Page 1

INDOOR COOKING

Vent Hood - Chimney

KVC

Installation, Use and Care Manual

Page 2

IF THE INFORMATION IN THIS MANUAL IS NOT FOLLOWED

EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING

PROPERTY DAMAGE, PERSONAL INJURY, OR DEATH.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

Installation and service must be performed by a qualified installer or service agency.

DO NOT REPAIR, REPLACE OR REMOVE ANY PART OF THE APPLIANCE UNLESS

SPECIFICALLY RECOMMENDED IN THE MANUAL. IMPROPER INSTALLATION,

SERVICE OR MAINTENANCE CAN CAUSE INJURY OR PROPERTY DAMAGE. REFER

TO THIS MANUAL FOR GUIDANCE. ALL OTHER SERVICING SHOULD BE DONE BY

A HESTAN AUTHORIZED SERVICE TECHNICIAN.

READ THESE INSTRUCTIONS CAREFULLY AND COMPLETELY BEFORE

INSTALLING OR USING YOUR APPLIANCE TO REDUCE THE RISK OF

FIRE, BURN HAZARD, OR OTHER INJURY. KEEP THIS MANUAL FOR

FUTURE REFERENCE.

SAFETY DEFINITIONS

THIS INDICATES THAT DEATH OR SERIOUS INJURY MAY OCCUR

AS A RESULT OF NOT OBSERVING THIS WARNING

THIS INDICATES THAT MINOR OR MODERATE INJURY MAY

OCCUR AS A RESULT OF NOT OBSERVING THIS WARNING.

THIS INDICATES THAT DAMAGE TO THE APPLIANCE OR

PROPERTY MAY OCCUR AS A RESULT OF NOT OBSERVING THIS

WARNING.

INSTALLER: LEAVE THIS MANUAL WITH THE OWNER OF THE APPLIANCE.

HOMEOWNER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Page 3

Message from Hestan:

Hestan’s award-winning culinary innovations and purpose-built features reinvented

the restaurant kitchen and redefined culinary experience in some of America’s most

acclaimed restaurants. Hestan now takes this performance from the back of the

house and puts it front and center in yours. Thoughtfully designed and meticulously

built, Hestan will serve you beautifully for years to come.

Hestan is the only residential brand born from the dreams and demands of

professional chefs. From ranges to refrigeration, every detail is designed to deliver

the performance and reliability expected in a restaurant – now available for you.

We appreciate you choosing Hestan, and we promise to deliver the very best to you.

Welcome to Hestan

Page 4

Page 5

TABLE OF CONTENTS

1 SAFETY PRECAUTIONS - BEFORE YOU BEGIN

4 MODEL NUMBERS

4 RATING LABEL

5 REGULATORY / CODE REQUIREMENTS

5 USING THE VENTILATION SYSTEM

6 CLEANING AND MAINTENANCE

9 TROUBLESHOOTING

10 DUCTING DO’S AND DON’TS

11 INSTALLATION

17 VENT ACCESSORIES

18 DUCT COVERS

19 PARTS / SERVICE

19 LIMITED WARRANTY

SAFETY PRECAUTIONS - BEFORE YOU BEGIN

EN

When properly cared for, your Hestan ventilation system will provide safe, reliable service for many

years. When using this ventilation system, basic safety practices must be followed as described in

the following pages.

IMPORTANT: Save these instructions for the local Utility Inspector’s use.

INSTALLER: Please leave these Installation Instructions with the owner.

OWNER: Please read these Instructions and save them for future reference.

ELECTRICAL SHOCK HAZARD

It is the responsibility of the user to have the appliance connected

by a licensed electrician in accordance with all applicable codes and

standards, including fire-related construction. See step 16 - “WIRING

CONNECTION:” on page15 for details.

ELECTRICAL SUPPLY AND GROUNDING

• This appliance must be grounded. See step 16 - “WIRING CONNECTION:” on page15 for

instructions.

• This appliance must be connected to 120 VAC Single Phase, 60 Hz, with a dedicated 20 amp

circuit.

• OWNER: Have the installer show you where the electric circuit breaker is located so you know

how to shut off the power to this appliance.

Suitable for use in covered outdoor applications when installed in a GFCI protected branch circuit.

©2019 Hestan Commercial Corporation

1

Page 6

SAFETY PRECAUTIONS - BEFORE YOU BEGIN

GENERAL SAFETY PRECAUTIONS

(CONT.)

EN

When properly cared for, your new Hestan ventilation hood has been designed to be a safe, reliable

ventilation system. Read all instructions carefully before using this ventilation system. When using

kitchen appliances, basic safety precautions must be followed.

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

a) Use this ventilation system only as intended by the manufacturer. If you have any questions,

contact the manufacturer.

b) Before servicing or cleaning unit, switch power off at service panel and lock the service

disconnecting means to prevent power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a prominent warning device, such as a

tag, to the service panel.

FOR GENERAL VENTILATING USE ONLY. DO NOT USE TO

EXHAUST HAZARDOUS OR EXPLOSIVE MATERIALS AND VAPORS.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a) Never leave burners or surface units unattended at high settings. Boilovers cause smoking and

greasy spillovers that may ignite. Heat oils slowly on low or medium settings.

b) Always turn hood ON when cooking at high heat or when flambéing food (i.e. Crepes Suzette,

Cherries Jubilee, Peppercorn Beef Flambé).

c) Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or filter.

d) Use proper pan size. Always use cookware appropriate for the size of the burner or surface

element.

TO REDUCE THE RISK OF INJURY TO PERSONS, IN THE EVENT OF

A RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING *:

a) SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal tray, then turn off the

burner. BE CAREFUL TO PREVENT BURNS. If the flames do not go out immediately,

EVACUATE AND CALL THE FIRE DEPARTMENT.

b) NEVER PICK UP A FLAMING PAN - You may be burned.

c) DO NOT USE WATER, including wet dish cloths or towels - a violent steam explosion will

result.

d) Use an extinguisher ONLY IF:

1. You have a Class ABC or Class K fire extinguisher and you already know how to operate it.

2. The fire is small and contained in the area where it started.

3. The fire department is being called.

4. You can fight the fire with your back to an exit.

2

* Based on “Kitchen Fire Safety Tips” published by NFPA.

©2019 Hestan Commercial Corporation

Page 7

SAFETY PRECAUTIONS - BEFORE YOU BEGIN

(CONT.)

BURN HAZARD

This ventilation system is intended for use with ranges or cooktops, which can get very hot during

operation. Observe the warnings and cautions for the cooking appliance.

This ventilation system should be serviced only by a Hestan authorized service technician. Contact

the nearest authorized service center for examination, repair or adjustment.

Do not repair or replace any part of the system unless specifically recommended. Refer service to

an authorized servicer.

Do not operate this ventilation system if it is not working properly or if it has been damaged, until

an authorized servicer has examined it.

Install or locate this ventilation system only in accordance with the Installation section of this

manual. Do not cover or block any openings on this ventilation system.

It is highly recommended that a suitable kitchen fire extinguisher (Class ABC or K) be readily

available and highly visible next to any cooking appliance.

SAFETY DURING CLEANING

Clean only ventilation system parts listed in this manual, in the manner specified in this manual.

Note: the “ventilating fans” and “filter” in the previous warnings refer to the blower wheels, blower

housing(s), and blower shield(s). See “CLEANING” on page7 for parts indentification and

cleaning instructions.

EN

THIS MANUAL SHOULD REMAIN WITH THE HOMEOWNER FOR FUTURE REFERENCE.

©2019 Hestan Commercial Corporation

3

Page 8

MODEL NUMBERS

MODEL NO. DESCRIPTION BLOWER PACKAGE

EN

KVC 30

KVC 36

KVC 42

KVC 48

KVC 54

30” Chimney-style 600 cfm Kitchen Ventilation System WM2L Dual

36” Chimney-style 600 cfm Kitchen Ventilation System WM2L Dual

42” Chimney-style 900 cfm Kitchen Ventilation System WM2L Dual + WM1L Single

48” Chimney-style 900 cfm Kitchen Ventilation System WM2L Dual + WM1L Single

54” Chimney-style 1200 cfm Kitchen Ventilation System Two WM2L Duals

POWER AND FLOW RATINGS

Blower

Package

Amps

CFM

SP@0.0”*

Equivalent

CFM **

CFM

SP@0.1”*

CFM

SP@0.2”*

CFM

SP@0.3”*

Minimum

Round Duct

WM2L Dual 2.9 600 900 531 480 430 8” (50 in.

WM2L Dual +

WM1L Single

Two WM2L

Duals

4.4 900 1350 804 725 655 AKVT6810:

10” (79 in.

5.8 1200 1800 1062 960 860 AKVT8812:

12” (113 in.

All units 115 VAC 60 Hz 1550 RPM

Size

Sones

2

) 6.5

2

)

2

)

***

6.3

6.6

* Static Pressure in inches water column.

** When comparing the Hestan system with blower units made by other manufacturers, use the “Equivalent CFM”.

*** Ratings in accordance with the Standard Test Code by the Energy Systems Laboratory of the Texas Engineering

Experiment Station.

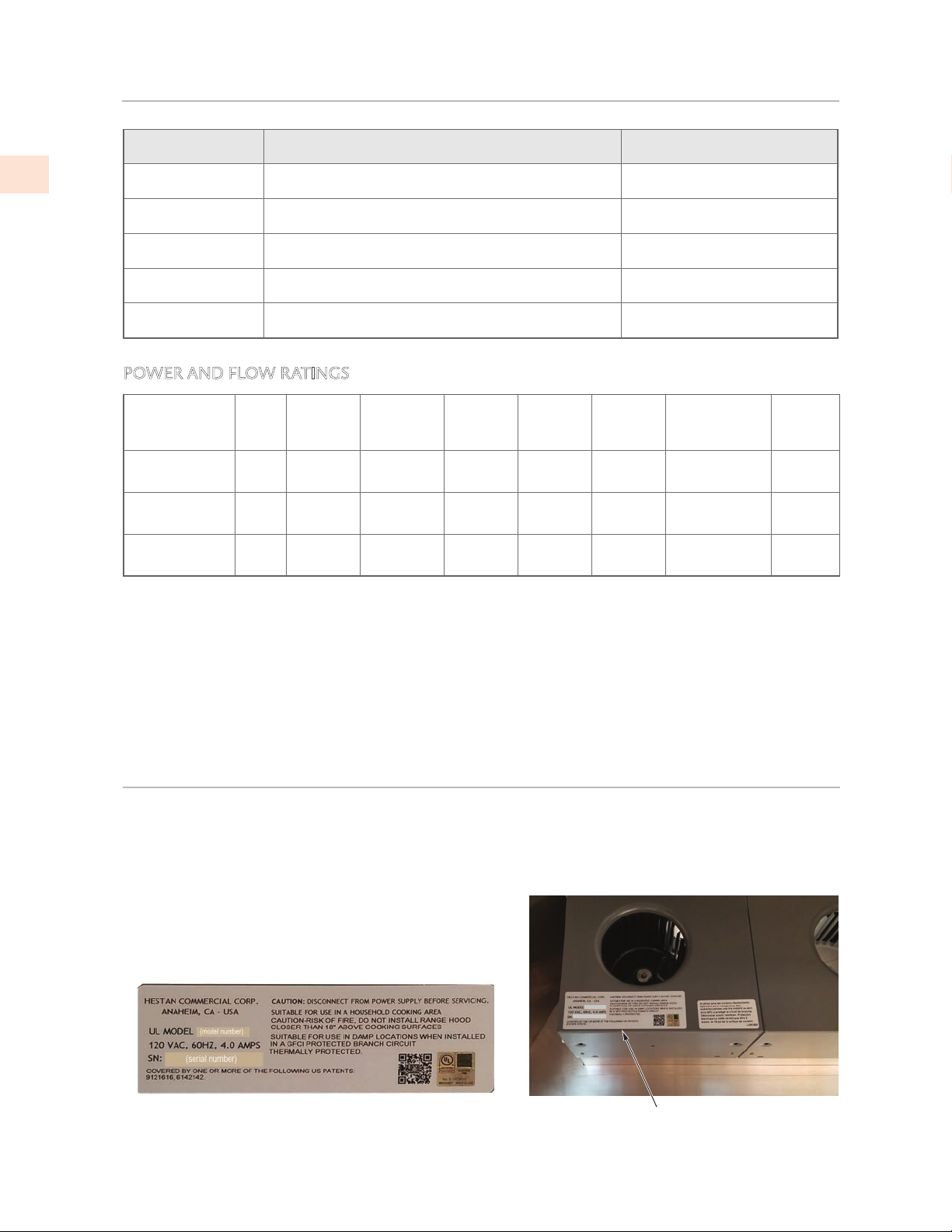

RATING LABEL

The rating label contains important information about your Hestan appliance such as the model and

serial number, electrical rating and the minimum installation clearances.

