Page 1

N a r k o m a t

+

A n e s t h e s i a S y s t e m

Operator’s Manual

Rev. 3.1 – 05/09

M

OD ER N SOL UT IO NS F OR ANE ST HE TI CS A ND INH AL AT IO N

Page 2

Page 3

H E Y E R N a r k o m a t+

Table of Contents

Page

Table of Contents ................................................................................................................................3

Table of Figures...................................................................................................................................6

1 Details of the Manufacturer / Apparatus.......................................................................................8

2 Description and Utilization of the Apparatus................................................................................9

2.1 General.....................................................................................................................................9

2.1.1 Product improvements.................................................................................................10

2.1.2 Responsibilities of operators........................................................................................11

2.1.3 Liability of the manufacturer.........................................................................................11

2.2 General precautions ...............................................................................................................12

2.2.1 Warning notes..............................................................................................................12

2.2.2 Caution notes...............................................................................................................13

3 Functional Description................................................................................................................14

3.1 Anesthesia ventilator ..............................................................................................................14

3.1.1 Fresh gas decoupling ..................................................................................................14

3.1.2 Constant volume provided by controlled ventilation....................................................14

3.1.3 Compliance compensation ..........................................................................................15

3.1.4 Bag-in-bottle system....................................................................................................15

3.2 Fresh gas dosing ....................................................................................................................15

3.3 Vaporizer mounting device and Vaporizers............................................................................16

3.4 Patient module........................................................................................................................17

3.4.1 Circuit absorber system...............................................................................................17

3.4.2 CO2 absorber...............................................................................................................17

3.4.3 Reservoir and manual ventilation bag .........................................................................17

3.4.4 Volume measurement..................................................................................................17

3.4.5 Oxygen measurement*................................................................................................17

3.4.6 Patient module heating................................................................................................18

3.5 Gas measurement*.................................................................................................................18

4 Operating Elements / Connections for Appliances ....................................................................19

4.1 Views of apparatus .................................................................................................................19

4.1.1 Front of apparatus........................................................................................................19

4.1.2 Rear of apparatus........................................................................................................20

4.1.3 Left side of apparatus ..................................................................................................21

4.1.4 Right side of apparatus................................................................................................22

4.2 Ventilator unit..........................................................................................................................23

4.2.1 Operating panel, ventilator keyboard...........................................................................24

4.2.1.1

"Ventilation Modes"- selection switch .................................................................24

4.2.1.2

"Push to Enter" - encoder button to change and confirm settings ......................25

4.2.1.3

Operating panel keys for insp. pause and exp. pause........................................25

4.2.1.4

"Settings" - panel keys for basic set-up ..............................................................25

4.2.1.5

"Alarms" - panel keys and displays for alarms....................................................26

4.2.1.6

Vent. Settings" - panel keys for direct selection display windows ......................26

4.3 Flow meter tube block including fresh gas dosing..................................................................27

4.4 Vaporizer mounting device .....................................................................................................28

4.5 Patient module (circuit system) ..............................................................................................29

4.6 Sample gas recirculation ........................................................................................................30

4.7 Vacuum source for bronchial suction (optional) .....................................................................31

4.8 Symbols on the Unit................................................................................................................32

5 Alarm Messages and Safety Devices ........................................................................................33

5.1 Alarm messages direct after the System start........................................................................34

5.2 Alarm Messages in Standby...................................................................................................35

5.3 Compliance test alarm messages ..........................................................................................36

5.3.1 Compliance test alarm messages................................................................................36

5.4 System test alarm messages .................................................................................................38

5.5 Alarm messages during normal operation..............................................................................40

5.5.1 Alarm messages during normal operation with the integrated Gas Module * .............45

5.5.2 Alarm messages during normal operation with the optional ventilation mode PCV....47

Rev. 3.1 – 05/09 HEYER Narkomat+, Operator’s manual 3 / 150

Page 4

H E Y E R N a r k o m a t+

5.6 Technical failure alarm message............................................................................................48

6 Start-Up and Functional Test.....................................................................................................48

6.1 Preparation of apparatus ........................................................................................................48

6.2 Pre-Operation Tests ...............................................................................................................49

6.3 Sample Tube Connection (optional integrated Gas Module) .................................................50

6.4 System Start ...........................................................................................................................51

6.5 Battery Control........................................................................................................................52

6.6 Sensor Test ............................................................................................................................52

6.6.1 Compliance Test..........................................................................................................54

6.7 System Test............................................................................................................................56

6.7.1 O2 sensor calibration* .................................................................................................58

6.7.2 Leak Test Fresh Gas Delivery System........................................................................62

6.8 Gas module verification*.........................................................................................................64

7 Operation in the Individual Functions.........................................................................................71

7.1 Standby mode.........................................................................................................................72

7.1.1 Standby mode menu window.......................................................................................73

7.1.2 Standby mode graphics window..................................................................................77

7.1.3 Standby mode options window....................................................................................78

7.1.4 Standby mode screen saver function..........................................................................79

7.2 Control Panel Keys in the Ventilation Modes CMV / (S)CMV / PCV * Adult / Child...............80

7.2.1 Menu-Window in the Ventilation Modes CMV / (S)CMV / PCV * Adult / Child............80

7.2.2 Graphic Window in the Ventilation Modes CMV / (S)CMV / PCV * Adult / Child ........81

7.2.3 Options Window in the Ventilation Modes CMV / (S)CMV / PCV * Adult / Child.........82

7.2.4 Automatic Anesthetic Agent and Agent Mixture Identification * ..................................83

7.2.5 Panel Key VT/V in the Ventilation Modes CMV / (S)CMV Adult / Child ......................85

7.2.6 Panel Key VT/V in the Ventilation Mode PCV Adult / Child.........................................86

7.2.7 Panel Key f in the Ventilation Modes CMV / (S)CMV / PCV Adult / Child...................87

7.2.8 Panel Key I:E in the Ventilation Modes CMV / (S)CMV / PCV Adult / Child................88

7.2.9 Panel Key PEEP in the Ventilation Modes CMV / (S)CMV / PCV Adult / Child ..........89

7.3 “Manual/spontaneous” ventilation mode.................................................................................90

7.3.1 “Manual/spontaneous” ventilation mode......................................................................90

7.3.1.1

Alarm limit setting in “manual/spontaneous” mode.............................................94

7.4 Controlled Ventilation Mode....................................................................................................98

7.4.1 CMV adult ventilation mode.........................................................................................99

7.4.1.1

Parameter Settings in CMV Adult Mode...........................................................104

7.4.1.2

Alarm limits setting in CMV adult mode............................................................105

7.4.1.3

Alarm limits setting in CMV child mode.............................................................108

7.5 Ventilation mode (S)CMV .....................................................................................................109

7.5.1 Ventilation mode (S)CMV ..........................................................................................110

7.5.1.1

Changing parameter settings in (S)CMV adult mode .......................................115

7.5.1.2

Alarm limits setting in (S)CMV adult mode .......................................................116

7.5.1.3

Alarm limits setting in (S)CMV child mode........................................................119

7.6 Ventilation mode PCV...........................................................................................................120

7.6.1 PCV adult ventilation mode .......................................................................................121

7.6.1.1

Changing graphic settings in PCV Adult mode.................................................126

7.6.1.2

Alarm limits setting in PCV adult mode.............................................................127

7.6.1.3

Alarm limits setting in PCV child mode.............................................................130

8 Dismantling and Reassembling................................................................................................131

8.1 Patient module......................................................................................................................131

8.1.1 CO2 absorber canister ...............................................................................................131

8.1.2 Bag-in-bottle system..................................................................................................131

8.1.3 Replacing the expiratory flow sensor.........................................................................133

8.1.4 Dismantling the ventilation pressure valve (APL)......................................................133

8.1.5 Replacing the diaphragm valves................................................................................135

8.1.6 Valves (emergency air, inspiration, and expiration valve).........................................137

8.2 Connecting and disconnecting of the vaporizers..................................................................137

9 Cleaning ...................................................................................................................................138

9.1 Cleaning and sterilizing the apparatus .................................................................................138

9.1.1 Cleaning the housing.................................................................................................138

9.2 Patient module......................................................................................................................138

9.2.1 Sterilizing the patient module.....................................................................................138

4 / 150 HEYER Narkomat+, Operator’s manual Rev. 3.1 - 05/09

Page 5

H E Y E R N a r k o m a t+

10 Preventive Maintenance and Servicing................................................................................139

10.1

General...........................................................................................................................139

10.1.1 Preventive Maintenance by a qualified technician.....................................................139

10.1.1.1 6 Month Service Interval ...................................................................................139

10.1.1.2 12 Month Service Interval .................................................................................140

10.1.1.3 36 Month Service Interval .................................................................................141

10.2

Servicing the Vaporizer..................................................................................................141

10.3

Other Servicing...............................................................................................................141

11 Specifications........................................................................................................................142

12 Warranty ...............................................................................................................................146

Rev. 3.1 – 05/09 HEYER Narkomat+, Operator’s manual 5 / 150

Page 6

H E Y E R N a r k o m a t+

V

Table of Figures

Fig. 1 Front view of the apparatus......................................................................................................................... 19

Fig. 2 Rear of the apparatus.................................................................................................................................. 20

Fig. 3 Left side view on the apparatus................................................................................................................... 21

Fig. 4 Right side view on the apparatus................................................................................................................. 22

Fig. 5 Ventilator display and airway pressure gauge ............................................................................................. 23

Fig. 6 Operating panel, ventilator keyboard........................................................................................................... 24

Fig. 7 Flow meter block including fresh gas dosing............................................................................................... 27

Fig. 8 Vaporizer mounting device.......................................................................................................................... 28

Fig. 9 Patient module (circuit system).................................................................................................................... 29

Fig. 10 Sample gas recirculation and .................................................................................................................... 30

Fig. 11 Vacuum source.......................................................................................................................................... 31

Fig. 12 Example of an alarm message during the booting procedure.................................................................... 34

Fig. 13 Example of an alarm message during the booting procedure.................................................................... 35

Fig. 14 Example of a sensor test alarm message.................................................................................................. 36

Fig. 15 Example of a system test alarm message................................................................................................. 38

Fig. 16 Example of an alarm message during normal operation............................................................................ 40

Fig. 17 “Major Technical Failure” alarm message.................................................................................................. 48

Fig. 18 First display message during system start................................................................................................. 51

