Page 1

OWNERS MANUAL

HF Oil Content Monitor

(OCM)

HF scientific inc.

3170 Metro Parkway

Ft. Myers, Fl 33916

Phone (239) 337-2116

Fax (239) 332-7643

Email: info@hfscientif ic.com

Catalog No. 22543 (1/03)

Rev. 3.9

Page 2

Page 3

Declaration of Conformity

Application of Council D irective

Standard to which Confor mity is Declared:

Product Safety – Tested and Pas sed CE EN61010-1: 1990 + A1: 1992 (73/32 EEC)

Immunity and Em issions – Tested and Passed EN61326: 1998, Class A

Manufacturer’s Name: HF scientific, inc.

Manufacturer’s Address: 3170 Metro Parkway, Fort Myers, Florida 33916-7597

Importer’s Name:

Importer ’s Addres s:

Type of Equipment: Oil Content Monitor

Model No: OCM 20075

I, the undersigned, hereby declare that the equipment specified above conforms to the above

Directive and Standard

Place: Fort Myers, Florida USA

(Signature)

Robert J. Maley, President

__________________________

OCM Rev 3.9 (1/03) i

Page 4

Page 5

Table of Contents

Declaration of Conformity...........................................................................................................i

Specifications................................................................................................................................1

1.0 Using this Instruction Manual .........................................................................................2

2.0 Unpacking the Instrument................................................................................................2

2.1 Packing List of Contents ............................................................................................. 2

2.2 Unpacking and Inspection of the Instrument and Accessories.................................2

3.0 Installation ........................................................................................................................ 3

3.1 Mounting and Site Selection .......................................................................................3

3.2 Plumbing ......................................................................................................................3

3.3 Electrical Connections.................................................................................................3

3.3.1 Power Source............................................................................................................4

3.3.2 Relay Connections....................................................................................................4

3.3.3 4-20 mA Output ....................................................................................................... 4

3.3.4 Unused Terminals....................................................................................................4

3.3.5 Cabinet Integrity......................................................................................................4

4.0 Becoming Familiar with the Instrument........................................................................5

4.1 The Touch Pad.............................................................................................................5

4.2 The Display................................................................................................................... 5

5.0 Routine Operation.............................................................................................................6

5.1 Routine Measurement ................................................................................................. 6

5.2 Security Access Feature..............................................................................................6

6.0 Instrument Configuration (SETUP mode).......................................................................7

6.1 Configuring the Alarms............................................................................................... 7

6.1.1 Alarm 1 .................................................................................................................... 7

6.1.2 Alarm 2 ................................................................................................................... 8

6.2 Setting 4-20mA Output ............................................................................................... 9

6.3 Security Code Access Option ...................................................................................... 9

7.0 Calibration Procedures...................................................................................................11

7.1 Standard Calibration Procedure ..............................................................................11

7.1.1 Clear Water (0 PPM) Calibration ........................................................................11

7.1.2 15 PPM Calibration...............................................................................................12

7.2 Zero Adjust Calibration............................................................................................13

8.0 Self-Diagnostics: System Troubleshooting................................................................... 15

8.1 System Warning Message(s) ..................................................................................... 15

OCM Rev. 3.9 (1/03) ii

Page 6

8.2 System Failure Error................................................................................................. 15

9.0 Routine Maintenance ..................................................................................................... 16

9.1 Cleaning the Optical Chamber (Sample Tube).......................................................16

9.2 Replacing the Desiccant Cartridge...........................................................................16

9.3 Replacing the Source Lamp ...................................................................................... 16

10.0 Technical Assistance, Replacement Parts and Warranty Claims..............................17

11.0 Warranty .........................................................................................................................18

12.0 Figures ............................................................................................................................19

13.0 Approvals ........................................................................................................................... 26

