Page 1

OPERAOPERA

OPERA

OPERAOPERA

TING & MAINTENTING & MAINTEN

TING & MAINTEN

TING & MAINTENTING & MAINTEN

ANCEANCE

ANCE

ANCEANCE

MANUMANU

MANU

MANUMANU

OIL CONTENT BILGE OIL CONTENT BILGE

OIL CONTENT BILGE

OIL CONTENT BILGE OIL CONTENT BILGE

ALAL

AL

ALAL

ALARMALARM

ALARM

ALARMALARM

Bilge Alarm CATALOG NO. 81099 (02/02)

Rev. 1.3

HF scientific, inc.

3170 Metro Parkway

Ft. Myers, FL 33916-7597

Phone: (239) 337-2116

Fax: (239) 332-7643

Page 2

At Sea SparAt Sea Spar

At Sea Spar

At Sea SparAt Sea Spar

ff

or the HF scientifor the HF scientif

f

or the HF scientif

ff

or the HF scientifor the HF scientif

icic

ic

icic

e Pe P

e P

e Pe P

,,

inc inc

,

inc

,,

inc inc

Qty. Description Cat.!No.

1In!line!calibrator 20098

2 Fuse!Ω !A/120V 50016

arar

ts Kitts Kit

ar

ts Kit

arar

ts Kitts Kit

. Bilg. Bilg

. Bilg

. Bilg. Bilg

Bilge!Alarm!Spare!Parts!Kit!Contents:

e e

AlarAlar

e

Alar

e e

AlarAlar

mm

m

mm

At Sea Spare Parts Kit

Cat. No. 81080

ï!!Clean,!calibrate!and!repair!your!instrument!in

!!!!the!field!or!at!sea

ï!!Avoid!rush!orders! for!spares!while!in!port

The!HF!Bilge! Alarm! Spare!Parts!Kit! contains! the!recommended!spare!parts!needed! for! standard! maintenance!and

repair.!!This!kit! contains! detailed!instructions! designed!to

allow!the!ship's!engineer!to!service!the!instrument!without

a!costly! port!service!call.

Save!40%!over!individually!priced!spare!parts!cost.

2Fuse!º!A / 2 4 0V 50017

1 Light!Detector!Assembly 80995

2 Lamps!for!Recirc./Overboard 81007

1 Photodiode! Assembly 81010

1 Side!Panel!Assembly 81025

1 Power!Supply!Board 81030

1 Amplifier!Board 81033

1 Instruction! Manual 81099

1 Cleaning!brush!for!sensor 81095

1 Rugged!plastic!case 81094

1 Source!Lamp 80996

scientifscientif

scientif

scientifscientif

Bilge Alarm (02/02)

Rev. 1.3

icic

ic

icic

,,

inc inc

,

inc

,,

inc inc

3170 Metro Parkway3170 Metro Parkway

3170 Metro Parkway

3170 Metro Parkway3170 Metro Parkway

Fort Myers, FL 33916-7597Fort Myers, FL 33916-7597

Fort Myers, FL 33916-7597

Fort Myers, FL 33916-7597Fort Myers, FL 33916-7597

Phone: (239) 337-2116Phone: (239) 337-2116

Phone: (239) 337-2116

Phone: (239) 337-2116Phone: (239) 337-2116

Fax: (239) 332-7643Fax: (239) 332-7643

Fax: (239) 332-7643

..

.

..

Fax: (239) 332-7643Fax: (239) 332-7643

Rev 4/98Rev 4/98

Rev 4/98

Rev 4/98Rev 4/98

Page 3

IMPORTANTIMPORTANT

IMPORTANT

IMPORTANTIMPORTANT

Calibration / Cleaning KitCalibration / Cleaning Kit

Calibration / Cleaning Kit

Calibration / Cleaning KitCalibration / Cleaning Kit

Note: This unit has been factory calibrated and should not require further adjustment.

Your Oil Content Bilge Alarm requires a calibration check every 3 - 4 months or anytime either mechanical or electrical

adjustments have been made to the unit.

The calibration procedure is detailed in this instruction manual and requires HF Part # 20098.

This kit should be ordered now so that material is available when calibration is required due to time constraints,This kit should be ordered now so that material is available when calibration is required due to time constraints,

This kit should be ordered now so that material is available when calibration is required due to time constraints,

This kit should be ordered now so that material is available when calibration is required due to time constraints,This kit should be ordered now so that material is available when calibration is required due to time constraints,

equipment adjustment or compliance agency request.equipment adjustment or compliance agency request.

equipment adjustment or compliance agency request.

equipment adjustment or compliance agency request.equipment adjustment or compliance agency request.

Please complete and mail to HF scientific, inc. 3170 Metro Parkway, Ft. Myers, Florida, U.S.A. 33916-7597.

PURCHASE ORDER FORMPURCHASE ORDER FORM

PURCHASE ORDER FORM

PURCHASE ORDER FORMPURCHASE ORDER FORM

Ship to: Bill to:

P.O. Number (if required):

Name:

Phone:

Qty. Description Cat. No. Price (each)

1 Oil Content Bilge Alarm Calibrator Kit & 20098 $230.00

Cleaning Brush

Bilge Alarm (02/02)

Rev. 1.3

Page 4

CONTENTSCONTENTS

CONTENTS

CONTENTSCONTENTS

PAGE

I. SPECIFICATIONS .................................................................................................................................1

II. WARNING NOTICE ..............................................................................................................................2

III. OPERATION...........................................................................................................................................2

IV. INSTALLATION ....................................................................................................................................2

V. ALARM CONNECTIONS .....................................................................................................................2

VI. START-UP ..............................................................................................................................................3

VII. CALIBRATION ......................................................................................................................................3

VIII. CALIBRATION CHECK .......................................................................................................................3

IX. ISOLATION VALVES ...........................................................................................................................4

X. SETTING ALARM LEVEL...................................................................................................................4

XI. INDICATING LAMPS ...........................................................................................................................4

XII. CLEANING SENSING MODULE WINDOWS ...................................................................................4

XIII. REPLACING SOURCE LAMP .............................................................................................................4

