Page 1

OWNER’S AND USER’S MANUAL

MTOL+TM Turbidimeter

Models 28052 & 28053

Read Manual and all product labels BEFORE

using the equipment. Do not use unless you

know the safe and proper operation of this

equipment. Keep this Manual available for

easy access by all users. Replacement

Manuals are available at HFscientific.com

HF scientific

3170 Old Metro Parkway

Ft. Myers, FL 33916

Phone: 239-337-2116

Fax: 239-332-7643

Toll free: 888-203-7248

E-Mail: HF.Info@WattsWater.com

Website: HFscientific.com

Catalog No. 29290

Page 2

Catalog No. 29290

Page 3

DECLARATION OF CONFORMITY

Application of Council Directive

Standards to Which Conformity is Declared:

Product Safety – Tested and passed:

LC (Part 1: General Requirements UL61010-1 Issued May 11 2012 Ed 3 and CAN/CSA

C22.2 #61010-1 issued May 11 2012)

Manufacturer’s Name: HF scientific, inc.

Manufacturer’s Address: 3170 Old Metro Parkway, Fort Myers, Florida 33916-7597

Importer’s Name:

Importer’s Address:

Type of Equipment: Process Turbidimeter

Model Name MTOL+TM

Model No: Model #28052 (Infrared), Model #28053 (White Light)

I, the undersigned, hereby declare that the equipment specified above conforms to the

above Directives and Standards.

Place: Fort Myers, Florida USA

(Signature)

Date: 26 January, 2018 Renato Trovo,

General Manager,

HF scientific inc.

Catalog No. 29290

Page 4

Attention Owners and Users

Thank you for purchasing the MTOL+™ turbidimeter. This equipment will provide safe

and productive operation as long as it is installed, used, maintained, and serviced in

accordance with the instructions in this manual and is properly maintained. Importantly,

unless the user is adequately trained and supervised, there is a possibility of death,

serious personal injury, property damage or damage to the equipment.

Owners and users of this equipment bear the responsibility to make certain that this

equipment is used properly and safely. READ THIS MANUAL carefully, learn how to

use and service this equipment correctly, and strictly follow all of the instructions

contained in this manual and the requirements of local, state and federal law. Failure to

do so could result in death, serious personal injury, property damage or damage to the

equipment. This manual should be considered a permanent part of your machine and

should be kept available for easy reference by any user.

Owners should not permit anyone to touch this equipment unless they are over 18 years

of age, are adequately trained and supervised, and have read and understand this

manual. Owners should also ensure that no unauthorized personnel come in contact

with this equipment.

If this equipment, or any of its parts, becomes damaged or needs repair, stop using the

equipment and contact an experienced service individual immediately. If the warning

labels or this manual are misplaced, damaged or illegible, or if you require additional

copies, please contact customer service at +1 (239) 337-2116 or 888-203-7248 for these

items at no charge.

Please remember that this manual and the warning labels do not replace the need to be

alert, to properly train and supervise users, and to use common sense when using this

equipment.

If you are ever uncertain about a particular task or the proper method of operating this

equipment, ask your supervisor, consult this manual, access www.hfscientific.com, or

contact us at 888-203-7248.

PRODUCT IDENTIFICATION

Please record your product’s identification and purchase information which will help in

the event you have questions or need any service.

Model:

Serial #:

MTOL+ (Mar 5, 2018)

Rev. 1.71

Date of purchase:

Seller name/address:

Page 5

Table of Contents

Section Page

Understanding Safety Information ........................................................ 1

Specifications ........................................................................................ 2

1.0 Overview ............................................................................................... 3

1.1 The MTOL+ ......................................................................... 3

1.2 The Display .......................................................................... 4

1.3 The Touch Pad .................................................................... 4

1.4 Vapor Purge ........................................................................ 5

2.0 Unpacking and Inspection .................................................................... 5

3.0 Installation ............................................................................................ 6

3.1 Site Selection ............................................................................. 7

3.2 Mounting .................................................................................... 7

3.3 Plumbing & Assembly ............................................................ 10

3.3.1 Initial Assembly ........................................................... 10

3.3.2 Connection of MTOL+ to System Plumbing ................ 10

3.3.3 Connecting the drain ................................................... 12

3.3.4 Connecting the water intake ........................................ 12

3.4 Electrical Connections ............................................................. 14

3.4.1 Electrical Power Connection ....................................... 15

3.4.2 Terminal Block (P1) Connections ................................. 16

3.4.3 Closing the Junction Box ............................................. 18

4.0 Setup, Configuration and Calibration ............................................... 19

4.1 Modes of Operation .................................................................. 19

4.2 Configuring the MTOL + .......................................................... 22

4.2.1 Configuring the 4-20 mA Output .................................. 22

4.2.2 Baud Rate ..................................................................... 24

4.2.3 Modbus Address ........................................................... 24

4.2.4 Configuring the Alarms .................................................. 25

4.2.4.1 Configuring Alarm 1 ......................................... 26

4.2.4.2 Configuring Alarm 2 ......................................... 27

4.2.5 Offset ............................................................................. 27

4.2.6 Access Code ................................................................. 28

4.2.7 Signal Averaging ........................................................... 29

4.2.8 Display Resolution ........................................................ 30

4.2.9 LCD Brightness ............................................................. 31

4.2.10 Display Units ................................................................. 31

4.2.11 Ultrasonic Cleaning ....................................................... 32

4.2.12 Modbus Parity & Modbus Stop Bits ............................... 32

4.2.13 4mA and 20mA Adjustment .......................................... 33

4.2.14 Instrument ID ................................................................. 34

4.2.15 Logging Interval ............................................................. 34

MTOL+ (Mar 5, 2018)

Rev. 1.71

Page 6

Table of Contents (continued)

Section Page

4.2.16 Download Logged Files ................................................ 35

4.2.17 Date and Time ............................................................... 35

4.2.18 Update Software ........................................................... 38

4.3 Calibrating the MTOL+, CAL Mode .......................................... 40

4.3.1 Calibration Standards .................................................... 40

4.3.1.1 Alternate Ranges ............................................... 40

4.3.2 Indexing Calibration Cuvettes ........................................ 41

4.3.3 Calibration Procedures .................................................. 41

4.3.4 Abort Calibration ........................................................... 43

4.3.5 Calibration Failure ......................................................... 43

4.3.6 Instrument Offset ........................................................... 43

5.0 Operation ........................................................................................... 45

5.1 Replacing or Installing the Desiccant Pouch ............................ 45

5.2 Starting the System .................................................................. 46

5.3 Routine Measurement: AUTO mode ........................................ 47

5.4 Data Retrieval .......................................................................... 47

5.4.1 USB Connection ............................................................ 46

5.4.2 File Downloads ............................................................. 47

5.4.3 Modbus Communication ................................................ 48

5.5 Patented Ultrasonic Cleaning ................................................... 49

5.6 Condensate on the Cuvette ..................................................... 49

5.7 Cleaning the Flow through Cuvette .......................................... 51

5.8 Replacing the Source Lamp ..................................................... 52

5.9 Factory Installed 24V Option ................................................... 52

6.0 Troubleshooting .................................................................................. 53

6.1 MTOL+ Fault Detection ............................................................ 53

6.1.1 Warnings ...................................................................... 53

6.1.2 Errors ............................................................................ 53

6.1.3 Failures ......................................................................... 53

6.2 Diagnostic Table ..................................................................... 54

6.3 Bubbles in the Sample ............................................................ 54

6.4 Technical and Customer Assistance ....................................... 55

7.0 Accessories and Replacement Parts List ........................................... 56

8.0 Limited Warranty ................................................................................ 58

MTOL+ (Mar 5, 2018)

Rev. 1.71

Page 7

Understanding Safety Information

This manual contains safety and use instructions that must be followed during the

installation, commissioning, operation, care and maintenance, and service of the

MTOL+. All responsible personnel must read this manual prior to working with this

instrument, and should familiarize themselves with the following safety symbols, signals,

and pictorials.

This is a safety-alert symbol.

• The safety alert symbol is shown alone or used with a signal word (DANGER,

WARNING or CAUTION), a pictorial and/or a safety message to alert you to

hazards.

• When you see this symbol alone or with a signal word on this instrument or in

this Manual, be alert to the potential for death or serious personal injury.

Safety signal words have the following meaning:

Identifies hazards which, if not avoided, will result in death or serious

injury.

Identifies hazards which, if not avoided, could result in death or

serious injury.

Identifies hazards which, if not avoided, will result in minor or

moderate injury.

Identifies practices, actions or failure to act which will result in

property damage or damage to the equipment.

Pictorials used on the equipment and in this Manual have the following

meanings:

This pictorial alerts you to the need to read the Manual.

1

This pictorial alerts you to electricity, electrocution and shock hazards.

