Page 1

Modular

Anesthesia System

Operator’s Manual

Rev. 1.1 – 07/07

MODERN SOLUTIONS FOR AN ESTHETICS AND INHALATION

Page 2

Page 3

HEYER Modular

Table of contents

1 Details of the Manufacturer........................................................................................................... 5

2 Description and Utilization of the Apparatus.............................................................................. 6

2.1

General ..................................................................................................................................... 6

2.1.1 Introduction........................................................................................................................6

2.1.2 Intended purpose...............................................................................................................6

2.1.3 Product improvements.......................................................................................................6

2.1.4 Responsibility of the operating personnel.......................................................................... 6

2.1.5 Liability of the manufacturer............................................................................................... 7

2.2 General precautionary measures.............................................................................................. 7

2.2.1 Warning directions............................................................................................................. 7

2.2.2 Precautionary measures....................................................................................................8

3 Functional description................................................................................................................... 8

3.1 Anesthesia ventilator................................................................................................................. 8

3.1.1 Fresh gas decoupling ........................................................................................................ 8

3.1.2 Constant volume provided by machine-controlled ventilation........................................... 8

3.1.3 Compliance compensation ................................................................................................ 9

3.1.4 Bag-in-Bottle System......................................................................................................... 9

3.2 Fresh gas dosing....................................................................................................................... 9

3.3 Vaporizer Mounting Device and Vaporizer............................................................................... 9

3.4 Patient module........................................................................................................................10

3.4.1 Circuit Absorber System.................................................................................................. 10

3.4.2 CO2 absorber................................................................................................................... 10

3.4.3 Reservoir and Manual Ventilation Bag............................................................................10

3.4.4 Volume Measurement...................................................................................................... 10

3.4.5 Oxygen Measurement ..................................................................................................... 10

3.4.6 Patient module heating.................................................................................................... 10

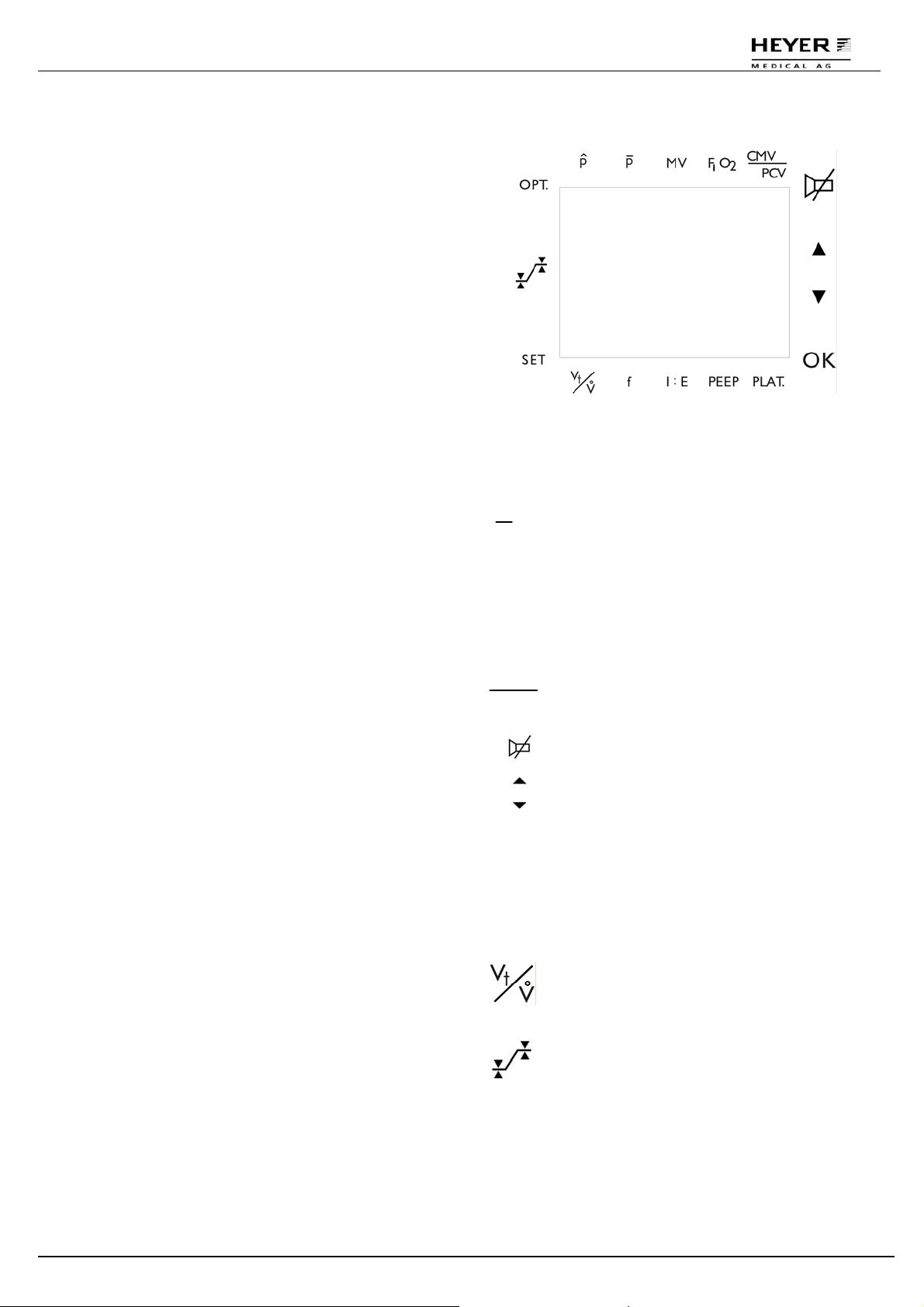

3.5 Touch Screen Display.............................................................................................................11

3.5.1 Symbol Description..........................................................................................................11

4 Operating Elements / Device Connections................................................................................ 12

4.1 Views of Apparatus................................................................................................................. 12

4.1.1 Front view / left-hand side view ....................................................................................... 12

4.1.2 Rear view / right-hand side view......................................................................................12

4.2 Ventilation unit......................................................................................................................... 13

4.2.1 "Ventilation Mode"- selector switch..................................................................................14

4.3 Flowmeter tube block with fresh gas dosing...........................................................................14

4.4 Vaporizer Mount......................................................................................................................15

4.5 Patient module (circle system)................................................................................................ 16

4.6 IR adapter ............................................................................................................................... 17

4.7 Compressed air injector for bronchial suction (optional) ........................................................ 17

4.8 Symbols on the apparatus......................................................................................................17

5 Alarm Messages and Safety Devices......................................................................................... 18

5.1 Alarm Messages and ..............................................................................................................19

Corrective Measures..........................................................................................................................19

5.1.1 Alarm messages during the compliance test...................................................................24

5.1.2 Alarm messages during the system test.......................................................................... 26

5.1.3 Alarm messages in normal mode....................................................................................27

5.1.4 Alarm message “Technical fault”.....................................................................................31

5.2 Test of alarm functions............................................................................................................ 31

6 Start-up and functional test ........................................................................................................32

6.1 Preparing for Operation .......................................................................................................... 32

6.2 Pre-Operation Tests................................................................................................................ 32

6.2.1 Compliance test............................................................................................................... 33

6.2.2 O2 Sensor Calibration......................................................................................................33

6.2.3 Leak test fresh gas system.............................................................................................. 34

7 Operation in the Individual Functions........................................................................................ 36

7.1 Standby Mode......................................................................................................................... 36

7.1.1 The Options Window in Standby Mode...........................................................................36

7.2 “Manual/Spontaneous” ventilation mode................................................................................ 36

7.2.1 Setting Alarm Limits in “Manual/Spontaneous” mode..................................................... 36

Rev. 1.1 – 07/07 HEYER Modular, Operator’s manual 3 / 50

Page 4

HEYER Modular

7.3 CMV Ventilation Mode............................................................................................................37

7.3.1 CMV Ventilation Mode..................................................................................................... 37

7.3.2 Setting Alarm Limits in CMV mode.................................................................................. 38

7.4 PVC Ventilation Mode.............................................................................................................38

7.4.1 PCV Ventilation Mode...................................................................................................... 39

7.4.2 Setting Alarm Limits in PCV mode................................................................................... 39

8 Alarm Elimination.........................................................................................................................40

9 Dismantling and Reassembling.................................................................................................. 41

9.1 The Patient Module.................................................................................................................41

9.1.1 The CO2 absorber............................................................................................................41

9.1.2 The Bag-in-Bottle System................................................................................................41

9.1.3 Exchanging the Expiratory Flow Sensor.......................................................................... 41

9.1.4 Dismantling the ventilation pressure valve......................................................................42

9.1.5 Replacing the control membranes................................................................................... 42

9.2 The Valves (expirations, inspiration and emergency air valve) .............................................. 42

9.3 Installing the Vaporizers.......................................................................................................... 43

10 Cleaning ........................................................................................................................................ 43

10.1 Cleaning the housing........................................................................................................... 44

10.2 The Patient Module.............................................................................................................44

11 Service and Maintenance ............................................................................................................ 44

11.1 General................................................................................................................................44

11.2 Maintenance Work .............................................................................................................. 44

11.2.1 Maintenance work on the ventilator / patient module...................................................... 44

11.2.2 Maintenance work by a qualified technician.................................................................... 44

11.2.3 Maintenance work after 1000 operating hours................................................................45

11.2.4 Maintenance work after 2000 operating hours................................................................45

11.3 Maintenance work on the vaporizer .................................................................................... 45

11.4 Other maintenance work..................................................................................................... 45

12 Technical data .............................................................................................................................. 46

13 Warranty........................................................................................................................................48

4 / 50 HEYER Modular, Operator’s manual Rev. 1.1 - 07/07

Page 5

HEYER Modular

1 Details of the Manufacturer

Apparatus: Anesthesia System HEYER Modular

Manufacturer: HEYER Medical AG

Internet: http://www.heyermedical.de

Subject to alterations, issued July 2007.