XIV. REPLACING SENSING MODULE MEASUREMENT DETECTOR ...............................................5

XV. REPLACING SENSING MODULE FAILSAFE LIGHT DETECTOR ..............................................5

XVI. TROUBLE SHOOTING GUIDE ...........................................................................................................6

XVII. TEST PROCEDURES FOR POWER SUPPLY BOARD ....................................................................7

XVIII. SPARE PARTS .......................................................................................................................................8

XIX. WARRANTY ..........................................................................................................................................10

LIST OF FIGURESLIST OF FIGURES

LIST OF FIGURES

LIST OF FIGURESLIST OF FIGURES

1 SYSTEM INSTALLATION DIAGRAM ..............................................................................................11

2 SENSOR INSTALLATION DIAGRAM...............................................................................................12

3 WIRING DIAGRAM ..............................................................................................................................13

4 INTERCONNECT WIRING ..................................................................................................................14

5 LOCATION OF PARTS .........................................................................................................................15

6 LOCATION OF PARTS .........................................................................................................................16

7 SENSOR CONNECTIONS ....................................................................................................................17

8 CONTROL MODULE OUTLINE .........................................................................................................18

9 SENSING MODULE OUTLINE ...........................................................................................................19

10 DISPLAY BOARD SCHEMATIC ........................................................................................................20

11 POWER SUPPLY SCHEMATIC ..........................................................................................................21

12 AMPLIFIER BOARD SCHEMATIC ....................................................................................................22

Bilge Alarm (02/02)

Rev. 1.3

Page 5

I. SPECIFICATIONS

Range 0 - 100 PPM

Outputs Recorder Output: 0-10 V.D.C., minimum impedance 500 ohms.

Digital display: 2 1/2 digit. Display Readings & Alarm Set Point.

Relay: Contacts rated at 5 amps. 120VAC, 28Vdc for Resistive Load.

Activates upon:

1.High alarm.

2.Light Source Burn Out.

3.Fouled windows.

Normal Operation: Fail safe; loss of power causes alarm.

Calibration check Check switch

Operating Conditions Power: 120/240 Volts

Protection: Fused primary

Temperature: 0-50 degrees C (122 degrees F.) (NOTE: When ambient

temperatures drop below 0 degrees C. (32 degrees F.), (Sensing Module must

be drained).

Humidity: To 95%

Vibration: - From 2Hz to 13.2 Hz + 1mm amplitude.

Rolling Angle: 0-22.5 degrees

Critical Measurement Response Time:

Display - 5 seconds or less.

Alarm - 16 seconds or less

Measured Flow Rate: 40 g.p.m. maximum.

Measured Pressure Range: 0-60 p.s.i.

Sensing Module Weight: 6 lbs., 11 oz. (3.03 kg)

Threads: 1" N.P.T. pipe (customer supplied).

Dimensions: (Refer to Figure 9)

Construction Materials: Body - Cast aluminum, neoprene O-Ring seals,

Borosilicate pressure windows.

Interconnecting Cable 7 Conductor, shielded. Rated 80 degrees C., 300V. U.L. listed/CSA Certified.

15 ft. supplied.

Indicating/Control Module Weight: 19 lbs. (8.62 kg)

Dimensions: (Refer to Figure 8) Electronic components are mounted in an oil

tight J.I.C. Enclosure with holes for 1/2" conduit.

+ 10%, 50/60 Hz

- From 13.2 Hz to 80 Hz with acceleration to .7G.

Amplifier P.C. Board has a plug-in connector and is fastened to the chassis for rigidity. It includes trim pots and Alarm

Set and Calibration switches (Refer to Item A, Figure 5).

Power Supply P.C. Board includes test points, a plug-in connector, and is also fastened to the chassis (Refer to Item

C, Figure 5).

Bilge Alarm (02/02)

Rev. 1.3

Page 1

Page 6

II. WARNING

The Sensing Module and the Indicating/Control Module

are shipped with the Interconnecting Cable connected

for reasons of convenience; however, electrical

installation including routing of the Interconnecting

Cable, power connections, calibration and servicing

should only be done by qualified electricians and in

accordance with applicable codes and regulations.

Caution should be exercised when working on

components inside the Indicating/Control Module while

power is on. Coming in contact with live components

may cause electrical shock or damage to equipment.

If there is a possibility of voltage spikes or power surges

to the instrument’s power supply module, an approved

line suppressor is recommended.

III. OPERATION

Cleaned water from oily-water filtering equipment is

continuously monitored.

separators must incorporate a suspended particle

filter. ”

Piping for the Sensing Module is arranged in the outlet

line of the Oily-Water Filtering Equipment. Cleaned

bilge water, up to 60 psi, flows through the module past

optical windows where the measurement is made. A

pre-focused incandescent light source provides a light

beam which passes through the bilge water. A detector,

placed at a 90° angle to the incident light beam, measures

light scattered by the dispersed oil in the bilge water. An

electrical output from the detector is transmitted through

a cable to the Indicating/Control Module where it is

processed. The measurement is displayed on the panel

in “PPM”.

The digital display on the front panel shows 2 1/2 digits

and can indicate readings up to 100 PPM accurately.

Readings over 100 PPM are not reliable. An “ON/OFF”

switch, for providing power to the Bilge Alarm, is also

located on the panel.

IV. INSTALLATION

The Bilge Alarm measures and displays the

concentration level of dispersed oil in the flowing

stream of cleaned water. The instrument consists of a

Sensing module and an Indicating/Control module. Oil

content of the cleaned bilge is continuously shown on

the Indicating/Control module’s digital display. An

adjustable alarm set-point function, used to set the

allowable oil concentration level, is located inside the

Indicating/Control module. When the Sensing Module

determines that the oil level exceeds the setpoint value,

for longer than 15 seconds, a relay operates the lights on

the display panel of the Indicating/Control Module.

