Page 1

MICRO 200 BW TURBIDIMETER

RANGE OPTION 0 - 1000 NTU

CATALOG NO. 21640 (5/05)

Rev. 3.1

HF scientific, inc.

3170 Metro Parkway

Ft. Myers, FL 33916-7597

Phone: (239) 337-2116

Fax: (239) 332-7643

Page 2

Page 3

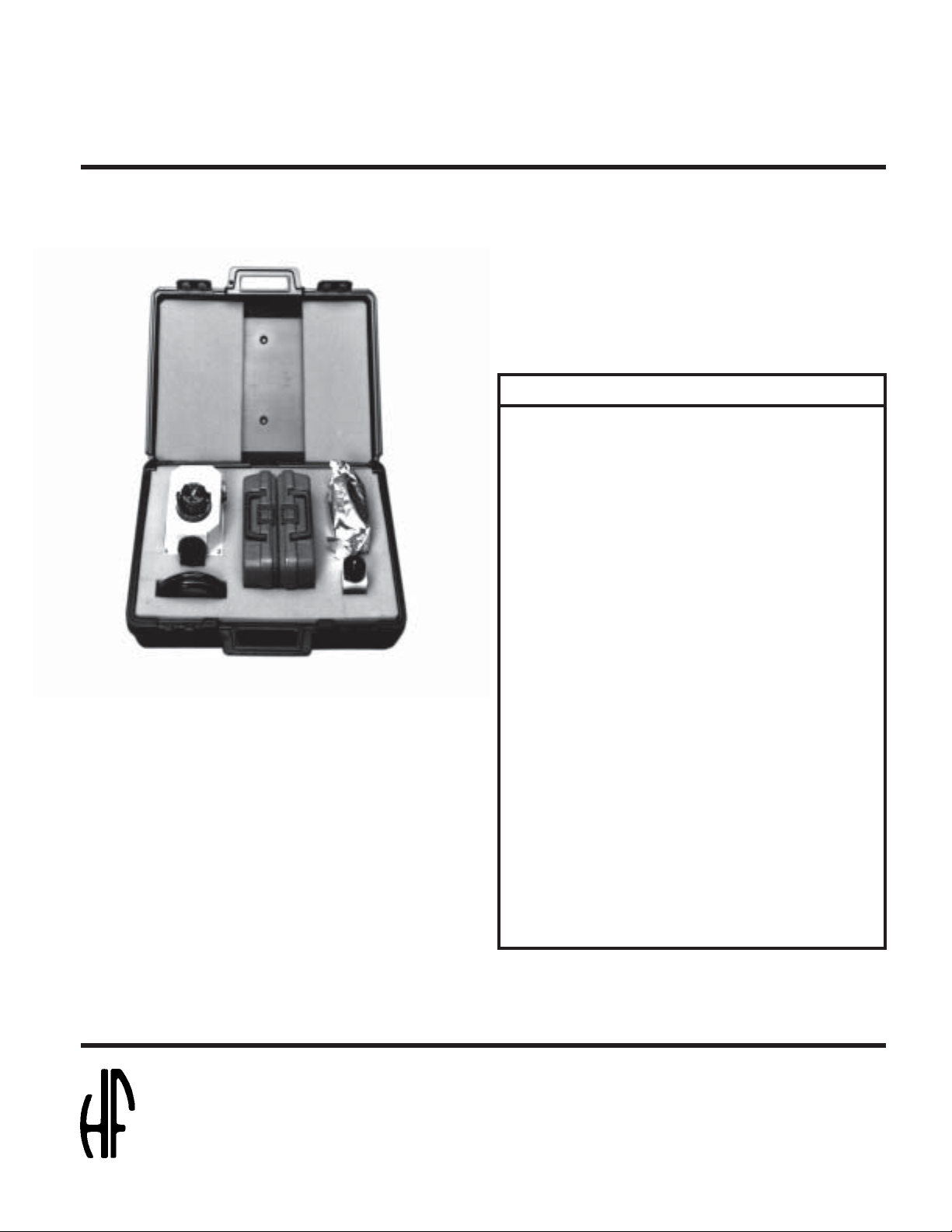

Field Service Kit

For the Micro 200 Series Turbidimeter

Field Service Kit Contents:

Qty. Description Cat. No.

1 Sensor (Electronics Portion Only) 19807

1 Desiccant Tray Assembly 21555

1 Lamp Module 21541

Field Service Kit, Catalog No. 19834

• Clean, Calibrate and Repair Your

Instrument in the Field

• Avoid Rush Orders for Spare Parts

• Virtually No Downtime

The HF Micro 200 Series Field

Service Kit contains the recommended

spare parts needed for standard

maintenance, repair, and calibration.

This kit is designed to allow the operator

or technician to service the instrument

without a costly service call.

1 Flow Head Assembly 50125

1 3 pk. cuvettes 50036

1 Secondary Standard Kit 19820

(0.02, 4, 10, 40, 100 NTU)

1 O-ring Kit 50136

12 ft. Tygon Tubing 21201

1 Bulkhead Assembly, 2 pk. 21148

1 Fuse, ½A 5 x 20 mm 20955

1 Fuse, 1A 5 x 20 mm 20956

1 O-ring 50144

1 O-ring 50140

1 Case 13520

scientific, inc.

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

3170 Metro Parkway

Ft. Myers, FL 33916-7597

Phone: (239) 337-2116

Fax: (239) 332-7643

www.hfscientific.com

Page 4

Page 5

FOREWORD

HF TURBIDIMETERS

HF turbidimeters are manufactured to meet design criteria for nephelometers as described in Standard Methods For

Examination of Water and Wastewater. HF turbidimeters are approved by the U.S. EPA* as a means to measure the

turbidity of potable water, waste water, and other liquids.

HF turbidimeters provide a linear display of turbidity, throughout all ranges, in Nephelometric Turbidity Units (NTU).

HF turbidimeters use solid state electronic components because they resist thermal variation and are not affected by

normal line voltage fluctuations.

HF turbidimeters can be calibrated using HF scientific factory certified Secondary Standards or Formazin. Factory

calibration is accomplished using HF scientific Secondary Standards, which are factory certified traceable to

Formazin, therefore, this instruction manual describes the proper procedures for calibration of HF turbidimeters using

Secondary Standards.

HF turbidimeter manuals are designed to assist the user in taking full advantage of the instrument in a majority of its

applications. However, in the event that unusual circumstances or problems, not covered by this manual, arise please

feel free to contact our local distributor or the manufacturer.

HF scientific, inc.

3170 Metro Parkway

Fort Myers, Florida 33916-7597

Phone: (239) 337-2116

Fax: (239) 332-7643

Our engineering staff is available to help you with your specific needs.

CERTIFICATION

Congratulations! We at HF scientific are proud to present you with the MICRO 200 BW turbidimeter. This instrument

represents the very latest in integrated circuit and display technology. As a result, the product is a rugged and reliable

instrument whose performance was tested thoroughly and found to meet its published specifications when it left the

factory.

*EPA approved means the instrument meets or exceeds the design and performance criteria as specified in the United

States Environmental Protection Agency method 180.1.

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 6

Page 7

DECLARATION OF CONFORMITY

Application of Council Directive: 73/23/EEC

Standard to which Conformity is Declared:

Product Safety Immunity EMI

UL3111-1 EN50082-1 EN55011 Group 1 Class A

CSA-C22.2 No.1010-1-92 IEC801-2 FCC Part 15 Class A

CE EN61010-1 IEC801-3

IEC901-4

Manufacture’s Name: HF scientific, inc.

Manufacture’s Address: 3170 Metro Parkway, Fort Myers, Florida 33916-7597

Importer’s Name:

Importer’s Address:

Type of Equipment: Turbidimeter

Model No.: Micro 200/200BW

I, the undersigned, hereby declare that the equipment specified above conforms

to the above Directive and Standard.

Place: Fort Myers, Florida USA

(Signature)

Robert J. Maley, President

(Full Name)

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 8

Page 9

DECLARATION OF CONFORMITY

Application of Council Directive: 73/23/EEC

Standard to which Conformity is Declared:

Product Safety Immunity EMI

UL3111-1 EN50082-1 EN55011 Group 1 Class A

CSA-C22.2 No.1010-1-92 IEC801-2 FCC Part 15 Class A

CE EN61010-1 IEC801-3

IEC901-4

Manufacture’s Name: HF scientific, inc.

Manufacture’s Address: 3170 Metro Parkway, Fort Myers, Florida 33916-7597

Importer’s Name:

Importer’s Address:

Type of Equipment: Backwash Sensor and Interface Kit

Model No.: 19276

I, the undersigned, hereby declare that the equipment specified above conforms

to the above Directive and Standard.

