Page 1

VT Miltop

e

s

M365-491

A company of Vision Technologies System

Operator’s Manual

Cabin Access

Point (CAP)

Part Numbers 901164-1

901164-2

901164-3

Page 2

e

s

3800 Richardson Road South

VT Miltop

A company of Vision Technologies System

Hope Hull, AL 36043

Tel: 334-284-8665

Fax: 334-613-6302

http://www.miltope.com

M365-491

Operator’s Manual

Cabin Access

Point (CAP)

Part Numbers 901164-1

901164-2

901164-3

October 2005

Revised March 2006

Page 3

M365-491 Operator’s Manual

TABLE OF CONTENTS

Chapter/Paragraph Page

LIST OF FIGURES.............................................................................................................iv

LIST OF TABLES...............................................................................................................iv

1 GENERAL INFORMATION...........................................................................................1-1

1-1 Introduction..................................................................................................1-1

1-2 Typographic Conventions............................................................................1-1

1-2.1 Keyboard Entries and Software Commands................................................1-1

1-2.2 Variables ......................................................................................................1-2

1-2.3 Screen Display .............................................................................................1-2

1-3 Terminology.................................................................................................1-2

1-4 Equipment Description ................................................................................1-2

1-5 Building a Wireless Local Area Network (WLAN).....................................1-3

1-5.1 Connecting to a Wired Local Area Network (LAN)....................................1-4

1-5.2 Connecting to a Wired Server......................................................................1-4

1-5.3 Instant Infrastructure....................................................................................1-5

1-5.4 Building a Multi-Cell Wireless Network.....................................................1-5

1-6 Building a Wireless Link.............................................................................1-5

1-7 Security........................................................................................................1-6

1-8 Specifications...............................................................................................1-7

1-9 Approved Antennas .....................................................................................1-9

1-10 Available Software and Manuals.................................................................1-12

1-11 Tools and Test Equipment Required............................................................1-13

2 EQUIPMENT SETUP.......................................................................................................2-1

2-1 Introduction..................................................................................................2-1

2-2 Unpacking and Inspection............................................................................2-1

2-3 Initial Setup..................................................................................................2-1

2-4 Configuration...............................................................................................2-1

3 INSTALLATION...............................................................................................................3-1

3-1 Introduction..................................................................................................3-1

3-2 Mounting......................................................................................................3-1

3-2.1 CAP Unit......................................................................................................3-1

3-2.2 Indoor Cabin Antenna..................................................................................3-1

3-2.3 Outdoor Antenna..........................................................................................3-1

3-3 Connecting the CAP ....................................................................................3-11

3-3.1 Input Power Requirements...........................................................................3-11

Table of Contents i

March/2006

Page 4

Operator’s Manual M365-491

TABLE OF CONTENTS (Cont’d.)

Chapter/Paragraph Page

3-3.2 10/100BaseT Ethernet Local Area Network (LAN) Ports...........................3-13

3-3.3 RF (Antenna) Output ...................................................................................3-14

3-3.4 Discrete Inputs .............................................................................................3-14

3-3.5 Discrete Outputs...........................................................................................3-15

3-3.6 Reset Input ...................................................................................................3-15

3-4 Configuring Wireless Client Stations (CWLU Configuration)....................3-15

3-5 Configuring the Ground-Based Network (TWLU Configuration)..............3-15

4 OPERATION .....................................................................................................................4-1

4-1 Introduction..................................................................................................4-1

4-2 Indicators......................................................................................................4-1

4-3 Operating Instructions..................................................................................4-1

4-4 Power Up .....................................................................................................4-1

4-5 Checking the Status of Your CAP...............................................................4-1

5 OPERATOR MAINTENANCE.......................................................................................5-1

5-1 Introduction..................................................................................................5-1

5-2 Inspection.....................................................................................................5-1

5-3 Cleaning Exterior Surfaces ..........................................................................5-1

5-3.1 Materials Required.......................................................................................5-1

5-3.2 Cleaning Procedure......................................................................................5-1

5-4 Installing Operating Software......................................................................5-1

6 TROUBLESHOOTING....................................................................................................6-1

6-1 Introduction..................................................................................................6-1

6-2 Client Station Problems...............................................................................6-1

6-2.1 Wireless Client Station Cannot Establish a Wireless Link

With the CAP...............................................................................................6-1

6-2.2 IP Address Mismatch...................................................................................6-2

6-2.3 Wireless Client Stations Cannot Connect to the Internet Via the CAP.......6-2

6-2.4 Computers Cannot Share Data or Resources With Other Computers .........6-3

6-2.5 Web Browser Cannot Connect to Management Tool..................................6-3

6-2.6 Low Throughput ..........................................................................................6-4

6-3 CAP Problems..............................................................................................6-4

6-3.1 CAP Allows Any Station to Connect, Regardless of Network

Name Being Used........................................................................................6-4

6-3.2 Lost Administrator Password.......................................................................6-4

ii Table of Contents

March/2006

Page 5

M365-491 Operator’s Manual

TABLE OF CONTENTS (Cont’d.)

Chapter/Paragraph Page

7 REGULATORY, WIRELESS INTEROPERABILITY, AND

HEALTH INFORMATION.............................................................................................7-1

7-1 Regulatory Information...............................................................................7-1

7-2 Wireless Interoperability.............................................................................7-3

7-3 Health Information......................................................................................7-3

GLOSSARY.......................................................................................................................G-1

Table of Contents iii

October/2005

Page 6

Operator’s Manual M365-491

Figure Page

1-1 Cabin Access Point (CAP)...................................................................................................1-3

1-2 Connecting to a Wired LAN................................................................................................1-4

1-3 Connecting to a Wired Server..............................................................................................1-4

1-4 Creating an Instant Infrastructure.........................................................................................1-5

1-5 Multi-Cell Wireless Network...............................................................................................1-6

1-6 Aircraft-to-Ground Wireless Link .......................................................................................1-6

2-1 CAP Packaging....................................................................................................................2-2

3-1 CAP Outline Dimensions.....................................................................................................3-2

3-2 Indoor Cabin Antenna Part Numbers 901167-1 and 901167-2 Outline Dimensions..........3-2

3-3 Antenna Part Number 901167-1 Radiation Pattern .............................................................3-3

3-4 Antenna Part Number 901167-2 Radiation Pattern .............................................................3-5

3-5 Outdoor Antenna Part Number 901058-1 Outline Dimensions...........................................3-7

3-6 Antenna Part Number 901058-1 Radiation Pattern (2.35 GHz)..........................................3-8

3-7 Outdoor Antenna Part Number 901563-2 Outline Dimensions...........................................3-9

3-8 Antenna Part Number 901563-2 Radiation Pattern .............................................................3-10

3-9 Connector Locations............................................................................................................3-11

3-10 RJ45 Male Connector Front View.......................................................................................3-13

4-1 CAP Indicators.....................................................................................................................4-2

5-1 Test Cable ............................................................................................................................5-2

5-2 Test Box Schematic Diagram ..............................................................................................5-3

5-3 Test Setup.............................................................................................................................5-4

Page

Table

1-1 CAP Unit Specifications......................................................................................................1-7

1-2 Specification Compliance....................................................................................................1-8

1-3 Approved Antennas .............................................................................................................1-9

1-4 Antenna Part Number 901167-1 Specifications...................................................................1-10

1-5 Antenna Part Number 901167-2 Specifications...................................................................1-10

1-6 Antenna Part Number 901058-1 Specifications...................................................................1-11

1-7 Antenna Part Number 901563-2 Specifications...................................................................1-12

1-8 Available Software and Manuals.........................................................................................1-13

3-1 I/O Connector J1 Pin Assignments......................................................................................3-12

3-2 CAP I/O Connector J1 to RJ45 Male Cross Reference .......................................................3-13

3-3 RF Output Connectors J2 and J3 Pin Assignments .............................................................3-14

4-1 CAP Indicators.....................................................................................................................4-2

5-1 Equipment Required for Software Installation....................................................................5-2

LIST OF FIGURES

LIST OF TABLES

iv Table of Contents

March/2006

Page 7

M365-491 Operator’s Manual

CHAPTER 1

GENERAL INFORMATION

1-1 INTRODUCTION

This manual provides instructions for setup, installation, operation, and operator maintenance of

Cabin Access Point (CAP), part numbers 901164-1, 901164-2, and 901164-3, hereinafter referred to

as the CAP. Configuration instructions for the operating software are provided in the operator’s

manual for your software. This manual is divided into seven chapters as follows:

a. Chapter 1, General Information. This chapter provides a description and specifications for the

CAP. Included is a description of the typographic conventions used to present information in

this manual.

b. Chapter 2, Equipment Setup. This chapter provides instructions for unpacking, inspecting, and

initial setup of your CAP.

c. Chapter 3, Installation. This chapter provides instructions for installation. CAP mounting and

connection instructions are provided in this chapter.

d. Chapter 4, Operation. This chapter provides the information you need to become familiar with

your CAP. Included are descriptions of indicators along with instructions to operate your CAP.

e. Chapter 5, Operator Maintenance. This chapter provides instructions for the periodic tasks

the operator should perform to maintain the CAP in proper working condition.

f. Chapter 6, Troubleshooting. This chapter provides instructions for troubleshooting that can be

performed by the operator.

g. Chapter 7, Regulatory, Wireless Interoperability, and Health Information. This chapter

provides information on international regulations, wireless interoperability standards, and radio

frequency (RF) health issues.

1-2 TYPOGRAPHIC CONVENTIONS

Various type styles are used in this manual to present instructions and indicate responses. The

following paragraphs define the conventions used.

1-2.1 Keyboard Entries and Software Commands

Keyboard entries and software commands are presented in boldface type. Instructions to press a key

that performs a function have the name of the key enclosed in < > symbols. For example,

instructions to type the command “DIR” followed by pressing the Enter key are presented as follows:

Type DIR <Enter>

Chapter 1 1-1

General Information October/2005

Page 8

Operator’s Manual M365-491

1-2.2 Variables

Variable expressions or terms that are user defined are presented in italic type. For example, an

instruction to enter a path followed by a backslash, followed by a filename, followed by pressing the

Enter key is presented as follows:

Type path\filename <Enter>

1-2.3 Screen Display

Responses that are displayed on a computer screen are presented in a sans-serif typeface. For

example, if the word “READY” is to be displayed on the screen, it is presented as follows:

The display will read READY.

1-3 TERMINOLOGY

The following terms are used frequently throughout this manual:

• Client Station: Any computer that uses the services provided by the CAP. This can

be a computer with a wireless Local Area Network (LAN) card

accessing the CAP directly, or a computer on a wired LAN that is

connected to the CAP.

• Management Station: Any computer that can access the CAP management tool.

• Wireless Cell: The area in which the CAP provides a wireless signal.

