Page 1

HEYER Modular

+

Anesthesia System

Service Manual

Rev.2.1.0

Software version Service software: 1.8

Page 2

Table of Contents

HEYER MEDICAL AG

Carl-Heyer-Strasse 1-3

56130 Bad Ems

Germany

Tel. +49 - 2603 – 791 - 3

Fax. +49 - 2603 – 791 - 209

E-mail: info@heyermedical.de

2

Page 3

Theory of Operation

0 Table of Contents

0 Table of Contents............................................................................................................................. 3

0.1 Table of Figures ........................................................................................................................6

1 General Information..........................................................................................................................7

1.1 Guidelines .................................................................................................................................7

1.2 Product improvements ..............................................................................................................7

1.3 Manufacturer’s Liability .............................................................................................................7

1.4 Manufacturer’s specification ..................................................................................................... 8

1.5 Updating status .........................................................................................................................8

1.6 Warning, Precautions and Notes ..............................................................................................9

1.6.1 Warnings............................................................................................................................ 9

1.6.2 Precautions......................................................................................................................10

1.6.3 Notes................................................................................................................................11

2 Theory of Operation .......................................................................................................................13

2.1 Microprocessor-Controlled Ventilator...................................................................................... 13

2.2 Patient Module ........................................................................................................................13

2.3 Gas Conditioning Unit .............................................................................................................13

2.4 The Ventilator Unit ..................................................................................................................13

2.5 Adjustable Alarms ...................................................................................................................13

2.5.1 P

2.6 Fresh Gas Decoupling ............................................................................................................14

2.7 Compliance compensation...................................................................................................... 14

2.8 Electrical supply ......................................................................................................................15

2.8.1 Electrical components...................................................................................................... 16

2.9 Power supply module.............................................................................................................. 17

2.9.1 Connectors on power supply board AVM 2-1.................................................................. 18

2.9.2 Fuses on power supply board AVM 2-1........................................................................... 19

2.9.3 Charging / discharging control for the battery:.................................................................20

2.9.4 Status Indicators Of Battery Control:...............................................................................20

2.10

2.10.1

2.11

2.11.1

2.11.2

2.11.2.1 Plug connectors on board AVM 3-1 ........................................................................ 24

2.11.2.2 Plug connectors on board AVM3-2 ......................................................................... 25

2.12

2.13

2.14

2.14.1

2.14.2

2.14.3

2.14.4

2.14.5

2.14.6

2.14.7

2.15

2.15.1

2.15.2

2.15.3

2.15.3.1 CMV mode, inspiration............................................................................................32

2.15.3.2 CMV mode, expiration.............................................................................................33

2.15.3.3 Manual mode, inspiration ........................................................................................34

2.15.3.4 Manual mode, expiration.........................................................................................35

2.15.3.5 Spontaneous mode, inspiration...............................................................................36

2.15.3.6 Spontaneous mode, expiration................................................................................ 37

2.15.4

2.15.4.1 Ventilation bellows system ......................................................................................38

2.15.4.2 Manual Respiration Bag / Reservoir........................................................................ 38

2.15.4.3 CO2 absorber...........................................................................................................38

limiting on alarm violation......................................................................................... 14

max

Module 1.............................................................................................................................. 21

Connectors on module 1..............................................................................................22

Ventilator Module 2, AVM 3-1 and AVM 3-2.......................................................................23

Parts list module 2........................................................................................................ 24

Connectors on module 2..............................................................................................24

Display................................................................................................................................. 25

Battery .................................................................................................................................25

Ventilator pneumatic............................................................................................................ 26

Ventilator pneumatic drive............................................................................................ 27

HP pressure reducer....................................................................................................27

LP- double stage pressure reducer..............................................................................27

Solenoid valves MV1 to MV4 .......................................................................................27

Pneumatic driving module............................................................................................28

Flow metering module..................................................................................................28

Tube color coding......................................................................................................... 28

The patient module (circle system).....................................................................................29

Front and back side view on the patient module..........................................................29

Bottom and back side view on the patient module.......................................................30

Functional representations of the patient module........................................................31

Components of the patient module..............................................................................38

Page 4

Theory of Operation

2.15.4.4 Inspiratory and expiratory valves............................................................................. 38

2.15.4.5 Airway pressure relief valve .................................................................................... 38

2.15.4.6 Room Air valve........................................................................................................38

2.15.4.7 Diaphragm valves.................................................................................................... 38

2.15.2.7.1 Status of the diaphragm valves:....................................................................... 39

2.15.2.7.2 Machine OFF Or Ventilator In Standby............................................................39

2.15.2.7.3 Manual / Spontaneous Mode, INSPIRATION And EXPIRATION....................39

2.15.2.7.4 CMV Child / Adult Mode, INSPIRATION.......................................................... 39

2.15.2.7.5 CMV Child / Adult, EXPIRATION.....................................................................39

2.15.2.7.6 CMV Adult, EXPIRATION And PEEP.............................................................. 39

2.15.2.7.7 Compliance Test Patient Module .....................................................................40

2.15.2.7.8 Leak Test Patient Module and Fresh Gas Module........................................... 40

3 Repair Information.......................................................................................................................... 41

3.1 Introduction .............................................................................................................................41

3.2 Warnings and precautions ......................................................................................................41

3.2.1 Precautions......................................................................................................................41

3.2.2 Warnings.......................................................................................................................... 41

3.3 Troubleshooting Guidelines ....................................................................................................42

3.4 Troubleshooting Charts........................................................................................................... 42

3.4.1 Error Messages during ventilation...................................................................................42

3.4.2 Alarm messages during the compliance test, leak test and O2 calibration..................... 46

3.4.2.1

3.4.3 Symptoms of Fuse Failures.............................................................................................49

3.5 Required Tools........................................................................................................................ 50

3.6 Disassembly instructions.........................................................................................................50

3.6.1 Connecting and disconnecting vaporizers....................................................................... 50

3.6.2 Removing the compressed gas tanks (PIN-Index)..........................................................50

3.6.3 Removing the Patient Module.......................................................................................... 51

3.6.4 Removing the CO2 Absorber Canister.............................................................................51

3.6.5 Removing the Bellows and Dome System ......................................................................51

3.6.6 Removing the Airway Pressure Limiting Valve (APL)......................................................51

3.6.7 Inspecting/replacing the Decoupling, Bellow and Expiratory Valves...............................52

3.6.8 Disassembling the Room Air, Inspiration and expiration valves...................................... 52

3.6.9 Removing the Gas Block Module....................................................................................52

3.6.10

3.6.11

3.6.12

3.6.13

3.6.14

3.6.15

4 Maintenance and Calibration ......................................................................................................... 55

4.1 Introduction .............................................................................................................................55

4.2 Calibration Warnings and Precautions.................................................................................... 55

4.3 Test Procedure........................................................................................................................56

4.3.1 General ............................................................................................................................56

4.3.2 Inspecting/replacing consumable parts...........................................................................56

4.3.3 Power supply checks.......................................................................................................61

4.3.4 Functional Tests...............................................................................................................62

4.3.4.1

4.3.4.2

4.3.4.3

4.4 Service Software.....................................................................................................................66

4.5 Key code Access.....................................................................................................................67

4.6 Navigation ...............................................................................................................................68

4.6.1 System Testing................................................................................................................70

4.6.2 Coefficient programming.................................................................................................. 79

4.6.2.1

4.6.2.2

4.6.2.3

4.6.2.4

4.6.2.5

4.6.2.6

Messages during the system tests...........................................................................47

Removing the flow tubes..............................................................................................52

Removing the pressure gauges ...................................................................................53

Removing the Module 2 Circuit Board Set................................................................... 53

Removing Module1 Circuit Board Set..........................................................................53

Removing the Power Supply Module........................................................................... 53

Removing Internal Regulators, Proportional Valve and Flow Divider.......................... 54

Pneumatic tests........................................................................................................62

Alarm Tests...............................................................................................................63

Electrical Tests ......................................................................................................... 65

O2 sensor calibration ................................................................................................79

P1 Pressure sensor calibration................................................................................. 81

P2 Pressure sensor calibration................................................................................. 83

Temperature Sensor Calibration ..............................................................................85

Proportional Valve Calibration..................................................................................87

Internal Flow Sensor Calibration ..............................................................................92

4

Page 5

Theory of Operation

4.6.2.7

4.6.2.8

5 Preventive Maintenance................................................................................................................. 99

5.1 6 Month Service Interval .........................................................................................................99

5.2 12 Month Service Interval .....................................................................................................100

5.3 36 Month Service Interval .....................................................................................................100

5.4 Cleaning................................................................................................................................ 101

5.4.1 Cleaning and disinfecting the apparatus .......................................................................101

5.4.2 Cleaning and sterilizing the Patient Module ..................................................................101

5.5 Battery Replacement and Maintenance................................................................................ 101

5.5.1 Battery replacement....................................................................................................... 101

5.5.2 Battery Maintenance......................................................................................................101

6 Order Information .........................................................................................................................103

Characteristic of the Proportional Valve...................................................................94

External Flow Sensor Calibration ............................................................................. 96

5

Page 6

Theory of Operation

0.1 Table of Figures

Fig. 1 Line Terminal Block, 120/230VAC Supply .................................................................................15

Fig. 2 Overview electrical components.................................................................................................16

Fig. 3 Power supply module .................................................................................................................17

