1

SCAN-LINE AQUA

OPERATING INSTRUCTIONS

UK

www.heta.dk

2

Congratulations on the purchase of

your new stove. We are confident

that you will enjoy using your new

investment, which you will get most

out of by following the advice and

instructions contained within this

guide.

Scan-Line Aqua conforms to both EN

13240 and 15a B-VG Austria.

This certification is your guarantee

For minimum clearance requirements from a flammable wall, refer

to the information plate on the

stove and the table on page 6 of this

guide.

Warning!

As your stove becomes

extremely hot during ope ration (in excess of 90°C),

please handle it with extre me caution.

Children should never touch the

stove.

Never place flammable objects under the ashpan.

Remember

1. Always ensure easy access to the

chimney cleaning hatch.

2. Ensure the room has adequate

ventilation.

3. Note that extraction fans ope-

that your new stove meets a range

of stringent specifications and requirements, which ensure it is made

from high-quality materials, is kind

to the environment and is efficient.

Your new stove is supplied with the

following:

a. Operating instructions

b. Warranty

c. A heat-resistant mitt

Installing the stove

The stove must always be installed in

accordance with applicable regulations for your particular area or

country, including installation of the

flue and connection of the stove to

it. Always consult your local chimney

sweep before carrying out installation, as you are responsible for

ensuring that all applicable regulations are complied with.

Clearance

Regulations regarding installation of

a stove near a flammable wall differ

from those for a non-flammable wall.

A stove may be positioned against

a wall made from non-flammable

material. However, to allow for sufficient cleaning space behind your

stove, we recommend a clearance of

at least 5cm from the wall.

INSTALLATION

TABLE OF CONTENTS

Installation ............................................................... .................. 2-4

Operating instructions ................................................... ........... 4-8

Connecting to a water system…..................................... ........ 9-11

Installing and commissioning Heta Aqua Kit K 36-20 .... ..... 13-17

Schematic diagrams............................................................ ... 18-19

3

rating in the same room as the

stove can weaken the chimney

draught, which can effect the

stove’s efficiency. It can also lead

to smoke escaping into the room

when opening the firing door

4. D

o not cover the air vents, if fitted.

Floor surface

Ensure the floor can bear the weight

of the stove and top-mounted steel

chimney, if applicable. The stove

must stand on a non-flammable surface such as steel plate or brick/tile.

The dimensions of the non-flammable surface used to cover the floor

area must comply with applicable

regulations for your particular area

or country.

Chimney connection

The chimney opening must comply

with national and local regulations.

However, the area of the opening

should not be less than 175 cm2,

which corresponds to a diameter of

150 mm. If a damper is fitted to the

flue gas pipe, there must be at least

20 cm2 of free passage when in the

closed position. If local regulations

permit, two closed fireplaces may

be connected to the same chimney.

However, you must be aware of local

regulations regarding how closely

they may be located to each other.

Stoves must never be connected to a

chimney that already has a gas-fired

heater connected to it.

An efficient stove places high demands on a chimney. Therefore, always have your local chimney sweep

assess the condition of your chimney

Connecting to a brick chimney

Build a thimble into the chimney

to accommodate the flue gas pipe.

The thimble and flue gas pipe must

not penetrate the chimney opening

itself, but must be flush with the inside of the chimney duct. The points

where brickwork, thimble and flue

gas pipe meet must be sealed with

fireproof material/beading.

Connecting to a steel chimney

When connecting a top-outlet stove

directly to a steel chimney, we recommend feeding the chimney pipe

inside the connecting pipe from the

stove, which will allow soot and

condensation to drop into the stove

itself rather than collecting on the

outside surface.

An installation must comply with applicable national and local regulations where a chimney is fed through

an internal ceiling. To avoid overloading the stove, it is important that

the chimney is supported by a loadbearing roof support.

Draught conditions

Poor draught may result in smoke

escaping from the stove when the

door is opened.

To ensure satisfactory combustion,

chimney draught for this oven should

be at least 10 PA, although some

smoke may still escape if the firing

door is opened when the stove is

burning strongly.

