Hestan KRD484GDNGBU, KRD484GDNGRD, KRD485GDLPBG, KRD485GDNGWH, KRD484GDLPOR Installation manual

...

INDOOR COOKING

Dual-Fuel Range

KRD

Installation Manual

EN

CAUTION

NOTICE

IF THE INFORMATION IN THIS MANUAL IS NOT FOLLOWED EXACTLY,

A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE,

PERSONAL INJURY, OR DEATH.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of

this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

1. Do not try and light any appliance.

2. Do not touch any electrical switch.

3. Do not use any phone in your building.

4. Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

5. If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency, or the gas

supplier.

READ THESE INSTRUCTIONS CAREFULLY AND COMPLETELY BEFORE

INSTALLING OR USING YOUR APPLIANCE TO REDUCE THE RISK OF FIRE,

BURN HAZARD, OR OTHER INJURY. KEEP THIS MANUAL FOR FUTURE

REFERENCE.

SAFETY DEFINITIONS

THIS INDICATES THAT DEATH OR SERIOUS INJURY MAY OCCUR

AS A RESULT OF NOT OBSERVING THIS WARNING.

THIS INDICATES THAT MINOR OR MODERATE INJURY MAY

OCCUR AS A RESULT OF NOT OBSERVING THIS WARNING.

THIS INDICATES THAT DAMAGE TO THE APPLIANCE OR

PROPERTY MAY OCCUR AS A RESULT OF NOT OBSERVING THIS

WARNING.

INSTALLER: LEAVE THIS MANUAL WITH THE OWNER OF THE APPLIANCE.

HOMEOWNER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

TIP OVER HAZARD

A child or adult can tip over a range and be killed.

Check installation of the anti-tip device per the Installation Manual.

Do not operate the range without this device in place.

Check engagement of anti-tip device if range is moved, such as when cleaning behind the unit.

To check engagement, carefully tip the range forward while pulling from the rear of the unit. The

range should not move more that 1 inch [2.5cm].

Failure to follow these instructions can result in death or serious burns to children and adults.

To reduce the risk of burns, do not move this appliance while hot.

©2019 Hestan Commercial Corporation

TABLE OF CONTENTS

1 SAFETY PRECAUTIONS - BEFORE YOU BEGIN

2 MODEL NUMBERS

3 RATING LABEL

3 REGULATORY / CODE REQUIREMENTS

3 LOCATION AND INSTALLATION / VENTILATION

14 BACKGUARD AND ACCESSORIES

15 INSTALLATION OF ANTI-TIP DEVICE

16 ELECTRICAL CONNECTIONS

18 GAS CONNECTION

20 FINAL SETUP

21 SERVICE

22 APPENDIX

SAFETY PRECAUTIONS - BEFORE YOU BEGIN

When properly cared for, your Hestan appliance will provide safe, reliable service for many years.

When using this appliance, basic safety practices must be followed as outlined below.

IMPORTANT: Save these instructions for the local Gas or Utility Inspector’s use.

EN

INSTALLER: Please leave these Installation Instructions with the owner.

OWNER: Please retain these Installation Instructions for future reference.

This range is NOT designed for installation in manufactured (mobile) homes or recreational park

trailers. Do NOT install this range outdoors.

ELECTRICAL SHOCK HAZARD

Disconnect power before installing or servicing appliance. Before turning

power ON, be sure all controls are in the OFF position. Failure to do so can

result in electrical shock or death.

ELECTRICAL GROUNDING

This appliance must be grounded. Grounding reduces the risk of electric shock

in the event of a short circuit. Read the ELECTRICAL CONNECTIONS section of this manual for

complete instructions.

This appliance is equipped with a 4-prong grounding plug for your protection against shock hazard

and should be directly plugged into a properly grounded receptacle. Do not cut or remove the

grounding prong from this plug.

ELECTRICAL SUPPLY

The appliance must be on its own dedicated circuit - 240 VAC, Single Phase, 60 Hz, with a current

rating as shown in the model number listing on pg. 2. Have the installer show you where the

electric circuit breaker is located so you know how to shut off the power to this appliance. It is the

responsibility of the user to have the appliance connected by a licensed electrician in accordance

with all local codes, or in the absence of local codes, in accordance with the National Electrical

Code. Read the ELECTRICAL CONNECTIONS section of this manual for complete details.