OCM Rev. 3.9 (1/03) iii

Page 7

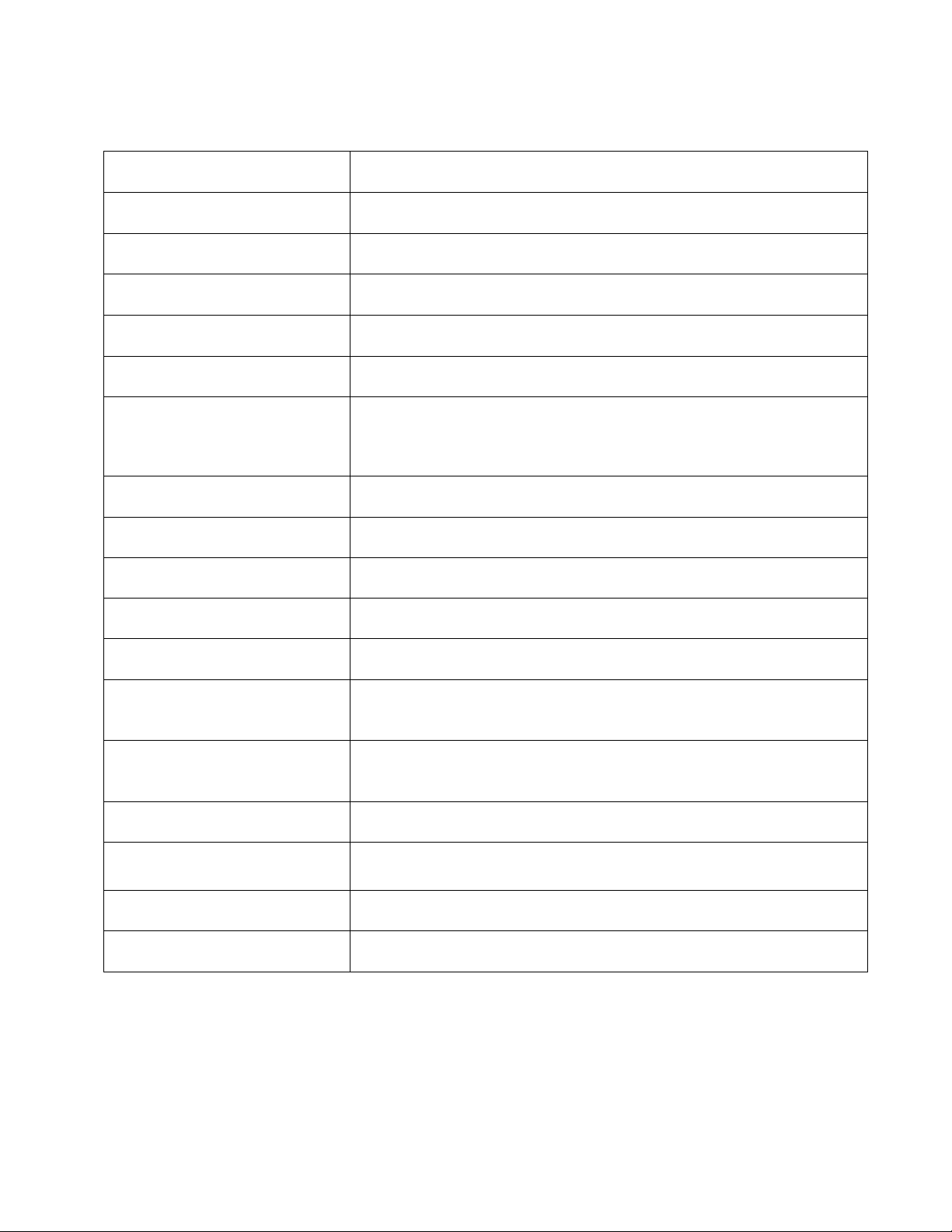

Specifications

Measurement Range

0-30 PPM, Trending 30-50 PPM

Accuracy Less than ±5 PPM

Resolution

1 PPM

Response Time Less than 20 seconds

Power Requirements 90-250 VAC, 47-90Hz, 6 VA

Display Liquid Crystal Display

Two User Settable Alar ms 120-240VAC 2A Form C Relay with s uppressors, or

120-240VAC 1A Form A Ze ro –crossing Solid State Relay

Analog Output Signals 4 - 20 mA

Water Pressure 0.1 - 8 bar ( 1-116 psi.)

Flow Rate 1 Liter/min. regulated (.26 Gal/min)

Operating Temperature Range

0°C – 50°C (34°F – 122°F)

Sample Temperature Range 1°C – 50°C (34°F – 122°F)

Year 2000 Compliance

Statement

Regulatory/Measurement

This instrument is fully Year 2000 (Y2K) compliant; it doe s not

use the date for ope ration in any form.

I.M.O. resolution MEPC. 60(33)

Compliance

Certifications See appendix for a pprovals

Approximate Dimensions

Shipping Weight

175mm W x 310mm H x 225mm D ( 6⅞” W x 12 ¼” H x 8•” D)

2.5 kg (5.5 lbs.)

Warranty 1 Year from date of shipment

OCM Rev. 3.9 (1/03) 1

Page 8

1.0 Using this Instruction Manual

Congratulations on your pur chase of a new HF scientif ic inc. oil content monitor (OCM).

This instrum ent has been designed f or simple and e asy measur ement of bilge oil in wa ter

and conforms to the requirements of I.M.O . resolution MEPC. 60(33).

This manual contains simple steps to follow to ensure that your instrument operates

properly. The following sections describe how to use and care for your new OCM. In

certain instances NOTES, or reminders, have been added to give further clarification to

the instructions. Refer to the Table of Contents to easily find specific topics.

2.0 Unpacking the Instrument

2.1 Packing List of Contents

Item Part# Quantity

OCM Bilge Alar m 19601 1

Instruction Manual (this

manual)

Male Quick Connectors 22519 2

Calibration Kit 19611 1

Black Nylon Tubing 22740 3 meters ( 10 ft.)

Desiccant Tubing 19610 1

2.2 Unpacking a nd Inspection of the Instrument and Accessories

Remove the instrument from the packing carton. Carefully inspect all items to ensure

that no visible damage has occurred during shipment. If the items you received do not

match your order, please immediately contact your local distributor or the HF scientific,

inc. Customer Service department.

22543 1

OCM Rev. 3.9 (1/03) 2

Page 9

3.0 Installation

3.1 Mounting and Site Sele ction

The OCM is designed for wall mounting. If wall mounting is not practical, the

instrument can be mounted on any suitable surface. Choose a location that is easily

accessible for operation and service and ensure that the front display rests at eye level.

The overall mounting dimensions of the instrument are shown in Figure 1. For ease of

service there should be about 45cm (18”) free area above the OCM. This will ensure

enough room for calibrations and for cleaning the optical well. The recommended

mounting screws (four required) are M6 (or ¼”).

It is important that the OCM be mounted within 18 meters of the oily water separator to

comply with the IMO requirement for a respons e time of 40 seconds.

3.2 Plumbing

The recommended plumbing for the instrument is shown in Figure 4. The OCM is

designed with an integral flow regulator which limits the flow to between 0.8 – 1.3

liters/minute depending on the system backpressure. Ensure that you supply the OCM

with a process flow capable of sustaining thes e levels. Quick- connect fittings are s upplied

on the inlet and outlet of the OCM. These f ittings help speed up calibration procedures.

The OCM is designed for use with semi-rigid tubing (¼” OD X .170” ID). Opaque

tubing is recommended if the tubing will be exposed to sunlight. Using this semi-rigid

tubing, the ins trument should be installed within 18 me ters of the sample line to com ply

with the IMO r equirement for a respons e time of 40 seconds. A valve is supplied at the

inlet side of the instrument to ease the calibration and cleaning procedures.

Note: The quick-connect fittings are designed with a special shut-off feature to prevent

flow of the process through the OCM when the line is disconnected.

The optional clean water supply must be oil-free. The clean water connection, along with

the optional drain connection, allows the OCM to be easily calibrated for the clean water

condition. If your clean water supply is seawater, the OCM can be zero adjusted with the

local seawater.

3.3 Electrical Connections

All of the electrical connections to the OC M a re made at the fie ld te rminal box located on

the lower sec tion of the instrument. Wiring should be run in through the grommet closest

to the connection terminal bloc k. The cable diameter for these gr ommets is rate d for 4.3 –

11.9 mm (0.170 –0.470”).