The nominal flue gas operating temperature is 236°C with an outdoor

temperature of 20°C.

The flue gas mass flow is 14.7 g/sec.

Chimney draught is generated by

the difference between the high

chimney temperature and low outdoor temperature.

The chimney’s length and insulation

4

- the chimney and flue gas pipe are

blocked

- the house is sealed (no through-

draught)

- negative pressure (poor draught

conditions) due to a cold chimney

or bad weather conditions can be

compensated for by increasing the

airflow into the stove.

Good draught occurs when:

- there is a significant difference in

temperature between the chimney

and outdoor air

- the weather conditions are clear

- there is a strong wind

- the chimney is at the correct height

of at least 4 m above the stove and

free of the roof ridge

as well as the ambient wind and

weather conditions also affect the

ability to generate sufficient negative pressure in the chimney.

Before lighting a stove that has not

been used for a long time, check

that the chimney and stove are not

blocked with soot, bird nests, etc.

Reduced draught can occur

when:

- the temperature difference is too

small, e.g. due to insufficient chimney insulation

- the outdoor temperature is too

high, e.g. during the summer.

- there is no wind outside

- the chimney is too low and is sheltered from the wind

- there is false air in the chimney

OPERATING INSTRUCTIONS

First firing

Your stove is treated with heatresistant paint, which hardens at a temperature of approx. 250°C. Ensure

the room is well ventilated, as the

hardening process produces a certain

amount of fumes and smell.

The firing door should remain slightly open during the first 1–2 firings

with around 1 kg wood and should

not be closed until the stove is cold.

This is to prevent the beading from

becoming stuck to the stove.

Wood fuel

The stove is EN approved for the

firing of wood fuel. You must therefore only burn clean, dry wood in

your stove. Never use your stove to

burn driftwood, as it may contain a

significant amount of salt, which can

damage both your stove and chimney. You must also avoid burning

rubbish, painted wood, pressureimpregnated wood or chipboard,

as these materials can release toxic

fumes and vapours. Correct firing

produces optimal heat and efficiency. It also avoids problematic smells

and smoke being released into the

atmosphere and reduces the risk of

chimney fire.

When burning damp wood, a large

proportion of the heat is wasted

during evaporation of the water.

Firing with damp wood is therefore

not only uneconomical, it also increases the risk of tarry soot, smoke

and environmental problems. Therefore, it is important to use dry wood,

i.e. wood with no more than 18 %

moisture content. This is achieved by

storing the wood for 1-2 years before use. Firewood with a diameter

of more than 10 cm should be split

5

Fig. 1 Fig. 2

Open Closed

before storage, and should be of an

appropriate length (approx. 22–30

cm) so they can be laid evenly on the

embers. Firewood stored outdoors

should be covered.

Examples of combustion values for

different woods

Wood type in cubic metres

equivalent to 1,000 litres of oil

Oak Beech Ash Birch Elm Spruce

7,0 7,0 7,2 8,0 8,9 10,4

Chimney fires

In the event of a chimney fire, close

the firing door and shut off the

secondary/start-up air to smother

the fire. Then call the fire service

immediately. Chimney fires are often

caused by incorrect operation or

long-term use of damp wood.

Regulating the air supply

Open the secondary air by moving

the operating handle at the back

of the side panel. Fig. 1 shows the

secondary air fully open. Gradually

shut off the secondary air by lowering the handle. The air supply is

fully shut off when the handle is as

shown in Fig. 2.

Open the start-up air to the stove by

sliding the start-up handle fully to

the right (front view). See Fig. 3.

Shut off the start-up air by sliding

Fig. 3 Fig. 4

Oben

Closed

the start-up handle fully to the left

(front view). See Fig. 4.

Igniting

To ignite the wood, place firelighters,

small paraffin ignition bags or small

pieces of firewood on the bottom

grate. Then place larger pieces of

firewood on top of the kindling

material perpendicular to the firing

door. Fully open the secondary air

and leave the firing door slightly

open (approx. 1 cm).