©2019 Hestan Commercial Corporation

1

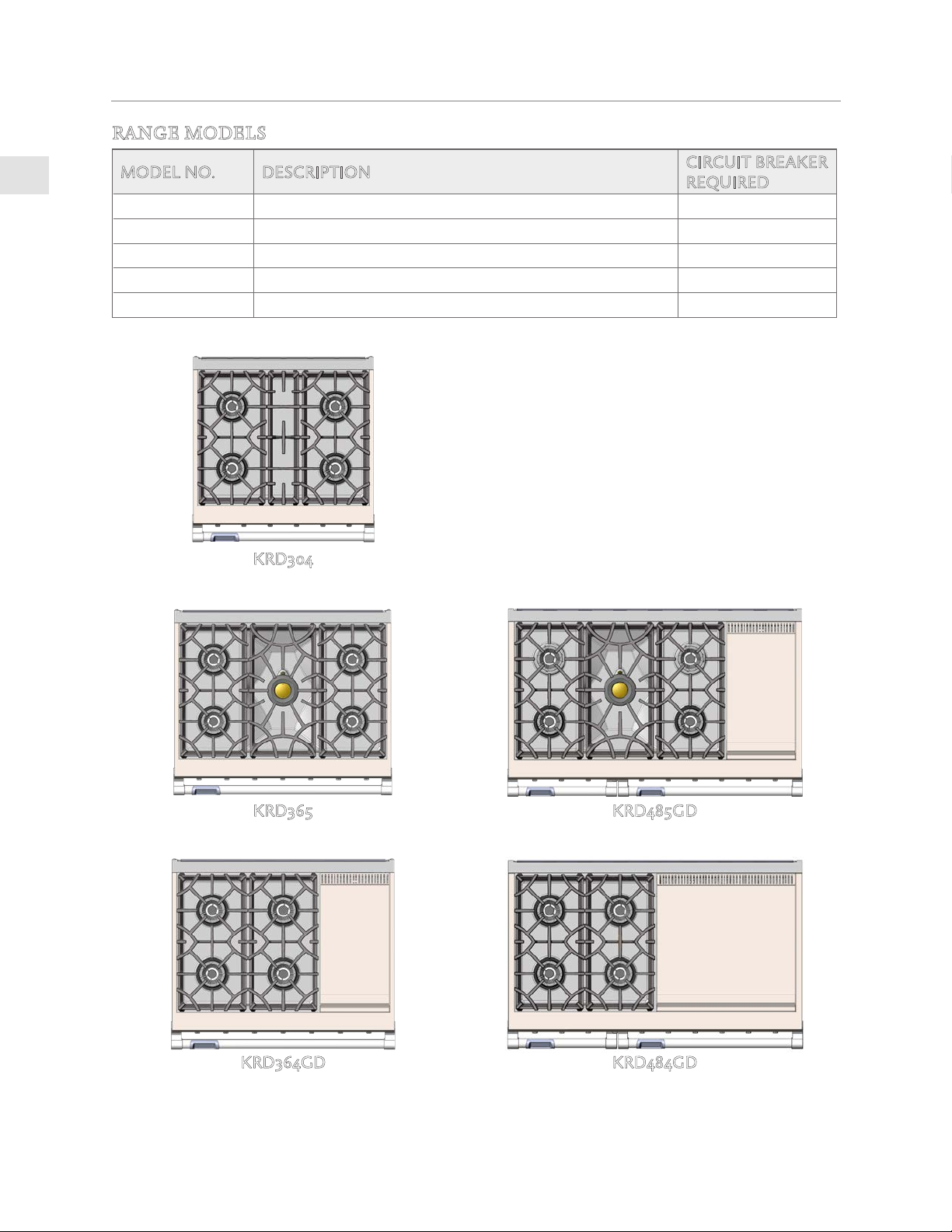

MODEL NUMBERS

RANGE MODELS

EN

MODEL NO. DESCRIPTION

KRD304-NG / -LP 30” DUAL-FUEL RANGE WITH 4 BURNERS 40 Amp

KRD365-NG / -LP 36” DUAL-FUEL RANGE WITH 5 BURNERS 40 Amp

KRD364GD-NG / -LP 36” DUAL-FUEL RANGE WITH 4 BURNERS & 12” GRIDDLE 40 Amp

KRD485GD-NG / -LP 48” DUAL-FUEL RANGE WITH 5 BURNERS, 2 OVENS, & 12”GRIDDLE 50 Amp

KRD484GD-NG / -LP 48” DUAL-FUEL RANGE WITH 4 BURNERS, 2 OVENS, & 24”GRIDDLE 50 Amp

KRD304

CIRCUIT BREAKER

REQUIRED

2

©2019 Hestan Commercial Corporation

KRD364GD

KRD485GDKRD365

KRD484GD

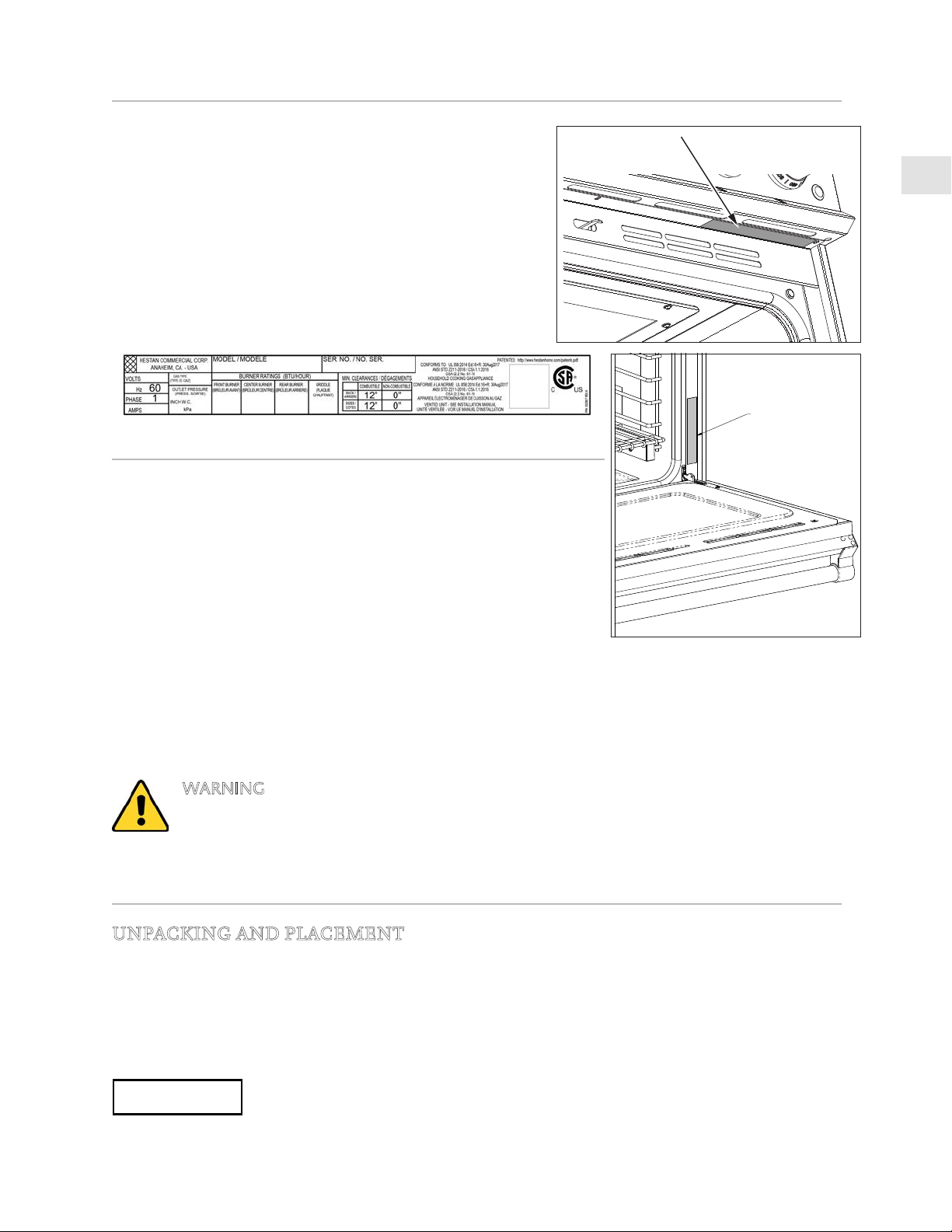

RATING LABEL

RATING LABEL

NOTICE

The rating label contains important information about your

Hestan appliance such as the model and serial number,

gas type and manifold pressure, electrical rating, the BTU

rating for each burner type, and the minimum installation

clearances.

The rating label is located in one of two places, as shown in

the figures on this page.

If service is necessary, contact Hestan Customer Care with

the model and serial number information shown on the label.

RATING LABEL

REGULATORY / CODE REQUIREMENTS

Installation of this cooking appliance must be made in accordance

with local codes. In the absence of local codes, this unit should

be installed in accordance with the National Fuel Gas Code

Z223.1/NFPA 54

B149.1

All Electrical Components must be electrically grounded in

accordance with local codes or in the absence of local codes with

the National Electrical Code

code

, or Propane Storage and Handling Code

CSA C22.1

, Natural Gas and Propane Installation code

B149.2

ANSI/NFPA 70

.

, or Canadian Electrical

ANSI

CSA

.

EN

STATE OF MASSACHUSETTS

Massachusetts requires all gas be installed using a plumber or gas fitter carrying the appropriate

Massachusetts license. All permanently installed natural gas or propane installations require a

T handle type manual gas valve be installed in the gas supply line to this appliance. Flexible gas

connector must not be longer than 48” [1.2 m].

CALIFORNIA PROPOSITION 65 - WARNING

WARNING This product can expose you to chemicals including carbon monoxide, which is

known to the State of California to cause birth defects or other reproductive harm.

For more information, go to www.P65Warnings.ca.gov.

LOCATION AND INSTALLATION / VENTILATION

UNPACKING AND PLACEMENT

Remove the outer carton and packing materials from the shipping pallet. Do not remove the plastic

film covering the stainless-steel surfaces. This film protects the finish from scratches until the

appliance is installed in its final position.

The unit is very heavy and should be handled with care. Use proper safety equipment, such as gloves,

and at least 2 persons to move the appliance into position to avoid injury and to avoid damage to the

floor or the appliance itself.

DO NOT USE A HAND TRUCK OR DOLLY ON THE FRONT OR REAR OF THE

RANGE. HANDLE AND MOVE FROM THE SIDES ONLY.

Do not lift or carry the appliance by the oven door or handle. This could damage

the door hinges.

©2019 Hestan Commercial Corporation

3

EN

APPLIANCE

LOCATION AND INSTALLATION / VENTILATION

The range is held onto the pallet with 4 large shipping bolts on both sides. Remove these bolts and

then move the range to the floor with the help of 2 persons.

(CONTINUED)

PREPARATION

Before moving the range, protect any finished flooring and

secure the oven door(s) closed to prevent damage.