The rating label is located on the blower housing.

If service is necessary, contact Hestan Customer Care

with the model and serial number information shown

on the label.

(model number)

(serial number)

4

Typical rating label

©2019 Hestan Commercial Corporation

Rating label location

Page 9

REGULATORY / CODE REQUIREMENTS

Installation of this ventilation system must be made in accordance with local codes. In the absence

of local codes, this unit should be installed in accordance with the National Electrical Code and

local codes.

This appliance must be electrically grounded in accordance with local codes or in the absence of

local codes with the National Electrical Code

C22.1

.

ANSI/NFPA 70

, or Canadian Electrical code

CSA

USING THE VENTILATION SYSTEM

FEATURES OF THE VENTILATION SYSTEM

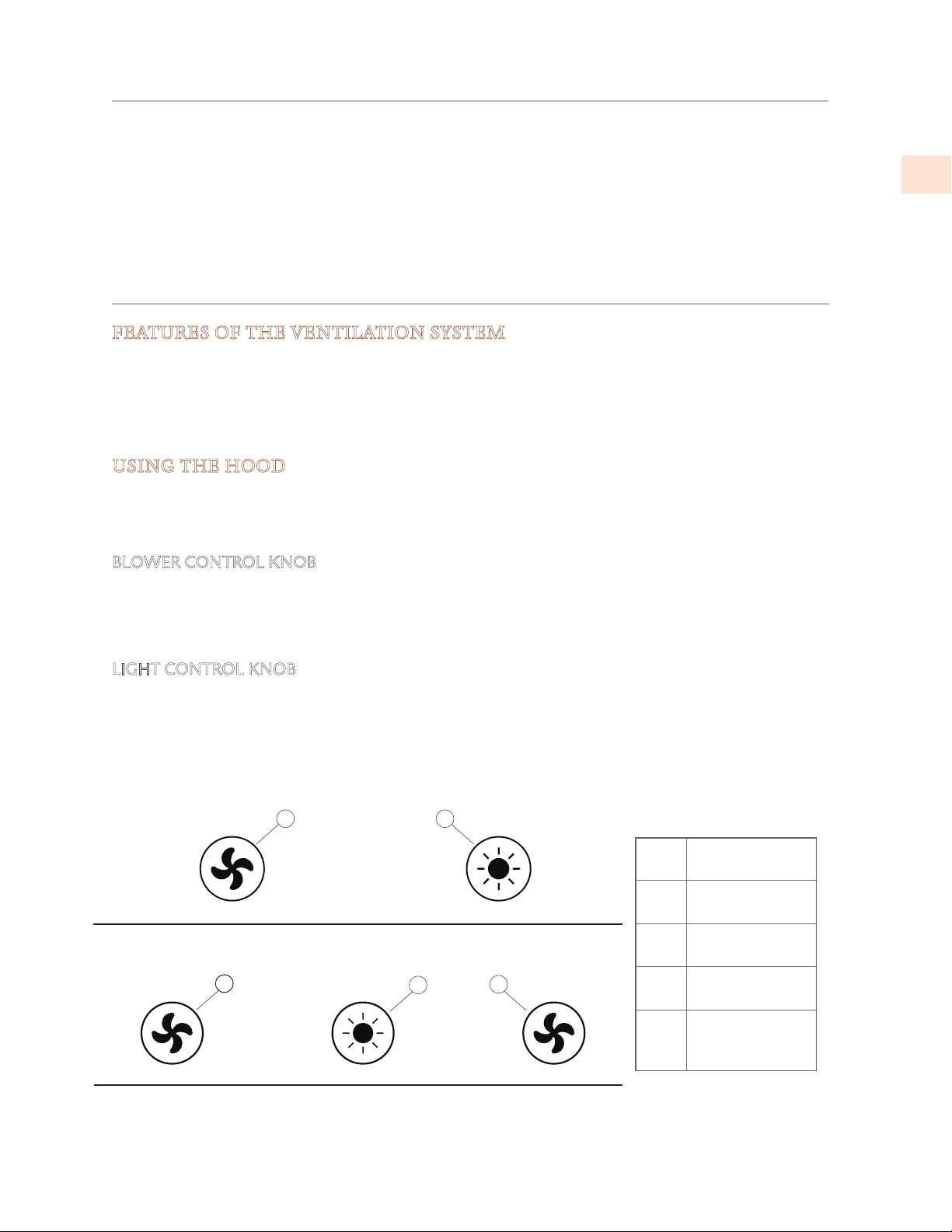

Speed controls are provided for each blower assembly. Two-blower systems will have one speed

control knob, while three- or four-blower systems will have two speed control knobs.

A control knob is provided for lighting intensity.

The controls layout will be similar to that shown below.

USING THE HOOD

The user can start with the a hood on the lowest setting, and then increase speed and/or turn

on additional blowers as required. Using the hood at high settings may increase heating or air

conditioning requirements and costs for the house.

EN

BLOWER CONTROL KNOB

To operate the blower(s), rotate the knob through the blower speed settings by turning it clockwise

(facing the knob).

Rotate the knob counter-clockwise to reduce the blower speed.

LIGHT CONTROL KNOB

To operate the lights, rotate the knob through the light intensity settings by turning it clockwise

(facing the knob). Rotate the knob counter-clockwise to dim the lights or turn them off.

Controls for two blowers

1

Controls for three and four blowers

3

2

Item Function

Blower control

1

Light control

2

Blower control

2

4

3

blowers 1 & 2

Blower control,

4

blower 3 or

blowers 3 & 4

©2019 Hestan Commercial Corporation

5

Page 10

CLEANING AND MAINTENANCE

CLEANING THE VENTILATION SYSTEM

EN

Cleaning requirements depend completely on usage and environment. The more high-heat and/or

greasy cooking, the more often the hood and blower will need cleaning.

The grease tray and blower aren’t visible from the outside, so they must be removed for inspection.

After you’ve inspected the tray a few times over the course of six months or a year, you’ll be able to

set a cleaning schedule according to your usage pattern.

HOOD CANOPY

Wipe down the interior and exterior of the hood as needed with a soft cloth and warm soapy

water (liquid dish detergent is acceptable). Do not use acids, abrasives, strong detergents, solvents,

or scouring pads. Stainless steel should be treated with a quality stainless steel cleaner such as

Stainless Steel Magic®. Follow all label instructions. Do not polish across the grain or in circles.

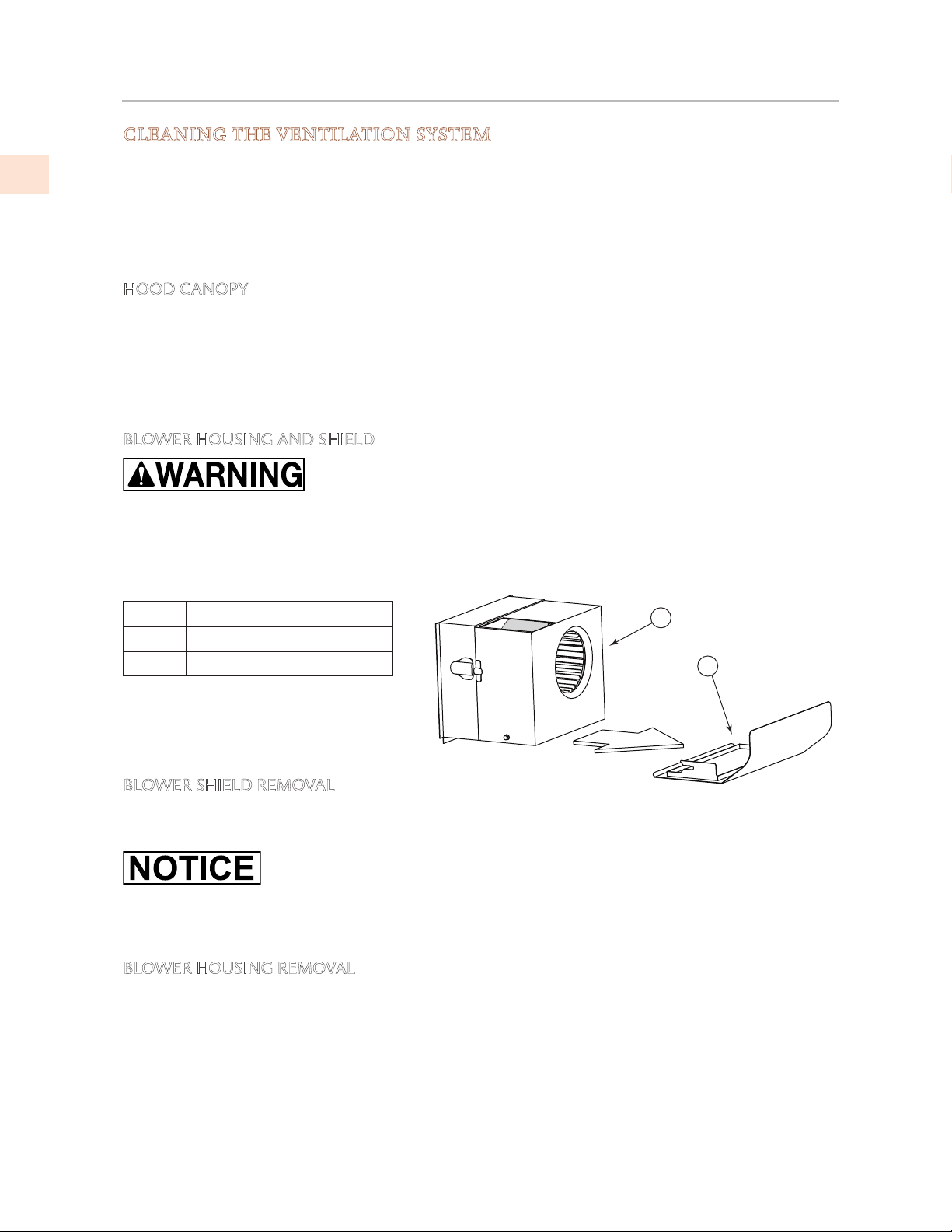

BLOWER HOUSING AND SHIELD

To reduce the risk of personal injury, be sure the power is turned off in

the hood before removing the shield(s) and blower housing(s).

The blower captures grease by-products in the blower housing(s) and blower shield(s). The blower

shields require more frequent cleaning than the blower housing but cooking usage determines how

often each item will need to be cleaned.

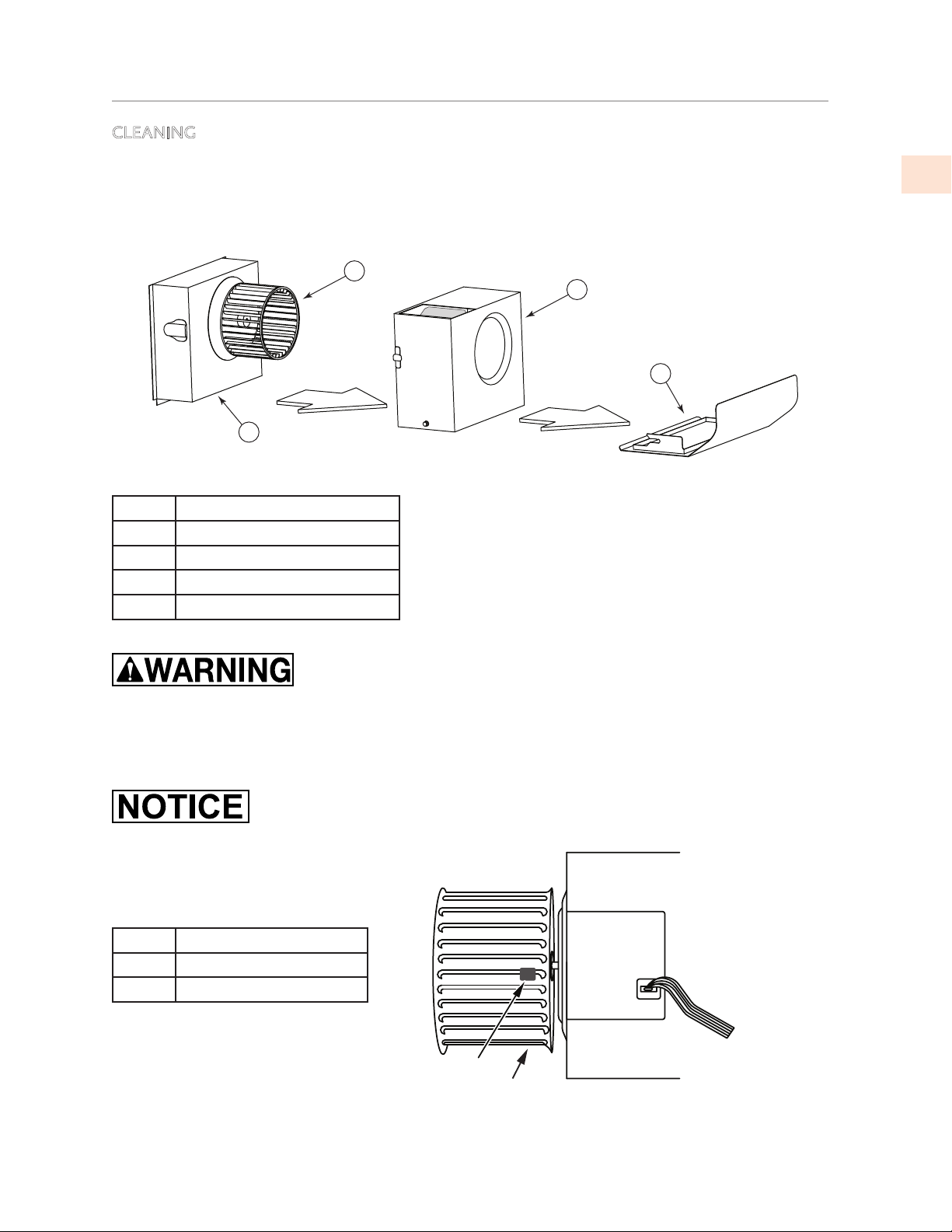

Item # Description

Blower housing with damper(s)

1

Blower shield

2

BLOWER SHIELD REMOVAL

The blower shields are easily removed

for cleaning by pulling the blower shield(s) toward the front of the hood.

