Heta Inspire 40H, Inspire 40, Inspire 45H, Inspire 55, Inspire 55H Operating And Installation Instructions

...

1

OPERATING AND INSTALLATION

INSTRUCTIONS

DANISH DESIGN . DANISH QUALITY . DANISH PRODUCTION

www.heta.dk

EN

INSPIRE 40-40H / 45-45H / 55-55H STOVE

is exempt for use in smoke control areas when burning dry wood

2

Declaration of Performance EN

_____________________________________________________________________________

_________________________________________________________________________________________

In case of any change of the above-mentioned production type this Declaration of Performance becomes invalid.

Heta A/S, Jupitervej 22, DK - 7620 Lemvig, Tlf.: +45 96630600, www.heta.dk

Page 1 of 1

Re

gulation No. 305/2011

DOP-Inspire 40-40H-1858-2016-EN

1. Unique identification code of product-type

Wood stoves

2. Product name

Inspire 40 – Inspire 40H

3. Intended use or uses of the construction

produc

t, in accordance with the applicable

technical specification

Room heater burning solid fuel without hot water supply

4. Name and contact address of the

manufacturer

Heta A/S; Jupitervej 22

DK – 7620 Lemvig; heta@heta.dk

5. Where applicable, name and E-mail address

of authorized representative

6. System of assessment and verification of

constancy of performance of the constructio

n

product

System

3

7. Notified body relevant to the assessment and

verification of constancy of performance

Technologisk Institut DK 8000 Århus C

Notified body No. 1235

8. De

clared Performance:

Harmonized technical specification EN 13240:2001/A2:2004

Emission CO: 0,088%

Nox: 92 mg/Nm³

Dust 27 mg/Nm³

Dust(NS3058/3059) 2,86 g/kg

OGS (CEN/TS 15883) 123 mgC/Nm³ ved 13% O2

9. F

ire safety :

Reaction to fire A1

Test of fire safety in connection with the burning of

wood.

Approved

Distance to combustible materials

Rear:

Sides distance to combustible materials

Distance to floor from lower edge of the door

Furniture Distance:

Minimum distances i mm

120/190 mm

340/400 mm

170 mm

900 mm

1

0. safety:

Mechanical resistance (to carry a chimney / flue) Not tested (NPD)

Electrical safety NA

Surface temperature Approved

Cleanability No specification

1

1. Thermal output :

Nominal heat output 4 kW

Energy efficiency

81 %

Fluegas temperature at nominal heat output T 262 °C

Water heating output NA

Maximum water operating pressure NA

The performance of the product identified in points1 and 2 is in conformity with the declared performance in point 8. This

declaration of performance is issued under the sole responsibility of the ma nufacturer.

Signed on behalf the manufacturer of:

____________________________________

Lemvig 18-08-2016. Lars Kirk HOD

η

Declaration of Performance EN

_____________________________________________________________________________

_________________________________________________________________________________________

In case of any change of the above-mentioned production type this Declaration of Performance becomes invalid.

Heta A/S, Jupitervej 22, DK - 7620 Lemvig, Tlf.: +45 96630600, www.heta.dk

Page 1 of 1

Re

gulation No. 305/2011

DOP-Inspire 45-45H-1987-2016

1. Unique identification code of product-type

Wood stoves

2. Product name

Inspire 45 – Inspire 45H

3. Intended use or uses of the construction

produc

t, in accordance with the applicable

technical specification

Room heater burning solid fuel without hot water supply

4. Name and contact address of the

manufacturer

Heta A/S; Jupitervej 22

DK – 7620 Lemvig; heta@heta.dk

5. Where applicable, name and E-mail address

of authorized representative

6. System of assessment and verification of

constancy of performance of the constructio

n

product

System

3

7. Notified body relevant to the assessment and

verification of constancy of performance

Technologisk Institut DK 8000 Århus C

Notified body No. 1235

8. De

clared Performance:

Harmonized technical specification EN 13240:2001/A2:2004

Emission CO: 0,0786%

Nox: 115 mg/Nm³

Dust 8 mg/Nm³

Dust(NS3058/3059) 1,89 g/kg

OGS (CEN/TS 15883) 74 mgC/Nm³ ved 13% O2

9. F

ire safety :

Reaction to fire A1

Test of fire safety in connection with the burning of

wood.

Approved

Distance to combustible materials

Rear:

Sides distance to combustible materials

Distance to floor from lower edge of the door

Furniture Distance:

Minimum distances i mm

150/195 mm

300 mm

120 mm

860 mm

1

0. safety:

Mechanical resistance (to carry a chimney / flue) Not tested (NPD)

Electrical safety NA

Surface temperature Approved

Cleanability No specification

1

1. Thermal output :

Nominal heat output 4,5 kW

Energy efficiency

84 %

Fluegas temperature at nominal heat output T 221 °C

Water heating output NA

Maximum water operating pressure NA

The performance of the product identified in points1 and 2 is in conformity with the declared performance in point 8. This

declaration of performance is issued under the sole responsibility of the manufacturer.

S

igned on behalf the manufacturer of:

____________________________________

Lemvig 18-08-2016. Lars Kirk HOD

η

3

4

Declaration of Performance EN

_____________________________________________________________________________

_________________________________________________________________________________________

In case of any change of the above-mentioned production type this Declaration of Performance becomes invalid.

Heta A/S, Jupitervej 22, DK - 7620 Lemvig, Tlf.: +45 96630600, www.heta.dk

Page 1 of 1

Re

gulation No. 305/2011

DOP-Inspire 55-55H-3900-2016-EN

1. Unique identification code of product-type

Wood stoves

2. Product name

Inspire 55 – Inspire 55H

3. Intended use or uses of the construction

produc

t, in accordance with the applicable

technical specification

Room heater burning solid fuel without hot water supply

4. Name and contact address of the

manufacturer

Heta A/S; Jupitervej 22

DK – 7620 Lemvig; heta@heta.dk

5. Where applicable, name and E-mail address

of authorized representative

6. System of assessment and verification of

constancy of performance of the construction

product

System 3

7. Notified body relevant to the assessment and

verification of constancy of performance

RRF Rhein -Ruhr feuerstätten Prüfstelle GmbH. 46047 Oberhausen,

Deutschland

Notified body No. NB 1625

8. De

clared Performance:

Harmonized technical specification

EN 13240:2001/AC:2006

Emission CO: 0,1%

Nox: 130 mg/Nm³

Dust 28 mg/Nm³

Dust(NS3058/3059) 1,97 g/kg

OGS (CEN/TS 15883) 100 mgC/Nm³ ved 13% O2

9. F

ire safety :

Reaction to fire A1

Test of fire safety in connection with the burning of

wood.