Place: Fort Myers, Florida USA

(Signature)

Robert J. Maley, President

(Full Name)

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 10

Page 11

MICRO 200 BW

TABLE OF CONTENTS

I. IMPORTANT INFORMATION ............................................................................................................................ 1

A. HOW TO USE THIS MANUAL ....................................................................................................................... 1

B. SPECIAL ENVIRONMENTAL CONSIDERATIONS .....................................................................................1

C. SPECIFICATIONS ............................................................................................................................................. 2

D. OPTIONS............................................................................................................................................................ 3

E. FIGURES ............................................................................................................................................................ 4

F. COMPLIANCE TESTING CERTIFICATION ................................................................................................. 5

II. INSTALLATION ..................................................................................................................................................... 6

A. PACKING LIST OF CONTENTS ..................................................................................................................... 6

B. UNPACKING AND INSPECTION ................................................................................................................... 6

C. MOUNTING ....................................................................................................................................................... 6

1. Analyzer....................................................................................................................................................... 6

2. Sensor - Turbidity........................................................................................................................................ 6

a. Installing Desiccant Tray ..................................................................................................................... 6

D. ANALYZER CONNECTIONS.......................................................................................................................... 8

1. Cable & Cord............................................................................................................................................... 8

2. Analyzer Power ........................................................................................................................................... 8

3. D/A Outputs - Voltage & Current............................................................................................................... 9

4. Recorder - Voltage ...................................................................................................................................... 9

5. Recorder - Current ....................................................................................................................................... 9

6. 4 - 20 mA Isolation...................................................................................................................................... 9

7. Alarm Contacts ............................................................................................................................................ 10

8. Cable Mount Ferrites................................................................................................................................... 10

E. TURBIDITY SENSOR....................................................................................................................................... 10

1. Interconnect Cable ....................................................................................................................................... 10

2. Inserts for Sample and Drain lines .............................................................................................................. 10

III. STEP-BY-STEP OPERATION .............................................................................................................................. 10

A. THEORY & HOW IT WORKS ......................................................................................................................... 10

1. Menu Guide to the MICRO 200 BW .......................................................................................................... 11

2. Turbidity Display ........................................................................................................................................ 12

3. Main Menu .................................................................................................................................................. 13

4. Alarm Menu................................................................................................................................................. 14

a. Alarm #1............................................................................................................................................... 14

5. Display Parameters ........................................................................................................... ........................... 15

a. Set Upper Limit .................................................................................................................................... 15

b. Set Average .......................................................................................................................................... 16

6. Utility Menu ................................................................................................................................................ 16

a. Screen Brightness/History .................................................................................................................... 17

b. Set Time ............................................................................................................................................... 17

c. Calibrate 0-1000 NTU ........................................................................................................................ 18

d. Comm Port ........................................................................................................................................... 19

e. Access Code Menu............................................................................................................................... 19

f. Security Access Code ........................................................................................................................... 20

g. Set Access Code ................................................................................................................................... 20

h. Self Test (4 - 20 mA Cal.).................................................................................................................... 21

i. Self Test (0 - 10 V Cal.)....................................................................................................................... 21

7. Wait Messages............................................................................................................................................. 22

8. Backwash Display ....................................................................................................................................... 23

a. Backwash Calibration .......................................................................................................................... 24

B. START UP .......................................................................................................................................................... 25

1. Indexing ....................................................................................................................................................... 25

2. Standardizing............................................................................................................................................... 25

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 12

Page 13

MICRO 200 BW

TABLE OF CONTENTS CONT.

IV. ROUTINE OPERATION........................................................................................................................................ 25

A. CONTINUOUS MONITORING FLOW THROUGH UNIT ............................................................................ 25

B. VAPORPURGE .................................................................................................................................................. 26

C. GRAB SAMPLES .............................................................................................................................................. 26

V. ROUTINE MAINTENANCE ................................................................................................................................. 26

A. CUVETTE CLEANING & CARE..................................................................................................................... 26

B. LAMP REPLACEMENT ................................................................................................................................... 28

C. CALIBRATION PROCEDURES ...................................................................................................................... 28

1. Calibration Standards .................................................................................................................................. 28

a. Secondary Standard Set (Optional) Cat. No. 19830............................................................................ 28

b. Standard Formazin Solutions ............................................................................................................... 29

2. Calibration Steps for 0-1000 NTU Range .................................................................................................. 29

VI. SECURITY ACCESS CODE.................................................................................................................................. 30

VII. TROUBLESHOOTING ......................................................................................................................................... 31

A. GENERAL NOTES............................................................................................................................................ 31

B. SPARE PARTS LIST FOR MICRO 200 BW ................................................................................................... 32

VIII. OPTIONS .............................................................................................................................................................. 33

BACKWASH ............................................................................................................................................................ 33

A. INSTALLATION ............................................................................................................................................... 33

1. Backwash Interface ..................................................................................................................................... 33

2. Junction Box ................................................................................................................................................ 33

3. Backwash Sensor ......................................................................................................................................... 33

a. Channel Mounting ................................................................................................................................ 33

b. Extension Handle Mounting ................................................................................................................ 33

B. BACKWASH SENSOR CONNECTIONS ........................................................................................................ 33

C. BACKWASH SENSOR MAINTENANCE ....................................................................................................... 34

1. Backwash Calibration ................................................................................................................................. 34

D. BACKWASH ALARMS .................................................................................................................................... 34

E. BACKWASH REMOTE SWITCHING ............................................................................................................ 34

1. Electrical Connections ................................................................................................................................ 34

a. Remote Switch ..................................................................................................................................... 34

b. Alarms .................................................................................................................................................. 34

c. Analog Outputs..................................................................................................................................... 35

d. Serial Port (optional) ............................................................................................................................ 35

2. Operation ..................................................................................................................................................... 35

SERIAL INTERFACES .......................................................................................................................................... 35

1. RS-232 Voltage Mode Interface ................................................................................................................. 36

2. RS-232 Current Loop Mode Interface ........................................................................................................ 36

3. RS-485 Interface.......................................................................................................................................... 36

4. Serial Printer ............................................................................................................................................... 36

WARRANTY .............................................................................................................................................................. 42

GLOSSARY .............................................................................................................................................................. 43

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 14

Page 15

I. IMPORTANT INFORMATION

A. HOW TO USE THIS MANUAL

The equipment has been designed for simple and easy operation. In keeping with that philosophy, this MICRO 200

BW User’s Manual has been written to simplify all steps in the procedures that follow.

THE MOST IMPORTANT ASPECT OF THIS MANUAL IS THAT YOU, THE USER, READ IT IN ITS

ENTIRETY AND REFER TO IT OFTEN. Figures and drawings have been used throughout the manual to show

you how and text has been used to enhance and clarify what you have been shown.

Again, please read the manual before attempting to install or operate the MICRO 200 BW. Pay particular attention

to the “warning” and “caution” messages throughout. Although the MICRO 200 BW is simple and easy to use, all

electrical and safety precautions must be followed. “Notes” have also been added to give further clarification or

reminders in certain instances.

B. SPECIAL ENVIRONMENTAL CONSIDERATIONS

The Liquid Crystal Display (LCD) is not recommended for outdoor installation. UV rays are damaging to the display.

For more details, see the Installation Section regarding Mounting of the MICRO 200 BW.