To make connections, insert a 3mm(1/8”) flat blade screwdrive r into the top slot of the

terminal block. Pivoting the handle of the screwdriver up c a uses the clamp to lowe r. You

can now insert the wire. Releasing the tension raises the clamp and tightens the

connection. Please note that these terminal blocks will accept wire gauges A WG 24-14.

As you read the following sections, ple a se refer to Figure 3 for c la rification of the

electrical connections.

Please follow all local and government recommendations and methods for insta lla tion of

electrical connec tions to and between the instrument and peripher a l de vic e s.

OCM Rev. 3.9 (1/03) 3

Page 10

3.3.1 Power Source

The power source re quired is 90 – 250VAC, 47- 90Hz. The power cons umption is 6VA.

Connections are made at the far right ha nd te rminals.

Please observe safe wiring practices. It is recommended that a circuit breaker or switch

be placed prior to the power connection to the OCM to allow for service.

Note: Only qualified electricians should be allowed to perform the installation of the

instrument as it involves a line voltage that could endanger life.

3.3.2 Relay Connections

Relay connections for Alarm 1 and Alarm 2 are located next to the power connection.

These relays are rated at 120-240VAC 2A for the mechanical. The optional solid state

relays are rated at 120-240VAC 1A.

The Sensor Alarm connection is located to the left of Ala rm 1. This rela y is rated for up

to 30VDC 2A.

3.3.3 4-20 mA Output

A 4-20 mA s ignal is pr ovided. This output is re fe renc ed to the sc ale of 0-30 P P M as s et at

the factor y but m ay be set to any por tion of the sc ale of 0-50 P PM. Connections f or the 420 mA are located next to the Sensor Alarm.

3.3.4 Unused Terminals

Located next to the 4-20mA outputs are some terminals that are not used in this

instrument. T he se terminals are not connected inside the ins trument and cannot be used.

3.4.5 Cabinet Integrity

To maintain the seal of the field terminal box, it is important to use suitable size cable

through the compression f ittings. If suitable size cable is not available, use vinyl tubing or

electrical tape to make up the differ ence. Tighten all compr ession fittings by hand. Do not

remove the plastic dowel plugs in unused fittings as these serve to complete the cabinet

seal. When clos ing the lid, ensure that no wires a re pinched and that the o-r ing is in good

condition. Tighten the four corner screws firmly.

OCM Rev. 3.9 (1/03) 4

Page 11

4.0 Becoming Familiar with the Instrument

The user interface of the OCM has been designed with a 4 key Touch Pad and a digital

user display with two rows of display information.

4.1 The Touch Pad

The MODE key is used to cycle between the four modes of the OCM: AUTO

(measurement) mode, CAL 0 ADJ (Zero Adjust Calibration) mode, SETUP

(Instrument Configuration) mode, and CAL (Calibration) mode. The

the option (or mode) that is highlighted or chosen. The

through lists and to increase or decrease settings. Please refer to the Menu Flow Chart

(Figure 8) while becoming familiar w ith the operation of the OCM.

Note: 1.While in the CAL or SETUP modes the relays are set in the alarm condition.

2. The instrument has an integral time-out feature that automatically returns the

system operation to the AUTO mode from either the CAL or SETUP modes when

more than 5 minutes have passed with no keypad activity.

4.2 The Display

Figure 4 illustrates all the graphics on the user display. The upper row of the display (1)

is used for reporting the oil concentr ation (in PPM) and to provide user guidance in the

customer settings routine. The lower row of the display (2) is used to communicate error

messages and a lso to provide us er guidance. The display ha s several status indicators (3),

which indicate the current operation mode of the instrument. Finally, several indicators

around the screen provide guidance w hen the customer setting routine is being used and

when the calibration routine is being used. Please note that not all of the indications on

this screen will be used at any one tim e.

andu arrows are used to scroll

t

key enters

↵↵↵↵

OCM Rev. 3.9 (1/03) 5

Page 12

5.0 Routine Operation

The OCM is designed to m easur e and display the concentr ation of oil (in PPM by weight)

in the bilge water according to I.M.O. resolution MEPC. 60(33). Readings above 50

PPM are outsi de of the range of this instrument.