Fig. 19 Second display message during system start............................................................................................ 51

Fig. 20 Display before sensor test......................................................................................................................... 52

Fig. 21 Display after the sensor test....................................................................................................................... 53

Fig. 22 Display prior to the compliance test........................................................................................................... 54

Fig. 23 Display after the compliance test as extended information........................................................................ 55

Fig. 24 Display after the compliance test as pass/fail information ......................................................................... 55

Fig. 25 System test selection display..................................................................................................................... 56

Fig. 26 Display of system test selection sub-menu................................................................................................ 57

Fig. 27 First display message of O2 sensor calibration.......................................................................................... 58

Fig. 28 Second display message of O2 sensor calibration..................................................................................... 59

Fig. 29 Third display message of O2 sensor calibration......................................................................................... 60

Fig. 30 Fourth display message of O2 sensor calibration....................................................................................... 61

Fig. 31 Display prior to the fresh gas system leak test .......................................................................................... 62

Fig. 32 Display after the Leak Test Fresh Gas Delivery System............................................................................ 63

Fig. 33 Display of the gas module verification ....................................................................................................... 64

Fig. 34 Connection of the tube system to the verification gas bottle...................................................................... 65

Fig. 35 Display No. 1 for gas measurement verification ........................................................................................ 65

Fig. 36 Display No. 2 for gas measurement verification ........................................................................................ 66

Fig. 37 Display No. 3 for gas measurement verification ........................................................................................ 67

Fig. 38 Display No. 4 for gas measurement verification ........................................................................................ 68

Fig. 39 Display No. 5 for gas measurement verification ........................................................................................ 69

Fig. 40 Display No. 6 for gas measurement verification ........................................................................................ 70

Fig. 41 Control panel ............................................................................................................................................. 71

Fig. 42 Standby mode display ............................................................................................................................... 72

Fig. 43 Standby mode menu window..................................................................................................................... 73

Fig. 44 "Set time" within the menu window............................................................................................................ 74

Fig. 45 "Load/save personal alarm limits" within the menu window....................................................................... 75

Fig. 46 "System test options“ within the menu window.......................................................................................... 76

Fig. 47 Standby mode graphic settings window..................................................................................................... 77

Fig. 48 Stand-by mode options display.................................................................................................................. 78

Fig. 49 Screen saver ............................................................................................................................................. 79

Fig. 50 Menu-Window in the ventilation mode CMV-Adult..................................................................................... 80

Fig. 51 Graphic-Window in the ventilation mode CMV-Adult................................................................................. 81

Fig. 52 Options-Window in the ventilation mode CMV-Adult ................................................................................. 82

Fig. 53 Vt adjustment in the ventilation mode CMV Adult...................................................................................... 85

Fig. 54

Fig. 55 Rate adjustment in the ventilation mode CMV Adult.................................................................................. 87

Fig. 56 I:E adjustment in the ventilation mode CMV Adult..................................................................................... 88

Fig. 57 PEEP adjustment in the ventilation mode CMV Adult................................................................................ 89

Fig. 58 "Manual/spontaneous settings" display 1 .................................................................................................. 90

Fig. 59 "Manual/spontaneous settings" display 2 .................................................................................................. 91

Fig. 60 "Manual/spontaneous settings" display 3 .................................................................................................. 92

Fig. 61 Ventilation pressure valve (APL) in CMV/SP setting.................................................................................. 93

Fig. 62 Ventilation pressure valve (APL) in 20 cmH2O setting.............................................................................. 93

Fig. 63 Alarm limits 1 in the Manual/spontaneous ventilation mode...................................................................... 94

Fig. 64 Display “Alarm limits 2 in the Manual/spontaneous ventilation mode”....................................................... 95

Fig. 65 Alarm limits in manual/spontaneous mode................................................................................................ 96

&

adjustment in the ventilation mode PCV Adult....................................................................................... 86

6 / 150 HEYER Narkomat+, Operator’s manual Rev. 3.1 - 05/09

Page 7

H E Y E R N a r k o m a t+

Fig. 66 Graphics window in manual/spontaneous ventilation mode ...................................................................... 97

Fig. 67 Display “ventilation mode adult”................................................................................................................. 99

Fig. 68 "CMV-Settings / Adult" display................................................................................................................. 100

Fig. 69"Start in CMV adult" ventilation mode display........................................................................................... 102

Fig. 70" CMV adult" ventilation mode display...................................................................................................... 103

Fig. 71 "Parameter setting during the CMV adult" ventilation mode display........................................................ 104

Fig. 72 Display “Alarm limits 1 in the CMV Adult ventilation mode ...................................................................... 105

Fig. 73 Display “Alarm limits 2 in the CMV Adult ventilation mode” ..................................................................... 106

Fig. 74 Alarm limits in the CMV Adult ventilation mode ....................................................................................... 107

Fig. 75 Alarm limits in the CMV Child ventilation mode ....................................................................................... 108

Fig. 76 Display “ventilation mode adult”............................................................................................................... 110

Fig. 77 "(S)CMV-Settings / Adult" display............................................................................................................ 111

Fig. 78 "(S)CMV adult" ventilation mode display 1 .............................................................................................. 113

Fig. 79 "(S)CMV adult" ventilation mode display 2 .............................................................................................. 114

Fig. 80"Parameter setting during the (S)CMV adult" ventilation mode display .................................................... 115

Fig. 81 "Alarm Settings" ventilation mode (S)CMV adult ..................................................................................... 116

Fig. 82 Display “Alarm limits 2 in the (S)CMV Adult ventilation mode” ................................................................ 117

Fig. 83 Alarm limits in the (S)CMV Child ventilation mode................................................................................... 118

Fig. 84 Alarm limits in the (S)CMV Child ventilation mode................................................................................... 119

Fig. 85 Display “ventilation mode adult”............................................................................................................... 121

Fig. 86 "PCV -Settings / Adult" display ................................................................................................................ 122

Fig. 87 "Start in PCV adult" ventilation mode display .......................................................................................... 124

Fig. 88 "PCV adult" ventilation mode display....................................................................................................... 125

Fig. 89 "Parameter setting during the PCV adult" ventilation mode display......................................................... 126

Fig. 90 Display “Alarm limits 1 in the PCV adult ventilation mode”...................................................................... 127

Fig. 91 Display “Alarm limits 2 in the PCV adult ventilation mode”...................................................................... 128

Fig. 92 Alarm limits in the PCV adult ventilation mode ........................................................................................ 129

Fig. 93 Alarm limits in the PCV Child ventilation mode........................................................................................ 130

Fig. 94 Dismantling of the patient module, front view .......................................................................................... 132

Fig. 95 Dismantling of the patient module, top view ............................................................................................ 134

Fig. 96 Dismantling of the valve bodies............................................................................................................... 136

Rev. 3.1 – 05/09 HEYER Narkomat+, Operator’s manual 7 / 150

Page 8

H E Y E R N a r k o m a t+

1 Details of the Manufacturer / Apparatus

Apparatus: Anesthesia system HEYER NARKOMAT

Manufacturer: HEYER Medical AG

Carl-Heyer-Strasse 1-3

56130 Bad Ems

Germany

Tel: ++49 2603 / 791-3

Fax: ++49 2603 / 70424

E-Mail: info@heyermedical.de

Software version: Display driver software: 3.0

Ventilator software: 2.5.n

+

Certificate-No.: 04 207-1743/98

8 / 150 HEYER Narkomat+, Operator’s manual Rev. 3.1 - 05/09

Page 9

H E Y E R N a r k o m a t+

2 Description and Utilization of the Apparatus

2.1 General

Introduction

The HEYER NARKOMAT+ anesthesia system represents a flexible anesthesia workplace for

implementing and monitoring inhalation anesthesia in the half-closed system and the nearly

closed system for low-flow techniques with minimum gas- and anesthetic agent utilization.

During the development of the system special emphasis was placed on the ergonomic design

and consequently, a secure and easy operation. Furthermore the excellent air-tightness of the

system ensures the economical daily high and low pressure utilization.

The standard model contains the following system components:

A. Electronic ventilator

The process-controlled ventilator allows constant-volume ventilation for all patient groups with

a body weight of 3 kg upwards. Due to the system compliance compensation, even small tidal

volumes can be precisely administered. The ventilation type CMV as the standard, the

(S)CMV and PCV as optional ventilation modes, as well as various forms of ventilation and

considerable variation options of the artificial ventilation cycle, facilitate a secure ventilation

even for complicated lung conditions. A comprehensive test and alarm management ensures

the required safety for patients and prevents out-of-control operating conditions. The clear

design of the user interface and the display allow the secure operation and a quick detection

of the selected ventilation parameters.

B. The patient module

The circular patient absorber system is highly integrated and compacted in an aluminum

block. The block is tempered to prevent the formation of condensation. The block also

contains an emergency air valve, a fresh gas reservoir in form of a hand-held anesthesia bag

and an expiratory flow sensor. A motor drive connects the module to the basic apparatus. All

sensors are continuously monitored during operation. The sensors are automatically

calibrated during the start-up of the apparatus.

C. Integrated fresh-gas dosing system including vaporizer unit

The flow meter tube block contains all mandatory safety equipment as well as a pneumatic

control system to maintain a minimum oxygen concentration of 25% in the fresh-gas flow

(ratio system).

Rev. 3.1 – 05/09 HEYER Narkomat+, Operator’s manual 9 / 150

Page 10

H E Y E R N a r k o m a t+

D. Integrated gas measurement

CO2

The continuous CO2 measurement is graphically shown as a capnogramm. The end

expiratory and inspiratory CO2 measurement will be shown as a numerical value. The CO2

values can be displayed in Vol% or mmHg.

N2O

The nitrous oxide measurement is similar to the CO2 measurement and will be shown in Vol%

in the form of numerical values.

O2

The display of the oxygen measurement is based on the same principles as the measurement

of CO2 and N2O and will be shown in Vol% in the form of numerical values.

Anesthesia gas

The gas module is equipped with an automatic anesthetic agent and anesthetic agent mixture

identification. The apparatus measures the agents Halothane, Isoflurane, Enflurane,

Desflurane and Sevoflurane. The display of the Anesthesia gas measurement is based on the

same principles as the measurement of CO2, N2O and O2 .

