Maintenance and Service Guide

HP Engage One Retail System, Model 141

HP Engage One Retail System, Model 143

HP Engage One Retail System, Model 145

© Copyright 2017, 2018 HP Development

Company, L.P.

ENERGY STAR® is a registered mark owned by

the U.S. government. Intel, Celeron, and Core

are trademarks of Intel Corporation in the

United States and/or other countries. Windows

is either a registered trademark or trademark

of Microsoft Corporation in the United States

and/or other countries.

The information contained herein is subject to

change without notice. The only warranties for

HP products and services are set forth in the

express warranty statements accompanying

such products and services. Nothing herein

should be construed as constituting an

additional warranty. HP shall not be liable for

technical or editorial errors or omissions

contained herein.

Second Edition: August 2018

First Edition: August 2017

Document Part Number: 925670-002

Product notice

This guide describes features that are common

to most models. Some features may not be

available on your computer.

Software terms

By installing, copying, downloading, or

otherwise using any software product

preinstalled on this computer, you agree to be

bound by the terms of the HP End User License

Agreement (EULA). If you do not accept these

license terms, your sole remedy is to return the

entire unused product (hardware and software)

within 14 days for a full refund subject to the

refund policy of your seller.

For any further information or to request a full

refund of the price of the computer, please

contact your seller.

Safety warning notice

WARNING! To reduce the possibility of heat-related injuries or of overheating the device, do not place

the device directly on your lap or obstruct the device air vents. Use the device only on a hard, at surface. Do

not allow another hard surface, such as an adjoining optional printer, or a soft surface, such as pillows or rugs

or clothing, to block airow. Also, do not allow the AC adapter to contact the skin or a soft surface, such as

pillows or rugs or clothing, during operation. The device and the AC adapter comply with the user-accessible

surface temperature limits dened by the International Standard for Safety of Information Technology

Equipment (IEC 60950-1).

iii

iv Safety warning notice

Table of contents

1 Product overview .......................................................................................................................................... 1

Standard features .................................................................................................................................................. 1

Integrated features ................................................................................................................................................ 3

Stand options ......................................................................................................................................................... 4

HP Engage One Basic I/O Connectivity Base components .................................................................................... 4

HP Engage One Advanced I/O Connectivity Base components ............................................................................. 5

Connecting an AC adapter to power ...................................................................................................................... 6

Locating the Engage One power button ................................................................................................................ 7

Locating the I/O connectivity base power button ................................................................................................. 7

Adjusting the Engage One head unit ..................................................................................................................... 8

Engage One serial number location ...................................................................................................................... 9

I/O connectivity base serial number location ........................................................................................................ 9

2 Illustrated parts catalog .............................................................................................................................. 10

Computer major components .............................................................................................................................. 10

Peripherals ........................................................................................................................................................... 12

Cables and adapters ............................................................................................................................................ 13

3 Routine care, SATA drive guidelines, and disassembly preparation .................................................................. 14

Computer operating guidelines and routine care ............................................................................................... 14

Touch screen maintenance .................................................................................................................................. 14

MSR maintenance ................................................................................................................................................ 15

Service considerations ......................................................................................................................................... 15

Tools and software requirements ..................................................................................................... 15

Screws ............................................................................................................................................... 15

Cables and connectors ...................................................................................................................... 15

Lithium coin cell battery .................................................................................................................... 15

Electrostatic discharge information .................................................................................................................... 16

Generating static ............................................................................................................................... 16

Preventing electrostatic damage to equipment ............................................................................... 16

Personal grounding methods and equipment .................................................................................. 17

Grounding the work area ................................................................................................................... 17

Recommended materials and equipment ........................................................................................ 18

4 Removal and replacement procedures ........................................................................................................... 19

Preparation for disassembly ............................................................................................................................... 19

v

Attaching an I/O connectivity base to the Engage One ....................................................................................... 20

Connecting a standalone I/O connectivity base to the Engage One ................................................................... 22

Conguring the I/O connectivity base’s powered serial ports ............................................................................ 22

Connecting a standalone optional ngerprint reader to the I/O connectivity base ........................................... 24

Attaching an optional ngerprint reader to the I/O connectivity base ............................................................... 25

Removing and attaching the Engage One head unit to the stand ...................................................................... 27

Mounting the Engage One head unit to a wall .................................................................................................... 28

Mounting the Engage One to a counter top ........................................................................................................ 30

Installing a security cable on the I/O connectivity base ..................................................................................... 32

Installing a security cable on the Engage One column ....................................................................................... 33

Installing a security screw on the Engage One head unit and stand .................................................................. 34

Installing a security screw on the Engage One head unit and VESA mount ....................................................... 35

Removing and replacing the column printer ....................................................................................................... 35

Removing the display panel ................................................................................................................................ 41

System board components .................................................................................................................................. 42

Installing a 2 x 20 customer-facing display (CFD) ............................................................................................... 43

Memory modules ................................................................................................................................................. 45

DDR4-SDRAM SODIMMs .................................................................................................................... 45

Removing a SODIMM ......................................................................................................................... 45

Removing and installing an M.2 solid-state drive (SSD) ..................................................................................... 48

Removing the WLAN module ............................................................................................................................... 49

Removing the heat sink ....................................................................................................................................... 51

Removing the fan assembly ................................................................................................................................ 52

Removing the speakers ....................................................................................................................................... 53

Removing the power button board ..................................................................................................................... 54

Removing the MSR (Magnetic Stripe Reader) ...................................................................................................... 55

MSR conguration ............................................................................................................................. 56

Removing the MSR LED board ............................................................................................................................. 58

Removing the system board ................................................................................................................................ 59

System board callouts ....................................................................................................................... 61

Removing the antennas ....................................................................................................................................... 62

5 Using the column printer .............................................................................................................................. 63

Standard features ................................................................................................................................................ 63

Printing features .................................................................................................................................................. 63

When to change the receipt paper ...................................................................................................................... 64

Loading the printer receipt paper ........................................................................................................................ 64

Thermal paper specications .............................................................................................................................. 65

Qualied paper grades ........................................................................................................................................ 65

Troubleshooting the printer ................................................................................................................................ 66

Printer tone and green LED ............................................................................................................... 67

vi

Printing issues ................................................................................................................................... 67

Printer does not function .................................................................................................................. 68

Latch failsafe ..................................................................................................................................... 69

Cleaning the printer ............................................................................................................................................. 69

6 Cable routing congurations ........................................................................................................................ 70

Cable matrix for Engage One with integrated column printer and basic I/O connectivity base ......................... 70

Cable matrix for Engage One with integrated column printer and advanced I/O connectivity base ................. 71

Cable matrix for Engage One without I/O connectivity base .............................................................................. 72

Cable matrix for Engage One with I/O connectivity base .................................................................................... 73

Cable matrix for Engage One with basic I/O connectivity base and standalone printer .................................... 74

Cable matrix for Engage One with advanced I/O connectivity base and standalone printer ............................. 75

7 Conguring the software .............................................................................................................................. 76

Touch screen calibration for Windows 10 Professional and Windows 10 IoT Enterprise for Retail .................. 76

Conguring optional HP integrated peripheral modules .................................................................................... 76

8 Computer Setup (F10) Utility ........................................................................................................................ 77

Computer Setup (F10) Utilities ............................................................................................................................ 77

Using Computer Setup (F10) Utilities ................................................................................................ 77

Computer Setup–Main ....................................................................................................................... 79

Computer Setup—Security ............................................................................................................... 81

Computer Setup—Advanced ............................................................................................................. 83

Recovering the Conguration Settings ............................................................................................................... 87

9 POST error messages and diagnostic front panel LEDs and audible codes ......................................................... 88

POST numeric codes and text messages ............................................................................................................. 88

Interpreting system validation diagnostic front panel LEDs and audible codes ................................................ 93

10 Password security and resetting CMOS ........................................................................................................ 95

Resetting the password jumper .......................................................................................................................... 95

Changing a Setup or Power-On password ........................................................................................................... 96

Deleting a Setup or Power-On password ............................................................................................................ 97

Clearing and resetting the CMOS ......................................................................................................................... 97

11 Using HP PC Hardware Diagnostics (UEFI) ..................................................................................................... 99

Downloading HP PC Hardware Diagnostics (UEFI) to a USB device .................................................................... 99

Using Remote HP PC Hardware Diagnostics (UEFI) settings (select products only) ........................................ 100

Customizing Remote HP PC Hardware Diagnostics (UEFI) settings ............................................... 100

vii

12 Troubleshooting without diagnostics ........................................................................................................ 101

Safety and comfort ............................................................................................................................................ 101

Before you call for technical support ................................................................................................................ 101

Helpful hints ...................................................................................................................................................... 102

Solving retail system-specic problems ........................................................................................................... 103

Solving general problems .................................................................................................................................. 104

Solving printer problems ................................................................................................................................... 108

Solving hardware installation problems ........................................................................................................... 109

Solving network problems ................................................................................................................................ 110

Solving memory problems ................................................................................................................................ 112

Solving USB ash drive problems ..................................................................................................................... 114

Solving Internet access problems ..................................................................................................................... 114

Solving software problems ............................................................................................................................... 116

13 System backup and recovery ..................................................................................................................... 117

Backing up, restoring, and recovering in Windows 10 ...................................................................................... 117

Creating recovery media and backups ............................................................................................ 117

Creating HP Recovery media (select products only) .................................................... 117

Using Windows tools ....................................................................................................................... 119

Restore and recovery ...................................................................................................................... 119

Recovering using HP Recovery Manager ...................................................................... 119

What you need to know before you get started ........................................ 119

Using the HP Recovery partition (select products only) ............................ 120

Using HP Recovery media to recover ......................................................... 120

Changing the computer boot order ............................................................ 121

Removing the HP Recovery partition (select products only) ..................... 121

Appendix A Power cord set requirements ....................................................................................................... 122

General requirements ........................................................................................................................................ 122

Japanese power cord requirements .................................................................................................................. 122

Country-specic requirements .......................................................................................................................... 123

Appendix B Statement of memory volatility ................................................................................................... 124

Nonvolatile memory usage ............................................................................................................................... 126

Questions and answers ..................................................................................................................................... 128

Using HP Sure Start (select models only) .......................................................................................................... 129

Appendix C Specications ............................................................................................................................. 130