Page 8

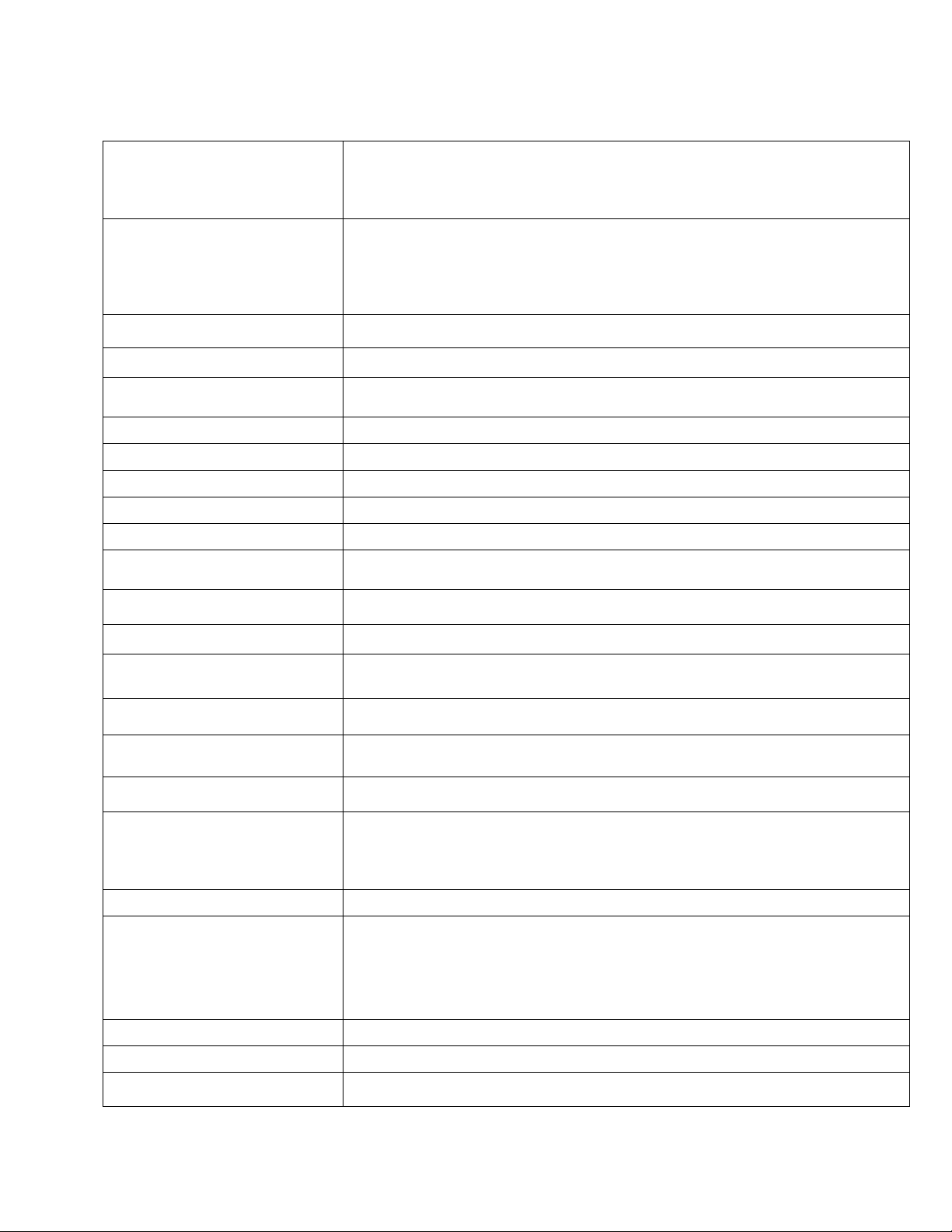

Specifications

Measurement Range

Accuracy

Resolution

Response Time

Display

Alarms

Analog Output

Communications Port

Data Storage

Software

Maximum Water Pressure

Flow Rate

0 – 100 NTU, factory configured

Model #28052 (Infrared) & Model #28053 (White Light)

0-10 NTU & 0-1000 NTU optional ranges (loaded on USB thumb drive)

±2% of reading or ±0.02 NTU below 40 NTU whichever is greater (0-100 and

0-1000 ranges)

±5% of reading above 40 NTU (0-100 and 0-1000 NTU ranges)

±2% of reading or ±0.02 NTU (0-10 NTU range)

0.0001 NTU (below 10 NTU)

Adjustable

Multi-Line Liquid Crystal Backlit Display

Two Programmable, 120-240VAC 2A Form C Relay

Powered 4-20 mA, 1000 Ω drive

Bi-directional RS-485, Modbus RTU

16 Gigabytes download via USB flash drive

Upgradeable via USB flash drive

Integral pressure regulator rated 7 bar (101.5 PSI)

100 ml/min. – 1.5 liter/min. (.026-.40 Gal/min)

Operating Temperature

Wetted Materials

Sample Temperature

Power Supply

Insulation Rating

Environmental Conditions

Enclosure

Regulatory Compliance

And Certifications

Instrument Weight

Shipping Weight

Limited Warranty

1°C – 50°C (34°F – 122°F)

Nylon, Borosilicate Glass, Silicone, Polypropylene, Stainless Steel, Viton,

Acetyl

1°C – 50°C (34°F – 122°F)

100 – 240 VAC, 47 – 63 Hz, 80VA

Double Insulated, Pollution Degree 2, Overvoltage Category II

Not recommended for outdoor use.

Altitude up to 2000 meters

Up to 95 % RH (non-condensing)

ABS

White Light Version compliant to U.S. EPA 180.1

Infrared Version compliant to ISO 7027 and DIN 27027

CE Approved, LC listed to UL 61010-1 3rd Edition: 2012

LC: Certified to CSA 22.2 No.61010-1-12: 2012

1.8 kg (4.0 lbs.)

2.8 kg (6.2 lbs.)

2 Years from date of invoice

2

Page 9

1.0 Overview

Shutoff Clamp

Display

Keypad

Water Inlet

Backpressure valve

USB Slot

Drain

Junction Box

1.1 The MTOL+ - Product Description

The MTOL+ process turbidimeter allows for the measurement of the turbidity of

process water on-line. The MTOL+ works by nephelometery; which means it

measures reflected light at 90° incident to the light beam. The white light MTOL+

(Model #28053) has been designed to meet the design criteria specified by the

US EPA 180.1 on turbidity measurement. The infrared MTOL+ (Model #28052)

was designed to meet the design criteria specified in ISO 7027 and DIN 27027

for the measurement of the turbidity of a sample. Both models have long life

lamps.

All models have ultrasonic cleaning. Refer to section 5.5 for more information.

A pressure regulator on the incoming line is a standard on all MTOL+ instruments

and will reduce pressures up to 7 bar (101.5 PSI) down to 1.03 bar (15 PSI).

The MTOL+ instruments are fully equipped with isolated 4-20mA, Modbus, two

alarms and ultrasonic cleaning. The only option is a flow alarm which must be

factory installed.

3

Page 10

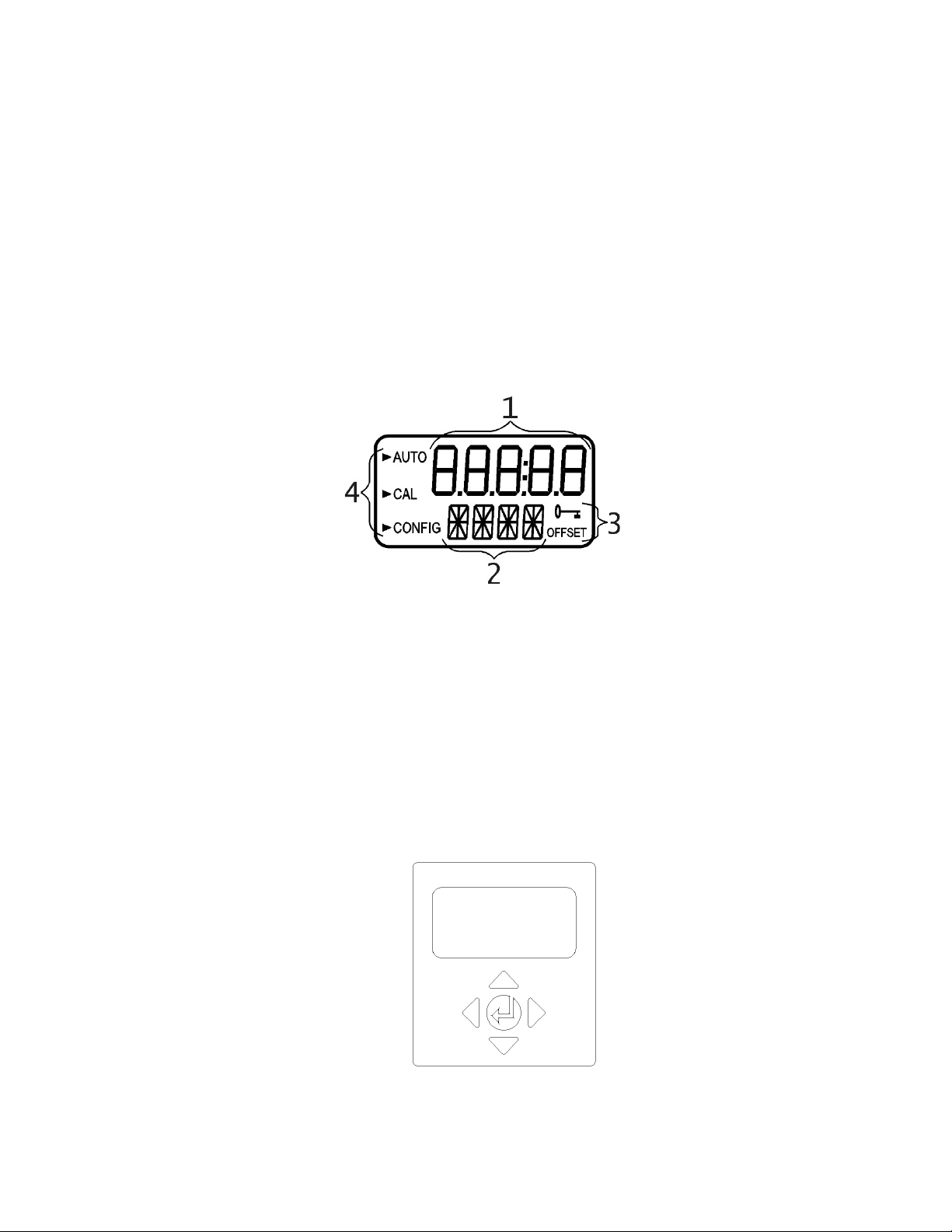

1.2 The Display

Figure 1 illustrates all the items that can appear on the display.

• The upper row of the display is used for reporting the turbidity levels and to

provide user guidance in the customer setting routine.

• The lower row of the display is used to communicate error messages and

provide user guidance.

• The display has two icons that are used to indicate the use of access code

and offset mode.

• In addition, mode arrows are used to indicate the current instrument

operating mode: AUTO (normal operation), CAL (calibration) and CONFIG

(configuration).

Figure 1 – Display used in the instrument.