MAC

The displayed Minimal Alveolar Concentration is calculated according to the following

formula:

EtAA[%] EtN20[%]

MAC (AA) = ------------ + ------------ xAA 100

AA = Anesthetic agent

Et = End expiratory concentration

x = Alveolar concentration of the Anesthetic agent for MAC =1 at 100% O2 and

patient age of 40 years.

2.1.1 Product improvements

HEYER MEDICAL AG retains the right to carry out modifications or to update the apparatus

and/or operating instructions without prior notification. These Operating Instructions explain all

features of the HEYER NARKOMAT+ anesthesia system and are correct at going to print.

Instructions and models produced at a later stage may already contain improvements or

modifications that were not included in previous models.

10 / 150 HEYER Narkomat+, Operator’s manual Rev. 3.1 - 05/09

Page 11

H E Y E R N a r k o m a t+

2.1.2 Responsibilities of operators

The correct functioning of the HEYER NARKOMAT+ anesthesia system can only be

guaranteed if the apparatus is operated and serviced in accordance with the information

provided by the manufacturer. The non-compliance with this information voids all guarantee

claims against HEYER MEDICAL AG.

NOTE: Before using the apparatus please study the Operating Instructions as well as the

section "General precautions", observing all information contained in these Operating

Instructions that are highlighted with CAUTION or WARNING. These Operating Instructions

only describe the operation of the apparatus. Information about service and repair by qualified

trained personnel are contained in the HEYER NARKOMAT+ SERVICE INSTRUCTIONS.

The apparatus may only be operated by qualified and trained skilled personnel. All operators

must fully observe these Operating Instructions or relevant additional documentation and

information provided by the manufacturer. They must also comply with the general

precautions detailed below and must be trained by authorized medical product consultants.

The apparatus may only be operated with an additional gas monitoring if a gas monitoring is

not included. The following conditions must be fulfilled (DIN 13 252):

At least the:

- anesthesia-gas concentration and

- the carbon dioxide concentration

must be monitored.

Upper and lower alarm limits must be set for these monitoring parameters. Upon reaching

one of these upper or lower alarm limits, an optical and acoustic alarm must be triggered.

The measuring adapter to be installed in the circular system or patient hose system must

contain ISO cones (DIN 13 252). These must be applied to the inspiration hose connection or

ideally to the Y piece. Measuring close to the tube is, however, recommended as this allows

the recording of the inspiratory and expiratory gas values. Monitors using the side-stream

procedure should be clearly preferred as a supplement to the additionally required gas

monitoring.

Any apparatus not functioning as described in these Operating Instructions must not be used

until the fault has been removed. The operators are responsible for any damage or injuries

caused by the incorrect operation or repair/servicing of the apparatus by unauthorized

personnel.

2.1.3 Liability of the manufacturer

HEYER MEDICAL AG shall only be liable for the safety, reliability and functionality of the

apparatus, if:

- the apparatus was operated in accordance with the information issued by the manufacturer;

- extensions, new adjustments, modifications or repairs have been carried out by an expert

authorized by the manufacturer;

- the apparatus was only operated in buildings containing grounding facilities according to the

IEC regulations.

Rev. 3.1 – 05/09 HEYER Narkomat+, Operator’s manual 11 / 150

Page 12

H E Y E R N a r k o m a t+

2.2 General precautions

2.2.1 Warning notes

NOTE: A warning note points out potentially dangerous situations which may cause injuries to

the patient or operating personnel.

Carry out the daily checks specified on the checklist and do not operate the system in case of

a fault until the fault has been repaired.

If possible, always connect the output of the ventilation pressure valve (APL) to the anesthetic

gas removal line, usually installed in the operating theatre.

The patient should furthermore be visually monitored by qualified personnel. In certain

situations, life-threatening circumstances may occur which may not necessarily trigger an

alarm.

Always set the alarm limits so that the alarm is triggered before hazardous situations occur.

Incorrectly set alarm limits may result in operating personnel not being aware of drastic

changes in the patient’s condition.

Always check that the displayed ventilation pressure value lies within an acceptable range

before activating the "Set Pmin/Pmax automatically" function, automatically setting new alarm

limits.

In order to prevent an electric shock, the apparatus (protection class I) may only be

connected to a correctly grounded mains connection (socket outlet with grounding contact).

Explosion hazard! The apparatus may not be operated near flammable anesthetic agents or

other flammable substances. No flammable anesthetic agents (i.e. ether, cyclopropane) may

be used.

As the apparatus may not be used with inflammable anesthetic agents (i.e. ether,

cyclopropane), no antistatic ventilation hoses or face masks are required (DIN VDE750, part

214).

Electric shock and fire hazard! Always switch off the apparatus and disconnect from mains

before cleaning.

Fire hazard! Fuses (i.e. additional sockets) may only be replaced by fuses of the same type

and with the same fuse value.

Electric shock hazard! The apparatus may only be opened by qualified or authorized experts.

The connection of apparatus via the additional socket may, in case of a failure of the

protective conductor, lead to a discharge current exceeding the permissible values.

Electromagnetic radiation disturbances exceeding the values of EN 60601-1-2, can affect the

function of the machine.

12 / 150 HEYER Narkomat+, Operator’s manual Rev. 3.1 - 05/09

Page 13

H E Y E R N a r k o m a t+

2.2.2 Caution notes

NOTE: A CAUTION note refers to a situation which may cause damage or the incorrect

function of the apparatus.

This apparatus may only be operated by trained, skilled medical staff.

Before starting the apparatus, the operating personnel must be familiar with the notes and

information contained in these Operating Instructions and must have been trained by a

medical product consultant.

If the apparatus does not function as described, the apparatus must be examined and

possibly repaired by qualified service personnel, before being used again.

Handle the apparatus with care to prevent damage or functional faults.

Ensure that the gas supply of the apparatus always complies with the technical specification.

Before the operation, the apparatus must be correctly calibrated and/or the respective

apparatus tests, as described in the Operating Instructions, must be carried out.

If the apparatus should show faults during the initial calibration or testing, the apparatus may

not be operated until the fault has been repaired by a qualified expert.

After servicing, a functional test and a sensor and system test must be carried out before

clinical use.

Only bacteriological filters with a low flow resistance must be connected to the patient module

and/or the patient connection.

* After the unit has been switched on, a warming period of 4 minutes is necessary to ensure

an exact measurement of the anesthesia gas values. The other breathing gas values are

within the ISO specifications after 1 min

* Only use the recommended pressure controller when doing the gas verification. A to high or

to low calibration gas flow can lead to faulty result.

* Use only the original tube system as measuring tube.

* The gas measurement tube system at the monitor must be connected before putting the

apparatus into use or changing the flow rate. Otherwise the apparatus might falsely detect a

tube blockage.

Rev. 3.1 – 05/09 HEYER Narkomat+, Operator’s manual 13 / 150

Page 14

H E Y E R N a r k o m a t+

3 Functional Description

3.1 Anesthesia ventilator

Ventilators are described according to the principle of controlling the change over from

inspiration to expiration. The NARKOMAT+ apparatus offers the following characteristics in

the controlled ventilation mode or so-called CMV mode (Controlled Mandatory Ventilation).

time-controlled:

The timely sequence of inspiration and expiration has been specified by the ventilation

frequency settings. The ratio of the inspiration to the expiration time of the individual

ventilation cycle is determined by the adjustable I/E ratio.

pressure limitation:

The tidal volume during controlled ventilation is supplied during the entire period of the

inspiratory flow and can be set as ventilation parameter. The inspiration is, however,

terminated before the tidal volume has been administered, once the measured airway

pressure reaches the set Peak pressure alarm limit.

constant volume:

The inspiratory flow to the patient required for ventilation with the set parameters, frequency f,

tidal volume T. Vol. and ventilation time ratio I/E, is automatically calculated by the ventilator.

This inspiratory flow is generated via the drive gas for the patient module. In standard

anesthesia ventilators, deviations to the tidal volume actually supplied to the patient could

occur due to the respective fresh gas setting and system compliance of the ventilation

system. The ventilator of the NARKOMAT+ apparatus supplies in each setting a constant

volume. The patient module containing the bellows is decoupled from the fresh gas, and the

system compliance of the patient module is automatically taken into consideration by the

ventilator when generating the tidal volume.

3.1.1 Fresh gas decoupling

During the fresh gas decoupling in the CMV mode, the fresh gas flow is directed into the

manual ventilation bag. The manual ventilation bag serves as a fresh gas reservoir. This

principle offers the following advantages for controlled ventilation:

1. The tidal volume is completely independent from the set fresh gas flow. The

ventilation is therefore also referred to as constant volume ventilation.

2. The fresh gas flow can be maintained at a very low level, i.e. below 500 ml/min,

depending on the patient. The manual ventilation bag serves as a reservoir for the

fresh gas administered during the inspiration. The entire fresh gas volume is available

during the next inspiration, i.e. not only the fresh gas stored in the reservoir but also

the fresh gas supplied during the expiration period.

3.1.2 Constant volume provided by controlled ventilation

During controlled CMV ventilation, the set tidal volume is administered irrespective of the

pulmonary circumstances. The ventilator drive represents, in principle, a constant flow

generator. The inspiratory flow of the ventilation gas is automatically adapted to the

respective settings of the tidal volume VT, the ventilation frequency RATE and the ventilation

time ratio I/E.

14 / 150 HEYER Narkomat+, Operator’s manual Rev. 3.1 - 05/09

Page 15

H E Y E R N a r k o m a t+

3.1.3 Compliance compensation

The administered tidal volume is corrected to the set value, set by the user, with the aid of the

compliance compensation. The system compliance of each ventilation system, i.e. the

compliance of patient hoses and the patient module, always leads to losses in the

administered tidal volume. The NARKOMAT+´s automatic compensation of the system

compliance can correct this volume loss with the aid of a control loop. For this purpose

several ventilation cycles are required with the drive gas flow being slightly increased above

the normal values, i.e. the values for achieving the set ventilation volume. The correct tidal

volume is, however, administered to the patient, whilst the slightly higher volume is absorbed

by the system compliance due to the effective compliance compensation.

