Hestan KVL48 Installation manual

INDOOR COOKING

Vent Hood - Liner

KVL

Installation, Use and Care Manual

IF THE INFORMATION IN THIS MANUAL IS NOT FOLLOWED

EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING

PROPERTY DAMAGE, PERSONAL INJURY, OR DEATH.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

Installation and service must be performed by a qualified installer or service agency.

DO NOT REPAIR, REPLACE OR REMOVE ANY PART OF THE APPLIANCE UNLESS

SPECIFICALLY RECOMMENDED IN THE MANUAL. IMPROPER INSTALLATION,

SERVICE OR MAINTENANCE CAN CAUSE INJURY OR PROPERTY DAMAGE. REFER

TO THIS MANUAL FOR GUIDANCE. ALL OTHER SERVICING SHOULD BE DONE BY

A HESTAN AUTHORIZED SERVICE TECHNICIAN.

READ THESE INSTRUCTIONS CAREFULLY AND COMPLETELY BEFORE

INSTALLING OR USING YOUR APPLIANCE TO REDUCE THE RISK OF

FIRE, BURN HAZARD, OR OTHER INJURY. KEEP THIS MANUAL FOR

FUTURE REFERENCE.

SAFETY DEFINITIONS

THIS INDICATES THAT DEATH OR SERIOUS INJURY MAY OCCUR

AS A RESULT OF NOT OBSERVING THIS WARNING

THIS INDICATES THAT MINOR OR MODERATE INJURY MAY

OCCUR AS A RESULT OF NOT OBSERVING THIS WARNING.

THIS INDICATES THAT DAMAGE TO THE APPLIANCE OR

PROPERTY MAY OCCUR AS A RESULT OF NOT OBSERVING THIS

WARNING.

INSTALLER: LEAVE THIS MANUAL WITH THE OWNER OF THE APPLIANCE.

HOMEOWNER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Message from Hestan:

Hestan’s award-winning culinary innovations and purpose-built features reinvented

the restaurant kitchen and redefined culinary experience in some of America’s most

acclaimed restaurants. Hestan now takes this performance from the back of the

house and puts it front and center in yours. Thoughtfully designed and meticulously

built, Hestan will serve you beautifully for years to come.

Hestan is the only residential brand born from the dreams and demands of

professional chefs. From ranges to refrigeration, every detail is designed to deliver

the performance and reliability expected in a restaurant – now available for you.

We appreciate you choosing Hestan, and we promise to deliver the very best to you.

Welcome to Hestan

TABLE OF CONTENTS

1 SAFETY PRECAUTIONS - BEFORE YOU BEGIN

4 MODEL NUMBERS

4 RATING LABEL

5 REGULATORY / CODE REQUIREMENTS

5 USING THE VENTILATION SYSTEM

6 CLEANING AND MAINTENANCE

9 TROUBLESHOOTING

10 DUCTING DO’S AND DON’TS

11 INSTALLATION

16 VENT ACCESSORIES

17 PARTS / SERVICE

17 LIMITED WARRANTY

SAFETY PRECAUTIONS - BEFORE YOU BEGIN

EN

When properly cared for, your Hestan ventilation system will provide safe, reliable service for many

years. When using this ventilation system, basic safety practices must be followed as described in

the following pages.

IMPORTANT: Save these instructions for the local Utility Inspector’s use.

INSTALLER: Please leave these Installation Instructions with the owner.

OWNER: Please read these Instructions and save them for future reference.

ELECTRICAL SHOCK HAZARD

It is the responsibility of the user to have the appliance connected by a

licensed electrician in accordance with all applicable codes and standards,

including fire-related construction. See step 11 - “WIRING CONNECTION:”

on page14 for details.

ELECTRICAL SUPPLY AND GROUNDING

• This appliance must be grounded. See step 11 - “WIRING CONNECTION:” on page14 for

instructions.

• This appliance must be connected to 120 VAC Single Phase, 60 Hz, with a dedicated 20 amp

circuit.

• OWNER: Have the installer show you where the electric circuit breaker is located so you know

how to shut off the power to this appliance.

Suitable for use in covered outdoor applications when installed in a GFCI protected branch circuit.

©2019 Hestan Commercial Corporation

1

SAFETY PRECAUTIONS - BEFORE YOU BEGIN

GENERAL SAFETY PRECAUTIONS

(CONT.)

EN

When properly cared for, your Hestan ventilation liner has been designed to be a safe, reliable

ventilation system. Read all instructions carefully before using this ventilation system. When using

kitchen appliances, basic safety precautions must be followed.

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

a) Use this ventilation system only as intended by the manufacturer. If you have any questions,

contact the manufacturer.

b) Before servicing or cleaning unit, switch power off at service panel and lock the service

disconnecting means to prevent power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a prominent warning device, such as a

tag, to the service panel.

FOR GENERAL VENTILATING USE ONLY. DO NOT USE TO

EXHAUST HAZARDOUS OR EXPLOSIVE MATERIALS AND VAPORS.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a) Never leave burners or surface units unattended at high settings. Boilovers cause smoking and

greasy spillovers that may ignite. Heat oils slowly on low or medium settings.

b) Always turn hood ON when cooking at high heat or when flambéing food (i.e. Crepes Suzette,

Cherries Jubilee, Peppercorn Beef Flambé).

c) Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or filter.

d) Use proper pan size. Always use cookware appropriate for the size of the burner or surface

element.