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 1

Page 16

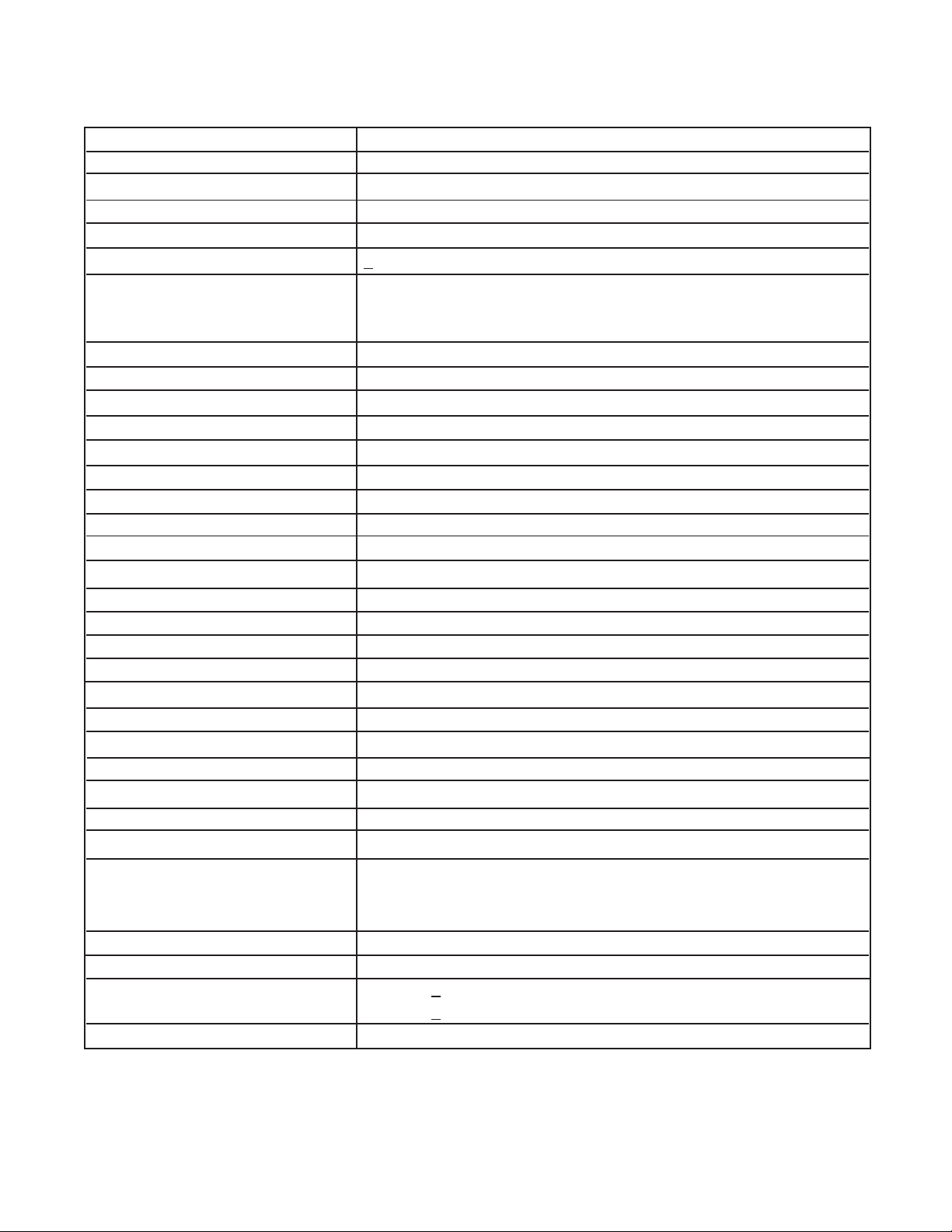

C. SPECIFICATIONS FOR THE MICRO 200 BW

Specification MICRO 200 BW

Ranges: 0 - 1000.0 NTU

Method: EPA approved* Nephelometric

Accuracy: 10% 0-1000.0 NTU

Repeatability: 1%

Linearity:

+1%

Resolution:

0 to 10 NTU 0.0001

1 to 100 NTU 0.01

Digital Display: LCD 6 digits

Analyzer Graphics: Built in LCD, Graphics recorder

Clock Graphics: Date and Time

Response Time: 1 to 8 seconds

Averaging Time (Electronic): 1, 16, 48 & 96 seconds, sliding average

Microprocessor: Motorola MC68HC11

Keyboard data entry system: 8 interacting membrane switches with tactile feedback

Security Code: Prevents unauthorized access to analyzer

Built in diagnostics: Yes

Analog Output, Isolated: Bracketed to .01 NTU, 4 - 20 mA & .1, 1 & 10 VDC 12 bit resolution D/A

Alarms: 1 system alarm, 2 (NTU or % T) alarms (Hi, Lo and Off)

Alarm Contact rating: Max. 250 VAC @ 5.0 A

Operating Temperature: 32° to 122°F (0°C to 50°C)

Storage Temperature: -4°F to 140°F (-20° to 60°C)

Optical Cleaning for NTU Sensor: Removable cuvette

Flow rate: 0.5 - 1.5 gpm (2000 ml/min - 6.0 L/m)

Positive System Pressure: 60 psi maximum (414 kPa or 4.22 kg/cm

3

)

Wetted surfaces: Nylon, C.A.B., PVC, Delrin-500, Borosilicate glass, Silicone

Lamp: External, pre-focused module

Standard Cable Length: 6 feet (1.83 m)

Sensor to analyzer distance: 250 feet (76.25 m) max. Over 50' lengths contact factory.

Dimensions

Analyzer: 13" x 11½” x 8" (330 x 290 x 200 mm)

NTU Sensor: 8¾” x 9¾” x 8" (225 x 250 x 200 mm)

NTU Sensor Case: NEMA 4X

CE Rating: Pollution Degree 2, Overvoltage Category III

Supply Voltage: 120 VAC

240 VAC

+ 10% 50/60 Hz

+ 10% 50/60 Hz

Power Consumption: 40 VA

*EPA approved means that the instrument meets or exceeds the design and performance criteria as specified in the

United States Environmental Protection Agency Method 180.1.

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 2

Page 17

C. SPECIFICATIONS FOR THE MICRO 200 BW CONTINUED

Specifications Micro 200 BW

Shipping Weight: Approximately 15 lbs. (6.8 kg)

Warranty: One year from date of shipment

Backwash Sensor - Optional:

Backwash Sensor: IR sensor measures 0 - 100% Transmittance

Sensor operating depth: 16 psi (32 ft.: 9.8 m) maximum depth

Standard cable length

Sensor to Analyzer/Interface: 30 feet (9.2 m)

Sensor to Analyzer distance: 1000 feet (305 m) max.

Backwash Sensor Dimensions: 3" Dia. x 7" H (75 x 175 mm)

Backwash Sensor Case: NEMA 4X

Repeatability: ± 1% Transmittance

Sensitivity: ± 1% Transmittance

Linearity: ± 1% Transmittance

Response time: Less than 10 seconds for a full scale change

Sensor operating temperature: 32 to 86°F (0°C to 30°C)

D. OPTIONS:

Specifications Micro 200 BW

Printer: 120/240V, 32 column, provides a 4 or 24 hour data printout of station, date,

time, high, low, average NEMA 4X enclosure. Includes 10 feet of

interconnect cable, paper printer roll, operating manual.

Computer Interface Serial Port: RS-232 or RS-485/RS-422 or current loop

Display Languages: English, French, German, Spanish, Italian or Swedish

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 3

Page 18

E. FIGURES

Figure No. Title Page No.

1 Desiccant Tray Installation......................................................................................... 6

2 Analyzer Outline Dimensions ....................................................................................7

3 Turbidity Sensor Outline Dimensions ........................................................................ 7

4 Access Cover Removal...............................................................................................8

5 Cable Routing .............................................................................................................8

6 Changing Analyzer Voltage/Fuse...............................................................................9

7 Analyzer Rear Cover Removal................................................................................... 9

8 4 - 20 mA Isolation Jumper (Removal) ...................................................................... 9

9 Reference Standard Indexing ...................................................................................25

10 Flow Through Cuvette Indexing...............................................................................26

11 Vaporpurge ............................................................................................................... 27

12 Critical Measurement Area.......................................................................................28

13 Lamp Replacement ................................................................................................... 28

14 Analyzer BNC Connection .......................................................................................33

15 Serial Interface Installation ....................................................................................... 35

16 Backwash Interface Outline Dimensions ................................................................. 37

17 Backwash Interface Voltage Selection..................................................................... 37

18 Junction Box Outline Dimensions ............................................................................ 38

19 Junction Box Wiring Diagram.................................................................................. 38

20 Backwash Sensor Outline Dimensions .....................................................................39

21 Backwash Channel Mounting................................................................................... 39

22 Backwash Extension Handle Mounting....................................................................40

23 RS-232 Voltage Connection ..................................................................................... 41

24 RS-232 Current Connection ...................................................................................... 41

25 RS-485 Connection ................................................................................................... 41

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 4

Page 19

F. COMPLIANCE TESTING CERTIFICATION

The Micro 200 BW has undergone extensive testing,

therefore, HF scientific, inc certifies that this instrument has met the following standards.

Product Safety

US standard tested by ETL testing labs to UL 3111

Canadian Standard tested by ETL to CSA 1010.

CE tested by ETL testing labs to EN61010-1

Pollution Degree 2, Installation Category (Overvoltage

Category) III

Immunity

Immunity testing by ETL testing labs to EN50082-1

including:

ESD Immunity to IEC 801-2

RF Immunity to IEC 801-3

Transient Burst Immunity to IEC 801-4

EMI

EMI tested by ETL testing labs to EN55011 Group 1

Class A.