3.1.4 Bag-in-bottle system

The so-called bag-In-bottle system is part of the patient section or circuit system. The gasconducting sections are divided from the ventilator into a primary (ventilator) and a secondary

circuit (patient). The gas volume provided by the drive is not directly administered to the

patient but instead compresses a bellows inside a pressure dome. As a result, the ventilation

gas contained in the bellows is administered to the patient. An increased drive volume,

flowing into the pressure dome, also increases the tidal volume. Once the drive-gas flow has

finished, also the pressure compensation between the primary and secondary circuit is

ended. A distinctive plateau in the ventilation pressure curve is formed, if the system does not

switch over to the expiration directly after the end of the inspiratory gas flow. For this purpose,

the drive volume contained in the pressure dome is maintained at a steady level for some

time. The Bellow is suitable for adults and children. An exchange of the bellows for different

patient groups is not necessary.

3.2 Fresh gas dosing

The set-up of the gas quantities administered to the patient is carried out on a measuring tube

block. This block contains measuring tubes that are also referred to as rotameters. These

measuring tubes consist of a vertical glass tube, containing a suspended body. As the glass

tubes expand towards the top, a certain gas flow lifts the suspended body to a respective

height. The gas flow is adjusted via valve spindles, located below the individual measuring

tube.

The setting of the O2/AIR or O2/N2O is selected with the change-over switch which opens the

respective gas line to the measuring tube block.

The fresh gas cannot be set with a mixture of AIR and N2O as, in this case, a decrease of the

oxygen content to below 21% could not be avoided.

The decrease of the oxygen content to below 21% is in theory also possible with O2 and N2O

gas dosing. Such unfavorable settings are, however, prevented by a pneumatic safety

system. This system, which is also referred to as RATIO system ensures the continuous

existence of a minimum O2 content of 25% in the dosed gas mixed with N2O. In case of an

increase of the N2O flow, the required O2 flow is also automatically increased. The thus set

fresh gas is then fed over a vaporizer, where it is mixed with anesthetic agent.

Rev. 3.1 – 05/09 HEYER Narkomat+, Operator’s manual 15 / 150

Page 16

H E Y E R N a r k o m a t+

3.3 Vaporizer mounting device and Vaporizers

The apparatus contains a Selectatec compatible vaporizer

accommodating two vaporizers. The vaporizer contains two chambers, with the bottom

section containing the liquid anesthetic agent. Via a woven metal wick, the top section of the

chamber is enriched with saturated anesthetic agent steam. The concentration of the

saturated steam at ambient temperatures is considerably higher than that acceptable for

clinical purposes. The desired concentration is achieved by a suitable mixing ratio of the gas

and anesthetic agent with a gas flow that is passed around this chamber. This is achieved

with the aid of the setting wheel. For this purpose, the ratio of the flows of the carrier gas is

adjusted by a bypass channel and the vaporizer channel in such a way, that the chosen

concentration is achieved at the vaporizer outlet. In the zero position of the vaporizer, this

bypass channel remains open whilst the vaporizer chamber is completely closed for the gas

flow.

Although the anesthetic agent steam concentration of the vaporizer chamber is saturated, the

absolute anesthetic agent content depends, however, on the temperature. Consequently, the

bypass channel contains a temperature compensation valve which in case of changes in the

steam pressure caused by temperature fluctuations, changes the set dilution ratio in such a

way that the anesthetic agent concentration issued is no longer dependant on the

temperature.

For further information see:

Instructions of the respective anesthetic agent vaporizer.

mounting device

16 / 150 HEYER Narkomat+, Operator’s manual Rev. 3.1 - 05/09

Page 17

H E Y E R N a r k o m a t+

3.4 Patient module

3.4.1 Circuit absorber system

The circuit absorber system consists of a ventilation system with CO2 absorber. This system

allows anesthetics to be carried out at extreme low fresh gas settings. The ventilation gas

contains various parts of re-breathing gas, i.e. expiratory gas freed from CO2 parts. This is

achieved with a circuit ventilation system, facilitating a re-breathing of the expiratory CO2containing gas. A circuit system with high re-breathing contents causes a reduction of the

consumption of anesthetic agents. This system also offers an improved breathing gas

conditioning. The patient module is designed as a circuit absorber system in the form of a

compact aluminum block. The hose connections normally required between the ventilator and

the circuit system are thus no longer needed.

3.4.2 CO2 absorber

The absorber serves to absorb the soda lime and aims to remove the CO2 from the expiration

air. The absorption process is a chemical reaction in which carbon dioxide is bound, most of

the reaction water evaporates and the calcium is removed. Consequently the spent soda lime

is dry and hard. The soda lime must be stored hermetically sealed, cool and dry in order not

to become malabsorbant.

3.4.3 Reservoir and manual ventilation bag

The reservoir consisting of a manual ventilation bag provides an inspiratory interim store for

the fresh gas. The reservoir pressure during machine and spontaneous breathing is limited to

1-2 cmH2O. During manual breathing, this valve also allows the manual adjusting of the

desired ventilation pressure.

3.4.4 Volume measurement

Volume measurement is carried out by using a flow meter, operating according to the hot-wire

anemometer principle, to measure the flow in the expiration branch. The ventilator processors

integrate this measured value with the displayed tidal and ventilation minute volume. The tidal

volume shown in the display is a measured value. The tidal volume displayed during

controlled ventilation is measured by an internal flow sensor and is not dependent on the

expiratory volume measurement.

3.4.5 Oxygen measurement*

The oxygen is metered by a measuring cell installed on the inspiration valve. This singlecathode measuring cell, also referred to as fuel cell, offers a longer life compared to other

oxygen cells and is less sensitive to existing anesthetic gases.

*not valid with the apparatus option with integrated gas module

Rev. 3.1 – 05/09 HEYER Narkomat+, Operator’s manual 17 / 150

Page 18

H E Y E R N a r k o m a t+

3.4.6 Patient module heating

The heating prevents the formation of condensation in the patient module and on the valve

caps of the inspiration and expiration valve. The heating positively contributes to a ventilation

gas conditioning. The heating mat also functions as a sealing mat and is installed between

the top and bottom section of the patient module. An electronic control integrated in the

ventilator, keeps the temperature of the patient module constant at an approx. 36°C. An overtemperature protection protects the apparatus against overheating.

3.5 Gas measurement*

The measurement of the single gases in the breathing gas is based on the principle that

different gases absorb a different wavelength of infrared light. A pump inside the apparatus

continuously sucks a breathing gas probe out of the respiratory circulation into the

measurement chamber via a sampling line which is included with the gas module. This gas

probe flows through the measurement chamber where the absorption of the different wave

lengths of infrared light is measured. Based on these measurements, a microprocessor

calculates the concentration of CO2, N2O and anesthesia gas.

The measurement of oxygen is done with a paramagnetic oxygen sensor. This principle of

measurement is based on the paramagnetic characteristics of the oxygen molecule, through

which the oxygen concentration can be measured magnetically.

