H&H Specialties 400 Installation Instructions

400 SERIES STANDARD DUTY

STRAIGHT TRACK

INSTALLATION INSTRUCTIONS

PLEASE READ INSTRUCTIONS THOROUGHLY

BEFORE BEGINNING.

A. BI-PARTING TRAVEL

BATTEN INSTALLATION

1. Place track either on the floor or on sawhorses under the batten

to which it will be attached. Make sure the tracks are overlapped

the proper amount, 2'-0" is considered standard. Stage left track

is always

refer to the section on splices in "Special Instructions."

2. Attach track at overlap with 1 set (two 405) overlap clamps

approximately 6" from each end. Install hangers (406) evenly

along the entire run of the track starting adjacent to end pulleys.

Refer to recommended spacing provided. Additional hangers may

be required due to site conditions. If the track is on the floo r,

installer may wish to attach the track to the batten and raise to a

comfortable working level. Refer to step 5 for attachment

instructions.

3. Attach end stops (409) to the onstage (center) ends of the track.

From the offstage ends of the track, install one master carrier (402,

417, 419, or 429) into each track. Next, install single carriers (401,

416, 418, or 428) into each track behind the master (1 single

carrier per foot of track).

4. Decide from which end the curtain will be operated. This is the

side that the double end pulley (403, 423, or 433) will be attached.

Attach pulley to end of track with chain bracket off to the side.

After attaching the double end pulley, go to the opposite side of

the track and install the single end pulley (404, 424, or 434).

Make sure that end pulleys are installed in a manner similar to that

indicated on the plan view detail in attached drawings.

5. Attach the track to the batten with either wire rope, welded link

chain, or pipe clamps. Use attachment method appropriate to

application. When using pipe clamps, a center pipe support (426)

should be used to eliminate twisting through the overlap.

IMPORTANT! Make sure track is parallel to floor before final

attachment. WARNING! After attaching track to batten, make

sure to balance the line set and leave at a comfortable working

level.

6. Attaching a rope clamp to one end of operating line, reeve the

OTHER end of line through the master carrier, single carriers, and

through center sheave of double end pulley. When reeving

operating line make sure that a rubber bumper is installed between

each carrier.

7. Reeve line through the floor block (408, 422, or 432) or the

sand bag tension pulley (643) and back over the other sheave of

the double end pulley.

8. Next, the line travels toward the single end pulley. Reeve the

line through the end stop & cord support, master carrier, single

placed downstage. If track needs to be spliced, please

carriers, and around the single end pulley. Make sure to put rope

clamps on the operating line when going through the master

carrier. CAUTION! Do not tighten at this time. The line

travels through the other end stop & cord support and terminates

where it started at the first master carrier. Place the line through

the master and attach the rope clamp to the operating line leaving

a small tail.

9. Make sure that all the slack in the line is on the double end

pulley side (side with the floor block). Also make sure that there

is sufficient line remaining to reach the intended finished height.

10. Slide each of the master carriers to the onstage (center) end

stops. Now tighten each of the clamps on each master carrier.

Raise the track to its desired height. Check to see that the floor

block or sand bag tension pulley is taking the slack out of the

operating line. Operate the track to make sure everything is

running smoothly. If not, go through the entire system and check

to make sure the components are installed properly.

11. The curtain may now be attached to the carriers.

WARNING! After attaching the curtain, the line set must be

balanced. Always use caution when working with an out-ofbalance line set.

12. Raise the curtain and track to the desired height and adjust the

floor tension block until the operating line has no slack in it. If a

sand bag tension pulley is used, make sure the bag is filled with

dry sand (not provided with sand bag) and the bag is securely

attached to the steel housing.

B. ONE-WAY TRAVEL

BATTEN INSTALLATION

1. Place the track either on the floor or on sawhorses under the

batten to which it will be attached. If track needs to be spliced,

refer to the section on splices in "Special Instructions."

2. Install hangers (406) evenly along the entire run of the track

starting adjacent to end pulleys. Refer to recommended spacing

provided. Additional hangers may be required due to site

conditions. If the track is on the floor, installer may wish to attach

the track to the batten and raise to a comfortable working level.

Refer to step 5 for attachment instructions.