Index ........................................................................................................................................................... 132

viii

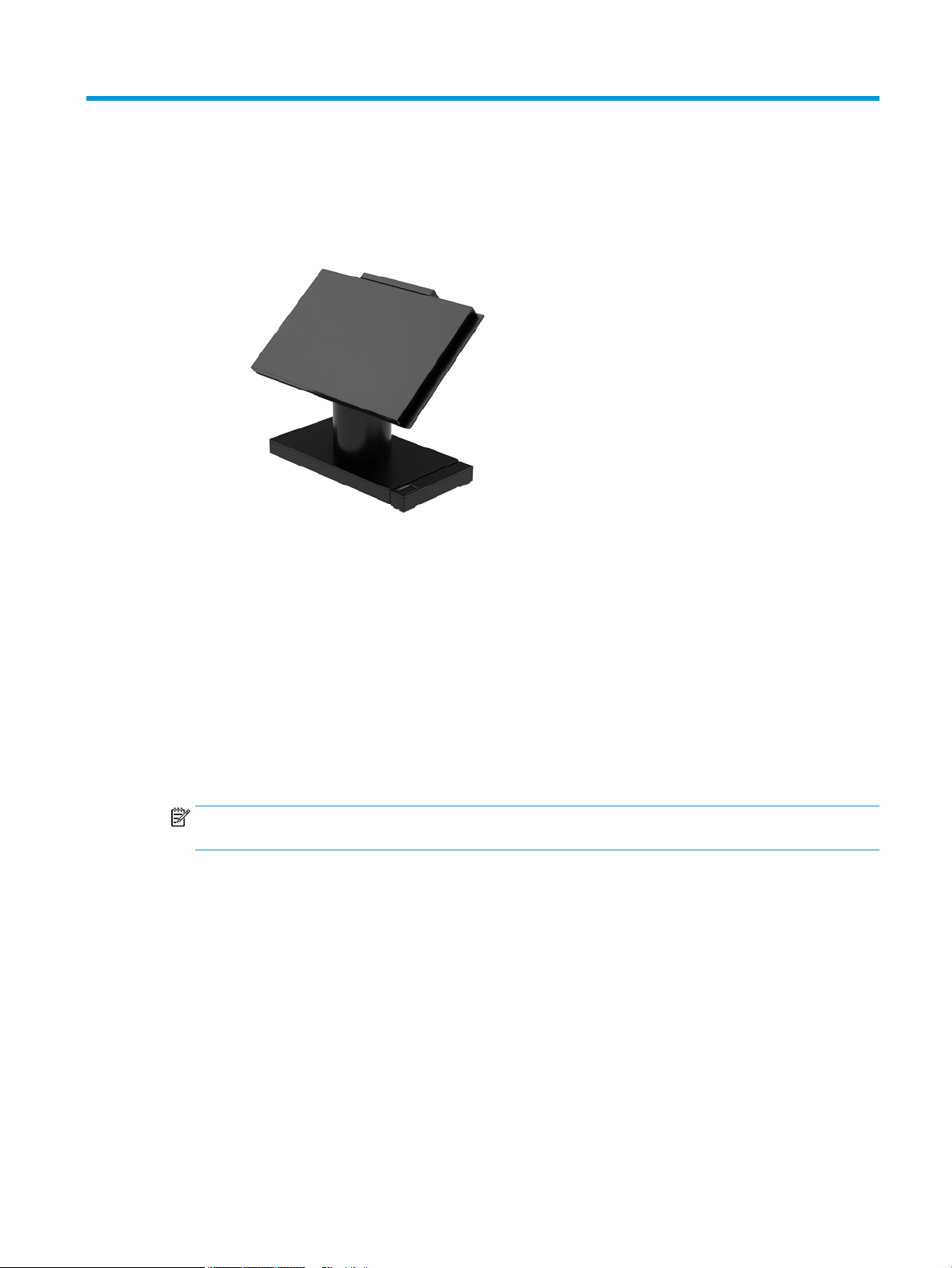

1 Product overview

Standard features

The HP Engage One Retail System is designed for long-term deployment within general retail, hospitality, and

other markets. It includes the following features:

●

Integrated All-in-One (AiO) form factor

●

14-inch diagonal display panel (wide-aspect ratio); FHD 1920 x 1080 resolution, sealed and chemically

hardened, anti-glare; anti-smudge

●

Model 141: anti-glare WLED SVA 300-nit panel with FHD 1920 x 1080 resolution and an Intel® Celeron®

3965U 2.2 GHz 2M 2133 2C6 processor

●

Model 143: anti-glare WLED UWVA 500-nit panel with FHD 1920 x 1080 resolution and an Intel® Core™

i3 - 7100U 2.40 GHz 3M 2133 2C6 processor

●

Model 145: anti-glare WLED UWVA 500-nit panel with FHD 1920 x 1080 resolution and an Intel® i5 7300U 2.60 GHZ 3MB 2133 2C6 processor

NOTE: Nits is the measure of the typical brightness of the panel as specied, prior to anti-glare

coating.

●

Optional 100 mm x 100 mm VESA mounting bracket

●

Optional counter top mounting bracket

●

Choice of a rotate/tilt stand with a 10° tilt range and 180° swivel capability, or a xed position stand

●

Optional HP peripherals:

–

HP Engage One integrated magnetic strip reader (MSR) (integrated into the head unit as congure

to order)

–

HP Engage One integrated 2 x 20 LCD customer-facing display (CFD), top mount

–

HP Engage One integrated column printer or standalone printer

–

HP Engage One 2D barcode scanner

–

HP Engage One biometric ngerprint reader

Standard features 1

●

DDR4 2400 MHz memory with up to 32 GB RAM

●

Operating system choices:

–

Windows® 10 IoT Enterprise 2016 LTSB 64-bit

–

Windows 10 Professional 64-bit

–

FreeDOS 2.0

●

HP Engage One Advanced I/O Connectivity Base (optional)

–

2 powered serial ports (0 V, 5 V, 12 V)

–

(2) 12 V powered USB ports

–

(1) 24 V powered USB port

–

4 USB 3.0 ports

–

1 cash drawer jack

–

1 RJ-45 network jack

–

1 video-out USB Type-C port

●

HP Engage One Basic I/O Connectivity Base (optional)

–

3 powered serial ports (0 V, 5 V, 12 V)

–

4 USB 2.0 ports

–

2 USB 3.0 ports

–

1 cash drawer jack

–

1 RJ-45 network jack

–

1 video out USB Type-C port

●

One internal SD card reader on the computer head unit and one external microSD card reader on the I/O

connectivity base

●

Universal audio jack with CTIA headset support on the I/O connectivity base

●

One M.2 SSD internal drive on the computer head unit

●

ENERGY STAR® compliant

2 Chapter 1 Product overview

Integrated features

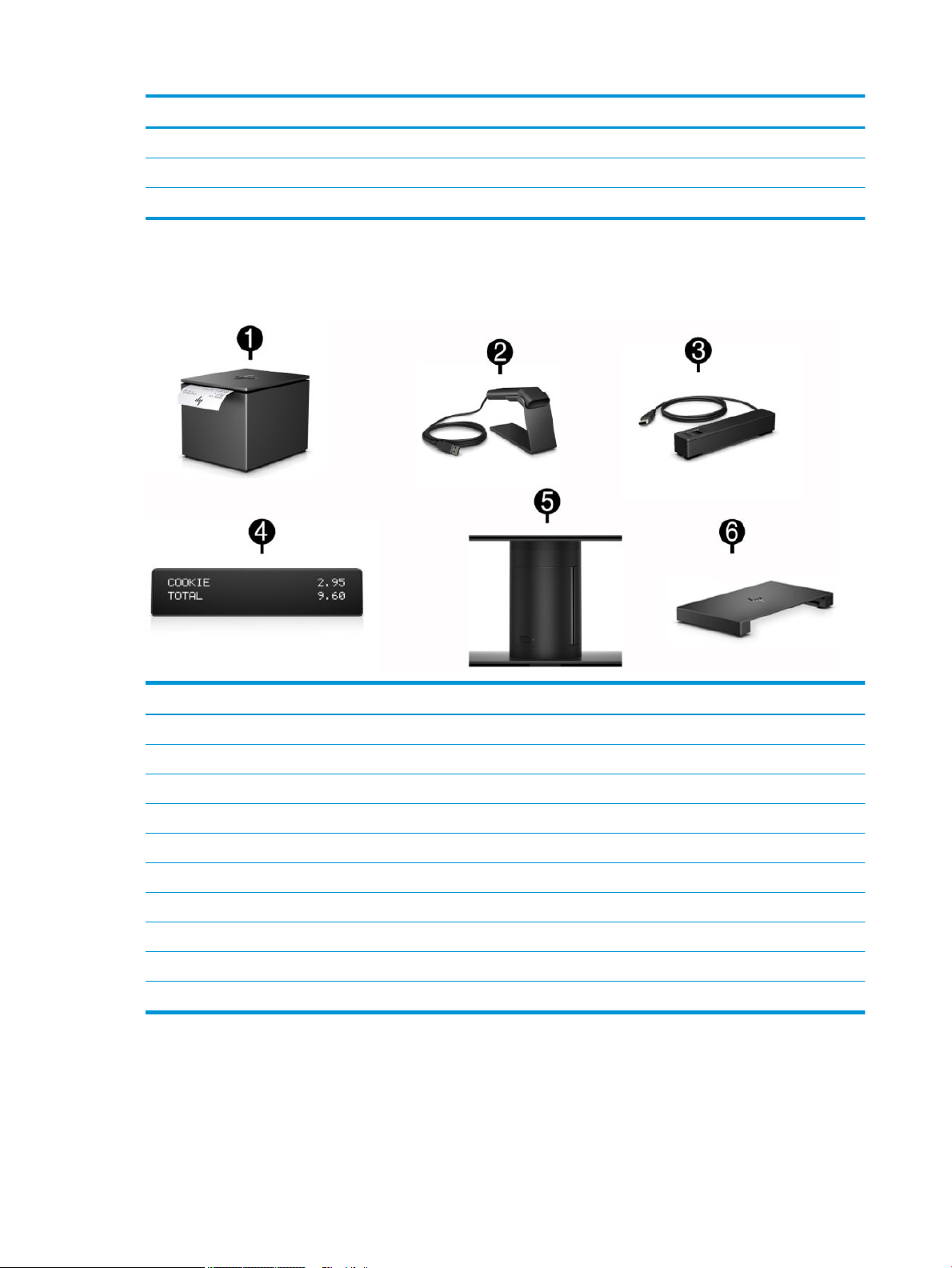

The integrated devices shown below are optional.

Features

(1) 14-inch diagonal display panel (wide-aspect ratio); FHD

1920 x 1080 resolution, sealed and chemically hardened,

anti-glare; anti-smudge

(2) HP Engage One Integrated Column Printer (5) HP Engage One Integrated MSR

(3) Choice of 2 Engage One I/O Connectivity Bases (6) HP Engage One Biometric Fingerprint Reader

Display panel options:

●

Anti-glare WLED SVA 300 nits panel

●

Anti-glare WLED UWVA 500 nits panel

NOTE: Nits is the measure of the typical brightness of the panel as specied, prior to anti-glare coating.