All items used on the display are shown in this figure

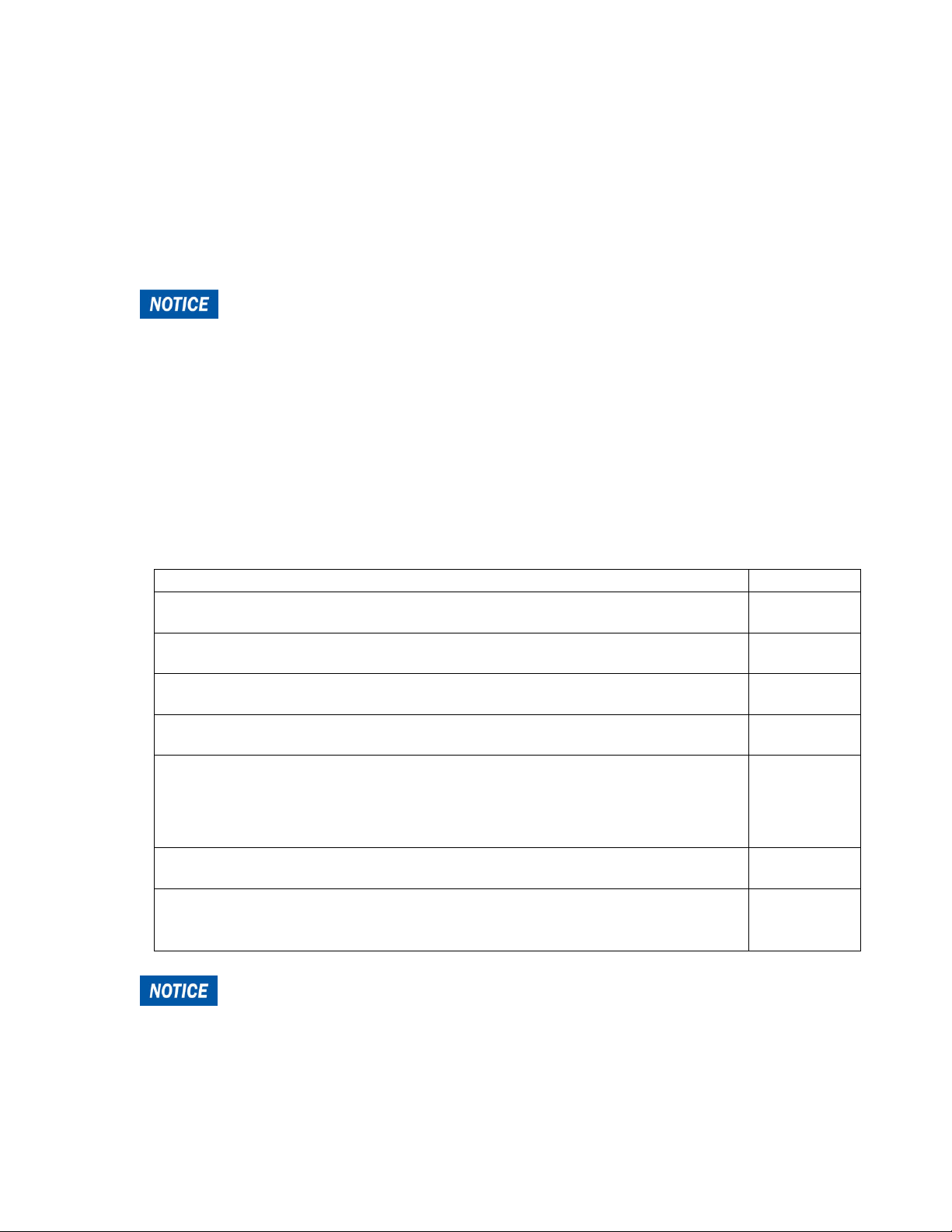

1.3 The Touch Pad

Figure 2 illustrates the touch pad. The touch pad has five buttons arranged in

star pattern with a center button.

• Right and left ⊳ buttons allow scrolling forward and backward through

the menus

• Up and down buttons are used to change selections

• The center button is used to accept a change.

Figure 2: Touch Pad

4

Page 11

Item

Quantity

1.4 Vapor Purge

• The MTOL+ is equipped with a continuous Vapor Purge system.

• A replaceable desiccant pouch in the lower portion of the instrument dries the air.

System heat is used to warm the air. A fan inside the instrument continuously

circulates heated dry air around the optical well and the flow through cuvette.

This feature eliminates the need for a dry purge line.

The MTOL+ monitors the replaceable desiccant pouch condition

continuously. The LCD display will show DESC on the lower line in the event that the

desiccant pouch needs replacement. Replacement desiccant pouches are available

from HF scientific or the local representative (Part # 21555R). Refer to section 5.1

Replacing or installing the Desiccant Pouch.

The MTOL+ creates its own internal environment. In this controlled environment

condensation cannot form. The cuvette is essentially bathed in warm, dry air.

2.0 Unpacking and Inspection

The table below indicates the items in the turbidimeter shipment.

MTOL+ Turbidimeter with Flow Through Assembly

Field Terminal Box with Interconnect cable

Owner’s and User’s Manual

Desiccant Pack

Tubing Kit: 1-shutoff clamp

1-backpressure valve

2-connecting tubing with fittings for flow through assembly

Screwdriver to make electrical connections in junction box

USB Flash Drive (Including files for optional ranges and user manual)

Remove the instrument from the packing carton. Carefully inspect all

items to ensure that no visible damage has occurred during shipment. If the

items received do not match the order, please immediately contact the local

distributor or the HF scientific Customer Service department.

1

1

1

1

1

1

1

5

Page 12

3.0 Installation

The MTOL+ must be mounted and installed in a suitable location, plumbed to

the sample water source (section 3.34), and hard-wired to electrical power (section 3.4).

Installation MUST be performed by qualified technicians, including licensed electricians,

following all instructions, complying with all local, state, federal and other governmental

requirements, and with all building and construction codes and standards.

If you have any questions or are uncertain about proper site location, installation or

connection of the MTOL+, please contact customer service at HF scientific.

• Installation MUST be performed by qualified technicians, including licensed

electricians, following all instructions, complying with all local, state, federal and other

governmental requirements, and with all building and construction codes and standards.

• MTOL+ is electrically powered. ALWAYS take proper precautions to recognize,

evaluate, and control electricity hazards during installation, programming, use and

service/maintenance.

• Use ONLY with water free of corrosive chemicals or other hazardous substances.

• ALWAYS leak check plumbing connections following installation and on a regular

basis.

• MTOL+ MUST be installed in an area isolated from vibration, and not susceptible to

freezing or temperature extremes. Mount on any suitable vertical and flat surface that

can support the product’s weight.

• Keep installation and work area clean, well-lighted, free of clutter and distractions, and

accessible only by authorized personnel and workers.

• MTOL+ must be located in accessible and well-lighted area for use, servicing, repair or

replacement by authorized personnel.

6

Page 13

3.1 Site Selection

Choose a site that is accessible and well-lighted for use, servicing, repair

or replacement by authorized personnel.

• MTOL+ should be located and mounted within 2-3 meters (6 to10 ft) of

the sampling point to ensure a quick response time.

• Installation/mounting site must be isolated from vibration, and not

susceptible to freezing or temperature extremes.

• Site must have a suitable vertical and flat surface that can support the

product’s weight and service operations 5kg (10lbs).

• There should be 20 cm (8 in) free area above the instrument. This will

ensure enough room for calibration and cuvette maintenance.

• Site must allow for mounting MTOL+ with front display positioned at

eye level 1.4 to 2 meters (approximately 4.5 to 6.5 feet from floor).

• MTOL+ is designed to have the Junction Box cradled under the upper

portion of the instrument – Select a site with enough space for proper

configuration when mounted.

3.2 Mounting

Described is for installation to a concrete surface. If needed

contact HF scientific for instruction to install on other surfaces.

Tools required:

Appropriate screwdriver or driver gun.

Mounting Template – last page of this Manual.

Masking tape for attaching Mounting Template to wall.

Any tools required by wall anchor manufacturer if used.

Hardware required:

7

4 Mounting screws for instrument enclosure - M6 (¼”). Either use concrete

screws or use a wall anchors & the supplied screws.

2 Mounting screws for terminal junction box - M4 (#8). Either use concrete

screws or use a wall anchors & the supplied screws.

Page 14

1. Using masking tape, affix the mounting template to the vertical surface of

the selected mounting location and mark location for screws.

• The MTOL+ is designed for vertical wall mounting. If wall

mounting is not practical, the instrument can be mounted on any

suitable vertical, flat surface.

• Make sure that the mounting position is level.