* only valid with the apparatus option with integrated gas module

18 / 150 HEYER Narkomat+, Operator’s manual Rev. 3.1 - 05/09

Page 19

H E Y E R N a r k o m a t+

4 Operating Elements / Connections for Appliances

4.1 Views of apparatus

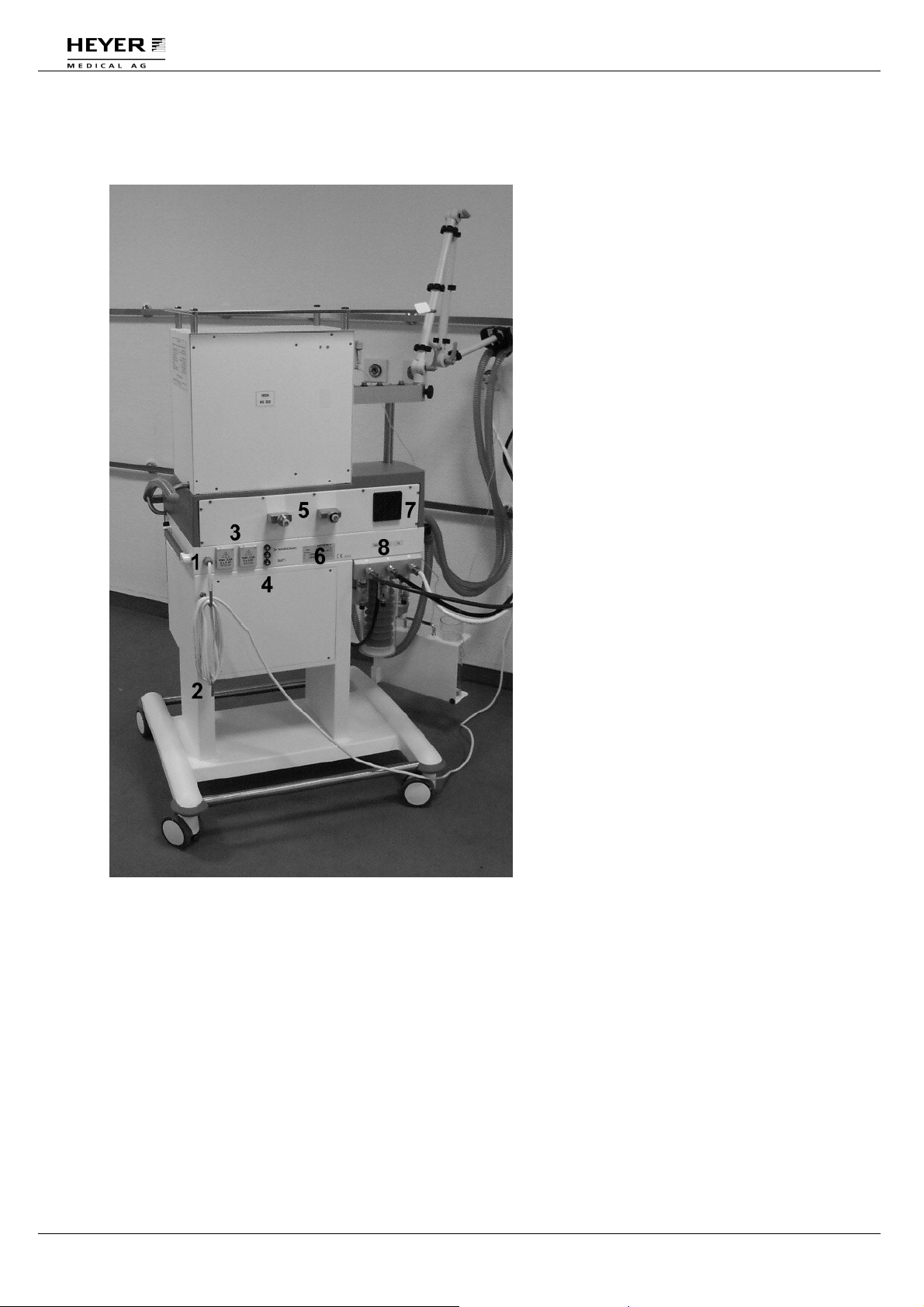

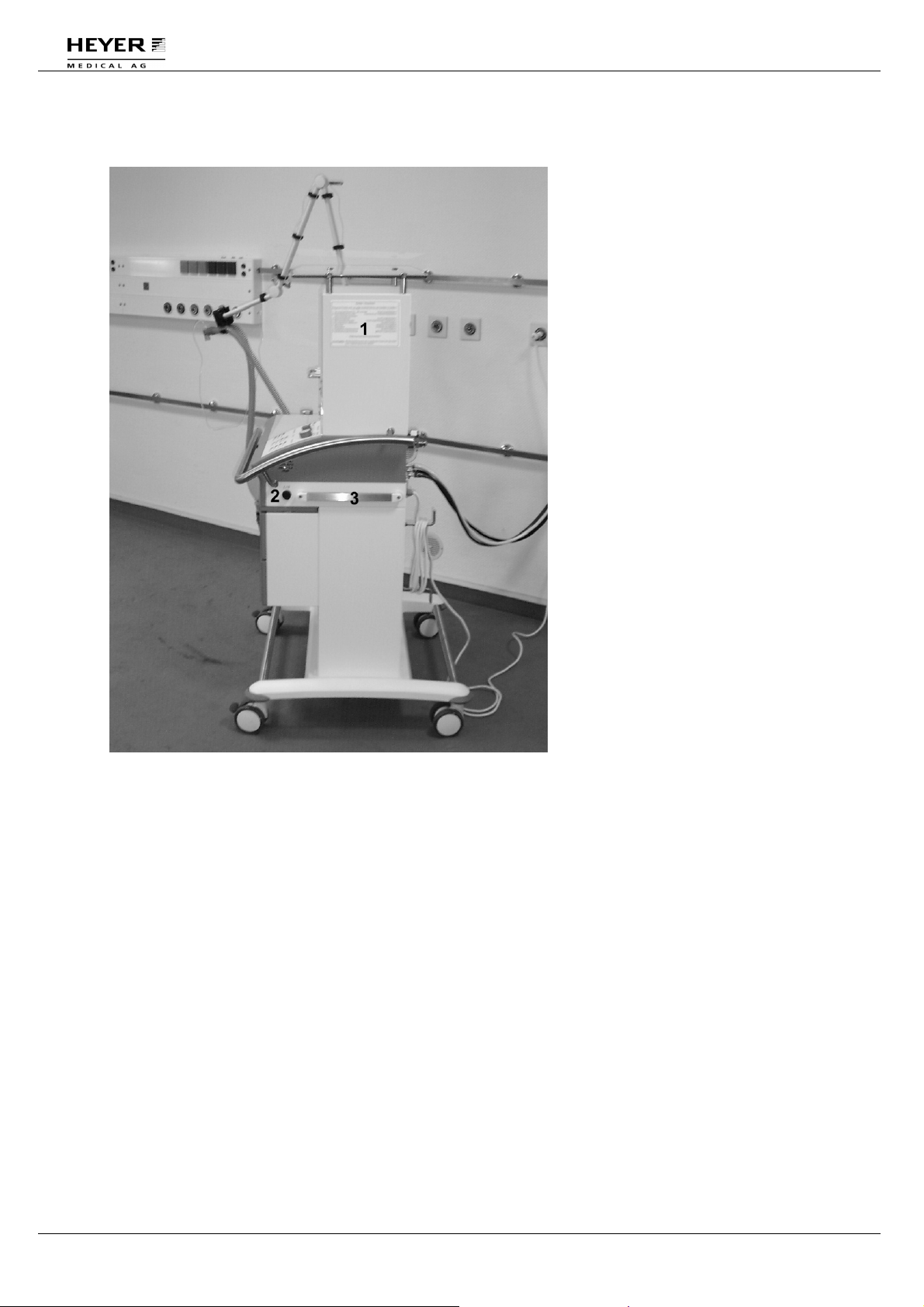

4.1.1 Front of apparatus

Fig. 1 Front view of the apparatus

1 Vaporizer mount

Selectatec* compatible

vap. mount for

connection of 2

vaporizers.

2 Flow meter block

6-fold flow meter block

with integrated Ratiosystem, O2-Bypass

and N20/AIR change

over switch.

3 Ventilator unit

Microprocessor

controlled ventilator

with TFT-display.

4 Control panel

Control panel with

keys, selector switch

and encoder (rotary

switch).

5 Patient module

Absorber circuit system

with integrated bag-inbottle system, active

and passive valves,

such as APL-valve.

Rev. 3.1 – 05/09 HEYER Narkomat+, Operator’s manual 19 / 150

Page 20

H E Y E R N a r k o m a t+

4.1.2 Rear of apparatus

Fig. 2 Rear of the apparatus

1 Mains cable

Voltage supply cable for

connecting the apparatus

to a socket with

grounding contact.

2 Cable hooks

3 Sockets

Additional devices

can be connected.

4 Circuit breakers

One 5A circuit breakers

for the ventilator unit ,

one 5A circuit breaker for

the battery and one 10A

(or two 5A) circuit breaker

for the convenient

receptacles

5 Cylinder jokes

Pin-index or DGAI

cylinder jokes, one for

N2O, one for O2.

6 Serial number

7 Fan

A fan provides ventilation

of the housing and

cooling of the integral

components.

8 Pipeline supply

connections

Connections for O2, AIR

and N2O from central gas

supply. Three pipeline

pressure gauges inform

about supply pressure.

20 / 150 HEYER Narkomat+, Operator’s manual Rev. 3.1 - 05/09

Page 21

H E Y E R N a r k o m a t+

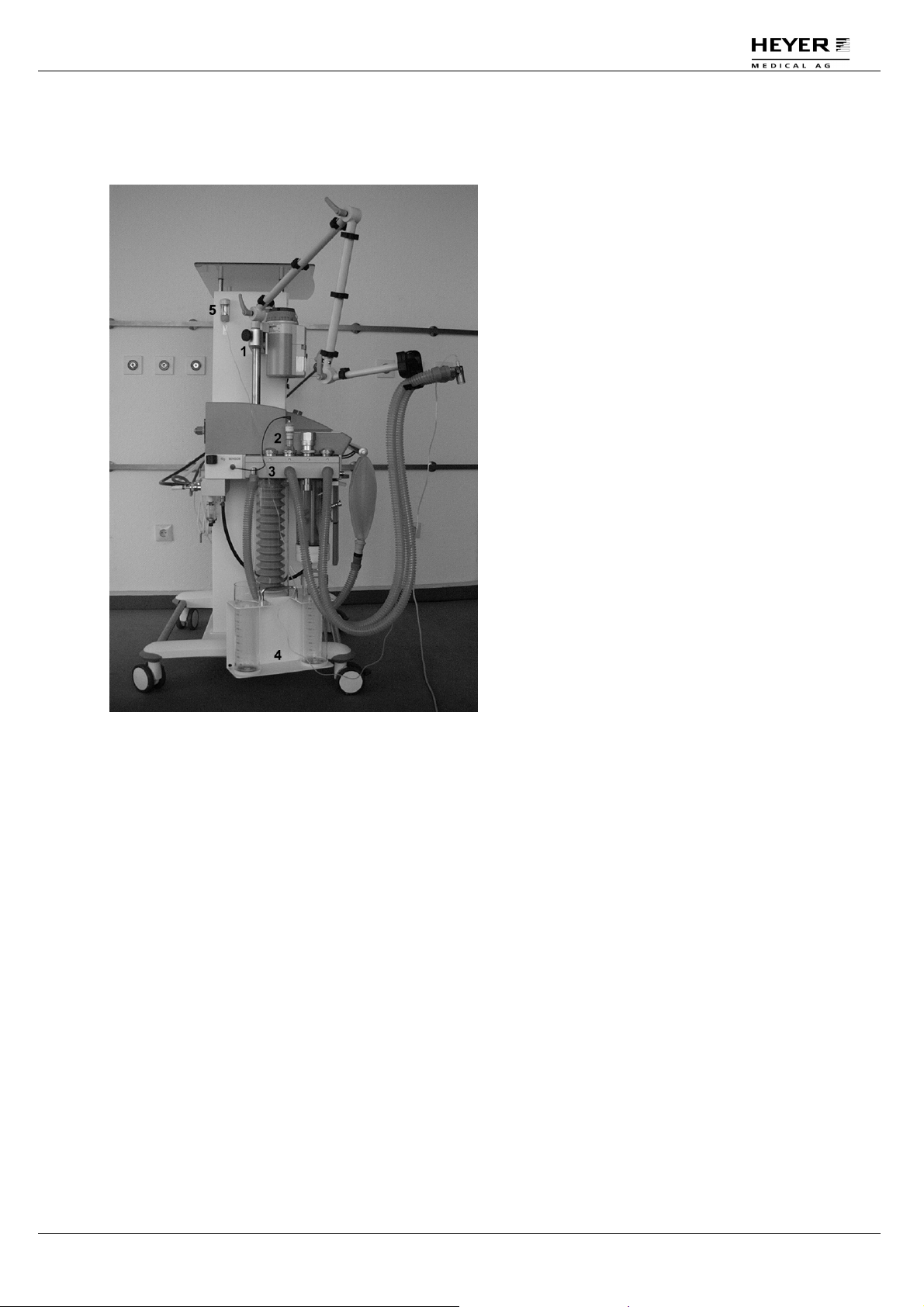

4.1.3 Left side of apparatus

Fig. 3 Left side view on the apparatus

1 Holder for patient arm

2 Oxygen-sensor with

cable*

3 Patient module

4 Suction stand with

glasses (option)