Approved

Distance to combustible materials

Rear:

Sides distance to combustible materials

Distance to floor from lower edge of the door

Furniture Distance:

Minimum distances i mm

150/220 mm

420 mm

430 mm

1200 mm

1

0. safety:

Mechanical resistance (to carry a chimney / flue) Not tested (NPD)

Electrical safety NA

Surface temperature Approved

Cleanability No specification

1

1. Thermal output :

Nominal heat output 6 kW

Energy efficiency

80 %

Fluegas temperature at nominal heat output T 263 °C

Water heating output NA

Maximum water operating pressure

NA

The performance of the product identified in points1 and 2 is in conformity with the declared performance in point 8. This

declaration of performance is issued under the sole responsibility of the manufacturer.

S

igned on behalf the manufacturer of:

____________________________________

Lemvig 18-08-2016. Lars Kirk HOD

η

5

Congratulations on your new wood stove, we are confident that you will be more than

satisfied with your new Heta stove. Especially if you follow the following advice and

instructions.

Inspire 40 wood stove is approved according to EN 13240, NS 3058 and 3059. These

approvals, means that the wood stove insert meets a variety of specifications and requirements, ensuring it is made of quality materials, minimum environmental impact

and that it has an optimum fuel economy.

Operating Instructions

Contents

Declaration of Performance ............................................................ 2-4

Before installation ........................................................................... 6-7

1. Operating instructions ........................................................................ 8

1.1 Before using ....................................................................................... 8

1.2 First firing ........................................................................................... 8

1.3 Regulating the airflow ........................................................................ 8

1.4 Lighting the stove ............................................................................... 8

1.5 Refueling ............................................................................................ 8

1.6 Emptying the ash ............................................................................... 9

1.7 Reduced burning ................................................................................ 9

1.8 Risk of explosion ................................................................................ 9

1.9 Draft conditions in the chimney ....................................................... 10

1.10 Fuel ................................................................................................... 10

1.11 Operating problems ......................................................................... 11

1.12 Chimney fires ................................................................................... 12

1.13 Troubleshooting ............................................................................... 13

1.14 Maintenance ..................................................................................... 13

1.15 Cleaning the glass ............................................................................ 13

1.16 Maintenance schedule ..................................................................... 13

1.17 Cleaning/Replacing bicks after chimney sweeping ......................... 14

1.18 Parts Inspire 40-40H ........................................................................ 15

1.19 Parts Inspire 45-45H ........................................................................ 16

1.20 Parts Inspire 55-55H ........................................................................ 17

1.21 Stove data table EN 13240 .............................................................. 18

1.22 Garantee ........................................................................................... 18

2. Installation Instructions .................................................................... 19

Heta A/S

Jupitervej 22,

DK-7620 Lemvig

Phone: +45 9663 0600

E-mail: heta@heta.dk

Copyright © 2014

Heta is a registered

trademark of Heta A/S

14.07.2016

0037-1395 Version 1

Printed in Denmark

Subject to printing errors

and changes.

6

BEFORE INSTALLATION

Heta wood stoves are quality products, therefore, your first impression is very important! We have

a good logistics network, which transports Heta products with great care for our dealers. Nevertheless, when in transport or handling, damage of the often-heavy stoves can occur. It is important that

upon receipt check your Heta product completely and report any damage or defects to your dealer.

The packaging must be disposed of as follows:

Wood is untreated and able to burn in the stove.

Plastic and cardboard you can drop off at your local recycling center.

Unpacking the stove

Required tools are not supplied.

7

With your new wood stove you should find the following:

Operating /

Instruction manual

Heta glove

Data plate

Q.C. check

Standard V1,30

Flue collar set

5032 0026

Outlet cover

4012 0005

Flue collar

4025 0007

Ash pan handle

1020-0001

1

BETJENIN GS- OG

OPSTILLI NGSVEJLEDNI NG

DANSK DESIGN . DANSK KVALIT ET . DANS K PRODUKTION

www.heta.dk

DK

INSPIRE 40- 40H / 45-45 H / 55-55H B RÆNDEOVNE

8150-0000-DK

CE

Heta A/S Jupitervej 22

7620 Lemvig Denmark

Produktions år: 2016

DS/EN 13229/A2:2004/NS 3058/3059

Serie nr:

Lukket ildsted

For indbygning

Brændsel

Ydelse nominel:

Røggas Temp:

Middel Co emision:

Middel Co emision I Mg/Nm3:

Støv

Virkningsgrad:

Nox (mg/Nm³)

Støv (NS 3058/3059) samlet vægtet partikelemision

Afstand til sidevæg foran front af indsats (målt fra lågekant) 150 mm.

Ovnen er egnet til intermitterende brug

Anvend kun godkendt brændsel

Indsatsen må tilsluttes røggas samleledning.

Træ

4 kW

216 C°

0.049 %

8 mg/Nm3

1,65 g/kg

84%

111 mg/Nm³

DOP-Inspire 40 Indsats-2215-2016

Inspire 40 Indsats

Produkt beskrivelse

614 mg/Nm3

For opbygning i øvrigt se installationsvejledning.

2 x M8x25 0008-0206

2 x M6x30 0008-1118

2 x Washer 0008-0501

2 x Nuts 0008-1402

8

1. OPERATING INSTRUCTIONS

1.1 Before using

Before the wood stove is used make sure required installation conditions, are met. See page

1.2 First firing

Heta wood stoves are, treated with a heat-resistant coating, which hardens at a temperature

of about 250° C. This curing process will cause

some smoke and odor, so there should be sufficient ventilation in order to avoid the door seal

sticking to the stove during this curing process,

open the door every ten minutes during the first

two hours of the first firing.

1.3 Regulating the air flow

The stoves combustion air is regulated by means

of a handle below the firing door.

The air is full open to the right, closed to the left.