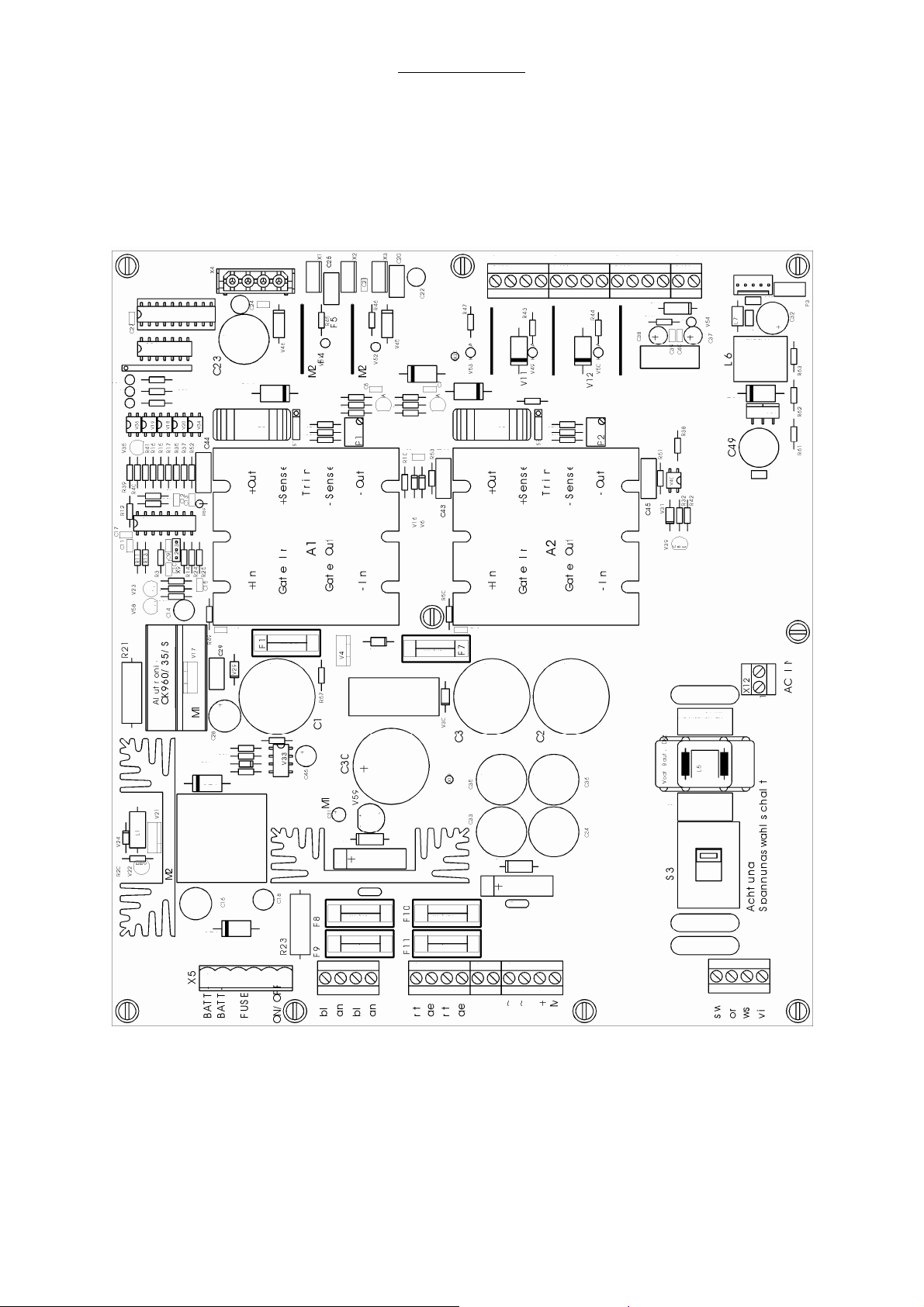

Fig. 4 Module 1 PC board..................................................................................................................... 21

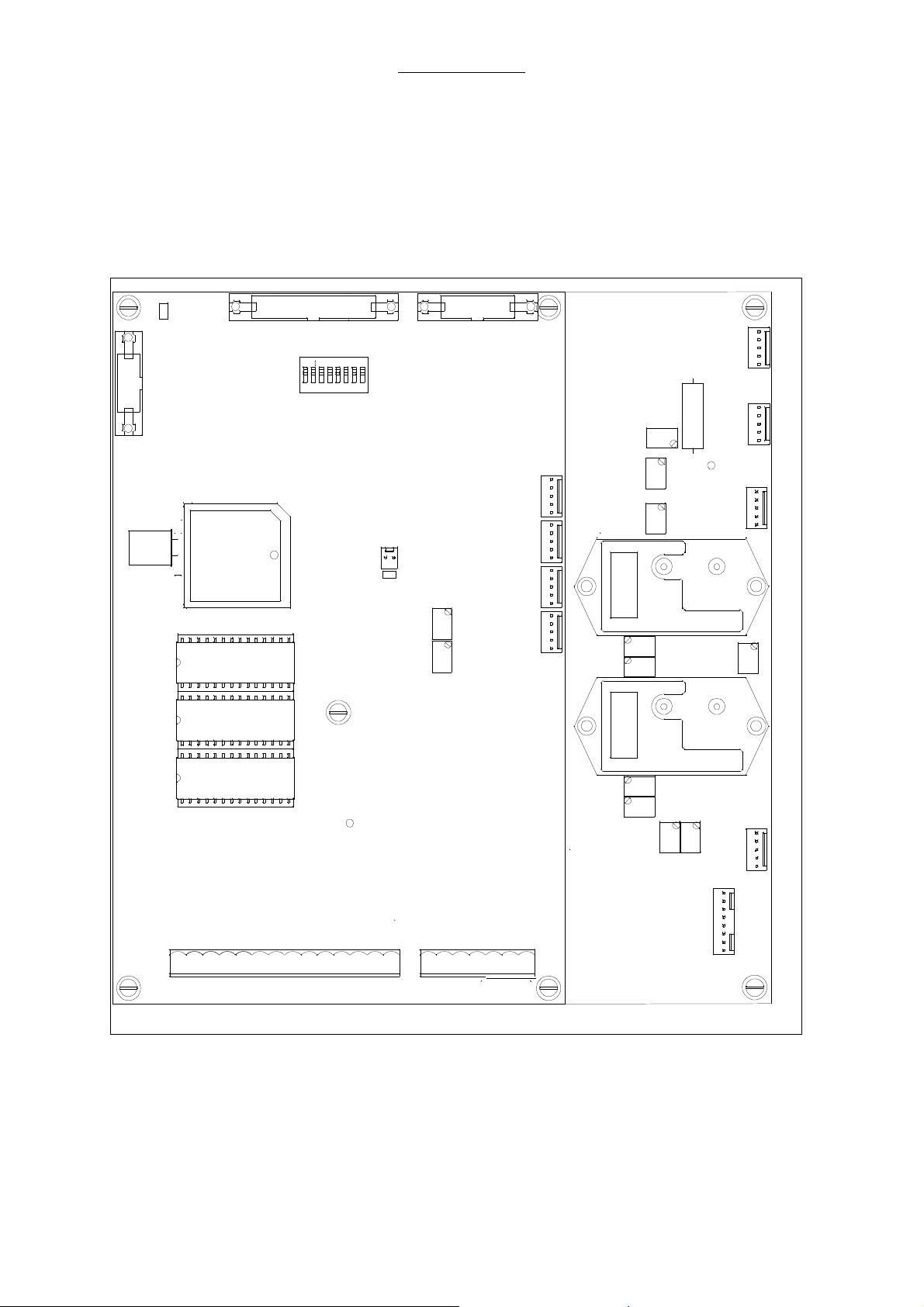

Fig. 5 View on module 2....................................................................................................................... 23

Fig. 6 Ventilator pneumatic...................................................................................................................26

Fig. 7 Top and backside view on the patient module........................................................................... 29

Fig. 8 Bottom and backside view on the patient module......................................................................30

Fig. 9 Survey of the patient module......................................................................................................31

Fig. 10 Survey of the patient module, CMV mode, inspiration............................................................. 32

Fig. 11 Survey of the patient module, CMV mode, expiration..............................................................33

Fig. 12 Survey of the patient module, Manual mode, inspiration......................................................... 34

Fig. 13 Survey of the patient module, Manual mode, expiration.......................................................... 35

Fig. 14 Survey of the patient module, Spontaneous mode, inspiration................................................36

Fig. 15 Survey of the patient module, Spontaneous mode, expiration ................................................ 37

Fig. 16 Patient module, front view........................................................................................................57

Fig. 17 Patient module, top view ..........................................................................................................58

Fig. 18 Supply inlet filters and water traps ........................................................................................... 59

Fig. 19 Power Supply Board.................................................................................................................61

Fig. 20 Alarm screen ............................................................................................................................63

Fig. 21 O2 Whistle adjustment (appearance may differ due to different configuration options).......... 64

Fig. 22 Initialization screen................................................................................................................... 66

Fig. 23 Key code entry screen..............................................................................................................67

Fig. 24 Main menu screen.................................................................................................................... 68

Fig. 25 Test menu screen.....................................................................................................................69

Fig. 26 Patient Module, motor control screen.......................................................................................70

Fig. 27 Docking station, Start/ Stop switches.......................................................................................71

Fig. 28 Pressure, O2 and Temperature screen ....................................................................................72

Fig. 29 Proportional valve test screen..................................................................................................75

Fig. 30 Drive Gas Outlet....................................................................................................................... 75

Fig. 31 Solenoid Valves MV-1 MV-4 test screen.................................................................................. 76

Fig. 32 Docking Station valve connectors ............................................................................................77

Fig. 33 Power and Heater Control screen............................................................................................78

Fig. 34 O2 Calibration screen ...............................................................................................................79

Fig. 35 P1 Calibration screen ...............................................................................................................81

Fig. 36 P2 Calibration screen ...............................................................................................................83

Fig. 37 Temperature Sensor screen.....................................................................................................85

Fig. 38 Proportional Valve Calibration screen......................................................................................88

Fig. 39 Docking Station, drive gas outlet.............................................................................................. 88

Fig. 40 Pressure Regulator for the Driving Gas with Test Port............................................................ 89

Fig. 41 Adjustment Screw on top of the Flow Divider ..........................................................................91

Fig. 42 Internal Flow Sensor Calibration Screen.................................................................................. 92

Fig. 43 Characteristic of the Proportional Valve screen....................................................................... 94

Fig. 44 External Flow Sensor Calibration screen................................................................................. 96

Fig. 45 How to measure the voltages U1 and U2.................................................................................98

6

Page 7

Theory of Operation

1 General Information

1.1 Guidelines

The information in this service manual exclusively refers to servicing and maintenance work of the

anesthesia system HEYER Modular+.

Please, read from the operator’s manual HEYER Modular+ the service, setting, maintenance and care

of the apparatus, normally carried out by the user.

These service instructions are to be used only by a skilled, trained and authorized service staff. The

servicemen must be provided with the specified special tools and accessories. This service manual is

utilized for business affairs and general customized information. HEYER gives no guarantee when

using the information.

The service technicians should have read and fully understood the service instructions prior to

beginning with their service duties. The functional principles of the apparatuses have also been

described in the user’s manual. The user’s manual contains general precautions, which are also of

importance to the service technician.

1.2 Product improvements

HEYER reserves the right to improve their products or revise the instructions without prior notice. This

manual deals with the status of the anesthesia system HEYER Modular+ at the time of issue.

HEYER is not obliged to retrofit former models subject to improvements and modifications. An

exception to be examined will be made when improvements or modifications due to design and

production deviations are influencing the patient’s safety or would entail malfunctioning of the

apparatus.