(4) HP Engage One 2 x 20 Customer-facing Display (CFD)

Integrated features 3

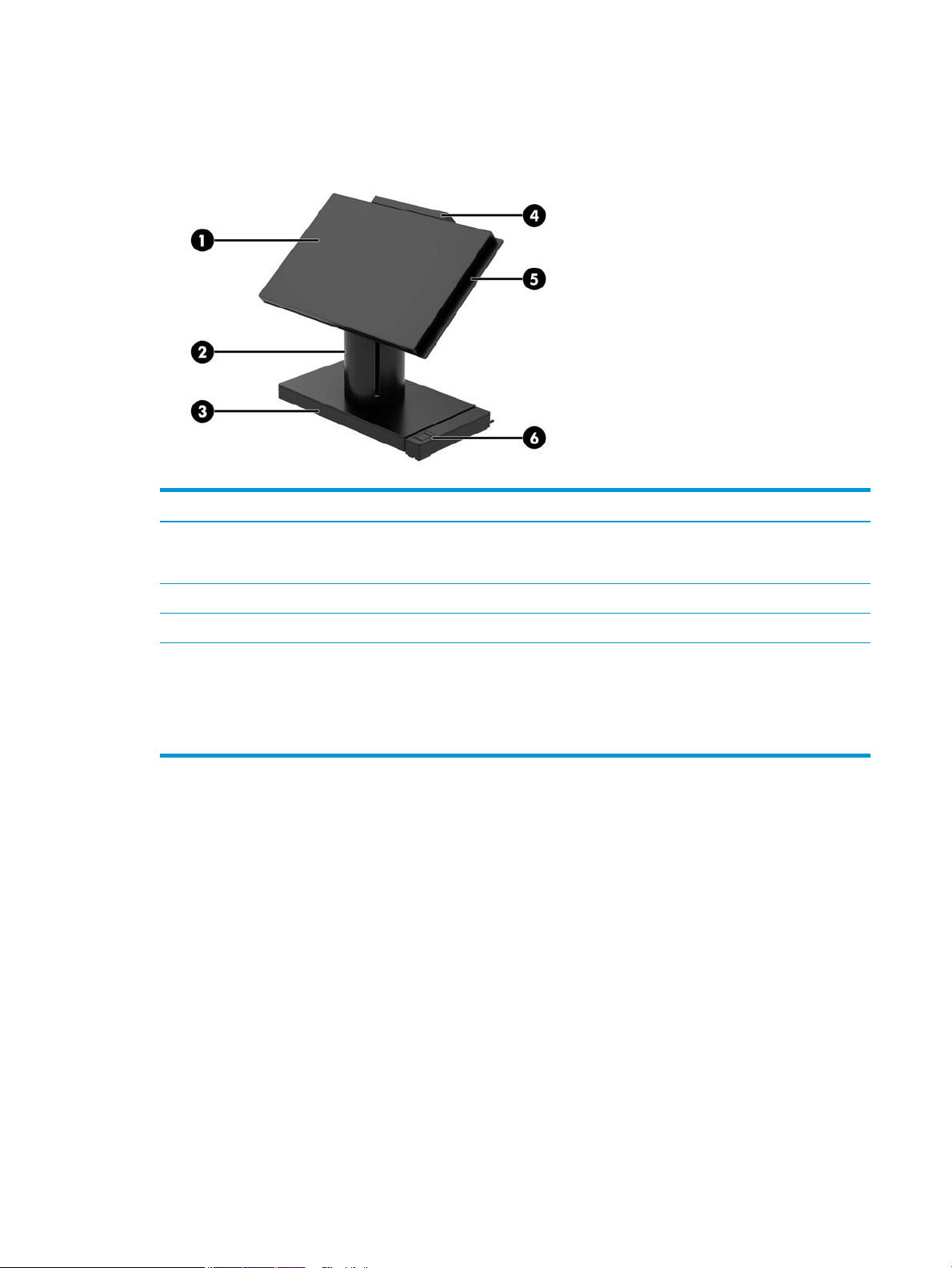

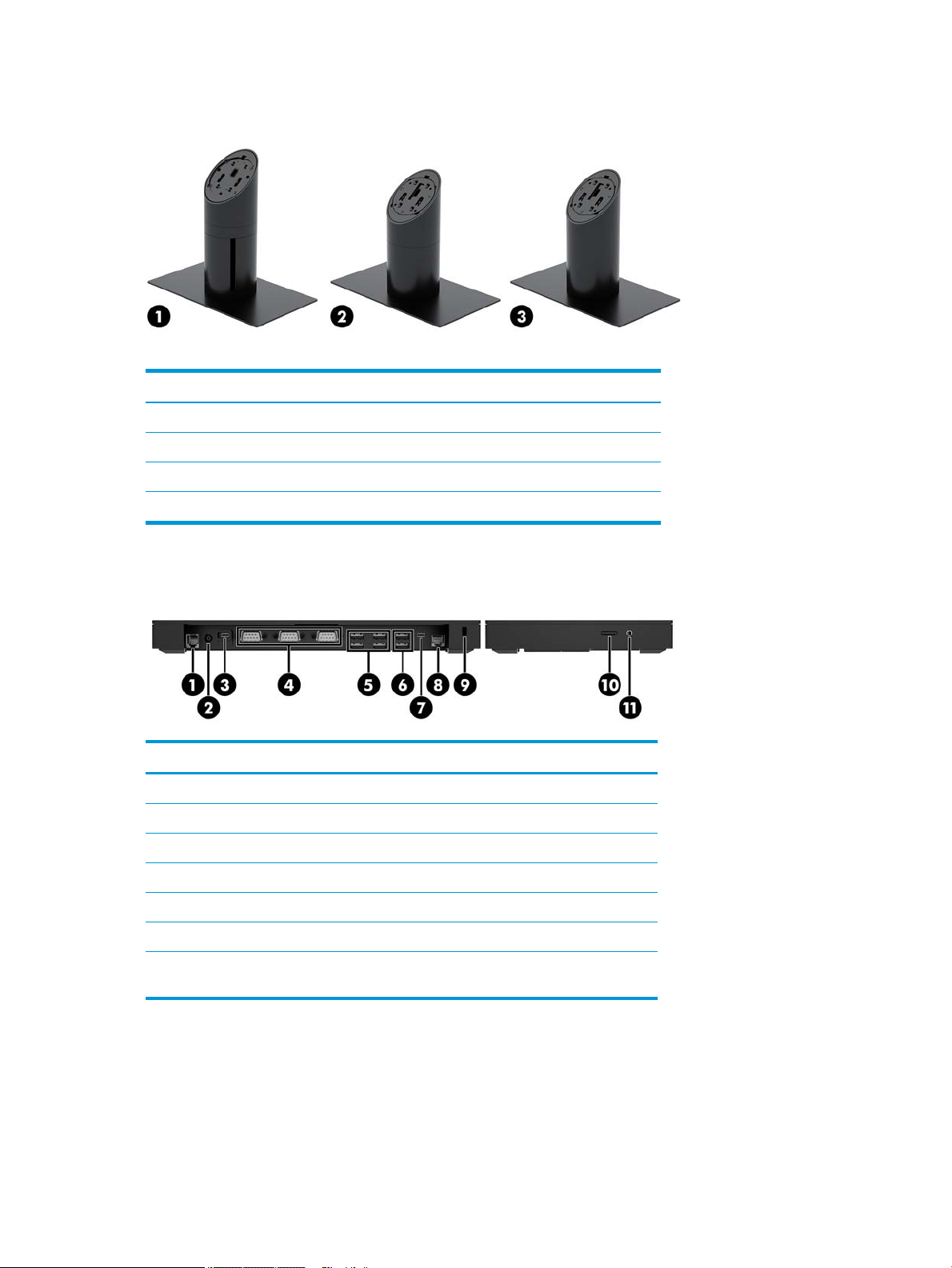

Stand options

Options

(1) HP Engage One Rotate/Tilt Stand with Integrated Column Printer

(2) HP Engage One Rotate/Tilt Stand

(3) HP Engage One Fixed Position Stand

NOTE: The stands are shown on a stability base.

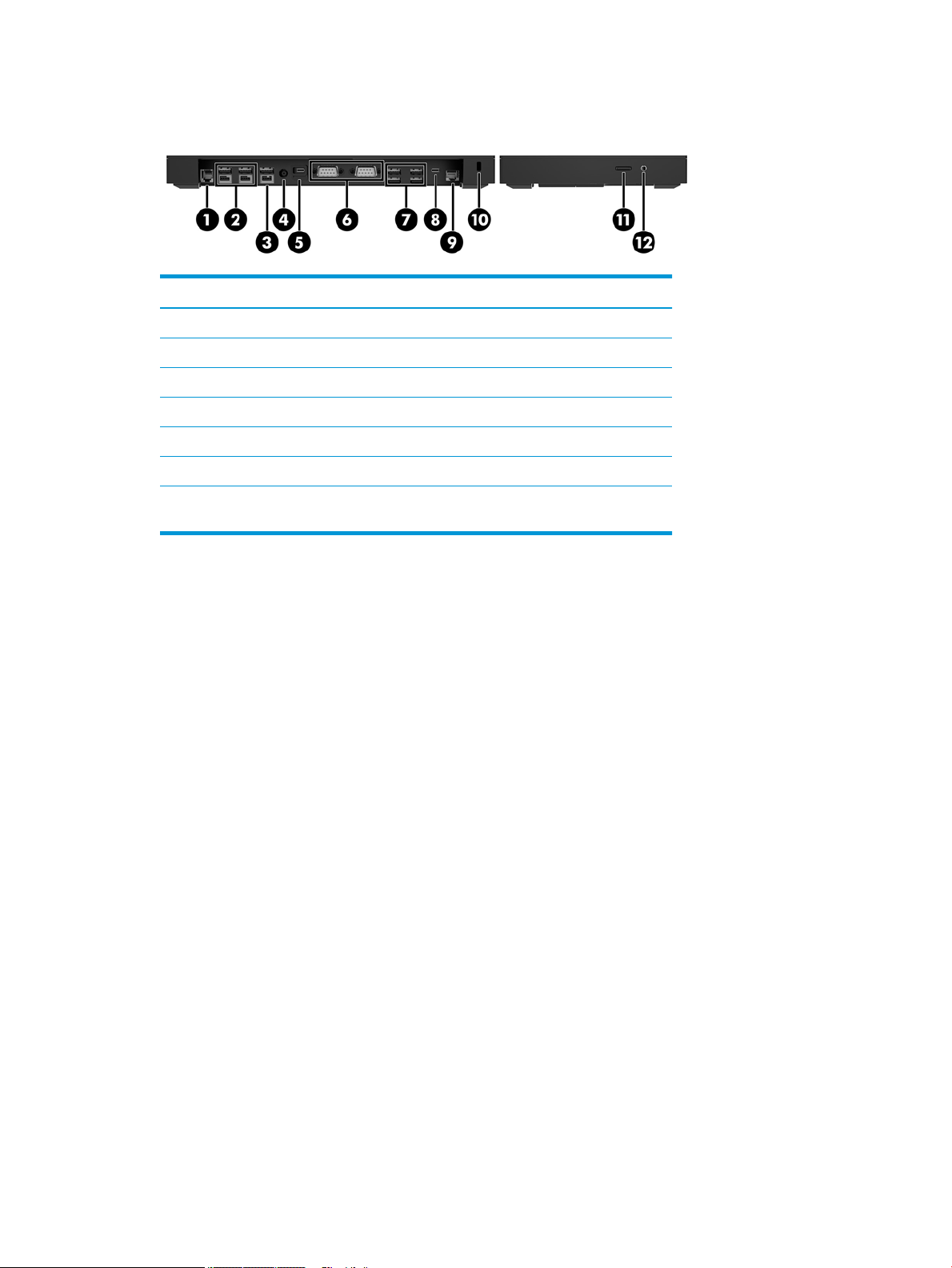

HP Engage One Basic I/O Connectivity Base components

Basic components

(1) Cash drawer jack (7) USB Type-C port

(2) Power connector (8) RJ-45 network jack

(3) USB Type-C power port (9) Security cable slot

(4) Powered serial ports (3) (10) MicroSD card reader

(5) USB 2.0 ports (4) (11) Headset jack

(6) USB 3.0 ports (2)

IMPORTANT: To avoid damage to the computer, DO NOT plug a telephone cable into the cash

drawer jack.