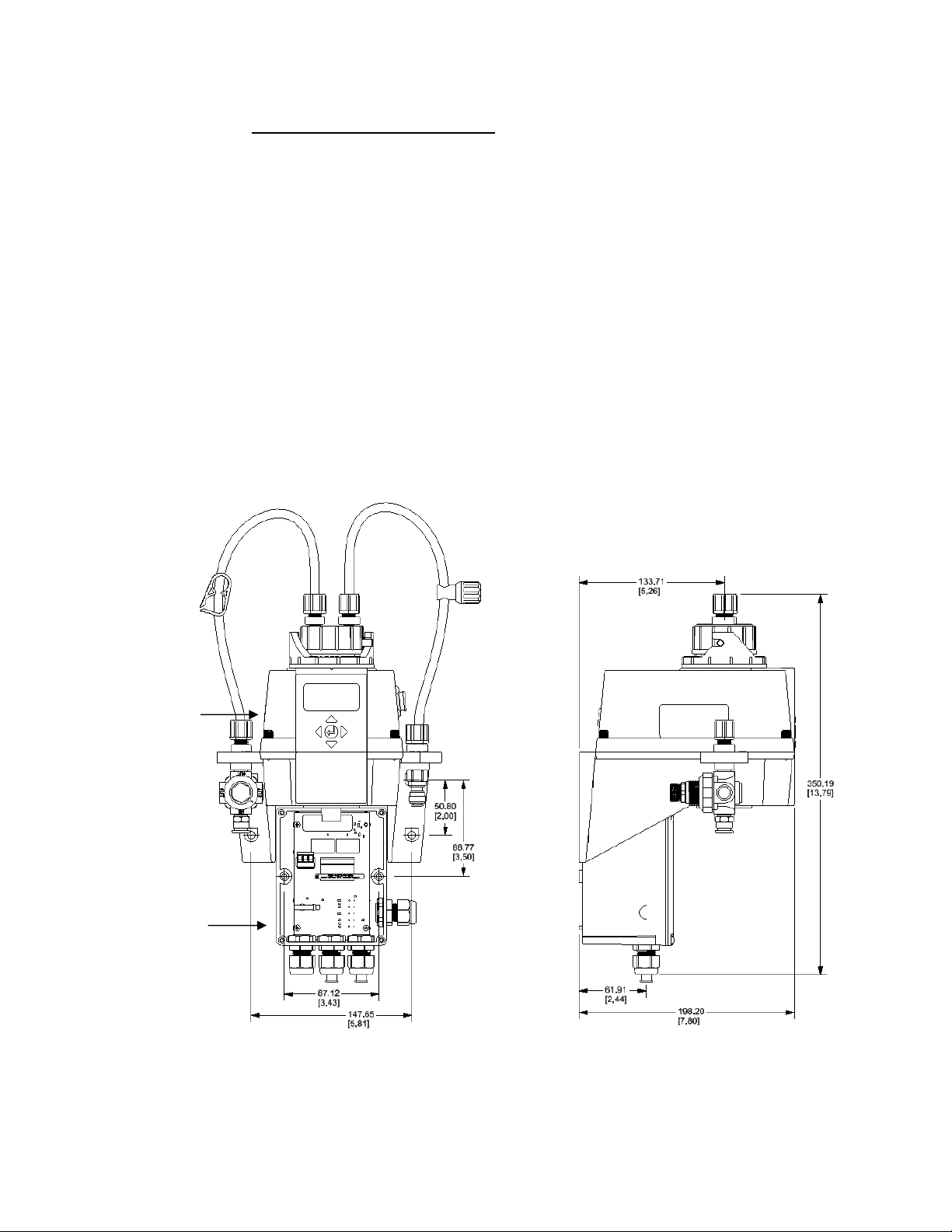

2. The overall mounting dimensions of the MTOL+ are shown in Figure 3,

below. Measure to confirm that the mounting location has sufficient space

and that there is at least 20 cm (8 in) free area above the instrument when

mounted. This will ensure enough room for calibration and cuvette

maintenance.

3. Carefully remove the mounting template from the wall, keeping it in one

piece for future reference and use.

4. Install wall anchors (if needed) - Following manufacturer’s instructions for

the wall anchors, and using the mounting template as a guide, insert wall

anchors for each mounting position.

5. Mount the Junction Box First. The MTOL+ is designed to have the

Junction Box cradled under the upper portion of the instrument containing

the key pad and display.

a. Position the Junction Box of the MTOL+ to match the 2 lower wall

anchors.

b. Mount the Junction Box first by inserting the M4 (#8) screws

through the 2 inside the Junction Box. Use wall anchors as

needed.

Using the screwdriver, hand-tighten both screws, ensuring that the

Junction Box is firmly and securely attached.

6. Mount the upper key pad and display section. After securely mounting

the junction box, mount the upper portion of the MTOL+ so that the

junction box is cradled under the upper portion.

a. Position the upper portion of the MTOL+ to match the remaining

holes or wall anchors.

b. Insert M6 (1/4”) screws though the 4 tabs on the upper portion of

the MTOL+ and into the wall anchors.

c. Using the screwdriver or driver gun, to tighten the screws, ensuring

that the upper portion is firmly and securely attached.

8

7. Confirm that MTOL+ is securely mounted to wall (or vertical surface) and

positioned:

Page 15

• Within 2-3 meters (6 to10 ft) of the sampling point to ensure a quick

response time.

• Isolated from vibration, and not susceptible to freezing or temperature

extremes.

• Suitable vertical and flat surface that can support the product’s weight

5 kg (10lbs).

• 20 cm (8 in) free area above the instrument, allowing room for

calibration and cuvette maintenance.

• Front display should be positioned at eye level or a suitable level to

read and reach controls - approximately 1.4 Meters (4.5 feet) to 2

meters (6.5 feet) from floor.

• Confirm that the unit is level.

Turbidity Sensor

Junction Box

9

Figure 3: Mounting Dimensions of the Instrument

Page 16

3.3 Plumbing & Assembly

ONLY qualified personnel should perform plumbing

connections following all instructions, complying with all local, state,

federal and other governmental requirements, and with all building and

construction codes and standards.

MTOL+ requires very little head pressure to operate 6.9kPa (1 PSI).

The flow through cuvette is rated for a flow of 100ml/min. - 1 liter/min. (0.026-

0.26Gal/min).

The integral pressure regulator is rated for a MAXIMUM pressure of 7 bar

(101.5 PSI).

The MAXIMUM allowable fluid temperature is 50°C (122°F).

3.3.1 Initial Assembly

The IN and OUT tubes must be connected to the MTOL+ before the

system is connected to the sample water source and drain.

1. Identify the IN tube. This is the tube with the white ratcheting clamp.

2. Install the IN tube between the sensor mounting ear marked IN and the

flow head connection marked IN. Secure both ends tightly.

3. Identify the OUT tube. This is the tube with the rotary backpressure valve.

4. Install the OUT tube between the sensor mounting ear marked OUT and

the flow head connection marked OUT. Secure both ends tightly.

3.3.2 Connection of MTOL+ to System Plumbing

Requirements:

Use ¼ inch OD flexible tubing (polyethylene or polypropylene) for connecting

the MTOL+.

Use Opaque tubing if tubing may be exposed to

sunlight. This will help limit algae growth.

10

MTOL+ has push-to-connect fittings for water inlet and drain connections.

Page 17

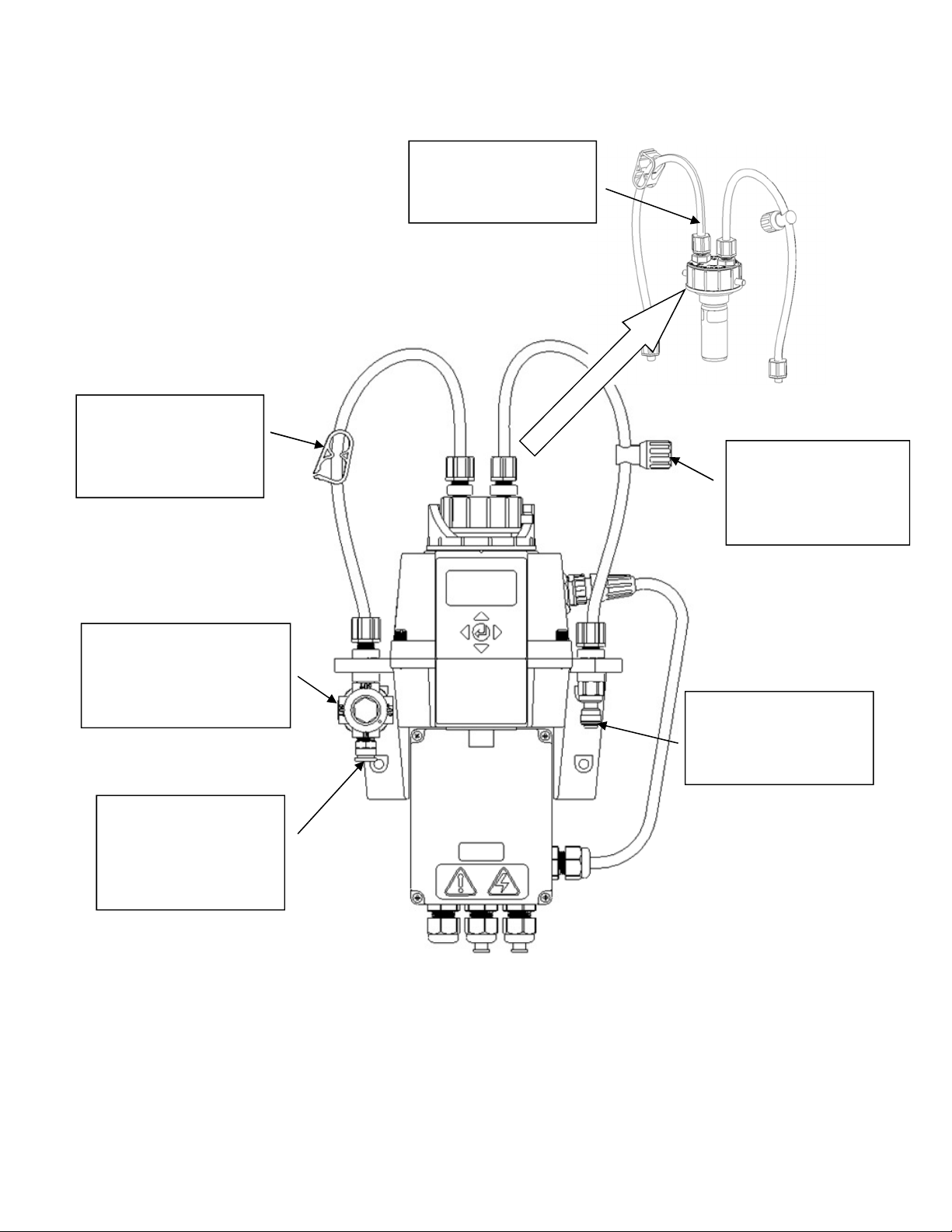

WATER INLET

TUBING

DRAIN

TUBING CONNECTION

PRESSURE REGULATOR

SHUTOFF CLAMP

This clamp allows for shutting

off the intake flow during

cuvette maintenance. Press

down to restrict water flow.

Flow Through Cuvette

The flow through cuvette is

rated for a flow of 100ml/min 1liter/min. (0.026-0.26Gal/min).

BACKPRESSURE VALVE

This valve allows for an

adjustment to reduce bubble

formation. Turn clockwise to

increase backpressure.