TO REDUCE THE RISK OF INJURY TO PERSONS, IN THE EVENT

OF A RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING *:

a) SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal tray, then turn off the

burner. BE CAREFUL TO PREVENT BURNS. If the flames do not go out immediately,

EVACUATE AND CALL THE FIRE DEPARTMENT.

b) NEVER PICK UP A FLAMING PAN - You may be burned.

c) DO NOT USE WATER, including wet dish cloths or towels - a violent steam explosion will

result.

d) Use an extinguisher ONLY IF:

1. You have a Class ABC or Class K fire extinguisher and you already know how to operate it.

2. The fire is small and contained in the area where it started.

3. The fire department is being called.

4. You can fight the fire with your back to an exit.

2

* Based on “Kitchen Fire Safety Tips” published by NFPA

©2019 Hestan Commercial Corporation

SAFETY PRECAUTIONS - BEFORE YOU BEGIN

(CONT.)

BURN HAZARD

This ventilation system is intended for use with ranges or cooktops, which can get very hot during

operation. Observe the warnings and cautions for the cooking appliance.

This ventilation system should be serviced only by a Hestan authorized service technician. Contact

the nearest authorized service center for examination, repair or adjustment.

Do not repair or replace any part of the system unless specifically recommended. Refer service to

an authorized servicer.

Do not operate this ventilation system if it is not working properly or if it has been damaged, until

an authorized servicer has examined it.

Install or locate this ventilation system only in accordance with the Installation section of this

manual. Do not cover or block any openings on this ventilation system.

It is highly recommended that a suitable kitchen fire extinguisher (Class ABC or K) be readily

available and highly visible next to any cooking appliance.

SAFETY DURING CLEANING

EN

Clean only ventilation system parts listed in this manual, in the manner specified in this manual.

Note: the “ventilating fans” and “filter” in the previous warnings refer to the blower wheel(s),

blower housing(s), and blower shield(s). See “CLEANING” on page7 for parts identification

and cleaning instructions.

THIS MANUAL SHOULD REMAIN WITH THE HOMEOWNER FOR FUTURE REFERENCE.

©2019 Hestan Commercial Corporation

3

MODEL NUMBERS

MODEL NO. DESCRIPTION BLOWER PACKAGE

EN

KVL 30

KVL 36

KVL 42

KVL 48

KVL 54

30” Ventilation Liner 600 cfm Kitchen Ventilation System WM2L Dual

36” Ventilation Liner 600 cfm Kitchen Ventilation System WM2L Dual

42” Ventilation Liner 900 cfm Kitchen Ventilation System WM2L Dual + WM1L Single

48” Ventilation Liner 900 cfm Kitchen Ventilation System WM2L Dual + WM1L Single

54” Ventilation Liner 1200 cfm Kitchen Ventilation System Two WM2L Duals

RATINGS

Blower

Package

Amps

CFM

SP@0.0”*

Equivalent

CFM **

CFM

SP@0.1”*

CFM

SP@0.2”*

CFM

SP@0.3”*

Minimum

Round Duct

Size

WM2L Dual 2.9 600 900 531 480 430 8” (50 in.

WM2L Dual

+ WM1L

4.4 900 1350 804 725 655 AKVT6810:

10” (79 in.

Single

Two WM2L

Duals

5.8 1200 1800 1062 960 860 AKVT8812:

12” (113 in.

All units 115 VAC 60 Hz 1550 RPM

* Static Pressure in inches water column.

Sones

2

) 6.5

2

)

2

)

***

6.3

6.6

** When comparing the Hestan system with blower units made by other manufacturers, use the “Equivalent CFM”.

*** Ratings in accordance with the Standard Test Code by the Energy Systems Laboratory of the Texas Engineering

Experiment Station.

RATING LABEL

The rating label contains important information about your Hestan appliance such as the model and

serial number, electrical rating, and minimum installation clearances.

The rating label is located on the blower housing.

If service is necessary, contact Hestan Customer Care with the model and serial number information

shown on the label.

(model number)

(serial number)

Typical rating label

4

Rating label location

©2019 Hestan Commercial Corporation

REGULATORY / CODE REQUIREMENTS

Installation of this ventilation system must be made in accordance with local codes. In the absence

of local codes, this unit should be installed in accordance with the National Electrical Code and

local codes.

This appliance must be electrically grounded in accordance with local codes or in the absence of

local codes with the National Electrical Code

C22.1

.