1-4 EQUIPMENT DESCRIPTION

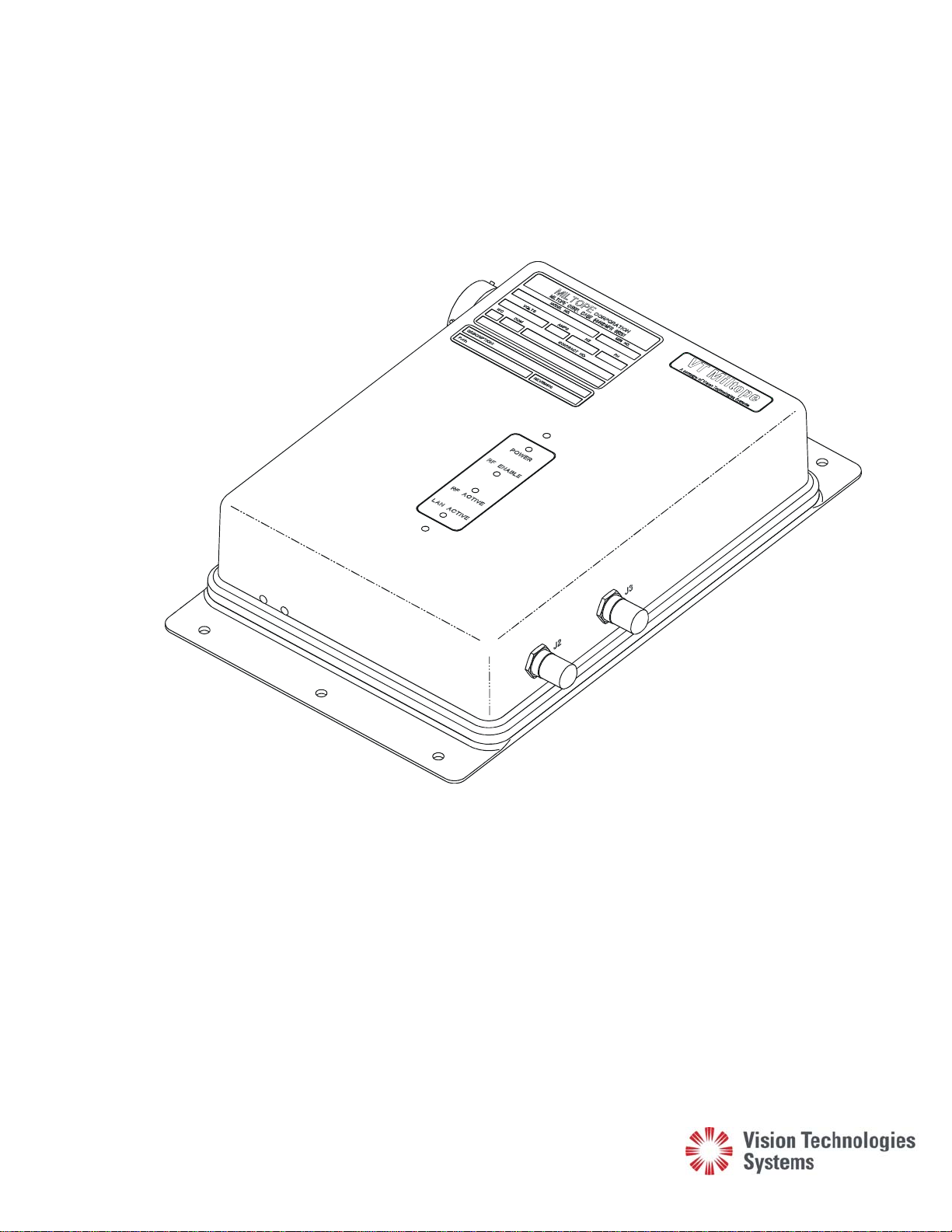

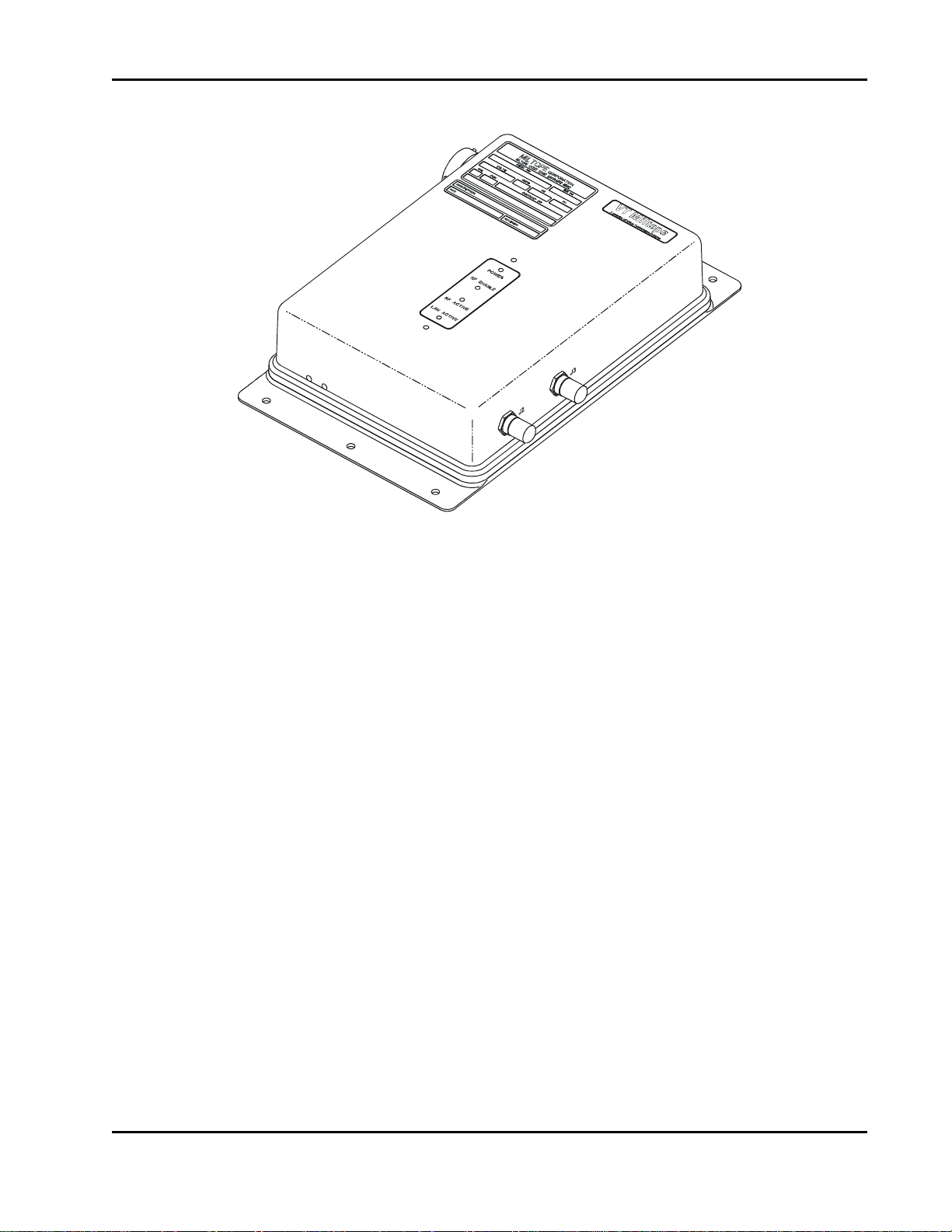

The Cabin Access Point (CAP) (

Figure 1-1) is a wireless communication device designed for use in

airborne environments. The CAP utilizes Direct Sequence Spread Spectrum (DSSS) radio

technology in the 2.4-GHz Industrial, Scientific and Medical (ISM) radio frequency spectrum to

communicate with IEEE 802.11b compliant wireless devices. The CAP utilizes Orthogonal

Frequency Division Multiplexing (OFDM) radio technology in the 2.4-GHz ISM radio frequency

spectrum to communicate with IEEE 802.11g compliant wireless devices and in the 5-GHz ISM

frequency spectrum to communicate with IEEE 802.11a compliant wireless devices. The CAP

provides a bridge between the aircraft IEEE 802.3 compliant wired Ethernet LAN and wireless

devices. Two aircraft level discrete inputs are provided for remote on/off control and RF

enable/disable. Two discrete outputs provide operational status. Operation of the CAP is controlled

by operating software. The CAP can be configured with CAP operating software to configure the

CAP as a cabin wireless LAN unit (CWLU) to create a wireless local area network (WLAN) aboard

the aircraft, or with wireless access bridge (WAB) operating software to configure the CAP as a

terminal wireless LAN unit (TWLU) to establish a wireless bridge between the aircraft network and

a ground-based network. The part number for the software installed in your CAP is indicated on the

software label located on the top of the CAP unit.

1-2 Chapter 1

October/2005 General Information

Page 9

M365-491 Operator’s Manual

0407231-

Figure 1-1. Cabin Access Point (CAP)

1-5 BUILDING A WIRELESS LOCAL AREA NETWORK (WLAN)

Configured as a CWLU, the CAP enables you to create a WLAN to link all your computers so that

they can share data and resources.

The CAP contains two radio frequency (RF) transmitter/receivers (tranceivers). Each tranceiver uses

radio waves in the 2.4 GHz band to communicate with IEEE 802.11b and IEEE 802.11g compliant

client stations or in the 5 GHz band to communicate with IEEE 802.11a compliant client stations.

Each transceiver is independently configurable for 2.4 GHz or 5 GHz operation. Radio waves

cannot penetrate metal, instead they are reflected. This means that the CAP is able to transmit

through wood or plaster walls, and closed windows. However, the metal skin of the aircraft or metal

partitions may block transmissions, or reduce signal quality by creating reflections. To serve users

separated by metal partitions will require a separate CAP unit in each area.

The CAP provides IEEE 802.11b and IEEE 802.11g wireless network coverage in a radius of up to

100 meters (300 feet) and IEEE 802.11a wireless network coverage in a radius of 30 meters

(100 feet), regardless of the orientation of the device. This is called a wireless cell.

To maximize coverage of the cell, the CAP is best installed in an open area with as few obstructions

as possible. Try to choose a location that is central to the area being served.

The following paragraphs provide an overview of the different types of connections you can make

using the CAP.

Chapter 1 1-3

General Information October/2005

Page 10

Operator’s Manual M365-491

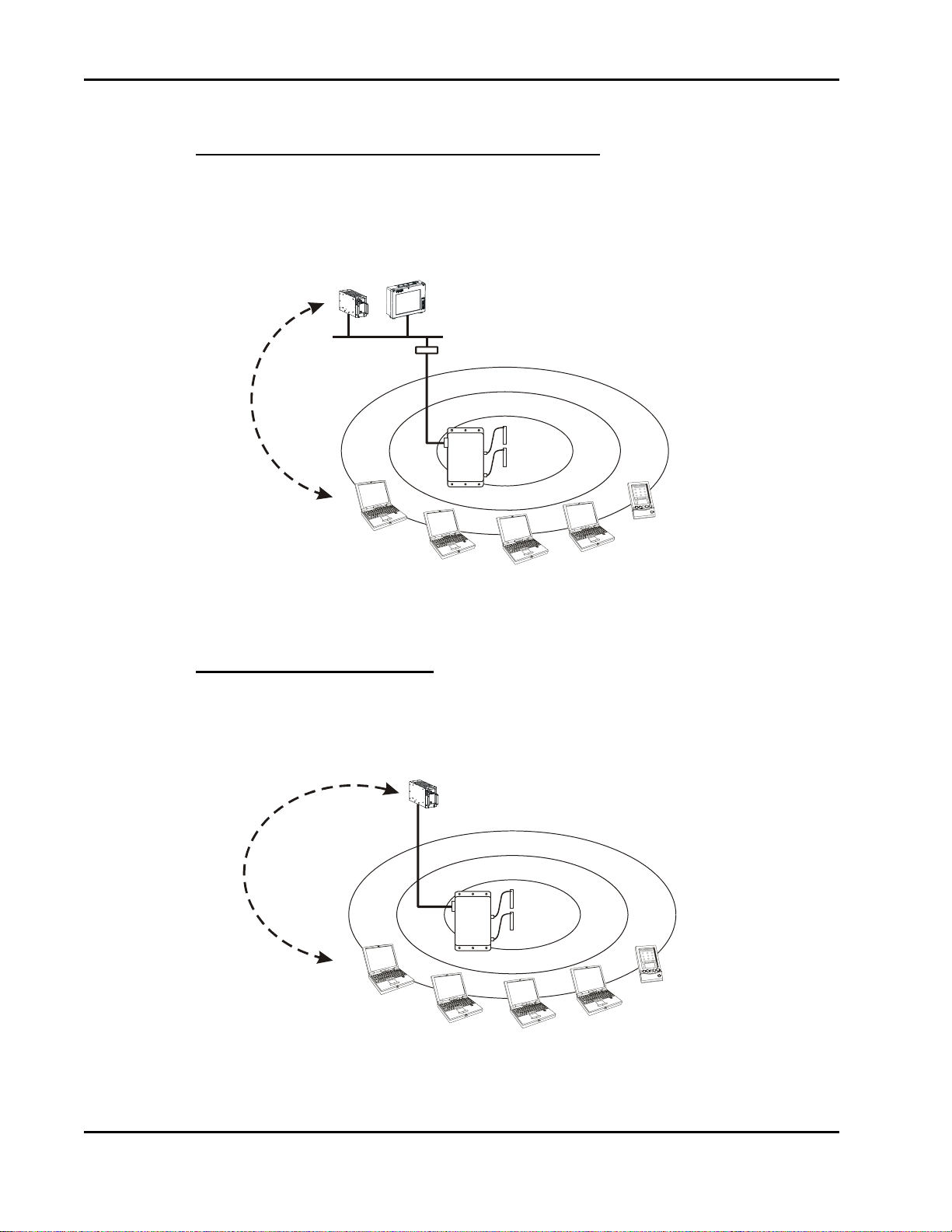

1-5.1 Connecting to a Wired Local Area Network (LAN)

By attaching the CAP to an Ethernet hub as shown in Figure 1-2, you can interconnect your wireless

network with a traditional wired local area network (LAN). This enables all users to share data and

resources.