Carl-Heyer-Straße 1-3

D-56130 Bad Ems

Germany

Tel.: +49 (0) 2603 / 791-3

Fax: +49 (0) 2603 / 70424

E-Mail: info@heyermedical.de

Rev. 1.1 – 07/07 HEYER Modular, Operator’s manual 5 / 50

Page 6

HEYER Modular

2 Description and Utilization of the

Apparatus

2.1 General

2.1.1 Introduction

The HEYER Modular anesthesia system

represents a flexible anesthesia workplace for

implementing and monitoring inhalation

anesthesia in the half-closed system and the

nearly closed system for low-flow techniques

with minimum gas and anesthetic agent

utilization.

During the development of the system special

emphasis was placed on the ergonomic design

and consequently the safe and easily learnable

operation. Furthermore the excellent airtightness of the system ensures the

economical daily high and low pressure

utilization.

The standard model contains the following

system components:

A. Electronic ventilator:

The processor-controlled ventilator allows

constant-volume ventilation for all patient

groups with a body weight of 3 kg upwards.

Due to the system compliance compensation,

even small tidal volumes can be precisely

administered. The ventilation type CMV as the

standard and PCV as the optional ventilation

type as well as considerable variation options

of the artificial ventilation cycle facilitate secure

ventilation for complicated lung conditions. A

comprehensive test and alarm management

ensures the required safety for patients and

prevents out-of-control operating conditions.

The clear design of the user interface and the

display allow the secure operation and a quick

detection of the selected ventilation

parameters.

B. Patient module

The circular patient absorber system is highly

integrated and compacted in an aluminum

block. This block is tempered to prevent the

formation of condensation. It also contains a

monitored emergency air valve, a fresh gas

reservoir in form of a hand-held anesthesia

bag and an expiratory flow sensor. All sensors

are continuously monitored during operation.

The sensors are automatically calibrated

during the start-up of the apparatus.

C. Integrated fresh gas dosing system

including vaporizer unit:

The flowmeter tube block contains all

mandatory safety equipment as well as a

pneumatic regulation system to maintain a

minimum oxygen concentration of 25% in the

fresh gas flow (ratio system).

2.1.2 Intended purpose

The Heyer Modular anesthesia system is

suitable to make available anesthetic gases

and to perform automatic or

spontaneous/manual ventilation with a circular

system in a semi-closed system. This

procedure can be used on adults as well as

children. The use of an open system to

anesthetize small children and newborns is

possible.

The Modular anesthetic system is intended for

use in operating rooms in clinics and mobile

doctor’s practices. It is not suitable for use in

the vicinity of MRI scanners. Possible

anesthetic procedures that are supported by

automatic or manual artificial ventilation are:

- Full anesthetic with volatile anesthetic

agents

- Full anesthetic with balanced anesthesia

- Full anesthetic with intravenously applied

anesthetic agents

- Partial anesthetic

2.1.3 Product improvements

HEYER Medical AG reserves the right to make

changes and/or to revise devices and/or

operating instructions without prior notice.

These instructions deal with all the

characteristics of the anesthetic system

HEYER Modular according to the state of

information at the time of going to print.

Instructions and devices created or

manufactured at a later date may already

include improvements or changes not featured

in earlier models.

2.1.4 Responsibility of the operating

personnel

The proper functioning of the anesthetic

system HEYER Modular is only warranted if

the apparatus is used and maintained n

accordance with the directions provided by the

manufacturer. Not observing these instructions

will void any warranty claims with regard to

HEYER Medical AG.

ATTENTION: Before using the apparatus,

please read the operating instructions, as

well as the section “General precautionary

measures” and observe in particular all

directions in these instructions that are

titled ATTENTION or WARNING. These

instructions merely describe the operation

of the device. A qualified professional can

find instructions regarding maintenance

and repair in the SERVICE INSTRUCTIONS

HEYER MODULAR.

6 / 50 HEYER Modular, Operator’s manual Rev. 1.1 - 07/07

Page 7

HEYER Modular

The device may only be operated by qualified,

trained professional personnel. Prerequisite for

this is the unlimited observance of these

operating instructions and/or additional

accompanying documents and manufacturer’s

indications, as well as the adherence to the

general precautionary measures listed in the

following, and the briefing by authorized

medical product consultants.

Additional gas monitoring is prescribed to

operate the device.

The following conditions must be met at a

minimum (DIN EN 740):

At least the following are to be monitored:

• concentration of the anesthetic gas

• concentration of carbon dioxide

For these additional monitoring parameters, it

must be possible to set upper and lower alarm

limits. When reaching one of these upper or

lower alarm limits, a visual or acoustic alarm

needs to be activated.

The measuring adapter to be inserted into the

circle system or patient’s tube system must be

equipped with ISO cones (DIN EN 740).

This is to be applied at the inspiration tube

connection or ideally the Y-piece.

Measurement close to the tube is

recommended, however, since this makes the

collection of inspiratory and expiratory gas

values possible. Monitors that work using the

sidestream procedure should definitely be

preferred in order to complement the

additionally required gas monitoring.

In case a device should not work as described

in these instructions, the device in question

may not be used until the fault is eliminated.

The operating personnel carry the

responsibility for damages and injuries whose

causes can be traced back to the improper

operation and/or repair/maintenance of the

device by unauthorized persons.

2.1.5 Liability of the manufacturer

The HEYER Medical AG is only liable for the

safety, reliability and functionality of the device

if:

- the device was operated corresponding to

the directions provided by the manufacturer.

- additions, new settings, changes or repairs

were carried out by professionals qualified

by the manufacturer.

- the device and was only operated in

buildings with facilities for protective

grounding in compliance with the regulations

of the IEC.

2.2 General precautionary measures

2.2.1 Warning directions

Avoiding potentially dangerous situations

in which an injury to the patient and/or the

operating personnel cannot be excluded.

Carry out the tests listed on the checklist daily

and in case of any fault that occurs do not use

the system until the fault has been eliminated.

Always connect the output of the ventilation

pressure valve for gas overflow with the

anesthetic gas ongoing flow installation,

usually installed in operating rooms.

The patient should also be observed closely by

qualified professional personnel. In certain

situations, life-threatening circumstances may

occur that don’t necessarily trigger an alarm.

Always set the alarm limits so that the alarm is

triggered before a hazardous situation occurs.

Incorrectly set alarm limits may result in

operating personnel not being aware of drastic

changes in the patient’s condition.

In order to prevent an electric shock, the

apparatus (protection class I) may only be

connected to a correctly grounded mains

connection (socket outlet with grounding

contact).

Danger of explosion! The device may not be

operated in the immediate vicinity of flammable

anesthetics of other flammable substances.

The use of flammable anesthetics (e.g. ether,

cyclopropane) is not permitted.

Since this device is not permitted for use with

flammable anesthetics (e.g. ether,

cyclopropane), the use of antistatic breathing

hoses and facemasks is not required (DIN EN

740).

Electric shock and fire hazard! Always switch

off the apparatus and disconnect it from the

mains before cleaning.

Fire hazard! The fuses (e.g. the additional

sockets) may only be replaced by fuses of the

same type and with the same fuse value.

Electric shock hazard! The device may only be

opened by qualified or authorized professional

personnel.

In case of a failure of the protective conductor

the connection of the apparatus via the

additional socket may lead to a discharge

current exceeding the permissible values.

Ambient interference caused by

electromagnetic radiation exceeding the

specifications of EN 60601-1-2 can influence

machine functions.

Rev. 1.1 – 07/07 HEYER Modular, Operator’s manual 7 / 50

Page 8

HEYER Modular

2.2.2 Precautionary measures

Avoid situations in which the device may

malfunction or be damaged.

This device may only be operated by trained

professional medical personnel.

Before putting the device into service, the

operating personnel must be familiar with the

directions and information in thes e instructions

and must have been briefed by a medical

product consultant.

If the apparatus does not function as

described, it must be examined and possibly

repaired by qualified service personnel before

being used again.

Treat the device with care in order to avoid

damages and faults in its functionality.

Always make sure that the device is supplied

with gas in a way that conforms to the

technical specifications.