The integral pressure regulator is

rated for a maximum pressure of 7

bar (101.5 PSI). The maximum

allowable fluid temperature is 50°C

(122°F).

CONNECTION

Use ¼” OD tubing with supplied

push-to-connect fitting.

Polyethylene or polypropylene

are recommended tubing types.

Use ¼” OD tubing with supplied

push-to-connect fitting. Do not

reintroduce drain sample back

into the process stream

Figure 4 Instrument parts identification

11

Page 18

3.3.3 Connecting the drain:

a. MTOL+ drain tubing MUST be routed to a suitable

sanitary sewer drain. Wetted materials are not FDA approved.

DO NOT return the drain sample or any water run through MTOL+

into the process stream or into any potable water supply.

b. Select a length of ¼ inch OD flexible tubing (Polyethylene or

polypropylene) long enough to directly connect the MTOL+ drain

connection point to a suitable sanitary sewer drain. Avoid

unnecessary bends or sags in tubing. Make sure there are no

kinks, twists, breaks, or damage of any kind in tubing.

c. Using a sharp utility knife, cut the end of the tubing square.

Remove any burrs or sharp edges before inserting into fitting.

d. Place a piece of tape ½ inch from end of tube to indicate how far

the tube should be inserted.

e. Push the tube into the Quick-Connect fitting on the right facing side

of the MTOL+, as shown in Figure 4.

f. Check to confirm that tube is pushed fully against the tube stop.

Gently but firmly pull on the tube to check that it is secure.

g. Connect the other end of the tube to a suitable sanitary drain or

trench following proper plumbing techniques applicable to your

facility and configuration.

3.3.4 Connecting the water intake:

a. Use MTOL+ ONLY with water. Connect water intake

ONLY to water free of corrosive chemicals or other hazardous

substances.

HF scientific accepts no responsibility for damage caused by the

introduction of vapors, fluids or other materials into the instrument

process stream which is not compatible with the instrument's

wetted materials. A list of the wetted materials can be found in the

specifications on page 2 of this manual.

b. Select a length of ¼ inch OD flexible tubing (Polyethylene or

polypropylene) long enough to directly connect the MTOL+ water

inlet connection point to water sampling point. Avoid unnecessary

bends or sags in tubing. Make sure there are no kinks, twists,

breaks, or damage of any kind in tubing.

12

Page 19

c. Using a sharp utility knife, cut the end of the tubing square.

Remove any burrs or sharp edges before inserting into fitting.

d. Place a piece of tape ½ inch from end of tube to indicate how far

the tube should be inserted.

e. Push the tube into the Quick-Connect fitting on the left facing side

of the MTOL+, as shown in Figure 4.

f. Check to confirm that tube is pushed fully against the tube stop.

Gently but firmly pull on the tube to check that it is secure.

g. Connect the other end of the tube to the water sample source

following proper plumbing techniques applicable to your facility and

configuration.

After completing water inlet and drain connections, check all tubing

and connections for any leaks, weeping, breaks or defects of any

kind. Repair/replace as needed.

13

Page 20

3.4 Electrical Connections

• MTOL+ is electrically powered. Installation MUST be performed by

licensed electrician following all instructions and comply with all local,

state, federal and other governmental requirements, and with all building

and construction codes and standards for all electrical connections and for

installation of electrical connections to and between the instrument and

any peripheral devices.

• ALWAYS take proper precautions to recognize, evaluate, and control

electricity hazards during installation, programming, use and

service/maintenance.

Requirements:

• The MTOL+ is equipped with a 100-240 VAC, 47-63 Hz switching power

supply. BEFORE installing, verify that the line voltage falls within

these specifications.

• A breaker or method of disconnecting power must be placed within 2

meters (6 feet) of the MTOL+.

• While making connections, refer to Figure 5. The MTOL+ is not supplied

with a power cord.

• All of the electrical connections to the instrument are made through the

MTOL+ Junction Box (see Figure 5), which should be located directly

under the sensor portion of the instrument.

• The power cable glands will accept cable diameters from 5.8mm (.230 in)

up to 10 mm (.395 in.).

• All terminals are designed to accept wires in the range of 12-30 AWG. All

wires should be stripped to a length of 6 mm (¼ in).

• A strain relief strap is provided to reduce tension on the power terminals.

14

Page 21

• The connections are labeled within the terminal box and are selfdescriptive (see Figure 5).

• Plugs are inserted into the alarm and 4-20mA/RS-485 cable glands when

shipped, to ensure a watertight seal. These plugs should be removed and

discarded when cabling to either of these connections.

• Maintain watertight seal. It is the owner’s and installer’s responsibility to

assure that the watertight seal is maintained after the terminal box has

been wired for operation. Failure to properly tighten any of the cable

glands around a cable or plug can create an electrical shock/electrocution

hazard.

3.4.1 Electrical Power Connection:

Make all connections at Junction Box and securely close BEFORE

making connections to power source and energizing MTOL+.

ONLY licensed electrician should perform installation. ALWAYS

take proper precautions to recognize, evaluate, and control electricity

hazards.

a. First, make sure that MTOL+ is completely de-energized and

disconnected from all power.

b. Perform required LOCK OUT/TAG OUT of electrical power.

c. Confirm that a breaker or method of disconnecting power is located

within 2 meters (6 feet) of the MTOL+.

d. All of the electrical connections to the instrument are made through

the MTOL+ Junction Box (see Figure 5), which should be located

directly under the upper portion of the instrument.

e. Carefully open the MTOL+ Junction Box (see Figure 5) by removing

the four cover screws.

f. With the Junction Box cover removed, the connections are visible

as shown in Figure 5.

g. The power cable glands will accept cable diameters from 5.8mm

(.230 in) up to 10 mm (.395 in.). All terminals are designed to

accept wires in the range of 12-30 AWG.

15

Page 22

h. Obtain and cut proper wires to make connections for your specific

installation and facility. All wires should be stripped to a length of 6

mm (¼ in).

i. The connections are labeled within the terminal box and are self-

descriptive (see Figure 5).

j. Make connections following all local, state, federal and other

governmental requirements, and all building and construction codes

and standards for all electrical connections.

Earth or Ground wire must be connected to terminal on the MTOL+ marked “G”

k. A strain relief strap is provided to reduce tension on the power

terminals. Pull this tight after completing the connections.

l. Perform all checks necessary to confirm proper wiring and safe

electrical connection.

3.4.2 Terminal Block (P1) Connections:

Shut off and disconnect all electrical power BEFORE making or

changing any connections. The terminal block (P1) is located close to the

power connection.

The terminal block for RS-485 (Modbus), 4-20 mA and Alarms has spring

loaded connections.

To open the connection, insert a 3mm (1/8 in) flat blade screwdriver into

the slot right above the electrical connection. Pulling up slightly on the

screwdriver opens the terminal block connection. Removing the

screwdriver tightens the connection.

There are two stacked rows of connections which are labeled on the PCB.

The alarm connections are on the upper row. The RS-485 and 4-20mA

are on the lower row.

.

16

These connections are rated for a wire size from 12-28 AWG, either solid

or stranded.

a. Alarm and I/O Connections.

• The Alarm 1 and Alarm 2 relays are mechanical relays rated at 120-240

VAC 2A.

• Note that the relays are labeled NO (Normally Open), NC (Normally

Closed) and C (Common).

• The normal condition is with power applied to the MTOL+ and in a nonalarm condition. Operation of these alarms is covered in section 4.2.4

Configuring the Alarms.

Page 23

• Connections are labeled beneath the large terminal block. These

connections are on the upper row.

b. RS-485/Modbus Connection

• The RS-485 half-duplex (2-wire) digital interface operates with differential

levels that are not susceptible to electrical interferences. Cable lengths up

to 900 meters (3000 ft.) can be implemented.

• The last device on each bus may require terminating with a 120-ohm

resistor to eliminate signal reflection on the line.

• Do not run RS-485 cables in the same conduit as power.

• Ensure that power is disconnected prior to making connections to present

damage to the instrument.

• Connections are labeled beneath the large terminal block. These

connections are on the left side on the lower row.

c. 4-20 mA Connection:

Make sure the MTOL+ is disconnected and not powered BEFORE

connecting the 4-20 mA.

• The 4-20 mA output is driven by a 24 VDC power source and can drive

recorder loads up to 1000 ohms.

• This 4-20 mA output is isolated from line power and earth ground.

• Do not run 4-20 mA cables in the same conduit as power.

• Connections are labeled beneath the large terminal block. These

connections are on the right side on the lower row.

• Operation of this output is covered in section 4.2.1 Setting the 4-20 mA.

17

Page 24

3.4.3 Closing the Junction Box.

Maintain watertight seal. Always make sure that the Junction

Box cover is firmly in place and securely closed. Water infiltration

can create electric shock/electrocution hazard and will damage

equipment.

• Securely close the Junction Box by replacing the cover and all four

cover screws.

Power Connection

Terminal Block (P1)

Alarm & I/O Connections

Figure 5: Electrical Connections for the MTOL+

---------------------------------------------------

18

Figure 6: Electrical Connections on Terminal Block (P1)

Page 25

4.0 Setup, Configuration and Calibration

Prior to use for the first time, the supplied desiccant pouch will need to be

installed.

Refer to section 5.1 Replacing or Installing the Desiccant Pouch.

Before using your MTOL+, you will need to familiarize yourself with the instrument’s

operating modes and functions, and perform some set up, configuration and calibration.

• The MTOL+ allows for the measurement of the turbidity of process water

on-line. The turbidity of the process water is usually reported in

Nephelometric Turbidity Units (NTU), but may be reported in Formazine

Nephelometric Units (FNU).

• Readings above 100 NTU are outside the pre-configured range of this

instrument. Readings above 110 NTU will cause the display to flash

indicating an over range condition.

• For a unit calibrated in the 0-10 NTU Range… Readings above 10 NTU

are outside range of this instrument. Readings above 11 NTU will cause

the display to flash indicating an over range condition.

