Page 1

Stilling Chamber

Instruction

Manual

Stilling Chamber (Cat. # 70919)

HF scientific, inc.

3170 Metro Parkway

Fort Myers, FL 33916-7597

Phone: (239) 337-2116

Fax: (239) 332-7643

Page 2

HF scientific, inc.

Stilling Chamber Part # 20106

STILLING CHAMBER COMPLETE WITH AUTOMATIC AIR RELEASE

It is only used on applications where the OnLine Monitor is measuring a

flowing stream of water or other liquid. The stilling chamber is used to

remove air bubbles from the liquid before it reaches the flow through unit of

the on-line turbidimeter. Air bubbles may cause unstable or incorrect

readings on the monitor.

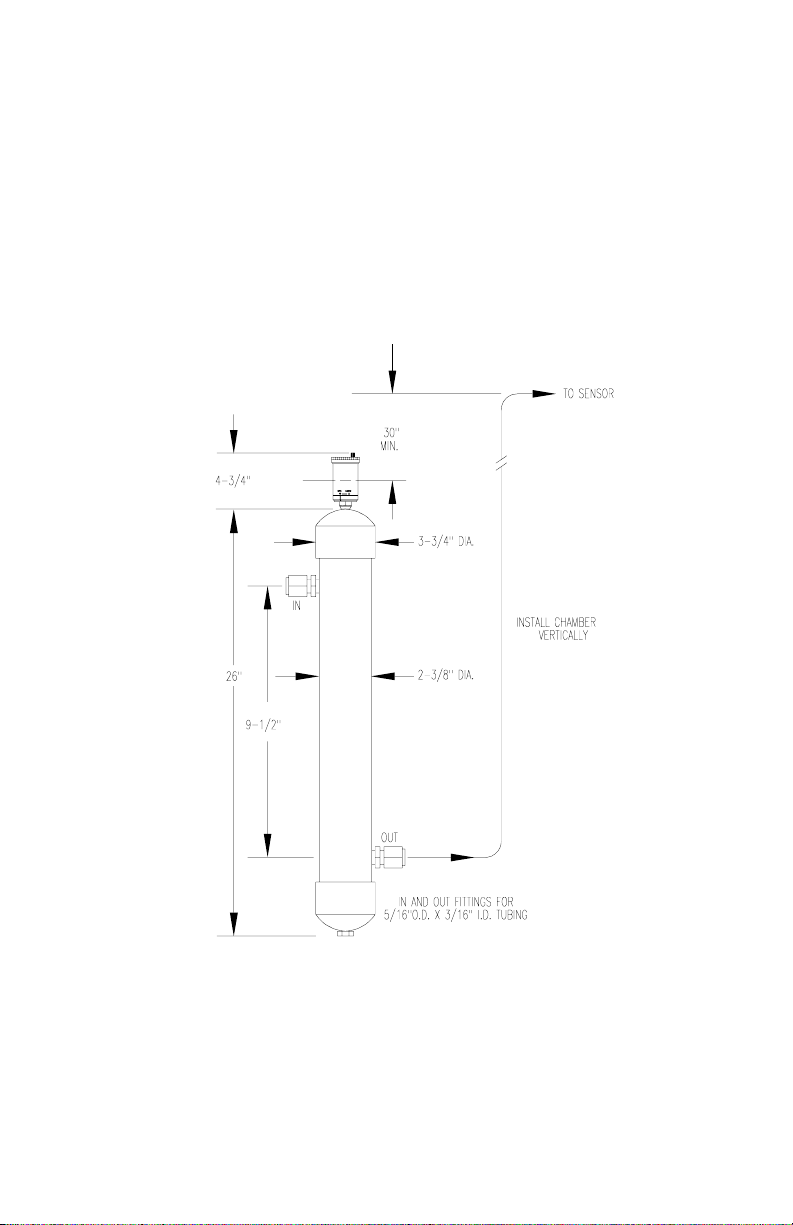

Figure 1

METHOD OF OPERATION

The stilling chamber is a cylinder approximately 2” (5cm) diameter x 26” (66

cm) long. The liquid enters the stilling chamber via the outlet fitting near

the top of the stilling chamber (see figure 1). As the liquid

Page 3

passes through the stilling chamber, its velocity becomes very low due to

the large diameter of the stilling chamber. This permits the fine air bubbles

in the liquid to rise to the top of the stilling chamber.

The automatic air vent in the top of the stilling chamber removes the air as

it collects at the top of the stilling chamber.

The stilling chamber should be located in the line before the liquid reaches

the sensor. The outlet from the stilling chamber should be run vertically at

least 30” (75cm) above the top of the automatic air release before being led

to the sensor.

The BRAUKMANN Automatic Air Vent has a maximum working pressure of

90 psi and maximum temperature range to 225°F (106° C). It is designed

for use on all types of hot water radiators, convectors, base board

convectors, heating units, venting pipes and fittings.

Figure 2 Shown in

OPERATING INSTRUCTIONS

Open Position

1. Before filling the system, make sure the red vent cap is securely

tight and that the valve is in the closed position (see figure 2) by

turning vent body clockwise. Use hands only to avoid damaging

the vent.

2. With the valve in the closed position, flush the system as required

to remove dirt, debris and contaminates.

3. Fill the system with the appropriate solution.

4. Start operation by turning the air vent body counter-clockwise to

the open position (see figure 2).

Page 4

5. Make sure the red vent cap is tightend all the way to the stop

position for proper operation. Use hands only to tighten.

RED VENT CAP

WITH LEAKAGE

BLACK COVER

ASSEMBLY

GUARD.

O-RING

SEAT AREAMAKE SURE

AREA IS FREE

OF DIRT AND

DEBRIS

CLEANING INSTRUCTIONS

VENT LEVER

SPRING

FLOAT

CONSTRUCTED

FOR EASY IN

LINE SERVICE.

SHUTOFF IS

BUILT-IN NO

DRAIN DOWN

REQUIRED.

Figure 3

1. Turn the vent body clockwise to the closed position, isolating the

vent from the system (see figure 2).

2. Remove the float assembly by unscrewing the top of the body

and lifting the black cover assembly up (see figure 3).

3. Carefully clean the seat area of any dirt or debris.

4. Carefully clean any dirt or debris from inside the vent chamber.

Page 5

5. Replace the float assembly, making sure that the O-ring is seated

properly (see figure 3).

6. Replace black cover assembly on air vent body. Using hands only

turn until handtight.

7. Operate by turning the air vent body counter clockwise to the

open position. Use hands only (see figure 3).

8. Make sure the red vent cap is tightend all the way to the stop

position for proper operation. Use hands only to tighten.

Loading...

Loading...