Before operating the device, it must be

properly calibrated and the corresponding

device tests need to be carried out, as

described in these instructions.

Should the device display any functional faults

during the calibration and tests prior to

operation, it may not be operated until the

faults have been eliminated by a qualified

professional.

After any maintenance tasks, a function test

and the compliance and system tests need to

be carried out before the device is put into

clinical use.

Only bacteriological filters with a low flow

resistance must be connected to the patient

module and/or patient connection.

3 Functional Description

3.1 Anesthesia ventilator

Ventilators are described according to the

principle of controlling the change over from

inspiration to expiration. The HEYER Modular

apparatus offers the following characteristics I

the controlled ventilation mode or so-called

CMV mode (Controlled Mandatory Ventilation).

- time-controlled:

The timely sequence of inspiration and

expiration has been specified by the ventilation

frequency settings. The ration of the inspiration

to the expiration time of the individual

ventilation cycle is determined by the

adjustable I/E ratio.

- pressure-limited:

The tidal volume during a controlled ventilation

is supplied during the entire period if the

inspiratory flow and can be set as a ventilation

parameter. The inspiration is, however,

terminated before the tidal volume has been

administered once the measured airway

pressure reaches the set peak pressure alarm

limit.

- constant-volume:

The inspiratory flow to the patient required for

a ventilation with the set parameters frequency

f, tidal volume V

and ventilation time ratio I/E,

t

is automatically calculated by the ventilator.

This inspiratory flow is generated via the drive

gas for the patient module. In standard

anesthesia ventilators deviations in the tidal

volumes actually administered to the patient

could occur due to the respective fresh gas

setting and system compliance of the

ventilation system. The ventilator of the

HEYER Modular apparatus supplies a constant

volume, as on the one hand the patient module

is uncoupled from the fresh gas system. On

the other hand the system compliance of the

patient module is automatically taken into

consideration by the ventilator when

generating the breathing volume.

3.1.1 Fresh gas decoupling

During fresh gas decoupling in CMV mode, the

fresh gas flow is directed into the manual

ventilation bag. The manual ventilation bag

thus serves as a fresh gas reservoir. This

principle offers the following advantages for

machine-controlled ventilation:

1. The tidal volume is completely independent

from the set fresh gas flow. This ventilation is

therefore referred to as constant volume

ventilation.

2. The fresh gas flow can be maintained at a

very low level, e.g. below 500 ml/min,

depending on the patient. The manual

ventilation bag serves as a fresh gas reservoir

for the fresh gas administered during

inspiration. The entire fresh gas volume is

available during the next inspiration, i.e. not

only the fresh gas stored in the reservoir but

also the fresh gas supplied during expiration.

3.1.2 Constant volume provided by

machine-controlled ventilation

During controlled CMV ventilation, the set tidal

volume is administered irrespective of the

pulmonary circumstances. In principle the

ventilator drive represents a constant flow

generator. The inspiratory flow of the

ventilation gas is automatically adapted to the

respective settings of the tidal volume V

, the

t

ventilation frequency rate f and the ventilation

time ratio I/E.

8 / 50 HEYER Modular, Operator’s manual Rev. 1.1 - 07/07

Page 9

HEYER Modular

3.1.3 Compliance compensation

The administered tidal volume is corrected to

the target value set by the user with the aid of

the compliance compensation. The system

compliance of each ventilation system i.e. the

compliance of patient hoses and the patient

module itself always leads to losses in the

administered tidal volume. In the case of the

HEYER Modular, a control loop can correct

this volume loss as an automatic

compensation function. For this purpose

several ventilation cycles are required. The

drive gas flow is then increased to just above

the normal values, i.e. values to achieve the

set ventilation volume. The correct tidal volume

is, however, administered to the patient, while

the slightly higher volume is absorbed by the

system compliance due to the effective

compliance compensation.

3.1.4 Bag-in-Bottle System

The so-called Bag-In-Bottle system is part of

the patient section or circuit system. The gasconducting sections are divided from the

ventilator into a primary (ventilator) and a

secondary circuit (patient). The gas volume

provided by the drive is not directly

administered to the patient but instead

compresses a bellows inside a pressure dome.

As a result the ventilation gas contained in the

bellows is administered to the patient. The

larger the drive volume flowing into the

pressure dome, the greater the tidal volume

will be. Once the drive gas flow has finished

the pressure compensation between the

primary and secondary circuit is also ended. A

distinctive plateau in the ventilation pressure

curve is formed if the system does not switch

over to the expiration directly after the end of

the inspiratory gas flow. For this purpose the

drive volume contained ion the pressure dome

us maintained at a steady level for some time.

The bellows are suitable for adults and

children. An exchange of the bellows for

different patient groups is not necessary.

3.2 Fresh gas dosing

The adjustment of the amounts of gas

delivered to the patient is handled at the

measuring tube block. It contains flow

measurement tubes, also described as

rotameters. These measuring tubes consist of

a vertically aligned glass tube with a floating

element inside. Since the glass tube widens

toward the top, a certain flow of gas will lift the

floating element to a corresponding height.

Adjusting the gas flow is handled by valve

spindles inside the respective measuring

tubes.

The choice between a setting of gas types

O

/AIR and/or O2/N2O is made via a change-

2

over switch, which opens the respective gas

line to the measuring tube block.

The fresh gas cannot be set with a mixture of

AIR and N

O as in this case a decrease of the

2

oxygen content to below 21% could not be

avoided.

Reducing the oxygen content to less than 21%

is theoretically also possible when dosing the

O

and N2O gases. Such unfavorable settings

2

are prevented by a pneumatic safety system.

This mechanism, also described as the “Ratio

system”, ensures a steadily present minimum

content of 25% O

along with the N2O in the

2

gas mix dosage. When raising the flow of N

the required flow of O

is also raised

2

automatically. The fresh gas thus adjusted will

be fed to the vaporizer automatically and

mixed with the anesthetic there.

3.3 Vaporizer mounting device and

vaporizer

The appliance contains a Selectatec®

compatible vaporizer mounting device

(standard configuration) for two vaporizers.

The vaporizer has a chamber, which contains

the anesthetic in liquid form in its lower part. A

wick made of metal mesh enriches the upper

part of the chamber with saturated vapors of

the anesthetic. The concentration of the

saturated vapor at room temperature is much

higher than is clinically justifiable. A suitable

mixing ratio of the gas with anesthetic with a

flow of gas passing by this chamber can lead

to the desired concentration. This is handled

by the adjusting wheel. This adjusts the ratio of

the streams of carrier gas via a bypass

channel and through the vaporizer chamber in

such a way that the desired concentration is

attained at the vaporizer outlet. In the zero

position of the vaporizer this bypass channel

remains open, while the vaporizer chamber is

completely closed off to the flow of gas.

The anesthetic vapor concentration in the

vaporizer chamber may be saturated, but the

absolute content of anesthetic is still

dependent on temperature. This is why there is

a temperature compensation valve in the

bypass channel, which in the case of vapor

pressure changes caused by temperature

fluctuations changes the set dilution ratio in

such a way that a temperature-independent

concentration output of the anesthetic is

warranted.

For additional indications see:

Operating instructions of the anesthetic

vaporizer used.

2

O,

Rev. 1.1 – 07/07 HEYER Modular, Operator’s manual 9 / 50

Page 10

HEYER Modular

3.4 Patient module

3.4.1 Circuit absorber system

A circuit absorber system is a ventilation

system with a CO

absorber. This system

2

allows anesthetics to be carried out at

extremely low fresh gas settings. The

ventilation gas contains various parts of rebreathing gas i.e. expiratory gas freed from

CO

parts. This is achieved with a circuit

2

ventilation system facilitating a re-breathing of

the expiratory CO

-containing gas. A circuit

2

system with high re-breathing contents causes

a reduction of the consumption of anesthetic

gases. This type of system also offers an

improved breathing gas conditioning.

The patient module is designed as a circuit

absorber system in the form of a compact

aluminum block. The hose connections

normally required between the ventilator and

the circuit system are thus no longer needed.

3.4.2 CO

absorber

2

The absorber serves to absorb the breathing

lime. It aims to remove the CO

from the

2

expiration air. The absorption process is a

chemical reaction in which carbon dioxide is

bound and most of the reaction water

evaporates and the lime is removed. This is

why used breathing lime is dry and hard. The

lime must be hermetically sealed for storage in

a cool and dry place so as not to become

malabsorbant.

3.4.3 Reservoir and manual ventilation

bag

The reservoir consisting of a manual ventilation

bag serves as an inspiratory interim storage

facility for the fresh gas. The reservoir pressure

during machine and spontaneous ventilation is

limited to 1-2 bar by the excess / ventilation

pressure valve, also known as the overflow

valve. This valve serves additionally for setting

the desired ventilation pressure for manual

ventilation.

3.4.4 Volume measurement

Volume measurement takes place by means of

measuring the flow in the expiration branch

using a flow sensor, which works according to

the hot-wire anemometer principle. The

ventilator processors integrate this measured

value with the displayed tidal and ventilation

minute volumes. The tidal volume shown in the

display is a purely measured value. The tidal

volume displayed during machine-controlled

ventilation is measured by an internal flow

sensor and is not dependent on the expiratory

volume measurement.