ANSI/NFPA 70

, or Canadian Electrical code

CSA

USING THE VENTILATION SYSTEM

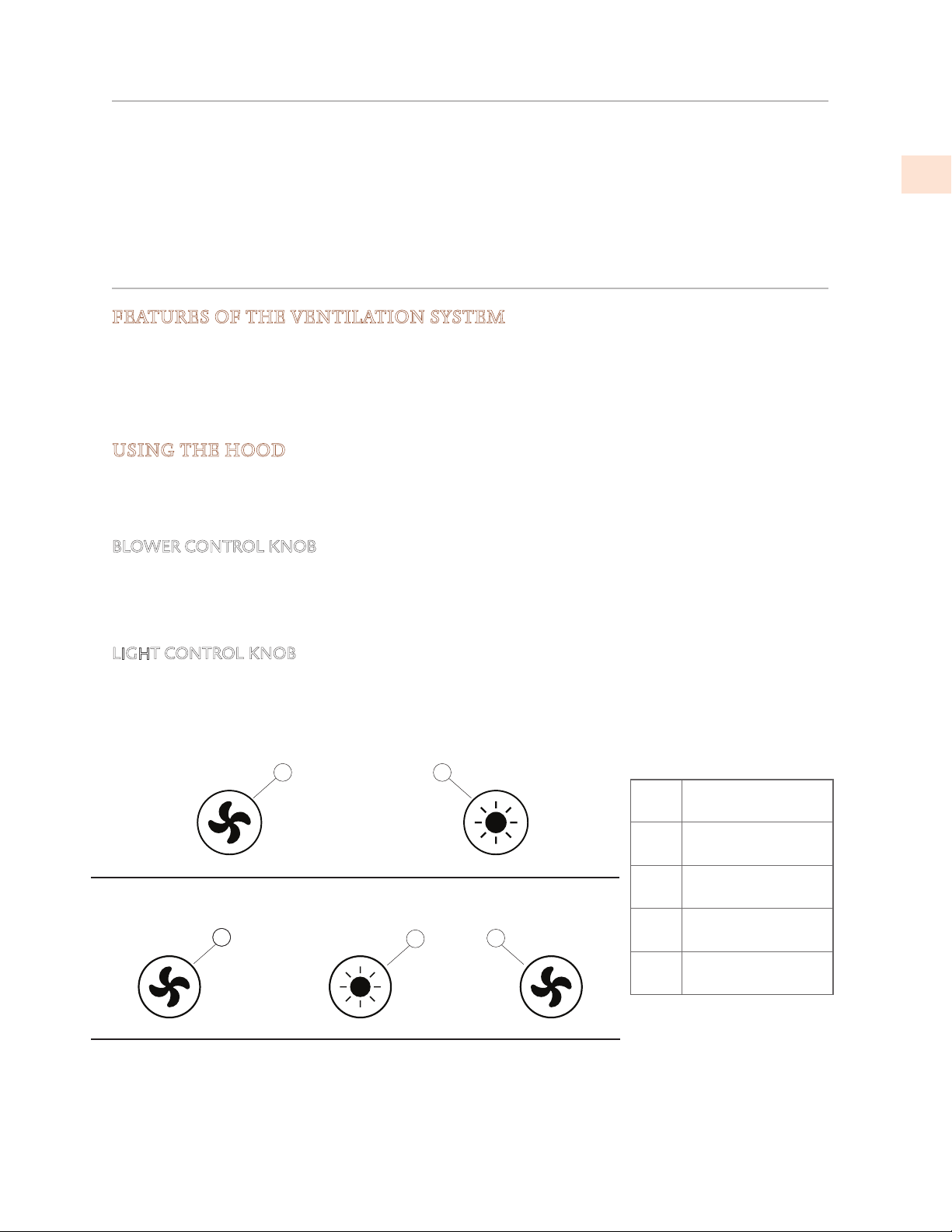

FEATURES OF THE VENTILATION SYSTEM

Speed controls are provided for the blower assembly. Two-blower systems will have one speed

control knob, while three- or four-blower systems will have two speed control knobs.

A control knob is provided for lighting intensity.

The controls layout will be similar to that shown below.

USING THE HOOD

The user can start with the a hood on the lowest setting, and then increase speed and/or turn

on additional blowers as required. Using the hood at high settings may increase heating or air

conditioning requirements and costs for the house.

EN

BLOWER CONTROL KNOB

To operate the blower(s), rotate the knob through the blower speed settings by turning it clockwise

(facing the knob).

Rotate the knob counter-clockwise to reduce the blower speed.

LIGHT CONTROL KNOB

To operate the lights, rotate the knob through the light intensity settings by turning it clockwise

(facing the knob). Rotate the knob counter-clockwise to dim the lights or turn them off.

Controls for two blowers

1

Controls for three and four blowers

3

2

Item Function

Blower control

1

Light control

2

Blower control

2

4

3

blowers 1 & 2

Blower control, blower

4

3 or blowers 3 & 4

©2019 Hestan Commercial Corporation

5

CLEANING AND MAINTENANCE

CLEANING THE VENTILATION SYSTEM

EN

Cleaning requirements depend completely on usage and environment. The more high-heat and/or

greasy cooking, the more often the hood and blower will need cleaning.

The grease tray and blower aren’t visible from the outside, so they must be removed for inspection.

After you’ve inspected the tray a few times over the course of six months or a year, you’ll be able to

set a cleaning schedule according to your usage pattern.

HOOD LINER

Wipe down the interior of the hood liner as needed with a soft cloth and warm soapy water (liquid

dish detergent is acceptable). Do not use acids, abrasives, strong detergents, solvents, or scouring

pads. Stainless steel should be treated with a quality stainless steel cleaner such as Stainless Steel

Magic®. Follow all label instructions. Do not polish across the grain or in circles.