5.1 Routine Measurement

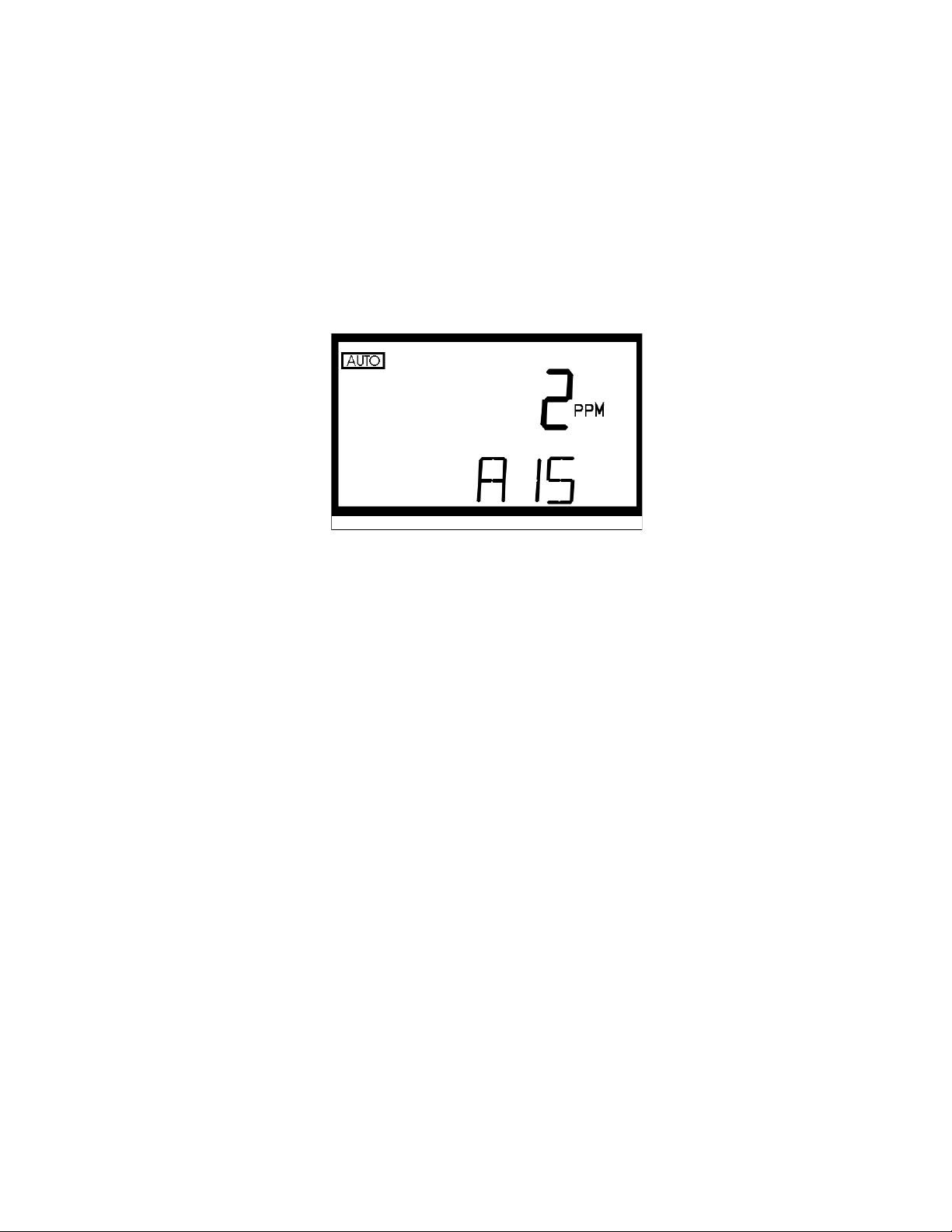

During normal oper ation, the instrument will have the AUTO block highlighted with the

current scal e displayed on the r ight side of the display, the m easure d reading on the upper

row of the display, and the current alarm level on the lower row of the display (see

illustration below).

The following steps describe how to measure the oil content of a sample using the

OCM:

1. Turn power on to the OCM. The instrument will be in the AUTO (measurement)

mode (the “AUTO” block should be illuminated). Allow instrument to w arm up for

at least 45 minutes.

2. When a continuous process stre am is flowing through the instrum ent, the instrument

will report the oil content of the sample by displaying it on the LCD screen.

3. Pressing the MODE button will allow you to sequentially access the calibration

routine (s ee section 6 for mor e information) and the configur ation/setup routine (see

section 7 for more information).

5.2 Security Access Feature

The OCM is equipped with a security access code feature that can be turned on or off

when configuring the instrument. Three access codes are used in the instrument: one for

instrument calibration (333), one for instrument configuration (444), and one to zero

adjust the instrument (222). These codes are not changeable and are required as input

whenever the customer presses the MODE button to access either the calibration routine

or the setup routine if the security feature is enabled.

If the security feature is enabled, the scr een shown in Figure 5 will be shown w hen you

press the MODE button. The security code has three numbers that are selectable one at a

time. Use the

key to accept the number. Then repeat the process for the next two numbers in the access

code. If you have selected a valid code the OCM will be directed to either the

calibration, the zero adjust, or the user setup mode depending on the access code that was

provided to the instrument. If the wrong access code is selected, the instrument will

return to the AUTO mode.

tu arrows to select the f irst number in the code and then press the

↵↵↵↵

OCM Rev. 3.9 (1/03) 6

Page 13

6.0 Instrument Configuration (SETUP mode)

The OCM provides you the ability to custom ize your instrument according to your needs

at any time during norm al operation. T his section descr ibes how you can customize your

instrument.

NOTE: To skip the selection of the SETUP mode, simply press the MODE key.