Be careful to keep the tray level if the hood has been recently used and the

grease might still be warm.

Inspect and clean the shield. (Details follow)

BLOWER HOUSING REMOVAL

To remove the blower housing:

1. Unsnap two suitcase latches, one on each side of the housing.

2. Support the housing and pull it away from the blower base.

1

2

6

3. While pulling it back, gently “tip” it downward to clear the blower wheel(s).

©2019 Hestan Commercial Corporation

Page 11

2

CLEANING AND MAINTENANCE

CLEANING

Clean the shield(s) and/or blower housing(s) in a sink of warm soapy water (liquid dish detergent)

and let soak for a few minutes. Wash with a sponge or dishcloth, rinse and let drain before

reinstalling. Alternatively, the blower housing(s) and blower shield(s) may be placed into a

dishwasher.

(CONT.)

2

3

4

1

Item # Description

Motor housing

1

Wheel

2

Blower housing with damper(s)

3

Blower shield

4

EN

To reduce the risk of personal injury, be sure the power is turned off in

the hood before removing the shield(s) and blower housing(s).

Regular cleaning of the blower housing should prevent grease accumulation on the blower wheel.

If grease build-up should occur, the blower wheel may easily be cleaned in place using a soft bristle

toothbrush and a common degreaser such as Formula 409®.

Take care not to move or lose the metal balancing clips that may be affixed to

the wheel.

Item # Description

Balancing clip

1

Blower wheel

2

1

©2019 Hestan Commercial Corporation

7

Page 12

EN

CLEANING AND MAINTENANCE

BLOWER WHEEL REMOVAL

For instances where the blower wheel must be removed, follow the instructions below.

• Removing the blower wheel requires a 1/8” hex wrench. This may be obtained from your local

hardware store or tool supply.

The wheel is retained by a set screw on the side of the hub of the wheel that tightens up against a

“flat” spot on the motor shaft. (See illustration on previous page.)

1. Locate the set screw on the side of the hub of the wheel

2. Insert wrench through the blades of the blower wheel and into the set screw.

3. Loosen the set screw 1/2 turn counterclockwise.

(CONT.)

If the wheel is difficult to remove, the area where the motor shaft makes contact with the

blower wheel hub may need to be sprayed with a common penetrating oil such as WD-40

After allowing the penetrating oil to soak for a few minutes, push the blower wheel forward

slightly, then gently pull the blower wheel off the motor shaft.

• Use caution to avoid bending or distorting the blower wheel and take care not to move or lose

the metal balancing clips that may be affixed to the wheel.

A soft bristle toothbrush with warm soapy water may be used to clean the blades, or soak the

blower wheel in warm soapy water.

BLOWER WHEEL INSTALLATION

When reinstalling the wheel onto the motor shaft, make sure the set screw makes direct contact

with the “flat spot” on the motor shaft.

1. Slide the blower wheel onto the motor shaft as far as it will go, making sure the back of the

blower wheel does not touch the motor mount screws protruding from the motor.

• If the motor is too far back, it will rub the motor mount screws, and if it is too far forward, it

will rub the inside of the blower housing.

2. Adjust the blower wheel slightly to find the correct front-to-rear location.

3. Tighten the set screw (clockwise) to lock the blower wheel in the correct position.

For hoods that have more than one blower wheel, make sure that white

blower wheels are matched up with white motor rings, and black blower

wheels are matched up with black motor rings.

®

.

8

The hood will not perform properly if blower wheels and motors are mismatched.

©2019 Hestan Commercial Corporation

Page 13

CLEANING AND MAINTENANCE

MOTOR REPLACEMENT

(CONT.)

To reduce the risk of personal injury, turn off power to the hood at the

breaker or the circuit disconnect before attempting to remove the

blower motor.

MOTOR IDENTIFICATION AND POSITIONING

Motors are color-coded; black and white motors have different rotations and must be installed in

the correct positions.

• Housings with a single blower use a white blower and wheel.

• Housings with two blowers use a white blower on the right and black on the left.

Make sure you have the correct motor in each housing position.

• If the replacement blower motor includes a blower wheel, then you can remove the motor and

wheel together. If you will re-use your existing wheel, then you may wish to remove the wheel

before removing the motor.

1. Remove the shield and blower housing as described in

“BLOWER WHEEL REMOVAL” on page8.

2. Use a ¼” nut driver to remove the three motor mount

screws that attach the motor to the hood.

3. Gently pull the motor forward and down.

4. Disconnect the wiring harness, remove the old motor.

EN

• To avoid damage to the blower wheel, you may wish to

install the motor and then install the wheel onto the motor.

5. Lift the new motor so you can connect the wiring

harness. Be sure to fully engage the electrical

connections and tighten the motor mount screws.

6. Check the blower wheel clearance and adjust

as needed, as described in “BLOWER WHEEL

INSTALLATION” on page8.

TROUBLESHOOTING

If the hood does not perform satisfactorily, check the following:

• Do the blowers run?

• Are the blower wheels installed on the correct motors? (black wheel on black motor, white

wheel on white motor)

• Are the motor and wheel assemblies installed in the correct locations?

• Check the damper doors in blower housing(s) - do they move/open freely?

• Check the dampers/vents to outside - do they open freely, with no obstructions?

• Check for damaged or obstructed ductwork.

©2019 Hestan Commercial Corporation

9

Page 14

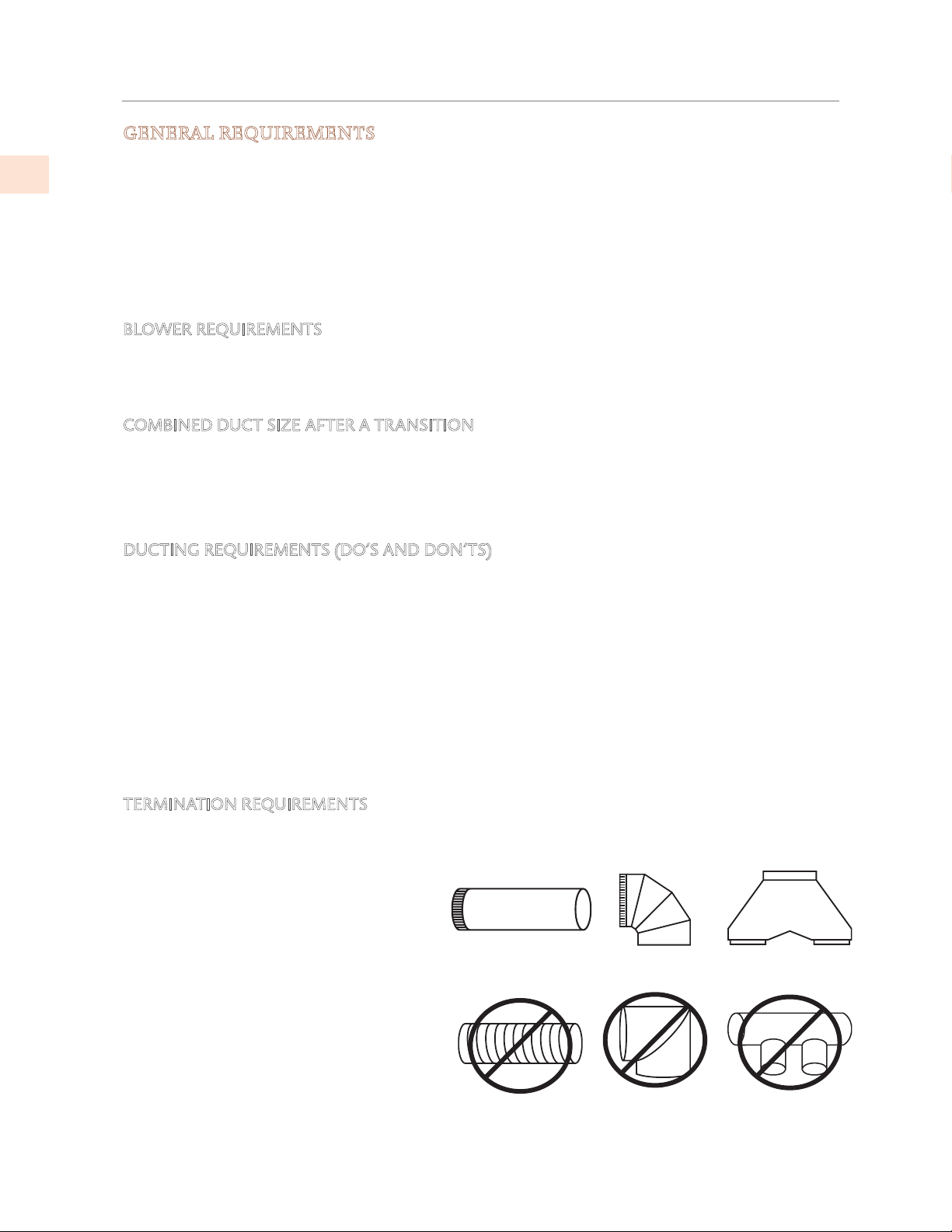

DUCTING DO’S AND DON’TS

GENERAL REQUIREMENTS

EN

Observe local codes regarding special duct requirements and placement of duct work against

combustibles.

• Using recommended transitions (see VENT ACCESSORIES) will ensure proper efficiency.

• Using recommended roof caps or wall louvers (see VENT ACCESSORIES) will ensure proper

efficiency.

• Use foil HVAC tape (not grey cloth duct tape) to seal all joints.

• The hood must be ducted to the outdoors without restrictions.

BLOWER REQUIREMENTS

The dual blower unit (WM2L, used in all systems) requires 8” round duct or equivalent (50 square

inches). The single blower unit (WM1L, used in addition to the dual blower unit in 900 CFM

systems) requires 6” round duct or equivalent (28 square inches).

COMBINED DUCT SIZE AFTER A TRANSITION

Single and Dual (WM1L & WM2L) combine to 10” round or equivalent 79 sq. in. when using a

multi-blower transition such as AKVT6810 (Optional).

Two Duals (Two WM2Ls) combine to 12” round or equivalent 113 sq. in. when using a multi-blower

transition such as AKVT8812 (Optional).

DUCTING REQUIREMENTS (DO’S AND DON’TS)

• NEVER reduce the duct size. When combining ducts together, the square inch area of

the outlet duct must be equal or greater than the total square inch area of the ducts being

combined.

• Only use smooth galvanized metal duct. Do not use flexible or corrugated duct. This type of

duct will restrict airflow and reduce performance.

• Make the duct run as short and as straight as possible with as few turns as possible.

• Avoid sharp-angled turns. Instead, use smooth, gradual turns such as adjustable elbows or 45

degree angled turns.

• For duct runs over 20 feet, increase the duct diameter by one inch for every ten feet of duct.

• When planning length, a 90 degree elbow is equivalent to 5 feet of duct.

10

TERMINATION REQUIREMENTS

Airflow must not be restricted at the end of the duct run.

A wall louver or roof cap is required for each duct run.

Every wall louver or roof cap must

include a gravity damper to prevent

back drafts.

Do not use screen wire or springloaded doors on wall louvers or roof

caps.

Do not terminate venting into an attic

or chimney.

