Page 1

Micro TUVMicro TUV

Micro TUV

Micro TUVMicro TUV

ON-LINE UV TRANSMISSIONON-LINE UV TRANSMISSION

ON-LINE UV TRANSMISSION

ON-LINE UV TRANSMISSIONON-LINE UV TRANSMISSION

SENSOR/SAMPLERSENSOR/SAMPLER

SENSOR/SAMPLER

SENSOR/SAMPLERSENSOR/SAMPLER

OPERATION & MAINTENANCEOPERATION & MAINTENANCE

OPERATION & MAINTENANCE

OPERATION & MAINTENANCEOPERATION & MAINTENANCE

MANUALMANUAL

MANUAL

MANUALMANUAL

Catalog #22810 (01/03)

HF scientific, inc.

3170 Metro Parkway

Fort Myers, FL 33916-7597

Phone: (239) 337-2116

Fax: (239) 332-7643

Page 2

Page 3

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

Page No. Page No.

Page No.

Page No. Page No.

1.01.0

1.0

1.01.0

1 3 TUV SYSTEM .......................................................................................................... 1

2.02.0

2.0

2.02.0

3.03.0

3.0

3.03.0

4.04.0

4.0

4.04.0

IMPORTANT INFORMATION IMPORTANT INFORMATION

IMPORTANT INFORMATION

IMPORTANT INFORMATION IMPORTANT INFORMATION

1.1 HOW TO USE THIS MANUAL ............................................................... 1

1.2 SPECIFICATIONS FOR THE TUV SENSOR/SAMPLER........................... 1

INSTALLATION INSTALLATION

INSTALLATION

INSTALLATION INSTALLATION

2.1PACKING LIST FOR THE TUV -------------------------------------------------------- 2

2.2 UNPACKING AND INSPECTION .......................................................... 2

2.3 MOUNTING ................................................................................................ 2

2.3.1 Sensor/Sampler Power .................................................................. 2

2.3.2 Removing and installing the Desiccant Tray .......................... 3

2.3.3 Sensor/Sampler Plumbing.................................................................. 3

2.4 COLD WEATHER KIT INSTALLATION .............................................. 3

2.4.1 Heating Cable Installation .......................................................... 3

2.4.2 Pipe Insulation Installation ........................................................ 4

STEP-BY-STEP OPERATION STEP-BY-STEP OPERATION

STEP-BY-STEP OPERATION

STEP-BY-STEP OPERATION STEP-BY-STEP OPERATION

3.1 THEORY OF OPERATION .......................................................................... 4

3.2 START UP ................................................................................................... 5

CALIBRATIONCALIBRATION

CALIBRATION

CALIBRATIONCALIBRATION

4.1 100%T CALIBRATION ............................................................................. 5

........................................................................................................................................................................

....................................................................................

........................................................................................................................................................................

....................................................................................... .......................................................................................

.......................................................................................

....................................................................................... .......................................................................................

..................................................................................................................

.........................................................

..................................................................................................................

......................................................................................................................

...........................................................

......................................................................................................................

11

1

11

22

2

22

44

4

44

55

5

55

5.05.0

5.0

5.05.0

6.06.0

6.0

6.06.0

7.07.0

7.0

7.07.0

FLOW FLOW

FLOW

FLOW FLOW

MAINTENANCEMAINTENANCE

MAINTENANCE

MAINTENANCEMAINTENANCE

6.1 SYSTEM CLEANING ............................................................................... 7

6.2 CUVETTE MAINTENANCE ......................................................................... 7

6.3 T-STRAINER MAINTENANCE .................................................................... 8

6.4 DESICCANT MAINTENANCE..................................................................... 8

6. 5 100% T CALIBRATION SOLUTION MAINTENANCE ................................. 8

6 .6 CLEANING THE INTAKE STRAINER ......................................................... 9

6. 7 REPLACING PUMP TUBING .......................................................................... 9

6. 8 REPLACING SYSTEM TUBING ..................................................................... 10

6. 9 SHUT DOWN PROCEDURE ........................................................................... 10

TROUBLESHOOTING TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING TROUBLESHOOTING

7.1 GENERAL NOTES .................................................................................... 10

7.2 TROUBLESHOOTING GUIDE ................................................................ 11

7.3 REPLACEMENT PARTS .......................................................................... 12

WARRANTY ...............................................................................................WARRANTY ...............................................................................................

WARRANTY ...............................................................................................

WARRANTY ...............................................................................................WARRANTY ...............................................................................................

APPENDIX A: MSDS ................................................................................APPENDIX A: MSDS ................................................................................

APPENDIX A: MSDS ................................................................................

APPENDIX A: MSDS ................................................................................APPENDIX A: MSDS ................................................................................

SENSOR .........................................................................................SENSOR .........................................................................................

SENSOR .........................................................................................

SENSOR .........................................................................................SENSOR .........................................................................................

..................................................................................... .....................................................................................

.....................................................................................

..................................................................................... .....................................................................................

..................................................................................................................................................

.........................................................................

..................................................................................................................................................

66

6

66

66

6

66

1010

10

1010

1818

18

1818

1919

19

1919

TUV (01/03) Page I

REV. 2.2

Page 4

Page 5

TABLE OF CONTENTS (Continued...)TABLE OF CONTENTS (Continued...)

TABLE OF CONTENTS (Continued...)

TABLE OF CONTENTS (Continued...)TABLE OF CONTENTS (Continued...)

FiguresFigures

Figures

FiguresFigures

Figure No.Figure No.

Figure No.

Figure No.Figure No.

11

1

11

22

2

22

33

3

33

44

4

44

55

5

55

66

6

66

77

7

77

TitleTitle

Title

TitleTitle

Desiccant Tray InstallationDesiccant Tray Installation

Desiccant Tray Installation

Desiccant Tray InstallationDesiccant Tray Installation

Quartz Flow Head AssemblyQuartz Flow Head Assembly

Quartz Flow Head Assembly

Quartz Flow Head AssemblyQuartz Flow Head Assembly

Sensor/Sampler Outline DimensionsSensor/Sampler Outline Dimensions

Sensor/Sampler Outline Dimensions

Sensor/Sampler Outline DimensionsSensor/Sampler Outline Dimensions

Interior/Exterior Plumbing Interior/Exterior Plumbing

Interior/Exterior Plumbing

Interior/Exterior Plumbing Interior/Exterior Plumbing

Power Input Cable Connections Power Input Cable Connections

Power Input Cable Connections

Power Input Cable Connections Power Input Cable Connections

Heater Cable Stripping InstructionsHeater Cable Stripping Instructions

Heater Cable Stripping Instructions

Heater Cable Stripping InstructionsHeater Cable Stripping Instructions

Cold Weather Kit Installation DetailsCold Weather Kit Installation Details

Cold Weather Kit Installation Details

Cold Weather Kit Installation DetailsCold Weather Kit Installation Details

.................................................... ....................................................

....................................................

.................................................... ....................................................

........................................................................................................

....................................................

........................................................................................................

................................... ...................................

...................................

................................... ...................................

and Electrical and Electrical

and Electrical

and Electrical and Electrical

........................................................................................

............................................

........................................................................................

................................... ...................................

...................................

................................... ...................................

ConnectionsConnections

Connections

ConnectionsConnections

................................ ................................

................................

................................ ................................

Page No.Page No.

Page No.

Page No.Page No.

... ...

...

... ...

33

3

33

77

7

77

11

1

11

11

1

11

11

1

11

1616

16

1616

1717

17

1717

33

3

33

44

4

44

55

5

55

TUV (01/03) Page II

REV. 2.2

Page 6

Page 7

DECLARATION OF CONFORMITYDECLARATION OF CONFORMITY

DECLARATION OF CONFORMITY

DECLARATION OF CONFORMITYDECLARATION OF CONFORMITY

Application of Council Directive: 89/336/EECApplication of Council Directive: 89/336/EEC

Application of Council Directive: 89/336/EEC

Application of Council Directive: 89/336/EECApplication of Council Directive: 89/336/EEC

Standards to which Conformity is Declared:Standards to which Conformity is Declared:

Standards to which Conformity is Declared:

Standards to which Conformity is Declared:Standards to which Conformity is Declared:

Product SafetyProduct Safety

Product Safety

Product SafetyProduct Safety

UL3101-1UL3101-1

UL3101-1

UL3101-1UL3101-1

CSA-C22.2 No. 1010-1-92CSA-C22.2 No. 1010-1-92

CSA-C22.2 No. 1010-1-92

CSA-C22.2 No. 1010-1-92CSA-C22.2 No. 1010-1-92

CE EN61010-1:1993 (73/23 EEC)CE EN61010-1:1993 (73/23 EEC)

CE EN61010-1:1993 (73/23 EEC)

CE EN61010-1:1993 (73/23 EEC)CE EN61010-1:1993 (73/23 EEC)

Manufacturer’s Name: Manufacturer’s Name:

Manufacturer’s Name:

Manufacturer’s Name: Manufacturer’s Name:

Manufacturer’s Address: Manufacturer’s Address:

Manufacturer’s Address:

Manufacturer’s Address: Manufacturer’s Address:

Type of Equipment: Type of Equipment:

Type of Equipment:

Type of Equipment: Type of Equipment:

Model No: Model No:

Model No:

Model No: Model No:

ImmunityImmunity

Immunity

ImmunityImmunity

EN50082-2:1995EN50082-2:1995

EN50082-2:1995

EN50082-2:1995EN50082-2:1995

HF scientific, inc.HF scientific, inc.

