en

Operating manual

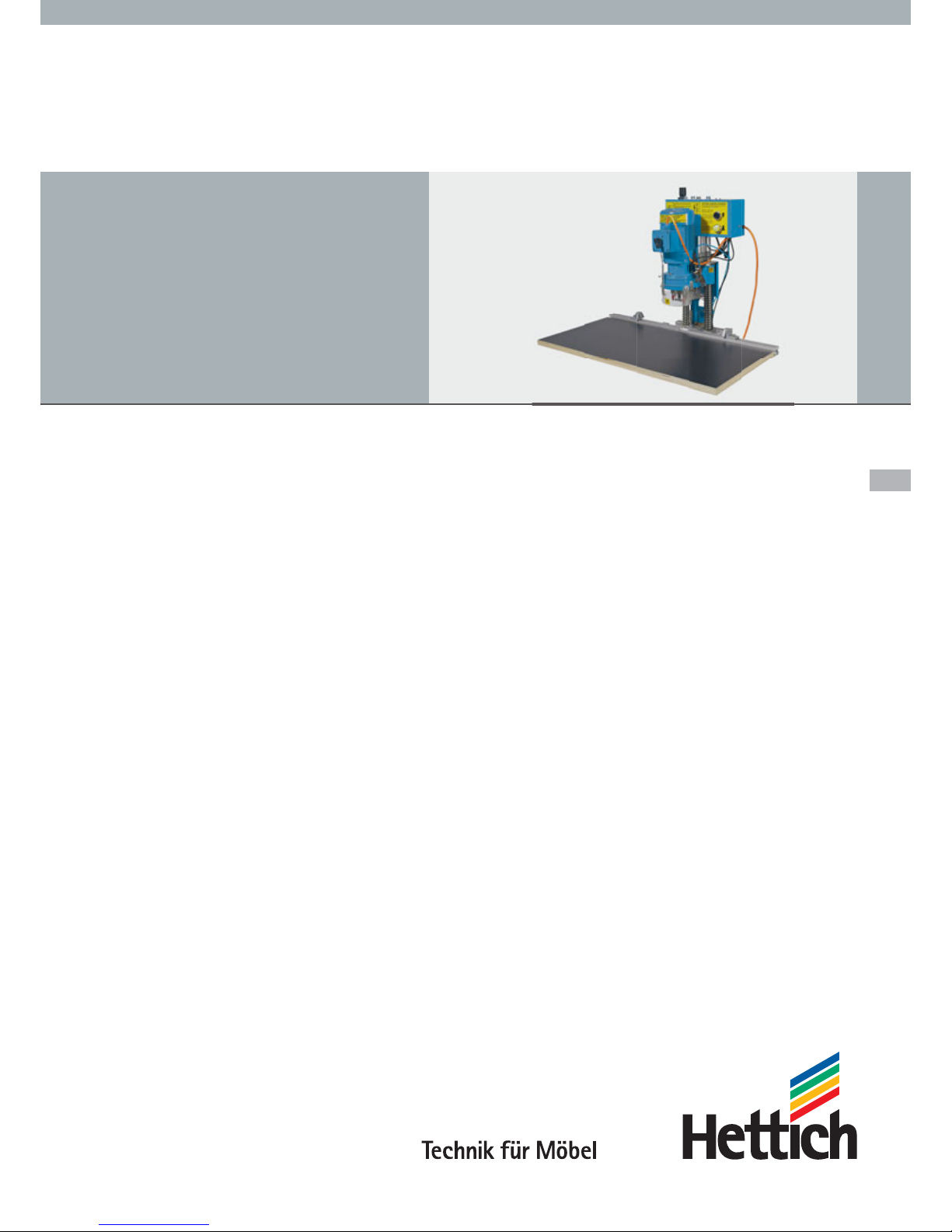

BlueMax Mini Type 3

2

en

EC Declaration of Conformity

EC Declaration of Conformity

within the meaning of EC Machinery Directive 2006/42/EC, Annex II A

Hereby declares Paul Hettich GmbH & Co. KG

Vahrenkampstraße 12 - 16

D-32278 Kirchlengern

the

Automatic Drilling Unit – BlueMax Mini Type 3, as a machine from

Paul Het

tich GmbH & Co. KG, Vahrenkampstraße 12 - 16,

D-32278 Kirchlengern

is a machine within the meaning of the Machinery Directive and that it conforms to the following applicable provisions:

Machinery Directive 2006/42/EC, Low Voltage Directive 2014/35/EU,

EMC Directive 2014/30/EU

The following harmonized standards have been applied*:

EN ISO 12100 2010; Safety of machinery - General principles for design -

Risk assessment and risk reduction

EN ISO 13857 2008-06; Safety of machinery – Safety distances to prevent hazard zones being reached

by upper and lower limbs

EN ISO 14120 2015; Safety of machinery – Movable guards – General requirements for the design and

construction of fixed and movable guards

EN 60204-1 2006/A1:2009; Safety of machinery – Electrical equipment of machines –

Part 1: General Requirements

EN 61000-6-2 2005; Electromagnetic compatibility (EMC) –

Part 6-2: Generic standards – Immunity for industrial environments

EN 61000-6-4 2007+A1:2011; Electromagnetic compatibility (EMC) –

Part 6-4: Generic standards – Emission standard for industrial environments

EN ISO 4414 2010; Pneumatic fluid power – General rules and safety requirements for systems

and their components

EN 349 1993+A1:2008; Safety of machinery; Minimum gaps to avoid crushing of parts of the

human body

This declaration of conformity shall become void if any major changes are made to the overall system or parts of the

system without written permission from the manufacturer.

* In relation to standards applied by subcontractors, see their separate EC Declarations of Conformity or Incorporation

Name / address of the person authorised to compile EC documentation:

Place, date: Kirchlengern, this 01.08.2017 Managing Director:

Name / signature

3

en

Foreword

WARNING

Read these operating instructions carefully in

order to obtain a thorough understanding of

the machine and how to handle and maintain it.

Operate the machine in the proper manner as

described in these instructions so as to avoid injury

and damage to the system. Do not operate the

machine on the basis of suppositions. Keep these

operating instructions to hand and consult them

if you are in any doubt as to carrying out any

particular procedure.

If any questions remain unanswered after reading

through the instructions, you must not put the

machine into operation. Settle any unanswered

questions first by consulting

Paul Hettich GmbH & Co. KG.

Service

Customer Service

Paul Hettich GmbH & Co. KG,

Vahrenkampstrasse 12 - 16, D-32278 Kirchlengern

Operating manual: Paul Hettich GmbH & Co. KG© 2017

Copyright to the operating instructions

The copyright to this operating manual remains with

Paul Hettich GmbH & Co. KG.

These operating instructions are intended for the operating

personnel. They contain regulations and drawings of a

technical nature that must not be duplicated either in

whole or in part, distributed, used without permission for

advertising purposes or communicated to others.

4

en

EC Declaration of Conformity 2

Foreword 3

Contents 4

1. Introduction 5

1. Introduction 5

2. Rating plate 5

3. Information for the owner 5

4. Verification of instruction 6

2. General

1. Intended use 8

2. Foreseeable incorrect use 8

3. Description of the machine 9

Space required by the machine 9

Machine life 9

4. Liability 9

3. Safety

1. Information on signs, symbols and markings 10

2. General 11

3. Safety advice for the user company 12

4. Noise 12

5.

Oils, greases and other chemical substances 12

6. Residual risk 12

7. Safety advice for operating personnel 12

Work which may be done by the operating personnel 13

Requirements on operators 13

8. Safety advice for operating the machine 13

9. Safety advice for carrying out maintenance work 13

10. Training / instruction 13

11. Personal protective equipment 13

4. Description of the machine

1. Technical specifications 14

2.

Controls 15

3. Setting up 15

4.

Safety guards 15

5. Labelling 16

5. Transportation and installation

1. Transportation 18

2.

Internal transportation 18

3. Checking delivery for missing items 19

4.

