Page 1

HF scientific

Website: HFscientific.com

OWNER’S AND USER’S MANUAL

TM

M100+

Models 28060 & 28061

Laboratory Turbidimeter

M100+ (January 2019)

Rev. 1.74

Read Manual and all product labels BEFORE

using the equipment. Do not use unless you

know the safe and proper operation of this

equipment. Keep this Manual available for

easy access by all users. Replacement

Manuals are available at HFscientific.com

3170 Old Metro Parkway

Ft. Myers, FL 33916

Phone: 239-337-2116

Fax: 239-332-7643

Toll-free: 888-203-7248

E-Mail: HF.Info@WattsWater.com

Page 2

M100+ (January 2019)

Rev. 1.74

Page 3

M100+ (January 2019)

Rev. 1.74

Page 4

M100+ (January 2019)

Rev. 1.74

Page 5

Attention Owners and Users

Model:

Date of purchase:

Thank you for purchasing the M100+™ turbidimeter. This equipment will provide safe

and productive operation as long as it is installed, used, maintained, and serviced in

accordance with the instructions in this manual and is properly maintained. Importantly,

unless the user is adequately trained and supervised, there is a possibility of personal

injury, property damage or damage to the equipment.

Owners and users of this equipment bear the responsibility to make certain that this

equipment is used properly and safely. READ THIS MANUAL carefully, learn how to

use and service this equipment correctly, and strictly follow all of the instructions

contained in this manual and the requirements of local, state and federal law. Failure to

do so could result in personal injury, property damage or damage to the equipment. This

manual should be considered a permanent part of your machine and should be kept

available for easy reference by any user.

Owners should not permit anyone to touch this equipment unless they are over 18 years

of age, are adequately trained and supervised, and have read and understood this

manual. Owners should also ensure that no unauthorized personnel comes in contact

with this equipment.

If this equipment, or any of its parts, becomes damaged or needs repair, stop using the

equipment and contact an experienced service individual immediately. If the warning

labels or this manual are misplaced, damaged or illegible, or if you require additional

copies, please contact customer service at +1 (239) 337-2116 or 888-203-7248 for these

items at no charge.

Please remember that this manual and the warning labels do not replace the need to be

alert, to properly train and supervise users, and to use common sense when using this

equipment.

If you are ever uncertain about a particular task or the proper method of operating this

equipment, ask your supervisor, consult this manual, access www.hfscientific.com, or

contact us at 888-203-7248.

PRODUCT IDENTIFICATION

Please record your product’s identification and purchase information which will help in

the event you have questions or need any service.

Serial #:

M100+ (January 2019)

Rev. 1.74

Seller name/address:

Page 6

Table of Contents

Section Page

Understanding Safety Information .............................................................................................................. 1

Specifications ............................................................................................................................................. 2

1.0 Overview ............................................................................................................................................ 3

1.1 The M100+ Product Description .................................................................................................... 3

2.0 Unpacking and Inspection ................................................................................................................. 4

3.0 Site Selection ..................................................................................................................................... 5

4.0 Setup, Configuration and Calibration ................................................................................................. 5

4.1 Operating Screens ........................................................................................................................ 6

4.2 Configuring the M100+ .................................................................................................................. 7

4.2.1 Screen Brightness ................................................................................................................ 8

4.2.2 Auto/Manual Readings ......................................................................................................... 8

4.2.3 Auto Power Down ................................................................................................................. 9

4.2.4 Touch Screen Calibration ..................................................................................................... 9

4.2.5 Set Date/Time ..................................................................................................................... 10

4.2.6 Delete Samples .................................................................................................................. 10

4.2.7 Data Resolution .................................................................................................................. 11

4.2.8 Offset .................................................................................................................................. 11

4.2.9 Device ID ............................................................................................................................ 11

4.2.10 Calibration Reminder ...................................................................................................... 12

4.2.11 Calibration Download ..................................................................................................... 12

4.2.12 Firmware Update ............................................................................................................ 13

4.2.13 Reset Defaults ................................................................................................................ 13

4.2.14 About Device .................................................................................................................. 14

4.3 Calibrating the M100+ ................................................................................................................. 14

4.3.1 Calibration Standards ......................................................................................................... 15

4.3.2 Care of ProCal Standards .................................................................................................. 16

4.3.3 Indexing Calibration Cuvettes ............................................................................................. 16

4.3.4 Calibration Procedures ....................................................................................................... 17

4.3.5 Alternate Calibration Ranges .............................................................................................. 19

4.3.6 Failed Calibration ................................................................................................................ 19

5.0 Operation ......................................................................................................................................... 20

5.1 Home Screen............................................................................................................................... 20

5.2 Trend Screen ............................................................................................................................... 21

5.3 Data Retrieval .............................................................................................................................. 21

5.3.1 USB Connection ................................................................................................................. 22

6.0 Troubleshooting ............................................................................................................................... 23

6.1 M100+ Fault Detection ................................................................................................................ 23

6.2 Diagnostic Table .......................................................................................................................... 23

6.3 Technical and Customer Assistance ........................................................................................... 23

7.0 Routine Maintenance ....................................................................................................................... 25

7.1 Cleaning the Cuvette ................................................................................................................... 25

7.2 Replacing the Source Lamp ........................................................................................................ 25

7.3 Battery ......................................................................................................................................... 25

8.0 Accessories and Replacement Parts List ........................................................................................ 26

9.0 Limited Warranty .............................................................................................................................. 27

M100+ (January 2019)

Rev. 1.74

Page 7

Understanding Safety Information

Identifies hazards which, if not avoided, will result in death or serious

Identifies hazards which, if not avoided, could result in death or

Identifies hazards which, if not avoided, will result in minor or

Identifies practices, actions or failure to act which will result in

This manual contains safety and use instructions that must be followed during the

installation, commissioning, operation, care and maintenance, and service of the M100+.