When the fire is burning with a steady flame and the chimney has heated

up (after about 10 min), close the

firing door. We recommend leaving

the secondary air fully open throughout the first firing, to ensure that

the stove and chimney are heated

thoroughly.

Stoking

We recommend stoking the stove

while there is still a good layer of

embers. Spread the embers across the

bottom grate and place up to 2 kg of

firewood on the embers in a single

layer perpendicular to the firing opening. Close the firing door and feed

in start-up air if required. The wood

will then ignite within 30–60 seconds.

When the wood is burning with a

steady flame, shut off the start-up air

if open. Then adjust the secondary

air to the required level. Nominal

operation (12 kW) is achieved when

the secondary air is fully open and

6

Stove data as per EN 13240 testing. Scan-Line Aqua

Particle

emission

mg/m

3

CO

%

Flue gas

mass

flow

g/s

Nominal

flue gas

temp.

c°

Flue

connector

pipe

mm ø

Firing

weight

kg

Draugh

min

mbar

Nominal

output

kW

PowerkWDistance to flammable

materials in mm

behind at the

the stove sides

Minimum

distance from

furniture

mm

Stove

weight

kg

55

0,07*

14,7 236

150

2 0,10 12 12 150 300 1000

160

* 0,07% - (875 mg/nm3)

The nominal heating effect is the effect at which the oven has been tested.

Testing was carried out with the secondary air fully open and start-up air fully closed.

the primary air is shut off. When

firing, do not place the wood too

closely together, as this will result in

poor and therefore less cost-effective combustion. Note that the startup air must not remain open during

normal operation, as overheating

may occur. It should therefore be

shut off when the wood is burning

with a steady flame.

Reduced combustion

To operate the stove with reduced

output, simply use a smaller amount

of wood when firing and reduce the

air supply. However, remember that

the secondary air must never be shut

off completely during firing, and it is

important to ensure that the embers

remain hot. Moderate heat is achieved when the fire settles, i.e. when

no more flames are visible and the

wood has become glowing charcoal.

Optimal firing

To achieve the most effective firing,

it is important for the air to be fed

in correctly. As a general rule, the

fire should be controlled by the secondary air so that it ignites the flue

gases. The secondary air circulating

inside the stove also prevents the

formation of soot on the glass panel. Note that sooting is inevitable

if both the start-up and secondary

air is shut off. When damp wood is

combined with the conditions described above, the soot can become

extensive and adhesive enough to

pull the door beading off when the

door is next opened.

Risk of explosion!!!

After placing wood in the

stove, it is very important

not to leave the stove un attended until it is burning

with a steady flame (nor mally within 30–60 seconds).

The large amount of gas produced

by adding an excessive amount of

wood, combined with insufficient air

supply, may lead to a risk of explosion. We also recommend leaving

a layer of ash at the bottom of the

combustion chamber.

Use caution when emptying the

ashpan. Hot embers can remain in

the ash for a long time.

7

BLOCKAGE

If smells or smoke escape from the

stove, it is important to establish

whether the chimney is blocked. A

small amount of draught is always

required to ensure satisfactory operation. However, note that chimney

draught is dependent on the outside

wind conditions. It may be necessary to fit a damper in the flue gas

pipe to regulate the draught in high

wind conditions. When sweeping

MAINTENANCE

Your stove is surface treated with

heat-resistant lacquer and should be

cleaned using a damp cloth. Commercially-available repair spray can

be used to repair damage to the

lacquer surface.

Cleaning the glass

Inefficient firing resulting from the

use of damp wood, etc. can lead to

sooting of the glass panel. However,

this can be removed easily using special glass cleaner or standard scouring liquid.

the chimney, be aware that soot, etc.

can collect in the smoke chamber

behind the stones. Excessive chimney

draught may cause wood to burn

too quickly. Also check the condition

of the door beading. Using damp

wood may produce insufficient heat,

as much of the heat energy is used

to dry the wood, which results in

increased heating costs and greater

risk of chimney sooting.