5 Water trap with gas

measurement inlet**

* Only valid without the

option gas module

**Only valid with the

option gas module

Rev. 3.1 – 05/09 HEYER Narkomat+, Operator’s manual 21 / 150

Page 22

H E Y E R N a r k o m a t+

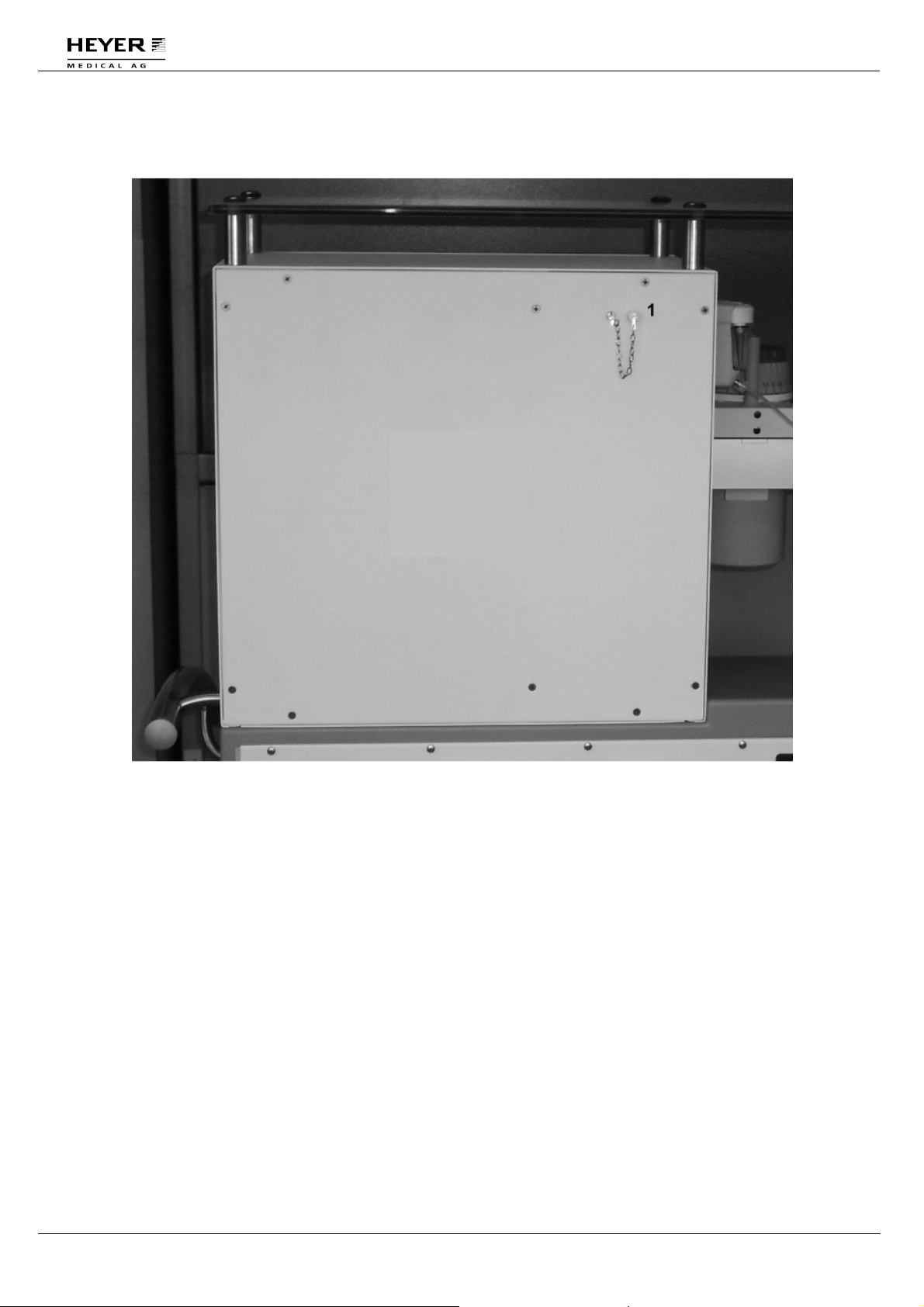

4.1.4 Right side of apparatus

1 Machine operation

checklist

The checklist informs

about several tests which

have to be carried out in

the start-up procedure.

2 Mains switch

With this switch, the

apparatus is switched

on/off and the mains

connection is activated.

During the operation, the

switch remains in the ON

position.

3 Rail mount 25 x 10

Fig. 4 Right side view on the apparatus

22 / 150 HEYER Narkomat+, Operator’s manual Rev. 3.1 - 05/09

Page 23

H E Y E R N a r k o m a t+

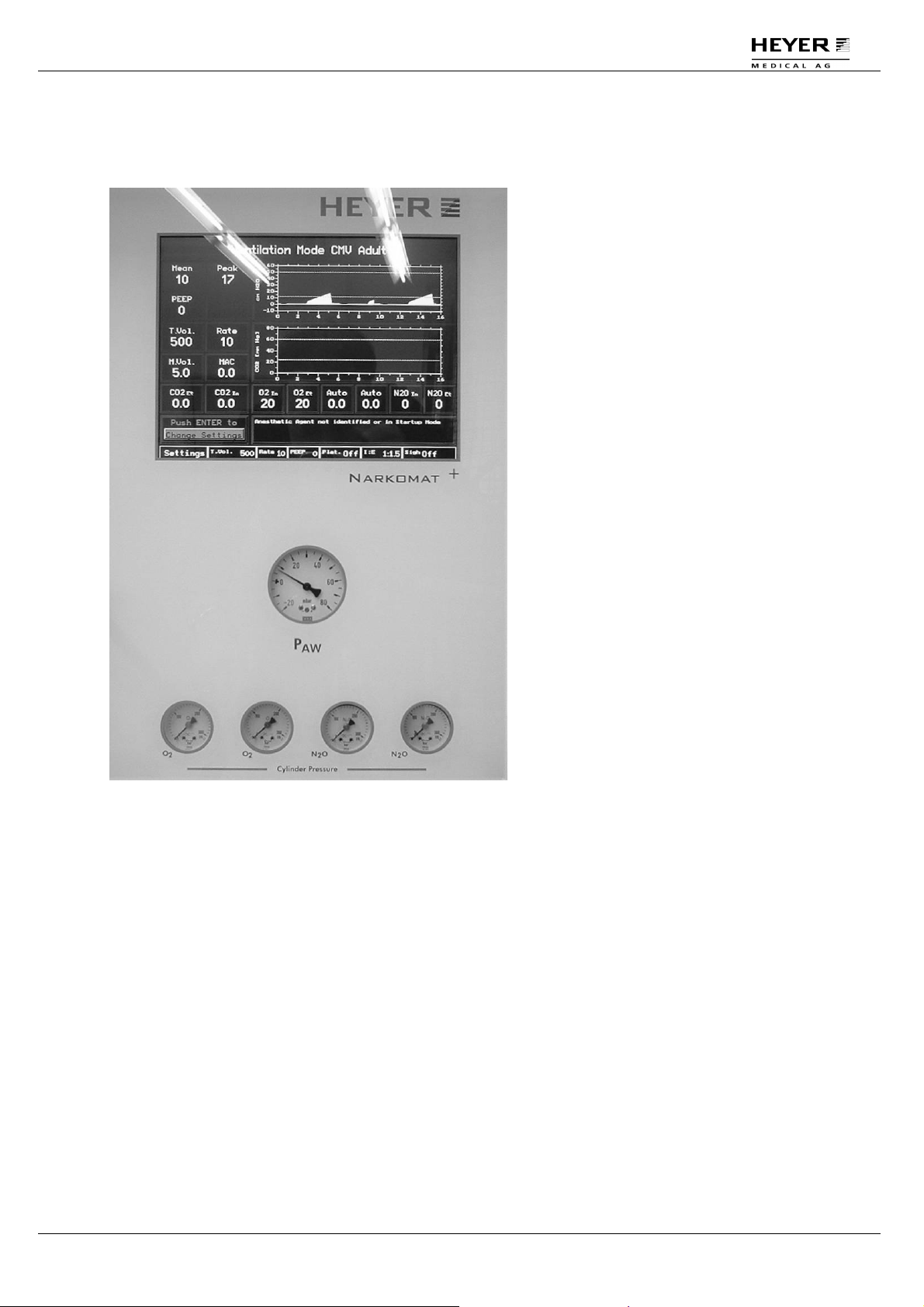

4.2 Ventilator unit

1

2

3

Fig. 5 Ventilator display and airway pressure gauge

1 Ventilator display

The ventilator uses a

color TFT display. This

display is high in contrast,

clearly visible also from

the side view and

provides all measured

values and settings of the

ventilator.

2 Airway pressure

gauge

Shows the airway

pressure on a pressure

gauge within a range of

-20 to 80 cmH2O.

3 Cylinder pressure

gauges

Shows the cylinder

pressure for each

cylinder on a pressure

gauge within a range of

0 to 315 kPa x 100 (315

bar).