4 Chapter 1 Product overview

HP Engage One Advanced I/O Connectivity Base components

Advanced components

(1) Cash drawer jack (7) USB 3.0 ports (4)

(2) Powered USB 12 V ports (2) (8) USB Type-C port

(3) Powered USB 24 V port (9) RJ-45 network jack

(4) Power connector (10) Security cable slot

(5) USB Type-C power port (11) MicroSD card reader

(6) Powered serial ports (2) (12) Headset jack

IMPORTANT: To avoid damage to the computer, DO NOT plug a telephone cable into the cash

drawer jack.

HP Engage One Advanced I/O Connectivity Base components 5

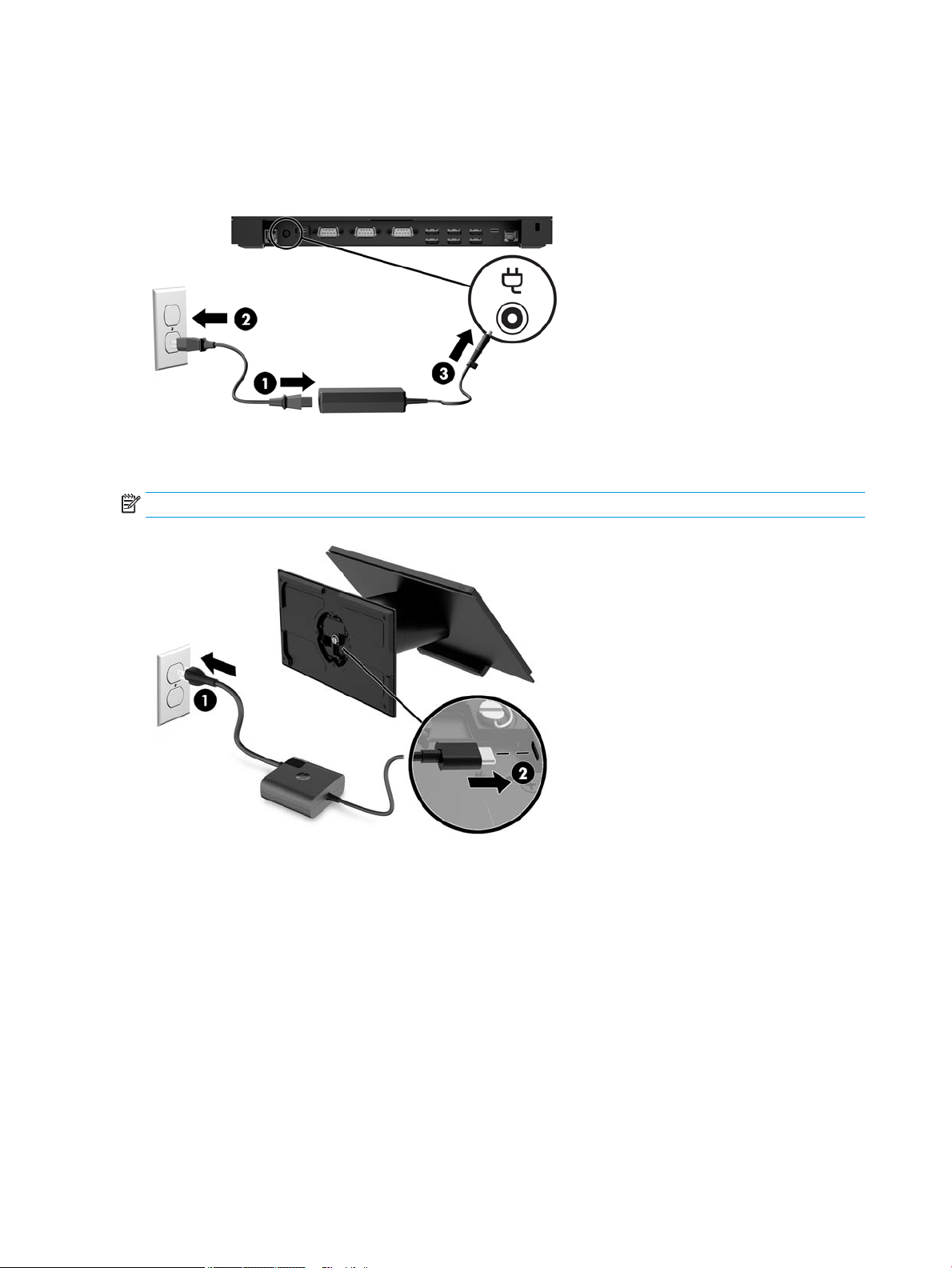

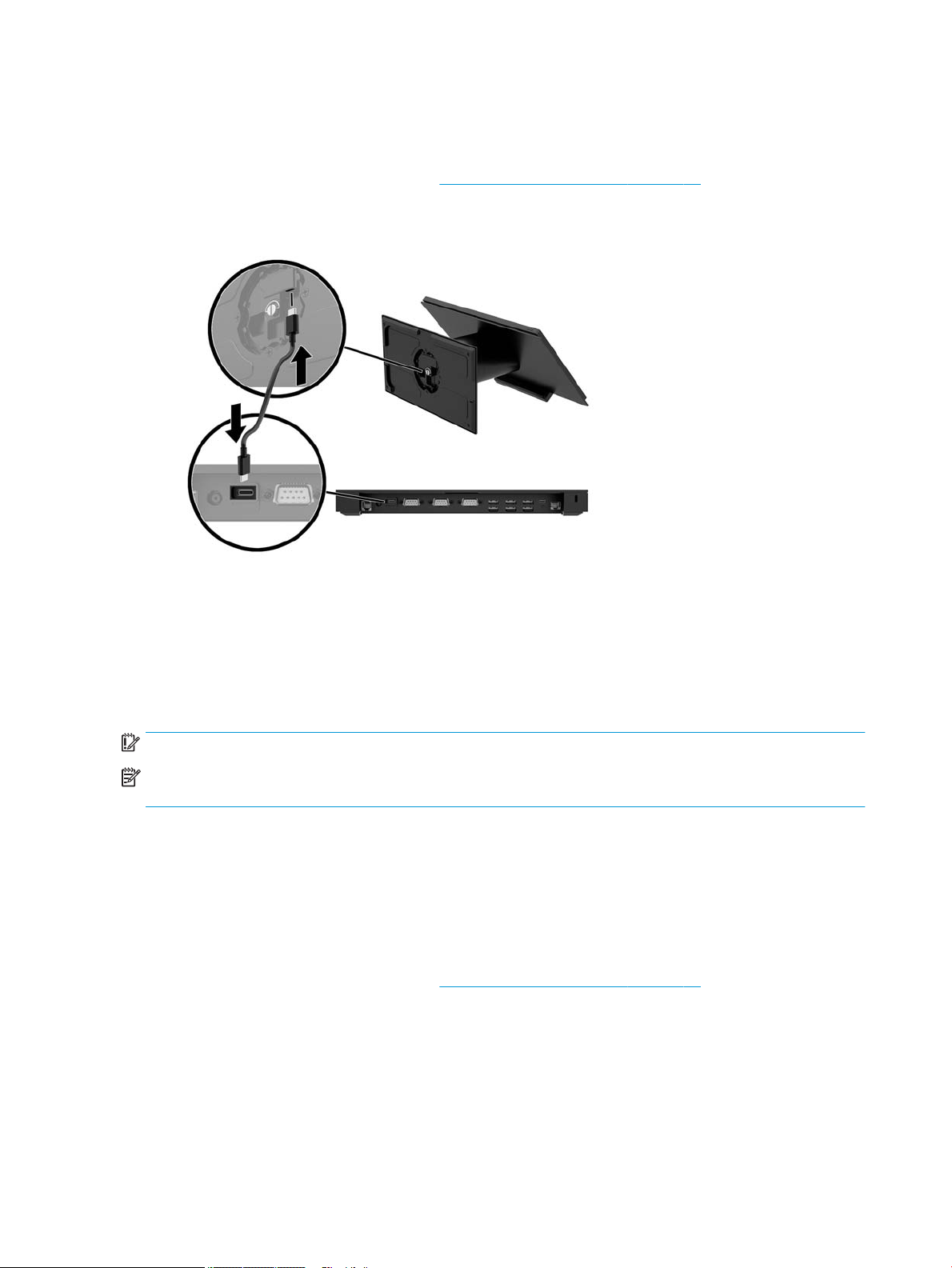

Connecting an AC adapter to power

To connect an AC adapter to the I/O connectivity base, connect one end of the power cord to the AC adapter (1)

and the other end to a grounded AC outlet (2), and then connect the AC adapter to the power connector on the

I/O connectivity base (3).

To connect an AC adapter to the computer when it is not connected to an I/O connectivity base, connect the AC

adapter to a grounded AC outlet (1), and then the connect the power adapter’s USB Type-C connector to the

USB Type-C power port on the underside of the stand or stability base (2).

NOTE: The image below is shown with a stability base.