8

Emptying the ashpan (Figs. 5-8)

5

6

7 8

Clearing soot after chimney sweeping and replacing the stones. (Figs. 9-12).

9

10

11

12

Warning

Unauthorised modification

of the stove and the use of

non-original parts will void

your warranty.

WARRANTY

Heta stoves undergo extensive

quality control before delivery

to our suppliers.

Your product is therefore guaranteed for 5 years against manufacturing

defects.

Your warranty does not cover:

- Consumables/breakable parts,

including: Fireproof stones in the

combustion chamber, glass, fire

rope and grate

- Damage resulting from incorrect

use

- Disassembly, transportation and re-

installation costs associated with a

warranty repair

Should you have cause to make a complaint, please quote our invoice no.

9

Attaching an outside air supply

(if required) Figs. 5–8.

Cut out and remove the metal cover

plate as shown using a diagonal

cutter.

Feed a duct through the hole in the

back plate.

Push the duct onto the ø100 mm

pipe welded behind the ashpan.

Secure the duct using a collar band.

Fig. 13

Fig. 14

Fig. 15

Fig. 16

10

CONNECTING TO A WATER SYSTEM

Aqua: Applications and

conditions of use.

Fig. 1 Scan-Line 580

The important information contained within this guide does not

encompass every situation. Common

sense and good workmanship, together with professional installation

and correct maintenance, will ensure

the reliability of your stove.

As Heta A/S is unable to give advice

on every type of installation, we have

produced this guide to help you

choose the best method of installing

your stove.

An AQUA stove gives you even more

possibilities than with a standard

stove, allowing you to have hot water, radiators and even floor heating

anywhere in the house.

You do, however, have to bear in

mind a few things:

The installation may only be carried

out by an authorised plumber and

must comply with all applicable legislation. You must also have a basic

understanding of how the stove

works. Do not install a stopcock between the stove and the rest of the

heating system. Incorrect operation

of the system may overheat the water and prevent it from circulating.

Never fire the stove while the boiler

is empty, as this may cause the copper cooling pipes to leak. Air trapped within the boiler may also lead

to a risk of explosion. To get the

best out of your heating system and

maintain efficient burning, we recommend that you use Heta’s AQUA

Kit, which releases water into the

system only when the stove reaches

the right temperature.

An AQUA stove must always be

fitted with an expansion tank, of

which there are two types: open

expansion and closed expansion.

Fig. 2 A: Open expansion tank

Fig. 2 B: Closed expansion tank

1: Vent pipe. 2 and 6: Tank.

3 and 8: Water. 4 and

9: Connection to system.

5: Pressurised air.

7: Membrane

.

11

Open expansion means that the

expansion tank (in this case located

at the top of the installation) is

open to the atmosphere. It must be

large enough to accommodate the

volume of expanded hot water in

the system. If the circulation in the

system stops while the stove is lit,

the temperature will rise sharply.

It is therefore necessary to protect

against excess pressure. An open

expansion tank that is correctly and

installed and of sufficient size protects against this by releasing excess

pressure to the atmosphere through

a vent pipe. The disadvantage of

open expansion is that the expansion tank must be located above the

rest of the system. The tank (and

access pipe) must also be protected

against frost, and oxygenation of

the water also necessitates some

form of corrosion protection within

the system.

With closed expansion, the expansion tank is hermetically sealed and

fitted with a membrane, which accommodates changes in water volume by compressing the air stored

on the other side of the membrane.

The advantage of this system is that

the expansion tank can be located

anywhere in the system. Also, as the

system is hermetically sealed, it is

not liable to the same oxygenation

problems of the open expansion

system. However, this system does

not protect against excess pressure

resulting from, for example, overheating. It is therefore necessary to

install some form of protection that

complies with relevant legislation.

For a closed expansion system, this

normally consists of a pressure relief

valve and emergency cooling circuit. The emergency cooling circuit

consists of a spiral-shaped pipe

built into the water tank, which is

connected directly to a cold water

supply at one end, running out to a

drain via a thermostat at the other.

The thermostat sensor is located in a

holder within the tank.