Green for “OVERBOARD” changes to red for

“RECIRCULATE”. Simultaneously two sets of relay

contacts activate independent alarm circuits. When the

oil level in the effluent water is once more below the

set-point value, the green lamp for “OVERBOARD”

will glow and the red lamp for “RECIRCULATE” will

shut off. The relay contacts will also deactivate. The

above performance is contingent upon and consistent

with the recommendations stated in the IMO

Recommendations for Performance and Test

Specifications for Oil Content Meters:

“Non foaming detergents should not be used in the

bilges for cleaning purposes, as the emulsifying

effects of some compounds seriously affect the

operation of the equipment. Non soluble suspended

solids can give false high readings. The oil water

Install the Sensing Module using 1" piping after the

Oily-Water Filtering Equipment.

To permit use of the Bilge Alarm Calibration Kit, as

well as a laboratory cleaning brush to clean the windows

by brushing through when required, connect piping as

shown in Figure #2. Sensor must be mounted vertically

as shown in Figure 2, page 12, to allow the use of

calibration kit Part No. 20098.

Piping should be in accordance with 46 C.F.R.

56.01-IOD (U.S.Coast Guard).

Connect Sensing Module to Indicating Control Module,

as per Figures #3, #4, #7. Seal the cable entrance to the

Sensing Module against the penetration of water vapor.

Connect Power Source through fused switch to

Terminals #6 and #7, in the Indicating/Control Module

per Figures #3 and #4. Connect ground to Terminal #E9

per Figures #3 and #6. Selection of 115 volt or 230 volt

operation can be made with the switch in the Indicating/

Control Module as shown in Figure #6, Item A. Use two

1/2 Amp fuse only for 120V; use two 1/4 Amp fuse for

240V.

NOTE: Change both fuses for either mode of operation.

V. ALARM CONNECTIONS

Contacts for the Alarm Relay are located in the Indicating/

Control Module. These are “Dry” contacts with ratings

Bilge Alarm (02/02)

Rev. 1.3

Page 2

Page 7

of 5 amps at 120VAC or 28 VDC resistive.

There are two sets of contacts which may be used to

operate valves, sound alarms, etc. These are wired as

follows refer to Figure #3 and #4. Note that the relay is

de-energized in the Alarm condition.

across terminals 10 (neg.) and 11 (pos.) in the

Indicating/Control Module, (Refer to Figure

#4).

EXAMPLES:

TB3 Set #1 Terminal #17 - Closed in the Alarm

Condition

Terminal #18 - Common

Terminal #19 - Open in the Alarm

Condition

TB3 Set #2 Terminal #20 - Closed in the Alarm

Condition

Terminal #21 - Common

Terminal #22 - Open in the Alarm

Condition

VI. START-UP

1. Turn on the Power Switch located on the Indicating/

Control Module.

2. Allow the instrument to warm-up for

approximately 30 minutes for stabilization. It is

recommended that the power to the instrument be

left on continuously except when servicing is

required.

3. Run clean oil-free water through the Sensing

Module.

4. Adjust the Zero Pot in the Indicating/Control

Module (Item B, Figure #6) to cause Digital

Display to indicate 00 PPM. NOTE: Negative

readings on the Digital Display are indicated by a

negative sign lighting up to the left of the Display

Digits. When making adjustments do not

over-adjust to negative values.

VII. CALIBRATION

The instrument has been factory calibrated in PPM.

However, if it is desired to check calibration, the

following procedure should be followed:

1. Run clean oil-free water through the Sensing

Module and adjust “Zero” control.

2. Using an In-Line Calibration Holder, HF Part

No. 20098, place a suitable calibration standard,

equivalent to a known value of oil in water, in the

Sensor.

3. When conditions have stabilized, observe

Recorder Output reading; it should read 10 Volts

DC for 100 PPM and any proportional linear

value between zero and 10 volts for lower values

(see example below). Recorder output is obtained

PPM (Oil in Water) Recorder Output Reading

100 PPM 10 Volts

15 PPM 1.5 Volts

4. Calibrate the Recorder Output to correct value

by adjusting the Trim Pot marked REC on the

Amplifier P.C. Board, (Refer to Item D, Figure

#5).

5. Adjust the Trim Pot marked DVM, on the same

P.C. Board, to cause the Digital Display to read

the correct value in PPM.

NOTE: 1. Whenever the value of the oil free water

changes, it can be “Calibrated Out” by simply

running a sample of the oil free water through the

Sensing Module and adjusting the “ZERO” Pot

in the Indicating/Control Module (Item B, Figure

#6) to obtain a reading of “00” on the Digital

Display.

2. Calibration should be checked after

components have been replaced, i.e., P.C. Board,

or Lamp, etc.

3. Whenever the instrument is re-calibrated a

new “Cal Check” number should be obtained

and recorded. See “Calibration Check” and follow

steps 1 through 4.

VIII. CALIBRATION CHECK

This is a procedure used to check that the electronic

function is still within the limits set by the Calibration

Check Number.

1. Open the Indicating/Control Module.

2. Activate the CAL Check Switch (Item F, Figure

5, Spring Return) and note reading.

3. With the Cal Check Switch returned to its normal

position and note reading.

4. Subtract the reading obtained in Step #3 above

from that obtained in Step #2.

5. Compare the value obtained, which is the current

Cal Check value, to the Cal Check number

supplied with the instrument, which is affixed to

the Indicating/Control Module Chassis. Should

this current value vary by more than three (3)

units from the original value, then the instrument

should be re-calibrated.

Bilge Alarm (02/02)

Rev. 1.3

Page 3

Page 8

IX. ISOLATION VALVES

6) even though the water appears clean, or when the

display shows a PPM count less that the true value.

Isolation valves should be operated to shut-off flow from

the Oily-Water Filter under each of the following

conditions:

- Conducting service on the Sensing Module.

- Calibration

- Replacement of Sensing Module

Otherwise always ensure that the valves are positioned to

provide flow to the Sensing Module.

X. SETTING ALARM LEVEL

Activate “Alarm Set” switch on the Amplifier P.C. Board

in the Indicating/Control Module (Item E, Figure 5).

While holding the “Alarm Set” switch “On” (spring

return) the Digital Display will read the Alarm Set Value.

Adjust the “Alarm” Trim Pot (Item G, Figure 5) while

holding the Switch “On”, to cause the Digital Display to

read desired Alarm Level. Release the “Alarm Set” Switch.

