Page 1

HPE Integrity NonStop X NS7 Planning Guide

Part Number: 799257-005

Published: September 2018

Edition: L15.08 and subsequent L-series R

VUs

Page 2

Contents

About This Document.............................................................................

Supported Release Version Updates (RVUs)............................................................................... 7

New and Changed Information in 799257–005............................................................................ 7

HPE Integrity NonStop X NS7 Systems................................................ 8

Core Licensing............................................................................................................................ 11

NonStop X NS7 Standard and Optional Hardware..................................................................... 12

c7000 Enclosure.............................................................................................................. 12

NonStop X NS7 Server Blades........................................................................................ 13

CLuster I/O Modules (CLIMs)...........................................................................................13

NonStop IO Expansion IB Switch.....................................................................................22

NonStop X FDR IB ADI Switch.........................................................................................23

Maintenance Switch......................................................................................................... 23

NonStop System Console................................................................................................ 23

UPS and ERM (Optional)................................................................................................. 24

Enterprise Storage System (Optional)............................................................................. 24

System Management Tools.........................................................................................................25

OSM Package.................................................................................................................. 25

Onboard Administrator (OA) and Integrated Lights Out (iLO)..........................................25

Management Subsystems for NS7 Systems....................................................................26

Technical Document for NS7 Systems........................................................................................26

Component Location and Identification.......................................................................................26

Rack and Offset Physical Location...................................................................................26

7

Site Preparation Guidelines for the NS7 System............................... 27

Rack Power and I/O Cable Entry................................................................................................ 27

Emergency Power-Off Switches................................................................................................. 27

EPO Requirement for NS7 Systems................................................................................ 27

EPO Requirement for R5000 UPS...................................................................................27

EPO Requirement for R12000/3 UPS..............................................................................27

Electrical Power and Grounding Quality..................................................................................... 28

Power Quality...................................................................................................................28

Grounding Systems..........................................................................................................28

Power Consumption.........................................................................................................28

Cooling and Humidity Control..................................................................................................... 28

Weight.........................................................................................................................................29

Flooring....................................................................................................................................... 29

Dust and Pollution Control.......................................................................................................... 29

Zinc Particulates..........................................................................................................................29

Space for receiving and unpacking the system.......................................................................... 29

Operational space for an NS7 System........................................................................................30

NS7 System Installation Specifications..............................................31

Racks ......................................................................................................................................... 31

AC power feeds in a rack................................................................................................. 31

Power Distribution Unit (PDU) types for an Advanced Series G2 rack............................ 31

2

Page 3

AC input power for an Advanced Series G2 rack....................................................................... 47

Enclosure AC Input for NonStop X Systems

NS7 Enclosure Power Loads...................................................................................................... 50

Dimensions and Weights for NS7 AC Systems.......................................................................... 53

Service Clearances for NS7 Racks..................................................................................53

Unit Sizes for NS7 Systems............................................................................................. 54

42U G2 Advanced Series rack physical specifications.................................................... 54

42U Intelligent Rack physical specifications.................................................................... 55

36U G2 Advanced Series Rack physical specifications...................................................55

36U Intelligent Rack physical specifications.................................................................... 56

NS7 Enclosure Dimensions............................................................................................. 56

NS7 Rack and Enclosure Weights With Worksheet.........................................................58

Rack Stability for NS7 Systems.................................................................................................. 61

Environmental Specifications for NS7 AC Systems....................................................................62

NS7 Heat Dissipation Specifications and Worksheet ......................................................62

Operating Temperature, Humidity, and Altitude Specifications for NS7 Systems............ 65

NS7 Cooling Airflow Direction.......................................................................................... 65

NS7 Blanking Panels....................................................................................................... 65

NS7 Typical Acoustic Noise Emissions............................................................................65

Tested Electrostatic Immunity for NS7 Systems...............................................................66

Nonoperating Temperature, Humidity, and Altitude Specifications for NS7 Systems................. 66

Calculating Specifications for NS7 Enclosure Combinations......................................................66

...............................................................................50

Managing NS7 System Resources ..................................................... 68

Planning Kernel Managed Swap (KMS) Space.......................................................................... 68

Default Naming Conventions for NS7 Systems.......................................................................... 68

Possible values of disk and tape LUNs for NS7 Systems...........................................................69

HPE Integrity NonStop X NS7 CG Systems........................................70

NEBS Required Statements....................................................................................................... 72

NS7 CG Standard and Optional Hardware................................................................................. 73

c7000 CG Enclosure........................................................................................................ 73

NonStop X Server Blade for NS7 CG Systems................................................................74

NonStop X FDR IB NS ADI Switches...............................................................................74

IP/Telco CLIM CG and IP/Telco CLIM NC........................................................................74

Storage CLIM CG and Storage CLIM NC ....................................................................... 74

Maintenance Switch CG...................................................................................................76

System Console .............................................................................................................. 76

HPE NonStop 240A Breaker Panel..................................................................................76

HPE NonStop 80A Fuse Panel CG..................................................................................78

HPE NonStop NS7 CG System Alarm Panel...................................................................79

System Installation Specifications for NS7 CG Systems..................80

DC Power Distribution for NS7 CG Systems.............................................................................. 80

NS7 CG Enclosure Power Loads.....................................................................................81

Dimensions and Weights of NS7 CG Systems .......................................................................... 84

Seismic Rack Specifications for NS7 CG Systems .........................................................84

Unit Sizes for NS7 CG Systems.......................................................................................85

Enclosure Dimensions for NS7 CG Systems................................................................... 86

Rack and Enclosure Weights Worksheet for NS7 CG Systems.......................................86

Environmental Specifications for NS7 CG Systems................................................................... 89

Heat Dissipation Specification and Worksheets for NS7 CG Systems............................ 89

Operating Temperature, Humidity, and Altitude................................................................92

3

Page 4

Site Power Cables for NS7 CG Systems.................................................................................... 92

Required Documentation

Requirements for Site Power or Ground Cables..............................................................92

................................................................................................. 92

Websites................................................................................................ 94

Support and other resources...............................................................95

Accessing Hewlett Packard Enterprise Support......................................................................... 95

Accessing updates......................................................................................................................95

Customer self repair....................................................................................................................96

Remote support.......................................................................................................................... 96

Warranty information...................................................................................................................96

Regulatory information................................................................................................................97

Documentation feedback............................................................................................................ 97

Cables.................................................................................................... 98

Cable Types and Connectors......................................................................................................98

UPS and Data Center Power Configurations......................................99

Supported UPS Configurations...................................................................................................99

NS7 System With a Fault-Tolerant Data Center...............................................................99

NS7 System With a Rack-Mounted UPS....................................................................... 100

SAS Disk Enclosures With a Rack-Mounted UPS......................................................... 102

Non-Supported UPS Configurations......................................................................................... 103

NS7 System With a Data Center UPS, Single Power Rail.............................................103

NS7 System With Data Center UPS, Both Power Rails.................................................105

NS7 System With Rack-Mounted UPS and Data Center UPS in Parallel......................107

NS7 System With Two Rack-Mounted UPS in Parallel..................................................108

NS7 System With Cascading Rack-Mounted UPS and Data Center UPS.....................110

Power Distribution Unit (PDU) Types for an Enterprise Series

Rack .....................................................................................................112

Four Intelligent PDUs Without UPS – (NA/JPN and INTL, Single-Phase and Three-Phase)... 113

Four Intelligent PDUs With Single-Phase UPS – (NA/JPN and INTL)...................................... 114

Four Intelligent PDUs With Three-Phase UPS (NA/JPN and INTL) .........................................115

Two Intelligent PDUs Without UPS — (NA/JPN and INTL, Single-Phase and Three-Phase)...116

Two Intelligent PDUs With Single-Phase UPS — (NA/JPN and INTL)..................................... 117

Two Intelligent PDUs With Three-Phase UPS — (NA/JPN and INTL)......................................118

Four Modular PDUs With Three-Phase UPS (NA/JPN and INTL)............................................ 119

Four Modular PDUs With Single-Phase UPS (NA/JPN and INTL)........................................... 120

Four Modular PDUs Without UPS — (NA and JPN, Single-Phase and Three-Phase).............121

Two Modular PDUs Without UPS — (NA/JPN and INTL, Single-Phase and Three-Phase).....122

Two Modular PDU Connections With Single-Phase UPS — (NA/JPN and INTL).................... 123

Two Modular PDU Connections With Three-Phase UPS — (NA/JPN and INTL).....................124

AC Input Power for Enterprise Series and Intelligent Racks.....................................................125

Enclosure AC Input for the Enterprise Series or Intelligent Rack............................................. 128

Warranty information..........................................................................130

Belarus Kazakhstan Russia marking........................................................................................ 130

Turkey RoHS material content declaration............................................................................... 131

4

Page 5

Ukraine RoHS material content declaration..............................................................................131

5

Page 6

©

Copyright

2015, 2018 Hewlett Packard Enterprise Development LP

Notices

The information contained herein is subject to change without notice. The only warranties for Hewlett

Packard Enterprise products and services are set forth in the express warranty statements accompanying

such products and services. Nothing herein should be construed as constituting an additional warranty.

Hewlett Packard Enterprise shall not be liable for technical or editorial errors or omissions contained

herein.

Confidential computer software. Valid license from Hewlett Packard Enterprise required for possession,

use, or copying. Consistent with FAR 12.211 and 12.212, Commercial Computer Software, Computer

Software Documentation, and Technical Data for Commercial Items are licensed to the U.S. Government

under vendor's standard commercial license.

Links to third-party websites take you outside the Hewlett Packard Enterprise website. Hewlett Packard

Enterprise has no control over and is not responsible for information outside the Hewlett Packard

Enterprise website.

Acknowledgments

Intel®, Itanium®, Pentium®, Xeon®, Intel Inside®, and the Intel Inside logo are trademarks of Intel

Corporation in the U.S. and other countries.

Microsoft® and Windows® are either registered trademarks or trademarks of Microsoft Corporation in the

United States and/or other countries.

Adobe® and Acrobat® are trademarks of Adobe Systems Incorporated.

Java® and Oracle® are registered trademarks of Oracle and/or its affiliates.

UNIX® is a registered trademark of The Open Group.

Page 7

About This Document

This guide provides an overview of HPE Integrity NonStop X NS7 systems, specifications for planning

system installation, and is intended for personnel who have completed Hewlett Packard Enterprise

training on NonStop X system support.

Supported Release Version Updates (RVUs)

This publication supports L15.08 and all subsequent L-series R

replacement publication.

VUs until otherwise indicated in a

New and Changed Information in 799257–005

This edition introduces the new:

HPE Integrity NonStop X NS7 X3 system

•

• HPE Integrity NonStop X NS3 Carrier-Grade (CG) X3 system

• HPE NonStop X Gen 10 CLIM

About This Document 7

Page 8

HPE Integrity NonStop X NS7 Systems

The HPE Integrity NonStop X NS7 system family introduces Intel® Xeon® x86 technology to NonStop by

using a new high bandwidth, low latency InfiniBand system interconnect that is fully-integrated with the

fault-tolerant HPE NonStop Operating system.

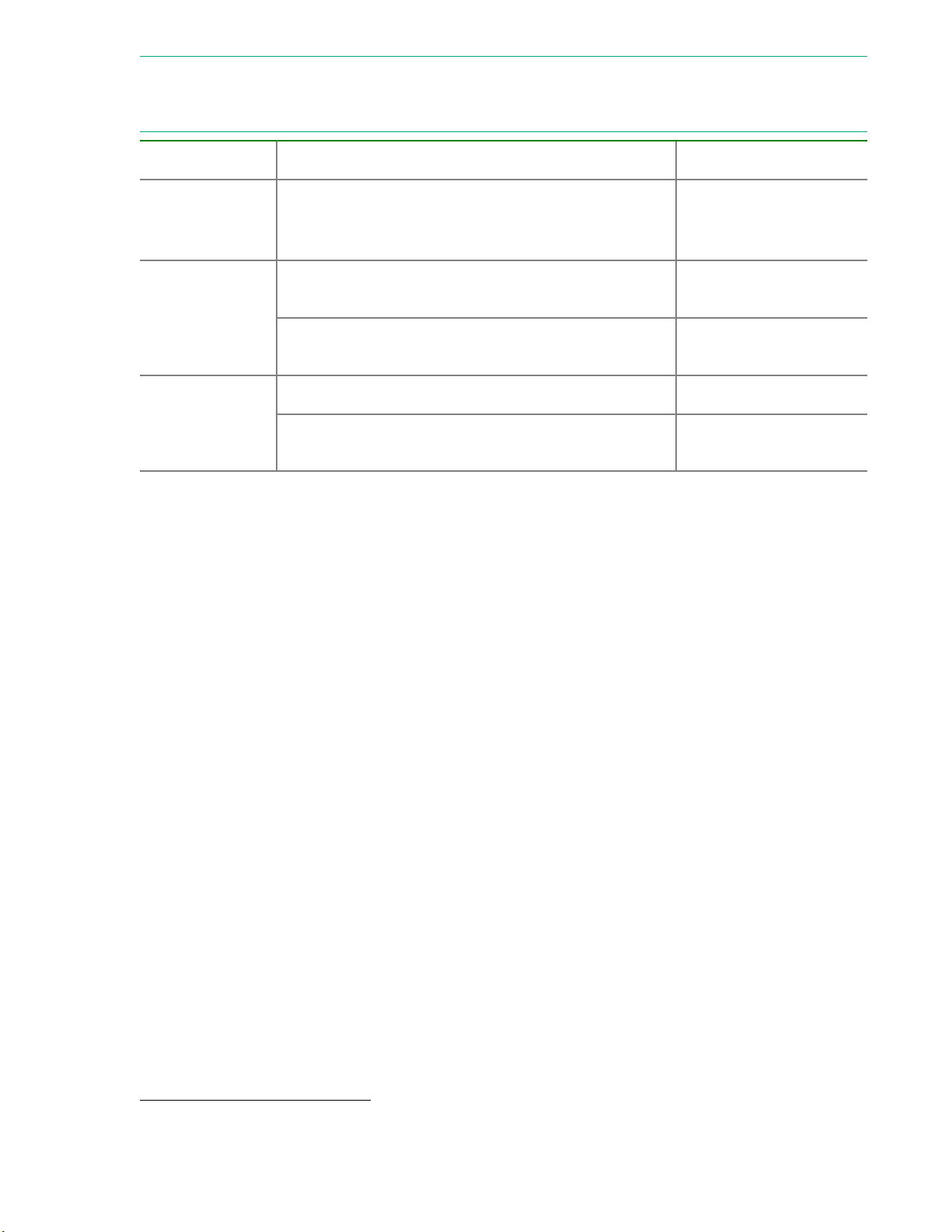

Table 1: Characteristics of the NS7 X1 introduced on L15.02

Processor/Processor model Intel®

Supported RVU for the

system

2-, 4-, and 6-core software

licensing options

Core licensing file This file is required; see

Minimum CLIM DVD

version required for RVU

Rack 36U or 42U

Processors 2 to 16 processors configured in pairs

Memory 64GB, 128GB, and 192GB memory configurations

KMSF See Planning Kernel Managed Swap (KMS) Space on page 68

Maximum CLIMs in a 16

CPU NonStop X system

Minimum CLIMs for faulttolerance

Xeon® x86 processors

L15.02 and later RVUs

Supported

Core Licensing

See the CLuster I/O Module (CLIM) Software Compatibility Guide

(L15.02+) for supported version

NOTE: This file is preinstalled on new systems

56 CLuster I/O Modules (CLIMs) — Storage, IP, or Telco

• 2 Storage CLIMs

2 Networking CLIMs (IP or Telco)

•

on page 11

Maximum SAS disk

enclosures per Storage

CLIM pair

Maximum SAS disk drives 100 per Storage CLIM pair

Tape support through

Storage CLIMs

Minimum/maximum IO

Expansion IB Switches

ESS support through

Storage CLIMs

Maintenance LAN Redundant configuration only

Minimum NonStop System

Consoles for fault-tolerance

Connection to NonStop X

Cluster Solution

8 HPE Integrity NonStop X NS7 Systems

A Storage CLIM pair supports a maximum of 4 SAS disk enclosures

HPE LTO6 Tape Data Cartridge, HPE NonStop BackBox VTC, HPE

NonStop BackBox VTR, and HPE Virtualized BackBox

0 to 4 (2 pairs)