Fig. 3 Emergency cooling circuit

1: Temperature control valve

2: Sensor

3: Cold water supply

4: Tank

5: Cooling coil

6: Drain

7 and 8: Flow and return

9: Pressure relief valve

If the system overheats, the thermostat will open at 95ºC, allowing cold

water to run through the cooling

coil to cool the tank. If this is insufficient, for example if the cold water

supply is stopped, the temperature

will continue to rise until the pressure causes the pressure relief valve

to open, allowing built-up steam to

escape.

If pockets of air become trapped

in the water system, there is a risk

that the water may stop circulating,

which in turn can lead to overheat-

12

ing. We therefore recommend installing an automatic air vent to allow

trapped air to escape.

Fig. 4 Example of an automatic air

vent

1: Tank

2: Air pocket preventing circulation

3: Automatic air vent (in this case, open)

A stove fitted with a water tank

may cause increased cooling of the

smoke, which can lead to problems

with chimney draught. Therefore, it

is important to use additional kindling and to leave the door slightly

open for longer than normal, so the

water in the tank can be heated as

quickly as possible. A system should

also be installed to maintain the correct temperature. We recommend a

system comprised of a thermostatic

switch and a circulation thermostat,

which ensure that water starts circulating only when it has reached the

required temperature.

Fig. 5 System for maintaining the

correct temperature

1: Cold water return

2: Hot water supply

3: Circulation thermostat

4: Thermostatic switch

5: Circulation pump

a: Circuit at 60°C

b: Circuit over 60°C

The circulation pump starts when

the water temperature in the tank

reaches 50ºC. At this temperature,

circulation only occurs in the tank/

Aqua kit, as the thermostat (Figs.

5,3) will not open and release water

to the rest of the system until the

tank temperature reaches 60ºC. This

process stops and starts the system

automatically. Therefore, you only

have to ensure that at least one

component that is able to dissipate

the heat is attached to the system,

such as an accumulation tank or an

open radiator.

13

Aqua kit K36-20

See special instructions for

Aqua kit on page 14

Connection

1

2

3

5

4

6

1. Water to drain. 12 mm copper pipe

2. Water connection.

Thermal cooling protection.

12 mm copper pipe

3. Return (cold) 1” RG

4. Flow (hot) 1” RG

5. Extra 1” RG

6. Submersible thermostat connector

1/2” RG

Submersible

thermostat0006-5009 TC 2

– E11513

SYR temperature valve

0006-5005 ¾”

3-way valve

K36-20 with

60° opening

Thermometer

– red

0006-5010

Bleed

valve

Pressure relief

valve

Grundfos

pump

UPS 15-40

Thermometer

blue

0006-5011

Example: Opened and closed expansion systems

Thermal protection*

Water connection*

Radiator and /

or floor heating

Central gas

or oil boiler

Thermostat /

Pump / Valve

Temperature sensor

Drain*

*Closed expansion

14

INSTALLING AND COMMISSIONING HETA

AQUA KIT K 36-20

1. GENERAL

1.1 Scope

These instructions describe the

function, installation, commissioning

and operation of Heta return-flow

temperature controller K36-20. For

other components such as regulators, refer to the relevant manufacturer’s documentation.

Sections marked with [Expert] are

intended for use by qualified professionals.

Please read these instructions

thoroughly before using the loading

valve assembly for the first time and

store them safely for future reference.

1.2 Product description

Heta return-flow loading valve

assembly K36-20 is a pre-installed fixture that maintains constant return

water temperature in Heta recessed

fireplaces and stoves.

• Ballcocks with integrated thermometer (flow and return)

• Pressure relief valve to prevent

excessive pressure

• Automatic bleed valve to prevent

air/gas bubbles in the heat exchanger

• Submersible thermostat to turn

the pump on and off depending

on temperature

• Thermal control valve with 60°C

opening temperature

Our packaging is made from recyclable materials.

1.3 Functional description

Heta return-flow loading valve assembly K36-20 prevents the boiler

from sooting by raising the return

water temperature with the help of

a thermal valve (through a bypass).