The Alarm Relay will activate 15 seconds after the PPM

Oil-in-Water content has constantly exceeded the Alarm

Set value.

XI. INDICATING LAMPS

Green light is ON, Red light is OFF, whenever Unit is

operating under Normal Conditions.

Red Light is ON and Green Light is OFF, during Alarm

Conditions.

The reading must remain over the alarm set value for 15

seconds to activate the alarm relay.

XII. CLEANING THE SENSING MODULE WINDOWS

The Sensing Module through which the fluid flows and in

which a light beam is projected to measure oil content in

the effluent contains three precision glass windows.

One indication that these windows may require cleaning

is when the system enters the recirculation mode and

remains in this mode even though a sample of the effluent

from the Oily-Water Filter appears clean.

A periodic cleaning routine should be established to

preclude the system from remaining in the recirculation

mode because of a fouled flow channel. The frequency of

the cleaning operation should be determined on the basis

of the type of fluids being processed and how often the

flow channel becomes contaminated during initial system

use. Procedure for cleaning is as follows:

1. Turn off the flow to the Sensing Module.

2. Remove the clean-out plugs shown in Figure 2.

3. Use a mild detergent on a laboratory cleaning brush

and pass the brush through the Sensing Module

flow channel several times. Then rinse with clean

water.

4. Replace the clean-out plugs.

5. Resume normal flow.

XIII. REPLACING SOURCE LAMP ASSEMBLY

The Source Lamp in the Sensing Module may burn out

occasionally and require replacement. This failure will

cause the Bilge Alarm to go into an Alarm Condition

(Refer to Figure 7).

1. Turn OFF the Power Switch at the Indicating/

Control Module.

2. Remove the four screws in Sensing Module End

Cap and remove the Sensing Module End Cap.

3. Unscrew all lug connections except at positions #1

and #2. Save all the screws as they will be needed

later.

4. Cut the shield wire for Failsafe Light Detector at

position #2.

5. Remove screws #8 & #9 and remove the Source

Lamp Assembly.

6. Replace source lamp assembly with new unit.

Check that orientation is correct, then reinstall

screws #8 & #9.

7. Replace all lug connections at the correct positions.

8. Solder shield wire for Failsafe Light Detector to

solder lug at position #2.

9. Replace Sensing Module End Cap and fasten four

screws.

10. Turn Power Switch ON at Indicating/Control

Module.

11. This completes the Source Lamp Assembly

replacement. Proceed to Section VII (Calibration)

and perform calibration as described.

Cleaning may also be required when oil-free water requires

considerable adjustment on the Zero Pot (Item B, Figure

Bilge Alarm (02/02)

Rev. 1.3

Page 4

Page 9

XIV. REPLACING SENSING MODULE

MEASUREMENT DETECTOR (Refer to Figure 7)

1. Turn OFF the Power Switch at the Indicating/

Control Module

2. Remove the four screws in Sensing Module End

Cap and remove the Sensing Module End Cap.

3. Cut wires at positions #5, #6, and #7.

4. Remove the brass Measurement Detector Cap,

located on the side of the sensor.

5. Remove the Measurement Detector Spacer.

6. Remove the Measurement Detector Assembly

including wires cut in step #3 above.

7. Install the replacement Measurement Detector

Assembly by feeding the wire of the assembly

though hole.

8. Carefully seat Measurement Detector in position.

9. Replace Light Detector Spacer and brass cap.

10. Solder three wires attached to Measurement

Detector to lugs on position #5, #6 & 7 (black wire

to #5, shield wire to #6 and red wire to #7).

11. Replace Sensing Module End Cap.

12. Turn ON the Power Switch at the Indicating/Control

Module and ensure that the Bilge Alarm is

responding correctly to changes in oil concentration.

13. This completes the Measurement Detector

replacement. Proceed to Section VII (Calibration)

and perform calibration as described.

8. Place replacement Light Detector Assembly and

Spacer in position and replace the Light Detector

Cap with the four screws previously removed.

9. Solder three wires attached to Light Detector

Assembly to lugs on positions #2, #3, and #4,

(shield wire to #2, black wire to #3, and red wire to

#4).

10. Replace the Sensing Module End Cap and Light

Detector Cap.

11. Turn ON the Power Switch at the Indicating/

Control Module and ensure that the Bilge Alarm is

in the normal condition with clean water in the

Sensing Module. Insert opaque object in Sensing

Module Flow channel to block light to Light

Detector to ensure that the Bilge Alarm goes into

the Alarm Condition.

12. This completes the Failsafe Light Detector

replacement procedure.

XV. REPLACING SENSING MODULE FAILSAFE

LIGHT DETECTOR (refer to Figure 7)

NOTE: The Light Detector is a failsafe feature which

draws attention to lamp burn-out or opaque

obstruction conditions and will not normally need

replacement during the life of the instrument).

1. Turn OFF the Power Switch at the Indicating/

Control Module.

2. Remove the four screws in Sensing Module End

Cap and remove the Sensing Module End Cap.

3. Cut the black and red wires at positions #3 and #4

and shield wire at position #2.

4. Remove the four screws in Light Detector Cap

located on opposite end of the Sensing Module and

remove Cap.

5. Remove Light Detector Spacer.

6. Remove Light Detector Assembly including wires

cut in #3 above.

7. Feed the three wires on the replacement Light

Detector Assembly through to positions #2, #3, and

#4.