6 Chapter 1 Product overview

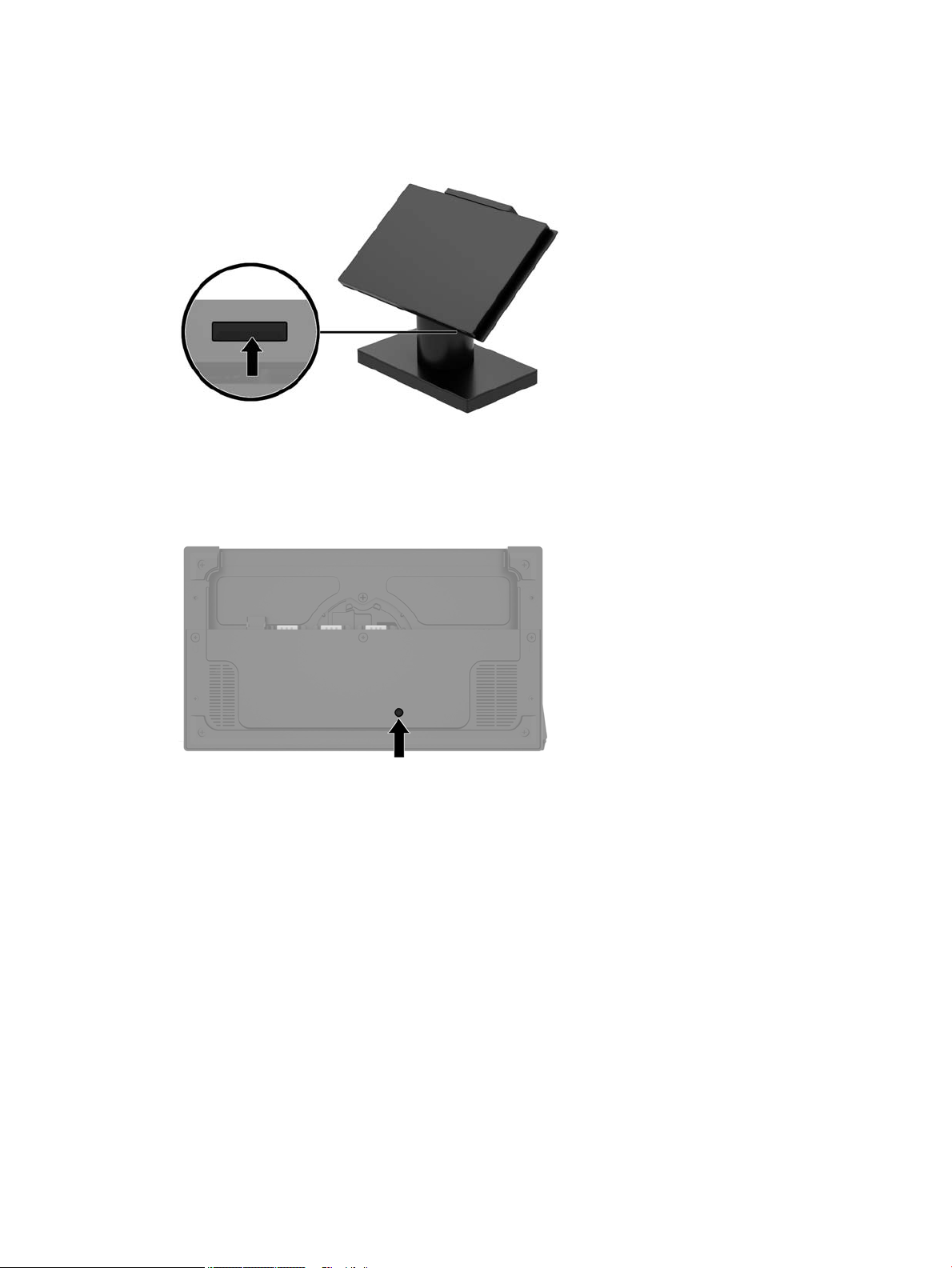

Locating the Engage One power button

The computer power button is located on the bottom right edge of the bezel.

Locating the I/O connectivity base power button

The I/O connectivity base power button is located on the underside of the I/O connectivity base.

The head unit controls the I/O connectivity base. When the head unit is turned o, the I/O connectivity base is

turned o and power is not available from the I/O connectivity base ports. The exception is the I/O

connectivity base’s USB Type-C port that connects to the head unit. That port will remain powered so that it

can continue to communicate with the head unit and allow the I/O connectivity base to turn back on when the

head unit is turned on.

After the system has been turned o, you can press the power button on the underside of the I/O connectivity

base to allow power to be available on the I/O connectivity base ports while the head unit remains turned o.

Locating the Engage One power button 7

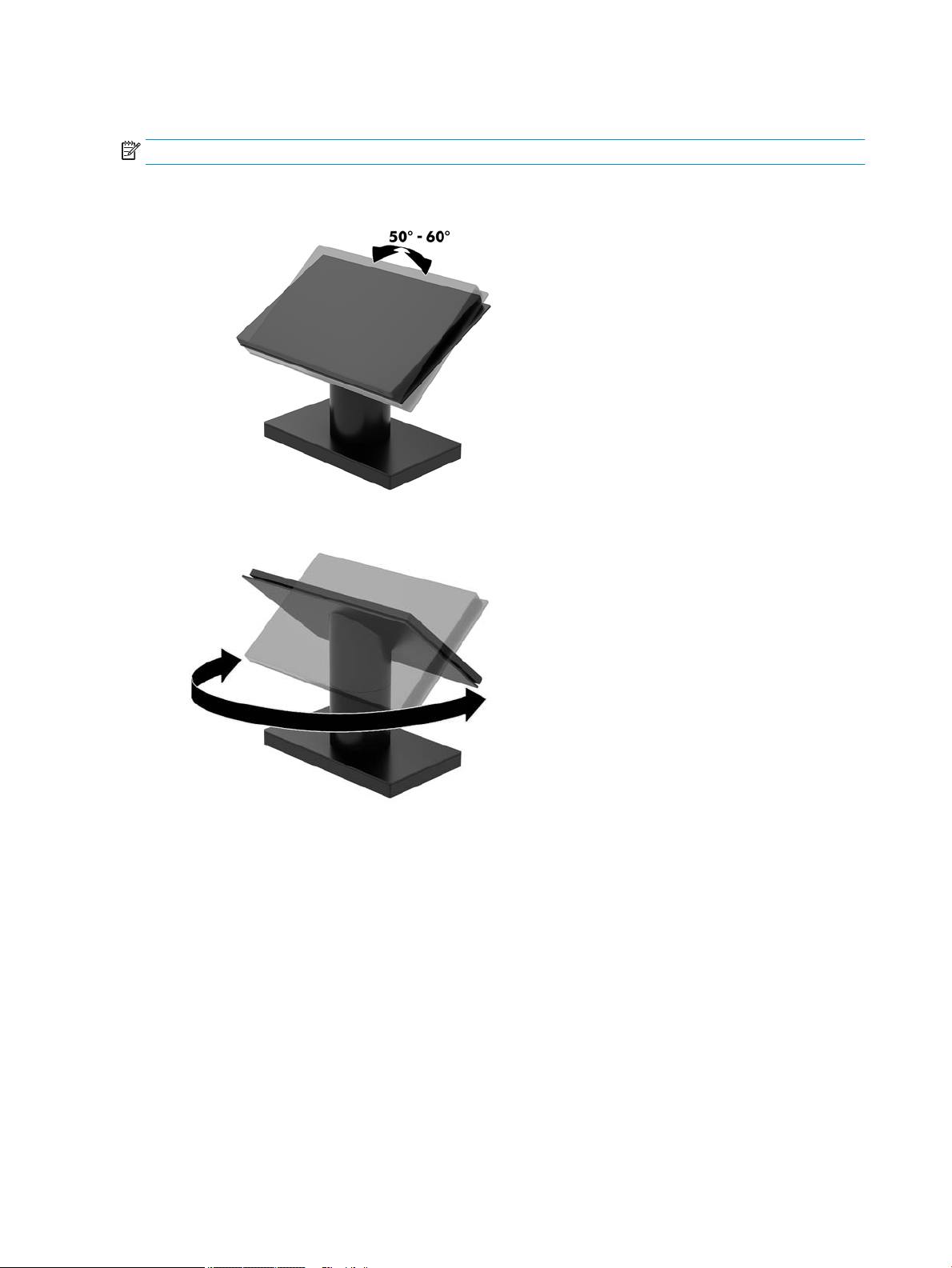

Adjusting the Engage One head unit

NOTE: The tilt and swivel features are only available on performance stands.

You can tilt and swivel the computer head to set it to a comfortable viewing angle. There is a 10° tilt range

that can be set between 50° and 60°.

The computer head unit can be swiveled 180° in either direction.

8 Chapter 1 Product overview

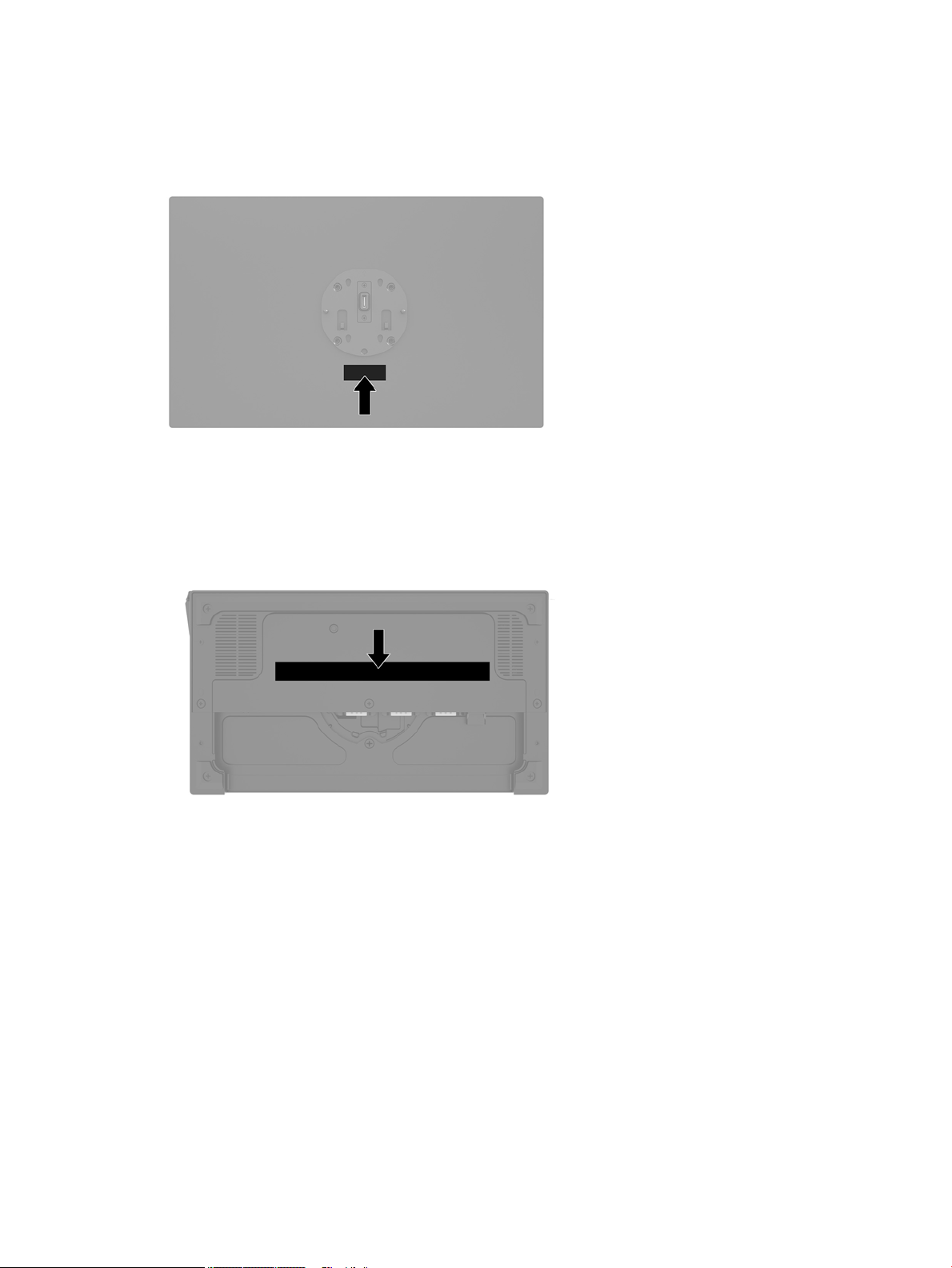

Engage One serial number location

Each computer has a unique serial number and a product ID number that are located on the exterior of the

computer. Keep these numbers available for use when contacting customer service for assistance.