©2019 Hestan Commercial Corporation

YES

Smooth duct Smooth gradual turn

NO

Flexible duct Sharp angled turns

Proper combining

of two ducts

Improper combining

of two ducts

Page 15

INSTALLATION

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

a) Installation work and electrical wiring must be done by qualified person(s) in accordance with

all applicable codes and standards, including fire-rated construction.

b) Sufficient air is needed for proper combustion and exhausting of gases through the flue

(chimney) of fuel burning equipment to prevent back drafting. Follow the heating equipment

manufacturer’s guideline and safety standards such as those published by the National Fire

Protection Association (NFPA), and the American Society for Heating, Refrigeration, and Air

Conditioning Engineers (ASHRAE) and the local code authorities.

c) When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden

utilities.

d) Ducted fans must always be vented to the outdoors.

TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCTWORK.

TO REDUCE THE RISK OF FIRE OR ELECTRICAL SHOCK, DO NOT USE THIS BLOWER WITH

ANY SOLID-STATE SPEED CONTROL DEVICE.

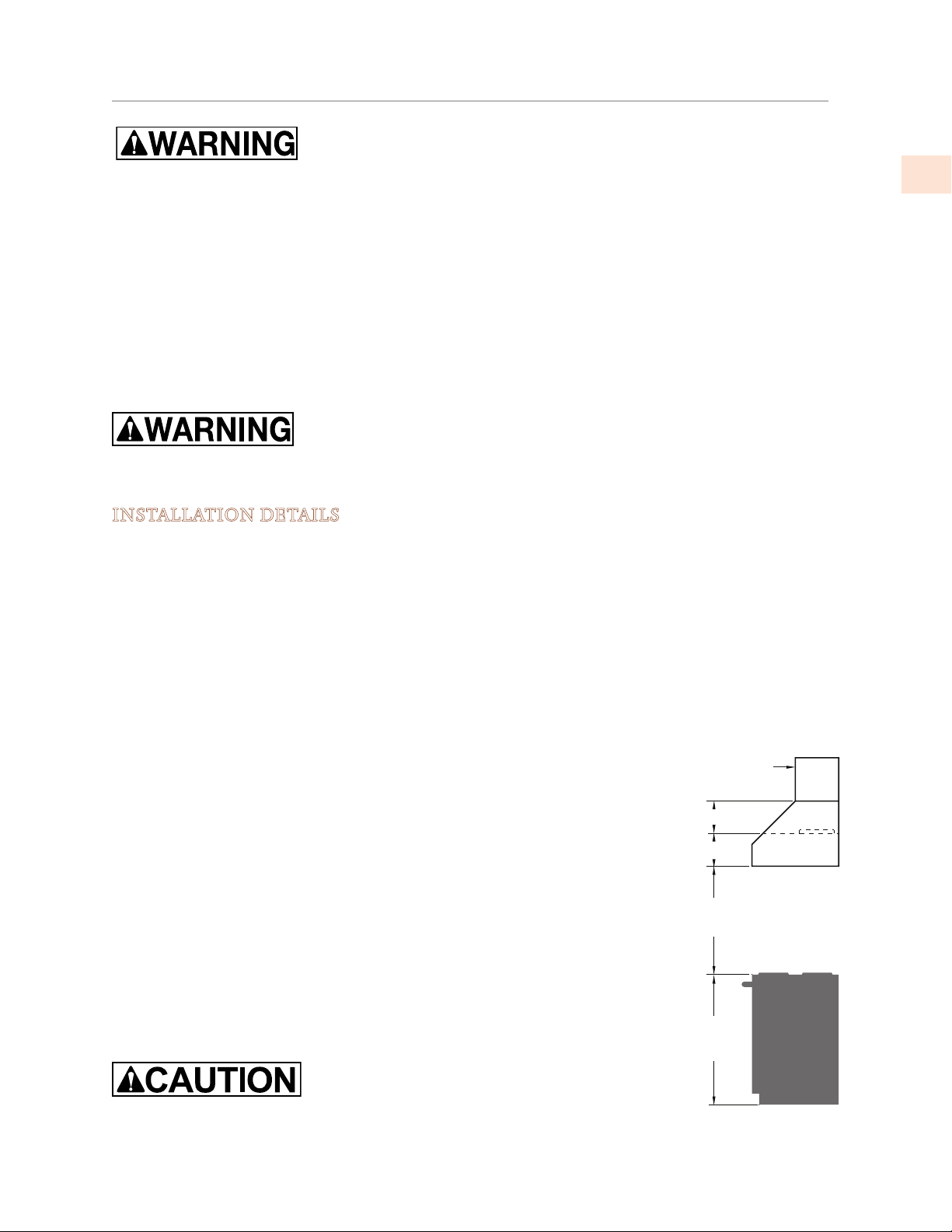

INSTALLATION DETAILS

EN

1. Read all instructions thoroughly before beginning installation. Note: These instructions apply

to Hestan hoods only.

• See “DUCTING DO’S AND DON’TS” on page10

• Weight and size: For safe installation, at least two people should be present to lift and hold the

hood. For larger hoods and installations with duct covers, it is advisable to have a third person

present to assist.

• Back Venting: If venting out the wall behind the hood instead of venting through the ceiling,

see “BACK VENTING” on page16 for details.

2. When installing a wall mount range hood, it is recommended that the bottom edge of the hood

be located no more than 30” above the cooking surface for optimum performance.

3. Duct Preparation

IF THE HOOD IS TO BE “BACK VENTED”, PROCEED DIRECTLY TO

STEP 4.

a) Consult the connection diagrams (following) for further details on

exhaust outlet placement.

b) Install the duct(s) from the outside of the home down to the

location of the exhaust outlet(s) on the top of the hood allowing

room for the transition (if applicable). If a transition is used, install

duct down to the location of the transition outlet plus 1”. This will

allow the transition to engage 1” inside of duct.

Optional duct

9”

[22.9 cm]

9”

[22.9 cm]

cover

30”

[76.2 cm]

c) Use foil HVAC tape (not gray cloth duct tape) to seal all joints. See

“VENT ACCESSORIES” on page17 for a listing of Hestan ducting

accessories.

Make sure that once the hood is mounted, the

motor cooling vents are not obstructed.

©2019 Hestan Commercial Corporation

36”

[91.4 cm]

11

Page 16

WM2L Dual Blower (600 CFM ) (Top View)

Connection Diagram (30-36” width)

Connection diagram (42”, 48” widths)

WM2L Dual + WM1L Single Blower (900 CFM) (Top View)

[45.7 cm]

EN

INSTALLATION

(CONT.)

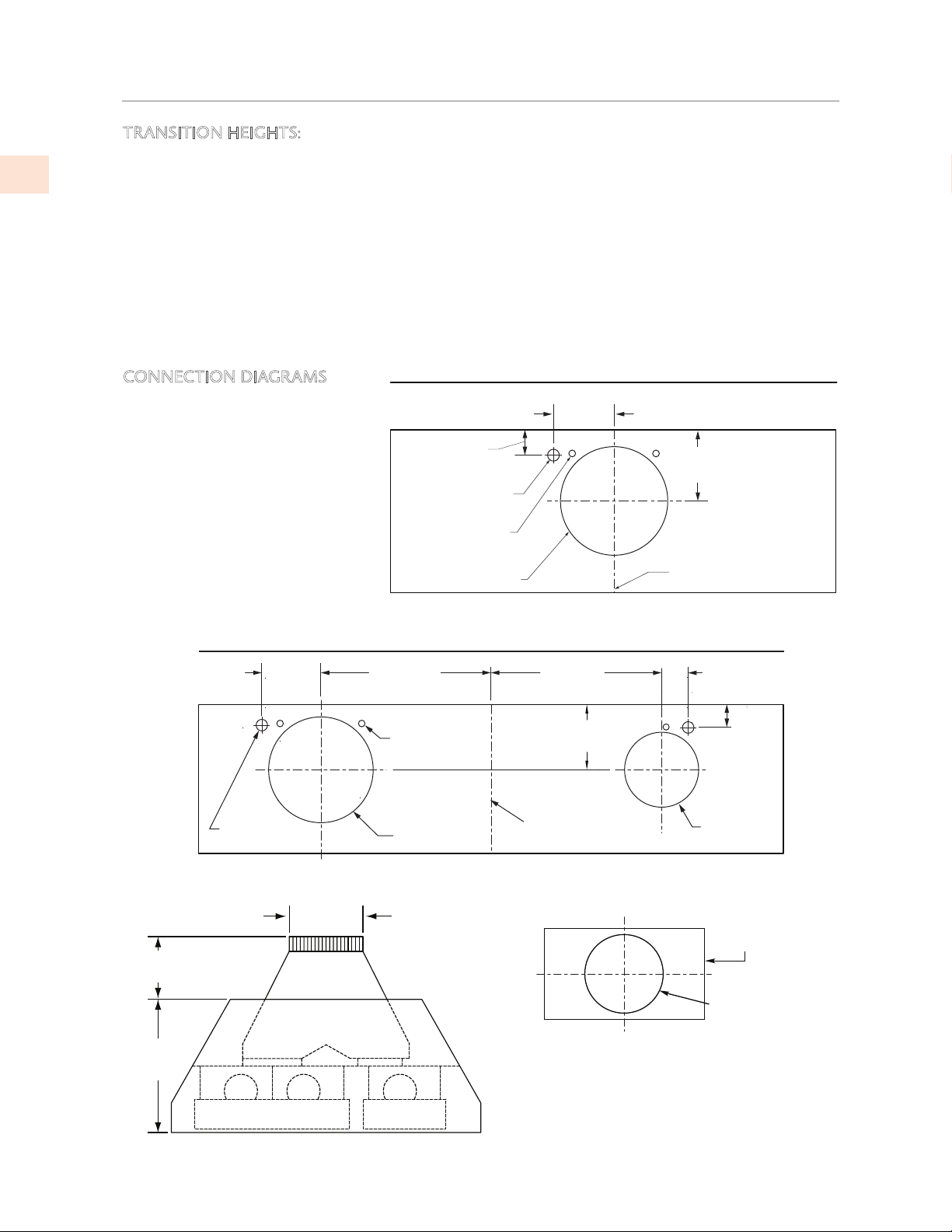

TRANSITION HEIGHTS:

Dual Blower (WM2L = 600 CFM): no transition - 8” round duct will connect directly to the

blower outlets, 9” below top edge of the hood.

Single and Dual Blower (WM1L + WM2L = 900 CFM): 6” round duct will connect directly

to the single blower outlet, 8” round will connect directly to the dual blower outlet.

The outlets are 9” below top of hood. If using the optional multi-blower transition

(AKVT6810, sold seperately), a 10” round duct connects to it 8-1/2” above top of hood.

Two Dual Blowers (Two WM2Ls = 1200 CFM): 8” round duct will connect directly to each

dual blower outlet. The outlets are 9” below the top of hood. If using the optional multiblower transition (AKVT8812, sold seperately), a 12” round duct connects to it 7-1/2”

above top of hood.

CONNECTION DIAGRAMS

5-1/2"

(Wall Side)

1-3/4"

[4.4 cm]

Electrical

Motor

Cooling

Vent (2)

8" [20.3 cm] Round

[14 cm]

5-1/4"

[13.3 cm]

Centerline

of Hood

(Wall

Side)

Electrical (2)

8-1/2"

[21.6 cm]

18"

5-1/2"

[14 cm]

Optional AKVT6810 transition

piece installed

12

©2019 Hestan Commercial Corporation

10"

[25.5 cm]

7-5/16"

[18.6 cm]

Motor

Cooling

Vent (3)

8" Round

(Front View)

7-5/16"

[18.6 cm]

5-1/4"

[13.3 cm]

Centerline

of hood

For 900 and 1200 CFM hoods, a transition

(AKVT6810 or AKVT8812) may be installed.

Its outlet will be located in the exact center of

the duct cover (left to right & front to rear).

1-7/8"

[4.8 cm]

1-3/4"

[4.4 cm]

6" [15.2 cm]

Round

Duct cover

(top of hood)

10" Dia. or 12" Dia.

transition centered

in cover

Page 17

Two WM2L Dual Blowers (1200 CFM) (Top View)

[45.7 cm]

INSTALLATION

5-1/2"

[14 cm]

(CONT.)

Connection diagram (54” width)

11"

[29.9 cm]

11"

[29.9 cm]

(Wall Side)

EN

Motor

Cooling

Vent (4)

8" [20.3 cm]

Round

1-3/4"

[4.4 cm]

5-1/4"

[13.3 cm]

8" [20.3 cm]

Round

Electrical (2)

Centerline

of Hood

4. Remove the hood from its packaging and place the back of the hood on the floor or countertop

in front of the wall where it will hang.