Rev. 3.1 – 05/09 HEYER Narkomat+, Operator’s manual 23 / 150

Page 24

H E Y E R N a r k o m a t+

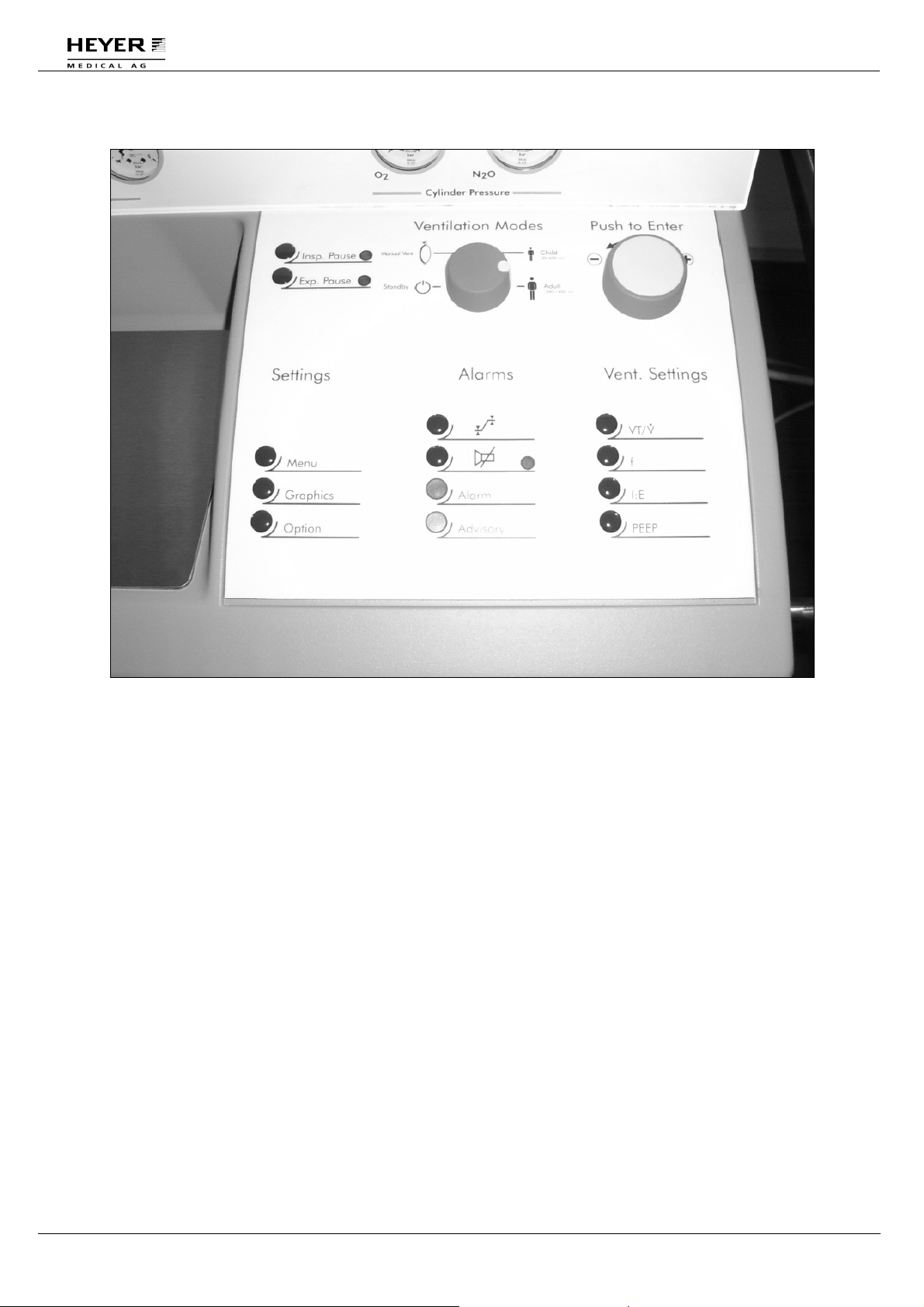

4.2.1 Operating panel, ventilator keyboard

Fig. 6 Operating panel, ventilator keyboard

4.2.1.1 "Ventilation Modes"- selection switch

This switch for the selection of ventilation modes has four positions:

Standby: Position for starting and implementing sensor and system tests.

Manual/spont.: In this position the ventilator is switched to the manual or

spontaneous ventilation mode.

Child (20-400 ml): In this position, the ventilator is switched to the mode for the

controlled ventilation of children.

Adult (300-1400 ml): In this position the ventilator is switched to the mode for the controlled

ventilation of adults.

24 / 150 HEYER Narkomat+, Operator’s manual Rev. 3.1 - 05/09

Page 25

H E Y E R N a r k o m a t+

4.2.1.2 "Push to Enter" - encoder button to change and confirm settings

With this encoder button the different parameter windows can be selected in the display. By

turning the button anti-clockwise or clockwise, the respective windows or selection buttons in

the display are selected. By pushing the direct selection button, functions or further windows

may be selected or opened. Rotary ventilator set-up buttons shown on the display, are also

operated by the direct selection button. The respective parameters are increased in clockwise

direction and decreased in anti-clockwise direction.

In case of changes, the changed settings or selections are confirmed and stored once

the button is pressed.

4.2.1.3 Operating panel keys for insp. pause and exp. pause

Insp. Pause: Upon pressing this key in the CMV mode, the green LED flashes and an

inspiratory pause of up to 5 sec. is inserted at the end of the next inspiration.

In order to terminate the pause early, the key may be pressed a second time,

after which the inspiratory pause is terminated.

Exp. Pause: Upon pressing this key in the CMV mode, the green LED flashes and an

expiratory pause of up to 30 sec. is inserted at the end of the next expiratory.

In order to terminate the pause early, the key may be pressed a second time,

after which the expiratory pause is terminated.

4.2.1.4 "Settings" - panel keys for basic set-up

Menu: This key opens a ventilator display window menu in all ventilation modes and

the standby position. The time and temperature of the patient module are

displayed. The alarm level of the acoustic alarms can be set and the alarm

limits for three personal settings may be stored or loaded. The test option

system display key opens another window in which comprehensive or brief

information may be selected for the result of the compliance test.

Graphics: This key opens a ventilator display graphic window in all ventilation modes

and the standby position. The time axis of the real-time ventilation pressure

and expiratory flow graphics to be displayed can be set to 16, 24 or 32

seconds.

Options This key opens a ventilator display graphic window in all ventilation modes

and the standby position. Here the anesthesia gas, the sample flow and the

displayed CO2 unit can be set. *

In the standby mode the patient module can be unlocked and the gas

measurement can be verified. *

*Only valid with option gas module

Rev. 3.1 – 05/09 HEYER Narkomat+, Operator’s manual 25 / 150

Page 26

H E Y E R N a r k o m a t+

V

V

4.2.1.5 "Alarms" - panel keys and displays for alarms

This key opens a display window in the manual/spontaneous, CMV,

(S)CMV or PCV ventilation modes for setting all available alarm limits.

The respective alarm limits can then be changed to the new settings.

By pressing the limits key a second time, an additional alarm window is

opened with additional adjustable alarm settings. By pressing the limits

key a third time the window is closed and the changed alarm limits are

stored.

This key switches off the sound of the acoustic alarms for a maximum

of 2 minutes. By pressing the key again, the sound is activated again

before the end of the 2 minute period.

4.2.1.6 Vent. Settings" - panel keys for direct selection display windows

For the respective parameters a smaller window is opened for a new setting or the alteration

of existing settings. With the aid of the encoder button, the current parameter setting can be

changed with a rotary display button. The changed setting is confirmed and stored by

pressing the encoder. Or the display window is closed by depressing the key again or

automatically after about 5 sec.

•

VT/

: In the CMV ventilation mode this key opens a display window for

setting the tidal volume VT.

•

In the PCV ventilation mode this key opens a display window

setting the maximum inspiratory flow.

f: This key opens a Rate display window in the CMV ventilation mode for

setting the ventilation frequency Rate.

I:E: This key opens an I:E display window in the CMV ventilation mode for

setting the ventilation time ratio I:E from inspiration to expiration time.

PEEP: This key opens a PEEP display window in the CMV ventilation mode

allowing a PEEP setting.

for

26 / 150 HEYER Narkomat+, Operator’s manual Rev. 3.1 - 05/09

Page 27

H E Y E R N a r k o m a t+

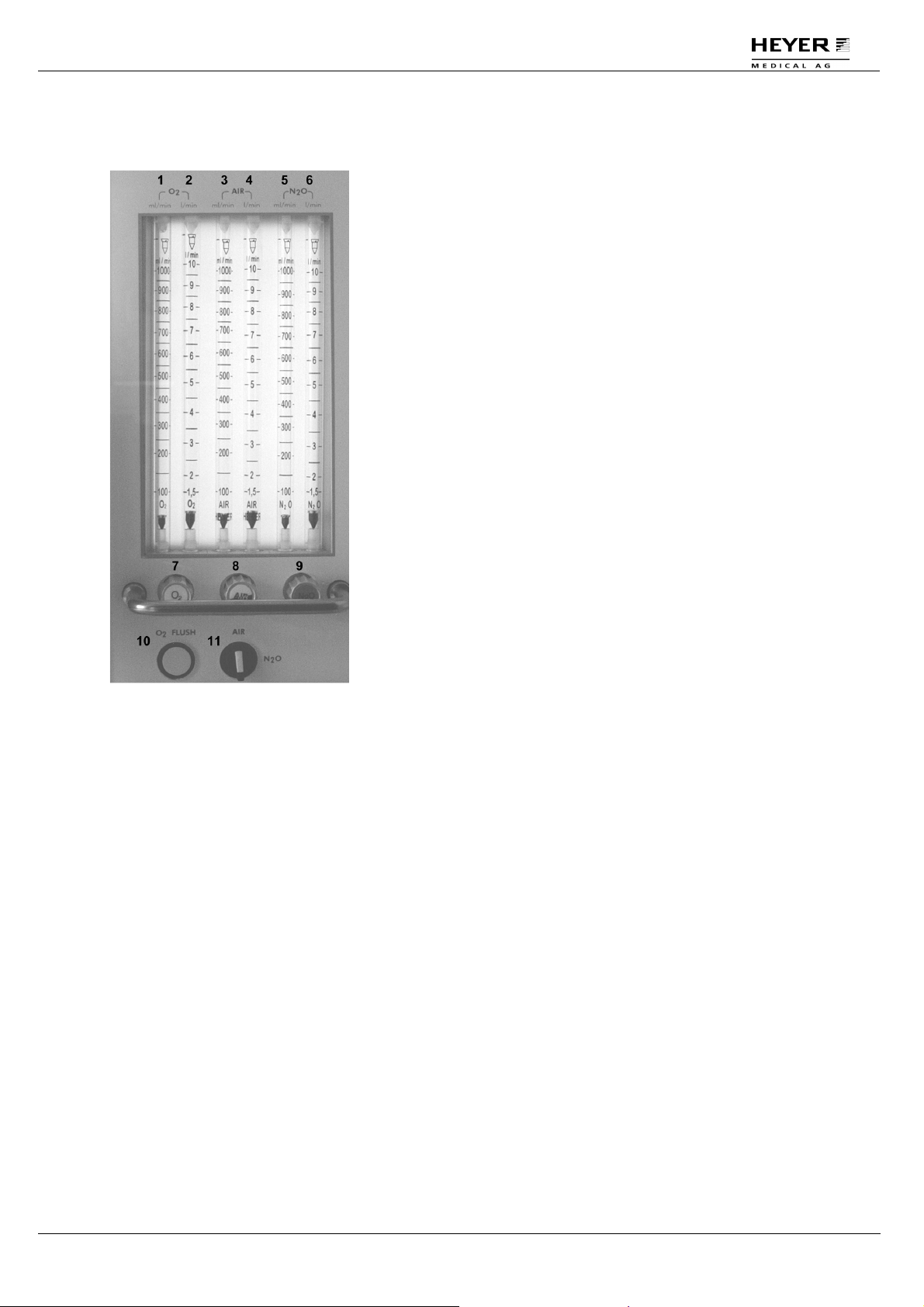

4.3 Flow meter tube block including fresh gas dosing

Fig. 7 Flow meter block including fresh gas dosing

1 Flow meter tube O

2 Flow meter tube O

3 Flow meter tube AIR

with a low measuring range for settings between 0 to 1000 ml/min

2

with a high measuring range for settings between 1,5 and 10 l/min

2

with a low measuring range for settings between 0 to 1000

ml/min

4 Flow meter tube AIR

with a high measuring range for settings between 1,5 and 10

l/min

5 Flow meter tube N2O

with a low measuring range for settings between 0 to 1000

ml/min

6 Flow meter tube N2O

with a high measuring range for settings between 1,5 is 10 l/min

7 Valve spindle for O2 gas dosing

8 Valve spindle for AIR gas dosing

9 Valve spindle for N2O gas dosing

10 O2 bypass

The O2 bypass supplies a high O2 flow (approx. 50 l/min) directly to the fresh gas outlet or

into the patient module. Upon releasing the bypass key, the key returns to its original

position and the O2 bypass is automatically interrupted.