HF scientific, inc.

HF scientific, inc.HF scientific, inc.

3170 Metro Parkway, Fort Myers, Florida 33916-75973170 Metro Parkway, Fort Myers, Florida 33916-7597

3170 Metro Parkway, Fort Myers, Florida 33916-7597

3170 Metro Parkway, Fort Myers, Florida 33916-75973170 Metro Parkway, Fort Myers, Florida 33916-7597

UV Transmission Sensor/SamplerUV Transmission Sensor/Sampler

UV Transmission Sensor/Sampler

UV Transmission Sensor/SamplerUV Transmission Sensor/Sampler

TUVTUV

TUV

TUVTUV

EMIEMI

EMI

EMIEMI

EN55011 Class AEN55011 Class A

EN55011 Class A

EN55011 Class AEN55011 Class A

Per 50081-2:1994Per 50081-2:1994

Per 50081-2:1994

Per 50081-2:1994Per 50081-2:1994

I, the undersigned, hereby declare that the equipment specified above conforms to the above I, the undersigned, hereby declare that the equipment specified above conforms to the above

I, the undersigned, hereby declare that the equipment specified above conforms to the above

I, the undersigned, hereby declare that the equipment specified above conforms to the above I, the undersigned, hereby declare that the equipment specified above conforms to the above

Directive and Standard Directive and Standard

Directive and Standard

Directive and Standard Directive and Standard

Place: Place:

Place:

Place: Place:

TUV (01/03) Page III

REV. 2.2

Fort Myers, Florida USAFort Myers, Florida USA

Fort Myers, Florida USA

Fort Myers, Florida USAFort Myers, Florida USA

____________________________________________________

__________________________

____________________________________________________

(Signature)(Signature)

(Signature)

(Signature)(Signature)

Robert J. Maley, President Robert J. Maley, President

Robert J. Maley, President

Robert J. Maley, President Robert J. Maley, President

(Full Name)(Full Name)

(Full Name)

(Full Name)(Full Name)

Page 8

Page 9

.0.0

1

1.1 HOW TO USE THIS MANUAL1.1 HOW TO USE THIS MANUAL

1.1 HOW TO USE THIS MANUAL

1.1 HOW TO USE THIS MANUAL1.1 HOW TO USE THIS MANUAL

This equipment, while sophisticated, has been designed for simple and easy operation. In

keeping with that philosophy, this TUV user’s manual has been written to simplify all steps

in the procedures that follow.

THE MOST IMPORTANT ASPECT OF THIS MANUAL IS THAT YOU, THE USER, READ IT

IN ITS ENTIRETY AND REFER TO IT OFTEN.

Pay particular attention to the “Warning” and “Caution” messages throughout. Although

the TUV is easy to use, all electrical and safety precautions must be followed. “Notes” have

also been added to give further clarification or reminders in certain instances.

1.21.2

1.2

1.21.2

Range: Single, 0 - 100% Transmission

Resolution: 1.0 % of value

Uncertainty: 1% of full scale

Lamp: Low pressure, Mercury vapor, 253.7 nm

Response Time: Reading is updated every 30 seconds

Microprocessor: 68HC05

Operating Temperature: (

Storage Temperature: -4°F (-20°C) to 140°F (60°C)

Optical Cleaning: Removable cuvette / Cleaning Solution Connection

Flow rate: 140 - ml/min – 180ml/min.

Sensor/Sampler-Analyzer Separation: Depending on site conditions, up to 1000 feet (300m)

Sensor/Sampler-C ontroller or Analyzer

communication: RS-485 Serial Port, 9600 Baud, Isolated 1.5kv

Sensor/Sampler Enclosure

Dimensions: 29.9” x 29.9" x 11.8" (760 x 760 x 300mm)

Pollution Degree: 2

Over voltage category: II

IMPORTANT INFORMATIONIMPORTANT INFORMATION

.0

IMPORTANT INFORMATION

.0.0

IMPORTANT INFORMATIONIMPORTANT INFORMATION

SPECIFICATIONS FOR THE SPECIFICATIONS FOR THE

SPECIFICATIONS FOR THE

SPECIFICATIONS FOR THE SPECIFICATIONS FOR THE

SpecificationSpecification

Specification

SpecificationSpecification

**

*) -4°F (-20°C) t o 122°F (50°C)

**

TUV SENSOR/SAMPLERTUV SENSOR/SAMPLER

TUV SENSOR/SAMPLER

TUV SENSOR/SAMPLERTUV SENSOR/SAMPLER

TUV Sensor/SamplerTUV Sensor/Sampler

TUV Sensor/Sampler

TUV Sensor/SamplerTUV Sensor/Sampler

* *

* When Cold Weather Kit is installed.

* *

1.31.3

1.3

1.31.3

A complete operating

to the operations manual of the controller or analyzer for installation, operation and maintenance

instructions.

TUV(01/03) Page 1

REV. 2.2

TUV SYSTEMTUV SYSTEM

TUV SYSTEM

TUV SYSTEMTUV SYSTEM

system consists of the TUV Sensor/Sampler and a controller or analyzer. Please refer

WARNING: IN ORDER TO PREVENT SERIOUS BURNS, NEVER EXPOSE ONE'S

SELF TO UV LIGHT FROM THE LAMP WITHIN THE SENSOR MODULE.

Page 10

2.02.0

2.0

2.02.0

INSTALLATIONINSTALLATION

INSTALLATION

INSTALLATIONINSTALLATION

2.12.1

2.1

2.12.1

A complete listing of replacement parts appears on page 12 of this manual.

2.22.2

2.2

2.22.2

Use extreme care when unpacking your TUV and check that all of the contents are included.

Check for any damage that may have occurred during shipping. If there is any shipping damage; notify the shipping company immediately and arrange for a prompt inspection. If there are any omissions,

report

this immediately to the Service Dept. at HF scientific, inc. for assistance.

PACKING LISTPACKING LIST

PACKING LIST

PACKING LISTPACKING LIST

CONTENTSCONTENTS

CONTENTS

CONTENTSCONTENTS

1) Sensor/Sampler enclosure 1

2) Cold Weather Kit 1

3) Cleaning Solution Kit 1

4) Desiccant Tray Kit 1

UNPACKING AND INSPECTIONUNPACKING AND INSPECTION

UNPACKING AND INSPECTION

UNPACKING AND INSPECTIONUNPACKING AND INSPECTION

FOR THE TUV FOR THE TUV

FOR THE TUV

FOR THE TUV FOR THE TUV

Heating Cable 25 ft.

8” Coupler 3

Wire Tie (Black) 15" 1

Pipe Insulation 7/8" I.D. x 6ft. 4

Enclosure Interface Assembly 1

Adhesive 1 tube

Heat Shrink Insulation see instructions

QUANTITYQUANTITY

QUANTITY

QUANTITYQUANTITY

2.32.3

2.3

2.32.3

2.3.2.3.

2.3.

2.3.2.3.

This system may be ordered as either 110-120VAC or 220-240VAC. The latter uses a prewired step-down

transformer mounted inside the Sensor/Sampler enclosure. The power required by the system is 480 VA.

Either unit may be cord connected or hard wired.

For North American installations (120VAC) a 15 foot (3.35 meter) power cord is provided. For all other

installations either the power cord must be customer-provided or the Sensor/Sampler may be hard wired. Actual

hard wire electrical supply requirements will depend on local codes/rules. Refer to Figure 5 for main electrical

supply connections.

If the unit is to be hard wired, the power cord (if provided) must be removed. First, remove the right screw from

the DIN rail containing the circuit breaker and GFI. Once this screw is removed, the clear shield can be slid to

the right, exposing the line terminals. Disconnect the cord from the GFI and ground block. Remove the wiring

duct covers by pressing the fingers inward and pulling the covers off. Remove the cord from the wiring duct,

loosen the bulkhead fitting on the bottom panel , and pull it through. The new wires can then be fed through the

bulkhead, into the wiring duct, and connected at the power input GFI breaker and ground block just as the power

cord was. Tighten the bulkhead fitting when finished.

MOUNTINGMOUNTING

MOUNTING

MOUNTINGMOUNTING

11

Sensor/Sampler PowerSensor/Sampler Power

1

Sensor/Sampler Power

11

Sensor/Sampler PowerSensor/Sampler Power

TUV (01/03) Page 2

REV. 2.2

Page 11

WARNING:WARNING:

WARNING:

WARNING:WARNING:

switch to allow for service. Observe all local wiring codes. Site connections should be wired by a Qualifiedswitch to allow for service. Observe all local wiring codes. Site connections should be wired by a Qualified

switch to allow for service. Observe all local wiring codes. Site connections should be wired by a Qualified

switch to allow for service. Observe all local wiring codes. Site connections should be wired by a Qualifiedswitch to allow for service. Observe all local wiring codes. Site connections should be wired by a Qualified

Electrician.Electrician.