Dealing with shipping damage 19

5. Site of installation 19

6. Start up

1. General 20

2. Starting up for the first time 21

3. Safety check 21

4. Malfunctions on start up 21

5. Carrying out trial run 21

6. Concluding start up 21

7. Operation

1. Preparing machine 22

Base frame for BlueMax Mini Type 3 22

Drilling spindles 22

Drill bits 23

Connecting to extractor system 23

Connecting to compressed air supply 23

Connecting to the power supply 23

Add on ”swivel unit with sensor roller“ 24

Connecting BlueMax Mini hose ”without foot pedal“ 24

Connecting BlueMax Mini hose ”with foot pedal“ 24

Add on ”hold-down clamp“ 24

Accessory fence extension 24

2. Preparing for work 25

Setting drilling depth 25

Edge distance 25

Pendulum stops 25

Hold-down clamp 25

Die 26

3. Operating 26

Hold-down clamp 26

4. Fitting Hettich hinges 27

Setting up 27

Drilling 27

Pressing in 28

8. Troubleshooting 30

9. Servicing and maintenance 30

Drilling head 30

Pneumatic valves 30

Labelling, information signs 31

10. Taking out of service 31

11

. Disposal 31

Protecting the environment 31

Scrapping 31

Oil and oily wastes 31

12. Replacement and expendable parts 32

Exploded drawings 35

Pneumatic circuit diagrams 38

Wiring diagrams 39

Contents

5

en

1. Introduction

These operating instructions are intended to make it easier for you

to become familiarised with the machine and use its capabilities

in the proper manner. The operating instructions contain

important information on operating the machine in a safe,

proper and cost effective manner. Following them will help to

avoid hazards, repair costs and down times, enhance reliability

and prolong service life.

Existing national regulations on preventing accidents and on

protecting the environment are also applicable.

The machine must only be assembled and installed by persons

instructed to do so by Paul Hettich GmbH & Co. KG. This also

applies in particular to starting it up for the first time.

The operating instructions must be available at the machine all

the time. The operating instructions must be read and applied by

any person entrusted with working with / on the machine, e.g.:

• Operation

• including setting up, troubleshooting while working, disposal

of production waste, care, disposing of consumables and

auxiliary substances,

• Maintenance

• Servicing, inspection, repair

• Handling

2. Rating plate

NOTE

The rating plate is located on the machine.

The rating plate shows the following information:

Manufacturer

Address

Type designation,

machine numbers

Year of manufacture

Technical specifications

(e.g. nominal pressure)

State all of the above details when requesting technical

information and ordering replacement parts.

Reproduction either in whole or in part is not permitted.

3. Information for the owner

In addition to these operating instructions and the accident

prevention regulations in force in the country of use or at

the place of application, it is also necessary to follow the

recognised code of safe and proper working practice.

Without the consent of Paul Hettich GmbH & Co. KG, the

machine owner must not make any additions, alterations or

modifications to the machine that may affect safety.

Replacement parts used must meet the technical

requirements defined by Paul Hettich GmbH & Co. KG. This is

always ensured when using genuine replacement parts from

the applicable replacement parts list.

Only ever deploy trained or instructed personnel and clearly

define personnel responsibilities with regard to operating,

servicing and repair.