HPE XP 7 Storage Array and HPE XP P9500 Storage Array

2

Supported. For more information, see the NonStop X Cluster Solution

Manual

Page 9

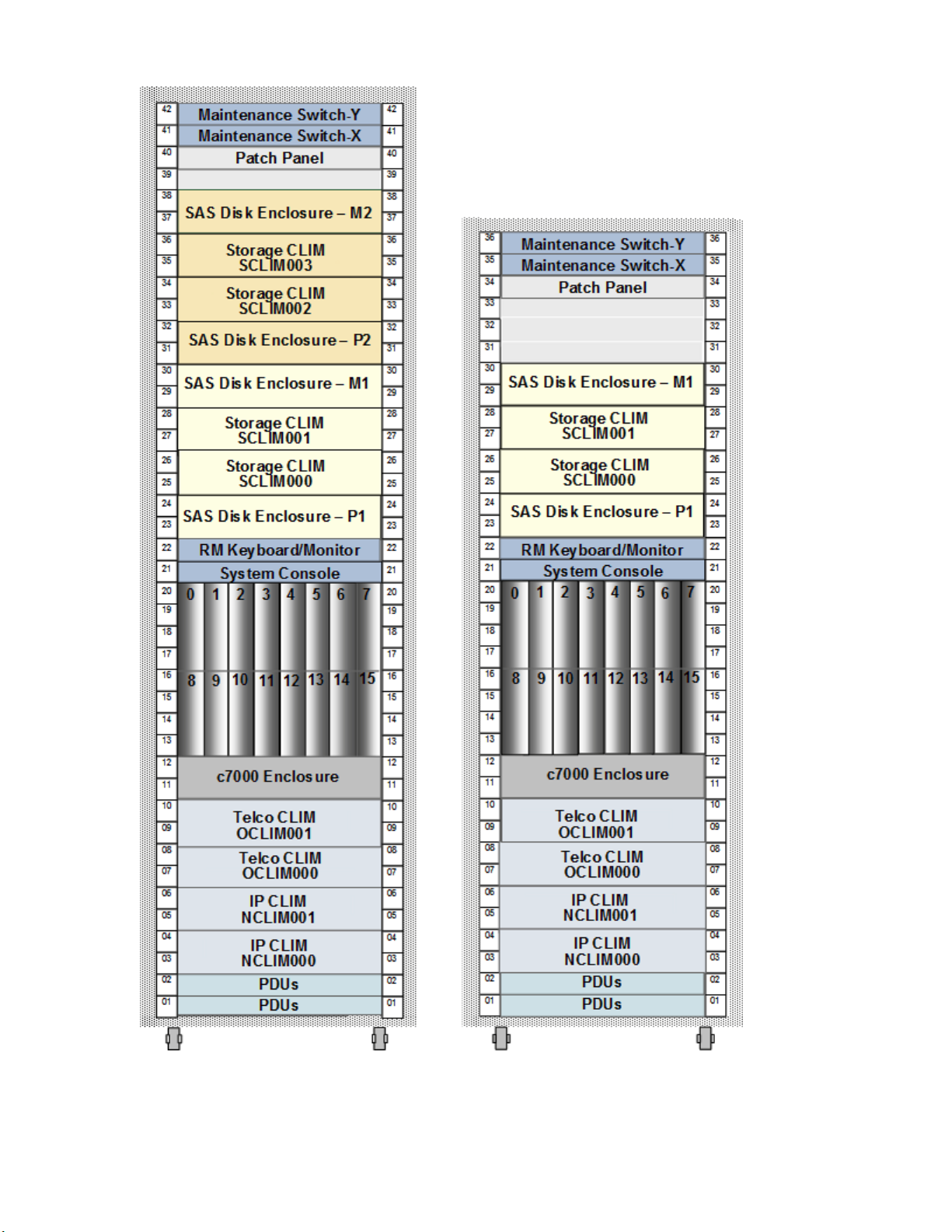

The following illustration shows two example configurations for AC power NS7 systems.

Figure 1: Example NS7 System Configurations (42U and 36U)

HPE Integrity NonStop X NS7 Systems 9

Page 10

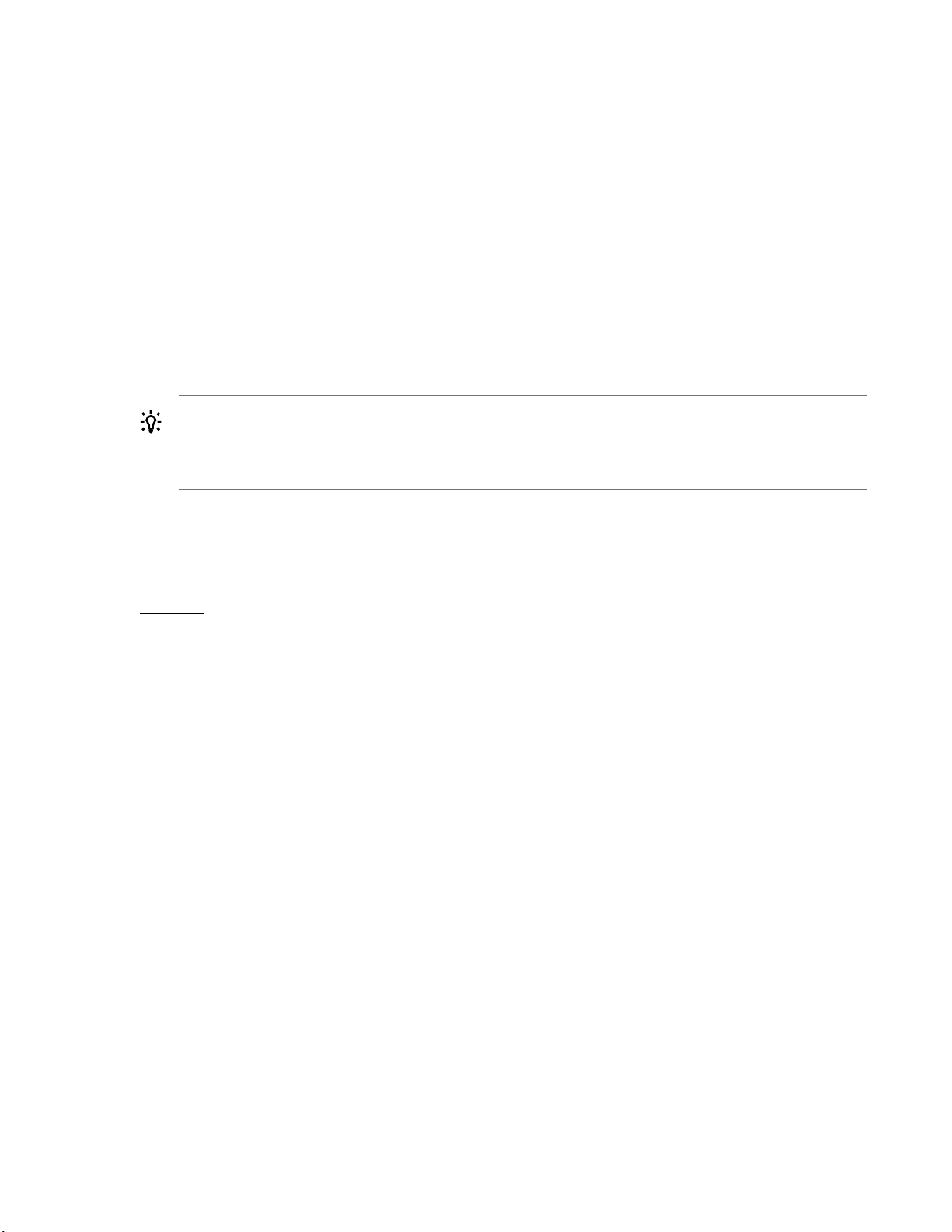

Table 2: Characteristics of the NS7 X2 introduced on L16.05

Processor/Processor model Intel®

Supported RVU for the

system

2-, 4-, and 6-core software

licensing options

Core licensing file This file is required; see

Minimum CLIM DVD

version required for RVU

Rack 36U or 42U

Processors 2 to 16 processors configured in pairs

Memory 64GB, 128GB, and 192GB memory configurations

Kernel Managed Swap

Facility

Maximum CLIMs in a 16

CPU NonStop X system

Minimum CLIMs for faulttolerance

Xeon® x86 processors

L16.05 and later RVUs

Supported

Core Licensing

See the CLuster I/O Module (CLIM) Software Compatibility Guide

(L15.02+) for supported version.

NOTE: This file is preinstalled on new systems.

See Planning Kernel Managed Swap (KMS) Space on page 68

56 CLuster I/O Modules (CLIMs) — Storage, IP, or Telco

• 2 Storage CLIMs

2 Networking CLIMs (IP or Telco)

•

on page 11

Maximum SAS disk

enclosures per Storage

CLIM pair

Maximum SAS disk drives 100 per Storage CLIM pair.

Tape support through

Storage CLIMs

Minimum/maximum IO

Expansion IB Switches

ESS support through

Storage CLIMs

Maintenance LAN Redundant configuration only

Minimum NonStop System

Consoles for fault-tolerance

Connection to NonStop X

Cluster Solution

A Storage CLIM pair supports a maximum of 4 SAS disk enclosures

HPE LTO6 Tape Data Cartridge, HPE NonStop BackBox VTC, HPE

NonStop BackBox VTR, and HPE Virtualized BackBox

0 to 4 (2 pairs)

HPE XP 7 Storage Array and HPE XP P9500 Storage Array

2

Supported. For more information, see the NonStop X Cluster Solution

Manual

10 HPE Integrity NonStop X NS7 Systems

Page 11

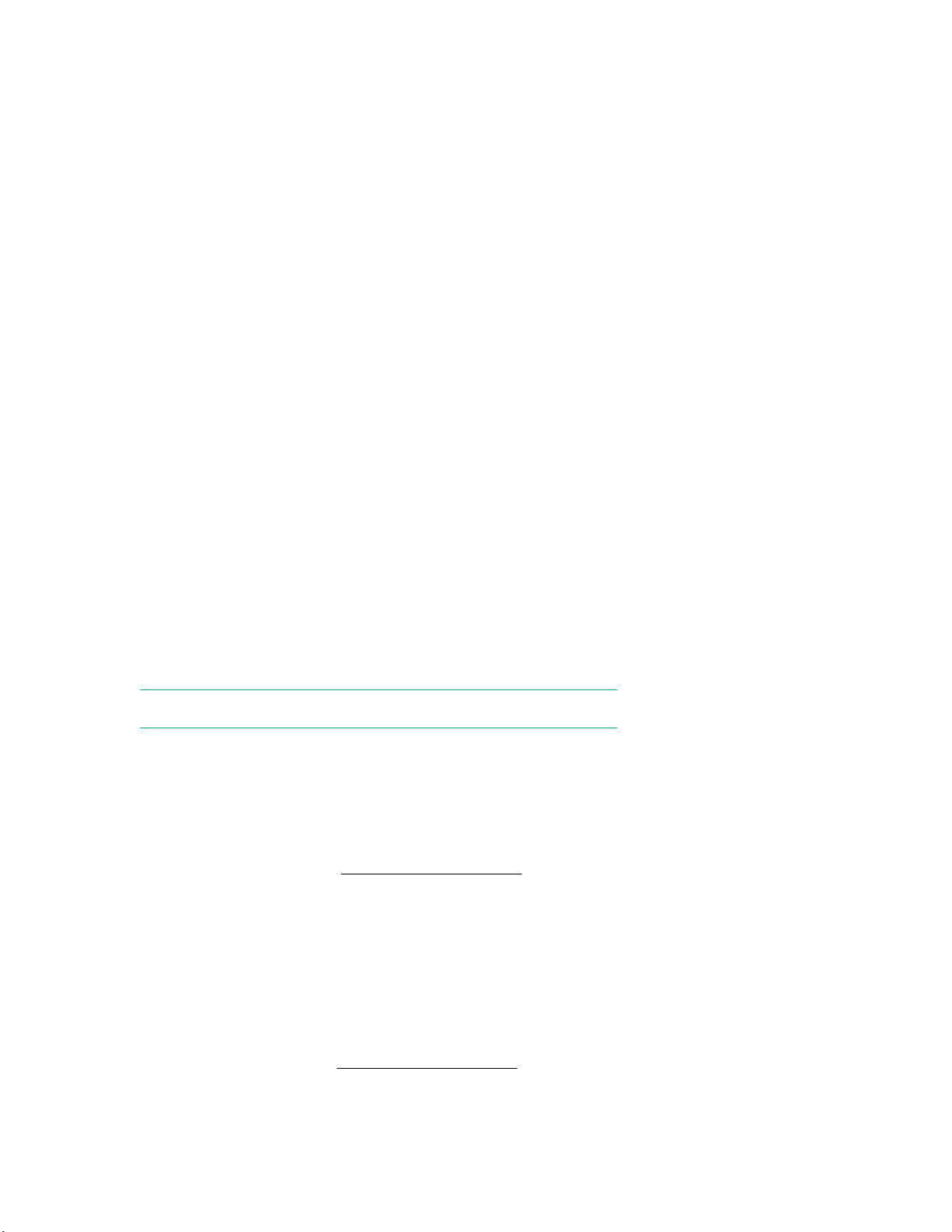

Table 3: Characteristics of the NS7 X3 introduced on L18.08

Processor/Processor model Intel®

Supported RVU for the

system

2-, 4-, and 6-core software

licensing options

Core licensing file This file is required; see

Minimum CLIM DVD

version required for RVU

Rack 36U or 42U

Processors 2 to 16 processors configured in pairs

Memory 64GB, 128GB, and 256GB memory configurations

Kernel Managed Swap

Facility

Maximum CLIMs in a 16

CPU NonStop X system

Minimum CLIMs for faulttolerance

Xeon® x86 processors

L18.08 and later RVUs

Supported

Core Licensing

See the CLuster I/O Module (CLIM) Software Compatibility Guide

(L15.02+) for supported version.