Electrician.

Electrician.Electrician.

2.3.2.3.

22

2.3.

2

2.3.2.3.

22

Before operating the unit for the first time, the desiccant tray,

foot valve and O-rings must be installed in the sensor housing.

These items are shipped in a moisture resistant pouch. Use care

when opening so as not to damage the contents. The smaller Oring #205 goes into the desiccant tray, at the foot valve seat. Oring #218 goes underneath the desiccant tray in the O-ring

groove provided in the housing. Refer to figure 1 for details. See

section 6.4 for maintenance instructions.

2.3.2.3.

33

2.3.

3

2.3.2.3.

33

There are two external connections required. The first is the source line with the strainer at its foot. The second

is the drain line. These hoses are shipped in separate plastic bags in the Sensor/Sampler enclosure. The source

and drain lines should not exceed 25 feet (7.6 m) in length. The flow rate may be substantially reduced if the

lines are extended any further. The sampling flow rate is 140 ml/min. - 180 ml/min.

If the power connection is to be hardwired, place If the power connection is to be hardwired, place

If the power connection is to be hardwired, place

If the power connection is to be hardwired, place If the power connection is to be hardwired, place

Removing and Installing the Desiccant TrayRemoving and Installing the Desiccant Tray

Removing and Installing the Desiccant Tray

Removing and Installing the Desiccant TrayRemoving and Installing the Desiccant Tray

Sensor/Sampler PlumbingSensor/Sampler Plumbing

Sensor/Sampler Plumbing

Sensor/Sampler PlumbingSensor/Sampler Plumbing

TUVTUV

on a separate circuit breaker or on a separate circuit breaker or

TUV

on a separate circuit breaker or

TUVTUV

on a separate circuit breaker or on a separate circuit breaker or

Figure 1

Desiccant Tray Installation

NOTE:NOTE:

NOTE:

NOTE:NOTE:

NOTE:NOTE:

NOTE:

NOTE:NOTE:

If any of the above conditions are not met, a flow error or an emergency drainage may occur.

2.42.4

2.4

2.42.4

2.2.

4.14.1

2.

4.1

2.2.

4.14.1

Disconnect power before installing the heating cable. The drain and intake lines must be sized to the proper

length before installing the heating cable. First, measure the amount of heating cable necessary to run from the

heating cable bulkhead on the bottom of the Sensor/Sampler enclosure to 2 inches above the maximum level of

the effluent stream and add 9 inches (230 mm) for the connections inside. If the heating cable needs to be cut

to length, make the cut at the open end, not the yellow sealed end. Next, prepare the cut end for connections

(see Figure 6). After the cable is prepared, unscrew the compression nut on the heating cable bulkhead on the

bottom of the instrument enclosure located between the intake and drain bulkheads (see Figure 7). Remove the

slotted through plug, it will be used later. Replace the compression nut, but do not tighten. Remove the cover of

the vertical wiring duct by pressing the fingers on the sides inward. Locate the heating cable power block (labeled

L3 & L4). The heating cable should now be stripped and prepared for power and ground connection at one end,

and sealed at the other. Feed the prepared end carefully through the bulkhead far enough to make the power and

ground hookup (about nine inches). Connect the power wires to the power block and the rolled braided shield wire

to the ground terminal block (see Figure 4). Run the heating cable into the wiring duct and through the fingers so

there are no kinks or slack in the cable. Replace the wiring duct cover. Unscrew the compression nut and allow

it to slide down the cable a few inches. The slotted through plug should be slit on one side to allow it to be wrapped

around the heating cable. Wrap it around the cable with the chamfered end down just below the bulkhead fitting.

Slide the plug into the bulkhead and tighten the compression nut behind it by hand. A wrench should not be

necessary.

Only route drain line to a free flowing drain.Only route drain line to a free flowing drain.

Only route drain line to a free flowing drain.

Only route drain line to a free flowing drain.Only route drain line to a free flowing drain.

Only use as much line as needed. The excess should be cut off.Only use as much line as needed. The excess should be cut off.

Only use as much line as needed. The excess should be cut off.

Only use as much line as needed. The excess should be cut off.Only use as much line as needed. The excess should be cut off.

COLD WEATHER COLD WEATHER

COLD WEATHER

COLD WEATHER COLD WEATHER

Heating Cable InstallationHeating Cable Installation

Heating Cable Installation

Heating Cable InstallationHeating Cable Installation

Refer to Figures 4, 6 and 7.

KIT KIT

INSTALLATIONINSTALLATION

KIT

INSTALLATION

KIT KIT

INSTALLATIONINSTALLATION

TUV (01/03) Page 3

REV. 2.2

Page 12

2.4.22.4.2

2.4.2

2.4.22.4.2

Pull the intake and drain lines out and lay them together with the heating cable (which should have already

been installed) as straight as possible. Slide the enclosure interface over all three lines up to the bulkhead

panel with the larger opening upward (see Figure 7). Using the 15-inch cable tie, cinch the interface around

the three bulkheads tightly. The insulation lenghts and the couplers are slit lenghtwise to allow assembly over

the lines, instead of running the lines through the insulation. Wrap a 6-foot length around the lines and cable

and slide it up to the interface.

Peel the backing tape from both sides of the slit and press together. Apply adhesive to the outside of the last

two inches on the end close to the interface. Slide the length into the interface no more than two inches while

twisting it to spread the adhesive evenly. Make sure that the intake and drain lines are not kinked. Wrap

another 6-foot length around the lines and cable and slide it up to the first length.

Peel the backing tape from both sides of the slit and press together. Apply some adhesive where the two pieces

butt together, then press and hold the joint until a bond is formed. The 8 inch sections of insulation are

designed to act as couplings between the 6 foot lengths. After the butt joint is bonded, apply more adhesive

around the joint not more than 4 inches in either direction. Take an 8-inch coupling and wrap it around the

joint, making sure it is centered. Peel the backing tape from both sides of the slit and press together. Hold

until the applied adhesive begins to set up. Repeat this process down to the end of the line. Cut off any excess

insulation 6 inches (150mm) above the intake filter. It is recommended that the insulated lines be run through

PVC pipe for extra protection and that any bends are very gradual to avoid kinks in the lines.

Pipe Insulation InstallationPipe Insulation Installation

Pipe Insulation Installation

Pipe Insulation InstallationPipe Insulation Installation

3.03.0

3.0

3.03.0

3.13.1

3.1

3.13.1

The HF scientific On-line UV Transmission Sensor/Sampler is intended to operate along with a controller

or analyzer to comprise a complete "system". The TUV Sensor/Sampler can perform all of it's own

internal control functions, but it has no form of input or output. The Sensor/Sampler communicates

to the controller or analyzer through an RS-485 data port. It is the controller or analyzer's job to ask

for readings and interpret them. The controller or analyzer is also responsible for initiating

calibrations, displaying data and supporting control functions. Please refer to the manuals accompanying the controller or analyzer for complete information of its operation.

The HF scientific On-line UV Transmission Sensor/Sampler is specifically designed to monitor the

transmission of 253.7nm light through fluid being pumped through the sensor cuvette. The low-pressure

mercury vapor lamp is temperature controlled by the Sensor/Sampler’s microprocessor, which turns the

lamp to the “on” state for a fraction of a second every 30 seconds. During this short interval several hundred

readings of the transmission are taken. These readings are digitally signal processed over the "on" time

period to preclude instantaneous fluctuations from biasing the value. Because the lamp is "on" for such

a short period, UV degradation of the optical path is held to an absolute minimum.

The Sensor/Sampler enclosure houses the sampling pump, control valve and a one gallon empty container

for the 100% transmission calibration fluid. The amount of calibration fluid is sufficient for approximately

15 calibrations, and is contained in a replaceable container. The calibration fluid is available as a

replacement item. The entire pump-head kit is replaceable and is available as Part No. 22041. The Sensor/

Sampler also houses the Sensor module, CPU module, Power Supply module, cabinet heater, T-strainer,

and flow sensor. Refer to Section 7.3 for replacement part numbers.

STEP-BY-STEP OPERATISTEP-BY-STEP OPERATI

STEP-BY-STEP OPERATI

STEP-BY-STEP OPERATISTEP-BY-STEP OPERATI

THEORY OF OPERATIONTHEORY OF OPERATION

THEORY OF OPERATION

THEORY OF OPERATIONTHEORY OF OPERATION

ONON

ON

ONON

The CPU module controls the lamp heat, serial port communication system, and many other housekeeping

functions. A signal from the flow sensor will shut the unit down if insufficient flow is detected for more

that 10 seconds. This safeguard will prevent a buildup of pressure if a line were to get clogged or excessive

leakage if a line or connector were to fail.

TUV (01/03) Page 4

REV. 2.2

Page 13

Inside the Sensor module, warm dry air is constantly circulated around the exterior of the sampling cuvette

to prohibit condensation. A desiccant tray is provided to dry the heated air. To avoid flooding in case of cuvette

breakage within the sensor housing, a foot valve is included which normally seals the drain connection from

the outside air. This valve is a float valve, which only opens in the presence of water. In case of cuvette

breakage the float valve directs water to the outside of the Sensor/Sampler enclosure through an emergency

drain.