1.3 Manufacturer’s Liability

HEYER can only be held liable for safety, reliability and fail-safe operation of the system, provided

that:

− the system was being operated in conformity with the instructions given by the manufacturer,

− certifications, readjustments, changes, or repairs have been carried out by authorized

personal,

− service and maintenance was being made in conformity with the instructions given by the

manufacturer.

− the system was operated in a building with grounding equipment in compliance with the

regulations issued by IEC, NFPA, and UL.

In no event will HEYER be liable for any special, incidental, or consequential damages, including loss

of profits, whether or not foreseeable and even HEYER has been advised of the possibility of such

loss or damage.

HEYER disclaims any liability arising from a combination of its product with products from other

manufacturers if the combination has not been endorsed by HEYER.

Buyer understands that the remedies noted in HEYER's limited warranty are its sole and exclusive

remedies.

Page 8

Theory of Operation

1.4 Manufacturer’s specification

+

Product: HEYER MODULAR

Manufacturer:

Heyer Medical AG

Carl-Heyer-Strasse 1-3

56130 Bad Ems

Germany

Tel. + 49 2603 / 791-3

Fax. +49 2603 / 791-209

E-mail: info@heyermedical.de

1.5 Updating status

State of this service manual: Rev. 2.1.0 of February 2004

8

Page 9

Theory of Operation

1.6 Warning, Precautions and Notes

Warnings alert the user to potential serious outcomes (death, injury or serious adverse events) to the

patient or user.

Precautions alert the reader to exercise special care necessary for the safe and effective use of the

device

Notes are a general information statement concerning the Modular+

Please read adhere to all warning, precautions and notes listed here and in the appropriate areas

throughout this manual.

1.6.1 Warnings

Warning: The Modular+ anesthesia machine works on line voltage and at high pressure.

Therefore, an electric shock hazard may exist when the instrument covers are

removed. Repair and calibration procedures should only be performed by

qualified personnel who follow proper servicing techniques. Warnings are given

in appropriate locations

Warning: In order to prevent an electrical shock, the machine (protection class I) may only

be connected to a correctly grounded mains connection (socket outlet with

grounding contact).

Warning: Possible explosion hazard. Do not operate near flammable substances.

Warning: The use of anti-static or electrically conductive breathing tubes, when utilizing

high frequency electric surgery equipment, may cause burns and is therefore

not recommended in any application of this machine.

Warning: Possible fire hazard. Fuses (i.e., additional sockets) must only be replaced by

fuses of the same type and with the same rating.

Warning: Possible shock hazard. The machine may only be opened by qualified and

authorized service personnel.

Warning: Compressed gasses are considered Dangerous Goods/hazardous Materials per

I.A.T.A. regulations. It is a violation of international law to offer any package or

over pack of dangerous goods for transportation without the package being

appropriately identified, packed, marked, classified, labeled and documented

according to I.A.T.A. regulations. Please refer to the applicable I.A.T.A

Dangerous Goods Regulations for further information.

Warning: Never block airflow at the drive gas outlet. Blocking the drive gas outlet raises

internal pressures above specified limits and will result in permanent damage to

internal sensors.

9

Page 10

Theory of Operation

1.6.2 Precautions

Caution: Refer to the maintenance intervals in the Preventive Maintenance section for

guidance on which steps are preformed when.

Caution: Use surgical gloves whenever touching or disassembling valves or other

internal components of the Patient Module.

Caution: If possible, always connect the output of the APL valve to the anesthetic

removal line, usually installed in the operation theater.

Caution: Carry out the daily checks specified on the checklist and do not operate the

system in case of a fault until the fault has been repaired.

Caution: The patient should be visually monitored by qualified personnel. In certain

situations circumstances may occur which may not necessarily trigger an

alarm.

Caution: Always set the alarm limits so that the alarm is triggered before a hazardous

situation occurs. Incorrectly set alarm limits may result in operation personnel

not being aware of changes in the patient’s condition.

Caution: This machine must only be operated by trained, skilled medical staff.

Caution: Before starting the machine, the operating personnel must be familiar with

operating instructions and must have been instructed by a qualified instructor.

Caution: If the machine does not function as described, the machine must be examined

and possibly repaired by qualified service personnel, before being returned to

use.

Caution: Handle the machine with care to prevent damage or functional faults.

Caution: Ensure that the gas supply of the machine always complies with the technical

specification.

Caution: Before clinical use, the machine must be correctly calibrated and/or the

respective machine tests performed, as described in the operation instructions.

Caution: If the machine should show faults during the initial calibration or testing, the

machine should not be operated until the fault has been repaired by a qualified

service technician.

Caution: After servicing, functional, sensor and system tests must be carried out before

clinical use.

Caution: Only bacteria filters with a low flow resistance must be connected to the patient

module and/or patient connector.

Caution: Failure to connect device to a grounded mains outlet may elevate leakage

current in excess of permissible values.

Caution: During transportation of the patient module, transportation should be applied to

the rear to protect the valve connectors.

Caution: After changing the CO2 absorbent, carry out a system leak test.

Caution: The spring in the top of the APL valve may not be stressed. After removal, place

to one side, taking care that the spring is not unduly loaded.

10

Page 11

Theory of Operation

Caution: Only Selectatec™ compatible vaporizers with interlock system may be used

with the Modular+ unit.

Caution: After each exchange of a vaporizer, carry out a system leak test.

Caution: Use cleaning agent sparingly. Excess fluid could enter the machine causing

damage.

Caution: The patient dome of the bellows system cannot be autoclaved. It is not in

contact with the ventilation gas. If soiled, the patient dome should be cleaned

with water and liquid cleaning agent. The unit can be disinfected with a standard

surface-disinfecting agent. Do not use alcohol.

Caution: Do not clean the machine while it is on and/or plugged in.

Caution: Pressing Quit at any time during the calibration procedure will cancel the

session’s settings and reload the previously stored calibration coefficients.

1.6.3 Notes

Note: Unauthorized servicing may void the remainder of the warranty. Check with the

factory or with a local authorized HEYER dealer to determine the warranty status

of a particular instrument.

11

Page 12

Theory of Operation

This page intentionally left blank

12

Page 13

Repair Information

2 Theory of Operation

The anesthesia system HEYER MODULAR+ represents a flexible employable workstation to apply

and monitor anesthesia inhalation in semi-closed and almost closed circuits in low flow techniques for

minimized consumption of gas and anesthetics.

The basic model Modular+ includes the following components:

2.1 Microprocessor-Controlled Ventilator

The Microprocessor-controlled ventilator allows with its dedicated patient module time-controlled,

pressure limited, and a constant volume controlled ventilation for all patient groups of a body weight of

3 kg upwards.

The system compliance of the patient module and respiratory tubes are automatically compensated by

the ventilator. Low tidal volumes, therefore, can be dosed very accurately.

Thanks to the different ventilation modes, a ventilation is feasible, even in case of complicated lung

conditions.

A comprehensive test and alarm management system prevents uncontrollable operating conditions

and therefore provides the patient a high safety standard.

The ergonomically designed control surface allows an easy operation of the ventilator. The display

informs about the selected ventilation parameters and the measured values for volume, pressure, FiO2

and shows real time curves of the expiratory flow and airway pressure.

2.2 Patient Module

The patient circuit is integrated in a compact aluminum block. This block is brought to a moderate

temperature to avoid the formation of water vapor. In additional, it includes a controlled emergency

valve, a reservoir in form of a manual respiratory bag and an expiratory flow sensor.

The patient module is automatically connected to the basic unit through a motor drive. A threaded

shaft pulls the block toward the basic unit, and all connections to the docking block are checked in the

compliance- and leak tests.

2.3 Gas Conditioning Unit

The flow meter block features all the necessary safety facilities, such as O2 pressure loss alarm and

N2O shut-off. An integrated pneumatically controlled system provides a minimum of 25% oxygen

concentration in the fresh gas flow at all flow settings (ratio system).

2.4 The Ventilator Unit

The microprocessor-controlled ventilator allows time-controlled, volume-constant and pressure-limited

(CMV) or pressure targeted (PCV) artificial respiration without assisted or synchronized control

functions. The system also allows manual respiration as well as spontaneous respiration of the patient.

Adjustable PEEP, breathing time ratios (I:E) and pressure sustaining plateau functions are available.

Volume-constant respiration is effected by the time control of the respirator and the fresh gas

decoupling of the patient module. The ventilator computes the inspiratory flow required for the settings

tidal volume (VT), respiratory rate and the ventilation time ratio (I:E). The resultant tidal volume (VT) is

delivered to the patient at high accuracy

2.5 Adjustable Alarms

Minimum and maximum alarm limit settings are available for Peak Pressure, Mean Pressure and FiO2

minimum alarm settings are available for tidal volume and minute volume.

Page 14

Repair Information

2.5.1 P

limiting on alarm violation

max

Exceeding the P

from exceeding the high alarm setting. In the CMV mode, the setting of the P

alarm limit automatically halts the inspiratory phase preventing airway pressure

max

peak pressure

max

provides pressure limitation. When reaching this pressure limit, a warning (alarm) “Peak greater than

P

” is displayed, and the inspiration is discontinued. The next inspiration is at a regular time interval,

max

the time control of the respiratory unit does not increase the respiratory rate. The result is a decrease

of the tidal volume “VT” and minute volume “M Vol.”. The respirator responses to pressure limitation

through displaying the P

alarm constantly.

max

2.6 Fresh Gas Decoupling

The tidal volume (VT) is adjusted independently of the adjusted fresh gas flow. This is achieved by

fresh gas decoupling. In inspiratory procedure the fresh gas flow is uncoupled by the decoupling and

expiratory diaphragm valves from the internal subsystem of the patient module. Fresh gas either is

filling the manual respiration bag (reservoir) or is led into the scavenging through the airway pressure

relief valve.

2.7 Compliance compensation

The tidal volume (VT) is automatically corrected in response to the compliance of the patient module

and patient tubes. Volume reduction due to system compliance is compensated as a result of this.