NOTE: This file is preinstalled on new systems.

See Planning Kernel Managed Swap (KMS) Space on page 68

56 CLuster I/O Modules (CLIMs) — Storage, IP, or Telco

• 2 Storage CLIMs

2 Networking CLIMs (IP or Telco)

•

on page 11

Maximum SAS disk

enclosures per Storage

CLIM pair

Maximum SAS disk drives 100 per Storage CLIM pair

Tape support through

Storage CLIMs

Minimum/maximum IO

Expansion IB Switches

ESS support through

Storage CLIMs

Maintenance LAN Redundant configuration only

Minimum NonStop System

Consoles for fault-tolerance

Connection to NonStop X

Cluster Solution

Core Licensing

A core license file is required for the system and is automatically included with new NonStop X systems

starting with L15.02 and later

A Storage CLIM pair supports a maximum of 4 SAS disk enclosures

HPE LTO6 Tape Data Cartridge, HPE NonStop BackBox VTC, HPE

NonStop BackBox VTR, and HPE Virtualized BackBox

0 to 4 (2 pairs)

HPE XP 7 Storage Array and HPE XP P9500 Storage Array

2

Supported. For more information, see the NonStop X Cluster Solution

Manual

. NS7 systems support 2-, 4-, and 6-core license options.

Anytime you upgrade the level of cores, expand your system by adding server blades, or migrate the

system, you must update your license file. Your service provider is responsible for obtaining and installing

HPE Integrity NonStop X NS7 Systems 1

1

Page 12

this license on your behalf. You will experience a system alarm and dialout if the license file is missing

from your system.

NonStop X NS7 Standard and Optional Hardware

• c7000 Enclosure on page

•

NonStop X NS7 Server Blades on page 13

• CLuster I/O Modules (CLIMs) on page 13

• SAS Disk Enclosures on page 21

• Maintenance Switch on page

•

NonStop X FDR IB ADI Switch on page

•

NonStop IO Expansion IB Switch

•

NonStop System Console on page

•

UPS and ERM (Optional)

•

Enterprise Storage System (Optional) on page

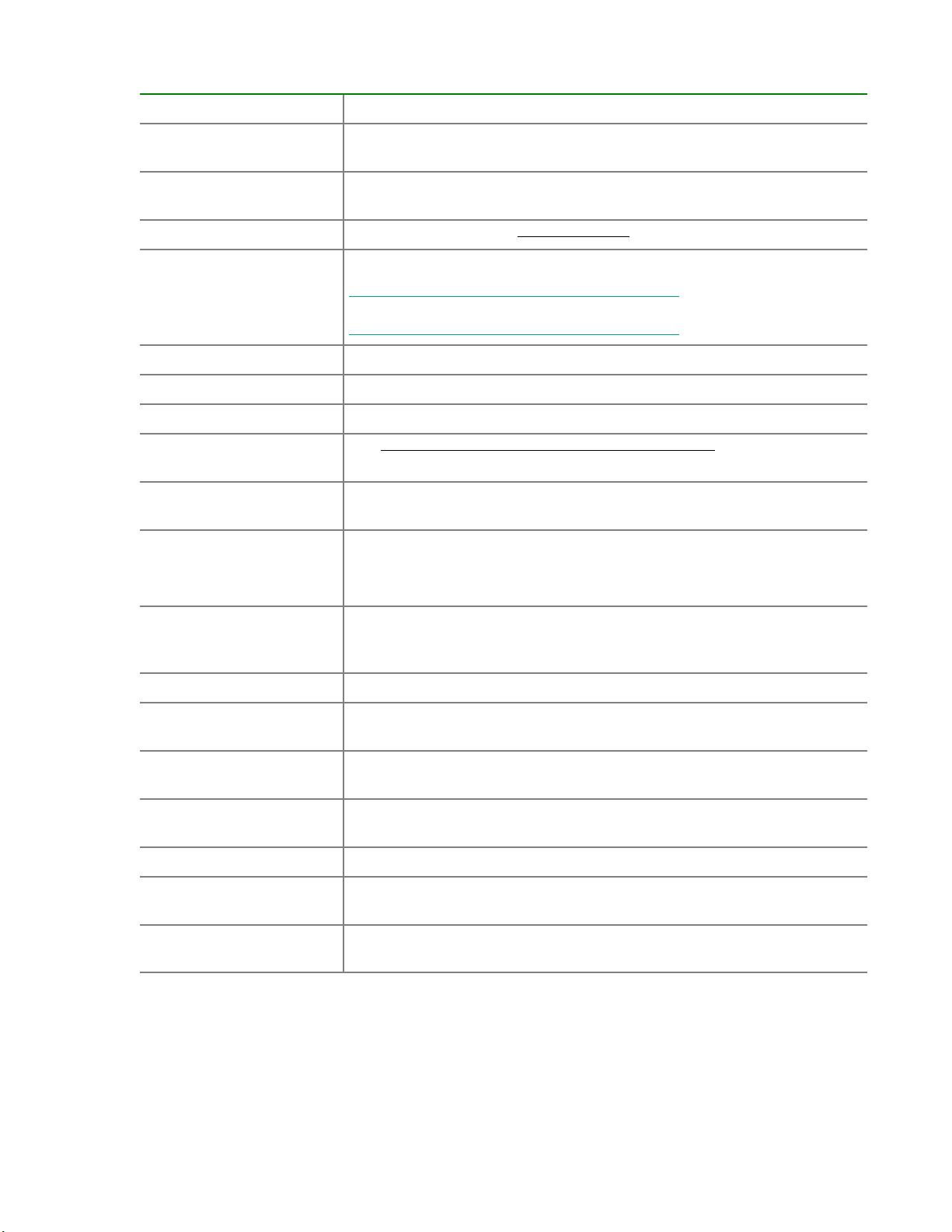

c7000 Enclosure

The c7000 enclosure unifies NonStop X server blades and redundant high-bandwidth InfiniBand

interconnects in a 10U footprint and features:

•

Up to 16 half-height NonStop X Server Blades in the c7000 enclosure – configured in pairs.

• Two Interconnect Ethernet switches that provide redundant Maintenance LAN connections for HSS

bootcode download.

12

23

23

on page 22

23

on page 24

24

• Two Interconnect InfiniBand switches that provide IB connectivity between processors and I/O

infrastructure.

• An Intelligent Infrastructure that supports enhanced midplane signal integrity and compatibility with

HPE Insight Control.

• Two Onboard Administrator (OA) modules manage and monitor the Intelligent Infrastructure and let

you monitor and control resources using the HPE Insight Display as described in the HPE

BladeSystem Onboard Administrator User Guide.

12 HPE Integrity NonStop X NS7 Systems

Page 13

NonStop X NS7 Server Blades

An NS7 system achieves full software fault tolerance by running the NonStop operating system on the

NonStop X NS7 Server Blades.

NS7 Server Blade characteristics

• Half-height server blade that features Intel Xeon processors and an InfiniBand

interface mezzanine card to provide InfiniBand fabric connectivity

Provides a maximum of 192 GB of memory per server blade

•

• One HPE 10Gb dual-port FlexibleLOM Ethernet Adapter

• One Infiniband FDR dual-port Host Channel Adapter (HCA)

• Environment Monitoring Services to OA

• Disk bays and Smart Array Controller are not used

NOTE: Different sever blade models cannot coexist in the same system. For example, a

BL460c Gen8 and a Gen9 server blade cannot coexist in the same system.

NS7 system Ships with

NS7 X3 BL460c Gen10 server blades

NS7 X2 BL460c Gen9 server blades

NS7 X1 BL460c Gen8 server blades

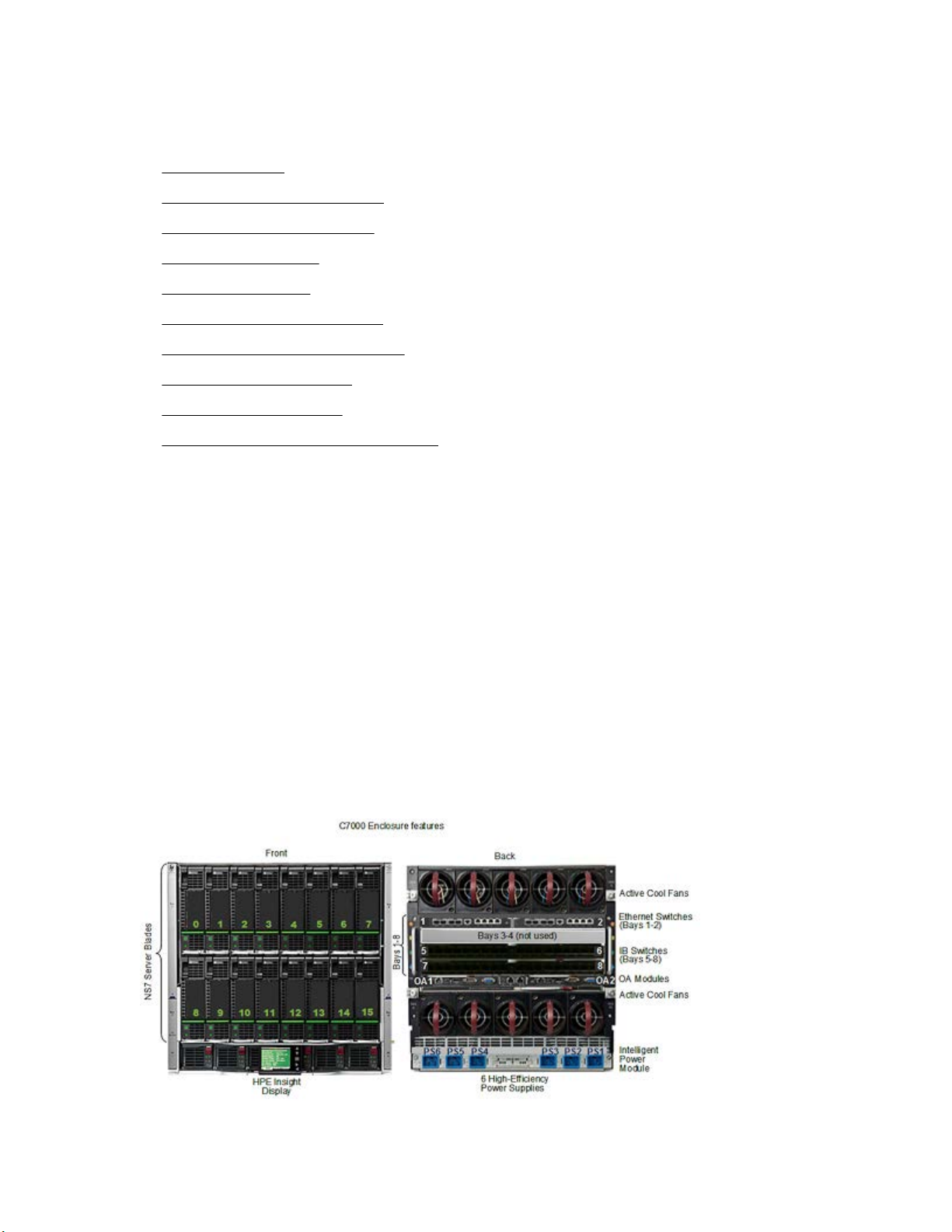

CLuster I/O Modules (CLIMs)

NS7 systems support the

page 16

subsystem.

To identify a CLIM, see the number on the rear label; this number is listed as the part number in OSM.

NS7 system Ships with

NS7 X3 Gen10 CLIMs

NS7 X2 Gen9 CLIMs

NS7 X1 Gen8 CLIMs

which function as I/O or Ethernet adapters and are managed by the Cluster I/O Protocols (CIP)

NS7 Storage CLIMs on page

NS7 Gen9 IP CLIM and Telco CLIM on

19,

HPE Integrity NonStop X NS7 Systems 13

Page 14

NS7 IP CLIM and Telco CLIM

The IP CLIM and T

10 Gigabit Ethernet (10GbE) adapters and provide five Ethernet ports with configuration options of all

copper (Option 1) or fiber/copper (Option 2).