The constant return-flow temperature ensures even combustion and

optimal energy utilisation.

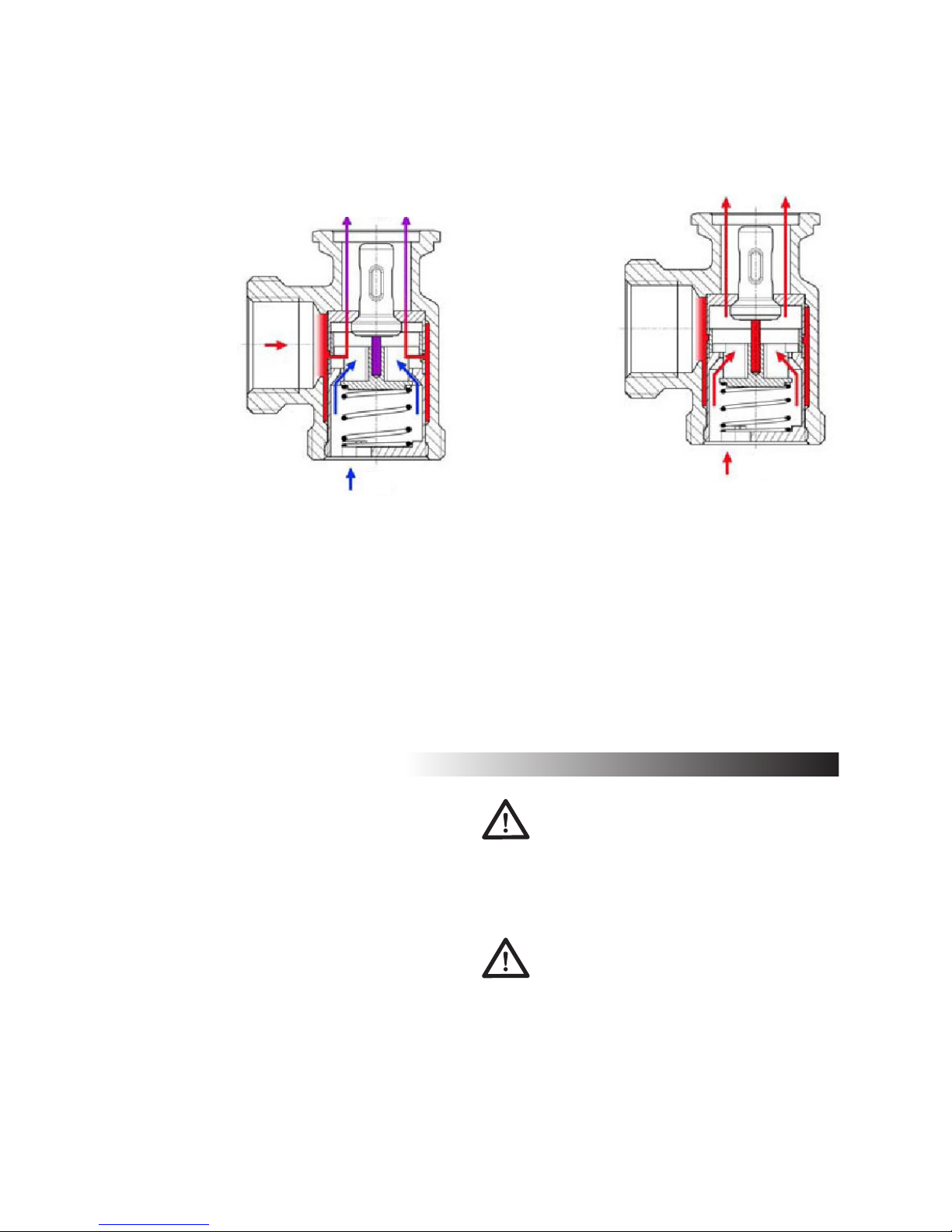

1. As long as the water temperature

in the boiler circuit remains below

the control valve opening temperature, the valve will prevent water

flowing into the accumulation tank.