Introduction

6

en

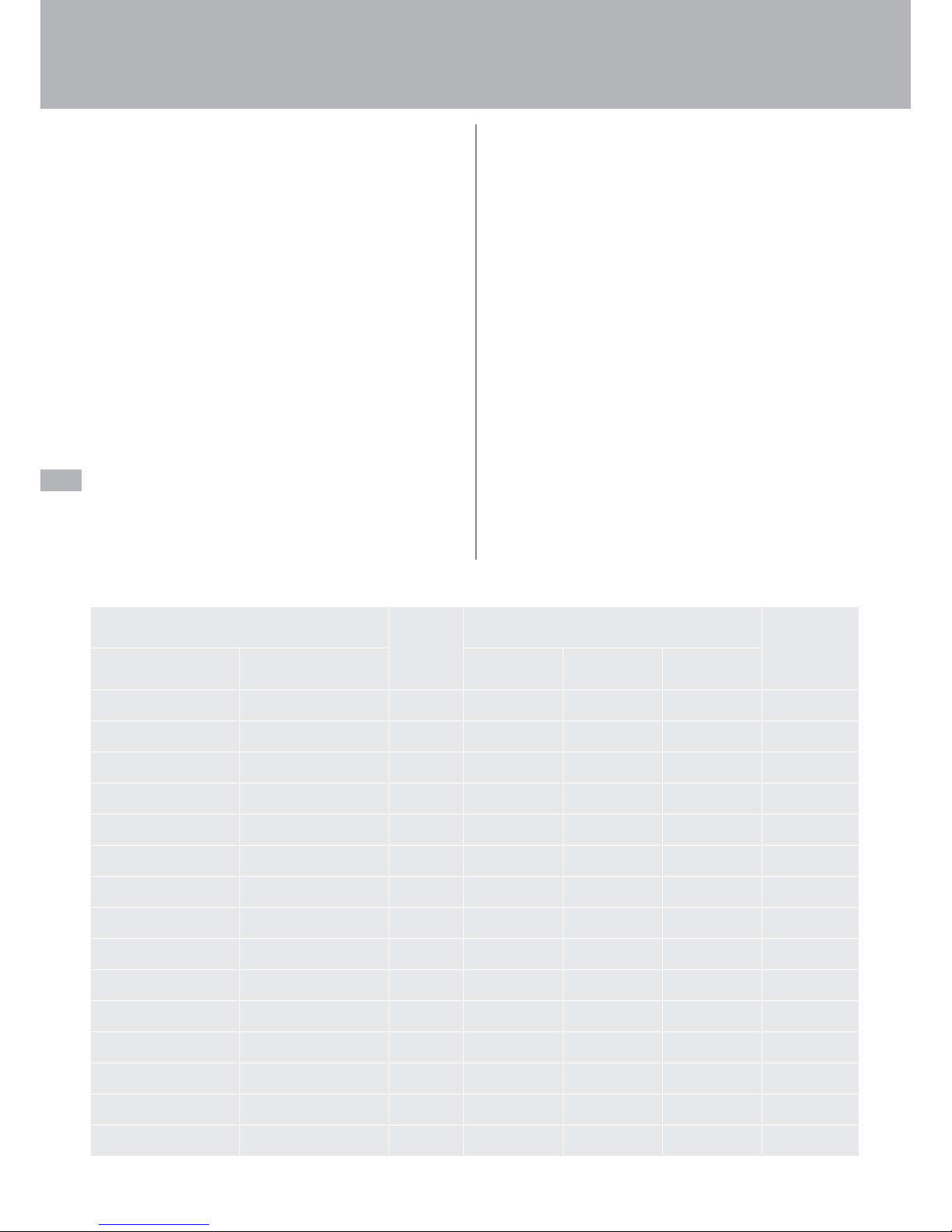

Name

Date

from / to

Type of instruction received

Signature of

the person

having received

instruction

Instructor Person instructed Operation Safety rules Servicing

4. Verification of instruction

By signing this protocol the undersigned confirms that the

following details and specifications are correct.

Confirmation

I hereby confirm that I have read and understood the

operating manual for the machine:

Designation BlueMax Mini Type 3

Type Automatic drilling and insertion machine

Machine no.

I furthermore undertake to observe and follow the general

safety precautions, the servicing and care instructions

as well as power-up and operating instructions and the

provisions relating to malfunctions. I am aware that any

failure to observe these instructions and provisions may lead

to accidents, put persons at risk and result in damage to

property and the machine.

Introduction

7

en

8

en

General

2. General

1.

Intended use 8

2. Foreseeable incorrect use 8

3. Description of the machine 9

Space required by the machine 9

Machine life 9

4. Liability 9

1. Intended use

WARNING

The machine must only be used in for its intended

purpose and be in a perfectly safe condition!

Operating safety is only guaranteed if the machine is

used for its intended purpose!

The BlueMax Mini Type 3 is a semi automatic drilling and

insertion machine for panel type workpieces. This machine

must only be used for working on flat panels made of woodbased materials, such as chipboard, blockboard panels, MDF,

solid wood or similar materials.

Any other use beyond this is deemed to be improper and non

intended use.

Intended use also includes following the operating, servicing

and maintenance conditions prescribed by the manufacturer.

Unauthorised changes to the machine will result in the

loss of product liability and liability on the part of the

manufacturer for resultant damage.

Any other use beyond this is deemed to be non intended

use. The manufacturer shall not be liable for any damage

this causes, with the risk involved being borne solely by

the user.

2. Foreseeable incorrect use

WARNING

Hazards may occur if the system is used incorrectly!