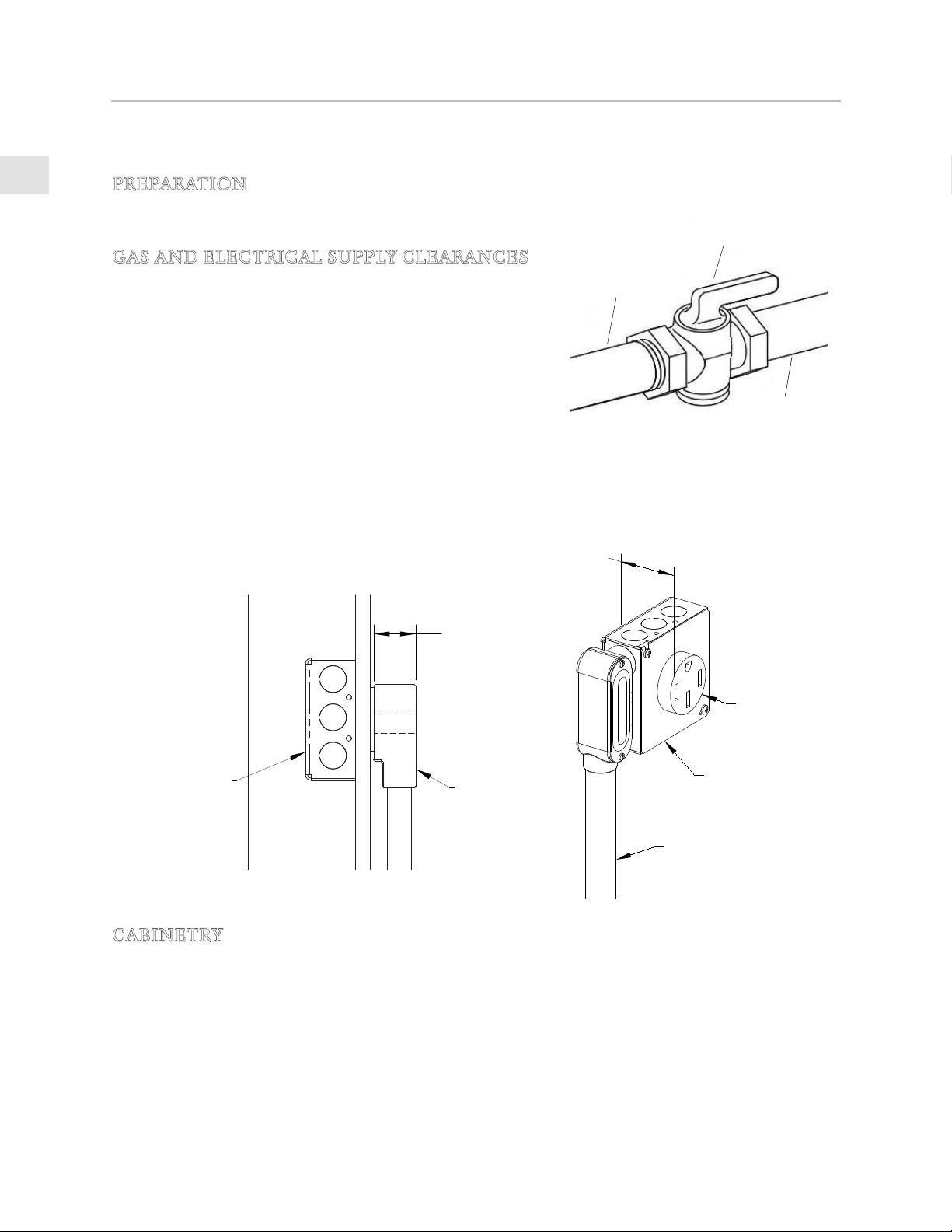

SHUTOFF VALVE

IN OPEN POSITION

GAS AND ELECTRICAL SUPPLY CLEARANCES

If not already in place, install a gas shut-off valve in an

easily accessible location for servicing of the range. Make

sure all users of the range know where this shut-off is

located, and how to shut off the gas. Any openings in the

wall or floor behind the appliance must be sealed. The

Installation Clearances on the following pages show where

the “G” and “E” zones should be located.

The range is designed to be installed nearly flush to the rear

wall*. It may be necessary to reposition the gas supply and

power receptacle / junction box in order to accommodate the range when pushed back against the

wall.

Wall-mounted junction box may protrude no more than 2-3/8” [6.1 cm] from wall and still allow the

back of the range to be nearly flush to rear wall.

GAS

SUPPLY

TO

* Unless installed in an island with no rear wall.

1-5/16"

[3.3 cm]

JUNCTION BOX

INSIDE WALL

POWER

CORD

2"

[5.1 cm]

RECEPTACLE

NEMA 14-50

JUNCTION

BOX

CONDUIT

CABINETRY

To eliminate the risk of burns or fire by reaching over heated surface units, cabinet storage space

located above the surface units should be avoided. If cabinet storage is to be provided, the risk can

be reduced by installing the required vent hood that projects horizontally a minimum of 5” [12.7 cm]

beyond the bottom of the cabinets.

4

©2019 Hestan Commercial Corporation

COVER PLATE

B

C

G

H

LOCATION AND INSTALLATION/VENTILATION

(CONTINUED)

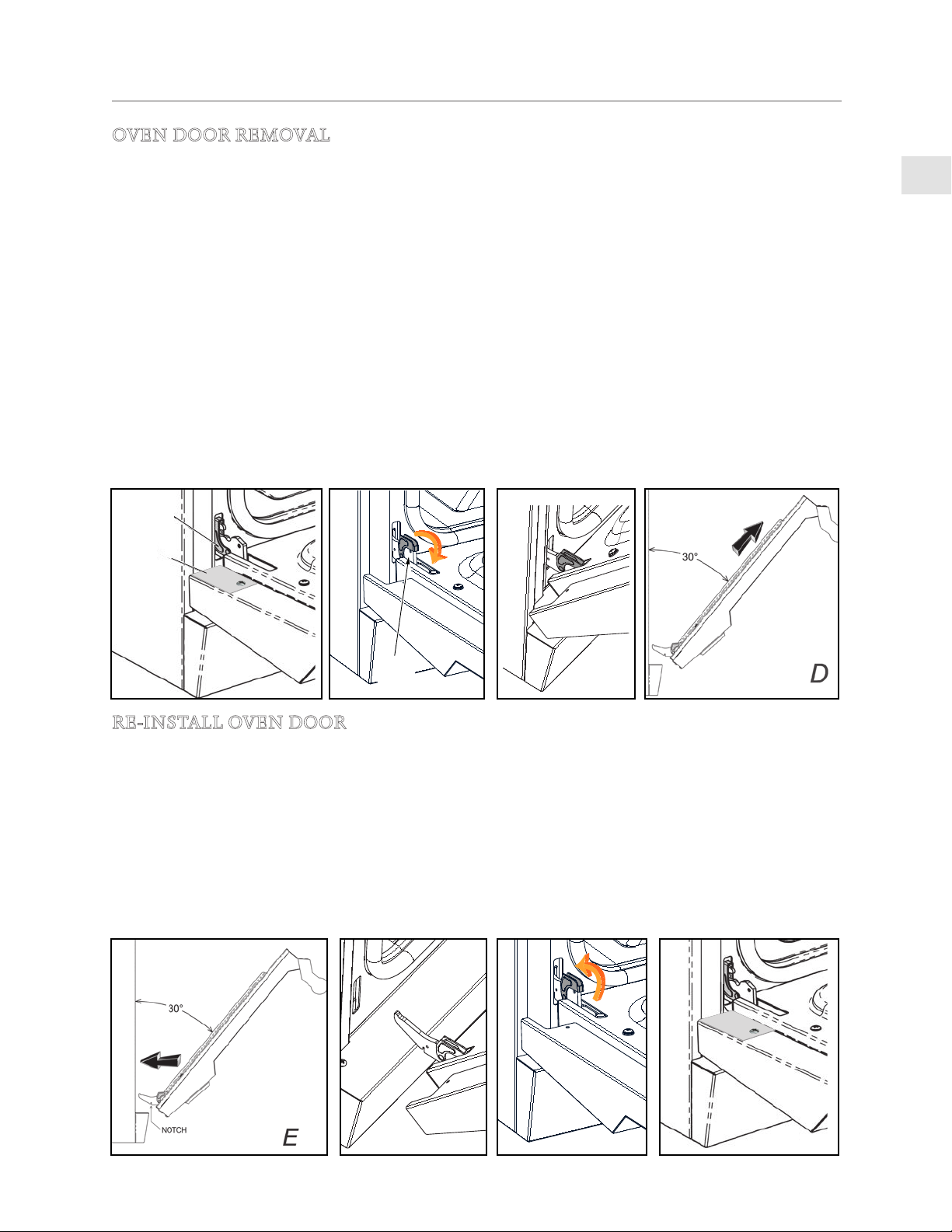

OVEN DOOR REMOVAL

If you have a very narrow door opening to your kitchen, the oven door(s) can be removed.

REMOVE ONLY IF ABSOLUTELY NECESSARY. Door removal should only be done by a certified

installer or service technician. Be sure the oven has completely cooled and the electrical power is

off. Failure to do so may result in electric shock or burn injury. Use caution when removing the

door, it is very heavy. Be careful to disconnect the wire inside the door.

1. Open oven door completely.

2. Locate cover near hinge to access wire connector inside. Using small needle-nose pliers and a

small flat-blade screwdriver, disconnect the wires inside the door. [ A ]

3. At each hinge location, swing the hinge clip forward until it stops. A screwdriver may be

needed to do this. [ B ]

4. Gently close the oven door until it stops against the hinge clips, or approximately 30° from the

closed position. Hold on firmly to both sides of the door (not the handle) and pull the door

straight up off the hinges. Ask an assistant to help direct the wires out of the bottom of the

door so it does not hang up on anything. Place the oven door in a safe location until needed.