3. Decide from which end the curtain will be operated. This is the

side that the double end pulley (403, 423, or 433) will be attached.

Do not attach the pulley to the end of the track at this time. Attach

to the opposite side of the track the single end pulley (404, 424, or

434). Make sure that both end pulleys will be mounted in such a

manner that both of the sheaves are on the same side of the track.

The upstage side is preferred for cosmetic reasons.

4. From the double end pulley side of the track, install a master

H & H Specialties Inc. 400 Series Installation

South El Monte, CA 91733 February 20, 2007

Page 1 of 3

carrier (402, 417, 419, or 429) into track. Next, install single

carriers (401, 416, 418, or 428) into track behind the master (1

single carrier per foot of track). Finally, attach the double end

pulley on the track.

that the carriers will still pass through the splice. CAUTION!

Wheels of 40 pivot device will not pass a 427 splice.

Dead Hung Installation

5. Attach the track to the batten with either wire rope, welded link

chain, or pipe clamps. Use method appropriate to application.

IMPORTANT! Make sure track is parallel to the floor before

final attachment. WARNING! After attaching track to batten,

make sure to balance the line set and leave at a comfortable

working level.

6. Attach a rope clamp to one end of operating line. Reeve the

OTHER end of the line through the master carrier, single carriers,

and through the center sheave of double end pulley. When reeving

operating line make sure that a rubber bumper is installed between

each carrier.

7. Reeve line through the floor block (408, 422, or 432) or

the sand bag tension pulley (643) and back over the other sheave

of the double end pulley.

8. Next, the line now travels to the single end pulley. Reeve

around the single end pulley and back to the master carrier. Place

the line through the master carrier and attach the rope clamp to the

operating line leaving a small tail.

9. Raise the track to the desired height. Check to see that the floor

block or sand bag tension pulley is taking the slack out of the

operating line. Operate the track to make sure everything is

running smoothly. If not, go through the entire system and check

to make sure the components are installed properly.

10. The curtain may now be attached to the carriers.

WARNING! After attaching the curtain, the line set must be

balanced. Always use caution when working with an out-ofbalance line set.

1. Determine where the hanging points for the track will be. Use

either wire rope or welded link chain to hang track. Hanging

points need to be at ends adjacent to end pulleys and evenly spaced

along the entire run of the track. Refer to recommended spacing

provided. Additional hangers may be required due to site

conditions. Hanging method must be adjustable to allow for

trimming the track parallel to floor.

2. Place track on the floor or on sawhorses in the exact location

that the track will be positioned. If the track is overlapped, allow

2'-0" for this purpose. Place track hangers on track under hanging

points.

3. Raise track in sections and attach to hanging points. Leveling

the track in sections is suggested. If the track is overlapped,

remember to attach the overlap clamps after both tracks are

correctly positioned. Depending on curtain material, the track may

need to be hung 1-3 inches higher than its finished height to allow

for fabric stretch. After the curtain has been hung for a period of

time, it may need to be re-trimmed.

4. Once the track has been hung and leveled, the track is rigged

the same as a batten mounted track for either one-way or bi-parting

(Steps 3,4 & 6-12).

Ceiling Mount

1. After determining the condition of the ceiling and its relation

to the floor, lay the track on the floor or on sawhorses in the

position that it will be installed. Using a plumb line, mark and

drill for attachment to ceiling under each structural support to

which it will be attached.

11. Raise the curtain and track to the desired height and adjust the

floor tension block until the operating line has no slack in it. If a

sand bag tension pulley is used, make sure the bag is filled with

dry sand (not provided with sand bag) and the bag is securely

attached to the steel housing.

C. DEAD HUNG OR CEILING MOUNT

INSTALLATION

Before Beginning.

1. When installing a dead hung track, a decision must be made

whether to install the track in sections or as a complete unit. Basis

for this decision is the ability of the installer to lift and hold the

track in place. The 410S track channel weighs 2.50 pounds per

foot. (50 pounds for a 20'-0" length).

2. If installing on a ceiling, make careful measurements to

determine if the ceiling is parallel to the floor. If not, shim the

track accordingly. Also, take careful measurements in determining

structural points in the ceiling to attach the track. Use appropriate

hardware to attach the track to the ceiling based on roof structure

and total track loads.