6.1 Conf iguring the Al a rms

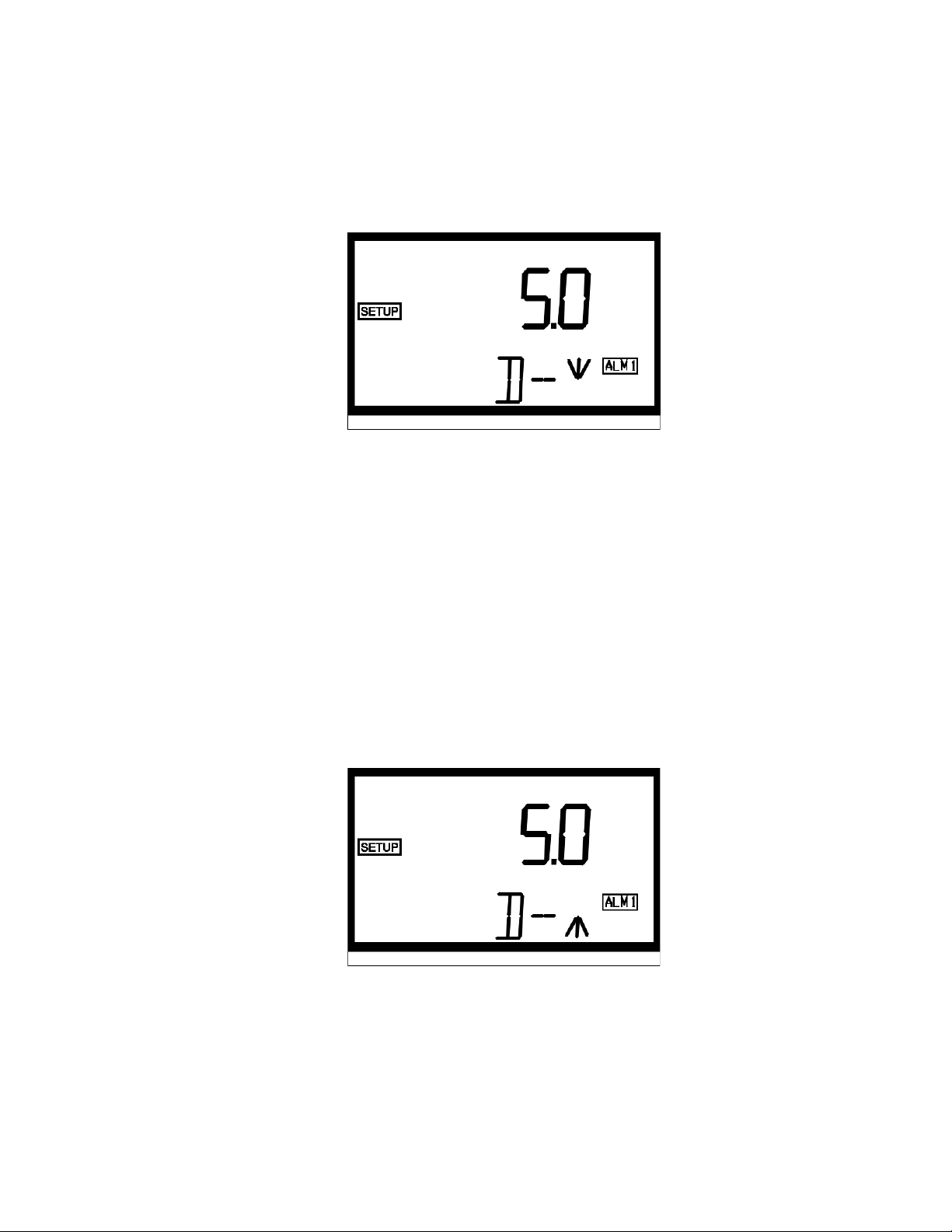

Enter the SETUP mode of the OCM by pressing the MODE key until SETUP is

illuminated. The level at which the alarm(s) will activate is called the set point. On the

OCM, the set point (S/P) can be set to either 5 or 15 ppm. The display will now indicate

that the set point (S/P) for both alarm 1 and alarm 2 are set to 15 PPM. Use the

keys to select a set point of 5 or 15 ppm. Press the ↵ key to accept each selection and to

tu

proceed to the next selection. Press

You may set delay times for initiating and disabling the alarm . The delay times are used

to prevent relay chatter close to the alarm limit. T he delay times are set at 0 se conds at

the factory. T he operations of the delays are:

Delay On: Once an alarm condition is met, the process must remain in alarm

condition for at least the time selected for the Delay On time level. If the

delay on time level is set at 15 seconds and the alarm condition is met

continuously for only 10 seconds, the alar m will not be initiated. H owever, if

the alarm condition is met continuously f or 15 seconds or more, the OCM will

indicate an alarm condition.

Delay Off: Likewise, once the process water leaves the alarm condition levels

it must remain out of the alarm condition for at least the time selected for the

Delay off time level. If the delay off time level is set to 10 seconds and the

process has exited out of the alar m condition, the alarm will be r e set only if

the process is out of the alarm condition for a continuous 10 seconds.

Otherwise, the OCM will still signal an alarm condition.

6.1.1 Programming Alarm 1

Alarm 1 Function: Alarm 1 is alw ays active . This is the alarm that should be connected

to the re-circulation apparatus. This alarm will activate when the oil concentration

exceeds the set point longer than the “Delay On” tim e.

Alarm 1 Delay Times: Delay On: The following display will appear to allow you to

select the number of seconds currently set for the “de l a y on” time.

now to set up the alar ms.

↵

OCM Rev. 3.9 (1/03) 7

Page 14

The current selected number of seconds will be shown. You can select the desired

number of seconds for the “del ay on” time for this alarm using the

Once you have set the de sired delay time, press the

Delay Off: Next, the following display w ill appear to allow you to select the number of

seconds curr e ntly set for the “delay off” time.

The current selected number of s econds will be shown. You can se lect the desired delay

on time for this alarm using the

button to accept it.

time, press the

6.1.2 Programming Alarm 2

Alarm 2 Function: Alarm 2 may be tur ned on, or of f . T his ala rm could, for exam ple, be

wired into the c ontrol room as an ear ly warning system f or the oil levels in your pr ocess

stream. You can use the

↵

toru

t

u

and

buttons to cycle through and select the desired function.

buttons. O nce you have s et the desir ed delay

button to accept it.

↵

t and

u

buttons.

Press the

If you selected to turn the alarm OFF, you will be immediately prompted to set up the

analog output f or the ins trument. If , on the other hand, you selected to tur n the alarm on

you will be prompted to set the delay times.

Alarm 2 Delay Times: Delay On: The following display will appear to allow you to

select the number of seconds currently set for the “de l a y on” time.

The current selected number of seconds will be shown. You can select the desired

number of seconds for the “del ay on” time for this alarm using the

Once you have set the de sired delay time, press the

Delay Off: Next, the following display w ill appear to allow you to select the number of

seconds curr e ntly set for the “delay off” time.

button to accept your selection.

↵↵↵↵

button to accept it.

↵

t

and

u

buttons.

OCM Rev. 3.9 (1/03) 8

Page 15

The current selected number of s econds will be shown. You can se lect the desired delay

u

and

on time for this alarm using the

button to accept it.

time, press the

Note: A system alarm will activate when an internal system failure occurs. Please note

that the user settable relays are failsafe in that they will activate if an internal

system failure or power loss occurs.

6.2 Setting 4-20mA Output

The output (O/P) selection allows you to turn the 4 – 20 mA analog output on, or off.

You can select the de sired analog output operation using the t and u keys . Once you

have set the desir e d ope ration, press the ↵ key to accept it.

If you selected to turn the 4- 20 mA output on, you will be prompted to set the upper and

lower oil content levels corresponding to the 4 mA and 20 m A output levels. First, you

will be prompted with the oil content level assigned to the 4 mA output level (OLV on

the lower row of the LCD displa y). Select the oil content level you wish to as sign to the

OLV using the t a nd u keys. Once you have set the desir ed level, press the ↵ key to

accept it.