The pump circulates the water in

the boiler circuit via the bypass, and

as there is less water in the boiler

circuit, it heats up more quickly.

tKR > tPR

tKR = tFIX

tKR < tBY

2. When the temperature in the boiler circuit reaches the control valve

opening temperature, it reduces the

bypass volume flow and opens the

accumulation tank circuit. The cold

return water from the accumulation

tank then mixes with the hot water

T

KR

T

BY

T

PR

15

from the boiler circuit in the control valve. This maintains constant

return-flow temperature to the

boiler and prevents the formation of

condensation in the boiler.

tKR > tFIX

tKR = tBY

3. When the return-flow temperature from the accumulation tank

exceeds the valve opening temperature, the control valve closes the

bypass completely. This allows the

water from the accumulation tank

to flow directly into the boiler.

tKR > tFIX

tKR = tPR

Temperatures: tBY = boiler flow

(bypass) tKR = boiler return flow

tPR = accumulation tank return flow

tFIX = opening temperature

2 SAFETY INSTRUCTIONS

Installation, commissioning and connection of the electrical components

require expert professional knowledge equivalent to that of an authorised plumber, heating installation

engineer, environmental technician

or equivalent. The following must

be adhered to when carrying out

installation and commissioning:

• relevant regional and national

regulations

• trade association regulations relating to safety at work

• general/safety instructions provided in this document

The person or contractor

carrying the installation is

responsible for ensuring it is

carried out correctly!

Note:

Risk of damage to materials

from mineral oil!

The EPDM seals must never come

into contact with substances containing mineral oil, as this will damage

the material and reduce its sealing

properties. If you are in any doubt,

contact the product manufacturer.

to determine whether solar fluid,

t

KR

t

BY

t

PR

t

KR

t

BY

t

PR

16

3 ASSEMBLY AND INSTALLATION [Expert]

3.1 Assembly of return-flow

loading valve assembly

1. Seal 1” double nipple in the

return-flow connector (no. 3).

2. Seal the safety section with the

vent to the extra connector (no.

4). The safety section is protected

by a lock nut. The cross joint can

be adjusted when the lock nut has

been loosened.

3. Seal the 1“ AG x ½“ IG reduction

section to the flow connector (no.

5). The immersion thermostat shell

can be sealed to the reduction

section.

4. Install the pre-assembled returnflow loading valve assembly.

Remember to fit the seals!

Start with the safety section.

First, connect everything and

1.

2.

3.

tighten by hand. Then align the

assembly and connect the pipes

(see connection diagram on the

following page). Before commissioning/pressure testing, be sure to

check and tighten all connections.

5. Connect the submersible thermostat as described in the separate

instructions and secure it.

6. Piping/connection diagram

KA

KW

grease or other products used

during installation contain mineral

oil. We accept no responsibility and

do not guarantee against damage

resulting from seals that have become damaged through exposure to

mineral oil.

Connection option A

Storage tank

Connection option B

Central heating system

Rückflusssperre

17

3.2 Electrical connection of return-flow loading valve assembly:

Wiring of submersible

thermostat connectors

The stove must never be used

without water and a functioning cold water supply [KV]

/ drain [KA] in the thermal

drain protection and relevant

safety fixtures. Otherwise,

Thermostat

Setting at ~ 55ºC

Heating pump

there is a risk of explosion, leading

to irreparable damage!

Note: Thermal drain protection is

not mandatory in Denmark when

using open expansion.

18

4 TECHNICAL DATA

Return-flow loading valve K36 DN 20

________________________________________________

Connectors

on heat production equipment: 1” external thread

to accumulation tank ¾” internal thread

________________________________________________

Materials

Fixtures brass

Seals EPDM/paper

Insulation EPP

Hydraulics

Max. temperature: 110°C

Max. pressure 4 bar

Kvs value 5.3

________________________________________________

5 PERFORMANCE

The stove has an output of approx. 3 kW on the water.