Controls for the Sensor/Sampler are Power On/Off, and the Pump On/Off. The CPU module contains L.E.D.

status lamps as shown below:

LED Name Purpose/Description

Lamp Heat Lamp Heater On (Blinking=Normal)

Pump Pump On

Lamp Lamp on (100 mS)

Valve Valve on during 100% Cal cycle

Flow Flow (On=NoFlow)

(Off=Normal Operation)

(Blinking=Low Flow)

The Sensor/Sampler also contains a thermostatically controlled heater that is used for cold climates. The

heater’s fan runs constantly even though the heating elements are only activated at the set temperature. (50°F)

3.23.2

3.2

3.23.2

NOTE: 100% T solution can be purchased from NOTE: 100% T solution can be purchased from

NOTE: 100% T solution can be purchased from

NOTE: 100% T solution can be purchased from NOTE: 100% T solution can be purchased from

(distilled water).(distilled water).

(distilled water).

(distilled water).(distilled water).

After the plumbing is complete the system needs to be bled of air. Turn the Sensor/Sampler power on. It may

take up to 8 minutes to purge the system of air. This will require that the CPU is reset, as it may shut off after

a few minutes of running air. Use the push button on the Power Supply Module to perform this.

Once the plumbing system is purged of all air and the flow head cleaned and locked in place, install the fresh

100%T solution container in the sampler inside the main cabinet.

4.04.0

4.0

4.04.0

The Sensor/Sampler requires calibrations occasionally to adjust for debris buildup on the cuvette. Calibrations are initiated by periods set in the analyzer, usually every 24-48 hours. A calibration consists of a dark

reading and a 100%T reading. Dark readings set the low end of the readable scale and 100%T calibrations set

the upper end.

4.14.1

4.1

4.14.1

START UPSTART UP

START UP

START UPSTART UP

HF scientificHF scientific

HF scientific

HF scientificHF scientific

WARNING: Using distilled water may affect accuracy of the WARNING: Using distilled water may affect accuracy of the

WARNING: Using distilled water may affect accuracy of the

WARNING: Using distilled water may affect accuracy of the WARNING: Using distilled water may affect accuracy of the

CALIBRATIONCALIBRATION

CALIBRATION

CALIBRATIONCALIBRATION

100%T CALIBRATION100%T CALIBRATION

100%T CALIBRATION

100%T CALIBRATION100%T CALIBRATION

. .

If necessary, it can be purchased If necessary, it can be purchased

.

If necessary, it can be purchased

. .

If necessary, it can be purchased If necessary, it can be purchased

TUVTUV

TUV

TUVTUV

locallylocally

locally

locallylocally

..

.

..

During a 100%T calibration the solenoid/valve will switch the source of fluid supply from the effluent

sample, to the 100%T water. It will pump this water for a predetermined time and then shut the pump

down. During this shutdown period the Sensor/Sampler’s CPU will perform several calibrations and

will adjust its gain to the amount of signal available dependant on the condition of the optical path (debris

or contaminant on the cuvette walls). The solenoid/valve will then return to providing the sample to the

pump intake and the pump will restart. At this time the Sensor/Sampler is returned to normal on-line

operation.

TUV (01/03) Page 5

REV. 2.2

Page 14

55

.0 .0

5

55

FLOW SENSORFLOW SENSOR

.0

FLOW SENSOR

.0 .0

FLOW SENSORFLOW SENSOR

The Sensor/Sampler has a flow sensor that will detect a flow failure, turn off the pump and indicate a flow

failure to the controller or analyzer. The flow sensor is ignored after the CPU is reset for the first few minutes

of operation to allow the system to prime with sample fluid. The flow sensor is also ignored after a calibration

for two minutes. The flow sensor should trip after ten seconds of no flow which is indicated by the FLOW LED

illuminated in the CPU Module of the Sensor/Sampler.

6.0 6.0

MAINTENANCEMAINTENANCE

6.0

MAINTENANCE

6.0 6.0

MAINTENANCEMAINTENANCE

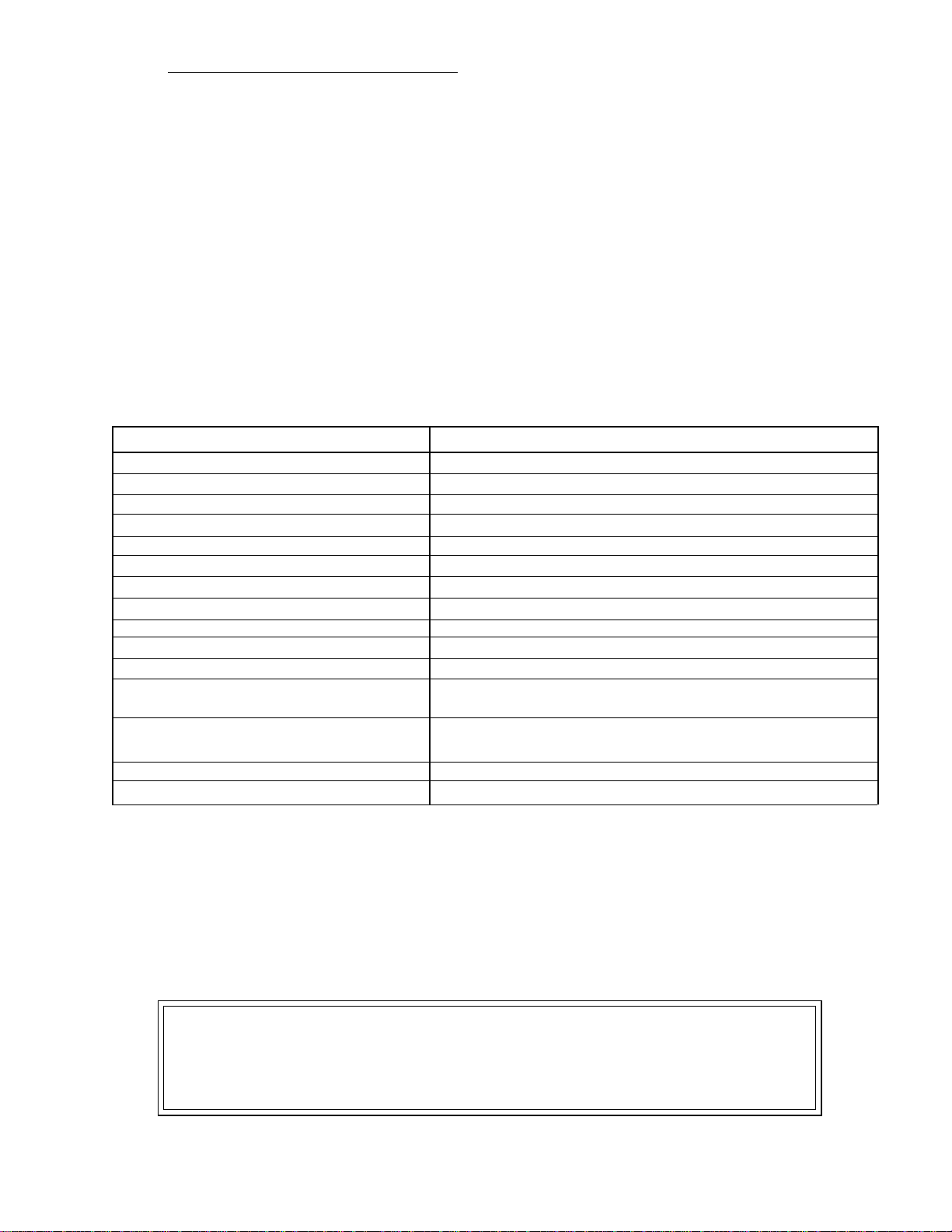

Recommended Maintenance IntervalsRecommended Maintenance Intervals

Recommended Maintenance Intervals

Recommended Maintenance IntervalsRecommended Maintenance Intervals

Maintenance Daily Weekly Monthly Every 3 Yearly Reference

Required Months Section

Check T – X 6.3

Strainer

Check cuvette X 6.2

Check 100% X 6.5

T level

Clean intake X 6.6

strainer

Clean T – X 6.3

strainer

Clean cuvette X 6.2

Check X 6.4

desiccant

colour

System X 6.1

cleaning

Replace pump X 6.7

tubing

Replace X 6.8

system tubing

Note: maintenance intervals may be more frequent in certain sites.

TUV (01/03) Page 6

REV. 2.2

Page 15

6.1 SYSTEM6.1 SYSTEM

6.1 SYSTEM

6.1 SYSTEM6.1 SYSTEM

WARNING:WARNING:

WARNING:

WARNING:WARNING:

the chemicals in this procedure. (See precauthe chemicals in this procedure. (See precau

the chemicals in this procedure. (See precau

the chemicals in this procedure. (See precauthe chemicals in this procedure. (See precau

CLEANINGCLEANING

CLEANING

CLEANINGCLEANING

The use of safety glasses is recommended. Follow all safety procedures withThe use of safety glasses is recommended. Follow all safety procedures with

The use of safety glasses is recommended. Follow all safety procedures with

The use of safety glasses is recommended. Follow all safety procedures withThe use of safety glasses is recommended. Follow all safety procedures with

tt

ions on M.S.D.S. data sheets)ions on M.S.D.S. data sheets)

t

ions on M.S.D.S. data sheets)

tt

ions on M.S.D.S. data sheets)ions on M.S.D.S. data sheets)

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

NOTE:NOTE:

NOTE:

NOTE:NOTE:

Avoid getting air into the system. Avoid letting the source line come out of theAvoid getting air into the system. Avoid letting the source line come out of the

Avoid getting air into the system. Avoid letting the source line come out of the

Avoid getting air into the system. Avoid letting the source line come out of theAvoid getting air into the system. Avoid letting the source line come out of the

source water.source water.

source water.

source water.source water.