3.4.5 Oxygen measurement

Oxygen measurement is metered by a

measuring cell installed on the inspiration

valve. This single-cathode measuring cell, also

referred to as a fuel cell, offers a longer service

life compare to other oxygen cells and is less

sensitive to existing anesthetic gases.

3.4.6 Patient module heating

The heating prevents the formation of

condensation in the patient module and on the

valve caps of the inspiration and expiration

valve. The heating positively contributes to a

ventilation gas conditioning. The heating mat

also functions as a sealing mat and is installed

between the top and bottom sections of the

patient module. An electronic control integrated

in the ventilator keeps the temperature of the

patient module constant at approx. 36°C. An

over-temperature protection protects the

apparatus against overheating.

10 / 50 HEYER Modular, Operator’s manual Rev. 1.1 - 07/07

Page 11

HEYER Modular

P

3.5 Touch screen display

The “Touch screen” display acts as the user

interface for the HEYER Modular. With the

exception of the ventilation mode dial, all data

input is done via light finger pressure on the

touch screen. Therefore it is no problem to

operate the system with moist or dirty hands.

To change a value, for instance, you press the

corresponding symbol of the value you wish to

change. The illumination of the selected

symbol will then be intensified as confirmation.

You can then increase or decrease the value

using the arrow symbols. To confirm the data

change, press the OK button.

3.5.1 Symbol description

P

MV

Fig. 1 Touch Screen Display

ˆ

Peak airway pressure in mbar

Mean airway pressure in mbar

Minute volume in liters

FiO

Inspiratory oxygen concentration

2

CMV

CMV or PCV ventilation mode

PCV

Mute switch for acoustic alarm signals

Cursor for increase or decrease of set

values

OK

PLAT.

PEEP

I:E

f

SET

OPT.

Confirmation of entered values

Plateau pressure in % of the inspiration

time

Positive Expiratory End Pressure

Inspiratory to expiratory ratio

Ventilation frequency

Tidal volume in mL in CMV mode;

Drive gas in l/min in PCV mode

Display change-over from measures

values to SET values

Alarm limits setting mode

Options

Rev. 1.1 – 07/07 HEYER Modular, Operator’s manual 11 / 50

Page 12

HEYER Modular

4 Operating Elements / Device

Connections

4.1 Views of apparatus

4.1.1 Front view / left-hand side view

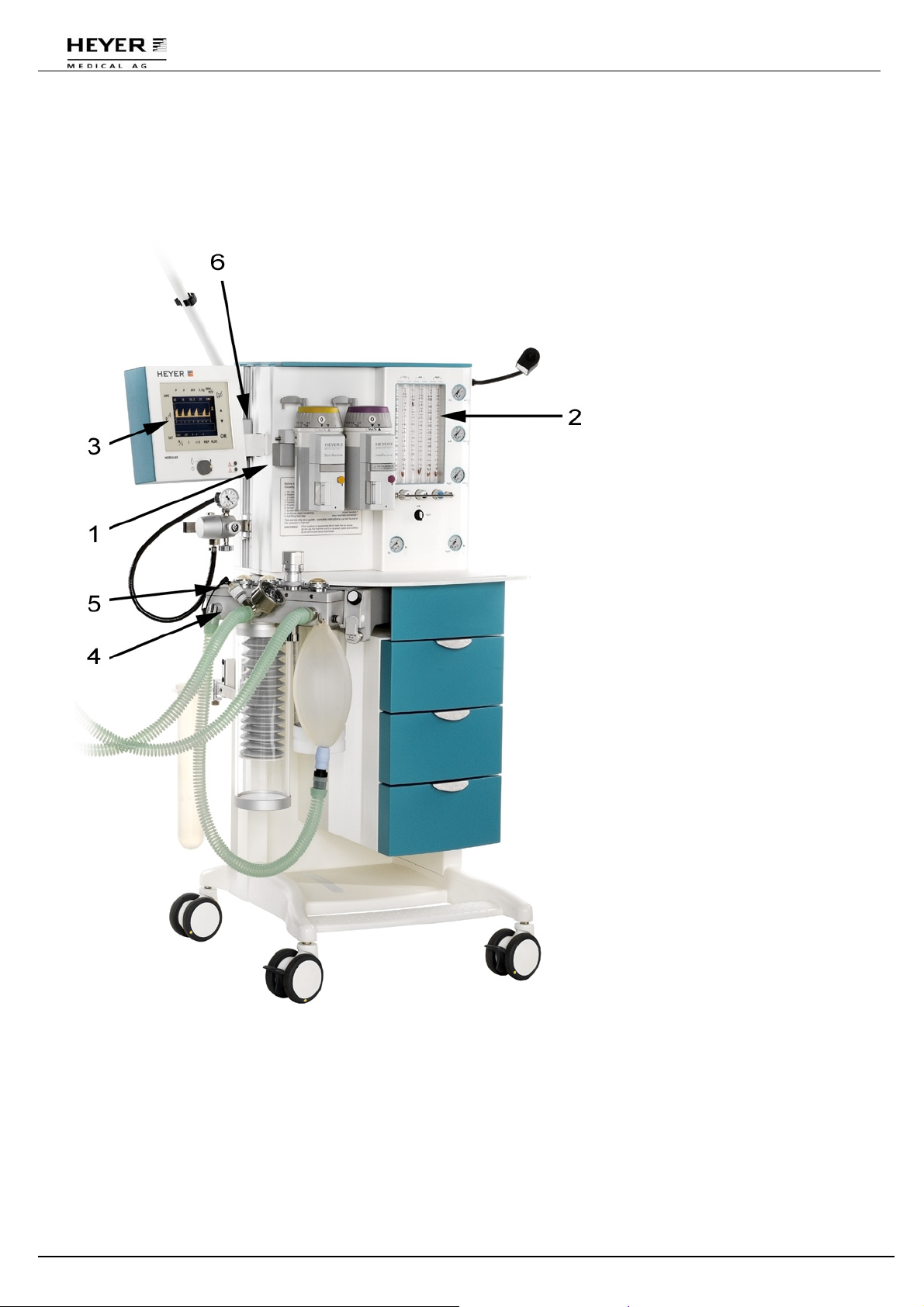

Fig. 2 Front view

1

Vaporizer mount

Selectatec

mount for two vaporizers

(As an option, a single mount for

Dräger vaporizers is available.)

®

compatible vaporizer

2 Flowmeter block

5-fold flowmeter block with

integrated ratio system,

bypass and N20/AIR change-

O

2

over switch.