The NS7 supports three generations of IP/Telco CLIMs: Gen10, Gen9, and Gen8.

elco CLIM are sometimes referred to as Networking CLIMs. These CLIMs function as

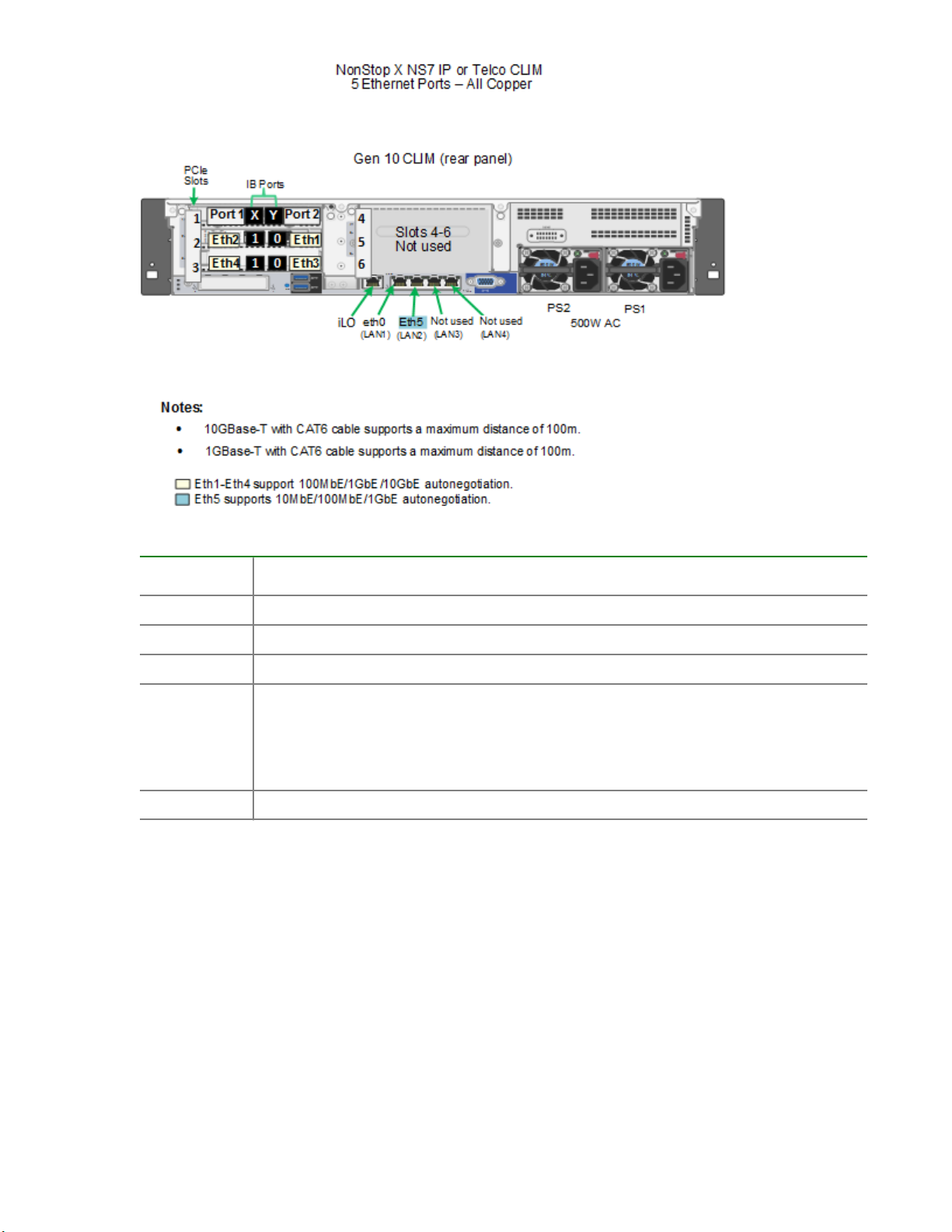

NS7 Gen10 IP and Telco CLIMs

NS7 Gen10 IP/T

Item Characteristics of NS7 Gen10 IP or Telco CLIM

Slot 1 InfiniBand interface card provides InfiniBand X-fabric and Y-fabric connections.

Slot 2 10GbE 2-port adapter copper NIC for Eth1 and Eth2 customer interfaces.

Slot 3 10GbE 2-port adapter copper NIC for Eth3 and Eth4 customer interfaces.

LAN1 - LAN4

iLO

elco CLIM Option 1 — Four 10GBase-T and One 1GBase-T Interfaces

• LAN1 is reserved for Maintenance LAN interface for maintenance support.

LAN2 provides 1GbE port for Eth5 interface.

•

• LAN3 and LAN4 are not used.

Maintenance LAN interface.

14 HPE Integrity NonStop X NS7 Systems

Page 15

NS7 Gen10 IP/Telco CLIM Option 2 — Four 10GBase-SR and One 1GBase-T Interfaces

Item Characteristics of NS7 Gen10 IP or Telco CLIM

Slot 1 InfiniBand interface card provides InfiniBand X-fabric and Y-fabric connections.

Slot 2 10GbE 2-port adapter for Eth1 and Eth2 customer interfaces.

Slot 3 10GbE 2-port adapter for Eth3 and Eth4 customer interfaces.

LAN1 - LAN4

iLO

• LAN1 is reserved for Maintenance LAN interface for maintenance support.

LAN2 provides 1GbE port for Eth5 interface.

•

• LAN3 and LAN4 are not used.

Maintenance LAN interface.

HPE Integrity NonStop X NS7 Systems 15

Page 16

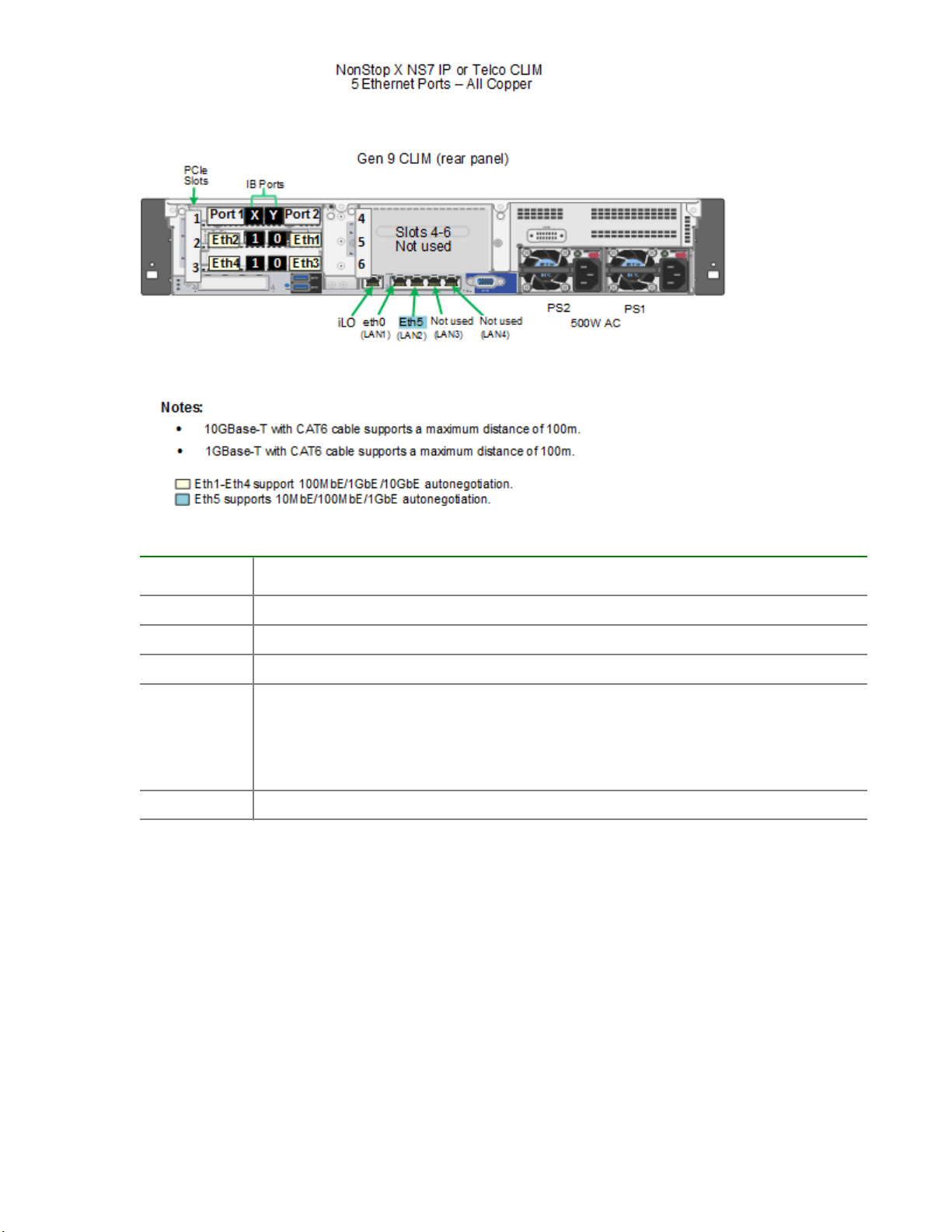

NS7 Gen9 IP CLIM and Telco CLIM

NS7 Gen9 IP/Telco Gen9 CLIM Option 1 — Four 10GBase-T and One 1GBase-T Interfaces

Item Characteristics

Slot 1 InfiniBand interface card provides InfiniBand X-fabric and Y-fabric connections.

Slot 2 10GbE 2-port adapter copper NIC for Eth1 and Eth2 customer interfaces.

Slot 3 10GbE 2-port adapter copper NIC for Eth3 and Eth4 customer interfaces.

LAN1 - LAN4

iLO

• LAN1 is reserved for Maintenance LAN interface for maintenance support.

LAN2 provides 1GbE port for Eth5 interface.

•

• LAN3 and LAN4 are not used.

Maintenance LAN interface.

16 HPE Integrity NonStop X NS7 Systems

Page 17

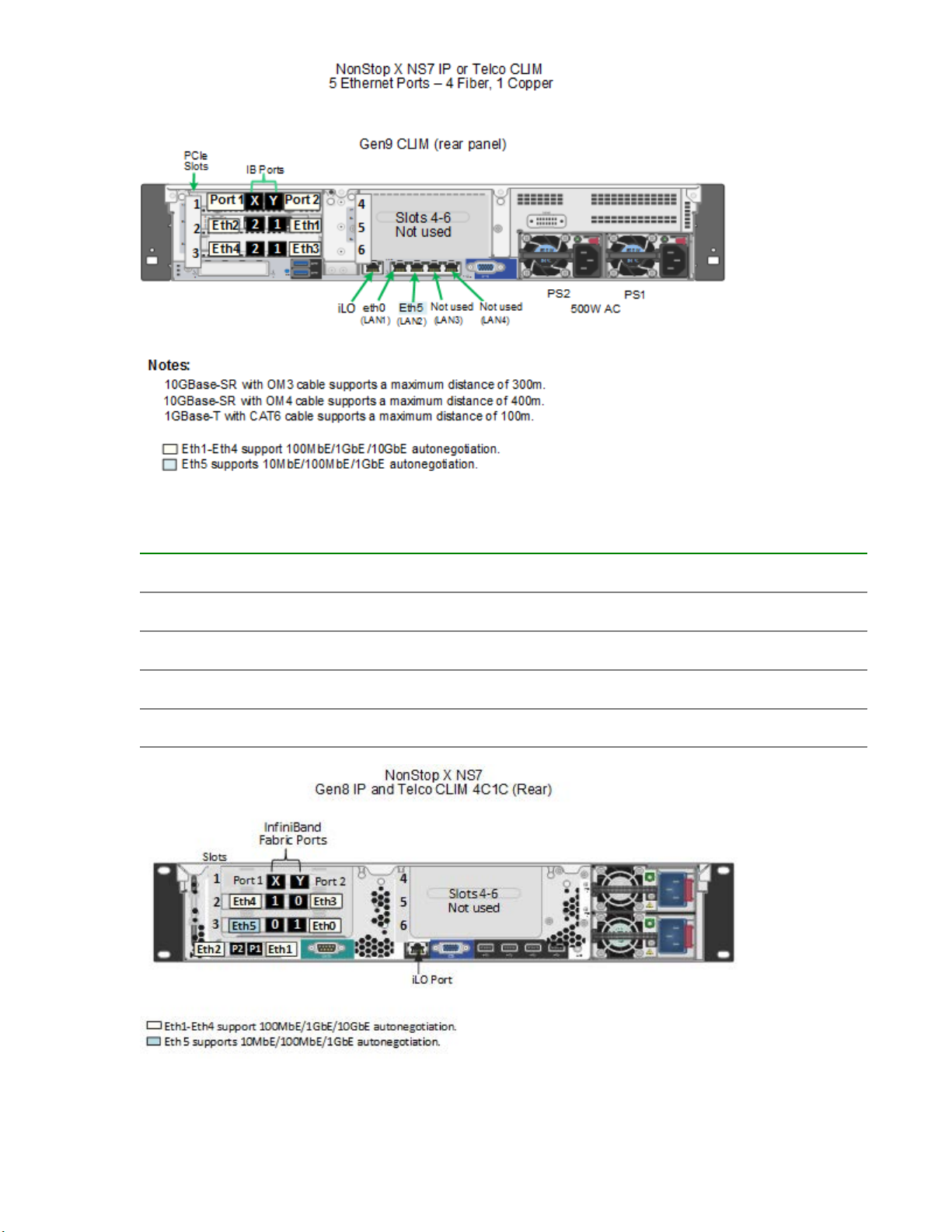

NS7 IP/Telco Gen9 CLIM Option 2 — Four 10GBase-SR and One 1GBase-T Interfaces

Item Characteristics

Slot 1 InfiniBand interface card provides InfiniBand X-fabric and Y-fabric connections.

Slot 2 10GbE 2-port adapter for Eth1 and Eth2 customer interfaces.

Slot 3 10GbE 2-port adapter for Eth3 and Eth4 customer interfaces.

LAN1 - LAN4

iLO

• LAN1 is reserved for Maintenance LAN interface for maintenance support.

LAN2 provides 1GbE port for Eth5 interface.

•

• LAN3 and LAN4 are not used.

Maintenance LAN interface.