The following situations in particular are deemed to

be foreseeable hazardous situations:

• improperly assembling, starting, operating and servicing

this machine,

• operating the machine with faulty safety guards,

• operating the machine with improperly fitted safety

guards,

• operating the machine with non-functioning safety

guards and protective equipment,

• failing to observe the information and instructions given

in the operating manual in relation to handling, storing,

assembling, starting, operating, servicing and setting up

this machine,

• unauthorised structural modifications,

• unauthorised changes to this machine‘s drive system

(power output, speed),

• inadequate monitoring of machine parts subject to

particular wear,

• improperly performed repairs and

• disasters caused by the impact of foreign objects and

Acts of God.

9

en

The situations above describe some of the residual hazards

which, despite being impermissible, may occur and harm the

health of staff.

The owner must observe the safety requirements defined

in the German Ordinance on Industrial Safety and Health

(Betriebssicherheitsverordnung).

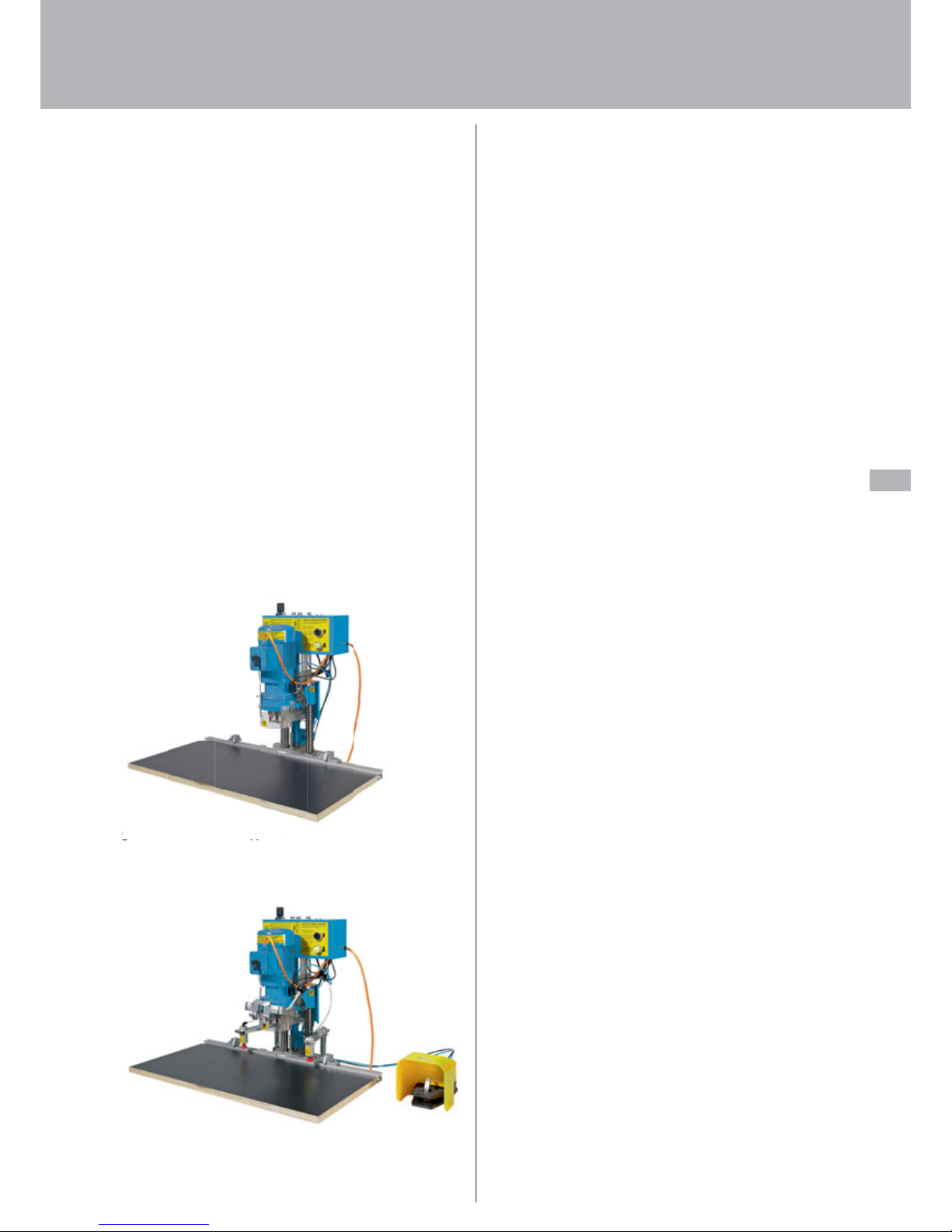

3. Description of the machine

The BlueMax Mini Type 3 is a semi automatic drilling and

insertion machine for panel type workpieces. This machine

must only be used for working on flat panels made of woodbased materials, such as chipboard, blockboard panels, MDF,

solid wood or similar materials.