14

Page 15

Repair Information

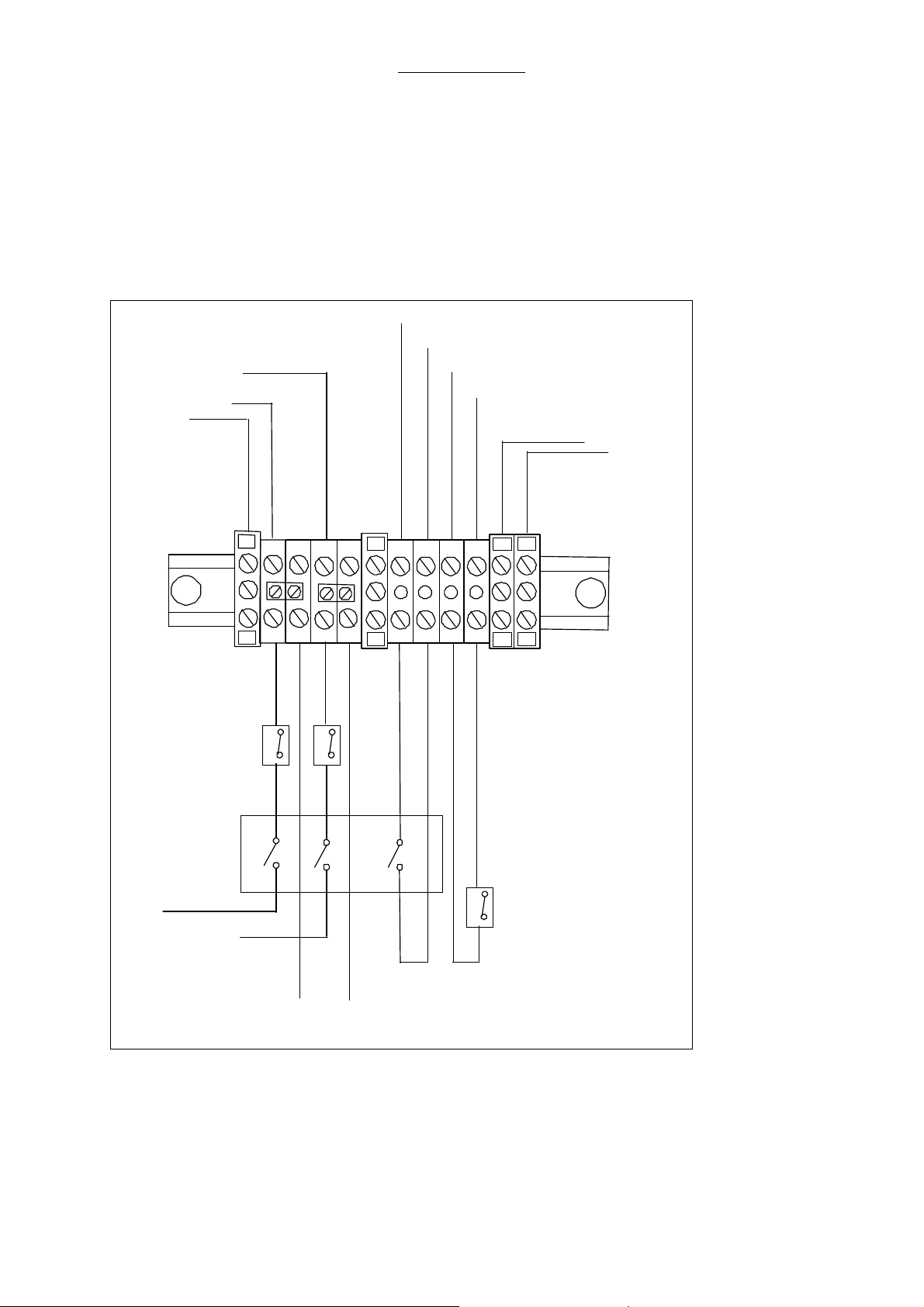

receptacles

2.8 Electrical supply

The line cord of the Modular+ is connected to an internal terminal block. Directly connected to this

terminal are convenience receptacles and the unit itself. Line supply to the receptacles is available

with the line cord connected. Line supply for the unit is switched by the main switch at the right side of

the unit. The two pole switched power supply is protected by each one 5A circuit breaker. The

switched line supply is connected to the AC IN connector on power supply board AVM 2-1. Another

third pole of the main switch is connected via the terminal to the board AVM 2-1 (X5:5,6), enabling to

detect a main switch OFF position or missing line supply.

Line cord

N 120/230 V

L 120/230 V

X5 pin 6

PE

X5 pin 5

X5 pin 4

X5 pin 3

power supply board

int. ground

wiring

Circuit breakers

ventilator

Main switch

Power

supply board

5 A

1

8

1 1

1

1

2

2

2

2

2

3

4

7

3

3 4

4

5

6

6

5

Circuit breaker

5 A

battery

Convenience

Fig. 1 Line Terminal Block, 120/230VAC Supply

The 120 V configuration has

additional circuit breakers

15

Page 16

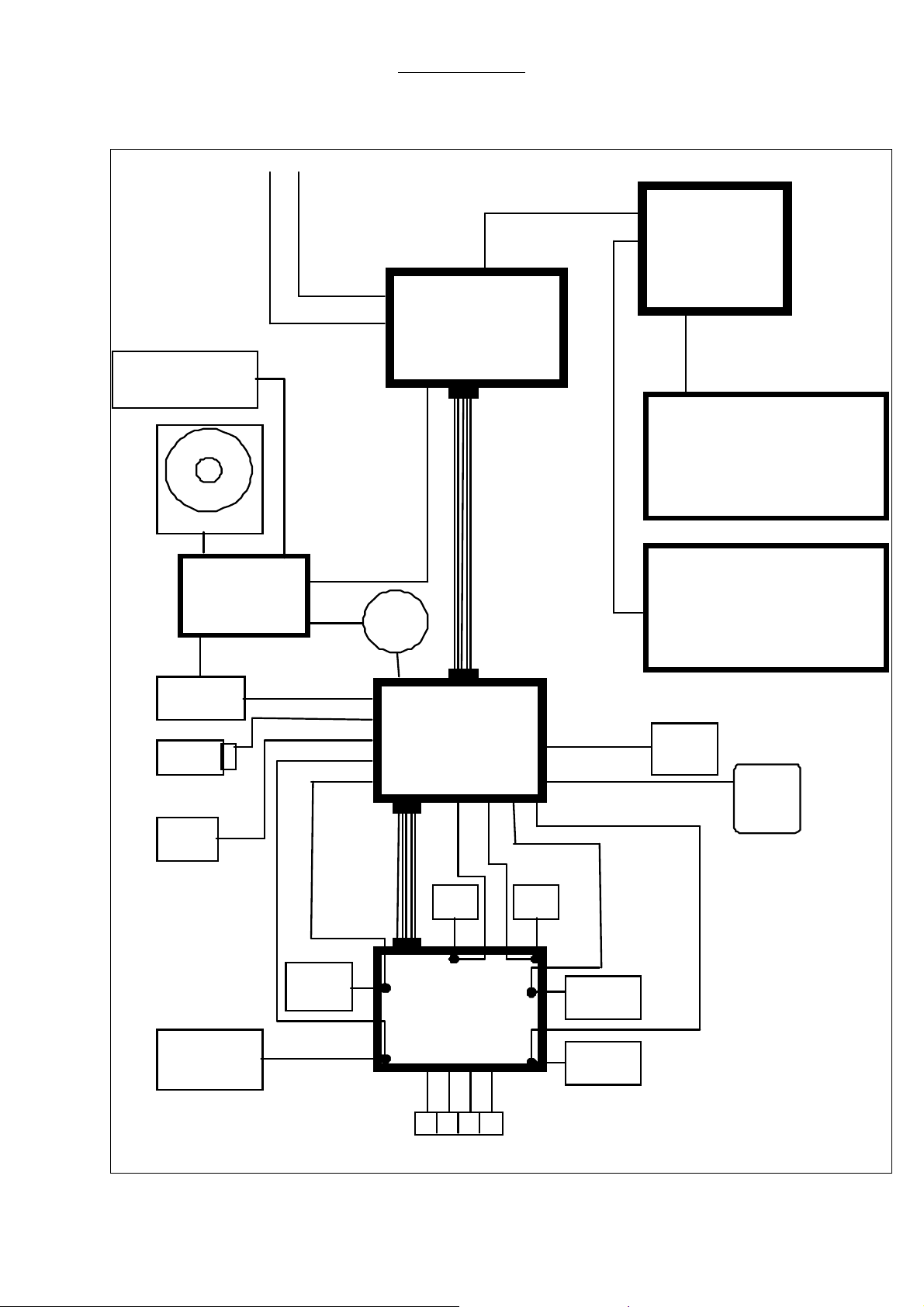

2.8.1 Electrical components

RS 232

interface

Option 1

RS 232

interface

Option 2

Repair Information

RS 232

interface

module 1

flow meter

backlight

transformer

battery

motor

power supply

module 1

Communication

RS 232

interface

Display

Controller

module 1

Display

module 1

main

switch

module 2

AVM 3-1

Supervisor

Touch Screen

PT 100

heat

blanket

I²C

fan

oxygen

sensor

proportional

valve

Fig. 2 Overview electrical components

interface

P2

module 2

AVM 3-2

Ventilation

solenoid valve

P1

ext. flow

sensor

int. flow

sensor

16

Page 17

Repair Information

2.9 Power supply module

The power supply module is located in the frame behind the drawers. This module serves for the

voltage supply of the ventilator modules 1 and 2, the flow meter block illumination, the patient circuit

heating blanket and the charging / discharging control for the battery. The power supply board allows

the supply with either 230VAC or 115VAC, the supply voltage can be selected with a switch on the

power supply board.