3. If track needs to be spliced with ceiling splice (427), splicing

is sometimes easier if done on the floor or on sawhorses. The

ceiling splice is a bolt through splice and care is needed to assure

2. Use a plumb line to determining the position of the track

relative to the ceiling. Raise the track and use appropriate hanging

method for job conditions. Make sure the track is parallel to the

floor and provisions have been made to trim for curtain stretch.

3. After the track is installed, it is rigged in the same way as a

batten mounted bi-parting or one-way track. (Steps 3,4 & 6-12).

Note: Clamp hangers and overlap clamps are not provided or used

with ceiling mounted COMPLETE tracks.

D. SPECIAL INSTRUCTIONS

Splicing Track

1. In order to have a smooth operating track it is important that the

track splices are installed properly and carefully. Do not over

tighten the fasteners.

2. Make sure that the ends of the track are smooth and no jagged

edges are protruding. Filing a slight downward bevel and

rounding the corners will help form a smooth splice. If the track

ends are not smooth, proper alignment may be impossible.

3. Loosen the splice and butt the track sections together in the

splice. Tighten the four 3/8" splice attachment bolts (on top of

H & H Specialties Inc. 400 Series Installation

South El Monte, CA 91733 February 20, 2007

Page 2 of 3

splice) until the track is held loosely. CAUTION! Do not

overtighten.

4. Tighten the 1/4" adjustment screws on the top of the track until

the track is seated firmly in the splice clamp. Next, tighten the

other side of the splice in the same manner. Make sure that the

track ends are still butted together. CAUTION! Do not over

tighten the bolts since deformation of the track is possible.

5. The adjustment screws on the side of the splice are used to hold

the side alignment of the track. Start by turning the screws on one

side of the splice until they touch the track, then do the same to the

other side. Any side misalignment may be adjusted by alternately

tightening or loosening various screws.

6. When the track is aligned, tighten the 3/8" splice attachment

bolts together. Caution! Make sure that the track stays in

alignment as you tighten the splice.