1.4 Lighting the stove

Place two pieces of wood on the bottom. Stack

kindling on top in layers with air between. Set

ting fire starter (bag, brick, paraffin) on the top,

now you are ready to light the fuel. The flames

must work from the top down

The use of lighter fluid, oils or any

liquid fuels is strictly forbidden

from use in a wood stove.

Fully open the combustion air into the start-up

air position and the door ajar (about one cm

open). Once the fire is established and the chimney is hot (after about ten minutes) closed door

and regulate the air into operating position. We

recommend, all of the first fuel is burned with

the combustion air fully open in the operating

position. This ensures the stove and chimney

are thoroughly heated.

Startup/Lighting

Scan the code and select a language.

1.5 Refueling

Refueling of your stove should be done while

there is still a good layer of embers. Distributethe embers with the majority of them to the front.

Place pieces of wood equivalent to about 1 kg

on top of the embers perpendicular to the door.

Now open the combustion air completely. If the

stove and/or chimney cools down too much, it

Baffle Plate

Air regulating handle

Stove door

1

3

4

Shaking

gratehandle

Ash pan

2

Closed

Open

Log

retainer

40-40H

45-45H

9

may be necessary to use the start-up air and

possibly have the door ajar.

The wood will then ignite within a very short time

(Typically 1 to 3 minutes). Once the fuel is Ignited

.

Close the door and regulate the air back to operating air. When the fire is well established, you

can now regulate the operating air to the desired

combustion level.

Rated output (see DOP of page 2) measured

when the combustion air is about 80% open.

Ensure when refueling that the wood is not too

close, it will cause poorer combustion, less heat

out-put and lower efficiency.

The fuel load, must be maintained below the top

series of air holes and within the outer vent in

each side. Fig. 5

When refueling be careful to place

the fuel into the combustion

chamber gently, (use the provided glove).

By not doing so you risk cracking or

breaking the vermiculite.

If there is reduced draft in the chimney, we recommend opening a window at stoking. This will

give better ventilation to the room and more oxygen for combustion.

1.6 Emptying the ash

By using the shaker grate, it rotates back and

forth so the ash falls through the holes and into

the ashtray, see Fig. 6. It is advantageous to

leave a layer of ash in the bottom of the combustion chamber on top of the grate as insulation.

For emptying the ash pan - use the supplied

handles 1020-0001 use of the ashtray tool, see

Fig. 7.

It is an advantage for the next firing to leave a

layer of ash lying in the bottom of the firebox.

Be careful when emptying the

ashes out. There can be hot embers

left for a long time.

1.7 Reduced burning

The stove is, designed for intermittent use.

It is important to maintain the layer of hot em-

bers. Lower heat out-put occurs when no flames

come from the tree, when it is becomes glowing

charcoal.

If you are looking for less heat out-put, achieve

this by fueling with smaller volumes of wood and

a lower operating air. You may not completely

close the operating air during firing.

Be aware that the stove will naturally soot if the

operating air is too low. This is not good for the

environment. There is also a risk for the glass,

t

he chimney and other parts will become sooted.

By a combination of the above and possibly

burning damp wood. Can lead to high levels of

soot that it becomes sticky. Causing the sealing

of the door to tear off when opening the door

the next day.

1.8 Explosion!!!

It is very important never to leave

The stove after start up or refueling,

before the fire is established.

(Typically 1 to 3 minutes)

Explosion can occur if filled with too much fuel

in the stove, the production of large volumes of

Maximum

wood filling

5

Vermiculite

(stone)

6

7

1020-0001-

Combustion

air

Combustion

air

6

10

gas, which can explode if the air supply becomes too low.

Warning!

One must always use cation around

the stove seen, as it gets very warm

during use. (In excess of 90° C).

Children should avoid contact with the stove.

Setting up a fence if you have small children may

be necessary.

Do not place flammable objects like drying racks,

furniture, curtains too close to the stove.

1.9 Draft conditions

and the chimney

Poor draft will not allow the stove to burn, as it

should. The glass can soot, requires cleaning of

the chimney more often, smoke can escape out

when the door is open and it gives poor fuel efficiency. Leading to unnecessary polluting of the

environment.

Good draft will allow the stove to achieve optimal combustion and the highest possible efficiency. Heta wood stoves are constructed so

that it itself provides an optimal blend of combustion air. This provides a high efficiency/heat,

clean glass and low environmental impact.

Minimum chimney draft for

Inspire 40-40H: 13

pascal

, Inspire 45-45H: 12

pascal

and Inspire 55-55H: 12

pascal

.

It is the draft that the stove has been tested and

approved on. The minimum draft is necessary

to provide clean burning, beautiful flame picture, as well as achieving the rated efficiency.

There is a risk of smoke escaping into the room

if the door is opened during vigorous firing, or if

there is a lack of air supply to the room, for ex. if

an extraction fan is in use.

Flue gas temperature at the rated output is for

Inspire 40-45H 263°C, relative to

20°C

Inspire 45-45H 221°C, relative to

20°C

Inspire 55-55H 263°C, relative to

20°C.

Flue gas flow is:

Inspire 40-40H: 3,7 g/sec.

Inspire 45-45H: 4,1 g/sec.

Inspire 55-55H: 5,7 g/sec.

The chimney height and diameter, as well as

the temperature difference between the flue gas

and outside temperature generates the chimney

draft. Chimney insulation is therefore important

as new efficient stoves create lower flue temperatures. Wind and weather conditions also influence draft, in some cases it may be disadvantageous wind direction, combined with the

position of the chimney can cause negative draft

(it blows through the chimney), causing smoke

escape from the stove.

Before using after a long period of inactivity,

check that the chimney is free for any blockages. (soot build-up, bird nests, leaves etc.).

Reduced draft can occur when:

• The temperature difference is too small

between smoke gasses and outdoor

temperature, for ex. poorly insulated chimney

• To short of a chimney

• The outside temperature is high, and indoor

temperature is low f. ex. in summer

• False air in the chimney

• Chimney is blocked

• Air tight house (lack of combustion air supply)

• Poorly placed chimney for the surroundings,

for ex. the ridge and trees may cause

turbulence

Good draft occurs when:

• The difference in temperature in the chimney

(warmer) and outside temperature (colder)

• It is clear weather

• The chimney has the right height min 4 meters

above the stove, and clear of the roof ridge

1.10 Fuel

Your new stove is EN approved for firing with

wood fuel. You must therefore only burn clean,

dry wood in your stove. Never use your stove

to burn driftwood, as this may contain a lot of

salt which can damage both the stove and the

11

chimney. Similarly, you must not fire your stove

with refuse, painted wood, pressure-impregnated wood or chipboard, as these materials can

emit poisonous fumes and smoke.