AIRBORNE

SERVER CABIN

SHARED DATA

AND RESOURCES

MANAGEMENT

TERMINAL

ETHERNET HUB

W

L

N

A

0407232-

Figure 1-2. Connecting to a Wired LAN

1-5.2 Connecting to a Wired Server

As shown in Figure 1-3, the CAP can be connected to a single server that has a traditional wired

Ethernet card. This allows the wired server to share data and resources with the computers on the

WLAN.

AIRBORNE

SERVER

SHARED DATA

AND RESOURCES

W

N

L

A

0407233-

Figure 1-3. Connecting to a Wired Server

1-4 Chapter 1

October/2005 General Information

Page 11

M365-491 Operator’s Manual

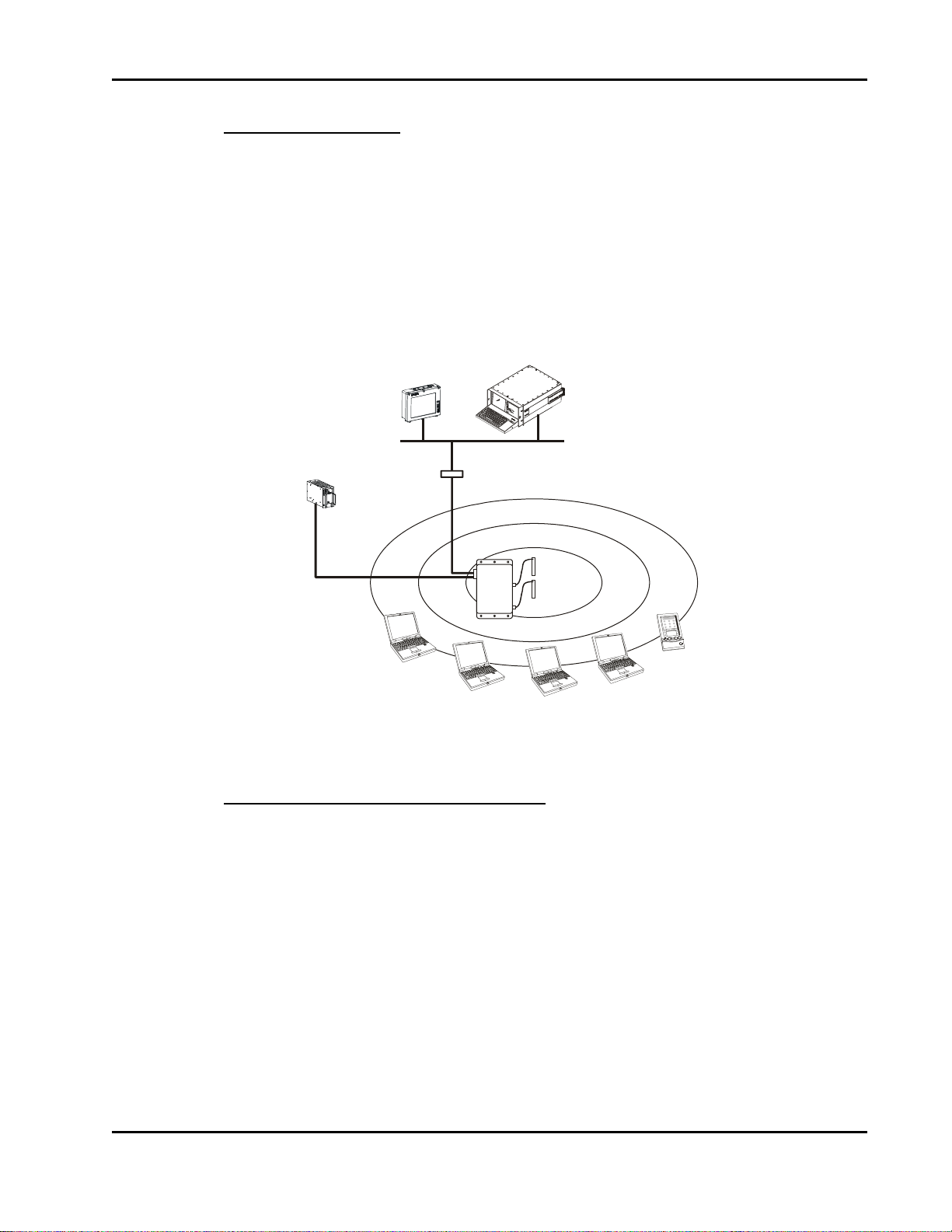

1-5.3 Instant Infrastructure

The CAP features an integrated two-port 100 Mbps Ethernet switch allowing you to quickly create a

complete networking infrastructure. Connect stand alone computers or link to an Ethernet hub to

interconnect your wireless network with a traditional wired local area network (LAN). (See

Figure 1-4.) This enables all users to share data and resources.

Unlike a hub which shares bandwidth between all connected stations, the CAP’s switch enables each

connected station to use the full 100 Mbps.

WIRED LAN

MANAGEMENT

TERMINAL

AIRBORNE

SERVER

CABIN

ETHERNET HUB

AIRBORNE

COMPUTER

W

N

L

A

0407234-

Figure 1-4. Creating an Instant Infrastructure

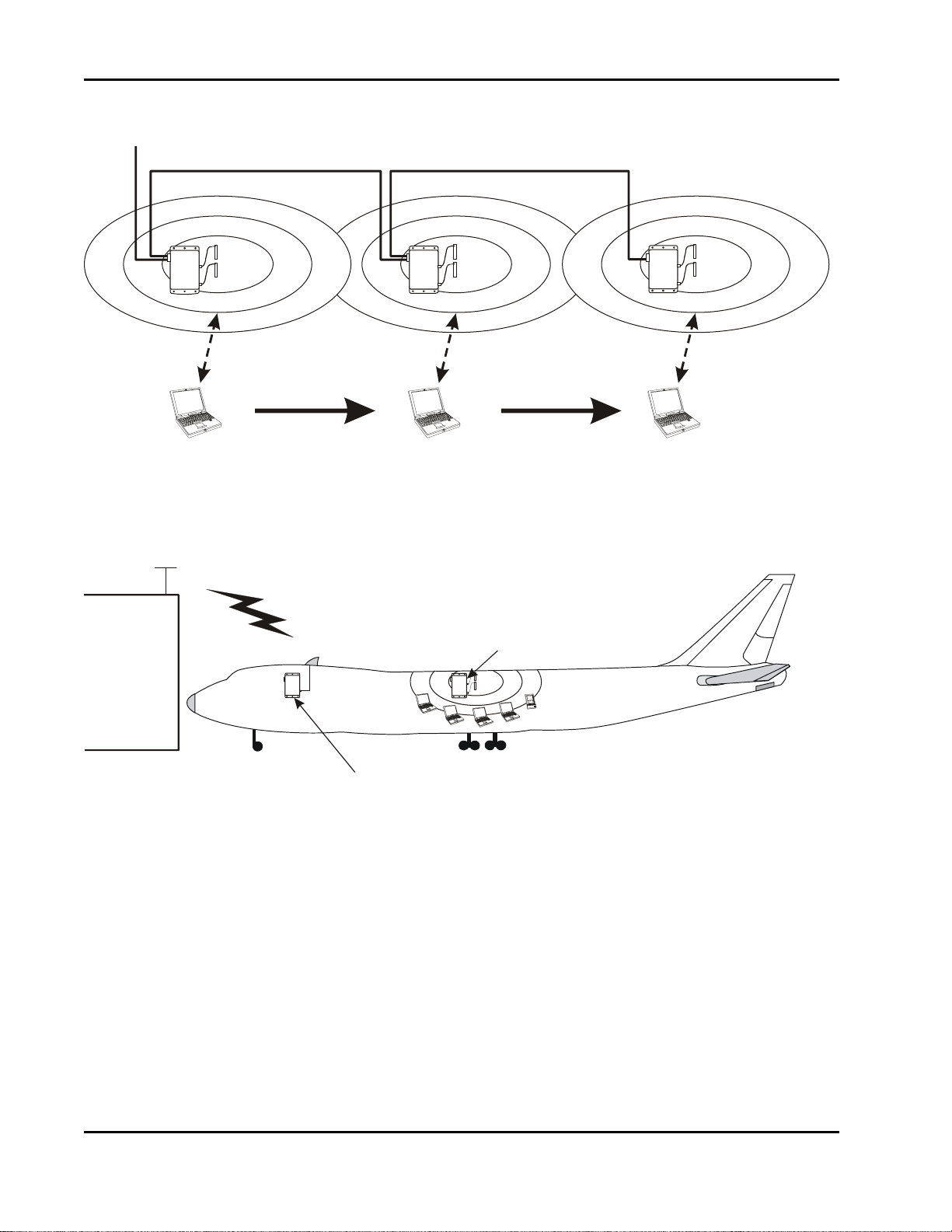

1-5.4 Building A Multi-Cell Wireless Network

As shown in Figure 1-5, several CAP units can be installed to provide multiple wireless cells for

coverage of large locations. Client computers are able to move between cells (called roaming),

without losing contact with the network. This is possible because the wireless network adapters in

the client computers automatically switch to the best available signal.

1-6 BUILDING A WIRELESS LINK

Configured as a TWLU, the CAP provides a wireless link between the LAN aboard the aircraft and a

ground-based LAN deployed in an airport terminal, hanger, fixed-based operation (FBO) facility, or

flight operations facility. (See

Figure 1-6.) The CAP has a range of 100 meters (300 feet) using the

IEEE 802.11b or IEEE 802.11g wireless network interface.

Chapter 1 1-5

General Information October/2005

Page 12

Operator’s Manual M365-491

ETHERNET LAN

W

N

L

A

CONNECTION AUTOMATICALL Y

SWITCHES

CLIENT MOVES CLIENT MOVES

W

N

L

A

CONNECTION AUTOMATICALL Y

SWITCHES

W

N

L

A

0407236-

Figure 1-5. Multi-Cell Wireless Network

CABIN ACCESS POINT

CONFIGURED AS

CABIN WIRELESS

LAN UNIT (CWLU)

CABIN ACCESS POINT

CONFIGURED AS

TERMINAL WIRELESS

LAN UNIT (TWLU)

0407235-

Figure 1-6. Aircraft-to-Ground Wireless Link

1-7 SECURITY

Security features available depend on the operating software installed. Refer to the applicable

software operator’s manual for security information

1-6 Chapter 1

October/2005 General Information

Page 13

M365-491 Operator’s Manual

1-8 SPECIFICATIONS

The technical specifications for the CAP unit are provided in Table 1-1. The CAP has been qualified

for airborne installation in accordance with Radio Technical Commission for Aeronautics (RTCA)

specification DO-160D and The Boeing Company document D6-36440, Standard Cabin Systems

Requirements Document as specified in Table 1-2.