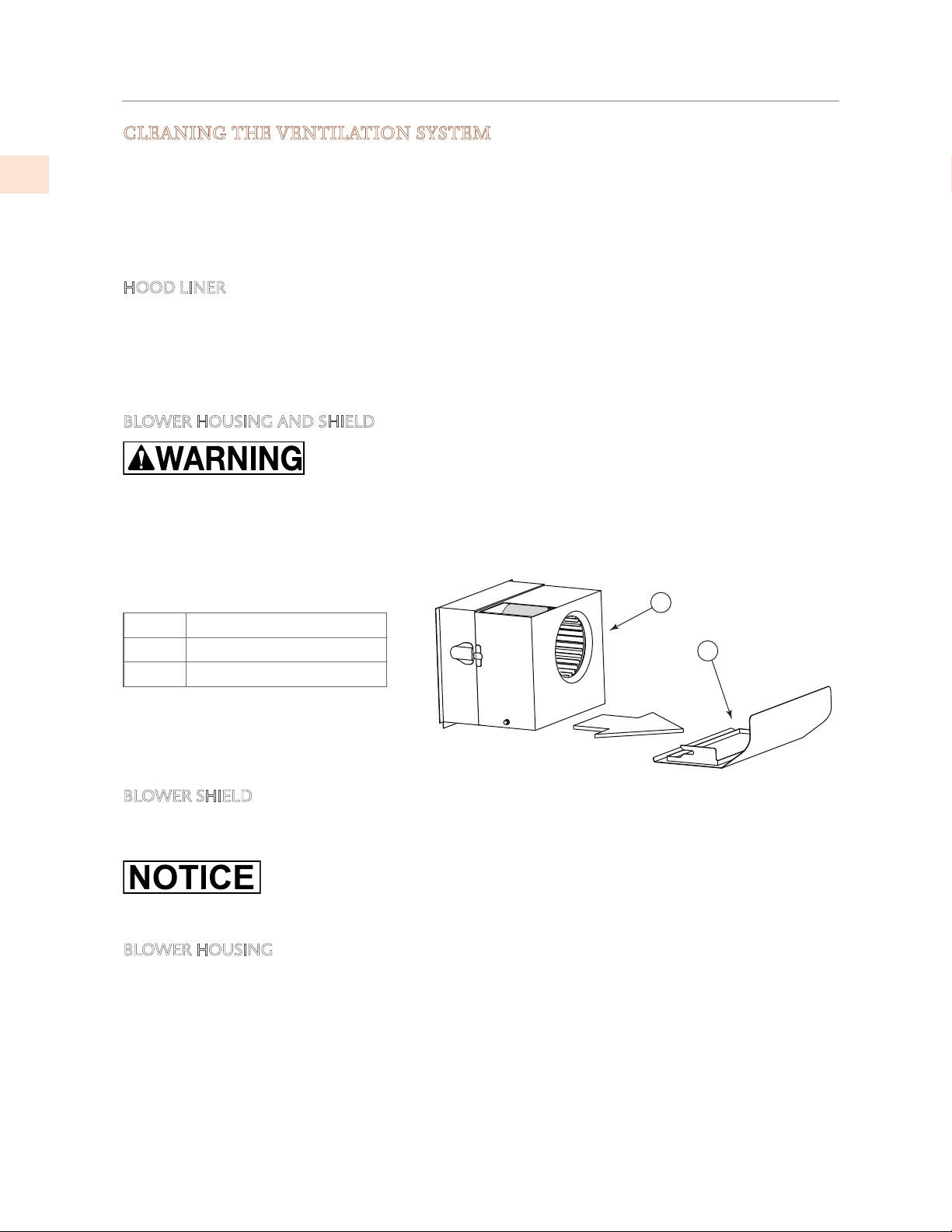

BLOWER HOUSING AND SHIELD

To reduce the risk of personal injury, be sure the power is turned off in

the hood before removing the shield(s) and blower housing(s).

The blower captures grease by-products in the blower housing(s) and blower shield(s). The blower

shields require more frequent cleaning than the blower housing but cooking usage determines how

often each item will need to be cleaned.

1

Item# Description

Blower housing with damper(s)

1

2

Blower shield

2

6

BLOWER SHIELD

The blower shields are easily removed for cleaning by pulling the blower shield(s) toward the front

of the hood.

Be careful to keep the tray level if the hood has been recently used and the

grease might still be warm.

Inspect and clean the shield. (Details follow)

BLOWER HOUSING

To remove the blower housing:

1. Unsnap two suitcase latches, one on each side of the housing.

2. Support the housing and pull it away from the blower base.

3. While pulling it back, gently “tip” it downward to clear the blower wheel(s).

©2019 Hestan Commercial Corporation

2

CLEANING AND MAINTENANCE

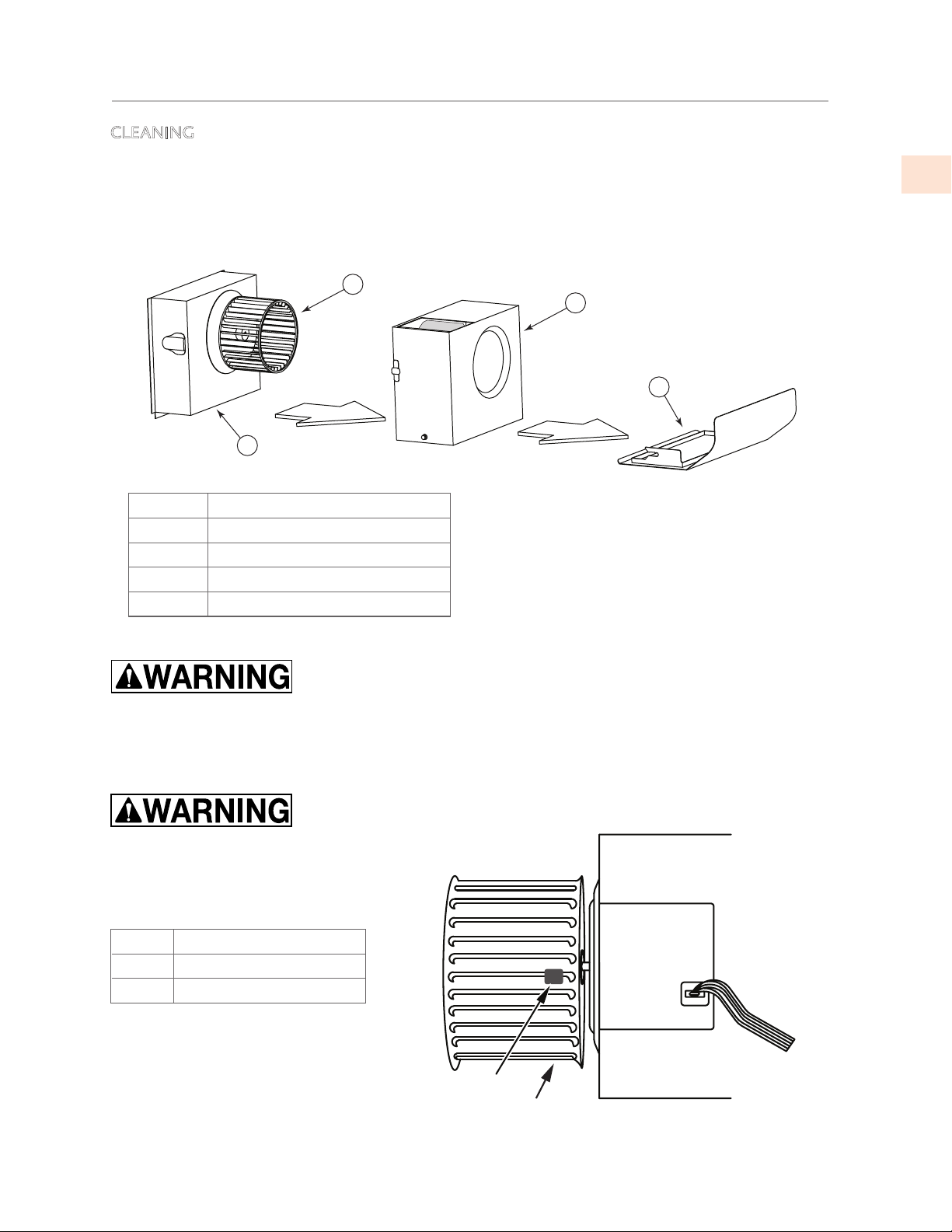

CLEANING

Clean the shield(s) and/or blower housing(s) in a sink of warm soapy water (liquid dish detergent)

and let soak for a few minutes. Wash with a sponge or dishcloth, rinse and let drain before

reinstalling. Alternatively, the blower housing(s) and blower shield(s) may be placed into a

dishwasher.

(CONT.)

2

3

4

1

EN

Item # Description

1

2

3

4

Regular cleaning of the blower housing should prevent grease accumulation on the blower wheel.

If grease build-up should occur, the blower wheel may easily be cleaned in place using a soft bristle

toothbrush and a common degreaser such as Formula 409®.

Item # Description

1

2

Motor housing

Wheel

Blower housing with damper(s)

Blower shield

To reduce the risk of personal injury, be sure the power is turned off in

the hood before removing the shield(s) and blower housing(s).

Take care not to move or lose the metal balancing clips that may be

affixed to the wheel.

Balancing clip

Blower wheel

1

©2019 Hestan Commercial Corporation

7

EN

CLEANING AND MAINTENANCE

BLOWER WHEEL REMOVAL

For instances where the blower wheel must be removed, follow the instructions below.

• Removing the blower wheel requires a 1/8” hex wrench. This may be obtained from your local

hardware store or tool supply.

The wheel is retained by a set screw on the side of the hub of the wheel that tightens up against a

“flat” spot on the motor shaft. (See illustration on previous page.)

1. Locate the set screw on the side of the hub of the wheel

2. Insert wrench through the blades of the blower wheel and into the set screw.

3. Loosen the set screw 1/2 turn counterclockwise.

(CONT.)

If the wheel is difficult to remove, the area where the motor shaft makes contact with the

blower wheel hub may need to be sprayed with a common penetrating oil such as WD-40

After allowing the penetrating oil to soak for a few minutes, push the blower wheel forward

slightly, then gently pull the blower wheel off the motor shaft.

• Use caution to avoid bending or distorting the blower wheel and take care not to move or lose

the metal balancing clips(1) that may be affixed to the wheel (2).

A soft bristle toothbrush with warm soapy water may be used to clean the blades, or soak the

blower wheel in warm soapy water.

BLOWER WHEEL INSTALLATION

When reinstalling the wheel onto the motor shaft, make sure the set screw makes direct contact

with the “flat spot” on the motor shaft.

1. Slide the blower wheel onto the motor shaft as far as it will go, making sure the back of the

blower wheel does not touch the motor mount screws protruding from the motor.

• If the motor is too far back, it will rub the motor mount screws, and if it is too far forward, it

will rub the inside of the blower housing.

2. Adjust the blower wheel slightly to find the correct front-to-rear location.

3. Tighten the set screw (clockwise) to lock the blower wheel in the correct position.

For hood liners that have more than one blower wheel, make sure that white

blower wheels are matched up with white motor rings, and black blower

wheels are matched up with black motor rings.

@

.

8

The hood will not perform properly if blower wheels and motors are mismatched.

©2019 Hestan Commercial Corporation

CLEANING AND MAINTENANCE

MOTOR REPLACEMENT

(CONT.)

To reduce the risk of personal injury, turn off power to the hood at the

breaker or the circuit disconnect before attempting to remove the

blower motor.