All responsible personnel must read this manual prior to working with this instrument and

should familiarize themselves with the following safety symbols, signals, and pictorials.

This is a safety-alert symbol.

• The safety alert symbol is shown alone or used with a signal word (DANGER,

WARNING or CAUTION), a pictorial and/or a safety message to alert you to

hazards.

• When you see this symbol alone or with a signal word on this instrument or in this

Manual, be alert to the potential for death or serious personal injury.

Safety signal words have the following meaning:

injury.

serious injury.

moderate injury.

property damage or damage to the equipment.

Pictorials used on the equipment and in this Manual have the following meanings:

This pictorial alerts you to the need to read the Manual.

This pictorial alerts you to electricity, electrocution and shock hazards.

1

Page 8

Specifications

forth in EPA method 180.1

lamp.

This model uses an IR

LED lamp.

±2% of reading or ±0.02 NTU below 40 NTU whichever is

±5% of reading above 40 NTU

new firmware via thumb drive (USB flash stick).

3. Three Year Battery Backup With no External Power

Range

Sample Temperature Range

0°C – 40°C (32°F – 104°F)

Dimensions

237mm W x 254mm L x 121mm H (10.75” W x 10” L x 4.75” H)

Shipping Weight

2.5 kg (5.5 lbs.)

Certifications

LC mark tested to UL and CSA.

Conforms to CE

Warranty

1 Year from date of shipment

M100+ White Light

Model 28060

M100+ Infrared

Model 28061

Measurement Range

Accuracy

†, ††

Repeatability††

Resolution

USB

Power Supply

Miscellaneous

Specifications

Conforms to specifications set

(Nephelometric Method)

§ This Model uses a tungsten filament

Conforms to specifications set forth in ISO 7027: Water

Quality - Determination of Turbidity.

0-4000 NTU

greater

< ±1% of reading or ± 0.02 NTU whichever is greater

Menu settable up to 0.0000 over the entire range

Printer or download logged data & calibration data & upload

UL, CSA & CE approved 12V DC, Wall Mount

1. USB port for logged data download and software updates.

2. Built-in Diagnostics

Operating Temperature

§

The specifications found in EPA method 180.1 are essentially the same as the specifications set out in method 2130B of the Standard

Methods for the Examination of Water and Wastewater 22

The M100 PLUS meets or exceeds, the specifications set forth in these methods.

1°C – 40°C (34°F – 104°F)

nd

edition and the specifications set out in ASTM Standard Method D1889-94.

†

Instrumental accuracy measured under controlled laboratory conditions at 25°C (77°F)

††

Both the accuracy and repeatability specifications for the M100+ are valid only for measurement of static (non-flowing) samples.