Bilge Alarm (02/02)

Rev. 1.3

Page 5

Page 10

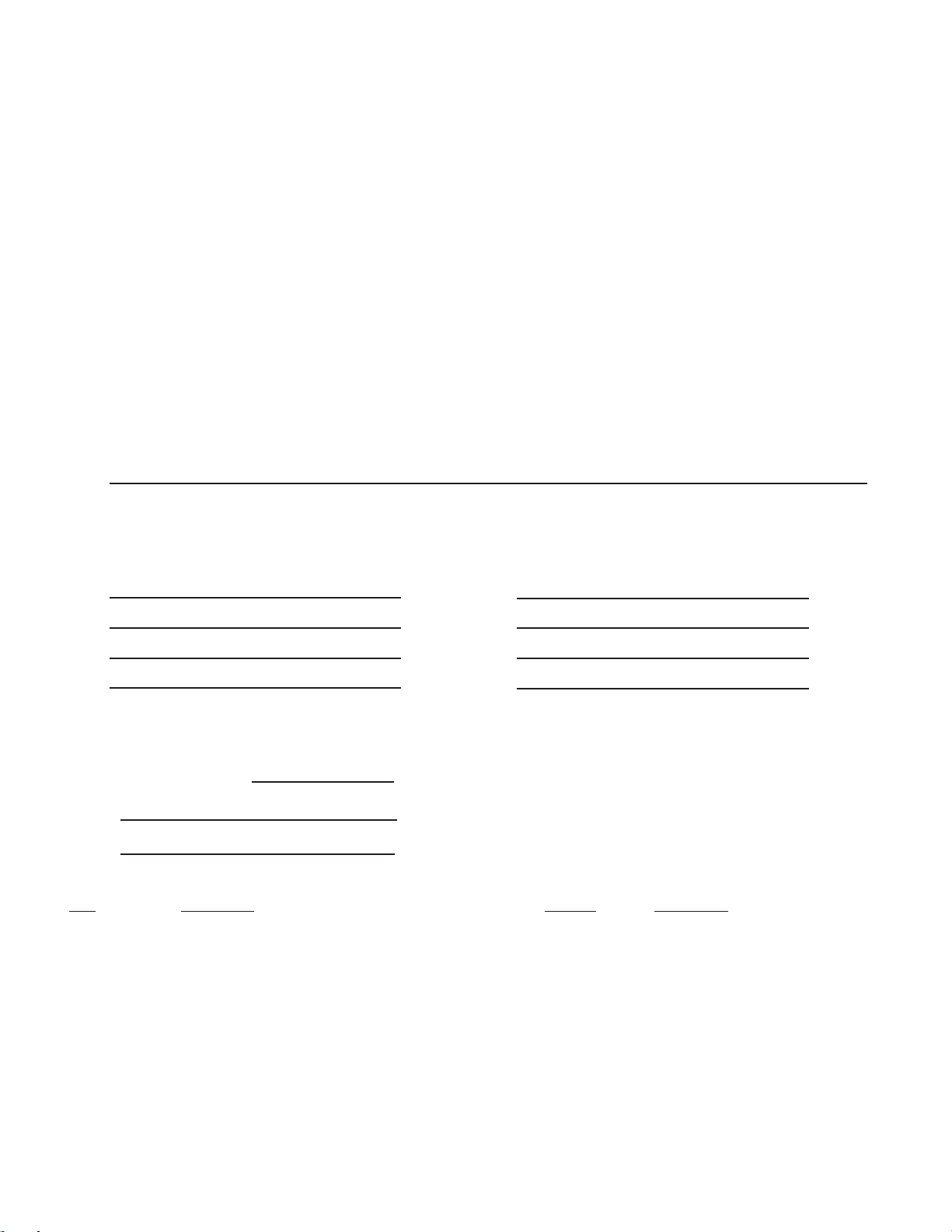

XVI. TROUBLE-SHOOTING GUIDE

SYMPTOMS PROBABLE CAUSE CORRECTIVE ACTION

Digital Display and/or indicating

lights do not light up.

Unit stays in recirculation mode when

reading is below alarm set point.

Digital display does not change with

changing concentration of oil.

1. No power to Indicating/Control

Module.

2. Blown fuses.

3. Defective power supply board.

4. Indicating lamp loose or burned

out.

1. Sensing Module Source Lamp

burned out.

2. Defective Failsafe Light Detector.

3. Alarm Relay Defective.

4. Defective Power Supply Board.

5. Opaque Obstruction in flow

channel.

1. Defective Amplifier Board.

2. Defective Digital Display.

3. Open leads from sensor.

4. Defective Measurement Detector

Sensing Module.

1. Turn on power switch. Check

facility input power source.

2. Replace fuses.

3. Test power supply board as

outlined under Test Procedures

and replace if defective.

4. Insert lamps properly or replace.

1. Replace Source Lamp. Re-check

calibration.

2. Replace Failsafe Light Detector.

3. Replace relay.

4. Test Power supply board as

outlined under Test Procedures

and replace if defective.

5. Clean sensing module windows

with detergent and a brush.

1. Replace amplifier board (Item

A, Figure 4) and re-calibrate.

2. Replace complete Front Panel

Assembly containing Digital

Display Indicating Lights, etc.

3. Inspect Leads and connecting

wiring for breaks.

4. Replace measurement detector.

Digital display shows negative but

Alarm and Recirculate light is on.

Bilge Alarm (02/02)

Rev. 1.3

1. Sensing Module Source Lamp

Defective.

2. Defective Amplifier PC Board.

3. Defective Digital Display.

4. Fouled windows in flow channel.

Page 6

1. Replace Source Lamp in Sensing

Module.

2. Replace amplifier PC board (Item

A, Figure 5) and recalibrate.

3. Replace complete Front Panel

Assembly.

4. Clean Sensing Module Windows

with detergent and a brush.

Page 11

XVI. TROUBLE-SHOOTING GUIDE (cont.)

SYMPTOMS PROBABLE CAUSE CORRECTIVE ACTION

Readout shows negative.

When oil concentration as indicated

by the digital Display, goes above

Alarm Set Point, Controls stays in

“Overboard” condition and does not

change to “Recirculate.”

“Cal Check” reading too high (see

“Calibration Check”).

1. Cleaner oil free water.

2. Defective amplifier PC board.

3. Defective Digital Display.

1. Defective Alarm Relay.

2. Defective Amplifier Board.

3. Defective Failsafe Light Detector.

1. Dirty Sensing Module Source

Lamp.

2. Defective Sensing Module

Source Lamp.

3. Defective Measurement Detector

in Sensing Module.

1. Adjust zero. See “Start-up.”

2. Replace amplifier PC Board

(Item A, Figure 5) and recalibrate.