↵

t

buttons. O nce you have s et the desir ed delay

Next, you will be prom pted with the oil content level assigned to the 20 mA output level

(OHV on the lower row of the LCD display). Select the oil content level you wish to

assign to the OHV using the t and u keys. Once you have set the de sired level, pre ss

the ↵ key to accept it. At this point you w ill be prompted to set up the security access

6.3 Selecting the Security Access Option

The OCM is equipped with a security access option. If this option is turned on, the user

must be able to input the correct access code for feature. The security key will be

highlighted on this display at this time and the lower row the mode they wish to enter .

OCM Rev. 3.9 (1/03) 9

Page 16

The three access codes us ed in the instrument: code 333 w ill provide access to ins trument

calibration, code 444 will provide access to instrument configuration, and 222 will

provide access to the zero adjust calibration. See section 5.2 for more information on this

security feature. T he security key will be highlighted on this display at this time and the

lower r ow of the display will indicate the opera tional status of the security access option

(on or off). You can change the operational status of this option using the

key to accept it. Pressing the ↵ key will

Once you have set the de sired s tatus, pres s the

forward you to the calibration mode of the instrument.

You have now completed the customer selectable parameters section of the instrument.

You can enter this menu at any time to re-set, or change, any of the parameters.

↵

and ukeys.

t

OCM Rev. 3.9 (1/03) 10

Page 17

7.0 Calibration Procedures

The OCM has been factory-calibrated at HF scientific, inc.. It is possible to use the

instrument directly out of the box. However, re-calibration of the instrument using oilfree water and the supplied 15 PPM calibration standard is recommended to allow the

user to become familiar with the operation of the instrument and the calibration

procedures

7.1 Standard Calibration Procedure

Two calibr ation points are re quired for complete calibra tion of the OCM; oil-free w ater,

and a 15 PPM calibration standard (available only from HF scientific, inc.). To ensure

the accuracy of the instrument, please follow the instructions detailed in the following

section.

7.1.1 Clear Water (0 PPM) Calibration

1. Shut off flow to the OCM.

2. Disconnect the source tubing.

3. Remove the cleanout plug on the O C M.

4. Open the drain valve to remove the seawater from the sample tube.

5. Close the drain.

6. Pour enough oil-free water in to the sample tube to fill it. De-ionized or

distilled water is r ecommended.

7. Open the drain.

8. Repeat steps 5 and 6 and then clean the sample tube using the cleaning brush

supplied with the instrument.

9. Open the drain.

10. Repeat steps 8 and 9 two more times to completely clean the sample tube.

11. Close the drain and fill the sample tube with the oil-free water.

12. Replace cleanout plug.

13. Press the MODE key three times to enter the calibration mode. The “CAL”

block will be illuminated and the display will read ”0 PPM” (see diagram).

14. P ress the

will appear on the upper row of the display and the word NO will appear on

OCM Rev. 3.9 (1/03) 11

key to initiate the calibration on 0 PPM water . The word CAL

↵↵↵↵

Page 18

the lower row of the LCD display.

15. This is the fina l step for calibra tion a t the 0 PPM level; if you wis h to skip this

step without calibrating the 0 PPM, simply press the

you are satisf ie d a nd wish to complete calibration on the 0 PPM level use the

arrows to select the word YES on the lowe r row of the display and then

tu

button to initiate calibration.

press the

↵↵↵↵

button. However, if

↵↵↵↵

16. Both the CAL and STORE blocks will flash during the operation. When the

calibration procedur e for the 0 PPM level is complete the CAL and STORE

blocks will stop flashing. Next you will proceed on to the 15 P PM Calibration.

7.1.2 15 PPM Calibration

1. Remove the cleanout plug on the O C M.

2. Open the drain valve to remove the w a ter from the sample tube.

3. Close the drain.

4. Pour the 15 PPM calibra tion standard into the well.

OCM Rev. 3.9 (1/03) 12

Page 19

5. Replace the cleanout plug.

6. Press the

will appear on the upper row of the LCD dis play and the word NO w ill appear

on the lower row of the LCD display.

7. This is the final step for calibration at the 15 PPM level; if you wish to exit

without calibrating simply press the

and wish to complete calibration on the 15 PP M level use the

select the word YES on the lower row of the display and then press the

button to initiate calibration.

key to initiate the calibration on 15 PPM w ater. The word CAL

↵↵↵↵

button. However, if you are satisfied

↵↵↵↵

tu arrows to

↵↵↵↵

button will complete calibration. The system w ill automatically

8. Press ing the

return to the AUTO mode

Notes: If you wish to exit the calibration mode you may do so at any time, prior to

initiating a calibration, by simply pressing the MODE key.

It i s no rmal fo r the sy ste m to c ount up to and dis play 13 -17 PPM, in the AU TO

mode, immediately following the 15 PPM calibration as the calibration solution is

still in the s ample tube.

7.2 Zero Adjust (0 ADJ) Calibration

In certain instances, the oil f ree w ater (seaw ater) leaving the bilge has different scattering

characteristics than the clear water used f or calibration. The OCM has been designed to

allow for you to account for this variation by adjusting the zero calibration with your oil

free water. Follow the steps below for this calibration procedur e:

1. Ensure that there is a good flow of oil-free sample to the OCM.

2. Press the MODE key once to enter the zero adjust calibration mode. The “CAL”

block will be illuminated on the display with “0 ADJ” shown on the display (see

OCM Rev. 3.9 (1/03) 13

↵↵↵↵

Page 20

below)

key to initiate the zero adjust calibration on your oil-free sample. The

Press the

word CAL will appear on the upper row of the L CD display and the word NO will

appear on the lower row of the LCD display.

↵↵↵↵

This is the final ste p for calibration f or the zero adjust; if you wish to exit without

calibrating simply press the

complete calibration on the zero adjust use the

on the lower row of the display and then pr e ss the

Both the CAL and STORE blocks will flash during the operation. When the

calibration procedure for the zero adjust is complete the CAL and STORE blocks

will stop flashing. T he program will return you to the automatic measurement mode.

button. However, if you are satisfied and wis h to

↵↵↵↵

arrows to select the word YES

tu

button to initiate calibration.