Correct firing using well seasoned wood provides optimal heat output and maximum efficiency. At the same time, correct firing prevents

environmental damage in the form of smoke

emissions and reduces the risk of chimney fires.

If the wood is damp and inadequately seasoned,

a large proportion of the energy in the fuel will

be used to vaporize the water, and this will all

disappear up the chimney. Thus, it is important

to use dry, well seasoned wood, i.e. wood with a

moisture content of less than 20 %. Achieve this

by storing the wood for 1–2 years before use.

Pieces of firewood with a diameter of more than

10 cm should be split before before storing. The

pieces of firewood should be of an appropriate

length (approx. 19-25 cm) so that they can lie

flat on the bed of embers.

If you store your wood outdoors, it is best to

cover it.

Examples of fuel values

for different woods and their typical densities

per cubic meter, specified for 100% wood with

a moisture content of 18%.

Wood kg/m3Wood kg/m

3

Beech 710 Alder 540

Ash 700 Scotch pine 520

Elm 690 Larch 520

Maple 660 Lime 510

Birch 620 Spruce 450

Mountain pine 600 Poplar 450

Willow 560

It is advised not to use oil-containing woods

like teak tree and mahogany, as this can cause damage to the glass.

Heating value in wood

You have to use about 2.4 kg normal wood to

replace one litre of heating oil. All woods have

almost the same heating value per kg, which is

about 5.27 kW/hour for absolute dry wood.

Wood with a moistness of 18% has a efficiency

of about 4.18 kW / hour per kg, and one litre

heating oil contains about 10 kW / hour.

CO2 release

At combustion 1000 litres of heating oil forms

3.171 tons CO2. As wood is a CO2 neutral heat/

energy source, you save the environment about

1.3 kg CO2 every time you have used 1 kg normal

wood.

1.11 Operational problems

The chimney must be swept at least once a

year, we recommend the use of a NACS (national association of chimney sweeps) registered

chimney sweep.

In the event of smoke or malodorous fumes are

being produced, you must first check to see

whether the chimney is blocked.

The chimney must, of course, always provide

the minimum draft necessary to ensure that it is

possible to regulate the fire. Please note, however, that chimney draft is dependent on the

weather conditions. In high winds, the draft can

become so powerful that it may be necessary to

fit a damper in the flue gas pipe to regulate the

draft.

When cleaning the chimney, soot and other

deposits may come to fall on the baffle plate,

remove and clean it. In cases where the wood

burns too quickly, this may be due to excessive

chimney draft. You should also check to make

sure that the door seal and ash pan seal is intact

and correctly fitting.

If the stove it generating too little heat, this may

be because you are firing with wet wood. In this

case, much of the heating energy is used to dry

the wood, resulting in poor efficiency, potentially damaging the vermiculite and an increased

risk of soot deposits in the chimney.

1.12 Chimney fire

In case of a chimney fire, which often results from

incorrect operation/maintenance or prolonged

use of damp wood, close the door and the air

supply completely, to help slow/smother the fire.

Call the fire department.

12

1.13 Troubleshooting table

Fault Cause Troubleshooting Solution

Lighting problems. When the

stove is cold, smoke seeps

into the room. Once the combustion chamber has heated

up, the stove burns well.

Inadequate chimney draft.

The chimney only has

sufficient draft when it is hot.

You can test using a lighter whether

flame is drawn into the combustion

chamber.

Improve the chimney.

The stove burns poorly after

the warm-up phase,

and the

glass slowly soots up.

Soot in the flue pipe. Check the flue pipe regularly, as the

problem arises slowly.

Clean regularly, and limit the use

of horizontal flue pipes. Do not use

firewood which generates large

quantities of ash.

Inadequate chimney draft.

The fault usually already occurs during

lighting. Measure the chimney draft

.

Improve the chimney draft.

Insufficient air supply. Check the air supply. Read the operating instructions and

instruct all users.

Damp wood. Use clean, dry wood with a maximum

moisture content of 20%.

Firewood should ideally be dried for

at least one year after splitting.

Firewood pieces too large. The optimum size is a length of 25 cm

and max. diameter of 10 cm.

Use smaller pieces of firewood.

Insufficient air supply to the

room. Range hoods, airtight

windows, etc.

Ensure there is sufficient fresh air

supply, open a window, check the

outdoor air supply.

Depending on the cause, windows

must be opened or the outdoor air

connection cleaned.

Insufficient air supply to the

room. Range hoods, airtight

windows, etc

Ensure there is sufficient fresh air

supply, open a window, check the

outdoor air supply.

Depending on the cause, windows

must be opened or the outdoor air

connection cleaned.

The vermiculite in the

combustion chamber is

becoming very worn.

Wood and flue gases wear

down the vermiculite.

Investigate whether the wear is

normal.

Normal wear and minor cracks are of

no significance. It should be replaced

when the steel of the combustion

chamber is visible.

Too rapid combustion. Too much chimney draft. T

o test, you can open the cleaning

hatch, but remember to close it again.

Measure the chimney draft and install

a damper in the flue pipe if necessary.

The door or ash pan/drawer

seal is defective.

While cold, close a piece of paper in

the door – the seal should hold the

paper gently in place so it does not

fall out by itself. Normal wear.

Replace the seal.

The vermiculite in the

combustion chamber is

cracked.

Shocks or impacts while

adding firewood.

Normal wear Cracks only have cosmetic signifi-

cance. Replace when the steel of the

combustion chamber is visible.

Steel surfaces in the

combustion chamber

have oxidised.

The temperature in the

combustion chamber is

too high.

Unsuitable fuel is being used (such as

coal). Check the quantity of firewood

being used, read the operating

instructions.

If there are clear cracks or weaknesses in the stove body, it must be

replaced.

