Page 1

™

MTOL+

Online &

™

M100+

Laboratory

Turbidimeter Systems

The MTOL+™ Online Turbidimeter has been specifically designed

for measuring the NTU of filtered water, re-use water, raw water

and many industrial applications. The MTOL+ features built-in

Ultrasonic auto-cleaning and data logging as well as easy set-up,

maintenance, and calibration. Calibration is completed using

ProCal™ EPA approved* NTU calibration standards.

The MTOL+ is compatible with the M100+ laboratory turbidimeter which offers a color touchscreen display and sample

data logging for multiple sample ID's. The M100+ also stores

calibration NTU values and the date/time of calibration.

The two units share calibration standards eliminating the need

for different calibration standards between laboratory and

process NTU.

On-site User Selectable Range

MTOL+ Ranges include: 0 - 10, 0 - 100, 0 - 1000 NTU

MTOL+ Standard Features

• Meets USEPA Method 180.1 or ISO 7027 design and

performance criteria

• Ranges 0 - 10 NTU, 0 - 100 NTU or 0 - 1000 NTU

(User-Selectable - Factory Set to 0 - 100 NTU)

• Small footprint - Takes up very little space

• Local Display/User Interface provided with each instrument

• Fast response time and inexpensive calibration low sample

volume (30 ml)

• Modular design reduces overall costs - Replace

electronics without stopping flow

• Removable sample cuvettes allow for easy cleaning

and calibrating

• Ultrasonic Cleaning Function

• Optics are not in contact with the sample reduces chance of false low readings

• Convenient reusable EPA Approved primary

calibration standards

• USE WITH BOTH Online & Lab units

• Same Standard set for both versions for

most applications

MTOL+

Online Process Turbidimeter

Factory default 0 - 100 NTU

M100+

Laboratory Turbidimeter

* ProCal NTU Standards are EPA approved for

use as primary NTU standards

HFscientific.com

Page 2

Model MTOL+ Turbidimeter System

The continuous monitoring NTU system shall include the online

model with power supply, display, user interface and sensor as

one single SKU. It will not be necessary to purchase a separate

module for display or power supply. The turbidimeter shall meet

all requirements specified by the USEPA Method 180.1 (White

Light Model), ISO 7027 (Infrared Model) and Standard Methods

2130B. The turbidimeter shall be Modbus compatible and have

a 4-20 mA output. The turbidimeter shall have the same optical

design as the M100+ laboratory turbidimeter.

The online turbidimeter shall have an ultrasonic auto-clean

system. Accuracy shall be 2% of reading or plus or minus 0.02,

whichever is greater, from 0-40 NTU, and 5% of reading or

plus or minus 0.02, whichever is greater, from 40-1000 NTU.

Resolution will be 0.001 NTU (user selectable).

The sensor shall utilize a rotational flow through assembly with

a 30ml measuring cuvette. The specially designed flow head

bubble rejection system will reduce the need for a bubble trap

and provide a faster response time. The sample stream will

remain under pressure, ensuring it will not be exposed to open

atmosphere, which can cause precipitants in some circumstances.

Precipitation of oxidized sample constituents can result in false

NTU readings. The sensor shall allow grab samples to be

measured without the need to stop sample flow to the flow head.

Calibration and standardization will be accomplished using small

volumes (30ml) of reusable primary standards. Primary Standards

shall be reusable for multiple online turbidimeters and also with

the M100+ laboratory turbidimeter. Calibration procedures can

be completed without disrupting the sample flow. Details of

calibration (date and time of last successful calibration) will

be stored on the analyzer. An integral part of the turbidimeter

system is the inclusion of a laboratory instrument specifically

designed to use the same calibration standards. The required

supporting laboratory instrument must be an HF scientific M100+

touchscreen model with USB data logging and ability to store the

date/time of the last calibration.

The process turbidimeter and the laboratory turbidimeter lamp

source and detector shall not come in contact with the sample,

eliminating false low readings. The turbidimeters shall use menu

driven software. The online turbidimeter enclosure shall be ABS.

The online turbidimeter will have data logging features, will store

the latest date/time of calibration and be user selectable for

ranges of 0 – 10 NTU, 0 – 100 NTU (factory default) or 0 – 1000

NTU. The online turbidimeter shall be HF scientific MTOL+

Online Turbidimeter.

MTOL+ Features & Benefits:

Optical design

The unique, shared optical design allows consistent readings

between the M100+ laboratory turbidimeter and the MTOL+. The

unique optical design ensures that the same calibration

standards can be used with the M100+ laboratory unit and

the MTOL+.

Bubble rejection system

The optical chamber of the MTOL+ has been designed to eliminate air in the sample while simultaneously creating a vortex

cleaning action throughout the optical chamber.

Calibration

(Online & Lab NTU—Use the same Standards)

Calibration with primary standards is completed using sealed

cuvettes, similar to laboratory procedures. This method of

calibration is fast, clean and reusable. On-screen menu prompts

guide you through the calibration procedure quickly and easily.