3. Replace complete Front Panel

Assembly.

1. Replace Relay.

2. Replace Amplifier PC Board

(Item A, Figure 5) and recalibrate.

3. Replace complete Front Panel

Assembly.

1. Clean Sensing Module

windows.

2. Check Sensing Module

Source Lamp and replace if

necessary.

3. Replace Measurement

Detector.

XVII. TEST PROCEDURES FOR POWER SUPPLY BOARD (LOWER PC BOARD IN Figure 3)

1. Turn Power OFF.

2. Remove Amplifier P.C. Board (Item A, Figure 5).

3. Unplug the Front Panel Harness Plug from the Socket, Item B, Figure 5.

4. Unplug the voltage plug from the socket, Item C, Figure 6.

5. Plug into socket (Item H, Figure 5) the Dummy Test Plug (Part #80276, supplied with instrument).

6. Turn Power ON.

7. Using a D.C. Volt Meter measure the voltages at the test points, i.e. between common (com) and each test point

on Power Supply Board. They should be within + 10% of value indicated and they should be stable.

8. If the voltages are not as indicated on every test point then replace Power Supply Board.

9. After testing and replacing Power Supply Board, if required, then turn Power OFF.

10. Remove Dummy Test Plug and reinstall Amplifier P.C. Board and replace Front Panel Harness Plug in socket Item

C, Figure 6.

11. Reinstall the voltage plug into the voltage socket.

12. Turn Power ON.

Bilge Alarm (02/02)

Rev. 1.3

Page 7

Page 12

XVIII. SPARE PARTS

RECORD

R6

C1

C2

+

+

1

D.V.M.

R7

C7

32 4 5 6

80101

ALARM

R8

Q1

SW1

R10

R1

+

R9

R2

C3

R4

C4

+

U3U1

C6

REC ALM

879 1011

SW2

C9

U6

C5

U5

U4

U2

R3

80103

12

13 1415

COM

1

+2.5

+5-5+15-15

ASSY 81030

+24

22

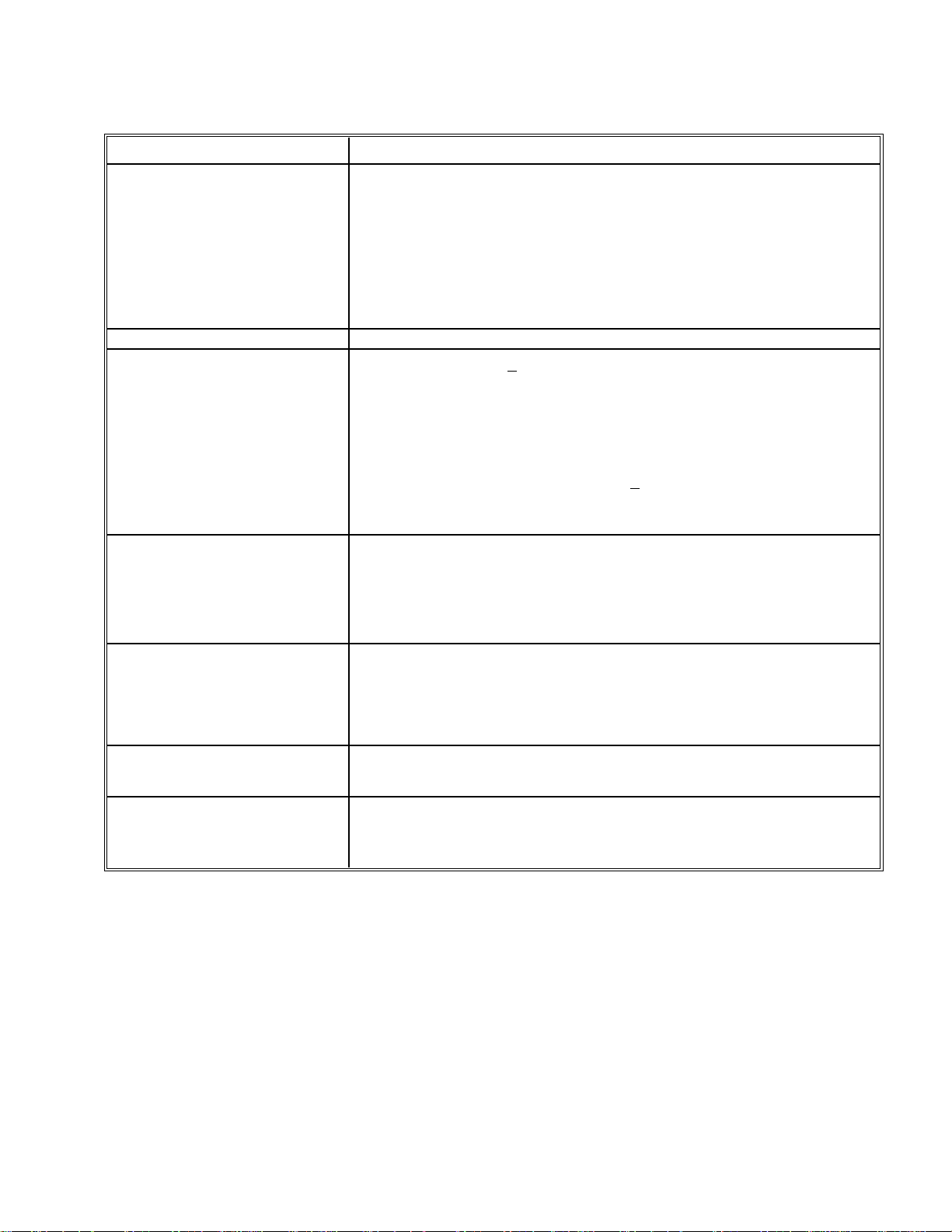

Amplifier P.C. Board Assembly

Catalog No. 81033

Qty. 1

SCIENTIFIC, INC.

OIL CONTENT IN PPM

BA-1

MA-1

BA-100

OIL CONTENT

BILGE ALARM

Mfg. in U.S.A.