RF Emissions to FCC Part 15 Class A by ETL testing

labs

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 5

Page 20

II. INSTALLATION

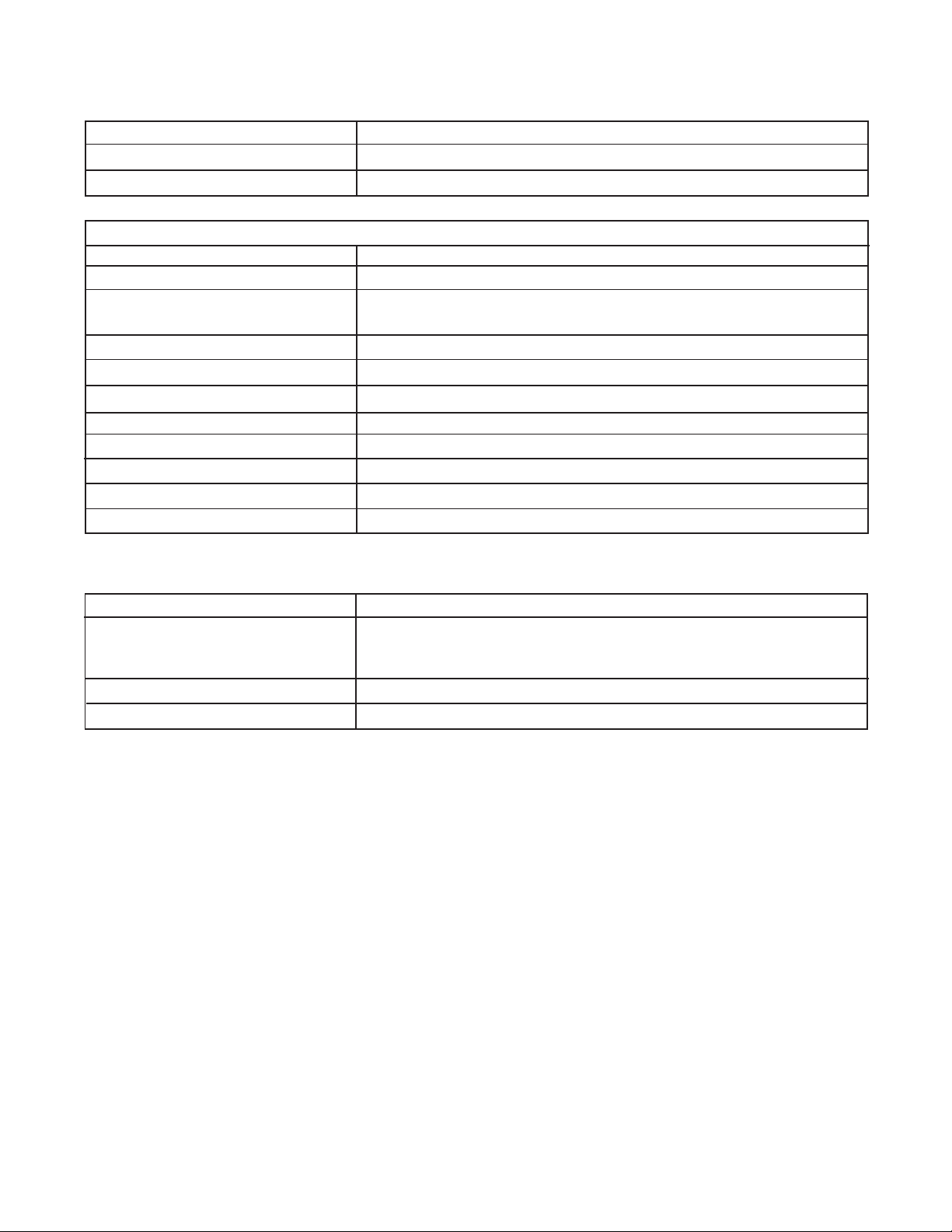

A. PACKING LIST FOR THE MICRO 200 BW

CONTENTS QUANTITY

Instruction Manual 1

MICRO 200 BW 1

must be mounted where it can be viewed at the backwash control station. In this example, for convenience

of maintenance, the turbidity sensor should be mounted

at the backwash station and have the water plumbed to

it. The analyzer must be mounted in a location that

avoids direct water contact. Refer to figure 2 on page 7

for outline dimensions. Allow enough room for the

analyzer to pivot on the mounting bracket upside down,

to make connections.

Desiccant Tray Assembly 1

Accessory kit - includes:

0.02 NTU reference standard 1

Flow control clamp (stainless steel) 1

Spare flow through cuvette 1

Light Shield Cap 1

A listing of recommended spare parts appears on page

32 of this manual.

B. UNPACKING AND INSPECTION

Use extreme care when unpacking your MICRO 200

BW and note that all of the contents are included. Check

for any damage that may have occurred during shipping. If there are any omissions, report this immediately to the your local distributor or the Quality Assurance Dept. at HF scientific, inc. If there is any shipping

damage; notify the shipping company immediately and

arrange for a prompt inspection.

C. MOUNTING

CAUTION: Instrument is not designed for outdoor

installation. The LCD screen will be damaged by UV rays. Contact factory for

available enclosures.

The maximum allowable ambient temperature is 122°F

(50°C).

NOTE: Be careful during installation not to violate the

moisture integrity of the sensor, interface or

analyzer housings. The analyzer requires approximately two hours to reach it’s final operating temperature. Further adjustment of the

LCD brightness may be required during this

period.

1. Analyzer

The location of the analyzer should be given careful

consideration. As an example, if the MICRO 200 BW

is to be used for performing backwash, the analyzer

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 6

After mounting, the angle of analyzer may be adjusted

for best visibility.

2. Sensor - Turbidity

For the outline drawing of the turbidity sensor refer to

figure 3 on page 7. Allow enough room for easy access

to both the flow through unit and the lamp module.

Avoid mounting the sensor in a location that will put

the sensor housing in contact with dripping water, as

this will present problems when performing periodic

maintenance.

The sensor is equipped with a foot valve, that opens in

case the flow through cuvette ruptures, to prevent

damage to the sensor. The foot valve drain tube can be

connected to a 5/8" (15.9 mm) tube (not supplied) to

direct the flow of water to a convenient drain. Keep the

length of this external tube to a minimum.

a. Installing & Replacing Pack Desiccant Tray

Before operating the

Micro 200BW for the

first time the replaceable desiccant pouch

must be installed.

Please refer to Figure

1 while installing fo r

the first time. To initially install unscrew

the four thumbscrews

and remove the electronics half of the sensor. Open the foil bag

and remove the

dessicant pouch and

the indicator card. Install these items and

replace the top portion

of the sensor.

Proper use of the

supplied desiccant is

essential in maintaining

the performance of the

Figure 1

Desiccant Tray Installation

Page 21

Figure 2

Analyzer Outline Dimensions

XX.XX=INCHES

(XX)=mm

8.780

(225)

9.802

(249)

Figure 3

Turbidity Sensor Outline Dimensions

8.062

(205)

Lamp

LAMP

MODULE

Module

HF #

21541

21541

5.820

(148)

HF #

2.000

(51)

1.000

(25)

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 7

Page 22

instrument. The desiccant pouch is designed to have a

long life; however, replacement of the desiccant pack

will be required from time to time. To determine the

condition of the desiccant, check the included humidity

indicator card. If required, a new foil sealed desiccant

pouch and indicator card are available from HF scientific inc. part #21555R.

It is essential that all enclosure seals be maintained. The

emergency drain and o-rings that are supplied with each

new instrument form part of the instrument humidity

seal. Inspect these items each time the desiccant pouch

is replaced. Replace any parts found to be defective.

D. ANALYZER CONNECTIONS

All connections are reached by removing the access

cover. Heed all warnings and precautions prior to

removal.

WARNING: Before removing access cover disconnect

all power from the MICRO 200 BW analyzer.

1) Unplug the instrument or

2) Turn off the power at the circuit breaker.

3) Remove power to alarm contacts if greater than 30

VAC is connected for external operations.

To remove the access cover (refer to figure 4):

1) Loosen the two analyzer clamping knobs.

2) Swivel the analyzer top forward, such that the back

is now facing you.

3) Re-tighten the two analyzer clamping knobs.

4) Loosen the 4 captive screws.

5) Remove access cover.

Figure 4

Access Cover Removal

WARNING: Do not restore power until the access

cover has been replaced and secured.

When routing the cabling for the following

sections, allow enough excess cable length

to swivel the analyzer upside down. Note

that a cable strap is provided on the mounting bracket. Refer to figure 5 for suggested

cable routing. Do not overtighten the four

captive screws when replacing cover.

→→

→→

→

Extra Cable

1. Cable & Cord

Interconnecting Cable: The standard interconnecting

cable between the analyzer and the turbidity sensor is

6 feet (1.83 meters) in length (Catalog No. 20853). This

length may be decreased without affecting instrument

performance. For longer cable lengths consult HF

scientific, inc.

WARNING: Ensure that power to the analyzer is

removed prior to connecting or disconnecting the sensor.

2. Analyzer Power

The power cord (120V) provided is 6 feet (1.83 meters)

long. The analyzer power requirement is 40 VA at

either 120 VAC or 240 VAC. The voltage setting of the

analyzer can be determined by removing the access

cover and looking at the fuse cartridge, just to the left

of the power cord receptacle. The voltage printed next

to the two triangles that point toward each other indicate

the selected voltage. To change the input voltage first

remove the power cord. The fuse cartridge can be

removed by prying upwards using a flat blade screwdriver in the slot provided. Pull the cartridge out, invert

and then reinsert. Refer to figure 6 on page 9. To replace

a blown fuse remove the fuse cartridge as in figure 6 on

page 9. Replace only the fuse for your selected voltage.