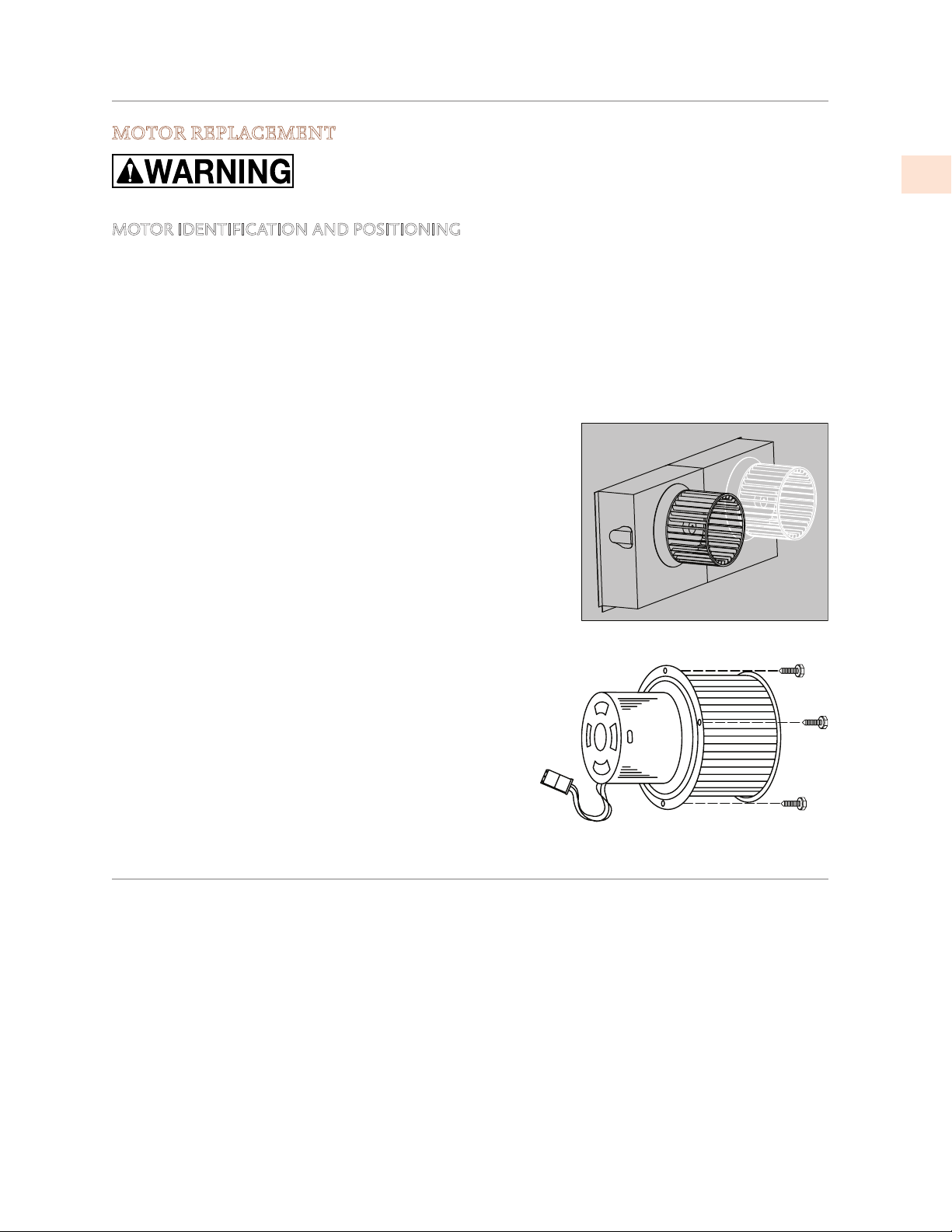

MOTOR IDENTIFICATION AND POSITIONING

Motors are color-coded; black and white motors have different rotations and must be installed in

the correct positions.

• Housings with a single blower use a white blower and wheel.

• Housings with two blowers use a white blower on the right and black on the left.

Make sure you have the correct motor in each housing position.

• If the replacement blower motor includes a blower wheel, then you can remove the motor and

wheel together. If you will re-use your existing wheel, then you may wish to remove the wheel

before removing the motor.

1. Remove the shield and blower housing as described in

“BLOWER WHEEL REMOVAL” on page8.

2. Use a ¼” nut driver to remove the three motor mount

screws that attach the motor to the hood.

3. Gently pull the motor forward and down.

4. Disconnect the wiring harness, remove the old motor.

EN

• To avoid damage to the blower wheel, you may wish to

install the motor and then install the wheel onto the motor.

5. Lift the new motor so you can connect the wiring

harness. Be sure to fully engage the electrical

connections and tighten the motor mount screws.

6. Check the blower wheel clearance and adjust

as needed, as described in “BLOWER WHEEL

INSTALLATION” on page8.

TROUBLESHOOTING

If the hood does not perform satisfactorily, check the following:

• Do the blowers run?

• Are the blower wheels installed on the correct motors? (black wheel on black motor, white

wheel on white motor)

• Are the motor and wheel assemblies installed in the correct locations?

• Check the damper doors in blower housing(s) - do they move/open freely?

• Check the dampers/vents to outside - do they open freely, with no obstructions?

• Check for damaged or obstructed ductwork.

©2019 Hestan Commercial Corporation

9

DUCTING DO’S AND DON’TS

GENERAL REQUIREMENTS

EN

Observe local codes regarding special duct requirements and placement of duct work against

combustibles.

• Using recommended transitions (see VENT ACCESSORIES) will ensure proper efficiency.

• Using recommended roof caps or wall louvers (see VENT ACCESSORIES) will ensure proper

efficiency.

• Use foil HVAC tape (not grey cloth duct tape) to seal all joints.

• The hood must be ducted to the outdoors without restrictions.

BLOWER REQUIREMENTS

The dual blower unit (WM2L, used in all systems) requires 8” round duct or equivalent (50 square

inches). The single blower unit (WM1L, used in addition to the dual blower unit in 900 CFM

systems) requires 6” round duct or equivalent (28 square inches).