If the system is not immediately put back into operationIf the system is not immediately put back into operation

If the system is not immediately put back into operation

If the system is not immediately put back into operationIf the system is not immediately put back into operation

water through the system to flush out any remaining cleaning agents.water through the system to flush out any remaining cleaning agents.

water through the system to flush out any remaining cleaning agents.

water through the system to flush out any remaining cleaning agents.water through the system to flush out any remaining cleaning agents.

For the following Steps use the Pump Switch to stop the pumping action, leaving the mainFor the following Steps use the Pump Switch to stop the pumping action, leaving the main

For the following Steps use the Pump Switch to stop the pumping action, leaving the main

For the following Steps use the Pump Switch to stop the pumping action, leaving the mainFor the following Steps use the Pump Switch to stop the pumping action, leaving the main

power switch ON. This prevents the system from cooling off.power switch ON. This prevents the system from cooling off.

power switch ON. This prevents the system from cooling off.

power switch ON. This prevents the system from cooling off.power switch ON. This prevents the system from cooling off.

after system cleaning after system cleaning

after system cleaning

after system cleaning after system cleaning

, ,

run cleanrun clean

,

run clean

, ,

run cleanrun clean

Step 1 - With the Pump Switch OFF, undo the quick connect just to the left of the T-strainer by

pressing the metal button and pulling it apart.

Step 2 - Using the cleaning kit provided, insert the quick connect to the T-strainer connection.

Drop the suction tube into 6% Sodium Hypochloride. Turn Pump ON for 5 minutes.

Turn pump OFF and let stand for 5 minutes before proceeding to next step.

Step 3 - Insert the suction line into a source of clean water. Turn the Pump Switch ON and pump

for 5 minutes.

Step 4 - Insert the suction line into a solution of 50/50% Lime-A-Way ® and water. Turn the Pump

Switch ON and pump for 5 minutes. Turn pump OFF and let stand for 5 minutes before

proceeding to next step.

Step 5 - Remove the cleaning solution kit from the quick connect and reconnect the source line.

Turn the Pump Switch ON.

Step 6 - Restart the system at the controller or analyzer.

6.26.2

6.2

6.26.2

It is recommended that the

visually for clarity daily. Altough the instrument

compensates for build-up on the glass, the cuvette

will need to be manually cleaned from time to time.

To visually inspect the cuvette, remove the flow head

from the sensor by gripping it with one hand while

twisting the locking collar counter-clockwise with

the other. Pull the flow head out of the sensor and

observe the condition of the glass. If the cuvette

requires manual cleaning, place a cover over the

sensor top so that no moisture or foreign objects will

enter the sensor. Also, turn the pump off at the

pump switch before removing the cuvette from the flow head. To remove the cuvette, hold the flow head

CUVETTECUVETTE

CUVETTE

CUVETTECUVETTE

MAINTENANCE MAINTENANCE

MAINTENANCE

MAINTENANCE MAINTENANCE

cuvette be checked

flow head

Remove any moisture.

Do not touch glass with

fingers

Quartz Flow Head Assembly

Screw and unscrew the cuvette

by gripping fingers on this

surface only.

cuvette

Figure 2

with one hand while turning the cuvette counterclockwise by gripping it at the top only. Refer to Figure 2.

The quartz cuvette supplied with the unit must be clean and free of all fingerprints. Cleaning is accomplished

by washing the interior and exterior of the cuvette in a mild liquid detergent solution (.5 ml/4L water). Then

rinse it thoroughly 8 to 10 times, in clean distilled water, to remove all streaks. To remove slime and scale

deposits, use diluted bleach to first remove slime and then use Lime-A-Way® to remove scale.

(NOTE: Dispose of in accordance with all applicable environmental regulations).

TUV(01/03) Page 7

REV. 2.2

Page 16

If the cuvette does not appear to be clean, use soft, lint-free tissues (i.e. Kimwipe® ) to wipe the inside then rinse

with clean water. Dry the outside completely prior to reinserting it into the optical well. Turn the cuvette into

the flow head by gripping at the top, turning clockwise, seat it with fingers only.

Place the flow head back into the sensor and lock in place by holding the flow head still while twisting the

locking collar clockwise. Turn the pump back on and restart the system.

NOTE: The instrument may have to be restarted a few times using the push button on the power supply

module if it has lost its prime during this operation.

6.6.

33

6.

6.6.

The T-strainer is designed to keep heavy solids from plugging internal orifices within the instrument. If the

T-strainer is not cleaned periodically, components such as the pump, solenoid and flow sensor could be damaged.

The T-strainer is designed such that the solids build up between the screen and the housing so that the user can

visually see how clogged it is. If the T-strainer is clogged, turn the pump switch off. Unclip the T-strainer by

pulling it out from its retaining clip. Hold it outside the enclosure to avoid spilling water inside. You may wish

to open the T-strainer over a bucket or drain as about 300ml of water will spill as the filter is opened. Unscrew

the clear body and remove the filter screen. Clean the screen and body thoroughly. Fill the body with clean

water. Reassemble the filter assembly and return it to the clip. Turn the pump switch ON and prime the system

by resetting the instrument. The instrument may be reset by turning the power supply module switch off and then

on.

T-STRAINER MAINTENANCET-STRAINER MAINTENANCE

3

T-STRAINER MAINTENANCE

33

T-STRAINER MAINTENANCET-STRAINER MAINTENANCE

NOTE: The instrument may have to be restarted a few times using the push button on the power supply

module if it has lost its prime during this operation.

6.6.

44

6.

6.6.

The desiccant beads are dark blue when dry and turn to a light pink when expended. Check the desiccant if after

cleaning, the TUV readings appear erroneously high. It is important to keep a cover on the sample well

of the sensor module if the quartz cuvette is out for more than a few minutes, to avoid saturating the

desiccant uselessly. A replacement desiccant tray complete with foot valve is available as Part No. 21555.

Refer to Figure 1 when replacing the desiccant.

NOTE: Moisture presence in the desiccant could cause erroneous readings.NOTE: Moisture presence in the desiccant could cause erroneous readings.

NOTE: Moisture presence in the desiccant could cause erroneous readings.

NOTE: Moisture presence in the desiccant could cause erroneous readings.NOTE: Moisture presence in the desiccant could cause erroneous readings.

Remember to dry the quartz cuvette of excess moisture before inserting it into the optical well. This will speed

up the evaporation time.

NOTE: The desiccant tray is nNOTE: The desiccant tray is n

NOTE: The desiccant tray is n

NOTE: The desiccant tray is nNOTE: The desiccant tray is n

6.6.

6.

6.6.

The 100% T calibration solution is in the 4 liter bottle that is mounted on the door of the TUV Sensor/

Sampler (Refer to figure 4). This bottle is shipped empty with the instrument and must be filled during

the installation. A full bottle is good for about 15 calibrations. Since automatic calibration cycles are user

settable, the life of a full bottle will vary. The bottle should be refilled or replaced when the level of solution

gets to within one inch from the bottom.

DESICCANT MAINTENANCEDESICCANT MAINTENANCE

4

DESICCANT MAINTENANCE

44

DESICCANT MAINTENANCEDESICCANT MAINTENANCE

otot

rechargeable. rechargeable.

ot

rechargeable.

otot

rechargeable. rechargeable.

55

100% T CALIBRATION SOLUTION MAINTENANCE100% T CALIBRATION SOLUTION MAINTENANCE

5

100% T CALIBRATION SOLUTION MAINTENANCE

55

100% T CALIBRATION SOLUTION MAINTENANCE100% T CALIBRATION SOLUTION MAINTENANCE

Replacement bottles of 100% T solution may be ordered from HF scientific.

To replace the bottle, disconnect the hose at the quick connect. Remove the bottle to replace or refill, reusing the

provided cap equipped with the quick connect.

TUV (01/03) Page 8

REV. 2.2

Page 17

A full bottle of 100% T solution will last for about 15 calibrations. The controller or analyzer will remind you

when the bottle is empty. Replacement is essential for proper operation.

6.66.6

6.6

6.66.6

There is an intake strainer at the begining of the intake line that prevents large particles from entering the system.

This strainer may get clogged and have to be cleaned. It should be checked periodically by pulling the intake line

up from the channel and visually inspecting the strainer. Clean the strainer using a brush and/or pressurized water

spray. If there is build-up within the strainer, it may be soaked in a 50/50% Lime-A-Way solution.