3 Ventilator unit

Microprocessor-controlled

ventilation unit with

EL display

4 Patient module

Absorber circuit system with

integrated "Bag-in-Bottle" system,

active and passive valves as well

as APL ventilation pressure valve

5 Oxygen sensor with

connecting cable

6 Mount for holding arm

4.1.2 Rear view / right-hand side view

12 / 50 HEYER Modular, Operator’s manual Rev. 1.1 - 07/07

Page 13

HEYER Modular

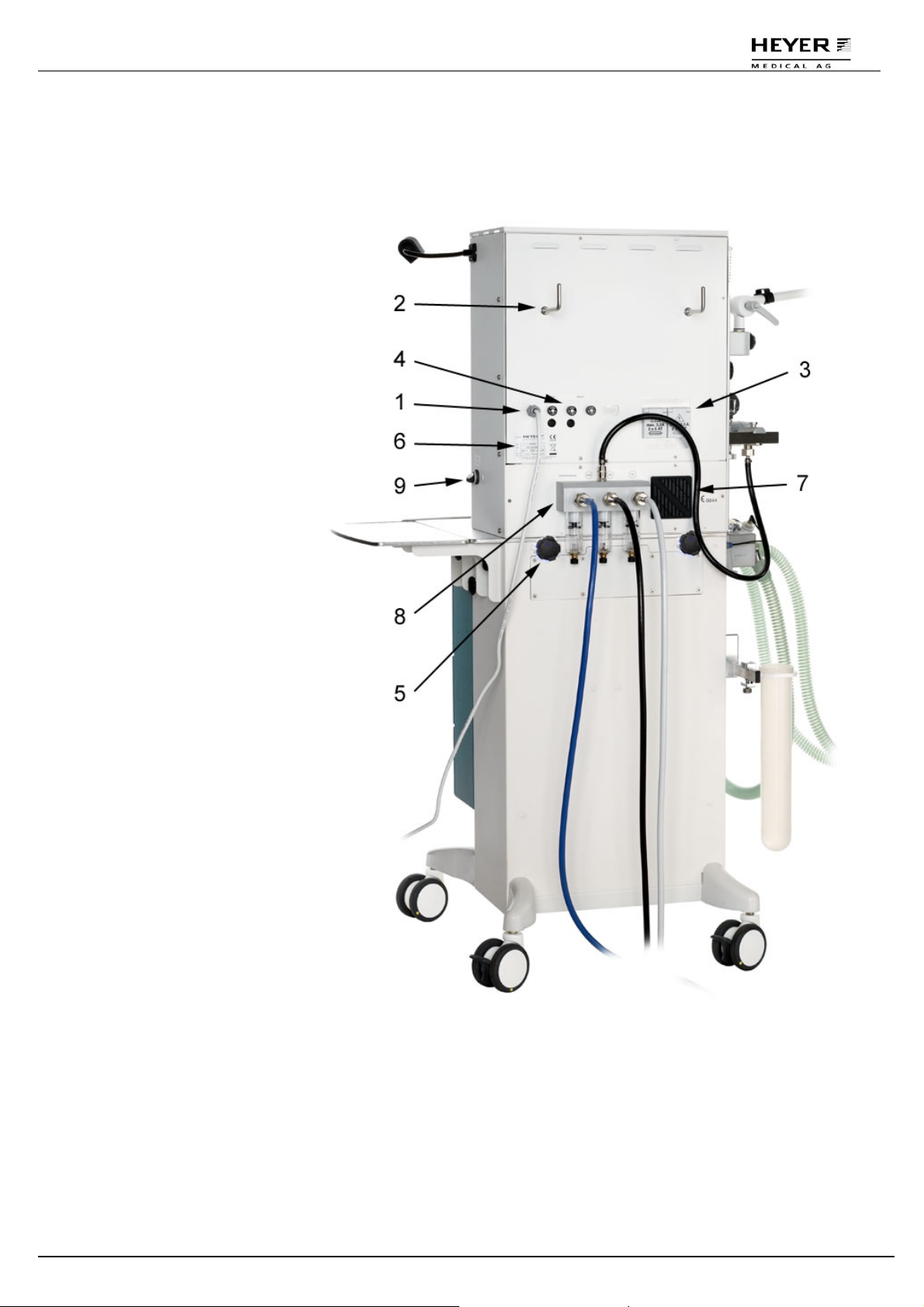

1 Mains cable

Power supply cable for the

connection of the apparatus to a

socket with grounding contact.

2 Hook for cable winding

3 Additional sockets

Other apparatus with a maximum

power consumption of 3.5 A each can

be connected to 2 additional sockets.

4 fuses (resetable)

Over current triggering device 5A, 2

each for the ventilator, one for the

backup battery for power supply in

the event of a mains failure.

5 Reserve bottles – connections

6 Type plate with serial number

7 Fan for housing ventilation

8 Mains connection for the central

gas supply

With 3 manometers for pressure

monitoring

9 Mains switch

The apparatus is switched on/off via

this switch and the supply of mains

voltage is created. This switch stays

in ON position during operation.

Fig. 3 Rear view

4.2 Ventilation unit

Rev. 1.1 – 07/07 HEYER Modular, Operator’s manual 13 / 50

Page 14

HEYER Modular

Fig. 4 Ventilator display and ventilation mode selector switch

The ventilator has a color LCD display (an EL

display is optionally available. This highcontrast display allows a clear overview of the

measured values and ventilator settings. A

clear side read-off is possible.

4.2.1 "Ventilation Mode"- selector switch

The rotary switch for the selection of the

ventilation mode has four positions:

Standby:

Position for the commissioning and

implementation of compliance and system

tests

Manual/Spont:

This position switches the ventilator to manual

ventilation or spontaneous ventilation mode.

CMV child:

This position switches the ventilator to CMV

mode for machine-controlled ventilation of

children.

CMV adult:

This position switches the ventilator to CMV

mode for machine-controlled ventilation of

adults.

4.3 Flowmeter tube block with fresh

gas dosing

14 / 50 HEYER Modular, Operator’s manual Rev. 1.1 - 07/07

Page 15

HEYER Modular

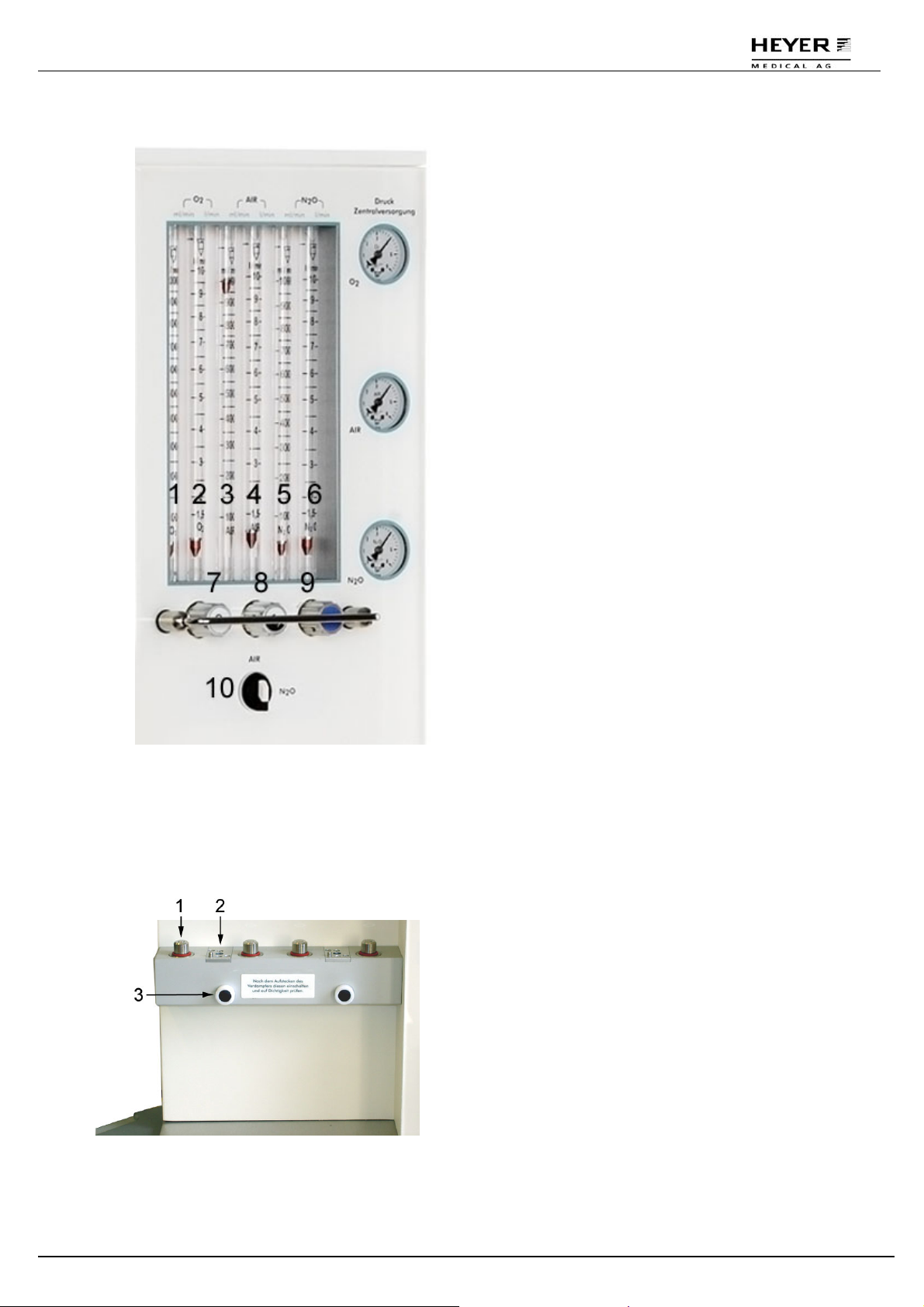

Fig. 5 Flowmeter tube block with fresh gas dosing

4.4 Vaporizer mount

Fig. 6 Vaporizer mount

1 Flowmeter tube O

2

with low measuring range, for settings from 0 to 1000

ml/min

2 Flowmeter tube O

2

with high measuring range, for settings from 1.5 to 10 l

3 Flowmeter tube AIR with low measuring range, for

settings from 0 to 1000 ml/min

4 Flowmeter tube AIR

with high measuring range, for settings from 1.5 to 10 l/min

5 Flowmeter tube N

Owith low measuring range, for

2

settings from 0 to 1000 ml/min

6 Flowmeter tube N

O

2

with high measuring range, for settings from 1.5 to 10 l/min

7 Valve spindle for O

gas dosing

2

8 Valve spindle for AIR gas dosing

9 Valve spindle for N

O gas dosing

2

10 N

O/AIR change-over switch

2

This switch allows the pre-selection of the gases N

AIR, which can subsequently be dosed with the respective

valve spindles. The previously set volume flow is retained

after switching back to the same gas type.

1 Valve cartridge of vaporizer mount

2 Locking device

3 Stop buffer (support) for vaporizer

O or

2

Rev. 1.1 – 07/07 HEYER Modular, Operator’s manual 15 / 50

Page 16

HEYER Modular

4.5 Patient module (circle system)

Fig. 7 Patient module (circle system)

1 Emergency air valve

2 Inspiration valve

3 Ventilation pressure valve

Including rotary regulator for setting the pressure

control during manual ventilation or for setting it as an

overflow valve for CMV or spontaneous ventilation.