The triangle on the fuse cartridge points to the fuse for

Figure 5

Cable Routing

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 8

Page 23

the voltage. The correct fuse ratings are 5 x 20 mm 1A

fast acting for 120 VAC and 5 x 20 mm ½A fast acting

for 240 VAC.

A power switch is located to the right of the power cord.

WARNING: If power connection is to be hardwired,

place each analyzer on a separate circuit

breaker or switch to allow for service.

Observe all local wiring codes.

▲

▲▲

▲▲

▲

▲▲

▲▲

▲▲

▲▲

▲

▲▲

▲▲

220-240V

220-240V

▲

BW analyzer).

5. Recorder - Current

A 4-20 mA current output is available. The connections

are made at the terminal block labeled Analog 4-20 mA

(J5). Use twisted pair shielded cable, 22 AWG - 14

AWG, with the shield tied to earth ground at the

recorder end. (Do not tie shield to ground at the

analyzer). The recorder load may be rated from 0-1000

ohms maximum. Terminal #1 is positive, terminal #2

is negative.

6. 4 - 20 mA Isolation

Isolation of the 4-20 mA recorder output may be

achieved by removing the jumper at J13. This procedure requires removal of the rear cover assembly. Refer

to figure 7 to remove the rear cover and figure 8 for

location of jumper.

▲▲

▲▲

▲

USE ONLY WITH 250V

110-120V

FUSES / EMPLOYER

UNIQUEMENT AVEC

DES FUSIBLES DE 250V

Figure 6

Changing Analyzer Voltage/Fuse

3. D/A Outputs - Voltage & Current

The full scale range of the recorder outputs, both

voltage and 4 - 20 mA, is determined by the upper and

lower limits selected by the user in the display parameters menu. Please note that either 4- 20 mA OR voltage

may be selected in the DISPLAY PARAMETERS

menu, but not both.

4. Recorder - Voltage

Recorder output voltage is selected at the terminal block

labeled ANALOG VOLTAGE (J6). Only one of these

voltages is to be selected at any time.

Recorder load for each voltage:

Figure 7

Analyzer Rear Cover Removal

Terminal 1 0 - 10V 50000 ohms or greater

Terminal 2 0 - 1V 5000 ohms or greater

Terminal 3 0 - 100mV 500 ohms or greater

Terminal 4 Common

Twisted pair shielded cable, 22 AWG - 14 AWG, is

recommended. Tie the shield to the ground terminal the

recorder end (Do not connect shield to MICRO 200

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Figure 8

Remove jumper J-13 to establish isolation

of the 4-20mA signal.

Page 9

Page 24

WARNING: While the chance is slight, there are fault

conditions under which a hazardous voltage could be exposed on the analog output

wires when the jumper J13 is

removed. To preclude this possibility HF

scientific strongly recommends, for personal protection, that a Ground Fault

Circuit Interrupter (GFCI), such as

LEVITON part number 6599 or 5299, be

used at the power connection.

7. Alarm Contacts

Connections are provided to the alarm relay contacts on

the terminal block labeled ALARMS.

NOTE: These are “fail safe” and will revert to an “alarm”

condition should the power be disconnected, for

any reason.

Refer to the Specifications to ensure that alarm contact

ratings are not exceeded.

NOTE: ALARM 1: Terminal Block J1

ALARM 2: Terminal Block J2

SENSOR ALARM: Terminal Block J3

The following are the connections for each of the relay

contacts:

Terminal 1: Normally Closed (N.C.) (open on alarm)

Terminal 2: Normally Open (N.O.) (closed on alarm)

Terminal 3: Common (C)

WARNING: Ensure that all external voltages in excess

of 30 volts are disconnected before attempting to make connections or disconnections from alarm terminal blocks.

The SENSOR ALARM contacts are provided to

indicate that the source lamp in the sensor module has

failed or that the MICRO 200 BW requires routine

standardization.

NOTE: For external analyzer connection, other than

power, #14 AWG is the largest wire the connecting terminals will accept.

8. Cable Mounted Ferrites

The interconnect cable has a cable mounted ferrite on

it, located near the analyzer. To maintain the CE rating

for EMI this ferrite HF #21140 must bein place when

operating the instrument.

Some input/output connections that are made to the

Micro 200BW will also require the addition of a ferrite

to maintain the CE rating for EMI. The following

connections require the addition of HF# 21138: Serial

Ports, Recorder Output - Current (4-20mA), Recorder

Output - Voltage.

E. TURBIDITY SENSOR

1. Interconnect Cable

The interconnecting cable from the analyzer is plug

connected at the sensor. If the interconnecting cable is

removed at the analyzer end, it should be reconnected

to terminal block labeled SENSOR INTERFACE (J8).

The cable wire colors are labeled in front of this

terminal block.

2. Inserts for Sample & Drain Lines

Plastic inserts (not needed with rigid tubing) are provided with the turbidity sensor and are intended for use

with 5/16" OD x 3/16" ID (7.94 mm OD x 4.76 mm ID)

flexible plastic tubing as sample and drain lines.

III. STEP-BY-STEP OPERATION

A. THEORY & HOW IT WORKS

The HF scientific, inc., MICRO 200 BW Turbidimeter

is specifically designed to monitor turbidity and backwash water in water filtration plants. This is done by

providing a linear display of turbidity in Nephelometric

Turbidity Units (NTU). The units, FTU and NTU, are

compatible. Optional backwash function is displayed

in Percent Transmission (% T).

The MICRO 200 BW is a continuous reading Nephelometric instrument that measures scattered light from

particles in suspension (turbidity). The optical signal

from the photodiodes is amplified and then converted

to a frequency. This frequency is dependent upon the

NTU level of the sample in the sample well. The

resultant signal is sent to the analyzer where it is

linearized for presentation on the display.

All operator controls are located on the front panel of

the MICRO 200 BW. Complete displays include LCD

indicators which blink in the event of an alarm of the

two user set alarms and a sensor alarm.

Each feature is clearly labeled and you will be taken,

step-by-step, through each one later in this section.

This approach ensures EASY use of the HF scientific,

inc., MICRO 200 BW.

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 10

Page 25

One of the most important features of the MICRO 200

BW is the ease of operation. You simply press the

Function Key, <F1-F5> for the selection you want to

access on the LCD screen.

The information contained in this manual will help

users take full advantage of the MICRO 200 BW’s

capabilities. In the event that unusual circumstances

arise that are not addressed in the manual, contact your

local distributor. Our engineering staff is also available

to help you with your specific needs.

The ROM program used in the MICRO 200 BW

contains confidential information which is the property

of HF scientific, inc. Unauthorized disclosure, distribution or copying is prohibited. COPYRIGHT © HF

SCIENTIFIC, INC. All rights reserved.

1. Menu Guide to the MICRO 200 BW

The following pages guide you through the menus in

MICRO 200 BW and provide insight on how to use

each of them. Probably the best way to learn the system

is by “hands on training”. After reading this section in

its entirety the user should follow through each of the

menus on the MICRO 200 BW. The user will find that

each of the menus is arranged in a logical manner. After

going through each of the menus once he will gain a

familiarity with the structure. Each function is clearly

labeled. A menu flow chart figure 26 is provided on

page 44 for further clarity.

before the alarm contacts can again close.

MENU: Display will change to the next highest

level or previous menu. If this button is

pushed several times you will always return to the MAIN MENU. This button is

also used to return to the turbidity display

once the range has been selected.

NOTE: There are places of selection, for instance, alarm

limits, graphic limits and time set where it is

possible to set a parameter which is not viable.

An example is the 13th month of the year in

Time Set, or the Hi Alarm limit set lower than

the Low Alarm limit. When this happens you

will be disallowed from leaving that menu and

the effect will be that the menu button will not

work. Examine and correct the parameters to

proceed.

The functions of F1-F5 will vary according to the

menu. The function will be shown beside each button.

The absence of a function beside a button indicates that

the button is not used in that menu.

The following buttons always retain the function described below:

ALARM: Turns alarm contacts to “OFF”. Once an

alarm condition is met, the display will

continue to flash until the alarm condition

is removed. Once the alarm level has been

exceeded, either Hi or Lo, the alarms will

reset when the alarm condition has returned to non-alarm value, including the

dead band value.