6.76.7

6.7

6.76.7

As with all peristaltic type pumps, the tubing will eventually wear out and need replacement. Replacement

tubing is available in a Pump Tubing Kit (Part # 22047). To replace the tubing, first remove the hose clamps

from the tubing at the pump head (twist clamp to disengage teeth). Pull the suction and discharge lines from

the pump head tubing (including the elbows). Rotate the pump head counterclockwise (see arrows in Figure A)

to disengage from the latch studs on the pump enclosure. Loosen the latch screws if necessary. DO NOT

REMOVE LATCH SCREWS.

CLEANING THE INTAKE STRAINERCLEANING THE INTAKE STRAINER

CLEANING THE INTAKE STRAINER

CLEANING THE INTAKE STRAINERCLEANING THE INTAKE STRAINER

REPLACING PUMP TUBINGREPLACING PUMP TUBING

REPLACING PUMP TUBING

REPLACING PUMP TUBINGREPLACING PUMP TUBING

FIGURE A

Grasp the tabs on the back cover of the pump head and pull straight out to remove. CAUTION: DO NOT

LOSE THE BEARING FROM THE CENTER HOLE ON THE BACK COVER. It is not necessary to remove

the spider and bearings from the housing.

FIGURE C

Remove the old tubing and retaining collars from the pump head. Position the spider as shown in Figure C.

Put the retaining collar on the new pump tubing as shown and position the collar in the pump head with the

open end facing outward. While rotating the spider counterclockwise, push the tubing into the housing to

center over the rollers as shown in Figure C. Replace the back cover on the pump head. BE SURE IT FITS

TIGHTLY AND FLUSH WITH THE HOUSING. Slide the pump head onto the motor drive shaft and turn it

clockwise to lock onto the 2 latch screws. Retighten the latch screws to secure the pump head. Push the

suction and discharge line elbows into the new pump tubing and secure with the hose clamps. Use pliers to

squeeze the clamps tightly. CAUTION: Hose clamps must be tightened securely to prevent leakage.

TUV(01/03) Page 9

REV. 2.2

FIGURE B

Page 18

6.86.8

6.8

6.86.8

All the tubing in the system should be checked at least yearly for wear. A Tubing Kit (Part# 22887) is available which contains enough tubing to replace all the tubing in the system. To replace a length of tubing, turn

the pump off and remove the piece of tubing from the system by unscrewing the compression nuts at both

ends. Slide the nuts back onto the tubing and remove the inserts from each end of the tubing. Remove the

nuts, measure the length of tubing and discard the worn tubing. Cut a piece of new tubing the same length as

the worn tubing. Slide the compression nuts onto the tubing from each end so that the threads are facing

outward and push an insert into each end. Slide the compression nuts up to the inserts and screw the new

tubing in place within the unit. Dress the tubing into the unit as it was before. Turn the pump back on and

resume normal operation.

NOTE: The instrument may have to be restarted a few times using the push button on the power supply

module if it has lost its prime during this operatio

6.6.

6.

6.6.

If the TUV is to be shut down for any long period of time, such as for winter, follow the procedure below

to prepare the Sensor/Sampler enclosure for storage.

Run two cleaning cycles as described in section 6.1. Clean the T-strainer as in section 6.3. After flushing with

the Lime-A-Way, fill the bottles with clean water and flush the system with at least four bottles of clean water.

Disconnect the cleaning solution line and leave the quick connect open. Run the system to bleed the lines of

water.

REPLACING SYSTEM TUBINGREPLACING SYSTEM TUBING

REPLACING SYSTEM TUBING

REPLACING SYSTEM TUBINGREPLACING SYSTEM TUBING

99

SHUT DOWN PROCEDURESHUT DOWN PROCEDURE

9

SHUT DOWN PROCEDURE

99

SHUT DOWN PROCEDURESHUT DOWN PROCEDURE

n.

Shut down all power to the system. Remove the cuvette and the 100%T solution. Disconnect the tubings to the

pump. Loosen the two pump head screws, then turn the pump head counterclockwise and remove. Store the

cuvette, 100%T solution and pump head in a safe place that is maintained at room temperature.

Before starting the system again, it is recommended that clean water be back-flushed through the source line

with a water hose to clean the source strainer and ensure that the line is clear. Check the drain line in the same

manner. Reinstall these lines, the cuvette, the pump head and the 100%T bottle. Start up the system as described

in section 3.2

7.0 7.0

7.0

7.0 7.0

7.1 7.1

7.1

7.1 7.1

Service and Technical Support are available from HF scientific, inc., 3170 Metro Parkway, Fort Myers, FL

33916-7597@ Phone (239) 337-2116, Fax (239) 332-7643

TROUBLESHOOTINGTROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTINGTROUBLESHOOTING

GENERAL NOTESGENERAL NOTES

GENERAL NOTES

GENERAL NOTESGENERAL NOTES

TUV (01/03) Page 10

REV. 2.2

Page 19

7.2 7.2

7.2

7.2 7.2

The following table will supply fundamental troubleshooting information. The guide assumes that the controls

and functions of the instrument are used correctly. The intention of the guide is to eliminate common faults,

not to troubleshot down to component level.

Sensor/Sampler:Sensor/Sampler:

Sensor/Sampler:

Sensor/Sampler:Sensor/Sampler:

TROUBLESHOOTING GUIDETROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDETROUBLESHOOTING GUIDE

SYMPTOMSYMPTOM

SYMPTOM

SYMPTOMSYMPTOM

Flow Stopped

Pump won't prime

Pump shuts down

SOLUTIONSOLUTION

SOLUTION

SOLUTIONSOLUTION

1. Ensure that the Pump Switch is ON.

2. There is a sieve located at the suction end of the source line

that functions as a filter for larger particles. Also, there is a

T-strainer which functions as a sacrificial element in that it will

clog before any of the internal path of the sensor/pump

stream. These should be checked as the most likely place of

blockage and either cleaned or replaced.

3. The system should be periodically cleaned (site-sensitive).

4. The flow switch may be clogged.

1. Clean T-strainer.

2. Check source line for blockage.

3. Check pump tubing for wear. Replace tubing if needed.

4. Check all tubing for kinks.

5. Check pump head for wear. Replace pump head if needed.

6. Check for blockage and check all tubing connections.

7. Check flow switch for blockage.

Observe flow LED during operation, could be air leakage

or plugged strainers.

Readings fluctuate

5-10 units

Error Codes/Alarms

TUV (01/03) Page 11

REV. 2.2

There may be moisture present in the desiccant tray or

cleaning solution in the standpipe.

Refer to Analyzer Manual.

Page 20

7.7.

7.

7.7.

33

REPLACEMENT PARTSREPLACEMENT PARTS

3

REPLACEMENT PARTS

33

REPLACEMENT PARTSREPLACEMENT PARTS

Part No. Description

19306 100% T Solution, 1 x 4 gallon/4L

20616 Heating Cable (120V)

20815 Wire Shielded RS-485 (per foot)

19403 Cleaning Solution Kit (includes modified cap, tubing and connectors)

21380 Quick Connect Coupler Assembly

22966 Cold Weather Kit (includes heating cable, insulation, hardware

and instructions)

21766 Cabinet Heater (120V)

22974 Cuvette, Quartz Threaded

21555 Desiccant Tray Kit (includes foot valve)

22887 Tubing Kit, On-line TUV (includes replacement tubing and fittings for

the entire instrument)

22041 Pump Head Kit (includes pump head and tubing clips)

22047 Pump tubing Kit (includes pump tubing and hose clamps)

22811 Source Tubing Assembly with strainer (25 ft.)

22884 Pump Motor Assembly

22977 Sensor Module

22982 Power Supply Module

22987 CPU Module

22990 Flow Sensor Assembly

22972 Quartz Flow Head Assembly

22298 T-Strainer Assembly

22299 Replacement T-strainer Screen

22240 Circuit Breaker

21366 Earth Leakage Breaker

50064 Step-Down Transformer (230v units only)

NOTE: For any other parts not shown here, please contact HF scientific, inc..

TUV (01/03) Page 12

REV. 2.2

Page 21

Figure 3

Sensor/Sampler Outline Dimensions

TUV(01/03) Page 13

REV. 2.2

Page 22

°20°

°

°

FLUID

100%T CALIBRATION

QUICK CONNECT

ASSEMBLY

T-STRAINER

CABINET HEATER

POWER

MODULE

POWER SUPPLY

BUTTON

(230V UNITS ONLY)

STEP-DOWN TRANSFORMER

CAUTION:SURFACE MAY BE HOT

0

ELECTRIC HEATER

EP 12 43

#

%#

#

.