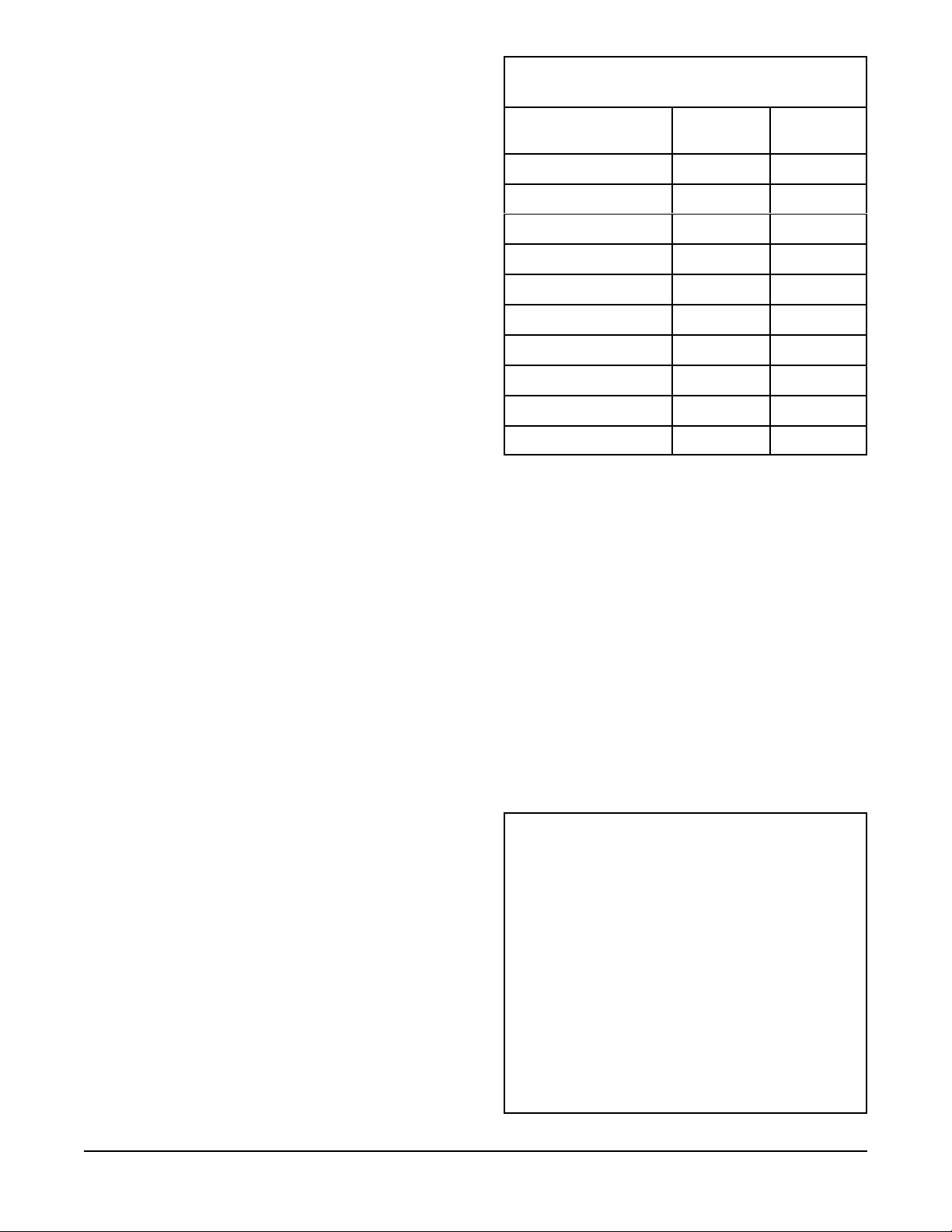

RECOMMENDED TRACK SUPPORT SPACING

Using 406 Clamp Hanger (in feet)

Curtain Weight

Per Carrier (pounds)

2810

3810

4810

5810

6810

779

10 7 8

410A 410S

Pivot Devices

1. Pivot devices allow for curtains to be positioned at different

angles relative to the track. The 40, 40B, 40X, and 40XB are freewheeling units. The addition of the optional 40BK and 40BKB

brake kit will prevent undesired movement of pivot along track.

2. The pivot devices are designed for either 1-3/8" O.D. tubing or

1" Sch. 40 pipe. Maximum recommended batten length is 6'-0".

Make sure that the batten is the proper length for the application.

3. Install the "C" clamps in each end of the curtain batten. These

are provided so that a cord may be tied between the two to aid in

turning the device. The cord should be long enough so that

adjustment may be done with the curtain at its proper trim.

4. WARNING! Tracks that include pivot devices must be

provided with a bolt through style end stop (411) to contain the

pivot device within the track assembly.

4. CAUTION! Do not attempt to adjust the curtain by means

of pulling on the fabric. Damage to the curtain and associated

hardware may result.

5. CAUTION! The recommended total load on the device must

not exceed 75 pounds.

Rear Fold Guide

1. Rear fold guides (412, 412A, or 413) are used when the curtain

needs to store in a pocket or a "sliding door" effect is desired.

2. The guide is attached to the carrier and is positioned offstage in

relation to the carrier. Rubber bumpers are place on each side of

the guide to insure quiet operation. Note: The master carrier and

carrier nearest the end pulley do not require a rear fold guide.

3. As the curtain is pulled open, it is pulled back into the pocket

flat and does not start to fold until the carrier stops. The curtain

does not billow as it moves offstage and will fold neatly in the

pocket.

15 5.5 5.5

20 4 4

25 3.5 3.5

For additional information, please refer to Catalog Fourteen,

pages 62-63. For tracks 10 feet or less in length it is recommended

that the track be supported at a minimum of three locations.

All recommendations stated are presented in good faith and based

upon generally accepted engineering principles. The user,

however, is cautioned that H & H Specialties Inc. cannot guarantee

the accuracy of the data presented in this table for every situation.

It is the customer’s responsibility to determine the suitability of H

& H Specialties’ products for any given application, taking into

account the specific requirements, the environment of use, and any

possible peculiarities of the application.