2

Page 9

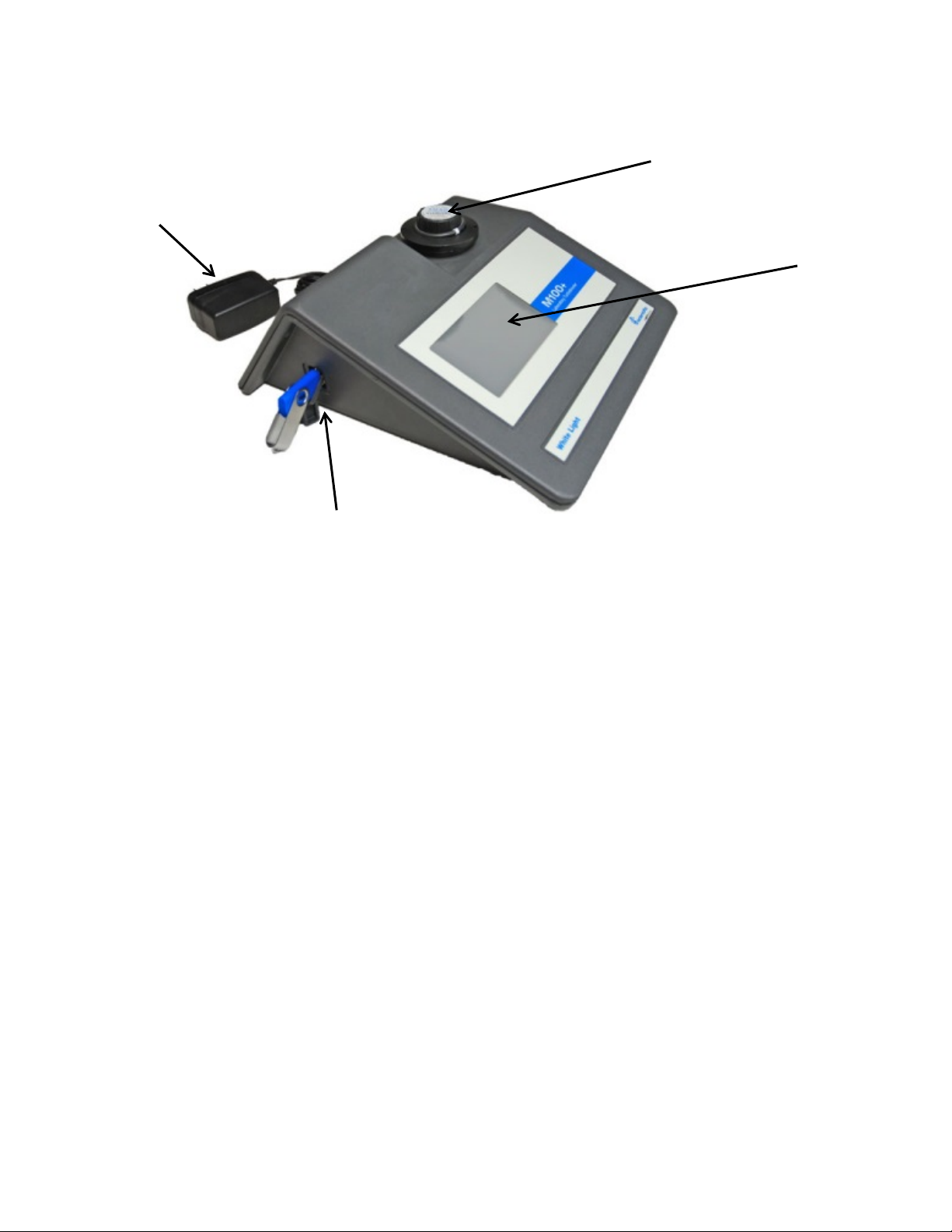

1.0 Overview

Power Supply

Touch screen

Standard Inserted in Optics

USB Connector

1.1 The M100+ Product Description

The M100+ is a process turbidimeter that allows for the laboratory measurement

of the turbidity of sample water. The white light M100+ has been designed to meet

the design criteria specified by the US EPA 180.1 on turbidity measurement. The

infrared M100+ was designed to meet the design criteria specified in ISO 7027

and DIN 27027 for the measurement of the turbidity of a sample. Both models

have long life lamps.

The M100+ instruments are equipped with a USB slot in order to download logged

data and calibration information and to update operating software.

The M100+ is equipped with a color touch screen for easy and efficient operation.

3

Page 10

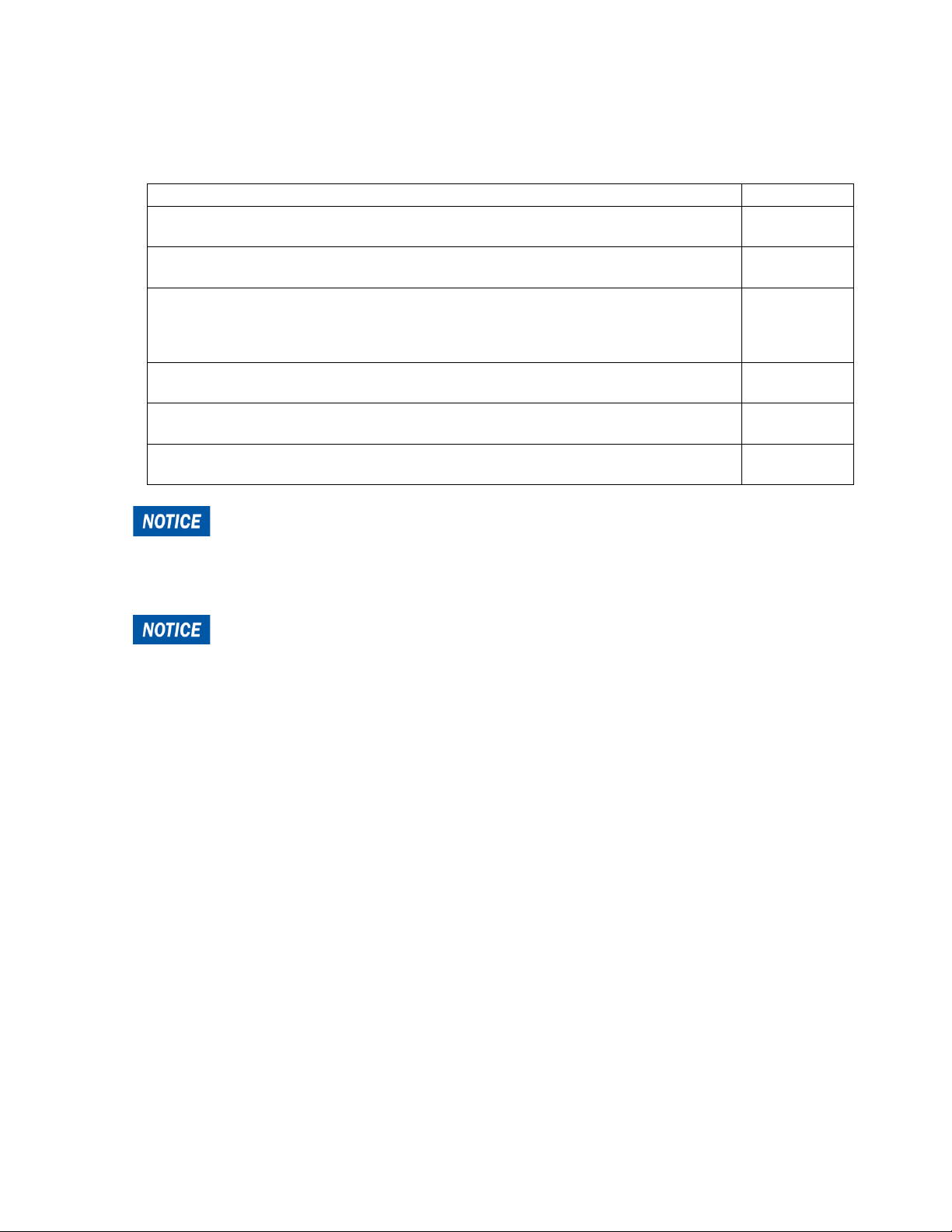

2.0 Unpacking and Inspection

Item

Quantity

(shipped in a separate box to ensure freshness)

The table below indicates the items in the turbidimeter shipment.