U.S.C.G. APPROVAL

NO. 162.050/3009/1

OVERBOARD

RECIRCULATE

ON

OFF

POWER

Control Panel Complete w/Digital Display Lamps and

Switch

Catalog No. 81025

Qty. 1

Power Supply P.C. Board Assembly

Catalog No. 81030

Qty1

LAMP

U

U

U

U

U

SHLD

Vo

Vcc

Source Lamp Assembly

Catalog No. 80996

Qty. 1

Bulbs for Recirculate and Overboard Lamps

Catalog No. 81007

Qty. 2

Bilge Alarm (02/02)

Rev. 1.3

Fuses, 1/2 Amp. SLO-BLO (110V) Catalog No.

50016

Qty. 2

Fuses, 1/4 Amp. SLO-BLO (220V) Catalog No. 50017

Qty. 2

(Pictures not available)

Page 8

Page 13

XVIII. SPARE PARTS (Cont'd)

Relay

Catalog No. 80134

Qty. 1

In-Line Calibrator Kit & Cleaning Brush

Catalog No. 20098

(Optional)

Qty. 1

Photo Diode Assembly

Catalog No. 81010

Qty. 1

Failsafe Light Detector

Catalog No. 80995

Qty. 1

Bilge Alarm Spare Parts Kit

(See literature at front of manual)

Catalog No. 81080

Bilge Alarm (02/02)

Rev. 1.3

(Optional)

Qty. 1

ORDER FROM:

HF scientific, inc.

3170 Metro Parkway

Fort Myers, Florida 33916-7597

Phone: (239) 337-2116

Fax: (239) 332-7643

Page 9

Page 14

XIX. WARRANTY

HF scientific, inc., as vendor, warrants to the original purchaser of the instruments to be free of defects in material and

workmanship, in normal use and service, for a period of one year from date of delivery to the original purchaser. HF scientific,

inc.’s, obligation under this warranty is limited to replacing, at its factory, the instrument or any part thereof. Parts which by

their nature are normally required to be replaced periodically, consistent with normal maintenance, specifically lamps

including fluorescent backlight, reagent, sensors, desiccant, electrodes, and fuses are excluded. Also excluded are accessories

and supply type items.

Original purchaser is responsible for return of the instruments, or parts thereof, to HF scientific, inc.’s factory. This

includes all freight charges incurred in shipping to and from HF scientific, inc.’s factory.

HF scientific, inc. is not responsible for damage to the instrument, or parts thereof, resulting from misuse, negligence or

accident, or defects resulting from repairs, alterations or installation made by any person or company not authorized by HF

scientific, inc.

HF scientific, inc. assumes no liability for consequential damage of any kind, and the original purchaser, by placement

of any order for the instrument, or parts thereof, shall be deemed liable for any and all damages incurred by the use or misuse

of the instruments, or parts thereof, by the purchaser, its employees, or others, following receipt thereof.

Carefully inspect this product for shipping damage, if damaged, immediately notify the shipping company and arrange

an on-site inspection. HF scientific, inc. cannot be responsible for damage in shipment and cannot assist with claims without

an on-site inspection of the damage.

This warranty is given expressly and in lieu of all other warranties, expressed or implied. Purchaser agrees that there is

no warranty on merchantability and that there are no other warranties, expressed or implied. No agent is authorized to assume

for HF scientific, inc. any liability except as above set forth.

HF scientific, inc.

3170 Metro Parkway

Fort Myers, Florida 33916-7597

Phone: (239) 337-2116

Fax: (239) 332-7643

Bilge Alarm (02/02)

Rev. 1.3

Page 10

Page 15

System Installation Diagram

Figure 1

Bilge Alarm (02/02)

Rev. 1.3

Page 11

Page 16

Bilge Alarm (02/02)

Rev. 1.3

Sensor Installation Diagram

Figure 2

Page 12

Page 17

U

WHT

4

3

RECIRCULATE

V/BLK

DIGITAL MODULE 81020

OVERBOARD

V/BLK

GRN

7

2

8

9

3

4

JP6

-5V

+5V

COM.

COM.

22

21

2011

CONT.

+12V

1918

+24V

Vc

1615

Vcc

J3

POWER SUPPLY MODULE 81030

+2.5V

+5V

10

9

-5V

87

+15V

~

-15V

65

COM.

~

T1

4

T1

3

T1

21

T1

BLK

POWER

1

2

GRN/WHT/BLK

WHT

BLK

6

1

1

4

3

WHT

WHT WHT

JP1

BLK

96

328

74

1

JP5

4

SW-2

BLK

CR1

K1

98765

11

9

J2

7

6

-15V

5

3

2

AMPLIFIER MODULE 81033

1

+15V

+15V

COM.

E1

E2

E3

-15V

ARC

RC3

SUPPRESSORS

EACH NETWORK

600VDC/250VAC

470 OHM, 0.1MFD

INDICATOR PANEL

1.0A

%8)+

0.5A

!"8)+

1.5A

"8)+

1

10

RC4

SENSOR

REMOTE

RED

BLACK

ORANGE

YELLOW

LAMP

-

+

Vc

IN THE ALARM CONDITION.

MAL OPERATION AND DE-ENERGIZED

RELAY IS ENERGIZED DURING NOR-

CONDITION.

*RELAY IS SHOWN IN DE-ENERGIZED

WHT/RED

#8)+#8)+

CT

CT

WHT

BLK

U

115V230V

2

1

3

4

5

6

SW1

BLK/RED

Vcc

-

+

GREEN

BROWN

WHITE

SHIELD SENSOR GND.

T1

COM.

TB2TB1

16

CONT.

+12V

ALARM RELAY

J2-1

J2-9

+12V

230v 1/4A

FUSES: 115v 1/2A

11

13

12

F

u

.01

C1

F1

24

23

K1-10

22

K1-9

2120

K1-8

K1-7

19

K1-6

18

K1-5

17

15

14

13

1211

+2.5V

10

0-10V

F2

Fu

.01 C3

- +

REC. OUT

9

.01 u F

GND.