5. With the hood on its back facing you, remove

the shield(s) and blower housing(s) as follows:

a) Remove the shipping tape that is securing

7-1/2"

[19.1 cm]

12"

[30.5 cm]

the blower shield(s) inside the hood.

b) Remove the blower shield(s) by lightly

pulling it toward the front of the hood.

18"

c) Gently close the back draft damper(s) from

the top side of the hood.

d) To remove the blower housing(s), unsnap

the suitcase latches (one on each side of

Optional AKVT8812

transition piece installed

(Front View)

the housing).

e) Support the housing and lift it away from the blower base, then tip it back toward you to

clear the blower wheel(s), and then pull it from the hood.

Make sure power is off at the supply panel / breaker during service or

installation.

6. One blower motor must be removed from each blower assembly to access the connection

box(es). The blower assembly will have a decal identifying the location of the connection

box(es). It is not necessary to remove the blower wheel from the motor.

a) Remove the three screws retaining the blower motor.

b) Pull the motor out far enough so you can reach its electrical connector.

c) Unplug the connector, set the blower motor and screws aside.

7. WIRING PREPARATION:

a) Install an appropriate 1/2” UL listed electrical wire clamp through each motor box

electrical opening on top of the hood.

b) Install electrical wiring from the service panel to the hood location for each motor box.

Consult the connection diagrams (on previous page) for further details on electrical

placement. See “ELECTRICAL SUPPLY AND GROUNDING” on page1 for power

requirements.

©2019 Hestan Commercial Corporation

13

Page 18

INSTALLATION

8. Mark the wall at the lower edge of the hood opening as follows:

(CONT.)

EN

a) Remove the duct cover from its packaging and remove the mounting screws from the base

of the duct cover.

b) Place the duct cover on the top of the hood and secure it using the mounting screws

previously removed.

c) Lift the hood and duct cover to the location on the wall where it will be installed and

lightly mark the wall with a short, horizontal mark along the bottom edge of the hood.

9. Find and mark location of mounting strip as follows:

a) Set the hood down so its back is accessible.

b) On the back side of the hood, measure the distance between the bottom edge of the hood

and the top edge of the wood mounting strip.

c) Measure this distance above the horizontal mark made in Step 8 and lightly mark the wall

with a level, horizontal line.

d) Measure where the center (left to right) of the hood will be and mark the upper, horizontal

line on the wall with a short, vertical centerline.

10. Attach the mounting strip to the wall as follows:

a) Remove the screws inside the top of the back of the hood that retain the wood mounting

strip that is recessed in the mounting channel. Note: Some retaining screws may be

located behind the blower(s).

b) Remove the wood mounting strip from the back of the hood and place the top edge of the

strip on the upper, level, horizontal line on the wall.

c) Referencing the vertical centerline from Step 9, center the mounting strip on the wall (left

to right) in the space where the hood will be located. Mark the strip at two or more stud

locations, and drill clearance holes in the wood strip to prevent splitting.

d) Using proper hardware, attach the mounting strip to at least two wall studs.

11. FOR BACK VENTING APPLICATIONS ONLY. IF NOT BACK VENTING, PROCEED DIRECTLY

TO STEP 12.

• Note: Wall studs may interfere with back venting installations. Additional framing may be

required. It is necessary to cut duct access hole(s) in the wall prior to installing the hood.

a) Remove and set aside the duct cover that was installed in step 8.

b) Hold the hood on the mounting strip by aligning the channel at the top of the back of the

hood over the wood mounting strip on the wall.

c) Place the appropriate elbow(s) on top of the hood in line with the hood exhaust collar(s).

On the wall, trace around the elbow(s). Remove the hood and elbow(s) from the wall.

d) Cut around the outside of the traced line(s), avoiding wall studs. Install the duct from the

outside of the home to the opening in the wall. Use foil HVAC tape (not grey cloth duct

tape) to seal all joints.

e) Place the duct cover back onto the top of the hood and reattach it to the hood.

12. Mark screw holes in mounting strip:

a) While holding the hood in place, mark locations on the mounting strip through the two

mounting holes in the channel at the top of the hood. Some mounting holes may be

located behind the blower(s).

14

©2019 Hestan Commercial Corporation

Page 19

INSTALLATION

b) Remove hood and drill 3/32” pilot holes at the center of marks in the wood strip to

prevent splitting.

13. FOR BACK VENTING APPLICATIONS ONLY.

IF YOU ARE NOT BACK VENTING, PROCEED DIRECTLY TO STEP 15.

a) Place the appropriate elbow on the top of the hood. Elbow should be placed with the

non-crimped end(s) on the inside of the collar(s) of the exhaust outlet(s). Use foil HVAC

tape (not grey cloth duct tape) to seal all joints.

b) Insert the electrical wire from the service panel into the electrical wire clamp on each

motor box. Tighten the wire clamp(s).

c) While securing the slack in the wire, lift the hood up to the wall and hang the hood on the

mounting strip, taking care to properly align the duct connection(s) between the elbow(s)

on the hood and the duct(s) in the wall.

d) Secure the hood to the mounting strip by aligning the mounting holes with the holes in

the mounting strip and installing the screws previously removed from the strip in step 10.

IF BACK VENTING, SKIP STEPS 14 AND 15. PROCEED DIRECTLY TO STEP 16.

14. NON-Back Venting:.

a) Insert the electrical wire from the service panel into the electrical wire clamp on each

motor box. Tighten the wire clamp(s).

(CONT.)

EN

b) Cut a piece of duct of sufficient length to meet the duct in the ceiling allowing room for

the transition (if applicable). If a transition is used, cut the duct to reach the transition

outlet plus 1”. This will allow the transition to engage 1” inside of the duct. See

“TRANSITION HEIGHTS:” on page12

c) One end of the duct must be crimped to fit inside the duct in the ceiling. Insert the non-

crimped end over the transition or into the exhaust collar(s) on the top of the hood and

seal with foil HVAC tape (not gray cloth duct tape).

15. Hang the hood:

a) While securing the slack in the wire, lift the hood up to the wall and hang the hood on the

mounting strip, taking care to properly align the duct connection(s) between the hood and

the duct in the ceiling.

b) Secure the hood to the mounting strip by aligning the mounting holes with the holes in

the mounting strip and installing the screws previously removed from the strip in step 10.

16. WIRING CONNECTION:

From inside the hood, using UL listed wire nuts, attach the “neutral” wire(s) to the white

lead(s), the “hot” wire(s) to the black lead(s), and the ground wire(s) to the green lead(s)

inside the motor box(es).

DO NOT OPERATE HOOD WITHOUT PROPER GROUND

CONNECTION.

17. Plug the connectors for the motor(s) back into the hood and reinstall the blower motor(s) using

the retaining screws that were removed in Step 7.

18. Replace the blower housing(s) and the blower shield(s). Make sure that the damper(s) open and

close smoothly.

19. Turn Power ON, verify operation: See “USING THE VENTILATION SYSTEM” on page5

for proper hood operation. Test all blower and light functions to ensure they are operating

properly.

©2019 Hestan Commercial Corporation

15

Page 20

INSTALLATION

BACK VENTING

(CONT.)

EN

When venting out through the wall, one or two elbow fittings are required, depending on the

blower configuration:

ELBOWS FOR 600 CFM

Hoods with 600 CFM blower systems require one 8” elbow.

ELBOWS FOR 900 CFM

Units with 900 CFM blower systems require one 8” elbow and one 6” elbow.

ELBOWS FOR 1200 CFM

Hoods with 1200 CFM blower systems require two 8” elbows, one for each 600 CFM blower unit.

Elbow and Transition Heights

(Drawing not to scale)

Height when

fully adjusted to

90 degrees:

Standard 6” [15.2 cm] round: 8-1/2” [21.6 cm]

Standard 8” [20.3 cm] round: 10-3/4” [27.3 cm]

H

12”

[30.5 cm]

8-1/2”

[21.6 cm]

600 CFM blower module uses 8” round

300 CFM blower module uses 6” round

8” Round

Optional

duct cover

8” Round

[20.3 cm]

Low profile elbow: 8” to 6” x 8-1/2”

Hestan P/N AKVBE8

[40.6 cm]

16”

6”

[15.2 cm]

9”

[22.9 cm]

Side View

16

©2019 Hestan Commercial Corporation

Page 21

VENT ACCESSORIES

A, B: 8-5/8”

A: 6”

B: 8”

A

B

WALL LOUVER

1-½” Flange

MODEL DESCRIPTION

AKVWL6 6” Round

AKVWL8 8” Round

12”

Back

View

8-½”

WALL LOUVER

A: 11”

B: 13”

A

B

A: 11”

B: 13”

MODELITEM ITEM

DESCRIPTION

AKVWL10 10” Round

AKVWL12 12” Round

Back

View

1-½” Flange

EN

MULTI-BLOWER TRANSITIONLOW PROFILE ELBOW

A: 10”

B: 12”

A:

6”

17-½”

B:

16-½”

8” Round

MODEL DESCRIPTION

AKVBE8

8” Round to 6” x 8-1/2” Rect.

LOW PROFILE ROOF CAP

(MINIMUM 4/12 PITCH)

16-¾”

MODEL DESCRIPTION

AKVRC6HP 6” Round

AKVRC8HP 8” Round

THE INFORMATION IN THIS DOCUMENT IS SUBJECT TO CHANGE AT ANY TIME WITHOUT NOTICE.

16”

16-¾”

6-½”

A:

23-¼”

B:

30-½”

ITEM

A

B

MODEL DESCRIPTION

AKVT6810 6” & 8” to 10”

AKVT8812 8” & 8” to 12”

LOW PROFILE ROOF CAP

(MINIMUM 4/12 PITCH)

22-½”

MODEL DESCRIPTION

AKVRC10HP 10” Round

AKVRC12HP 12” Round

10-½”

20-¾”

©2019 Hestan Commercial Corporation

17

Page 22

DUCT COVERS

EN

HESTAN

MODEL #

KVDC1812 DUCT COVER, VENTILATION, 18W X 12H KVC30

KVDC1812-XX DUCT COVER, VENTILATION, 18W X 12H (COLOR) KVC30

KVDC2412 DUCT COVER, VENTILATION, 24W X 12H KVC36

KVDC2412-XX DUCT COVER, VENTILATION, 24W X 12H (COLOR) KVC36

KVDC3012 DUCT COVER, VENTILATION, 30W X 12H KVC42

KVDC3012-XX DUCT COVER, VENTILATION, 30W X 12H (COLOR) KVC42

KVDC3612 DUCT COVER, VENTILATION, 36W X 12H KVC48

KVDC3612-XX DUCT COVER, VENTILATION, 36W X 12H (COLOR) KVC48

KVDC4212 DUCT COVER, VENTILATION, 42W X 12H KVC54

KVDC4212-XX DUCT COVER, VENTILATION, 42W X 12H (COLOR) KVC54

KVDC1824 DUCT COVER, VENTILATION, 18W X 24H KVC30

KVDC1824-XX DUCT COVER, VENTILATION, 18W X 24H (COLOR) KVC30

KVDC2424 DUCT COVER, VENTILATION, 24W X 24H KVC36

KVDC2424-XX DUCT COVER, VENTILATION, 24W X 24H (COLOR) KVC36

KVDC3024 DUCT COVER, VENTILATION, 30W X 24H KVC42

KVDC3024-XX DUCT COVER, VENTILATION, 30W X 24H (COLOR) KVC42

KVDC3624 DUCT COVER, VENTILATION, 36W X 24H KVC48

KVDC3624-XX DUCT COVER, VENTILATION, 36W X 24H (COLOR) KVC48

KVDC4224 DUCT COVER, VENTILATION, 42W X 24H KVC54

KVDC4224-XX DUCT COVER, VENTILATION, 42W X 24H (COLOR) KVC54

DESCRIPTION

HOOD

MODEL

USE WITH

18

KVDC1836 DUCT COVER, VENTILATION, 18W X 36H KVC30

KVDC1836-XX DUCT COVER, VENTILATION, 18W X 36H (COLOR) KVC30

KVDC2436 DUCT COVER, VENTILATION, 24W X 36H KVC36

KVDC2436-XX DUCT COVER, VENTILATION, 24W X 36H (COLOR) KVC36

KVDC3036 DUCT COVER, VENTILATION, 30W X 36H KVC42

KVDC3036-XX DUCT COVER, VENTILATION, 30W X 36H (COLOR) KVC42

KVDC3636 DUCT COVER, VENTILATION, 36W X 36H KVC48

KVDC3636-XX DUCT COVER, VENTILATION, 36W X 36H (COLOR) KVC48

KVDC4236 DUCT COVER, VENTILATION, 42W X 36H KVC54

KVDC4236-XX DUCT COVER, VENTILATION, 42W X 36H (COLOR) KVC54

NOTE: -XX indicates color model.