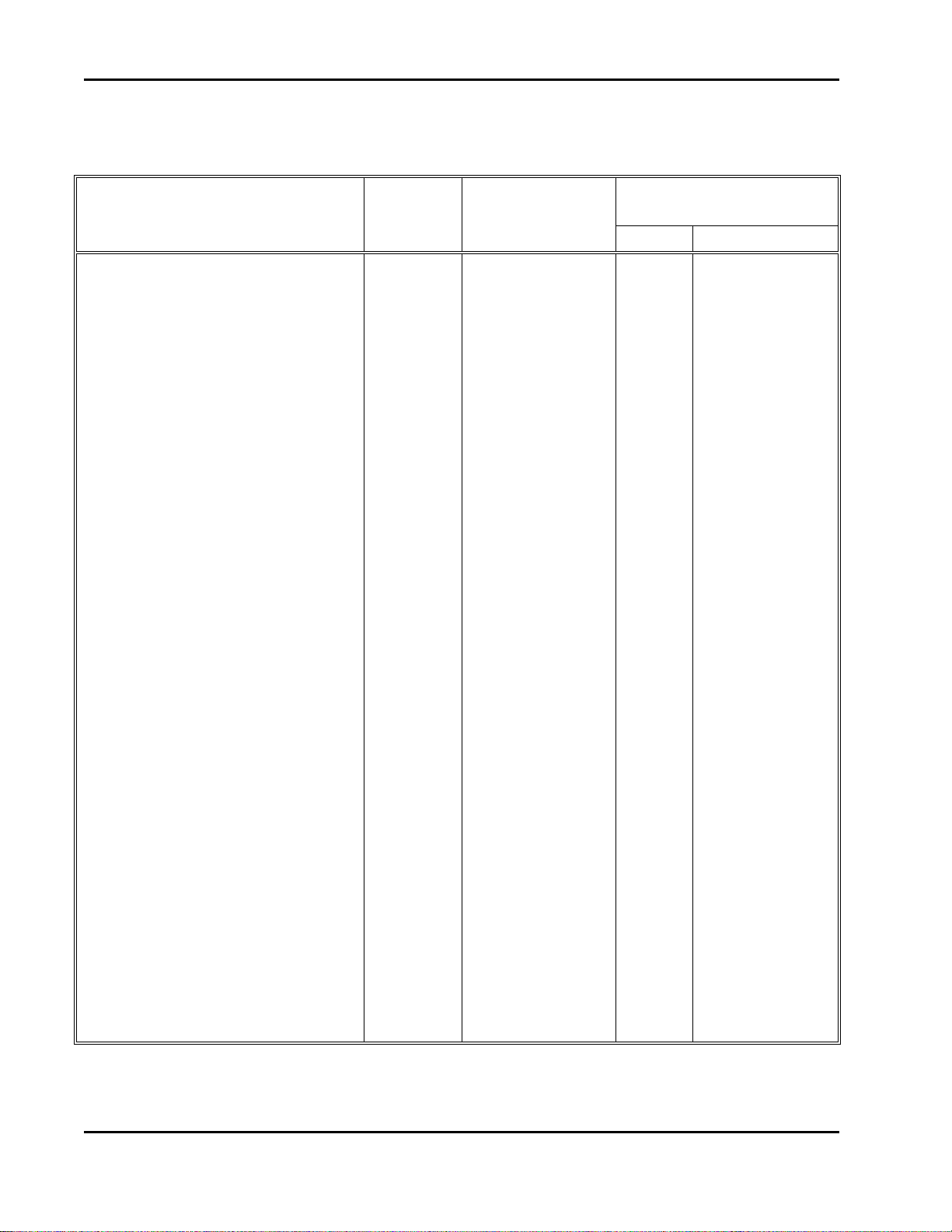

Table 1-1. CAP Unit Specifications

Characteristic Specification

Wireless LAN Interface IEEE 802.11a compliant OFDM 5 GHz, 54 Mbits/second wireless LAN

12 non-overlapping channels in North America

19 non-overlapping channels in Europe

4 non-overlapping channels in Japan

IEEE 802.11b compliant DSSS 2.4 GHz, 11 Mbits/second

14-channel wireless LAN

IEEE 802.11g compliant OFDM, 54 Mbit/second

14-channel wireless LAN

Wireless Range 100 meters (300 feet) for IEEE 802.11b/g

30 meters (100 feet) for IEEE 802.11a

Wired Interfaces Two IEEE 802.3 compliant Ethernet 10/100BaseTx channels,

100 Mbits/second (autoranging)

Two discrete inputs (on/off control and RF enable)

Two discrete outputs (on/off status and RF status)

Power Interruption 200 ms holdup capability

Input Power 97 – 134 VAC, 360 – 800 Hz, or 18 – 32 VDC, 15 W maximum

(DC input available on part numbers 901164-2 and 901164-3 only)

Size 2.4 inches x 8.23 inches x 11.5 inches

Weight Less than 5 pounds

Temperature Range

Operating

Non-operating

Altitude

Operating

Non-operating

Humidity (operating) 5% to 95% relative humidity, non-condensing

-15°C to +55°C

-55°C to +85°C

Atmospheric pressure equivalent to –15,000 to +15,000 feet

Atmospheric pressure equivalent to –15,000 to +40,000 feet

Chapter 1 1-7

General Information October/2005

Page 14

Operator’s Manual M365-491

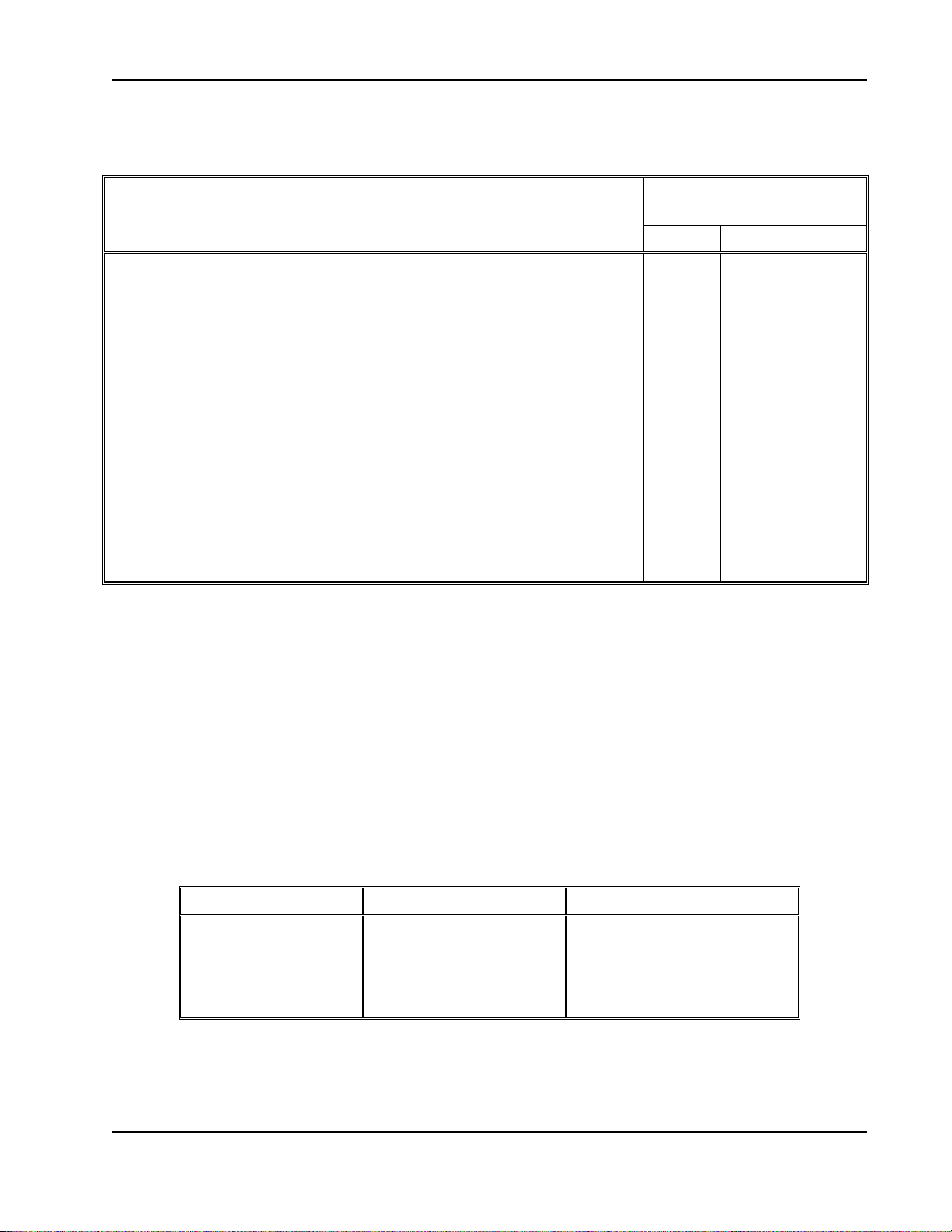

Table 1-2. Specification Compliance

Boeing

D6-36440

Characteristic Section Airbus Section Category

Temperature 7.2.1.1 4.5 A1 modified

Loss of Cooling 7.2.1.2 4.5.4 B

Altitude 7.2.1.3 4.6.1 A1 (15,000 feet)

Decompression 7.2.1.3 4.6.2 A1 (45,100 feet)

Overpressure 7.2.1.3 4.6.3 A1

Touch Temperature 7.2.2 <15°C rise

Temperature Variation 7.2.3 5.0 C

Humidity 7.2.4 6.3.2 A

Waterproofness 7.2.5 10.3.1 W

Vibration (random) 7.2.7 8.7.2 C/C1

Vibration (windmilling) (901164-3) ABD513.5201-01

Curve 4B

Operational Shock 7.2.8 7.2 B (6g)

Magnetic Effect 15.0 C

Crash Safety 7.3 B (20g)

Power Input 7.3.2.1a 16.0 A/E

Power Input, Power Failure 7.3.2.1f >0.85 lagging

Power Input, Input Capacitance

(EMI)

Current Harmonics (901164-3) 16.6.2

Voltage Spikes 7.3.2.2 17.0 A

Grounding and Bonding 7.3.2.4

Induced Signal Susceptibility 7.3.3.2 19.0 C

Audio Frequency Conducted

Susceptibility

Audio Frequency Emissions 7.3.3.5 8.3

Radio Frequency Susceptibility,

Conducted

Radio Frequency Susceptibility,

Radiated

7.3.2.1g <2.5µF/kVA

7.3.3.3 18.3.2 Z modified

7.3.3.4.1 20.4 T

7.3.3.4.2 20.5 T

DO-160D

line-to-line

<0.2µF

line-to-gnd)

1-8 Chapter 1

January/2006 General Information

Page 15

M365-491 Operator’s Manual

Table 1-2. Specification Compliance (Continued)

Boeing

D6-36440

Characteristic Section Airbus Section Category

Radio Frequency Emissions,

Conducted

Radio Frequency Emissions,

Radiated

Lightning Induced Transient

Susceptibility

Electrostatic Discharge 7.3.3.8 25.5 A (3kV – 15 kV)

Dielectric Breakdown &

Insulation Resistance (901164-3)

1-9 APPROVED ANTENNAS

7.3.3.6.1 21.3 M

7.3.3.6.2 21.4 M plus Boeing

22.0 XXE1

ABD0100.1.8

Para 1.3.1:

Leakage current

<10 mArms

Para 1.3.2:

Leakage current

<5 µA

DO-160D

HF notch

Table 1-3 lists the antennas approved for use with the CAP. Antennas are selected based on CAP

configuration (CWLU or TWLU) and wireless interface. Specifications for the Miltope antennas are

provided in

Chapter 1 1-9

General Information February/2006

Table 1-4 through Table 1-7.

Table 1-3. Approved Antennas

Configuration

CWLU IEEE 802.11a/b/g Miltope 901167-1, 901167-2

CWLU IEEE 802.11a/b/g Gore GSC10-82701-XX*

TWLU IEEE 802.11b/g Miltope 901058-1

TWLU IEEE 802.11a/b/g Miltope 901563-2

* For installation information for Gore antenna part number GSC10-82701-XX,

contact W. L. Gore & Associates, 402 Vieve’s Way, Elkton, MD 21921,

800-311-3060, www.gore.com.