↵↵↵↵

OCM Rev. 3.9 (1/03) 14

Page 21

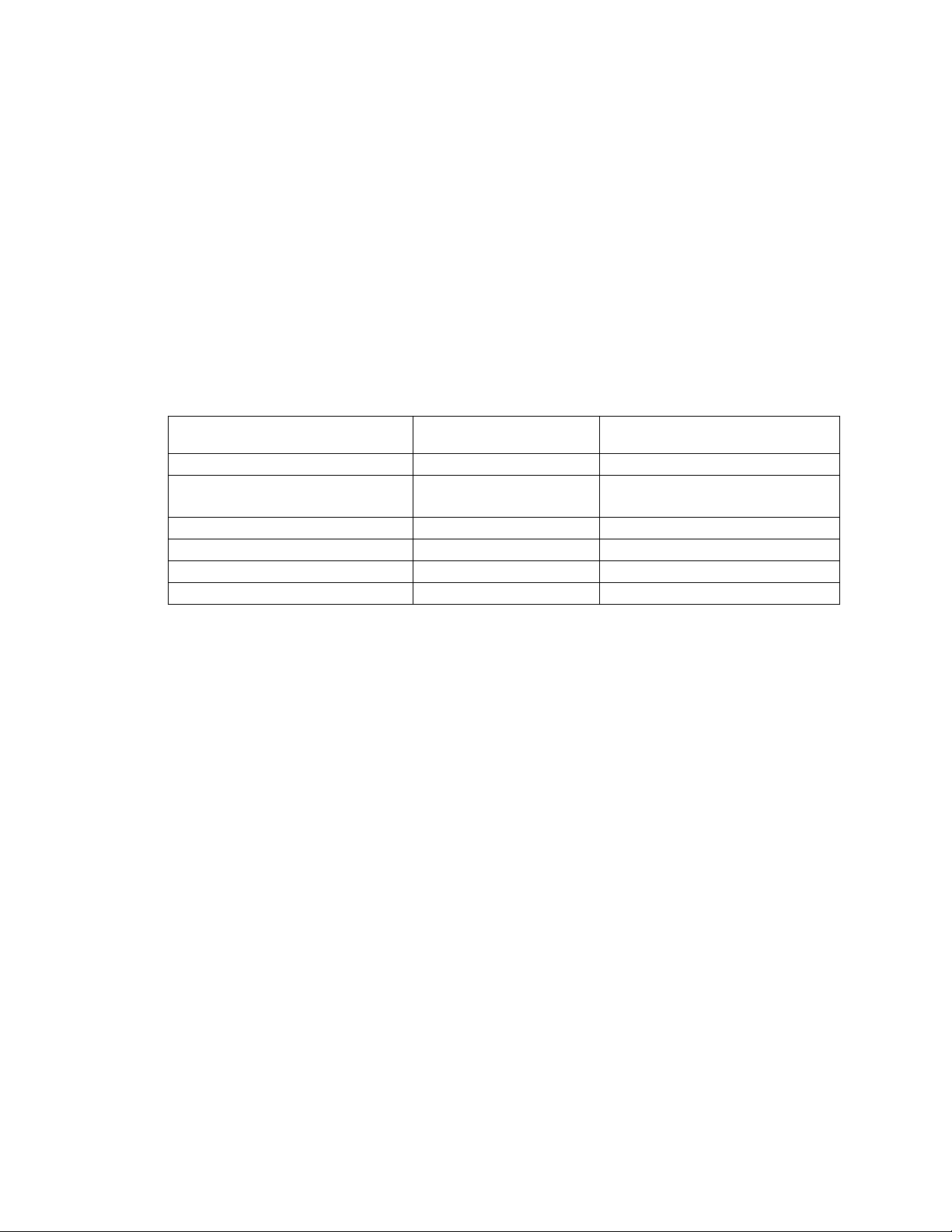

8.0 Self-Diagnostics: System Troubleshooting

8.1 System Warning Message(s)

Automatic warning messages are generated by the OCM to provide you with specific

diagnostic information about the instrument. These are only messages and they do not

indicate failure of any component in the instrument. The following table lists the warning

messages and their associated meanings:

WARNING ASSOCIATED MEANING TYPICAL CAUSE

W01

W02 Calibration Failure

W03 Analog Loop Failure

W05

O-r Sample Over-Range

WNG

Water used for 0 ADJ is too

Multiple Warning conditions

Lamp Failure

cloudy

are met

Lamp has too low an output. The lamp

must be replaced followed by a

calibration.

The wrong standard was used or there

is an internal failure.

The 4-20mA is activated and the loop

is open.

The 0 ADJ water was determined to

be too cloudy for the instrument to

operate properly. Replace water and

calibrate again.

The sample presented to the OCM is

over 50 PPM.

A combination of the above warning

conditions has been met.

If any of the above conditions occurs, the sensor relay will automatically be set to the

alarm position.

8.2 S yst em F ailu re Error

The instrument is indic ating an error when “SFE ” is displayed on the lower row of the

display. This is a gene ral system failure. W hen this message is obse rved, contact the HF

scientific, inc. Technical S ervices department to determine a resolution to the problem.

If any of the above conditions occurs, the sensor relay will automatically be set to the

alarm position.

OCM Rev. 3.9 (1/03) 15

Page 22

9.0 Routine Maintenance

9.1 Cleaning the Optical Chamber (Sample Tube)

Proper me asurement of the oil content of sam ple water requires that the sa mple tube be

free of debris. Cleaning the sample tube is accomplished by first purging the system:

1. Stop the flow of sample water to the OCM.

2. Run oil free water for several minutes through the instrument and then shut off the

flow to the instrument (ensure that the sample tube re mains full with clean water).

3. Remove the cleanout plug and then clean the interior of the sample with the brush

provided. If necessary, you may use any common non-abrasive detergent to help in

the removal of a ny residual buildup on the sample tube .

4. Empty the sample cham ber to drain and then r e-attach the flow of sam ple water to the

OCM.

Once cleaned, the OCM can be put back into operation.

9.2 Replacing the Desiccant Cartridge

Proper use of the supplied desiccant cartridge is essential in maintaining the performance

of the instrument. The desiccant cartridge has been designed to have a long life. The

desiccant cartridge should be replaced when the color of the desiccant (as viewed through

the sight glass) has turned pink.