M100+ Laboratory Turbidimeter

Accessory Kit for M100+ (2 empty sample cuvettes with caps)

Full Range Calibration Kit High Range A, High Range B, 1000 NTU,

10 NTU & 0.02 NTU

Quick Start Guide

Flash Drive Containing Full Owner’s and User’s Manual

Wall Mount Power Supply with Ferrite

A ferrite is included with the power supply. This should be looped twice

through the cord near the side that connects to the instrument to eliminate EMI

interference.

Remove the instrument from the packing carton. Carefully inspect all items

to ensure that no visible damage has occurred during shipment. If the items

received do not match the order, please immediately contact the local distributor

or the HF scientific Customer Service department.

1

1

1

1

1

1

4

Page 11

3.0 Site Selection

The M100+ must be used in a suitable dry location with adequate ventilation. It

should not be located where chemicals such as chlorine are located. It must be operated

and stored between 1 and 40°C. The instrument should be used on a stable table top

and less than 90 cm (3 feet) from a power source.

Power Requirements:

• The M100+ requires 12VDC for proper operation. The provided supply is rated at

1A.

• The M100+ is supplied with a wall mount power supply intended for operation with

100-240 VAC, 47-63 Hz power source. BEFORE installing, verify that the line

voltage falls within these specifications.

• Connect the wall mount power supply to the rear panel of the M100+.

• An optional Euro wall mount power supply is available.

4.0 Setup, Configuration and Calibration

Before using your M100+, you will need to familiarize yourself with the

instrument’s operating modes and functions and perform some setup, configuration, and

calibration.

• The M100+ allows for the measurement of the turbidity of water. The

turbidity of the water is usually reported in Nephelometric Turbidity Units

(NTU) but may be reported in Formazin Nephelometric Units (FNU). This

is user selectable.

• Readings up to 4400 are possible but readings above 4000 are outside of

the rated specifications. Readings above 4400 NTU will cause the display

to flash indicating an over-range condition.

• During normal operation, the instrument will be at the HOME screen. This

is this screen where measurements can be viewed.

• Please note, some features depicted in this manual may change with

future firmware updates.

5

Page 12

Home ( ) screen is the normal reading

Trend ( ) screen is used for displaying

a serial printer.

Calibration ( ) screen is used for

specifications.

Setup ( ) screen is where configuration

according to needs and preferred

operation at any time during normal

menus to facilitate

instrument configuration. This is also

where logged files and calibration logs

can be downloaded and where new

software, when available, can be

uploaded.

4.1 Operating Screens

There are four main operating screens in the form of Icons, Home ( ),

Trend ( ), Calibration ( ), and Setup ( ). To change between screens,

simply touch the appropriate icon.

screen. This is the default mode when

power is applied or restored. The other

three operation screens are limited to 15

minutes with no key presses after which

the screen will return to Home.

trend information. This information can be

downloaded to the USB stick or printed to

calibration. The instrument was

calibrated and tested prior to leaving the

factory. Therefore, it is possible to use

the instrument directly out of the box.

Under normal conditions, re-calibration is

required once every three months.

Quarterly calibration ensures

performance within accuracy

changes can be made. In the Setup

screen, you can customize the instrument

operation. The Setup screen has been

split into sub-

6

Page 13

4.2 Configuring the M100+

The M100+ has been designed to provide the ability to customize the instrument

according to your needs at any time during normal operation. The Setup screen

has been split into sub-menus to facilitate instrument configuration. This section

describes how to use each of the sub-menus to configure the instrument.

Turn Power “ON:” After confirming that the M100+ is safely and properly

plugged into a suitable power source, simply touch the screen to turn the

instrument on. Depending on the setting, the instrument will usually power down

automatically.

There is a setting (Auto Power Down) that allows the instrument to

stay on and require a manual shut down. An On/Off button will appear

on the Home screen. It is not recommended to leave the instrument on constantly

as it may cause drift and premature degradation of the lamp. The drift can be

corrected by more frequent calibrations.

The following configuration settings can be performed in the Setup

screen:

• Screen Brightness

• Auto/Manual Readings

• Auto Power Down

• Touch Screen Calibration

• Set Time/Date

• Delete Samples

• Data Resolution

• Offset

• Device ID

• Calibration Reminder

• Calibration Download

• Log Download

• Firmware Update

• Reset Defaults

• About Device

The Setup screen has quite a few menu selections. Use the slider on the righthand side to access to all of the selections.

• At any time any of the Home, Trend, Calibration and Setup screens can be

pressed and implemented.

• To select any of the Setup options identified below, press Setup icon and then

select the option that you wish to change.

7

Page 14

4.2.1 Screen Brightness

• Press the Setup icon. Select Screen Brightness.

• Adjust current Screen Brightness.

• Use & or the drag cursor.

• Push to save and return to Setup Menu.

4.2.2 Auto/Manual Readings

• Press the Setup icon. Select Auto/Manual Readings.