• For a unit calibrated in the 0-1000 NTU Range… Readings above 1000

NTU are outside the range of this instrument. Readings above 1100 NTU

will cause the display to flash indicating an over range condition.

• During normal operation, the instrument will have the arrow beside AUTO

highlighted with the current scale displayed on the lower row of the display

and the measured reading on the upper row of the display (see illustration

below).

4.1 Modes of Operation

There are four modes of operation, AUTO, CAL, CONFIG & HOLD. To

change between AUTO, CAL, HOLD and CONFIG use the and then

the button to select.

a. AUTO mode is the normal automatic operation. This is the default

mode when power is applied or restored. The other three modes of

operation are limited to 15 minutes with no key presses after which

they will return to AUTO made operation.

19

Page 26

b. CAL is the calibration mode. All reading outputs and alarms are

held while in this mode of operation. The instrument was calibrated

and tested prior to leaving the factory. Therefore, it is possible to

use the instrument directly out of the box. Under normal conditions,

re-calibration is required once every three months. Quarterly

calibration ensures performance within accuracy specifications.

• Enter the CAL mode of the instrument by pressing the or

buttons until the arrow beside CAL is illuminated, then

press the

• Use the and buttons to move forward and backward

through the calibration points.

• To exit the CAL mode start a calibration point after the

countdown starts press or . When the screen shows

ABRT press the

• Relay contacts and the 4-20mA will be frozen (held at the

current state) while the instrument is in the calibration mode.

• While in the calibration mode, the instrument has a time-out

feature that automatically returns the system operation to the

AUTO mode after a fifteen (15) minute period of inactivity.

c. CONFIG is the configuration mode. In CONFIG mode, you can

customize the instrument according to needs and preferred

operation at any time during normal operation. The CONFIG mode

has been split into sub-menus to facilitate instrument configuration.

This is also where logged files and calibration logs can be

downloaded and where new software, when available, can be

uploaded.

button.

button.

20

• Enter the CONFIG mode of the instrument by pressing the

or buttons until the arrow beside CONFIG is

illuminated, then press the

• To exit the CONFIG mode at any time, press the

• The ⊳ and buttons are used to move forward and

backward through the menus.

• All reading outputs and alarms are held while in this mode of

operation. Relay contacts and the 4-20mA will be frozen

(held at the current state) while the instrument is in the

configuration mode. While in the configuration mode, the

instrument has a time-out feature that automatically returns

the system operation to the AUTO mode after a fifteen (15)

minute period.

button.

button.

Page 27

• Shown below is a Flow Chart depicting the options under the

configuration operation:

d. HOLD mode is intended for servicing the instrument and holds the

outputs and alarms. During this mode the 4-20mA and alarms are

frozen. This mode can be used to ensure that no changes

accidentally are made to the instrument. This mode will time out

after 15 minutes and revert back to AUTO mode.

• Enter the HOLD mode of the instrument by pressing the

or buttons until the arrow beside HOLD is illuminated,

then press the

Figure 6 MTOL+ Flow Chart

button.

• Once selected the letters above will change from OFF to

21

ON.

Page 28

• The HOLD mode can be used during any maintenance

functions such as changing the cuvette or desiccant without

affecting alarms or the 4-20mA output signals.

• CAL, CONFIG & HOLD are limited to 15 minutes after which

time they automatically revert to AUTO mode.

4.2 Configuring the MTOL+

The MTOL+ has been designed to provide the ability to customize the

instrument according to needs at any time during normal operation. The

CONFIG mode has been split into sub-menus to facilitate instrument

configuration. This section describes how to use each of the sub-menus

to configure the instrument. In the sections below each sub-menu under

the CONFIG mode is discussed in the order that they are reached by

circling through the CONFIG mode, as identified in the flow chart located

previously.

Turn Power “ON:” After confirming that the MTOL+ is safely and

properly mounted, connected and installed, turn the instrument ON by

connecting or turning on the power.

22

To enter the CONFIG Mode: Enter the CONFIG mode by pressing the

or buttons until the arrow beside CONFIG is illuminated, then press the

button.

To exit the CONFIG Mode: To exit the CONFIG mode at any time, press

the

button. Use the ⊳ and buttons to move forward and backward

through the menus.

4.2.1 Configuring the 4-20mA Output

The 4mA can be set higher than the 20mA level to invert

the output current if required. This may be required to

control a dosing pump.

Page 29

• See 4.2.13 to calibrate the 4-20mA output.

Enable 4-20mA – Enable or Disable 4-20mA Output: Enter the

CONFIG mode by pressing the and buttons until the arrow beside

CONFIG is displayed, then press the

appear only if the 4-20mA is enabled. If disabled skip down to 4.2.2

• This will be the first menu shown unless the option flow switch was

ordered. Use the or buttons to select whether the 4-20mA will be On

or OFF. Press the button to accept the setting and move to the next

menu or the

button to exit and return to AUTO.

button. The next three menus

Setting 4mA - Setting the 4mA:

• The first prompt will be the turbidity limit assigned to the 4mA output level:

• Select the turbidity level to assign to the 4MA using the and buttons.

The factory setting is 0.02 NTU.

Setting 20mA - Setting the 20mA:

• Next, select the turbidity level to assign to the 20mA output level using the

and buttons. The factory setting is 100.00 NTU.

23

• 20MA is displayed on the lower row of the LCD display. Select the

turbidity level to assign to the 20MA using the and buttons.

• Once the desired level has been set, press the button to accept the

setting and move to the next menu or the

button to exit and return to

Page 30

AUTO.

Error Level - Configuring the Error Level:

• In case of an error in the MTOL+, the 4-20 mA reading can be used to

indicate a problem by sending the current to either 4.00 mA, 2.00 mA.

0.00 mA, or OFF.

• The factory default setting is OFF and the 4-20mA is unaffected by any

error condition.

• To change the Error Level, enter the CONFIG mode by pressing the

and buttons until the arrow beside CONFIG is illuminated, then press

the

button.

• Press the button to move to the next menu until ERLV is displayed.

• Select the desired ERLV by using the and buttons then press the

button to accept the setting and move to the next menu or the

exit and return to AUTO.

4.2.2 Baud Rate - Selecting the RS–485 Baud Rate

• Select the desired baud rate (1200, 2400, 4800, 9600, or 19200) for

operation of the I/O port.

To change the Baud Rate: Enter the CONFIG mode by pressing the

and buttons until the arrow beside CONFIG is illuminated, then press

the

button.

• Press the button to move to the next menu until BAUD is displayed.

• Select the desired BAUD rate by pressing the or buttons to change

the displayed baud rate.

button to

24

Page 31

• Press the button to accept the setting and move to the next menu or the

button to exit and return to AUTO.

4.2.3 Modbus Address – Address Selection

• Select the Modbus address of the MTOL+ from 1 to 255. For more

information on Modbus refer to the Modbus Manuals Cat #29291. This

manual can also be downloaded for no charge at www.hfscientic.com.

To change the Modbus Address: Enter the CONFIG mode by pressing

the and buttons until the arrow beside CONFIG is illuminated, then

press the

• Press the button to move to the next menu until ADDR is displayed.

• Select the address using or buttons.

button.

• Press the button to accept the setting and move to the next menu or the

button to exit and return to AUTO.

4.2.4 Configuring the Alarms

• Two relays are provided that are designed to operate as two independent

programmable alarms. Three types of information must be input to fully

program each alarm:

a. The alarm function (HI, LO, OFF or Error)

b. The alarm set point (level at which the alarm activates)

c. The delay time for the alarm: The time that the set point must be

exceeded prior to alarm activation and the time before resetting the alarm

(prevents chatter in the relay).

a. Alarm Function: The alarms can either be turned OFF or

programmed to operate in one of three different manners:

25

• HI alarm: the relay changes state when the measured turbidity level

is higher than the programmed alarm level for a prescribed time.

• LO alarm: the relay changes state when the measured turbidity level

is lower than the programmed alarm level for a prescribed time.

• Error: the relay changes state when a system error occurs. If a

Page 32

system error occurs a message will appear on the lower row of the

screen describing the problem.

b. Alarm Set Point: The level at which an alarm activates is called

the alarm set point. On the instrument, the alarm set point is

designated as “S/P”. The set point is adjustable to any valid

turbidity level over the range of the instrument in steps of 0.01 NTU.

c. Alarm Delay Time: The alarm delay times are used to prevent

tripping the alarm when the turbidity level is close to the set point.

The function of the delay times is as follows:

• Delay On: The turbidity level must exceed the alarm set point

continuously for at least this number of seconds before the alarm

activates.

If the “delay on” time is set at 5 seconds and the process

turbidity exceeds the set point continuously for only 4

seconds, the alarm will not be activated. However, if

process turbidity exceeds the set point continuously for 5

seconds or more; the instrument will activate the alarm.

• Delay Off: The turbidity level must not exceed the alarm set point

continuously for at least this number of seconds prior to

deactivation of the alarm.

If the “delay off” time is set to 5 seconds and the process has

exited out of the alarm condition, the alarm will be reset only

if the process is out of the alarm condition for a continuous 5

seconds. Otherwise, the instrument will still signal an alarm

condition.

4.2.4.1 Alarm 1 - Configuring Alarm 1

Alarm 1 Function: The ALM1 is displayed and the display

indicates the current function of Alarm 1 (HI, LO, OFF or Error).

• Use the or buttons to cycle through and select the desired

function.

• Press the button to accept it and move to the next menu.

• If the alarm was turned OFF a prompt will appear to set up Alarm 2

(go to section 4.2.10.2). If, on the other hand, one of the other HI

or LO was selected, a prompt will appear to set the delay times.

Alarm 1 Set Point: Set Point is indicated by “S/P” shown on the

lower row of the display, and is used to select the set point for this

alarm.

• Select the desired alarm level by using the and buttons.

26

Page 33

• Once the desired set point has been set, press the button to

accept it and move to the next menu.

• Alarm 1 Delay Times:

1. Delay On: The following display will appear to allow you to

select the number of seconds currently set for the “delay on”

time.