Once the alarm button is pushed the alarm

relay is inactive until the reading has once

again reached a non-alarm value (keep in

mind the dead band value). After this the

alarm level must be once again exceeded

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 11

Page 26

2. Turbidity Display

9

5

6

1

F1

F2

7

8

3

ALARM

MENU

F3

F4

2

4

F5

This is the turbidity display. The display shown above is fairly typical. The display has the following parameters:

1 - CURRENT TURBIDITY READING: 477.5 NTU

2 - GRAPH TIME BASE: 24 HOURS

3 - GRAPH UPPER LIMIT: 600 NTU

4 - GRAPH LOWER LIMIT: 400 NTU

5 - ALARM 1 SETTING: ALARM ON HIGHER THAN 550 NTU

6 - ALARM 2 SETTING: ALARM ON LOWER THAN 100 NTU

7 - TIME: 1:28 PM (SHOWN IN 24 HOUR CLOCK MODE)

8 - DATE: MAY 12 1992

9 - GRAPH OF TURBIDITY HISTORY (High, Ave. & Low)

To leave the turbidity display and get to the Main Menu push MENU. F1 - F5 are nonfunctional in this display. Please note

that the graph history shows the highest readings, the lowest readings and the average readings taken within the sample period.

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 12

Page 27

3. Main Menu

Main Menu

F1

F2

F3

F4

This is the main menu. It is the starting point for all sub-menu selections. Shown below are all function key selections and their

purpose.

Selection Options:

F1: Changes screen to ALARM MENU

Select this option to set the value at which the alarm contacts will change for Alarm #1 & Alarm #2.

Alarms

Display Parameters

Utility

Turbidity Backwash

Ver: M200BW-7B210ME6

ALARM

MENU

F5

F2: Changes screen to DISPLAY PARAMETERS MENU

Select this option to: Set upper limit

Set lower limit

Select time base

Set average

Select D to A

Set digit suppression

F3: Changes screen to UTILITY MENU

Select this option to: Set screen brightness

Clear graph history

Set time & date

Calibrate & Adjust offset

Set up serial port parameters

Disable/Enable & Set access code

Run self test diagnostics

F4: Changes screen to TURBIDITY DISPLAY

Select this option to display current turbidity and graph turbidity history.

F5: Changes screen to BACKWASH DISPLAY

Select this option to display and graph a backwash cycle if backwash option is connected.

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 13

Page 28

4. Alarm Menu

Alarm Menu

F1

F2

F3

F4

This is the ALARM MENU. The left side of the screen shows the selections as described below. The right side shows the current

settings. In the example above:

Alarm 1 is set to 1000 NTU and is off

Alarm 2 is set to 200 NTU and will alarm below 200 NTU

The Dead Band is set to 10%

Selection Options:

F1: Not Used

F2: Selects ALARM 1 setpoint MENU

F3: Selects ALARM 2 setpoint MENU

F4: Selects the DEAD BAND for the alarms to 2.5%, 5%, or 10%

F5: Not Used

Alarm 1 1ØØØ. Off

Alarm 2 Ø2ØØ. Lo

Dead Band 1Ø%

ALARM

MENU

F5

a. Alarm #1

F1

F2

F3

F4

This is the Alarm #1 Menu. In this menu you can set the value at which the alarm contacts for Alarm #1 will change. The purpose

of the function buttons are shown below. The current setting is displayed in the center top of the screen. Alarm #2 is displayed

and used exactly the same as this menu.

Selection Options:

F1: Not Used

F2: Selects the digit to change as indicated by the flashing cursor

F3: Increments the selected digit (increases it)

F4: Decrements the selected digit (decreases it)

F5: Selects Alarm #1 to High, Low or Off

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Digit

Up

Down Select Hi;Lo;Off

Flashing cursor

Alarm #1

1ØØØ. OFF

Page 14

ALARM

MENU

F5

Page 29

5. Display Parameters

Display Parameters

F1

F2

F3

F4

This is the Display parameters Menu. The sub-menu selections are described below. In the example above:

Upper Limit is set to 999 NTU Lower Limit is set to zero NTU

Time Base is set to 60 minutes D to A is set for 4 to 20 mA

Note: The D to A automatically calibrates to upper & lower (for our example you will get 4mA at 0 NTU & 20 mA @ 999

NTU)

Selection Options:

F1: Selects UPPER LIMIT MENU

F2: Selects LOWER LIMIT MENU

F3: Selects Time Base between 60 minutes and 24 hours

F4: Selects Set Average Menu

F5: Selects D to A between 4-20 mA or 0 to10 volts

Upper Limit 999.

Lower Limit ØØØ.

Select Time Base 6Ø Min.

Set Average Select D to A

4 to 2Ø mA

ALARM

MENU

F5

Flashing cursor

a. Set Upper Limit

Set Upper Limit

F1

F2

F3

F4

This is the Set Upper Limit Menu. This is where you can change the upper limit for both the graphical display and the high setting

to which the D to A output is calibrated. The set lower limit menu is identical to this and is not shown.

Selection Options:

F1: Not Used

F2: Selects the Digit to change as indicated by a flashing cursor

F3: Increments the selected Digit (increases it)

F4: Decrements the selected digit (decreases it)

F5: Not Used

Digit

Up

Down

999.

ALARM

MENU

F5

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 15

Page 30

b. Set Average

Set Average

F1

F2

F3

F4

This is the Set Average Menu. This is where you can make changes to the averaging period. Readings are updated at a rate of one

per second. A higher averaging time will give smoother curves to the graphical display and to recording devices and helps “wash

out” anomalies. Always use the X1 setting when taking grab sample readings. Suppression or “Holding” the least significant digits

to zero may be set here. The X1 setting is automatically selected while in the calibration menu.

Selection Options:

F1: Selects each reading (one second)

F2: Selects Averaging of the last sixteen readings (16 seconds)

F3: Selects Averaging of the last forty-eight readings (48 seconds)

F4: Selects Averaging of the last ninety-six readings (96 seconds)

F5: Selects between 1 digit, 2 digits & none of the least significant digit suppression

X1

XØ1

X16

X48

X 9 6 Digit Suppress

Ø

ALARM

MENU

F5

6. Utility Menu

Utility

F1

F2

F3

F4

This is the Utility Menu. The available sub-menu selections are listed below.

Selection Options:

F1: Selects Screen Brightness & Clear History Menu (from graphs)

F2: Selects Set Time & Date Menu

F3: Selects Calibration Menu

F4: Selects serial port & Access code set-up menu

F5: Performs a check of internal critical voltages

Screen Brightness/History

Set Time

Calibrate

Comm Port Self Test

ALARM

MENU

F5

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 16

Page 31

a. Screen Brightness/History

Screen Brightness/History

F1

F2

F3

F4

This is the screen brightness and clear history menu. In this menu you can adjust the screen intensity in increments by

successively pressing F2 or F3. The intensity level will be stored when you leave this menu. Variations in ambient temperature

will cause shifts in the brightness level.

F4 allows you to clear the graph history from both the turbidity and backwash screens.

Selection Options:

F1: Not Used

F2: Adjusts the screen intensity brighter a step each time pushed

F3: Adjusts the screen intensity dimmer a step each time pushed

F4: Clears the graph history from screens

F5: Not Used

Dimmer

Brighter

Clear History

ALARM

MENU

F5

b. Set Time

F1

F2

F3

F4

This is the set time and date menu. From this menu you can set the time and date to local time. Time and date are presented

on the turbidity and backwash displays and printer reports.. The clock accepts the new time and date when you push MENU.

Invalid statements will disallow leaving this menu (see Section VII. Troubleshooting).

Selection Options:

F1: Not Used

F2: Selects digit to change as indicated by flashing cursor.

F3: Increments the selected digit (increases digit)

F4: Decrements the selected digit (decreases digit)

F5: Not used

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Flashing cursor

22:Ø6

Ø7-23-92

Digit

Up

Down

Set Time

ALARM

MENU

F5

Page 17

Page 32

c. Calibrate 0 - 1000 NTU

F1

Calibrate

Ø4Ø26 Hz

(Current Frequency)

Ø.Ø2NTU Ø.Ø227

○○○○○○○○○○○○○○○○

ALARM

F2

F3

1ØØ.ØNTU 18Ø.6

4ØØ.ØNTU 4Ø2.5

○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○

MENU

4Ø2.6 NTU

(Current Reading)

F4

1ØØØ.ØNTU 1ØØØ.Ø

○○○○○○○○○○○○○○

F5

This is the turbidity calibration menu.

Sensor Calibrate is provided to adjust the sensor output for variations in lamp intensity. WHEN YOU PERFORM A SENSOR

CALIBRATE YOU MUST HAVE A 1000 NTU STANDARD IN THE WELL OR YOU MAY GET A SENSOR FAIL

MESSAGE.

F1, F2, F3 & F4 are selected calibration points which are used to calibrate the analyzer to the sensor. Any combination may

be used, however, the stated accuracy will not be achieved without using all four points. The analyzer uses the calibration values

to linearize the readings in this range. The recommended step-by-step procedure is on page 29.

Caution: Do not press F1-F4 unless the indicated standard is in the optical well.

The calibration points are shown on the left side of the screen and are selection options. The right side of the screen shows the

stored real frequency for each calibration point.

