operating track it is important that

the track splices are installed properly and carefully. Make sure

that the ends of the track are smooth and no ragged edges are

protruding.

2. Whenever possible, splices should be located on straight

DISCLAIMER

This product is designed for moving curtains or, in

some cases, scenery.

NONE OF THE ITEMS DESCRIBED HEREIN ARE

DESIGNED, INTENDED OR WARRANTED FOR

THE USE OF LIFTING OR TRANSPORTING

PEOPLE OR OTHER LIVING OBJECTS.

H & H Specialties Inc. makes no representation of the

suitability of any product for any application unless

specific design drawings are made by the factory and

the products are installed in precisely the manner

detailed by our design staff.

H & H Specialties Inc. 700 Series Installation

South El Monte, CA 91733 December 08, 2007

Page 1 of 1

&

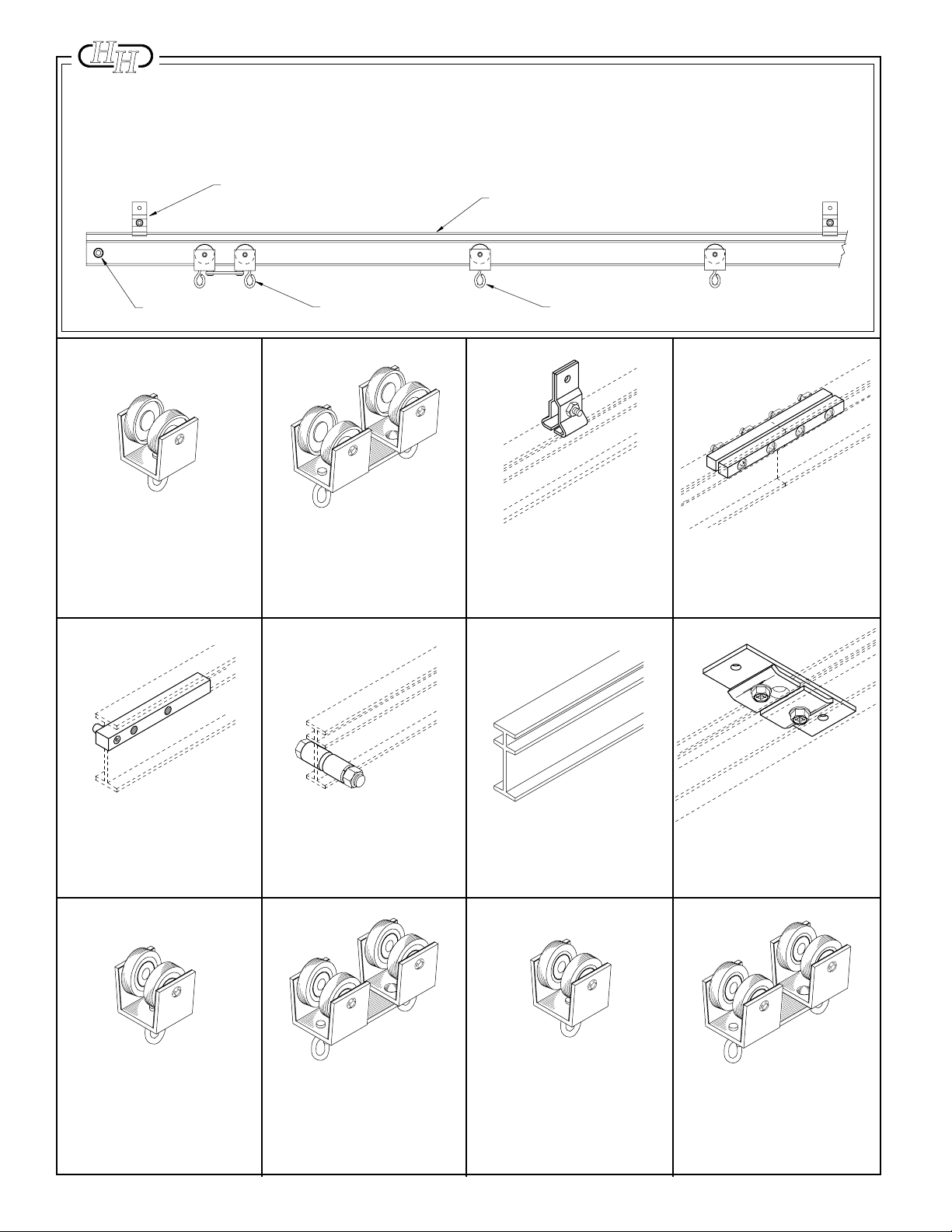

700 SERIES LIGHT-DUTY CURVED TRACK

706 CLAMP HANGER

710 TRACK

COMPLETE TRACK

MODEL NUMBERS

701A

716A

728A

709 END STOP

No. 701 SINGLE CARRIER

2 Delrin wheels riveted to extruded aluminum

body with swivel hook. Nylatron glide strips

reduce friction and noise.

702 MASTER CARRIER

No. 702 MASTER CARRIER

2 Delrin wheel assemblies with swivel pivot

on steel connecting plate. 1 pair recommended for each walk-along curtain.

701 SINGLE CARRIER

No. 706 CLAMP HANGER

Formed steel brackets clamp to track.

Adjusts to any position. Suspend track with

welded chain or wire rope.1 pair pictured.

Steel plates align and lock track together. 1

No. 707 SPLICE

pair pictured.

No. 707FX SPLICE

DRILL FIXTURE

Hardened tool steel drill fixture for field drilling

of track for 707 splices.

No. 716 SINGLE CARRIER

Nylon-tired shielded ball bearing wheels

riveted to extruded aluminum body with

swivel hook. Nylatron glide strips reduce

friction and noise.

36

Bolt with steel spacers to prevent carriers

No. 709 END STOP

from traveling beyond desired location. 1 pair

required for each track.

No. 717 MASTER CARRIER

2 nylon-tired shielded ball bearing wheel

assemblies with swivel pivot on steel connecting plate. 1 pair recommended for each

walk-along curtain.

Mill finish 6063-T5 extruded aluminum

No. 710 TRACK

5/8" wide x 1-11/16" high, .094" thick. 20'

stock length.

No. 728 SINGLE CARRIER

Neoprene-tired shielded ball bearing wheels

riveted to extruded aluminum body with

swivel hook. Nylatron glide strips reduce

friction and noise.

No. 711 CEILING HANGER

Steel plate mounts flush to ceiling. Track

clamps to bracket with offset clips.

No. 729 MASTER CARRIER

2 neoprene-tired shielded ball bearing wheel

assemblies with swivel pivot on steel connecting plate. 1 pair recommended for each

walk-along curtain.

Loading...

Loading...