All parts being worked on are fed into the machine by hand.

Flat panels made of wood-based materials are laid on the

work table and, by way of option, fixed in place with the

clamping equipment. The drilling process is initiated by

pressing the start button. The start button must remain

pressed until the drilling process has been completed. Using

the integrated insertion facility (optional), the relevant

fittings are pressed into place by means of a manually

operated press in frame (optional). This concludes the

machining process.

Fig. 1: BlueMax Mini Type 3

Fig. 2: BlueMax Mini Type 3 with accessories

g

. 1: BlueMax Mini

Typ

e 3

Space required by the machine

The space required by the BlueMax Mini Type 3 is largely

determined by the dimensions of the machine base frame.

Machine life

The machine‘s life will depend on whether or not it is used

for its intended purpose, on adherence to regular servicing

intervals and on the regular replacement of expendable parts.

4. Liability

Defects must only be rectified by competent personnel.

Our liability is restricted to damage caused while using

the system in the intended manner. We shall not be liable

for safety defects not yet identifiable on the basis of the

current state of the art.

Failure to:

• observe safety advice for operating personnel

• observe advice on particular hazards

• observe the ban on unauthorised modifications and

changes

• use replacement and expendable parts or auxiliary

materials other than those approved by the manufacturer

will rule out any liability on our part for the

consequences.

10

en

Safety

3. Safety

1. Information on signs, symbols and markings 10

2. General 11

3. Safety advice for the user company 12

4. Noise 12

5. Oils, greases and other chemical substances 12

6. Residual risk 12

7. Safety advice for operating personnel 12

Work which may be done by the operating personnel 13

Requirements on operators 13

8. Safety advice for operating the machine 13

9. Safety advice for carrying out maintenance work 13

10. Training / instruction 13

11. Personal protective equipment 13

1. Information on signs, symbols and markings

The safety advice in the operating instructions is structured

as follows:

DANGER

This danger advice draws attention to an immediately

dangerous situation that will lead to death or serious

injuries if the safety measures are not followed.

WARNING

This danger note draws attention to a potentially

dangerous situation that may lead to death or serious

injuries if the safety measures are not followed.

CAUTION

This danger note draws attention to a potentially

dangerous situation that may lead to minor or slight

injuries if the safety measures are not followed.

NOTE

This advice draws attention to potential damage

to property or to a process of particular interest /

importance that may occur if the safety measures are

not followed.

In the operating instructions, hazard points are identified as

follows:

DANGER

Danger from electric shock!

Working on live components in the improper manner

presents a danger to life!

Work on electrical equipment must only be carried

out by authorised electricians!

WARNING

Hearing damage warning!

Some areas of the facility can reach noise levels of

over 80 dB (A).

Wear ear protectors when working in noisy areas!

WARNING

Danger from wood dust!

Wood dust can affect the respiratory tract. For this

reason, wear a dust protection mask.

11

en

WARNING

Fire risk!

Grinding and welding work must never be performed

on this machine.

Follow welding regulations and accident prevention

regulations.

WARNING

Explosion protection!

Machine is not explosion-protected. Do not install

near paint shops.

WARNING

Warning - Hand injuries!

Hands could be crushed, drawn in or otherwise

injured.

Never reach into the system‘s moving parts!

Wear hand protection!

WARNING

Warning - Hot surfaces / objects!

There is a risk of injury from touching hot surfaces

(e.g. electric motors).

Do not touch!

2. General

The machine described in the operating instructions is built

to the state of the art and safe to operate. It complies with

DIN EN 12100.

Hazard zones are made safe in compliance with the

regulations. However, the machine may present hazards if

it is used by untrained personnel improperly or not for the

intended purpose.