Fig. 3 Power supply module

17

Page 18

Repair Information

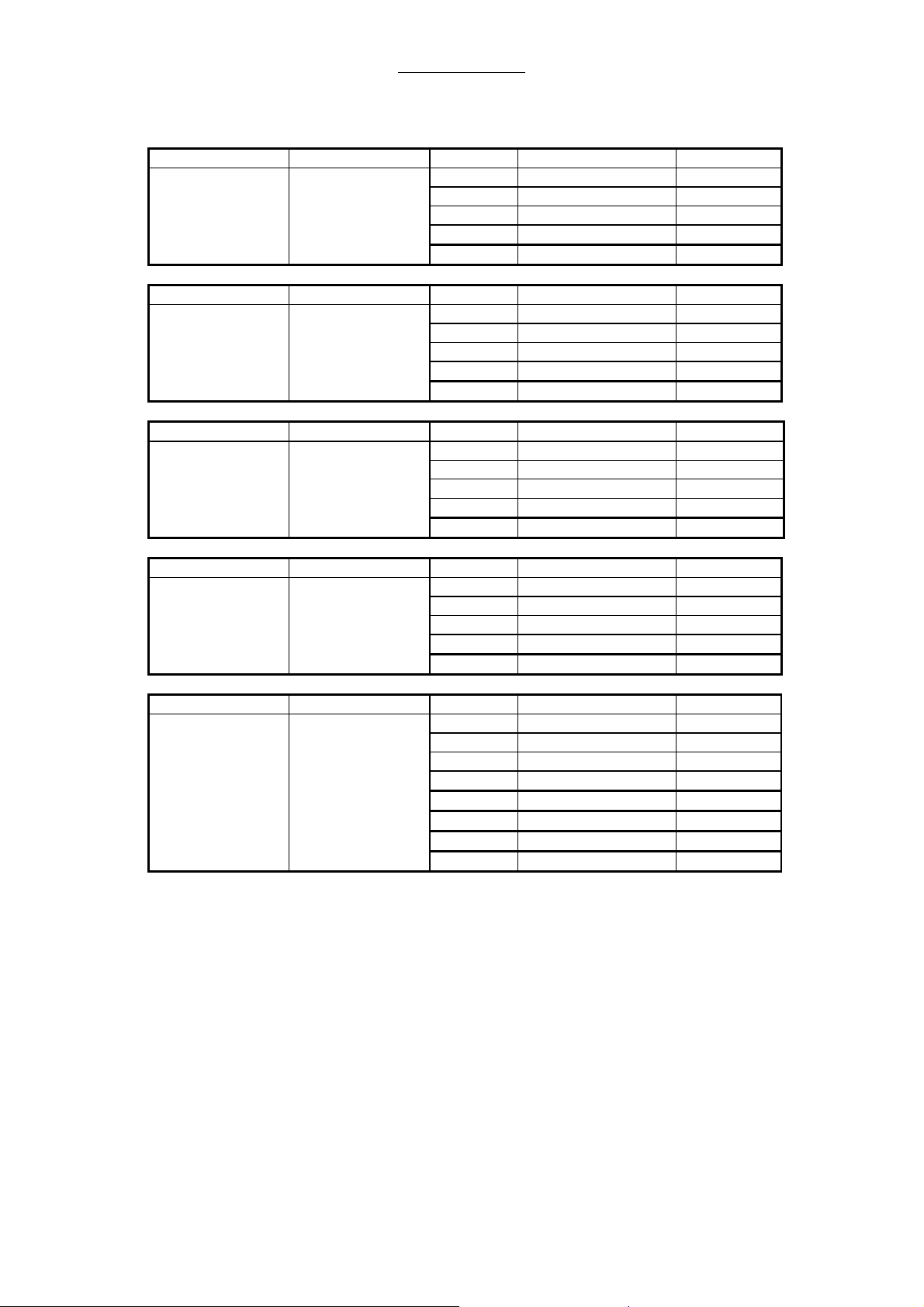

2.9.1 Connectors on power supply board AVM 2-1

Connector connected to Pin. def. Func. / Signal Color / No.

X1 Module 1 X1-1 +5V yellow

X1-2 GND red

X1-3 GND green

X1-4 +12V blue

Connector connected to Pin. def. Func. / Signal Color / No.

X2 X2-1 +5V

X2-2 GND

X2-3 GND

X2-4 +12V

Connector connected to Pin. def. Func. / Signal Color / No.

X3 X2-1 -

X2-2 -

X2-3 GND

X2-4 +12V

Connector connected to Pin. def. Func. / Signal Color / No.

X4 X4-1 +5V

X4-2 GND

X4-3 GND

X4-4 +12V

Connector connected to Pin. def. Func. / Signal Color / No.

X5 Battery, X5-1 BATT+ brown

Fuse for Battery X5-2 BATT- black

Main switch X5-3 Cir.break. bat. black 6

X5-4 Cir.break. bat. black 5

X5-5 Main switch black 4

X5-6 Main switch. black 3

Connector connected to Pin. def. Func. / Signal Color wire isolat.

X6 Transformer X6-1 sec.IIa 15VAC blue

RT110/12 secondary X6-2 sec IIa green

X6-3 sec. IIb 15VAC blue

X6-4 sec IIb green

Connector connected to Pin. def. Func. / Signal Color wire isolat.

X7 Transformer X7-1 prim.I, L120/230V

RT110/12 primary X7-2 prim.I, N120/230V

X7-3 prim.II,L120/230V

X7-4 prim. II, . violet

Connector connected to Pin. def. Func. / Signal Col. wire isolat.

X11 Transformer X11-1 Sec.Ia 22VAC red

RT110/22 secondary X11-2 Sec Ia yellow

X11-3 Sec. Ib 22VAC red

X11-4 Sec Ib yellow

AC

AC

AC

black/

orange

white

18

Page 19

Repair Information

Connector connected to Pin. def. Func. / Signal Color / No.

X12 int. connection X12-1 AC, N 110V/230V blue

AC IN terminal X12-2 AC , L 110V/230V black

Connector connected to Pin. def. Func. / Signal Color / No.

X13 Module 2 X13-1 +12V red

Board X13-2 GND blue

AVM 3-2 X13-3 +5V(1) red

X13-4 GND blue

Connector connected to Pin. def. Func. / Signal Color / No.

X14 Module 2 X14-1 +5V(2) red

Board X14-2 GND blue

AVM 3-2 X14-3 -12V red

X14-4 GND blue

Connector connected to Pin. def. Func. / Signal Color / No.

X15 Module 2 X15-1 Control Sign. white

Board X15-2 Control Sign. white

AVM 3-2 X15-3 Control Sign. white

X15-4 Control Sign. white

Connector connected to Pin. def. Func. / Signal Color / No.

X16 Module 2 X16-1 GND blue

AVM 3-2 X16-2 +31V red

Connector connected to Pin. def. Func. / Signal Color / No.

X17 solid state relay X17-1 22VAC to heat. bl. black

heating blanket X17-2 22VAC to relay black

X17-3 + Control voltage black

X17-4 GND black

Connector connected to Pin. def. Func. / Signal Color / No.

X22 DC-AC convert. X22-1 +supply voltage red

for flow meter X22-2 -

illumination X22-3 -

X22-4 GND black

2.9.2 Fuses on power supply board AVM 2-1

Fuse No. Fuse value Fuse protects

F1 4 A MT, medium slow-blow DC / DC-converter +5V

F7 8 A M, medium -blow DC / DC-converter +12V

F8 8 A M, medium -blow Transformer, Sec. IIa

F9 8 A M, medium -blow Transformer, Sec. IIb

F10 10 A T, slow-blow Transformer, Sec. Ia

F11 10 A T, slow-blow Transformer, Sec. Ib

19

Page 20

Repair Information

2.9.3 Charging / discharging control for the battery:

The charging / discharging control for the battery is also located on the power supply board AVM 2-1.

Status indicators as red, green and yellow LEDs are located on the board to show functions like check

or charging of the battery.

2.9.4 Status Indicators Of Battery Control:

LED LED light Battery status

LED yellow (V28) continuous charging

LED yellow (V28) flashing check

LED green (V37) continuous fully charged

LED red (V38) flashing or continuous. defect

20

Page 21

Repair Information

2.10 Module 1

Ventilator module 1 consists of two processor boards. This module serves for the operation of touch

screen interface with different menus displayed on the display.

All safety functions, e.g. the complete ventilator control, are located on ventilator module 2. Module 1

is connected to module 2 by means of an RS 232C- interface. Module 1 serves to give the functions

for parameter and alarm settings to module 2. Module 2 sends the measured parameters or generated

alarm signals to module 1 to display.

Fig. 4 Module 1 PC board

21

Page 22

Repair Information

2.10.1 Connectors on module 1

Connector connected to Plug conf. Func. / Signal

X4 Module 2 10 pole communication

with module 2

Connector connected to Plug conf. Func. / Signal

X5 EL Display 20 pole Connected to the

display

Connector connected to Plug conf. Func. / Signal

X6 Power supply 4 pole Power suppy

Connector connected to Plug conf. Func. / Signal

X7 Touch screen 32 pole communication

with touch screen

Connector connected to Plug conf. Func. / Signal

X8 Module 2 14 pole communication

with module 2

Connector connected to Plug conf. Func. / Signal

X9 Module 2 28 pole communication

with module 2

Connector connected to Plug conf. Func. / Signal

X10 Selector switch 14 pole communication

With the selector

switch

Connector connected to Plug conf. Func. / Signal

X19 LCD Display Flat cable

connector

Connector connected to Plug conf. Func. / Signal

X20

(on the

backside)

Display

illumination

4 pole Power supply

Connected to the

display

display

illumination

22

Page 23

Repair Information

2.11 Ventilator Module 2, AVM 3-1 and AVM 3-2

Ventilator module 2 serves for the active ventilator control. Module 2 consists of two CPU boards, the

CPU board AVM3-1 with µP1 serves for a continuous validation of control actions generated by CPU

board AVM3-2 and for the communication between module 2 and module 1.

The CPU board AVM3-2 with µP2 generates all active control signals, after a validation of these

signals by µP1, AVM3-2 is enabled to operate the different active elements like the solenoid vales and

proportional valve.

Keyboard Alarm Panel

RS232

X4

P1

P2

X3X2

CPU-board

IF

EF

1

O2

1

P9

PV

1

X8

X9

X10

X11

AVM 3-2

P3

P5

1

1

1

1

P6

P1

P8

P7

P1

P1

P11

P10

R33

Pressure

Sensor #2

Pressure

Sensor #1

P2P1

X5

1

X7

GND

X1

X8

P2

P2

P2

X3

X1

1

7

23

456

8

MD

1

ON

CPU-board

AVM 3-1

X13

X7

1

GND

Q1

V29

V30

V38

V19

AVM 3-1

Software

+12 GND

GND

+5(1)

1

X15

GND

GND

+5(2)

Power Supply

-12

Fig. 5 View on module 2

DIS/AC

HTON

M

BATT

+31

1

X16

swrtrs wsswge

Motor

(-) (+) -> lösen

Endsch.

Start

X11

1

gn

23

Page 24

Repair Information

2.11.1 Parts list module 2

Pos. No. Description Order No.

1 Ventilator module 2, complete 460-1150

2.11.2 Connectors on module 2

2.11.2.1 Plug connectors on board AVM 3-1

Connector connected to Plug conf. Func. / Signal

X2 Module 1 28 pole communication

with module 1

Connector connected to Plug conf. Func. / Signal

X3 Module 1 14 pole communication

with module 1

Connector connected to Plug conf. Func. / Signal

X4 Module 1 10 pole communication

with module 1

Connector connected to Pin. def. Func. / Signal Color / No.

X7 PT-100 sensor X7-1 temperature dep. blue

X7-2 resistance red

Connector connected to Pin. def. Func. / Signal Color / No.

X9 Fan ventilator X9-1 +12V red

FAN pneumatic X9-2 fan control signal yellow

module X9-3 n.c.

X9-4 n.c.

X9-5 GND black

Connector connected to Pin. def. Func. / Signal Color / No.

X10 Driving gas X10-1 +12V white

Driving gas switch switch to detect X10-2 GND brown

a failure of the gas X10-3 n.c.

supply X10-4 n.c.