To remove the old desiccant cartridge, simply unscrew the cartridge from the front of the

case by rotating the cartridge counter-clockwise (see Figure 6). Once removed, place the

new cartridge into the instrument with the reverse movements. Then continue using the

instrument as normally instructed.

9.3 Replacing the Source Lamp

Periodically the source lamp will require replacement. Please note that a failed lamp will

indicate a W01 on the LCD screen.

To replace the lamp:

Note: Refer to Figure 7 when following these steps.

1. Open the sensor portion of the OCM by unscrewing the four sensor cover screws.

These screws should remain captive in the sensor cover even when fully loosened.

2. Pull the electronics module out enough to reach the lamp setscrew on the optic ring. If

you pull the module out too far, simply realign the board with the marked slots and

push back in.

3. Use a .050” Allen wrench to loosen the lamp setscrew on the right side of the large

optic ring. Do NOT loosen the setscrew on the lamp collar.

4. Pull the lamp and collar out.

5. Undo the lamp terminal connections by flipping up the terminal block levers.

6. Discard the lamp.

7. Insert the new lamp. Note that the collar controls the alignment of the replacement

lamp. The lamp will only fit in place when the pin of the collar fits into the hole of the

optic ring. Tighten the lamp setscrew.

8. Attach the leads to the terminal block (lamp is not polarity sensitive). Lock the levers

down firmly.

9. Ensure that the lamp is on. Light should be shining into the optic ring.

OCM Rev. 3.9 (1/03) 16

Page 23

10. Push the electronics module back in and tighten the four sensor cover screws.

Please note that the OCM will require a complete calibration as described in sections

6.1.1 and 6.1.2.

10.0 Technical Assistance, Replacement Parts and Warranty Claims

Accessory or Replacement Part HF scientific Part Number

Calibration Kit 19611

White Light Sourc e 19940

Desiccant cartridge

OCM Electronic s and Touch pad 19612

If for any reason you need technica l assistance re ga rding this instrument ple a se do not

hesitate to contact the HF Technical Services Department:

HF scientific, inc.

3170 Metro Parkway

Fort Myers, Florida 33916-7597

Phone: (239) 337-2116 Fax: (239) 332- 7643

Email: info@hfscientif ic.com

19610

OCM Rev. 3.9 (1/03) 17

Page 24

11.0 Warranty

HF scientific, inc., as manufacturer, warrants to the original purchaser of this instrument

that it will be free of defects in material and workmanship, in normal use and service, for

a period of one year from date of delivery to the original purchaser. HF scientific, inc.’s,

obligation under this warranty is limited to replacing, at its factory, the instrument or any

part thereof. Parts, which by their nature normally require periodic replacement,

consistent with normal maintenance, specifically lamps (including the LCD backlight),

calibration standards, desiccant, sensors, are excluded. Also excluded are accessories and

supply type items.

Original purchaser is responsible for return of the instruments, or parts thereof, to HF

scientific, inc.’s factory. This includes all freight charges incurred in shipping to and

from HF scientific, inc.’s factory.

HF scientific, inc. is not responsible for damage to the instrument, or parts thereof,

resulting from misuse, negligence or accident, or defects resulting from repairs,

alterations or installation made by any person or company not authorized by HF

scientific, inc.

HF scientific, inc. assumes no liability for consequential damage of any kind, and the

original purchaser, by placement of any order for the instrument, or parts thereof, shall be

deemed liable for any and all damages incurred by the use or misuse of the instruments,

or parts thereof, by the purchaser, its employees, or others, following receipt thereof.

Carefully inspect this product for shipping damage, if damaged, immediately notify the

shipping company and arrange an on-site inspection. HF scientific, inc. cannot be

responsible for damage in shipment and cannot assist with claims without an on-site

inspection of the damage.

This warranty is given expressly and in lieu of all other warranties, expressed or implied.

Purchaser agrees that there is no warranty on merchantability and that there are no other

warranties, expressed or implied. No agent is authorized to assume for HF scientific, inc.

any liability except as set forth above.

HF scientific, inc.

3170 Metro Parkway

Fort Myers, Florida 33916-7597

Phone: (239) 337-2116

Fax: (239) 332-7643

OCM Rev. 3.9 (1/03) 18

Page 25

12.0 Figures

Figure 1: Mounting Dim e nsions for the instrument [inches (mm)]

OCM Rev. 3.9 (1/03) 19

Page 26

Figure 2: Recomm ended Plumbing for the instrument.

OCM Rev. 3.9 (1/03) 20

Page 27

Figure 3: Electrical connections for the instrument.

OCM Rev. 3.9 (1/03) 21

Page 28

f

(3)

Figure 4: Graphics of the LCD Display. The upper row o

the display is identified as item (1). The lower row of the

display is identified as item (2). Several status indicators are

identified as item (3). Several other indicators are shown as

item (4). Finally, the prompt for the security access code is

shown as item (5).

Figure 5: The LCD Display shown when the security code is to be

entered. The prompt for the security access code is shown as item

(1). The three digits that are modified to the correct access code are

shown as item (2). The code that is to be modified will flash until

you accept the value you select.

(1)

(1)

(5)

(2)

(4)

(2)

OCM Rev. 3.9 (1/03) 22

Page 29

Figure 6: Location and removal of the desiccant cartridge on the instrument.

OCM Rev. 3.9 (1/03) 23

Page 30

Figure 7: Lamp Replacement.

OCM Rev. 3.9 (1/03) 24

Page 31

Figure 8: Menu Flow Chart

OCM Rev. 3.9 (1/03) 25

Page 32

13.0 Approvals

OCM Rev. 3.9 (1/03) 26

Page 33

OCM Rev. 3.9 (1/03) 27

Page 34

OCM Rev. 3.9 (1/03) 28

Page 35

OCM Rev. 3.9 (1/03) 29

Page 36

OCM Rev. 3.9 (1/03) 30

Page 37

OCM Rev. 3.9 (1/03) 31

Loading...

Loading...