The layouts for the MTOL+ and M100+ have a similar "feel" making the UI transition from one to the other easy.

Modular design

One-piece mounted design allows for simple mounting and

minimal use of space. Wide range of measurement (0-1000 NTU)

allows for measurement of both low NTU filtered water or raw

water with one analyzer, eliminating the need to learn multiple

models. Optical design increases accuracy and provides more

consistent readings with online, laboratory and portable

turbidimeters. Calibrate the new M100+ laboratory turbidimeter

with the same standards as the MTOL+ for greatly improved comparison functionality between lab and online.

Light source

White light is recommended for use in turbidimeters reporting

results under US EPA 180.1 (US standard) jurisdiction. The

white light is Tungsten filament, krypton gas filled, and has a life

expectancy of 5 to 7 years. Infrared light is recommended for

use in turbidimeters reporting results under ISO 7027 (European

standard) jurisdiction. Infrared light is also recommended for

some waste water final effluent and industrial applications where

color is present in the sample stream.

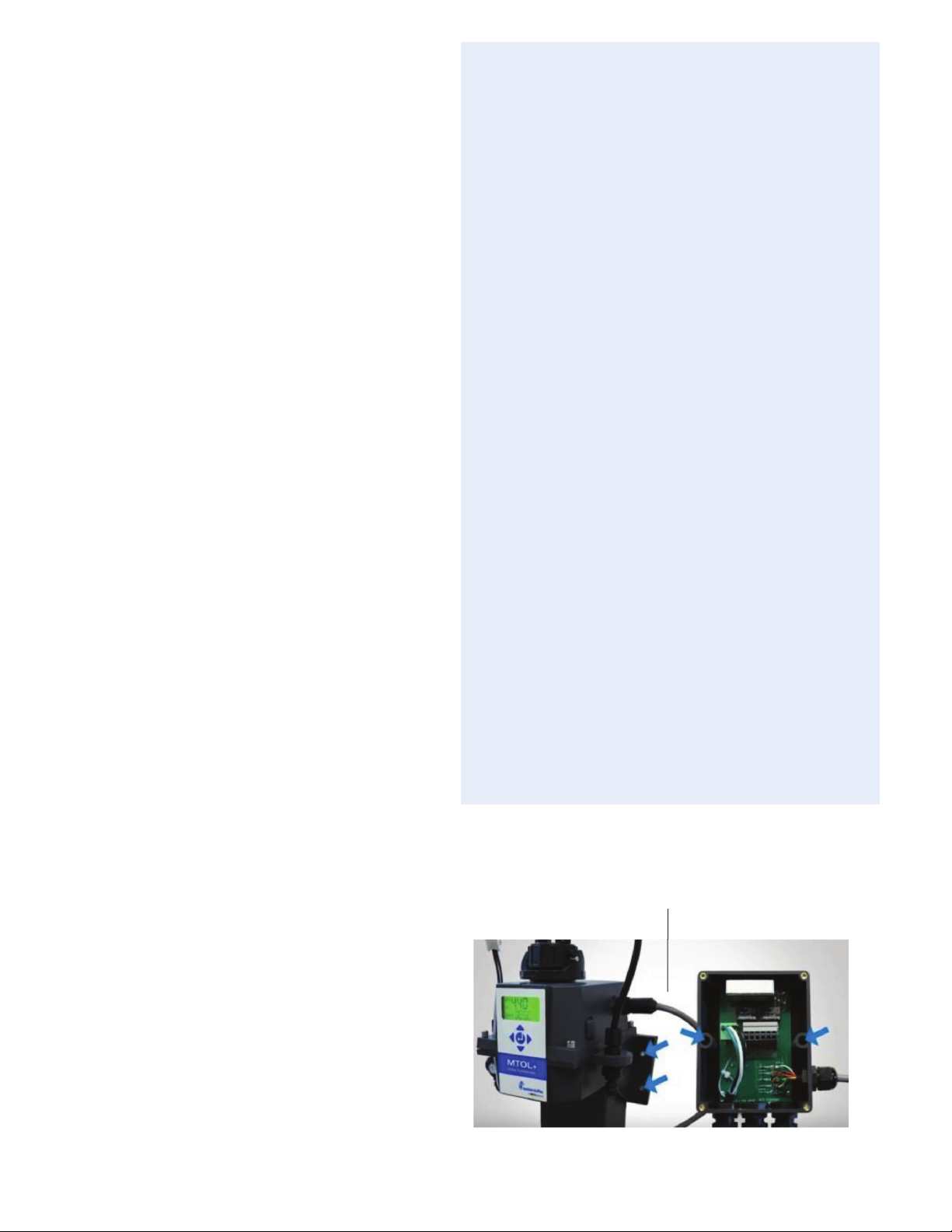

Sensor Base Installation allows

up to 1/4" hardware

Power Supply/Junction Box installation

allows up to 3/16" hardware

Page 3

[5,81]

Technical Specifications

MTOL+ (Online Turbidimeter) M100+ (Lab Turbidimeter)