The stove whistles Too much chimney draft To test, you can open the cleaning

hatch, but remember to close it again.

Install a damper.

The stove 'clunks' Usually due to tension in the

metal plates.

Generally only occurs while heating

up and cooling down.

Adjust the metal plates.

The stove ticks Normal expansion and

contraction due to

temperature changes.

A normal sound. Ensure that the temperature in the

combustion chamber is as constant

as possible.

The stove creaks. The temperature in the com-

bustion chamber is too high.

Use less firewood. Also check the seal

in the ash pan/drawer.

See the operating instructions.

The stove smells.

The surface is steaming.

The paint on the stove surace is not yet fully hardened.

See the operating instructions

regarding the first firing.

Ensure there is sufficient ventilation.

Condensation in the

combustionchamber.

Moisture in the vermiculite. C

heck the condition of the vermiculite.

Evaporates by itself after the stove has

been lit a few times.

Damp wood. Measure the moisture content. Use dry firewood.

Condensation from the flue

pipe.

The pipe is too long or the

chimney is too cold.

Check the flue pipe's length and heat

loss.

Improve the flue pipe, insulate the

chimney.

Damp wood Measure the moisture content. Use dry firewood.

13

1.14 Maintenance

The surface of the stove is treated with a heatresistant paint. The stove should be cleaned

with a damp cloth.

Any damage to the surface in the form of chips

or scratches can be repaired using touch-up

paint, which is available in spray cans.

1.15 Cleaning the glass

Incorrect firing, for example using wet wood,

can result in the viewing window becoming

covered in soot. This soot can be easily and

effectively removed by using proprietary stove

glass cleaner.

Stove Owner

Qualified

Technicia

Maintenance / Period

Before

Autum

Daily

2-3

days

30

days

60-90

days

1st Year 2st Year

Cleaning the chimney (see. Chimney)

C

Cleaning the chimney and stove

C C

Cleaning the stoves firebox

C VI C

Cleaning combustion air intake

C C

Cleaning ash bucket (small)

C VI VI

Cleaning ash bucket 8 Liter

C VI C

Cleaning of the firebox

C VI C

Checking / switch, gasket for door

C/S VI C/S

Checking / changing, gasket for glass

C/S VI C/S

Checking / switch, gasket for ashpan

C/S VI C/S

Checking / changing gasket for flue pipe

C/S VI C/S

Checking / changing vermiculite

C/S VI C/S

Lubricate hinges

L VI L

Lubricate lock

L VI L

1.16 Diagram for the maintenance

For the lubricant used a heat-resistant product. (300c)

C = Cleaning

C/S = Checking /Switch

L = Lubricate

VI = Visual Inspection, pos. cleaning/replacing/adjusting

14

1.17 Cleaning after sweeping

or before replacing vermiculite stones

Note: it may be necessary to clean/vaccum the holes and air ducts behind the rear stone

Order of removing Fire bricks.

Replace in reverse order. Starting with Fig. 6.

1

5

6

7

2

3

5 6

7

7

1

4

1

5

4

7

6

4

3

2

3

2

Inspire 40-40H + 45-45H

Inspire 55-55H

Pos. No. Name Qty.

1 5013-0008 Handle 1

2 5013-0009 Set of glass clips 1

3 0021-0053 Glass 1

4 4005-0042 Door, with glass tape 1

5 0008-9086 Hinge Pin 2

6 0023-3013 Glass seal 3x8 mm 1.3 m

7 0023-3008 Door seal ø12 1.5 m

8 1020-0001 Handle for ash pan 1

9 1518-0091 Ash pan 1

10 0030-0020 Shaking grate 1

Pos. No. Name Qty.

11 0030-0201 Shaking grate, Ø195 mm 1

12 0015-2013 Shaking grate handle 1

13 1019-0026 Log retainer 1

14 0023-0150 Baffle plate 1

15 0023-0153 Left stone 1

16 0023-0152 Right stone 1

17 0023-0177 Left back stone 1

18 0023-0178 Right back stone 1

19 0023-0154 Bottom stone 2

20 5032-0026 Flue collar set 1

4 -

- 5 x2

-7

-6

- 1

- 9

3 -

2 x4

- 8

11-

-12

-10

13 -

14 -

15 -

17-

19

18

- 16

20-

15

1.18 Parts Inspire 40-40H Stove

16

1.19 Parts Inspire 45-45H Stove

Pos. No. Name Qty.

1 5013-0008 Handle 1

2 5013-0009 Set of glass clips 1

3 0021-0053 Glass 1

4 4005-0042 Door, with glass tape 1

5 0008-9086 Hinge Pin 2

6 0023-3013 Glass seal 3x8 mm 1.3 m

7 0023-3008 Door seal ø12 1.72 m

8 0023-3008 Door seal ø12 0,4 m

9 1020-0001 Handle for ash pan 1

10 1518-0091 Ash pan 1

11 0030-0020 Shaking grate 1

Pos. No. Name Qty.

12 0030-0201 Shaking grate, Ø195 mm 1

13 0015-2013 Shaking grate handle 1

14 1019-0026 Log retainer 1

15 0023-0150 Baffle plate 1

16 0023-0153 Left stone 1

17 0023-0152 Right stone 1

18 0023-0177 Left back stone 1

19 0023-0178 Right back stone 1

20 0023-0154 Bottom stone 2

21 5032-0026 Flue collar set 1

4 -

- 5 x2

7-

6 -

- 1

-9

3 -

-2 x4

-14

- 11

- 21

- 10

13 -

15 -

16 -

18 -

- 20 -

19 -

- 17

12-

8 -

17

1.20 Parts Inspire 55-55H Stove

Pos. No. Name Qty.

1 5013-0008 Handle 1

2 5013-0009 Set of glass clips 1

3 0021-0030 Glass 1

4 4005-0047 Door, with glass tape 1

5 0008-9086 Hinge Pin 2

6 0023-3013 Glass seal 3x8 mm 1.55 m

7 0023-3008 Door seal ø12 1.88 m

8 0023-3008 Door seal ø12 0,52 m

9 1020-0001 Handle for ash pan 1

10 1518-0106 Ash pan 1

11 0030-0020 Shaking grate 1

Pos. No. Name Qty.