HPE Integrity NonStop X NS7 Systems 17

Page 18

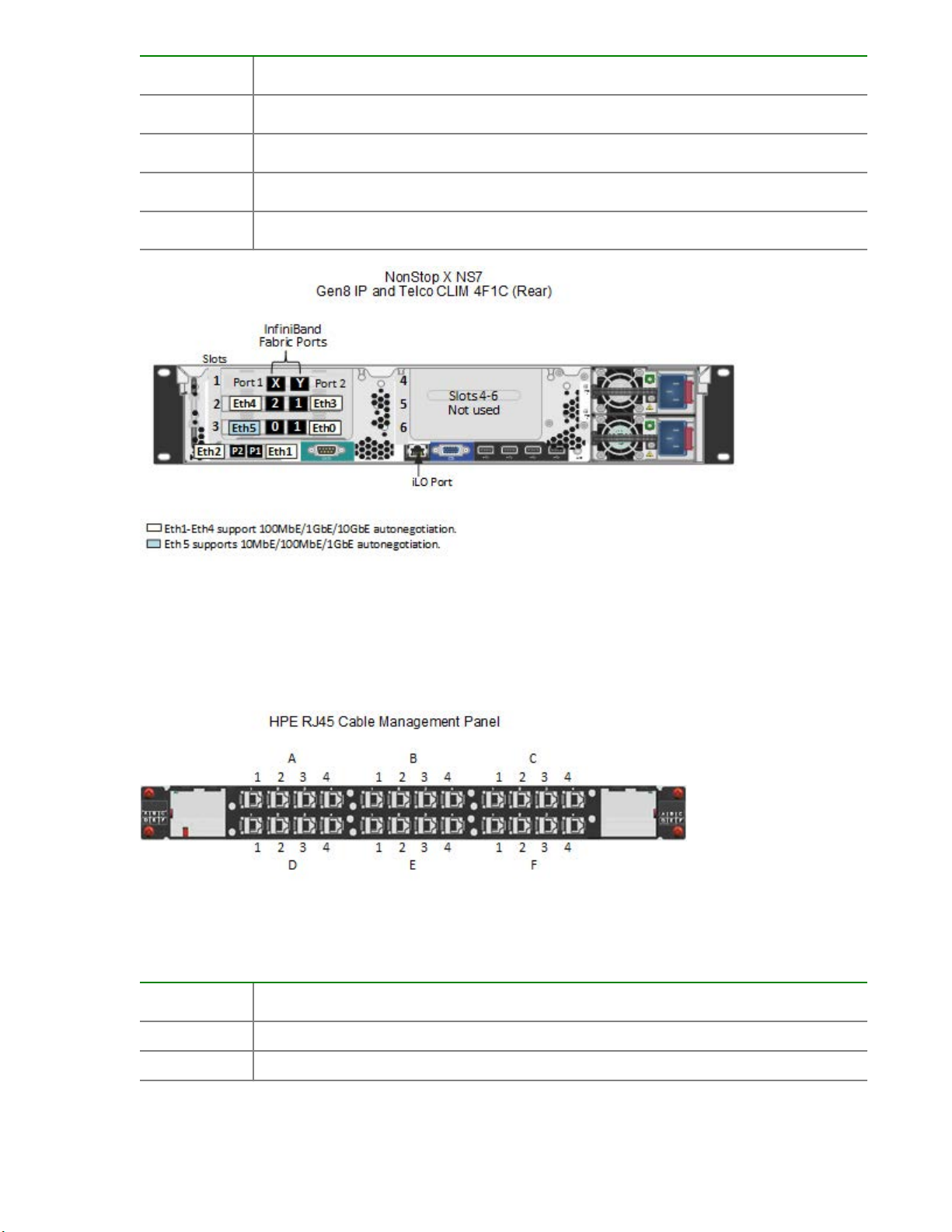

NS7 Gen8 IP CLIM and Telco CLIM

NS7 Gen8 IP or Telco CLIM Option 1 — Four 10GBase-T and One 1GBase-T

Interface Characteristics of Gen8 IP or Telco CLIM

Slot 1 InfiniBand interface card which provides the IB fabric connections

Slot 2 10GbE 2-port adapter for Eth4 and Eth3 customer ports

Slot 3 1GbE 2-port adapter for Eth5 customer port and Eth0 for maintenance support.

FlexLOM 10GbE 2-port adapter for Eth2 and Eth1 customer ports

IP or Telco CLIM Option 2 — Four 10GBase-SR and One 1GBase-T

18 HPE Integrity NonStop X NS7 Systems

Page 19

Interface Characteristics of Gen8 IP or Telco CLIM

Slot 1 InfiniBand interface card which provides the IB fabric connections

Slot 2 10GbE 2-port adapter for Eth4 and Eth3 customer ports

Slot 3 1GbE 2-port adapter for Eth5 customer port and Eth0 for maintenance support.

FlexLOM 10GbE 2-port adapter for Eth2 and Eth1 customer ports

CLIM patch panel

CLIM Cable Management Patch Panels

The HPE CLIM uses two Cable Management patch panels for RJ45 and LC (optical) connections. The

RJ45 patch panel is shown below

service provider to the CLuster I/O (CLIM) Installation and Configuration Guide (15.02+).

NS7 Storage CLIMs

A Storage CLIM functions as an I/O adapter supporting SAS disk drives and SAS tapes and optionally

ESS and FC tape devices using 3 PCIe HBA slots.

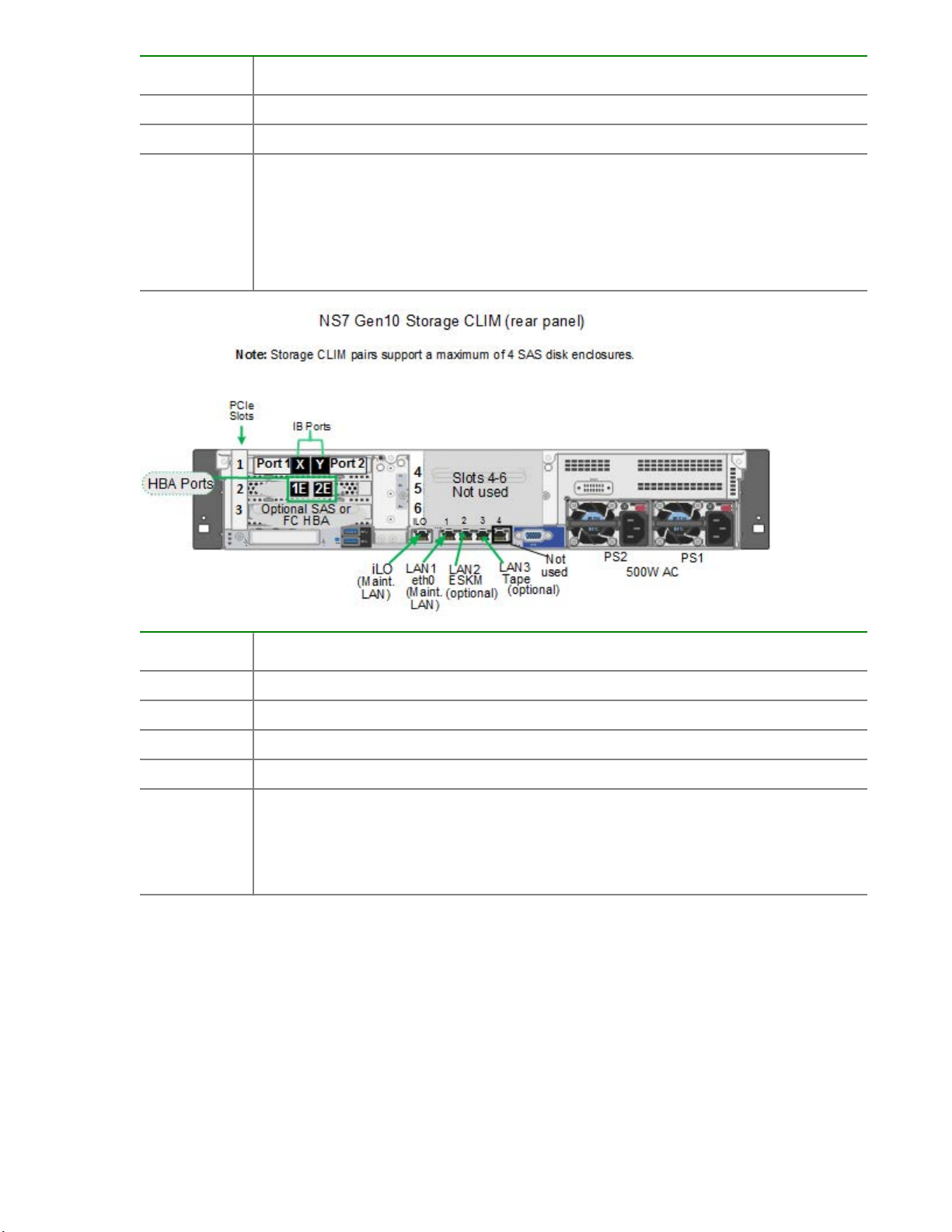

Item Characteristics of Gen10 Storage CLIM

Slot 1 InfiniBand interface card provides InfiniBand X-fabric and Y-fabric connections.

. Both are preinstalled in new systems. For more information, refer your

Slot 2 SAS HBA with two 12G SAS ports: 1E, 2E.

Table Continued

HPE Integrity NonStop X NS7 Systems 19

Page 20

Item Characteristics of Gen10 Storage CLIM

Slot 3 Optional order of SAS HBA with two 12G SAS ports or FC HBA with 16Gb FC ports.

iLO

LAN1 - LAN4

Provides maintenance services and connects to Maintenance LAN.

• LAN1 is reserved for Maintenance LAN interface for maintenance support.

LAN2 provides 1GbE port for Eth1 interface to support ESKM (optional).

•

• LAN3 provides 1GbE port for Eth2 interface to support Virtualized BackBox.

• LAN4 is not used.

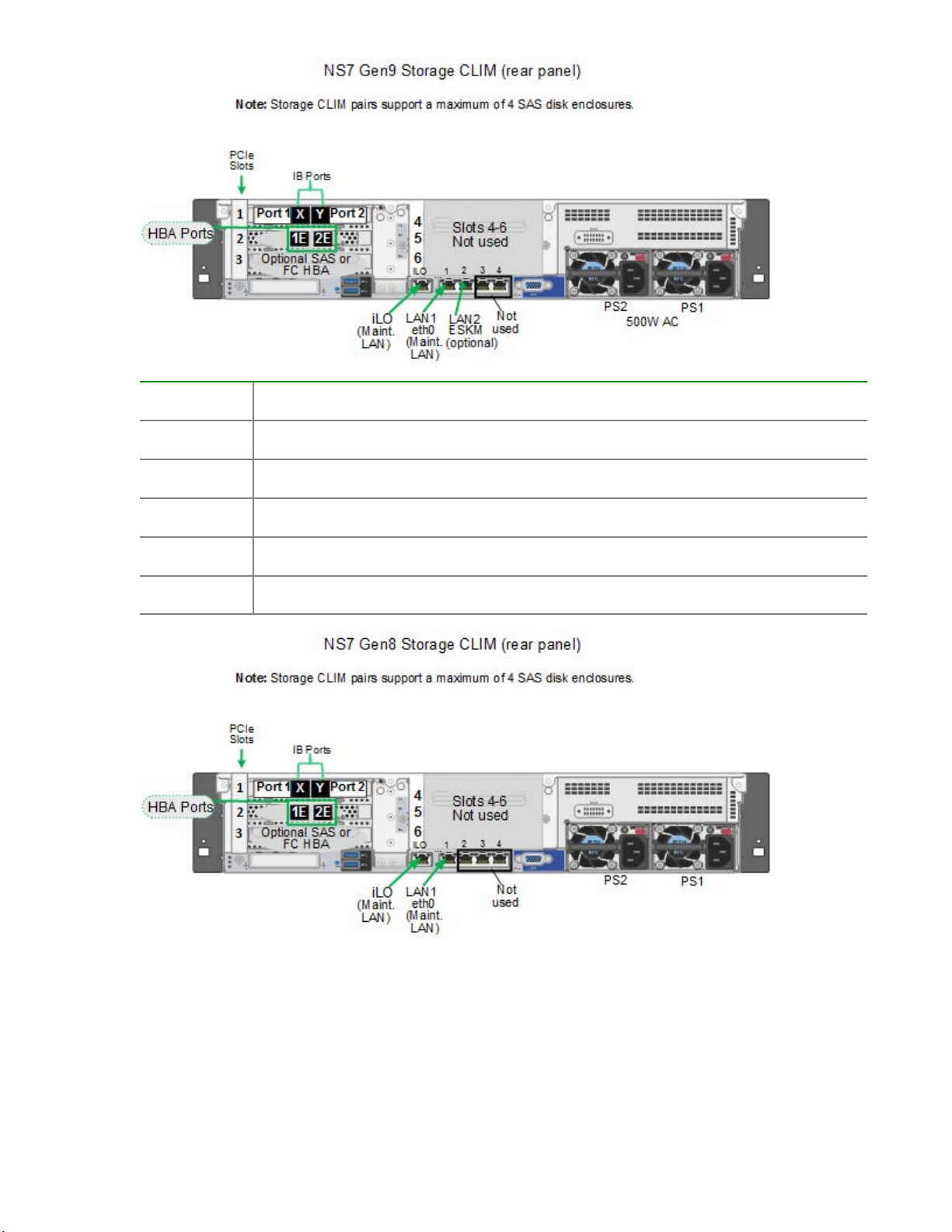

Item Characteristics of Gen9 Storage CLIM

Slot 1 InfiniBand interface card provides InfiniBand X-fabric and Y-fabric connections.

Slot 2 SAS HBA with two 12G SAS ports: 1E, 2E.

Slot 3 Optional order of SAS HBA with two 12G SAS ports or FC HBA with 16Gb FC ports.

iLO Provides maintenance services and connects to Maintenance LAN.

LAN1 - LAN4

• LAN1 is reserved for Maintenance LAN interface for maintenance support.

• LAN2 provides 1GbE port for Eth1 interface to support ESKM (optional).

• LAN3 and LAN4 are not used.

20 HPE Integrity NonStop X NS7 Systems

Page 21

Item Characteristics of Gen8 Storage CLIM

Slot 1 InfiniBand interface card provides InfiniBand X-fabric and Y-fabric connections.

Slot 2 SAS HBA with two 6G SAS ports: 1E, 2E.

Slot 3 Optional order of SAS HBA with two 6G SAS ports or FC HBA with 8Gb FC ports.

iLO Provides maintenance services and connects to Maintenance LAN.

LAN1 LAN1 is reserved for Maintenance LAN interface for maintenance support.

SAS Disk Enclosures

The HPE D3700/3710 SAS disk enclosures provide the storage capacity for a Storage CLIM. The

enclosures hold 25 2.5” SAS Smart Carrier HDDs and SSDs with redundant power and cooling as

described in the HPE D3600/D3700 Disk Enclosure User Guide.

The following illustration shows the front and rear panel of the D3700 SAS Disk Enclosure.

HPE Integrity NonStop X NS7 Systems 21

Page 22

NOTE: The D3710 SAS disk enclosure uses the same firmware file, IO modules, drive locations, and

hardware FRUs as the D3700 but has a dif

ferent bezel.

CAUTION: If the WRITECACHE attribute is enabled on an HDD or SSD disk volume that is

connected to a Storage CLIM, using a rack-mounted UPS to prevent data loss on that volume is

recommended. The WRITECACHE enabled (WCE) option controls whether write caching is

performed for disk writes.