-BK for Stealth - Black -WH for Froth - White -RD for Matador - Red

-YW for Sol - Yellow -OR for Citra - Orange -BG for Tin Roof - Burgundy

-PP for Lush - Purple -BU for Prince - Blue -GR for Grove - Green

-GG for Pacific Fog - Graphite Gray -TQ for Bora Bora – Turquoise

©2019 Hestan Commercial Corporation

Page 23

PARTS / SERVICE

SERVICE DATA RECORD

The rating label contains the model number and serial number of the appliance. See page4 for

the location of the rating label.

Now is a good time to write this information below in the space provided. Keep your invoice for

warranty validation.

Model Number _________________________________

Serial Number __________________________________

Date of Installation or Occupancy __________________

PARTS LIST

Please visit the Hestan website to access the parts list for your Hestan Indoor product:

www.hestanhome.com.

SERVICE

All warranty and non-warranty repairs should be performed by qualified service personnel. To

locate an authorized service agent in your area, contact your Hestan dealer, local representative, or

the manufacturer. Before you call, please have the model number and serial number information

ready.

EN

Hestan Commercial Corporation

3375 E. La Palma Avenue

Anaheim, CA 92806

(888) 905-7463

LIMITED WARRANTY

WHAT THIS LIMITED WARRANTY COVERS

Hestan Commercial Corporation (“HCC”) warrants to the original consumer purchaser of a Hestan

Indoor Cooking product (the “Product”) from an HCC authorized dealer that the Product is free

from defective materials or workmanship for a period of two (2) years from the date of original

retail purchase or closing date for new construction, whichever period is longer (“Limited Warranty

Period”). HCC agrees to repair or replace, at HCC’s sole option, any part or component of the

Product that fails due to defective materials or workmanship during the Limited Warranty Period.

This Limited Warranty is not transferable and does not extend to anyone beyond the original

consumer purchaser (“Purchaser”). This Limited Warranty is valid only on Products purchased

and received from an HCC authorized dealer in the fifty United States, the District of Columbia

and Canada. This Limited Warranty applies only to Products in non-commercial use and does not

extend to Products used in commercial applications.

HOW TO OBTAIN WARRANTY SERVICE

If the Product fails during the Limited Warranty Period for reasons covered by this Limited

Warranty, the Purchaser must immediately contact the dealer from whom the Product was

purchased or HCC at 888.905.7463.

©2019 Hestan Commercial Corporation

19

Page 24

EN

LIMITED WARRANTY

Purchaser is responsible for making the Product reasonably accessible for service or for paying the

cost to make the Product reasonably accessible for service. Service is to be provided during normal

business hours of the authorized Hestan Commercial Service Provider. To the extent Purchaser

requests service outside of the normal business hours of the authorized Hestan Commercial Service

Provider, Purchaser will pay the difference between regular rates and overtime or premium rates.

Purchaser is required to pay all travel costs for travel beyond 50 miles (one way) from the nearest

authorized Hestan Commercial Service Provider.

EXTENSIONS TO TWO YEAR LIMITED WARRANTY PERIOD:

IN ADDITION TO THE TWO-YEAR LIMITED WARRANTY, THE FOLLOWING COMPONENTS

HAVE EXTENDED WARRANTY COVERAGE AS SPECIFICALLY SET FORTH BELOW:

1. The Product’s gas burners (excludes appearance), electric heating elements, blower motors

(ventilation hoods), electronic control boards, magnetron tubes and induction generators

(where applicable) are warranted to be free from defects in material and workmanship under

normal non-commercial use and service for a period of five (5) years of the original Purchaser.

This excludes surface corrosion, scratches, and discoloration which may occur during normal

use and is limited to replacement of the defective part(s), with the Purchaser paying all other

costs, including labor, shipping and handling, as applicable.

WHAT THIS LIMITED WARRANTY DOES NOT COVER:

This Limited Warranty does not cover and HCC will not be responsible for and will not pay for:

damage to or defects in any Product not purchased from an HCC authorized dealer; color variations

in color finishes or other cosmetic damage; failure or damage from abuse, misuse, accident, fire,

natural disaster, commercial use of the Product, or loss of electrical power or gas supply to the

Product; damage from alteration, improper installation, or improper operation of the Product;

damage from improper or unauthorized repair or replacement of any part or component of the

Product; damage from service by someone other than an authorized agent or representative of the

Hestan Commercial Service Network; normal wear and tear; damage from exposure of the Product

to a corrosive atmosphere containing chlorine, fluorine, or any other damaging chemicals; damage

resulting from the failure to provide normal care and maintenance to the Product; damage HCC

was not notified of within the Limited Warranty Period; and incidental and consequential damages

caused by any defective material or workmanship.

(CONT.)

20

ARBITRATION:

This Limited Warranty is governed by the Federal Arbitration Act. Any dispute between Purchaser

and HCC regarding or related to the Product or to this Limited Warranty shall be resolved by

binding arbitration only on an individual basis with Purchaser. Arbitration will be conducted by the

American Arbitration Association (“AAA”) in accordance with its Consumer Arbitration Rules or by

JAMS. The arbitration hearing shall be before one arbitrator appointed by the AAA or JAMS. The

arbitrator shall not conduct class arbitration and Purchaser shall not bring any claims against HCC

in a representative capacity on behalf of others.

LIMITATION OF LIABILITY:

This Limited Warranty is the final, complete and exclusive agreement between HCC and Purchaser

regarding the Product.

THERE ARE NO EXPRESS WARRANTIES OTHER THAN THOSE LISTED AND DESCRIBED

ABOVE. NO WARRANTIES WHETHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT

LIMITED TO, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE SHALL APPLY AFTER THE LIMITED WARRANTY PERIOD STATED

ABOVE. NO OTHER EXPRESS WARRANTY OR GUARANTY GIVEN BY ANY PERSON, FIRM

OR CORPORATION WITH RESPECT TO THIS PRODUCT SHALL BE BINDING ON HCC. HCC

©2019 Hestan Commercial Corporation

Page 25

LIMITED WARRANTY

ASSUMES NO RESPONSIBILITY THAT THE PRODUCT WILL BE FIT FOR ANY PARTICULAR

PURPOSE, EXCEPT AS OTHERWISE PROVIDED BY APPLICABLE LAW.

HCC SHALL NOT BE LIABLE FOR LOSS OF REVENUE OR PROFITS, FAILURE TO REALIZE

SAVINGS OR OTHER BENEFITS, OR ANY OTHER SPECIAL, INCIDENTAL OR CONSEQUENTIAL

DAMAGES CAUSED BY THE USE, MISUSE OR INABILITY TO USE THE PRODUCT, REGARDLESS

OF THE LEGAL THEORY ON WHICH THE CLAIM IS BASED, AND EVEN IF HCC HAS BEEN

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. NO RECOVERY OF ANY KIND AGAINST

HCC SHALL BE GREATER IN AMOUNT THAN THE PURCHASE PRICE OF THE PRODUCT.

WITHOUT LIMITING THE FOREGOING, YOU ASSUME ALL RISK AND LIABILITY FOR

LOSS, DAMAGE OR INJURY TO YOU AND YOUR PROPERTY AND TO OTHERS AND THEIR

PROPERTY ARISING OUT OF THE USE, MISUSE OR INABILITY TO USE THE PRODUCT NOT

CAUSED DIRECTLY BY THE NEGLIGENCE OF HCC. THIS LIMITED WARRANTY STATES YOUR

EXCLUSIVE REMEDY.

No oral or written representation or commitment given by anyone, including but not limited

to, an employee, representative or agent of HCC will create a warranty or in any way increase

the scope of this express Limited Two Year Warranty. If there is any inconsistency between

this Limited Warranty and any other agreement or statement included with or relating to the

Product, this Limited Warranty shall govern. If any provision of this Limited Warranty is found

invalid or unenforceable, it shall be deemed modified to the minimum extent necessary to make

it enforceable and the remainder of the Limited Warranty shall remain valid and enforceable

according to its terms.

(CONT.)

EN

INTERACTION OF LAWS WITH THIS LIMITED WARRANTY:

Some states, provinces or territories may not allow limitations on how long an implied warranty

lasts or the exclusion or limitation of incidental or consequential damages, so the above limitations

or exclusions may not apply to you. Some states, provinces or territories may provide for

additional warranty rights and remedies, and the provisions contained in this Limited Warranty

are not intended to limit, modify, take away from, disclaim or exclude any mandatory warranty

requirements provided by states, provinces or territories, including certain implied warranties. This

warranty gives you specific legal rights, and you may also have other rights which vary depending

on location.

Any questions about this Limited Warranty may be directed to

Hestan Commercial Corporation at (888) 905-7463

©2019 Hestan Commercial Corporation

21

Page 26

LE NON-RESPECT À LA LETTRE DE CES INSTRUCTIONS PEUT CAUSER

UN INCENDIE OU UNE EXPLOSION, QUI POURRAIT ENTRAÎNER DES

DOMMAGES MATÉRIELS, DES BLESSURES OU LA MORT.

Ne pas entreposer ou utiliser d’essence ou tout autre liquide ou gaz inflammable à

proximité de cet appareil ou de tout autre appareil.

L’installation et le service doivent être effectués par un installateur qualifié ou une agence

de service.

NE PAS RÉPARER, REMPLACER OU ENLEVER TOUTE PIÈCE DE L’APPAREIL, SAUF

SI SPÉCIFIQUEMENT RECOMMANDÉ DANS LES MANUEL. UNE INSTALLATION,

UN ENTRETIEN OU UNE MAINTENANCE INCORRECTS PEUT ENTRAÎNER DES

BLESSURES OU DES DOMMAGES MATÉRIELS. CONSULTEZ CE MANUEL DE

L’ORIENTATION. TOUS LES AUTRES SERVICES DEVRAIENT ÊTRE EFFECTUÉS PAR

UN TECHNICIEN DE SERVICE HESTAN AUTORISÉ.

LISEZ ATTENTIVEMENT ET COMPLÈTEMENT CES INSTRUCTIONS

AVANT D’INSTALLER OU D’UTILISER VOTRE APPAREIL AFIN DE RÉDUIRE

LES RISQUES D’INCENDIE, DE BRÛLURE OU D’AUTRES BLESSURES.

CONSERVER CE MANUEL POUR RÉFÉRENCE FUTURE.

DÉFINITIONS DE SÉCURITÉ

CECI INDIQUE QUE L’INOBSERVATION DE CET AVERTISSEMENT

PEUT ENTRAÎNER DES BLESSURES GRAVES VOIRE MORTELLES.

CECI INDIQUE QUE L’INOBSERVATION DE CET AVERTISSEMENT

PEUT ENTRAÎNER DES BLESSURES MINEURES OU MODÉRÉES.

CECI INDIQUE QUE L’INOBSERVATION DE CET AVERTISSEMENT

PEUT ENTRAÎNER DES DOMMAGES DE L’APPAREIL OU DES DÉGÂTS

MATÉRIELS.

INSTALLATEUR: LAISSER CE MANUEL AVEC LE PROPRIÉTAIRE DE

L’APPAREIL.

PROPRIÉTAIRE: CONSERVEZ CE MANUEL POUR RÉFÉRENCE FUTURE.

Page 27

Un message de Hestan

Les innovations culinaires primées de Hestan et les caractéristiques spéciales ont

réinventé la cuisine du restaurant et redéfini l’expérience culinaire dans certains

des restaurants les plus acclamés de l’Amérique. Hestan prend maintenant cette

performance à l’arrière de la maison et la met au centre de la vôtre. Pensé et

méticuleusement conçu, Hestan vous servira magnifiquement pour les années à

venir.

Hestan est la seule marque résidentielle née des rêves et des exigences des chefs

professionnels. De la cuisinière à la réfrigération, chaque détail est conçu pour

offrir la performance et la fiabilité attendues dans un restaurant - maintenant

disponible pour vous.

Nous apprécions que vous ayez choisi Hestan, et nous nous engageons à vous

offrir le meilleur.

Bienvenue à Hestan

Page 28

Page 29

TABLES DES MATIERES

1 PRÉCAUTIONS DE SÉCURITÉ - AVANT DE COMMENCER

4 NUMÉROS DE MODÈLE

4 PLAQUE SIGNALÉTIQUE

5 RESPECT DE LA RÉGLEMENTATION ET DES CODES EN VIGUEUR

5 MODE D’EMPLOI

6 NETTOYAGE ET ENTRETIEN

9 DÉPANNAGE

10 BONNE PRATIQUE DE CANALISATION

11 INSTALLATION

18 ACCESSOIRES DE VENTILATION

19 CACHE - CONDUIT

20 PIÈCES / SERVICE

20 GARANTIE LIMITÉE

PRÉCAUTIONS DE SÉCURITÉ - AVANT DE COMMENCER

Lorsque votre système de ventilation Hestan est correctement entretenu, il assure un service sûr

et fiable pendant de nombreuses années. Lors de l’utilisation de ce système de ventilation, les

pratiques de sécurité de base doivent être suivies comme décrit dans les pages suivantes.