COMBINED DUCT SIZE AFTER A TRANSITION

Single and Dual (WM1L & WM2L) combine to 10” round or equivalent 79 square inches using a

multi-blower transition such as AKVT6810 (Optional)

Two Duals (Two WM2Ls) combine to 12” round or equivalent 113 square inches using a multiblower transition such as AKVT8812 (Optional)

DUCTING REQUIREMENTS (DO’S AND DON’TS)

• NEVER reduce the duct size. When combining ducts together, the square inch area of

the outlet duct must be equal or greater than the total square inch area of the ducts being

combined.

• Only use smooth, galvanized, metal duct. Do not use flexible or corrugated duct. This type of

duct will restrict airflow and reduce performance.

• Make the duct run as short and as straight as possible with as few turns as possible.

• Avoid sharp-angled turns. Instead, use smooth, gradual turns such as adjustable elbows or 45

degree angled turns.

• For duct runs over 20 feet, increase the duct diameter by one inch for every ten feet of duct.

• When planning length, a 90 degree elbow is equivalent to 5 feet of duct.

10

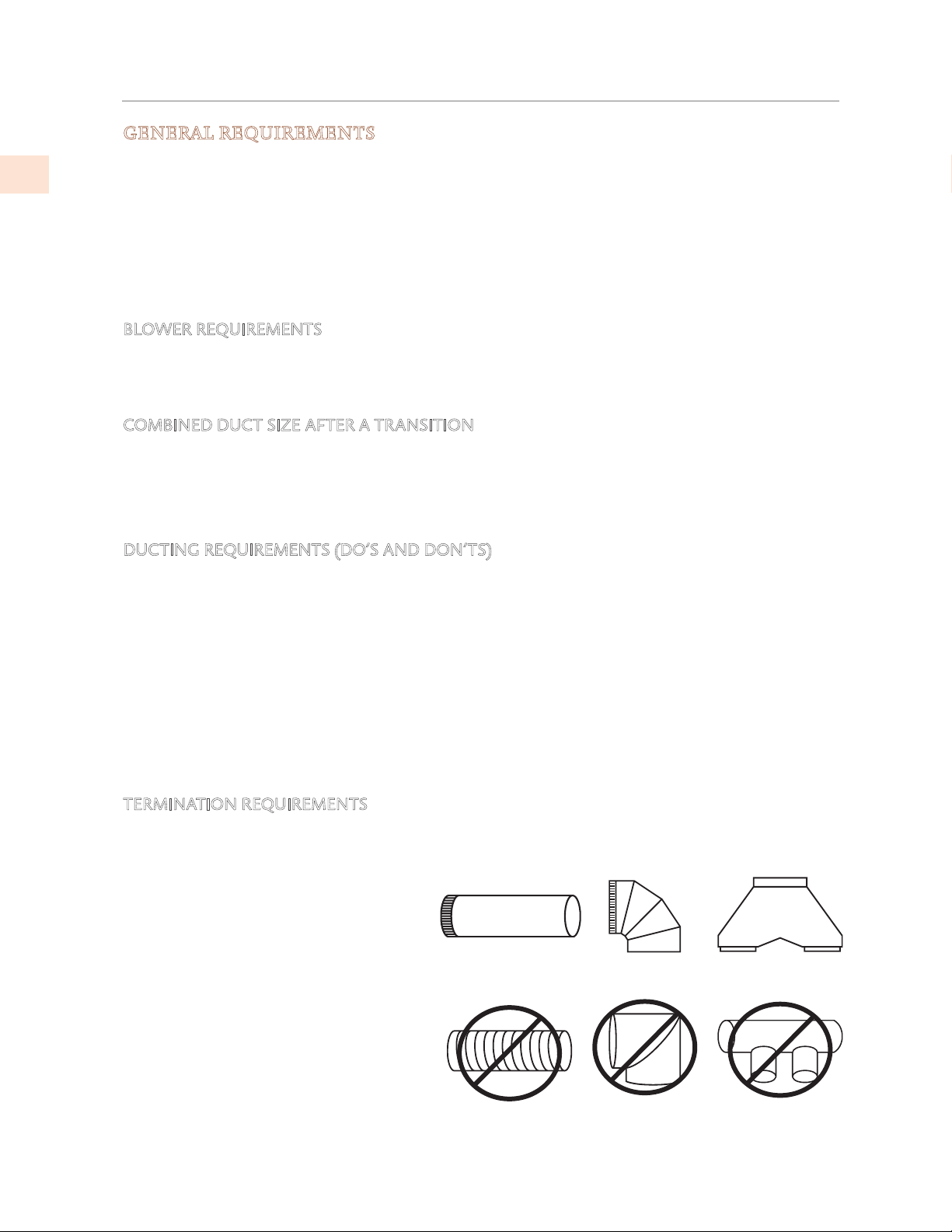

TERMINATION REQUIREMENTS

Airflow must not be restricted at the end of the duct run.

A wall louver or roof cap is required

for each duct run.

Every wall louver or roof cap must

include a gravity damper to prevent

back drafts.

Do not use screen wire or springloaded doors on wall louvers or roof

caps.

Do not terminate venting into an

attic or chimney.

©2019 Hestan Commercial Corporation

YES

Smooth duct Smooth gradual turn

NO

Flexible duct Sharp angled turns

Proper combining

of two ducts

Improper combining

of two ducts

INSTALLATION

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

a) Installation work and electrical wiring must be done by qualified person(s) in accordance with

all applicable codes and standards, including fire-rated construction.

b) Sufficient air is needed for proper combustion and exhausting of gases through the flue

(chimney) of fuel burning equipment to prevent back drafting. Follow the heating equipment

manufacturer’s guideline and safety standards such as those published by the National Fire

Protection Association (NFPA), and the American Society for Heating, Refrigeration, and Air

Conditioning Engineers (ASHRAE) and the local code authorities.

c) When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden

utilities.

d) Ducted fans must always be vented to the outdoors.

TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCTWORK.

TO REDUCE THE RISK OF FIRE OR ELECTRICAL SHOCK, DO NOT USE THIS BLOWER WITH

ANY SOLID-STATE SPEED CONTROL DEVICE.

INSTALLATION DETAILS

EN

1. Read all instructions thoroughly before beginning installation. Note: These instructions apply

to Hestan hood liners only.

• See “DUCTING DO’S AND DON’TS” on page10.

• Weight and size: For safe installation, at least two people should be present to lift and hold the

liner. For larger liners, it is advisable to have a third person present to assist.

• Back Venting: If venting out the wall behind the hood instead of venting through the ceiling,

see “BACK VENTING” on page15 for details.

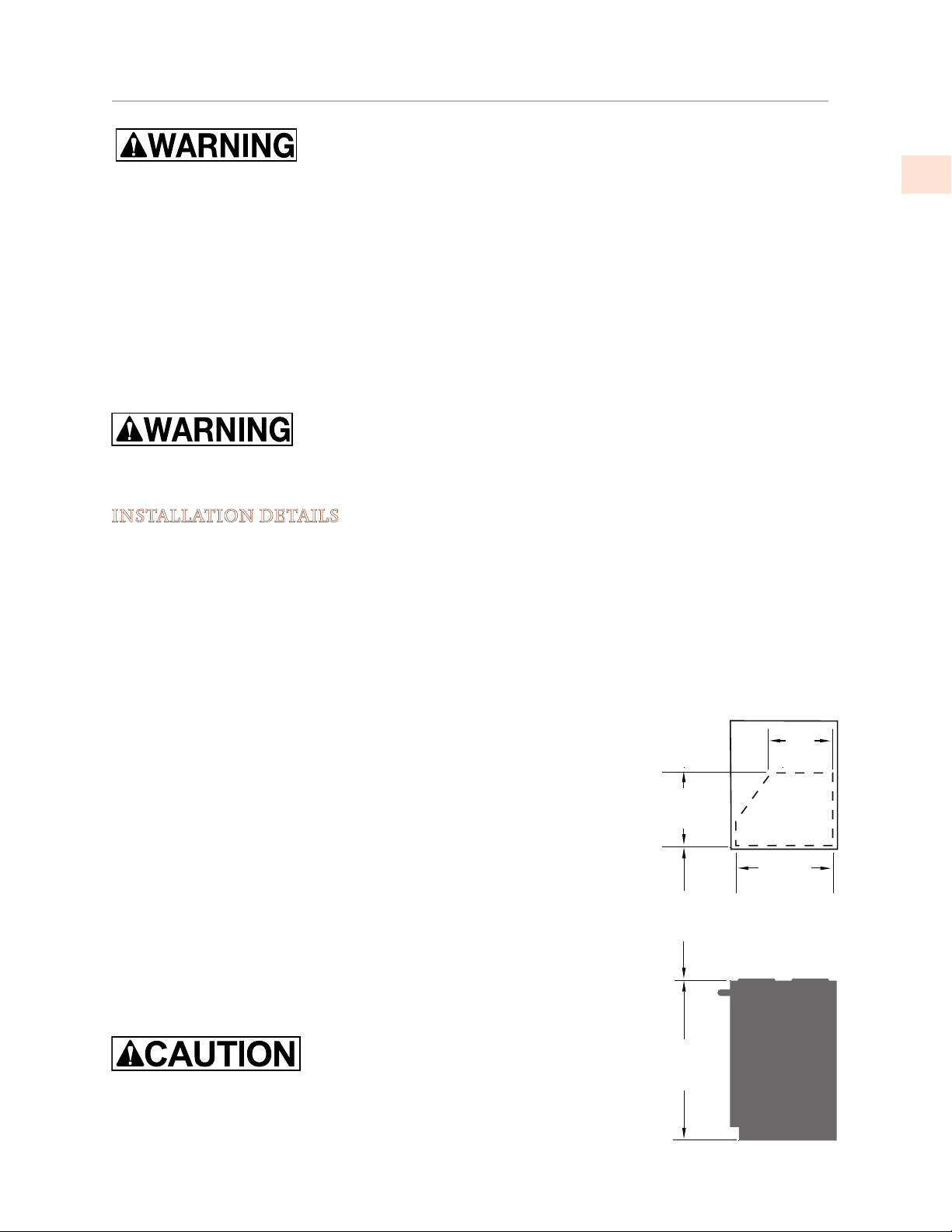

2. When installing a Hestan hood liner, it is recommended that the

bottom edge of the liner be located no more than 30” above the

cooking surface for optimum performance.

3. Install the duct(s) from the outside of the house down to the

location of the exhaust outlet(s) on the top of the liner, allowing

room for the optional transitions, if used.

a) If back venting, the elbows should be installed so that the non-

crimped end(s) are on the inside of the collar(s) of the exhaust

outlet(s). If a transition is used, install the duct so it will engage

1” of the transition outlet.

b) Consult the connection diagrams (following) for further details

on exhaust outlet placement.

c) Use foil HVAC tape (not gray cloth duct tape) to seal all joints.

See “VENT ACCESSORIES” on page16 for available Hestan

vent accessories.

Cabinet with

vent liner

12”

[30.5 cm]

30”

[76.2 cm]

12”

[30.5 cm]

22-1/2”

[57.2 cm]

Make sure that once the liner is mounted,

the motor cooling vents are not obstructed.

©2019 Hestan Commercial Corporation

36”

[91.4 cm]

11

Loading...

Loading...