11 N2O/AIR change-over switch

This switch allows the pre-selection of N2O or AIR, which can then be dosed with the

respective valve spindles. The previously set volume flow is retained after switching back

to the same gas type.

Rev. 3.1 – 05/09 HEYER Narkomat+, Operator’s manual 27 / 150

Page 28

H E Y E R N a r k o m a t+

4.4 Vaporizer mounting device

Fig. 8 Vaporizer mounting device

1 Fixing knob for patient arm

2 Valve cartridge of vaporizer mount

3 Locking device

4 Stopping face

28 / 150 HEYER Narkomat+, Operator’s manual Rev. 3.1 - 05/09

Page 29

H E Y E R N a r k o m a t+

4.5 Patient module (circuit system)

Fig. 9 Patient module (circuit system)

1 Emergency air valve

2 Inspiration valve

3 Oxygen sensor*

(fuel cell)

4 Ventilation pressure valve (APL valve): Including rotary regulator for setting the

pressure control during manual ventilation or for setting it as a 2 cmH2O release valve

during CMV or spontaneous ventilation.

5 Expiration valve

6 Hose connection branch

7 Outlet of ventilation pressure valve

(APL-valve):

The anesthetics gas scavenging system is connected to this point.

8 Hose connection for inspiration branch

9 Hose connection for reservoir/manual ventilation bag

10 Bellows including bellows dome

11 CO

absorber canister

2

*only the apparatus option without the gas module

Rev. 3.1 – 05/09 HEYER Narkomat+, Operator’s manual 29 / 150

Page 30

H E Y E R N a r k o m a t+

4.6 Sample gas recirculation

Fig. 10 Sample gas recirculation

1 Sample gas recirculation connector*

The gas return line from external monitors operating according to the side stream

procedure are connected to the "Sample gas recirculation" adapter at the rear side. The

sample gas is putted back to the reservoir bag by this adapter.

* only the apparatus option without the gas module

30 / 150 HEYER Narkomat+, Operator’s manual Rev. 3.1 - 05/09

Page 31

H E Y E R N a r k o m a t+

4.7 Vacuum source for bronchial suction (optional)

Fig. 11 Vacuum source

1 Tube clamp for suction tube/finger tip

2 Quick coupling AIR for vacuum source

3

Vacuum source (injector) with vacuum gauge and control knob

4 Connection for tube to suction glass "vacuum" connector

Rev. 3.1 – 05/09 HEYER Narkomat+, Operator’s manual 31 / 150

Page 32

H E Y E R N a r k o m a t+

4.8 Symbols on the Unit

Attention, check the accompanying documents

I/0

On/Off (connection to the power supply)

32 / 150 HEYER Narkomat+, Operator’s manual Rev. 3.1 - 05/09

Page 33

H E Y E R N a r k o m a t+

5 Alarm Messages and Safety Devices

The NARKOMAT+ anesthesia system displays alarm messages on the ventilator display

during operation. The alarm message is displayed until the fault condition that triggered the

alarm is resolved. High priority alarms are displayed against a light background in the alarm

window. Low priority alarms are displayed against a dark background. The switching of the

alarm muting key does not influence the alarm shown on the display.

In the following, all alarm situations that may arise during the different operating conditions

are explained.

There are three priority levels of the alarms:

No. Alarm LEDs Acoustic

1 Continues red Continues tone

2 Red blinking Intermitting tone

3 Yellow blinking

Rev. 3.1 – 05/09 HEYER Narkomat+, Operator’s manual 33 / 150

Page 34

H E Y E R N a r k o m a t+

5.1 Alarm messages direct after the System start

Direct after the switching on and booting of the system, alarm messages are displayed in the

bottom section of the screen. The alarm has to be acknowledged by pushing the encoder

button before the booting procedure continues.

Direct after the switching on

and booting of the system,

alarm messages are

displayed in the bottom

section of the screen. The

operating conditions can be

checked and, if necessary,

errors can be corrected.

Fig. 12 Example of an alarm message during the booting

procedure

34 / 150 HEYER Narkomat+, Operator’s manual Rev. 3.1 - 05/09

Page 35

H E Y E R N a r k o m a t+

5.2 Alarm Messages in Standby

In standby, the alarm messages are display in the middle section of the screen.

In standby, the alarm

messages are display in the

middle section of the screen.

The operating conditions

can be checked and, if

necessary, errors can be

corrected.

Fig. 13 Example of an alarm message during the booting

procedure

Rev. 3.1 – 05/09 HEYER Narkomat+, Operator’s manual 35 / 150

Page 36

H E Y E R N a r k o m a t+

5.3 Compliance test alarm messages

During or after the compliance test, alarm messages are displayed in the middle or top

section of the screen

During or after the

compliance test, alarm

messages are displayed in

the middle or top section of

the screen

The operating conditions

can be checked and, if

necessary, errors can be

corrected.

Fig. 14 Example of a sensor test alarm message

If the system was locked because of a sensor failure, only use the apparatus in case of an

emergency for manual ventilation and contact a service technician if the compliance test fails

repeatedly.

5.3.1 Compliance test alarm messages

Alarm message Significance/ cause Corrective action

System Resistance too high Resistance of patient hoses or

bacteria filter is too high.

Compliance test Passed.

Leak rate is higher than 600

ml/min. Tighten valve rings

The leakage of the circle system

and the patient hoses is higher than

600 ml/min at 40 cm H2O.

Check breathing circuit

Press OK to continue

Replace bacteria filter and

breathing circuit. Use the

Compliance test in Standby /

OPTIONS to retest. If all else

fails call Service.

Ventilator may be used safely

with adequate fresh gas flows.

If necessary use the

Compliance test in Standby /

OPTIONS to retest after

tightening the breathing circuit

and valve rings.

36 / 150 HEYER Narkomat+, Operator’s manual Rev. 3.1 - 05/09

Page 37

H E Y E R N a r k o m a t+

Compliance test alarm messages (continued)

Alarm message Significance/ cause

Compliance out of range The compliance of the connected

patient hoses lies outside the range

of 3.0 to 9.9 ml/cm H2O.

System Error

Cal Required –

Call Service

Data for parameter or alarm limit

settings was not saved correctly,

the data exchange between the

ventilator modules and on-screen

display is faulty or the startup test

for Internal circuit EEPROM has

failed.

Check Diaphragm Valves The system has detected a

pressure increase. The diaphragm

valves may be leaking drive gas

into the circle system.

Pressure Reading out of

tolerance

Perform Compliance Test

The system has detected a fault on

one or both pressure sensors.

when convenient

Flow/Volume Readings not

available

Replace Flow Sensor - Call

Service

During the test, the hotwire sensor

did not pass its test. Sensor may be

faulty.

Flow/Volume Readings not

available

Replace Flow Sensor - Call

Service

During the test, the hotwire sensor

did not pass its test. Sensor may be

faulty.

Valve Error:

Use Manual Ventilation

Call Service

Vent Error:

Use Manual Ventilation

The proportional valve for

generating the ventilation volume

does not function correctly.

The automatic test routine has

detected a processor control fault.

Call Service

Calibrate Breathing System

Perform Compliance Test

when convenient

One or more solenoid valves

actuating the bellows valve have

failed.

Patient module unlocked The Patient module is not adapted

correctly in the docking station.

Corrective action

Replace bacteria filter and

breathing circuit. Use the

Compliance test in Standby /

OPTIONS to retest. If all else

fails call Service.

Retry function. Reboot

machine. If all else fails call

Service.

Remove the Breathing circuit

from the Docking Station and

check the Decoupling and

Expiratory valves for intact

membranes. Replace as

required or call Service.

Perform the Compliance test in

Standby / OPTIONS. If all else

fails call Service.

Retry function. Perform the

Compliance test in Standby /

OPTIONS

Reboot machine. If all else fails

call Service.

Retry function. Reboot

machine. If all else fails call

Service.

Perform the Compliance test in

Standby / OPTIONS. If all else

fails call Service.

Call Service.

Remove the Breathing circuit

from the Docking Station.

Check the Bellows valve

actuation. Perform the

Compliance test in Standby /

OPTIONS. If all else fails call

Service.

Check if the Patient module is

adapted correctly. If else fails,

call service

Rev. 3.1 – 05/09 HEYER Narkomat+, Operator’s manual 37 / 150

Page 38

H E Y E R N a r k o m a t+

5.4 System test alarm messages

During or after the sensor test, alarm messages are displayed in the lower section of the

ventilator display:

If the system cannot create

a sufficient pressure

increase in the breathing

circuit, the following fault

message is for instance

displayed in the lower

section of the system test

window.

Fig. 15 Example of a system test alarm message

38 / 150 HEYER Narkomat+, Operator’s manual Rev. 3.1 - 05/09

Page 39

H E Y E R N a r k o m a t+

System test alarm messages (continued)

Alarm message

System Resistance too high Resistance of patient hoses or

Leakage greater than 200 ml/min The fresh gas system leakage test

Compliance out of range The compliance of the connected

System Error

Cal Required –

Call Service

Calibrate Breathing System

Perform Compliance Test when

convenient

CPU Error:

Use Manual Ventilation Call

Service

O2 Cell is out of range

Replace O2 Sensor

Press OK to Start

O2 concentration too high.

Expose Sensor to room air.

Press OK to start.

Significance/ cause Corrective action

bacteria filter is too high.