FR

IMPORTANT: Conservez ces instructions pour l’inspecteur d’utilitaires local.

INSTALLATEUR: Veuillez laisser ces instructions d’installation avec le propriétaire.

PROPRIÉTAIRE: Veuillez lire ces instructions et les sauvegarder pour référence future.

RISQUE DE CHOC ÉLECTRIQUE

Il est de la responsabilité de l’utilisateur de connecter l’appareil par un électricien

agréé conformément à tous les codes et normes applicables, y compris la

construction liée au feu. Lisez étape 16 - «CONNEXION DU CÂBLAGE:» à la

page 16 pour plus de détails.

ALIMENTATION ÉLECTRIQUE ET MISE A LA TERRE

• Cet appareil doit être mis à la terre. Lisez étape 16 - «CONNEXION DU CÂBLAGE:» à la page

16 pour plus de détails.

• Cet appareil doit être connecté à un circuit dédié 120 VAC monophasé, 60 Hz, 20 ampères.

• PROPRIÉTAIRE: Demandez à l’installateur de vous indiquer l’emplacement du disjoncteur

électrique pour savoir comment couper l’alimentation de cet appareil.

Convient pour une utilisation dans des applications extérieures couvertes lorsqu’il est installé dans

un circuit protégé par GFCI.

©2019 Hestan Commercial Corporation

1

Page 30

PRÉCAUTIONS DE SÉCURITÉ - AVANT DE COMMENCER

(SUITE)

PRÉCAUTIONS GÉNÉRALES DE SÉCURITÉ

Lorsqu’il est correctement entretenu, votre hotte de ventilation est un système de ventilation sûr et

fiabl. Lisez attentivement toutes les instructions avant d’utiliser ce système de ventilation. Lors de

l’utilisation d’appareils de cuisine, des précautions de sécurité de base doivent être respectées.

FR

POUR RÉDUIRE LES RISQUES D’INCENDIE, D’ÉLECTROCUTION

OU DE BLESSURES, OBSERVEZ CE QUI SUIT:

a) N’utilisez cet appareil que de la manière prévue par le fabricant. Si vous avez des questions,

contactez le fabricant.

b) Avant de procéder à l’entretien ou au nettoyage de l’unité, éteignez le panneau de service et

verrouillez les moyens de déconnexion du service afin d’éviter toute mise sous tension

accidentelle. Lorsque les moyens de déconnexion du service ne peuvent pas être verrouillés,

fixez fermement un dispositif d’avertissement proéminent, tel qu’une étiquette, sur le panneau

de service.

POUR USAGE VENTILATOIRE GÉNÉRAL UNIQUEMENT. NE PAS

UTILISER POUR L’ÉCHAPPEMENT DE MATÉRIAUX OU DE

VAPEURS DANGEREUX OU EXPLOSIVES .

POUR RÉDUIRE LE RISQUE D’UN FEU DE GRAISSE SUR LA

CUISINIÈRE:

a) Ne laissez jamais des brûleurs ou des unités de surface sans surveillance à des réglages élevés.

Les débordements provoquent le tabagisme et les débordements graisseux qui peuvent

s’enflammer. Chauffer les huiles lentement sur les réglages bas ou moyens.

b) Allumez toujours le hotte lorsque vous cuisinez à feu vif ou lorsque vous flambez de la

nourriture (c.-à-d. Crêpes Suzette, cerises jubilées, poivres de bœuf Flambe).

c) Nettoyer fréquemment les ventilateurs. La graisse ne doit pas s’accumuler sur le ventilateur ou

le filtre.

d) Utilisez la taille de casserole appropriée. Utilisez toujours des ustensiles de cuisine adaptés à la

taille de l’élément de surface ou du brûleur.

POUR RÉDUIRE LES RISQUES DE BLESSURES EN CAS DE FEU DE

GRAISSE SUR LA CUISINIÈRE, OBSERVEZ CE QUI SUIT:

a) ÉTOUFFER LES FLAMMES avec un couvercle hermétique, une plaque à biscuits ou un plateau

métallique, puis éteignez le brûleur. SOYEZ PRUDENT POUR PRÉVENIR LES BRÛLURES.

Si les flammes ne s’éteignent pas immédiatement, ÉVACUER ET APPELER LE SERVICE DES

INCENDIES.

b) NE JAMAIS RAMASSER UN PAN INFLAMMABLE - Vous pourriez être brûlé

c) N’UTILISEZ PAS D’EAU, y compris des torchons ou des serviettes humides - une violente

explosion de vapeur se produira.

d) Utilisez un extincteur UNIQUEMENT si:

1. Vous savez que vous avez un extincteur de type ABC ou type K, et vous savez déjà comment

l’utiliser.

2. Le feu est petit et contenu dans la zone où il a commencé.

3. Le service d’incendie est appelé.

4. Vous pouvez combattre le feu avec votre dos à une sortie.

* - Basé sur «Kitchen Fire Safety Tips» publié par NFPA.

2

©2019 Hestan Commercial Corporation

Page 31

PRÉCAUTIONS DE SÉCURITÉ - AVANT DE COMMENCER

(SUITE)

RISQUE DE BRÛLURE

Ce système de ventilation est conçu pour être utilisé avec des cuisinières ou tables de cuisson, qui

peuvent devenir très chauds pendant le fonctionnement. Respectez les avertissements et les mises

en garde concernant l’appareil de cuisson.

Ce système de ventilation doit être réparé uniquement par un technicien agréé Hestan. Contactez

le centre de service agréé le plus proche pour l’examen, la réparation ou le réglage.

Ne réparez ou ne remplacez aucune partie du système à moins d’une recommandation spécifique.

Renvoyer le service à un réparateur agréé.

N’utilisez pas ce système de ventilation s’il ne fonctionne pas correctement ou s’il a été endommagé

jusqu’à ce qu’un réparateur agréé l’ait examiné.

Installez ou localisez ce système de ventilation uniquement conformément à la section Installation

de ce manuel. Ne pas couvrir ou bloquer les ouvertures de ce système de ventilation.

Il est fortement recommandé de disposer d’un extincteur de cuisine adapté (type ABC ou type K)

facilement disponible et très visible à proximité de tout appareil de cuisson.

FR

SÉCURITÉ PENDANT LE NETTOYAGE

Nettoyez uniquement les pièces du système de ventilation indiquées dans ce manuel, de la manière

spécifiée dans ce manuel.

Remarque: les «ventilateurs» et «filtre» dans les avertissements précédents se réfèrent à la roue(s)

du soufflante, la boîtier(s) de la soufflante, et la bouclier de la soufflante.

CE MANUEL DOIT RESTER AVEC LA PROPRIÉTAIRE POUR RÉFÉRENCE FUTURE.

©2019 Hestan Commercial Corporation

3

Page 32

NUMÉROS DE MODÈLE

FR

NO.

DESCRIPTION

MODÈLE

KVC 30 Système de Ventilation de Cuisine 600 CFM à style Cheminée de 30 po

[76,2 cm]

KVC 36 Système de Ventilation de Cuisine 600 CFM à style Cheminée de 36 po

[91,4 cm]

KVC 42 Système de Ventilation de Cuisine 900 CFM à style Cheminée de 42 po

[106,7 cm]

KVC 48 Système de Ventilation de Cuisine 900 CFM à style Cheminée de 48 po

[121,9 cm]

KVC 54 Système de Ventilation de Cuisine 1200 CFM à style Cheminée de 54 po

[137,2 cm]

PUISSANCE ET FLUX D’AIR NOMINAL

Paquet de

Ventilateur

WM2L

ventilateurs

double

WM2L double +

WM1L Unique

WM2L

ventilateurs

double à deux

Ampéres

2,9 600 900 531 480 430 8 po (50 po

4,4 900 1350 804 725 655 AKVT6810:

5,8 1200 1800 1062 960 860 AKVT8812:

CFM

SP@0,0 *

Équivalent

CFM **

CFM

SP@0,1 *

CFM

SP@0,2 *

SP@0,3 *

CFM

VENTILATEURS

UTILISÉS

WM2L ventilateurs double

WM2L ventilateurs double

WM2L double + WM1L

unique

WM2L ventilateurs double

à deux

WM2L ventilateurs double

à deux

Taille minimale du

conduit rond

2

)

[20,3 cm (322,6 cm2)]

10 po (79 po

[25,4 cm (509,7 cm2)]

12 po (113 po

[30,5 cm (729 cm2)]

2

Sones

)

2

)

***

6,5

6,3

6,6

Toutes les unités 115 VAC 60 Hz 1550 RPM [1 CFM = 1.7 m³/hr]

* Pression Statique en pouces de colonne d’eau.

** Lorsque vous comparez avec des unités soufflantes fabriquées par d’autres fabricants, utilisez le «équivalent CFM».

*** Cotes conformes au Standard Test Code du Energy Systems Laboratory de la Texas Engineering Experiment Station.

PLAQUE SIGNALÉTIQUE

La plaque signalétique donne des informations importantes sur cet appareil Hestan telles que

le numéro de modèle et de série, les caractéristiques électriques et les dégagements minimum

d’installation.

La plaque signalétique se trouve sur le boîtier de soufflante.

Si un entretien est nécessaire, contactez le service clientèle de Hestan avec les informations sur le

modèle et le numéro de série figurant sur la plaque.

(model number)

(serial number)

4

Plaque signalétique typique

©2019 Hestan Commercial Corporation

Emplacement de la

plaque signalétique

Page 33

RESPECT DE LA RÉGLEMENTATION ET DES CODES EN VIGUEUR

L’installation de cet appareil de cuisson doit être effectuée conformément aux codes locaux. En

l’absence de tels codes, installer cet appareil conformément au National Electrical Code et les codes

locaux.

Tous les composants électriques doivent mis à la terre conformément aux codes locaux ou, en

l’absence de tels codes, au National Electrical Code

l’électricité du Canada

CSA C22.1.

ANSI/NFPA 70

ou au Code national de

MODE D’EMPLOI

CARACTÉRISTIQUES DU SYSTÈME DE VENTILATION

Des contrôles de vitesse sont fournis pour chaque ensemble de soufflante. Les systèmes à deux

soufflantes auront un bouton de contrôle de la vitesse, tandis que les systèmes à trois ou quatre

souffleries auront deux boutons de contrôle de la vitesse.

Un bouton de contrôle est fourni pour l’intensité de l’éclairage.

La disposition des commandes sera similaire à celle montrée ci-dessous.

UTILISATION DE LA HOTTE

L’utilisateur peut commencer avec la hotte au réglage le plus bas, puis augmenter la vitesse et / ou

activer des ventilateurs supplémentaires au besoin. L’utilisation de la hotte à des réglages élevés

peut augmenter les exigences de chauffage ou de climatisation et les coûts pour la maison.

FR

BOUTON DE COMMANDE DE VENTILATEUR

Pour faire fonctionner la (les) soufflante(s), faites tourner le bouton dans les réglages de vitesse du

ventilateur en le tournant dans le sens horaire (en faisant face au bouton).

Tournez le bouton dans le sens anti-horaire pour réduire la vitesse du ventilateur.

BOUTON DE CONTRÔLE DE LA LUMIÈRE

Pour faire fonctionner les lumières, faites tourner le bouton à travers les réglages d’intensité

lumineuse en le tournant dans le sens horaire (en faisant face au bouton). Tournez la bouton dans le

sens anti-horaire pour atténuer les lumières ou les éteindre.

Commandes pour deux ventilateurs

1

Les contrôles pour trois et quatre ventilateurs

3

2

2

4

Article Fonction

Contrôle du

1

ventilateur

Contrôle de la

2

lumière

Contrôle des

3

ventilateurs 1 et 2

Contrôle du

4

ventilateur 3 ou

des ventilateurs 3

et 4

©2019 Hestan Commercial Corporation

5

Page 34

FR

NETTOYAGE ET ENTRETIEN

NETTOYAGE DU SYSTÈME DE VENTILATION

Les exigences de nettoyage dépendent entièrement de l’utilisation et de l’environnement. Plus la

cuisson est chaude et / ou grasse, plus le hotte et le souffleur doivent être nettoyés.

Le bac à graisse et le ventilateur ne sont pas visibles de l’extérieur, ils doivent donc être retirés pour

inspection.

Après avoir inspecté le bac plusieurs fois au cours de six mois ou d’un an, vous pouvez définir un

programme de nettoyage en fonction de votre mode d’utilisation.