NEVER release the hinge clips and try to close the hinges. Doing so will snap the hinges closed

with great force which could cause injury. [ C & D ]

HINGE CLIP

EN

AND SCREW

Hinge

A

clip

RE-INSTALL OVEN DOOR

1. Hold the door firmly on both sides (NOT FROM THE HANDLE) at approximately 30° from the

closed position and insert the hinges into the slots in the oven. The bottom edge of each hinge

has a notch which must seat inside the slot opening. DO NOT FORCE OR BEND OR TWIST

THE DOOR! [ E & F ]

2. Slowly open the door all the way. Swing the hinge clips away from you until completely inside

the slot opening and fully seated. A screwdriver may help you do this. [ G ]

3. Re-attach the wire connector and assure it is securely inside the door. Re-install the cover. [ H ]

4. Gently close the oven door to check for smooth operation.

F

©2019 Hestan Commercial Corporation

5

EN

CAUTION

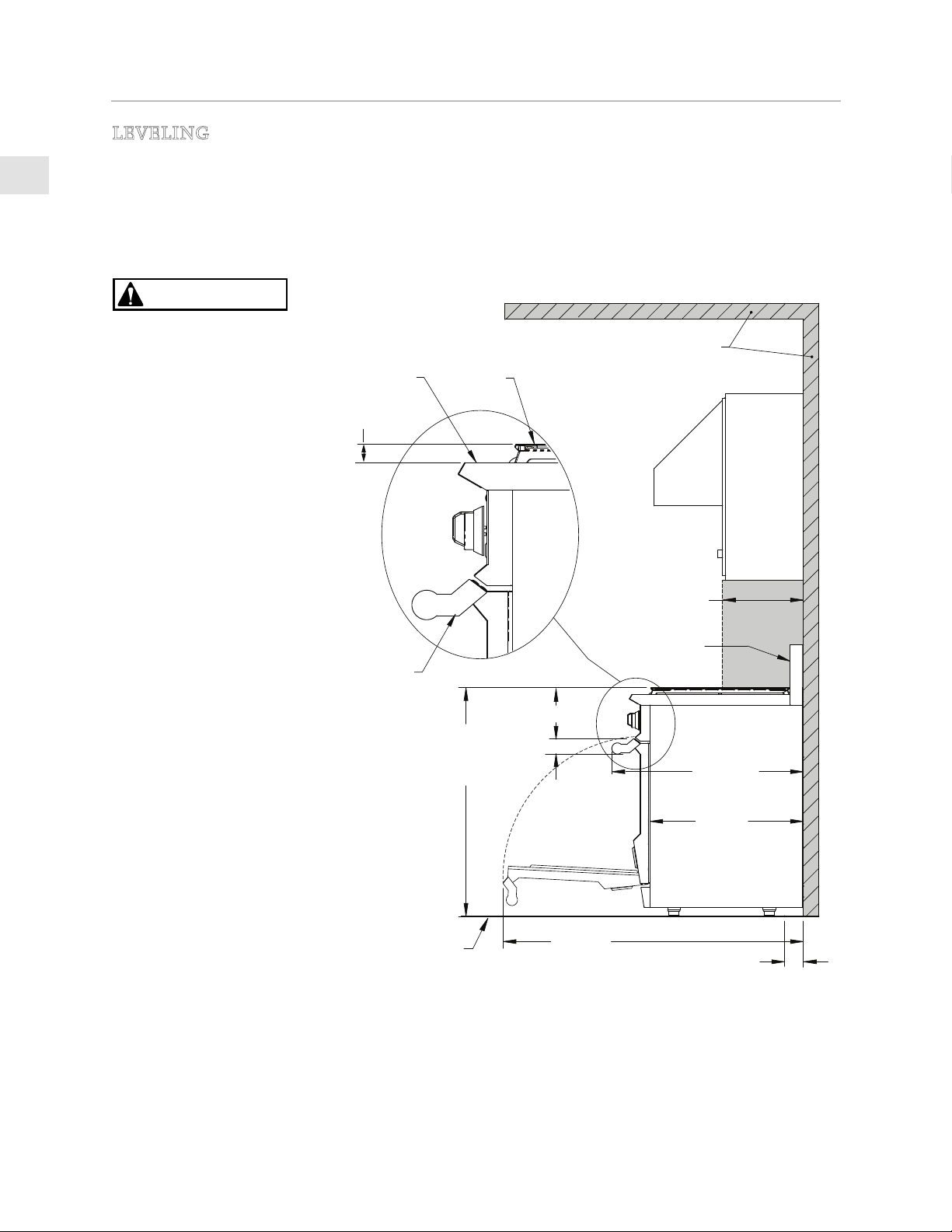

INSTALLATION CLEARANCES WITH LOW BACKGUARD

SIDE VIEW

LOCATION AND INSTALLATION/VENTILATION

(CONTINUED)

LEVELING

The range must be level, especially those models featuring a griddle. Raise or lower the range to the

desired height by adjusting the leveling legs under the range. The legs can be turned by hand. It may

be necessary to use a lever or other lifting device to assist in temporarily raising the unit to turn the

legs. Do not lift or lever from the front or back, only from the sides.

Leveling 48” models: The 48” ranges have 6 legs. They should be adjusted so that all six share the

weight of the range.

The appliance top must be

level with or higher than

the adjacent countertop

surfaces. Failure to adjust

the height may expose the

adjacent cabinets to excessive

heat which may damage the

APPLIANCE

REF 1.12”

[2.84 cm]

TOP

COOKING

SURFACE

cabinets or countertop.

HANDLE

END CAP

38-3/8 - 36-7/8”

[97.5 - 93.7]

TO COOKING

SURFACE

7” [17.7]

2-5/8”

[6.7]

COMBUSTIBLE

MATERIALS

13” [33]

MAX.

LOW

BACKGUARD

30-13/16”

[78.3]

24-11/16”

[62.7]

MAX.

RECESS

DEPTH

6

©2019 Hestan Commercial Corporation

FINISHED

FLOOR

DIMENSIONS IN BRACKETS [ ] ARE IN CM.

48-5/16”

[122.7]

3”

[7.6]