12 0030-0201 Shaking grate, Ø195 mm 1

13 0015-2013 Shaking grate handle 1

14 1027-0417 Baffe support 1

15 0023-0170 Baffle plate 1

16 0023-0173 Left stone 1

17 0023-0172 Right stone 1

18 0023-0171 Left back stone 1

19 0023-0175 Right back stone 1

20 0023-0174 Bottom stone 2

21 5032-0026 Flue collar set 1

4 -

- 5 x2

7-

6 -

- 1

-9

3 -

-2 x4

-14

- 11

- 21

- 10

13 -

15 -

16 -

18 -

- 20 -

19 -

- 17

12-

8 -

18

1.21 Stove data table in accordance with en 13240 testing

Tested as a freestanding oven and with uninsulated flue

Stove tyoe

Inspire

Nominal

fluegas

tempera-

ture

C°

FluemmFuel

volume

kg

Draft

min.

mbar

Nominal

output

tested

kW

Actual

efficiency

%

Distance to flamable materials i mm Stove

weight

kg

at the

sides

Door bottom

to combustible floor

rear the

stove

to

furnitures

Inspire 40-40H

263

ø120/

ø150

1,3

0,13

4,5 81

340*/

400

170

120*/

190

900

74/

91

Inspire 45-45H

221

ø120/

ø150

1,3

0,12

4,9 84 300 120

150*/

195

860

80/

104

Inspire 55-55H

263

ø120/

ø150

1,5

0,12

6,3 80 420 430

150*/

220 1200

108/

131

* Installed with an insulated flue.

The nominal output is the output to which the stove has been tested.

The test was carried out with the combustion air 65%.

1.21 Guarantee

Heta wood stoves, subjected to a strict quality

control during production and before delivery to

the dealer.

Therefore, the stoves guarantee is

FOR FIVE YEARS

Against defects in manufacturing

The guarantee does not cover:

Wearing parts / fragile parts such as:

- Vermiculite stones in the combustion

chamber, glass, seals and the casted bottom

or shaking grate.

- Damage caused by improper use.

- Transportation costs for warranty repair.

- Assembly / disassembly of warranty repair.

Should you have cause to make a complaint,

please quote our invoice no.

Warning

Any unauthorized alterations to the

stove and the use of non-original

parts will void the warranty.

19

Installation Instructions

Contents

2. Installation instructions ..................................................................... 20

2.1 Distance requirements ...................................................................... 20

2.2 Floor .................................................................................................. 20

2.3 Chimney connection ......................................................................... 20

2.4 Combustion air and ventilation ........................................................ 21

2.5 Stovedrawings/measurments ............................................................22

2.6 Clearances for installation - EN 13240 40-45-55 .............................. 23

2.7 Clearances for installation - EN 13240 40H-45H-55H .......................24

2.8 Mounting the flue collar ..................................................................... 25

2.9 Changing to a back flue outlet .......................................................... 25

3. Data plate .......................................................................................... 26

4. Appendix A ........................................................................................ 27

Remember

The stove and chimney installation, must comply with

local regulations, including those referring to national

and European standards.

20

2. Installation instructions

The stove installation must be in accordance

with national, European and possibly local regulations. You must follow local regulations with

regard to installation of chimney and connection

to the chimney. We recommend that you let a

professional Heta dealer install the stove. Alternatively, you can ask the local chimney sweep

before installation. Be aware that it is always the

owner himself who has responsibility for ensuring that applicable rules are complied with.

A modern stove places heavy demands on the

chimney due to the high efficiency. It may be

necessary to enhance or even replace an old

chimney.

Remember

1. Always ensure free access to any cleaning

doors in a chimney.

2. Always ensure ample fresh air to the room.

3. Exhaust/extraction fans in the house can reduce or create negative draft in the chimney.

Reduced draft can lead to the stove having

a

dverse combustion properties. It may result

in smoke coming out of the stove when the

door is open. A negative draft due to an

exhaust/extraction fan can cause the chimney to work in reverse, drawing smoke into

the house because of the fan.

4. Any air vents must not be covered.

2.1 Distance Provisions

There is a difference between installation next

to

flammable wall or non-flammable wall. If the wall

is made of non-flammable material, the stove

in

principle may be placed flush against it.

We recommend a minimum of 5 cm to facilitate

air circulation around the stove.

The minimum distance to combustibles can be

found on the model plate provided with the stove or on page 18 of this manual.

Pay special attention to the distance to flammable floor, which is also applicable, although there

is a steel/glass plate on the floor. The floor must

be constructed of f. eg. concrete, tile or similar

non-combustibles up to 170mm valid from the

bottom edge of the stoking door of the stove.

170 mm for Inspire 40-40H,

120 mm for Inspire 45-45H,

430 mm for Inspire 55-55H

2.2 Floor

You must ensure that the floor can support the

weight of the stove and a top-mounted steel

chimney.

In front of the fireplace insert, the substrate

must consist of non-combustible material, for

ex. Steel/glass plate, stone or tile floor. The size

of the non-combustible surface must follow the

applicable national and local regulations. Protecting your floor from embers that may fall out

of the oven.

Distances see data table page 18.

Pay special attention to the distance from flam-

mable floor, which is also valid even if there are

a steel, glass, stone or tile over flammable materials. It is the floor itself, which must be nonflammable. (Concrete, tile or similar). These

stoves can be installed on a 12 mm non combustible hearth.

2.3 The chimney connection

The chimney opening must follow national and

local regulations. However, the area of the opening should never be less than 115 cm

2

, which

corresponds to a diameter of 121 mm. If a damper

is fitted in the flue gas pipe, there must always

be at least 20 cm

2

of free passage, even when

the damper is in its “closed” position.

If local regulations permit, two contained stoves

can be connected to the same chimney. However, you must abide by local regulations regarding the distance between the two connections.

The insert stove must never be connected to

a chimney that is linked to a gas fire stove.

Connection to a brick chimney

Brick a thimble into the chimney and seat the

flue gas pipe in this.

The thimble and flue gas pipe must not penetra-

An efficient stove makes high

demand on chimney

properties

– so always have your local

chimney sweep evaluate your

chimney.