• In this screen, a selection can be made of continuous readings (Auto) or for

a single reading (Manual).

• If Auto is selected the rate of updates can be selected from 1 to 60

seconds using the & buttons.

• Select to save and confirm.

• If Manual is chosen, a button will appear in the Home icon to take

readings.

• Manual readings take approximately 10 seconds to display. It will say

“capturing” to indicate that it is processing.

8

Page 15

4.2.3 Auto Power Down

• Press the Setup icon. Auto Power Down.

• The M100+can be set to power down automatically.

• The factory setting is to power down after 30 minutes.

• To save lamp life it is recommended that auto power down is used.

• The time can be adjusted using the & buttons.

• If you need to keep the instrument on you can select OFF for the Auto

Power Down. In this case, you will turn the M100+ off using the button

on the Home screen.

4.2.4 Touch Screen Calibration

• Press the Setup icon. Select Touch Screen Calibration.

• This has been factory adjusted.

• Adjust if the alignment is needed.

• May need to be done if new software downloaded.

• Five position setup.

• If this calibration fails. Restart by pulling and reinserting the power plug.

Press top screen time banner for 5 seconds to reset to factory default

screen setting. Then attempt the calibration again.

9

Page 16

4.2.5 Set Date/Time

• Press the Setup icon. Select Set Date/Time.

• Date/Time: Set the date and time by using the & buttons.

When complete, press the to save the setting and return to Setup menu.

• Time Format: Allows you to select 12 or 24 hour time. This menu will

change slightly if the 24-hour format is selected. Use the & buttons to

select your option.

• Daylight Saving Time: Allows you to enable Daylight Saving Time in

the USA, Canada and other countries that follow the US Energy Savings

Act of 2005.

4.2.6 Delete Samples

• Press the Setup icon. Select Delete Samples.

• Select either All or By Sample ID.

• If Sample ID is selected, select sample.

• Press to delete sample.

10

Page 17

4.2.7 Data Resolution

• Press the Setup icon. Select Data Resolution.

• Sets the resolution or number of digits after decimal point shown in Home

screen.

• Use & to set the resolution. The screen shows a representation.

• Push to save and return to Setup Menu.

4.2.8 Offset

• Press the Setup icon. Select Offset.

• Adjusts the reading slightly to allow for agreement with another instrument.

• Turn On to use then use the & buttons to set the offset.

• Allowable resolution is -1.00 to +1.00 in increments of 0.01 NTU

4.2.9 Device ID

• Press the Setup icon. Select Device ID.

• Sets the Device ID for data logging purposes.

• Touching the number box brings up and keypad. Enter the number on the

keypad and press the .

• This returns to screen above. If this is acceptable press .

• If this is not acceptable press the .

11

Page 18

4.2.10 Calibration Reminder

• Press the Setup icon. Select Calibration Reminder.

• Sets how often a calibration reminder comes up on Home screen.

• The USEPA recommends calibration every quarter (90 days).

• Use the & buttons to set period in days.

• Set to OFF if not desired.

• Push to save and return to Setup Menu.

4.2.11 Calibration Download

• Press the Setup icon. Select Calibration Download.

• Allows USB thumb drive download of calibration history.

• Insert USB thumb drive into the USB port.

• Push to transfer the information and return to the Setup screen.

• See Data Retrieval section 5.3 for more information.

12

Page 19

4.2.12 Firmware Update

• Press the Setup icon.

• This screen is used to update firmware via USB.

• Insert the USB thumb drive containing the software into the USB port.

• Push to continue.

• If the inserted USB thumb drive contains a lower revision number than that

currently installed, then the M100 will ask if you are sure you want to

continue.

• Push to continue.

• The upload will take several minutes. During the initial upload, the screen

will show “busy” and screen anomalies may appear until the upload is

complete.

• Finally, the screen will turn off when complete.

• Any firmware updates will be posted to our website www.hfscientific.com.

• The current firmware version is shown in About Device. See 4.2.16 below.

4.2.13 Reset Defaults

• Press the Setup icon.

• This menu allows resetting the calibration and/or settings. This clears the

calibration and new calibration will be required to operate the instrument.

• Settings may change so these should be checked.

13

Page 20

4.2.14 About Device

• Press the Setup icon.

• This menu shows the current setting of the Device ID, the lamp type, and

the firmware revision number.

• Firmware revision can be compared to available firmware on the website.

• Push to continue.

4.3 Calibrating the M100+

• The instrument was calibrated and tested prior to leaving the factory.

Therefore, it is possible to use the instrument directly out of the box. Under

normal conditions, re-calibration is required once every three months.

Quarterly calibration ensures performance within accuracy specifications.

The EPA and ISO recommend that on-line turbidimeters be

calibrated with a primary standard at least once every three

months if they are to be used for reporting purposes.

14

Page 21

4.3.1 Calibration Standards

• If the M100+ will be used over the entire range of 0.02 to 4000 NTU, a

complete calibration as described below will be required which includes the

two High Range standards.

• If instrument accuracy is only required below 1000 NTU, a calibration may

be performed using the 1000 NTU standard, the 10 NTU standard, and

0.02 NTU standard. To calibrate starting at 1000 NTU, simply press the

1000 button on the calibration screen.

• If instrument accuracy is only required below 10 NTU, such as for potable

water, a calibration may be performed using only a 10 NTU and a 0.02

NTU standard. To calibrate starting at the 10 NTU, simply press the 10

button on the calibration screen.