LOCATION OF GAS AND

ELECTRICAL ON FLOOR

LOCATION AND INSTALLATION/VENTILATION

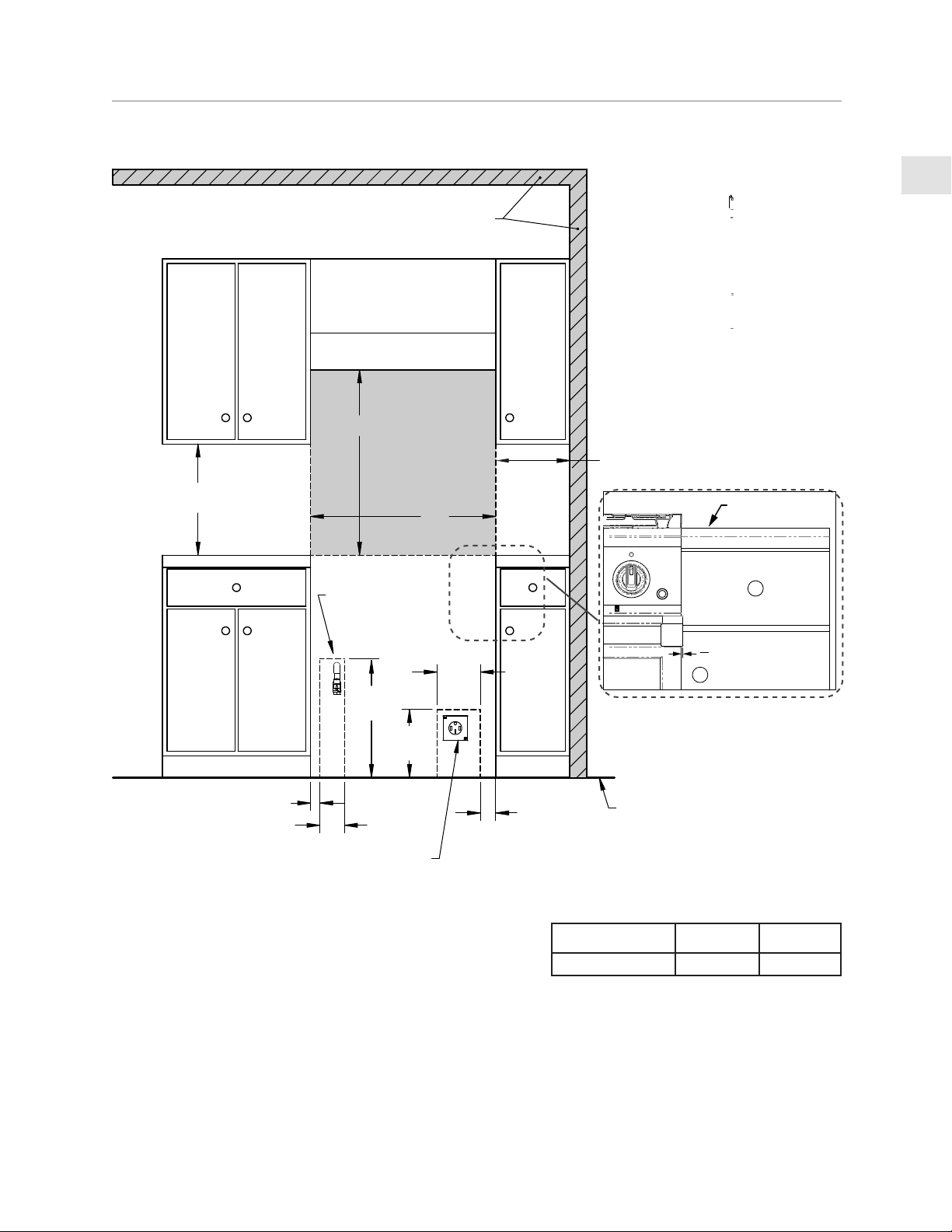

INSTALLATION CLEARANCES 30” WITH LOW BACKGUARD

FRONT VIEW

COMBUSTIBLE

MATERIALS

VENT HOOD

V

18" [45.7]

MIN.

W

MIN. CLEARANCE

TO NEAREST

COMBUSTIBLE

SIDE SURFACE

12"

[30.5]

(CONTINUED)

EN

COUNTERTOP

RECOMMENDED

GAS SHUT-OFF

VALVE LOCATION

18"

[45.7]

G

11"

[27.9]

7"

[17.8]

DIMENSIONS IN

BRACKETS [ ] ARE

IN CM.

FULL OVERLAY

DRAWER FACE

1

"

[3.2 mm]

8

FULL OVERLAY

CABINET DOOR FACE

E

1-1/2"

[3.8]

ELECTRICAL

SUPPLY

4"

[10.2]

LOCATION

NOTES:

• SHADED AREAS INDICATE WHERE COMBUSTIBLE MATERIALS ARE NOT ALLOWED.

• APPLIANCE TOP MUST BE LEVEL OR HIGHER THAN THE ADJACENT COUNTERTOP SURFACES.

• “G” IS GAS CONNECTION ZONE ON REAR WALL. MOUNT SHUT-OFF VALVE AS HIGH AS POSSIBLE IN THIS

ZONE FOR EASY ACCESS WHEN RANGE IS INSTALLED.

• “E” IS ELECTRICAL SUPPLY ZONE.

• “W” IS APPLIANCE OPENING.

NOTE: HANDLE END CAPS PROTRUDE 1/8” BEYOND EACH SIDE OF THE RANGE. ALLOWANCE MAY BE

NEEDED FOR ADJACENT DRAWERS OR CABINETRY.

• “V” IS MIN. CLEARANCE TO REQUIRED VENTILATION HOOD.

2-1/2"

[6.4]

RANGE MODEL

KRD304 30” [76.2] 30” [76.2]

FINISHED

FLOOR

W

V (MIN)

©2019 Hestan Commercial Corporation

7

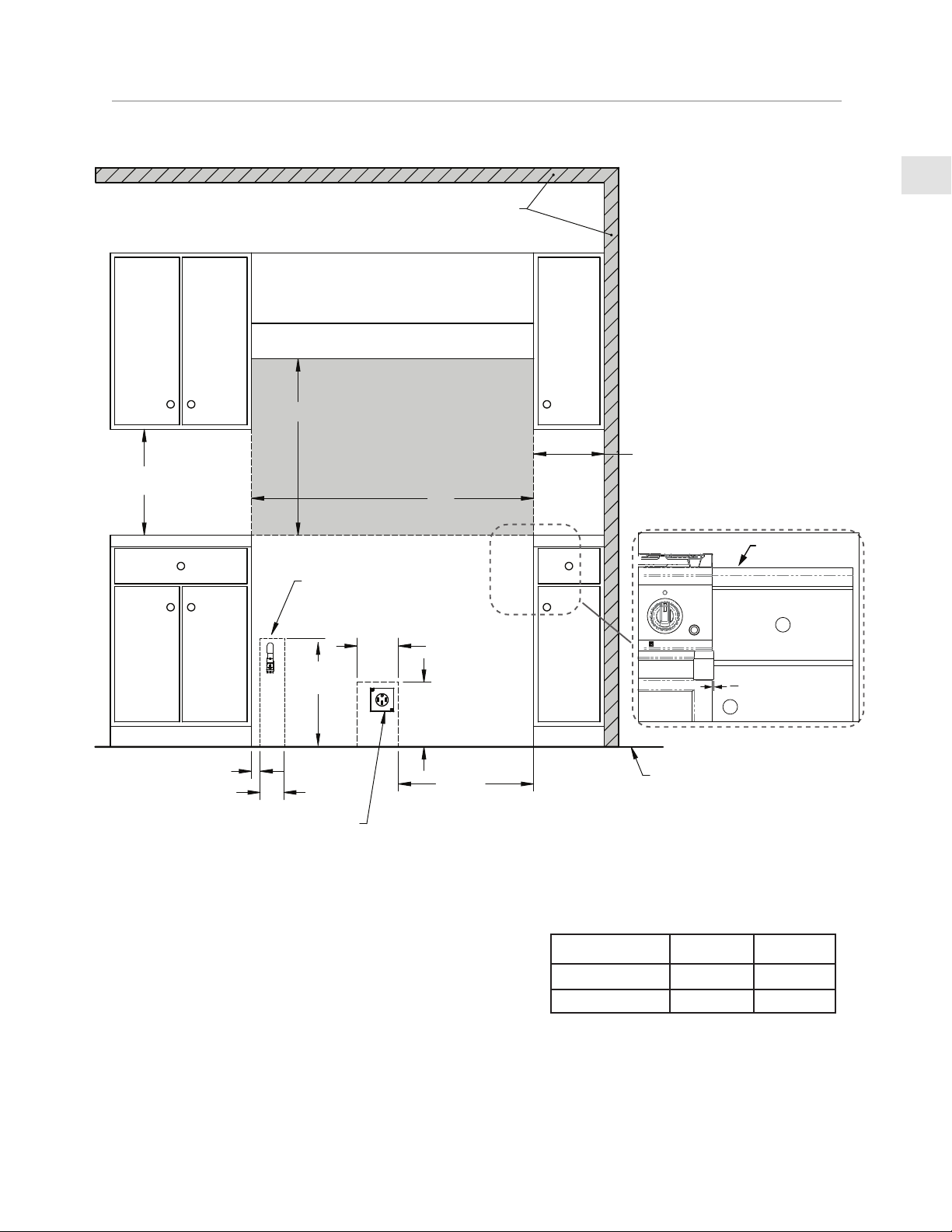

LOCATION AND INSTALLATION/VENTILATION

INSTALLATION CLEARANCES 36” WITH LOW BACKGUARD

EN

COMBUSTIBLE

MATERIALS

VENT HOOD

V

18” [45.7]

MIN.

W

(CONTINUED)

MIN. CLEARANCE

TO NEAREST

COMBUSTIBLE

SIDE SURFACE

12”

[30.5]

COUNTERTOP

RECOMMENDED

GAS SHUT-OFF

3”

[7.6]

[12.7]

5”

VALVE LOCATION

9-1/2”

[24.1]

18”

[45.7]

G

19”

[48.3]

ELECTRICAL

SUPPLY

LOCATION

E

6”

[15.2]

2-1/2”

[6.4]

5”

[12.7]

DIMENSIONS IN

BRACKETS [ ] ARE

IN CM.

FINISHED

FLOOR

FULL OVERLAY

DRAWER FACE

1

"

[3.2 mm]

8

FULL OVERLAY

CABINET DOOR FACE

FRONT VIEW

RANGE MODEL

NOTES:

• SHADED AREAS INDICATE WHERE COMBUSTIBLE MATERIALS ARE

NOT ALLOWED.