Wireless Interface Antenna Part Number

Page 16

Operator’s Manual M365-491

Table 1-4. Antenna Part Number 901167-1 Specifications

Characteristic Specification

Frequency Range 2.39 GHz – 2.49 GHz and 4.9 – 5.9 GHz

Typical Gain 2.5 dBi at 2.45 GHz, 2 dBi at 5.0 GHz,

3.0 dBi at 5.25 GHz and 5.8 GHz

Peak Gain 3.5 dBi at 2.45 GHz, 2.5 dBi at 5.0 GHz,

3.5 dBi at 5.25 GHz and 5.8 GHz

VSWR <4.0:1

Nominal Impedance 50 ohms

Radome Material Ultem 1000 Thermoplastic

Cable 7.25-inch Plenum, RG-316U coaxial

Polarization Horizontal

Grounding Protection DC Grounded

Connector Type Male TNC

Size 0.48 inch x 4.7 inches x 0.5 inch

Weight 1 ounce

Operating Temperature Range -40°C to +71°C

Table 1-5. Antenna Part Number 901167-2 Specifications

Characteristic Specification

Frequency Range 2.39 GHz – 2.49 GHz and 4.9 – 5.9 GHz

Typical Gain -4.0 dBi at 2.45 GHz, -3.5 dBi at 5.15 GHz,

-1.0 dBi at 5.25 GHz, -2.2 dBi at 5.85 GHz

Peak Gain 2.6 dBi at 2.4 GHz, 0 dBi at 5.15 GHz,

1.2 dBi at 5.25 GHz and 5.85 GHz

VSWR <4.0:1

Nominal Impedance 50 ohms

Radome Material Ultem 1000 Thermoplastic

Cable 7.25-inch Plenum, RG-316U coaxial

Polarization Horizontal

Grounding Protection DC Grounded

Connector Type Male TNC

Size 0.48 inch x 4.7 inches x 0.5 inch

Weight 1 ounce

Operating Temperature Range -40°C to +71°C

1-10 Chapter 1

January/2006 General Information

Page 17

M365-491 Operator’s Manual

Table 1-6. Antenna Part Number 901058-1 Specifications

Characteristic Specification

Frequency Range 2.2 GHz – 2.5 GHz

Radiation Pattern Omni-directional

Typical Gain 4.15 dBi at 2.35 GHz

Peak Gain 5.00 dBi at 2.35 GHz

Input Power 1000 Watts peak, 50 Watts continuous

VSWR ≤ 1.5:1

Nominal Impedance 50 ohms

Material A-356 Aluminum Alloy Casting

Finish Skydrol Resistant Enamel

Polarization Vertical

Grounding Protection DC Grounded

Lightning Protection DC Grounded per MIL-A-9094, B-5087

Connector Type Female TNC

Size 1.3 inches x 5.17 inches x 1.75 inches

Weight 3 ounces

Operating Temperature Range -53°C to +85°C

Altitude -1,800 feet to +70,000 feet

Chapter 1 1-11

General Information March/2006

Page 18

Operator’s Manual M365-491

Table 1-7. Antenna Part Number 901563-2 Specifications

Characteristic Specification

Frequency Range

J1

J2

Typical Gain 4.00 dBi at 2.45 GHz, 4.45 dBi at 2.50 GHz,

Peak Gain 4.75 dBi at 2.45 GHz, 4.85 dBi at 2.50 GHz,

Radiation Pattern Omni-directional

Input Power 1000 Watts peak, 50 Watts continuous

VSWR ≤ 2.0:1

Nominal Impedance 50 ohms

Material Aluminum Alloy 6061-T6, Thermoset Plastic

Finish Skydrol Resistant Polyurethane Enamel

Polarization Vertical

Lightning Protection DC Grounded per MIL-A-9094, B-5087

Connector Type Female TNC

Size 2.86 inches x 5.12 inches x 2.00 inches

Weight 7 ounces

Operating Temperature Range -54°C to +85°C

Altitude -1,800 feet to +70,000 feet

1.9 GHz – 2.5 GHz

4.8 – 5.875 GHz

4.80 at 4.80 GHz, 4.85 dBi at 5.25 GHz,

3.45 dBi at 5.875 GHz

5.00 dBi at 4.8 GHz, 5.00 dBi at 5.25 GHz,

4.00 dBi at 5.875 GHz

Gloss White FED-STD-595 Color 17925

1-10 AVAILABLE SOFTWARE AND MANUALS

In addition to this operator’s manual, an Air Transport Association (ATA) Specification 2200

compliant abbreviated component maintenance manual (ACMM) 44-30-07 (Miltope part number

M365-493) is available. Software operator’s manuals are available to support the operating software

installed. Miltope standard software operator’s manuals are listed in

and manuals for custom configurations are available upon request.

1-12 Chapter 1

March/2006 General Information

Table 1-8. Operating software

Page 19

M365-491 Operator’s Manual

Table 1-8. Available Software and Manuals

Software

CAP

Part Number

901164-1, -2 Cabin Access Point (CAP) 999057 M365-506

901164-3 Multifunction Access Point (MAP) 999105 M365-524

Miltope Standard Default Parameters 999086 M365-525

901164-1, -2 Wireless Access Bridge (WAB) 999041-1 M365-503

1-11 TOOLS AND TEST EQUIPMENT REQUIRED

Equipment required for setup of your CAP is listed in the applicable operating software operator’s

manual. Tools and material required for maintenance of the CAP are listed in Chapter 5.

Description Part Number

Operator’s

Manual Part

Number

Chapter 1 1-13/1-14

General Information March/2006

Page 20

M365-491 Operator’s Manual

CHAPTER 2

EQUIPMENT SETUP

2-1 INTRODUCTION

This chapter provides instructions for unpacking, inspection, and setup of the Cabin Access Point

(CAP). Procedures for configuring the CAP operating software depend on the software installed.

Refer to the operator’s manual for your software for configuration instructions. The CAP must be

configured as described in the operating software operator’s manual prior to installation on the

aircraft.

2-2 UNPACKING AND INSPECTION

The CAP is packed in a cardboard carton lined with cushioning material to protect the unit during

shipment. The packing material should be saved for reuse in the event shipment of the unit is

necessary. A packing list is enclosed in or attached to the carton. Use the packing list to check the

contents of the carton during unpacking. Inspect the CAP before, during, and after unpacking for

any sign of shipping damage. Check for dents, breaks, water (moisture) damage, or any evidence of

mishandling. If any damage is discovered, file a complaint with the carrier, noting all damage and

notify Miltope Corporation of the action taken. To unpack the CAP, refer to Figure 2-1 and proceed

as follows:

a. Position carton so that arrows on shipping label point upward.

b. Cut sealing tape on top of carton and open carton.

c. Remove upper foam cushion.

d. Remove CAP from carton.

e. Remove CAP from polybag.

f. Inspect CAP for any sign of shipping damage.

2-3 INITIAL SETUP Prior to installing your CAP, the unit should be connected in a simple network configuration

in the laboratory environment.

Once the CAP is operating in the simple network, it can be configured for your specific installation.

Refer to the operating software operator’s manual for instructions on setting up your CAP unit in the

laboratory environment.

2-4 CONFIGURATION

Prior to installation of the CAP, the unit must be configured for your specific application as

described in the operator’s manual for your operating software.

Chapter 2 2-1

Equipment Setup October/2005

Page 21

Operator’s Manual M365-491

M

UPPER FOA

CUSHION

POLYBAG

CARDBOARD

CARTON

CAP UNIT

0407237-

Figure 2-1. CAP Packaging

2-2 Chapter 2

October/2005 Equipment Setup

Page 22

M365-491 Operator’s Manual

CHAPTER 3

INSTALLATION

3-1 INTRODUCTION

This chapter provides instructions for installation of the Cabin Access Point (CAP). After

configuring the CAP as described in the operating software operator’s manual, use the instructions

provided in this chapter to install the CAP. Installation of the CAP must be performed by personnel

authorized to perform maintenance on the aircraft.

3-2 MOUNTING 3-2.1 CAP Unit

Six mounting holes are provided on the CAP. Figure 3-1 shows the CAP outline dimensions and

mounting-hole locations. Mount the CAP using number 10 mounting hardware. Although not

mandatory for specification compliance, it is recommended that the CAP unit be mounted to a

grounded surface within the aircraft. An unpainted area around each mounting hole provides ground

connection to the mounting surface.

3-2.2 Indoor Cabin Antenna

Two antennas are required for each CAP unit configured as a cabin wireless LAN unit (CWLU).

Two mounting holes are provided on antenna part numbers 901167-1 and 901167-2. The antenna is

fitted with a 7.25-inch cable that connects to the CAP RF output connector. Figure 3-2 shows the

outline dimensions and mounting-hole locations for the antenna. The radiation pattern for antenna

part number 901167-1 is shown in Figure 3-3. The radiation pattern for antenna part number

901167-2 is shown in

recommended that the antennas be mounted a minimum of six inches apart. Contact W. L. Gore &

Associates, 402 Vieve’s Way, Elkton, MD 21921, 800-311-3060, www.gore.com for installation

information for leaky line antenna, Gore part number GSC10-82701-XX.

3-2.3 Outdoor Antenna

An antenna mounted on the exterior of the aircraft is required for a CAP unit configured as a

terminal wireless LAN unit (TWLU). The antenna is fitted with TNC female connector(s). Use a

TNC Male-to-TNC Male 50-ohm coaxial cable to connect the antenna to the CAP unit.

shows the outline dimensions and mounting hole locations for antenna part number 901058-1

(IEEE 802.11b/g operation).

dimensions and mounting hole locations for antenna part number 901563-2 (IEEE 802.11a and

IEEE 802.11b/g operation).

number 10 mounting hardware.

Chapter 3 3-1

Installation February/2006

Figure 3-4. Mount the antenna using number 6 mounting hardware. It is

Figure 3-5

Figure 3-6 shows the radiation patters. Figure 3-7 shows the outline

Figure 3-8 shows the radiation patterns. Mount the antenna using

Page 23

Operator’s Manual M365-491

9

2X 0.09

I/O CONNECTOR

1.29

M83723/72R2041N

MATING CONNECTOR

M83723/77R2041N

J1

DESCRIPTION:

P/N:

3.30

±0.25

MILTOPE

CAGE

PART NO.

VOLTS AMPS

CORPORATION

HZ PH

REVISION:

SER NO.

(7.85)

WC

DOM

EXT . AN TENNA

MATING CONNECTOR

TNC PLUG

2 PLACES

9.04

3X 10.750

9.16

5.90

±0.25

1.23

3X 0.375

1.10

±0.25

2.40

2X 0.733

NOTES: 1. All dimensions are in inches.

2. Dimensions in parenthesis are for reference only.

Figure 3-1. CAP Outline Dimensions

2X 2.750

7.50±0.25

2X 5.500

6.97

6X 0.203

11.50

J3

J2

6X 0.38

PAINT MASKING

3. Tolerances:

X.XX (2 Places) = ±0.03

X.XXX (3 Places) = ±0.010

4. denotes center of grav ity.

4.4

2.49

2X 1.28

0407238-

0.50

1TLP3/901167-1 REV

S/N

NOTES: 1. All dimensions are in inches.

2. Tolerances:

0.12

4X R0.20

0.19

2X 0.166

(MATING CONNECTOR FRT-1212-B)

0.240

3.375

4.17

TNC PLUG

0.48

THE ANTENNA RADIATES RADIO FREQUENCY

(RF) POWER. TO AVOID EXCEEDING FEDERAL

COMMUNICATIONS COMMISSION (FCC) RADIO

FREQUENCY EXPOSURE LIMITS, HUMAN

PROXIMITY TO THE ANTENNA SHALL BE NO

LESS THAN EIGHT INCHES (20 CENTIMETERS)

WHILE RF IS ENABLED.