This may then result in risks to life and limb, jeopardise the

machine and prevent it from working efficiently.

Any person given the task of installing, starting, operating,

servicing or repairing the machine at the user‘s premises

must have read and understood these instructions, in

particular the section on ”Safety precautions“.

In his or her own interest, the safety officer at the user

company should obtain written conformation from operating

personnel that they have received instruction and training

and are familiar with all safety precautions before they use

the machine for the first time.

The safety guards must never be removed or taken out of

operation.

If safety guards need removing for maintenance and repair

work, they must be refitted as soon as such work has been

completed.

The machine must only be used if it is in proper working

order and operated by trained, authorised personnel.

Work requiring specialised knowledge (e.g. electrical,

pneumatic system) must only be carried out by persons

specifically trained and suitable to do so.

Before attempting any work on the machine, turn the main

switch to the ”0“ position (OFF), make the machine safe and

disconnect from the compressed air supply.

Switch off energy sources before carrying out repair, servicing,

installation or cleaning work.

Energy sources:

• Electrical energy

• Pneumatic energy

CAUTION

Danger from residual energy!

Stored energy will not be dissipated even after switching

the system off at the main switch.

Dissipate residual or stored energy!

Switch off / dissipate energy sources:

For safety regulations applicable to third party devices, refer

to the documentation from the third party manufacturers

(operating instructions for bought in units).

Electrical energy via the motor switch / machine‘s main

switch. Additionally attach a notice when servicing or other

work is being carried out on the machine.