I/O connectivity base serial number location

Each I/O connectivity base has a unique serial number and a product ID number that are located on the

exterior of the I/O connectivity base. Keep these numbers available for use when contacting customer service

for assistance.

Regulatory information is located in the base plate or wall mount. Install the base plate or wall mount back

after disassembly.

Engage One serial number location 9

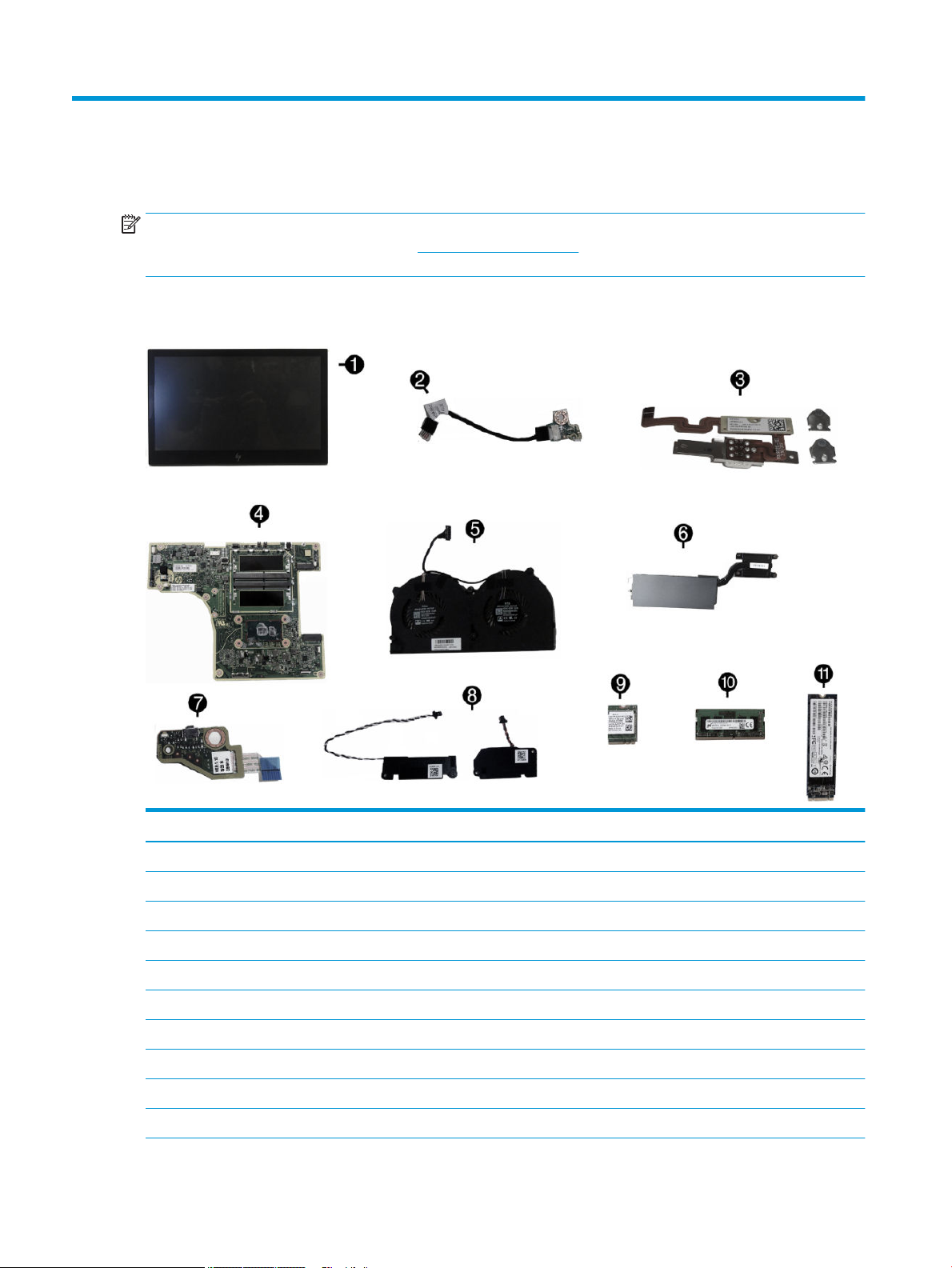

2 Illustrated parts catalog

NOTE: HP continually improves and changes product parts. For complete and current information on

supported parts for your computer, go to http://partsurfer.hp.com, select your country or region, and then

follow the on-screen instructions.

Computer major components

Item Description

(*) Whole unit (not illustrated)

(1) Display panel

Touch, 500 nits

Touch, 300 nits

(2) MSR LED board and cable

(3) MSR board and cable

(4) System board (includes replacement thermal material)

Includes embedded Intel Core i5-7300U processor

Includes embedded Intel Core i3-7100U processor

Includes embedded Intel Celeron 3965U processor

10 Chapter 2 Illustrated parts catalog

Item Description

(5) Fan assembly

(6) Heat sink

For use in models with 500 nit displays

For use in models with 300 nit displays

(7) Power button board

(8) Speakers, left and right

(9) WLAN module

Intel Dual Band Wireless-AC 8265 (vPro)

Intel Dual Band Wireless-AC 8265 (non-vPro)

Realtek RTL8723BE-VB 802.11 bgn 1x1 Wi-Fi + BT4.0 Combo Adapter

(10) Memory modules (SODIMM, DDR4-2400)

16 GB

8 GB

4 GB

(11) Solid state drives (NVMe)

1 TB, TLC

512 GB, PCIe

512 GB, TLC, PCIe

512 GB, value, PCIe

512 GB, SATA-3, TLC

256 GB, TLC, PCIe

256 GB, value, PCIe

256 GB, SATA-3, TLC

128 GB, PCIe

128 GB, SATA-3, TLC

* Power supply, external

180 W

120 W

65 W, USB Type-C

* Stand, xed position

* Stand, rotate/tilt

* Thumb screw, stand base

* Security locking screw

* Printer external power supply

Computer major components 11

Item Description

* Table Mount Kit

* VESA wall mount

* Backplate guide

*

not illustrated

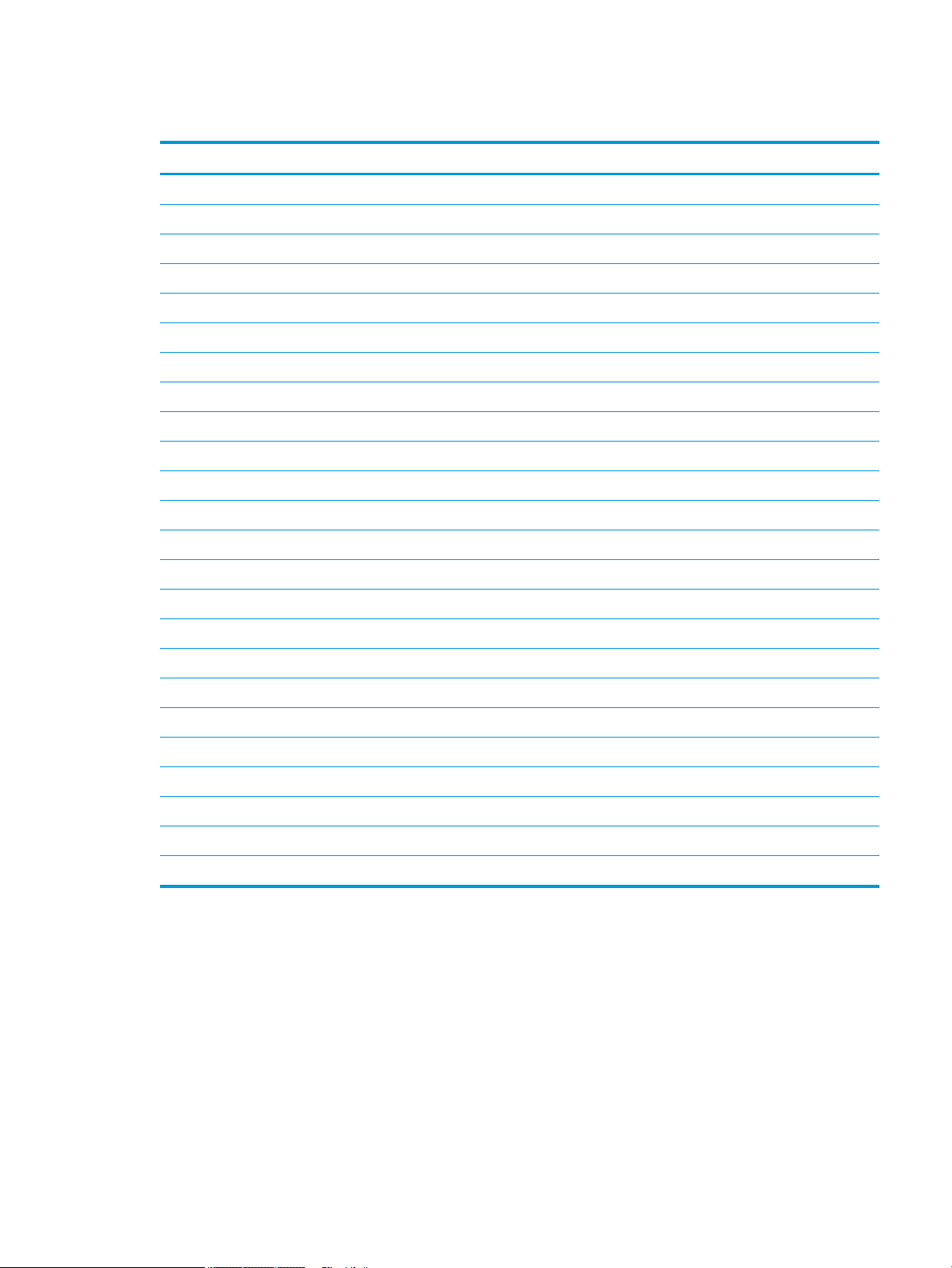

Peripherals

Description

(1) HP Engage One Serial USB Thermal Printer

(2) HP Engage One 2D Barcode Scanner

(3) HP Engage One Fingerprint Reader

(4) HP Engage One Top Mount 2x20 CFD

HP L8010t 10.1" Touch CFD

HP L8010 10.1" Non-Touch CFD

(5) HP Engage One Column Printer, black or white

(6) I/O Connectivity Base

Advanced (includes powered USBs)