4 Expiration valve

5 Oxygen measuring cell

6 Connection for inspiration hose

7 Hose connection for reservoir/ manual ventilation

bag

Outlet of the ventilation pressure valve

8

Here the anesthetic gas suction unit is connected.

9 Connection for expiration hose

10 Fresh gas outlet

11 O

12 CO

13 Bellows with pressure dome

bypass

2

The O

bypass supplies a high flow of O2 (approx.

2

50 l/min) directly to the fresh gas outlet or to the

patient module. When releasing the O

bypass

2

button, this returns to its original position and the

bypass is interrupted automatically.

O

2

absorber

2

16 / 50 HEYER Modular, Operator’s manual Rev. 1.1 - 07/07

Page 17

HEYER Modular

4.6 IR adapter

Fig. 8 IR adapter

4.7 Compressed air injector for

bronchial suction (optional)

Fig. 9 Suction

4.8 Symbols on the apparatus

Caution! Please observe the

following documentation

On / Off (connection to power

supply)

IR adapter

1

IR adapter

The optical infrared interface allows the connection

of computers or monitoring systems.

1

Compressed air injector (drive for suction unit)

Compressed air injector with vacuum display and

vacuum regulating button.

Connection for vacuum hose

2

Connection for hose to suction glass connection

“vacuum”

Rev. 1.1 – 07/07 HEYER Modular, Operator’s manual 17 / 50

Page 18

HEYER Modular

5 Alarm Messages and Safety

Devices

The HEYER Modular anesthesia system

shows alarm messages on the EL display

during operation. The alarm message is

displayed until the fault condition that triggered

the alarm is resolved.

High-priority alarms are display against a light

background. Low-priority alarms are display

against a dark background.

The alarm indication on the display is not

affected by pressing the mute button for the

acoustic alarm. A bell will appear on the righthand side of the screen to indicate the acoustic

alarm suppression.

In the following information all alarms able to

occur during the various operating statuses are

explained.

18 / 50 HEYER Modular, Operator’s manual Rev. 1.1 - 07/07

Page 19

HEYER Modular

5.1 Alarm messages and corrective measures

Alarm message

Compliance test carried

out

Test passed

Leak rate is more than

300 ml/min. Please

check breathing circuit.

Press OK to continue

Test passed

Leak rate is more than

600 ml/min. Please

check breathing circuit.

Press OK to continue

ATTENTION!

Use Manual ventilation

mode only.

System Resistance too

high.

Compliance out of

range.

Leak test Complete

Leak rate is higher than

500 ml/min. Verify that

APL is set to MAX

position CO

absorber,

2

vaporizers locked.

Leak test Complete

Leak rate is higher than

1,000 ml/min. Verify that

APL Valve is set to MAX

position CO

absorber,

2

vaporizers locked.

Cause Corrective Measures

The initial compliance test was

carried out successfully.

The initial compliance test was

carried out successfully. Leak rate is

between 300-600 ml/min .

The leak rate of the circuit and the

patient hoses is greater than 600

ml/min at 40 Pa x 100.

The compliance test was not carried

out or not passed. Machinecontrolled ventilation is not possible

until the compliance test has been

passed.

The resistance of the ventilation

hoses or the bacteriological filter is

too high.

The compliance of the connected

ventilation hoses is outside the

permissible range of 3.0 to 9.9

ml/mbar.

The leak rate of the entire circuit

higher than 500 ml/min at 40 Pa x

100.

The leak rate of the entire circuit

higher than 1,000 ml/min at 40 Pa x

100.

The system is ready for operation.

The ventilator can be safely operated

with an adequate fresh gas flow. If

necessary repeat the compliance test in

the OPTIONS menu after having

tightened the cap nuts and correcting the

hose connections.

The ventilator can be safely operated

with an adequate fresh gas flow. If

necessary repeat the compliance test in

the OPTIONS menu after having

tightened the cap nuts and correcting the

hose connections.

Carry out the compliance test in the

Standby/OPTIONS menu. If this is not

successful, please call a service

technician.

Renew the bacteriological filter and/or

the ventilation hoses. Carry out the

compliance test in the

Standby/OPTIONS menu. If this is not

successful, please call a service

technician.

Remove the bacteriological filter and/or

the ventilation hoses. Carry out the

compliance test in the

Standby/OPTIONS menu. If this is not

successful, please call a service

technician.

The ventilator can be safely operated

with an adequate fresh gas flow. If

necessary repeat the compliance test in

the OPTIONS menu after having

tightened the cap nuts and correcting the

hose connections to the vaporizer and

absorber.

The ventilator can be safely operated

with an adequate fresh gas flow. If

necessary repeat the compliance test in

the OPTIONS menu after having

tightened the cap nuts and correcting the

hose connections to the vaporizer and

absorber.

Rev. 1.1 – 07/07 HEYER Modular, Operator’s manual 19 / 50

Page 20

HEYER Modular

Alarm message

Cause Corrective Measures

O2 Sensor Calibration

Successful

O2 cell invalid.

Press OK to start

O2 Calibration is OK. System is ready for the FiO2

measurement.

The O2 call either has a concentration

of <21% O

, is not connected or

2

faulty.

Expose O

connection to room air with 21% O

replace.

sensor with connected cable

2

2

or

O2 concentration too

high. Expose Sensor to

room air.

The O2 call either has a concentration

of <21% O

, or is faulty.

2

Expose O

O

or replace.

2

sensor to room air with 21%

2

Press OK to start

A P N E A The system is not measuring an

expiratory volume of the patient.

Check the ventilation of the patient and

the hose connections. The initial Apnea

alarm tone can be selected between 15,

30 and 45 sec. A continuous tone

sounds after 2 min Apnea.

Breathing Circuit

Disconnection

No relevant pressure increase

measured during ventilation.

Connect ventilation hoses.

Peak pressure greater

than alarm limit

The peak pressure is higher than the

set alarm limit P

max

.

Check the tidal volume setting, check

that P

is reached, the ventilator

max

changes over to expiration and check

the P

setting.

max

Peak pressure below

alarm limit

FiO2 lower than O2 min The measured FiO2 value is lower

FiO2 greater than FiO2

alarm limit

Tidal volume lower than

V

min

t

Check Vent Dial

position.

Minute volume below

alarm limit

The peak pressure is lower than the

set alarm limit P

than the set alarm limit FiO

max

.

min.

2

The measured FiO2 value is higher

than the set alarm limit FiO

max.

2

The measured V

the set alarm limit V

value is lower than

t

min.

t

The vent dial has been in a position

that is not allowed for longer than 3

sec.

The measured minute volume value

is lower than the set alarm limit AMV

min.

Check the tidal volume and/or plateau

setting. Check the hose connections.

Verify that the O

and check the O

supply is adequate

2

alarm setting.

2

Check the fresh gas composition and the

O2 alarm setting.

Check the tidal volume setting and the

Vt alarm setting.

Turn the vent dial to a permissible

position. Select a ventilation mode and

re-start ventilation.

Check the ventilation parameters and

the AMV min alarm setting.

PEEP greater than P

The measured PEEP value is higher

min

than the set alarm limit P

min

.

Check the correct APL valve and the

P

alarm setting.

min

20 / 50 HEYER Modular, Operator’s manual Rev. 1.1 - 07/07

Page 21

HEYER Modular

Alarm message

Cause Corrective Measures

PEEP greater than

PEEP setting

Unable to attain target

pressure. Adjust flow or

I:E ratio

Set APL Valve to

CMP/SP position

The measured PEEP value is higher

than the set PEEP value.

The inspiration time is too short

and/or the drive gas flow is too low.

Reminder for the user that the APL

valve must always be in CMV/SP

position for machine-controlled

ventilation. This message appears

when the measured PEEP

value is

higher than the set PEEP value.

Ambient air intake;

Check Fresh Gas setting

Too high pressure or no

expiration.

The room air valve in the patient

module is opening.

A continuous ventilation pressure

without a significant change of the

pressure value is measured.

Invalid CMV parameters The set parameters require a drive

gas flow that cannot be achieved by

the ventilator. The AMV must not

exceed 20 l/min and the inspiratory

flow must not be higher than 75 l/min.

PCV Setting not valid. The combination of the set ventilation

parameters cannot be realized by the

ventilator.

Expiratory time too

short.

Resume Ventilation

The expiration time is not sufficient to

completely fill the bellows.

Ventilation can be resumed after

having stopped due to lack a drive

gas.

System pressurized The system is measuring too high a

pressure in the circuit.

System vented The system cannot build up any

pressure during the compliance test

or fresh gas test.

Drive Gas missing; after

standby then CMV

The compressed air supply that

drives the ventilator has failed.

Check the correct APL valve setting.

Check the settings of I:E, frequency and

drive gas flow.

Set the APL valve to CMV/SP position if

this is not already the case.

Check whether the fresh gas flow is

adequate and the patient is

spontaneously breathing.

Set the APL valve to CMV/SP position.

Check whether the set values are

correct.

Change the PCV settings.