X10-5 n.c.

Connector connected to Pin. def. Func. / Signal Color / No.

X11 over temperature X11-1 22VAC when red

HTSEC switch (NC) X11-2 switch is open blue

patient X11-3 n.c.

block heating X11-4 n.c.

X11-5 n.c.

24

Page 25

Repair Information

2.11.2.2 Plug connectors on board AVM3-2

Connector connected to Pin. def. Func. / Signal Color / No.

X5 internal X5-1 signal (+1-5 V) orange

IF flow sensor X5-2 +10V mint

X5-3 GND. violet

X5-4 n. c.

X5-5 n. c.

Connector connected to Pin. def. Func. / Signal Color / No.

X7 external X7-1 flow dep. signal. red

EF flow sensor X7-2 n.c.

X7-3 n.c.

X7-4 n.c.

X7-5 flow dep. signal. blue

Connector connected to Pin. def. Func. / Signal Color / No.

X8 Oxygen cell X8-1 n. c.

O2 X8-2 + voltage fuel cell red

X8-3 - voltage fuel cell blue

X8-4 n.c.

X8-5 n.c.

Connector connected to Pin. def. Func. / Signal Color / No.

X3 proportional X3-1 + 12V blue

PV valve X3-2 n. c.

X3-3 control volt. 0-5V gray

X3-4 n.c.

X3-5 GND green

Connector connected to Pin. def. Func. / Signal Color / No.

X11 solenoid X11-1 GND ( MV4) brown / 1

valve X11-2 + 10V (MV4) red / 2

block X11-3 GND (MV3) orange / 3

X11-4 + 10V (MV3) yellow / 4

X11-5 GND (MV1) green /5

X11-6 + 10V (MV1) blue / 6

X11-7 GND (MV2) violet / 7

X11-8 + 10V (MV2) gray / 8

2.12 Display

The display of the ventilator is a LCD or EL type. It is connected to the module 1.

2.13 Battery

The battery is a maintenance free seal lead acid type. The recharging time is a maximum of 7 hours

with a fully depleted battery. The backup time is about 30 minutes with a fully charged battery. To

prevent unintended loss of battery operation, it is recommended to replace it with a new HEYER

battery every 3 years.

25

Page 26

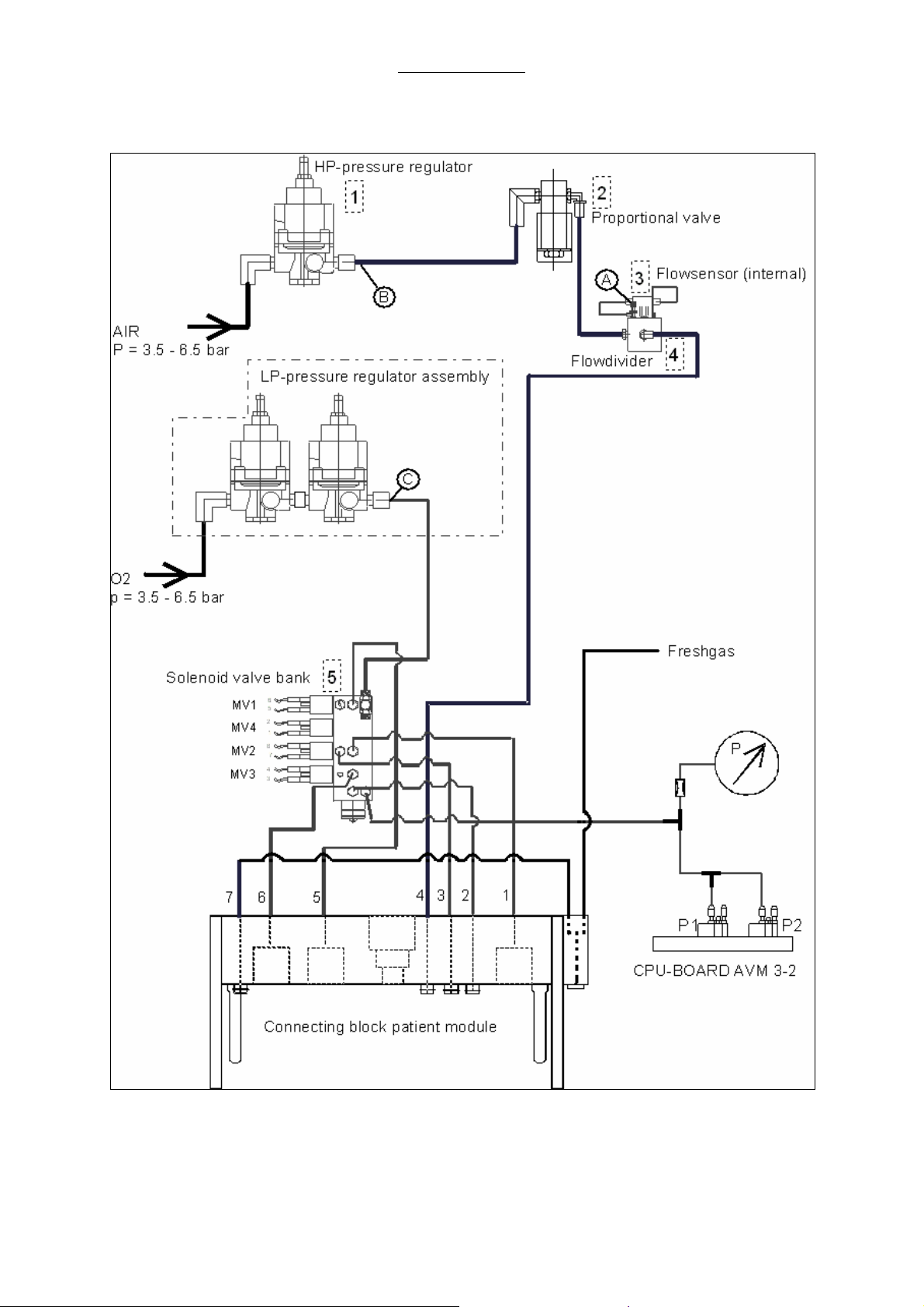

2.14 Ventilator pneumatic

Repair Information

Fig. 6 Ventilator pneumatic

26

Page 27

Repair Information

2.14.1 Ventilator pneumatic drive

Air or Oxygen, in the CMV mode, serves as driving gas for the ventilator. In addition to the flow meter

block, a pressure reducer, reducing the supply pressure to 200 kPa (2 bar; 29 PSI), is supplied by the

Air or oxygen connection. This pressure represents the high system pressure of the ventilator. The

pressure reducer is named HP pressure reducer.

The HP pressure reducer is placed ahead of the proportional valve that generates the driving gas flow

during the inspiratory phase. This flow is led through the flow divider and fills the bellows dome that

surrounds the silicone bellow.

In response to the inspiratory and expiratory phases of a respiration cycle, the pneumatic valves

(diaphragm valves) of the patient module are activated by solenoid valves.

These solenoid valves, MV1, MV3, and MV2 are supplied by a second pressure reducer assembly

(LP- double stage pressure reducer) at the low system pressure, together with MV4, with about 20 kPa

(200 mbar; 2.9 PSI)// 25 kPa (250 mbar; 3,63PSI).

Cyclic activation of the proportional valve and solenoid valves is steered by the processors of module

2 according to the parameters set on the control panel of the ventilator.

A description of the individual components will be found in the following chapters:

2.14.2 HP pressure reducer

The HP pressure reducer serves for a stabilization of the supply pressure for the proportional valve.

The flow generated by the proportional valve thus becomes independent of pressure variations.

The setting of the HP pressure reducer (200 kPa (2 bar; 29 PSI)) at the same time determines the

maximum inspiratory flow of 75 +0/-4 L/min with respect to the respirator.

2.14.3 LP- double stage pressure reducer

This pressure reducer assembly is supplied with oxygen in parallel to the measuring tube block or ratio

system, respectively. It reduces the input pressure to 20 kPa (200 mbar; 2.9 PSI)// 25 kPa (250 mbar;

3,63PSI), and is connected to the solenoid valve bank.

2.14.4 Solenoid valves MV1 to MV4

The solenoid valves MV1, MV2, MV3 and MV4 are mounted on a bank behind the patient module

docking station to which the tubes to the docking station of the patient module and the LP- double

stage pressure reducer are connected.

MV1: This solenoid valve activates, in the CMV mode, the valve for closing the outlet of the bellows

dome (bellows control valve) through the line 5, when driving gas flows in for inspiration. It is supplied

by the LP- double stage pressure reducer.

MV2: This solenoid valve activates, in the CMV mode, the valve closing the expiratory channel of the

patient module (expiratory valve), via MV2 through the line 1. It is supplied by the LP- double stage

pressure reducer via MV4.

MV3: This solenoid valve activates, in the CMV mode, the valve for the fresh gas decoupling

(decoupling valve) through the line 6. It is supplied by the LP- double stage pressure reducer.

MV4: This solenoid valve is used for internal supply of MV2 with pressure of the LP- reducer.

27

Page 28

Repair Information

2.14.5 Pneumatic driving module

The driving module consists of the proportional valve and flow divider with an internal flow sensor. The

proportional valve supplied by the HP pressure reducer generates a driving gas flow of 0-75 l/min in

relation to the control voltage of the proportional valve of 0 - 5VDC.

The control voltage of the PV, required for the pre-selected parameter settings, is generated by the

CPU board AVM 3-2.

The driving gas flow Q

Q

drive gas

VT = generated tidal volume

Ti = Inspiratory time

= VT/Ti with Q

drive gas

is in the following in relationship with the tidal volume:

drive gas

= driving gas flow

2.14.6 Flow metering module

The flow metering module attached to the proportional valve consists of a flow sensor with a

measuring range of 0 - 1 l/min and a flow divider. The flow divider splits the total flow in a ratio of 79: 1,

and the bypass flow is lead to the flow sensor. A closed loop that allows high accuracy and back up in

the generation of the tidal volume results from this configuration via the module 2 CPU-boards.

2.14.7 Tube color coding

Despite the local color coding system, all the pneumatic tubes inside the apparatus will be according

to the coding label inside the unit, if it is not according to the local color coding system, next to the flow

meter block. Typically it will be according to one of the follow standards.

Gas ISO 32 Standard US standard

O2 White Green

N2O Blue Blue

AIR Black/White Yellow

On the outside of the apparatus, the coding will be as ordered.