• The current selected number of seconds will be shown. Select

the desired number of seconds for the “delay on” time for this

alarm using the and buttons. Once the desired delay time

has been set, press the button to accept it and move to the

next menu.

2. Delay Off: Next, the following display will appear to select the

number of seconds currently set for the “delay off” time.

• The current selected number of seconds will be shown. Select

the desired delay off time for this alarm using the and

buttons. Once the desired delay time has been set, press the

button to accept it and move to the next menu.

• After the settings for Alarm 1 have been completed, prompts will

allow for the set-up of the information on Alarm 2.

4.2.4.2 Alarm 2 - Configuring Alarm 2

Repeat the procedure listed in section 4.2.10.1 to set up the

parameters for alarm 2.

27

Page 34

4.2.5 Offset – Offset Reading Adjustment

• A reading offset can be made to allow for the MTOL+ to agree with

another instrument if desired.

• This range is limited to ± 1NTU.

• For more information refer to section 4.3.6.

To change the Offset: Enter the CONFIG mode by pressing the and

buttons until the arrow beside CONFIG is illuminated, then press the

button.

• Press the button to move to the next menu until OFST is displayed.

• Select the offset using the or buttons to turn the function On.

• When the OFST is turned ON it will stay illuminated in AUTO

as a reminder that it is being used.

• Select the offset using the or buttons.

• Press the button to accept the setting and move to the next menu or the

button to exit and return to AUTO.

4.2.6 Access Code - Setting Security

• The MTOL+ is equipped with a security access feature that can be

activated. If this option is turned ON, the user is required to input an

access code into the instrument to get to any mode other than AUTO. A

three digit code is used.

• HF Scientific highly recommends the use of a security access code

in order to help prevent unauthorized access to the system and data.

• When the CODE is turned On the icon will be illuminated in

AUTO as a reminder that an access code is being used.

Setting Security on/off: Enter the CONFIG mode by pressing the and

buttons until the arrow beside CONFIG is illuminated, then press the

button.

28

• Press the button to move to the next menu until CODE is displayed.

• Use the or buttons to select the setting. (On or OFF).

Page 35

Setting Security Code: With the security feature enabled (“ON”), press

the button. The screen shown in the illustration below will appear:

• The 3 digit security code is set one digit at a time. Using the or

buttons, select each digit. The flashing digit is the number that is currently

being adjusted.

• Once a digit is selected, press the button to move on to the next

number.

• Now enter the second number in the code. Proceed as with the first

number followed by .

• Repeat the process for the third, and finish with the button.

• When the code is turned On, the code must be used to exit

AUTO

• If a valid access code has been selected, the instrument will be directed to

the calibration mode. If the wrong access code is selected, the instrument

will return to the AUTO mode.

• If the access code was set On from AUTO press or . The next screen

will allow entering the three digit code into the instrument. The security

code is entered one digit at a time using the or to select the digit and

to advance to the next digit. Accept the code by pressing the

4.2.7 Signal Averaging - Setting Speed of Response

• The averaging can be used to smooth out the response to spikes or

unstable readings that may be caused by bubbles or small debris.

• The response is done by averaging readings. Both displayed and output

values of NTU are affected in this menu. The default setting is 1; however,

button.

29

Page 36

up to 60 readings can be averaged.

• To avoid reading air and other anomalies, select a higher averaging.

• Select the lowest averaging where monitoring of rapid changes is needed.

These are one second intervals so the maximum averaging is 60 seconds.

• The factory default is 10.

To change the Averaging: Enter the CONFIG mode by pressing the

and buttons until the arrow beside CONFIG is illuminated, then press

the

button.

• Press the button to move to the next menu until RESP is displayed.

• Use the or buttons to select the setting for the speed of response

desired.

• Press the button to accept the setting and move to the next menu or the

button to exit and return to AUTO.

4.2.8 Display Resolution - Setting Resolution

• The instrument is equipped with the ability to display several levels of

resolution. The instrument can display up to four digits to the right of the

decimal place for turbidity readings below 10 NTU. The default setting is

000.00 If the last digit or two is not stable, adjust the resolution to hide

these insignificant digits.

To change the Resolution: Enter the CONFIG mode by pressing the

or buttons until the arrow beside CONFIG is illuminated, then press the

button.

• Press the button to move to the next menu until RES is displayed, then

press the

• Change the resolution by pressing the or button.

• When the desired digit resolution has been selected, press the button to

accept it and move to the next menu or the

AUTO.

button.

button to exit and return to

30

Page 37

4.2.9 LCD Brightness - Setting the LCD backlight brightness

• The LCD backlight brightness may need to be adjusted. This is of

particular interest if multiple instruments are located in the same area and

it is desired for the entire group to have the same appearance. Ten levels

are available. The default brightness is 8.

To adjust Backlight Brightness: Enter the CONFIG mode by pressing

the and buttons until the arrow beside CONFIG is illuminated, then

press the

• Press the button to move to the next menu until BRT is displayed.

• Change the brightness by pressing the or button.

button.

• When the desired brightness has been selected, press the button to

accept it and move to the next menu or the

AUTO.

4.2.10 Display Units - Setting Displayed Units

• The most common unit is NTU (Nephelometric Turbidity Units) however

the instrument can display in FNU (Formazine Nephelometric Units).

• All instruments are shipped from the factory set in NTU mode.

Setting/Changing Units: Enter the CONFIG mode by pressing the

and buttons until the arrow beside CONFIG is illuminated, then press

the

button.

• Press the button to move to the next menu until UNIT is displayed.

• Use the or buttons to select the setting NTU or FNU.

• Press the button to accept it and move to the next menu or the

button to exit and return to

31

Page 38

button to exit and return to AUTO.

4.2.11 Ultrasonic Cleaning - Cleaning Function

• This allows for a selection menu to turn off the ultrasonic cleaning

function if desired. The default mode is On.

Setting the ultrasonic cleaning: Enter the CONFIG mode by pressing

the and buttons until the arrow beside CONFIG is illuminated, then

press the

• Press the button to move to the next menu until CLN is displayed.

• Select On or OFF using the and buttons.

button.

• Press the button to accept I the setting and move to the next menu or

the

button to exit and return to AUTO.

4.2.12 Modbus Parity & Modbus Stop Bits - RS485 Parameters

• These two menus will be used to set the balance of the RS-485

parameters.

• The default is no Parity (nOnE), 1 Stop Bit.

Modbus Parity – Setting the Modbus Parity: Enter the CONFIG mode

by pressing the and buttons until the arrow beside CONFIG is

illuminated, then press the

• Press the button to move to the next menu until PRTY is displayed.

• Make selections using the and buttons

• Press the button to accept it and move to the setting stop bits

button.

32

Modbus Stop Bits – Setting the Modbus Stop Bits: Enter the CONFIG

mode by pressing the and buttons until the arrow beside CONFIG is

illuminated, then press the

button.

Page 39

• Press the button to move to the next menu until STOP is displayed.

• Make selections using the and buttons

• Press the button to accept it and move to the next menu or the

button to exit and return to AUTO.

4.2.13 4mA and 20mA Adjustment

• If the 4-20 mA setting is turned On, two menus will appear one for each 4

and 20mA adjustment.

4mA Adjustment:

• The first menu outputs a constant 4mA while allowing for a small amount

of adjustment. This adjustment will allow the operator to make the

MTOL+ agree with a PLC or SCADA system. The adjustment limits are ±

200 counts or about ± 0.2 mA.

• This setting will be slightly different on each instrument as

each MTOL+ will be factory set to 4.00mA. Press the button when

adjustments are complete to save this setting and move on to the 20mA

adjustment.

Setting the 4mA Levels: Enter the CONFIG mode by pressing the

and buttons until the arrow beside CONFIG is illuminated, then press

the

button.

33

• Press the button to move to the next menu until 4MA is displayed.

• Adjust setting using the and buttons.

• Press the button when adjustments are complete to save this setting

and move on to the 20mA adjustment.

20mA Adjustment:

• This menu operates similar to the previous menu. This menu outputs a

constant 20 mA while allowing for a small amount of adjustment. The

adjustment limits are ± 1000 counts or about ± 1 mA.

Page 40

• This setting will be slightly different on each instrument as each MTOL+

will be factory set to 20.00mA.

Setting the 20mA Levels: Enter the CONFIG mode by pressing the

and buttons until the arrow beside CONFIG is illuminated, then press

the

button.

• Press the button to move to the next menu until 20MA is displayed.

• Adjust setting using the and buttons.

• Press the button to accept the setting and move to the next menu or the

button to exit and return to AUTO.

4.2.14 Instrument ID – Instrument Unique Number Identification

• This menu provides the instrument with a unique ID up to 4 digits. This ID

can be used when logged data is downloaded. This enables the data to be

associated with a particular instrument or location.

Setting the instrument ID: Enter the CONFIG mode by pressing the

and buttons until the arrow beside CONFIG is illuminated, then press

the

button.

• Press the button to move to the next menu until ID is displayed.

• Use the and buttons to select the value of the first number. Use the

to select the next number and repeat the process for all numbers. Scroll

through the numbers to the next menu.

4.2.15 Logging Interval – Setting the interval for logged files

• This menu determines how often readings are logged. The setting is in

minutes. This can be set from 1 minute to 60 minutes.

34

Setting the logging interval: Enter the CONFIG mode by pressing the

Page 41

and buttons until the arrow beside CONFIG is illuminated, then press

the

button.

• Press the button to move to the next menu until INVL is displayed.

• The value can be adjusted by using the and buttons.

• Once the value is set, press the button to accept it and move to the next

menu or the

4.2.16 Download Logged Files – Select to Download

• This menu is used to download CSV files to a flash drive. The selections

are No download (NO), Calibration file only (CAL), All Files (ALL) or

individual month (Jan, Feb…). Once the data stick is inserted in the USB

slot on the right side of the instrument push the

is inserted you will get an Error (Err). See section 5.4.2 File Downloads

for more information. The upper display will flash while the download is

taking place and show dOnE when complete.