• We recommend that the following materials be used during calibration to

achieve the full-scale accuracy stated in this manual:

High Range A ProCal Calibration Standard available from HF scientific

High Range B ProCal Calibration Standard available from HF scientific

1000 NTU ProCal Calibration Standard available from HF scientific

10.0 NTU ProCal Calibration Standard available from HF scientific

0.02 NTU ProCal Calibration Standard available from HF scientific

is used to calibrate the instrument, ensure that a fresh stock suspension of

Formazin is used to achieve the accuracy quoted for the instrument.

A Formazin Stock Solution Kit is available from HF scientific (Catalog No.

50040).

The HF scientific ProCal, primary calibration standards (refer to section 8.0

Accessories and Replacement Parts List), are more stable than Formazin

and have a minimum shelf life of 12 months. Prior to recalibration, review

the expiration dates, to ensure that the standards have not expired.

It is well known that diluted Formazin is unstable. If Formazin

15

Page 22

4.3.2 Care of ProCal Standards The information below is provided as a general guidelines for the proper care of ProCal standards.

• ProCal standards should only be handled by the top, black cap or by the

very bottom of the cuvette.

• Keep the cuvette glass clean of fingerprints and debris.

• Cuvettes can be cleaned with any domestic glass cleaner and the provided

microfiber cloth.

• Prevent ProCal standards from freezing. This will most likely destroy them.

• Standards under 100 NTU must be freshly poured from the supplied bottle

as they are are not stable in the glass cuvette.

• There are no need to shake standards, but standards over 1000 NTU

should be upended gently before use.

• Replace standards at the expiration date.

4.3.3 Indexing Calibration Cuvettes To achieve the greatest accuracy, and account for normal scratches and aberrations in cuvette glass when calibrating, HF Scientific recommends indexing the cuvettes.

Standards and standard kits purchased from HF

Scientific are supplied with indexing rings. Complete

instructions regarding how to index the cuvettes are

included in the calibration kits.

The following steps allow repeatable indexing of calibration standards:

1. With the instrument in the Home screen, insert the standard.

2. Indexing is best performed if the automatic reading is enabled and set

to 1 sec/reading. See section 4.2.2 for more information on

Auto/Manual Readings.

3. Slowly rotate the standard, inside the optical well, one complete

revolution (360º). While rotating the standard slowly, observe the

measured turbidity and locate the position of the cuvette having the

lowest reading.

4. With the calibration standard positioned at the location having the

lowest turbidity reading, install the Indexing Ring over the cap on the

standard so that the pointer of the Indexing Ring faces directly forward.

When using the standards in the future, always insert the standard so that

the pointer of the indexing ring faces forward. Slowly rotate the standard

back and forth about 5° to find the lowest point. The standard is now

indexed and ready for use.

16

Page 23

4.3.4 Calibration Procedures

Select Range

Command button:

calibration.

Formazin Calbration Screen

ProCal Calibration Screen

• Select the calibration function of the instrument by pressing the Calibrate

icon.

• Select the appropriate calibration standard - either Formazin or ProCal then press .

• The calibration menu will be displayed as shown above.

• On the left-hand side are selections for the range for calibration. Select the

highest value required for your application.

• Ensure standards are indexed as described in section 4.3.3 prior to

calibration.

• The calibration standards should be cleaned with a microfiber cloth and

any standard window cleaner solution.

• Handle standards only by the black cap to prevent fingerprints or other

smudges from affecting the readings.

• Have the standards prepared for the range you intend to calibrate.

• To calibrate for 0-4000 NTU using ProCal, you will need the High Range A,

High Range B, 1000 NTU, 10 NTU, and 0.02 NTU standards.

• To calibrate for 0-4000 NTU using Formazin, you will need the 4000 NTU,

1000 NTU, 10 NTU, and 0.02 NTU standards.

• The command button will guide you through the calibration.

Follow directions

that appear here for

17

Page 24

Calibration steps (Using ProCal):

1. Press the High Range A button on the left side of the screen.

2. Insert the High Range A standard.

3. Press the Command button in the middle of the screen to start the

calibration.

4. A countdown will appear from 30.

5. When the count is complete the screen will request the High Range B.

6. Press the High Range B button on the left side of the screen.

7. Insert the High Range B standard.

8. A countdown will appear from 30.

9. When the count is complete the screen will request the 1000 NTU.

10. Insert the 1000 NTU standard.

11. Press the Command button start the calibration of the 1000 NTU.

12. A countdown will appear from 60.

13. When the count is complete the screen will request the 10 NTU.

14. Insert the 10 NTU standard.

15. Press the Command button start the calibration of the 10 NTU.

16. A countdown will appear from 60.

17. When the count is complete the screen will request the 0.02 NTU.

18. Insert the 0.02 NTU standard.

19. Press the Command button start the calibration of the 0.02 NTU.

20. A countdown will appear from 30.

21. When complete, all the buttons on the left should be all green and the

Command button should say Calibration Good

Calibration steps (Using Formazin):

1. Press the 4000 button on the left side of the screen.

2. Insert the 4000 NTU standard.

3. Press the Command button in the middle of the screen to start the

calibration.