21

te the chimney opening itself, but must be flush

with the inside of the chimney duct. Joins between brickwork, the thimble and flue gas pipe

m

ust be sealed with fireproof material and / or

beading

. Heta A/S stresses that it is of utmost

im

portance that this is done correctly with very

tight joints

. As mentioned earlier, we recommend

that setup and installation be left to a professional Heta dealer.

Connection to a steel chimney

When fitting a connection from a top outlet stove

directly to a steel chimney, we recommend fitting the chimney tube inside the flue gas spigot

so that any soot and condensation drops into

the stove itself rather than collecting on the exterior surface of the stove.

For connections to chimneys that are run through

ceilings, all national and local regulations regarding distance to flammable material must be followed. It is important that the chimney is fitted

with roof support so that the top panel of the

stove is not required to bear the entire weight

of the chimney (excessive weight may damage

the stove).

2.4

Combustion air and Ventilation

The insert stove is approved as a room air dependent insert stove in accordance with EN 13240.

All the combustion air in the inset stove comes

from the room in which it is fitted. However, by

connecting a sealed air inlet to the insert stove’s

air intake connector, the stove can be supplied

with external combustion air. In this respect, the

following requirements must be met:

• Only approved materials may be used from

the ventilation unit to the air inlet vent.

• The air inlet vent must be fitted correctly and

insulated to prevent formation of condensate.

The cross section of the vent and grille must

be at least 78 cm².

• If the vent leads out into the open air, please

note that the grille must be fitted with suitable

wind protection. There must be no risk that

the grille can get clogged by leaves, etc.

Ventilation

Adequate ventilation must be provided in accordance with building regulations (Doc J Oct

2010) especially when installing in newer build

properties when the stove is not going to be installed to an outside air supply.

The Inspire 40-40H, 45-45H and 55-55H has a

nominal output of less than 5kW and does not

need additional ventilation in older properties

where it will be ventilated

by natural leakage.

Houses built after 2008 where the air leakage

rate is less than than 5 m3 / hour / m2 then a ventilator equivalent to 550 mm2 per kW output will

be required (4.5 kW x 550 mm = 2475 mm2) unless the stove is connected to an outside fresh

air supply.

22

H

I

G

D

F

A

B

E

C

100

Type A B C D E F G H I

Inspire 40 113 460 467 367 190 596 160 585 106

Inspire 40H 113 460 737 367 460 866 430 855 377

Inspire 45 116 540 451 377 165 566 211 555 79

Inspire 45H 116 540 751 377 465 866 511 855 380

Inspire 55 130 652 451 403 165 566 212 555 79

Inspire 55H 130 652 806 403 520 922 567 910 434

F: Measurements to openings

2.5 Stovedrawings/measurments

23

Not combustible material

Combustible material

C

B

B

Min. 300

A

2.6 Clearances for installation EN 13 240 - Inspire 40-45-55

B B

C

A

A

BB

C

A

D

Min.

300

Snit A-A

A

B B

Min. 300

Snit B-B

The dimensions are the

minimum dimensions,

unless otherwise stated.

Srove

Minimum

dimensions i

mm

Distance to flamable materials

A

rear the

stove

B

at the

sides

C

door bottom to

combustible floor

D

to

furnitures

Inspire 40

120*/

190

340*/

400

170 900

Inspire 45

150*/

195

300 120 860

Inspire 55

150*/

220

420 430 1200

Clearances

- Insulated flue

* Installed with an insulated flue.

24

2.7 Clearances for installation EN 13 240 - Inspire 40H-45H-55H

B B

C

A

A

BB

D

C

A

Min.

300

Snit A-A

A

B B

Min. 300

Snit B-B

Not combustible material

Combustible material

- Insulated flue

The dimensions are the

minimum dimensions,

unless otherwise stated.

B

B

A

Stove

Minimum

dimensions i

mm

Distance to flamable materials

A

rear the

stove

B

at the

sides

C

door bottom to

combustible floor

D

to furnitures

Inspire 40H

120*/

190

340*/

400

170 900

Inspire 45H

150*/

195

300 120 860

Inspire 55H

150*/

220

420 430 1200

* Installed with an insulated flue.