Which equates to:

- 130 l water flow per hour at 20°C between the thermometers

- 172.5 l water flow per hour at 15°C between the thermometers

- 260 l water flow per hour at 10°C between the thermometers

The installed pump (Grundfos UPS 15-40) is triggered

- at level III (at 520 l/h) at approx. 3.2 m WS (pressure loss)

this equates to approx. 40 m of Ø 18 x 1.5 mm copper pipe.

- at level II (at 520 l/h) at approx. 2.5 m WS (pressure loss)

this equates to approx. 30 m of Ø 18 x 1.5 mm copper pipe.

- at level I (at 520 l/h) at approx. 1.3 m WS (pressure loss)

this equates to approx. 15 m of Ø 18 x 1.5 mm copper pipe.

As a rule, the pump is capable of running at level I.

19

Jupitervej 22

7620 Lemvig

Tlf. 96630600

Fax 96630616

Teg type

Teg

Godk

.

Bukke nummer

Mål uden tolerancer efter DS/ISO 2768-1-m

Buk 1

8038-0002-00.asm

Scanline 580 Aqua

8038-0002-00

Samlingstegning

04-11-2007

Vægt

Materiale type

170,7 kg

Solid Edge

Saml.

SBS

8038-0002-00-plance.dft

Areal

25-08-2008

Buk 2

Skære nummer

Valseindstilling

Sidst opdateret

1 2

Valsetryk

Montere

Bearbejdning

1265

500

977

A

DETAIL A

66

143

31

121

271

299

101

1515

2

1

3

5

4

6

2

1

1 12 mm . Thermische Ablaufsicherung-Einlauf Kaltwasser

2 12 mm . Thermische Ablaufsicherung-Auslauf Kaltwasser

3 1" IG. Kessel Rücklauf

4 1" IG. Kessel Vorlauf.

5 1" IG. Exstra.

6 1/2 Muffe Tauchhülse der Thermichen Ablaufsicherung

1 Cu-rør for vand til afløb - kogningssikring - For lukket anlæg.

2 Cu-rør for vandtilslutning - Termostatsikring for kogning.

3 Retur (kold). 1" RG.

4 Fremløb (varm). 1" RG.

5 Ekstra 1" RG.

6 Dykrør 1/2" RG.

DETAIL A

1 Copper pipe for water to drain

- boil protection - For closed systems

2 Copper pipe for water connection

- Thermostatic boil protection

3 Return (cold) 1” RG

4 Flow (hot) 1” RG

5 Extra 1” RG

6 1/2” RG submersible connector

20

462,1

2

7

Pos.

Nr.

Vare Nr. Titel Materiale Antal

1* 0008-0003 M6 x 20 rundhoved 1

2 0008-0040 M5 X 10 unbrako 2

3 0008-1201 M6x16 Sekskantskrue elforzinket 2

4* 0008-1402 Møtrik M6 el forz. 1

5 0020-3024 Rensesektion 1

6 0023-0075 Røgvender Støbt Skamolsten 1

7 1013-0396 Løftekrog til bundrist Blankt rundstål ø6 0004-1403 1

8 1523-0021 Heta Stensæt for SL-500 Saml. 1

9 1525-0001 Røgtud Tysk udgave 1

10 4530-1104 Compact Line aqua formontage Saml. 1

11 5005-0024 Låge Kompakt Line Saml. 1

510,5

96

Jupitervej 22

7620 Lemvig

Tlf. 96630600

Fax 96630616

Teg type

Teg

Godk

.

Bukke nummer

Mål uden tolerancer efter DS/ISO 2768-1-m

Buk 1

7108-0001.asm

Kompakt Line Aqua

7108-0001

Samlingstegning

16-06-2008

Vægt

Materiale type

92,6 kg

Solid Edge

Saml.

LSK

7108-0001.dft

Areal

11-08-2008

Buk 2

Skære nummer

Valseindstilling

Sidst opdateret

1 2

Valsetryk

Montere

Bearbejdning

3

10

145,6

20

8

5

1325,1 308

514,1

6

11

9

165,5

23-10-2009 0037-1162

Loading...

Loading...