X.X (1 Places) = ±0.03

X.XX (2 Places) = ±0.010

WARNING

0407261-

Figure 3-2. Indoor Cabin Antenna Part Numbers 901167-1 and 901167-2 Outline Dimensions

3-2 Chapter 3

October/2005 Installation

Page 24

M365-491 Operator’s Manual

ANTENNA ORIE NTATI ON , Y CUT ANTENN A OR IENTATION, X CUT

2.45GHz, Y Cut 2.45GHz, X Cut

5.0GHz, Y Cut 5.0GHz, X Cut

Figure 3-3. Antenna Part Number 901167-1 Radiation Pattern (Sheet 1 of 2)

Chapter 3 3-3

Installation October/2005

Page 25

Operator’s Manual M365-491

5.25GHz, Y Cut 5.25GHz, X Cut

5.8GHz, Y Cut 5.8GHz, X Cut

Figure 3-3. Antenna Part Number 901167-1 Radiation Pattern (Sheet 2 of 2)

3-4 Chapter 3

October/2005 Installation

Page 26

M365-491 Operator’s Manual

ANTENNA ORIENTATION, Y CUT ANTENNA ORIENTATION, X CUT

2.45 GHz, Y Cut 2.45 GHz, X Cut

5.15 GHz, Y Cut 5.15 GHz, X Cut

Figure 3-4. Antenna Part Number 901167-2 Radiation Pattern (Sheet 1 of 2)

Chapter 3 3-5

Installation October/2005

Page 27

Operator’s Manual M365-491

5.25 GHz, Y Cut 5.25 GHz, X Cut

5.85 GHz, Y Cut 5.85 GHz, X Cut

Figure 3-4. Antenna Part Number 901167-2 Radiation Pattern (Sheet 2 of 2)

3-6 Chapter 3

October/2005 Installation

Page 28

M365-491 Operator’s Manual

Figure 3-5. Outdoor Antenna Part Number 901058-1 Outline Dimensions

Chapter 3 3-7

Installation October/2005

Page 29

Operator’s Manual M365-491

Figure 3-6. Antenna Part Number 901058-1 Radiation Pattern (2.35 GHz)

3-8 Chapter 3

March/2006 Installation

Page 30

M365-491 Operator’s Manual

4.74

2.16

0.34

2.86

0.490

0.980

4X R0.62

2X 0.688 THRU

4X 0,38 THRU

1.86

1.100

1.08 1.44

CONNECTOR J2

4.800 - 5.875 GHz

TYPE “TNC” FEMALE

(IEEE 802.11a)

5.12

NAMEPLATE

1.400

3.600

3.60

2X 1.15

REF

CONNECTOR J1

1.900 - 2.500 GHz

TYPE “TNC” FEMALE

(IEEE 802.11b/g)

1.00

2.00

NOTES: 1. All dimensions are in inches.

4X 0.385 X 100°

4X 0.36±0.02

0.228

0.218

THRU

4X

2. Tolerances:

X.XX (2 Places) = ±0.03

X.XXX (3 Places) = ±0.010

1.00

2.00

0.02 STK

0.98

4X R0.62

0.49

1.82

5.08

GASKET, NEOPRENE - WOVEN ALUM

WARNING

THE ANTENNA RADIATES RADIO FREQUENCY (RF) POWER. TO AVOID EXCEEDING FEDERAL

COMMUNICATIONS COMMISSION (FCC) RADIO FREQUENCY EXPOSURE LIMITS, HUMAN

PROXIMITY TO THE ANTENNA SHALL BE NO LESS THAN EIGHT INCHES (20 CENTIMETERS)

WHILE RF IS ENABLED.

0506021A

Figure 3-7. Outdoor Antenna Part Number 901563-2 Outline Dimensions

Chapter 3 3-9

Installation February/2006

Page 31

Operator’s Manual M365-491

Figure 3-8. Antenna Part Number 901563-2 Radiation Pattern

3-10 Chapter 3

March/2006 Installation

Page 32

M365-491 Operator’s Manual

3-3 CONNECTING THE CAP

All power and interface connections except the RF (antenna) output are provided at input/output

(I/O) connector J1 shown in Figure 3-9. Table 3-1 provides the pin assignments for I/O connector

J1. To ensure specification compliance, use of double-shielded cables is recommended. RF

(antenna) output connections are provided at connectors J2 and J3. Connector J2 is the RF output

for radio card 2 and connector J3 is the RF output for radio card 1. Refer to the applicable operating

software operator’s manual for radio card configuration instructions. The following paragraphs

describe the input power requirements and available interfaces.

3-3.1 Input Power Requirements

CAP part numbers 901164-2 and 901164-3 operate from an external 97 to 134 volt AC, 360 to

800 Hz or 18 to 32 volt DC, 15 W external power source. The CAP can be connected to both AC

and DC power sources simultaneously. If the DC input voltage is greater than 24 volts, the CAP will

operate from the DC source. If the DC input is 24 volts or less, the CAP will operate from the AC

source. CAP part number 901164-1 operates from 97 to 134 volts AC, 360 to 800 Hz input power

only.

I/O CONNECTOR J1

CORPORATION

MILTOPE

VOLTS AMPS

DESCRIPTION:

P/N:

CAGE

PART NO.

HZ PH

REVISI ON:

SER NO.

WC

DOM

Figure 3-9. Connector Locations

EXTERNAL ANTENNA

(RF OUTPUT)

CONNECTOR J3

EXTERNAL ANTENNA

(RF OUTPUT)

CONNECTOR J2

0407262-

Chapter 3 3-11

Installation March/2006

Page 33

Operator’s Manual M365-491

Table 3-1. I/O Connector J1 Pin Assignments

Pin* Signal Pin* Signal

1 Chassis Ground 22 Chassis Ground (Shield)

2 Reset 23 Ethernet LAN Port 2 Rx+

3 Reset Ground 24 Ethernet LAN Port 2 Tx+

4 No connection 25 Ethernet LAN Port 2 Tx5 No connection 26 Ethernet LAN Port 1 Rx6 No connection 27 Ethernet LAN Port 1 Tx7 No connection 28 Chassis Ground

8 Chassis Ground 29 Reserved

9 Ethernet LAN Port 2 Rx- 30 Reserved

10 Ethernet LAN Port 1 Rx+ 31 Reserved

11 Ethernet LAN Port 1 Tx+ 32 No connection

12 Chassis Ground 33 Digital Ground

13 Chassis Ground 34 Reserved

14 Discrete Input 1 (on/off control) 35 Reserved

15 Discrete Input 2 (RF enable/disable) 36 No connection

16 Reserved 37 28 VDC Return (901164-2, -3 only)

17 No connection 38 28 VDC Positive (901164-2, -3 only)

18 115 VAC Phase (hot) 39 Chassis Ground

19 115 VAC Neutral 40 Chassis Ground

20 Discrete Output 1 (on/off status) 41 Chassis Ground

21 Discrete Output 2 (RF status)

* Use M83723/77R2041N for mating connector.

3-12 Chapter 3

March/2006 Installation

Page 34

M365-491 Operator’s Manual

3-3.2 10/100BaseT Ethernet Local Area Network (LAN) Ports

Two IEEE 802.3 compliant 10/100BaseT Ethernet LAN ports are provided at I/O connector J1. One

port can be connected to an existing on-board LAN or wired server, while the other port can be used

to connect additional computers to the LAN via an Ethernet hub or to enable the connection of a

second CAP unit. Standard (straight-through) connection is used when connecting to an Ethernet

hub. Crossover connection is required when connecting directly to a computer or server, or

connecting to a second CAP unit. Table 3-2 provides cross-reference pin assignment information

between CAP I/O connector J1 and RJ45 male connectors.

Table 3-2. CAP I/O Connector J1 to RJ45 Male Cross Reference

RJ 45 Male Connector (Figure 3-9)

Standard Crossover

LAN Port

CAP I/O

Connector J1 Signal

Port 1 10 Rx+ 3 1

11 Tx+ 1 3

26 Rx- 6 2

27 Tx- 2 6

Port 2 9 Rx- 6 2

23 Rx+ 3 1

24 Tx+ 1 3

25 Tx- 2 6

PIN 1

PIN 8

0503043-

Figure 3-10. RJ45 Male Connector Front View

Chapter 3 3-13

Installation March/2006

Page 35

Operator’s Manual M365-491

3-3.3 RF (Antenna) Output

WARNING

The CAP antenna radiates radio frequency

(RF) power. To avoid exceeding federal

communications commission (FCC) radio

frequency exposure limits, human proximity

to the antenna shall be no less than eight

inches (20 centimeters) while RF is enabled.

The CAP is designed to be used with two indoor antennas when configured as a CWLU (using CAP

operating software) or one outdoor antenna when configured as a TWLU (using WAB operating

software). The two indoor antennas connect to the two RF output connectors shown in

Figure 3-9.

Connector J2 is the RF output for radio 2 and connector J3 is the RF output for radio 1. The outdoor

antenna connects to RF output connector J3 shown in Figure 3-9. Table 3-3 provides the pin

assignments for the RF output connectors.

To comply with Federal Communications Commission (FCC) requirements, attenuation is required

between the CAP and the antenna for IEEE 802.11b and/or IEEE 802.11g operation at maximum

transmit power. This attenuation is typically accomplished by connecting a minimum of six feet of

RG-58 coaxial cable (or alternate coaxial cable with equivalent attenuation characteristics) between

the CAP and the antenna. If no extension cable is connected between the CAP and the antenna, the

applicable radio transmit power must be set to a maximum value of 15 dBm. Refer to the applicable

operating software operator’s manual for instructions for setting radio transmit power.

Table 3-3. RF Output Connectors J2 and J3 Pin Assignments

Connector Component* Signal

Center Conductor RF Signal

Shield RF Return

* Use TNC Plug for mating connector.

3-3.4 Discrete Inputs

Two ground/open type discrete inputs as defined by ARINC 763-2 are provided via I/O connector J1

to enable external control of CAP operation. An external controller or switch panel can be used to

power up the CAP and enable wireless operation. Connecting a ground to on/off control (pin 14)

causes the CAP to power up. When the ground is disconnected, the CAP will power down.

Connecting a ground to RF enable/disable (pin 15) will enable wireless operation. When the ground

is disconnected, wireless operation is disabled. The wired LAN remains operational when wireless

operation is disabled.

3-14 Chapter 3

March/2006 Installation

Page 36

M365-491 Operator’s Manual

3-3.5 Discrete Outputs

Two ground/open type discrete outputs as defined by ARINC 763-2 are provided via I/O connector

J1. Discrete output 1 (on/off status) is low when the CAP is powered up. Discrete output 2 (RF

status) is low when wireless operation is enabled.

3-3.6 Reset Input

The CAP reset function is accessible via I/O connector J1 pins 2 and 3. Connecting pins 2 and 3

together will cause the CAP to reset as follows:

• Momentary (less than five seconds) connection causes the CAP to restart;

• Connection for more than five seconds and less than ten seconds (LAN ACTIVE and

RF ACTIVE indicators flash slowly, one flash per second) causes the CAP to reset all

configuration parameters to the factory default settings;

• Connection for more than ten seconds (LAN ACTIVE and RF ACTIVE indicators flash rapidly,

two flashes per second) causes the CAP to enter Trivial File Transfer Protocol (TFTP) mode for

loading new firmware.

The reset input is not intended for connection in normal operation. The reset input is for

maintenance operation only. Compliance with specifications is not guaranteed when the reset input

is connected.

3-4 CONFIGURING WIRELESS CLIENT STATIONS

(CWLU CONFIGURATION)

Computers used as wireless client stations must be equipped with a wireless LAN card compliant

with IEEE standard 802.11a, b, or g and Wireless Fidelity (WiFi) certification as defined by the

Wireless Ethernet Compatibility Alliance (WECA).

Configure the wireless LAN card as follows:

• Wireless network name (ESSID) set to be compatible with operating software configuration.

• Encryption disabled

• TCP/IP installed and configured to use the wireless adapter

• IP address set in accordance with operating software configuration.

3-5 CONFIGURING THE GROUND-BASED NETWORK

(TWLU CONFIGURATION)

The ground-based network must be connected to a wireless access point compliant with

IEEE 802.11 a, b, or g and WiFi certification as defined by WECA.

Chapter 3 3-15

Installation March/2006

Page 37

Operator’s Manual M365-491

Configure the wireless access point as follows:

• Wireless network name (ESSID) set to be compatible with operating software configuration.

• Encryption disabled.

• IP address compatible with operating software configuration.

3-16 Chapter 3

March/2006 Installation

Page 38

M365-491 Operator’s Manual

CHAPTER 4

OPERATION

4-1 INTRODUCTION

The Cabin Access Point (CAP) does not require day-to-day management for successful, efficient

operation. The most you will want to do is inquire about status and statistics.