Basic (does not include powered USBs)

12 Chapter 2 Illustrated parts catalog

Cables and adapters

Description

Touch cable, 300/500nits

WLAN antenna cables

Printer serial cable

Printer USB cable

Fingerprint reader cable, USB Type-A to micro USB, 0.3 meter

Fingerprint reader cable, USB Type-A to micro USB, 1.8 meter

Column printer cable, 2 meter, 24V powered USB

Column printer cable, 26 cm, 24V powered USB

Column printer cable, 2 meter, USB Type-B to Type-A

Column printer cable, 23 cm, USB Type-B to Type-A

Column printer cable, 50 cm, cash drawer

24V to Y (Hosiden/Type-B), powered USB cable (for use with HP POS Hybrid Printer, MICR with Imaging Module)

24V powered USB cable (power only), Hosiden

USB Type-C cable, coiled

USB Type-C cable, straight

USB Type-C cable, 20V/3A, 0.43 meter

USB Type-C cable, 20V/3A, 1.8 meter

USB Type-C cable, VESA

USB Type-C cable connector restraint kit

Adapters

USB to serial

USB Type-C to VGA

USB Type-C to DisplayPort

USB Type-C to HDMI

Cables and adapters 13

3 Routine care, SATA drive guidelines, and

disassembly preparation

This chapter provides general service information for the computer. Adherence to the procedures and

precautions described in this chapter is essential for proper service.

CAUTION: When the computer is plugged into an AC power source, voltage is always applied to the system

board. You must disconnect the power cord from the power source before opening the computer to prevent

system board or component damage.

Computer operating guidelines and routine care

Follow the guidelines below to properly set up and care for the computer:

●

HP recommends a 17 mm clearance around the vents on the computer head unit and I/O connectivity

base for heat dissipation.

●

Keep the computer away from excessive moisture, direct sunlight, and extremes of heat and cold.

●

Never operate the computer with any access panels removed.

●

Do not stack computers on top of each other or place computers so near each other that they are subject

to each other’s recirculated or preheated air.

●

If the computer is to be operated within a separate enclosure, intake and exhaust ventilation must be

provided on the enclosure, and the same operating guidelines listed above will still apply.

●

Keep liquids away from the computer and I/O connectivity base.

●

Never cover the vents on the computer or I/O connectivity base with any type of material.

●

Install or enable power management functions of the operating system or other software, including

sleep states.

●

Turn o the computer before you do either of the following:

–

Wipe the exterior of the computer with a soft, damp cloth as needed. Using cleaning products may

discolor or damage the nish.

–

Occasionally clean the air vents on all vented sides of the computer. Lint, dust, and other foreign

matter can block the vents and limit the airow.

NOTE: For more information on your retail system care and maintenance, refer to “Retail Point of Sales

Systems - Routine Care and Maintenance” available at http://www.hp.com/support.

Touch screen maintenance

Keep your display and touch sensor clean. The touch sensor requires very little maintenance. HP recommends

that you periodically clean the glass touch sensor surface. Be sure to turn o your display before cleaning.

Typically, an isopropyl alcohol and water solution ratio of 50:50 is the best cleaning agent for your touch

sensor. It is important to avoid using any caustic chemicals on the touch sensor. Do not use any vinegar-based

solutions.

14 Chapter 3 Routine care, SATA drive guidelines, and disassembly preparation

Apply the cleaner with a soft, lint-free cloth. Avoid using gritty cloths. Always dampen the cloth and then

clean the sensor. Be sure to spray the cleaning liquid onto the cloth, not the sensor, so that drips do not seep

inside the display or stain the bezel.

MSR maintenance

To clean the MSR (magnetic strip reader), swipe a standard cleaning card through the MSR a couple of times.

You can order a standard cleaning card online. You can also put a thin oil-free cloth around a credit card.

Service considerations

Listed below are some of the considerations that you should keep in mind during the disassembly and

assembly of the computer.

Tools and software requirements

To service the computer, you need the following:

●

Torx T-15 screwdriver

●

Flat-bladed screwdriver (may sometimes be used in place of the Torx screwdriver)

●

Phillips #2 screwdriver

●

Phillips #1 screwdriver

●

Diagnostics software

●

Tamper-resistant T-10 screwdriver

Screws

The screws used in the computer are not interchangeable. They may have standard or metric threads and may

be of dierent lengths. If an incorrect screw is used during the reassembly process, it can damage the unit. HP

strongly recommends that all screws removed during disassembly be kept with the part that was removed,

then returned to their proper locations.

CAUTION: As each subassembly is removed from the computer, it should be placed away from the work area

to prevent damage.

Cables and connectors

Most cables used throughout the unit are at, exible cables. These cables must be handled with care to

avoid damage. Apply only the tension required to seat or unseat the cables during insertion or removal from

the connector. Handle cables by the connector whenever possible. In all cases, avoid bending or twisting the

cables, and ensure that the cables are routed in such a way that they cannot be caught or snagged by parts

being removed or replaced.

CAUTION: When servicing this computer, ensure that cables are placed in their proper location during the

reassembly process. Improper cable placement can damage the computer.

Lithium coin cell battery

The battery that comes with the computer provides power to the real-time clock and has a minimum lifetime

of about three years.

MSR maintenance 15

See the appropriate removal and replacement chapter for the chassis you are working on in this guide for

instructions on the replacement procedures.

WARNING! This computer contains a lithium battery. There is a risk of re and chemical burn if the battery is

handled improperly. Do not disassemble, crush, puncture, short external contacts, dispose in water or re, or

expose it to temperatures higher than 140ºF (60ºC). Do not attempt to recharge the battery.

NOTE: Batteries, battery packs, and accumulators should not be disposed of together with the general

household waste. In order to forward them to recycling or proper disposal, please use the public collection

system or return them to HP, their authorized partners, or their agents.

Electrostatic discharge information

A sudden discharge of static electricity from your nger or other conductor can destroy static-sensitive

devices or microcircuitry. Often the spark is neither felt nor heard, but damage occurs. An electronic device

exposed to electrostatic discharge (ESD) may not appear to be aected at all and can work perfectly

throughout a normal cycle. The device may function normally for a while, but it has been degraded in the

internal layers, reducing its life expectancy.

Networks built into many integrated circuits provide some protection, but in many cases, the discharge

contains enough power to alter device parameters or melt silicon junctions.

Generating static

The following table shows that:

●

Dierent activities generate dierent amounts of static electricity.

●

Static electricity increases as humidity decreases.

Relative Humidity

Event 55% 40% 10%

Walking across carpet

Walking across vinyl oor

Motions of bench worker

Removing DIPs from plastic tube

Removing DIPs from vinyl tray

Removing DIPs from Styrofoam

Removing bubble pack from PCB

Packing PCBs in foam-lined box

These are then multi-packaged inside plastic tubes, trays, or Styrofoam.

7,500 V

3,000 V

400 V

400 V

2,000 V

3,500 V

7,000 V

5,000 V

15,000 V

5,000 V

800 V

700 V

4,000 V

5,000 V

20,000 V

11,000 V

NOTE: 700 volts can degrade a product.

35,000 V

12,000 V

6,000 V

2,000 V

11,500 V

14,500 V

26,500 V

21,000 V

Preventing electrostatic damage to equipment

Many electronic components are sensitive to ESD. Circuitry design and structure determine the degree of

sensitivity. The following packaging and grounding precautions are necessary to prevent damage to electric

components and accessories.

16 Chapter 3 Routine care, SATA drive guidelines, and disassembly preparation

●

To avoid hand contact, transport products in static-safe containers such as tubes, bags, or boxes.

●

Protect all electrostatic parts and assemblies with conductive or approved containers or packaging.

●

Keep electrostatic sensitive parts in their containers until they arrive at static-free stations.

●

Place items on a grounded surface before removing them from their container.

●

Always be properly grounded when touching a sensitive component or assembly.

●

Avoid contact with pins, leads, or circuitry.

●

Place reusable electrostatic-sensitive parts from assemblies in protective packaging or conductive

foam.

Personal grounding methods and equipment

Use the following equipment to prevent static electricity damage to equipment:

●

Wrist straps are exible straps with a maximum of one-megohm ± 10% resistance in the ground cords.

To provide proper ground, a strap must be worn snug against bare skin. The ground cord must be

connected and t snugly into the banana plug connector on the grounding mat or workstation.

●

Heel straps/Toe straps/Boot straps can be used at standing workstations and are compatible with

most types of shoes or boots. On conductive oors or dissipative oor mats, use them on both feet with

a maximum of one-megohm ± 10% resistance between the operator and ground.

Static Shielding Protection Levels

Method Voltage

Antistatic plastic

Carbon-loaded plastic

Metallized laminate

Grounding the work area

To prevent static damage at the work area, use the following precautions:

●

Cover the work surface with approved static-dissipative material. Provide a wrist strap connected to the

work surface and properly grounded tools and equipment.

●

Use static-dissipative mats, foot straps, or air ionizers to give added protection.

●

Handle electrostatic sensitive components, parts, and assemblies by the case or PCB laminate. Handle

them only at static-free work areas.

●

Turn o power and input signals before inserting and removing connectors or test equipment.

●

Use xtures made of static-safe materials when xtures must directly contact dissipative surfaces.

●

Keep work area free of nonconductive materials such as ordinary plastic assembly aids and Styrofoam.

●

Use eld service tools, such as cutters, screwdrivers, and vacuums, that are conductive.

1,500

7,500

15,000

Electrostatic discharge information 17

Recommended materials and equipment

Materials and equipment that are recommended for use in preventing static electricity include:

●

Antistatic tape

●

Antistatic smocks, aprons, or sleeve protectors

●

Conductive bins and other assembly or soldering aids

●

Conductive foam

●

Conductive tabletop workstations with ground cord of one-megohm +/- 10% resistance

●

Static-dissipative table or oor mats with hard tie to ground

●

Field service kits

●

Static awareness labels

●

Wrist straps and footwear straps providing one-megohm +/- 10% resistance

●

Material handling packages

●

Conductive plastic bags

●

Conductive plastic tubes

●

Conductive tote boxes

●

Opaque shielding bags

●

Transparent metallized shielding bags

●

Transparent shielding tubes

18 Chapter 3 Routine care, SATA drive guidelines, and disassembly preparation

4 Removal and replacement procedures

NOTE: HP continually improves and changes product parts. For complete and current information on

supported parts for your computer, go to http://partsurfer.hp.com, select your country or region, and then

follow the on-screen instructions.

Adherence to the procedures and precautions described in this chapter is essential for proper service. After

completing all necessary removal and replacement procedures, run the Diagnostics utility to verify that all

components operate properly.