Clearances

25

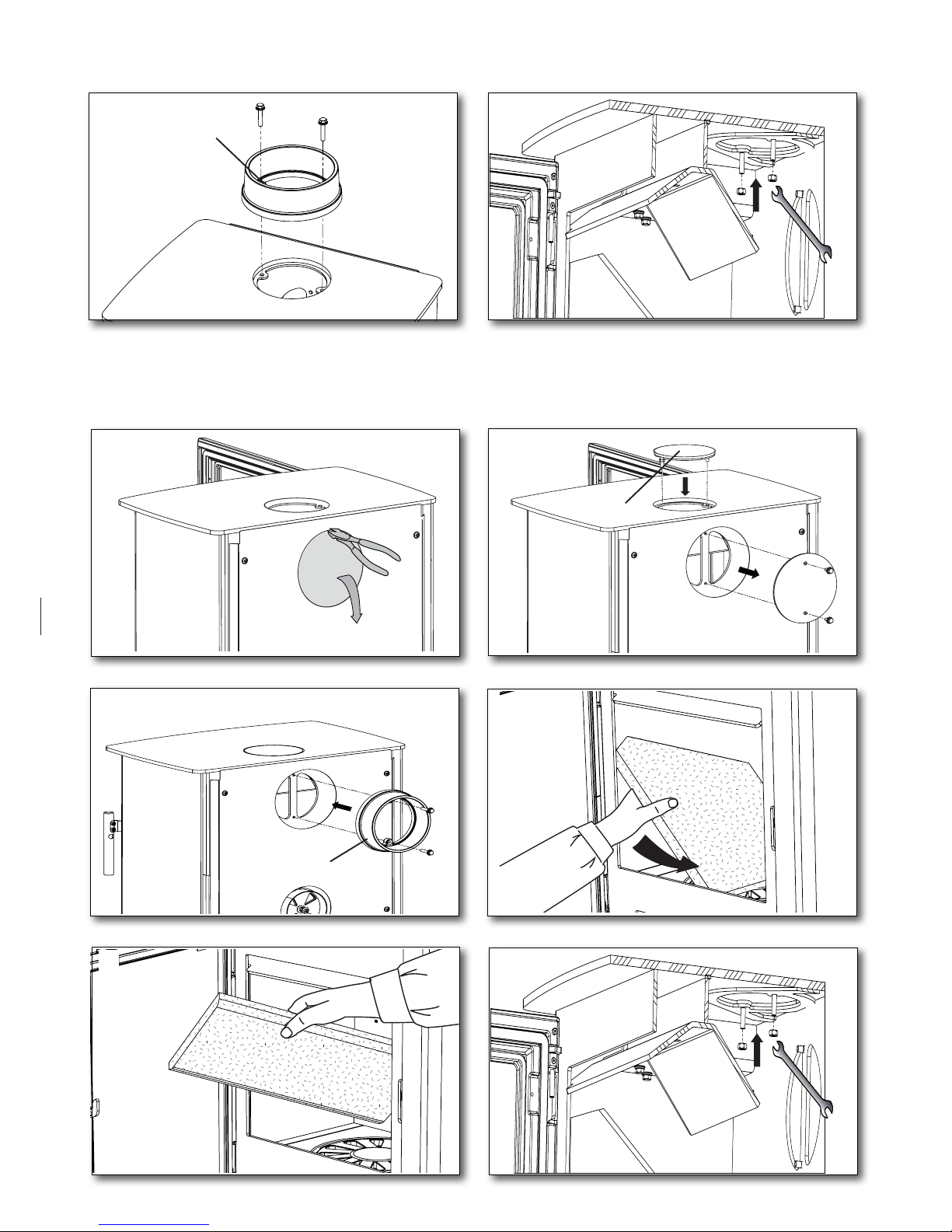

2.8 Mounting of the flue collar

2

3

5

4

6

2.9 Changing to a back outlet

1

4025-0007-

4025-0007-

2

1

4012-0004-

26

3. Data Plate

8050-0000-EN

CE

Heta A/S Jupitervej 22

7620 Lemvig Denmark

Production år:

2013

Product Description Serial No:

(Figures in parentheses are for insulated flue pipe)

Distance to combustible back wall

Distance to the side wall (From the door edge) 150 mm

Distance from lower edge to the floor

Distance to combustible wall (furniture)

Emission of CO in combustion products:

Emission of CO in combustion products:

1103 Mg/Nm³

Flue gas temperature: 262 C°

Dust 27 mg/Nm3

Thermal output 4 kw

Engery efficiency: 81%

Dust (NS3058/3059) 2,86 g/kg

Fuel types Multifuel

Appliance is suitable for multiple chimney allocation.

Only use the permitted fuel.

read the instructions carefully

DOP-Inspire 40 -1858-2016

0,12%

170 mm

DS/EN 13240, AEA, NS 3058/3059

(120) 190 mm

(340) 400 mm

900 mm

Inspire 40 / 40H

Note your own number here

Inspire 40-40H

Inspire 45-45H

Inspire 55-55H

8052-0000-EN

CE

Heta A/S Jupitervej 22

7620 Lemvig Denmark

Producon år:

2013

Product Descripon Serial No:

(Figures in parentheses are for insulated flue pipe)

Distance to combusble back wall

Distance to the side wall (From the door edge) 150 mm

Distance from lower edge to the floor

Distance to combusble wall (furniture)

Emission of CO in combuson products:

Emission of CO in combuson products:

982Mg/Nm³

Flue gas temperature: 221 C°

Dust 13 mg/Nm3

Thermal output 4,5 kw

Engery efficiency: 84%

Dust (NS3058/3059) 2,24 g/kg

Fuel types Mulfuel

Appliance is suitable for mulple chimney allocaon.

Only use the permied fuel.

read the instrucons carefully

DOP-Inspire 40 -1987-2016

0,08%

120 mm

DS/EN 13240, AEA, NS 3058/3059

(150) 195 mm

300 mm

860 mm

Inspire 45 / 45H

8055-0000-EN

CE

Heta A/S Jupitervej 22

7620 Lemvig Denmark

Production år: 2013

Product Description Serial No:

(Figures in parentheses are for insulated flue pipe)

Distance to combustible back wall

Distance to the side wall (From the door edge) 150 mm

Distance from lower edge to the floor

Distance to combustible wall (furniture)

Emission of CO in combustion products:

Emission of CO in combustion products:

1250 Mg/Nm³

Flue gas temperature: 263 C°

Dust 28 mg/Nm3

Thermal output 6,3 kw

Engery efficiency: 80%

Dust (NS3058/3059) 2,80 g/kg

Fuel types Multifuel

Appliance is suitable for multiple chimney allocation.

Only use the permitted fuel.

read the instructions carefully

DOP-Inspire 55 -3900-2016

0,10%

430 mm

DS/EN 13240,:2001/A2:2004,AEA,NS 3058/3059

(150) 220 mm

420 mm

1200 mm

Inspire 55 / 55H

27

4. Appendix A

The Clean Air Act 1993 and Smoke Control

Areas Under the Clean Air Act local authorities

may declare the whole or part of the district of

the authority to be a smoke control area. It is

an offence to emit smoke from a chimney of a

building, from a furnace or from any fixed boiler

if located in a designated smoke control area. It

is also an offence to acquire an ”unauthorised

fuel” for use within a smoke control area unless

it is used in an ”exempt” appliance (”exempted”

from the controls which generally apply in the

smoke control area).

The Secretary of State for Environment, Food

and Rural Affairs has powers under the Act to

authorise smokeless fuels or exempt appliances for use in smoke control areas in England.

In Scotland and Wales this power rests with

Ministers in the devolved administrations for

those countries. Separate legislation, the Clean

Air (Northern Ireland) Order 1981, applies in

Northern Ireland. Therefore it is a requirement

that fuels burnt or obtained for use in smoke

control areas have been ”authorised” in Regulations and that appliances used to burn solid fuel

in those areas (other than ”authorised” fuels)

have been exempted by an Order made and signed

by the Secretary of State or Minister in the

devolved administrations.

The Inspire 40 have all been recommended as

suitable for use in smoke control areas when

burning dry wood logs.

Further information on the requirements of the

Clean Air Act can be found here: https://www.

gov.uk/ smoke-control-area-rules

Your local authority is responsible for implementing the Clean Air Act 1993 including designation and supervision of smoke control areas

and you can contact them for details of Clean

Air Act requirements.

28

Loading...

Loading...