100

40

O

42

13

I

O

O

+"

2C4.0

1

CIRCUIT BREAKER

2

PUMP SWITCH

PUMP/SOLENOID MODULE

ON

OFF

756 98

L

N

PUMP HEAD KIT

HEATING CABLE

CONNECTIONS

5 6789

L3

L4

SHIELD

HEATING CABLE LINE

HEATING CABLE LINE

HEATING CABLE BULKHEAD

INTAKE TUBING BULKHEAD

POWER CORD BULKHEAD

Figure 4

Interior/Exterior Plumbing and Electrical Connections

CPU MODULE

POWER CORD CONNECTIONS

RS 485 CONNECTIONS

EARTH LEAKAGE BREAKER

PE 1 32 4

SENSOR MODULE

QUARTZ CUVETTE

RS 485 BULKHEAD

EMERGENCY DRAINS

(INSIDE SENSOR)

FLOW SENSOR ASSEMBLY

DRAIN TUBING BULKHEAD

DESSICANT TRAY ASSEMBLY

QUARTZ FLOW HEAD ASSEMBLY

FLOW SWITCH

FLOW SWITCH

RS 485A (RED)

RS 485 SHIELD

RS 485B (BLACK)

TUV(01/03) Page 14

REV. 2.2

Page 23

TUV (01/03) Page 15

REV. 2.2

Figure 5

Power Input Cable Connections

Page 24

Figure 6

Heater Cable Stripping Instructions

TUV (01/03) Page 16

REV. 2.2

Page 25

Figure 7

Cold Weather Kit Installation Details

TUV (01/03) Page 17

REV. 2.2

Page 26

WARRANTY

HF scientific, inc., as manufacturer, warrants to the original purchaser of the instruments to be

free of defects in material and workmanship, in normal use and service, for a period of one year from

date of delivery to the original purchaser. HF scientific, inc.'s, obligation under this warranty

is limited to replacing, at its factory, the instrument or any part thereof. Parts which by their nature are

normally required to be replaced periodically, consistent with normal maintenance, specifically lamps,

reagent, desiccant, sensors, electrodes and fuses are excluded. Also excluded are accessories and supply type

items.

Original purchaser is responsible for return of the instruments, or parts thereof, to HF scientific, inc.'s

factory. This includes all freight charges incurred in shipping to and from HF scientific, inc.'s factory.

HF scientific, inc. is not responsible for damage to the instrument, or parts thereof,

resulting from misuse, negligence or accident, or defects resulting from repairs, alterations or installation

made by any person or company not authorized by HF scientific, inc.

HF scientific, inc. assumes no liability for consequential damage of any kind, and the

original purchaser, by placement of any order for the instrument, or parts thereof, shall be deemed liable

for any and all damages incurred by the use or misuse of the instruments, or parts thereof, by the

purchaser, its employees, or others, following receipt thereof.

This warranty is given expressly and in lieu of all other warranties, expressed or implied.

Purchaser agrees that there is no warranty on merchantability and that there are no other warranties, expressed or implied. No agent is authorized to assume for HF scientific, inc. any liability except

as above set forth.

HF scientific, inc.

3170 Metro Parkway

Fort Myers, FL 33916-7597

Phone: (239) 337-2116

Fax: (239) 332-7643

TUV(01/03) Page 18

REV. 2.2

Page 27

APPENDIX A

DATE: August 11, 1998

REVISION: 3

MATERIAL SAFETY DATA SHEETMATERIAL SAFETY DATA SHEET

MATERIAL SAFETY DATA SHEET

MATERIAL SAFETY DATA SHEETMATERIAL SAFETY DATA SHEET

HF scientific, inc.

3170 Metro Parkway

Fort Myers, FL 33916-7597

239-337-2116

EMERGENCY CONTACT:EMERGENCY CONTACT:

EMERGENCY CONTACT:

EMERGENCY CONTACT:EMERGENCY CONTACT:

SECTION 1 PRODUCT IDENTIFICATIONSECTION 1 PRODUCT IDENTIFICATION

SECTION 1 PRODUCT IDENTIFICATION

SECTION 1 PRODUCT IDENTIFICATIONSECTION 1 PRODUCT IDENTIFICATION

PRODUCT NAME: 100% T Reference Solution

CATALOG NUMBERS: P19310 AND 905004

CHEMICAL FAMILY: NA

SYNONYMS: NA

FORMULA:

SECTION 2 HAZARDOUS INGREDIENTSSECTION 2 HAZARDOUS INGREDIENTS

SECTION 2 HAZARDOUS INGREDIENTS

SECTION 2 HAZARDOUS INGREDIENTSSECTION 2 HAZARDOUS INGREDIENTS

Hazardous

Ingredients OSHA PEL ACGIH TLV

No hazardous or carcinogenic material greater than or equal to 0.1%

SECTION 3 PHYSICAL DATASECTION 3 PHYSICAL DATA

SECTION 3 PHYSICAL DATA

SECTION 3 PHYSICAL DATASECTION 3 PHYSICAL DATA

BoilingBoiling

Boiling

BoilingBoiling

Solubility In Water:Solubility In Water:

Solubility In Water: Miscible

Solubility In Water:Solubility In Water:

Vapor PressureVapor Pressure

Vapor Pressure

Vapor PressureVapor Pressure

Melting Point:Melting Point:

Melting Point: Not applicable

Melting Point:Melting Point:

Appearance And Odor:Appearance And Odor:

Appearance And Odor: Clear, colorless solution. No appreciable odor

Appearance And Odor:Appearance And Odor:

Vapor Density (Air=1):Vapor Density (Air=1):

Vapor Density (Air=1): Not found

Vapor Density (Air=1):Vapor Density (Air=1):

Specific Gravity (H20=1):Specific Gravity (H20=1):

Specific Gravity (H20=1): Ap pr ox im ately 1

Specific Gravity (H20=1):Specific Gravity (H20=1):

Percent Volatile By Vol:Percent Volatile By Vol:

Percent Volatile By Vol: Not found

Percent Volatile By Vol:Percent Volatile By Vol:

Evaporation Rate (Butyl Acetate=1):Evaporation Rate (Butyl Acetate=1):

Evaporation Rate (Butyl Acetate=1): Like water

Evaporation Rate (Butyl Acetate=1):Evaporation Rate (Butyl Acetate=1):

SECTION 4 FIRE AND EXPLOSION HAZARDSECTION 4 FIRE AND EXPLOSION HAZARD

SECTION 4 FIRE AND EXPLOSION HAZARD

SECTION 4 FIRE AND EXPLOSION HAZARDSECTION 4 FIRE AND EXPLOSION HAZARD

DATADATA

DATA

DATADATA

Flash Point (Method Used):Flash Point (Method Used):

Flash Point (Method Used): Not flammable

Flash Point (Method Used):Flash Point (Method Used):

Flammable Limits:Flammable Limits:

Flammable Limits: Not flammable

Flammable Limits:Flammable Limits:

Fire Extinguishing Media:Fire Extinguishing Media:

Fire Extinguishing Media: Suitable to cause of fire

Fire Extinguishing Media:Fire Extinguishing Media:

Fire Fighting Procedures: Fire Fighting Procedures:

Fire Fighting Procedures: Suitable to cause of fire

Fire Fighting Procedures: Fire Fighting Procedures:

Unusual Fire And Explosive Hazards:Unusual Fire And Explosive Hazards:

Unusual Fire And Explosive Hazards: None

Unusual Fire And Explosive Hazards:Unusual Fire And Explosive Hazards:

HF scientific, inc.

3170 Metro Parkway

Fort Myers, FL 33916-7597

239-337-2116

Water, CAS # 7732-18-5, >99.9%

Formaldehyde, CAS # 50-00-0, <0.1%

Point:Point:

Point: Approx 100 deg C

Point:Point:

(mm Hg):(mm Hg):

(mm Hg): Not found

(mm Hg):(mm Hg):

Emergency First Aid Procedures:

Eyes: Immediately flush eyes gently with copious quantities of

water for a minimum of 15 minutes. Use fingers to assure that eyelids are

separated and that eye is being irrigated. Call a physician.

Skin: Skin:

Skin: Remove contaminated clothing. Flush contaminated area with

Skin: Skin:

copious quantities of water for 15 minutes. Call a physician.

Ingestion: Ingestion:

Ingestion: Unless large quantities are ingested, no problems should occur.

Ingestion: Ingestion:

If symptoms develop, see a physician.

Inhalation: Inhalation:

Inhalation: Unless large quantities are inhaled, no problems should

Inhalation: Inhalation:

occur. If symptoms develop, see a physician.

SECTION 6 REACTIVITY DATASECTION 6 REACTIVITY DATA

SECTION 6 REACTIVITY DATA

SECTION 6 REACTIVITY DATASECTION 6 REACTIVITY DATA

Stability: Stability:

Stability: Stable under normal conditions of storage and use.

Stability: Stability:

Conditions To Avoid:Conditions To Avoid:

Conditions To Avoid: Do not breathe vapors.

Conditions To Avoid:Conditions To Avoid:

Incompatibilities (Materials To Avoid):Incompatibilities (Materials To Avoid):

Incompatibilities (Materials To Avoid): Avoid oxidizing agents,

Incompatibilities (Materials To Avoid):Incompatibilities (Materials To Avoid):

alkalies, and nitrogen dioxide.

Hazardous Decomposition Products:Hazardous Decomposition Products:

Hazardous Decomposition Products: Should not form.

Hazardous Decomposition Products:Hazardous Decomposition Products:

Hazardous Polymerization:Hazardous Polymerization:

Hazardous Polymerization: Will not occur under normal conditions of

Hazardous Polymerization:Hazardous Polymerization:

use and storage.