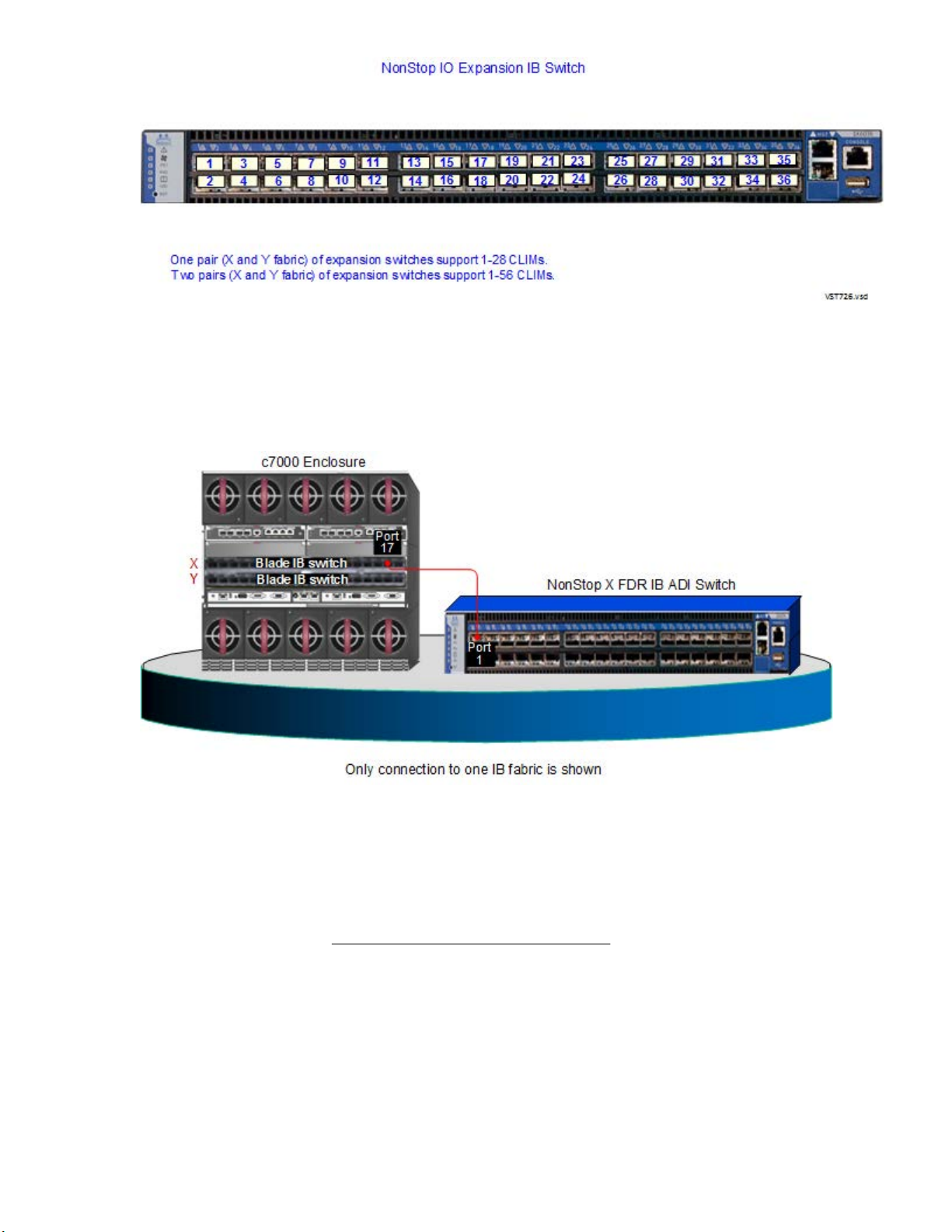

NonStop IO Expansion IB Switch

NOTE: For information about the cluster switch used by the NonStop X Cluster Solution, see the NonStop

X Cluster Solution Manual.

The HPE NonStop IO Expansion 36 port, IB FDR Managed switch provides InfiniBand connectivity to

support CLIM I/O connections.

For information on connecting the switch, refer your service provider to the Technical Document for NS7

Systems on page 26 and the CLuster I/O (CLIM) Installation and Configuration Guide (L15.02+).

22 HPE Integrity NonStop X NS7 Systems

Page 23

NonStop X FDR IB ADI Switch

HPE NonStop X FDR IB ADI switches provide IB fabric connections to support NonStop Application

Direct Interface (NSADI) on NS7 systems running L16.05 and later L-series R

existing kernel level IB system interconnect by providing a direct IB interconnect between NonStop Kernel

(NSK) user space and external server-based applications running on Linux.

VUs. NSADI extends the

Maintenance Switch

The NonStop Maintenance Switch provides the communication network between

components. The c7000 enclosure, CLIM, UPS, PDUs, IO Expansion IB Switch, and system consoles

have maintenance interfaces.

A NonStop X system requires multiple connections to the maintenance switch. For more information, refer

your service provider to the

System Hardware Installation Manual.

Technical Document for NS7 Systems on page 26

NonStop System Console

The NonStop system console manages the system and runs maintenance and diagnostic software in

concert with the OSM console tools. T

running Windows Server 2008, 2012, or 2016. New system consoles arrive preconfigured with all

required HPE and third-party console software.

NS7 system

and the NonStop X

o manage the system, an NS7 requires two system consoles

HPE Integrity NonStop X NS7 Systems 23

Page 24

In a future RVU if you need to update your console software, use the HPE NonStop System Console

Installer DVD to install these updates as described in the NonStop System Console Installer Guide.

NOTE: Procedures related to creating or modifying the dedicated service LAN and the system console

configurations on that LAN, must be performed by an authorized Hewlett Packard Enterprise service

provider as described in the Nonstop Dedicated Service LAN Installation and Configuration Guide for

NonStop X systems.

UPS and ERM (Optional)

A rack-mounted uninterruptible power supply (UPS) is optional but recommended to provide power during

power failures when a site UPS is not available.

NOTE: For information on using OSM to manage a site UPS, monitor AC power

see the OSM Configuration Guide.

Hewlett Packard Enterprise supports these rack-mounted UPS modules. Both support up to two HPE

ERMs per UPS; no mixing of UPS and ERM types.

Supported UPS UPS Manuals

Single-phase R5000 HPE UPS R5000 User Guide

Three-phase R12000/3 HPE 3 Phase UPS User Guide

UPS and ERM checklist

√ Verify:

UPS and ERMs are in the lowest portion of the system to avoid tipping and stability issues.

No more than two HPE ERMs are used per UPS; no mixing of UPS or ERM types.

, or for power fail support,

HPE UPS Network Module User Guide

HPE UPS Management Module User Guide

Your service provider has changed the manufacturing default setting ride-through time for the

optional HPE-supported to the appropriate value for the system as described in the NonStop X

System Hardware Manual

If the optional HPE R5000 UPS has been installed, the UPS output voltage setting must be

manually reset by your HPE service provider as instructed in the NonStop X System Hardware

Manual.

Your UPS configuration is supported. See UPS and Data Center Power Configurations on page

99.

Enterprise Storage System (Optional)

An Enterprise Storage System (ESS) is a collection of magnetic disks, their controllers, and a disk cache

in one or more standalone racks. For more information about these connection types, see your Hewlett

Packard Enterprise service provider

24 HPE Integrity NonStop X NS7 Systems

.

Page 25

NOTE: The Fibre Channel Storage Area Network (SAN) switch power cords might not be compatible with

the rack PDU. Contact your Hewlett Packard Enterprise service provider to order replacement power

cords, if needed.

Connection Interfaces, Ports, and Cables Fibre Channel Switches

Direct connect Uses two Fibre Channel HBA interfaces on Storage

CLIM (LC-MMF)

1

Switched Uses four Fibre Channel ports (LC-LC) on a Fibre

Channel SAN switch

Uses Fibre Channel HBA interfaces on Storage CLIM

(LC-MMF)

Combination of

direct and

switched

1

The FC HBA interfaces on the Storage CLIM must be ordered.

For fault tolerance, the primary and backup paths to an ESS logical device (LDEV) must go through

ferent Fibre Channel switches.

dif

Some Storage Area Network (SAN) procedures, such as reconfiguration, can cause the affected switches

to pause. If the pause is long enough, I/O failure occurs on all paths connected to that switch. If both the

primary and the backup paths are connected to the same switch, the LDEV goes down. See the

documentation that accompanies the ESS.

Uses two Fibre Channel ports for each direct connection 1

Uses four Fibre Channel ports for each switched

connection

0

1 or more

1 or more

1

System Management Tools

OSM Package

The HPE Open System Management (OSM) product is the required system management tool for a

NonStop X system. There are several OSM tools and online help for managing the system. For more

information, see the OSM Configuration Guide, the help within the OSM tool, or the OSM Service

Connection User's Guide (L15.02+).

For information on using OSM tools to manage the NonStop Maintenance LAN and system console

configurations, refer your service provider to the Nonstop Dedicated Service LAN Installation and

Configuration Guide for NonStop X Systems.

Onboard Administrator (OA) and Integrated Lights Out (iLO)

The OA is the enclosure's management, processor

c7000 enclosure and NonStop Server Blades. The OA software is integrated with OSM and the

Integrated Lights Out (iLO) management interface. The iLO enables you to perform activities on the

system from a remote location and provides anytime-access to system management information such as

hardware health, event logs, and configuration to troubleshoot the NonStop X Server Blades.

The OA can generate a full inventory, status and configuration report of all the components the OA

supports; this is the so called SHOW ALL report. For details on how to generate this report, see:

http://www.hpe.com/info/OAlog

, subsystem, and firmware base and supports the

HPE Integrity NonStop X NS7 Systems 25

Page 26

Management Subsystems for NS7 Systems

The Cluster I/O Protocols (CIP) subsystem provides a configuration and management interface for I/O on

the system. The CIP subsystem has several tools for monitoring and managing the subsystem. The

Subsystem Control Facility (SCF) also provides monitoring and management of the CIP subsystem. For

more information on using these subsystems, see the Cluster I/O Protocols (CIP) Configuration and

Management Manual.

Technical Document for NS7 Systems

Each new NS7 includes a detailed T

and which describes:

• Rack included with the system and each enclosure installed in the rack

• Rack U location at the bottom edge of each enclosure

• Each cable with source, destination, connector type, cable part number, and connection labels

TIP: It is important to retain all NS7 system records in an Installation Document Packet, including

echnical Document for your system and any configurations forms. To add CLIM configuration

the T

forms to your Installation Document Packet, have your service provider copy the forms from the

CLuster I/O Module (CLIM) Installation and Configuration Manual (L15.02+)

echnical Document that serves as the connection map for the system

Component Location and Identification

Each system resource is identified by a unique case sensitive ASCII resource name. A name can range

from one to a maximum of 64 characters. The components in the system ship with preassigned naming

conventions that you can change. For more information, see Default Naming Conventions for NS7

Systems on page

For the IP addresses of system components, refer your service provider to the NonStop X System

Hardware Installation Manual.

Rack and Offset Physical Location

68.

Rack name and rack of

is located on an external label affixed to the rack, which includes the system name plus a 2-digit rack

number.

Rack offset is labeled on the rails in each side of the rack. These rails are measured vertically in units

called U, with one U measuring 1.75 inches (44 millimeters). The rack is 36U with U1 located at the

bottom and 36U at the top or 42U with U1 located at the bottom and 42U at the top. The rack offset is the

lowest number on the rack that the component occupies.

26 HPE Integrity NonStop X NS7 Systems

fset identify the physical location of components in an NS7 system. The rack name

Page 27

Site Preparation Guidelines for the NS7 System

This chapter provides guidelines for preparing a site for an NS7 system.

Rack Power and I/O Cable Entry

Depending on how the racks are ordered from Hewlett Packard Enterprise and the routing of the AC

power feeds at the site, AC power cords for the PDUs exit either:

Top: Power and I/O cables are routed from above the rack.

•

• Bottom: Power and I/O cables are routed from below the rack.

Emergency Power-Off Switches

Emergency power of

computer equipment contains batteries capable of supplying more than 750 volt-amperes (VA) for more

than five minutes. Systems that have these batteries also have internal EPO hardware for connection to a

site EPO switch or relay. In an emergency, activating the EPO switch or relay removes power from all

electrical equipment in the computer room (except that used for lighting and fire-related sensors and

alarms).

f (EPO) switches are required by local codes or other applicable regulations when

EPO Requirement for NS7 Systems

NS7 systems without an optional UPS (such as an HPE R12000/3 or HPE R5000 UPS) installed in the

rack do not contain batteries capable of supplying more than 750 volt‑amperes (V

minutes, so they do not require connection to a site EPO switch.

EPO Requirement for R5000 UPS

NOTE: T

The rack-mounted R5000 UPS is supported for a single-phase power configuration. Each UPS contains

batteries, has an EPO circuit, and can be optionally installed in a rack. For site EPO switches or relays,

consult your Hewlett Packard Enterprise site preparation specialist or electrical engineer regarding

requirements.

If an EPO switch or relay connector is required for your site, contact your Hewlett Packard Enterprise

representative or see the manual for your UPS for connectors and wiring for the UPS. For information on

the R5000 UPS manual, see UPS and ERM (Optional) on page 24

wo UPS are required for a single-phase power configuration.

A) for more that five

.

EPO Requirement for R12000/3 UPS

The rack-mounted R12000/3, UPS is supported for a three-phase power configuration. This UPS contains

batteries, has a remote EPO (REPO) port, and can be optionally installed in a rack. For site EPO switches

or relays, consult your Hewlett Packard Enterprise site preparation specialist or electrical engineer

regarding requirements.

If an EPO switch or relay connector is required for your site, contact your Hewlett Packard Enterprise

representative or see the manual for your UPS for connectors and wiring. For information on the

R12000/3 UPS manual, see UPS and ERM (Optional) on page

24.

Site Preparation Guidelines for the NS7 System 27

Page 28

Electrical Power and Grounding Quality

Proper design and installation of a power distribution system for a system requires specialized skills,

knowledge, and understanding of appropriate electrical codes and the limitations of the power systems for

computer and data processing equipment. For power and grounding specifications, see Enclosure AC

Input for NonStop X Systems on page 50.

Power Quality

This equipment is designed to operate reliably over a wide range of voltages and frequencies, described

in Enclosure AC Input for NonStop X Systems on page 50

ranges are exceeded. Severe electrical disturbances can exceed the design specifications of the

equipment. Common sources of such disturbances are:

• Fluctuations occurring within the facility’s distribution system

• Utility service low-voltage conditions (such as sags or brownouts)

• Wide and rapid variations in input voltage levels or input power frequency

• Electrical storms or large inductive sources (such as motors and welders)

• Faults in the distribution system wiring (such as loose connections)

To protect the system from electrical disturbances, use a dedicated power distribution system, power

conditioning equipment, and lightning arresters on power cables. For assistance, consult with your

Hewlett Packard Enterprise site preparation specialist or power engineer.

. However, damage can occur if these

Grounding Systems

The site building must provide a power distribution safety ground/protective earth for each AC service

entrance to all system equipment. This safety grounding system must comply with local codes and any

other applicable regulations for the installation locale.