In the center of the screen are two numbers. The top number shows the current real frequency reading (decimal adjusted). The

lower number shows the corrected or linearized frequency. In most instances the numbers on this screen can be ignored. They

do, however, serve as a useful diagnostic tool.

See page 28 for complete step-by-step instructions.

Selection Options:

F1: Stores the standardize frequency

F2: Stores the 100 NTU frequency

F3: Stores the 400 NTU frequency

F4: Stores the 1000 NTU frequency

F5: Performs a sensor calibration with 1000 NTU in well

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 18

Page 33

d. Comm Port

Comm Port Menu

F1

F2

F3

F4

This is the communications or serial port menu. This menu will have no purpose unless you have one of the optional serial ports

installed. See page 35 for more details.

Selection Options:

F1: Selects the baud rate between 300, 600, 1200, 2400, 4800 & 9600

F2: Selects the address from 0 to F, HEXADECIMAL

F3: Selects serial printer mode on & serial printer mode off

F4: Used to change access code

F5: Not Used

e. Access Code Menu

Set Baud 9600

Set Address 0

Select Printer

Printer Off

Access Code Reporting

Menu 4 Hour

ALARM

MENU

F5

Access Code Menu

F1

F2

F3

Access Code

Off

Change Code

F4

To enter to this menu, you first need to enter an access code. If no previous code has been entered, the master code F1, F4, F3,

F5 may be used.

Selection Options:

F1: Not Used

F2: Toggles between Access code off and Access code on

F3: Used to select a new Access Code

F4: Not Used

F5: Not Used

ALARM

MENU

F5

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 19

Page 34

f. Security Access Code

Please enter Access Code

F1

F2

ALARM

MENU

F3

F4

This screen is encountered when leaving the turbidity or backwash displays and when changing the Access Code. Use only

the F1, F2, F3, F4 or F5 buttons to enter the Access Code. Refer to page 30 for complete instructions.

F5

g. Set Access Code

Set Access Code

F1

F2

F1 F2 F3

Accept; press Menu===>

ALARM

MENU

F3

F4

This screen is encountered after the previous screen when changing the Access Code. Enter the new Access Code using the

F1, F2, F3, F4 or F5 buttons. Refer to page 30 for complete instructions.

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 20

F5

Page 35

h. Self Test (4 - 20 mA Cal.)

SELF TEST

F1

F2

F3

F4

This is the self test menu. Upon entering this menu all internal critical power supplies are checked and displayed. You may also

calibrate the 4-20 mA D to A output while in this menu. NOTE: You should have some load (up to 1000 Ohms) connected

to the 4 - 20 mA terminals when it is calibrated or it will give you a message indicating a defective 4 - 20 mA line. The display

shows only 0 - 10V Cal or 4 - 20 mA Cal as previously selected in the display parameters menu.

Selection Options:

F1: Not Used

F2: Not Used

F3: Not Used

F4: Not Used

F5: Performs a 4-20 mA calibration

i. Self Test (0 - 10 V Cal.)

GND .ØØØ1

+5 Ref. 5.ØØ6

-5 Ref. -4.99Ø

5V 4.978

+15 14.99

+15 Sen. 15.Ø4

-15 -14.79

-21 -21.24

+24 24.47

4 - 2Ø mA Cal.

ALARM

MENU

F5

SELF TEST

F1

F2

F3

F4

This is the self test menu. Upon entering this menu all internal critical power supplies are checked and displayed. You may also

calibrate the 0-10 volt output while in this menu. The display shows only 0 - 10V Cal or 4 - 20 mA Cal as previously selected

in the display parameters menu.

Selection Options:

F1: Not Used

F2: Not Used

F3: Not Used

F4: Performs a 0-10 volt calibration

F5: Not Used

GND .ØØØ1

+5 Ref. 5.ØØ6

-5 Ref. -4.99Ø

5V 4.978

+15 14.99

+15 Sen. 15.Ø4

-15 -14.79

-21 -21.24

+24 24.47

Ø - 1Ø V Cal.

ALARM

MENU

F5

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 21

Page 36

7. Wait Messages

F1

F4

F1

F2

F3

F2

Please Wait

Working . . . . . . .

4 - 2Ø mA Cal.

ALARM

MENU

F5

ALARM

MENU

F4

F1

F4

F3

F2

F3

Working . . . . . . .

F5

Ø - 1ØV Cal.

ALARM

MENU

Working . . . . . .

F5

These screens indicate that the analyzer is performing some calculations or storing information. This typically occurs when the

analyzer is powered up or when a change in display parameters has been made.

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 22

Page 37

8. Backwash Display

F1

F4

F2

F3

9

65

1

OFF

Ø9Ø.Ø

Ø1Ø.Ø

7

8

3

ALARM

MENU

F5

2

4

This is the backwash display. It is only meaningful if Backwash option is connected. The screen above shows a typical backwash

cycle. In this mode, updates are made to the screen every 6 seconds. The reading is updated every second. The display shows

the following parameters:

1 - CURRENT %T READING: 97.1 %T

2 - GRAPH TIME BASE: 12 MINUTES

3 - GRAPH UPPER LIMIT: 0 %T

4 - GRAPH LOWER LIMIT: 100 %T

5- ALARM 1 SETTING: ALARM TURNED OFF

6- ALARM 2 SETTING: ALARM ON LOWER THAN 10.0 % T

7 - TIME: 1:28 PM (SHOWN IN 24 HOUR CLOCK MODE)

8 - DATE: MAY 12 1992

9 - GRAPH OF BACKWASH HISTORY (with optional Backwash connected)

To leave the backwash display and get to the Main Menu push MENU. F1 - F5 are nonfictional in this display.

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 23

Page 38

a. Backwash Calibration

Calibrate

F1

Ø9984 Hz

ALARM

Ø99.8Ø% T

F2

1ØØ.Ø%T 1ØØØ5.Hz

○○○○○○○○○○○○○○

MENU

F3

F4

This is the backwash calibration menu and usable only with Backwash Sensor connected. To get to it you must first enter

backwash from the main menu. You will be asked if you wish to calibrate. If you respond with yes (F2) you will reach the

calibration screen above. If you respond with no (F3) you will go directly to the backwash display menu. After the calibration

procedures have been completed, press the menu button to reach the backwash display screen.

There is only one point of calibration for backwash, 100% T. The sensor must be placed in what is to be considered 100% T

water (preferably the same water as used in the backwash process). Pressing F2 will then calibrate the analyzer to the 100%

T frequency of the sensor. The right hand side of the screen shows the stored real frequency number.

In the center of the screen are two numbers. The top number shows the current real frequency reading (decimal adjusted). The

lower number shows the corrected or linearized frequency. In most instances the numbers on this screen can be ignored. They

do, however, serve as a useful diagnostic tool.

F5

The function keys F1, F3, F4 & F5 are not used in this menu.

See page 34 for complete maintenance procedures.

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 24

Page 39

B . START UP

Before placing the MICRO 200 BW on line we recommend that you standardize the instrument. The following sections describe the required procedures.

2. Standardizing

The reference standard (cuvette) supplied with the

MICRO 200 BW is a pure liquid sealed in glass. It has

a value of 0.02 NTU.

1. Indexing

The United States Environmental Protection Agency

(U.S. EPA) recommends that cuvettes used for instrument calibration or sample measurement be indexed.

To comply with U.S. EPA standards, the MICRO 200

BW includes an Indexing Ring for quick and repeatable

indexing of the refernce standard.

To index the calibration standard you must be in the

calibration menu. Observe the top center (current

frequency) reading while performing the following steps:

a. Slowly rotate the standard, inside the optical well,

one complete revolution (360°). While rotating the

standard slowly, observe the measured turbidity

and locate the position of the cuvette having the

lowest reading.

b. With the calibration standard positioned at the

location having the lowest turbidity reading, install the

Indexing Ring over the cap on the standard so that the

pointer of the Indexing Ring faces directly forward.

Standardization is performed in the calibration menu

see page 18 for more details. While in the calibration

menu perform the following operations:

a. Place the Reference Standard in the Optical Well.

b. Index the Reference Standard as previously de-

scribed.

c. Allow a few seconds for the standard to stabilize.

d. Press the F1 button to accept the frequency.

NOTE: This operation “calibrates” the .02 NTU refer-

ence standard in the range of interest. If both

ranges maybe used this operation should be

performed on both ranges.

CAUTION: Avoid scratching the surface of the cu-

vette. Keep the cuvette surface clean and

free of dust. A scratched or dirty and

dusty cuvette will cause analysis error.

For instructions (See: V. ROUTINE

MAINTENANCE).

When using the standards in the future, always insert the

standard so that the pointer of the indexing ring faces

forward. Slowly rotate the standard back and forth

about 5° to find the lowest point. The standard is now

indexed and ready for use.

Figure 9 shows a calibration standard being indexed.

NOTE: This Calibration Standard is only Indexed to

the Turbidimeter for which it was aligned.