SECTION 7 SAFE HANDLING AND USESECTION 7 SAFE HANDLING AND USE

SECTION 7 SAFE HANDLING AND USE

SECTION 7 SAFE HANDLING AND USESECTION 7 SAFE HANDLING AND USE

Steps To Be Taken In Case Material Is Released Or Spilled:Steps To Be Taken In Case Material Is Released Or Spilled:

Steps To Be Taken In Case Material Is Released Or Spilled: Wipe up

Steps To Be Taken In Case Material Is Released Or Spilled:Steps To Be Taken In Case Material Is Released Or Spilled:

with absorbent material.

Waste disposal methodWaste disposal method

Waste disposal method: Dispose of in accordance with all applicable

Waste disposal methodWaste disposal method

federal, state and local environmental regulations.

Precautions To Be Taken In Handling & Storing:Precautions To Be Taken In Handling & Storing:

Precautions To Be Taken In Handling & Storing: Store tightly closed.

Precautions To Be Taken In Handling & Storing:Precautions To Be Taken In Handling & Storing:

Protect from dust or other particular matter.

Other Precautions:Other Precautions:

Other Precautions: Do not return used material to the bottle.

Other Precautions:Other Precautions:

SECTION 8 CONTROL MEASURESSECTION 8 CONTROL MEASURES

SECTION 8 CONTROL MEASURES

SECTION 8 CONTROL MEASURESSECTION 8 CONTROL MEASURES

Respiratory ProtectionRespiratory Protection

Respiratory Protection: Not required in normal use

Respiratory ProtectionRespiratory Protection

Ventilation systems:Ventilation systems:

Ventilation systems: Gen e r al m e ch a n ical ventilation adequate under

Ventilation systems:Ventilation systems:

normal conditions of use and storage.

Skin protectionSkin protection

Skin protection: Not required. Gloves recommended.

Skin protectionSkin protection

Eye Protection:Eye Protection:

Eye Protection: Splash goggles recommended

Eye Protection:Eye Protection:

Other Protective Equipment:Other Protective Equipment:

Other Protective Equipment: Lab coat and eye wash station recom-

Other Protective Equipment:Other Protective Equipment:

mended

Work/Hygienic Practices:Work/Hygienic Practices:

Work/Hygienic Practices: Wash after handling

Work/Hygienic Practices:Work/Hygienic Practices:

NO GUARANTEE IS MADE AS TO THE ACCURACY OF ANYNO GUARANTEE IS MADE AS TO THE ACCURACY OF ANY

NO GUARANTEE IS MADE AS TO THE ACCURACY OF ANY

NO GUARANTEE IS MADE AS TO THE ACCURACY OF ANYNO GUARANTEE IS MADE AS TO THE ACCURACY OF ANY

DATA OR STATEMENT CONTAINED HEREIN. WHILE THISDATA OR STATEMENT CONTAINED HEREIN. WHILE THIS

DATA OR STATEMENT CONTAINED HEREIN. WHILE THIS

DATA OR STATEMENT CONTAINED HEREIN. WHILE THISDATA OR STATEMENT CONTAINED HEREIN. WHILE THIS

MATERIAL IS FURNISHED IN GOOD FAITH, NO WARRANTYMATERIAL IS FURNISHED IN GOOD FAITH, NO WARRANTY

MATERIAL IS FURNISHED IN GOOD FAITH, NO WARRANTY

MATERIAL IS FURNISHED IN GOOD FAITH, NO WARRANTYMATERIAL IS FURNISHED IN GOOD FAITH, NO WARRANTY

EXPRESS OR IMPLIED, OR MERCHANTABILITY, FITNESS OREXPRESS OR IMPLIED, OR MERCHANTABILITY, FITNESS OR

EXPRESS OR IMPLIED, OR MERCHANTABILITY, FITNESS OR

EXPRESS OR IMPLIED, OR MERCHANTABILITY, FITNESS OREXPRESS OR IMPLIED, OR MERCHANTABILITY, FITNESS OR

OTHERWISE IS MADE. THIS MATERIAL IS OFFERED ONLYOTHERWISE IS MADE. THIS MATERIAL IS OFFERED ONLY

OTHERWISE IS MADE. THIS MATERIAL IS OFFERED ONLY

OTHERWISE IS MADE. THIS MATERIAL IS OFFERED ONLYOTHERWISE IS MADE. THIS MATERIAL IS OFFERED ONLY

FOR YOUR CONSIDERATION, INVESTIGATION AND VERIFI-FOR YOUR CONSIDERATION, INVESTIGATION AND VERIFI-

FOR YOUR CONSIDERATION, INVESTIGATION AND VERIFI-

FOR YOUR CONSIDERATION, INVESTIGATION AND VERIFI-FOR YOUR CONSIDERATION, INVESTIGATION AND VERIFICATION AND HF SCIENTIFIC, INC., INCLUDING ITS DIVI-CATION AND HF SCIENTIFIC, INC., INCLUDING ITS DIVI-

CATION AND HF SCIENTIFIC, INC., INCLUDING ITS DIVI-

CATION AND HF SCIENTIFIC, INC., INCLUDING ITS DIVI-CATION AND HF SCIENTIFIC, INC., INCLUDING ITS DIVISIONS, AFFILIATES, SUBSIDIARIES AND SUPPLIERS, SHALLSIONS, AFFILIATES, SUBSIDIARIES AND SUPPLIERS, SHALL

SIONS, AFFILIATES, SUBSIDIARIES AND SUPPLIERS, SHALL

SIONS, AFFILIATES, SUBSIDIARIES AND SUPPLIERS, SHALLSIONS, AFFILIATES, SUBSIDIARIES AND SUPPLIERS, SHALL

NOT IN ANY EVENT BE LIABLE FOR SPECIAL, INCIDENTAL,NOT IN ANY EVENT BE LIABLE FOR SPECIAL, INCIDENTAL,

NOT IN ANY EVENT BE LIABLE FOR SPECIAL, INCIDENTAL,

NOT IN ANY EVENT BE LIABLE FOR SPECIAL, INCIDENTAL,NOT IN ANY EVENT BE LIABLE FOR SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH ITSOR CONSEQUENTIAL DAMAGES IN CONNECTION WITH ITS

OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH ITS

OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH ITSOR CONSEQUENTIAL DAMAGES IN CONNECTION WITH ITS

PUBLICATION. LIKEWISE, NO STATEMENT MADE HEREINPUBLICATION. LIKEWISE, NO STATEMENT MADE HEREIN

PUBLICATION. LIKEWISE, NO STATEMENT MADE HEREIN

PUBLICATION. LIKEWISE, NO STATEMENT MADE HEREINPUBLICATION. LIKEWISE, NO STATEMENT MADE HEREIN

SHALL BE CONSTRUED AS A PERMISSION OR RECOMMEN-SHALL BE CONSTRUED AS A PERMISSION OR RECOMMEN-

SHALL BE CONSTRUED AS A PERMISSION OR RECOMMEN-

SHALL BE CONSTRUED AS A PERMISSION OR RECOMMEN-SHALL BE CONSTRUED AS A PERMISSION OR RECOMMENDATION FOR THE USE OF ANY PRODUCTION IN A MANNERDATION FOR THE USE OF ANY PRODUCTION IN A MANNER

DATION FOR THE USE OF ANY PRODUCTION IN A MANNER

DATION FOR THE USE OF ANY PRODUCTION IN A MANNERDATION FOR THE USE OF ANY PRODUCTION IN A MANNER

THAT MIGHT INFRINGE EXISTING PATENT.THAT MIGHT INFRINGE EXISTING PATENT.

THAT MIGHT INFRINGE EXISTING PATENT.

THAT MIGHT INFRINGE EXISTING PATENT.THAT MIGHT INFRINGE EXISTING PATENT.

SECTION 5 HEALTH EFFECTS AND FIRST AIDSECTION 5 HEALTH EFFECTS AND FIRST AID

SECTION 5 HEALTH EFFECTS AND FIRST AID

SECTION 5 HEALTH EFFECTS AND FIRST AIDSECTION 5 HEALTH EFFECTS AND FIRST AID

Routes Of Entry:Routes Of Entry:

Routes Of Entry: Inhalation? Yes. Skin? Yes. Ingestion? Yes.

Routes Of Entry:Routes Of Entry:

Health Hazards (Acute & Chronic):Health Hazards (Acute & Chronic):

Health Hazards (Acute & Chronic): May cause irritation in sensitive

Health Hazards (Acute & Chronic):Health Hazards (Acute & Chronic):

people.

Carcinogenicity: Carcinogenicity:

Carcinogenicity: NTP? IARC Monographs? OSHA Regulated?

Carcinogenicity: Carcinogenicity:

Signs & Symptoms Of Exposure:Signs & Symptoms Of Exposure:

Signs & Symptoms Of Exposure: Irritation.

Signs & Symptoms Of Exposure:Signs & Symptoms Of Exposure:

Medical Conditions Generally Aggravated By Exposure:Medical Conditions Generally Aggravated By Exposure:

Medical Conditions Generally Aggravated By Exposure: People with

Medical Conditions Generally Aggravated By Exposure:Medical Conditions Generally Aggravated By Exposure:

preexisting skin disorders or eye problems. People with impaired liver,

kidney or respiratory function may be more susceptible to the effects.

Not Applicable

TUV(01/03) Page 19

REV. 2.2

Page 28

Loading...

Loading...