28

Page 29

Repair Information

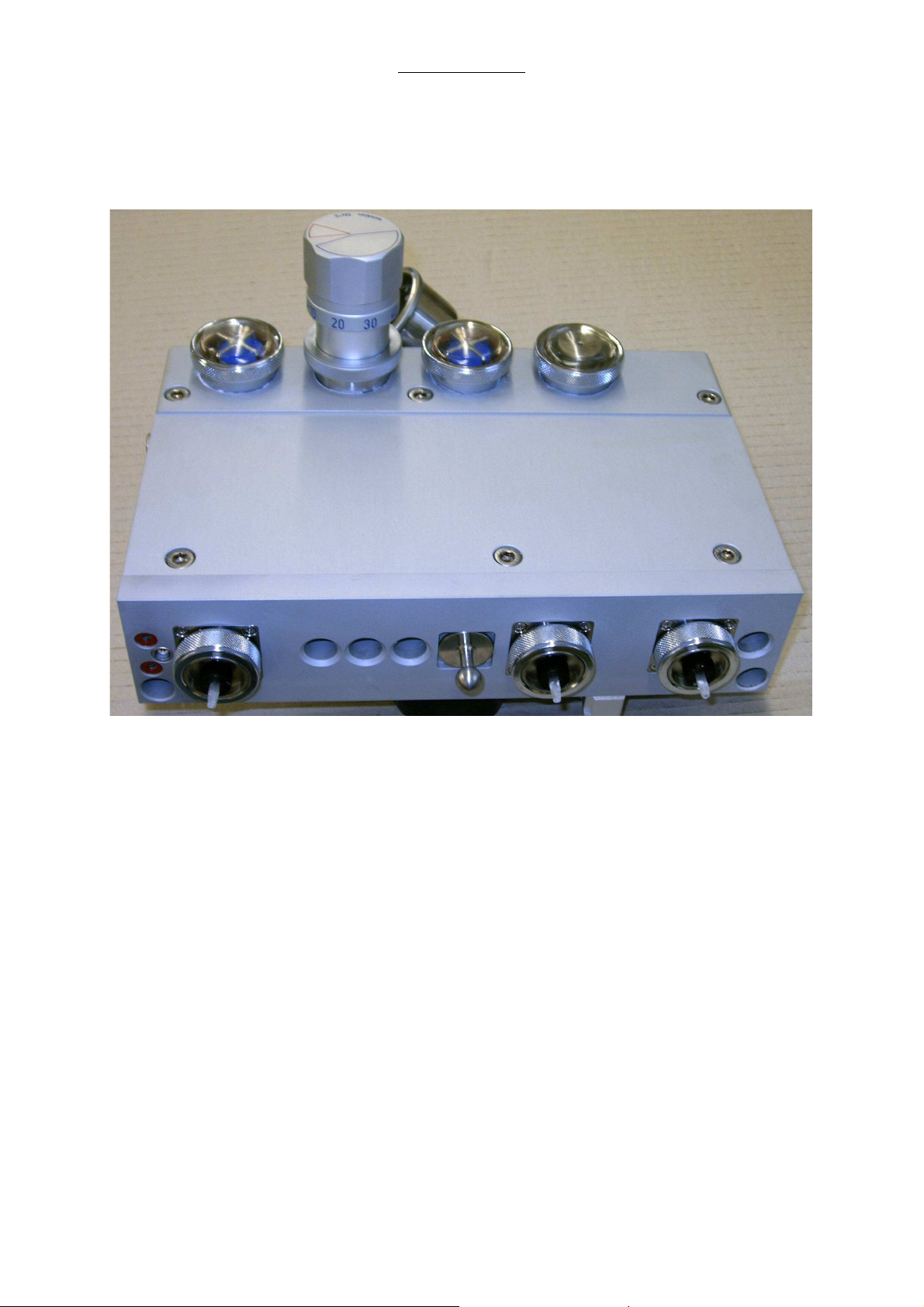

2.15 The patient module (circle system)

2.15.1 Top and back side view on the patient module

1 2 3 4

6

5 12 15

8 9 10 11 13 14

7 7

Fig. 7 Top and backside view on the patient module

Pos. Description

1. Expiratory valve (passive)

2. Airway pressure limiting valve (APL)

3. Inspiratory valve (passive)

4. Room air valve, emergency air valve

5. Connector of expiratory flow sensor

6. Connectors of power supply heating blanket

7. Bores for guiding pins of connecting block

8. Expiratory valve (active)

9. Port for pressure measurement

10. Port for expiratory valve activation in the manual mode

11. Port for driving gas

12. Locking bolt

13. Bellows diaphragm valve

14. Decoupling diaphragm valve

15. Port for fresh gas

29

Page 30

Repair Information

1 2

3

4

5

2.15.2 Bottom and back side view on the patient module

6

7

8

Fig. 8 Bottom and backside view on the patient module

Pos. Description

1

2

3

4

5

6

7

8

Fixing screws for locking bolt

Exhaust for driving gas

Driving gas in- and outlet to bellows dome

Thread for CO2 absorber canister fixing, outlet from patient module to absorber

Inlet for re-breathing gas from absorber to patient module

Connector for bellows

Inlet for ambient air valve / emergency air valve

Port for anesthetic gas scavenging tube (30 mm cone)

30

Page 31

Repair Information

2.15.3 Functional representations of the patient module

gasmonitoring

2

V

5

3

41

6

11

7

8

9

10

Fig. 9 Survey of the patient module

Pos. Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Patient's y-piece

Side stream gas monitor

Inspiratory bacterial filter

Expiratory bacterial filter

Airway pressure monitor connection

Inspiratory valve (passive)

Expiratory valve (passive)

Spirometry sensor

Airway pressure limiting valve (APL)

Waste gas outlet

Expiratory valve

Room air valve, emergency air valve

Ventilator control pneumatic

CO2 absorber

Bellows

Decoupling valve

Bellows dome

Bellows valve

Reservoir / manual ventilation bag

P

12

13

14

16

15

17

18

V

19

31

Page 32

2.15.3.1 CMV mode, inspiration

gas monitoring

Repair Information

P

expiratory valve

V

V

is > 2 mbar

MV3 ="1"

MV2 ="1"

decoupling valve

bellows valvewhen reservoir pressure

Fig. 10 Survey of the patient module, CMV mode, inspiration

MV4 ="1"

MV1 ="1"

32

Page 33

2.15.3.2 CMV mode, expiration

gas monitoring

Repair Information

expiratory valve

V

when reservoir pressure

is > 2 mbar

P

V

MV3 ="0"

MV2 ="0"

MV4 ="0"

decoupling valve

bellows valve

Fig. 11 Survey of the patient module, CMV mode, expiration

MV1 ="0"

33

Page 34

2.15.3.3 Manual mode, inspiration

gas monitoring

Repair Information

P

expiratory valve

V

when the set respiratory

pressure is attained

V

MV3 ="0"

MV2 ="0"

MV4 ="0"

MV1 ="0"

Fig. 12 Survey of the patient module, Manual mode, inspiration

decoupling valve

bellows valve

34

Page 35

2.15.3.4 Manual mode, expiration

gas monitoring

expiratory valve

Repair Information

decoupling valve

V

MV3 ="0"

MV2 ="0"

MV4 ="0"

MV1 ="0"

Fig. 13 Survey of the patient module, Manual mode, expiration

bellows valve

35

Page 36

Repair Information

2.15.3.5 Spontaneous mode, inspiration

gas monitoring

P

emergency air valve opens

at p < - 3 mbar

expiratory valve

V

decoupling valve

when reservoir pressure

is > 2 mbar

V

MV3 ="0"

MV2 ="0"

MV4 ="0"

MV1 ="0"

Fig. 14 Survey of the patient module, Spontaneous mode, inspiration

bellows valve

36

Page 37

Repair Information

2.15.3.6 Spontaneous mode, expiration

gas monitoring

P

expiratory valve

V

decoupling valve

waste gas

V

MV3 ="0"

MV2 ="0"

MV4 ="0"

MV1 ="0"

Fig. 15 Survey of the patient module, Spontaneous mode, expiration

bellows valve

37

Page 38

Repair Information

2.15.4 Components of the patient module

2.15.4.1 Ventilation bellows system

The ventilator’s driving system can be characterized as a constant flow generator. The driving gas of

this generator fills the bellows dome to compress the bellows. The breathing gas is pressed out of the

bellows into the circuit. Due to the weight of the descending bellows, it is self-filling when the driving

gas flow is stopped. The bellows control valve enables the escape of the driving gas.

2.15.4.2 Manual Respiration Bag / Reservoir

In the manual mode this device acts as a normal breathing bag, enabling the user to ventilate the

patient manually. In CMV mode this bag acts as a reservoir for fresh gas in the inspiration phase. In

the expiratory phase the re-breathing gas and the fresh gas are accumulated in this reservoir. The

bag’s in- and deflation corresponds to the volume balance of the breathing circuit and the patient.

When a volume loss occurs, the bag deflates breath by breath and finally collapses. Such a collapsing

breathing bag is an indicator for a leakage. The breathing bag must collapse if the fresh gas flow,

reduced by the patient’s uptake, is not able to compensate the leakage.

2.15.4.3 CO2 absorber

The soda lime inside the absorber retains the carbon dioxide from the re-breathing gas. The flow

orientation is upstream.

2.15.4.4 Inspiratory and expiratory valves

To ensure the gas flow direction the two one-way-valves in the inspiratory limb and expiratory limb are

integrated inside the patient module. These valves are seen activating form the top of the module.

2.15.4.5 Airway pressure relief valve

In CMV position the APL valve closes the re-breathing system towards the scavenging line and limits

the reservoir pressure to a constant value of 2 cmH2O. In manual mode the APL valve acts as a

normal spring loaded pressure relief valve, limiting the maximum pressure in the re-breathing system.

2.15.4.6 Room Air valve

Due to the tendency of the descending bellows to refill itself by creating a negative pressure inside the

bellows this valve prevents the patient from becoming any negative pressure by opening the

diaphragm and allowing ambient air to refill the bellows.

2.15.4.7 Diaphragm/Membrane valves

Inside the patient module valves operate the expiratory line, the bellows dome outlet and the fresh gas

decoupling line during the CMV-mode. These valves are controlled by pressured gas to open or close

the valve’s path. All valves are open when not inflated. The power gas for these valves is controlled by

the ventilator’s valve bank using a supply pressure of about 20 kPa (200 mbar; 2.9 PSI)// 25 kPa (250

mbar; 3,63PSI) from the ventilator pneumatic.

38

Page 39

Repair Information

2.15.2.7.1 Status of the diaphragm/membrane valves:

The diaphragm valves are pneumatically operated by solenoid valves. The following list shows the

correspondence between diaphragm valve, solenoid valve and pressure port.