• APPLIANCE TOP MUST BE LEVEL OR HIGHER THAN THE ADJACENT COUNTERTOP SURFACES.

• “G” IS GAS CONNECTION ZONE ON REAR WALL. MOUNT SHUT-OFF VALVE AS HIGH AS POSSIBLE IN THIS

ZONE FOR EASY ACCESS WHEN RANGE IS INSTALLED.

• “E” IS ELECTRICAL SUPPLY ZONE.

• “W” IS APPLIANCE OPENING.

NOTE: HANDLE END CAPS PROTRUDE 1/8” BEYOND EACH SIDE OF THE RANGE. ALLOWANCE MAY BE

NEEDED FOR ADJACENT DRAWERS OR CABINETRY.

• “V” IS MIN. CLEARANCE TO REQUIRED VENTILATION HOOD.

KRD365 36” [91.4] 30” [76.2]

KRD364GD 36” [91.4] 30” [76.2]

W

V (MIN)

8

©2019 Hestan Commercial Corporation

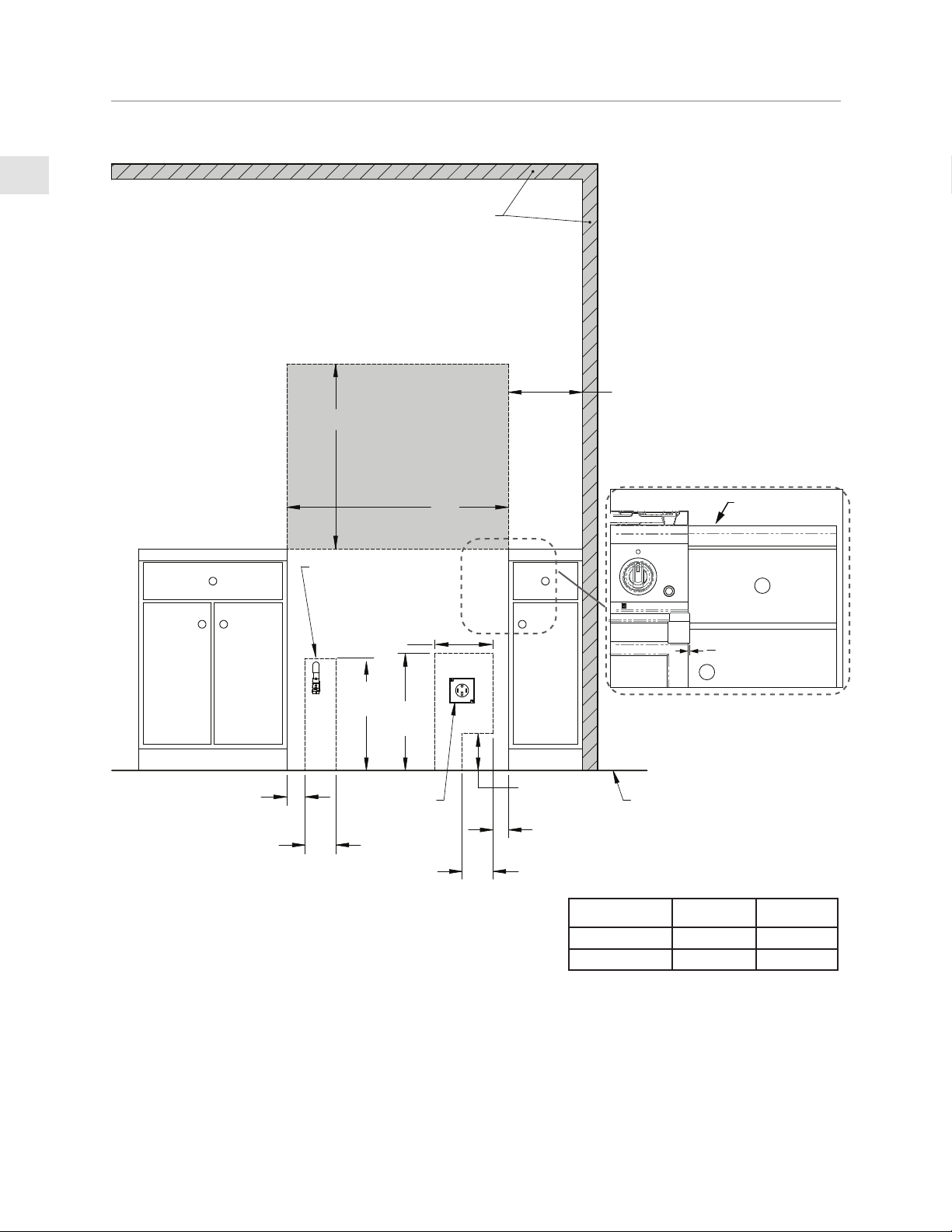

LOCATION AND INSTALLATION/VENTILATION

(CONTINUED)

INSTALLATION CLEARANCES WITH LOW BACKGUARD

48"

COMBUSTIBLE

MATERIALS

VENT HOOD

V

18” [45.7]

MIN.

RECOMMENDED

GAS SHUT-OFF

VALVE LOCATION

18”

[45.7]

G

7”

[17.8]

W

11”

[27.9]

E

MIN. CLEARANCE

TO NEAREST

COMBUSTIBLE

SIDE SURFACE

12”

[30.5]

COUNTERTOP

FULL OVERLAY

DRAWER FACE

1

"

[3.2 mm]

8

FULL OVERLAY

CABINET DOOR FACE

EN

1-1/2”

[3.8]

ELECTRICAL

SUPPLY

4”

[10.2]

LOCATION

23”

[58.4]

DIMENSIONS IN BRACKETS [ ] ARE IN CM.

FINISHED

FLOOR

FRONT VIEW

NOTES:

RANGE MODEL

• SHADED AREAS INDICATE WHERE COMBUSTIBLE MATERIALS

ARE NOT ALLOWED.

• APPLIANCE TOP MUST BE LEVEL OR HIGHER THAN THE

ADJACENT COUNTERTOP SURFACES.

• “G” IS GAS CONNECTION ZONE ON REAR WALL. MOUNT SHUT-OFF VALVE AS HIGH AS POSSIBLE IN THIS

ZONE FOR EASY ACCESS WHEN RANGE IS INSTALLED.

• “E” IS ELECTRICAL SUPPLY ZONE.

• “W” IS APPLIANCE OPENING.

NOTE: HANDLE END CAPS PROTRUDE 1/8” BEYOND EACH SIDE OF THE RANGE. ALLOWANCE MAY BE

NEEDED FOR ADJACENT DRAWERS OR CABINETRY.

• “V” IS MIN. CLEARANCE TO REQUIRED VENTILATION HOOD.

KRD485GD 48” [121.9] 30” [76.2]

KRD484GD 48” [121.9] 30” [76.2]

©2019 Hestan Commercial Corporation

W

V (MIN)