Check the settings of I:E and ventilation

frequency.

Select a ventilation mode. Resume

ventilation.

Relieve the pressure in the system and

close the fresh gas supply.

Check whether the O2 cell and

ventilation hoses are correctly

connected. If necessary set the APL

valve to maximum position.

Check the compressed air supply.

Rev. 1.1 – 07/07 HEYER Modular, Operator’s manual 21 / 50

Page 22

HEYER Modular

Alarm message

Cause Corrective Measures

Caution! Ventilator has

stopped. Check position

of mode selector switch

AC Power lost, using

Battery

AC Power lost, using

Battery

30 min. (to 10 min)

The selector switch has been in an

impermissible position for more than

12 sec.

Mains voltage failure. Machine

running on batteries.

About 20 min battery supply

remaining.

Turn the selector switch to a permissible

position. Select a ventilation mode and

resume ventilation.

Check the mains connector. Call a

service technician if required.

Check the mains connector.

remaining

AC Power lost, using

Battery

5 min remaining

About 5 min battery supply

remaining.

Machine-controlled ventilation will end in

approx. 5 minutes. The display will

remain until the battery is fully

discharged. The patient can be manually

ventilated as long as compressed air is

available.

AC Power lost, using

Battery. Battery running

low. Use Manual

Ventilation

EEPROM – Error during

writing.

Data exchange faulty. The data exchange between the

Pressure sensor faulty. The system h as detected a fault on

Breathing system is

unlocked.

The voltage supplied by the battery is

too low for machine-controlled

ventilation. The display will go out

within a few minutes.

Data for parameters or alarm limit

settings were not correctly stored.

ventilation modules has failed.

one or both pressure sensors.

The breathing system is not correctly

adapted.

Check the mains connector. Call a

service technician if required.

Repeat function. Call a service

technician if required.

Repeat function. Restart the machine.

Call a service technician if required.

Repeat function. Restart the machine.

Call a service technician if required.

Carefully push the patient module into

the docking station and lock it.

Hotwire measurement

invalid

The hotwire did not pass the test. It

may be damaged.

Repeat function. Restart the machine.

Call a service technician if necessary.

22 / 50 HEYER Modular, Operator’s manual Rev. 1.1 - 07/07

Page 23

HEYER Modular

Alarm message

Cause Corrective Measures

System vented or drive

gas missing

The system was not able to build up

pressure.

Fault in CPU system The automatic test has detected a

fault in the processor system.

CPU monitor failure

The processor monitoring system has

detected a fault.

Expiration valve blocked The airway pressure is not being

reduced during the expiration phase.

Fault on solenoid

valve(s)

One or more solenoid valve(s)

has/have failed.

Check the bellows valve. The system has detected a pressure

increase. The control membranes

could leak and control gas could

penetrate the system.

Fault in proportional

valve

The proportional valve that regulates

the tidal volumes is not working

properly.

Pressure Reading out of

tolerance.

The system has detected a fault on

one or both pressure sensors.

Flow/Volume Readings

not available Replace

Flow Sensor –Call

Service

Flow Error: Use Manual

Ventilation Call Service

The external flow sensor that

measures the expiration volume is

faulty.

The internal flow sensor and/or the

measurement of the generated drive

gas is not working properly.

Temp Sensor readings

not available Call

The temperature sensor in the patient

module is defective.

Service

Temp Sensor out of

tolerance

The control system for the patient

module heating or the heating mat is

defective.

Check the drive gas supply and verify

that the system is closed.

Call a service technician.

Call a service technician.

Inspect the APL valve and check the

control membranes on the back of the

patient module.

Repeat the compliance test in standby

mode. If the problem still exists, please

call a service technician.

Check the control membranes.

Carry out the compliance test in the

Standby/OPTIONS menu. If this is not

successful, please call a service

technician.

Carry out the compliance test in the

Standby/OPTIONS menu. If this is not

successful, please call a service

technician.

Carry out the compliance test in the

Standby/OPTIONS menu. If this is not

successful, please call a service

technician.

Carry out the compliance test in the

Standby/OPTIONS menu. If this is not

successful, please call a service

technician.

Carry out the compliance test in the

Standby/OPTIONS menu. If this is not

successful, please call a service

technician.

Inform the service department.

Rev. 1.1 – 07/07 HEYER Modular, Operator’s manual 23 / 50

Page 24

HEYER Modular

Alarm message

Cause Corrective Measures

Fan Error Check Fan

Call Service

The fan for the ventilation of the

housing and the cooling of installed

Inform the service department.

modules is defective.

EEPROM data not

saved!

The start-up test for the internal

circuits has detected an error.

Call a service technician.

EEPROMS are defective.

System error, call a

service technician.

The ventilator has a technical defect,

machine-controlled ventilation is not

Call a service technician.

possible.

5.1.1 Alarm messages during the

compliance test

During and after the system test, alarm

messages are displayed in the lower part of

the system test window:

Fig. 10 Example of an alarm message during the compliance

test

If the system is error-locked due to a sensor

fault, only use the apparatus in an emergency

for manual ventilation and inform the technical

service department in the case of repeated

failure of the compliance test.

24 / 50 HEYER Modular, Operator’s manual Rev. 1.1 - 07/07

Page 25

HEYER Modular

Alarm messages during the compliance

test (continuation)

# Alarm message Meaning/Cause Alarm type

S1 System Resistance too high. The resistance of the patient

System alarm

hoses or the bacteriological

filters is too high.

S2 Leak rate too high. The leak rate of the patient

System alarm

module including the patient

hoses is greater than 100

ml/min.

S3 Compliance incorrect The compliance of the

System alarm

connected patient hoses is

outside the range able to be

compensated by the ventilator

of 3.0 to 9.9 ml/mbar.

S4 Error while saving. Saving of data for parameter

System alarm

and/or alarm limit setting was

faulty.

S5 Check the bellows valves. The system has detected a

System alarm

pressure increase. The

bellows valves are leaking.

S6 Pressure sensors faulty. The system has detected a

System alarm

fault on one or both of the

double pressure sensors.

S7 Flow Error: Use Manual

Ventilation Call Service

Test of internal flow sensor

indicates a defect or an

System alarm

internal mis-adjustment of the

ventilator.

S8 Flow/Volume Readings not

available Replace Flow

Sensor –Call Service

The external flow sensor has

not measured the required

flow during the test,

System alarm

calibration was not

successful. Sensor may be

faulty.

S9 Proportional valve def. The proportional valve of the

System alarm

ventilator is defective.

S10 Flow control system def. The flow control system of the

System alarm

ventilator for the breathing

volume is defective.

S11 No data exchange The data exchange between

System alarm

the modules of the ventilator

for the control and the display

representation is faulty.

S12 Fault on solenoid valve(s) One or several of the solenoid

System alarm

valves for the control of the

bellows valves in the patient

module is/are defective.

Rev. 1.1 – 07/07 HEYER Modular, Operator’s manual 25 / 50

Page 26

HEYER Modular

5.1.2

During and after the system test, alarm

messages are displayed in the lower part of

the system test window:

Alarm messages during the system

test

If the total leakage of the system exceeds 300

ml/min at 40 mbar, this message is displayed

in the bottom part of the system test window,

for example.

Fig. 11 Example of an alarm message during the

compliance test

# Alarm message Meaning/Cause Alarm type

T1 O2 cell is faulty. The O2 cell has been

correctly calibrated. Please

check O

test.

T2 System Resistance too high. The resistance of the

patient hoses or the

bacteriological filters is too

high.

T3 Leak rate greater than

300 ml/min.

T4 Compliance incorrect The compliance of the

T5 Error while saving. Saving of the data was

T6 Check the bellows valves. The system has detected a

T7 No data exchange The data exchange

The leakage test for the

fresh gas system has

detected a leakage greater

than 300 ml/min.

connected patient hoses is

outside the range able to be

compensated by the

ventilator.

faulty.

pressure increase. The

bellows valves indicate a

leak, please check.

between the modules of the

ventilator for the control and

the display representation

is faulty.

cell and repeat

2

System alarm

System alarm

System alarm

System alarm

System alarm

System alarm

System alarm

26 / 50 HEYER Modular, Operator’s manual Rev. 1.1 - 07/07

Page 27

HEYER Modular

5.1.3 Alarm messages in normal mode

During and after normal operation, alarm

messages are displayed in the lower part of

the ventilation mode window:

Tidal Volume lower than VTE

Ppeak pressure greater than alarm limit

Fig. 12 Example of an alarm message during normal mode

After each activation of CMV mode, for

example, the following alarm message appears

as a reminder to check the setting of the

ventilation pressure valve (APL) in the lower

part of the ventilator display.

Rev. 1.1 – 07/07 HEYER Modular, Operator’s manual 27 / 50

Page 28

HEYER Modular

Alarm messages in normal mode

(continuation)

# Alarm message Meaning/Cause Alarm type

B1 Fault in CPU system The self-testing routine of the

CPU system has detected a

fault in the CPU control

system.

B2 CPU monitor failure The monitoring function for

the CPU has failed.