For proper grounding/protective earth connection, consult with your Hewlett Packard Enterprise site

preparation specialist or power engineer

.

Power Consumption

The power consumption and inrush currents per connection can vary because of the unique combination

of enclosures housed in the rack. Calculate the total power consumption for the hardware installed in the

rack as described in NS7 Enclosure Power Loads

Cooling and Humidity Control

Cooling airflow through each enclosure in the system is front-to-back. Because of high heat densities and

hot spots, an accurate assessment of air flow around and through the system equipment and specialized

cooling design is essential for reliable system operation. For an airflow assessment, consult with your

Hewlett Packard Enterprise cooling consultant or your heating, ventilation, and air conditioning (HV

engineer.

NOTE: Failure of site cooling with the system continuing to run can cause rapid heat buildup and

excessive temperatures within the hardware. Excessive internal temperatures can result in full or partial

system shutdown. Ensure that the site’

running.

s cooling system remains fully operational when the system is

on page 50.

AC)

28 Site Preparation Guidelines for the NS7 System

Page 29

Weight

otal weight must be calculated based on what is in the specific rack, as described in

T

Enclosure Weights With Worksheet.

Flooring

NS7 Rack and

NonStop NS7 systems can be installed either on the site’

equipment or on raised flooring with power and I/O cables entering from underneath. Because cooling

airflow through each enclosure in the racks is front-to-back, raised flooring is not required for system

cooling.

The site floor structure and any raised flooring (if used) must be able to support the weight of the installed

system, individual racks, and enclosures as they are moved into position. To determine the total weight of

the installation, see

For your site’

appropriate floor system engineer. If raised flooring is to be used, the rack is optimized for placement on

24‑inch floor panels.

s floor system, consult with your Hewlett Packard Enterprise site preparation specialist or an

NS7 Rack and Enclosure Weights With Worksheet on page 58.

Dust and Pollution Control

NS7 systems do not have air filters. Any computer equipment can be adversely af

microscopic particles in the site environment. Airborne dust can blanket electronic components on printed

circuit boards, inhibiting cooling airflow and causing premature failure from excess heat, humidity, or both.

Metallically conductive particles can short circuit electronic components. Tape drives and some other

mechanical devices can experience failures resulting from airborne abrasive particles.

For recommendations to keep the site as free of dust and pollution as possible, consult with your heating,

ventilation, and air conditioning (HVAC) engineer or your Hewlett Packard Enterprise site preparation

specialist.

Zinc Particulates

s floor with the cables entering from above the

fected by dust and

Over time, fine whiskers of pure metal can form on electroplated zinc, cadmium, or tin surfaces such as

aged raised flooring panels and supports. If these whiskers are disturbed, they can break of

airborne, possibly causing computer failures or operational interruptions. This metallic particulate

contamination is a relatively rare but possible threat. Kits are available to test for metallic particulate

contamination, or you can request that your site preparation specialist or HVAC engineer test the site for

contamination before installing any electronic equipment.

Space for receiving and unpacking the system

WARNING: A fully populated rack is unstable when moving down the unloading ramp from its

shipping pallet. A falling rack can cause serious or fatal personal injury

√ Verify

There is adequate space to receive and unpack the system from shipping cartons and pallets and

to remove equipment using supplied ramps. For physical dimensions of the system equipment, see

Dimensions and Weights for NS7 AC Systems on page 53

Enough personnel are present to remove and transport each rack to the installation site.

.

.

f and become

Table Continued

Site Preparation Guidelines for the NS7 System 29

Page 30

√ Verify

Tiled or carpeted pathways have temporary hard floor covering to facilitate moving the racks which

have small casters.

Door and hallway width and height, the floor and elevator loading, accommodate the system

equipment, personnel, and lifting or moving devices. If necessary

obstructing doorway or wall.

Operational space for an NS7 System

√ Verify

NS7 system site layout, uses the equipment dimensions, door swing, and service clearances listed

in Dimensions and Weights for NS7 AC Systems on page 53 and takes advantage of existing

lighting and electrical outlets.

Airflow direction and current or future air conditioning ducts are not obstructed. Eliminate any

obstructions to equipment intake or exhaust air flow

28.

Adequate space planning to allow for future equipment.

. See

, enlarge or remove any

Cooling and Humidity Control on page

Site layout plan includes provisions for things such as channels or fixtures used for cable routing,

cables, patch panels, and storage areas.

30 Site Preparation Guidelines for the NS7 System

Page 31

NS7 System Installation Specifications

This chapter provides specifications necessary for system installation planning. All specifications in this

chapter assume that each enclosure in the rack is fully populated. The maximum current for each AC

service depends on the number and type of enclosures installed in the rack. Power

loads are less when enclosures are not fully populated; for example, a SAS disk enclosure with fewer

disks.

Racks

The rack is an EIA standard 19-inch, 36U or 42U rack. The rack comes equipped with front and rear

doors and includes a rear extension that makes it deeper than some industry-standard racks.

are mounted along the rear extension without occupying any U-space in the rack and are oriented inward,

facing the components within the rack.

• For instructions on grounding the G2 Advanced Series rack or using the HPE Rack Ground Bonding

Kit (P9L11A), refer your service provider to the Rack Options Installation Guide for the HPE Advanced

G2 Series

• For instructions on grounding the Enterprise series rack (formerly known as the Intelligent rack) using

the HPE Rack Ground Bonding Kit (BW891A), ask your service provider to see the instructions in the

HPE Rack Options Installation Guide.

, weight, and heat

The PDUs

AC power feeds in a rack

Systems can be ordered with the AC power cords for the PDU installed either:

•

Top: Power and I/O cables are routed from above the rack.

• Bottom: Power and I/O cables are routed from below the rack.

Each PDU is wired to distribute the load segments to its receptacles.

Power Distribution Unit (PDU) types for an Advanced Series G2 rack

A NonStop X NS7 uses an Advanced Series G2 rack (36U or 42U). The rack supports Intelligent PDUs

(iPDUs) and G2 Basic modular PDUs.

The PDUs use a core and extension bar design with the following configuration rules.

PDU configuration rules

•

The same PDU type, power phase, and power region must be used.

◦ Do not mix single-phase and three-phase PDUs.

◦ Do not mix PDU types (for example, do not mix iPDUs and modular PDUs).

◦ Do not mix NA/JPN and International power regions.

• For either top or bottom power feed cables, the PDU cores must be mounted at the bottom of the rack.

• PDU cores are mounted in the same 1U space.

◦ One PDU core occupies the rear mounting rail.

◦ One PDU core occupies the front mounting rail.

NS7 System Installation Specifications 31

Page 32

◦ The breakers face outward.

The output receptacles face inward.

◦

• Rear-mounted PDU cores connect to the extension bars on the right side of the rack.

• Front-mounted PDU cores connect to the extension bars on the left side of the rack and to an UPS (if

present).

◦ UPS does not change the number of PDU cores in the rack.

◦ PDU and UPS must have the same power input specification.

NOTE: A rack with a c7000 enclosure requires a four PDU core configuration. Racks without a c7000

enclosure use a two PDU core configuration.

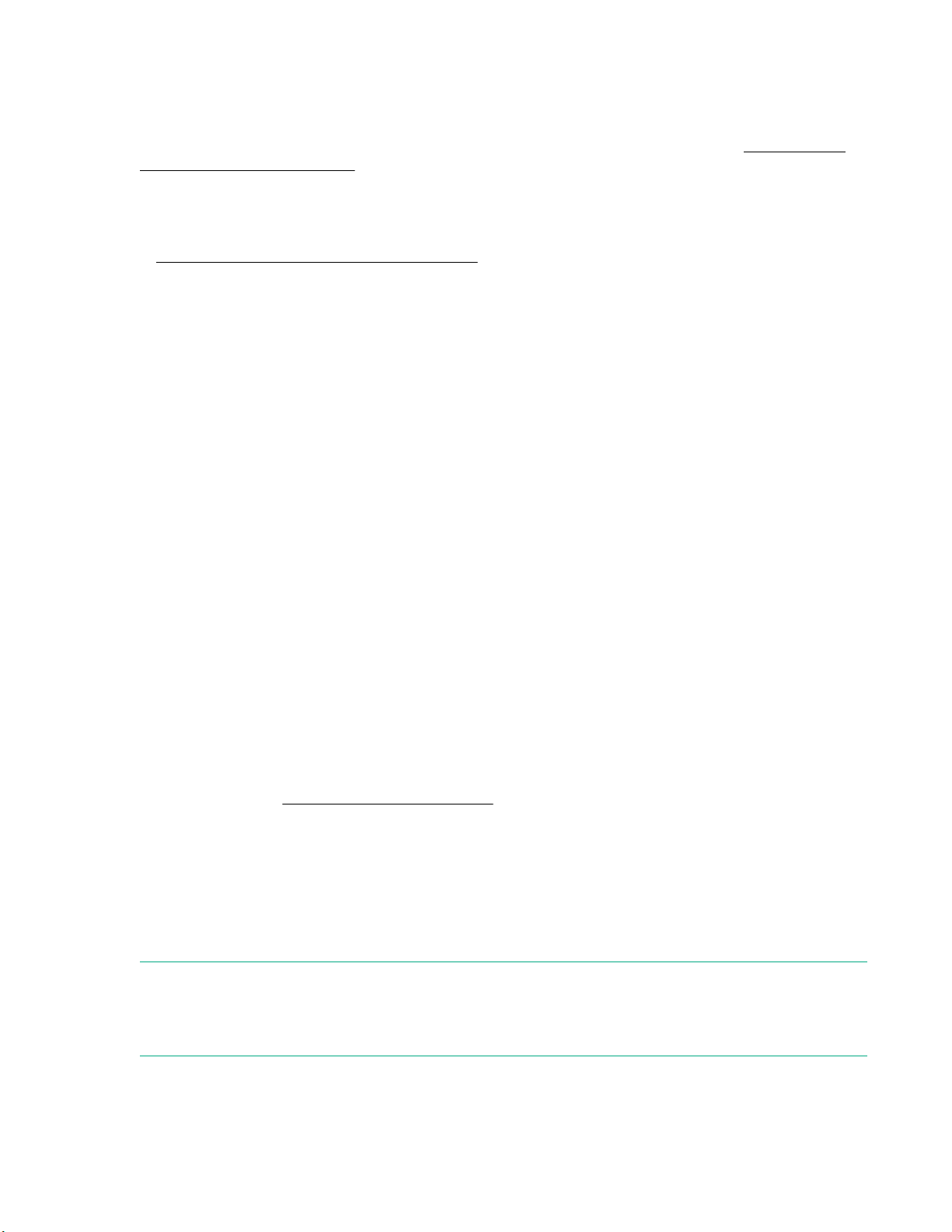

This tables lists the PDUs, supported configurations, and links to examples for an Advanced Series G2

rack. The examples use a 42U rack.

PDU

ypes

T

iPDU Four PDU cores without UPS

Supported PDU

Configurations

Four PDU cores with UPS

Two PDU cores without UPS

Two PDU cores with UPS

Examples of Configurations

Four Intelligent PDUs in an Advanced Series G2 rack

without UPS – (NA/JPN and INTL) on page 33

Four Intelligent PDUs in an Advanced Series G2 rack

with single-phase UPS – (NA/JPN and INTL)

34

Four Intelligent PDUs in an Advanced Series G2 rack

with three-phase UPS (NA/JPN and INTL) on page

Two Intelligent PDUs in an Advanced Series G2 rack

without UPS — (NA/JPN and INTL)

Two Intelligent PDUs in an Advanced Series G2 rack

with single-phase UPS — (NA/JPN and INTL) on page

37

Two Intelligent PDUs in an Advanced Series G2 rack

with three-phase UPS — (NA/JPN and INTL) on page

38

on page 36

on page

35

G2 Basic

Modular

32 NS7 System Installation Specifications

Four PDU cores without UPS

Four G2 Basic Modular PDUs in an Advanced Series

rack without UPS — (NA/JPN and INTL) on page 39

Table Continued

Page 33

PDU

ypes

T

Supported PDU

Configurations

Examples of Configurations

Four PDU cores with UPS

Two PDU cores without UPS

Two PDU cores with UPS

Four Modular G2 Basic PDUs in an Advanced Series

G2 rack with single-phase UPS (NA/JPN and INTL) on

page 41

Four Modular G2 Basic PDUs in an Advanced Series

rack with Three-Phase UPS (NA/JPN and INTL) on

page 42

Two Modular G2 Basic PDUs in an Advanced Series

rack with three-phase UPS — (NA/JPN and INTL)

page 43

Two Modular G2 Basic PDUs in an Advanced Series

rack with single-phase UPS — (NA/JPN and INTL) on

page 44

Two G2 Basic Modular PDUs in an Advanced Series

G2 rack without a c7000 enclosure or UPS — (NA/JPN

and INTL) on page

45

on

Four Intelligent PDUs in an Advanced Series G2 rack without UPS – (NA/JPN and INTL)

This illustration shows the power configuration for 4 iPDUs (without UPS) in an Advanced Series G2 rack.

For detailed power specifications and connector types, see AC input power for an Advanced Series G2

rack.

NS7 System Installation Specifications 33

Page 34

Figure 2: Four iPDUs Without UPS — (NA/JPN and INTL, Single-Phase and Three-Phase)

Four Intelligent PDUs in an Advanced Series G2 rack with single-phase UPS – (NA/JPN

and INTL)

This illustration shows the power configuration for 4 iPDUs and 2 single-phase UPS's in an Advanced

Series G2 rack. For detailed power specifications and connector types, see AC input power for an

Advanced Series G2 rack.

34 NS7 System Installation Specifications

Page 35

Figure 3: Four iPDUs With Single-Phase UPS — (NA/JPN and INTL)

Four Intelligent PDUs in an Advanced Series G2 rack with three-phase UPS (NA/JPN and

INTL)

This illustration shows the power configuration for 4 iPDUs and 2 single-phase UPS's in an Advanced

Series G2 rack. For detailed power specifications and connector types, see AC input power for an

Advanced Series G2 rack.

NS7 System Installation Specifications 35

Page 36

Figure 4: Four iPDUs With Three-Phase UPS — (NA/JPN and INTL)

Two Intelligent PDUs in an Advanced Series G2 rack without UPS — (NA/JPN and INTL)

This illustration shows the connections for two iPDUs in an Advanced Series G2 rack without a UPS. For

detailed power specifications and connector types, see AC input power for an Advanced Series G2

rack.