9

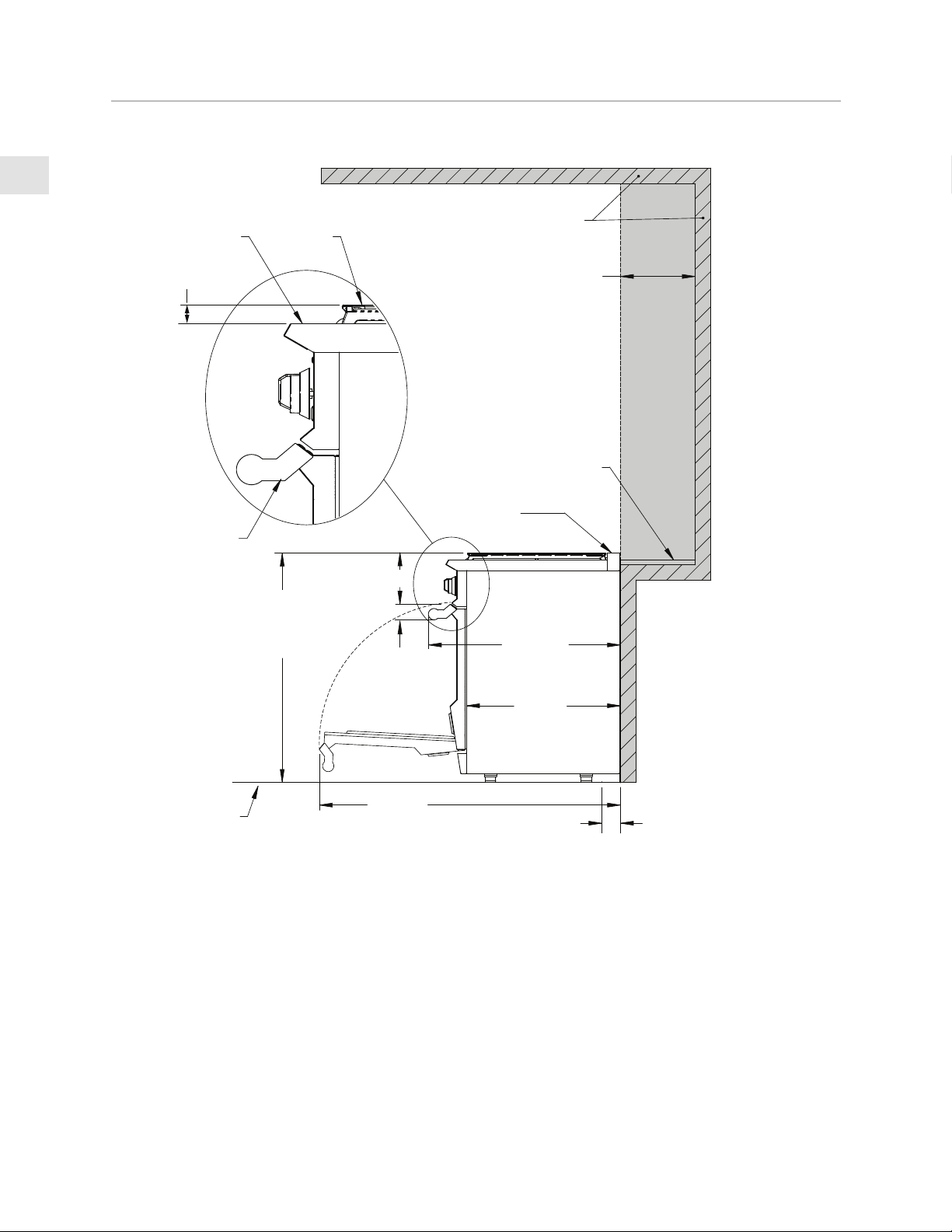

EN

INSTALLATION CLEARANCES WITH ISLAND TRIM

SIDE VIEW

LOCATION AND INSTALLATION/VENTILATION

(CONTINUED)

APPLIANCE

TOP

REF 1.12”

[2.84 cm]

COOKING

SURFACE

MIN. CLEARANCE

TO COMBUSTIBLE

SURFACES WITH

For Island Trim installations,

HANDLE

END CAP

7” [17.7]

38-3/8 - 36-7/8”

[97.5 - 93.7]

TO COOKING

SURFACE

2-5/8”

[6.7]

COMBUSTIBLE

MATERIALS

ISLAND TRIM

counter surface should

have a cantilever surface

meeting the rear of

the Island Trim

ISLAND

TRIM

30-13/16”

[78.3]

24-11/16”

[62.7]

MAX.

RECESS

DEPTH

12”

[30.5]

10

FINISHED

FLOOR

DIMENSIONS IN BRACKETS [ ] ARE IN CM.

©2019 Hestan Commercial Corporation

48-5/16”

[122.7]

3”

[7.6]

LOCATION OF GAS

AND ELECTRICAL

ON FLOOR

LOCATION AND INSTALLATION/VENTILATION

INSTALLATION CLEARANCES 30” WITH ISLAND TRIM

COMBUSTIBLE

MATERIALS

12"

V

[30.5]

MIN. CLEARANCE

TO NEAREST

COMBUSTIBLE

SIDE SURFACE

(CONTINUED)

EN

1-1/2"

[3.8]

ELECTRICAL

RECOMMENDED

GAS SHUT-OFF

VALVE LOCATION

18"

[45.7]

G

[10.2]

SUPPLY

LOCATION

[27.9]

4"

11"

W

7"

[17.8]

E

2-1/2"

[6.4]

DIMENSIONS IN

BRACKETS [ ] ARE

IN CM.

FINISHED

FLOOR

COUNTERTOP

FULL OVERLAY

DRAWER FACE

1

"

[3.2 mm]

8

FULL OVERLAY

CABINET DOOR FACE

FRONT VIEW

RANGE MODEL

KRD304 30” [76.2] 30” [76.2]

NOTES:

• SHADED AREAS INDICATE WHERE COMBUSTIBLE MATERIALS ARE NOT ALLOWED.

• APPLIANCE TOP MUST BE LEVEL OR HIGHER THAN THE ADJACENT COUNTERTOP SURFACES.

• “G” IS GAS CONNECTION ZONE ON REAR WALL. MOUNT SHUT-OFF VALVE AS HIGH AS POSSIBLE IN THIS

ZONE FOR EASY ACCESS WHEN RANGE IS INSTALLED.

• “E” IS ELECTRICAL SUPPLY ZONE.

• “W” IS APPLIANCE OPENING.

NOTE: HANDLE END CAPS PROTRUDE 1/8” BEYOND EACH SIDE OF THE RANGE. ALLOWANCE MAY BE

NEEDED FOR ADJACENT DRAWERS OR CABINETRY.

• “V” IS MIN. CLEARANCE TO REQUIRED VENTILATION HOOD.

W

V (MIN)

©2019 Hestan Commercial Corporation

11

LOCATION AND INSTALLATION/VENTILATION

INSTALLATION CLEARANCES 36” WITH ISLAND TRIM

EN

COMBUSTIBLE

MATERIALS

V

(CONTINUED)

12”

[30.5]

MIN. CLEARANCE

TO NEAREST

COMBUSTIBLE

SIDE SURFACE

COUNTERTOP

FULL OVERLAY

DRAWER FACE

1

"

[3.2 mm]

8

FULL OVERLAY

CABINET DOOR FACE

W

V (MIN)

3”

[7.6]

[12.7]

5”

W

RECOMMENDED

GAS SHUT-OFF

VALVE LOCATION

9-1/2”

[24.1]

18”

[45.7]

G

19”

[48.3]

ELECTRICAL

SUPPLY

LOCATION

FRONT VIEW

E

6”

[15.2]

2-1/2”

[6.4]

5”

[12.7]

DIMENSIONS IN

BRACKETS [ ]

ARE IN CM.

FINISHED

FLOOR

RANGE MODEL

KRD365 36” [91.4] 30” [76.2]

KRD364GD 36” [91.4] 30” [76.2]

NOTES:

• SHADED AREAS INDICATE WHERE COMBUSTIBLE MATERIALS ARE NOT ALLOWED.

• APPLIANCE TOP MUST BE LEVEL OR HIGHER THAN THE ADJACENT COUNTERTOP SURFACES.

• “G” IS GAS CONNECTION ZONE ON REAR WALL. MOUNT SHUT-OFF VALVE AS HIGH AS POSSIBLE IN THIS

ZONE FOR EASY ACCESS WHEN RANGE IS INSTALLED.

• “E” IS ELECTRICAL SUPPLY ZONE.

• “W” IS APPLIANCE OPENING.

NOTE: HANDLE END CAPS PROTRUDE 1/8” BEYOND EACH SIDE OF THE RANGE. ALLOWANCE MAY BE

NEEDED FOR ADJACENT DRAWERS OR CABINETRY.

• “V” IS MIN. CLEARANCE TO REQUIRED VENTILATION HOOD.