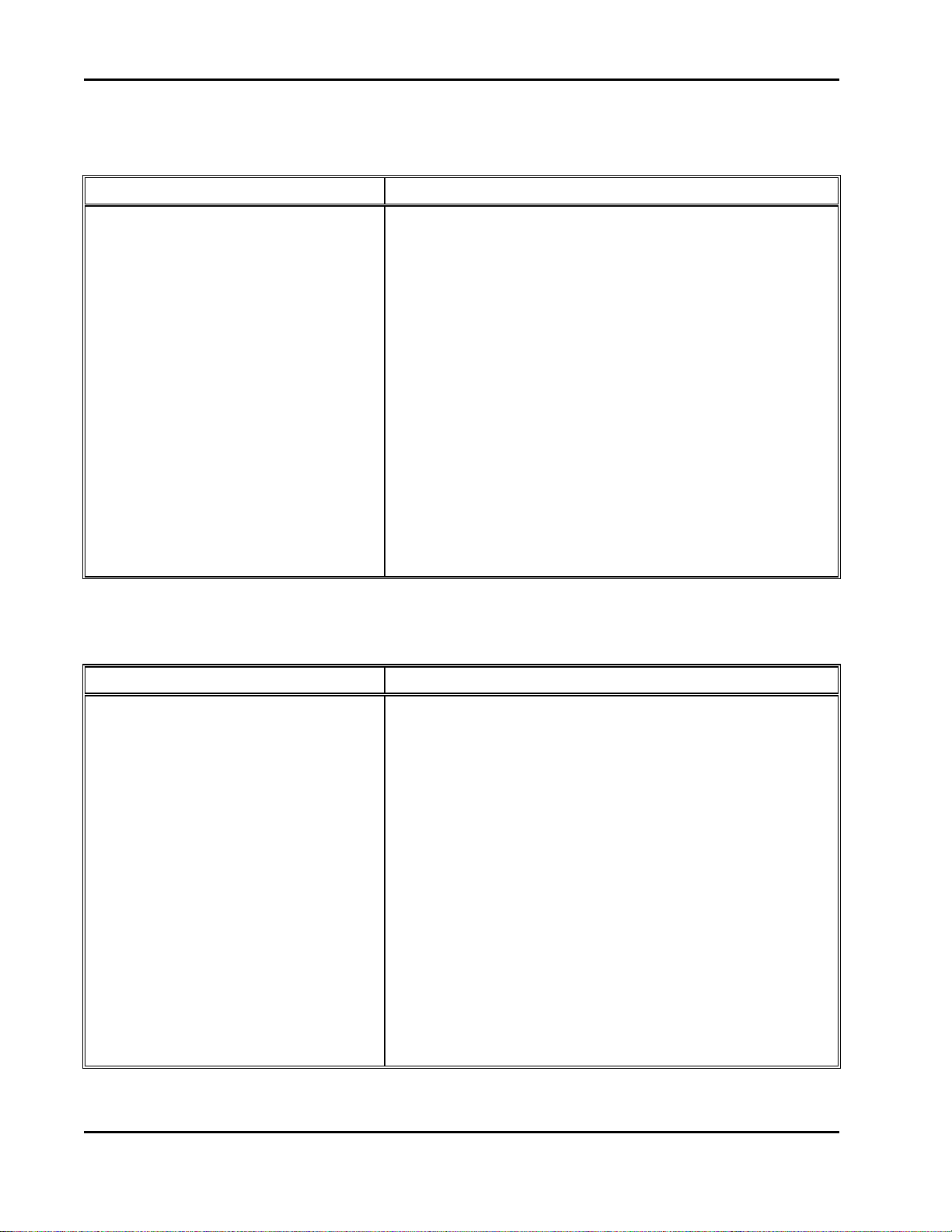

4-2 INDICATORS Figure 4-1 illustrates the CAP indicators. Table 4-1 describes the function of each indicator.

4-3 OPERATING INSTRUCTIONS

The CAP is designed for unattended operation. Avionics level discrete inputs enable remote control

of CAP operation. Discrete inputs are provided to enable or disable CAP operation, and to enable or

disable RF transceiver operation. Chapter 3 of this manual provides information on use of the

discrete inputs.

4-4 POWER UP

The CAP powers up automatically when power is applied provided that ground signals are applied at

the on/off control and the RF enable/disable discrete inputs. When the POWER and RF ENABLE

indicators are lit green, the CAP is fully operational. If either indicator is lit amber, CAP operation is

disabled. Refer to Chapter 3 of this manual for information on use of the discrete inputs.

NOTE

The CAP takes approximately 45 seconds to

power up and enable the RF (configuration

dependent).

4-5 CHECKING THE STATUS OF YOUR CAP

Checking the operational status of the CAP requires access to the management tool. Refer to the

applicable operating software operator’s manual for instructions on accessing the management tool

and checking CAP operational status.

Chapter 4 4-1

Operation March/2006

Page 39

Operator’s Manual M365-491

E

CORPORATION

MILTOPE

VOLTS AMPS

DESCRIPTION:

P/N:

CAGE

PART NO.

HZ PH

REVISION:

SER NO.

WC

DOM

POWER

INDICATOR

POWER

Indicator

RF ENABLE

RF ENABLE

INDICATOR

RF ACTIVE

RF ACTIVE

LAN ACTIVE

INDICATOR

LAN ACTIV

INDICATOR

0407263-

Figure 4-1. CAP Indicators

Table 4-1. CAP Indicators

Function

POWER

Indicator

RF ENABLE

Indicator

RF ACTIVE

Lit green to indicate CAP is powered up and enabled for operation. Lit amber to

indicated CAP is powered up, but operation is disabled (standby mode).

Lit green to indicate RF output is enabled.

Lit amber to indicated RF output is disabled.

Flashes green to indicated RF data transfers are occurring.

Indicator

LAN ACTIVE

Flashes green to indicate LAN data transfers are occurring.

Indicator

4-2 Chapter 4

October/2005 Operation

Page 40

M365-491 Operator’s Manual

CHAPTER 5

OPERATOR MAINTENANCE

5-1 INTRODUCTION

This chapter contains instructions for the routine preventive maintenance the operator should

perform to maintain the Cabin Access Point (CAP) in proper working condition. Operator

maintenance consists of inspection for signs of damage and cleaning the exterior surfaces.

Information is also provided for installing the operating software. Any unauthorized repair or

modification of your CAP will void your warranty. Breaking the Miltope quality seal on the CAP

will void the warranty. Inspection and cleaning should be performed as dictated by environmental

conditions.

5-2 INSPECTION

Regular inspection will help ensure proper operation of your CAP. Inspect the exterior of the unit

for any loose or missing hardware, or damage that would prevent proper operation.

5-3 CLEANING EXTERIOR SURFACES 5-3.1 Materials Required

• Lint-Free Cloth

• Soft-Bristle Brush

• Mild Detergent

5-3.2 Cleaning Procedure

Remove dust or dirt from external surfaces of the CAP with a lint-free cloth or soft-bristle brush. If

necessary, moisten cloth with a solution of mild detergent and water.

5-4 INSTALLING OPERATING SOFTWARE

CAP operation is controlled by the operating software. Operating software can be installed or

updated via the management tool. Instructions for installing or updating software are provided in the

applicable operating software operator’s manual. Equipment required to install operating software is

listed in Table 5-1. To install operating software, connect the CAP as shown in

follow the instructions provided in the operating software operator’s manual.

Figure 5-3 and

Chapter 5 5-1

Operator Maintenance October/2005

Page 41

Operator’s Manual M365-491

050603

3

Table 5-1. Equipment Required for Software Installation

Item Manufacturer Model/Part Number

115 VAC, 400 Hz, Single Phase Power Source Invertron 1501L

28 VDC, 2 A Power Source

Vector-Vio WP707B

(901164-2 and 901164-3 only)

Personal Computer with Pentium Processor,

Commercially available

64 MB RAM, and 10/100 Base TX Network

Capability

JavaScript Enabled Web Browser Microsoft

Netscape

Test Cable Locally manufactured

(See

Figure 5-1.)

Test Box Locally Manufactured

(See Figure 5-2.)

72 INCHES (182.9 CM)

TWISTED

PAIR

TWISTED

PAIR

TWISTED

PAIR

TWISTED

PAIR

P1

26

10

11

27

9

23

24

25

Internet Explorer 6.0

Netscape 7.01

P

2

ETHERNET

1

RJ-45 MALE

3

CONNECTOR

6

P2

2

ETHERNET

1

RJ-45 MALE

3

CONNECTOR

6

P1

TWISTED

PAIR

TWISTED

PAIR

14

15

2

3

33

18

19

22

38

37

39

NOTES:

M83723/77R2041N

OR EQUIVALENT

1. Use 24 gauge 4-conductor category 5 twisted pair cable where indicated.

1

2

DB9S CONNECTOR

3

TO TEST BOX

4

8

LINE (HO T )

NEUTRAL

GROUND

DC POS.

DC RTN.

GROUND

AC INPUT

POWER

OR

DC INPUT

POWER

(901164-2 AND

901164-3 ONLY)

For all other wires, use 22 gauge.

2. Connector P3 can be used to connect to a second computer.

1-

Figure 5-1. Test Cable

5-2 Chapter 5

October/2005 Operator Maintenance

Page 42

M365-491 Operator’s Manual

S1

S2

OFF

ON

DISABLE

ENABLE

POWER

SUPPLY

RF

0310242-

POWER ON/OFF (DISCRETE_IN_01)

1

RF ENABLE/DISABLE (DISCRETE_IN_02)

2

RESET

CONNECTOR J1

DB9P

3

RESET GROUND

4

5

6

7

DIGITAL GROUND

8

9

S3

RESET

PARTS LIST: J1 DB9P Panel Moun t Connector

S1 and S2 SPST Toggle Switches, 28 VDC, 0.1 A Min.

S3 SPST Momentary pushbutton switch, 28 VDC, 0.1 A Min.

All wires are 22 gauge.

Figure 5-2. Test Box Schematic Diagram

NOTE

Units are configured at the factory for cabin

wireless LAN unit (CWLU) operation using

CAP operating software or for terminal

wireless LAN unit (TWLU) operation using

wireless access bridge (WAB) operating

software. This configuration cannot be

changed in the field.

Chapter 5 5-3

Operator Maintenance October/2005

Page 43

Operator’s Manual M365-491

-

P1

I/O CONNECTOR J1

CABIN ACCESS POINT (CAP)

P3

USE OF P3 IS OPTIONAL

FOR CONNECTION TO

SECOND COMPUTER

TEST CABLE

(SEE FIGURE 5-1)

CONNECTOR J3

RF OUT

RF OUT

CONNECTOR J2

ETHERNET PORT

COMPUTER WITH 10/100BASETX ETHERNET CAPABILITY

P1

J1

P2

POWER

SUPPLY

ON

RF

ENABLE

RESET

0510211

115 VAC

(97 - 134 VAC)

360 - 800 Hz

INPUT POWER

OR

(901164-2 AND 901164-3 ONLY)

28 VDC

(18 - 32 VDC)

INPUT POWER

OFF

DISABLE

TEST BOX

(SEE FIGURE 5-2)

Figure 5-3. Test Setup

5-4 Chapter 5

October/2005 Operator Maintenance

Page 44

M365-491 Operator’s Manual

CHAPTER 6

TROUBLESHOOTING

6-1 INTRODUCTION

This chapter provides instructions for isolating and correcting faults in the cabin access point (CAP).

Operator level troubleshooting and repair are limited to correcting errors in the configuration. This

chapter provides troubleshooting information related to the CAP unit hardware. Refer to the

applicable operating software operator’s manual for troubleshooting procedures related to software

configuration issues. If a fault cannot be corrected using the procedures provided in this chapter or

in the operating software operator’s manual, contact VT Miltope for authorization to return your

CAP for factory repair. Any unauthorized repair or modification of your CAP will void your

warranty.

6-2 CLIENT STATION PROBLEMS 6-2.1 Wireless Client Station Cannot Establish a Wireless Link With the CAP Symptoms

The wireless client or ground-based access point software cannot find the CAP. If your wireless

software has a status display, the CAP is not visible in it.

Causes on the CAP

• Power not applied to the CAP (POWER indicator not lit).