4. A countdown will appear from 30.

5. When the count is complete the screen will request the 1000 NTU.

6. Insert the 1000 NTU standard.

7. Press the Command button start the calibration of the 1000 NTU.

8. A countdown will appear from 60.

9. When the count is complete the screen will request the 10 NTU.

10. Insert the 10 NTU standard.

11. Press the Command button start the calibration of the 10 NTU.

12. A countdown will appear from 60.

13. When the count is complete the screen will request the 0.02 NTU.

14. Insert the 0.02 NTU standard.

15. Press the Command button start the calibration of the 0.02 NTU.

16. A countdown will appear from 30.

17. When complete, all the buttons on the left should be all green and the

Command button should say Calibration Good

18

Page 25

4.3.5 Alternate Calibration Ranges

• Alternately you could choose to calibrate to 1000 NTU, which requires

1000 NTU, 10 NTU, and 0.02 NTU. Press the 1000 button on the left side

and start at step 5 above.

• A calibration for the only the 10 NTU range requires only the 10 NTU and

0.02 NTU. Press the 10 button on the left side and start at step 9 above.

• For the two alternate ranges, these will still read the full range with a

reduced accuracy above the range of calibration.

4.3.6 Failed Calibration In the case of a failed calibration, the last good calibration is restored once the user exits to the Home Screen. A failure will be evident at the calibration screen will show all red.

The instrument can be used with this calibration with a potentially reduced

accuracy. The bad calibration will be noted in the calibration log and as a

reminder, a yellow diagnostic banner will show on the home screen

indicating that the last calibration had failed and that the instrument was

using the previous calibration. The only way to remove this indication is to

successfully complete a calibration.

Check the standards for cleanliness and expiration date. If everything looks

good, attempt the calibration again. If the calibration fails after the second

attempt, the most likely causes are that standards are bad or the lamp

needs replacement.

19

Page 26

5.0 Operation

Calibration

On/Off

Sample ID (Name)

NTU/FNU

Reading List

Current Reading

Update Reading

Time

Diagnostic Banner

Home

Setup

Trend

5.1 Home Screen

All operations start on the Home screen. Refer to the above figure for all

operations.

• When the instrument is in Automatic Readings (section 4.2.2.), Update

Reading button will not show. This is used only for manual updates.

• The current reading is always shown in the large number format.

• Toggle between NTU & FNU by touching the button.

• Pressing Sample ID brings up a keypad to allow you to provide a name.

• Sample ID shows up to five previous readings. All readings are saved. See

Trend screen below.

• The instrument can be turned off manually even if Auto Power Down is

selected.

20

Page 27

5.2 Trend Screen

Screen Selection

Sample ID

Selection

Time

Download/Print

Graph

To get session

readings

• Select Sample ID first.

• After a reading session in the Home screen, if Trend screen is

selected, the Reading List from the Home screen is cleared but this

information is now saved under Sample ID in the Trend screen. If a

new session is started in the Home screen under the same Sample

ID the readings will be appended to the session readings.

• The axis scaling of the Sample graph can be adjusted in Chart

Range & Options (see section 4.2.4).

• If a USB thumb drive is connected, Session Readings shown will be

transferred to the flash drive after pressing Download/Print.

• If USB printer is connected, Session Readings shown will be printed

after pressing Download/Print.

• Sample ID will be saved until deleted. See Delete Samples section

4.2.7.

5.3 Data Retrieval

• All data is saved in CSV format and is date & time stamped.

• There are several methods to download particular information.

• Sample ID Data can be downloaded to a USB thumb drive or printed in the

Trend screen after pressing Download/Print.

• Calibration data can be downloaded into an inserted USB thumb drive in

the Calibration Download menu after pressing the button. See section

4.2.12 for more information on Calibration Download

• Logged data can be downloaded to an inserted USB thumb drive in the Log

Download menu after pressing the button. See section 4.2.13 for more

information on log download.

21

Page 28

5.3.1 USB Connection

The M100+ has two USB connections, a USB-A on the side and a

USB-B on the back. Only the side connection is active at this time. The USB-B at

the back of the instrument may be used in a future firmware update.

The USB-A connection can be used to upload new software or download

logged data and calibration reports via a USB thumb drive.

Firmware uploads (updated firmware) can be made by loading the firmware

onto a USB thumb drive and inserting it into the USB-A connector. The

update will not affect configurations or stored data; however it always

advisable to check the configuration as menus may change.

To upload firmware:

• See section 4.2.14 for more information on firmware

updates.

for software updates.

To keep the USB contacts from getting contaminated a

USB plug cover is provided. It is recommended that

this cover is replaced whenever the USB is not being

used.

A USB- Type B plug is provided at the back. This is currently not

active but was supplied for a potential future update. Keep the

supplied plug in place to prevent damage.

• Check our website

22

Page 29

6.0 Troubleshooting

Symptom

Cause

Cure

Clean the inside and outside of the

deionized water. Do not shake

samples.

thumb drive is not fully

Bubbles in solution

See readings higher than expected

above.

Incorrect screen calibration

Hold upper (time) banner on any screen

for 5 seconds to load default screen

shown in section 4.2.5

6.1 M100+ Fault Detection

The M100+ performs continuous diagnostic monitoring. The diagnostic indicator in

the Home screen will display any errors or warnings in writing.

• A green indicator shows that everything is good.

• A red indicator denotes an error.

• Potential errors are a bad lamp or the reading is taking place in a band that

has not been calibrated.