Valve Bellows valve Exp. valve Decoupling valve

controlled by MV 1 MV 2 MV 4 MV 3

connected to port # 5 1 3 6

wire # 5, 6 7, 8 1, 2 3, 4

In the following the status of the diaphragm/membrane valves are shown corresponding to the

selected ventilation mode of the ventilator.

2.15.2.7.2 Machine OFF or Ventilator In Standby

Valve MV 1 MV 2 MV 3 MV 4

Activity OFF OFF OFF OFF

Pressure on port 5, No 1, No 6, No no sup. of MV2

2.15.2.7.3 Manual / Spontaneous Mode, INSPIRATION and EXPIRATION

Valve MV 1 MV 2 MV 3 MV 4

Activity OFF OFF OFF OFF

Pressure on port 5, No 1, No 6, No no sup. of MV 2

2.15.2.7.4 CMV Child / Adult Mode, INSPIRATION

Valve MV 1 MV 2 MV 3 MV 4

Activity ON ON ON ON

Pressure on port 5, Yes 1, Yes 6, Yes supply of MV 2

2.15.2.7.5 CMV Child / Adult, EXPIRATION

Valve MV 1 MV 2 MV 3 MV 4

Activity OFF OFF OFF OFF

Pressure on port 5, No 1, No 6, No no sup. of MV 2

2.15.2.7.6 CMV Adult, EXPIRATION and PEEP

Valve MV 1 MV2 MV3 MV4

Activity OFF ON OFF ON

Pressure on port 5, No 1, Yes 6, No supply of MV2

39

Page 40

Repair Information

2.15.2.7.7 Compliance Test Patient Module

The compliance test patient module is divided in 3 phases.

Phase 1. Flow into the re-breathing system and test of flow sensors.

Valve MV 1 MV2 MV3 MV4

Activity ON OFF ON ON

Pressure on port 5, Yes 1, No 6, Yes no sup. of MV2

Phase 2. Pressure increase up to test pressure 40 cmH2O, calculation of system compliance.

Valve MV 1 MV2 MV3 MV4

Activity ON ON ON ON

Pressure on port 5, Yes 1, Yes 6, Yes supply of MV2

Phase 3. Test of pressure loss.

Valve MV 1 MV2 MV3 MV4

Activity ON ON ON ON

Pressure on port 5, Yes 1, Yes 6, Yes supply of MV2

2.15.2.7.8 Leak Test Patient Module and Fresh Gas Module

Valve MV 1 MV2 MV3 MV4

Activity ON OFF OFF OFF

Pressure on port 5, Yes 1, No 6, No no sup. of MV2

40

Page 41

Maintenance and Calibration

3 Repair Information

3.1 Introduction

This chapter of the service manual provides the necessary technical information to perform repairs to

the instrument. The most important perquisites for effective troubleshooting are a trough

understanding of the instruments functions, as well as understanding the principals of operation.

3.2 Warnings and precautions

In the event the instrument covers are removed, observe the following warnings and guidelines

3.2.1 Precautions

1. Do not short components leads together

2. The instrument covers must not be removed by anyone other than qualified technical personnel

who have received supplementary instructions regarding maintenance of medical equipment

and/or have equivalent experience in this area.

3.2.2 Warnings

1. This device operates using compressed gas at high pressures. When attaching emergency gas

tanks, always open tank valves slowly, watching the cylinder gauge indicate the tank pressure.

When disconnecting the tanks, always close the valves slowly. Use the Modular+ flow meters to

bleed down the pressure, watching the cylinder gauge indicating the depleting tank pressure,

before disconnecting the tank from the yoke. Always open and close tank valves fully.

2. This device operates using compressed gas at high pressures from the hospital central supply.

When connecting gas supply lines, attach the hose connection to the machine before connecting

the quick disconnect fitting to the hospital source. Disconnect the supply hose from the hospital

source connection prior to disconnecting it from the Modular+ gas connection fittings.

3. Whenever flowing anesthetic gases, nitrous oxide, oxygen, or any hospital gas always use the

appropriate agent evacuation system.

4. Never oil or grease any oxygen equipment unless the lubricant used is made and approved for

this kind of service. In general, oils and greases oxidize readily, and in the presence of oxygen

burn violently.

Page 42

Maintenance and Calibration

3.3 Troubleshooting Guidelines

1. Identify the problem – Due to the wide variety of potential symptoms, certain problems may be

more subtle than others. Following the guidelines of the tests will help determine the problem if

one exists.

2. Avoid shorting component leads together – During repair procedures, it can be tempting to

make a quick series of measurements. Always turn the power off before connecting and

disconnecting the test leads and probes. The accidental shorting of leads can easily stress the

components and cause a second failure (aside from the safety risk).

3. Use the proper equipment – The equipment listed below is suggested to fulfill a wide range of

troubleshooting requirements. It is imperative to use the designated equipment in order to ensure

proper results of any and all test procedures.

4. Clean up the repair area – After any repair, clean off the repair area.

3.4 Troubleshooting Charts

3.4.1 Error Messages during ventilation

Display message Cause Corrective action User

Vent Error:

Use Manual Ventilation

Call Service

CPU Error: Use Manual

Ventilation

Call Service

Set APL valve to

CMV/SP position

Flow Error: Use Manual

Ventilation

Call Service

Valve Error:

Use Manual Ventilation

Call Service

No communication between

AVM 3-1 and AVM 3-2

(ventilator microprocessor

boards) for more than 8 sec.

No communication

between AVM 3-1 and module

1 (user interface) for more than

20 sec.

System Failure (Module 1)

Watchdog Error (Module

2)

AVM3-2

PPEAK is greater than 10 mbar

and lowest expiration pressure

after the expiration still greater

than PPEAK–2mbar

No pressure relief in the

expiration

CMV, PCV

After the first five breaths in

CHILD resp. after the first three

breaths ADULT: Last

inspiratory flow is lower than

0,05 L/min, even though more

than 2.00 L/min were set at the

prop. valve

Sensor does not deliver any

values

AVM3-2 CMV

The internal actual flow value is

measured during the inspiration

and may not exceed the

following desired value x factor

1.5:

AVM3-2 PCV

The same as CMV, but other

tolerance

Prop. Valve faulty

Finish the case with manual

ventilation;

Take the machine out of use;

Call Service

Finish the case with manual

ventilation;

Take the machine out of use;

Call Service

Set APL to the CMV/SP

position

Reset automatically after

pressure relief, Restart of the

ventilation after request.

Finish the case with manual

ventilation;

Take the machine out of use;

Call Service

The intermitting tone is reset via

the mute button

(acknowledgement)

Reset the error message via

the compliance test

Corrective action

Service technician

Exchange module 2 (ventilator

microprocessor boards)

Exchange either the module 2,

the module 1 or the

communication cable

connecting the two modules

If resetting the APL valve does

not solve the problem, check

the correct functions of the APL

valve, solenoid valves and the

diaphragm valves

Recalibrate the proportional

valve, internal flow sensor and

the characteristic of the

proportional valve. If that does

not solve the problem,

exchange the

1. proportional valve

2. internal flow sensor

Recalibrate the proportional

valve, internal flow sensor and

the characteristic of the

proportional valve. If that does

not solve the problem,

exchange the

1. proportional valve

2. internal flow sensor

42

Page 43

Maintenance and Calibration

Display message Cause Corrective action User

Valve Error: Use Manual

Ventilation

Call Service

Calibrate Breathing

System

Perform Compliance Test

when convenient

Pressure Reading out of

tolerance

Perform Compliance Test

when convenient

No drive gas; please

check

Flow/Volume Readings

not available

Replace Flow Sensor –

Call Service

A P N E A

Breathing Circuit

Disconnect

PEEP greater than Pmin

FiO2 lower than FiO2

min

Tidal Volume lower than

VTE

Peak pressure greater

than alarm limit

Peak pressure below

alarm limit

Minute Volume below

alarm limit

PEEP greater than

PEEP-Setting

FiO2 greater than FiO2

alarm limit

Check Vent Dial position

AVM3-2 CMV/ PCV

The actual internal flow value

should be 0 during expiration

AVM3-2 CMV, PCV

Difference between the set and

the detected state of each

solenoid valve for more than

200 ms

AVM3-1, AVM3-2

A difference between the two

pressure sensors of more than

10 mbar

AVM3-1

Monitoring of the pressure

switch for the driving gas

AVM3-1 during ventilation

External flow sensor is broken

or short-circuited

AVM3-1. Manual/ spontaneous

Within a period of 15 to 60

seconds a expiration cannot be

detected

AVM3-1 CMV, (S)CMV, PCV

The peak pressure PPEAK is

lower than 0.5 mbar and lower

then the set pressure limit Pmin

AVM3-1 CMV, (S)CMV, PCV

The end expiratory pressure is

greater than the set pressure

limit Pmin

AVM3-1

The measured O2 value is

lower than the set O2min limit

AVM3-1

The measured VTE value is

lower than the set VTEmin limit

AVM3-1

The measured Ppeak value is

greater than or equal to the set

Pmax limit

AVM3-1

The measured Ppeak value is

lower than the set Pmin limit

AVM3-1

The calculated M.Vol value is

lower than the set M.Vol min

limit

AVM3-1

The measured PEEP value is 5

mbar higher than the set PEEP

AVM3-1

The measured FiO2 value is

greater than the set FiO2max

limit

AVM3-1

The selector switch position is

monitored An invalid position

must be eliminated within two

seconds. After this the alarm

message appears.

Finish the case with manual

ventilation;

Take the machine out of use;

Call Service

The intermitting tone is reset via

the mute button

(acknowledgement)

Reset the error message via

the compliance test

The intermitting tone is reset via

the mute button

(acknowledgement)

Reset the error message via

the compliance test

Ensure the driving gas supply,

restart the ventilation on

request.

The intermitting tone is reset via

the mute button

(acknowledgement)

Reset the error message via

the compliance test

Create expiration Ensure the correct function of

Create a pressure increase in

the inspiration phase

Lower the end expiratory

pressure or raise the pressure

limit Pmin

Increase the O2 value or raise

the limit O2min

Increase the VTE value or raise

the limit VTEmin

Decrease the Ppeak value or

raise the limit Pmax

Increase the Ppeak value or

lower the limit Pmin

Increase the ventilation rate or

the VTE value or lower the limit

Pmin

Decrease the PEEP value or

raise the set PEEP

Decrease the FiO2 value or

raise the set FiO2max limit

The last detected valid position

is maintained until a new valid

position is detected, then the

message disappears

Corrective action

Service technician

Recalibrate the proportional

valve, internal flow sensor and

the characteristic of the

proportional valve. If that does

not solve the problem,

exchange the

1. proportional valve

2. internal flow sensor

Check the correct voltage