Direct ceiling attachment of tracks has not been evaluated as the

support structure, method of attachment, and attachment

requirements may vary widely from project to project. A qualified

person should be consulted for this application.

DISCLAIMER

This product is designed for moving curtains or, in

some cases, scenery.

NONE OF THE ITEMS DESCRIBED HEREIN ARE

DESIGNED, INTENDED OR WARRANTED FOR

THE USE OF LIFTING OR TRANSPORTING

PEOPLE OR OTHER LIVING OBJECTS.

H & H Specialties Inc. makes no representation of the

suitability of any product for any application unless

specific design drawings are made by the factory and

the products are installed in precisely the manner

detailed by our design staff.

H & H Specialties Inc. 400 Series Installation

South El Monte, CA 91733 February 20, 2007

Page 3 of 3

&

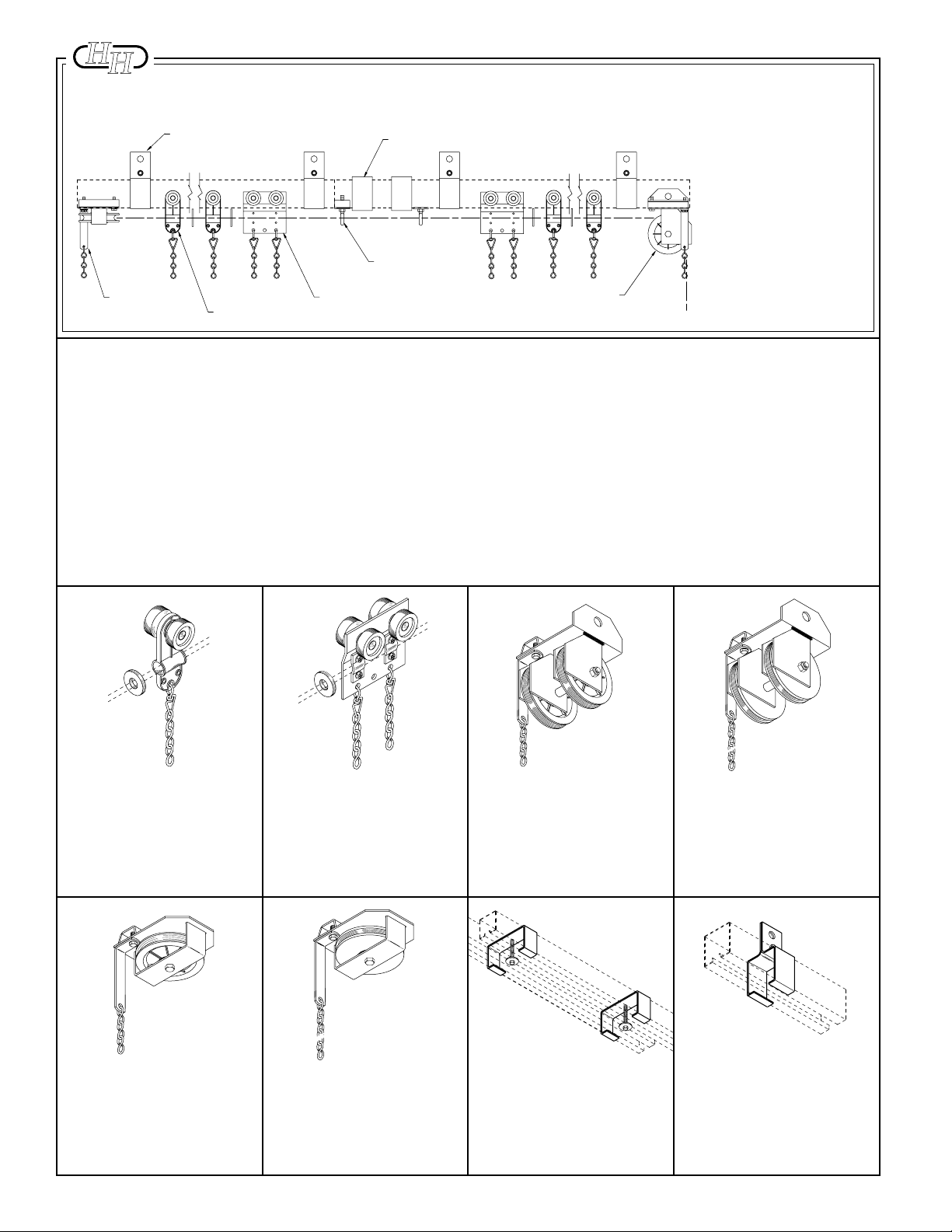

COMPLETE TRACK

400 SERIES HEAVY-DUTY STRAIGHT TRACK

MODEL NUMBERS

401A 401S

406 CLAMP HANGER

405 OVERLAP CLAMP

416A 416S 416P

418A 418S 418P

428A 428S

BLACK

COMPLETE TRACK

MODEL NUMBERS

401SB

416SB 416PB

418SB 418PB

428SB

404 SINGLE

END PULLEY

401 SINGLE CARRIER

409 END STOP &

CORD SUPPORT

402 MASTER CARRIER

403 DOUBLE

END PULLEY

The 400 Series is a straight track offered in many models for a variety of project requirements. This heavy-duty track

is available in galvanized steel, black powder-coated steel and mill finish aluminum. In addition to the traditional zinc

plated finish, all hardware items are available in black finish to meet the demands of the theatrical industry.

Model 401S is recommended for moderately heavy curtains up to 60 feet in width. It utilizes ball bearing carriers with

polyethylene wheels and 4" end pulleys. Model 428S is an economical upgrade to urethane wheels and 6" pulleys

when a quiet track is desired for larger curtains.

Models 416S and 418S feature improved carriers with a custom designed, sealed ball bearing in each wheel. The

416 carrier is equipped with nylon-tired wheels for minimized friction when moving heavy loads. The 418 carrier has

been redesigned with a urethane tire that combines durability with quiet operation. Each is complemented by 6"