12

©2019 Hestan Commercial Corporation

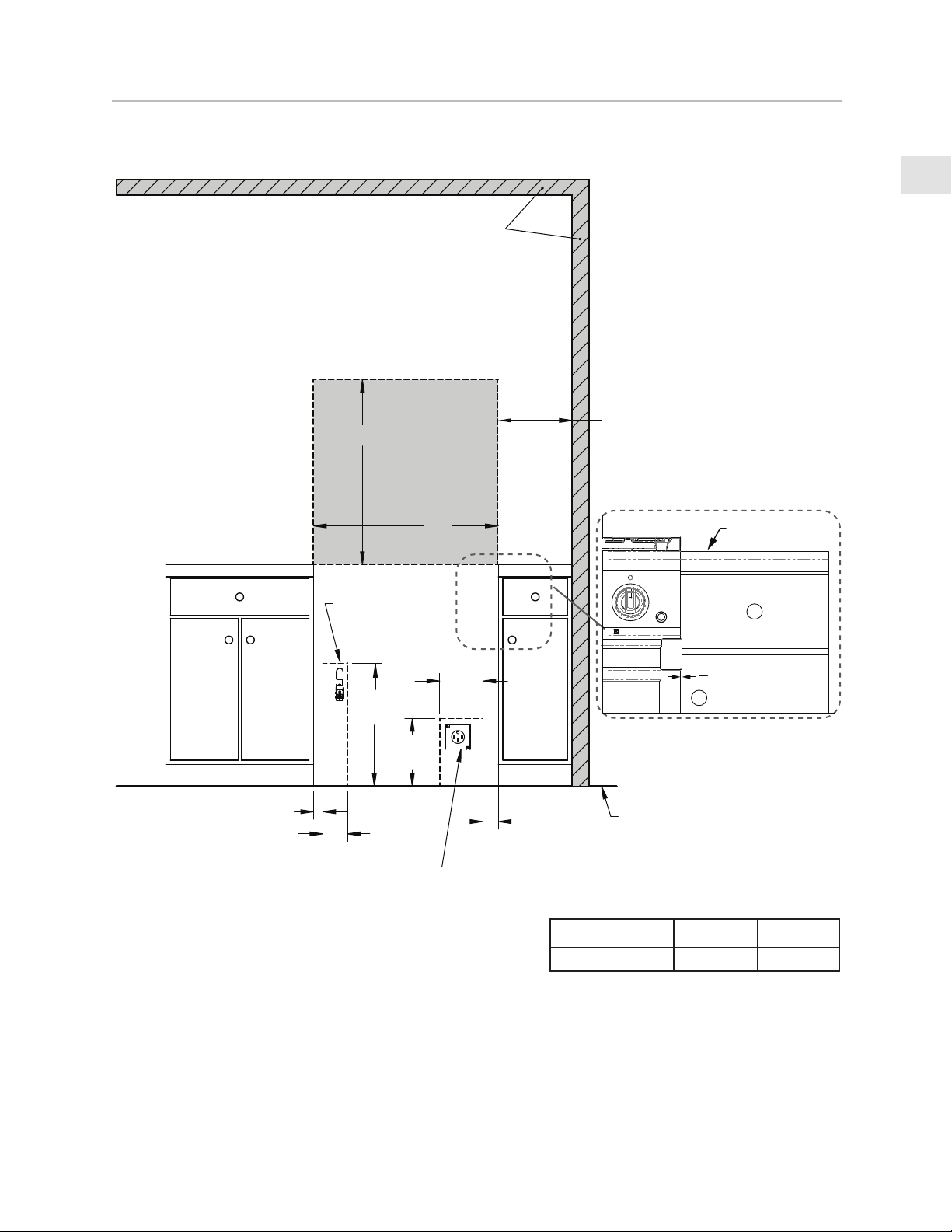

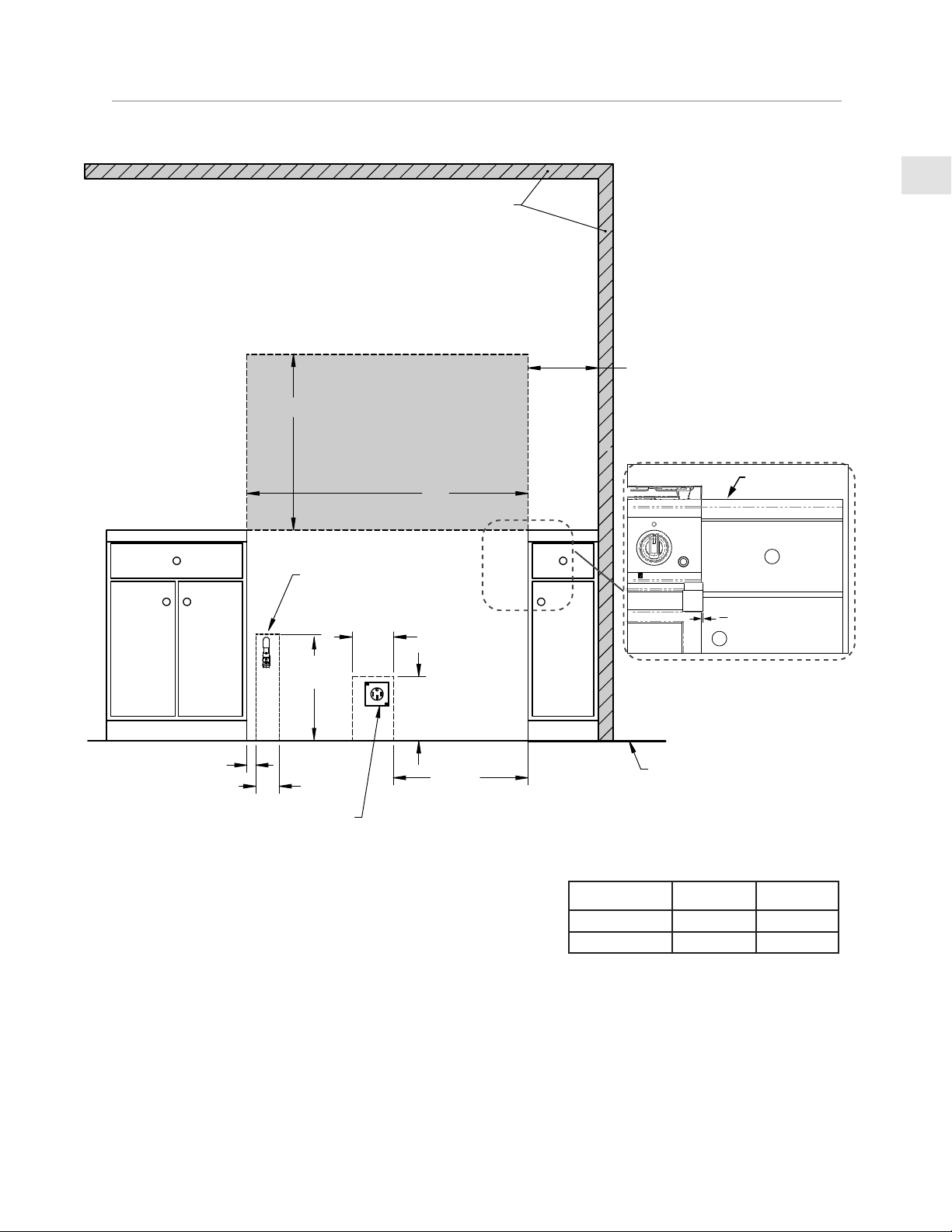

LOCATION AND INSTALLATION/VENTILATION

INSTALLATION CLEARANCES 48" WITH ISLAND TRIM

FRONT VIEW

COMBUSTIBLE

MATERIALS

12”

[30.5]

V

MIN. CLEARANCE

TO NEAREST

COMBUSTIBLE

SIDE SURFACE

(CONTINUED)

EN

W

RECOMMENDED

GAS SHUT-OFF

VALVE LOCATION

7”

[17.8]

18”

[45.7]

G

11”

[27.9]

E

1-1/2”

[3.8]

ELECTRICAL

SUPPLY

4”

[10.2]

LOCATION

23”

[58.4]

COUNTERTOP

FULL OVERLAY

DRAWER FACE

1

"

[3.2 mm]

8

FULL OVERLAY

CABINET DOOR FACE

DIMENSIONS IN

BRACKETS [ ] ARE

IN CM.

FINISHED

FLOOR

RANGE MODEL

KRD485GD 48” [121.9] 30” [76.2]

KRD484GD 48” [121.9] 30” [76.2]

W

V (MIN)

NOTES:

• SHADED AREAS INDICATE WHERE COMBUSTIBLE MATERIALS ARE NOT ALLOWED.

• APPLIANCE TOP MUST BE LEVEL OR HIGHER THAN THE ADJACENT COUNTERTOP SURFACES.

• “G” IS GAS CONNECTION ZONE ON REAR WALL. MOUNT SHUT-OFF VALVE AS HIGH AS POSSIBLE IN THIS

ZONE FOR EASY ACCESS WHEN RANGE IS INSTALLED.

• “E” IS ELECTRICAL SUPPLY ZONE.

• “W” IS APPLIANCE OPENING.

NOTE: HANDLE END CAPS PROTRUDE 1/8” BEYOND EACH SIDE OF THE RANGE. ALLOWANCE MAY BE

NEEDED FOR ADJACENT DRAWERS OR CABINETRY.

• “V” IS MIN. CLEARANCE TO REQUIRED VENTILATION HOOD.

©2019 Hestan Commercial Corporation

13

Loading...

Loading...