LA HOTTE

Essuyez l’intérieur et l’extérieur de la hotte si nécessaire avec un chiffon doux et de l’eau chaude

savonneuse (un détergent à vaisselle liquide est acceptable). N’utilisez pas d’acides, d’abrasifs,

de détergents puissants, de solvants ou de tampons à récurer. L’acier inoxydable doit être traité

avec un nettoyant d’acier inoxydable de qualité tel que Stainless Steel Magic®. Suivez toutes les

instructions de l’étiquette. Ne pas polir à travers le grain ou dans les cercles.

BOÎTIER ET BOUCLIER

Pour réduire le risque de blessure, assurez-vous que l’alimentation est

coupée dans le hotte avant de retirer le(s) bouclier(s) et le(s) boîtier(s)

du soufflante.

Le ventilateur capture les sous-produits de la graisse dans le(s) boîtier(s) de la soufflante et le(s)

bouclier(s) de la soufflante. Le(s) bouclier(s) nécessitent un nettoyage plus fréquent que le boîtier

du soufflante, mais la fréquence de cuisson détermine la fréquence à laquelle chaque élément doit

être nettoyé.

Article Description

Boîtier de soufflante avec porte(s)

1

amortissante

Bouclier de soufflante

2

BOUCLIER

Les boucliers sont facilement retirés pour le nettoyage en tirant le(s) bouclier(s) vers l’avant de la

hotte.

Veillez à maintenir le bac à niveau si la hotte a été récemment utilisée et si la graisse

est encore chaude.

Inspectez et nettoyez le bouclier. (Détails à suivre)

BOÎTIER DE SOUFFLERIE

Pour retirer le boîtier de la soufflante:

1. Déverrouillez deux loquets de valise, un de chaque côté du boîtier.

1

2

2. Soutenez le boîtier et retirez-le de la base du souffleur.

3. Tout en le tirant vers l’arrière, faites-le doucement basculer vers le bas pour dégager la (les)

roue(s) du souffleur.

6

©2019 Hestan Commercial Corporation

Page 35

NETTOYAGE ET ENTRETIEN

2

NETTOYAGE

Nettoyez le(s) bouclier(s) et /ou le(s) boîtier(s) du soufflante dans un évier d’eau chaude savonneuse

(détergent à vaisselle liquide) et laissez tremper pendant quelques minutes. Laver avec une éponge

ou un torchon, rincer et laisser égoutter avant de réinstaller. Il est également possible de placer le(s)

boîtier(s) de la soufflante et le(s) bouclier(s) de la soufflante dans un lave-vaisselle.

(SUITE)

2

3

4

1

Article Description

1

2

3

4

Boîtier du moteur

Roue de soufflante

Boîtier de soufflante avec porte(s) amortissante

Bouclier de soufflante

FR

Pour réduire le risque de blessure, assurez-vous que l’alimentation est

coupée dans le hotte avant de retirer le(s) bouclier(s) et le(s) boîtier(s)

du soufflante.

Un nettoyage régulier du boîtier de la soufflante devrait empêcher l’accumulation de graisse sur

la roue de la soufflante. Si une accumulation de graisse se produit, la roue de la soufflante peut

facilement être nettoyée à l’aide d’une brosse à dents à poils doux et d’un dégraissant commun tel

que Formula 409

Article Description

Clip d’équilibrage

1

Roue de soufflante

2

®

.

Veillez à ne pas déplacer ou perdre les clips d’équilibrage en métal qui peuvent être

fixés à la roue.

1

©2019 Hestan Commercial Corporation

7

Page 36

FR

NETTOYAGE ET ENTRETIEN

RETRAIT DE LA ROUE

Pour les cas où la roue de soufflante doit être retirée, suivez les instructions ci-dessous.

• Le retrait de la roue de soufflante nécessite une clé hexagonale de 1/8 po. Ceci peut être

obtenu auprès de votre quincaillerie ou de votre fournisseur d’outils local.

La roue est retenue par une vis de réglage sur le côté du moyeu de la roue (1) qui se resserre contre

un point «plat» sur l’arbre du moteur. (Voir l’illustration à la page précédente.)

1. Localiser la vis de réglage sur le côté du moyeu de la roue

2. Insérer une clé à travers les lames de la roue de ventilateur et dans la vis de réglage.

3. Desserrez la vis de réglage d’un demi-tour dans le sens antihoraire.

Si la roue est difficile à enlever, la zone où l’arbre du moteur entre en contact avec le moyeu de

la roue de soufflante peut nécessiter une pulvérisation d’une huile pénétrante commune telle

que WD-40®.

Après avoir laissé tremper l’huile pénétrante pendant quelques minutes, poussez légèrement la

roue de la soufflante vers l’avant, puis retirez doucement la roue de la soufflante de l’arbre du

moteur.

• Faites attention à ne pas plier ou déformer la roue de la soufflante et veillez à ne pas déplacer

ou perdre les clips d’équilibrage métalliques qui peuvent être fixés sur la roue.

Une brosse à dents à poils doux et de l’eau chaude savonneuse peut être utilisée pour nettoyer les

lames ou faire tremper la roue de la soufflante dans de l’eau chaude savonneuse.

(SUITE)

INSTALLATION DE LA ROUE

Lors de la réinstallation de la roue sur l’arbre du moteur, assurez-vous que la vis de réglage est en

contact direct avec le «point plat» sur l’arbre du moteur.

1. Faites glisser la roue du ventilateur sur l’arbre du moteur aussi loin que possible, en vous

assurant que l’arrière de la roue du ventilateur ne touche pas les vis de montage du moteur qui

dépassent du moteur.

• Si le moteur est trop en arrière, il frottera les vis du support du moteur, et s’il est trop en avant,

il frottera l’intérieur du boîtier du ventilateur.

2. Ajustez légèrement la roue de la soufflante pour trouver l’emplacement correct de l’avant vers

l’arrière.

3. Serrez la vis de réglage (dans le sens des aiguilles d’une montre) pour verrouiller la roue du

ventilateur dans la bonne position.

Pour les hottes qui ont plus d’une roue de soufflante, assurez-vous que les roues

blancs sont assorties avec des anneaux de moteur blanc, et les roues noires sont

assorties avec des anneaux de moteur noir.

Le hotte de ventilation ne fonctionnera pas correctement si les roues du soufflante et les moteurs

sont incompatibles.

8

©2019 Hestan Commercial Corporation

Page 37

NETTOYAGE ET ENTRETIEN

(SUITE)

REMPLACEMENT DU MOTEUR

Pour réduire le risque de blessure, coupez l’alimentation du disjoncteur

ou du disjoncteur avant d’essayer de retirer le moteur de la soufflante.

IDENTIFICATION ET POSITIONNEMENT DU MOTEUR

Les moteurs sont codés par couleur. Les moteurs noir et blanc ont des rotations différentes et

doivent être installés dans les bonnes positions.

• Les boîtiers avec une seule soufflante utilisent un roue blanc.

• Les boîtiers avec deux soufflante utilisent une roue blanc sur la droite et noire sur la gauche.

Assurez-vous d’avoir le bon moteur dans chaque position du boîtier.

• Si le moteur de soufflante de remplacement comprend une roue de soufflante, vous pouvez

retirer le moteur et la roue ensemble. Si vous réutilisez votre roue existante, vous pouvez

retirer la roue avant de retirer le moteur.

1. Retirez le bouclier et le boîtier de la soufflerie comme

décrit dans «RETRAIT DE LA ROUE» à la page8.

2. Utilisez un tourne-écrou ¼ po pour retirer les trois vis du

support moteur qui fixent le moteur à la boîtier.

FR

3. Tirez doucement le moteur vers l’avant et vers le bas.

4. Débranchez le faisceau de câblage, retirez l’ancien moteur.

• Pour éviter d’endommager la roue de soufflante, vous

pouvez installer le moteur, puis installer la roue sur le moteur.

5. Soulevez le nouveau moteur pour pouvoir connecter le

faisceau de câblage. Assurez-vous de bien engager les

connexions électriques et serrez les vis de fixation du

moteur.

6. Vérifiez le jeu des roues de la soufflerie et réglez au

besoin, comme décrit dans «INSTALLATION DE LA

ROUE» à la page8.

DÉPANNAGE

Si la hotte ne fonctionne pas de manière satisfaisante, vérifiez les points suivants:

• Est-ce que les soufflantes courent?

• Les roues de la soufflante sont-elles installées sur les bons moteurs? (roue noire sur le moteur

noir, roue blanc sur le moteur blanc)

• Les ensembles moteur et roue sont-ils installés aux bons emplacements?

• Vérifiez les portes d’amortissement dans le boîtier du soufflante - bougent-ils / s’ouvrent-ils

librement?

• Vérifiez les registres / évents à l’extérieur - ouvrent-ils librement, sans obstacles?

• Vérifiez s’il y a des conduits endommagés ou obstrués.

©2019 Hestan Commercial Corporation

9

Page 38

FR

OUI

NON

aiguisés

Mauvaise combinaison

de deux conduits

BONNE PRATIQUE DE CANALISATION

EXIGENCES GÉNÉRALES

Respectez les codes locaux en ce qui concerne les exigences de conduits spéciaux et le placement

du conduit contre les combustibles.

• L’utilisation des transitions recommandées (voir ACCESSOIRES DE VENTILATION) garantira

une efficacité adéquate.

• L’utilisation des chapeaux de toit ou des évents murales recommandés (voir ACCESSOIRES DE

VENTILATION) garantira une efficacité adéquate.

• Utilisez du ruban adhésif HVAC métalliquee (pas de ruban adhésif en toile grise) pour sceller

tous les joints.

• La hotte doit être canalisée vers l’extérieur sans restriction.

EXIGENCES DE SOUFFLEUR

Le ventilateur double (WM2L, utilisé dans tous les systèmes) nécessite un conduit rond de 8 po

[20,3 cm] ou équivalent (50 po² - 322,6 cm²). Le ventilateur simple (WM1L, utilisé dans les systèmes

900 CFM) nécessite un conduit rond de 6 po ou équivalent (28 po² - 180,6 cm²).

TAILLE DE CONDUIT COMBINÉE APRÈS UNE TRANSITION

Simple et double (WM1L et WM2L) combinent à 10 po [25,4 cm] rond ou équivalent 79 po² [509,7

cm²] en utilisant une transition multi-soufflante telle que AKVT6810 (optionnel).

Doubles à deux (deux WM2L) se combinent à 12 po [30,5 cm] rond ou équivalent 113 po² [729 cm²]

en utilisant une transition multi-soufflante telle que AKVT8812 (optionnel).

EXIGENCES DE CANALISATION (BONNE PRATIQUE DE CANALISATION)

• NE JAMAIS réduire la taille du conduit. Lors de la combinaison de conduits, la surface en

pouces carrés du conduit de sortie doit être égale ou supérieure à la surface totale en pouces

des conduits combinés.

• Utiliser seulement des conduits métalliques lisses et galvanisés. N’utilisez pas de conduit

flexible ou ondulé. Ce type de conduit limitera le flux d’air et réduira les performances.

• Faire le chemin le plus court possible et aussi droit que possible avec aussi peu de tours que

possible.

• Évitez les virages serrés. Au lieu de cela, utilisez des virages lisses et progressifs tels que les

coudes réglables ou les virages angulaires de 45 degrés.

• Pour les conduits de plus de 20 pieds [6 m], augmentez le diamètre du conduit d’un pouce [2,5

cm] pour chaque 10 pieds [3 m] de conduit.

• Lors de la planification de la longueur, du conduit, un coude de 90 degrés est équivalent à 5

pieds [1,5 m] de conduit.

CONDITIONS DE TÉRMINAISION

Le flux d’air ne doit pas être limité à la fin du parcours du conduit.

Un évent mural ou un chapeau de toit est

requis pour chaque passage de conduit.

Chaque évent mural ou un chapeau de toit

doit inclure un amortisseur à gravité pour

éviter les retours d’air.

Conduit lisse Virage progressif

lisse

Bonne combinaison

de deux conduits

N’utilisez pas de moustiquaires ou de portes

à ressort sur les évents murales ou les

chapots de toit.

10

Ne pas terminer l’évacuation dans un grenier

ou une cheminée.

©2019 Hestan Commercial Corporation

Conduit flexible Virages angulaires

Page 39

INSTALLATION

POUR RÉDUIRE LES RISQUES D’INCENDIE, DE CHOC

ÉLECTRIQUE OU DE BLESSURE, OBSERVEZ CE QUI SUIT:

a) Les travaux d’installation et de câblage électrique doivent être effectués par des personnes

qualifiées conformément à tous les codes et normes applicables, y compris la construction

résistante au feu.

b) Une quantité suffisante d’air est nécessaire pour assurer une combustion et une évacuation

correctes des gaz à travers la cheminée de l’équipement de combustion du carburant afin