• CAP is disabled by no input to on/off discrete input (POWER indicator lit amber).

• CAP transceiver disabled by no input to RF enable discrete input (RF ENABLE indicator lit

amber).

• WEP encryption is enabled on CAP, but not on the client station. (Refer to operating software

operator’s manual.)

• Security filters are enabled.

Causes on the client station or ground-based access point

• Wireless adapter is not properly installed or configured (wrong drivers, conflicts with other cards

in the system).

• Wireless adapter software is not active.

• Two wireless adapters are installed, and are creating a configuration conflict.

• Incorrect network name (ESSID). Make sure it matches the setting on the CAP. (Refer to

operating software operator’s manual.)

• Incorrect WEP keys. Make sure that the keys match those set on the CAP. (Refer to operating

software operator’s manual.)

Chapter 6 6-1

Troubleshooting October/2005

Page 45

Operator’s Manual M365-491

6-2.2 IP Address Mismatch

Before you troubleshoot this problem, make sure that problem described in paragraph 6-2.1 does not

exist.

Symptoms

• The client station is unable to access network resources, Web, or e-mail, or aircraft network is

unable to access ground-based network resources.

• The client station is unable to renew its IP address.

Cause on the CAP

• IP address configuration on CAP is not compatible with network and/or client stations. (Refer to

operating software operator’s manual.)

Causes on the client station

• TCP/IP is not installed or not properly configured.

6-2.3 Wireless Client Stations Cannot Connect to the Internet Via the CAP

Before you troubleshoot this problem, make sure that problem described in paragraph 6-2.2 does not

exist.

Symptoms

• Web pages time out.

• E-mail cannot be retrieved from external e-mail servers.

Causes on the CAP

• Network Address Translation (NAT) and/or Virtual Private Network (VPN) is not compatible

with network and/or client stations. (Refer to operating software operator’s manual.).

• Security filters are enabled.

Causes on the client station

• Browser not installed or configured properly (set to use a proxy server, set to use dial-up

connection instead of LAN).

• Client station may not be on the same subnet as the CAP.

• No VPN client software is installed.

• VPN client software installed but not started.

• VPN client software has wrong username, password, or IP address set.

Other cause

• DHCP server on LAN is not returning the IP address of the CAP as gateway.

• ISP is down.

6-2 Chapter 6

October/2005 Troubleshooting

Page 46

M365-491 Operator’s Manual

6-2.4 Computers Cannot Share Data or Resources With Other Computers

Before you troubleshoot this problem, make sure that problem described in paragraph 6-2.2 does not

exist.

Symptoms

Network neighborhood does not show other computers on the wireless or wired network (Windows)

or cannot ping other computers from a computer using the Linux operating system.

Causes on the client station

• Wrong workgroup names being used.

• NetBIOS not enabled.

6-2.5 Web Browser Cannot Connect to Management Tool

Before you troubleshoot this problem, make sure that problem described in paragraph 6-2.2 does not

exist.

Symptoms

Management tool home page does not open.

Causes on the CAP

• Local access

o Web port was changed in the management tool from default setting. (Refer to

operating software operator’s manual.)

• Remote access

o Management tool security settings are set to block access on the VPN. (Refer to

operating software operator’s manual.)

o CAP is not powered up (POWER indicator not lit).

o CAP is disabled by no input at on/off discrete input (POWER indicator is lit amber).

o Another client station is currently logged in.

o A web server is running on the internal network using a static mapping for HTTPS

port 443.

Causes on a local client station

• Wrong IP address was specified. If VPN security is being used, you must specify the starting

address of the VPN server address range. (Refer to operating software operator’s manual.)

Causes on a remote client station (via Internet)

• Wrong IP address was specified. Use the address visible on the home page. This address may

change if you restart the CAP.

Chapter 6 6-3

Troubleshooting October/2005

Page 47

Operator’s Manual M365-491

6-2.6 Low Throughput Symptoms

Client computers are experiencing delays when transmitting. One or more of following statistics on

the wireless status page are excessively high: Tx multiple retry frames, Tx single retry frames,

Tx deferred transmissions

Causes

• Too many client stations are using the network, or one or more clients is monopolizing the

bandwidth with excessively large transfers.

• Signal quality to one or more stations is poor or being subject to interference (interference caused

by cordless phone or microwave oven for example). This can cause excessive retransmissions of

data and collisions. Both create overhead that will slow down overall throughput.

• Antenna installation not optimized for adequate coverage area.

• One or more CAP units are sharing the same operating frequency. This can cause excessive

retransmissions to occur, especially if the units are close together.

• The CAP is sharing the same operating frequency with third-party wireless device nearby. This

can cause excessive retransmissions to occur, especially if the units are close together.

6-3 CAP PROBLEMS 6-3.1 CAP Allows Any Station to Connect, Regardless of Network Name Being Used

This problem occurs when accept any network name is enabled on the wireless configuration

page. (Refer to operating software operator’s manual.)

6-3.2 Lost Administrator Password

Refer to operating software operator’s manual.

6-4 Chapter 6

October/2005 Troubleshooting

Page 48

M365-491 Operator’s Manual

CHAPTER 7

REGULATORY, WIRELESS INTEROPERABILITY, AND HEALTH INFORMATION

7-1 REGULATORY INFORMATION

The CAP complies with the following radio frequency and safety standards.

Canada - Industry Canada (IC)

This Class B digital apparatus meets all requirements of the Canadian Interference Causing

Equipment Regulations. Operation is subject to the following two conditions: (1) this device may

not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

Cet appareillage numérique de la classe B répond à toutes les exigences de l'interférence canadienne

causant des règlements d'équipement. L'opération est sujette aux deux conditions suivantes: (1) ce

dispositif peut ne pas causer l'interférence nocive, et (2) ce dispositif doit accepter n'importe quelle

interférence reçue, y compris l'interférence qui peut causer l'opération peu désirée.

This device has been designed to operate with antennas having a maximum gain of 3 dB for units

configured with Cabin Access Point (CAP) operating software or 5 dB for units configured with

Wireless Access Bridge (WAB) operating software. Antennas having a higher gain are strictly

prohibited per regulations of Industry Canada. The required antenna impedance is 50 ohms.

Europe - EU Declaration of Conformity

Users must select wireless operational settings that conform to local regulations. If more than one

unit is deployed, users must ensure that frequencies are spread among different channels according to

channel availability.

USA - Federal Communications Commission (FCC)

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment also complies with RTCA

specification DO-160D section 21.3 (conducted emissions) and section 21.4 (radiated emissions),

category M (modified for 2.4 GHz transmission frequency). RTCA specification DO-160D applies

to equipment installed and operated aboard aircraft. This equipment generates, uses and can radiate

radio frequency energy. If not installed and used in accordance with the instructions provided in this

manual and the applicable operating software operator’s manual, it may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user/installer is

encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment on a circuit different from that to which the receiver is connected.

Chapter 7 7-1

Regulatory, Wireless Interoperability, and Health Information October/2005

Page 49

Operator’s Manual M365-491

WARNING

Changes or modifications to this device not

expressly approved by Miltope Corporation

could void the user’s authority to operate the

equipment.

Miltope Corporation is not responsible for any interference caused by unauthorized modification of

the CAP, or the substitution or attachment of connecting cables and equipment (antennas) other than

that specified by Miltope Corporation.

The correction of interference caused by such unauthorized modification, substitution or attachment

is the responsibility of the user/installer.

WARNING

Exposure to Radio Frequency (RF) Radiation

In accordance with FCC requirements of human

exposure to radio frequency fields, the radiating

element shall be installed such that a minimum

separation distance of 20 cm (8 inches) is

maintained between it and the user or general

population.

Taiwan - Directorate General of Telecommunications (DGT)

a. The low power radio frequency regulations issued by Ministry of Transportation and

Communications in Taiwan state the following requirements:

Clause 14: For certified low power radio frequency electric machinery, companies, firms, or

users shall not change the frequency, increase the power, or change the features and functions of

the original design without permission.

Clause 15: Any use of low power radio frequency electric machinery shall not affect the aviation

safety or interfere with legal communications. In event that any interference is found, the use of

such machinery shall be stopped immediately, and using of such products should resume only

after improvements are made to eliminate all interference caused.

The legal communications mentioned above refer to radio communications operated in

accordance with telecommunication laws and regulations. Low power radio frequency electric

machinery shall tolerate legal communications or interference from radiological,

electromechanical devices for industrial, scientific, and medical uses.

7-2 Chapter 7

October/2005 Regulatory, Wireless Interoperability, and Health Information

Page 50

M365-491 Operator’s Manual

b.

Wireless information transfer devices operate in the 5.25-5.35 GHz band are limited to indoor

use.

7-2 WIRELESS INTEROPERABILITY

The CAP is designed to be interoperable with any wireless LAN product that is compliant to:

• The IEEE 802.11a, b, or g standard on wireless LANs, as defined and approved by the Institute

of Electrical and Electronics Engineers.

• The Wireless Fidelity (WiFi) certification as defined by the Wireless Ethernet Compatibility

Alliance (WECA).

7-3 HEALTH INFORMATION

The CAP, like other radio devices, emits radio frequency electromagnetic energy. The level of

energy emitted by the CAP is much less than the electromagnetic energy emitted by other wireless

devices, such as mobile phones.

Because the CAP operates within the guidelines found in radio frequency safety standards and

recommendations, Miltope Corporation believes that the CAP is safe for use by consumers. These

standards and recommendations reflect the consensus of the scientific community and result from

deliberations of panels and committees of scientists who continually review and interpret the

extensive research literature.

Chapter 7 7-3/7-4

Regulatory, Wireless Interoperability, and Health Information October/2005

Page 51

M365-491 Operator’s Manual

GLOSSARY

Term Definition

3DES Triple Data Encryption Standard (168 Bit)

ARINC Aeronautical Radio, Incorporated

CAP Cabin Access Point

CRC Cyclic Redundancy Check

CWLU Cabin Wireless LAN Unit

DHCP Dynamic Host Configuration Protocol

Diffie-Hellman Key Cryptography Algorithm/Technique

DN Distinguished Name

DNS Domain Name Server/Service

DSSS Direct Sequence Spread Spectrum

ESSID Extended Service Set Identifier (Wireless Network Name)

FTP File Transfer Protocol

HTTPS Hyper Text Transfer Protocol Secure

IEEE Institute of Electrical and Electronic Engineers

IKE Internet Key Exchange

IP Internet Protocol

IPSec Secure Internet Protocol

ISAKMP Internet Security Association and Key Management Protocol

L2TP Layer 2 Tunneling Protocol

LAN Local Area Network

LDAP Lightweight Directory Access Protocol

MAC Media Access Control

MD5 Message Digest 5

MPDU MAC Protocol Data Unit

MSCHAP v.2 Microsoft Challenge Handshake Authentication Protocol

MSDU MAC Service Data Unit

NAT Network Address Translation

Oakley Group Key Cryptography Algorithm/Technique

OFDM Orthogonal Frequency Division Multiplexing

PFS Perfect Forward Secrecy

PLCP Physical Layer Convergence Procedure

PPTP Point-to-Pont Tunneling Protocol

RADIUS Remote Authentication Dial-In User Server/Service

RFC 2865 Request For Comments - RADIUS

RFC 2866 Request For Comments - RADIUS Accounting

RIP Routing Information Protocol

RTCA Radio Technical Commission for Aeronautics

SA Security Association

SHA-1 Secure Hashing Algorithm 1

SNMP Simple Network Management Protocol

SSL Secure Sockets Layer

Glossary G-1

October/2005

Page 52

Operator’s Manual M365-491

GLOSSARY (Cont’d.)

Term Definition

TCP/IP Transmission Control Protocol/Internet Protocol

TFTP Trivial File Transfer Protocol

TWLU Terminal Wireless LAN Unit

VPN Virtual Private Network

WAB Wireless Access Bridge

WECA Wireless Ethernet Compatibility Alliance

WEP Wired Equivalency Privacy

WiFi Wireless Fidelity

WINS Windows Internal Naming Service

WLAN Wireless Local Area Network

X.509 Authentication Framework Implementation – Digital Certificate

G-2 Glossary

October/2005

Loading...

Loading...