NOTE: Not all features listed in this guide are available on all computers.

Preparation for disassembly

See Routine care, SATA drive guidelines, and disassembly preparation on page 14 for initial safety procedures.

1. Remove/disengage any security devices that prohibit opening the computer.

2. Shut down the computer properly through the operating system, then turn o any external devices.

3. Disconnect the power cord from the power outlet.

CAUTION: Regardless of the power-on state, voltage is always present on the system board as long as

the system is plugged into an active AC outlet. You must disconnect the power cord and wait

approximately 30 seconds for the power to drain to avoid damage to the internal components of the

computer.

4. Disconnect all cables from the rear I/O connectors.

CAUTION: The screws used in the computer are of dierent thread sizes and lengths; using the wrong screw

in an application may damage the unit.

NOTE: During disassembly, label each cable as you remove it, noting its position and routing. Keep all

screws with the units removed.

Preparation for disassembly 19

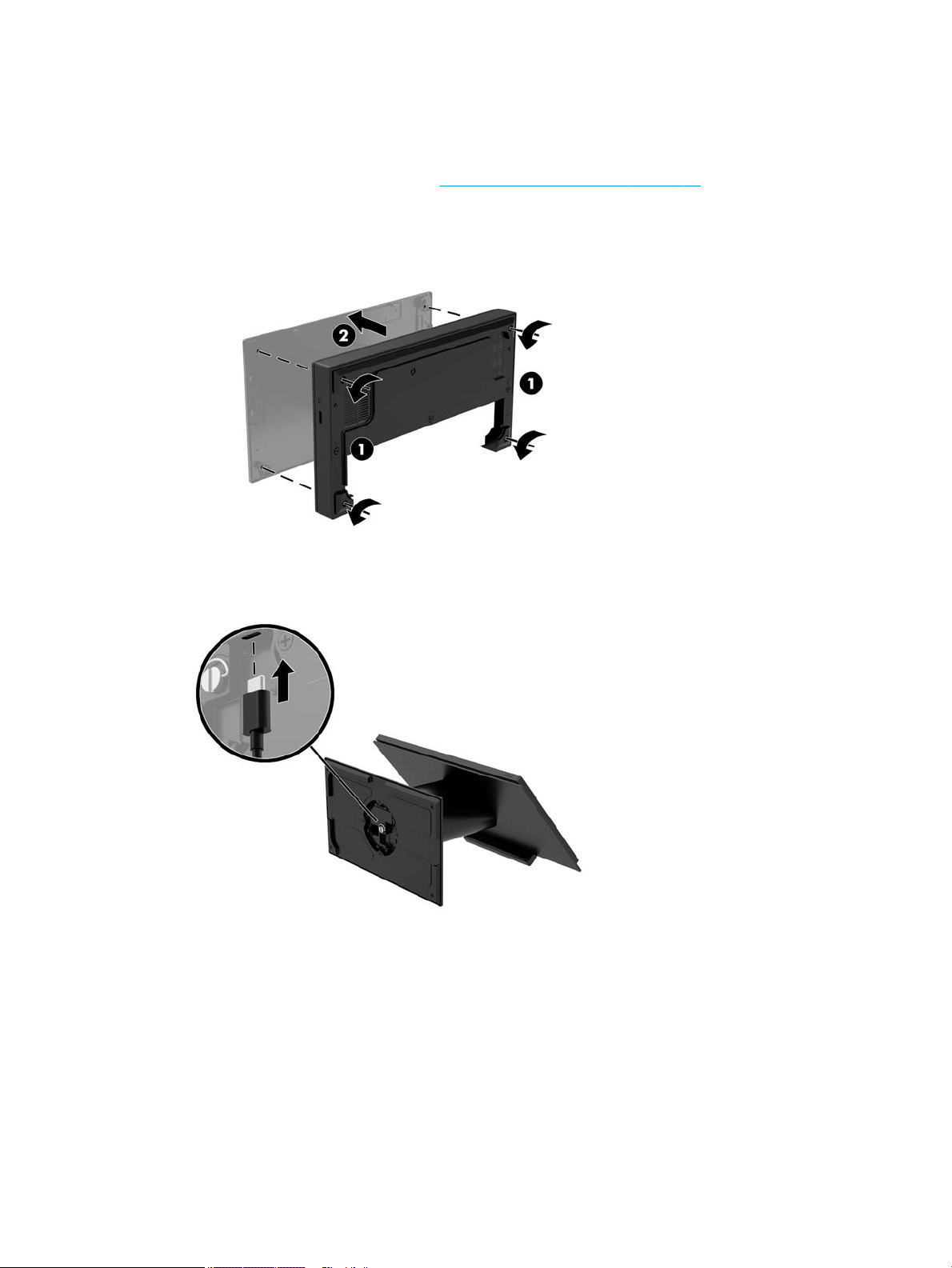

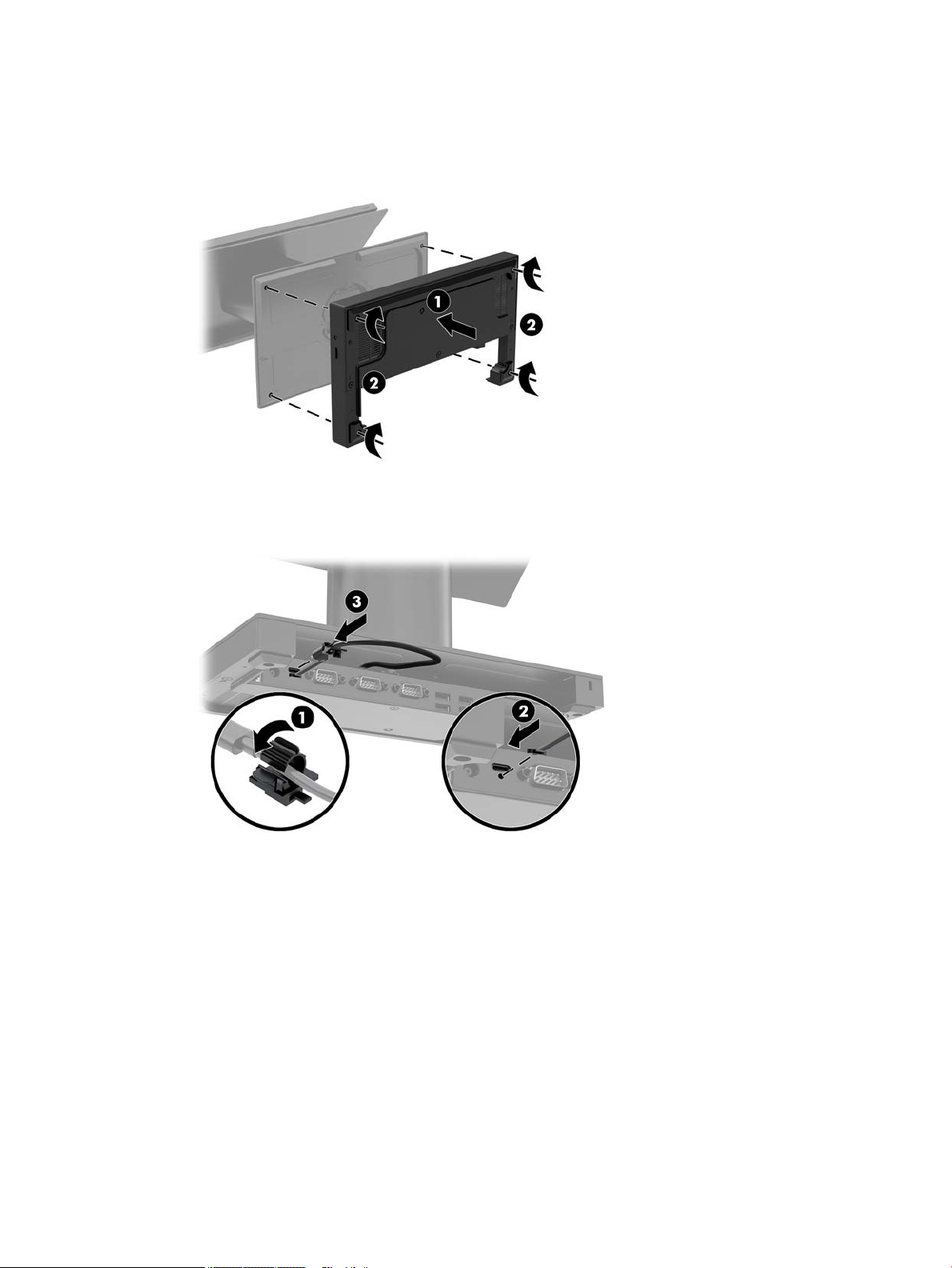

Attaching an I/O connectivity base to the Engage One

You can attach an I/O connectivity base to the bottom of the computer’s stand.

1. Prepare the computer for disassembly (Preparation for disassembly on page 19).

2. Remove the cover on the I/O connectivity base by removing the four screws on the underside of the I/O

connectivity base (1), and then lifting the cover o the I/O connectivity base (2).

3. Connect the USB Type-C power cable to the USB Type-C port on the underside of the stand’s column.

20 Chapter 4 Removal and replacement procedures

4. Place the I/O connectivity base onto the bottom of the stand (1), and then tighten the four screws on the

underside of the I/O connectivity base (2) to secure the I/O connectivity base to the stand. Be sure that

the USB Type-C power cable is routed through the gap between the back of the I/O connectivity base and

the stand.

5. To connect and secure the USB Type-C power cable, attach the cable clip to the cable (1), insert the cable

tie into the hole (2) below the USB Type-C port on the hub, and then slide the cable clip onto the cable tie

and connect the cable to the port (3).

6. Connect the I/O connectivity base’s AC adapter to the I/O connectivity base and a grounded AC outlet.

Attaching an I/O connectivity base to the Engage One 21

Connecting a standalone I/O connectivity base to the Engage One

1. Prepare the computer for disassembly (Preparation for disassembly on page 19).

2. Connect the USB Type-C power cable to the USB Type-C port on the underside of the stand’s column and

to the USB Type-C power port on the I/O connectivity base.

3. Connect the I/O connectivity base’s power supply to the I/O connectivity base and a grounded AC outlet.

Conguring the I/O connectivity base’s powered serial ports

The serial ports can be congured as standard (non-powered) serial ports or powered serial ports. Some

devices use a powered serial port. If the serial port is congured as a powered port, devices that support a

powered serial interface do not require an external power source.

IMPORTANT: The system must be powered o before connecting or disconnecting serial port devices.

NOTE: The I/O connectivity base ships with all serial ports congured in standard non-powered serial mode

(0 volts) by default.

There are three voltage settings for each serial port.

●

0 volts

●

5 volts

●

12 volts

To change the voltage settings for a powered serial port:

1. Prepare the computer for disassembly (Preparation for disassembly on page 19).

22 Chapter 4 Removal and replacement procedures

Loading...

Loading...