Range Options 0-10 NTU, 0-100 NTU (Default), 0-1000 NTU 0-4000 NTU

Measurement Principle Nephelometric (90 degree scattered light) Nephelometric (90 degree scattered light)

Accuracy

2% of reading ±.02 NTU (below 40 NTU) 5% of reading

(above 40 NTU)

Resolution 0.001 (selectable) 0.0001 (selectable)

Response Time Adjustable (5-500 seconds) Selectable-Manual or Auto Mode

Flow Rate 0.026-.26 gpm (100 ml/min-1000 ml/min) NA

Standard Outputs 4-20 mA Galvanic Isolated or RS-485 Modbus NA

User Alarms 2 User Settable Alarms NA

Security Code User Selectable-Prevents Unauthorized Access NA

Storage Temperature -4°F to 140°F (-20°C to 60°C) -4°F to 140°F (-20°C to 60°C)

Data Logging Yes Yes

Store Calibration Data Yes Yes

Operating Temperature 34°F to 122°F (1°C to 50°C) 34°F to 104°F (1°C to 40°C)

Input Pressure 1-101 psi (built in regulator set at 15 psi) NA

Enclosure ABS ABS

White Light Version compliant to U.S. EPA 180.1

Regulatory Compliance

and Certifications

Infrared Version compliant to ISO 7027 and DIN 27027

CE Approved, LC listed to UL 61010-1 3rd Edition: 2012

LC: Certified to CSA 22.2 No.61010-1-12: 2012

Warranty 2 Years from ship date 1 year from ship date

2% of reading ±.02 NTU (below 40 NTU) 5% of

reading (above 40 NTU)

White Light Version compliant to U.S. EPA 180.1

Infrared Version compliant to ISO 7027

LC mark tested to UL and CSA.

Conforms to CE

Online Process Turbidimeter

Backpressure Valve to prevent dissolved

gases from releasing in the optics.

Shut off Clamp

Inlet Pressure Regulator

Max input 101psi

Factory set to 5psi

Laboratory Turbidimeter

Dimensions:

10.75" W x 10" L x 4.75" H

50.80

[2,00]

88.77

[3,50]

133.71

[5,26]

350.19

[13,79]

Sample Inlet and Outlet

1/4" OD push to

connect fittings

87.12

[3,43]

147.65

61.91

[2,44]

198.20

[7,80]

Provide at least 8 inches of free space above the sensor to allow removal

for the flow head for maintenance and calibration.

Page 4

Ordering Information Turbidimeter System:

When ordering a complete turbidimeter system please order as many online units (MTOL+) as are required and at least

one M100+ laboratory turbidimeter (M100+ includes a set of ProCal Calibration Standards, 0-4000 NTU).

MTOL+ M100+

Ordering Information

Cat. No. Model

28053

28052

White Light 0-100

Infrared 0-100

NTU

Range

Calibration Kits/Standards

Part # Description

39953

39950

39957

39825

39824

50040

ProCal Calibration Kit 0.02, 10, 100 NTU

ProCal Calibration Kit 0.02, 1, & 10 NTU

ProCal Calibration Kit 0.02, 10, & 1000 NTU

ProCal Calibration Standard 10 NTU, 125 ml

ProCal Calibration Standard 100 NTU, 125 ml

Formazin Stock Solution Kit

Spare Parts

Part # Description

21555R

20779S

24166S

24082S

21369S

50036

24306S

21062

02852

02853

Dessicant Refill

Power Cord 120 VAC / 240 VAC

Replacement Ultrasonic Cuvette Assembly

Replacement Lamp Assembly White Light

Replacement Lamp Assembly IR Light

Replacement Cuvettes, non-ultrasonic (3 Pack)

Pressure Regulator

Replacement Tubing Kit

Electronic Service Module for MTOL+ IR Light

Electronic Service Module for MTOL+ White Light

USEPA

Method

180.1

x

x

ISO

7027

Ordering Information

Cat. No. Model

28060

28061

White Light 0-4000

Infrared 0-4000

NTU

Range

Calibration Kits/Standards

Part # Description

39940

39941

39957

39825

50040

ProCal Calibration Kit

(0-4000 NTU for M100+ White Light)

ProCal Calibration Kit

(0-4000 NTU for M100+ Infrared)

ProCal Calibration Kit (0-1000 NTU)

ProCal Calibration Standard 10 NTU, 125 ml

Formazin Stock Solution Kit

Spare Parts

Part # Description

50051

50052

24082S

21369S

Cuvettes 28 x 70 mm, 3 pack

Cuvettes 28 x 70 mm, 10 pack

Replacement Lamp Assembly White Light

Replacement Lamp Assembly IR Light

USEPA

Method

180.1

x

ISO 7027

x

Manufacturer’s Representative

USA: T: (239) 337-2116 • Toll-Free (888) 203-7248 • F: (239) 332-7643 • HFscientific.com

Latin America: T: (52) 81-1001-8600 • HFscientific.com

F-HF-Turbidimeter 1926 © 2019 HF scientific

Loading...

Loading...