Setting the data download: Enter the CONFIG mode by pressing the

and buttons until the arrow beside CONFIG is illuminated, then press

the

button.

• Press the button to move to the next menu until DOWN is displayed.

• The selection can be adjusted by using the and buttons.

button to exit and return to AUTO.

button. If no data stick

35

• Once the selection is made press the button to accept it and move to

the next menu or the

4.2.17 Date and Time – Setting of Instrument Time & Date

• The MTOL+ has a displayed date (month / day / year) and time (hour /

minute / Daylight Savings) that must be set upon initial installation/setup.

The next five menus are used for this setup.

Setting Month: Enter the CONFIG mode by pressing the and

buttons until the arrow beside CONFIG is illuminated, then press the

button.

• Press the button to move to the next menu until MNTH is displayed,

button to exit and return to AUTO.

Page 42

then press the

• Change the month by pressing the or button.

• When the desired month has been selected, press the button to accept

it and move to the next menu or the

Setting Day: Enter the CONFIG mode by pressing the and buttons

until the arrow beside CONFIG is illuminated, then press the

• Press the button to move to the next menu until DAY is displayed, then

press the

• Change the day by pressing the or button.

button.

button.

button to exit and return to AUTO.

button.

• When the desired day has been selected, press the button to accept it

and move to the next menu or the

Setting Year: Enter the CONFIG mode by pressing the and buttons

until the arrow beside CONFIG is illuminated, then press the

• Press the button to move to the next menu until YEAR is displayed,

then press the

• Change the year by pressing the or button.

•

button.

button to exit and return to AUTO.

button.

36

• When the desired year has been selected, press the button to accept it

Page 43

and move to the next menu or the

Setting Hour: Enter the CONFIG mode by pressing the and buttons

until the arrow beside CONFIG is illuminated, then press the

• Press the button to move to the next menu until HOUR is displayed,

then press the

• Change the hour by pressing the or button.

• When the desired hour has been selected, press the button to accept it

and move to the next menu or the

button.

button to exit and return to AUTO.

button.

button to exit and return to AUTO.

Setting Minute: Enter the CONFIG mode by pressing the and

buttons until the arrow beside CONFIG is illuminated, then press the

button.

• Press the button to move to the next menu until MIN is displayed, then

press the

• Change the minute by pressing the or button.

• When the desired minute has been selected, press the button to accept

it and move to the next menu or the

Daylight Savings Time: DST is valid for use in the USA, Canada, and

other countries or locations that follow the US Energy Savings Act of

2005.

button.

button to exit and return to AUTO.

37

• Enter the CONFIG mode by pressing the and buttons until the arrow

beside CONFIG is illuminated, then press the

• Press the button to move to the next menu until DST is displayed, then

button.

Page 44

press the

• Change the Daylight Savings Time by pressing the or button until

ON is displayed.

• Press the button to accept it and move to the next menu or the

button to exit and return to AUTO.

4.2.18 Update Software - Install Latest Software or Change Range

• Enter the CONFIG mode by pressing the and buttons until the arrow

beside CONFIG is illuminated, then press the

• Press the button to move to the next menu until UPDT is displayed,

then press the

• The software version can be determined by pressing and holding down

the and buttons for about 1 second. The first number shown is the

version and second number displayed is the model number. This can be

performed anytime during AUTO Mode.

• Software updates can only be made if a USB flash drive is installed with a

newer version of software than the one currently installed in the MTOL+. If

either a flash drive is not installed or a newer version of software is not

detected the following screen will appear.

• Range changes can be made with either the current or later versions.

These other ranges were included on a flash drive included with the

instrument when new.

• Once a flash drive with valid files are found, select the desired range to

update using the and buttons.

button.

button.

button.

38

Page 45

• While the system is updating, the word “busy” appears as it performs a

self-check of the software installation.

• If the MTOL+ finds a flash drive with a previous version of software it will

show the word FILE. You will need an updated file on the flash drive.

• Once installed the system will automatically turn off and restart. The entire

process takes about 60 seconds to complete.

Be certain to check the configuration as changes may have taken

place either with new software or a new range.

39

Page 46

4.3 Calibrating the MTOL+, CAL Mode

• The instrument was calibrated for the 0-100 NTU range and tested prior to

leaving the factory. Therefore, it is possible to use the instrument directly

out of the box. Under normal conditions, re-calibration is required once

every three months. Quarterly calibration ensures performance within

accuracy specifications.

The EPA and ISO recommend that on-line turbidimeters be

calibrated with a primary standard at least once every three

months if they are to be used for reporting purposes.

• Relay contacts and the 4-20mA will be frozen (held at the current state)

while the instrument is in the calibration mode. While in the calibration

mode, the instrument has a time-out feature that automatically returns the

system operation to the AUTO mode after a fifteen (15) minute period of

inactivity.

4.3.1 Calibration Standards

• If the MTOL+ will be used over the entire range of .02 to 100 NTU a

complete calibration as described below will be required, but you must

retain the same calibration schedule as described above.

• If instrument accuracy is only required below 10 NTU, such as for potable

water, a calibration may be performed using only a 10 NTU and a 0.02

NTU standard.

• We recommend that the following materials be used during calibration to

achieve the full-scale accuracy stated in this manual:

100 NTU

ProCal

ProCal

ProCalProCal

Calibration Standard available from HF scientific

40

10.0 NTU

0.02 NTU

4.3.1.1 Alternate Ranges

NTU the instrument must be recalibrated.

• The calibration values will be 10 NTU, 1 NTU and .02 NTU for 0-10 NTU

range.

• The calibration values will be 1000 NTU, 10 NTU and .02 NTU for 0-1000

NTU range.

• Calibration kits are available for the optional ranges.

• Make changes as needed to the instructions in section 4.3.3 below.

ProCal

ProCal

ProCalProCal

ProCal

ProCal

ProCalProCal

• If the range is changed from the factory setting of 0-100

Calibration Standard available from HF scientific

Calibration Standard available from HF scientific

Page 47

It is well known that diluted Formazine is unstable. If

Formazine is used to calibrate the instrument, ensure that a fresh stock

suspension of Formazine is used to achieve the accuracy quoted for the

instrument.

A Formazine Stock Solution Kit is available from HF scientific (Catalog No.

50040).

The HF scientific ProCal, primary calibration standards (refer to section

11.0 Accessories and Replacement Parts List) are more stable than

Formazine and have a minimum shelf life of 12 months. Prior to

recalibration, review the expiration dates, to ensure that the standards

have not expired.

4.3.2 Indexing Calibration Cuvettes

To achieve the greatest accuracy, and account for normal scratches and

aberrations in cuvette glass when calibrating, HF Scientific recommends

indexing the cuvettes.

Standards and standard kits purchased from HF Scientific are supplied

with indexing rings. Complete instructions regarding how

to index the cuvettes are included in the calibration kits.

The following steps allow repeatable indexing of

calibration standards:

1. With the instrument operating in AUTO mode insert

the standard into the optical well.

2. Slowly rotate the standard, inside the optical well, one

complete revolution (360º). While rotating the

standard slowly, observe the measured turbidity and locate the position

of the cuvette having the lowest reading.

3. With the calibration standard positioned at the location having the

lowest turbidity reading, install the Indexing Ring over the cap on the

standard so that the pointer of the Indexing Ring faces directly forward.

When using the standards in the future, always insert the standard so that

the pointer of the indexing ring faces forward. Slowly rotate the standard

back and forth about 5° to find the lowest point. The standard is now

indexed and ready for use.

41

4.3.3 Calibration Procedures

It is recommended that the measurement chamber be kept

covered during the calibration period and that the flow through cuvette be

replaced immediately after the calibration to prevent premature saturation

Page 48

of the desiccant.

1. Select the calibration function of the instrument by pressing the

once. The arrow beside CAL will be illuminated on the display. The lower

display shows alternating 100 (the value of the standard that is requested)

and

. The upper display shows the real-time reading to allow the standard

to be indexed. Refer to section 4.3.2 for information on indexing cuvettes.

2. Remove the flow through unit.

3. Insert the requested 100 NTU standard. Index the standard to the lowest

value on the upper display.

4. To calibrate for 10 NTU and below only, press the button to bypass the 100

NTU and proceed to step 7.

5. Press the

6. The lower display will count down from 30.

7. When complete, the lower display will now change to show alternating 10 and

, requesting the 10.0 NTU standard.

8. If the alternating 10 and is not displayed, push theuntil this display is

shown.

9. Insert the requested 10.0 NTU standard. Index the standard to the lowest

value on the upper display.

10. Press the

11. The lower display will count down from 60.

12. When complete, the lower display will now change to show alternating 02 and

, requesting the 0.02 NTU standard.

button to initialize the calibration.

button to initialize the calibration.

button

42

Page 49

13. Insert the requested 0.02 NTU standard. Index the standard to the lowest

value on the upper display.

14. Press the

15. The lower display will count down from 30.

16. When complete the instrument will show CAL Good. Press the

accept. The display will briefly show STRT and then go to AUTO.

4.3.4 Abort Calibration

• If at any time during the calibration process, you can abort the calibration

by pushing theuntil the screen displays ABRT then press the

The instrument returns to AUTO operation.

• The instrument will save and use any points that were calibrated

successfully. It should be noted that the calibration log will report any

missed calibration values or failed calibrations.

4.3.5 Calibration Failure

• The MTOL+ will test the validity of the calibration and only good

calibrations will be saved for use.

• If the calibration fails the message below will show. Press the

accept.

• The instrument will revert to the last valid calibration. Check the standards

and recalibrate if desired.

• The failed calibration will be discarded, however a record of a failed

calibration with the time and date is stored.

4.3.6 Instrument Offset

• Refer to section 4.2.5

• It is possible to use an offset factor in the instrument rather than

performing a physical calibration.

button to initialize the calibration.

button to

button.

button to

43

• This procedure is not recommended in lieu of regular instrument

calibration but it can be used to make the MTOL+ agree with another

instrument.

Page 50

• This calibration technique will make the instrument accurate only at

turbidity levels in the immediate vicinity of the grab sample and not in the