B3 Expiration valve blocked The ventilation pressure is not

falling during expiration.

B4 Flow Error: Use Manual

Ventilation Call Service

B5 Fault in proportional valve The proportional valve for the

B6 Fault on solenoid valve(s) One or several of the solenoid

B7 Pressure sensors faulty. The system has detected a

B8 Drive gas failure The compressed air supply

B9 Ext. flow sensor faulty. The external flow sensor for

B12 A P N E A No breathing or ventilation

B13 Breathing Circuit

Disconnection

B14 PEEP greater than P

The measured PEEP value is

min

The internal flow sensor for

the measurement of the

generated breathing volume is

not working properly.

generation of the breathing

volume is not working

properly.

valves for the control of the

bellows valves in the patient

module is/are defective.

fault on one or both of the

double pressure sensors.

that generates the drive gas

for the ventilator has failed.

expiratory volume

measurement in the patient

module is defective.

activity has been detected via

the expiratory volume

measurement.

No adequate pressure

increase measured during

ventilation.

higher than the set pressure

limit P

min

.

System alarm

System alarm

System alarm

System alarm

System alarm

System alarm

System alarm

System alarm

System alarm

Alarm for patient monitoring

Alarm for patient monitoring

Alarm for patient monitoring

28 / 50 HEYER Modular, Operator’s manual Rev. 1.1 - 07/07

Page 29

HEYER Modular

# Alarm message Meaning/Cause Alarm type

B15 FiO2 lower than FiO2 min The measured FiO2 value is lower

than the set minimum oxygen

B16 Tidal volume lower than Vt

min

B17 Peak pressure greater than

alarm limit

B18 Peak pressure below alarm

limit

B19 Minute volume below alarm

limit

B20 FiO2 greater than FiO2 alarm

limit

concentration limit FiO

The measured tidal volume Vt value

is lower than the set limit for V

The peak pressure P

than the set pressure limit P

The peak pressure P

the set pressure limit P

The breathing minute volume AMV is

lower than the set limit AMV min.

The measured FiO2 value is higher

than the set minimum oxygen

concentration limit FiO

min.

2

is higher

peak

max

is lower than

peak

.

min

max.

2

min.

t

.

B21 PEEP exceeded The measured PEEP value is higher

than the pre-set value.

B22 Temperature sensor defective The temperature sensor in the

Alarm for patient

monitoring

Alarm for patient

monitoring

Alarm for patient

monitoring

Alarm for patient

monitoring

Alarm for patient

monitoring

Alarm for patient

monitoring

Alarm for patient

monitoring

System alarm

patient module is defective.

B23 Fault on patient module

heating

The control system for the patient

module heating or the heating mat is

System alarm

defective.

B24 Fan failure The fan for the ventilation of the

System alarm

housing and the cooling of installed

modules is defective.

B25 AC Power lost, using Battery The mains voltage supply has failed,

System alarm

the apparatus is running on power

supply form the installed battery.

B26 Too high pressure or no

expiration

A continuous ventilation pressure

without a significant change of the

System alarm

pressure value is measured.

B27 Power supply failure The power supply from the battery is

System alarm

no longer given and will fail shortly.

B28 Ambient air intake; Check

Fresh Gas setting

The emergency valve in the patient

module is opening, please check the

System alarm

fresh gas setting and increase the

fresh gas flow if necessary.

Rev. 1.1 – 07/07 HEYER Modular, Operator’s manual 29 / 50

Page 30

HEYER Modular

# Alarm message Meaning/Cause Alarm type

B30 Set APL Valve to CMP/SP

position

Reminder that the ventilation

pressure valve (APL) must

System alarm

also be switched to CMV/SP

position after activating CMV

mode.

B31 f min not reached The measured breathing

Alarm for patient monitoring

frequency f falls below the set

limit for f min.

B32 f max exceeded The measured breathing

Alarm for patient monitoring

frequency f exceeds the set

limit for f max.

B33 Invalid CMV parameters The set parameters for

System alarm

ventilation in CMV mode give

an inspiratory flow that can no

longer be achieved by the

machine. A minute volume of

> 20 L/min, and/or an

inspiratory flow of > 80 L/min

are considered as the limit

values here.

B57 P

lower than selected

peak

plateau

The peak pressure P

peak

achieved in PC mode does

Patient alarm

not reach the set plateau

pressure.

Check the PCV parameters

and increase the set

inspiratory flow if necessary.

B58 PCV set values not possible The inspiratory flow set in

Patient alarm

PCV mode cannot be

generated in combination with

the parameters for frequency

and I/E ratio. Please check

the parameter settings.

B59 Expiratory time too short. The remaining expiratory time

Patient alarm

in PCV mode to too short with

the set parameters. Check the

parameter settings for

frequency and I/E ratio.

30 / 50 HEYER Modular, Operator’s manual Rev. 1.1 - 07/07

Page 31

HEYER Modular

5.1.4 Alarm message “Technical fault”

# Alarm message Meaning/Cause Alarm type

H01 Technical fault The ventilator indicates a

System alarm

serious technical fault and

stops machine-controlled

ventilation in CMV mode.

This alarm is not displayed in the other used

alarm windows of the various displays. This

fault is displayed in a window of its own due to

its exceptionally high priority level.

Fig. 13 Alarm message “Technical fault”

5.2 Test of alarm functions

APNEA: Please switch the selector switch for

ventilation mode to Manual/Spontaneous

position and wait for 30 seconds without

carrying out any ventilation action. After this

time the alarm message “APNEA“ must appear

on the screen.

P>P

: Please switch the selector switch for

max

ventilation mode to CMV position. Connect the

apparatus to a test lung and sect the

ventilation parameters and alarm settings such

that the airway pressure will reach the upper

alarm limits. Make sure that the inspiration

phase is no active and check the alarm

message ”P greater than P

after 3 ventilation cycles.

FiO2>O2

: Expose the O2 measuring cell to

min

the ambient air and select a O

“ on the screen

max

-min value

2

higher than 25%. After 3 ventilation cycles the

alarm message “FiO

2>O2 min

“ must appear on

the screen.

Rev. 1.1 – 07/07 HEYER Modular, Operator’s manual 31 / 50

Page 32

HEYER Modular

6 Start-up and Functional Test

6.1 Preparing for operation

1. Install the apparatus in such a way that the

operating panel at the font of the apparatus

is within easy reach and the flow measuring

tubes can be easily read.

2. When the apparatus has been installed in

the correct position, engage the brakes on

the front rollers to prevent accidental

movement.

3. Connect the gas connection lines to the gas

connections near the rear of the unit. Check

that the pressure of the gas supply

complies with the specifications of the

apparatus. Connect the gas supply by

plugging the connectors into the gas supply

sockets. Ensure that the connectors are not

in the park position.

4. Plug the mains cable into a grounded

socket. Switch on the power supply using

the mains switch at the rear side of the

apparatus.

5. Wait until the ventilator display requests the

compliance test. If the patient module

should not yet be connected to the

apparatus, remove the transportation cover

if necessary and push the patient module

into the mount. After pushing in the patient

module as far as it will go, lock it in by

turning the lever on the underside of the

swivel mechanism.

6. Next equip the patient module with the

”Bag-In-Bottle” system, consisting of the

bellows and the patient dome. Attach the

CO

absorber. Connect the set of hoses for

2

the anesthesia gas scavenging to the outlet

of the overflow/ventilation pressure valve.

Create the connection to the anesthetic gas

suction unit.

7. Connect the manual ventilation bag to the

corresponding hose on the patient module.

Connect the patient hose set to the

inspiratory and expiratory connections.

2. Start the compliance test on the apparatus.

Follow the instructions on the ventilator

display.

3. Carry out the leak test and the O2

calibration. Instructions on these

procedures also appear on the ventilator

display.

4. Ensure that a suitable independent device

for manual ventilation (e.g. ambulatory bag)

is available at or near the apparatus.

5. If required, start the additional monitoring

for CO

and anesthesia gases and if

2

available for the ECG and check their

function according to the respective

operating instructions. The gas return line

from monitors operating according to the

sidestream procedure should be connected

to the connection at the rear side labeled

measuring gas return.

6.2 Pre-operative tests

The tests and examinations described below

must be carried out before each system start.

They are also listed on the check list on the

apparatus.

1. Install and lock the vaporizers to be used

on the device.

32 / 50 HEYER Modular, Operator’s manual Rev. 1.1 - 07/07

Page 33

HEYER Modular

6.2.1 Compliance test

When the automatic self-test of the system has

been completed, the following display appears

for the performance of the compliance test.

details on the determined system compliance

and leakage of the patient module.

Fig. 14 Display before the compliance test

Follow the instructions on the ventilator display

and activate by pressing the OK button on the

touch screen display.

The system now checks and calibrates all

sensors such as e.g. the expiratory flow sensor

and the pressure sensors. Also the internal

sensors of the ventilator drive and the active

components such as pneumatics control

valves are checked during the compliance test.

The patient module, patient connection hoses,

the Y-piece etc. are also tested for leaks.

Furthermore the system compliance to which