end pulleys for rigging curtains of virtually any length. The Premier versions, Models 416P and 418P, are the best in

heavy-duty straight tracks. They incorporate 1/2" operating line, rear fold guides and 8" end pulleys for maximum

ease of operation of very heavy stage curtains.

2 polyethylene wheels riveted to black Super

SINGLE CARRIER

Tough nylon body with shielded ball bearing.

Heavy-duty hook, swivel, and trim chain for

curtain attachment. Supplied with 1 rubber

bumper.

No. 401 - Zinc plated.

No. 401B - Black finish.

SINGLE END PULLEY

4" diameter Nylatron GS sheave with shielded

ball bearing. Steel housing clamps to underside of track. Chain bracket for securing

offstage curtain edge. 3/8" groove.

No. 404 - Zinc plated.

No. 404B - Black finish.

18

MASTER CARRIER

4 polyethylene wheels riveted to steel body

with 2 shielded ball bearings. 2 clamps

provided for anchoring operating line or

cable. Supplied with 1 rubber bumper. 1 pair

required for overlapping tracks.

No. 402 - Zinc plated.

No. 402B - Black finish.

No. 404M BLACK

SINGLE END PULLEY

Heavy duty 4" diameter Nylatron sheave with

sealed precision ball bearings. Steel housing

clamps to underside of track. Chain bracket

for securing offstage curtain edge. 3/16"

groove for use with motorized tracks.

DOUBLE END PULLEY

4" diameter Nylatron GS sheaves with

shielded ball bearings. Steel housing clamps

to underside of track. Chain bracket for securing offstage curtain edge. 3/8" groove.

NO. 403 - Zinc plated.

No. 403B - Black finish.

OVERLAP CLAMP

Formed steel clamps to align track at overlap.

1 set pictured.

No. 405 - Zinc plated.

No. 405B - Black finish.

No. 403M BLACK

DOUBLE END PULLEY

Heavy-duty 4" diameter Nylatron GSM

sheaves with sealed precision ball bearings.

Steel housing clamps to underside of track.

Chain bracket for securing offstage curtain

edge. 3/16" groove for use with motorized

tracks.

CLAMP HANGER

Formed steel brackets clamp to track.

Adjusts to any position. Suspend track with

welded chain or wire rope.

1 pair pictured.

NO. 406 - Zinc plated.

NO. 406B - Black finish.

Loading...

Loading...