• A yellow indicator is a warning and could show either faulty database or the

device plugged into the USB is incompatible

Bubbles in solution

Readings are higher than expected

USB download not working

Readings are erratic

Readings are lower than expected Instrument out of calibration Recalibrate. Refer to section 4.3

Screen calibration not working

Instrument out of calibration Recalibrate Refer to section 4.3

Check

inserted

Thumb drive is not formatted

stored

cuvette with a detergent solution. Rinse

with

Insert USB thumb drive fully

Format to FAT32

calibration then go to calibrate screen as

6.2 Diagnostic Table

6.3 Technical and Customer Assistance

If for any reason assistance is needed regarding this instrument please do not

hesitate to contact either the HF scientific Technical Service Department or the

HF scientific Customer Service Department for parts orders.

HF scientific

3170 Old Metro Parkway

Fort Myers, Florida 33916-7597

Phone: (239) 337-2116 Fax: (239) 332-7643

Toll-free: 888-203-7248

23

Page 30

Email: HF.Info@Wattswater.com

www.hfscientific.com

24

Page 31

7.0 Routine Maintenance

Routine maintenance includes calibration, as mentioned, in section 4.3 and

cleaning of the cuvettes.

7.1 Cleaning the Cuvette

Measurement cuvettes used for the sample should be clean and free of marks or

scratches.

Cleaning is accomplished by cleaning the interior and exterior with a detergent

solution and then rinsing several times with distilled or deionized water. Ensure

the cuvettes are clean prior to use.

If cuvettes become scratched or stained they should be replaced. Replacement

cuvettes are available from HF scientific your local HF scientific agent. Use Cat #

50051pack of 3 cuvettes with caps or 50052 for a pack of 10 cuvettes with caps.

7.2 Replacing the Source Lamp

The Infrared and White Light source lamps in the M100+ instruments are

designed for long life. These lamps, however, are not covered by the warranty. If

the lamp should need replacement, we recommend calling HF Service

Department for assistance. These can also be purchased with instructions to

change. Calibration will be required if a lamp change is made.

7.3 Battery

This instrument uses a battery for back up of the clock feature with an expected

life of over 3 years. The battery is non-rechargeable and no attempt to charge it

should be made. If the battery needs to be replaced contact HF scientific and

arrange for service.

25

Page 32

8.0 Accessories and Replacement Parts List

ProCal

ProCal

ProCal

The items shown below are recommended accessories and replacement parts.

Accessory Cat. # Photo

Replacement Lamp Assembly White Light with

Instructions

Replacement Lamp Assembly IR Light with

Instructions

Operating Manual, M100+ 29293 N/A

Calibration Kit, .02, 10 & 1000 NTU

Calibration Kit, .02, 10, 1000,

High Range A & High Range B

24082S

21369S

39957

39940

Calibration Standard 10 NTU 125ml

Formazin Stock Kit 50040 N/A

Formazin Stock Solution, 4000 NTU, 500 ml

Replacement Cuvette – 3 Pack

Replacement Cuvette – 10 Pack

39825

70914

50051

50052

26

Page 33

9.0 Limited Warranty

HF scientific inc., as a vendor, warrants to the original purchaser of this instrument that it will be

free of defects in material and workmanship, in normal use and service, for a period of one year

from date of invoice. HF scientific inc.’s obligation under this warranty is limited to replacing, at

its factory, the instrument or any part thereof. Parts, which by their nature are normally required

to be replaced periodically, consistent with normal maintenance, specifically reagent, desiccant,

sensors, lamps, and fuses are excluded. Also, excluded is accessories and supply type items.

The original purchaser is responsible for the return of the instruments, or parts thereof, to HF

scientific’ inc.’s factory. This includes all freight charges incurred in shipping to and from HF

scientific inc.’s factory.

HF scientific inc .is not responsible for damage to the instrument, or parts thereof, resulting from

misuse, environmental corrosion, negligence or accident, or defects resulting from repairs,

alterations or installation made by any person or company not authorized by HF scientific inc.

The remedy described in the first paragraph of this warranty shall constitute the sole and

exclusive remedy for breach of warranty. HF scientific inc. assumes no liability for incidental,

consequential or special damage of any kind, and the original purchaser, by placement of an order

for the instrument, or parts thereof, shall be deemed liable for any and all damages incurred by the

use or misuse of the instruments, or parts thereof, by the purchaser, its employees, or others,

following receipt thereof.

Carefully inspect this product for shipping damage, if damaged, immediately notify the shipping

company and arrange an on-site inspection. HF scientific inc cannot be responsible for damage in

shipment and cannot assist with claims without an on-site inspection of the damage.

This warranty is given expressly and in lieu of all other warranties, expressed or implied.

Purchaser agrees that there is no warranty on merchantability or fitness for a particular purpose

and that there are no other warranties, expressed or implied. HF scientific inc hereby specifically

disclaims all other warranties, express or implied. No agent is authorized to assume for HF

scientific inc., any liability except as set forth above. Some States do not allow limitations on how

long an implied warranty lasts, and some States do not allow the exclusion or limitation of

incidental or consequential damages.

Therefore the above limitations may not apply to you. This

Limited Warranty gives you specific legal rights, and you may have other rights that vary from

State to State. You should consult applicable state laws to determine your rights. SO FAR AS IS

CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT

BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM

THE DATE OF ORIGINAL SHIPMENT.

HF scientific, Inc.

3170 Old Metro Parkway

Fort Myers, Florida 33916-7597

Phone: (239) 337-2116

Fax: (239) 332-7643

Toll-free: 888-203-7248

Email: HF.Info@Wattswater.com

Website: www.hfscientific.com

27

Loading...

Loading...