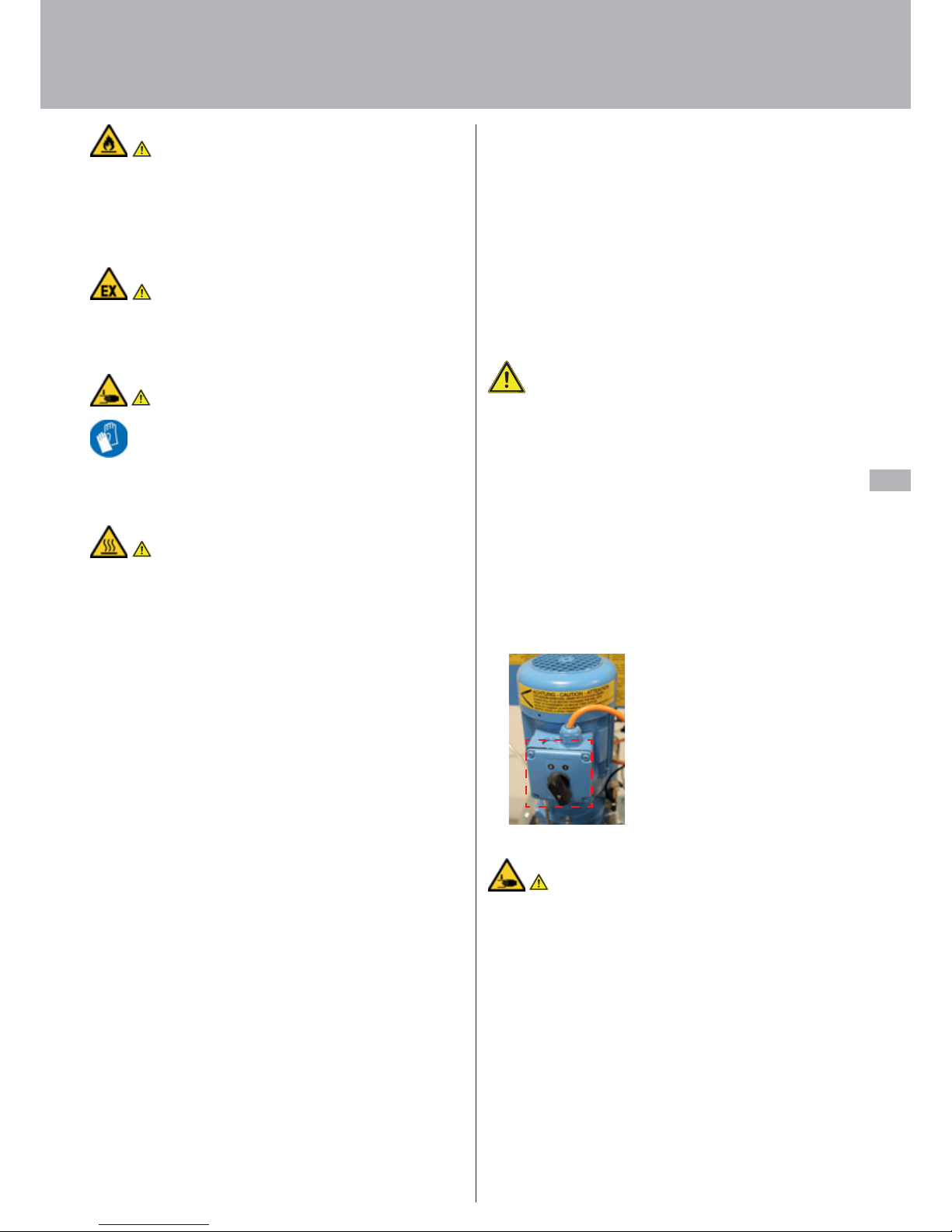

Fig. 3: Main switch

WARNING

Warning - Hand injuries!

The main switch only shuts down the drive system,

not the pneumatic system!

The machine has no emergency stop button or

emergency stop facility. This means it is necessary to

take particular care when handling and working on

this machine.

12

en

Pneumatic energy through the supply connection on the

machine frame. Make sure that all machine components are

depressurised and any stored energy is dissipated. As part of

the installation process, the owner will provide a mechanical

main cock at which the machine can be disconnected from

the compressed air supply.

Fig. 4: Pneumatics servicing unit

3. Safety advice for the user company

All persons entrusted with operating the machine (including

line managers) must familiarise themselves with the section

on ”Safety“. The safety advice must be followed.

The machine must only be used if it is in proper working

order. The user company will issue clear responsibilities, e.g.

for servicing, cleaning or repair, and ensure that the persons

carrying out this type of work have received the training

necessary for it.

The safety regulations applicable in the owner‘s country

must also be observed. Refrain from any work that adversely

affects operating safety.

The operating personnel will check the machine for changes

or malfunctions, report such to the safety officer responsible

and, if necessary, take the machine out of operation.

Only appropriate tools may be used for the work that needs

to be done; remove tools after completing work. The place at

which staff work must be selected in such a way as to ensure

that work operations can be viewed at all times, the machine

can always be stopped immediately and safety is never at

risk.

WARNING

Never:

• reach into the machine when it is operating

• remove covers and take safety guards out of operation

• hinder unobstructed access to the controls

• continue operating the machine if changes occur that

adversely affect safety

• manipulate or circumvent safety guards

4. Noise

The weighted equivalent continuous sound level

is > 89 dB (A).

WARNING

Hearing damage warning!

Local conditions may produce elevated sound pressure

and cause noise induced hearing loss!

Operating personnel must be provided with appropriate

protective equipment or be protected by other measures!

Wear ear protectors when working with the machine!

5. Oils, greases and other chemical substances

When handling oils, greases and other chemical substances,

you must observe and follow the applicable regulations and

safety data sheets of the manufacturers of these substances

with regard to storing, handling, using and disposing of

them.

When working with caustic substances, you must wear

protective equipment of suitable material (safety goggles,

rubber gloves, rubber boots, protective clothing).

In the event of contact with the eyes or skin, immediately

rinse the area affected with copious quantities of water.

Appropriate facilities (eye wash bottle, wash basin, shower)

must be provided near the work area.

6. Residual risk

CAUTION

Residual hazards!

Handling the machine involves residual hazards that

could not be eliminated by design measures.

Pay attention to the residual risks in the Technical

Documentation!

The machine reflects the state of the art and is built in

accordance with recognised safety regulations. All the same,

the user or third parties may still be exposed to hazards.

The machine must be used

• for the intended purpose

• in an absolutely safe state

WARNING

Risk of injury!

Never remove safety devices or render them ineffective

by making changes to the machine!

Malfunctions presenting a safety risk must be rectified

without delay!

Before attempting servicing and cleaning work, switch

off the entire machine and disconnect from the

compressed air supply!

7. Safety advice for operating personnel

• Work on the machine must only be carried out by

instructed, skilled personnel

• Only skilled personnel who have received training or

instruction must be deployed

Safety

Loading...

Loading...