E9

C2

EARTH

8

76

LINE

115/230V

TB3

RC2

RC1

Bilge Alarm (02/02)

Rev. 1.3

10K

ZERO

ADJUST

10 TURN

Wiring Diagram

Figure 3

Page 13

Page 18

LINE

115/220

VAC

CONTROL CIRCUIT

TO

120/240VAC

1

4

3-32VDC

17

18

TB3

GREEN

WHITE

BLACK

TB1

6

POTTER & BRUMFIELD

10 AMP

ZERO CROSSING

2

SOLID STATE RELAY

SSRT-240D10

+

3

(OPTIONAL)

22

20

21

23

19

E9

EARTH

8

7

GROUND

24

NOTES:

(1) RELAY CONTACTS AT TB3

17 & 18 AND TB3-20 &21

ARE CLOSED IN THE RECIR CULATE MODE. RELAY CON TACTS AT TB3-18&19, AND

TB3-21&22 ARE CLOSED IN

THE OVERBOARD MODE.

(2) INTERCONNECT CABLE IS A

MANHATTAN CABLE #M4665.

8 WIRE, 20 AWG., SHIELDED

CABLE. BLUE WIRE NOT USED.

(3) JUMPER WIRE SHOWN FROM TB3

(21) TO (24) USED ONLY WITH

OPTIONAL ZERO CROSSING RELAY.

YELLOW

ORANGE

BLACK

RED

SHIELD

-

VC

+

VCC

+

-

0-10V

OUTPUT

TB2

+

_

WHITE

GREEN

BROWN

REMOTE

SENSOR MODULE

10 11 12 13 14

9

15 16

Figure 4

Interconnecting Wiring

Bilge Alarm (02/02)

Rev. 1.3

Page 14

Page 19

(B)

(A) Amplifier P.C. Board

REC

D.V.M

ALARM

CAL

CHECK

ALARM

SET

(D)

(G)

(F)

(E)

(H)

Bilge Alarm (02/02)

Rev. 1.3

(C) Power Supply P.C. Board

Figure 5

Location of Parts

Page 15

Page 20

Bilge Alarm (02/02)

Rev. 1.3

Page 21

REC

D.V.M.

ALM

CAL

CHK

ALM

SET

COM

15\V

+15V

+2.5V

+24V

-5V

+5V

(B)

-

(C)

Bilge Alarm (02/02)

Rev. 1.3

E9

(A)

Figure 6

Location of Parts

Page 16

Page 22

Bilge Alarm (02/02)

Rev. 1.3

Page 23

6

5

7

SHLD

8

Vcc

LAMP

Vo

3

4

Sensor Connections

Figure 7

1

2

9

Bilge Alarm (02/02)

Rev. 1.3

Page 17

Page 24

10-3/4

273.1

3/8

9.5

.281

DIA.

7.14

10-HOLES

1-3/8

34.9

.875

DIA.

22.2

4-HOLES

4.0

101.6

2.0

50.8

11-1/8

282.6

1.0

25.4

5-1/4

133.4

1-3/8

34.9

6-1/4

158.7

DIMENSIONS=

6.5

165.1

INCHES

MM

2.0

50.8

2.0

50.8

2.0

50.8

10.0

254

Bilge Alarm (02/02)

Rev. 1.3

11-1/2

292.1

Control Module Outline

Figure 8

Page 18

Page 25

C

L

1 NPT

2-PLACES

1/2 NPT

3 3/4

95.3

C

L

DIMENSIONS=

4 1/2

114.3

INCHES

MM

6 1/8

155.6

5.0

127

3 1/4

82.5

DIA.

C

L

2.0

50.8

DIA.

3 1/2

88.9

3 5/8

92.1

C

L

Bilge Alarm (02/02)

Rev. 1.3

Sensing Module Outline

Figure 9

Page 19

C

L

Page 26

5V

g

g

DS4

a

4

+

C6

10

35V

mfd

R3

24.3K

R4

475

ohm

b

4

DS3

a

3

f

3

e

d

b

3

3

c

33

3

DS2

a

2

f

2

e

2

d

b

2

2

c

2

2

136

REF HI

R1

1M

IN

0.01

mfd

C1

R2

47.5K

31

IN HI

30

IN LO

REF LO COMM C+REF C-REF INT BUFF A/Z OSC3 OSC2 OSC1

35 32

20

+5V POL

(MINUS)

34

16

mfd

C2

0.1

33 27

C3

0.22

mfd

24

15

ICL7107CPL

22 12

17

18

11

U1

28

R5

47.5K

38 39

29

C4

C5

0.47

100pf

mfd

19 23

AB4 A3 B3 C3 D3 E3 F3 G3 A2 B2 C2 D2 E2 F2 G2

10 9

R6

100K

14

13 25

21

GND

26

40

-5V

Bilge Alarm (02/02)

Rev. 1.3

Figure 10

Digital Display Schematic Drawing

Page 20

Page 27

Bilge Alarm (02/02)

Rev. 1.3

Figure 11

Power Supply Schematic

Page 21

Page 28

IN

C3

3.3mfd

R4

1.21M

+15V

7

2

1

5

2

3

U3

308

+

1

3

4

C4

-15V

100pf

+

C6

3.3mfd

+

C7

3.3mfd

R3

6

8

1K

+15V

-15V

C1

+

3.3mfd

R6

RECORDER

+15V

7

2

U1

308

3

+

4

-15V

+

C8

10mfd

R9

1.21M

1

500K

8

C2

100pf

6

2

ALARM SET

2N5785

+15V

2

3

-

-15V

U5

741

+

7

4

2

3

+15V

U4

311

+

-15V

+

6

8

5

4

C5

1mfd

R2

1.82M

+15V

R10

15K

C9

.01mfd

10K

NORM.

SW2

R7

5K

D.V.M.

+15V

R8

ALARM

SW1

-15V

6

4

8

3

U6

LM

555

7

1

R1

182K

6

7

1

+15V

2

3

-15V

U2

741

+

7

6

4

ZERO POT

6

OUT

7

10V REC. OUT

9

ALARM OUT

11

Bilge Alarm (02/02)

Rev. 1.3

Figure 12

Amplifier Board Schematic

Page 22

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Loading...

Loading...