Figure 9

Reference Standard Indexing

IV. ROUTINE OPERATION

A. CONTINUOUS MONITORING FLOW

THROUGH UNIT

The standard flow through unit supplied with the instrument is designed to operate at pressures up to a

maximum of 60 p.s.i. (414 kPa or 4.22 kg/cm3) and

temperatures to a maximum of 122° F (50° C) fluid

temperature. Flow rates through the unit can be adjusted from 0.5 gpm (200 ml/min) to a maximum of

approximately 1.5 gpm (5.7 liters/minute). The speed

of sensing turbidity changes will depend on the length

of the take-off line, the diameter of the take-off line,

and the flow rate or velocity through the take-off line.

By using a high flow rate and keeping the lines small,

approximately 3/16 inch (4.8 mm) I.D. and relatively

short length, the response time is kept to a minimum.

Consult HF scientific, inc. when unusually long connections are required.

Depending on the type of fluid being monitored, a

pressure drop through the line can cause gas or air to

come out of solution and form bubbles which will

create errors in the turbidity measurements. This can be

prevented by creating a slight back pressure on the

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 25

Page 40

discharge side of the flow through unit using the

stainless steel flow control valve (Catalog #50004)

supplied. Increasing the size of the incoming line will

also help this condition.

NOTE: Since each application is different, the amount

of back pressure required to eliminate bubbles

must be determined and modified on site during

operation by the customer.

A plastic shut-off clamp is provided on the inlet side of

the flow through unit in order to completely stop flow

to facilitate changing the cuvette. See the section on

cuvette cleaning and care for more information.

The U.S. EPA recommends that cuvettes used for

instrument calibration, standardization, or sample measurement be indexed. For quick indexing of the flow

through cuvette, a rotational flow through assembly

with locking collar is supplied.

To index your flow through cuvette, slowly rotate the

flow through at least one revolution, while observing

the reading, to locate the position of the lowest reading.

Without moving the flow through, press down on it and

turn the locking collar until the flow through assembly

is securely locked in place. See figure 10.

The desiccant beads are dark blue when dry and turn to

a light pink when expended. Check the desiccant on a

quarterly basis or if after cleaning the cuvette readings

appear erroneously high to ensure proper operation of

the vaporpurge feature. It is important to keep a cover

on the sample well if the flow through head is out for

more than a few minutes, to avoid saturating the

desiccant uselessly. A replacement desiccant tray com-

plete with foot valve is available from HF scientific or

your local representative HF part# 21555. See figure 1

on page 6 when replacing the desiccant.

Remember to dry the flow through cuvette of excess

moisture before inserting it into the optical well.

This will speed up the evaporation time.

NOTE: If it should become necessary to return the

sensor to the factory, you need only return the

upper sensor assembly and not the base. IF

RETURNING THE BASE, THE DESICCANT

TRAY MUST BE REMOVED BEFORE SHIP-

PING.

C. GRAB SAMPLES

Take extreme care when handling any sample cuvettes.

Surface scratches, dust or finger smudges will cause

analysis error. Examine each cuvette carefully before

the sample is drawn and placed in the Optical Well. We

recommend that the cuvette be wiped clean with a lintfree laboratory tissue before the sample is drawn.

Handle Reference Standard and cuvettes by the top

portion only.

Figure 10

Flow Through Cuvette Indexing

B. VAPORPURGE

The MICRO 200 BW is equipped with a continuous

vaporpurge system. A fan inside the sensor continuously circulates heated, dry air around the optical well

and the flow through cuvette. This feature eliminates

the need for connection of a dry purge line. See Figure

11.

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

To take a reading of a grab sample:

1. Set Averaging to 1 second (see page 16).

2. Remove the flow through unit and insert grab

sample cuvette in Optical Well.

3. The turbidity value of the grab sample will now be

displayed on the readout. Allow at least two up

dates (five to ten seconds) for best accuracy before

noting the reading.

NOTE: Settling particles or air in the sample may cause

the digital reading to “hunt”. For best results

take readings before turbid particles settle but

after air bubbles have been allowed to escape.

V. ROUTINE MAINTENANCE

A. CUVETTE CLEANING & CARE

Cuvettes must be clean and free of marks or scratches

in the critical area (see figure 12 on page 28). Cleaning

Page 26

Page 41

Figure 11

Vaporpurge

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 27

Page 42

is accomplished by washing the interior and exterior of

the cuvette in a detergent solution, then rinsing thoroughly 8 to 10 rinses in clean, distilled water, to remove

all streaks.

Flow shut-off clamp!

" Flow

Control Valve

Figure 13

Lamp Replacement

C. CALIBRATION PROCEDURES

1. Calibration Standards

Figure 12

Critical Measurement Area

The sample flow must be shut off, with the flow shutoff clamp on the inlet flexible tubing, when the cuvette

in the flow through unit is to be cleaned or changed (see

figure 13).

Replace the cuvette if scratches or marks in the critical

area affect readings.

Store reusable cuvettes (Catalog No. 50036, pkg of 3)

in a clean dust-free environment.

B. LAMP REPLACEMENT

Periodically the LAMP MODULE, Cat. #21541, in the

sensor will require replacement. It is recommended that

one spare lamp for each MICRO 200 BW be kept on

hand at all times. A burned out lamp is indicated by a

flashing SENSOR AL indicator on the analyzer display. TO CHANGE THE LAMP MODULE SIM-

PLY TURN THE OUTSIDE LOCKING RING

COUNTER CLOCKWISE, AND PULL THE

MODULE STRAIGHT OUT. Reverse the procedure

to install the replacement module. For accurate operation a complete calibration is recommended after a

lamp module replacement. See page 29 for calibration

instructions. Refer to figure 13.

a. Secondary Standard Set (optional) Catalog No.

19830

HF Secondary Standards are recommended and certified by HF scientific. They are traceable to freshly

prepared formazin primary standards. These standards

are very easy to use off the shelf anytime without

preparation making them an ideal turbidity standard. A

Certificate of Traceability is available on request to HF

scientific Customer Service Department. HF Secondary Standards may be used for calibration of HF turbidimeters. Order from HF scientific, inc.

NOTE: Do not freeze standards. Do not leave standards

in the measuring well for extended periods. Do

not shake standards.

Specific instructions for using certified Secondary

Standards are included with the kit.

Each Secondary Standard Kit contains:

-- Instructions

-- 0.02 Reference Standard

-- Certified Secondary Standards 100.0, 400.0,

1000 NTU Standards are contained in preselected

cuvettes with light shield caps.

-- A sturdy storage case

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

Page 28

Page 43

b. Standard Formazin Solutions

Calibration of this instrument is based on Formazin, a

material which is made by polymerization.

Calibration samples may be obtained by diluting Formazin stock suspension using “Turbidity-Free” water.

Formazin stock suspension can be prepared by the user

(Reference Standard Methods For Examination of Water

and Wastewater) or a kit can be purchased from, HF

scientific, inc., Catalog No. 50040.

Each kit contains:

-- Instruction manual

-- 1 liter of 4000 NTU Stock Suspension

-- 1 Gallon (3.79 liters) turbidity-free water

-- 4 Sample cuvettes (28 mm)

-- 4 Light Shield Caps

-- Graduated Pipettes 1 ea. in 1 ml, 10 ml, &

25 ml

-- 1 Reference Standard

NOTE: When the prepared samples start to flocculate,

they are unreliable and fresh ones must be

made. This will occur more rapidly for the

lower value diluted suspensions.

2. Calibration Steps 0-1000 NTU Range (Also See

Section IV)

To meet stated accuracy it is advisable to allow both the

analyzer and sensor to come to its optimum operating

temperature, which can take approximately two hours.

After this point you can proceed with the following

procedure.

4. A sensor calibration is first performed which adjusts the sensor for lamp variations. Then the

frequency at the time of this selection is saved as the

calibration frequency for the 1000 NTU standard.

The frequency is displayed in the right hand column.

5. Insert the 400 NTU standard.

6. Rotate the standard while observing the frequency

until the lowest reading is noted.

7. Press the F3 key.

8. The frequency at the time of this selection is saved

as the calibration frequency for the 400 NTU

standard. This frequency is displayed in the right

hand column.

9. Insert the 100 NTU standard.

10. Rotate the standard while observing the frequency

until the lowest reading is noted.

11. Press the F2 key.

12. The frequency at the time of this selection is saved

as the calibration frequency for the 100 NTU

standard. This frequency is displayed in the right

hand column.

13. Insert the Reference Standard.

14. Rotate the Reference Standard to its index point.

15. Press the F1 key.

16. The frequency for the 0.02 NTU standard is saved.

This frequency is displayed in the right hand column.

Standardization should be performed after after 1000

NTU (Full Scale) Calibration, although it is possible to

standardize at any time without performing a complete

calibration.

Although it is possible to calibrate at any combination