36 NS7 System Installation Specifications

Page 37

Figure 5: Two Intelligent PDUs Without UPS— (NA/JPN and INTL, Single-Phase and Three-Phase)

Two Intelligent PDUs in an Advanced Series G2 rack with single-phase UPS — (NA/JPN

and INTL)

This illustration shows the power configuration for 2 iPDUs and a single-phase UPS in an Advanced

Series G2 rack. For detailed power specifications and connector types, see AC input power for an

Advanced Series G2 rack.

NS7 System Installation Specifications 37

Page 38

Figure 6: Two Intelligent PDUs With Single-Phase — (NA/JPN and INTL)

Two Intelligent PDUs in an Advanced Series G2 rack with three-phase UPS — (NA/JPN

and INTL)

This illustration shows the power configuration for 2 iPDUs and a three-phase UPS in an Advanced

Series G2 rack. For detailed power specifications and connector types, see AC input power for an

Advanced Series G2 rack.

38 NS7 System Installation Specifications

Page 39

Figure 7: Two Intelligent PDUs With Three-Phase UPS — (NA/JPN and INTL)

Four G2 Basic Modular PDUs in an Advanced Series rack without UPS — (NA/JPN and

INTL)

This illustration shows the power configuration for four single-phase modular PDUs in an Advanced

Series G2 rack without a UPS. For detailed power specifications and connector types, see AC input

power for an Advanced Series G2 rack.

NS7 System Installation Specifications 39

Page 40

Figure 8: Four G2 Basic Modular PDUs without UPS — (NA/JPN and INTL, Single-Phase)

This illustration shows the power configuration for four three-phase modular PDUs in an Advanced Series

G2 rack without a UPS. For detailed power specifications and connector types, see AC input power for a

NonStop System in an Advanced Series G2 rack.

40 NS7 System Installation Specifications

Page 41

Figure 9: Four G2 Basic Modular PDUs without UPS — (NA/JPN and INTL, Three-Phase)

Four Modular G2 Basic PDUs in an Advanced Series G2 rack with single-phase UPS

(NA/JPN and INTL)

This illustration shows the power configuration for 4 modular G2 Basic PDUs and 2 single-phase UPS's in

an Advanced Series G2 rack. For detailed power specifications and connector types, see AC input

power for an Advanced Series G2 rack.

NS7 System Installation Specifications 41

Page 42

Figure 10: Four Modular G2 Basic PDUs with single-phase UPS — (NA/JPN and INTL)

Four Modular G2 Basic PDUs in an Advanced Series rack with Three-Phase UPS

(NA/JPN and INTL)

This illustration shows the power configuration for 4 modular G2 Basic PDUs and one three-phase UPS in

an Advanced Series G2 rack. For detailed power specifications and connector types, see AC input

power for an Advanced Series G2 rack.

42 NS7 System Installation Specifications

Page 43

Figure 11: Four Modular G2 Basic PDUs with three-phase UPS — (NA/JPN and INTL)

Two Modular G2 Basic PDUs in an Advanced Series rack with three-phase UPS —

(NA/JPN and INTL)

This illustration shows the connections for 2 modular G2 Basic PDUs in an Advanced Series G2 rack with

a three-phase UPS and without a c7000 enclosure. For detailed power specifications and connector

types, see AC input power for an Advanced Series G2 rack.

NS7 System Installation Specifications 43

Page 44

Figure 12: Two Modular G2 Basic PDUs with a three-phase UPS — (NA/JPN and INTL)

Two Modular G2 Basic PDUs in an Advanced Series rack with single-phase UPS —

(NA/JPN and INTL)

This illustration shows the connections for 2 modular G2 Basic PDUs in an Advanced Series G2 rack with

a single-phase UPS and without a c7000 enclosure. For detailed power specifications and connector

types, see AC input power for an Advanced Series G2 rack.

Figure 13: T

44 NS7 System Installation Specifications

wo Modular G2 Basic PDUs with single-phase UPS and without c7000 enclosure

Page 45

Two G2 Basic Modular PDUs in an Advanced Series G2 rack without a c7000 enclosure

or UPS — (NA/JPN and INTL)

This illustration shows the power configuration for 2 modular G2 Basic PDUs in an Advanced Series rack

without a c7000 enclosure or UPS. For detailed power specifications and connector types, see AC input

power for an Advanced Series G2 rack.

Figure 14: Two Modular G2 Basic PDUs without UPS or c7000 — (NA/JPN and INTL, Single-Phase

and Three-Phase)

NS7 System Installation Specifications 45

Page 46

46 NS7 System Installation Specifications

Page 47

AC input power for an Advanced Series G2 rack

The following tables provide the power specifications for AC input power in an Advanced Series G2 rack.

CAUTION: Be sure the hardware configuration and resultant power loads of each enclosure within

the system do not exceed the capacity of the branch circuit according to applicable electrical codes

and regulations.

Select circuit breaker ratings according to local codes and any applicable regulations for the circuit

capacity

. Note that circuit breaker ratings vary if your system includes an optional rack-mounted UPS.

NS7 System Installation Specifications 47

Page 48

Table 4: North America/Japan single-phase power specifications

R5000 single-phase

UPS

Output Load 4500 W 24 A 24 A

Input Voltage 200 – 208 V 200 – 208 V 200 – 240 V

Input Connector NEMA L6-30P NEMA L6-30P NEMA L6-30P

Output Voltage 200 – 208 V N/A N/A

Output Connectors 1 x L6-30R

4 x C19

4 x C13

iPDU single-phase G2 Basic Modular

single-phase

6 x C19 6 x C19

Notes UPS outputs are connected to the compatible PDU inputs.

Table 5: North America/Japan three-phase power specifications

R12000 three-phase

UPS

Output Load 12 kW 24 A 24 A

Input Voltage 208V 3P Wye 208V 3P Delta 208V 3P Delta

Input Connector IEC309 560P9 NEMA L15-30P NEMA L15-30P

Output Voltage 208V 3P Delta N/A N/A

iPDU three-phase G2 Basic Modular 3-

phase

Output Connectors 2 x NEMA L15-30R 6 x C19 6 x C19

Notes UPS outputs are connected to the compatible PDU inputs.

48 NS7 System Installation Specifications

Page 49

Table 6: International single-phase power specifications

R5000 single-phase

UPS

Output Load 4500 W 32 A 32 A

Input Voltage 220 – 240 V 200 – 240 V 200 – 240 V

Input Connector IEC309 332P6

(32 A)

Output Voltage 220 – 240 V N/A N/A

Output Connectors 1 x IEC309 332R6

4 x C19

4 x C13

iPDU single-phase G2 Basic Modular

single-phase

IEC309 332P6

(32 A)

6 x C19 6 x C19

IEC309 332P6

(32 A)

Notes UPS outputs are connected to the compatible PDU inputs.

Table 7: International three-phase power specifications

R12000 three-phase

UPS

Output Load 12 kW 16 A/phase 16 A/phase

Input Voltage 380-415V 3P Wye 380-415V 3P Wye 380-415V 3P Wye

Input Connector IEC309 532P6 IEC309 516P6 IEC309 516P6

Output Voltage 400V 3P Wye N/A N/A

iPDU three-phase G2 Basic Modular 3-

phase

Table Continued

NS7 System Installation Specifications 49

Page 50

R12000 three-phase

UPS

Output Connectors 2 x IEC309 309 516C6 6 x C19 (20 A) 6 x C19 (20 A)

Notes UPS outputs are connected to the compatible PDU inputs.

iPDU three-phase G2 Basic Modular 3-

Enclosure AC Input for NonStop X Systems

Enclosures (IP CLIM, SAS disk enclosure, and so forth) require:

Specification Value

Nominal input voltage 200/208/220/230/240 V AC RMS

Voltage range 180-264 V AC

Nominal line frequency 50 or 60 Hz

Frequency ranges 47-53 Hz or 57-63 Hz

Number of phases 1

phase

Single-phase c7000 enclosures require:

Specification Value

Voltage range 200-240 VAC

Nominal line frequency 50 or 60 Hz

Frequency ranges 47-53 Hz or 57-63 Hz

Number of phases 1

NS7 Enclosure Power Loads

The total power and current load for a rack depends on the number and type of enclosures installed in it.

Therefore, the total load is the sum of the loads for all installed enclosures.

In normal operation, the AC power is split equally between the power feeds on the two sides (left and

right) of the rack. However

side must carry the power for all enclosures in that rack.

NOTE: For NS7 CG system specifications, see

Systems on page 80.

, if AC power fails on one side of the rack, the power feed(s) on the remaining

System Installation Specifications for NS7 CG

Power and current specifications for each type of enclosure are:

50 NS7 System Installation Specifications

Page 51

Enclosure Type AC Power Lines per

Enclosure

Products used by NS7 X1

AC systems

Typical Power

Consumption (V

1

A)

Maximum Power

Consumption (VA)

2

BL460c Gen8 CPU

(64 GB RAM)

BL460c Gen8 CPU

(128 GB RAM)

BL460c Gen8 CPU

(192 GB RAM)

Products used by NS7 X2

AC systems

BL460c Gen9 CPU

(64 GB RAM)

BL460c Gen9 CPU

(128 GB RAM)

BL460c Gen9 CPU

(192 GB RAM)

Products used by NS7 X3

AC systems

- 230 230

- 260 260

- 290 290

- 300 300

- 315 315

- 330 330

BL460c Gen10 CPU

- 277 332

(64 GB RAM)

BL460c Gen10 CPU

- 287 342

(128 GB RAM)

BL460c Gen10 CPU

- 309 364

(256 GB RAM)

64GB Memory kit 20 20

Gen10 Storage CLIM 2 140 190

Gen10 Networking CLIM,

2 135 185

4C/1C (IP or Telco)

Gen10 Networking CLIM,

2 135 185

4F/1C (IP or Telco)

D3710 SAS disk enclosure,

2 75 125

empty

Table Continued

NS7 System Installation Specifications 51

Page 52

Enclosure Type AC Power Lines per

Enclosure

Typical Power

Consumption (V

1

A)

Maximum Power

Consumption (VA)

2

400GB SSD, 12G SAS,

- 8 8

SFF, SC

300GB, 15k rpm HDD, 12G

- 4 7

SAS, SFF, SC

Rack-mounted system

1 127 188

console (NSCR216)

Rack-mounted keyboard

1 36 36

and monitor

Deskside system console 1 53 153

Deskside system console

1 23 26

monitor

Common products used

by all NS7 systems:

c7000 enclosure 6 810 1250

Maintenance switch

1 9 15

(Ethernet)

FDR IB ADI switch (for

2 207 234

NSADI)

FDR IB switches expansion 2 207 234

FDR IB cluster switch (for

2 207 234

NonStop X Cluster

Solution)

Common products used

by NS7 X1 and NS7 X2

AC systems:

Gen8 Storage CLIM 2 130 160

Gen8 Networking CLIM,

2 126 156

4C/1C (IP or Telco)

Gen8 Networking CLIM,

2 128 158

3C/2F (IP or Telco)

Gen9 Storage CLIM 2 140 190

Table Continued

52 NS7 System Installation Specifications

Page 53

Enclosure Type AC Power Lines per

Enclosure

Typical Power

Consumption (V

1

A)

Maximum Power

Consumption (VA)

2

Gen9 Networking CLIM,

4C/1C (IP or Telco)

Gen9 Networking CLIM,

3C/2F (IP or Telco)

32GB Memory kit 7 7

D3700 SAS disk enclosure,

empty

400GB SSD, 12G SAS,

SFF, SC

300GB, 15k rpm HDD, 12G

SAS, SFF, SC

Rack-mount system

console

Console keyboard and

monitor

Deskside system console 1 135 145

2 135 185

2 135 185

2 75 125

- 6 6

- 4 7

1 129 129

1 36 36

Deskside system console

monitor

1

Typical = measured at 22C ambient temp

2

Maximum = measured at 35C ambient temp

1 23 26

Dimensions and Weights for NS7 AC Systems

This subsection provides the dimensions and weights for racks and enclosures.

Service Clearances for NS7 Racks

Aisles: 6 feet (182.9 centimeters)

Front: 3 feet (91.4 centimeters)

Rear: 3 feet (91.4 centimeters)

NS7 System Installation Specifications 53

Page 54

Unit Sizes for NS7 Systems

Enclosure Type Height (U)

Rack 42 or 36

c7000 enclosure 10

CLIMs 2

SAS disk enclosures 2

CLIM patch panel (RJ45 and Fiber) 1

FDR IB ADI switch 1

FDR IB managed switch, expansion 1

IB FDR managed switch, IB cluster 1

Maintenance switch (Ethernet) 1

R5000 UPS (single-phase power) 3

ERM for single-phase UPS 3

R12000/3 UPS (three-phase power) 6

ERM for three-phase UPS 3

Rack-mount system console 1

Keyboard and monitor for system console 1

42U G2 Advanced Series rack physical specifications

Item Height Width Depth Weight

in. cm in. cm in. cm

Rack 78.98 200.60 23.54 121 44.3 59.0 Depends

Shipping

(palletized)

85.35 216.79 35.43 89.99 50.87 129.20

on the

enclosures

installed.

See Rack

and

Enclosure

Weights

With

Worksheet

.

54 NS7 System Installation Specifications

Page 55

42U Intelligent Rack physical specifications

Item Height Width Depth Weight

in. cm in. cm in. cm

Rack 78.7 199.9 23.3 59.0 47.6 121 Depends

Shipping

(palletized)

85.8 218 35.4 90 57.8 147

36U G2 Advanced Series Rack physical specifications

Item Height Width Depth Weight

on the

enclosures

installed.

See NS7

Rack and

Enclosure

Weights

With

Worksheet

on page

58

in. cm in. cm in. cm

Rack 68.66 200.60 23.54 59.78 42.72 108.52 Depends on

the

Shipping

(palletized)

85.35 216.79 35.43 89.99 50.87 129.20

enclosures

installed.

See NS7

Rack and

Enclosure

Weights

With

Worksheet

on page

58.

NS7 System Installation Specifications 55

Page 56

36U Intelligent Rack physical specifications

Item Height Width Depth Weight

in. cm in. cm in. cm

Rack 68.2 173.1 23.3 59.06 47.6 121 Depends

Shipping

(palletized)

85.8 218 35.4 90 57.8 147

NS7 Enclosure Dimensions

on the

enclosures

installed.

See NS7

Rack and

Enclosure

Weights

With

Worksheet

on page

58.

Enclosure

ype

T

c7000

enclosure (1phase)

CLIMs (all

models)

D3700/3710

SAS disk

enclosure

CLIM patch

panels

Maintenance

switch

(Ethernet)

Rack-mount

system

console

Height Width Depth

in cm in cm in cm

17.4 44.1 17.5 44.4 32 81.2